Dewing rapid dissipating lens module

A lens module and fast technology, applied in the camera body, optics, instruments, etc., can solve the problems of condensation on the lens and affect the imaging quality, and achieve the effect of controlling production costs, avoiding additional processes, and improving imaging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure and effect of the present invention will now be described in detail with reference to the following embodiments in conjunction with the accompanying drawings.

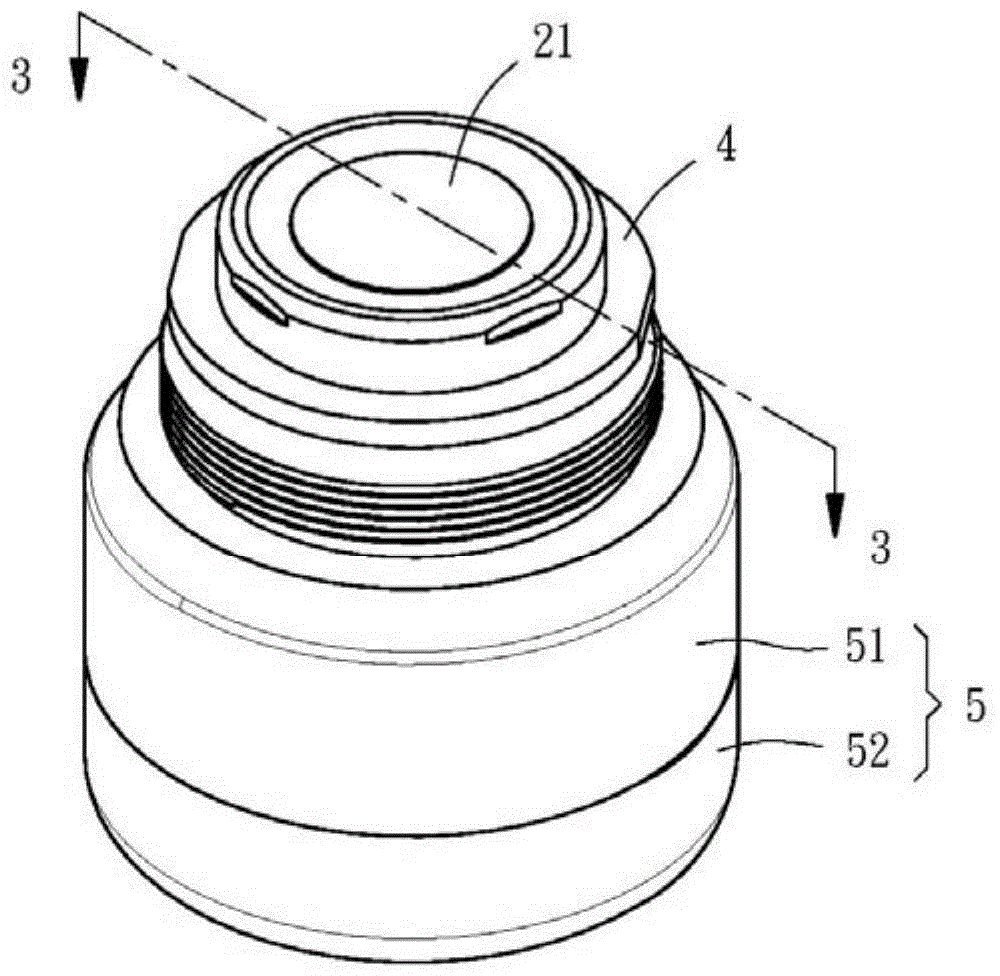

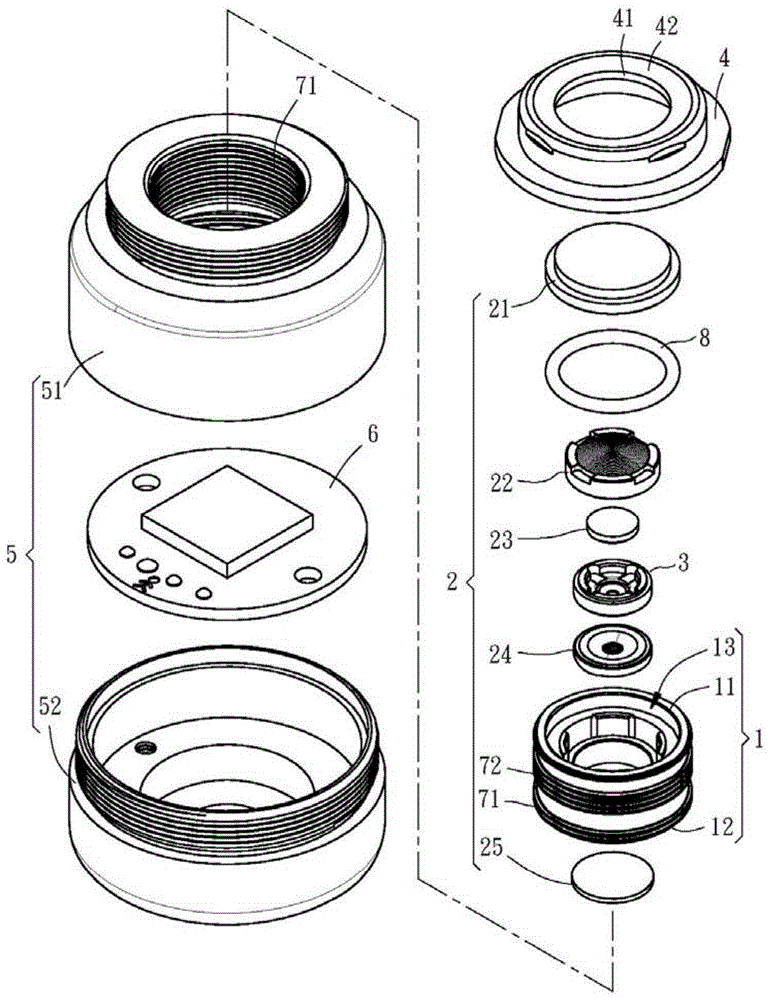

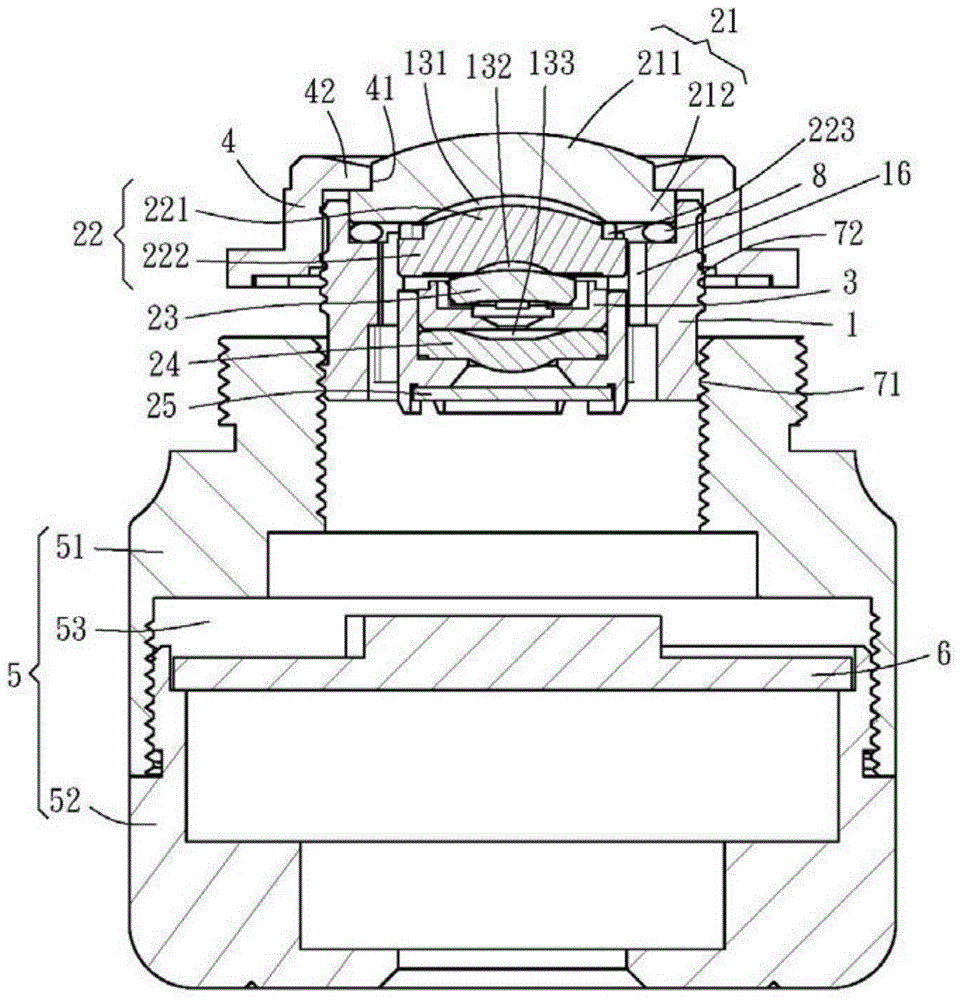

[0027] like figure 1 , figure 2 As shown, it is a preferred embodiment of a lens module with rapid condensation and dissipation of the present invention: the lens module with rapid condensation and dissipation includes a lens barrel 1, a lens group 2, a socket 3, a limiter 4, A module holder 5 and a photosensitive member 6 . Two ends of the lens barrel 1 are provided with through holes 11 , 12 , and an accommodating space 13 therein. The two through holes 11 and 12 communicate with each other through the accommodating space 13 to define a light transmission path; the lens group 2 and the holder 3 are accommodated in the accommodating space 13 of the lens barrel 1, and the lens group 2 has a plurality of lenses 21-25 , wherein the lens 21 is the outermost outer lens, and the lenses 22-25 are oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com