Air micro-cavity type fiber hydrophone, manufacturing method of the same, and signal detection method

A fiber optic hydrophone and signal detection technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of reducing the applicability and flexibility of the sensor, difficult to guarantee the repeatability of the sensor, and high process requirements. , to overcome the lack of repeatability of device structure parameters, reduce the difficulty of manufacturing, and avoid the process of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment firstly discloses an air microcavity fiber optic hydrophone, which includes an optical fiber whose end surface is coated with a light-absorbing material and an air microcavity generated by optical heating on the end surface of the optical fiber.

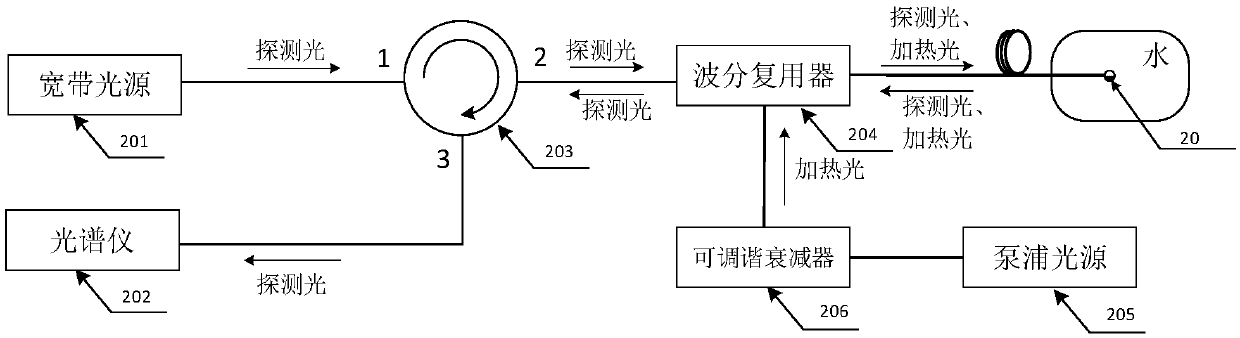

[0036] Using the air microcavity fiber optic hydrophone of this embodiment, an air microcavity is generated at the fiber end face by an optical heating method to form a Fabry-Perot interferometer, wherein the fiber end face / air microcavity and the air microcavity / liquid two The reflected light from the two interfaces interferes to form interference fringes. When the air microcavity is subjected to external pressure, its cavity length will change, and the change of reflection spectrum interference fringes will be manifested in the form of optical path difference change. By detecting the wavelength shift of the interference spectrum, the measurement of the external pressure is realized. Since the air microcavity...

Embodiment 2

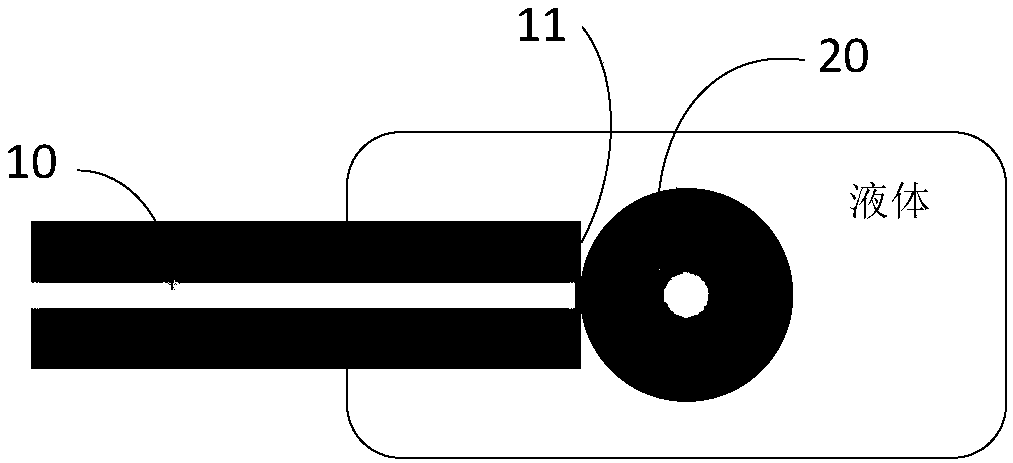

[0046] This embodiment discloses an air microcavity fiber optic hydrophone. see figure 1 , figure 1 It is the structural schematic diagram of the air microcavity fiber optic hydrophone of the present embodiment, the air microcavity fiber optic hydrophone of the embodiment of the present invention, comprises the transmission optical fiber 10, the air microcavity 20 that has end face plated with light absorbing material 11; Wherein , the transmission optical fiber 10 is immersed in the liquid, the air microcavity 20 is located at the center of the fiber end face, and the air microcavity 20 constitutes a Fabry-Perot cavity. The interface between the end face of the transmission fiber 10 and the air microcavity 20 and the interface between the air microcavity 20 and the liquid are two reflection surfaces of the Fabry-Perot cavity.

[0047] The air microcavity 20 in the above-mentioned sensor is easy to process and is located at the center of the end face of the transmission opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com