Patents

Literature

42results about How to "Reduce the amount of concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cast-in-situ X-shaped concrete pile construction method

InactiveCN101021070ALarge specific surface areaReduce the amount of concreteBulkheads/pilesRebarReinforced concrete

The present invention relates to a construction method of in-situ X-shaped reinforced concrete pile. It is characterized by that the lower portion of its vibrating head is connected with cover plate, the cover plate is connected with X-shaped steel sleeve, said X-shaped steel sleeve has a hollow cavity, the lower end of X-shaped steel sleeve is connected with prefabricated X-shaped reinforced concrete pile shoe. Its construction method includes the following steps: starting vibrating head to downwards drive the X-shaped steel sleeve, and under the protection of prefabricated X-shaped pile shoe driving the X-shaped steel sleeve into foundation, pouring the concrete into the hollow cavity interior of X-shaped steel sleeve, utilizing the vibrating head to make vibration, upwards drawing out the X-shaped steel sleeve from ground, remaining the X-shaped reinforced concrete pile shoe in the foundation so as to form the invented in-situ X-shaped reinforced concrete pile.

Owner:史本良

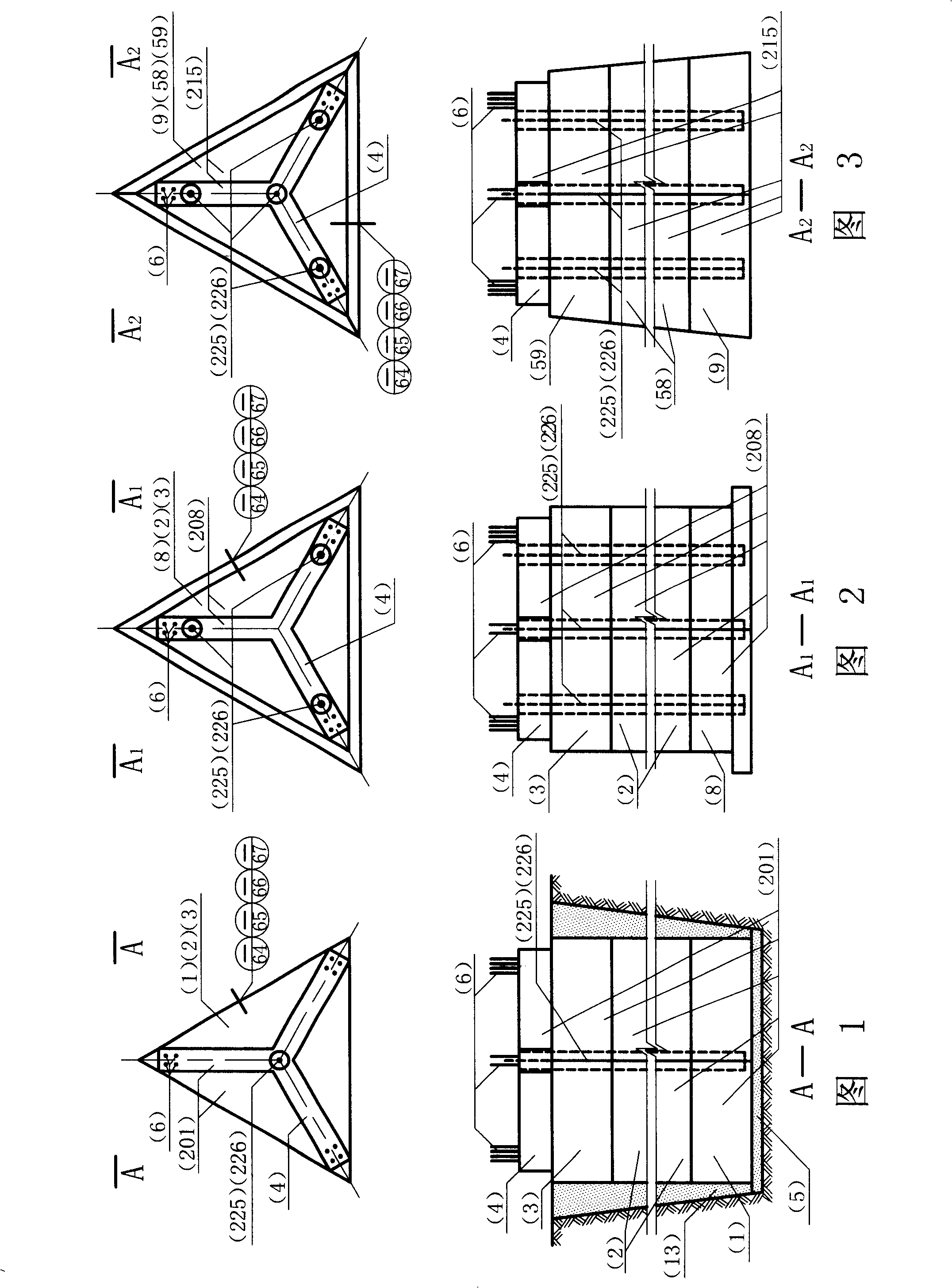

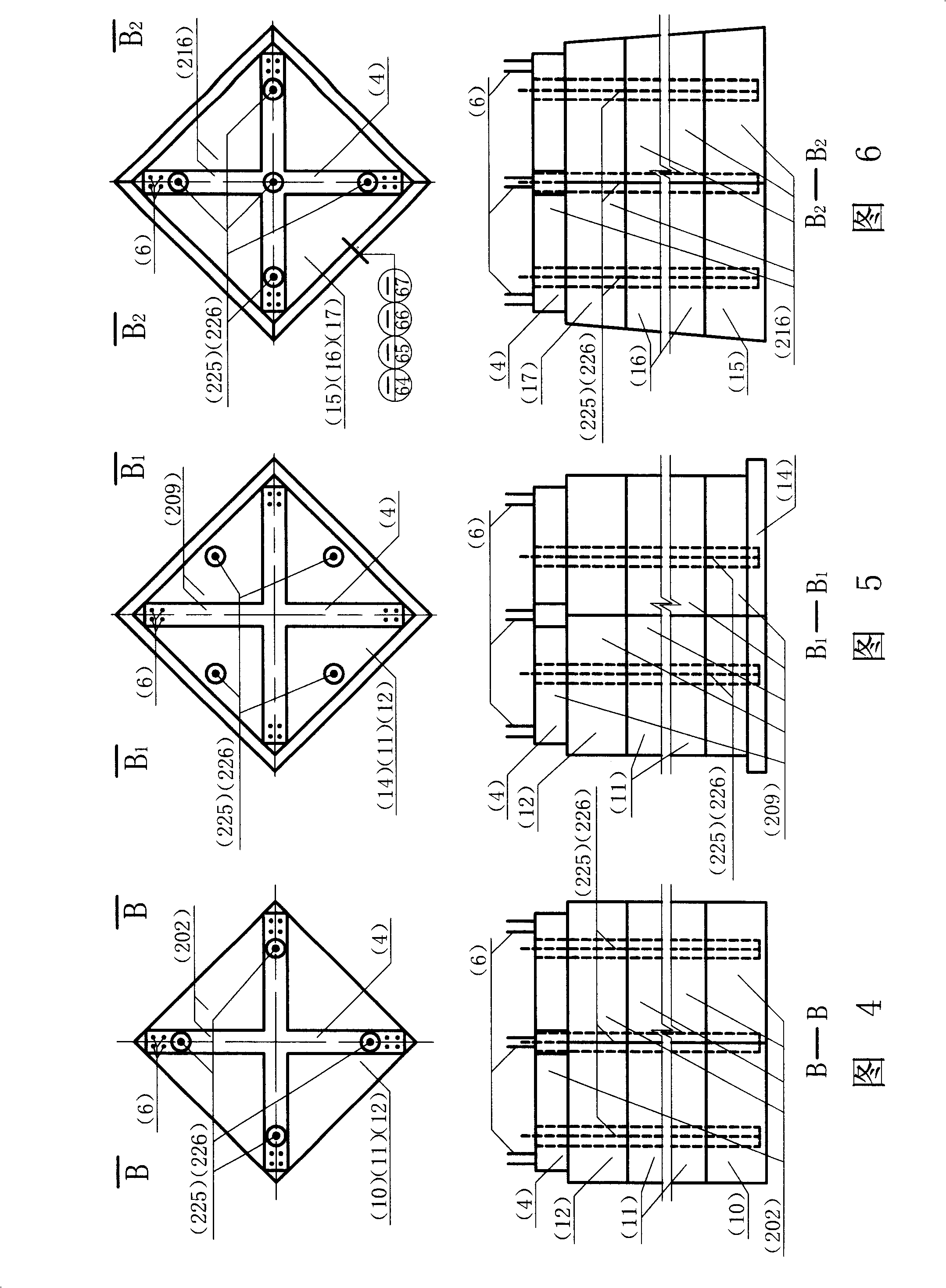

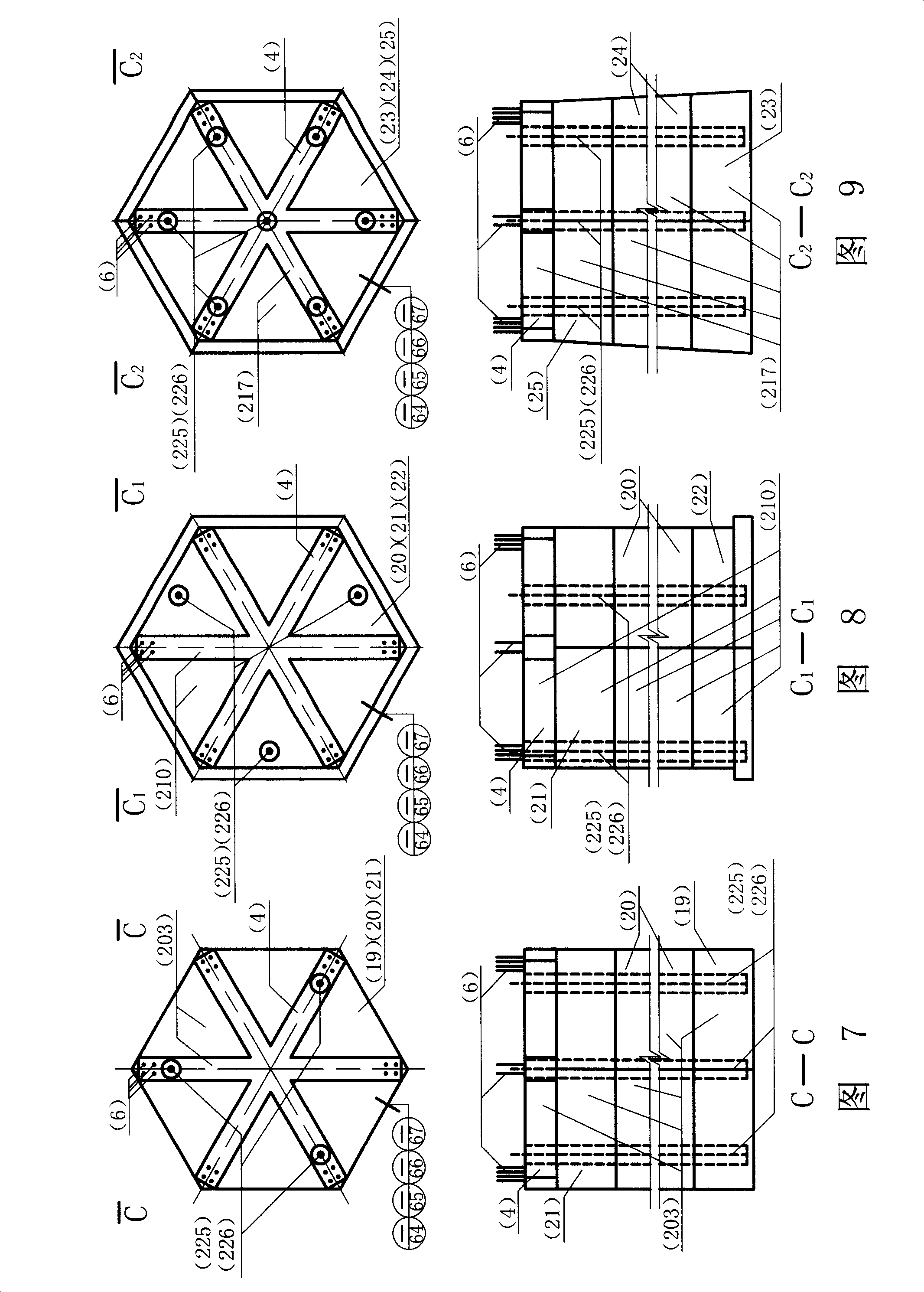

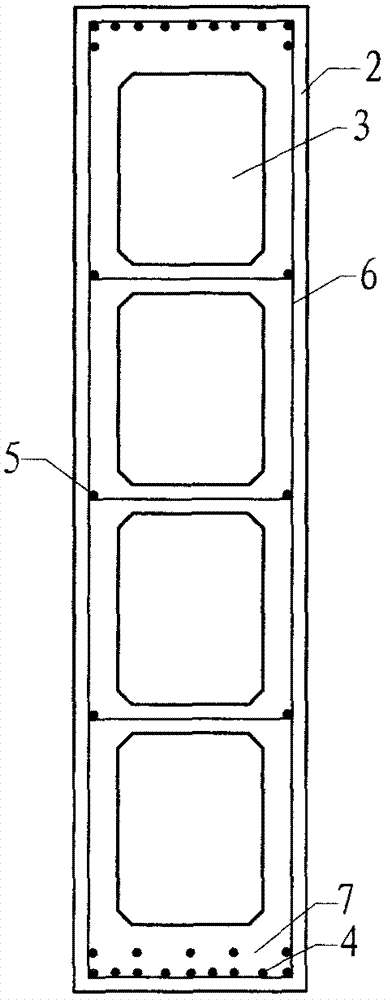

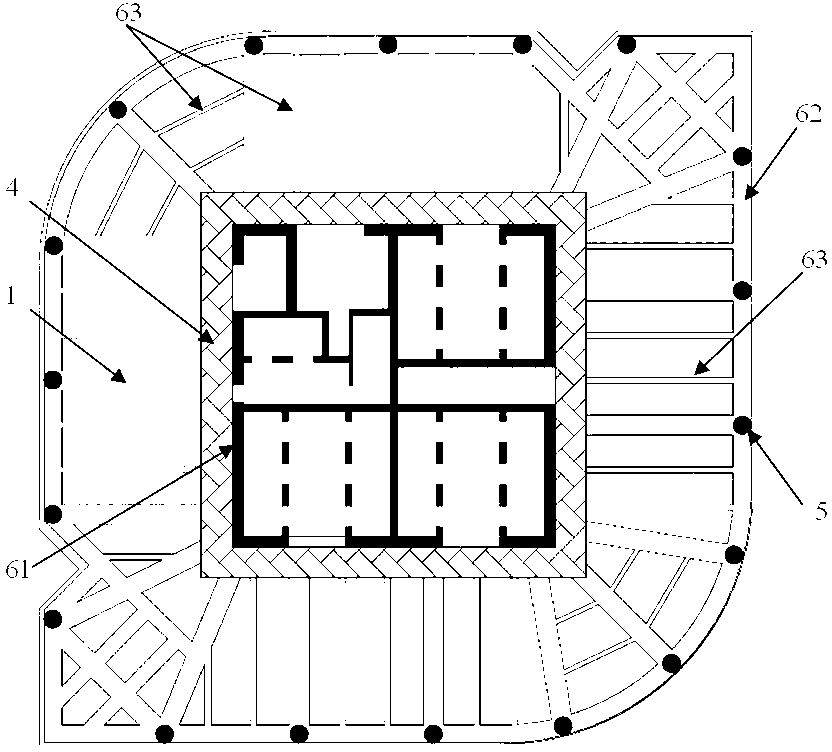

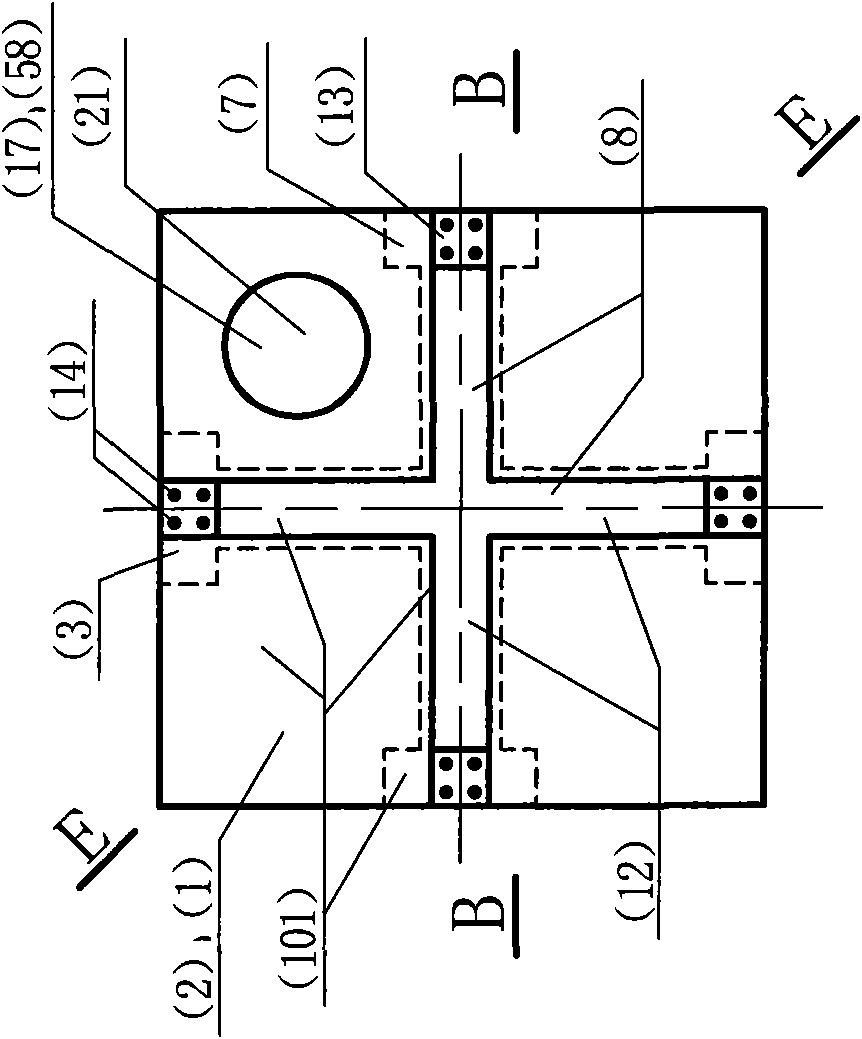

Vertical combined novel foundation of mast mechanical equipment

InactiveCN101255700ATake full advantage of side pressureSmall footprintFoundation engineeringResource savingEconomic benefits

A novel mast mechanical equipment vertical assembling foundation is a regular polygon prism, cylinder or polygon prism concrete independent foundation structure which is obtained by vertically assembling the concrete prefabricated part. The invention is widely suitable for the mast mechanical equipment which periodically moves or is fixedly used in fields of building, electric power, information,geological industry and military industry. The invention is mainly characterized in that the horizontal side pressure and the friction of the foundation soil are fully utilized for increasing the dumping resistance of the foundation. The invention has the advantages of small accommodation area, high installing and detaching velocity, no water operation on the construction side, providing new condition for the foundation installing at the high-cold and dry areas, predominant resource-saving and energy-saving and environment-protecting benefits, and evident economic benefit.

Owner:赵正义

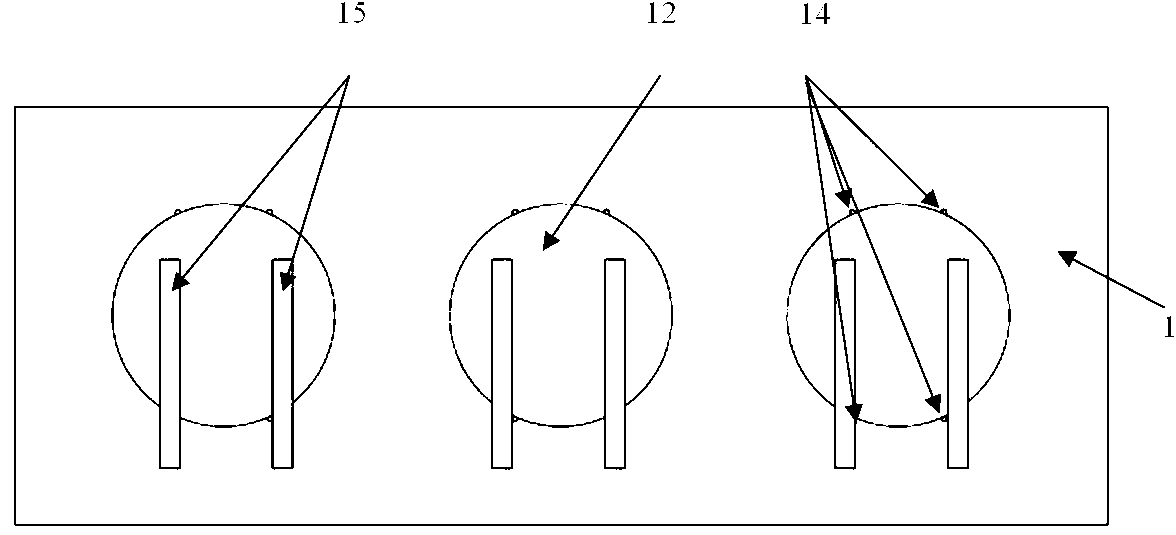

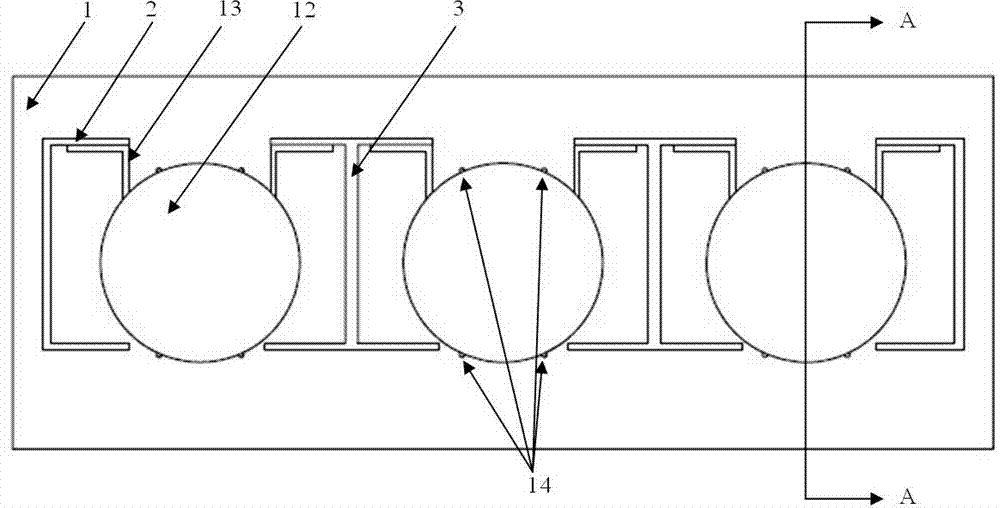

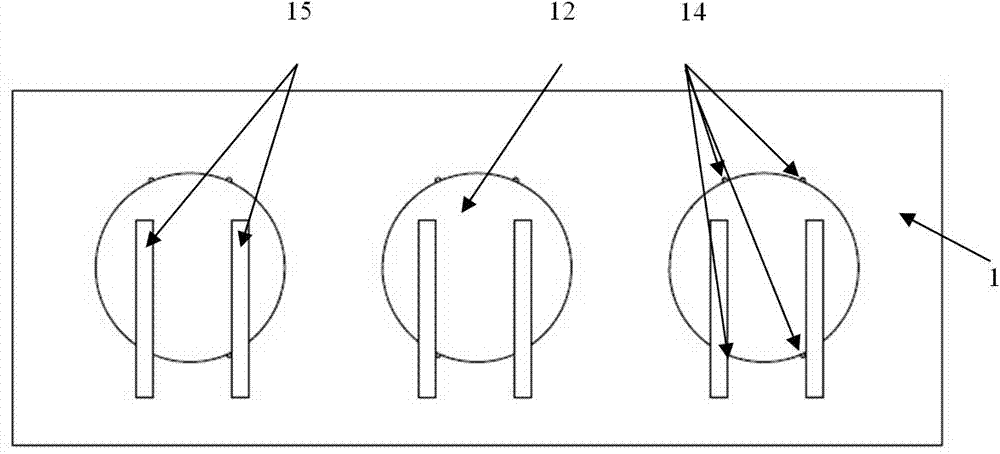

Cover die for construction of composite-section ribbed floor and construction method thereof

ActiveCN109680929ASolve mold problemsReduce production processForms/shuttering/falseworksReinforced concreteEngineering

The invention discloses a cover die for construction of a composite-section ribbed floor and a construction method thereof. The cover die comprises two cylinders or one cylinder and one box or two boxes, wherein each cylinder is of a cylindrical surrounding body structure of which the upper part and lower part are communicated; the cylinders comprise a cylinder I and / or a cylinder II; each box isof a cavity body structure of which one end is opened and the other end is sealed; the boxes comprise a box I and / or a box II; the cylinder I is sheathed above the exterior of the cylinder II, and / orthe box I is sheathed above the exterior of the cylinder II, and / or the box I is sheathed above the exterior of the box II; a lower flange die cavity of a cast-in-situ concrete rib is formed between the cylinder and / or the box; a web plate die cavity of a cast-in-situ concrete dense rib is formed between the adjacent cylinders and / or the boxes. One of the cover die is reserved in a reinforced concrete prefabricated rib cylinder or box, and the other one is a detachable and repeatedly used cylinder die, or is a prefabricated concrete cylinder reserved in the floor. The cover die is a construction die with the advantages that the production is simple; the construction is convenient; the construction period is short; the manufacturing cost is low; the good use effect is obtained.

Owner:贵州皆盈科技开发有限公司

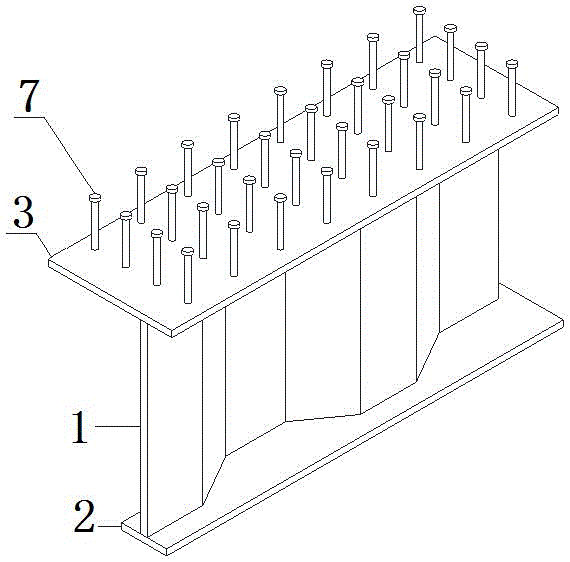

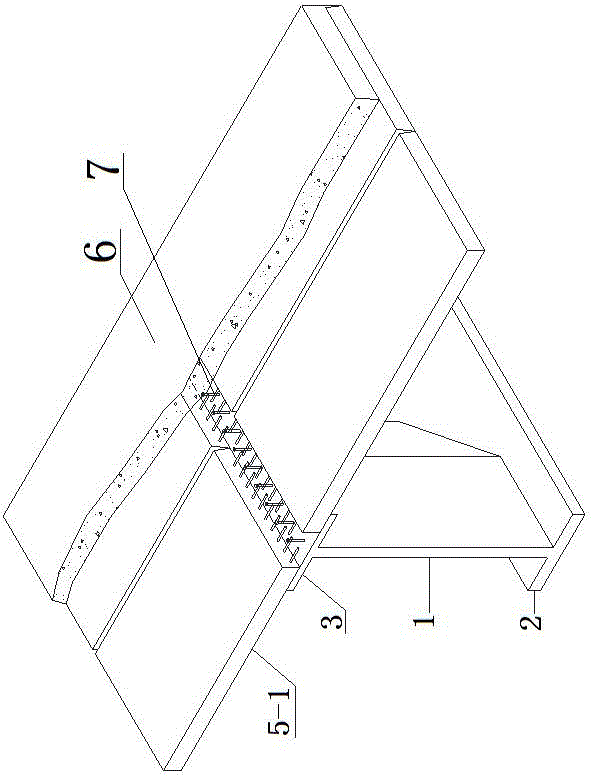

Corrugated steel web few-main-beam structure

InactiveCN105133486AReduce the amount of concreteReduce the weight of the main beamBridge structural detailsBridge deckBox girder

The invention discloses a corrugated steel web few-main-beam structure which comprises a plurality of corrugated steel web main beams, a concrete prefabricated plate arranged on corrugated steel webs, and a bridge deck pavement layer is laid on the concrete prefabricated plate. According to the corrugated steel web few-main-beam structure, a corrugated steel web combined structure is adopted, the use efficiency of steel and concrete materials is fully developed, the use amount of concrete is reduced, the dead load of the main beams is reduced, energy conservation and environmental friendliness are achieved, and the economic performance is good. Structural key parts of the corrugated steel web main beams and a concrete bridge deck slab are factorized, the concrete bridge deck slab is prefabricated in a factory and can reduce the additional stress caused by shrinkage and creep of the concrete, the product quality is easily ensured, and compared with a cast-in-place mode, the process of demounting and mounting a formwork is omitted, the wet work amount on the field is reduced, the construction period is shortened, and the construction progress is shortened. The smooth passing of the road can be achieved under a bridge in the construction process of the bridge, fast construction can be achieved, the influences on the existing traffic are small, and the social benefits are good. A basis is provided for factory standardized and prefabricated production and field assembly building of a 30 m-50 m corrugated steel web PC box girder bridge, and the application fields are expanded.

Owner:HENAN DAJIAN BRIDGE STEEL STRUCTURE

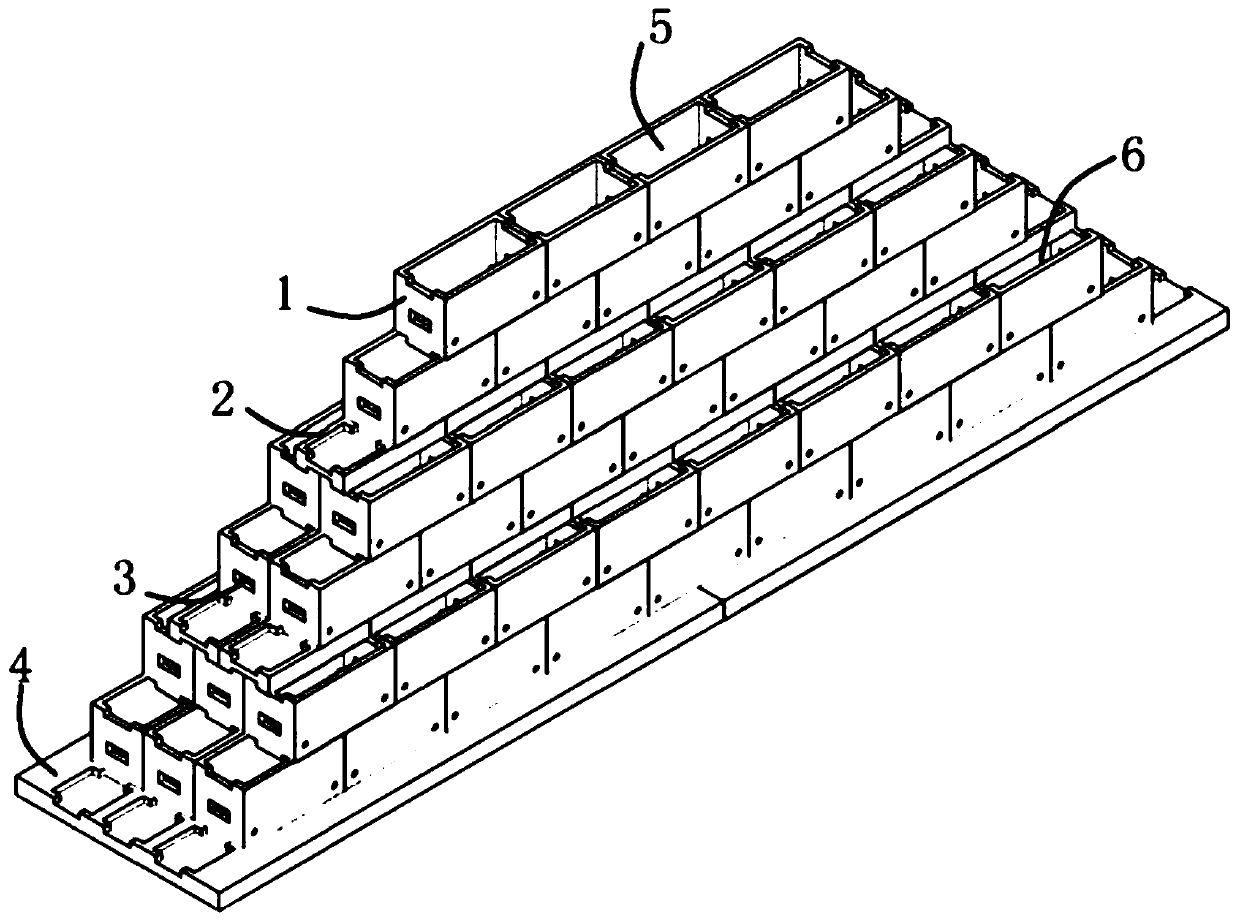

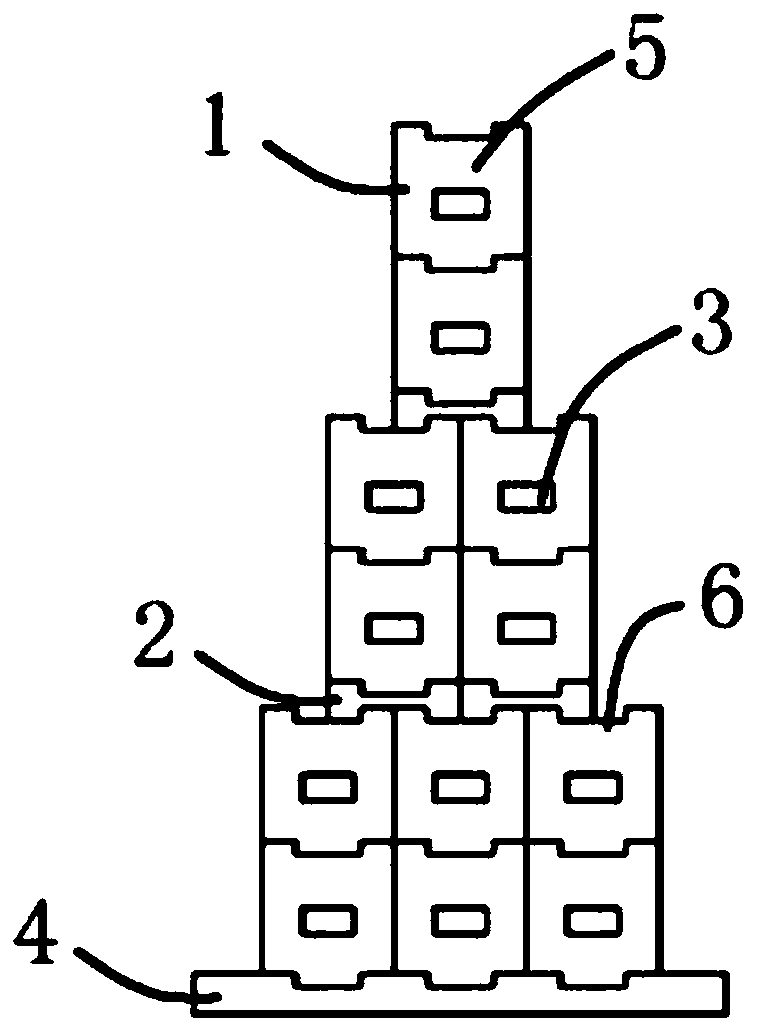

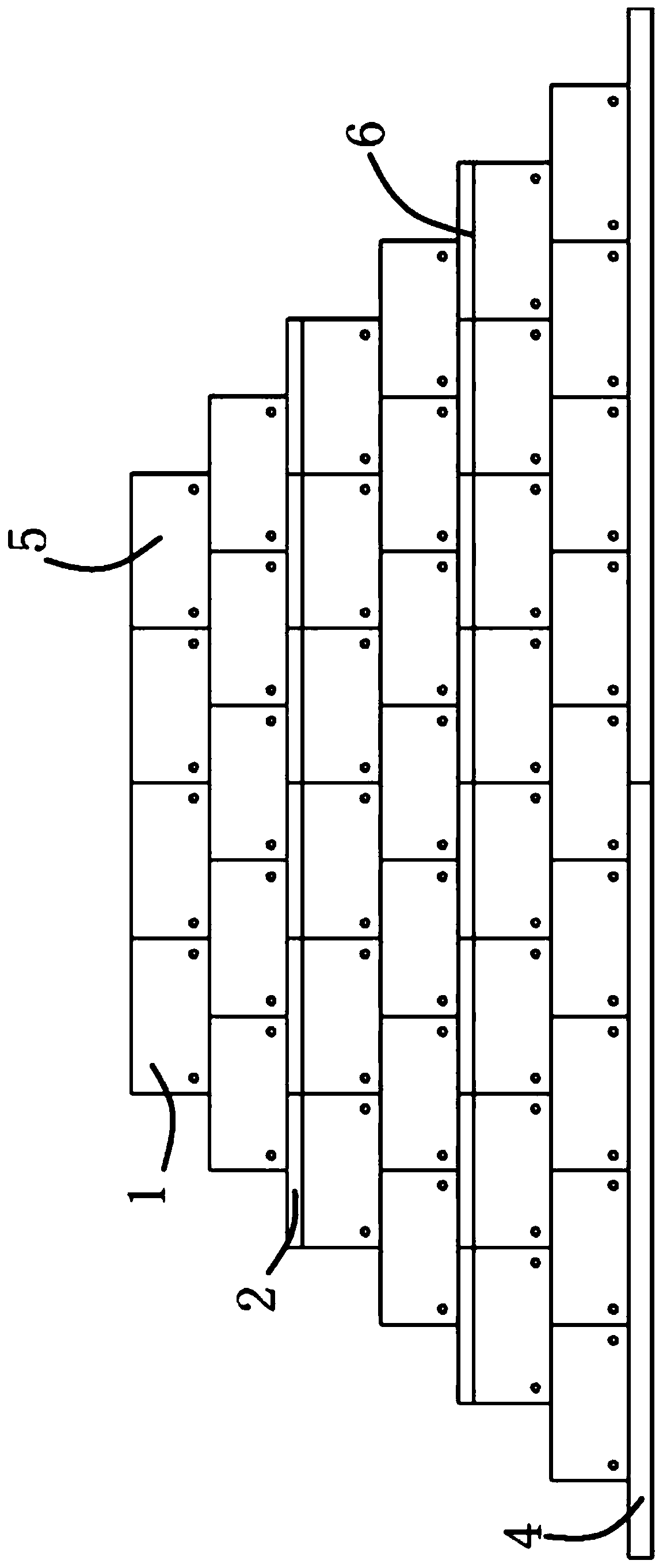

Fabricated concrete box retaining wall and construction method thereof

PendingCN110241849AReduce abandonmentLow costArtificial islandsUnderwater structuresRetaining wallMultiple layer

The invention discloses a fabricated concrete box retaining wall and construction method thereof. The fabricated concrete box retaining wall comprises a cast-in-situ foundation and a wall body arranged on the cast-in-situ foundation, concave string-shaped grooves are formed in the upper surface of the cast-in-situ foundation, the wall body is of a multiple-layer structure, each layer of the wall body comprises a plurality of prefabricated concrete box single bodies, the end parts of the two adjacent prefabricated concrete box single bodies in a single layer wall body are connected through side wall clamping blocks, compared with a traditional gravity retaining wall, according to the fabricated concrete box retaining wall, hollow concrete boxes are filled with waste soil stone materials, masonry or concrete cubic amount is reduced about 40 %, the cubic meter of earth and stone waste in engineering is utilized reasonably, the waste cubic of engineering is reduced, the engineering cost can be reduced over 15 %, the smallest assembling unit of the fabricated concrete box retaining wall is the prefabricated concrete box single bodies, all the prefabricated concrete box single bodies are the same in size, standardized production is facilitated, assembling construction is convenient, and the field construction period can be lowered over 30 %.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

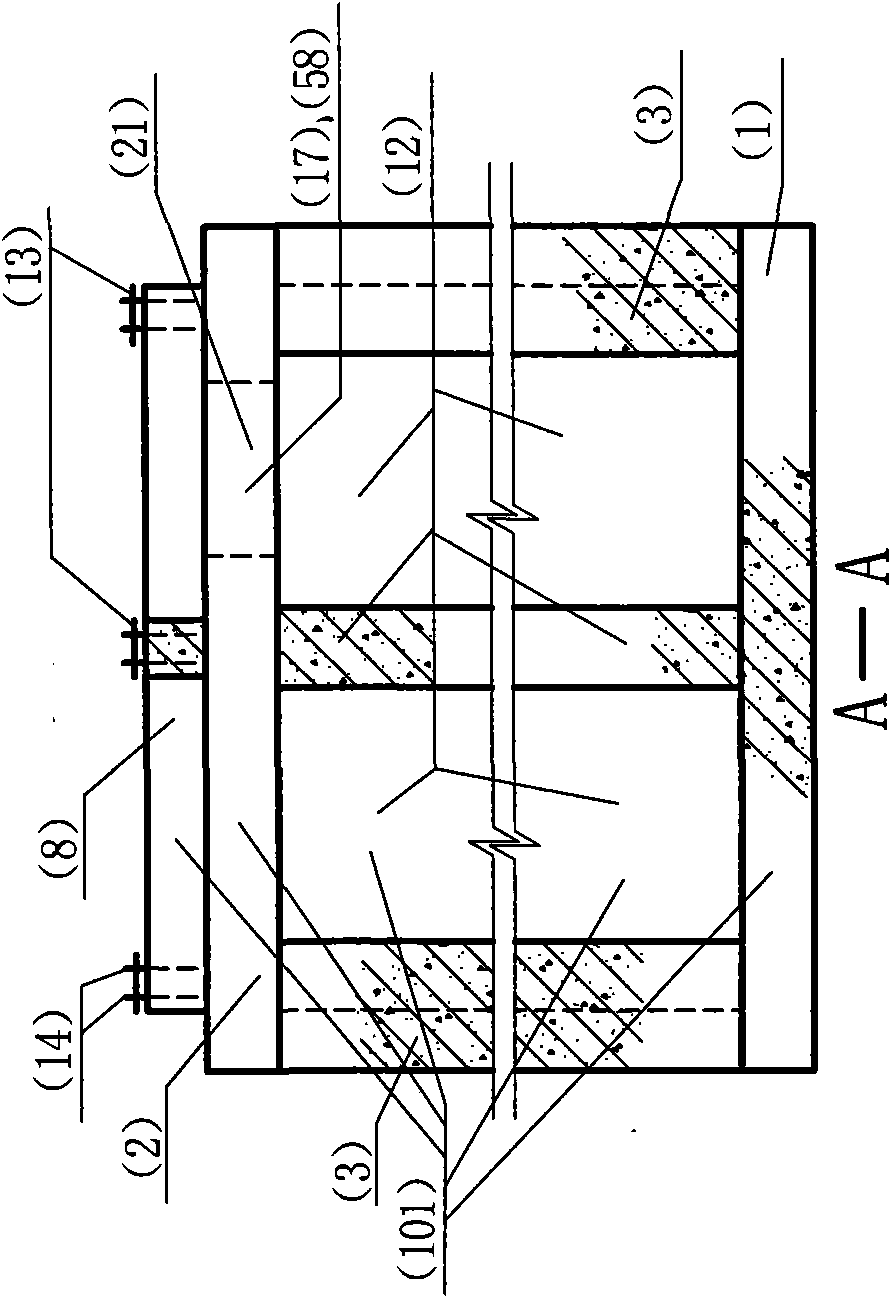

Cast-in-situ concrete hollow board

The invention is a cast-in-site concrete hollow slab, comprising reinforced concrete, and hollow bodies, where the hollow bodies are wrapped in the reinforced concrete and alternate with cast-in-site reinforced concrete ribs, cast-in-site reinforced concrete top plate and infrabasal slab are on and under the hollow bodies respectively, the hollow body is formed by outer walls, and it is characterized in that: the hollow body is equipped with reinforcing bar packing strip or / and fill block, and the side outer wall of the hollow body is equipped with rib space width limiting piece. Thus, it can effectively prevent reinforcing bars rusting; besides, the rib space width limiting piece can effectively assure the width of hidden rib in building cover consistent with the designed width; and it is applied to cast-in-site reinforced concrete or prestressed reinforced concrete hollow building covers, roofs, wall bodies, foundation soleplates and hollow bridges, especially hollow, beam-free building covers.

Owner:湖南邱则有专利战略策划有限公司

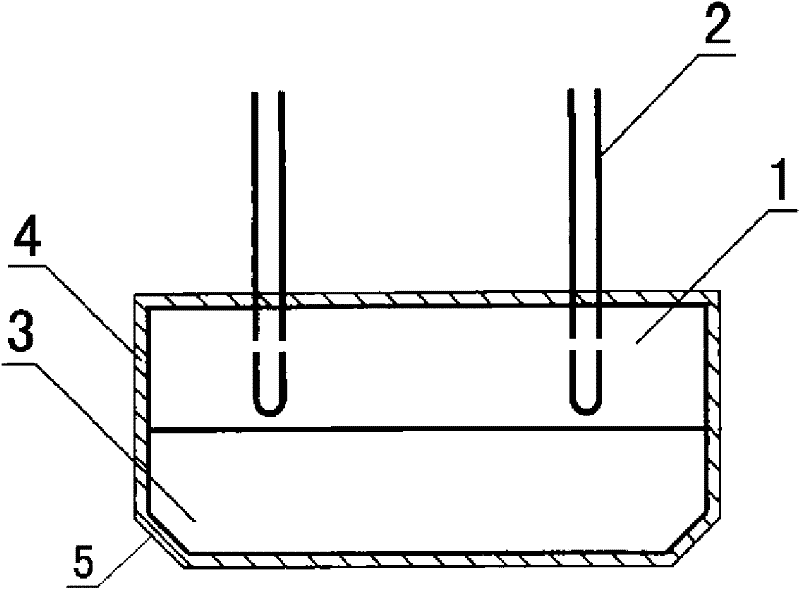

Perlite polyphenylene compound filling block, method for preparing same and filled floor plate construction method

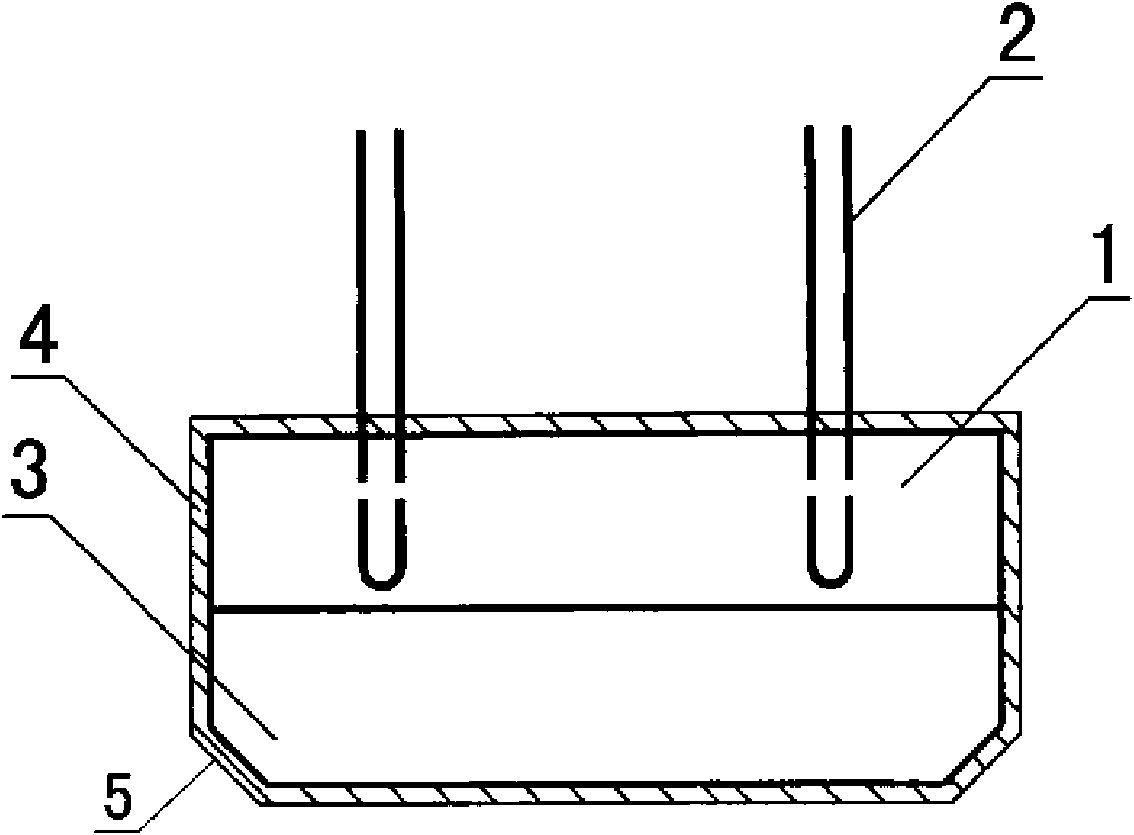

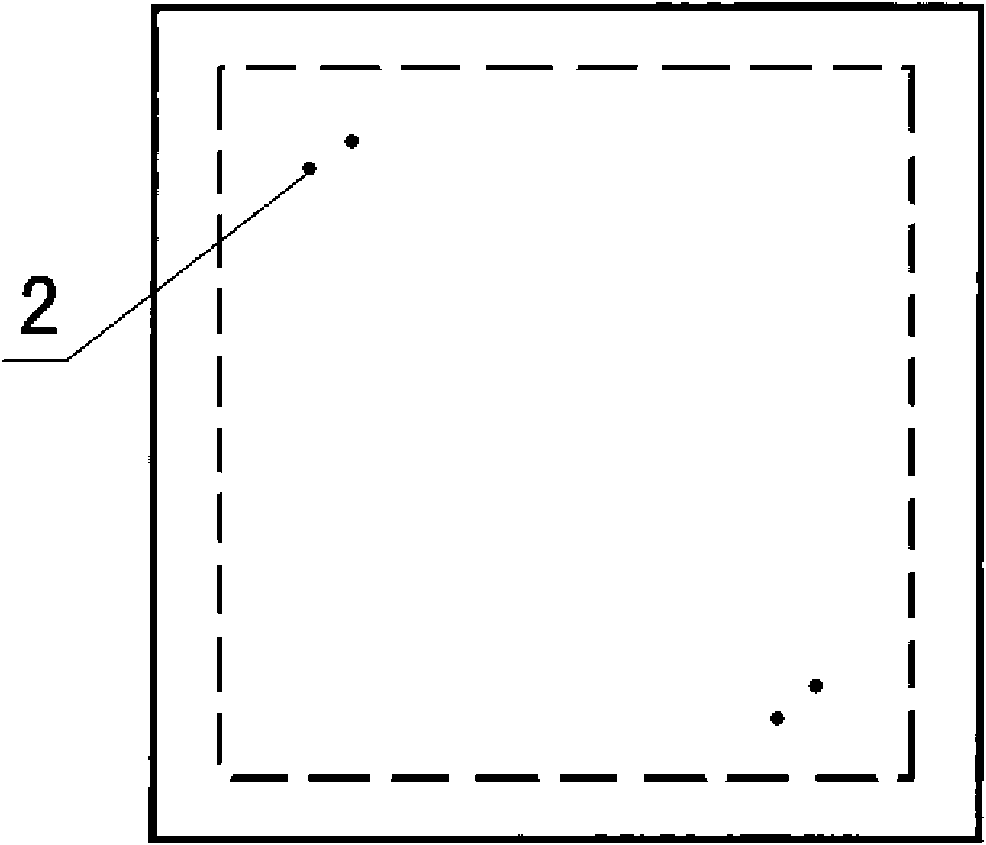

InactiveCN101684676ALight weightAvoid deformationConstruction materialCeramic shaping apparatusCombustionRebar

The invention provides a perlite polyphenylene compound filling block, a method for preparing the same and a filled floor plate construction method, wherein the perlite polyphenylene compound fillingblock is a cuboid with the rectangular top surface; and a block body is formed by up-and-down lamination of a rectangular expanded perlite agglomerate and a polyphenylene plate, and the outer surfaceof the block body is wrapped by a plastic adhesive tape, a positioning metallic wire is embedded in the expanded perlite agglomerate in advance, the bottom part of the positioning metallic wire is U-shaped, both ends of the positioning metallic wire upward pass the expanded perlite agglomerate and are extended to the outer side of the plastic adhesive tape. The perlite polyphenylene compound filling block has low cost, relatively light deadweight and insusceptibility to breakage, combustion and deformation, and can effectively solve the problem that the block body is susceptible to water absorption; when the perlite polyphenylene compound filling block is arranged in the floor plate in advance, the cement consumption of the floor plate is reduced, the weight of the floor plate is reduced,the whole deadweight of the structure of the building is reduced, but the bearing capacity of the floor plate is not lowered; moreover, the total consumption of reinforcing steel bars in the floor plate and the building is also lowered.

Owner:杨晓宏

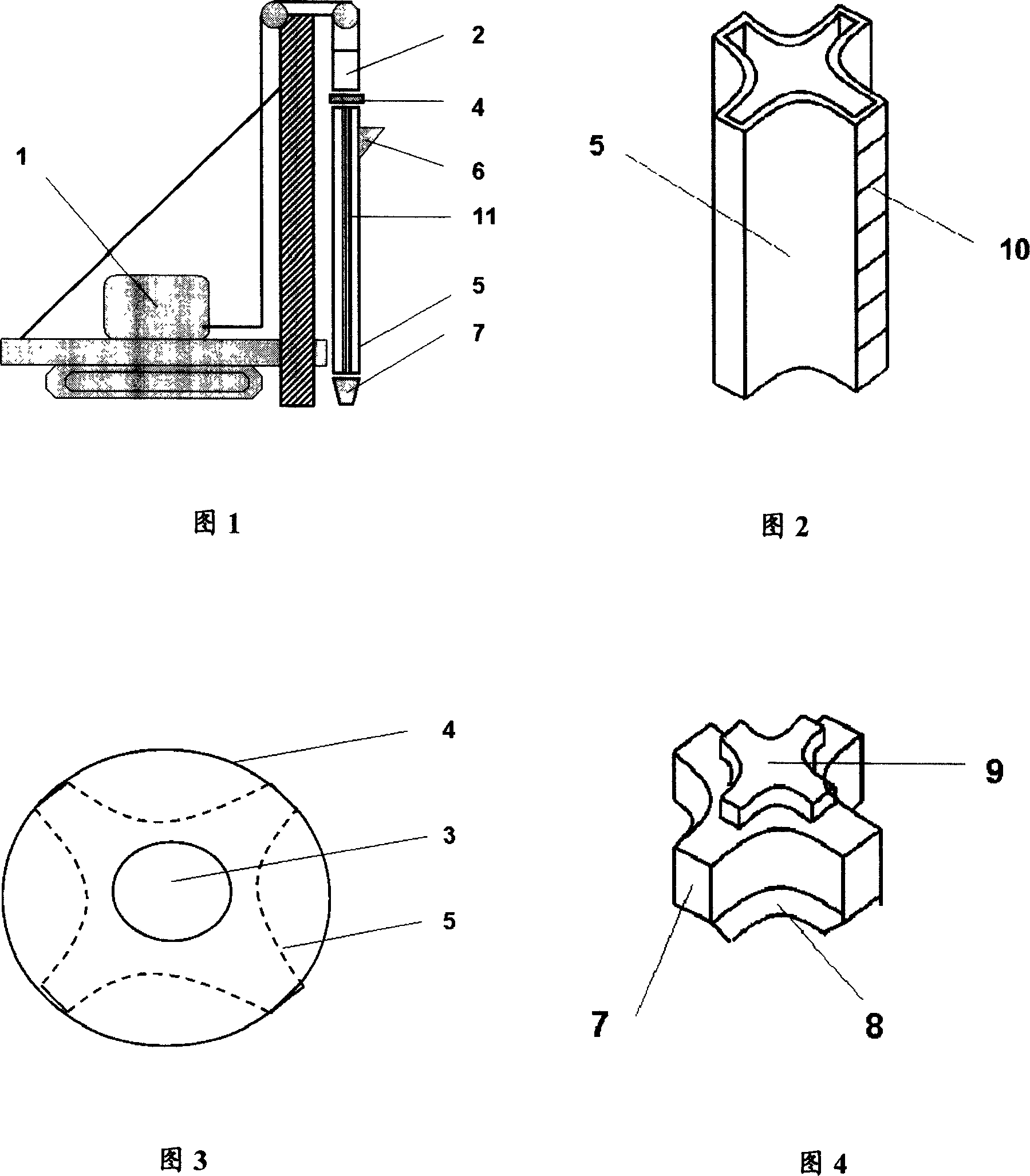

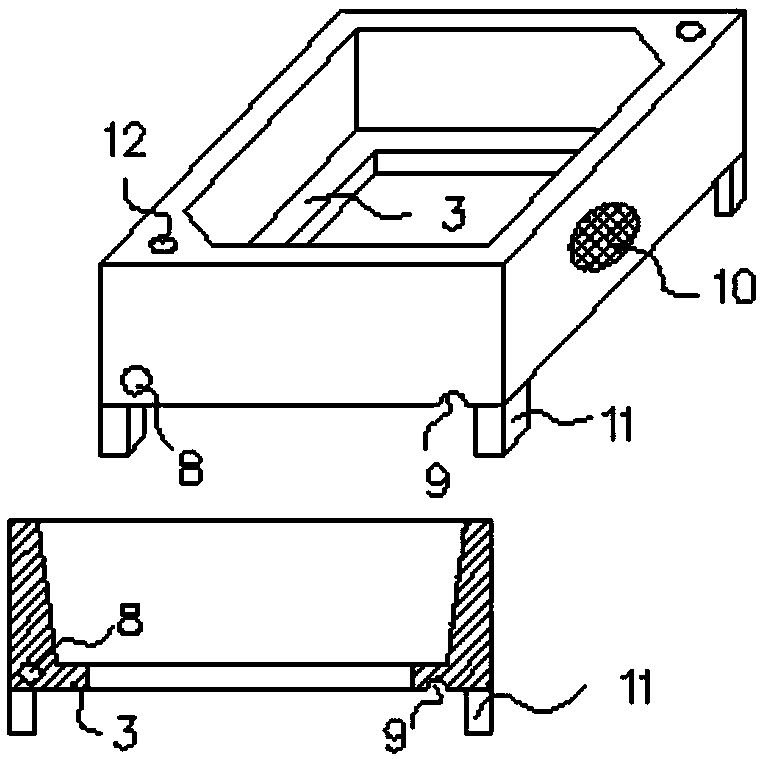

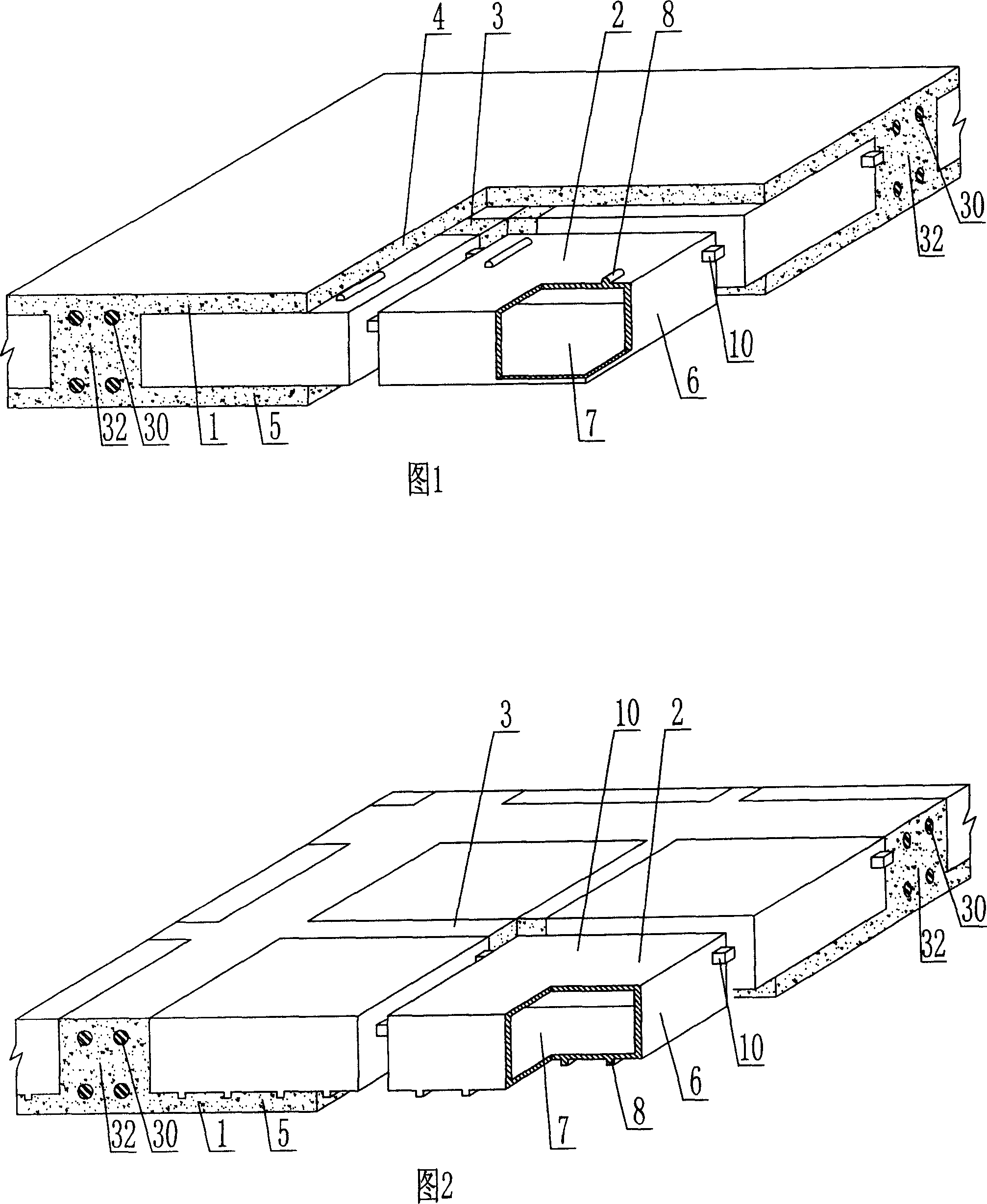

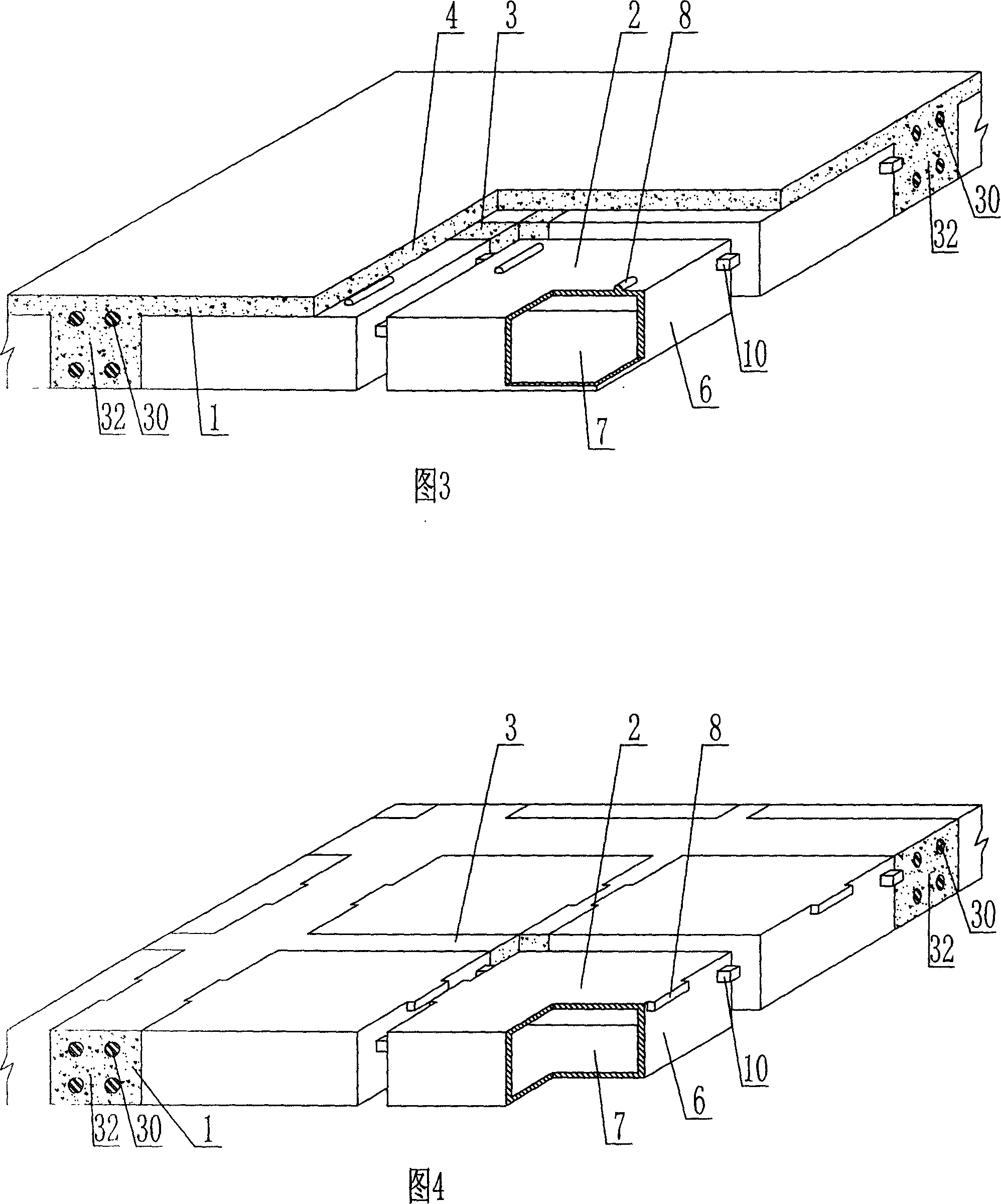

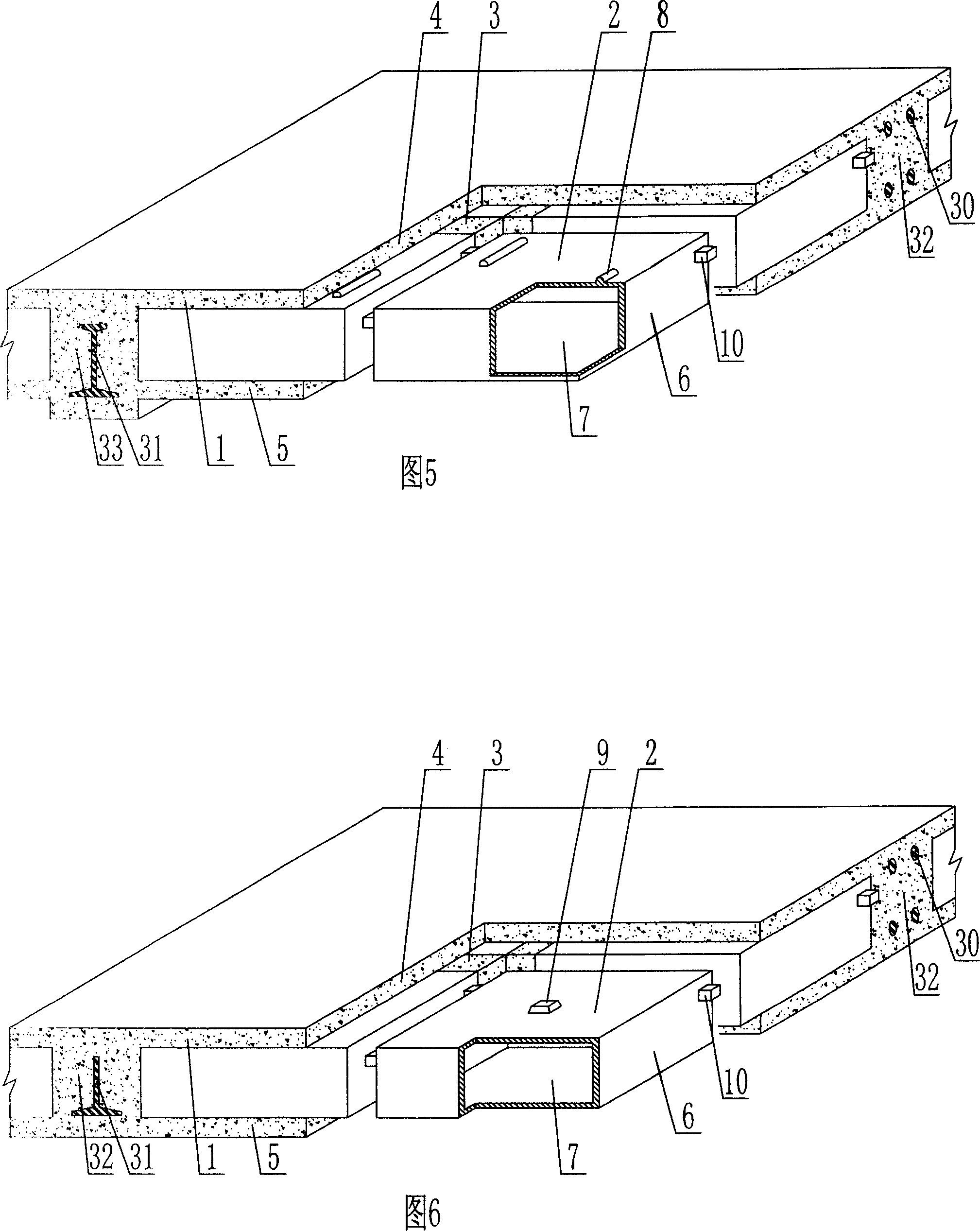

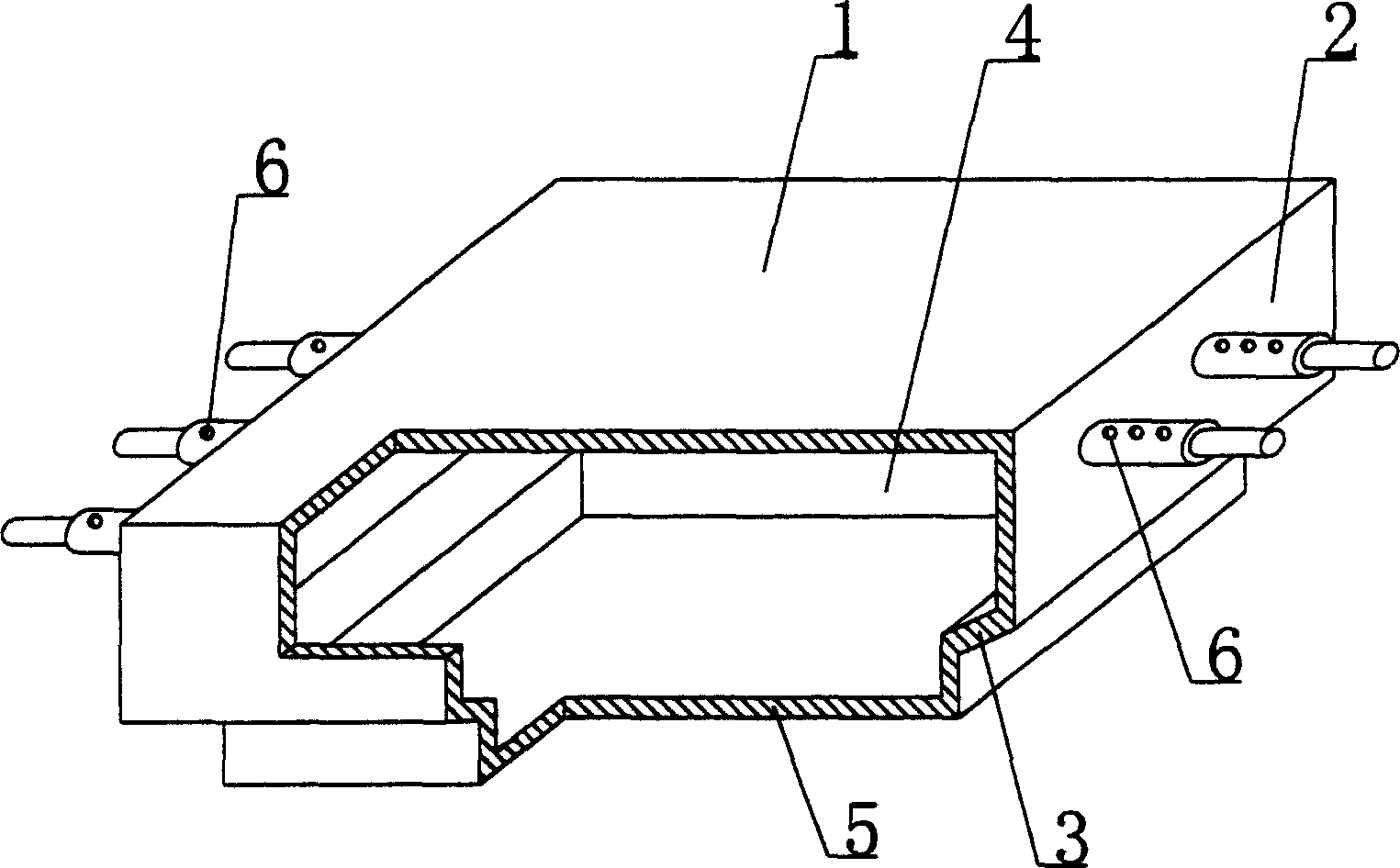

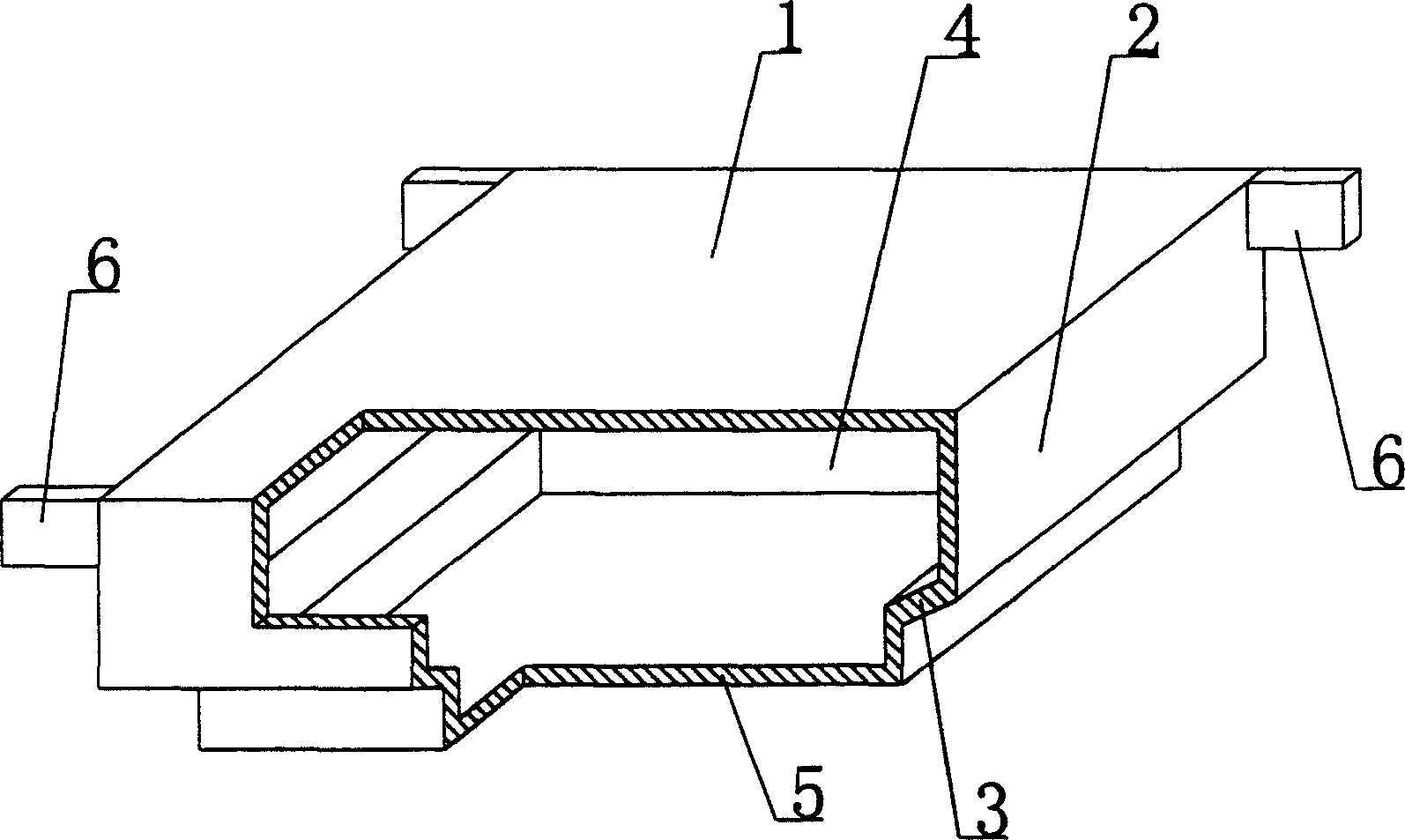

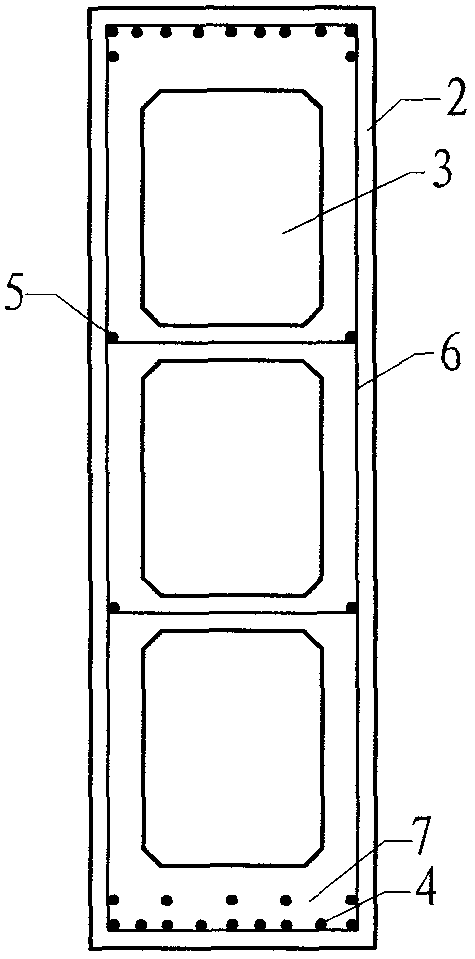

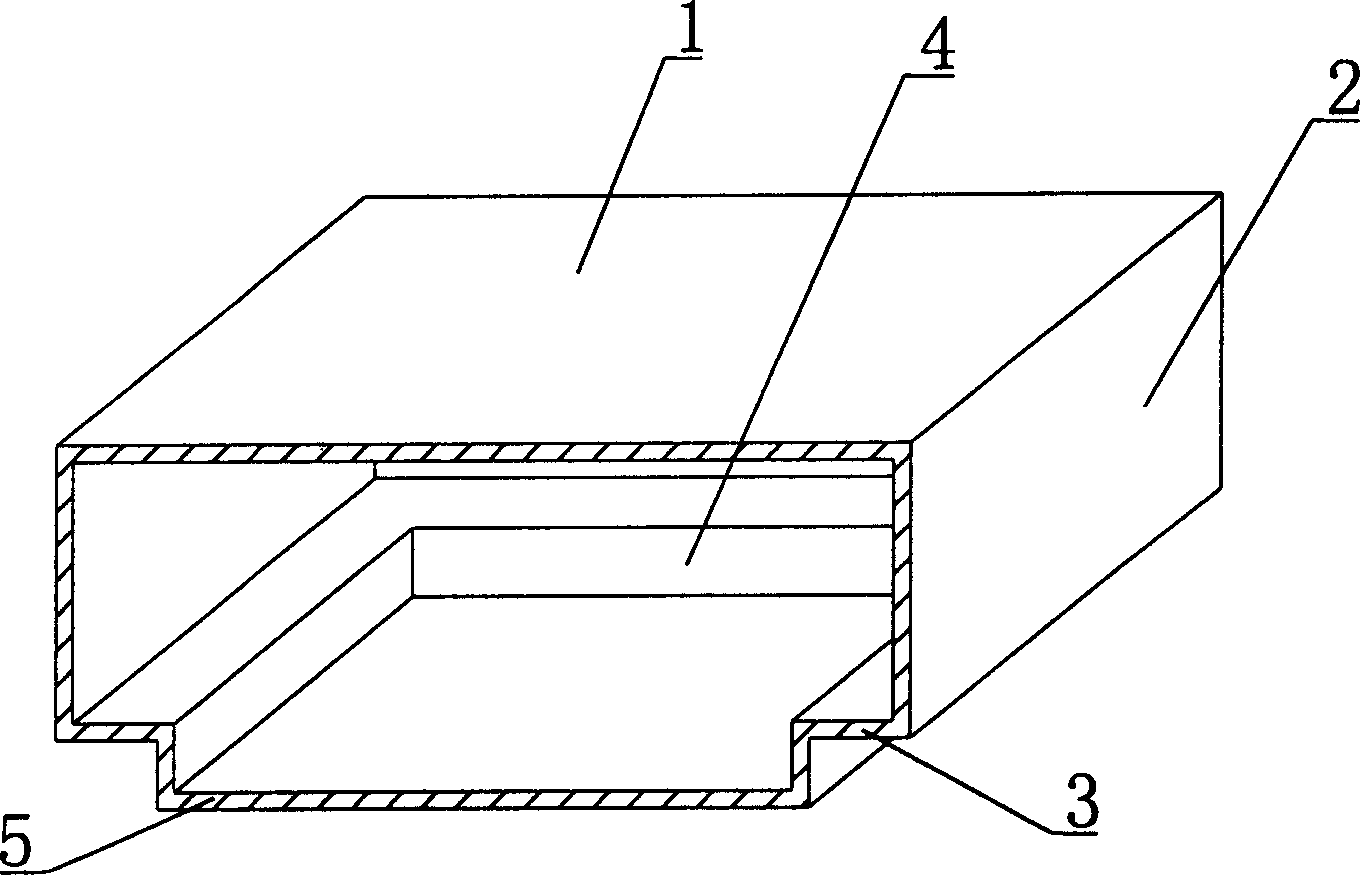

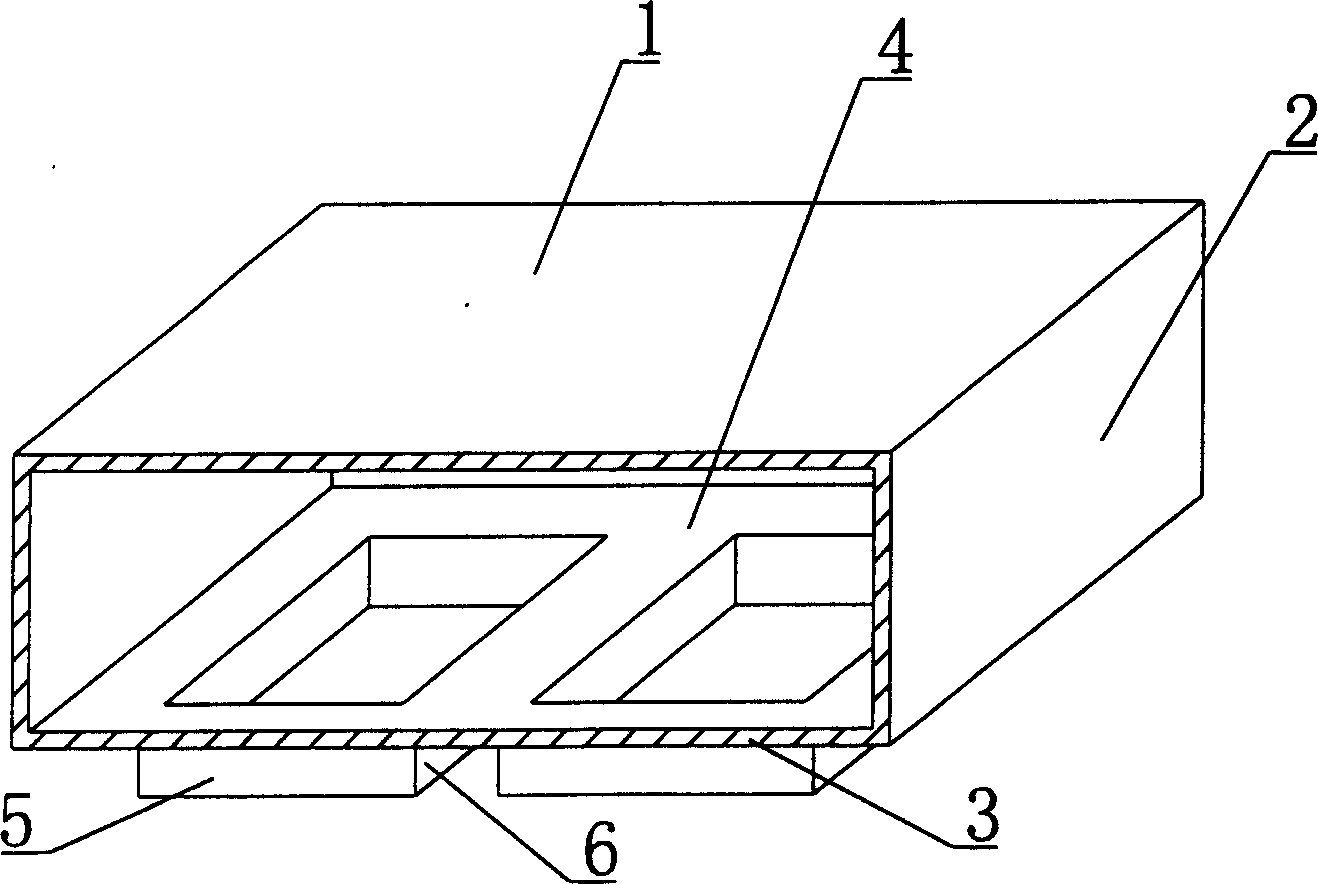

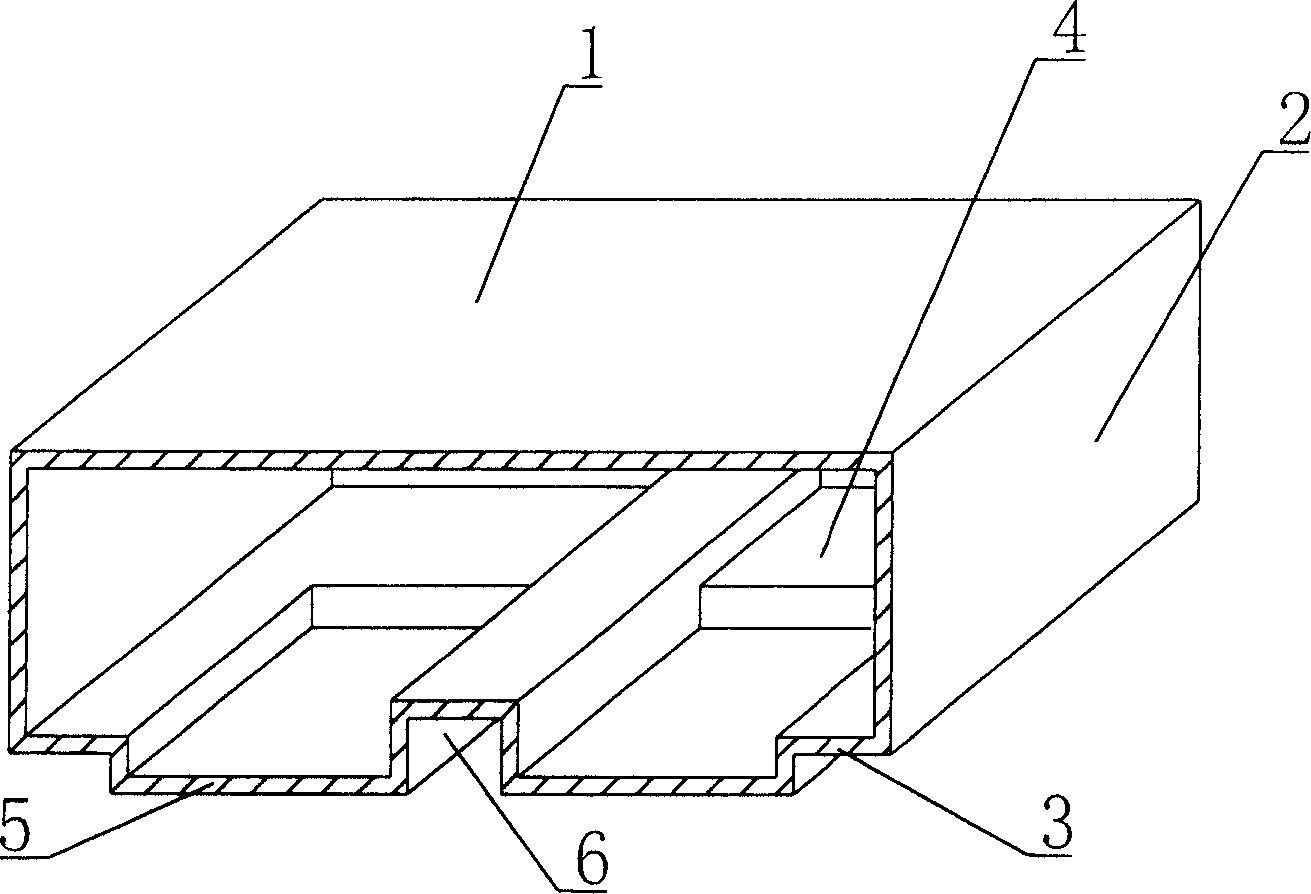

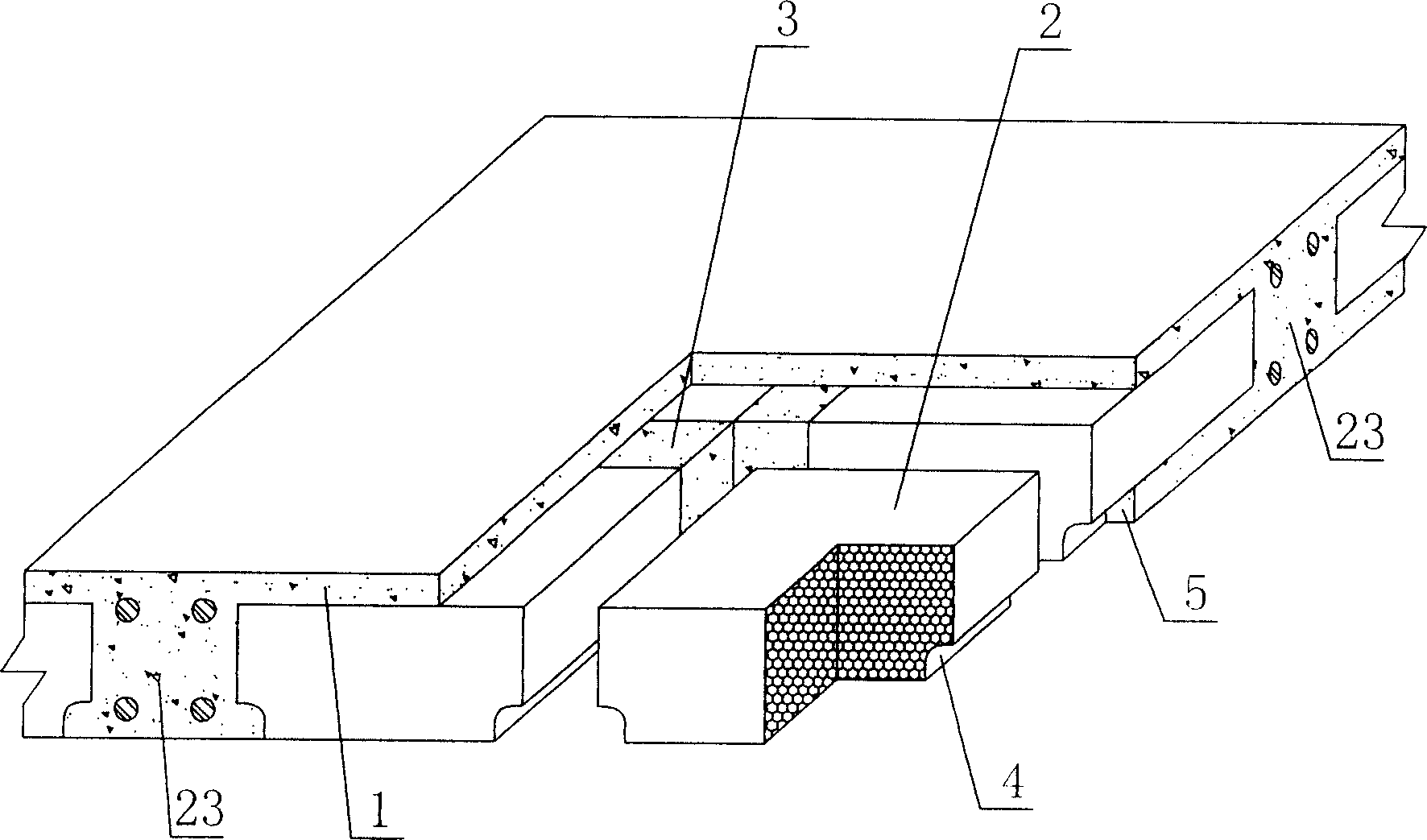

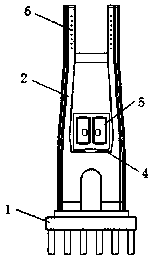

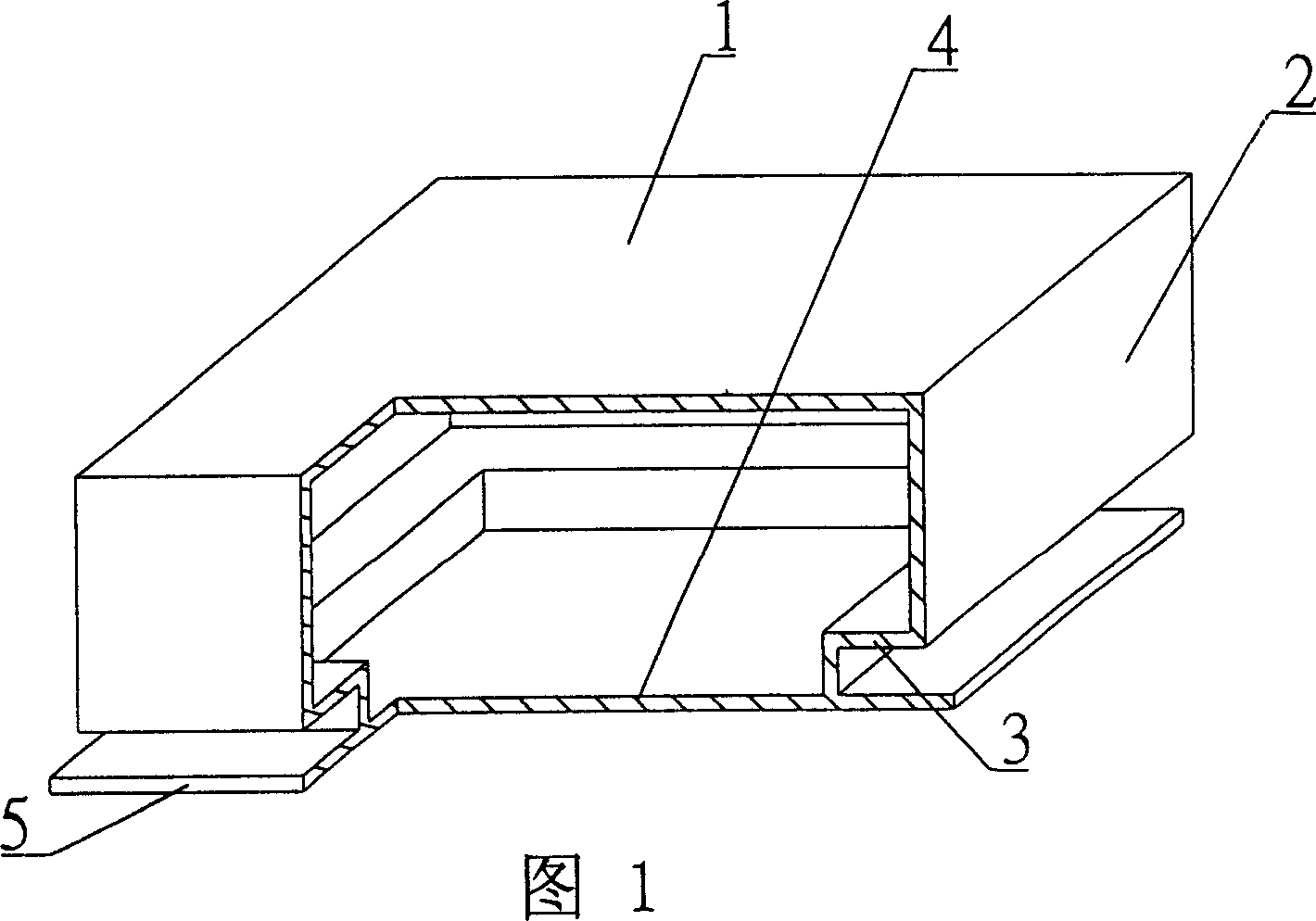

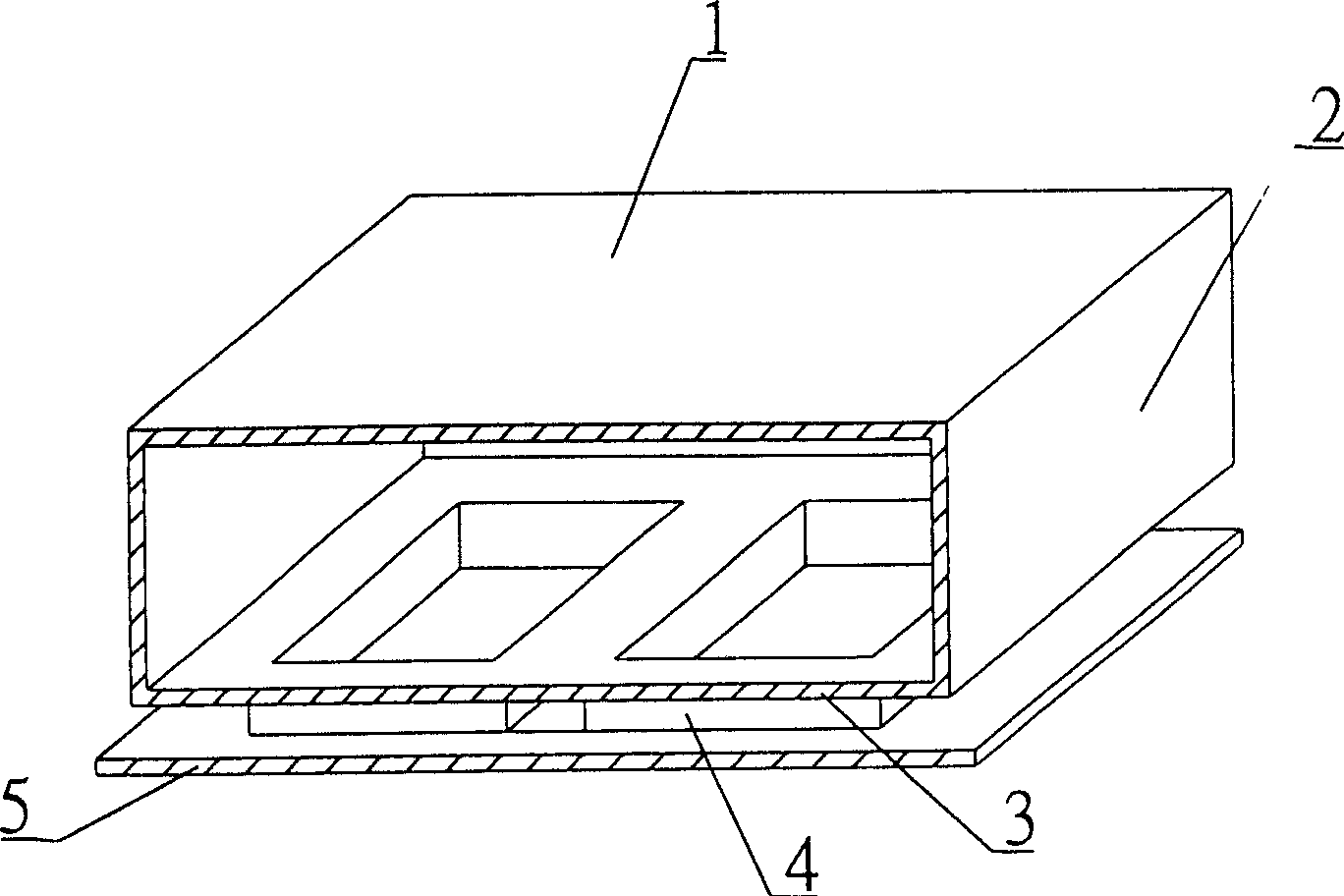

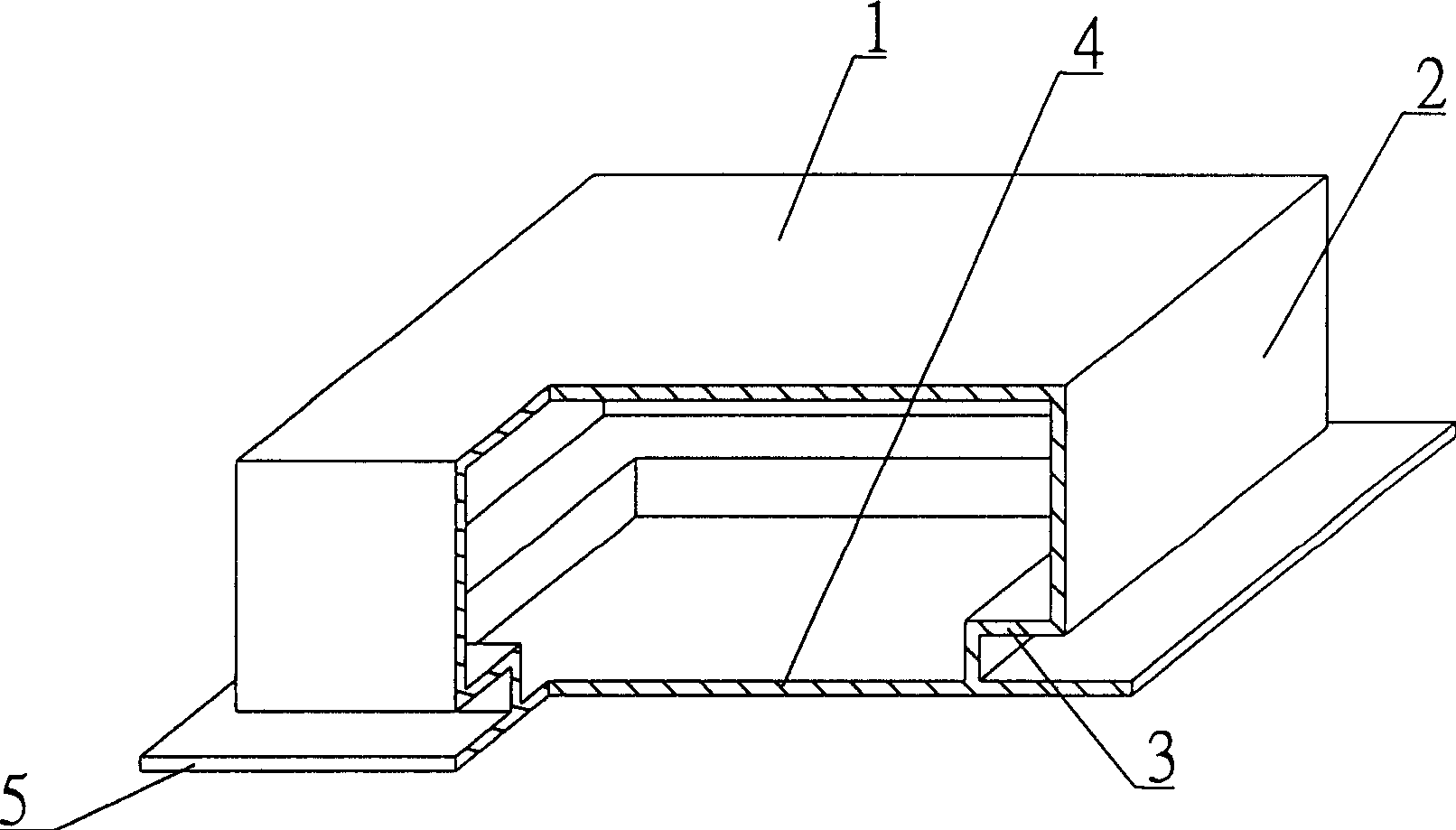

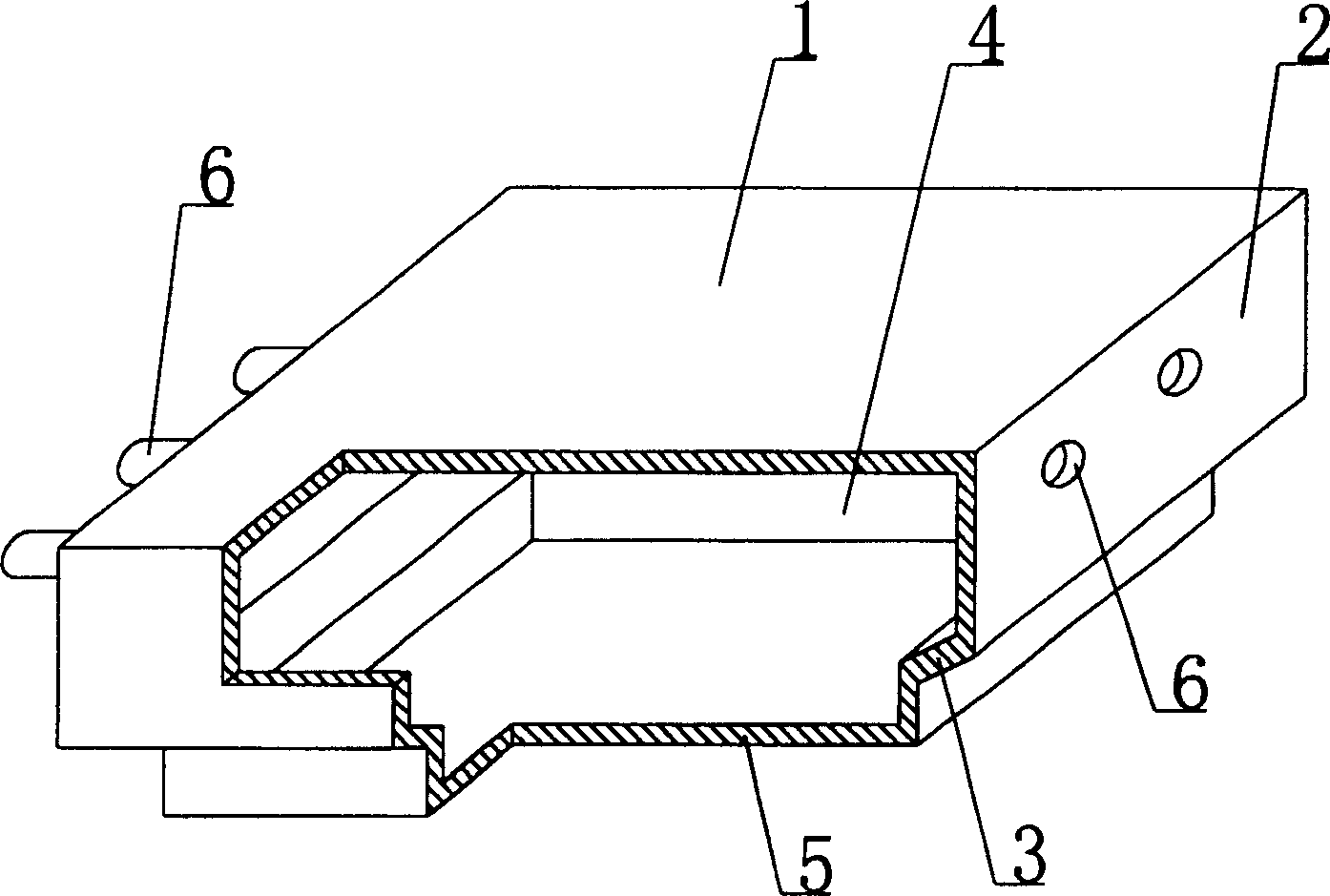

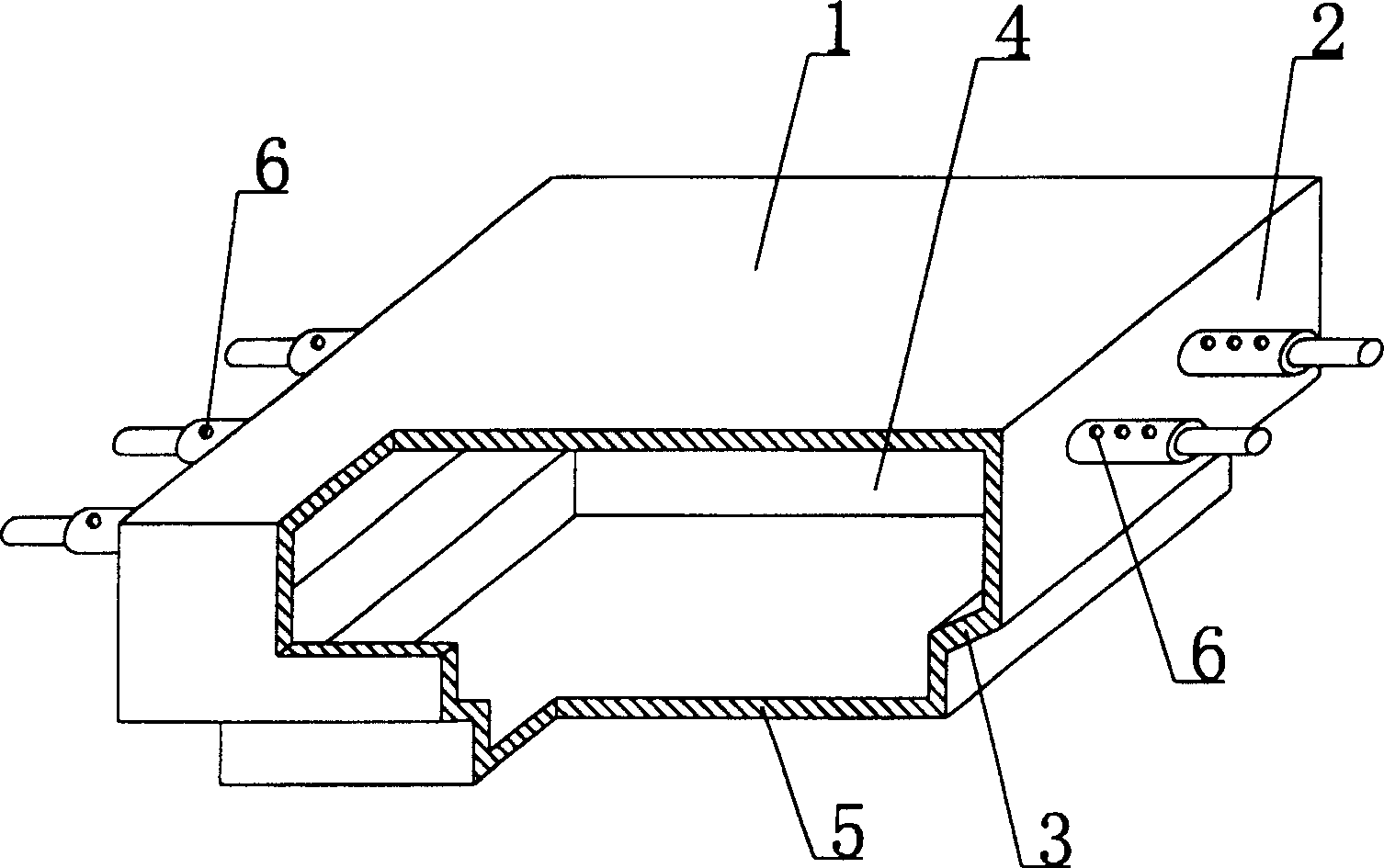

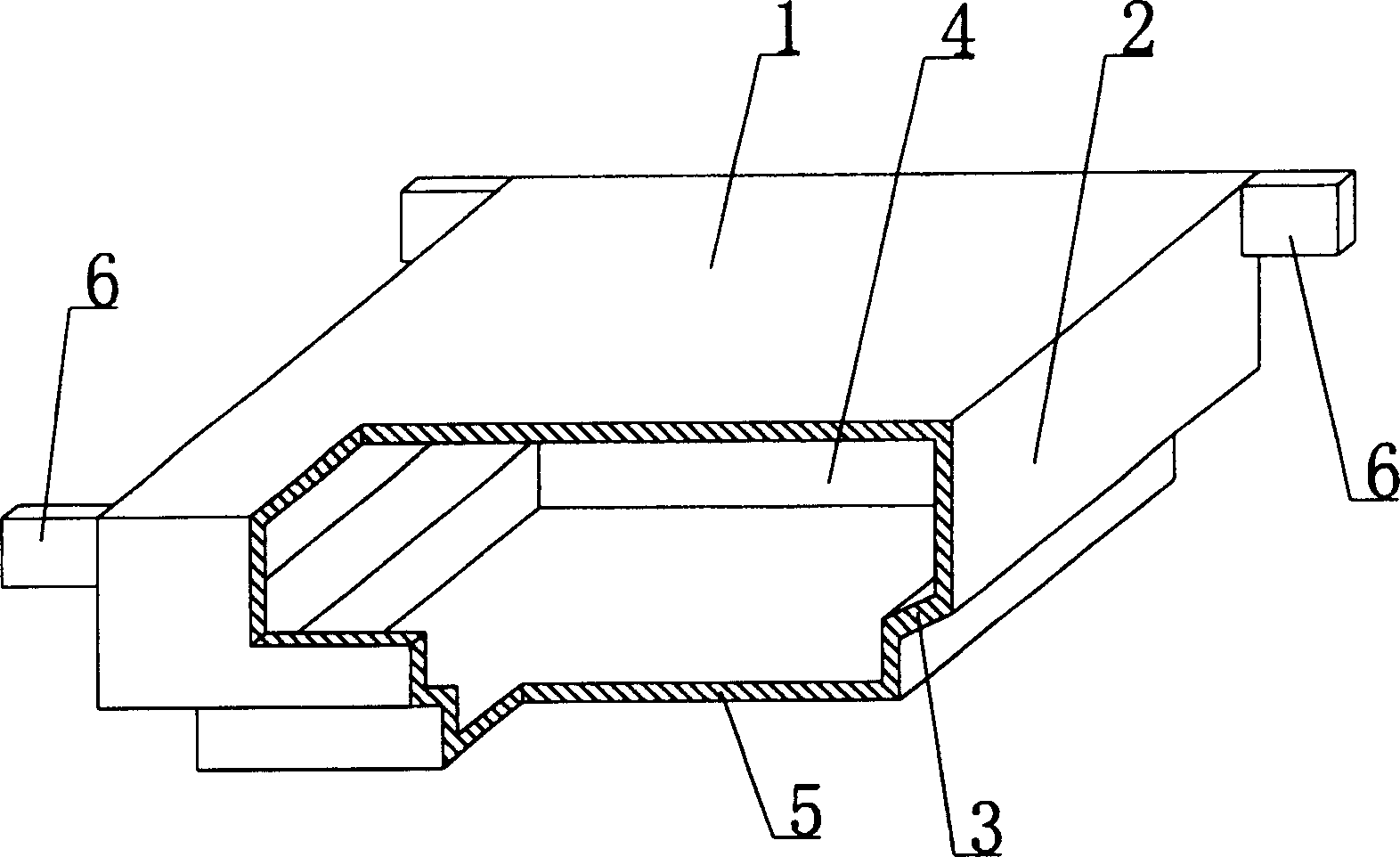

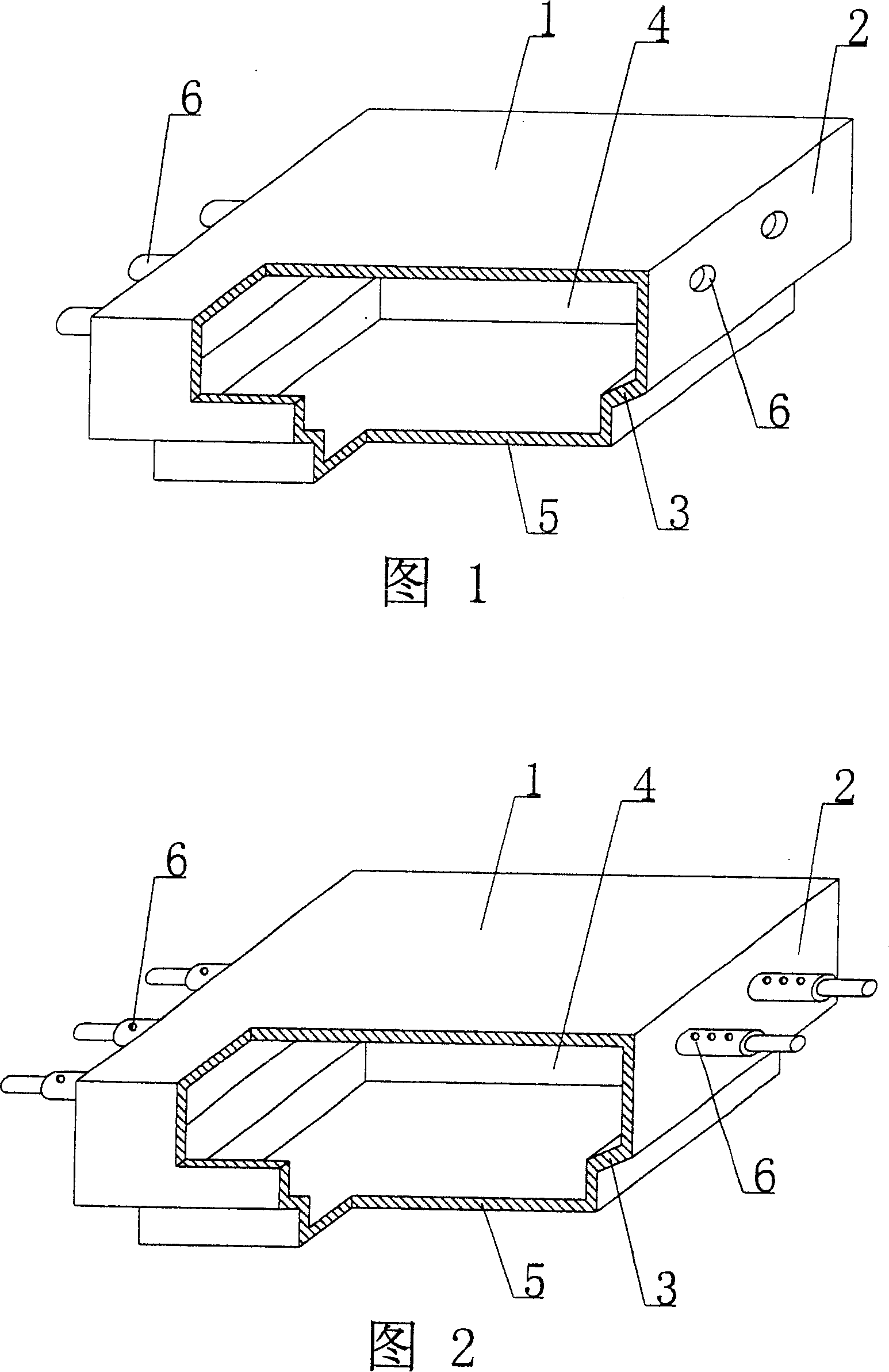

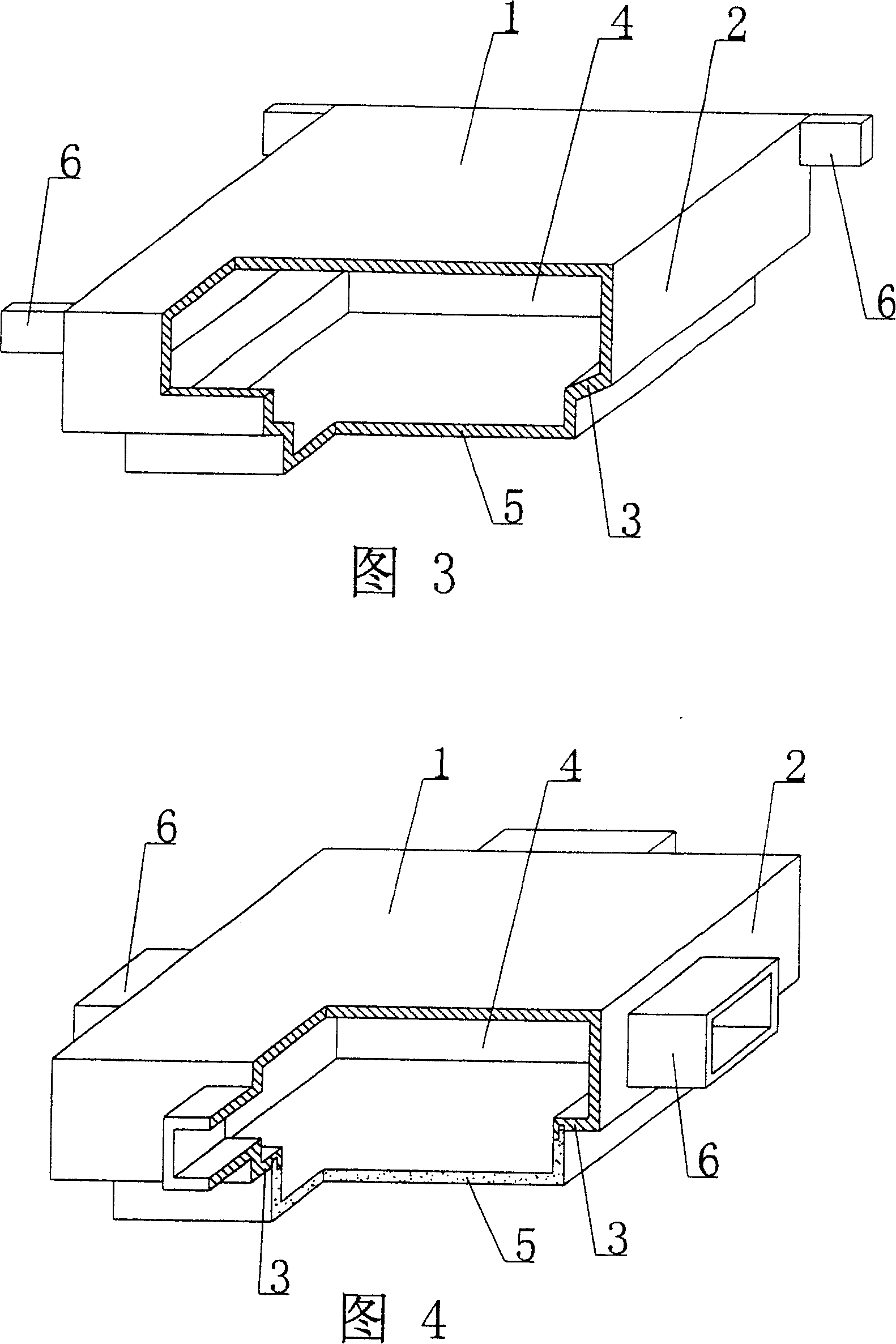

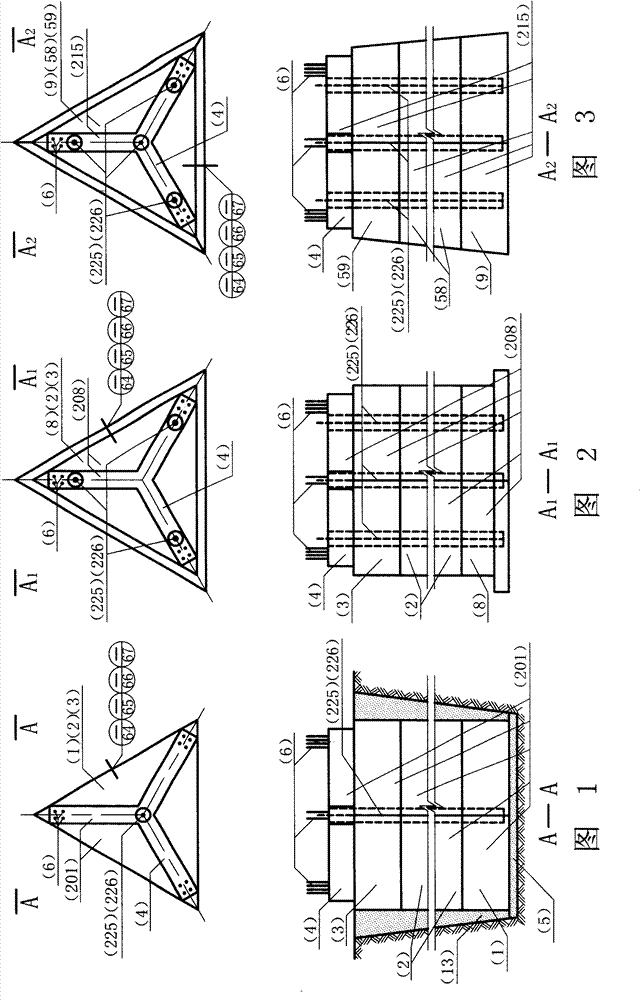

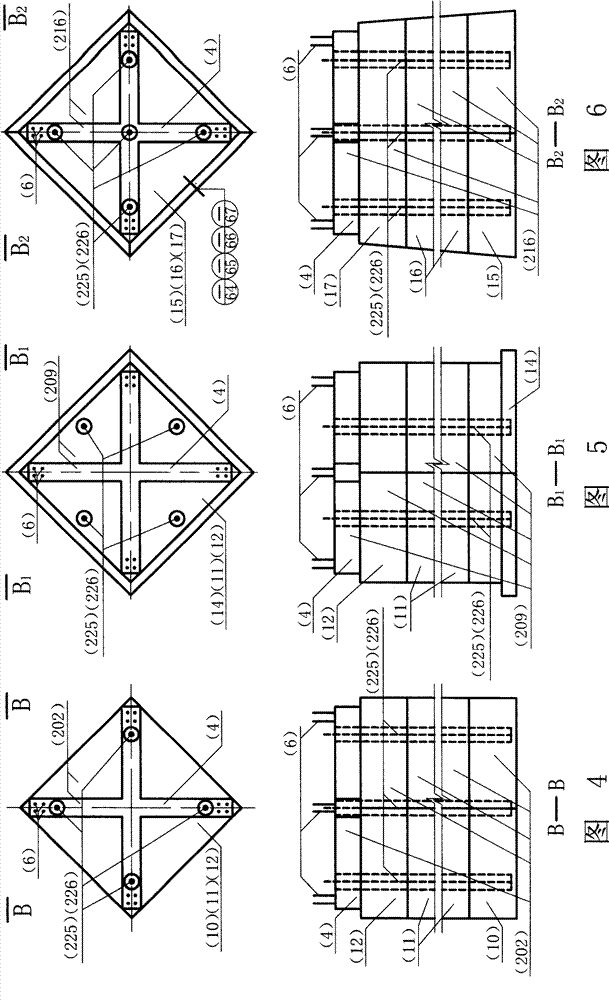

Thin wall molded case member

Disclosed is a thin-walled shuttering cavity component, which comprises an upper plate (1), a surrounding side-wall (2) and a lower bottom (3), the three parts are encircled to form a cavity (4), characterized in that at least one boss module (5) protrudes the lower bottom (3), and at least one connecting piece (6) is arranged on at least one surrounding side-wall (2). The shuttering component greatly improves the mechanical properties of the floor when being applied to the dense rib floor, reduces section size of the dense rib, reduces reinforcing steel bar and concrete consumption, and it is easy to lay and connect shuttering components, shift or displacement and unconformity of on-site casting concrete rib width and concrete protective layer thickness between shuttering components are avoided. The invention is suitable for on-site casting hollow floor, roof, soleplate, wall and empty bridge with on-site casting reinforced concrete or prestressed reinforced concrete, especially for hollow mushroom floor.

Owner:湖南邱则有专利战略策划有限公司

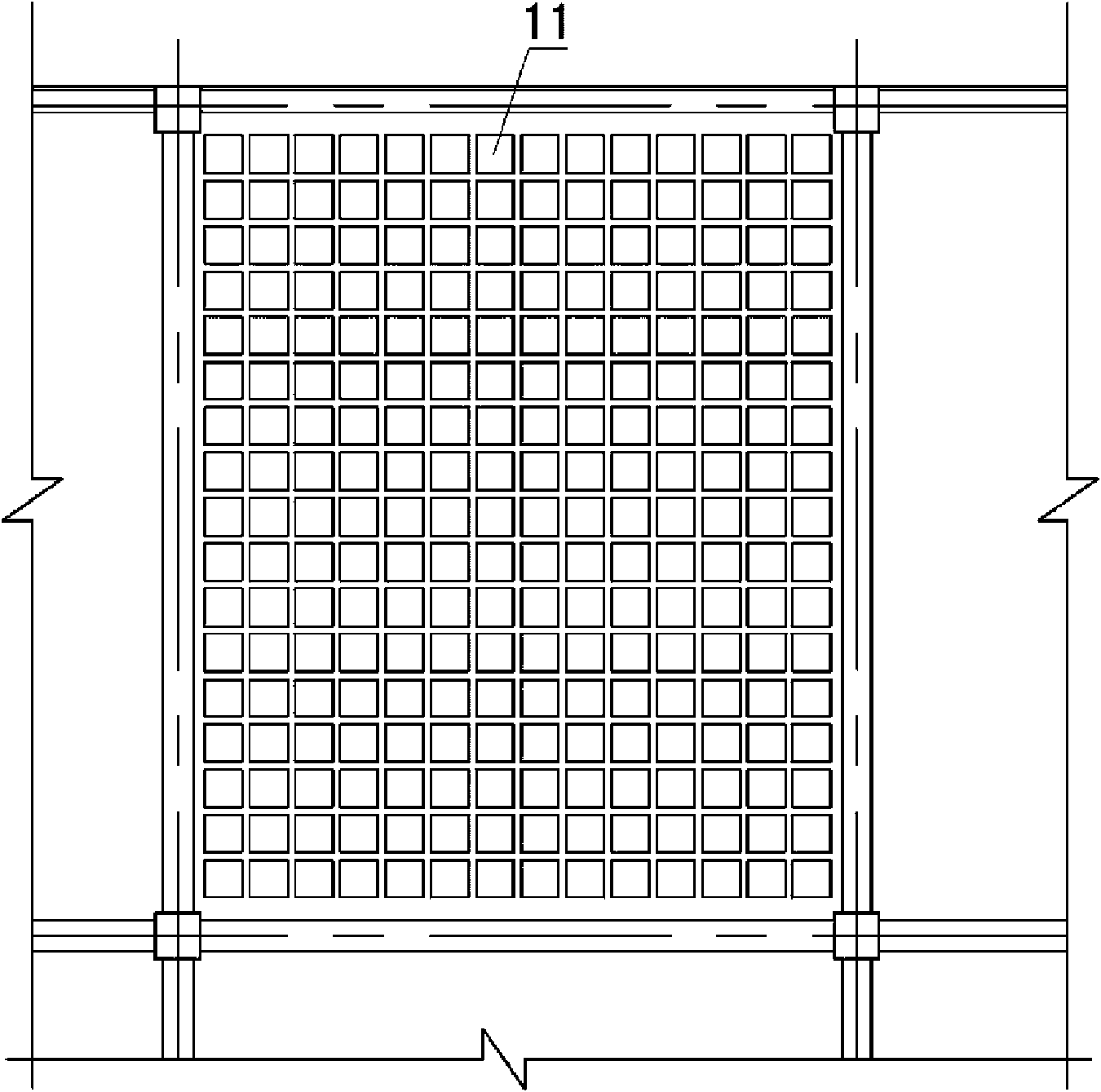

Construction technology of basement cast-in-situ hollow floor slab steel mesh box

The invention relates to a construction technology of a basement cast-in-situ hollow floor slab steel mesh box. The construction technology comprises the following steps that the placement position lines of reinforcing steel bars and box formworks are determined; floor slab floor iron and box formwork side rib beams are bound, specifically, the floor slab floor iron and the box formwork side rib beams are bound sequentially according to the positions of the placement position lines; an embedded pipeline is laid; cushion blocks are arranged on the lower portion of steel mesh box formworks to bemounted and used for guaranteeing the thickness of concrete on the lower portions of the box formworks; the steel mesh box formworks are mounted; after the steel mesh box formworks are placed, floorslab upper iron is bound; a construction facilitating channel is built, and a concrete conveying tube is erected, so that constructors can operate and walk through conveniently, and the box formworksand floor slab reinforcement steel bar finish products are protected; concealed check acceptance is conducted; concrete pouring is conducted; maintenance is conducted; the formworks are disassembled;and a post-pouring area is arranged. According to the construction technology, the cost is saved, the usage amount of concrete is saved through the method, the self weight of the structure is lowered,the engineering cost is lowered, the effect of earthquake is reduced, the using function is improved, and the practical space is expanded.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

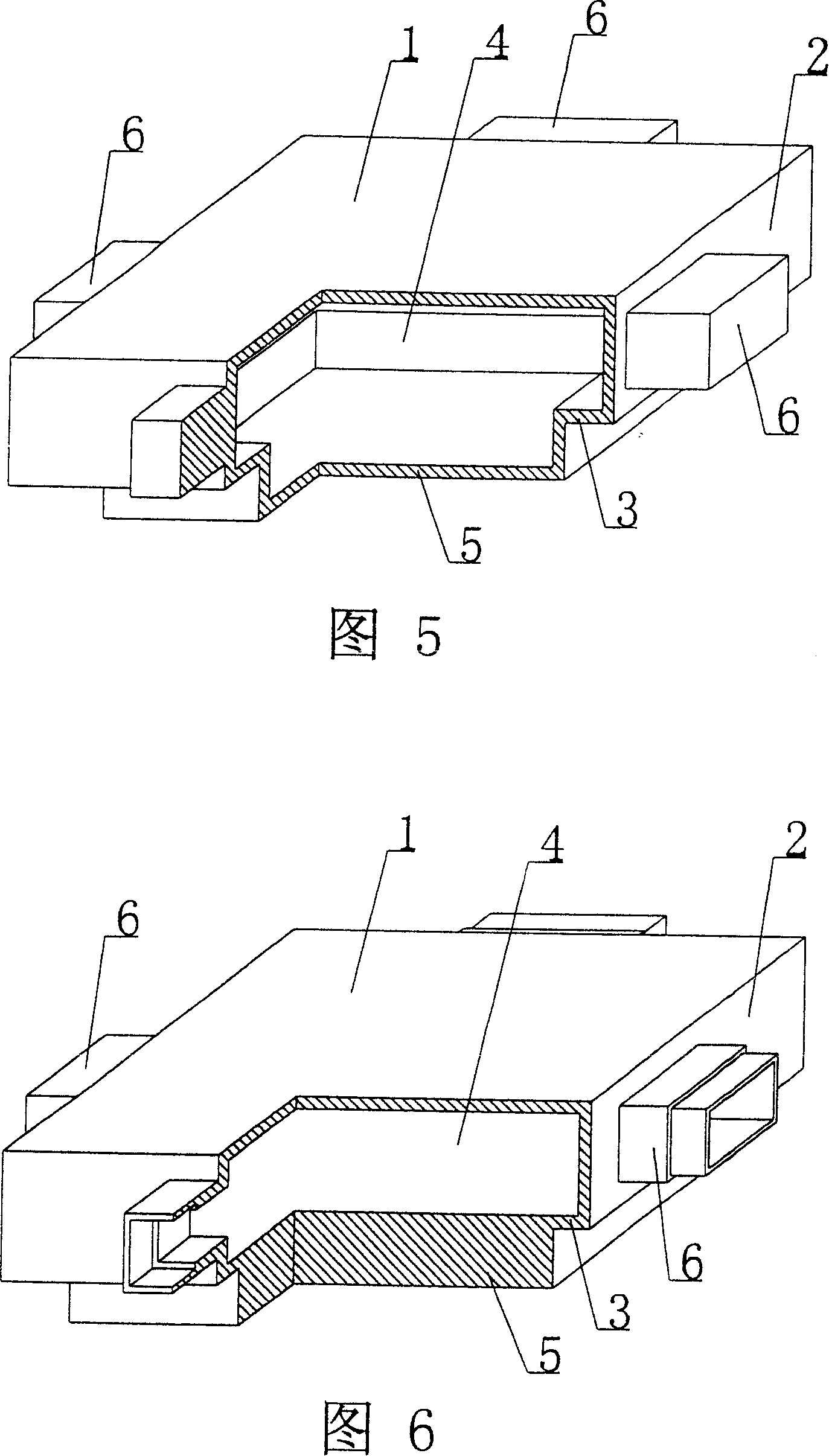

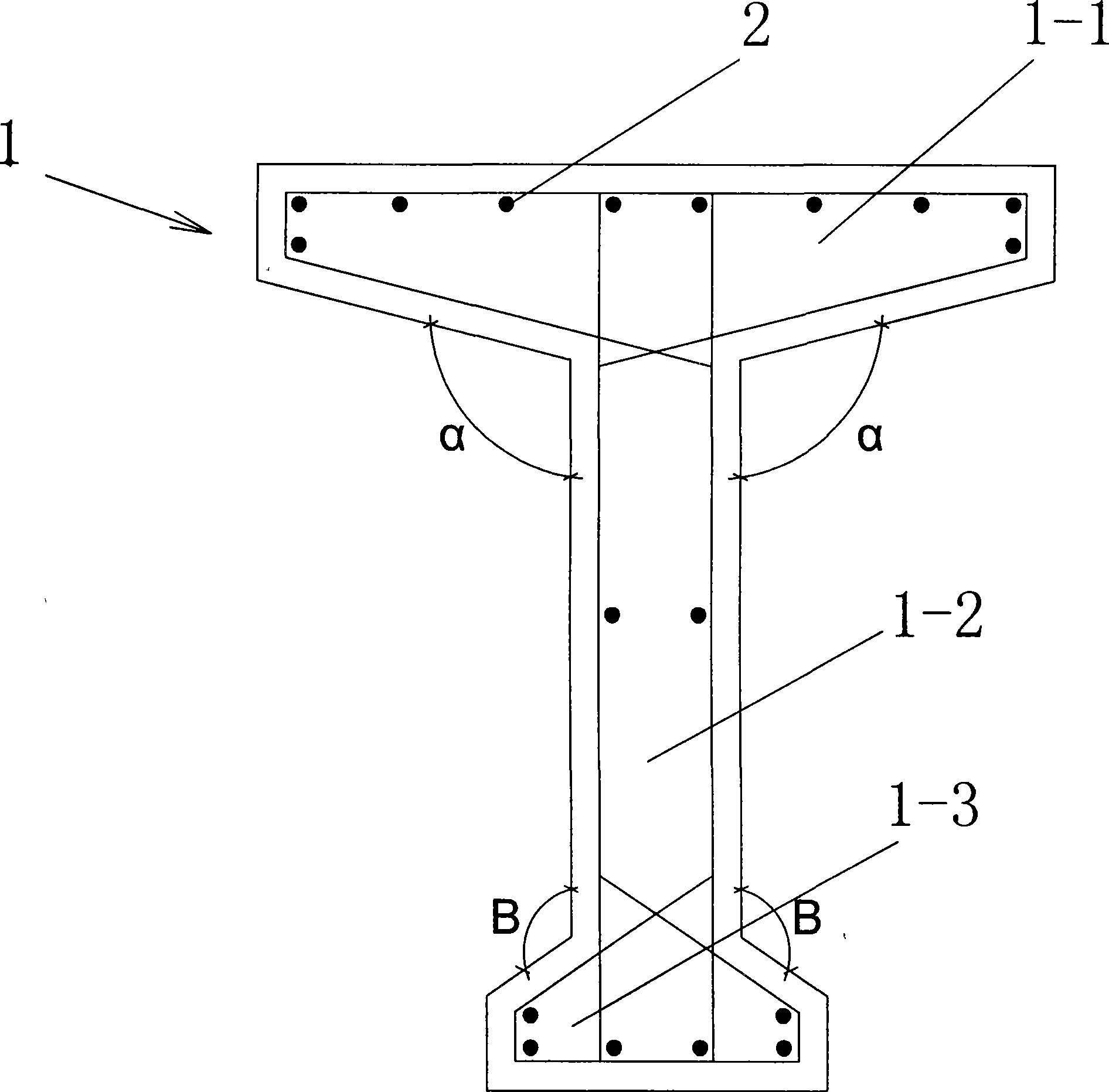

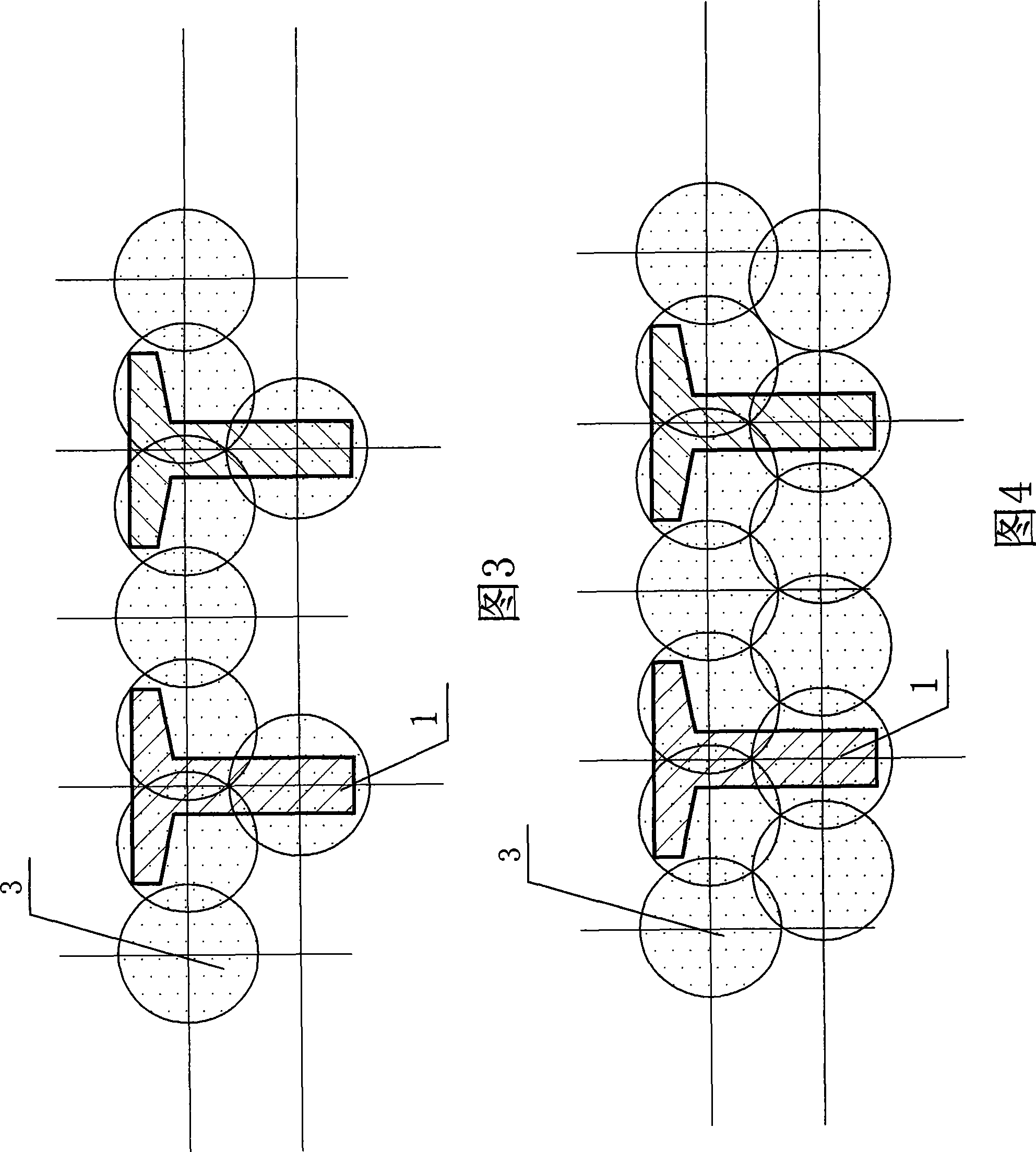

Cantilever supporting structure combining sheet pile and T-shaped thin-wall pile

InactiveCN103924601AGive full play to comprehensive advantagesReduce distortionCoastlines protectionExcavationsPre stressEngineering

A cantilever supporting structure combining a sheet pile and a T-shaped thin-wall pile comprises the T-shaped pile, the sheet pile and a cap beam. The cantilever supporting structure is characterized in that the T-shaped pile comprises a T-shaped concrete body, a prestress steel strand and a shear resisting mesh, the sheet pile comprises a rectangular concrete body and a prestress steel strand, the sheet pile is vertically arranged on the outer side of the flange of the T-shaped pile, and the cap beam is arranged at the top of the T-shaped pile and the top of the sheet pile. According to the cantilever supporting structure, the large-separation-distance prestress T-shaped pile is adopted as a bending resistant and shear resistant component, advantages of the T-shaped pile is brought into full play, deformation is small, and cost is greatly reduced.

Owner:杨众 +1

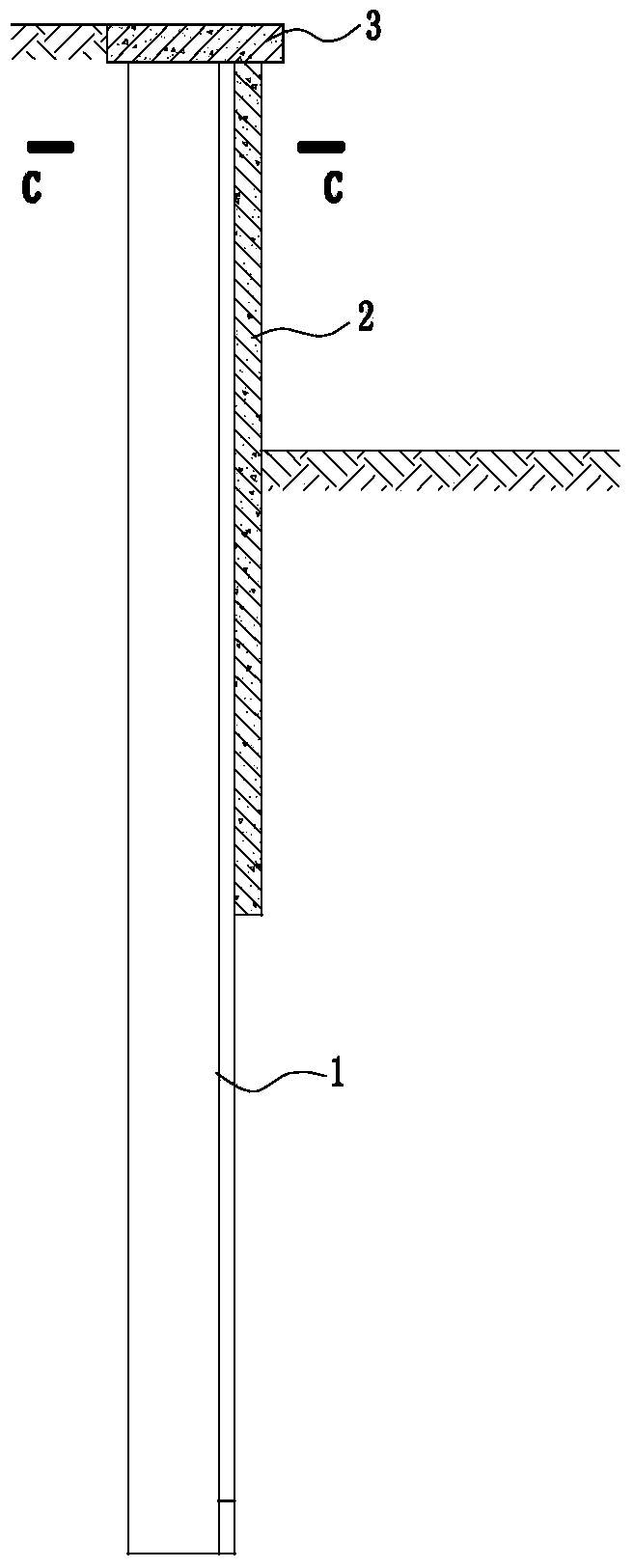

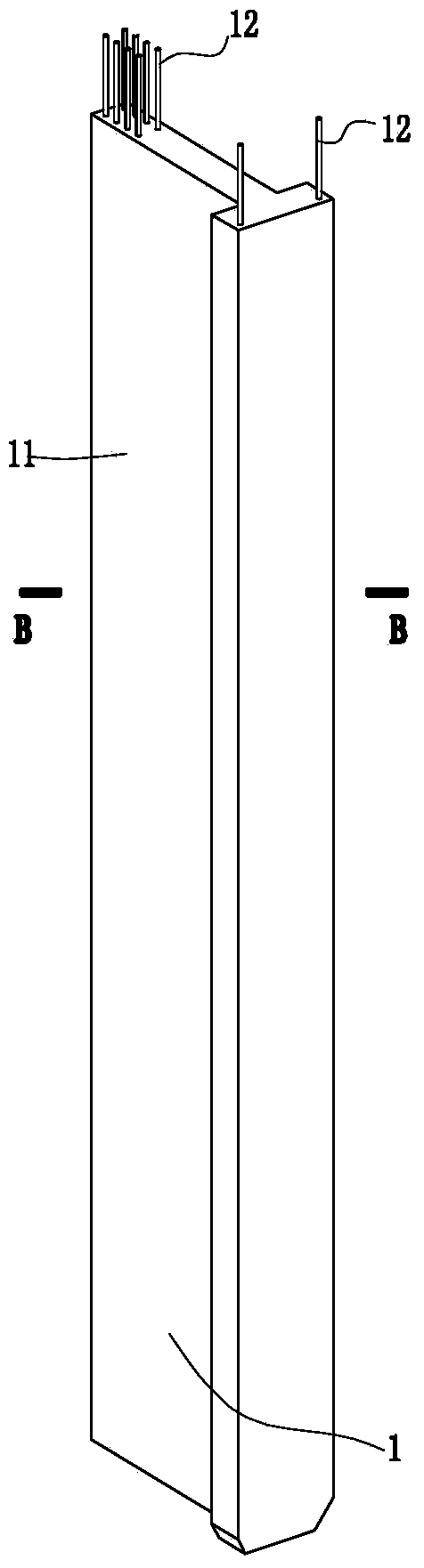

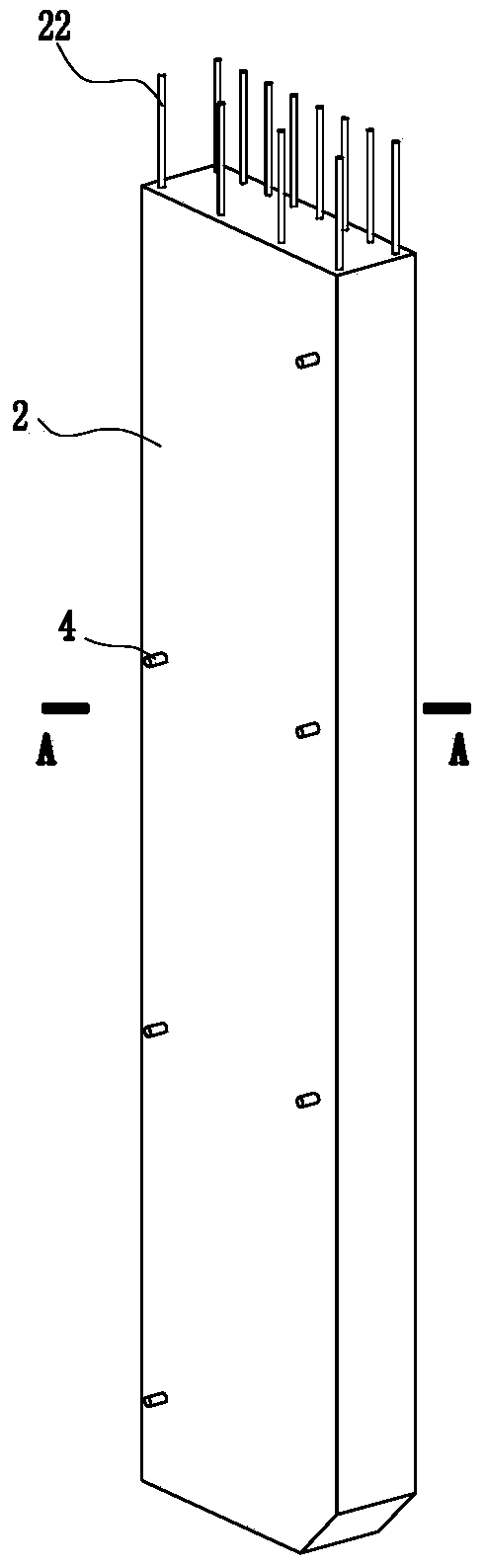

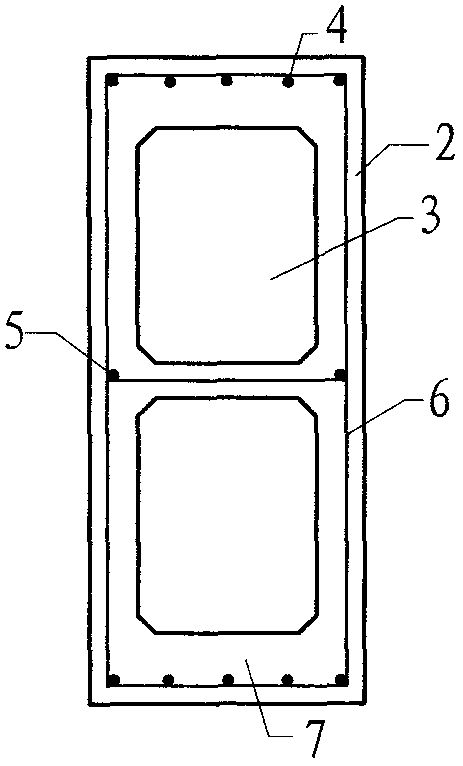

Precast reinforced concrete hollow lateral-force resisting pile and pile embedding method

InactiveCN102828504AIncrease stiffnessStrong bending and shear resistanceBulkheads/pilesReinforced concretePre stress

The invention discloses a precast reinforced concrete hollow lateral-force resisting pile comprising a pile body with a rectangular cross section; the pile body comprises a reinforcement cage; the pile body is provided with a hollow area along a vertical axis direction of the pile body, wherein the hollow area runs through the whole pile body; the reinforcement cage comprises a plurality of pre-stressed main reinforcements, a web reinforcement and a reinforcement stirrup; both ends of the long side of the rectangular section of the pile body are thickened areas in which the pre-stressed main reinforcements are arranged. The precast reinforced concrete hollow lateral-force resisting pile has the following beneficial effects: the bending resistance effective height of the long side of the rectangular section is increased by the reasonable arrangement of the hollow area; meanwhile, the concrete thickened areas are arranged at both ends of the long side of the rectangular section, the high-strength pre-stress reinforcements are arranged, and the overall bending shear resistance of the pile body is greatly enhanced, so that an enclosure pile wall has great bending shear resistance, and the demands of deep-pit enclosure works are met; and the pile embedding method of the precast reinforced concrete hollow lateral-force resisting pile has the following advantages of convenience in construction, simplicity, fastness, and the like, and meanwhile, the construction efficiency is increased.

Owner:HANGZHOU NANLIAN BASE FOUND ENG +1

Novel composite floor system for super high-rise building

InactiveCN103321294ALarge spanReduce lossLoad-supporting elementsTube (structure)Architectural engineering

The invention provides a novel composite floor system for a super high-rise building and aims to overcome the defects that an existing high-rise building is small in span, large in self-weight, large in occupied space and the like. The novel composite floor system is characterized in that an interlayer composite floor system assembly is arranged on the top of each layer of the ground portion of the super high-rise building; each interlayer composite floor system assembly is composed of a core tube wall cap and a beam, wherein the core tube wall cap is a closed annular frame body; each beam is composed of a beam body and a wide and flat beam skeleton assembly. The novel composite floor system for the super high-rise building has the technological effects that the height of the beams in the novel composite floor system is only 8% to 15% of that of beams in a traditional technological structure, and therefore building space losses are saved; the usage amount of reinforcing bars and concrete in the beams is reduced due to the fact that hollow steel tubes are arranged internally, the self-weight of the structure is reduced, and structural stiffness is enhanced; in addition, due to the fact that the core tube wall caps and the beams are integrated, namely, the span of the beams is increased, therefore, labor and materials are saved, usable areas are increased, and firmness and durability of the building are improved.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

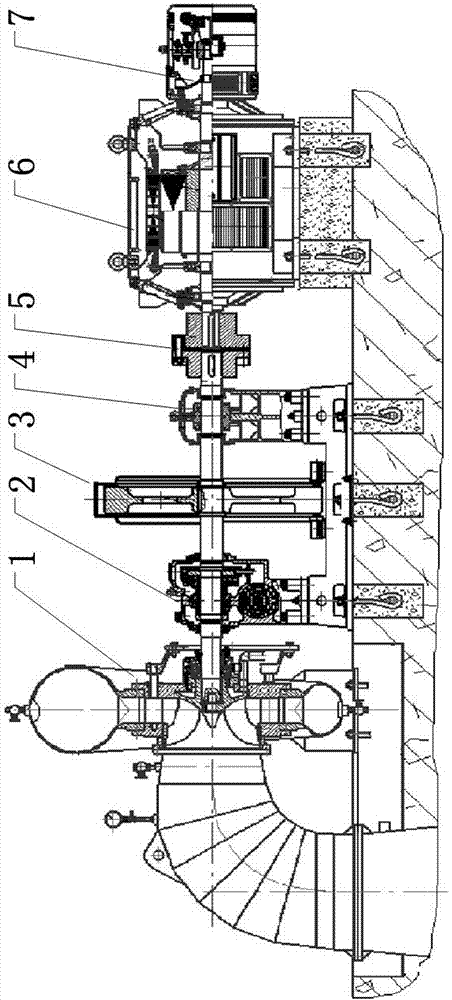

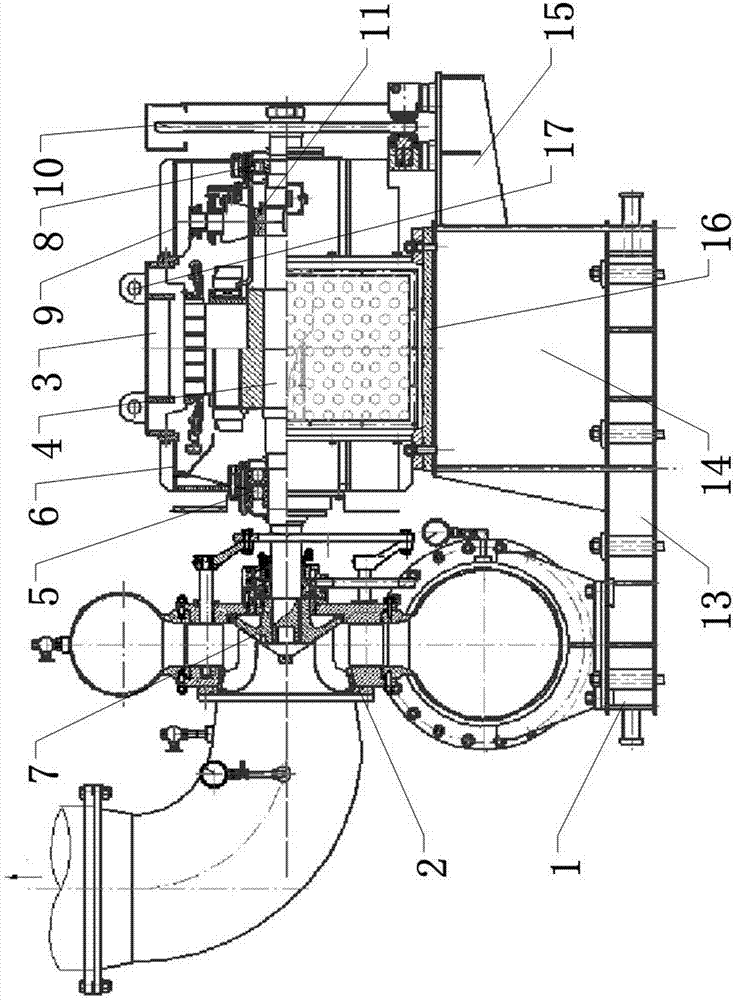

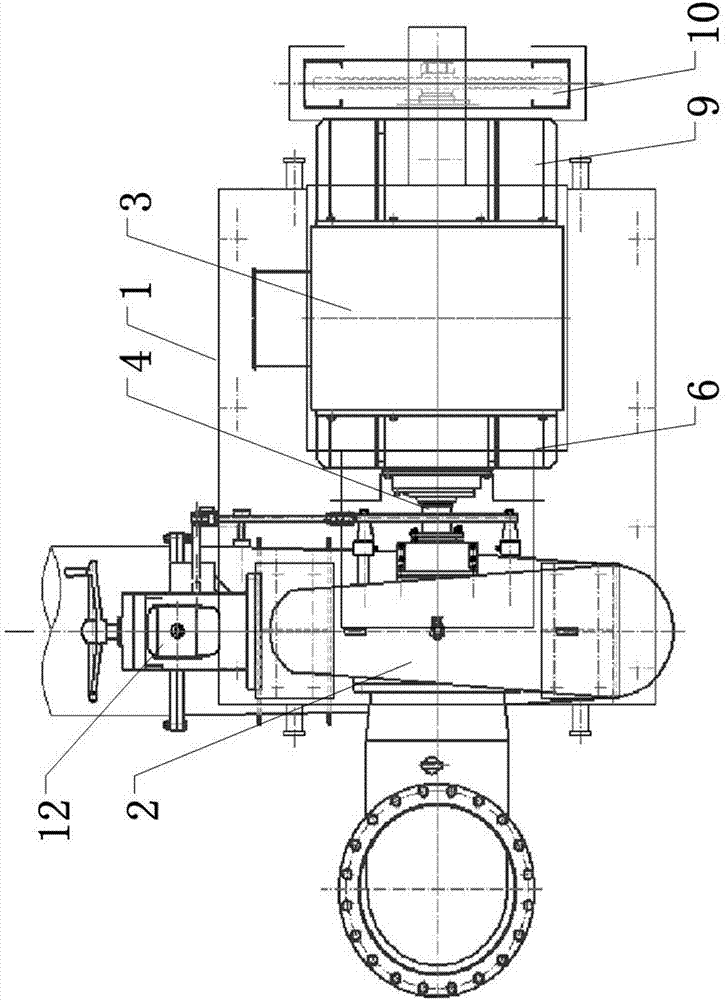

Horizontal type micro equipped water-turbine generator set

InactiveCN107178461AUse low headReduce trafficMachines/enginesEngine componentsBall bearingWater turbine

The invention discloses a horizontal micro-integrated hydro-generator set, which comprises a chassis arranged on the ground foundation, a micro-turbine fixedly installed on the left side of the upper part of the chassis, and a miniature water turbine fixedly installed on the right side of the upper part of the chassis. Brush excitation generator; the internal rotation of the miniature brushless excitation generator is provided with a main shaft, and the front end of the main shaft is arranged in the front end cover of the miniature brushless excitation generator through two ball bearings, and the front end of the main shaft It is fixedly arranged on the runner of the micro-turbine; the rear end of the main shaft is arranged in the rear end cover of the miniature brushless excitation generator through a cylindrical roller bearing, and the rear end of the main shaft is fixedly connected with a flywheel. The invention can not only develop and utilize the recyclable or multi-functional hydraulic resources hidden in daily production and daily life, but also has a simple structure and does not require complex on-site assembly and debugging, which greatly shortens the construction time of hydropower stations.

Owner:河南瑞发水电设备有限责任公司

Thin-wall mould casing member

Owner:邱则功

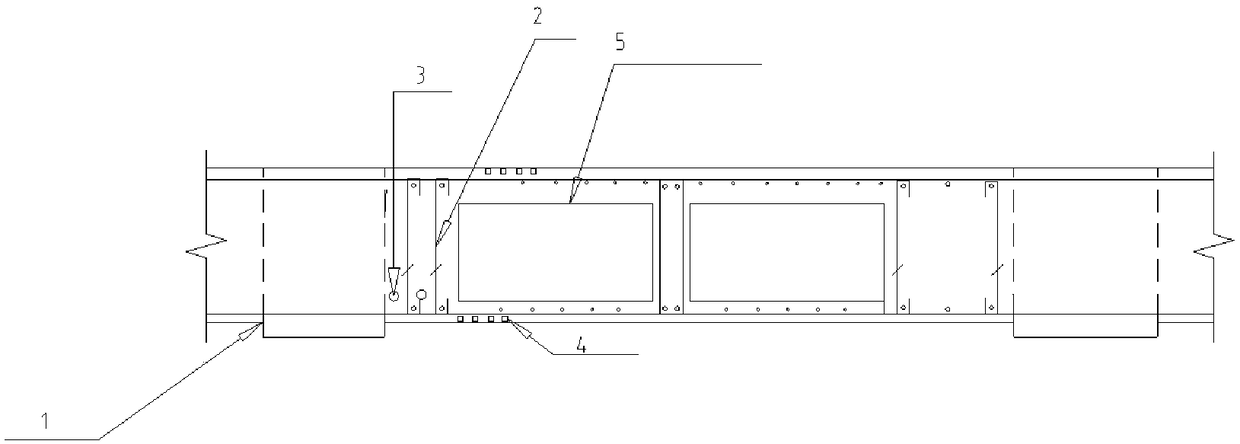

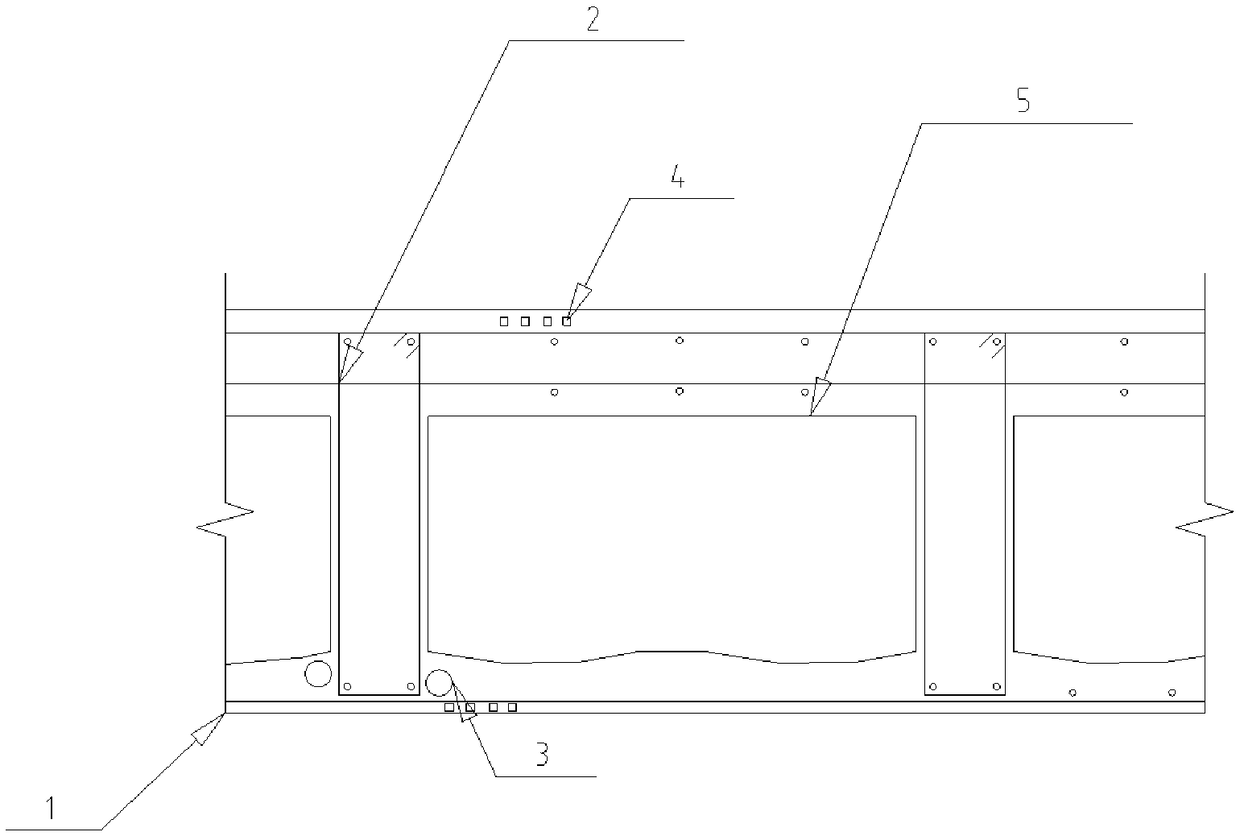

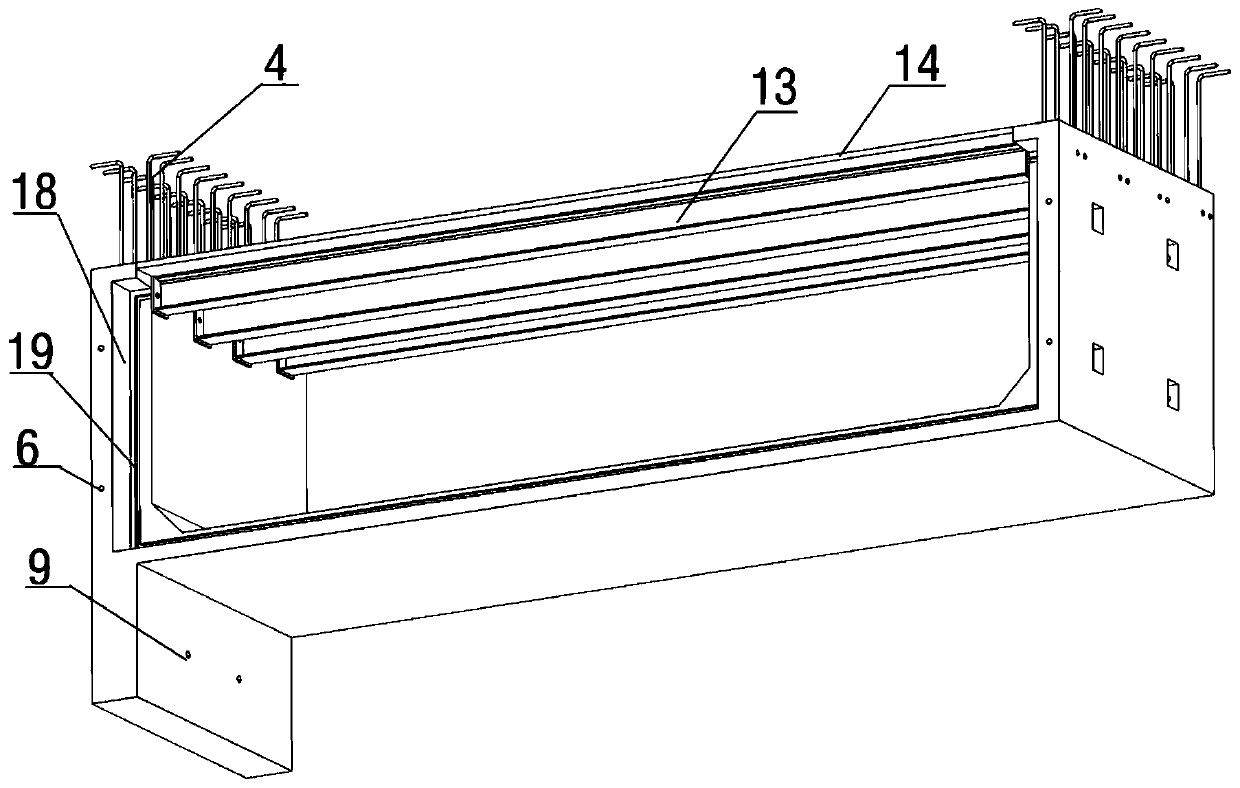

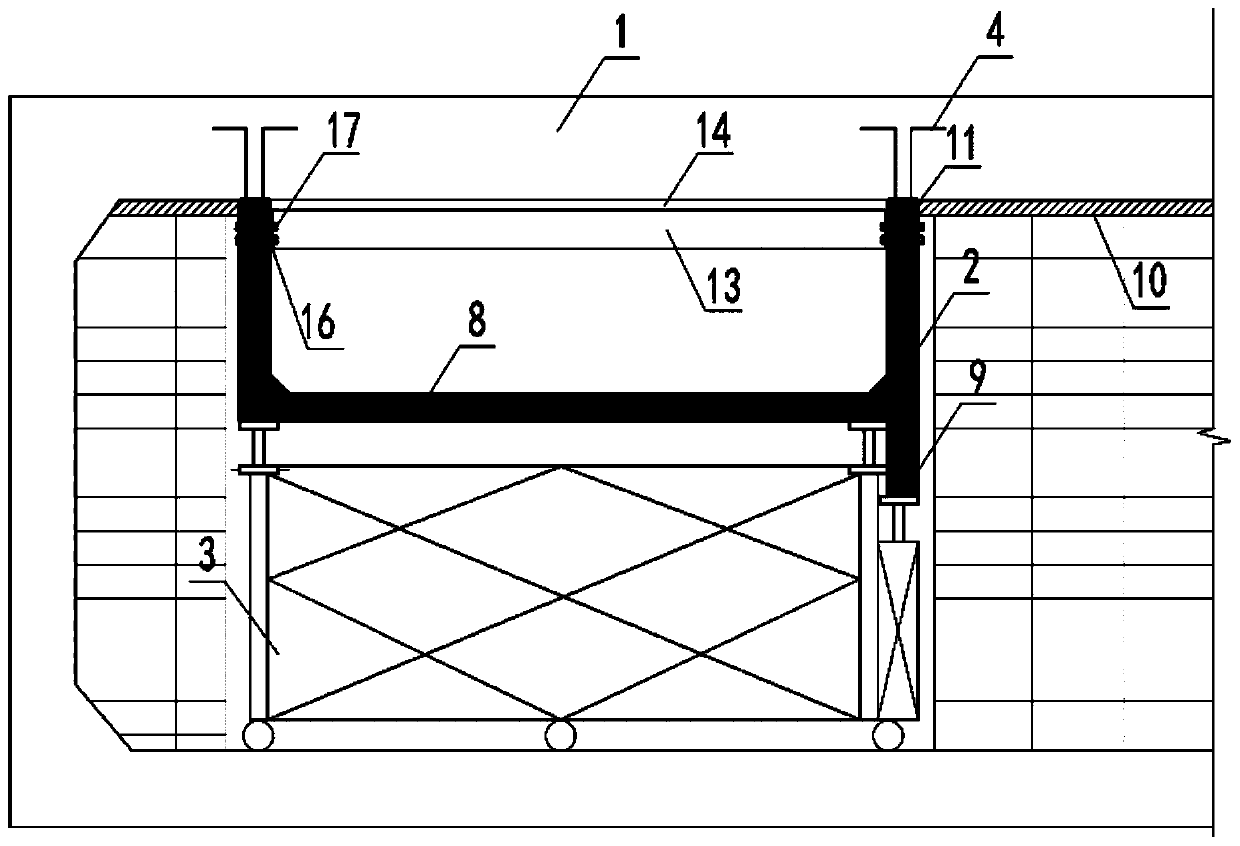

Prefabricated rail top air duct for metro station and construction method of air duct

PendingCN110700873AReduce the amount of concreteLight weightTunnel/mines ventillationRebarMetro station

The invention provides a prefabricated rail top air duct for a metro station and a construction method of the air duct, belongs to the technical field of constructional engineering, and relates to a construction method for constructing of the metro station prefabricated rail top air duct, simultaneous constructing of the metro station prefabricated rail top air duct and a cast-in-place middle plate, rear hanging constructing of the metro station prefabricated rail top air duct and the cast-in-place middle plate, and simultaneous constructing of the metro station prefabricated rail top air ductand a prefabricated overlapped middle plate. The prefabricated rail top air duct for the metro station comprises two side plates and a bottom plate which are integrally formed into a U-shaped structure. Reinforcing steel bars are arranged at the upper portions of the two side plates. Detachable supporting structures are further arranged at the upper portions of the two side plates. Each supporting structure is a combination of a timber formwork and structural steel. The two side plates, the bottom plate and the supporting structures form the port of the air duct. One face of the port of the air duct is provided with a concave opening. The prefabricated rail top air duct has the advantages that no secondary civil engineering construction is needed, the structural steel for construction canbe recovered, the weight is light, and the sealing effect is good.

Owner:JIANHUA CONSTR MATERIALS (CHINA) CO LTD

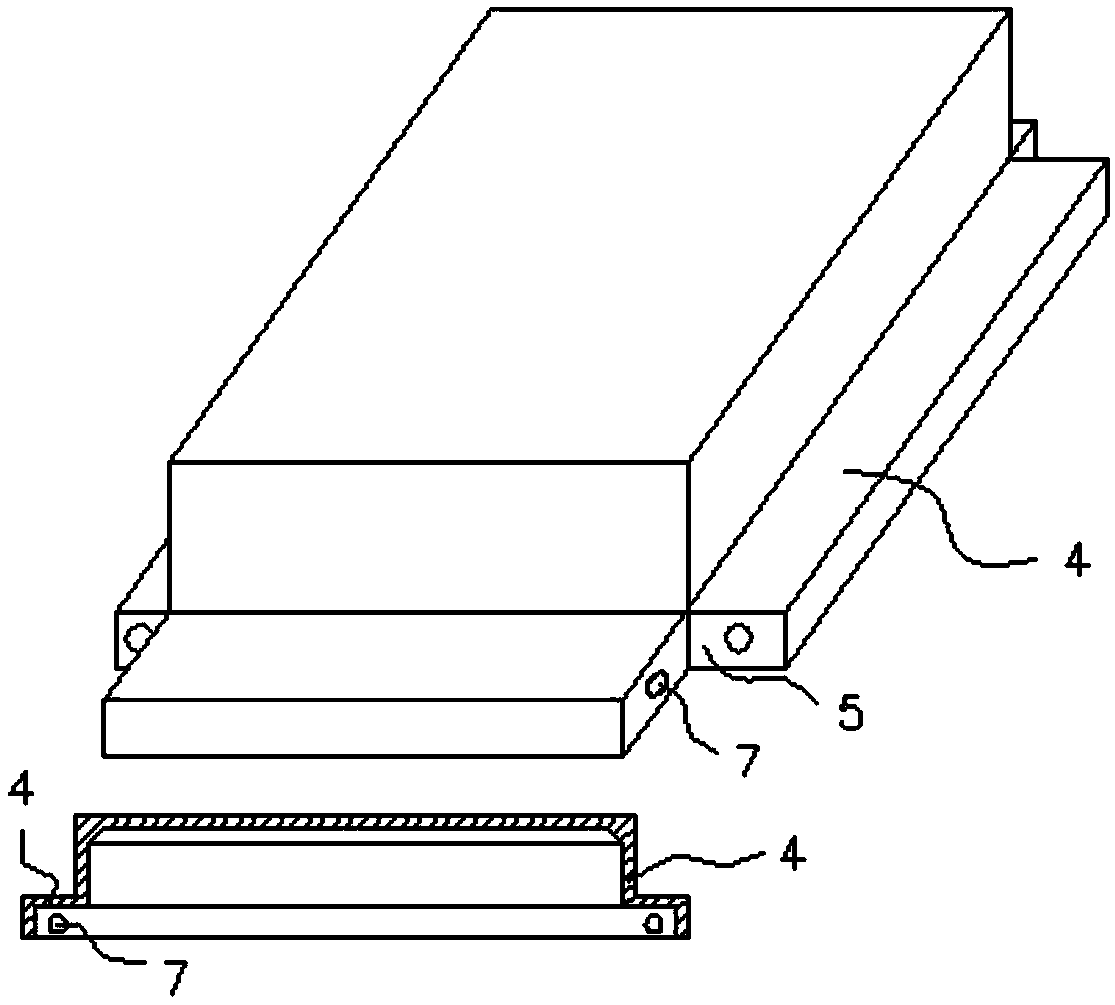

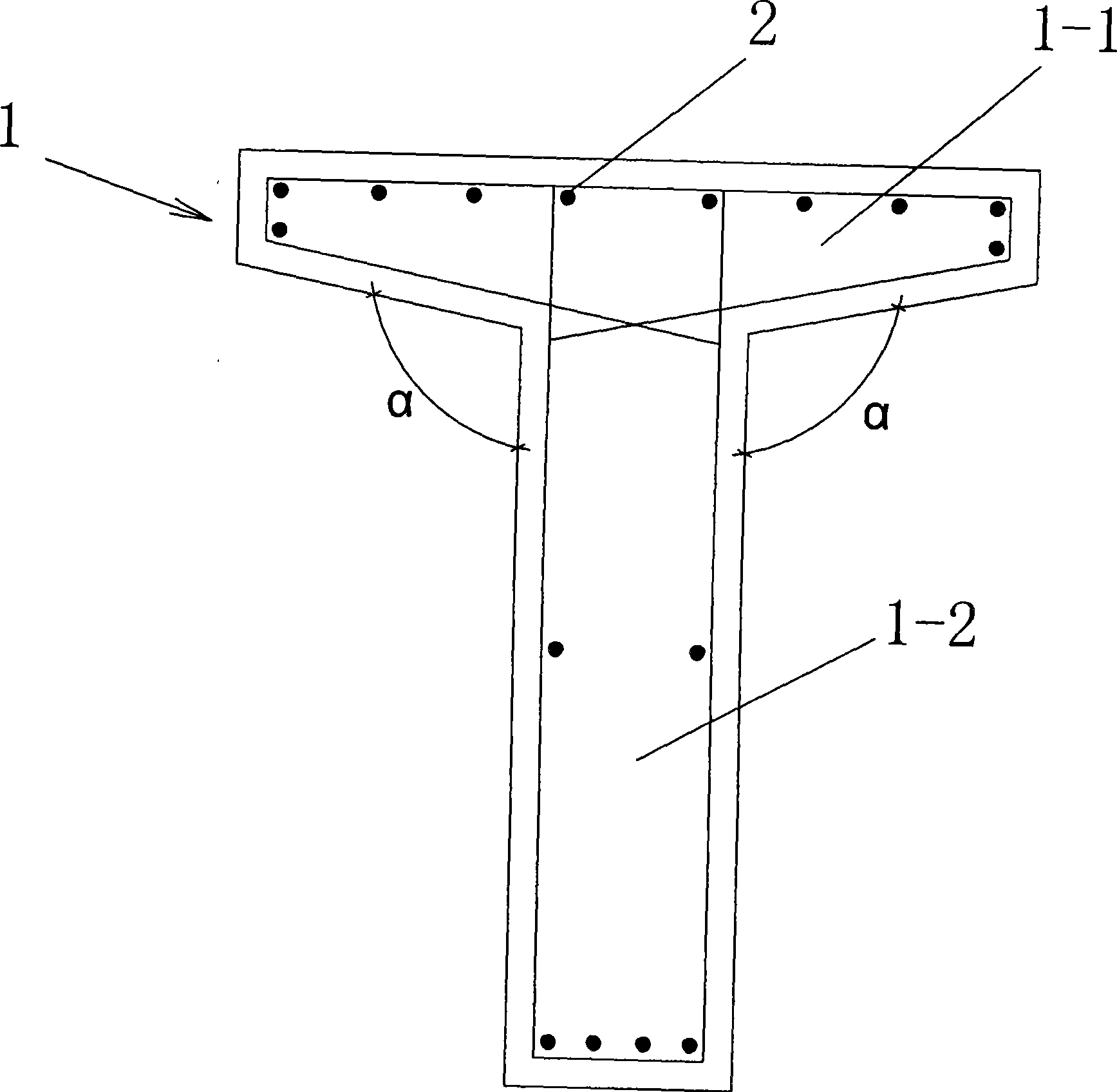

Cast-in-situ reinforced concrete slab

InactiveCN1840807AImprove mechanical propertiesReduce section sizeFloorsForms/shuttering/falseworksPre stressRebar

Disclosed is a cast-in-situ reinforced-bar concrete slab, which comprises a reinforced-bar concrete (1) and polyhedral solid lightweight shuttering member (2), the shuttering member (2) is enclosed in the reinforced-bar concrete (1), and arranged alternatively, a cast-in-situ reinforced-bar concrete rib (3) is arranged between them, characterized in that least one of the transverse corners on the lower portion of the shuttering member (2) is configured to be an internal corner (4), the cast-in-situ reinforced wing rim (5) is formed on the cast-in-situ concrete position at the internal corner (4) position, a reversed T-shape rib is formed by the cast-in-situ reinforced bar concrete rib (3). The invention can be applied to cast-in-situ reinforced concrete or prestressed reinforcement concrete's storied-building roofings, house roofings, walls, foundation bedplates and bridges, especially for flat slabs.

Owner:邱则有

Vertical combined base of concrete prefabricated parts of mast type mechanical equipment

InactiveCN101619578ATake full advantage of side pressureSmall footprintFoundation engineeringSmall footprintVertical force

The invention relates to a vertical combined base of concrete prefabricated parts of mast type mechanical equipment, which is an independent concrete base structure formed by combining the concrete prefabricated parts and also an independent base of the mast type mechanical equipment commonly formed by non-concrete materials which take solid dispersed materials such as sand, stones, soil, and the like as representative materials. The combined base is suitable for the mast type mechanical equipment with smaller vertical force and overturning moments in the fields of buildings, electrical power, information, military, and the like. The invention has the main characteristics of small concrete part volume and occupation area, high assembly and disassembly speed, displaced reuse, great cost reduction, resource saving and environmental protection.

Owner:赵正义

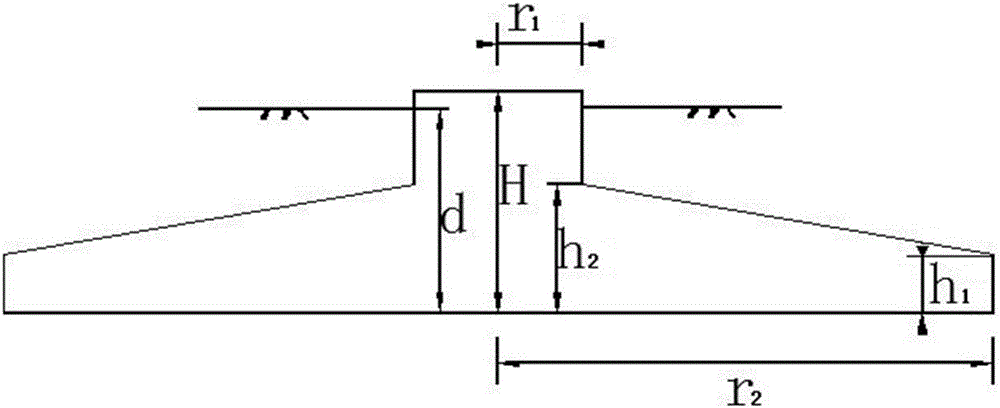

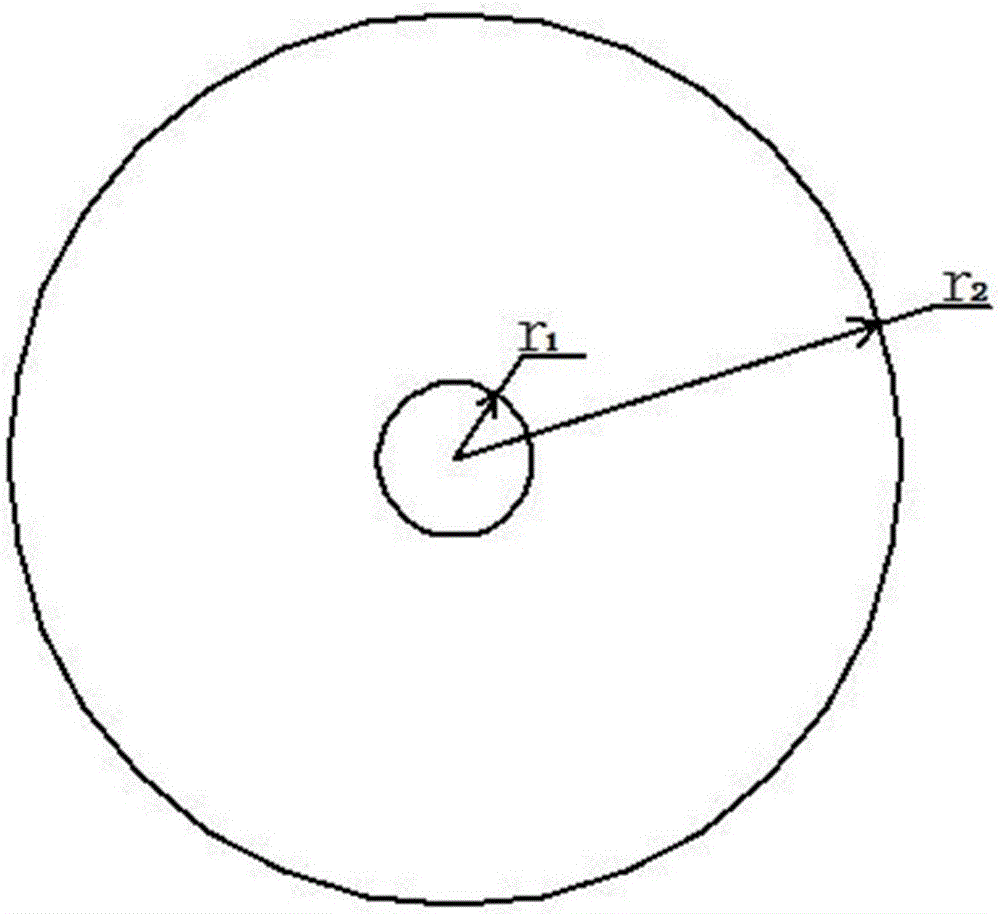

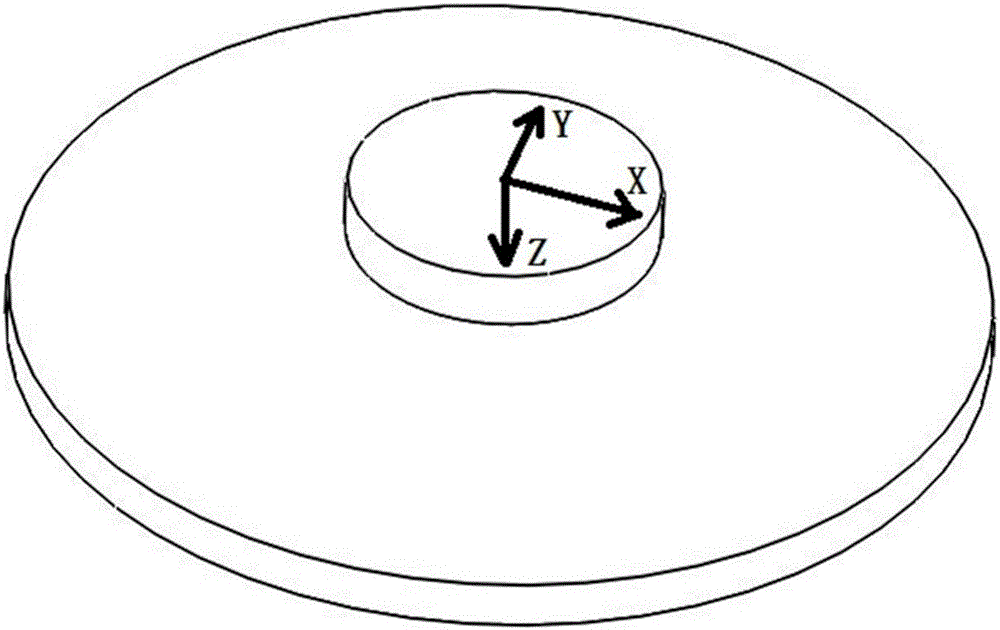

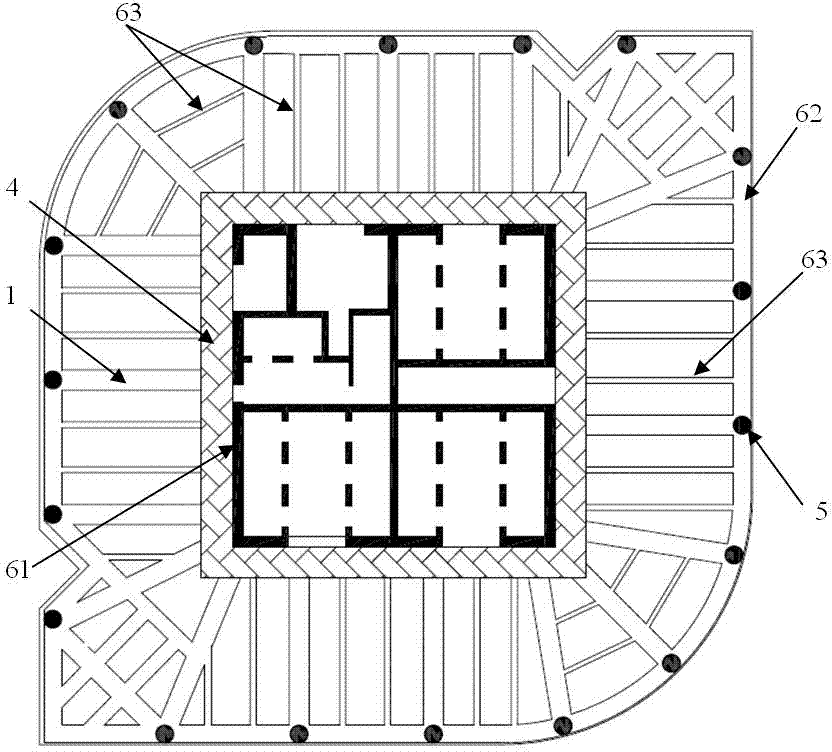

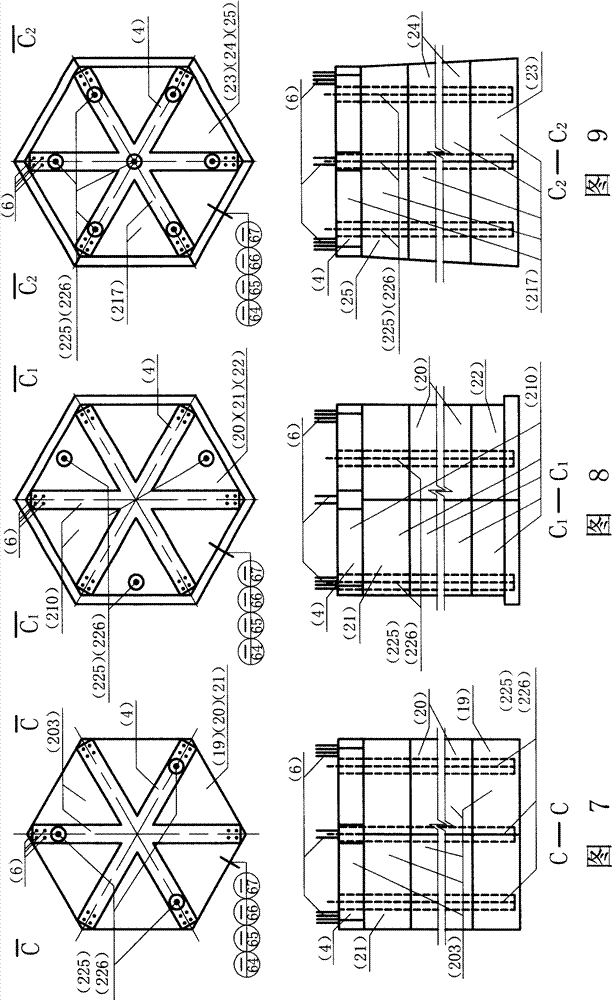

Foundation structure design method for gravity type extended foundation of perpendicular axis fan

ActiveCN106120838AReduce crack widthReduce the amount of concreteFoundation engineeringRebarWind power

The invention discloses a foundation structure design method for a gravity type extended foundation of a perpendicular axis fan and belongs to the field of construction of fan foundations of wind power plants. The foundation structure design method comprises the steps that A, the load value of the fan is corrected to the standard value of the load of the fan; B, in the normal working condition, a foundation bottom radius is determined; C, in the extreme working condition, a foundation bottom radius is determined; D, a foundation bottom radius capable of meeting the requirements of the normal working condition and the extreme working condition simultaneously of the is selected; and E, according to the formula h2>=0.38x(r2- r1), the thickness of the root portion of the foundation is determined. The gravity type extended foundation designed through the foundation structure design method is applied to the perpendicular axis fan, and on the premise that the safety requirement is met, the gravity type extended foundation can be constructed more economically. Under the conditions that design parameters and guideposts are all reasonable, according to the foundation structure design method, optimal design is conducted on a foundation structure mainly through optimization of original load data and references so as to achieve the purposes that project amount of concrete and rebars of the fan foundation and project investment are reduced.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

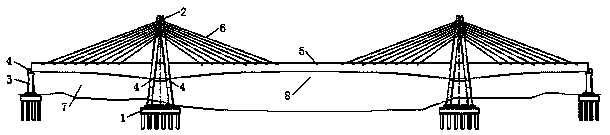

Cable stayed bridge with semi-floating truss type bridge towers

PendingCN110130201ALarge vertical sizeReduce thicknessCable-stayed bridgeBridge structural detailsCable stayedEngineering

The invention discloses a cable stayed bridge with semi-floating truss type bridge towers. The cable stayed bridge with the semi-floating truss type bridge towers comprises side piers on the two sidesand the bridge towers located on the middle part, wherein supporting seats are arranged on the middle parts of the bridge towers and are arranged at the upper ends of the side piers separately, a main beam which bears bridge floor load is arranged on the supporting seats, a plurality of pairs of stay cables are arranged between the bridge towers and the main beam, and the bridge towers are separated from the main beam. According to the cable stayed bridge with the semi-floating truss type bridge towers, the space truss type bridge towers are adopted, the longitudinal dimensions of the bridgetowers are large, and the bearing platform thickness and the concrete quantity of lower foundations of a large-span bridge are effectively reduced; two rows of longitudinal supporting seats are arranged on each bridge tower, the temperature deformation of the main beam is reduced, the problem that creep deformation of the large-span concrete main beam is difficult to control is effectively solved,and it is beneficial to bridge floor driving, especially to the riding comfort and the comfort level of high speed railway driving; and no fixed supporting seat is arranged, for paving a continuouslywelded rail track large-span railroad bridge, the temperature span can be effectively reduced, track temperature regulators are prevented from being arranged, and the maintenance workloads are reduced.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

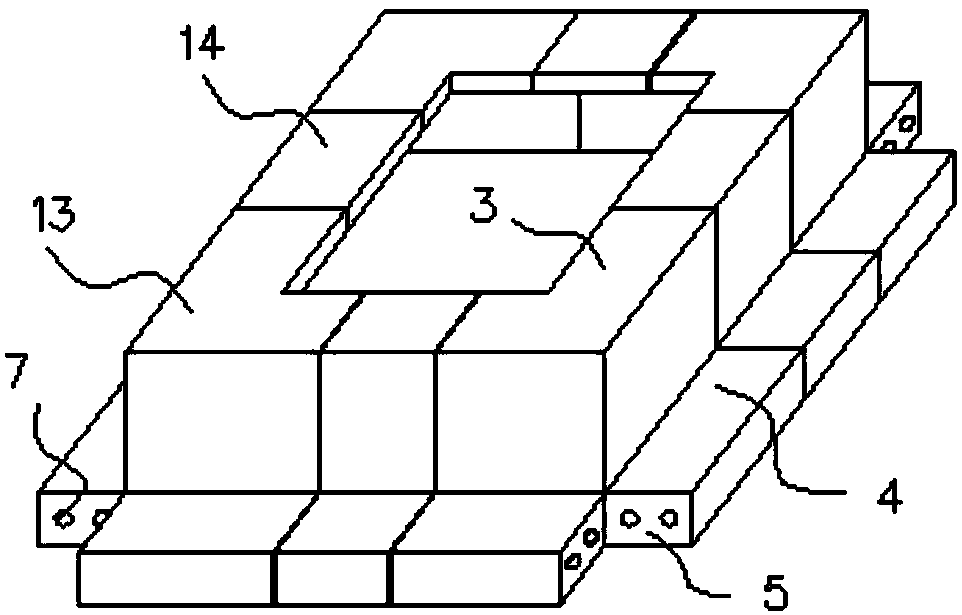

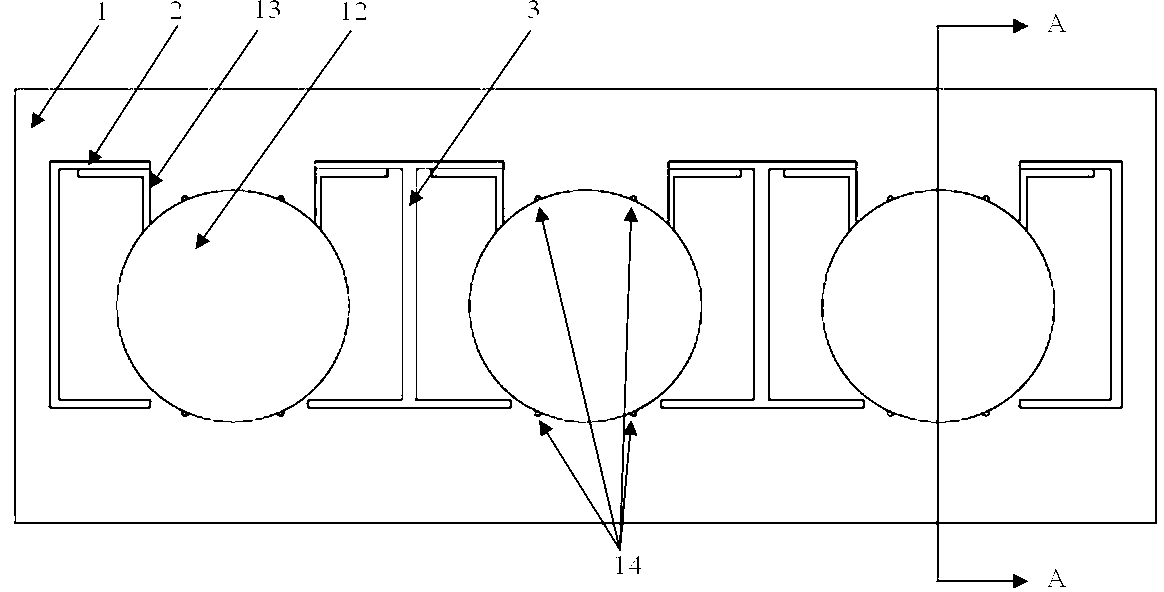

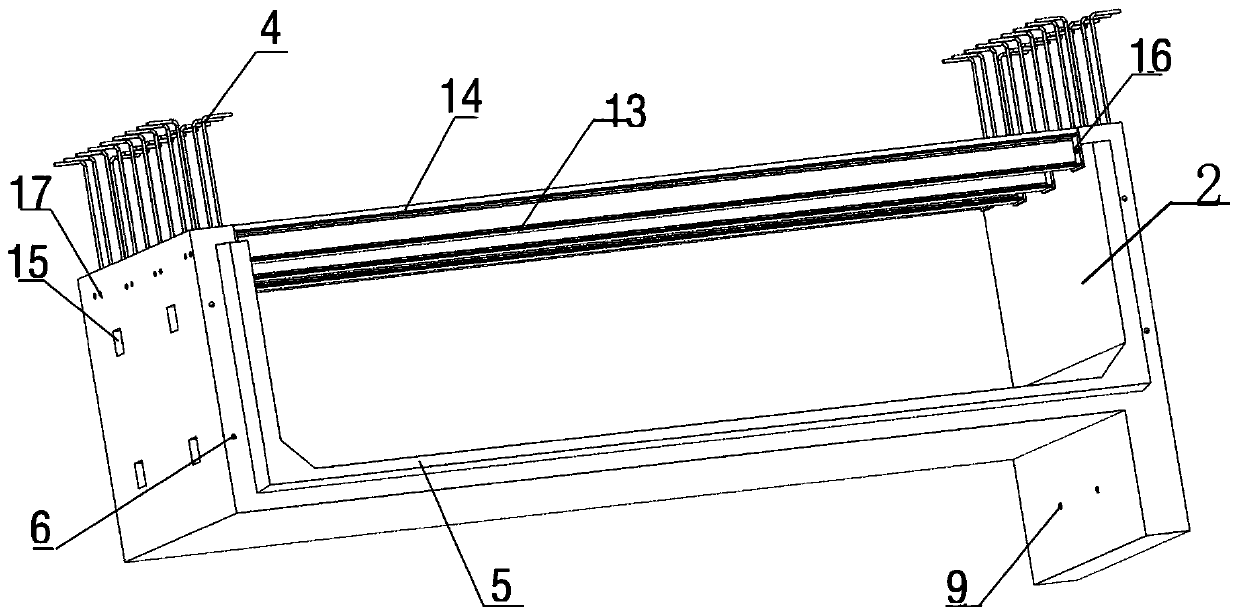

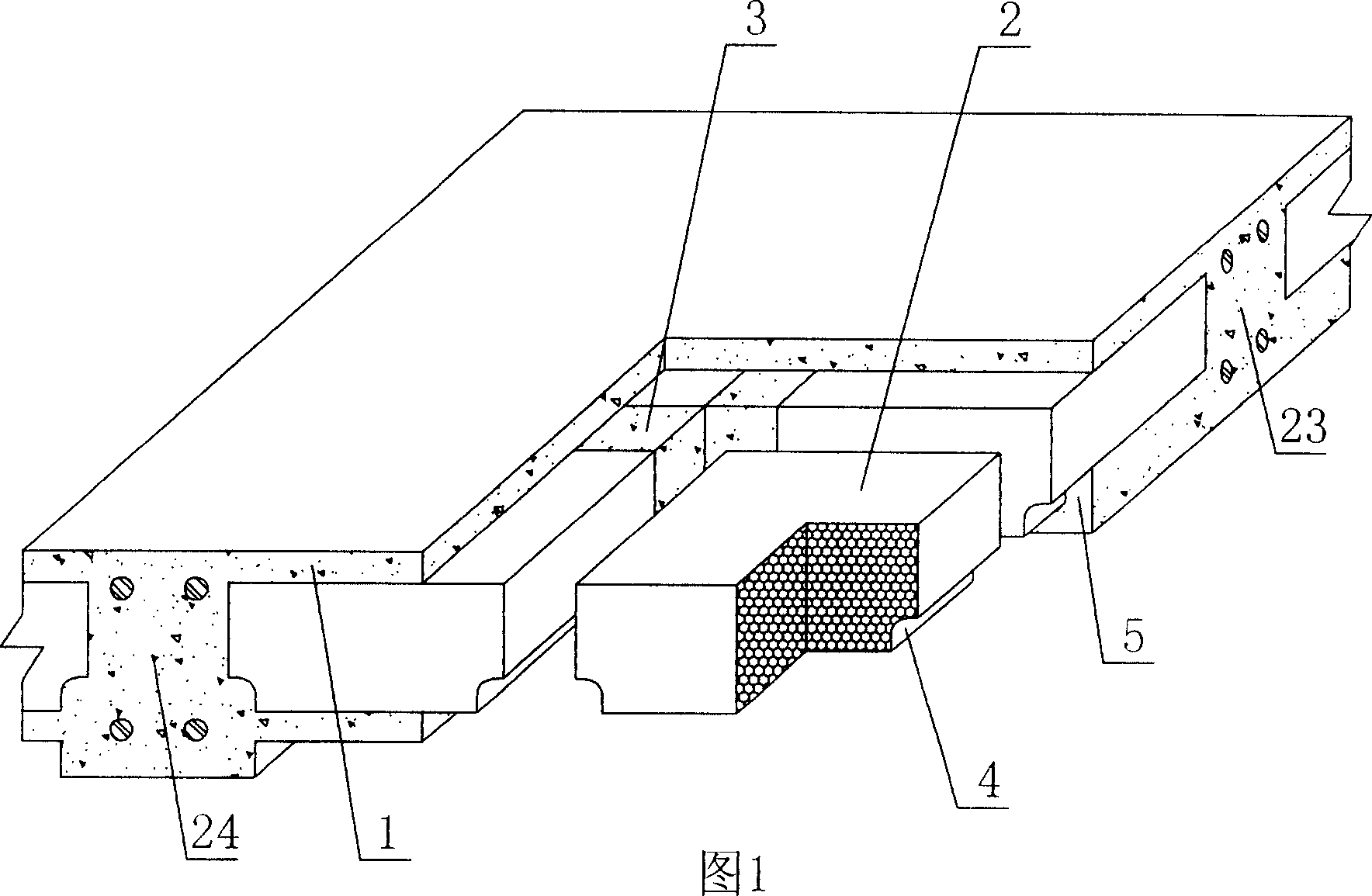

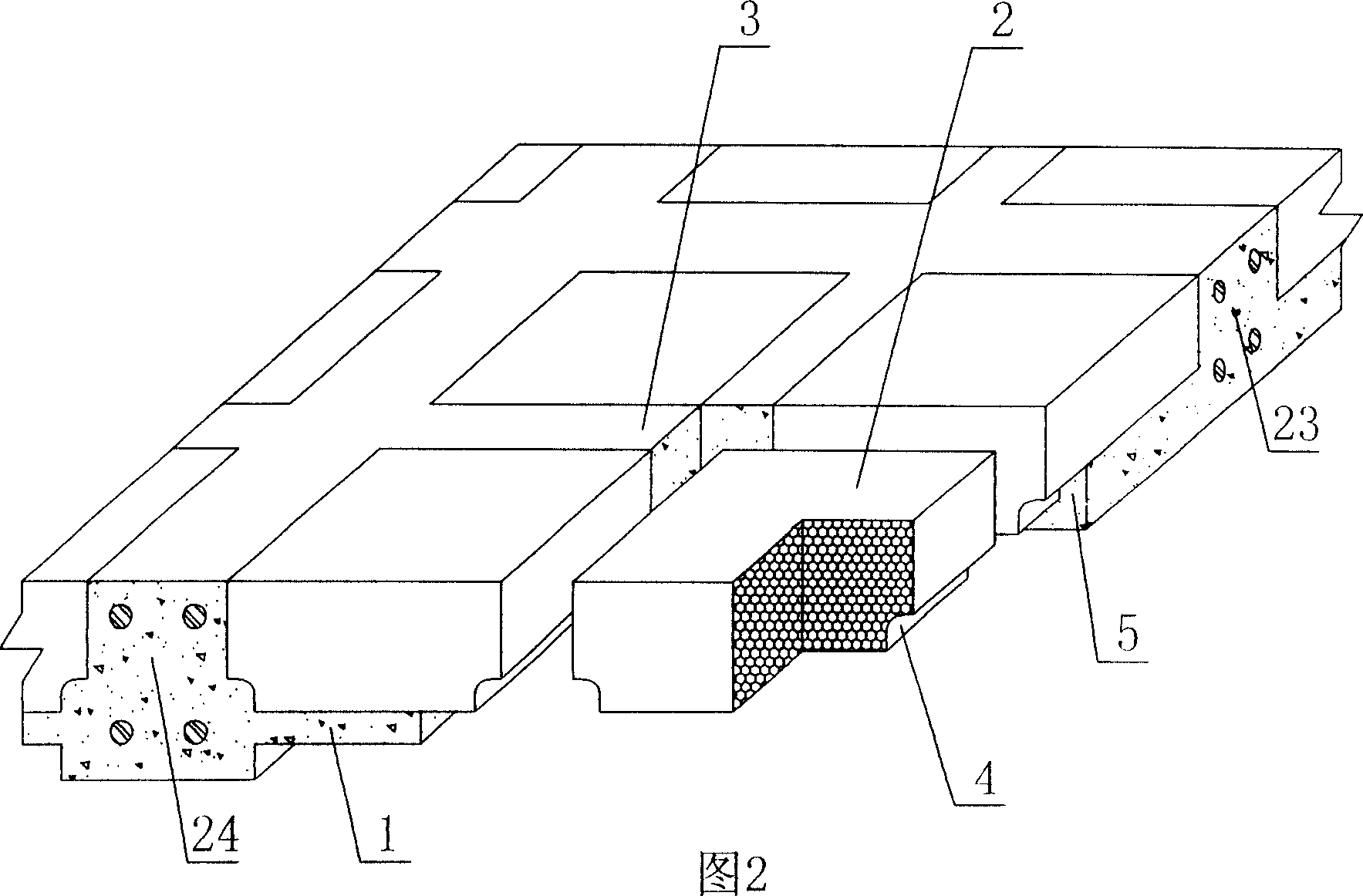

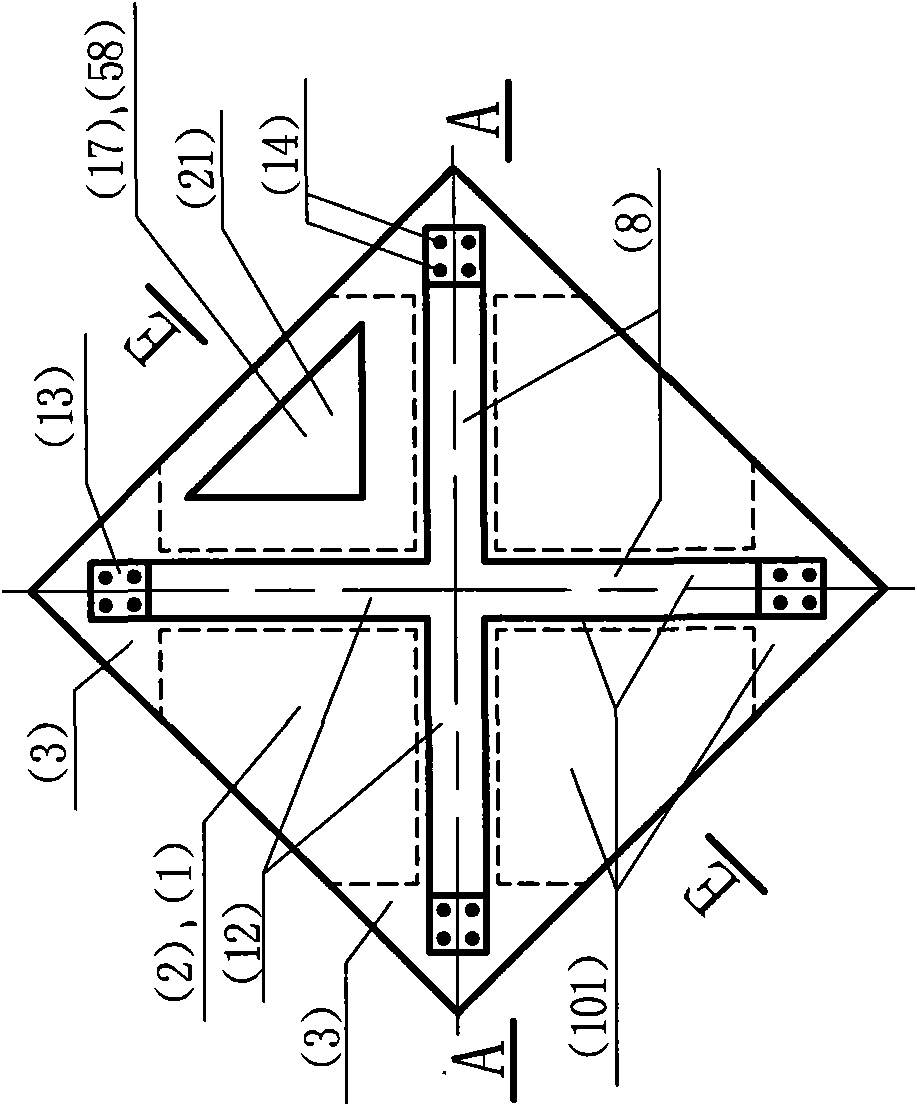

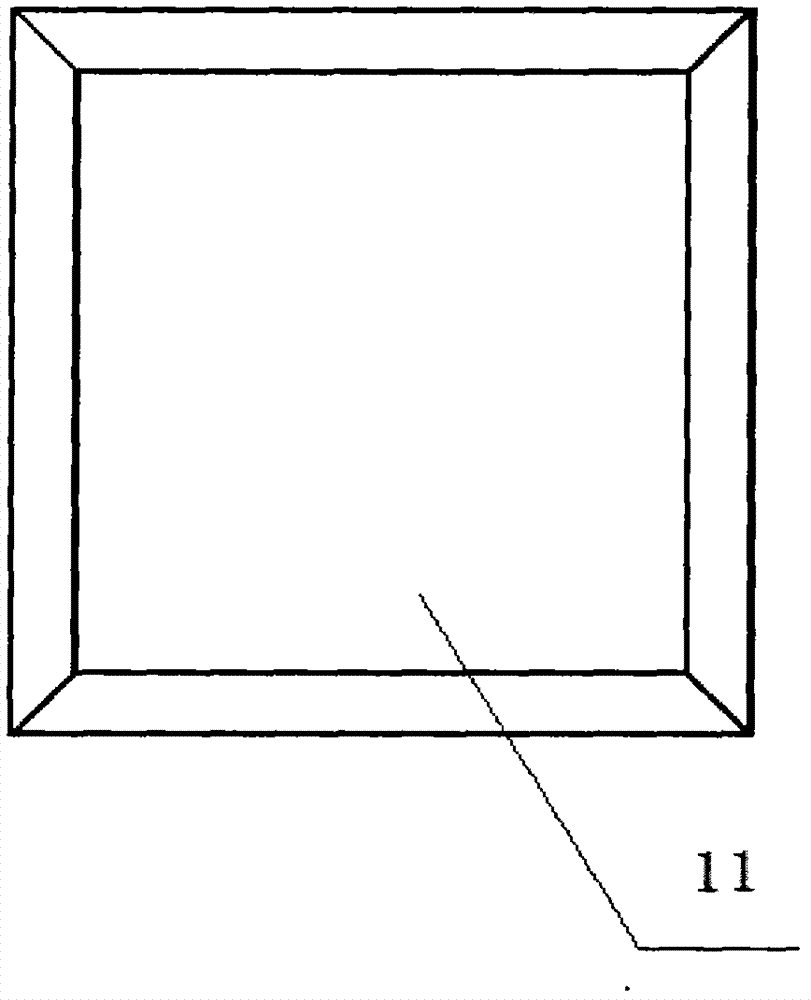

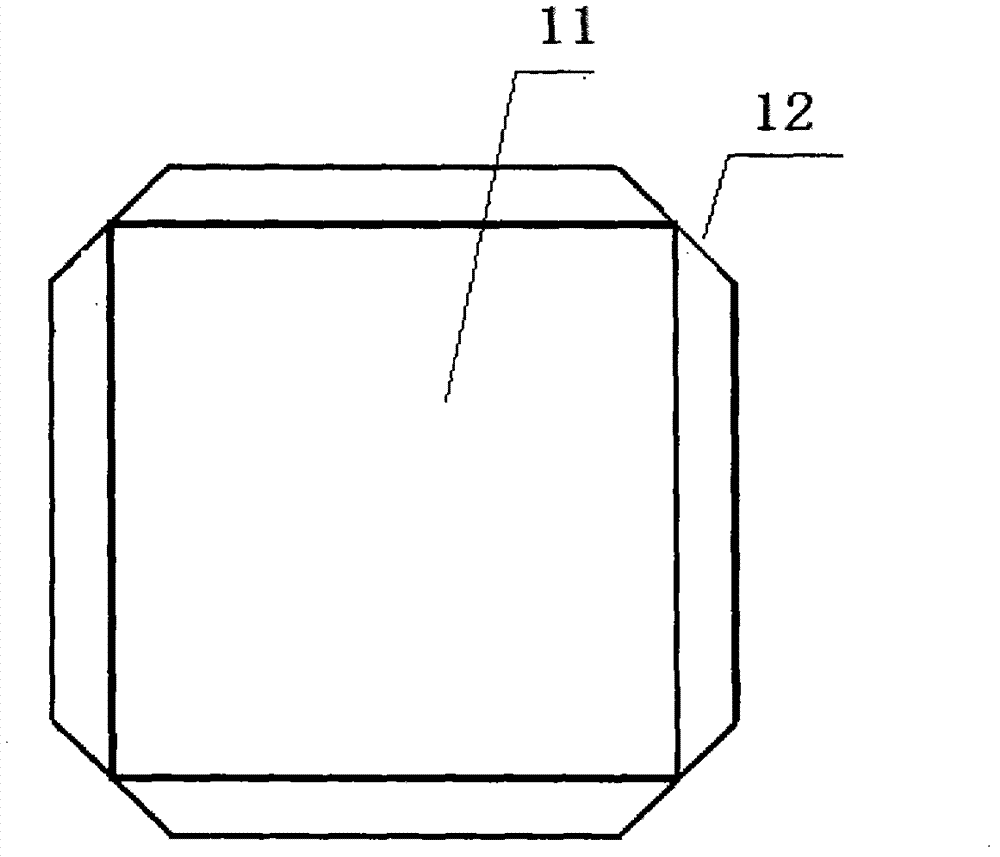

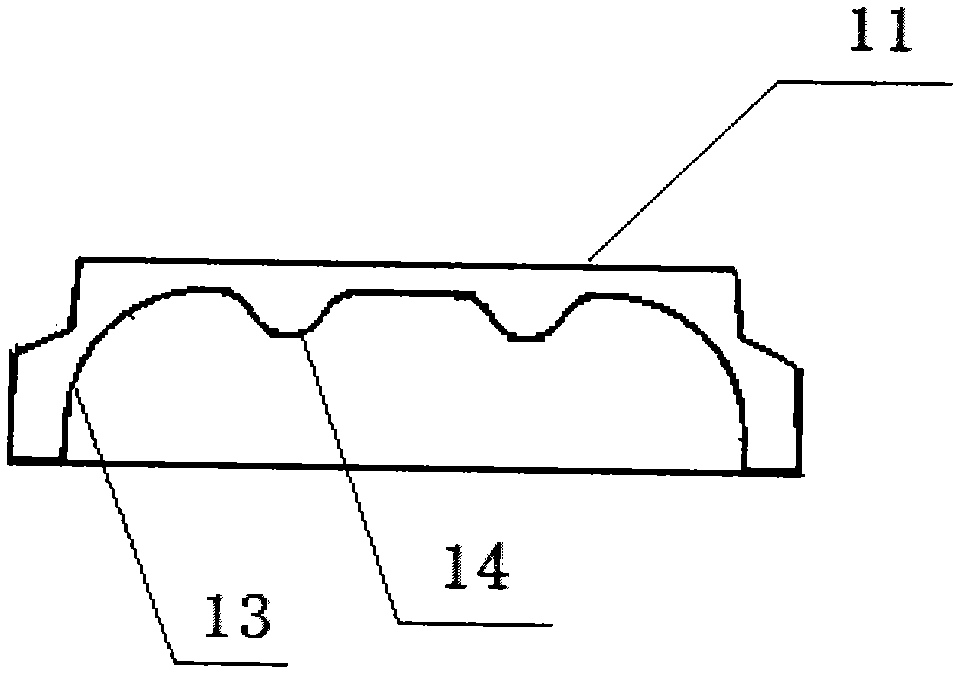

Building plaster mold box and open-web floor slab structure using same

The invention relates to a building plaster mold box and an open-web floor slab structure using the same. The building plaster mold box comprises a mold box body, wherein a foot pace (11) is arranged outside the mold box body, a hollow mold cavity (13) is formed in the mold box body, reinforcing ribs (14) are arranged at the bottom of the hollow mold cavity (13), and the reinforcing ribs (14) are plural and crossly connected in transverse and vertical directions. The cross or #-shaped reinforcing ribs are designed at the bottom of the mold cavity of the building plaster mold box disclosed by the invention, and glass fiber is taken as a reinforcing material, so that the mechanical strength of the mold box is greatly improved and a fracture load value is not less than 1KN.

Owner:CHENGDU JINCHENGMENGZHEN TECH CO LTD

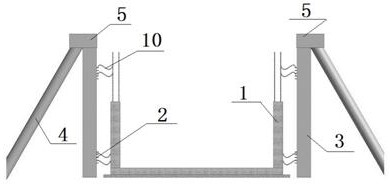

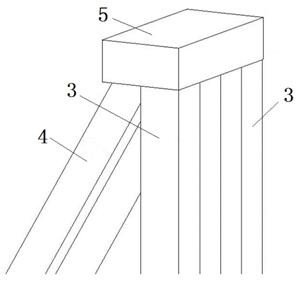

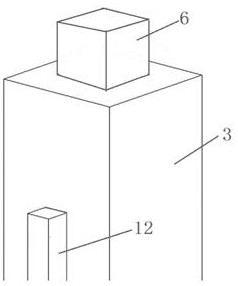

Support construction structure and process of fully prefabricated, spliced and superposed comprehensive pipe gallery

PendingCN111733878AReduce thicknessReduce steel usageArtificial islandsExcavationsArchitectural engineeringPipe

The invention belongs to the technical field of comprehensive pipe gallery construction, and in particular relates to a support construction structure and process of a fully prefabricated, spliced andsuperposed comprehensive pipe gallery. The support construction structure comprises a prefabricated comprehensive pipe gallery and further comprises prefabricated support piles, a prefabricated external anchor pile and a prefabricated crown beam. Adjacent prefabricated support piles are in bell-and-spigot joint together, the prefabricated support piles and the prefabricated external anchor pile are in bell-and-spigot joint to the prefabricated crown beam, and the prefabricated comprehensive pipe gallery and the prefabricated support pile are connected by a wet process. Construction of prefabricated and spliced structural parts is carried out fully from a foundation pit support in construction of the comprehensive pipe gallery to later main body structure, and the support structure and themain body structure are superposed fully to reduce the thickness of the main body structure, so that the steel amount and the concrete amount of the structural parts are alleviated, the cost is saved, the occupied area for construction is reduced, and the construction period is shortened.

Owner:JINAN URBAN CONSTR GRP

Mould casing member

Owner:湖南邱则有专利战略策划有限公司

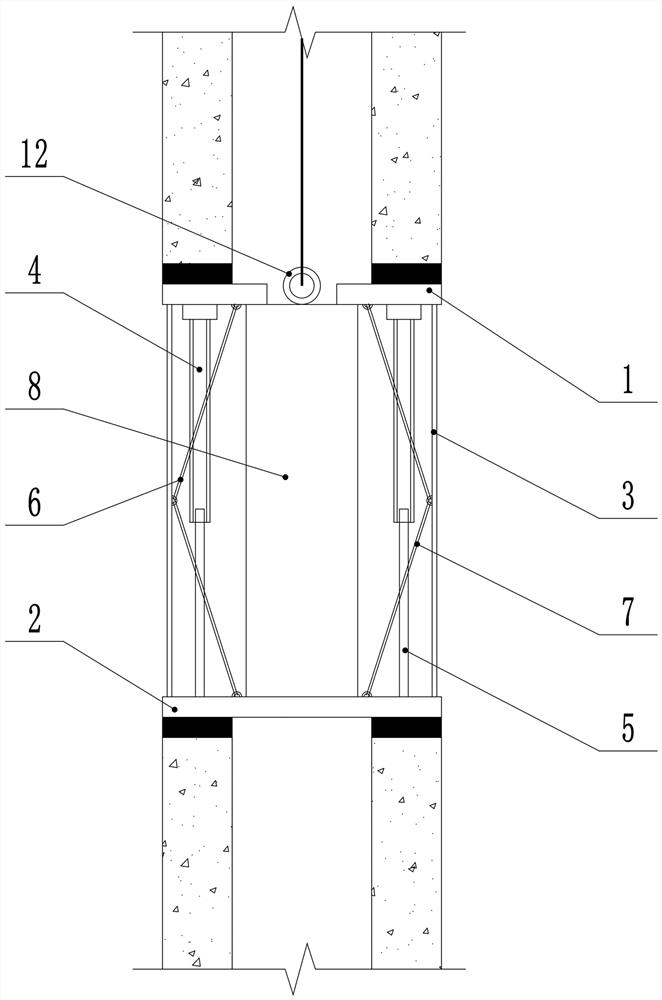

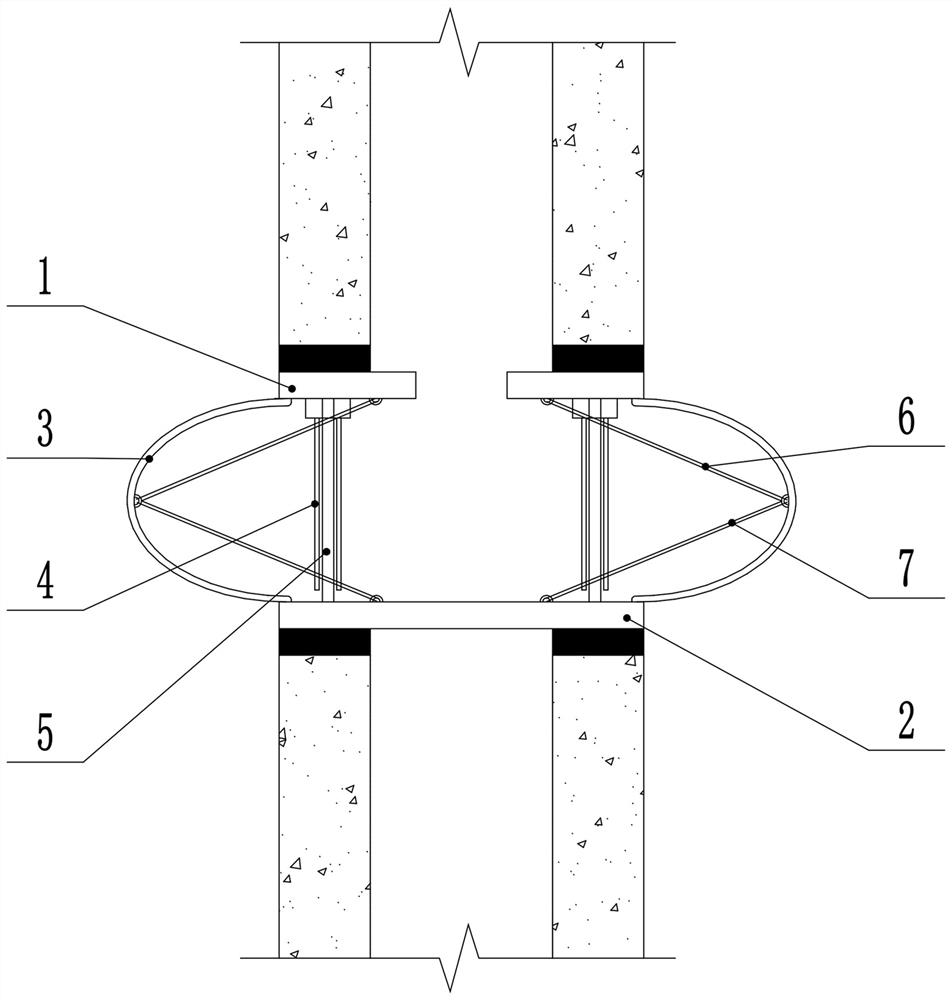

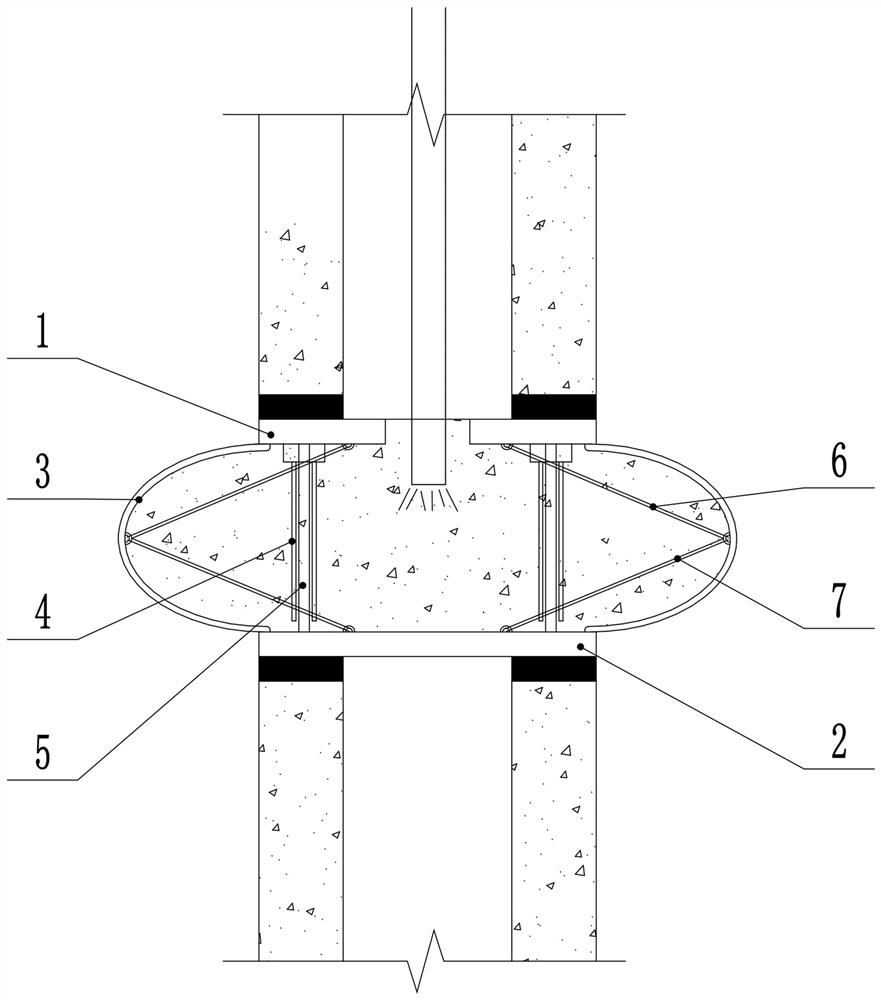

An extruded and expanded branch-disc pile connection structure for prestressed pipe piles

ActiveCN112323790BRealize pile operationImprove bearing capacityBulkheads/pilesRectangular aperturePre stress

The present invention relates to the technical field related to the pile connection structure of prestressed pipe piles, in particular to an extruded and expanded branch disk pile connection structure for prestressed pipe piles, aiming to solve the poor compression and pullout bearing capacity of existing prestressed pipe piles technical issues. It includes an upper end plate and a lower end plate. A rectangular hole is opened in the center of the upper end plate. A cylinder is fixedly connected between the upper end plate and the lower end plate. There are multiple casings evenly distributed in the cylinder, and there are multiple sleeves evenly distributed in the cylinder along its circumference. Each link assembly is composed of an upper link and a lower link that are symmetrically distributed up and down. The upper link and the lower link are arranged obliquely. The upper end of the upper link is hinged on the lower surface of the upper end plate, and the lower link The lower end of the connecting rod is hinged on the upper surface of the lower end plate, and the lower end of the upper connecting rod and the upper end of the lower connecting rod are jointly hinged on the inner wall of the cylinder; a pressure-bearing column is also arranged, the cross-section of the pressure-bearing column is rectangular, and the pressure-bearing column The height of the column is equal to the distance between the upper and lower end plates.

Owner:TAIYUAN UNIV OF TECH

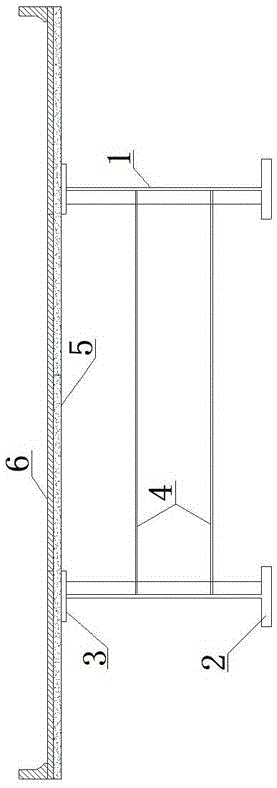

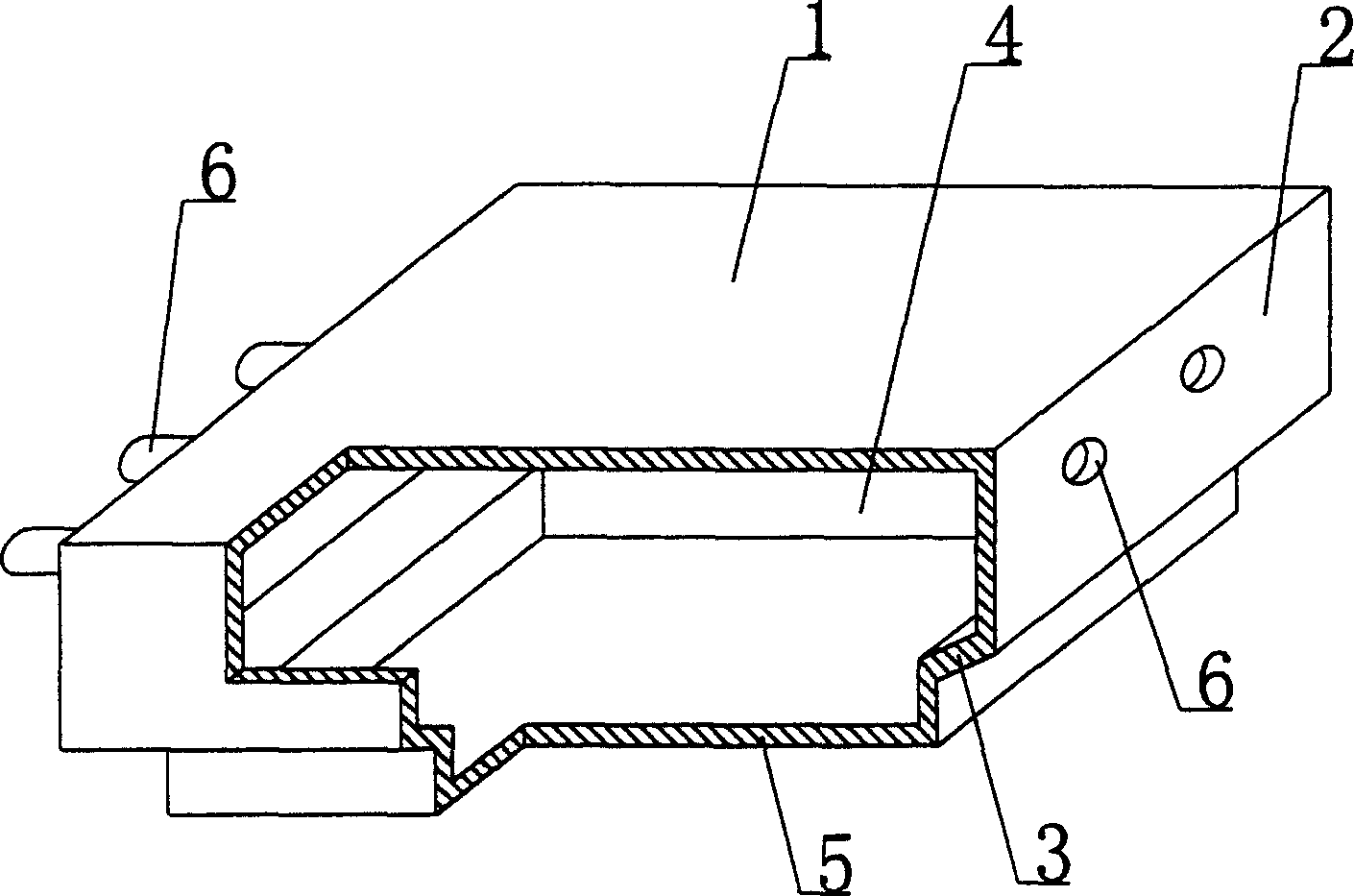

Thin wall molded case member

Disclosed is a thin-walled shuttering cavity component, which comprises an upper plate (1), a surrounding side-wall (2) and a lower bottom (3), the three parts are encircled to form a cavity (4), characterized in that at least one boss module (5) protrudes the lower bottom (3), and at least one connecting piece (6) is arranged on at least one surrounding side-wall (2). The shuttering component greatly improves the mechanical properties of the floor when being applied to the dense rib floor, reduces section size of the dense rib, reduces reinforcing steel bar and concrete consumption, and it is easy to lay and connect shuttering components, shift or displacement and unconformity of on-site casting concrete rib width and concrete protective layer thickness between shuttering components are avoided. The invention is suitable for on-site casting hollow floor, roof, soleplate, wall and empty bridge with on-site casting reinforced concrete or prestressed reinforced concrete, especially for hollow mushroom floor.

Owner:湖南邱则有专利战略策划有限公司

Novel composite floor system for super high-rise building

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Thin wall mould component

The invention is a thin wall mold shell component, comprising top plate, side walls and bottom plate, which compose a cavity and characterized in that the bottom plate is provided with at least a boss module protruded from it, at least a pair of opposite side walls is provided with at least a pair of opposite connection parts, which transversely extend from the top plate, and at least a pair of opposite connection parts is in the same line. It is applied to hollow building covers, house covers, walls, foundation slabs and hollow bridge beams of cast-in-site reinforced concrete or prestressed reinforced concrete, especially beamless building covers.

Owner:湖南邱则有专利战略策划有限公司

Method for embedding cement mixing soil curtain into prefabricated reinforced concrete anti-lateral-force pile

InactiveCN101078216BNo pollution in the processImprove flexural strengthExcavationsSlurryEngineering

The invention relates to a method that cement mixed soil curtain implants lateral force resistance pile of prefabricated reinforced concrete. Main procedures are described as follows. In construction site, cement mixer is used to mix soil in the whole journey or in upper water-stopping curtain part to form curtain along the implanting depth aiming to soil quality and soil extruding status; then it is implanted into pile body by pile driver to form retaining and waterproof enclosure wall. Thereinto pile body adopts prefabricated reinforced concrete T-shape / I-shape pile. Because powerful mixing soil or drilling machine is used to dig hole and inject grout, it is suitable for enclosure project of all kinds of soil qualities in principle. The beneficial effect of invention is that reinforcement ribs of T-shape or I-shape section are located at two ends of section; compared with circular pile with reinforcement ribs distributed along round face, the bending strength can be improved by more than 20% and the section area only is half of corresponding circular pile, namely concrete amount is saved in half. Ant it is provided with rapid construction speed, reliable quality, no noise and no pollution to circumstance by carrying slurry out so on.

Owner:严平 +1

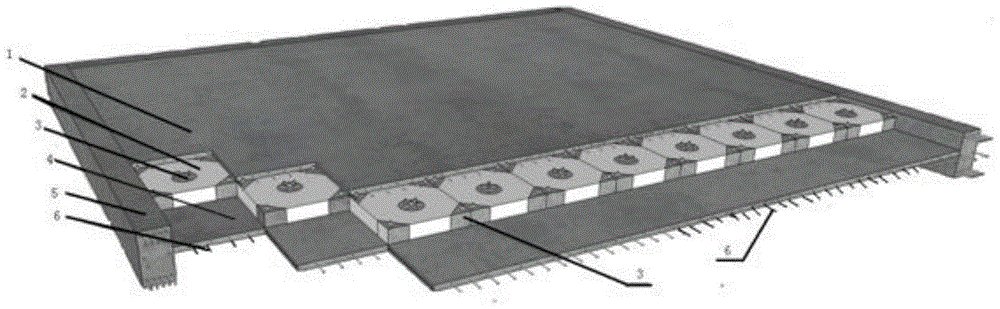

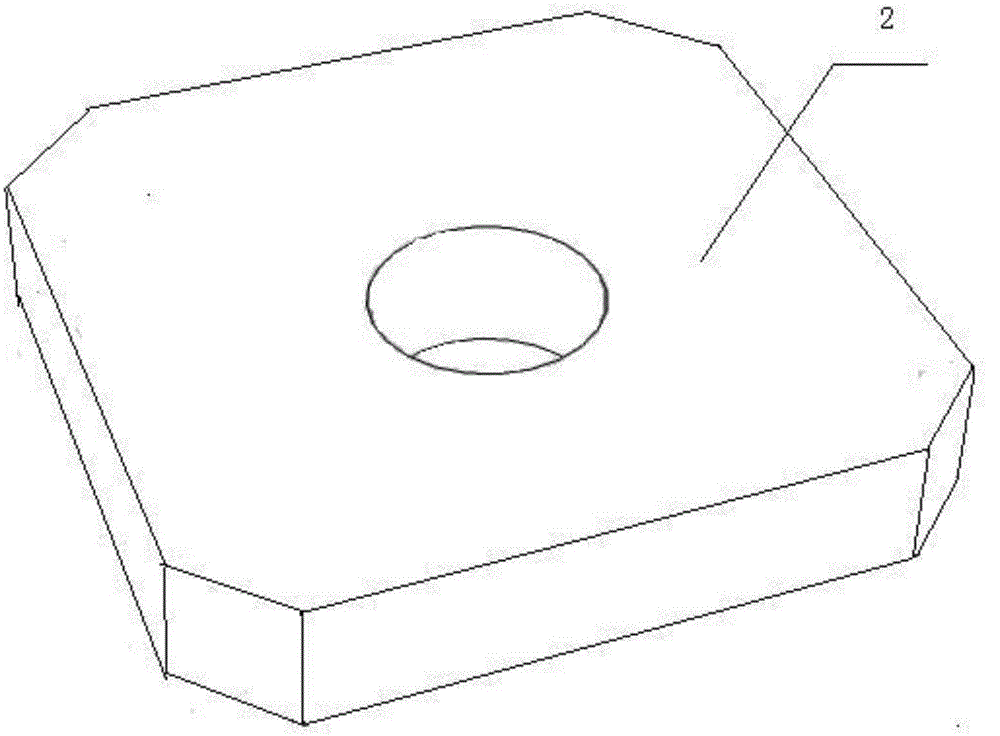

Rib-free beam mold box sandwiched reinforced concrete floor system

A rib-free beam mold box sandwiched reinforced concrete floor system comprises a double-layer reinforcement cage and a light insulation board mold box, wherein the double-layer reinforcement cage is composed of reinforcement meshes arranged on the upper layer and lower layer respectively. The light insulation board mold box is formed by shearing four right angles of a square mold box and is in central symmetry. A hole is formed in the central point of the light insulation board mold box. The rib-free beam mold box sandwiched reinforced concrete floor system has the advantages that by adopting floors of the system, a large span can be realized and the self weight of structural members can be lowered; integral on-site casting is adopted in the construction technology of the floors, the construction processes are simplified compared with common beam slab structures, the height of floor systems can be lowered, and the heat insulation effect and the sound insulation effect are good.

Owner:CHINA AEROSPACE CONSTR GROUP

Perlite polyphenylene compound filling block, method for preparing same and filled floor plate construction method

InactiveCN101684676BLight weightSolve the problem of easy water absorptionConstruction materialCeramic shaping apparatusCombustionRebar

The invention provides a perlite polyphenylene compound filling block, a method for preparing the same and a filled floor plate construction method, wherein the perlite polyphenylene compound filling block is a cuboid with the rectangular top surface; and a block body is formed by up-and-down lamination of a rectangular expanded perlite agglomerate and a polyphenylene plate, and the outer surfaceof the block body is wrapped by a plastic adhesive tape, a positioning metallic wire is embedded in the expanded perlite agglomerate in advance, the bottom part of the positioning metallic wire is U-shaped, both ends of the positioning metallic wire upward pass the expanded perlite agglomerate and are extended to the outer side of the plastic adhesive tape. The perlite polyphenylene compound filling block has low cost, relatively light deadweight and insusceptibility to breakage, combustion and deformation, and can effectively solve the problem that the block body is susceptible to water absorption; when the perlite polyphenylene compound filling block is arranged in the floor plate in advance, the cement consumption of the floor plate is reduced, the weight of the floor plate is reduced,the whole deadweight of the structure of the building is reduced, but the bearing capacity of the floor plate is not lowered; moreover, the total consumption of reinforcing steel bars in the floor plate and the building is also lowered.

Owner:杨晓宏

Vertical combined novel foundation of mast mechanical equipment

InactiveCN101255700BTake full advantage of side pressureSmall footprintFoundation engineeringResource savingEconomic benefits

Owner:赵正义

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com