Foundation structure design method for gravity type extended foundation of perpendicular axis fan

A technology for expanding the foundation and foundation structure, which is applied in the field of wind farm fan foundation construction, can solve the problems of affecting the progress of the project, increasing the area of the bottom of the foundation, increasing the amount of concrete in the foundation, and achieving the effect of saving engineering costs and reducing the amount of concrete in the foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] According to the information provided by the manufacturer, determine the loads of the vertical axis fan under normal working conditions and extreme working conditions, as shown in Table 1.

[0062] Table 1:

[0063]

[0064] Correct the load value of the vertical axis fan provided by the manufacturer with the safety factor K 0 =1.35 for correction, get Table 2.

[0065] Table 2:

[0066]

[0067] Determine the bearing capacity of foundation soil according to geological data:

[0068] Foundation bearing capacity f a =800kPa.

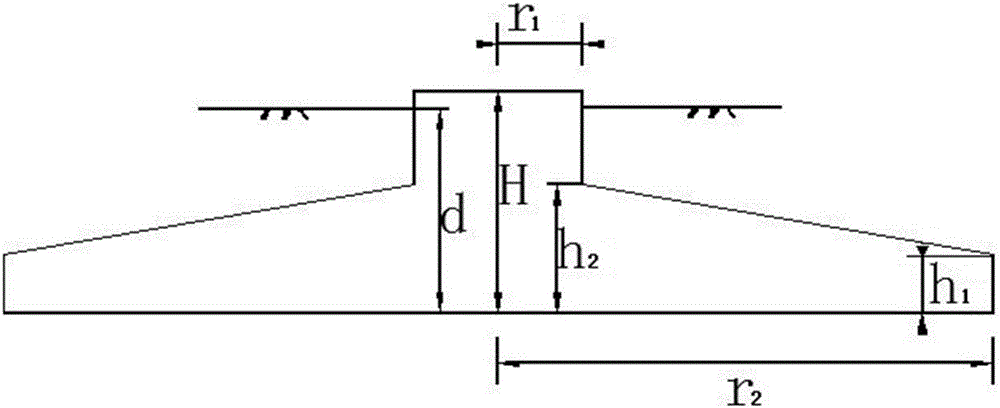

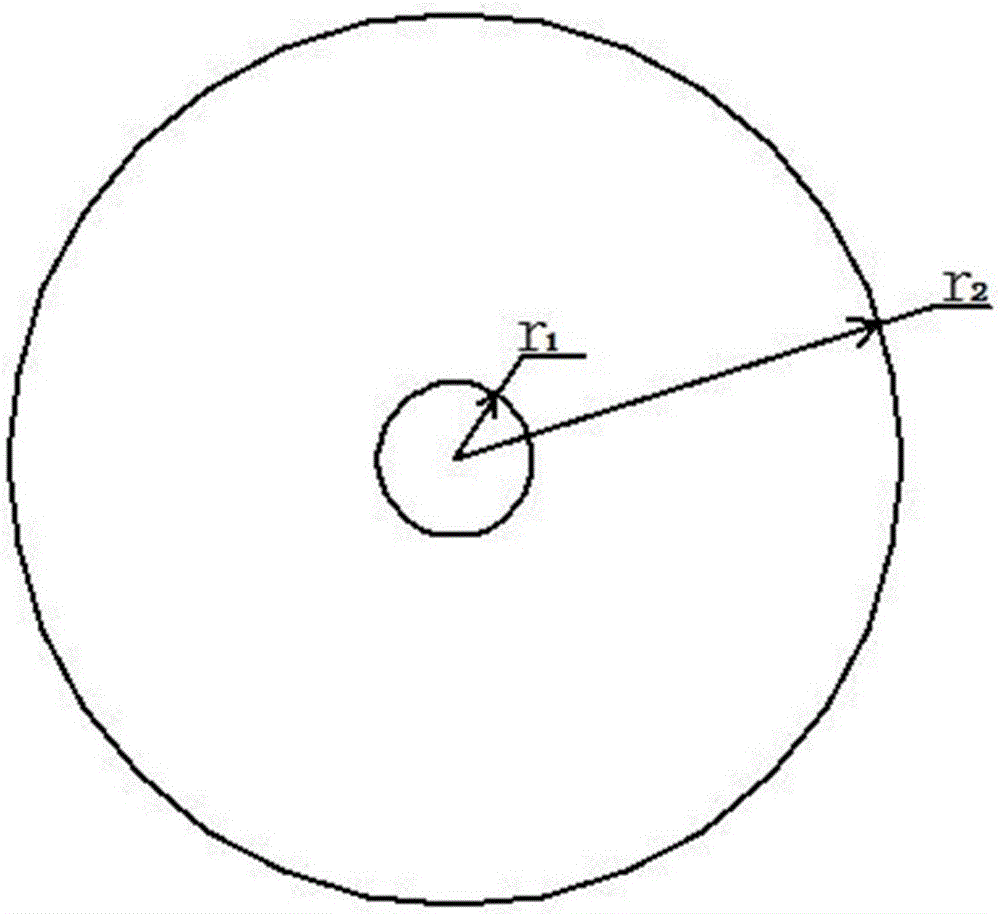

[0069] Follow Step B: Under normal working conditions, calculate the base stress with the standard values in Table 2, so as to determine the base bottom radius.

[0070] In the calculation, it is assumed that the foundation bottom radius r 2 =9m; use the following formula to calculate the base stress.

[0071] σ m i n m a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com