Steel reinforced concrete column-steel beam joint locally adopting fiber reinforced concrete

A fiber-reinforced, concrete column technology, applied in building types, building components, earthquake-proof, etc., can solve the problems of low restraint effect of stirrups on the core area of nodes, insufficient rotation capacity of nodes, and easy occurrence of brittle failure, so as to increase the rotation of nodes. capacity, improve the shear bearing capacity of joints, and reduce the effect of repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

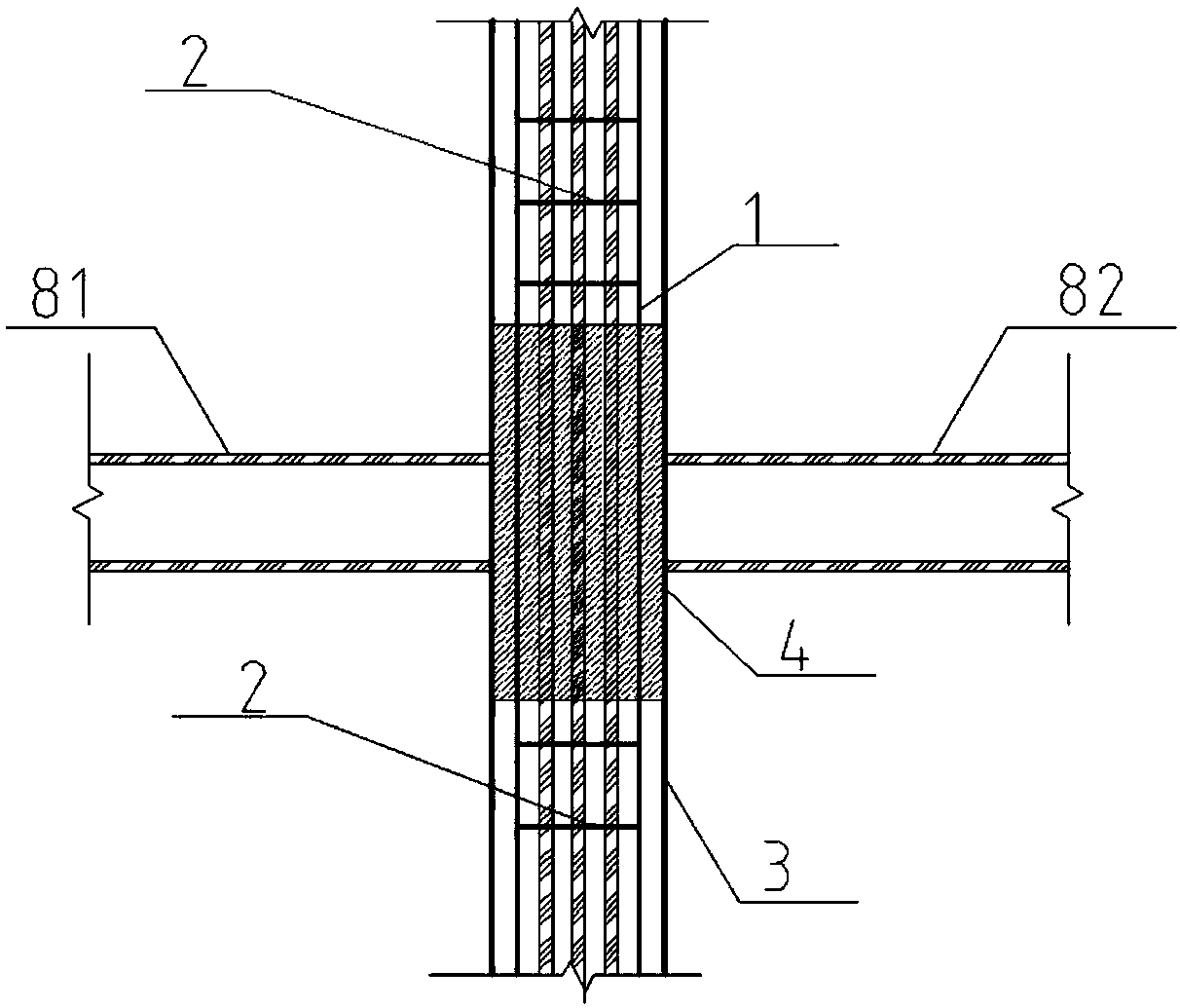

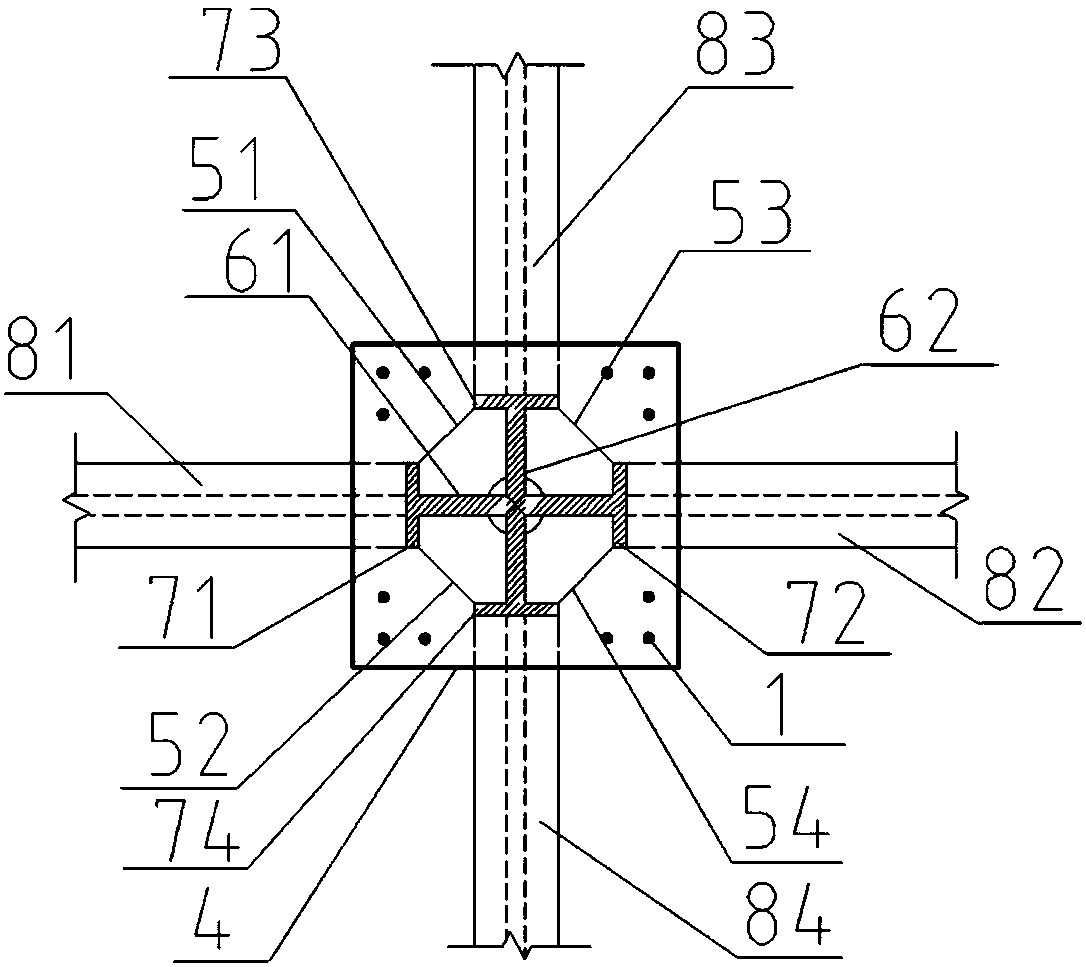

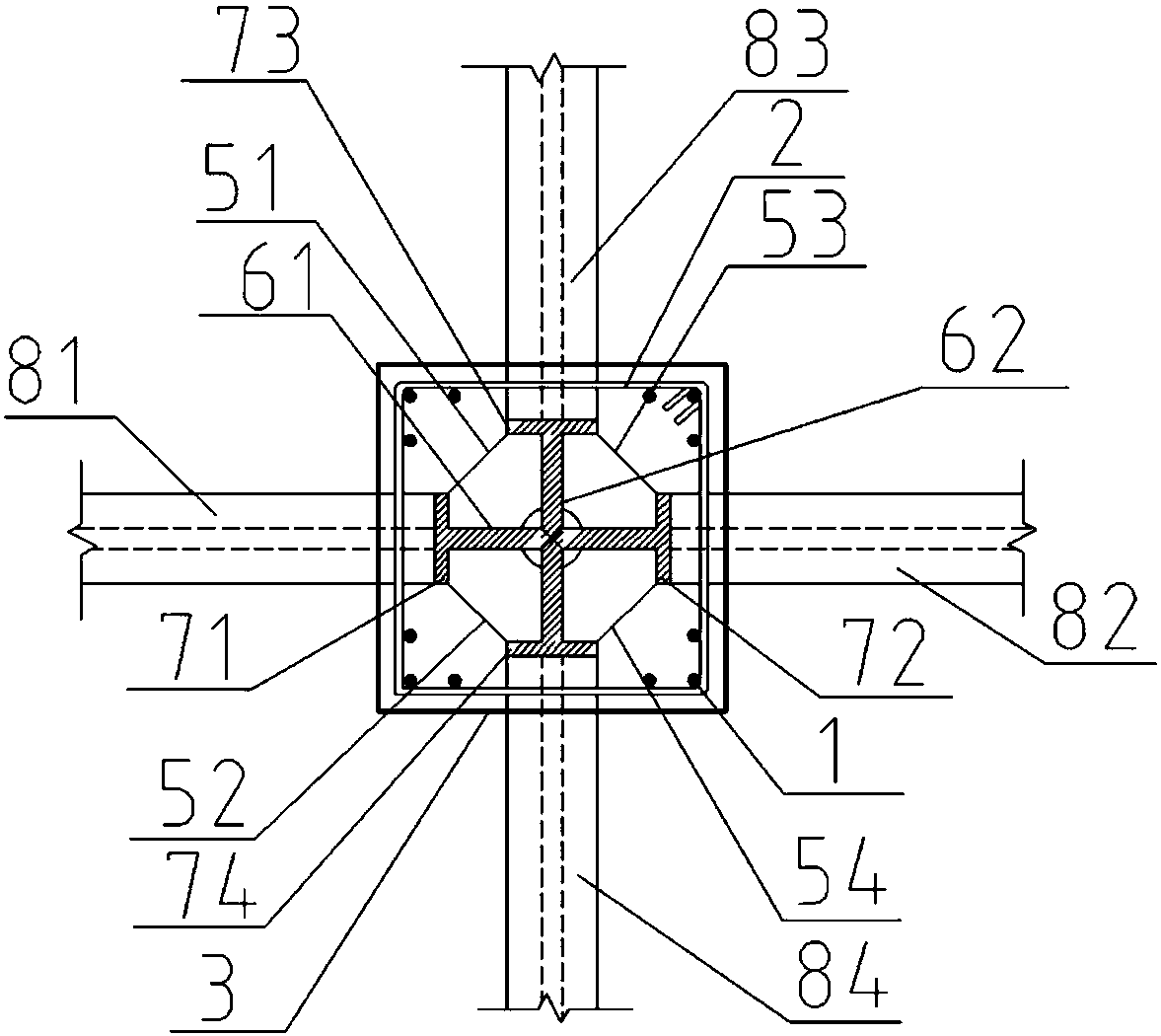

[0020] see figure 1 , figure 2 as well as image 3 , the section steel concrete column-steel beam joint structure using fiber-reinforced concrete in the present invention comprises core section steel, fiber-reinforced concrete 4, a first stiffener 51, a second stiffener 52, a third stiffener 53, a fourth stiffener Rib 54, the first steel beam 81, the second steel beam 82, the third steel beam 83, the fourth steel beam 84 and several longitudinal steel bars 1; the core section steel includes the first section steel web fixedly connected (welded) into a cross section steel structure plate 61 and the second steel web 62, the two ends of the first steel web 61 are respectively welded with the first steel flange 71 and the second steel flange 72, and the two ends of the second steel web 62 are respectively welded with the third Shaped steel fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com