Annular steel-steel support connecting joint structure for steel structure and externally-hung wall plate

A technology for hanging wall panels and connecting nodes, which is applied in building structure, building components, earthquake resistance, etc., can solve the problem of not being used in large quantities, and achieve the effect of speeding up the construction progress, saving labor costs, and saving maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments. Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this application belongs.

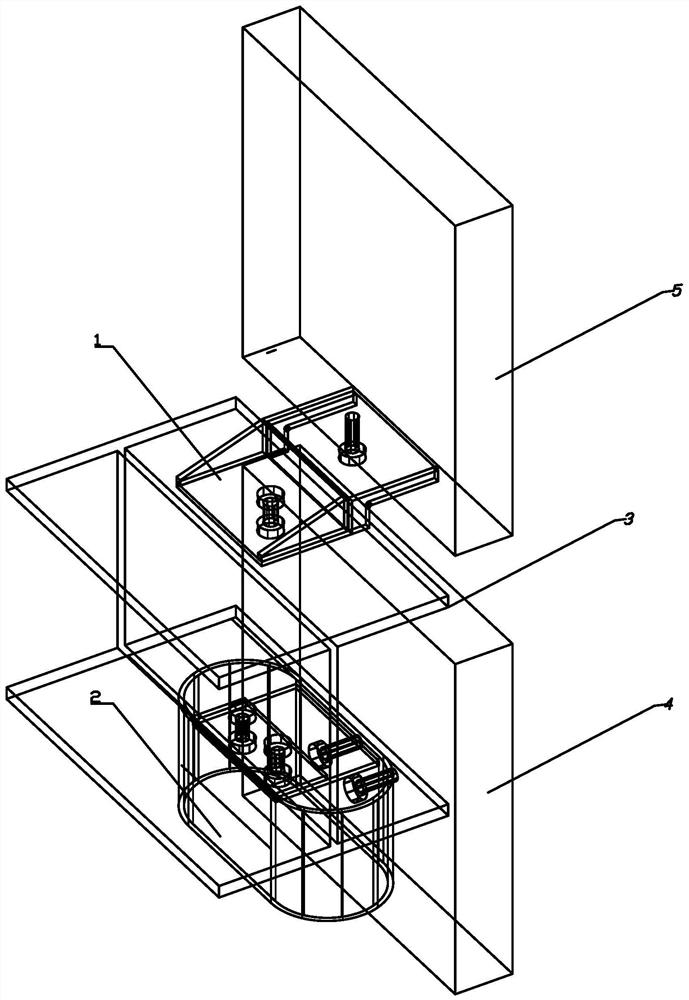

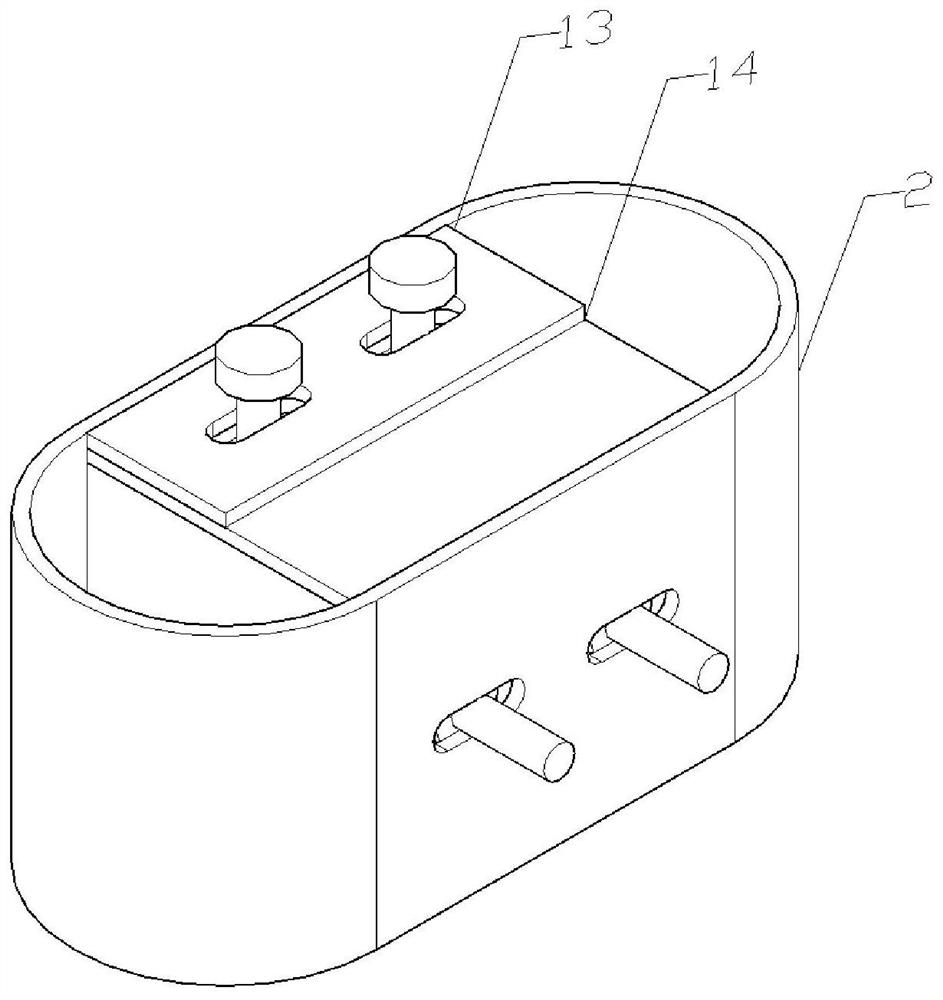

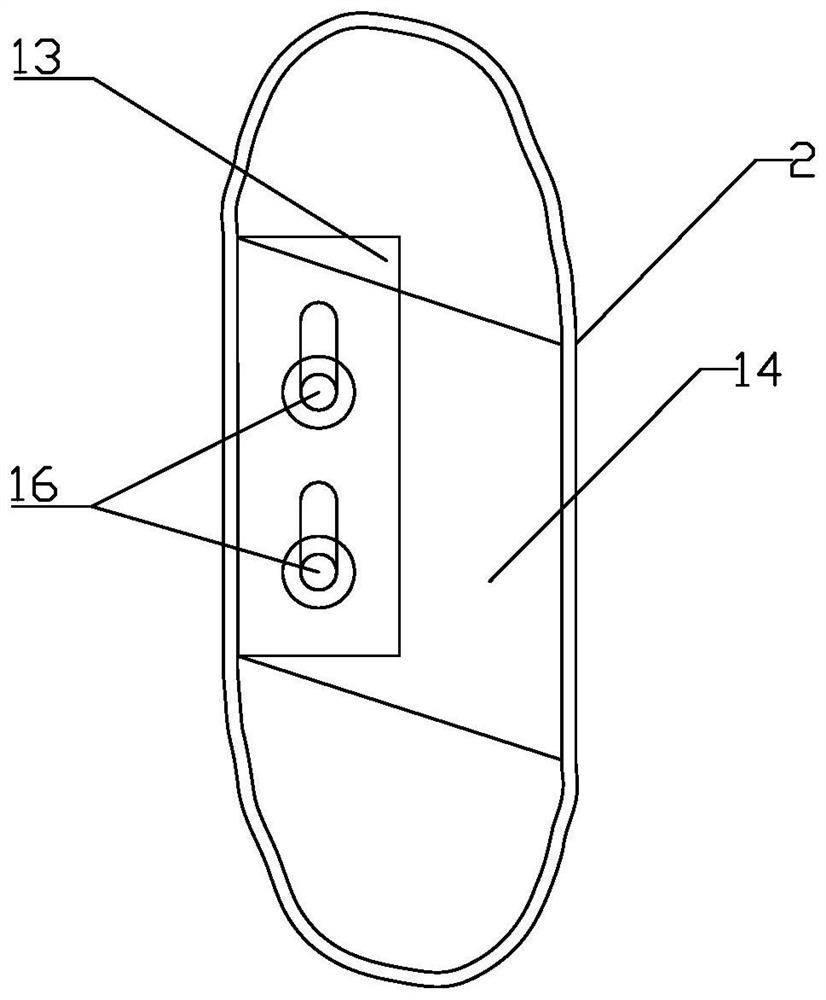

[0030] Such as figure 1 and Figure 4 As shown, the ring-shaped steel-steel bracket connection node structure used for the steel structure and the external wall panel includes the lower external wall panel 4 and the upper external wall panel 5, and the lower external wall panel 4 is connected to the upper external wall panel through the frame beam 3 The plate 5 is connected, and the frame beam 3 is provided with an upper node connection device and a lower node ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com