Patents

Literature

59results about How to "Full use of strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

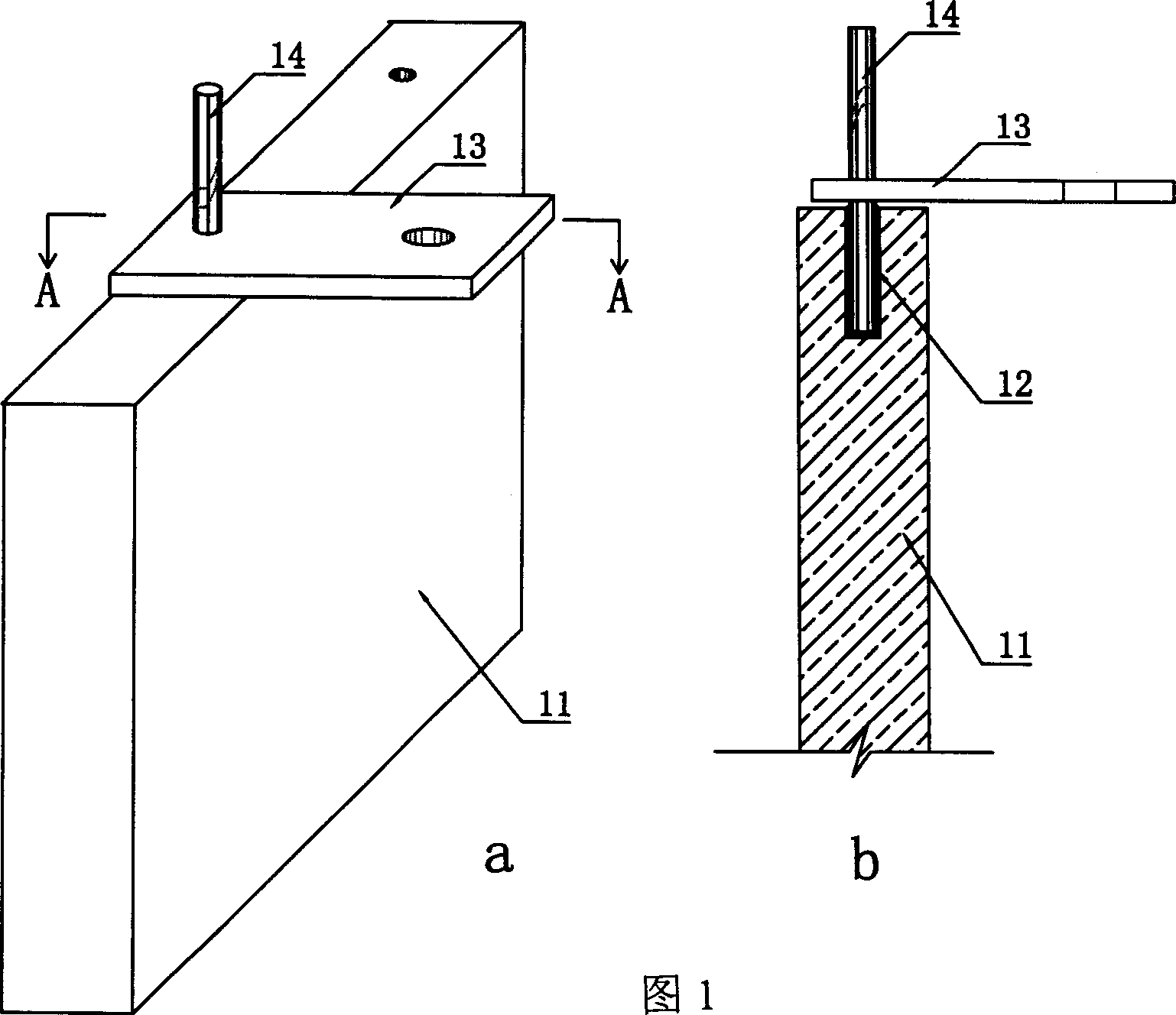

Hanger embedded decorative panel of stone material and its making method

An embedded hanger type decorative stone slab is composed of surfacial stone layer, embedded hangers in the slot on the back of said surficial stone layer, and insulating layer on the back of said surficial layer. It is possible to attach a reinforcing layer to it. Its advantages are less consumption of stone, low cost, and high stress performance.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +1

SCS (structure cabling system) encased structure based on PBL (planetary boundary layer) stiffening ribs

InactiveCN102979251ALight structureImprove seismic performanceArched girdersStrutsMechanical propertyStructure based

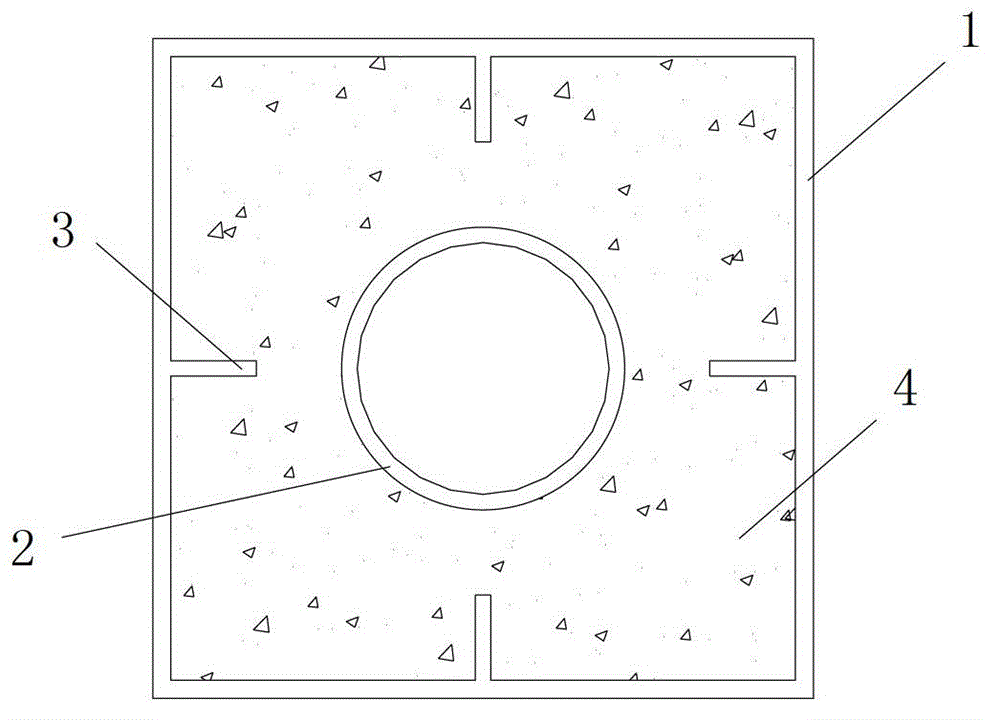

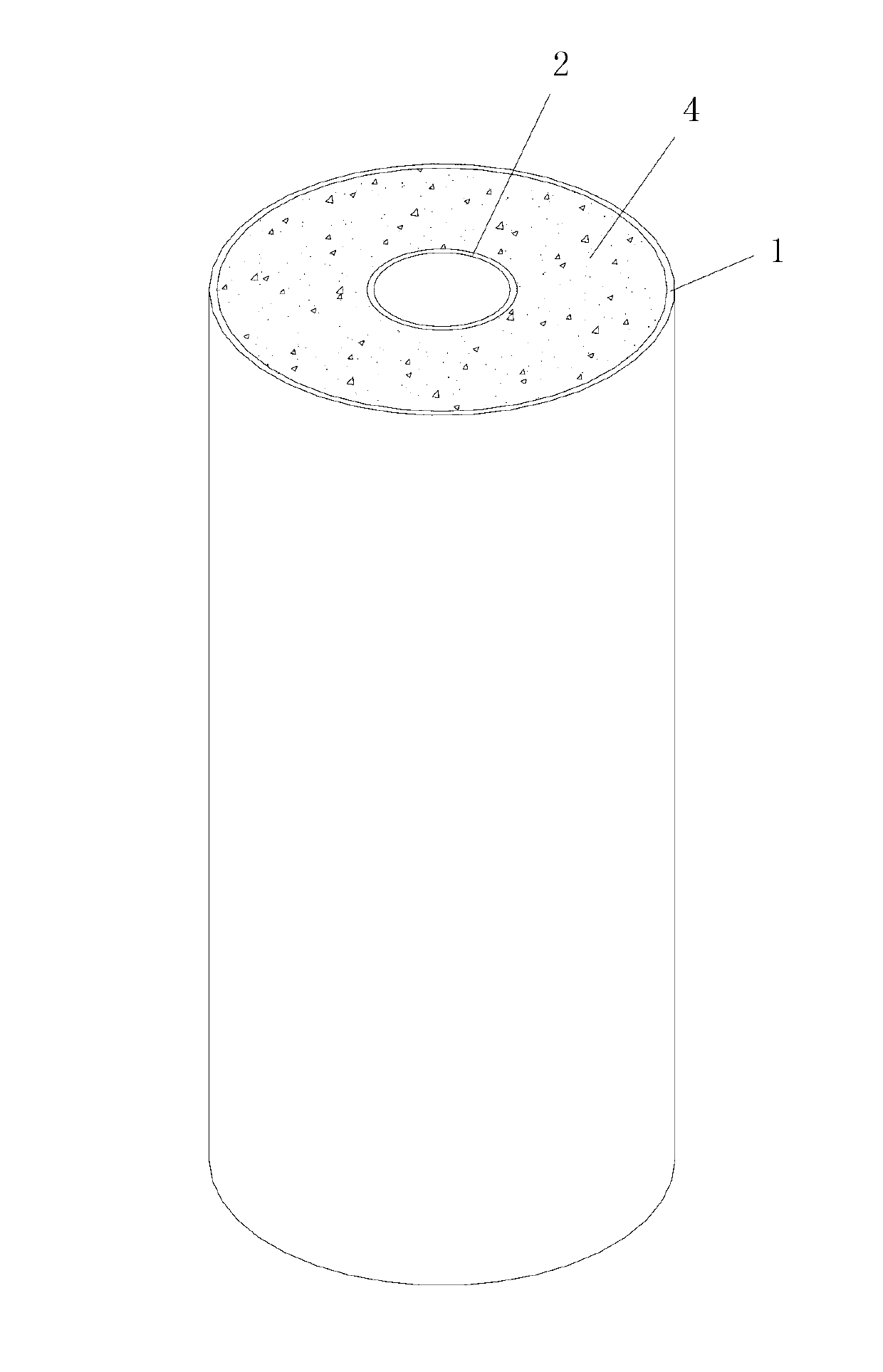

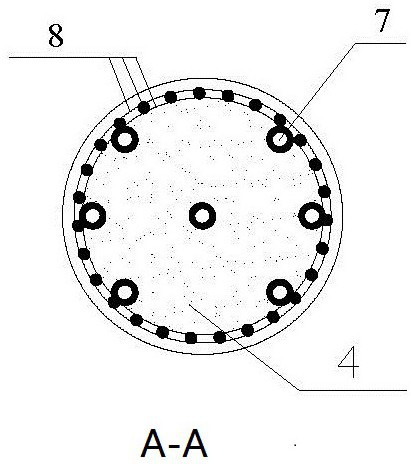

The invention discloses an SCS (structure cabling system) encased structure based on PBL (planetary boundary layer) stiffening ribs. The SCS encased structure comprises an outer steel tube, an inner steel tube, a plurality of PBL stiffening ribs arranged between the outer steel tube and the inner steel tube, and a concrete structure which is poured and molded by concrete filled inside a cavity between the outer steel tube and the inner steel tube, wherein the outer steel tube, the inner steel tube and the plurality of PBL stiffening ribs are equal in longitudinal length; the plurality of PBL stiffening ribs are arranged along the peripheral direction of the inner steel tube; the inner lateral wall of each PBL stiffening rib and the inner lateral wall of the inner steel tube are fastened and connected into a whole, and the outer lateral wall and the outer lateral wall of the outer steel tube are fastened and connected into a whole. The SCS encased structure is simple in structure, reasonable in design, convenient to construct, low in construction cost, excellent in mechanical property, and good in using effect, and the problems of large dead load of the existing encased structure, poor connection performance of the outer steel tube and the internal concrete, and small hoop effect of the outer steel tube on the internal concrete can be effectively solved.

Owner:CHANGAN UNIV

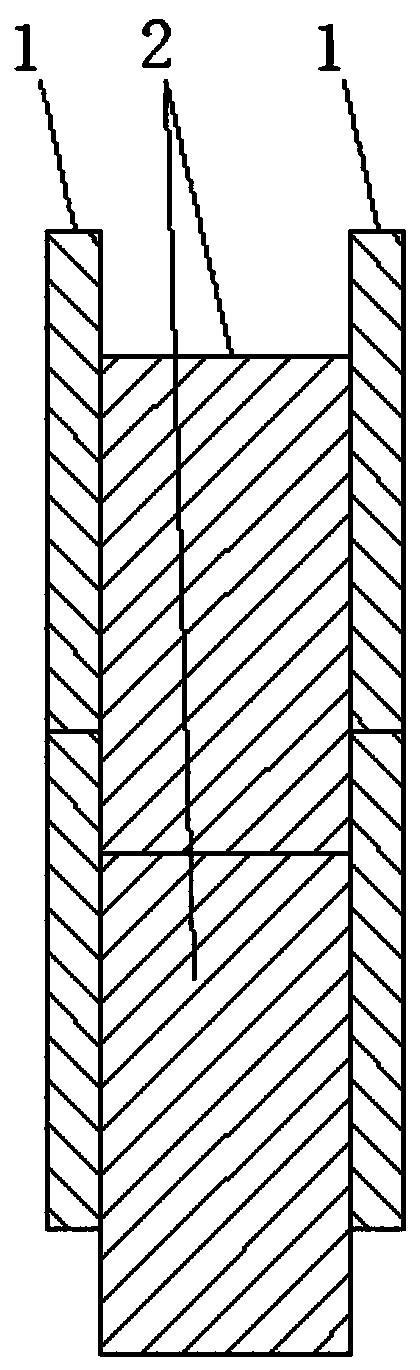

SCS (structure cabling system) encased structure based on longitudinal stiffening ribs

InactiveCN102979250ASimple structureReasonable designArched girdersStrutsMechanical propertyStructure based

The invention discloses an SCS (structure cabling system) encased structure based on longitudinal stiffening ribs. The SCS encased structure comprises an outer steel tube, an inner steel tube, a plurality of longitudinal stiffening ribs arranged at the inner lateral wall of the outer steel tube, and a concrete structure which is poured and molded by concrete filled inside a cavity between the outer steel tube and the inner steel tube, wherein the outer steel tube and the inner steel tube are coaxially arranged; the plurality of longitudinal stiffening ribs are arranged along the peripheral direction of the inner steel tube; the outer steel tube, the inner steel tube and the plurality of longitudinal stiffening ribs are equal in the longitudinal length, and the transverse width of each longitudinal stiffening rib is the distance between the outer steel tube and the inner steel tube at the arranged positions. The SCS encased structure is simple in structure, reasonable in design, convenient to construct, low in construction cost, excellent in mechanical property, and good in using effect, and the problems of large dead load of the existing encased structure, poor connection performance of the outer steel tube and the internal concrete, and small hoop effect of the outer steel tube on the internal concrete can be effectively solved.

Owner:CHANGAN UNIV

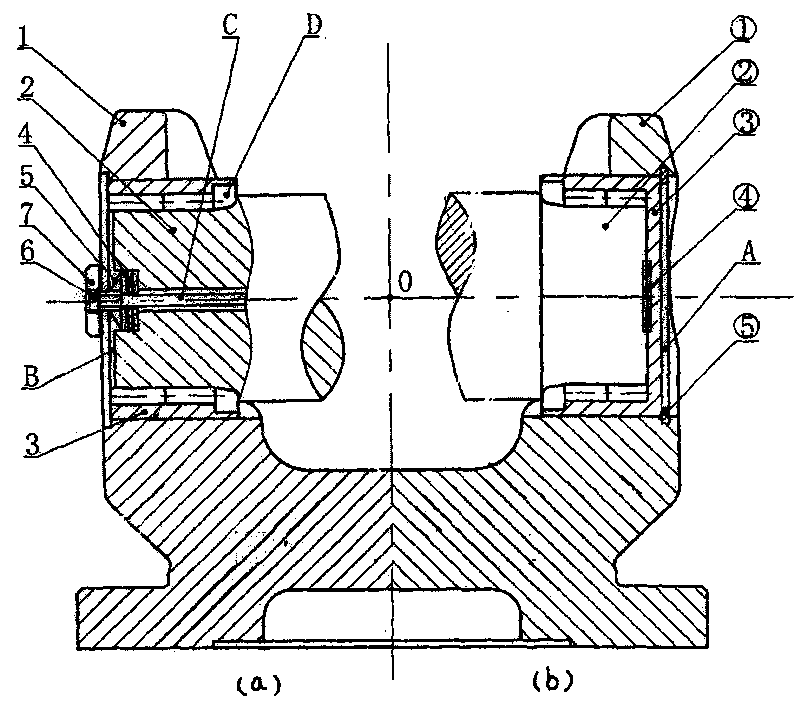

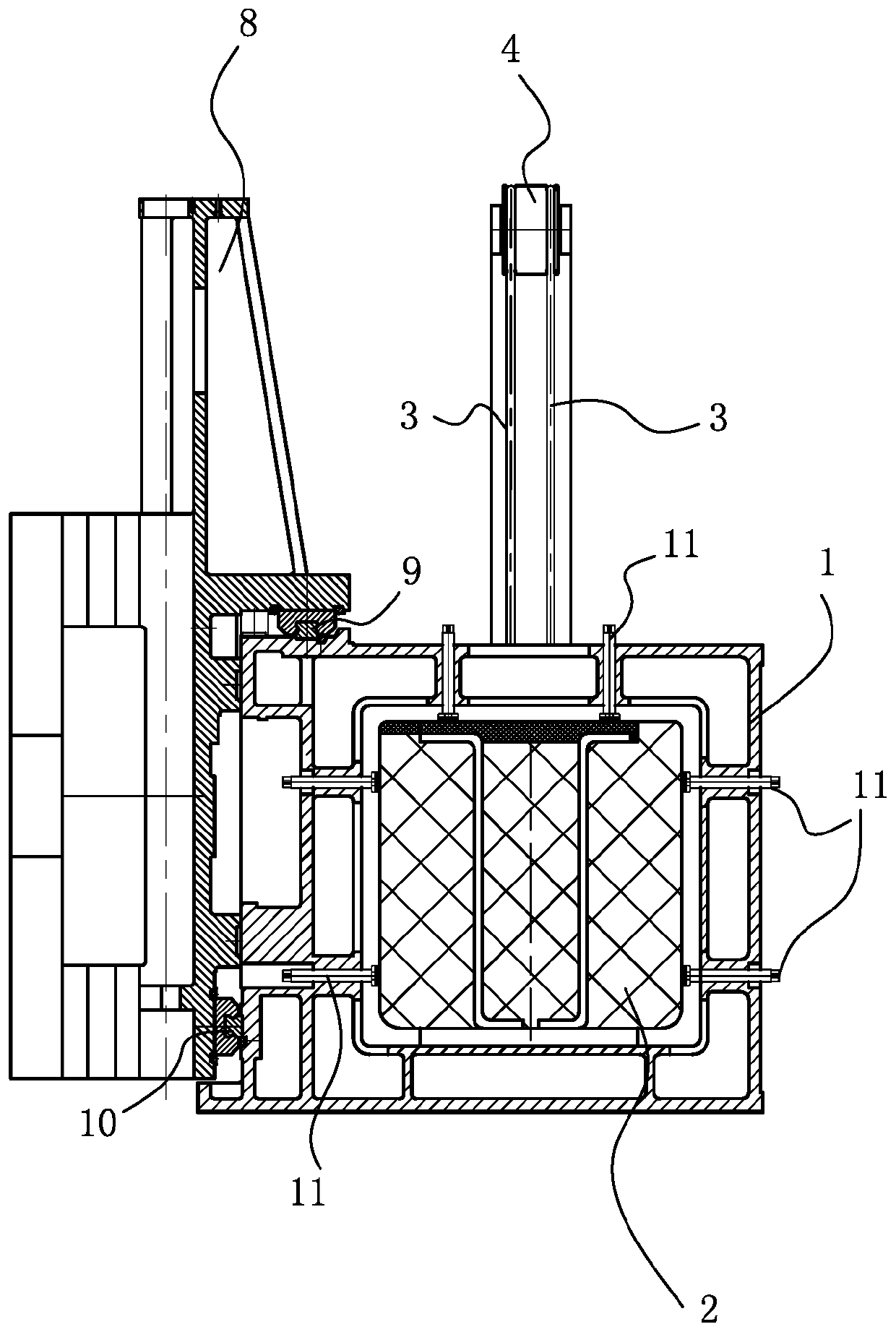

Eight-line symmetrical balancing type large reciprocating compressor

ActiveCN101832246AEven by forceFull use of strengthPositive displacement pump componentsMulti-stage pumpsEngineeringDrive motor

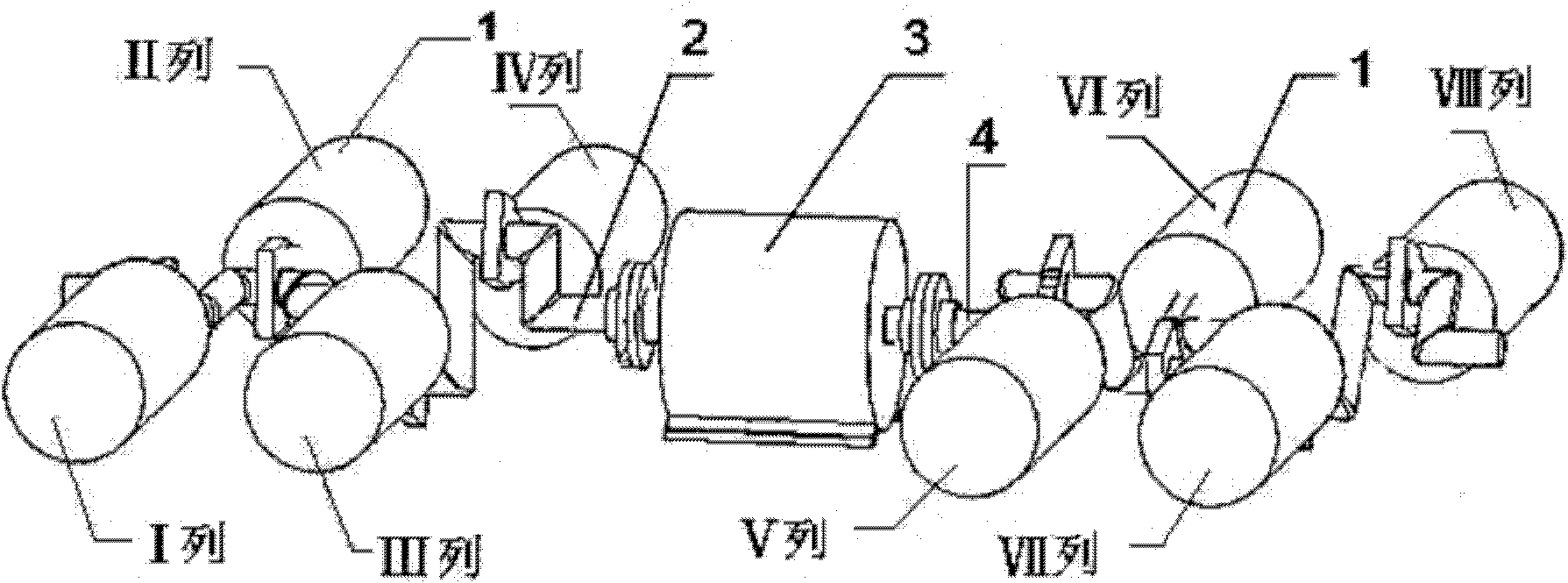

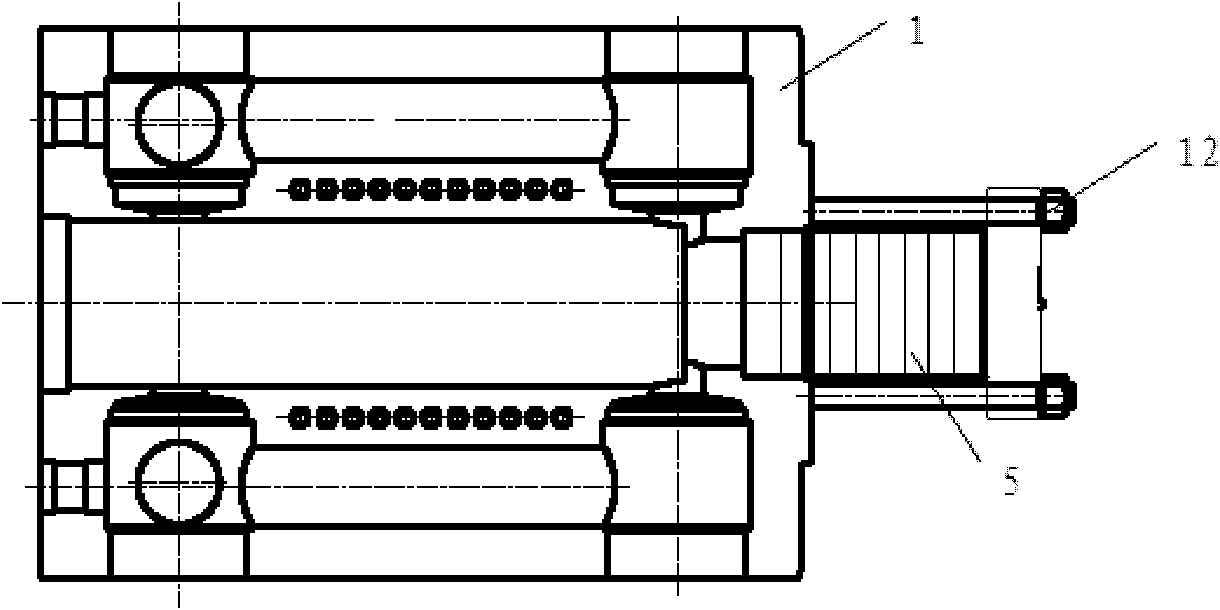

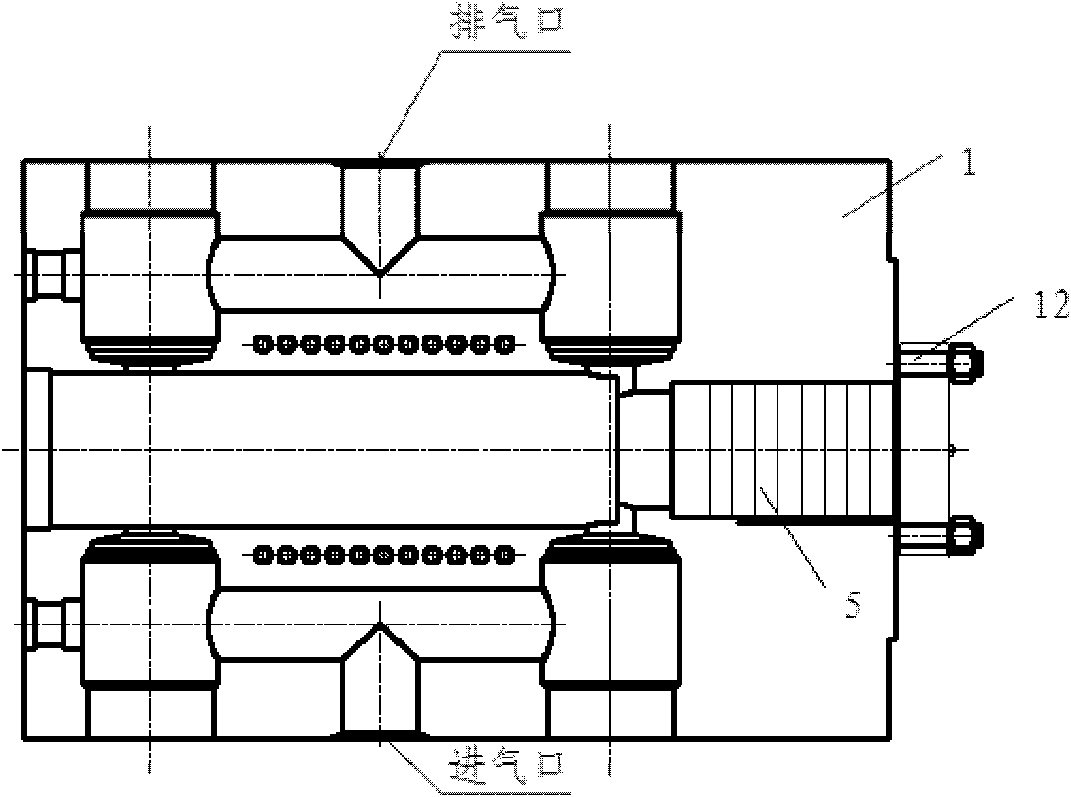

The invention discloses an eight-line symmetrical balancing type large reciprocating compressor which comprises a driving motor, crankshafts and eight lines of air cylinders. The reciprocating compressor is characterized in that four lines of air cylinders are connected with one crankshaft and arranged on one side of the driving motor; the other four lines of air cylinders are connected with the other crankshaft and arranged on the other side of the driving motor; and the two crankshafts have the same structure. Cranks corresponding to the first and second lines of air cylinders are arranged in one plane and are vertical to the planes of cranks corresponding to the third and fourth lines of air cylinders. Cranks corresponding to the fifth and sixth lines of air cylinders are arranged in one plane and form an angle of 45 degrees with the planes of the cranks corresponding to the first and second lines of air cylinders. The planes of cranks corresponding to the seventh and eighth lines of air cylinders are vertical to the planes of the cranks corresponding to the fifth and sixth lines of air cylinders. The air cylinders corresponding to the cranks in the same plane form a moving line, and the moving line is provided with a cross head for connecting a connecting rod with a piston rod, wherein the side force of one connecting rod acting on the cross head always faces downwards, and the side force of the other connecting rod acting on the cross head always faces upwards.

Owner:宝鸡市博磊化工机械有限公司

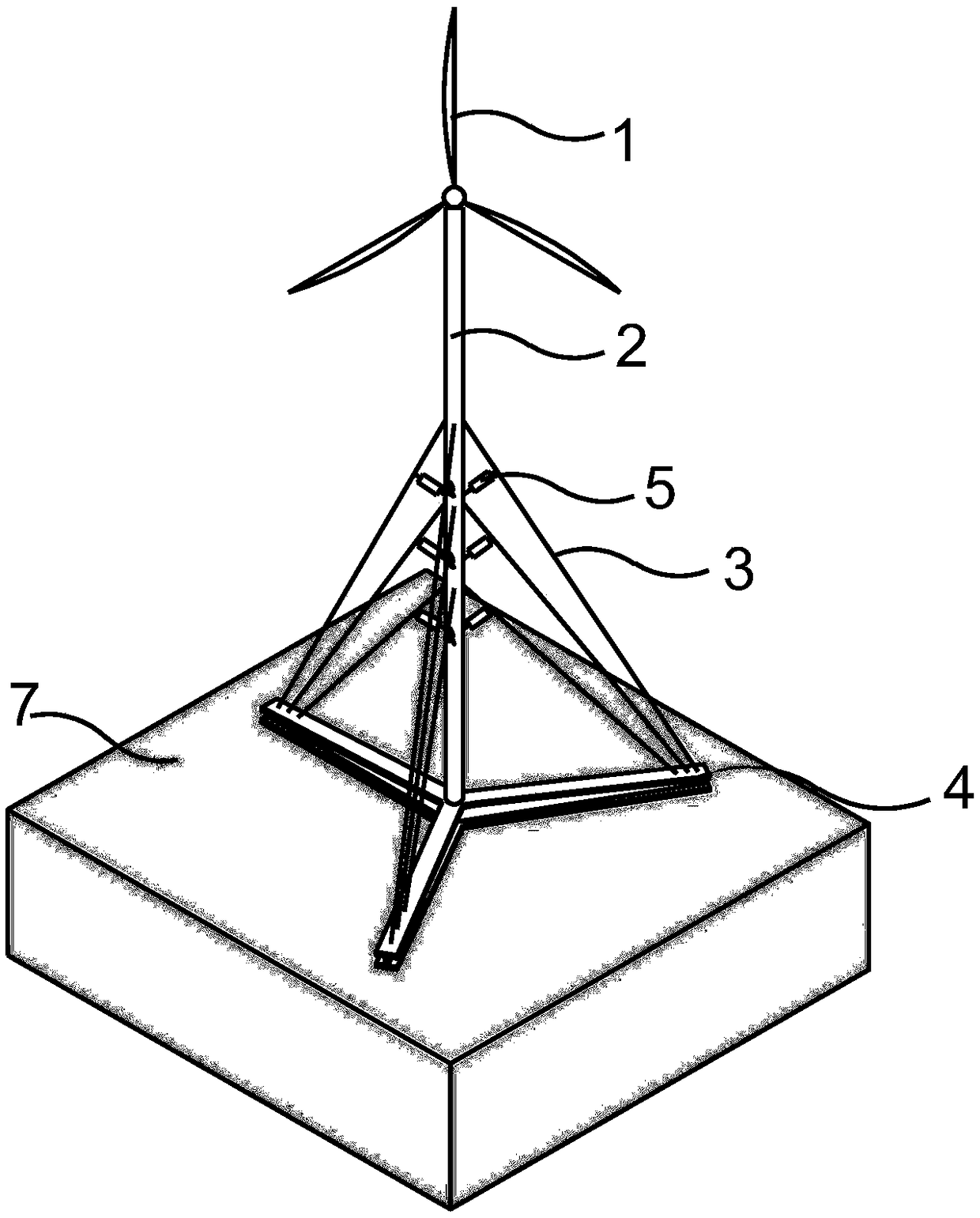

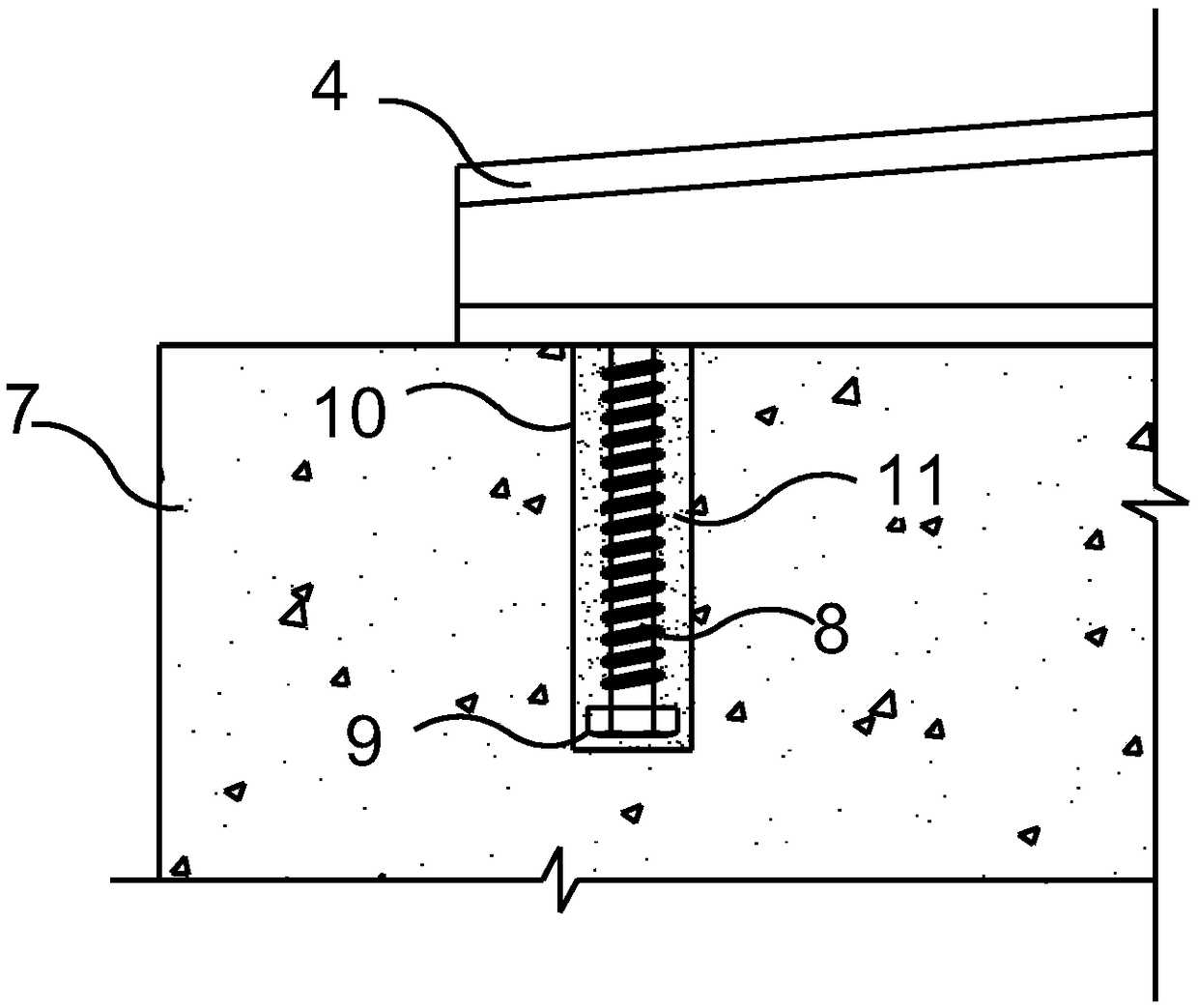

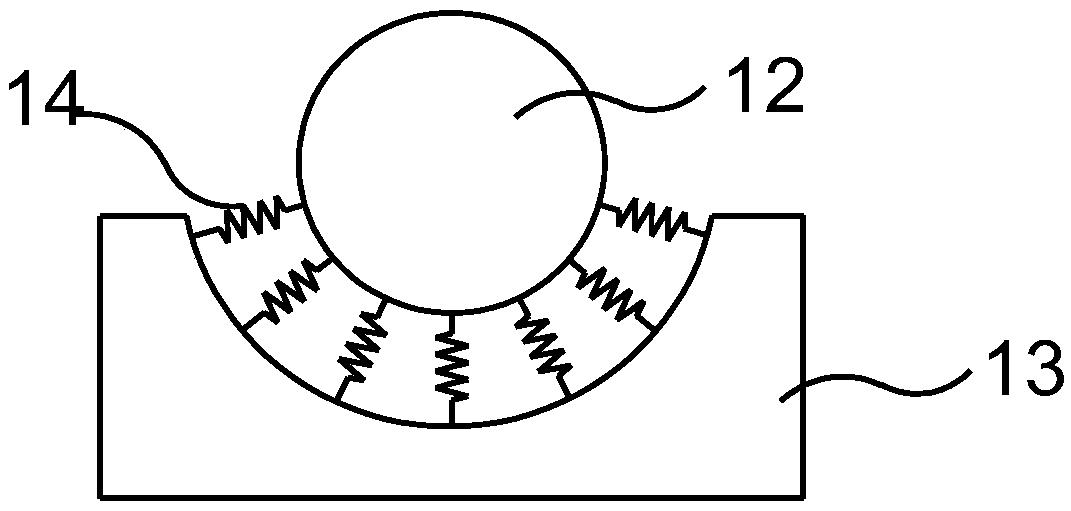

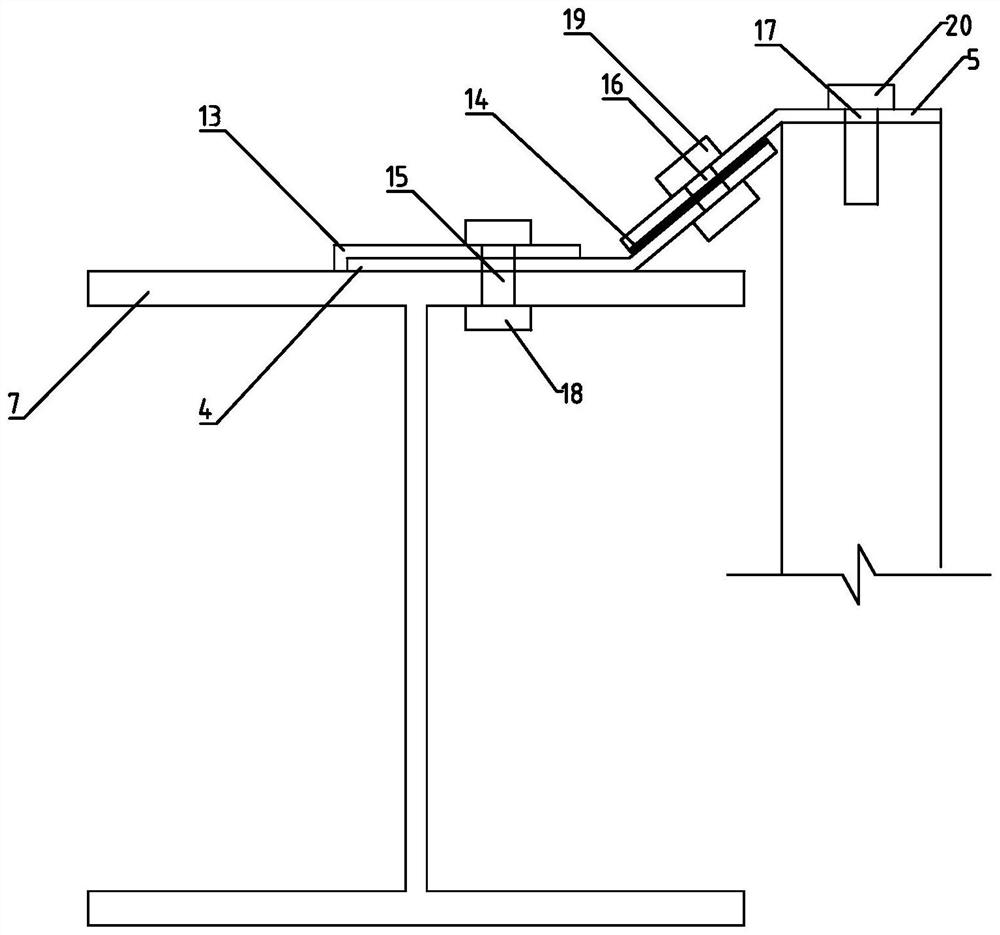

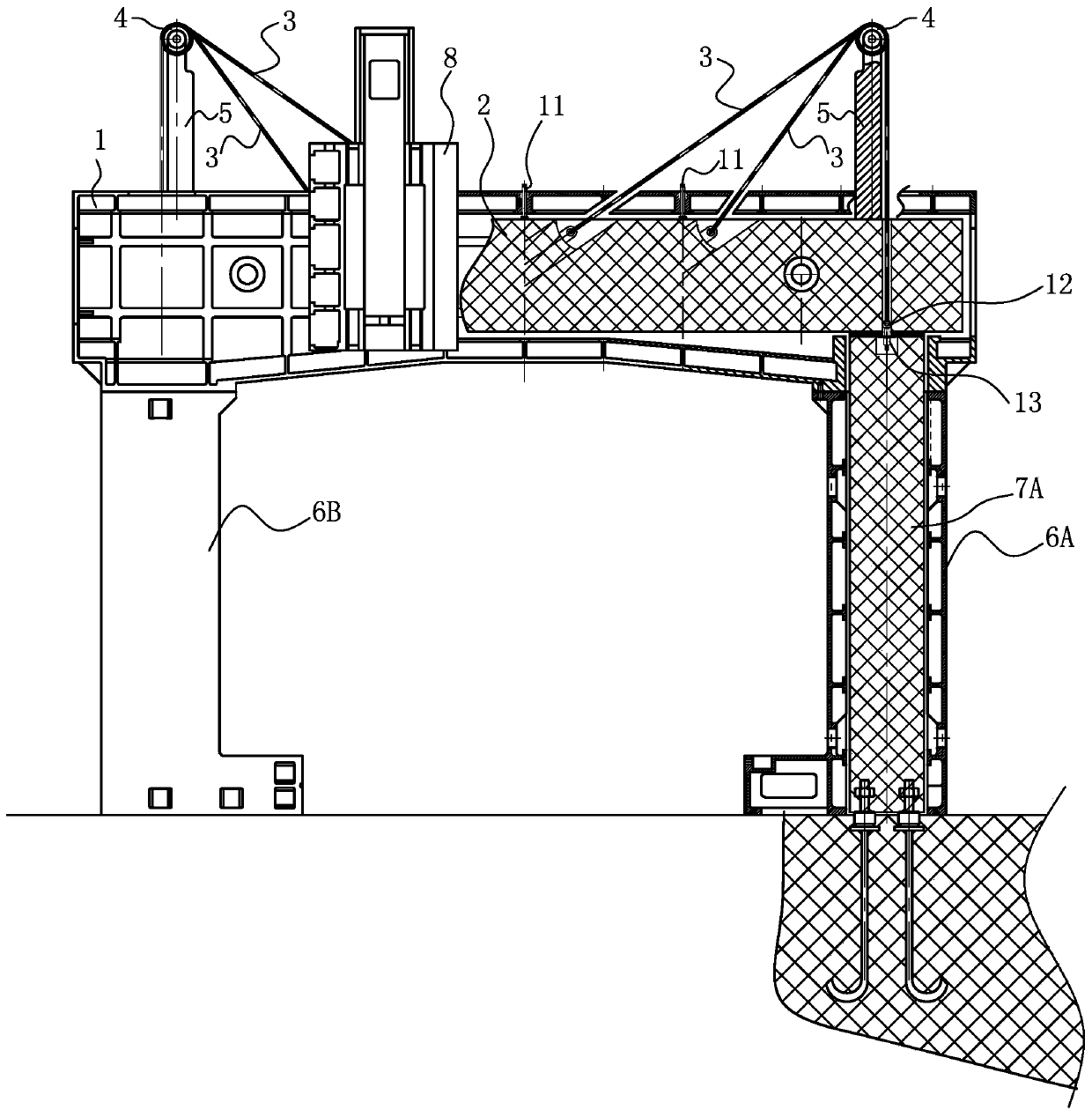

Wind-power tower barrel based on stay cable-steel beam self-balance system

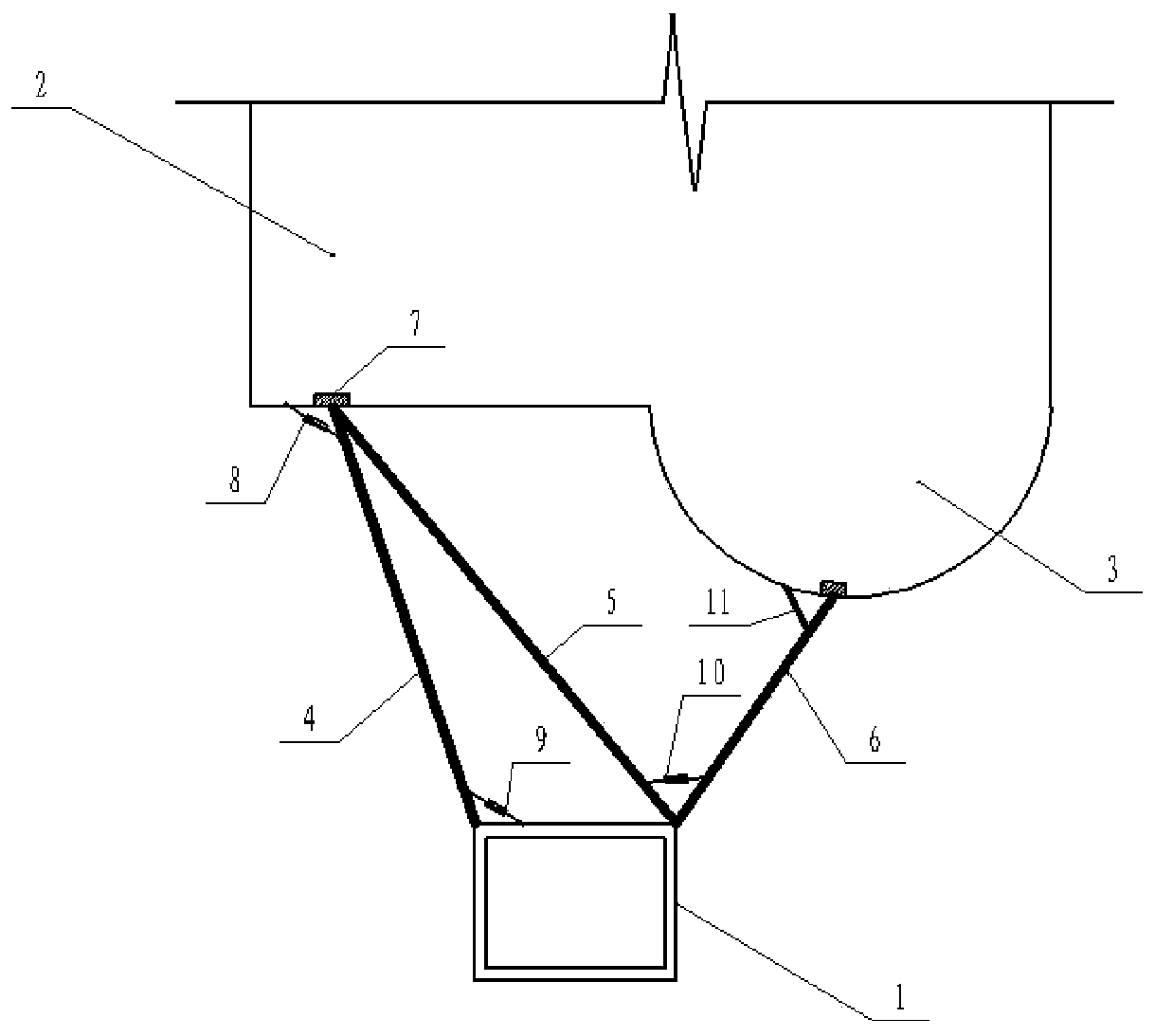

PendingCN109372701AReduce bending momentReduce section sizeWind motor supports/mountsWind energy generationVibration attenuationElectricity

The invention discloses a wind-power tower barrel based on a stay cable-steel beam self-balance system, and relates to the technical field of wind power generation. The system comprises a fan, the tower barrel, a stay cable, a linking beam, a stay cable vibration-attenuation damper, a mass damper and a base, wherein the two ends of the stay cable are separately anchored on the tower barrel and thelinking beam; the linking beam is connected with the tower barrel, and the end part of the linking beam is connected with the base; one fan is arranged on the top of the tower barrel, and the mass dampers is arranged on the tower barrel; and the stay cable vibration-attenuation damper is mounted on the stay cable. According to the tower barrel, the stay cable is arranged to reduce bending momentof a tower body, so that the tower barrel main bears vertical axial pressure, and therefore, strength of the material can be sufficiently utilized, and the section dimension of the tower barrel is reduced. The tower barrel is simple in structure, is good in vertical and integral stability, and is a brand-new wind-power tower barrel structural form.

Owner:CHONGQING UNIV

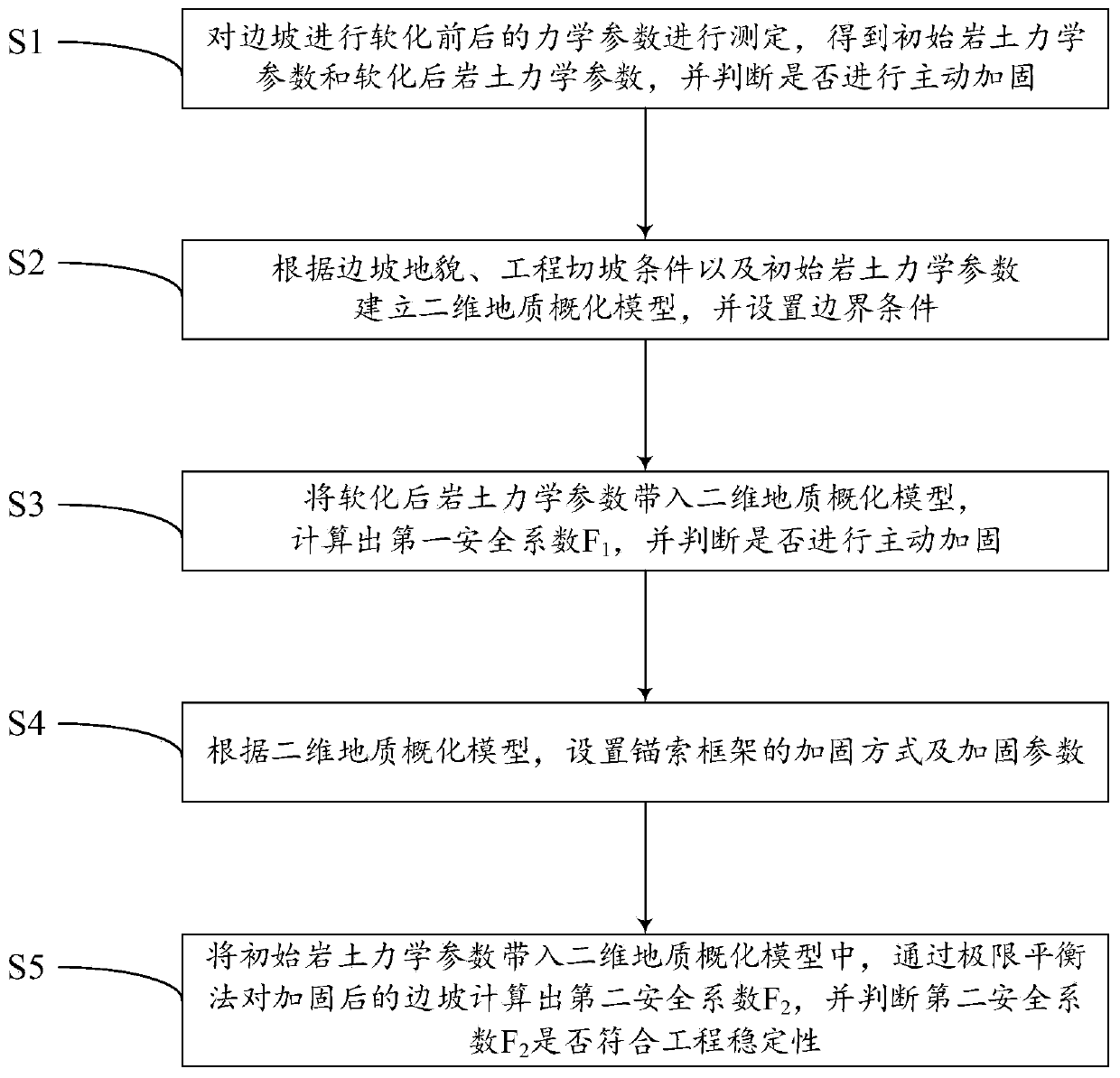

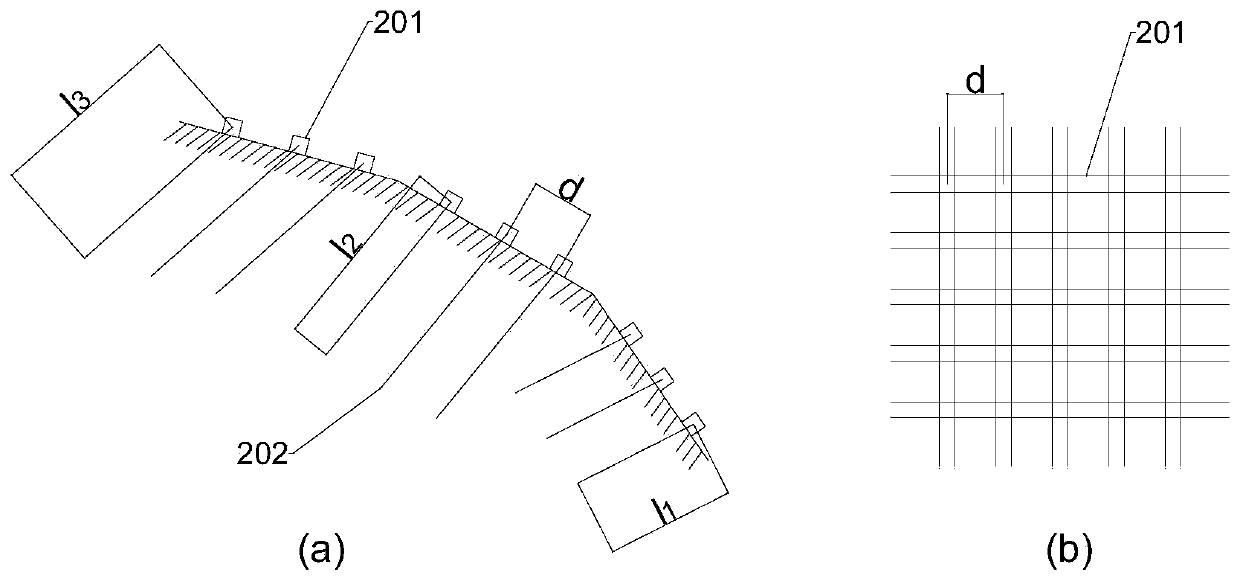

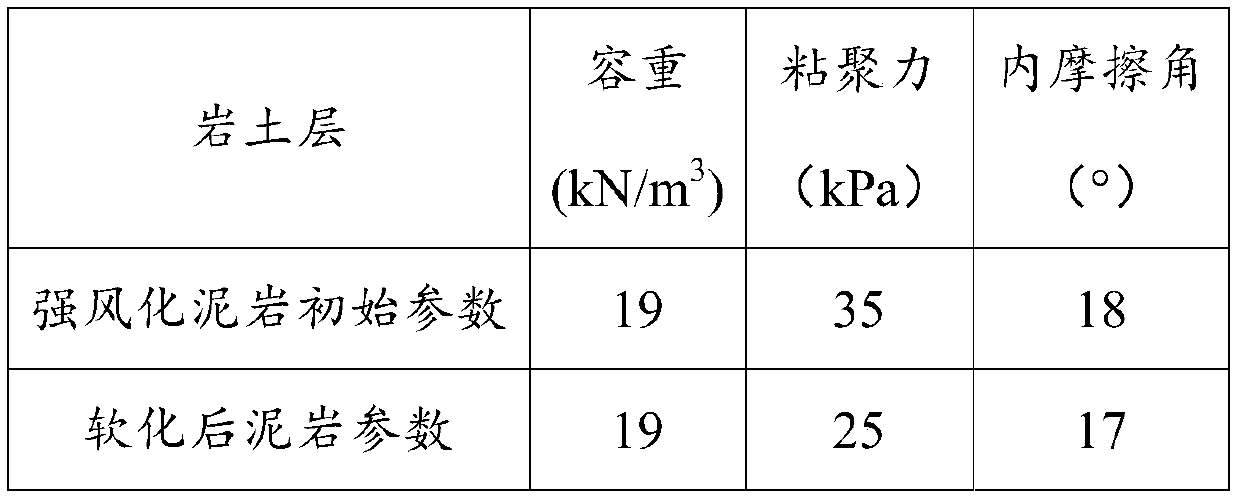

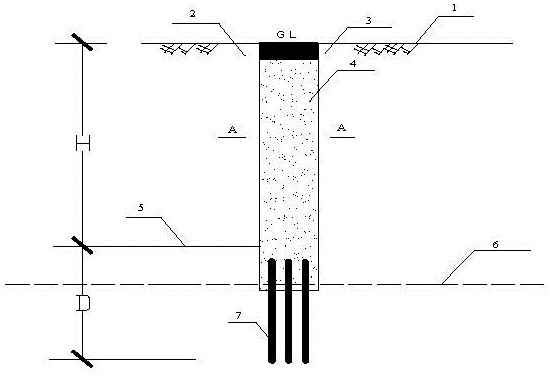

Initiative strengthening method specific to unstable slope

InactiveCN111350197ALow reinforcement costFull use of strengthClimate change adaptationExcavationsSoil mechanicsStructural engineering

The invention discloses an initial strengthening method specific to an unstable slope. The initial strengthening method includes the steps that mechanics parameters obtained before and after softeningof the slope are measured, and whether initiative strengthening needs to be conducted or not is judged; a two-dimensional geological generalized model is established, and boundary conditions are set;rock and soil mechanics parameters obtained after softening are brought into the two-dimensional geological generalized model, a first safety coefficient F1 is calculated, and whether initiative strengthening needs to be conducted or not is judged; a strengthening manner and strengthening parameters of an anchor cable frame are set according to the two-dimensional geological generalized model; and initial rock and soil mechanics parameters are brought into the two-dimensional geological generalized model, a second safety coefficient F2 is calculated on the strengthened slope, and whether thesecond safety coefficient conforms to project stability or not is judged. By means of the initiative strengthening method, rock and soil physical and mechanics parameter changes obtained before and after excavation are taken into consideration, the anchor cable frame is immediately adopted for conducting initiative strengthening on the slope after excavation, the strength in the rock and soil initial state is sufficiently utilized, the phenomenon that the rock and soil strength is greatly reduced when the slope is deformed and softened after excavation is avoided, and slope plants can be effectively protected against damage.

Owner:云南大永高速公路有限公司 +1

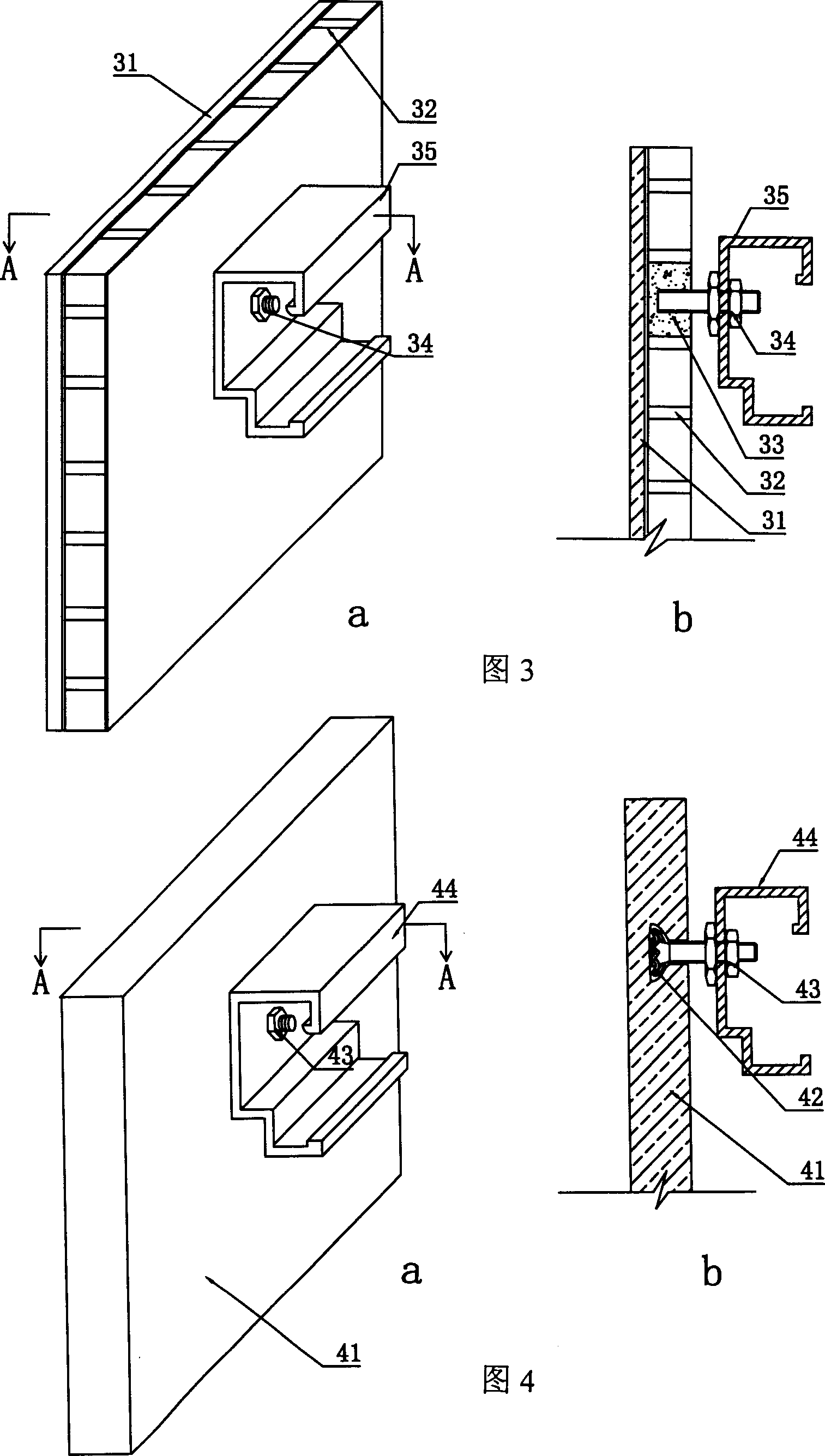

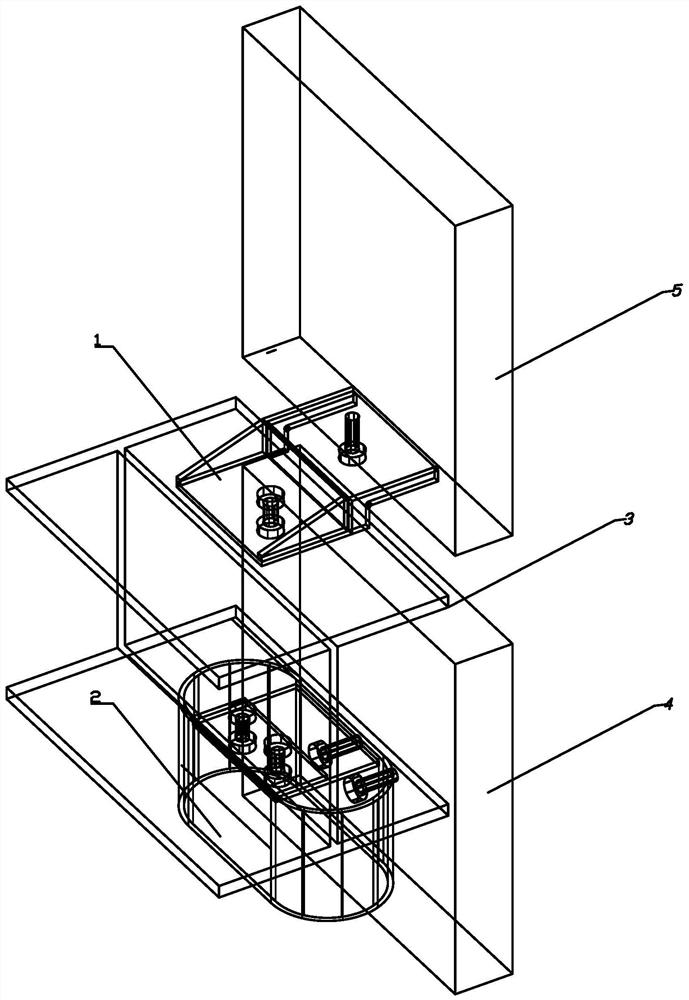

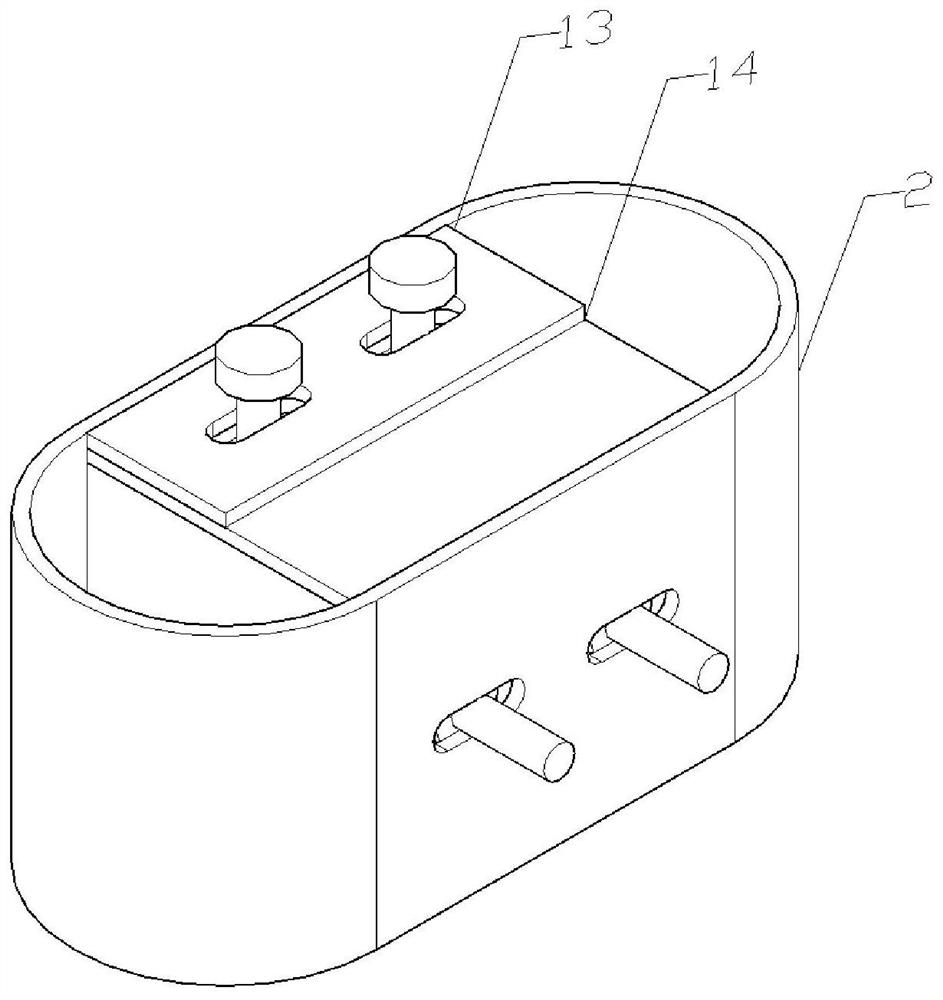

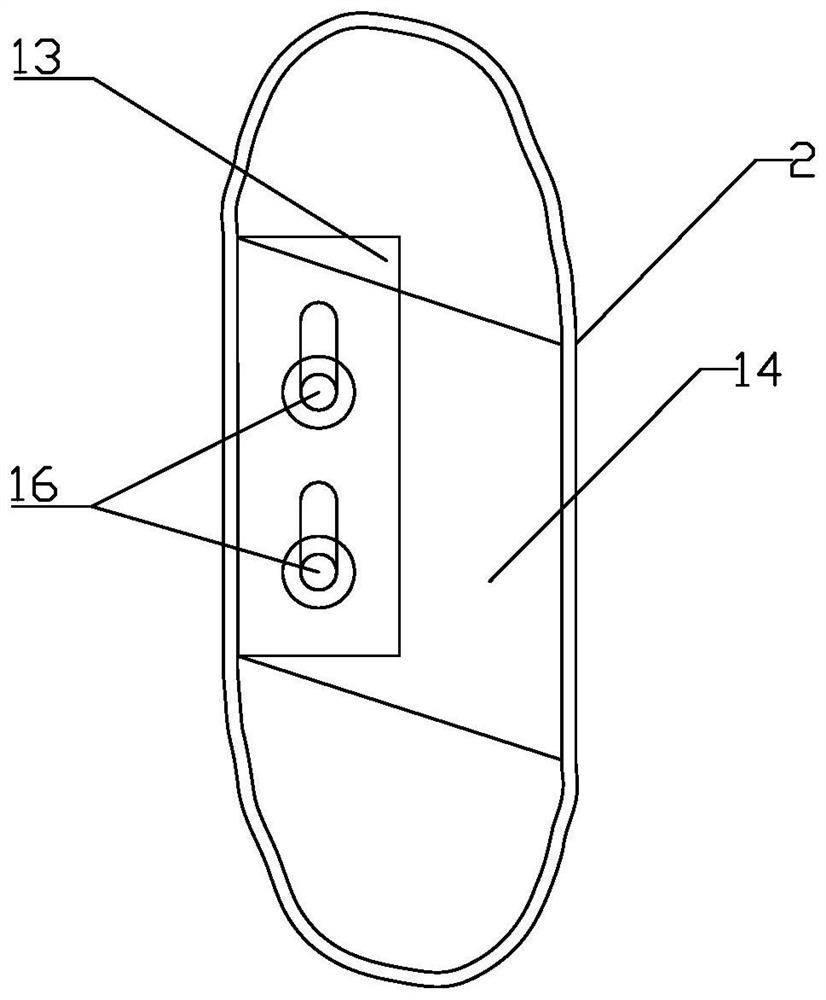

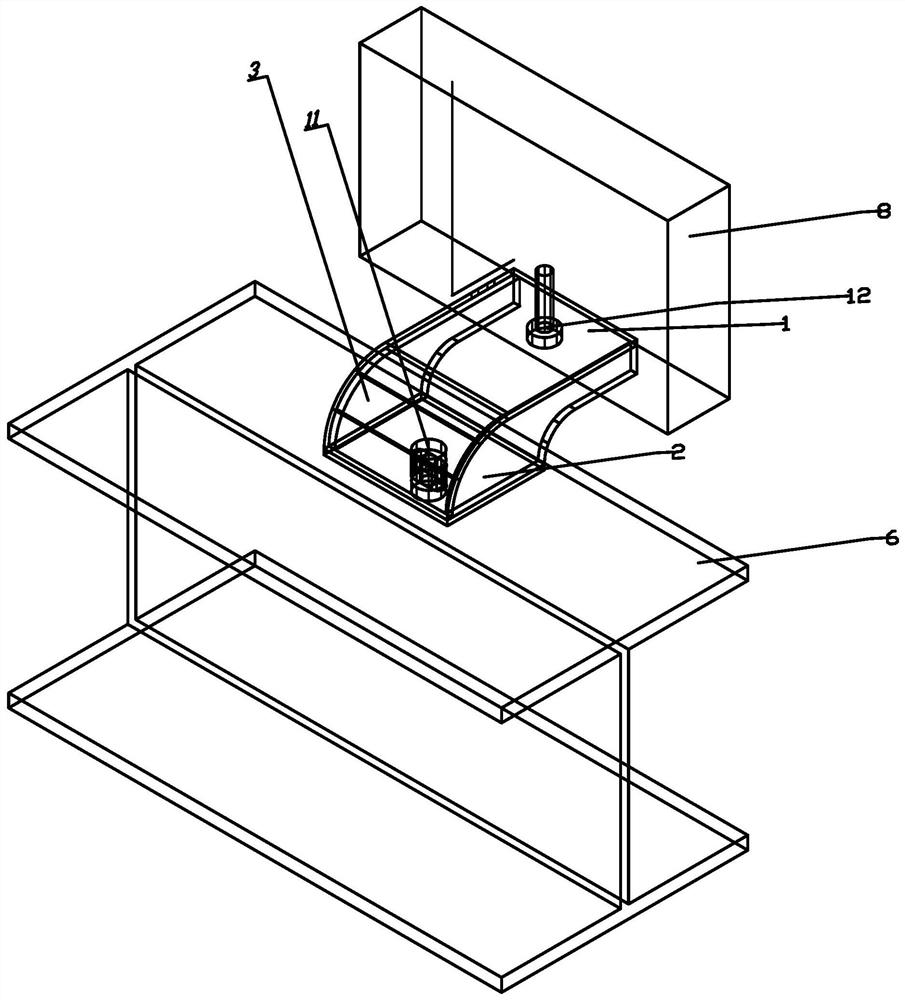

Annular steel-steel support connecting joint structure for steel structure and externally-hung wall plate

PendingCN112663797AAvoid wet work such as grouting on siteReduce labor costsProtective buildings/sheltersShock proofingUpper jointRebar

The invention discloses an annular steel-steel support connecting joint structure for a steel structure and an externally-hung wall plate. The annular steel-steel support connecting joint structure comprises a lower-layer externally-hung wall plate and an upper-layer externally-hung wall plate, the lower-layer externally-hung wall plate is connected with the upper-layer externally-hung wall plate through a frame beam, and the frame beam is provided with an upper joint connecting device and a lower joint connecting device; the upper joint connecting device comprises an upper joint annular steel plate, a connecting steel plate and an embedded part; at least more than one energy dissipation steel sheet is arranged on the upper joint annular steel plate; the connecting steel plate is located on the inner surface of the upper joint annular steel plate and makes contact with a lower flange of the frame beam; the embedded part is located in the lower layer externally-hung wall plate and connected with the upper joint annular steel plate; and the embedded part comprises a bolt sleeve, an anchoring steel bar and an embedded part steel plate, the lower joint connecting device comprises a steel support, a first long hole is formed in the position, connected with the steel support, of the frame beam, and the steel support is connected with the frame beam in a fastened mode through a first bolt.

Owner:SOUTH CHINA UNIV OF TECH

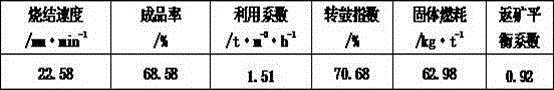

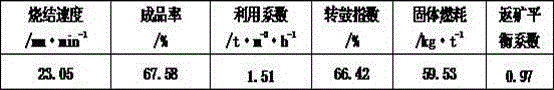

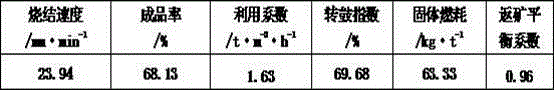

Sintered ore containing specular hematite and preparation method of sintered ore

Owner:WUHAN IRON & STEEL (GROUP) CORP

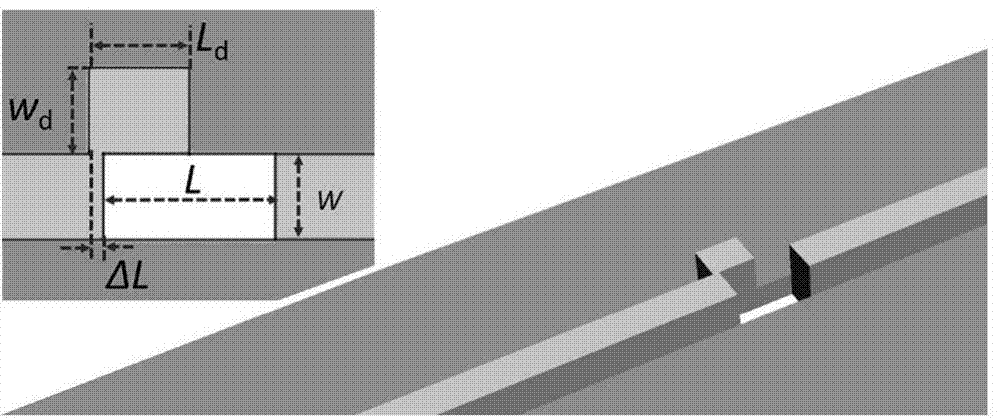

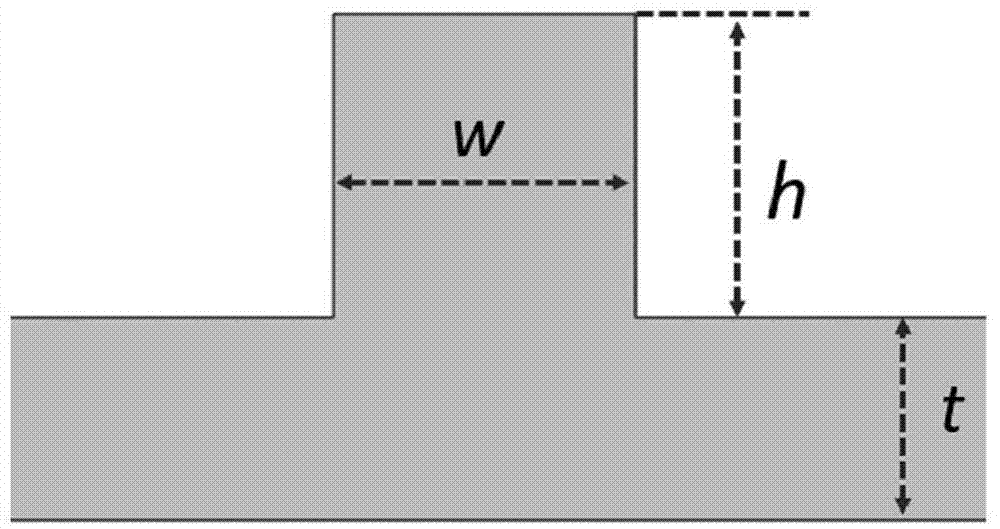

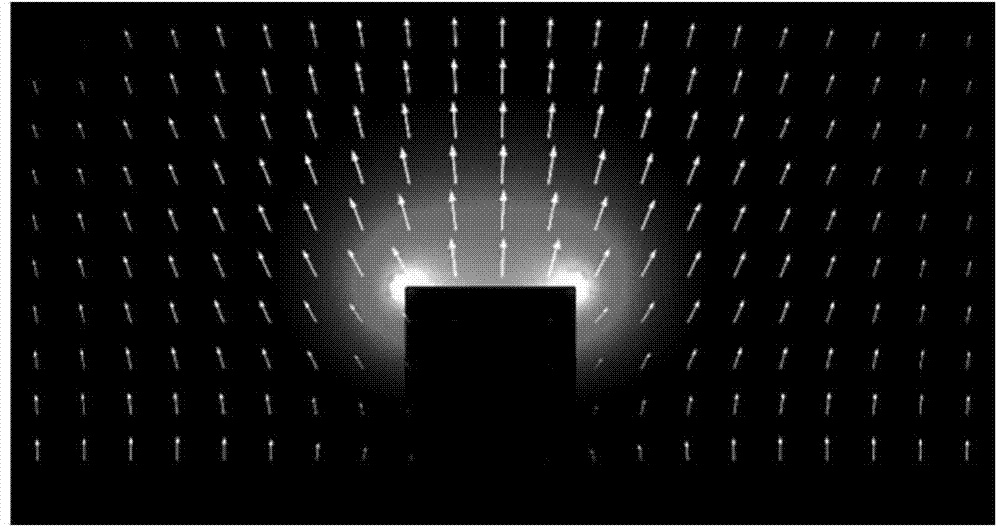

Surface plasmon polariton directional coupler independent of polarization and control method thereof

The invention discloses a surface plasmon polariton directional coupler independent of polarization and a control method thereof. Asymmetric defective pore structures are processed on ridge waveguide with sub-wavelength so that an SPP mode can be obtained through directional coupling by using p-polarization and s-polarization incident light; the ridge waveguide only supports single mode; the SPP mode under which light is transmitted along the ridge waveguide is obtained by directional coupling of p-polarization and s-polarization incident light due to influence of defects; Transmission of the SPP mode, which is obtained by coupling ofp-polarization and s-polarization incident light, can be along the same and the opposite directions by adjusting defective geometric parameters; the overall intensity of the coupled SPP mode can be modulated by fully utilizing s-polarization incident light under the situation of transmission along the same direction; and information of polarization coded incident light is preserved under the situation of transmission along the opposite direction so that the SPP mode coupling process is independent of polarization.

Owner:PEKING UNIV

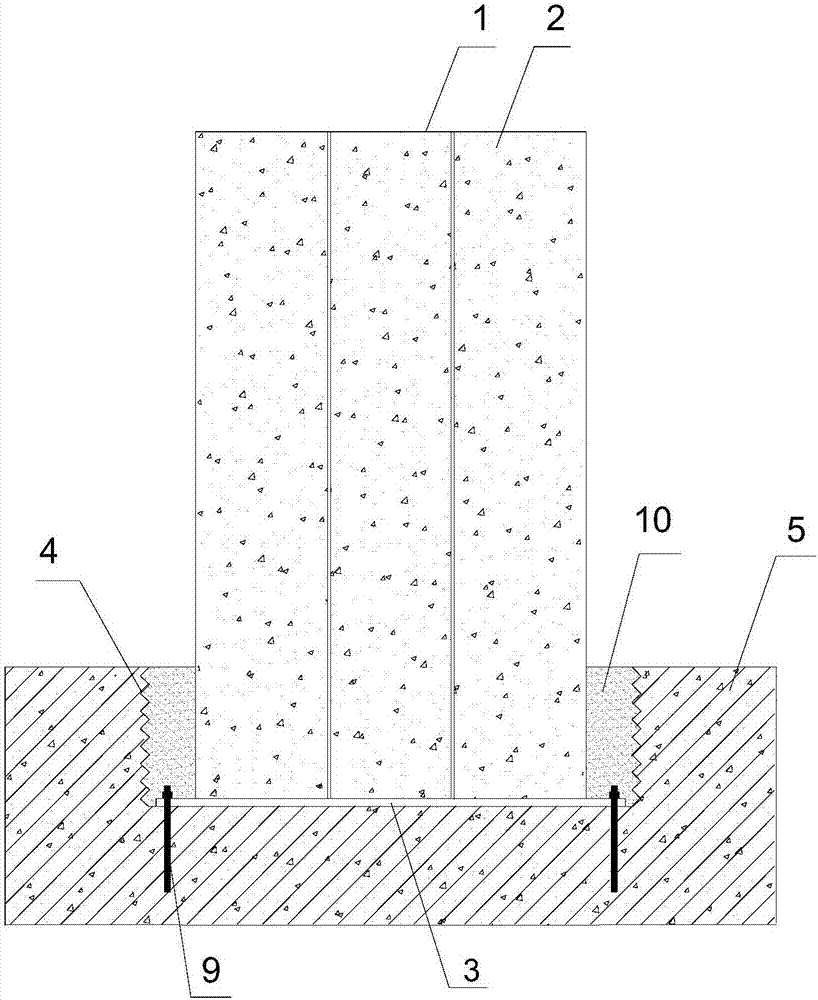

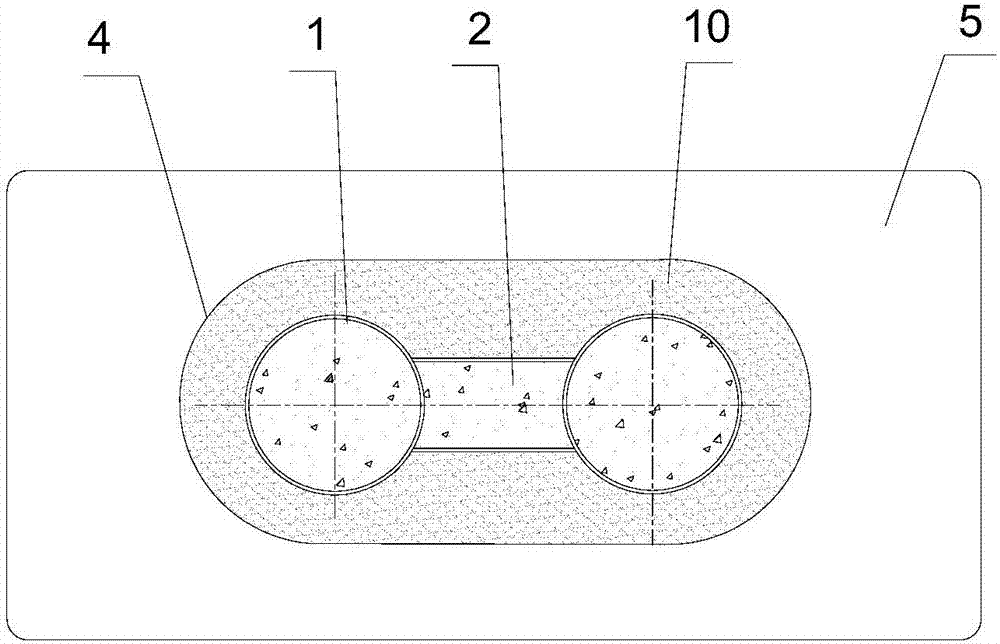

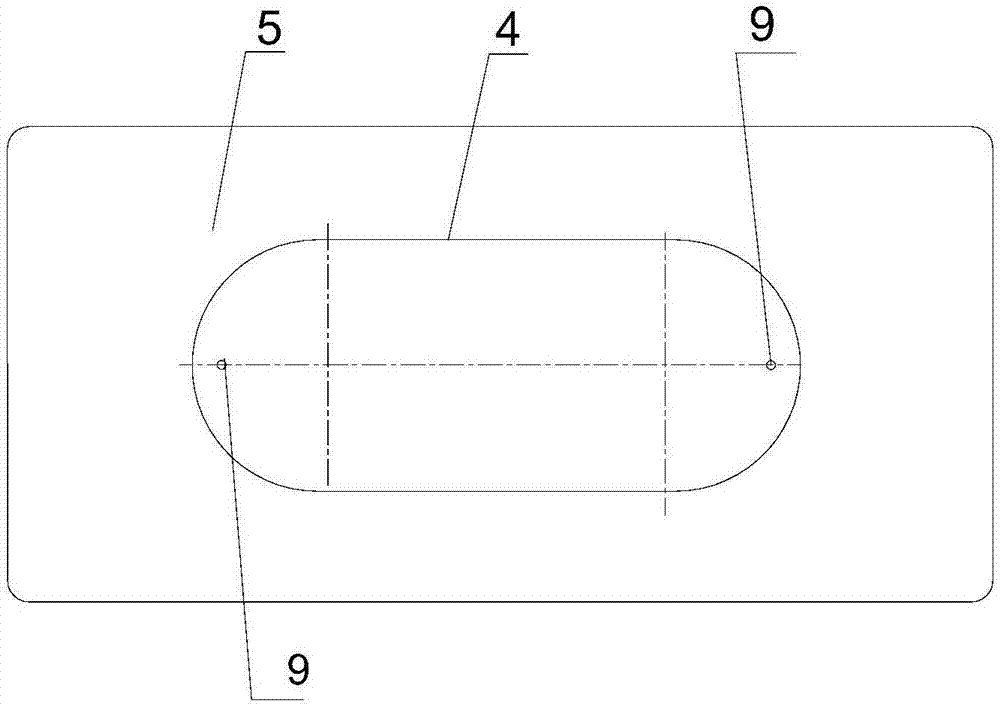

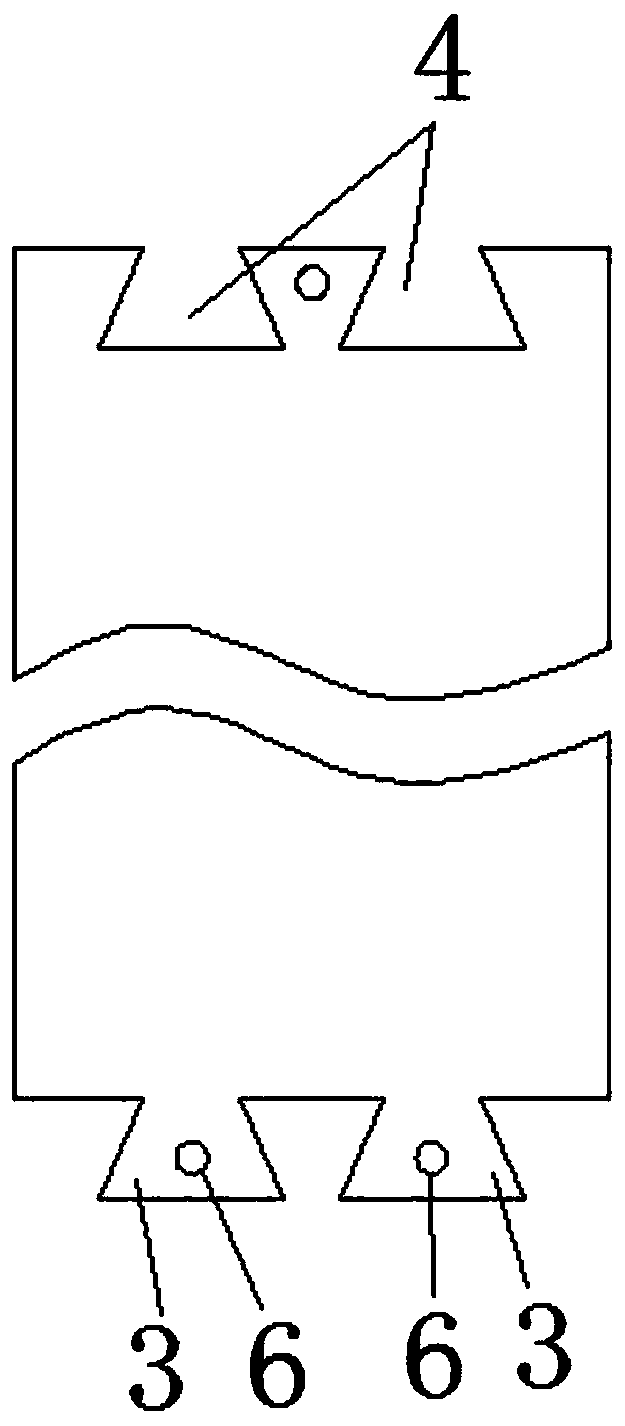

Composite pier with dumbbell-shaped concrete filled steel tubes, and structure and method for collection with cushion cap

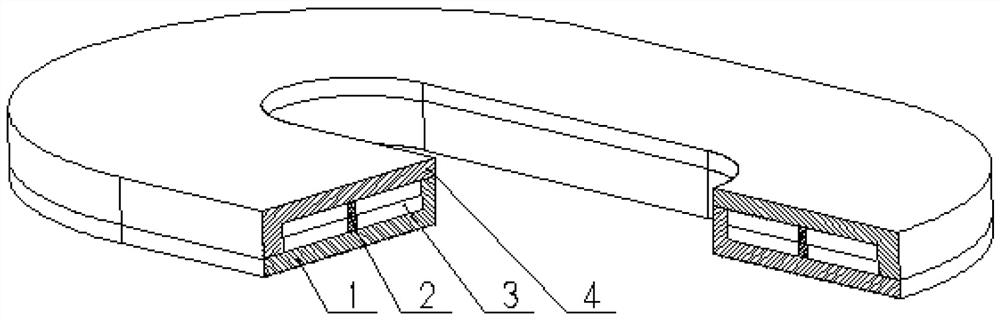

ActiveCN107190635AAvoid the disadvantages of poor constraint effectReduce the cross-sectional areaBridge structural detailsBridge erection/assemblyReinforced concreteRebar

The invention discloses a composite pier with dumbbell-shaped concrete filled steel tubes. The pier comprises two round steel tubes and a dumbbell-shaped steel tube which is welded between the two round steel tubes, composed of two layers of steel plates and symmetric along a form center connecting line of the two round steel tubes, wherein the two layers of steel plates and the round steel tubes are welded by angle welding seams. An end plate is welded on the bottom of the dumbbell-shaped steel tube; the outer profile of the end plate is larger than the outer profile of the cross section of the dumbbell-shaped steel tube; one anchor bolt hole is formed in two sides of the end plate along the horizontal bridge direction of the pier; and the dumbbell-shaped steel tube is filled with concrete. The pier and a cushion cap are connected through embedding of a grouting corrugated sleeve. According to the invention, the dumbbell-shaped steel tube and the reinforced concrete cushion cap are pre-cast components; factory pre-fabrication requirements can be satisfied; assembly is achieved on site; and rapid construction is carried out. The pier disclosed by the invention is characterized by high axial and flexural bearing capacities, high ductility and high horizontal rigidity; construction is convenient; on-site operations and web operations are fewer; demands for rapid construction can be satisfied; and the pier is applicable to major bridge projects especially high pier structures.

Owner:TIANJIN UNIV

Filler material for furnace of baking powder of charcoal

This invention relates to a filling material for carbon torrefying furnace. The filling material is mixed from: fly ash particles (sizes 2-12 mm) 1-50 wt. %, anode torrefied broken particles (sizes 1-8 mm) 1-50 wt. %, and calcined coke particles as balance. The filling material has such advantages as high strength, good air permeability, good heat conductance, low oxidation loss and can be directly used in carbon torrefying furnace.

Owner:河南华慧有色工程设计有限公司 +1

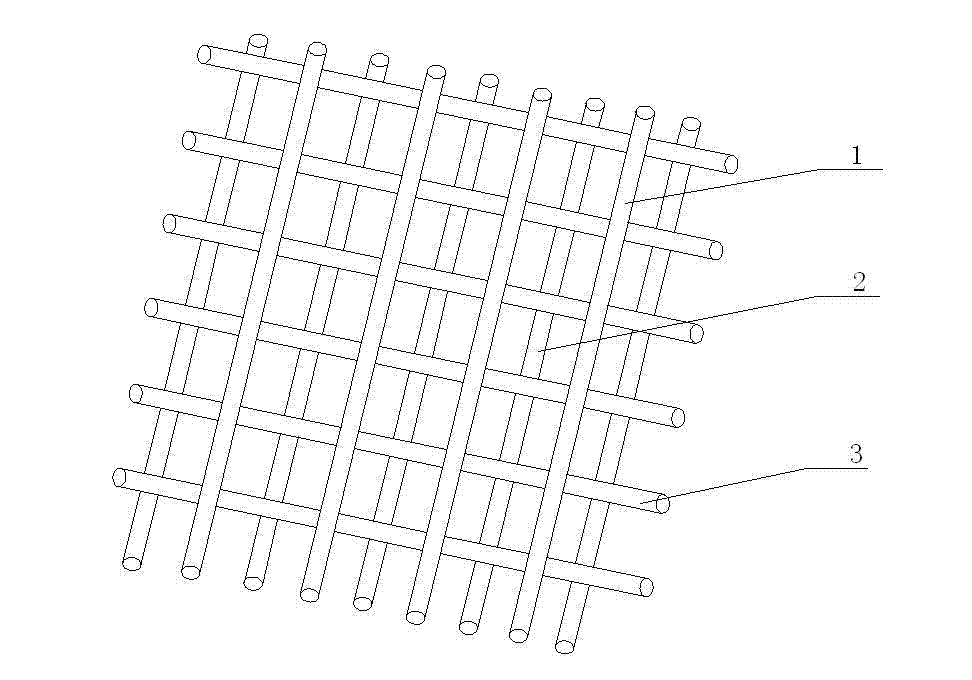

Fiberglass cloth and production process thereof

The invention relates to fiberglass cloth and a production process thereof. The fiberglass cloth comprises a warp yarn layer and a weft yarn layer, the warp yarn layer comprises an upper layer of warp yarns and a lower layer of warp yarns, and the upper layer of warp yarns and the lower layer of warp yarns are arranged in parallel; the weft yarn layer is positioned between the upper layer of warp yarns and the lower layer of warp yarns; and the upper layer of warp yarns, the lower layer of warp yarns and the weft warn layer are adhered through adhesives or by hot-pressing butt fusion. The weft yarn layer is sandwiched between the upper layer of warp yarns and the lower layer of warp yarns, a phenomenon that the yarns are distorted due to vertical crossed arrangement of warp yarns and weft yarns is avoided, the strength of the yarns is sufficiently utilized, and damage to the yarns in a spinning process is low. In addition, the upper layer of warp yarns and the lower layer of warp yarns are laid by continuous production equipment, weft yarns are circularly twined between the upper layer of warp yarns and the lower layer of warp yarns, production efficiency is greatly improved, and the fiberglass cloth can completely replace the traditional fiberglass cloth.

Owner:HAINING WELLINGTON NEW MATERIAL

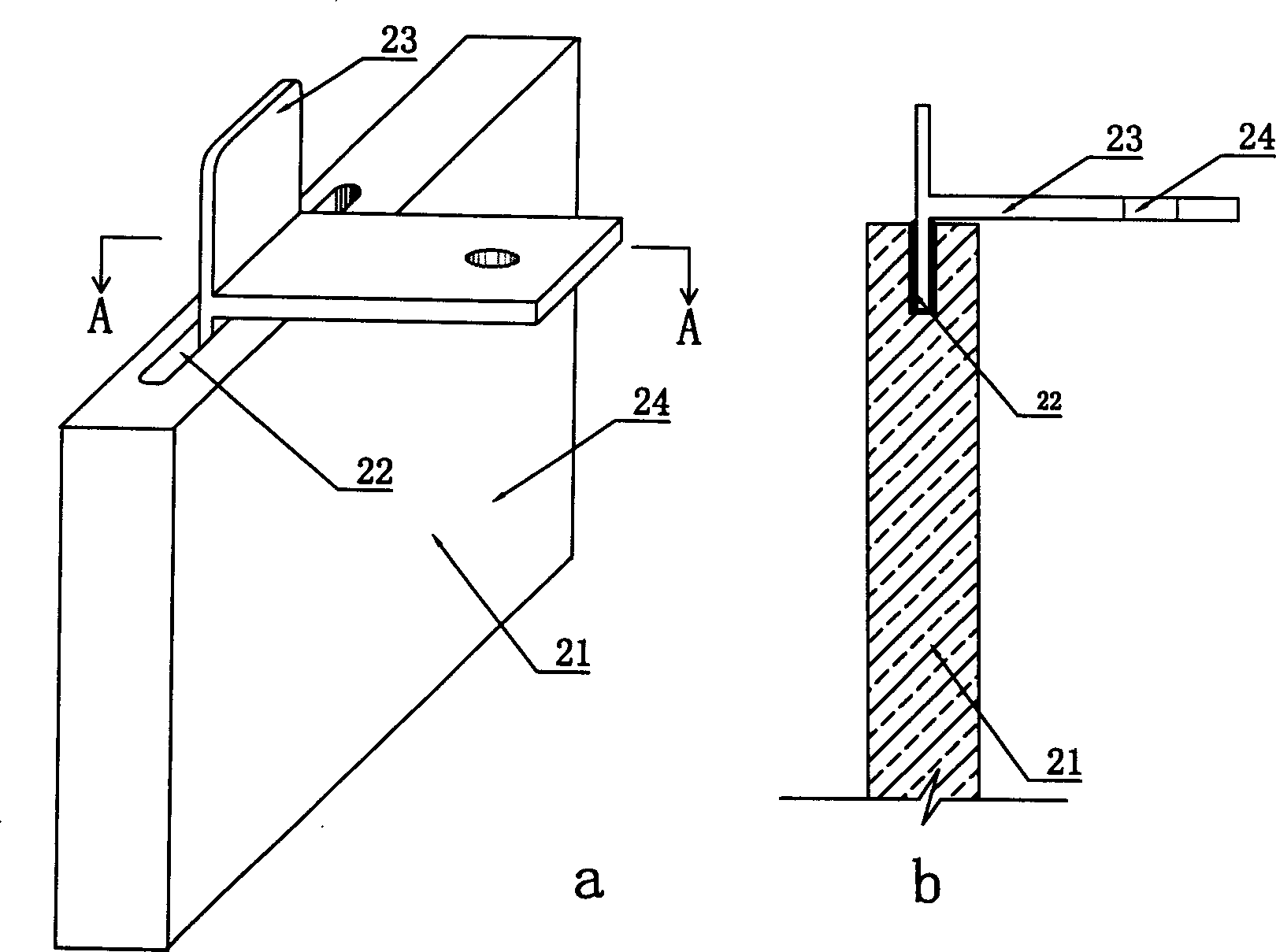

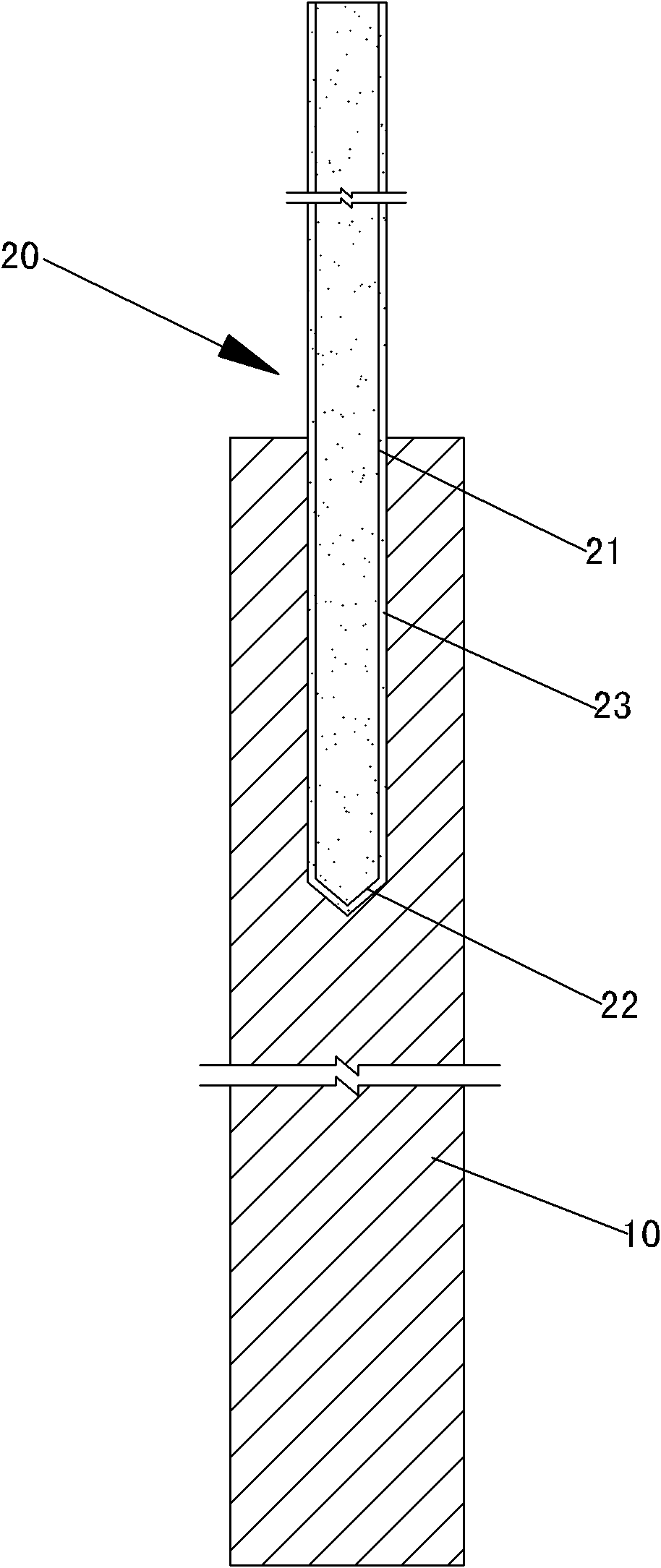

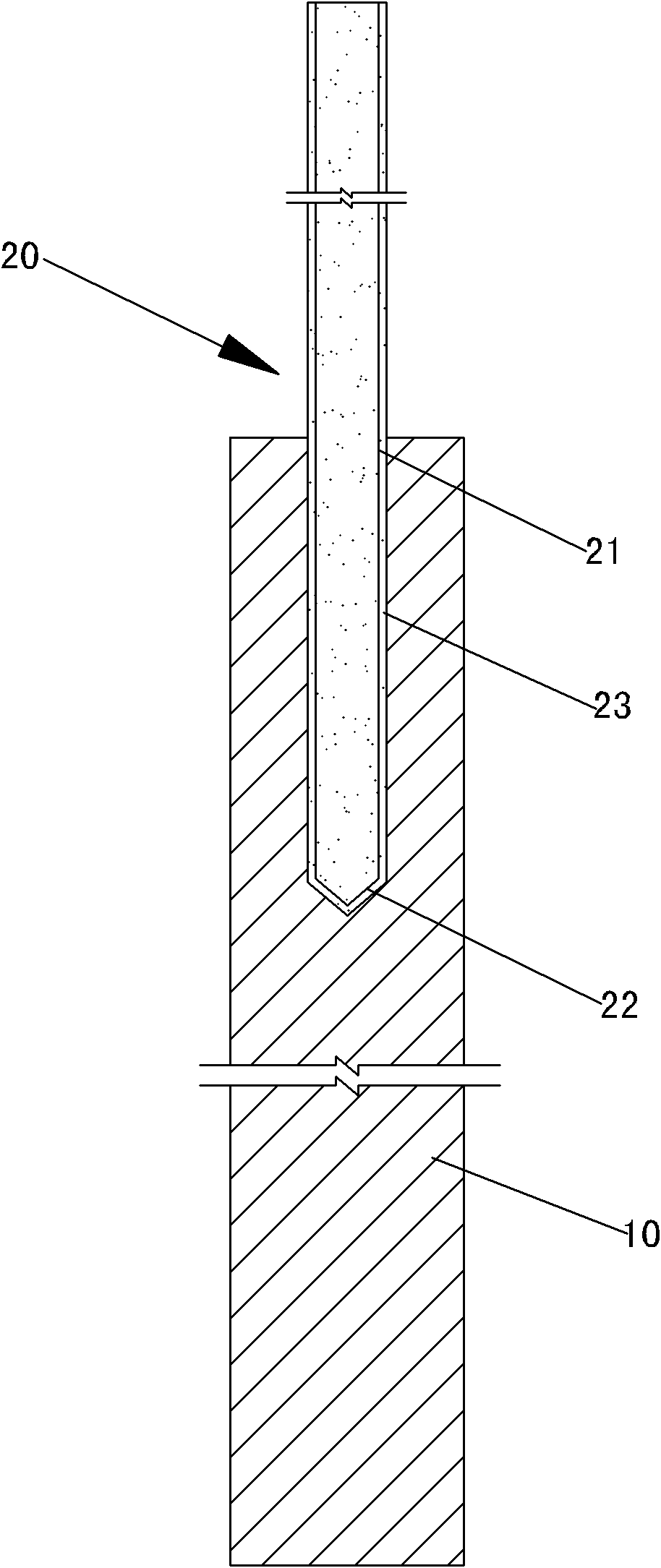

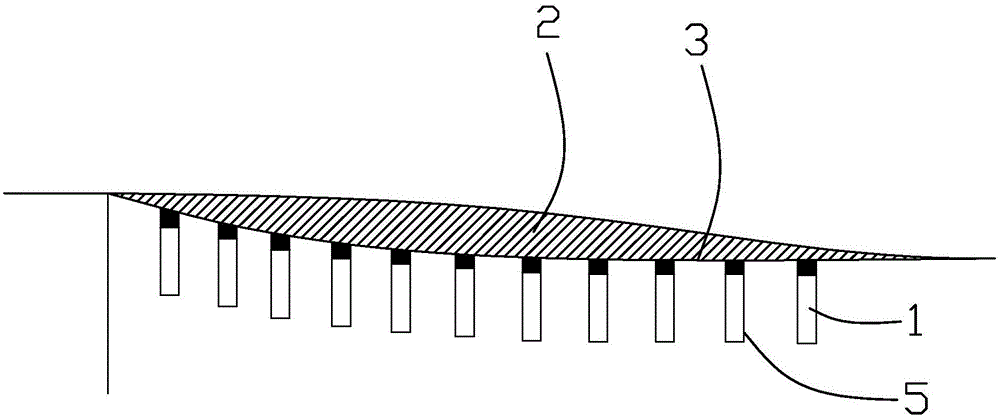

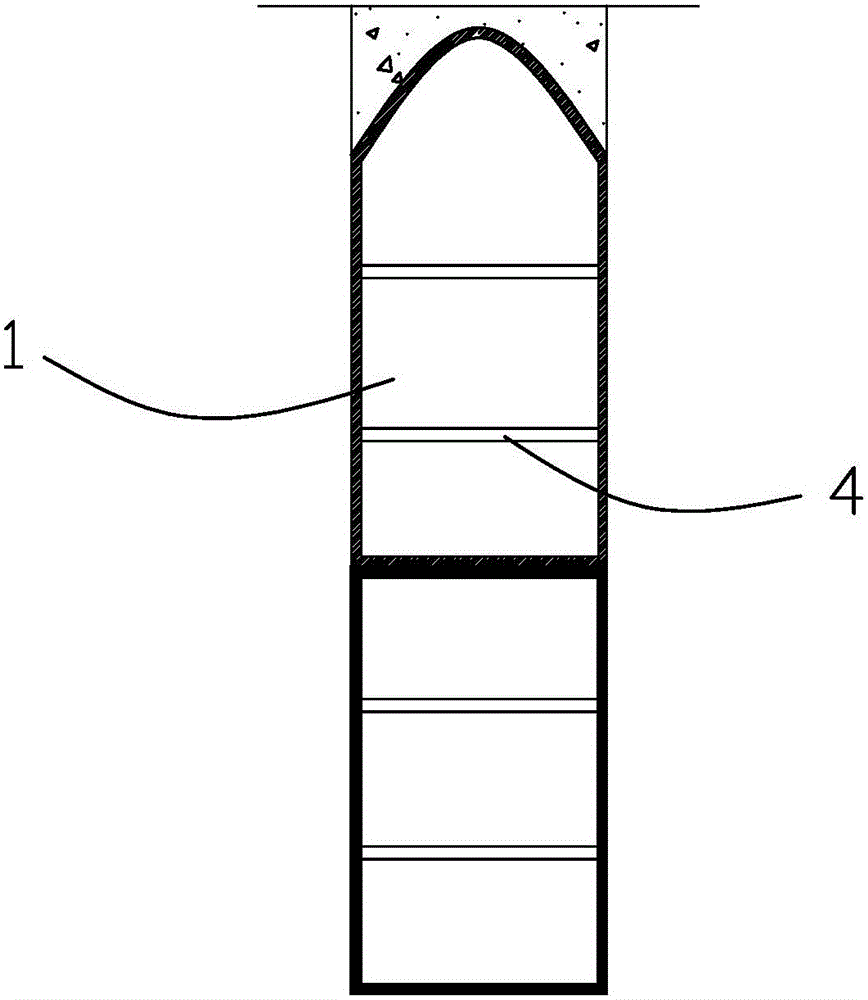

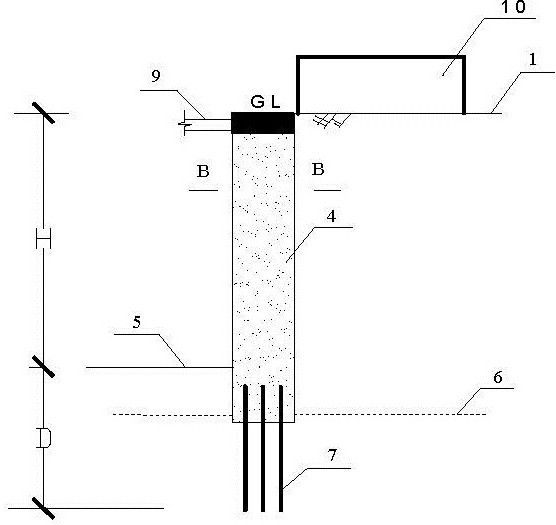

Supporting stand column for foundation pit and construction method of supporting stand column

ActiveCN102162252AReduce targeting requirementsReduce positioning costsExcavationsBulkheads/pilesEngineeringSteel tube

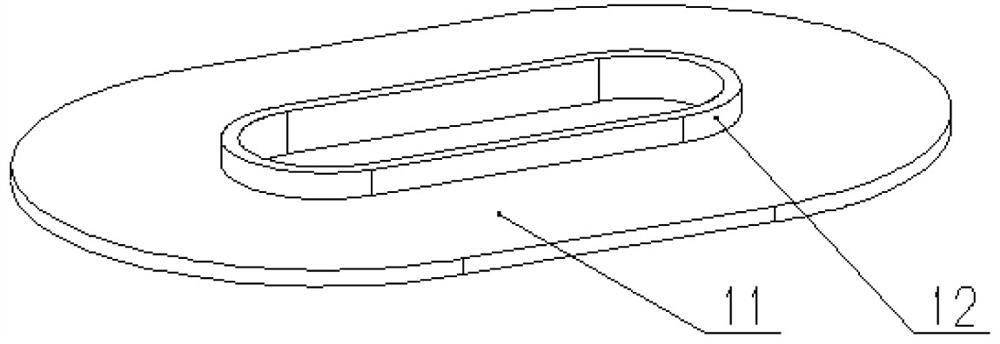

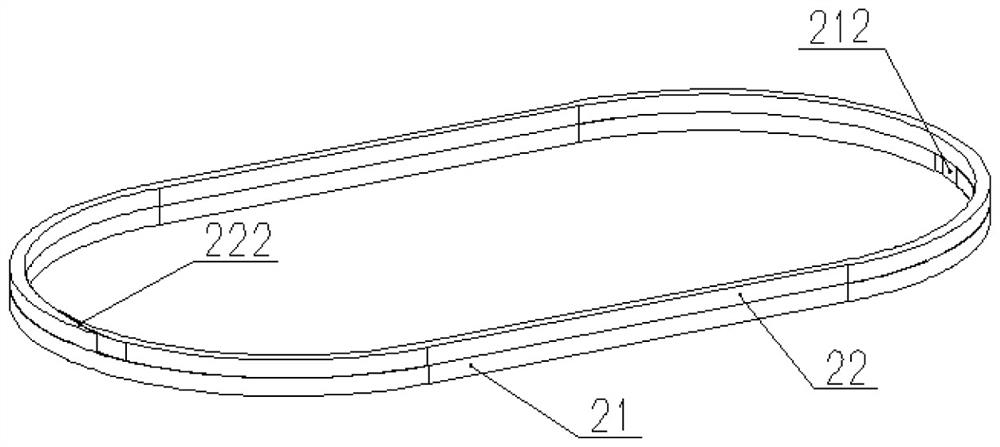

The invention discloses a supporting stand column for a foundation pit and a construction method of the supporting stand column. The construction method comprises the following steps of: 1, preparing a steel tube (21) and a tapered base (22), wherein the lower port of the steel tube (21) is fixedly connected with the upper port of the tapered base (22) in a sealing manner so that the steel tube (21) and the tapered base (22) are matched with each other to form an insertion part (20), and an inner hole of the steel tube (21) and an upward tapered cavity of the tapered base (22) are matched to form an inner cavity (23); 2, drilling and pouring concrete so as to form a caisson pile (10); 3, inserting the insertion part (20) before the caisson pile (10) is condensed finally and inserting the lower part of the insertion part (20) into the caisson pile (10); and 4, pouring concrete into the inner cavity (23) of the insertion part (20).

Owner:厦门市政城市开发建设有限公司 +1

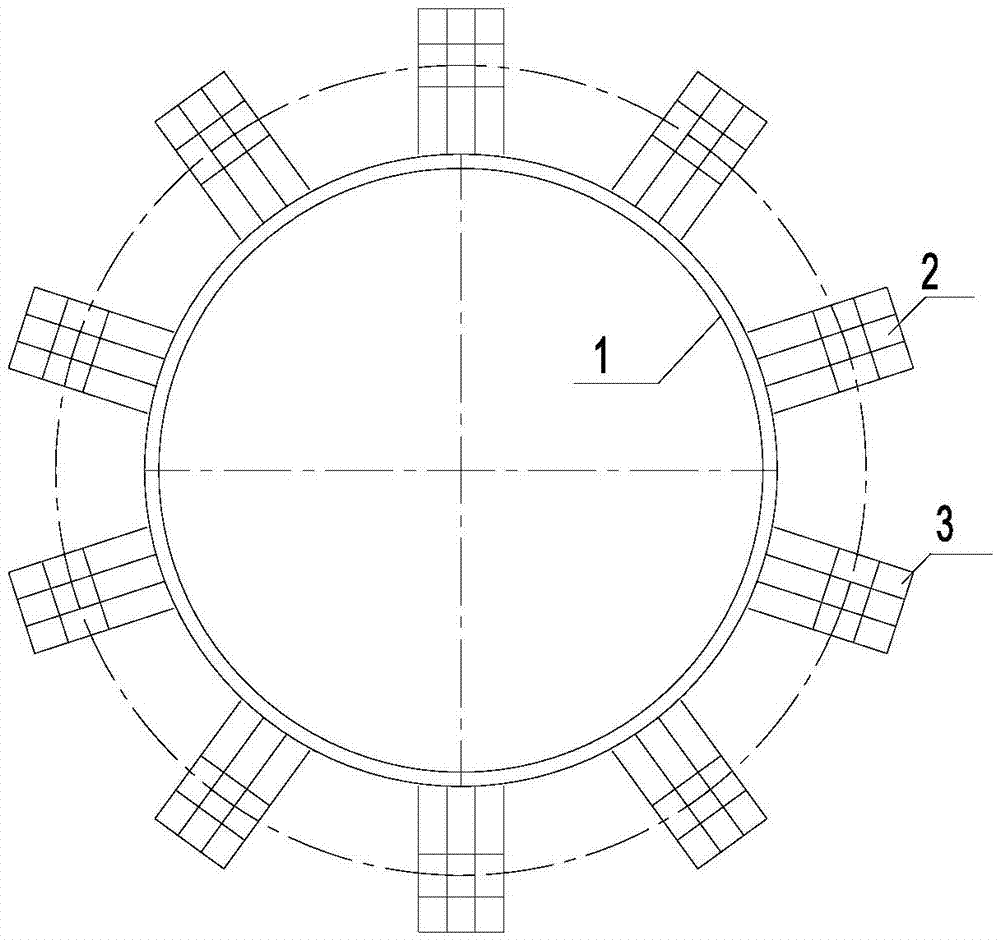

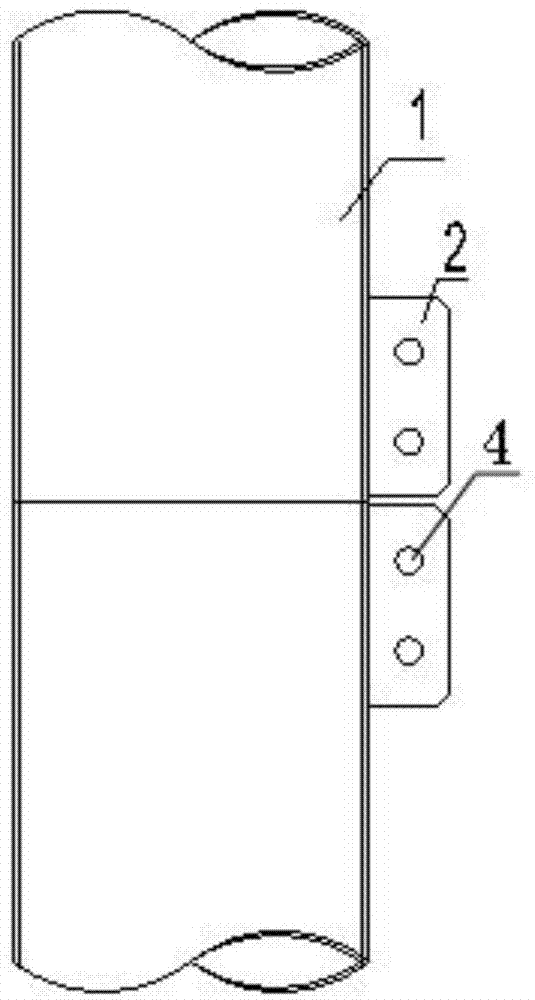

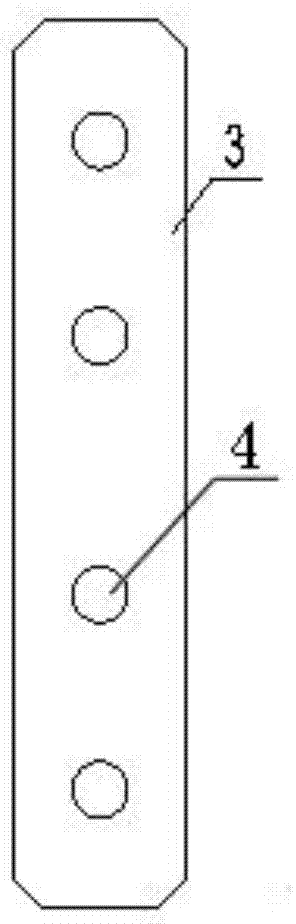

Novel steel pipe butting connector

The invention relates to a novel steel pipe butting connector applied to transmission and transformation lines. The novel steel pipe butting connector comprises two main pipes to be butted. Butt ports of the main pipes are provided with a plurality of insert plates respectively arranged in the same horizontal plane. The insert plates are fixed through connecting plates. The novel steel pipe butting connector used in the ways of butting steel pipes with insert plates is simple in structure, attractive in appearance, capable of clearly transmitting force, and applicable to steel pipe towers and poles; compared to the traditional flange connecting way, the way of butting the steel pipes with insert plates has the advantages that machining is convenient, no casting is needed, the production cost is low, machining efficiency can be improved effectively, engineering cost can be reduced, and resources can be saved.

Owner:STATE GRID CORP OF CHINA +3

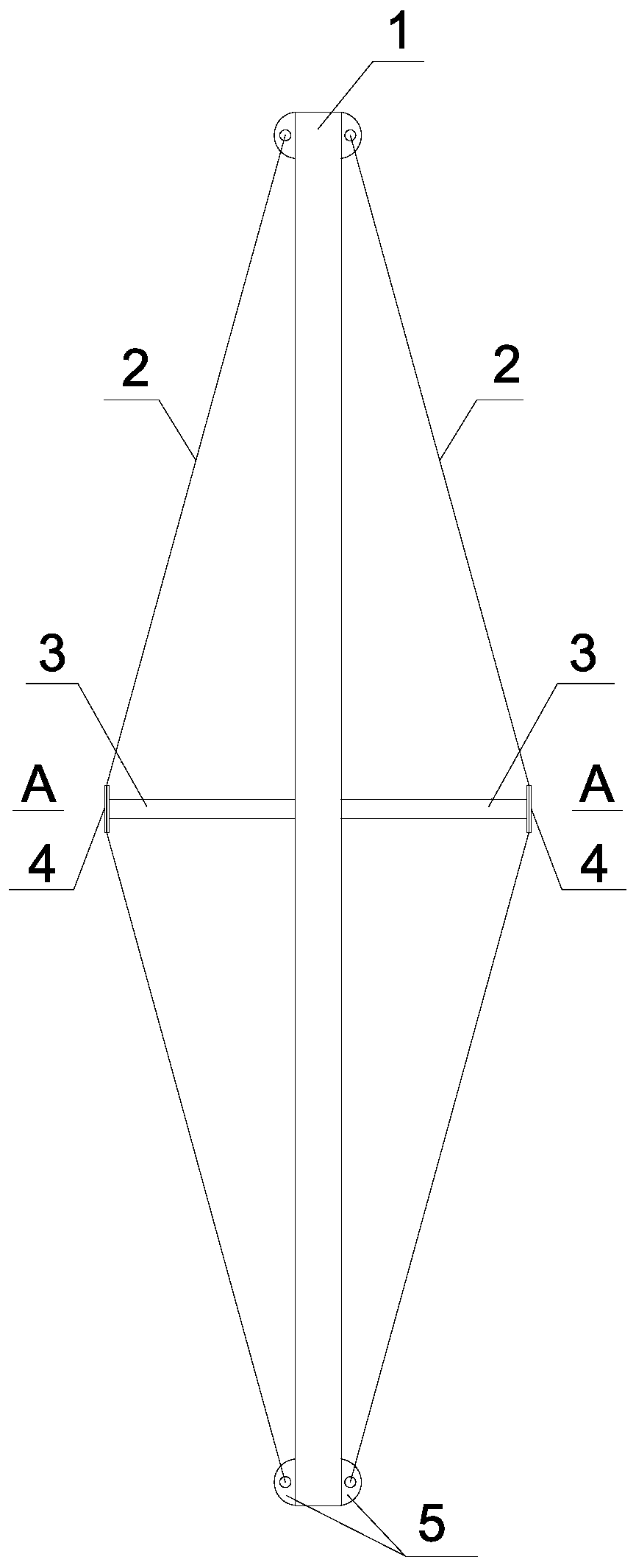

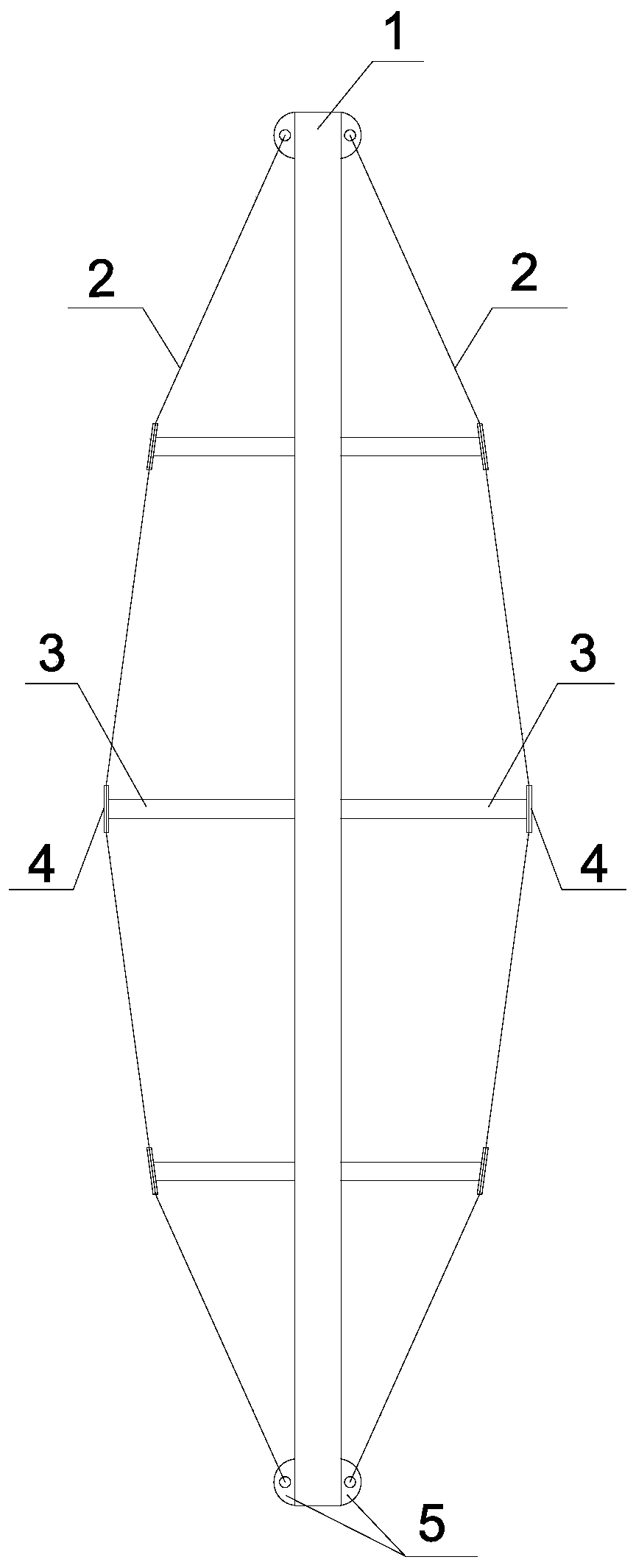

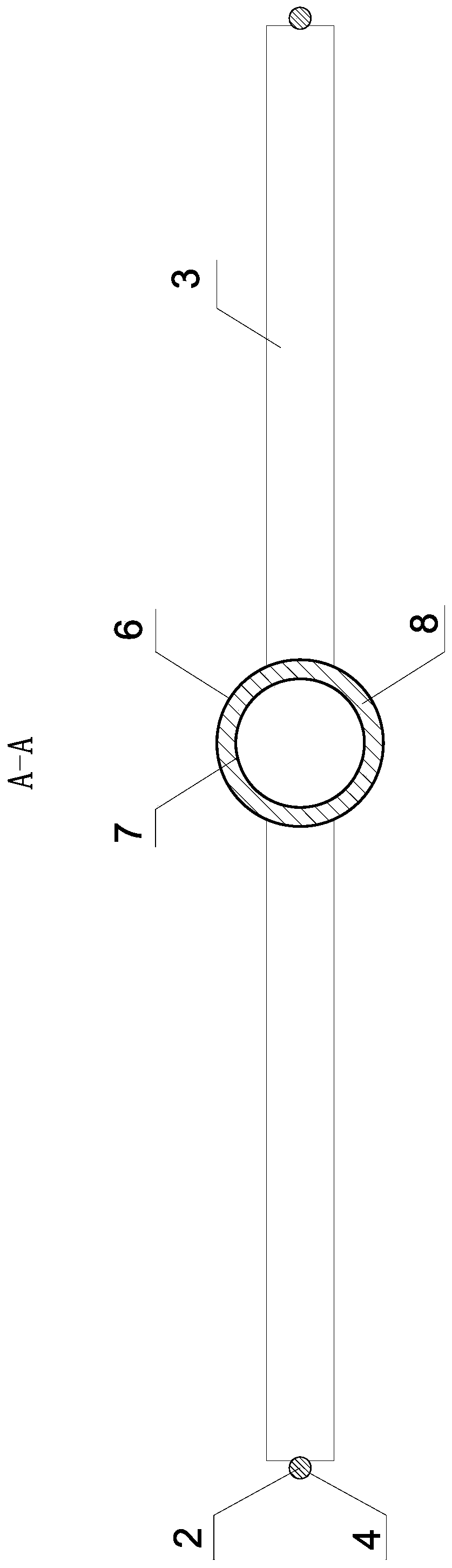

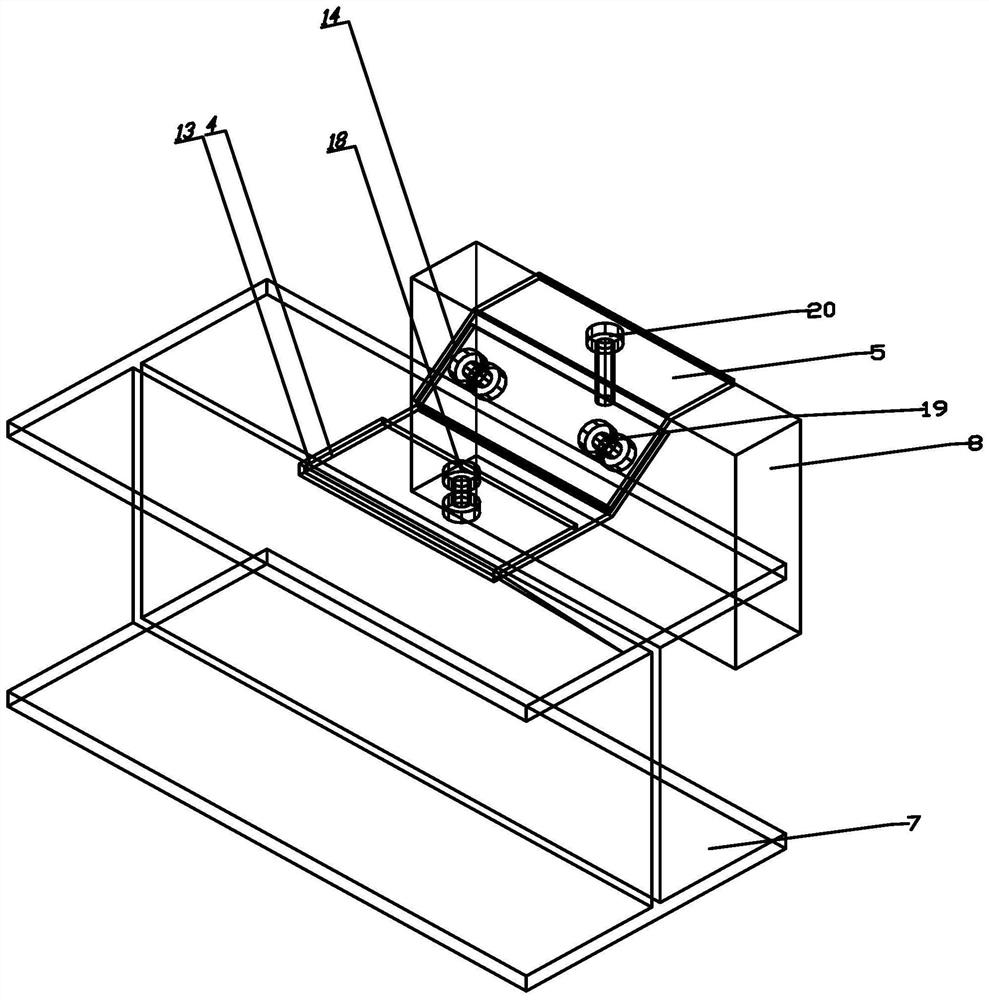

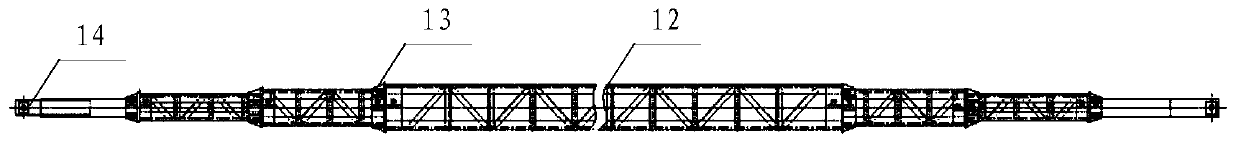

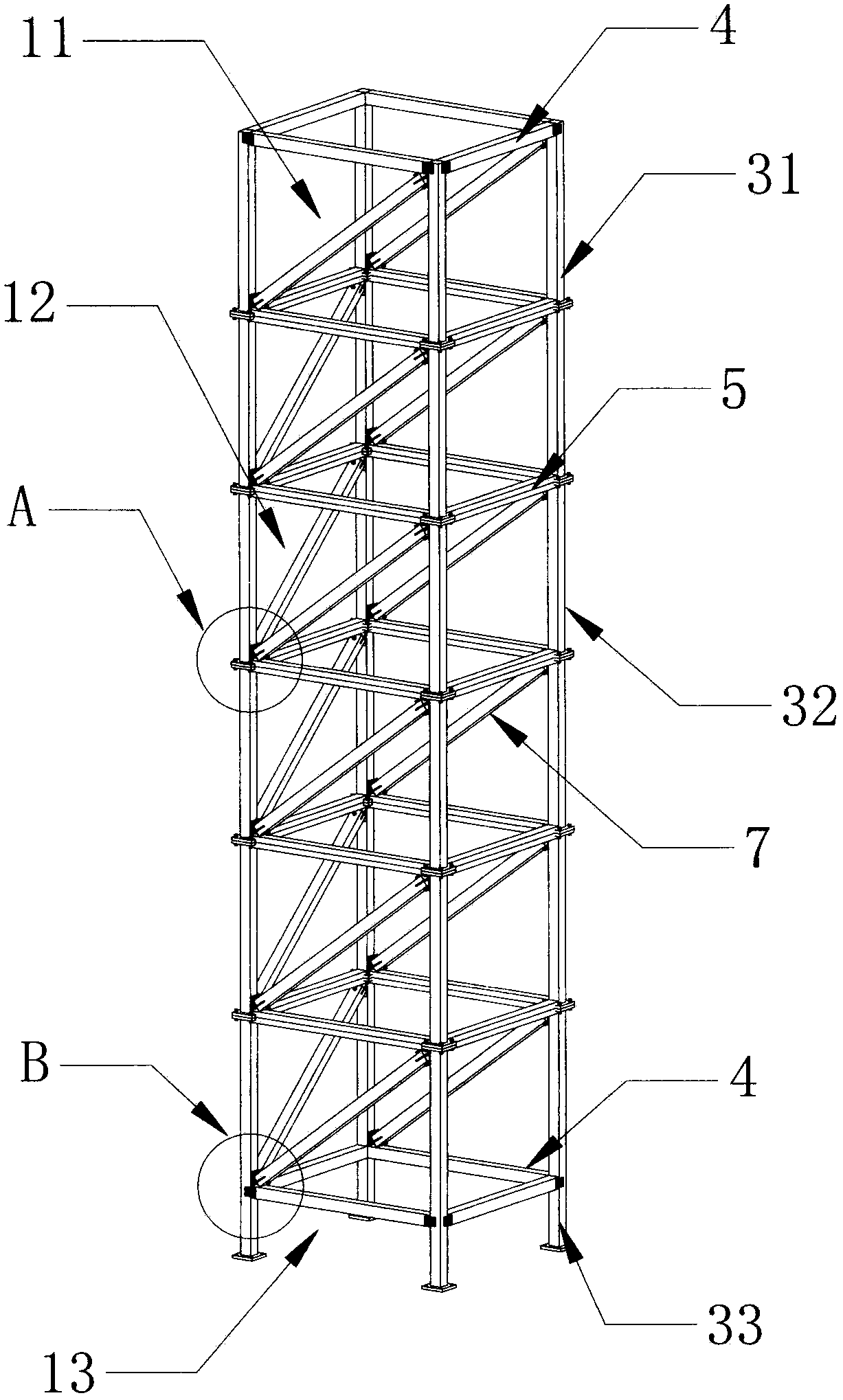

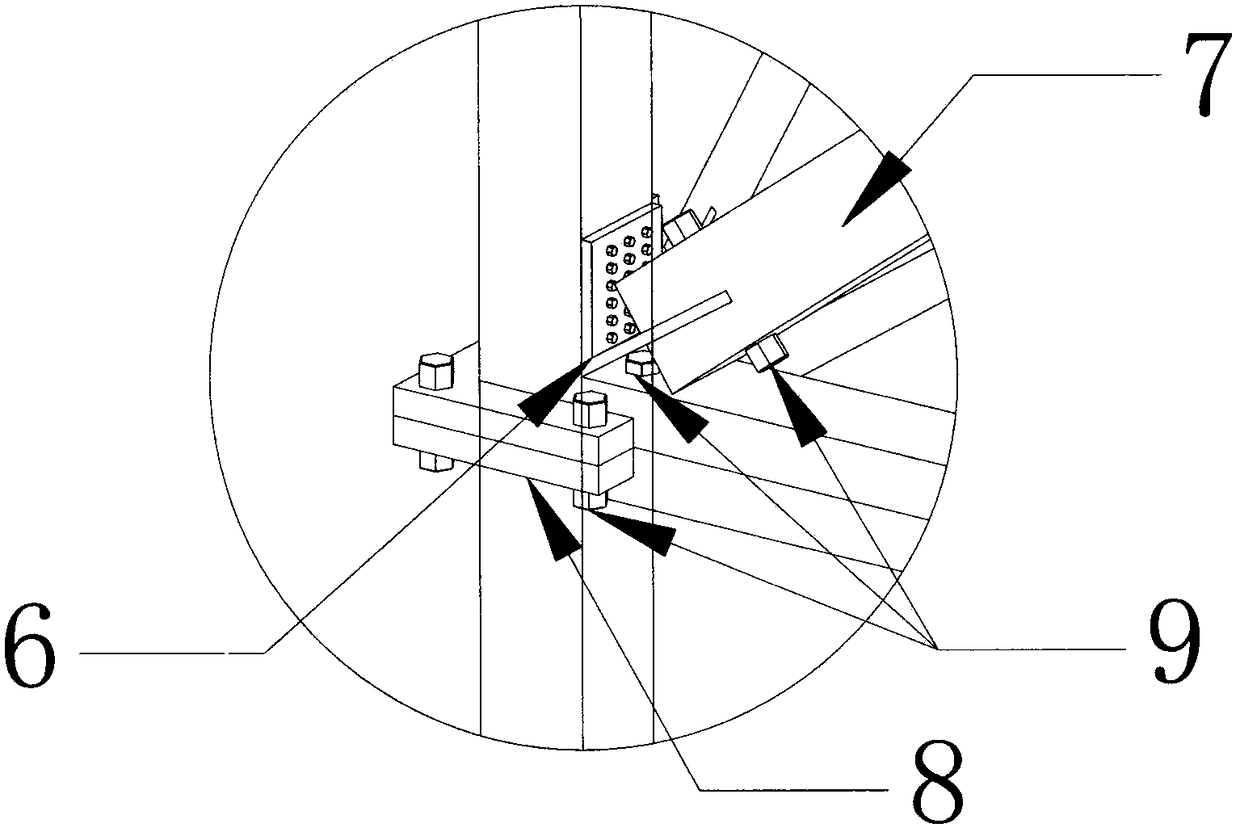

Fabricated stay bar prestressing sandwich pipe concrete combined member

InactiveCN110318496AReduce calculation lengthPrevent local bucklingStrutsBuilding reinforcementsPre stressEngineering

A fabricated stay bar prestressing sandwich pipe concrete combined member comprises a sandwich pipe concrete column, prestressed cables, stay bars, cableways and cable heads. Each pair of stay bars issymmetrically arranged and is perpendicular to the sandwich pipe concrete column, and the ends of the stay bars are fixedly connected with the cableways. The prestressed cables penetrate into the cableways, and the two ends of each prestressed cable are fixedly connected to the cable heads mounted at the two ends of the sandwich pipe concrete column correspondingly. The axes of the stay bars, theaxes of the cableways and the axis of the sandwich pipe concrete column are located in the same plane. The two prestressed cables on the two sides of the sandwich pipe concrete column are symmetrically arranged in an inclined broken line manner. The fabricated stay bar prestressing sandwich pipe concrete combined member has the advantages of being high in bearing capacity, good in fire resistingperformance and fast to construct.

Owner:HARBIN INST OF TECH

Connecting joint of fabricated steel structure and prefabricated externally-hung wall panel with damping performance

ActiveCN112814223AIncreased slip loadPrevent slippingWallsProtective buildings/sheltersUpper jointEngineering

The invention discloses a connecting joint of a fabricated steel structure and a prefabricated externally-hung wall panel with damping performance. The connecting joint of the fabricated steel structure and the prefabricated externally-hung wall panel with the damping performance comprises a lower frame beam, an upper frame beam and an externally-hung wall panel, wherein the lower frame beam is connected with the externally-hung wall panel through a lower joint connecting piece, and the upper frame beam is connected with the externally-hung wall panel through an upper joint connecting piece; the lower joint connecting piece comprises an arc-shaped steel plate, a connecting steel plate and a rib plate; the connecting steel plate is connected with the lower frame beam in a fastening mode through bolts; the arc-shaped steel plate is connected with the externally-hung wall panel in the fastening mode through high-strength bolt; the high-strength bolt is sleeved with at least one belleville spring; the upper joint connecting piece comprises a first steel plate and a second steel plate connected with the first steel plate, and the first steel plate is connected with the upper frame beam; a steel cover plate is arranged at the position, connected with the first steel plate, of the upper frame beam; the second steel plate is connected with the externally-hung wall panel through the bolts; a rubber sheet is arranged between the first steel plate and the second steel plate.

Owner:GUANGZHOU CONSTR ENG +2

Sequence control system (SCS) concrete filled steel tube bridge pier with shear nails added at bottom

InactiveCN102995554ASimple structureReasonable designBridge structural detailsSequence controlMechanical property

The invention discloses an SCS concrete filled steel tube bridge pier with shear nails added at bottom. The SCS concrete filled steel tube bridge pier comprises an outer steel tube, an inner steel tube, a top end shear resistant structure, a bottom end shear resistant structure and a concrete structure. The inner steel tube is sleeved inside the outer steel tube, the top end shear resistant structure is distributed between the top end of the outer steel tube and the top end of the inner steel tube, the bottom end shear resistant structure is distributed between the bottom end of the outer steel tube and the bottom end of the inner steel tube, the concrete structure is molded by pouring concrete filled in a cavity between the outer steel tube and the inner tube after the top end shear resistant structure and the bottom end shear resistant structure are distributed, the inner steel tube is a round steel tube, the outer steel tube and the inner steel tube are coaxially distributed, the outer steel tube is an outer steel tube one or two, the shape of the cross section of the outer steel tube one is a circle, and the shape of the cross section of the outer steel tube two is a rectangle or regular polygon. According to the SCS concrete filled steel tube bridge pier with stiffening ribs added at the bottom, the structure is simple, the design is reasonable, the construction is convenient, the construction cost is low, the mechanical property and the usage effect are good, and problems in concrete filled steel tube bridge piers are solved.

Owner:CHANGAN UNIV

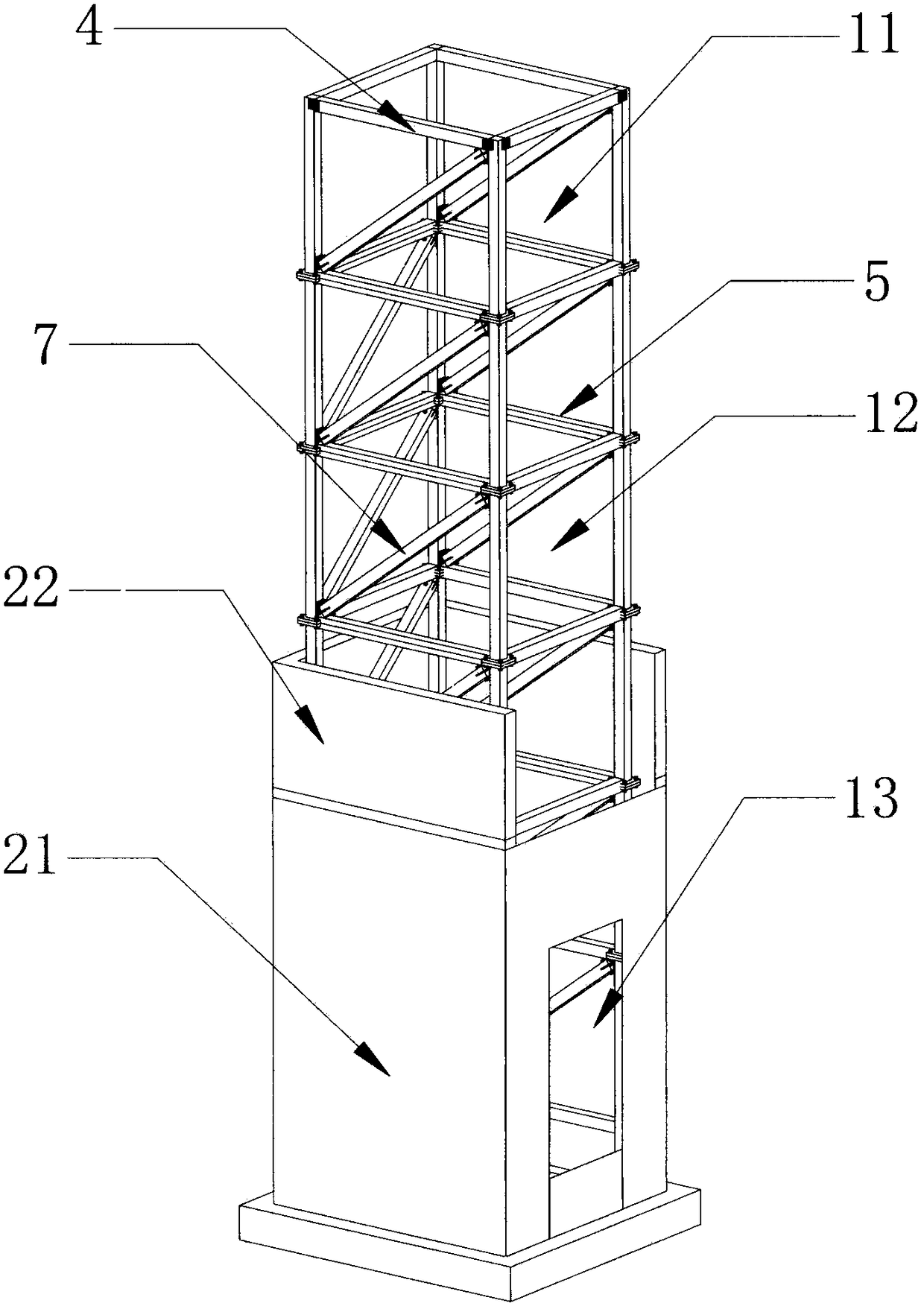

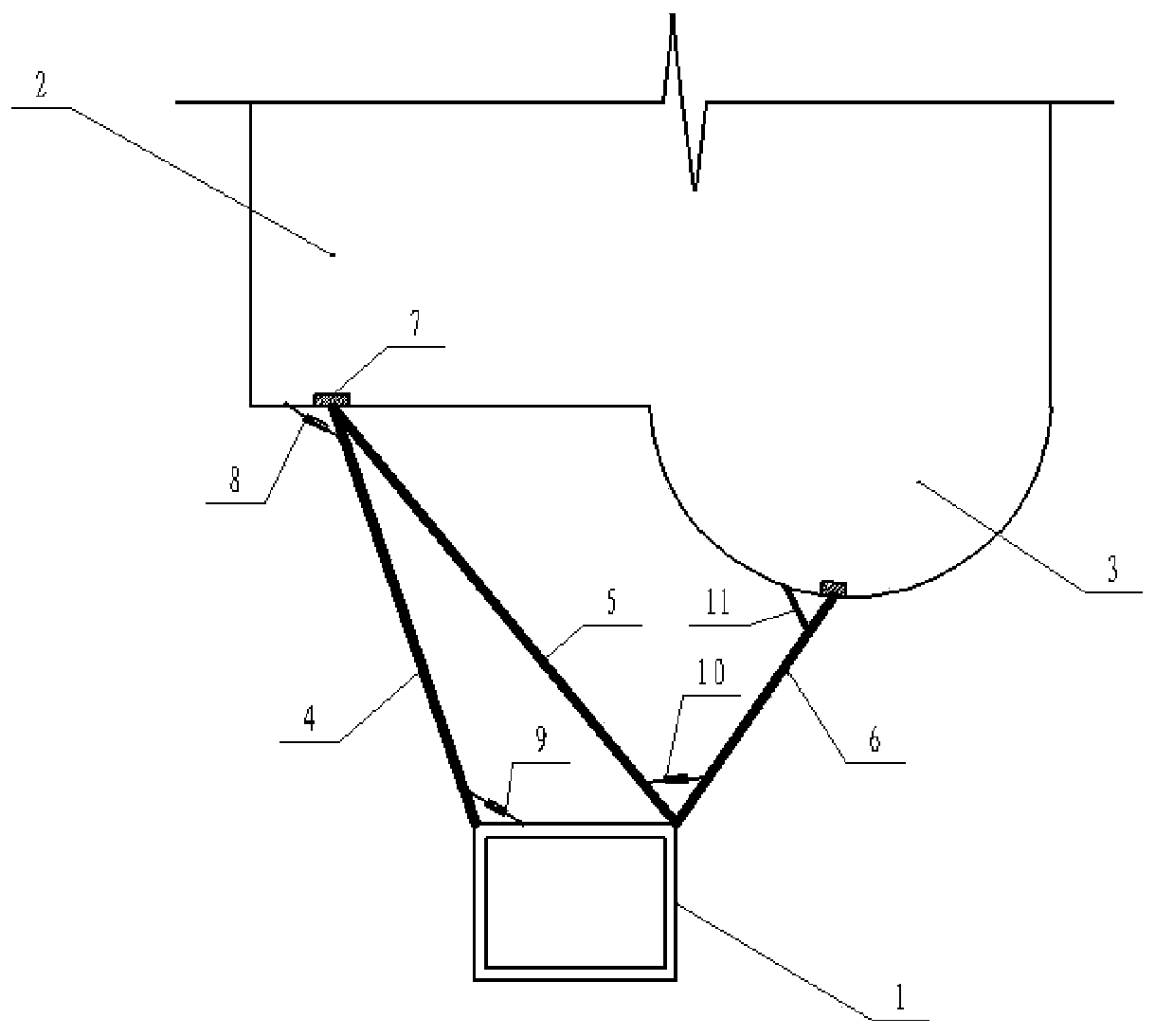

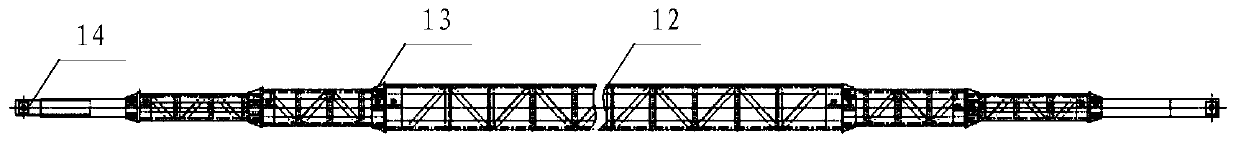

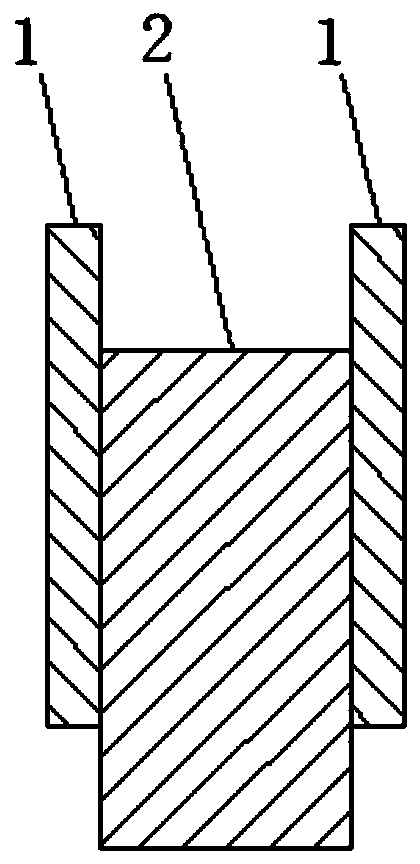

Variable cross section truss type tower crane overlength adhesion construction method

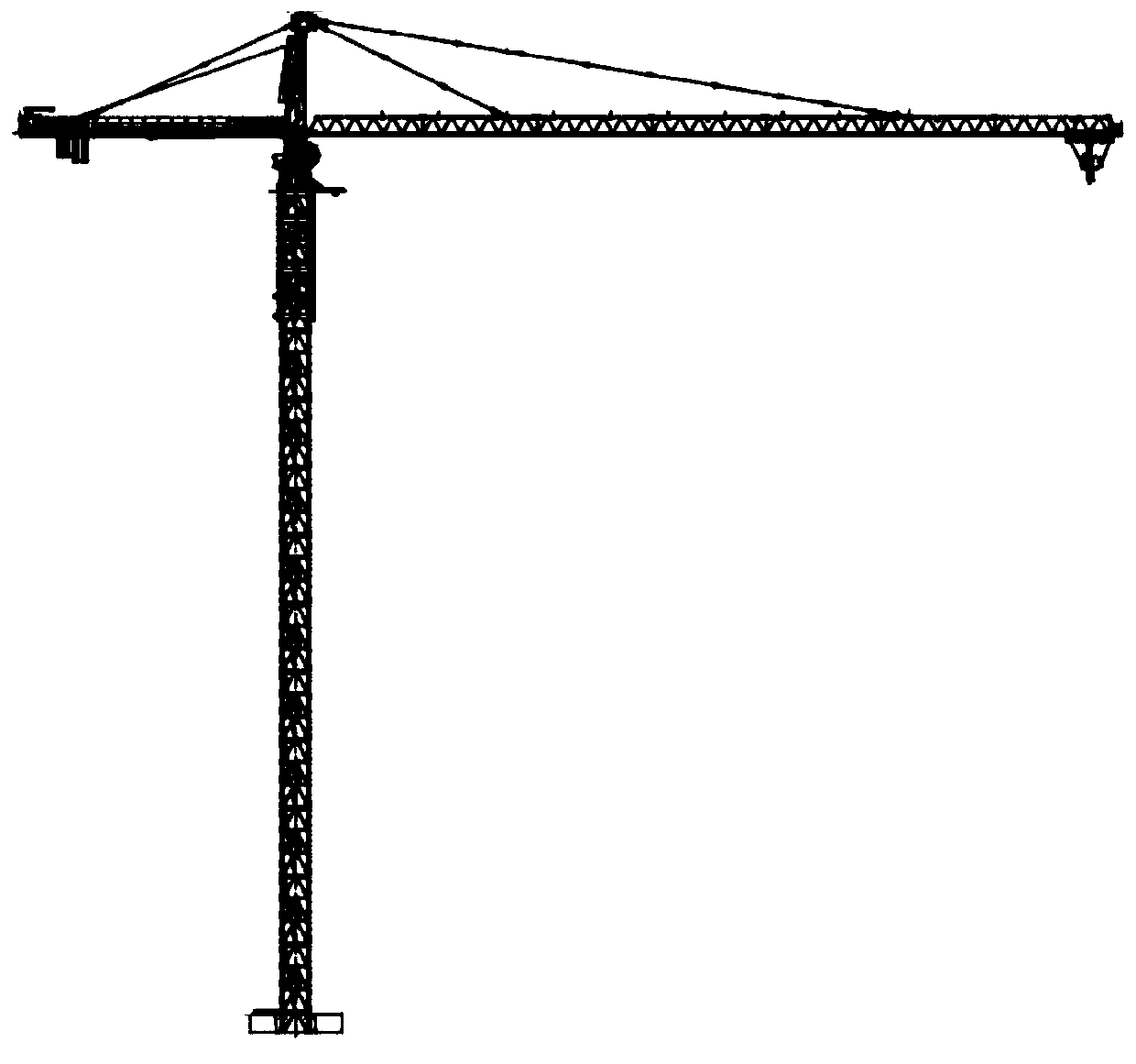

ActiveCN110143529AMeet the needs of attachment distanceIncrease profitCranesArchitectural engineeringTower crane

The invention discloses a variable cross section truss type tower crane overlength adhesion construction method. An adhesion frame of a tower crane and a building are included, the adhesion frame comprises a first corner and a second corner which are used for connection, an adhesion rod set comprises a first adhesion rod, a second adhesion rod and a third adhesion rod, the first adhesion rod enables the first corner and a first part of a building body to be in adhesion connection, the second adhesion rod enables the second corner and the first part of the building body to be in adhesion connection, the third adhesion rod enables the second corner to be in adhesion connection with the second part of the building body, and the first adhesion rod and the second adhesion rod are in hinged connection with an embedded wall plate through a double lug plate pin shaft. The material strength is sufficiently used, material is saved, self weight is reduced, rigidity is increased, the adhesion distance needs of the tower crane with the length of 15 to 30 meters can be met, the safety property is improved, and the service life of the tower crane can be prolonged.

Owner:山东中建众力设备租赁有限公司

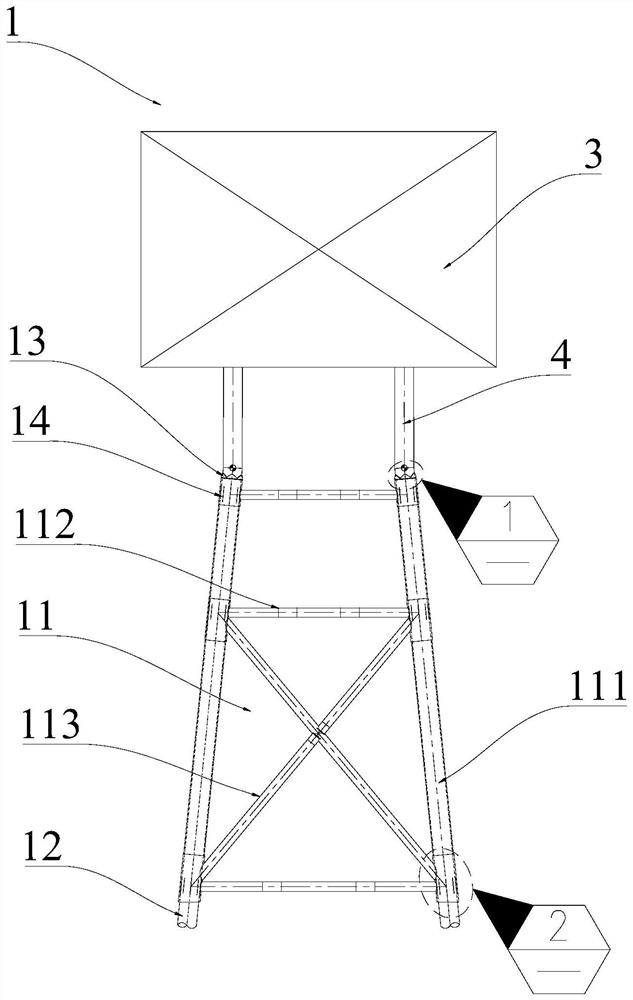

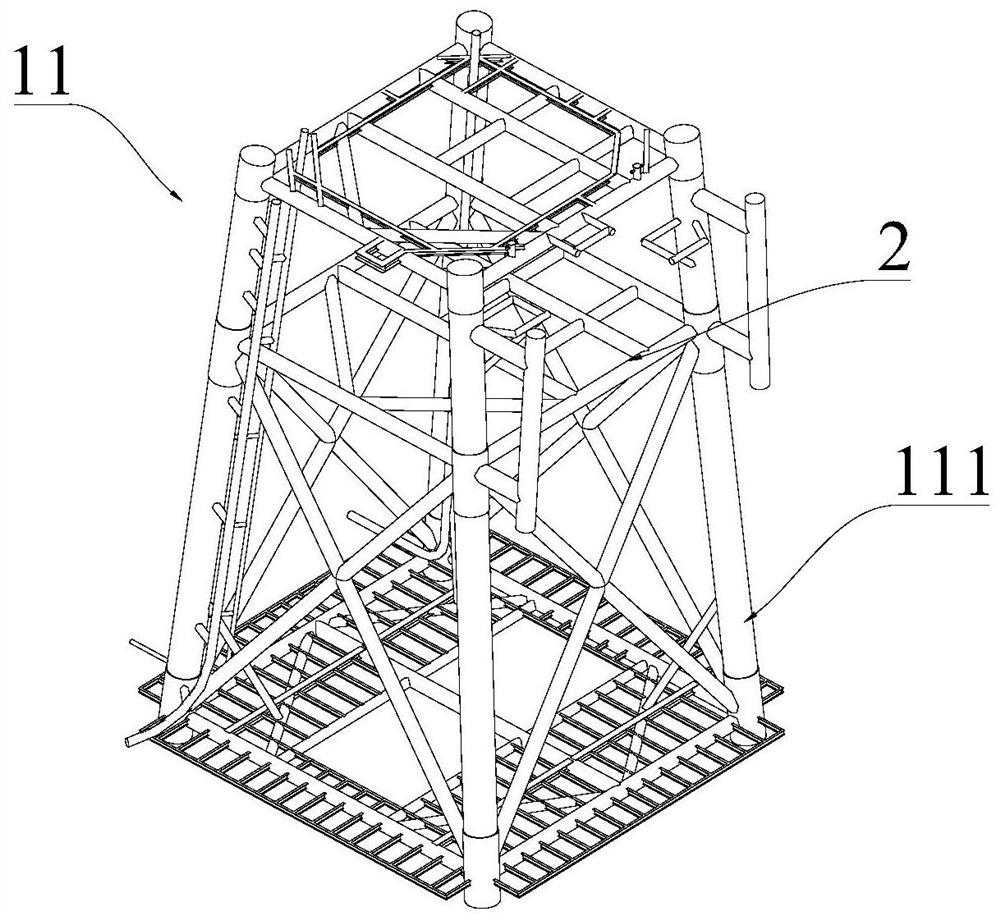

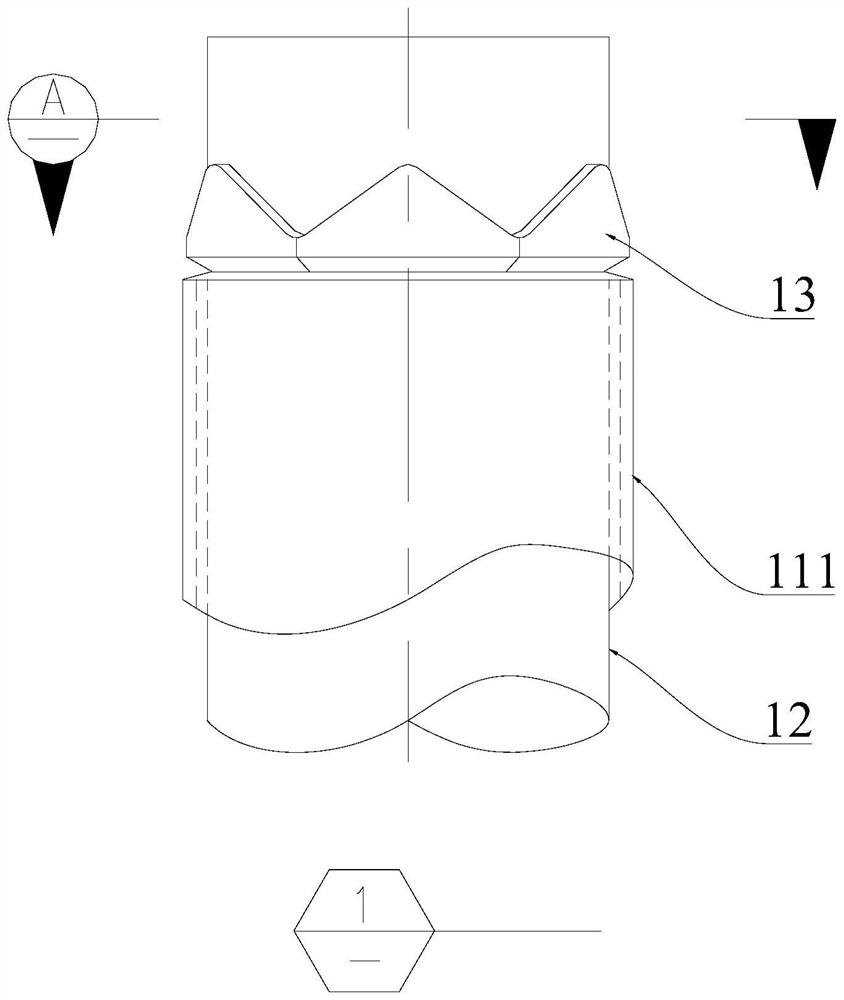

Jacket platform

InactiveCN112112182ASave construction period and construction costEnsure smooth insertionFoundation engineeringGroutSeabed

The invention discloses a jacket platform. The jacket platform is mainly suitable for shallow water leg inner piles and comprises a jacket and steel piles, wherein the steel piles are downwards inserted into jacket legs of the jacket and fixed to a seabed; the jacket platform further comprises crown plates and gap plates, the crown plates are connected to the outer walls of the steel piles in a sleeving mode, the bottoms of the crown plates are fixed to the top ends of the jacket legs to connect the jacket legs and the steel piles into a whole, and then environmental loads borne by the jacketand dead weight are transmitted to the steel piles; the gap plates are arranged between the inner walls of the jacket legs and the outer walls of the steel piles, the plurality of gap plates are arranged surrounding the steel piles at intervals and are fixed to the inner walls of the jacket legs. Furthermore, when the jacket platform is in a working state, the loads between the jacket and the steel piles are transmitted, the design that the loads of the jacket are transmitted to the steel piles through the crown plates and the gap plates and finally transmitted to pile foundations fully utilizes the strength of the jacket legs, the steel piles and the crown plates, due to the fact that grouting is not needed, the defects of a traditional grouting scheme are avoided, and meanwhile, the construction period and the construction cost can be greatly saved.

Owner:OFFSHORE OIL ENG

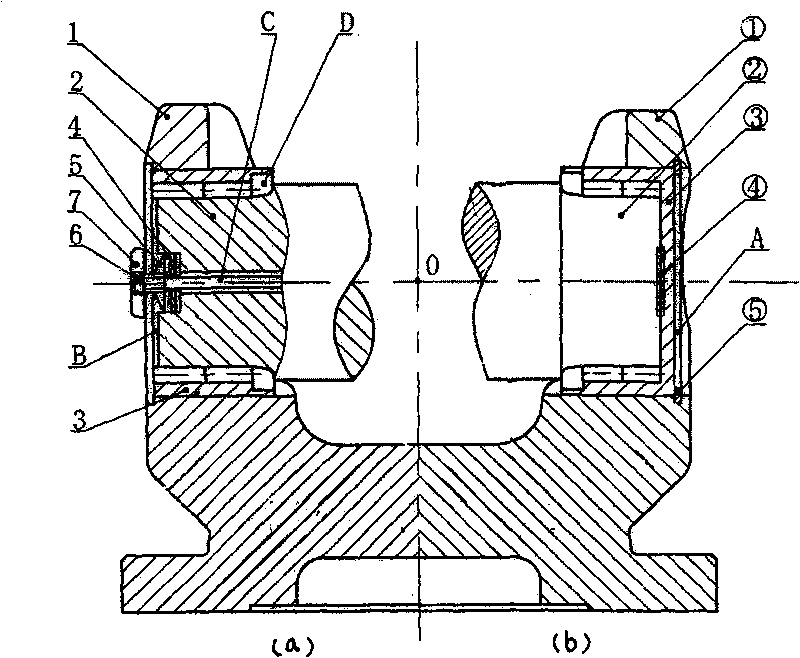

Double universal joint pin cardan joint

InactiveCN101705970AFull use of strengthIncrease contact areaYielding couplingUniversal jointFlying height

The invention discloses a double universal joint pin cardan joint comprising a flange jaw, a universal joint pin and a bearing, wherein a cross screw and a nut connect two forks of the flange jaw into a whole, i.e. the flange jaw, the bearing, the cross screw and the nut are connected to form a sealed jaw; a flying height B exists between the universal joint pin and the bearing; two ends of the cross screw are provided with a plane bearing and a laminated spring; the hollow C of the universal joint pin only accounts for 7-8% of universal joint pin cross section; the hollow C of the universal joint pin is provided with a squirming lubrication system; and a gap D next to the bearing is provided with a seal. Compared with the prior art, transmission capacity is overall improved by 28-30%; the floating universal joint pin without string action gaps can automatically balance on the structural central point O of the structure, thus reducing additional stress produced by an additional moment; the double universal joint pin cardan joint is especially suitable for high-speed rotation and has stable transmission and long service life.

Owner:乐清市联轴器厂

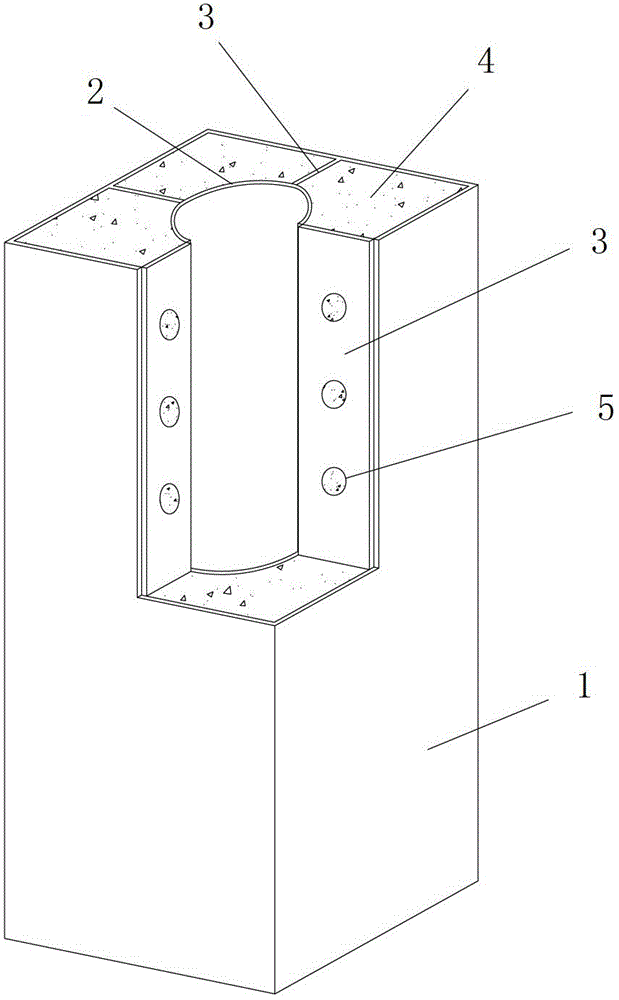

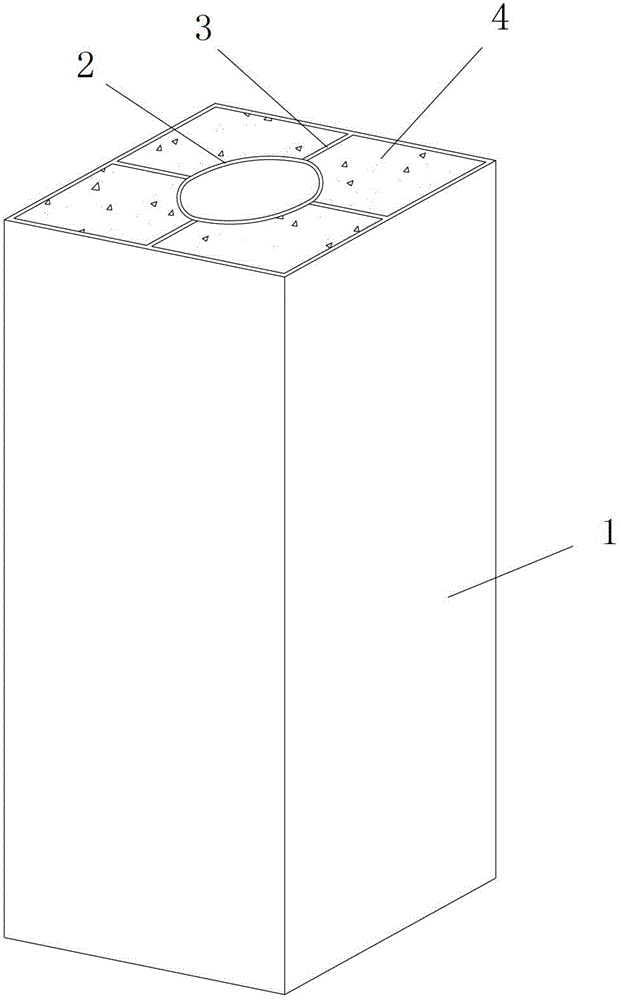

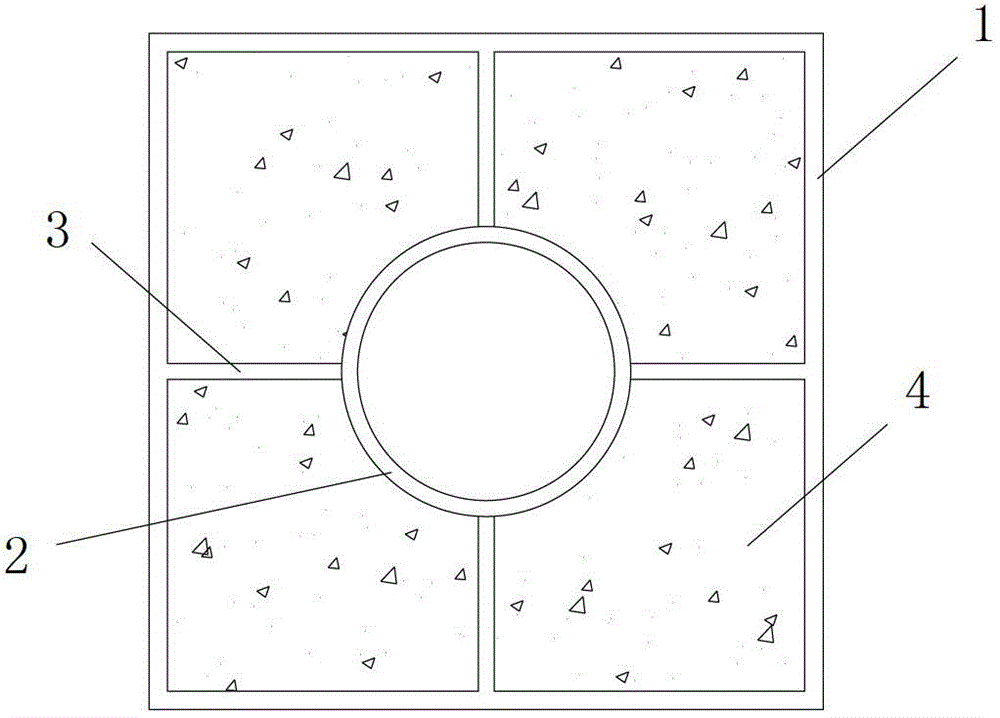

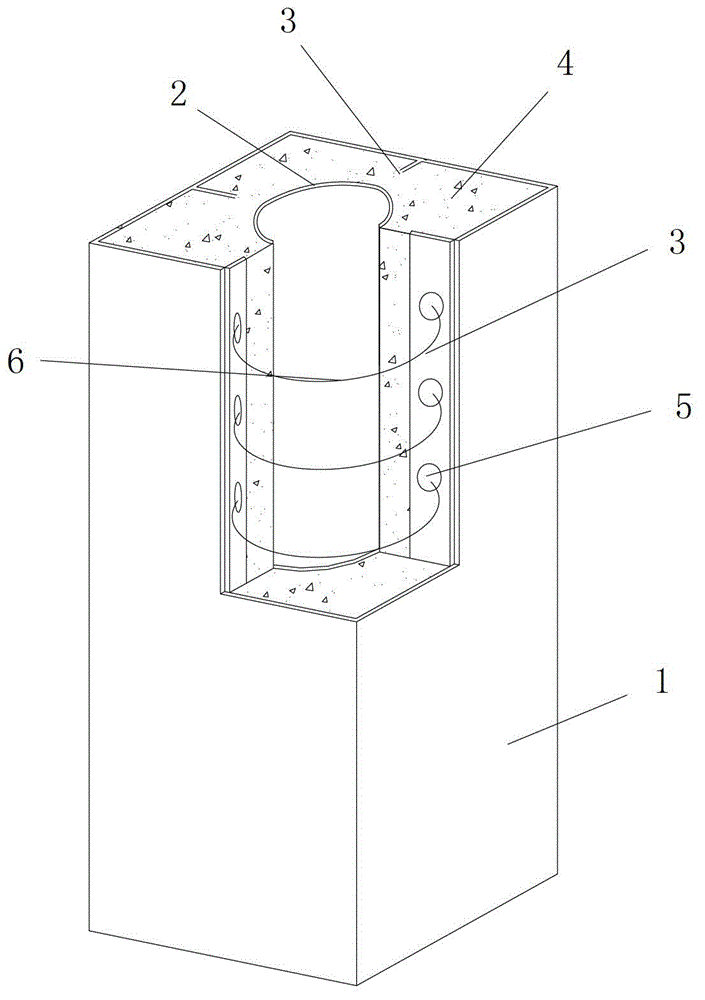

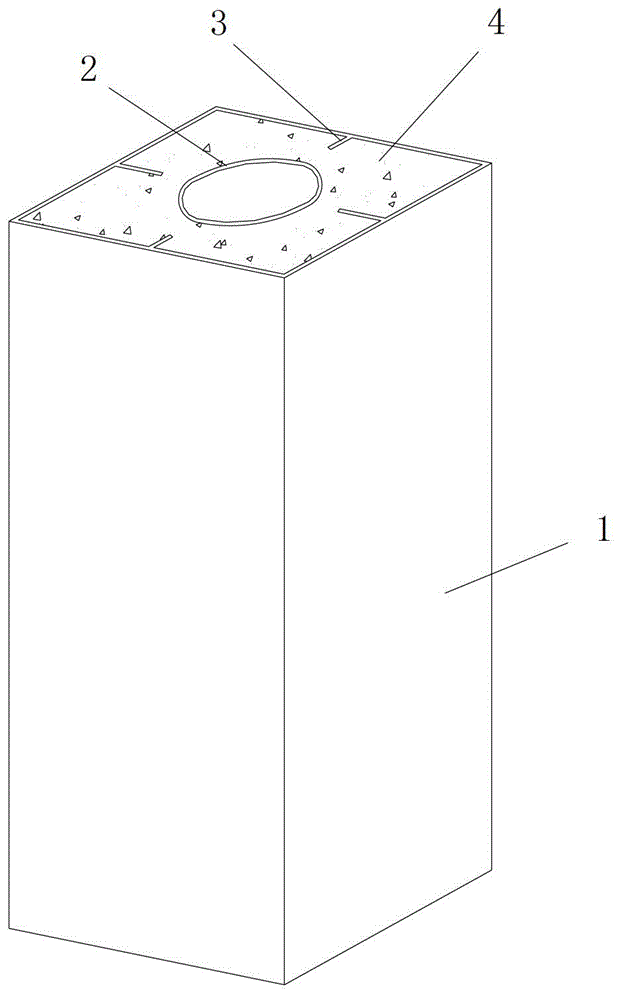

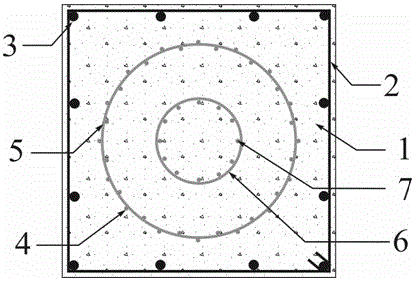

Reinforced concrete double composite core column and construction method thereof

InactiveCN106760210AFull use of strengthSolve the brittleStrutsPillarsReinforced concrete columnAxial pressure

The invention relates to a reinforced concrete double composite core column and a construction method thereof. Under the precise of guaranteeing the column ductility requirement, how to improve the axial pressure ratio limiting value of the column so as to effectively reduce the size of the cross section of the reinforced concrete column gradually becomes a prominent problem in the practice of reinforced concrete structural engineering. The reinforced concrete double composite core column comprises a concrete column. An outer core and an inner core which are coaxial with the concrete column are arranged in the concrete column. The outer core comprises an outer core stirrup and outer core longitudinal bars alternately fixed inside and outside the outer core stirrup. The inner core comprises an inner core stirrup and inner core longitudinal bars on the inner side of the inner core stirrup. A periphery stirrup of the concrete column is arranged on an outer ring of the outer core, and periphery longitudinal bars are arranged on the inner side of the periphery stirrup. The anti-seismic performance and the axial pressure ratio limiting value of the reinforced concrete column can be effectively improved, and the construction method is simple and easy to popularize.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

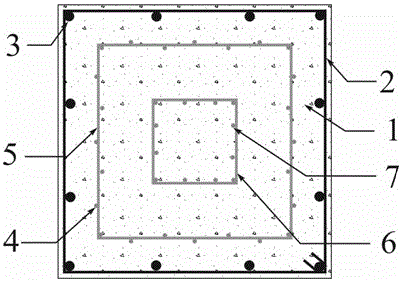

Bridgehead car jump restoration and precaution method based on load reduction

ActiveCN105926421AEffective control strengthEffective controlRoads maintainenceFoam concreteRoad surface

The invention discloses a bridgehead car jump restoration and precaution method based on load reduction. The problem that car jump at bridgeheads exists in the prior art is solved, and the problems that methods adopted at present has high requirements for materials, a long curing time is needed during forming, the construction period is long, and the influence on traffic operation is large are solved. The method comprises the steps that holes are drilled at intervals in the original road face of a bridgehead; hollow barrels are buried in the holes, and the holes are backfilled until the holes are flush with the original road face of the bridgehead; and a road face is additionally laid on the original road face of the bridgehead to restore the bridgehead line shape. The method has the advantages that through the load reduction method, the strength and performance of the original road face are fully used to achieve the purpose of load reduction, and then later settlement is effectively controlled and treated; the hollow barrels are buried in the holes, the curing time needed by slurry or foam concrete is omitted, the displacement work amount is reduced, and the influence period on the traffic is short; and machines are not needed for mounting, and construction is simpler, more convenient and more economical than that of foam concrete.

Owner:姜正晖

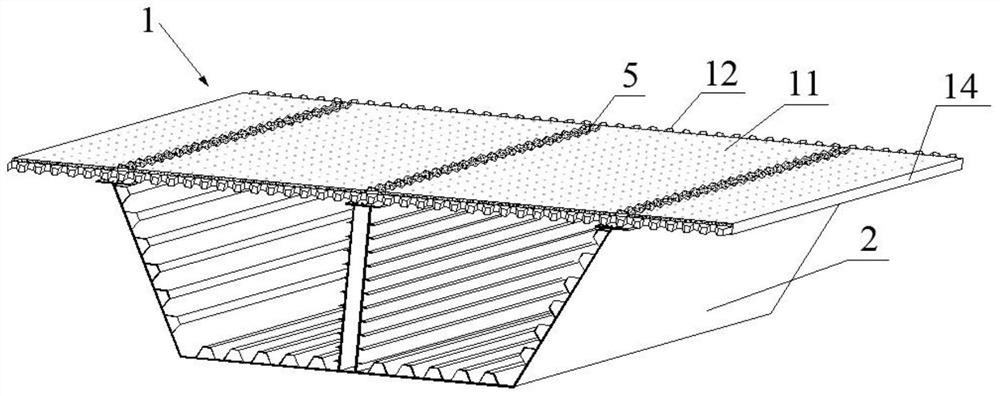

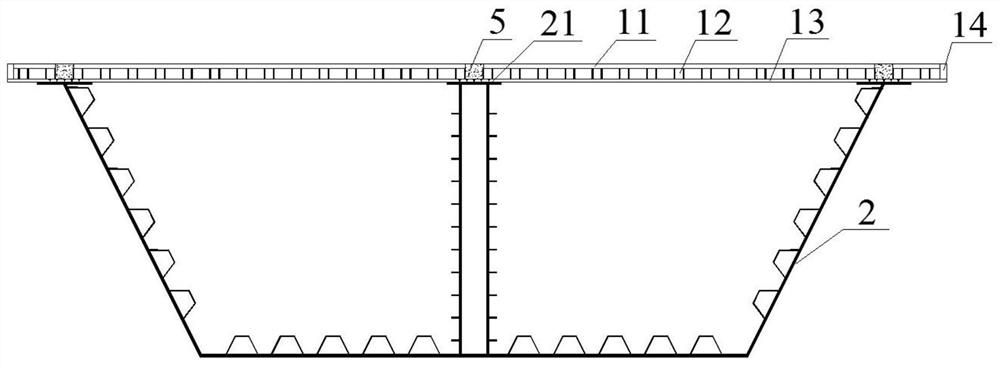

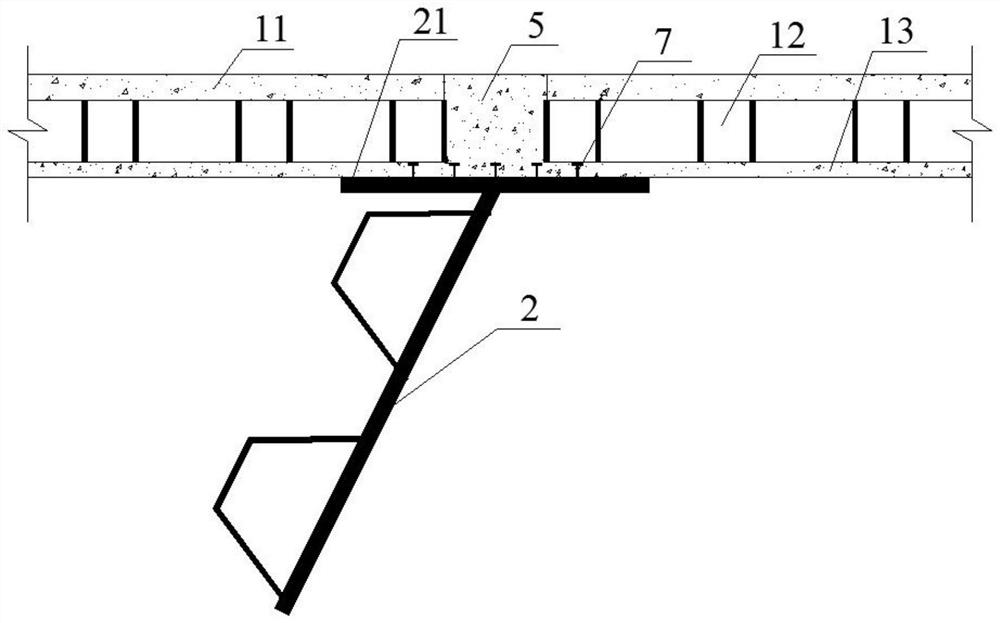

UHPC honeycomb precast slab-steel box girder composite beam structure and construction method

PendingCN111764249ALose weightGuaranteed compressive and flexural performanceBridge structural detailsArchitectural engineeringHoneycomb

The invention relates to a UHPC honeycomb precast slab-steel box girder composite beam structure and a construction method, and relates to the technical field of bridge structures. The composite beamstructure comprises a UHPC honeycomb precast slab and a steel box girder, wherein the UHPC honeycomb precast slab is arranged to be of a honeycomb sandwich structure and sequentially comprises an upper skin plate, a honeycomb core material, a lower skin plate and two side skin plates which are tightly connected with the left side face and the right side face of the honeycomb core material respectively from top to bottom, and the lower surface of the lower skin plate is fixedly connected with the steel box girder. The high-strength characteristic of the UHPC material, the light weight, compression resistance and bending resistance of the honeycomb sandwich structure and the shear capacity of the steel box girder component are fully utilized, the problem that the bridge deck is prone to cracking can be solved, and the dead weight of the bridge structure can be reduced. Besides, the UHPC honeycomb precast slab and the steel box girder are precast into a whole through a factory and then transported to the site for segmental assembly, so that the efficiency can be improved, and the construction period can be shortened. Therefore, the self-weight of the bridge structure can be reduced, the cost can be reduced, the construction efficiency can be improved, and the construction period can be shortened.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

Steel-bamboo composite elevator structure

The invention relates to a steel-bamboo composite elevator structure which comprises a main body structure and an enclosure structure, and the main body structure is formed by a top steel-bamboo composite truss unit, a middle steel-bamboo composite truss unit and a bottom steel-bamboo composite truss unit in an up-down spliced mode, a system with trusses on the three faces and a frame on one faceis assembled, and the face with the frame faces the use side of a building. The enclosure structure is formed by a base for mounting the main body structure and an ALC lightweight concrete partition wall in an up-down spliced mode. The main body structure of an elevator is combined in a unit dividing mode, is provided with miniaturized components, is easy to install, disassemble and transport, andis connected through bolts overall, and a welding process is avoided. The steel-bamboo composite elevator structure is borne by a bamboo web pole, a bamboo crossbeam and a steel vertical column in acombined mode, the advantages of two materials are utilized, bamboo resources are fully used, the concept of environment-friendly building development in China is followed, and the enclosure structurehas the characteristics of light weight, high strength, heat preservation, sound insulation and good durability.

Owner:NANJING FORESTRY UNIV

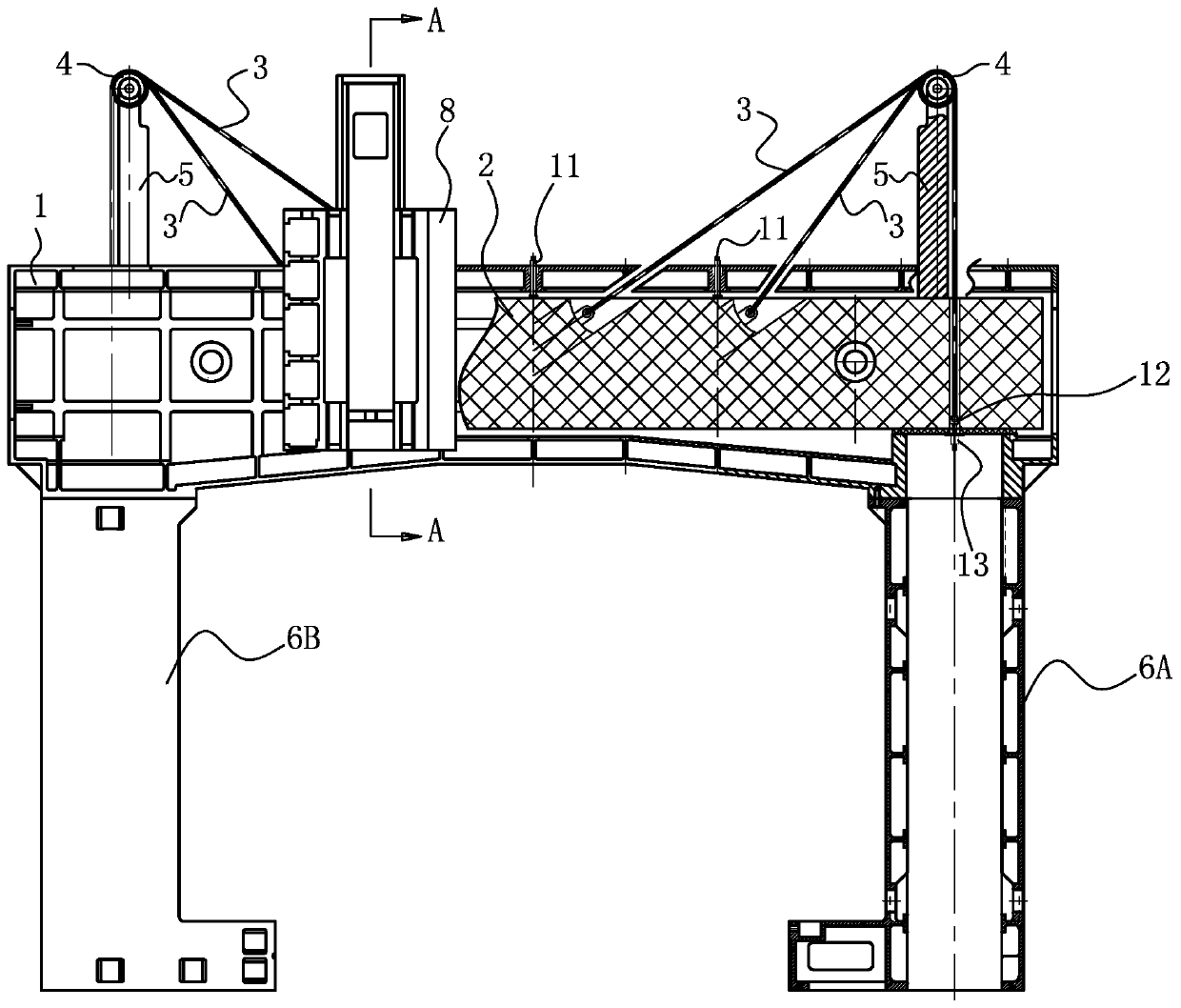

Large-span heavy gantry numerical control machine tool

PendingCN110877207ABalance deflectionImprove straightnessLarge fixed membersNumerical controlPolymer concrete

The invention discloses a large-span heavy gantry numerical control machine tool. An unloading beam made of polymer concrete materials is arranged in a hollow cavity of a beam of the large-span heavygantry numerical control machine tool. Supporting bases upwards penetrating through the beam are arranged at the two ends of the unloading beam correspondingly and provided with sliding wheels. A balance rope is wound around the sliding wheels, the first end of the balance rope is connected to the part, on the outer side, of the unloading beam, and the second end is connected to the part, on the inner side, of the unloading beam. According to the large-span heavy gantry numerical control machine tool, on one hand, the middle portion of the unloading beam can be upwards jacked by adjusting thetightness of the balance rope, the force is transmitted to the beam through an adjusting screw, the deflection of the beam can be effectively balanced, the moving linearity of a transverse moving sliding base on the beam is improved, and accordingly the machining precision of the machine tool is improved; and on the other hand, good strength of stand columns and the beam made of cast iron materials is sufficiently utilized, due to the character of excellent vibration damping performance of the unloading beam and a supporting core column made of the polymer concrete materials, vibration absorption is accelerated, the two parts are combined, and mutual complementation is achieved.

Owner:高密宏泰机床制造有限公司

Foundation pit support pile using steel pipe pile to replace cast-in-place pile rock-socketed

The invention relates to a foundation pit support pile using a steel pipe pile to replace a cast-in-place pile rock-socketed, and belongs to the field of foundation engineering. The foundation pit support pile comprises an upper support cast-in-place pile and a lower rock-socketed steel pipe pile, wherein the rock-socketed steel pipe pile consists of a plurality of steel pipes embedded into a bedrock and cement paste poured; and the upper parts of the steel pipes extend into the support cast-in-place pile to be lapped with a pile body reinforcing bar. During construction, a hole is formed in acomplete bedrock surface, after the hole is formed, the hole is drilled by a drilling machine, the steel pipes are placed into the hole, and the cement paste is poured into the hole, so that the steel pipes and the bedrock are fixedly connected into a whole, and the rock-socketed replacement of the support cast-in-place pile is realized. The method has the advantages that the hole diameter of thesteel pipe pile is larger, the number of holes is small, the centering is easy during pipe placement, the cost is low, the construction speed is high, and the process is simple. A karst cave can be vertically spanned in a karst area, so that materials are saved, and the stability of a rock-socketed section of the support pile is ensured. Meanwhile, in a bedrock fracture development area, the strength of the bedrock is greatly improved by pouring the cement paste, and the problem of strength of the bedrock due to fracture development is solved.

Owner:广东省有色矿山地质灾害防治中心

High-temperature superconducting magnet and preparation method thereof

PendingCN113782295AImprove temperature distributionSmall temperature differenceSuperconducting magnets/coilsCoils manufactureElectric machineSuperconducting Coils

The invention relates to a high-temperature superconducting magnet, which is composed of a magnet lower bottom plate, a magnet upper cover plate, a superconducting coil and M spacer blocks, wherein M is larger than or equal to 1, the magnet lower bottom plate is composed of a lower bottom plate body and a lower bottom plate boss, the magnet upper cover plate is composed of an upper cover plate body and an upper cover plate boss, each spacer block is of an annular structure with a notch,, and is connected with the magnet upper cover plate and the magnet lower bottom plate respectively, the superconducting coil is composed of one or two sub superconducting coils, each sub superconducting coil is composed of N single-cake coils, N is larger than or equal to 2, one spacer block is arranged between every two adjacent single-cake coils, and the two adjacent single-cake coils are connected in series into a whole through a superconducting strip. The invention also discloses a preparation method of the high-temperature superconducting magnet. According to the invention, great innovation is provided in the aspects of reducing the temperature difference in the magnet, reducing the overall thermal stress of the superconducting coil, fully utilizing the strength of each turn of superconducting tape, realizing the stress design of the superconducting coil and the like, and the high-temperature superconducting magnet is particularly suitable for being used in a high-temperature superconducting motor.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

Filler material for furnace of baking powder of charcoal

This invention relates to a filling material for carbon torrefying furnace. The filling material is mixed from: fly ash particles (sizes 2-12 mm) 1-50 wt. %, anode torrefied broken particles (sizes 1-8 mm) 1-50 wt. %, and calcined coke particles as balance. The filling material has such advantages as high strength, good air permeability, good heat conductance, low oxidation loss and can be directly used in carbon torrefying furnace.

Owner:河南华慧有色工程设计有限公司 +1

A super-long attachment construction method for a variable-section truss tower crane

ActiveCN110143529BMeet the needs of attachment distanceIncrease profitCranesArchitectural engineeringTower crane

The invention discloses a variable cross section truss type tower crane overlength adhesion construction method. An adhesion frame of a tower crane and a building are included, the adhesion frame comprises a first corner and a second corner which are used for connection, an adhesion rod set comprises a first adhesion rod, a second adhesion rod and a third adhesion rod, the first adhesion rod enables the first corner and a first part of a building body to be in adhesion connection, the second adhesion rod enables the second corner and the first part of the building body to be in adhesion connection, the third adhesion rod enables the second corner to be in adhesion connection with the second part of the building body, and the first adhesion rod and the second adhesion rod are in hinged connection with an embedded wall plate through a double lug plate pin shaft. The material strength is sufficiently used, material is saved, self weight is reduced, rigidity is increased, the adhesion distance needs of the tower crane with the length of 15 to 30 meters can be met, the safety property is improved, and the service life of the tower crane can be prolonged.

Owner:山东中建众力设备租赁有限公司

Cold storage plate convenient to install

The invention discloses a cold storage plate convenient to install, and belongs to the field of plates. The cold storage plate comprises two surface layer plates and an insulating layer arranged between the two surface layer plates, the two surface layer plates are staggered with the insulating layer, and the two end parts, staggered with the insulating layer, of the surface layer plates are provided with a convex joint and a concave slot which are matched with each other. The cold storage plate further comprises a pressing plate, at least two screw holes are formed in the pressing plate, threaded holes matched with the screw holes are formed in the two end parts of the surface layer plates, and the pressing plate is connected to the end parts of the two adjacent surface layer plates through screws. The cold storage plate convenient to install has simple structure and reasonable design, not only is convenient to install and splice, but also has the effects of high shear resistance andprevention of the establishment of cold and hot bridges inside and outside a cold storage.

Owner:安徽国天节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com