Novel steel pipe butting connector

A technology for butt jointing of steel pipes and connectors, applied in building types, towers, buildings, etc., can solve the problems of high site construction requirements, high cost, and complex construction, and achieve the effect of beautiful appearance, low cost, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

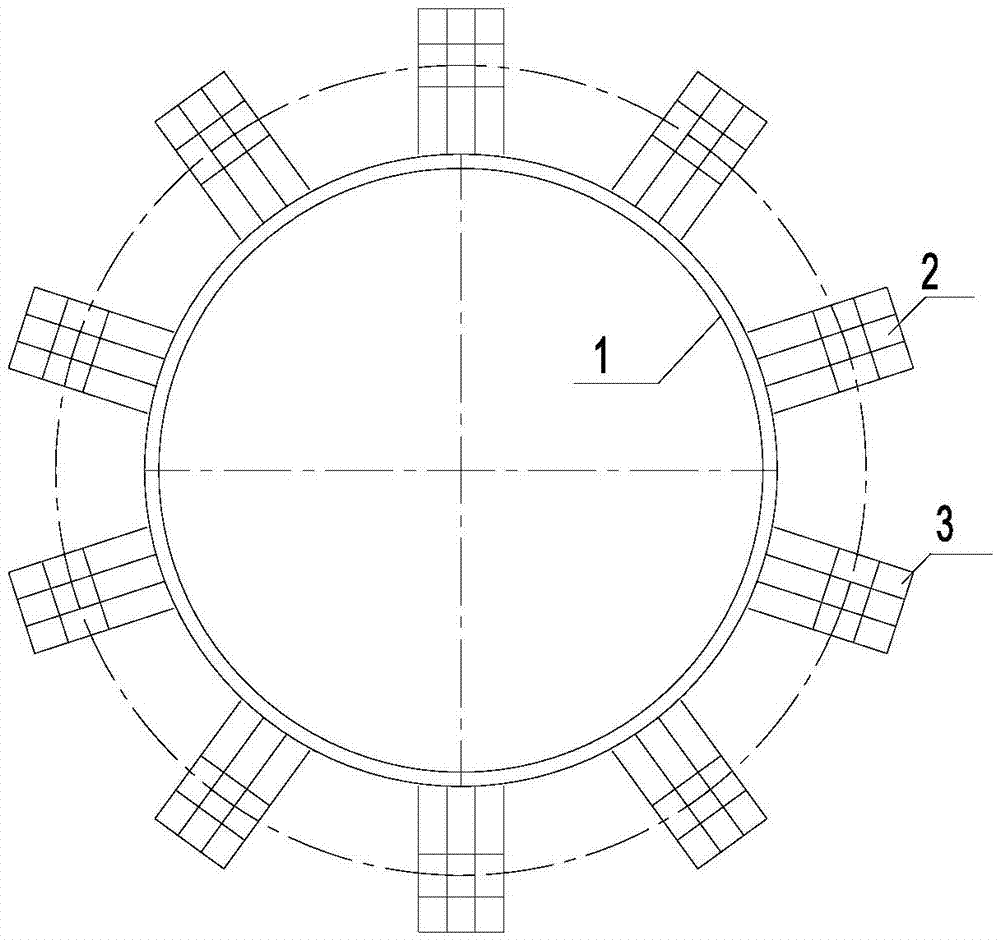

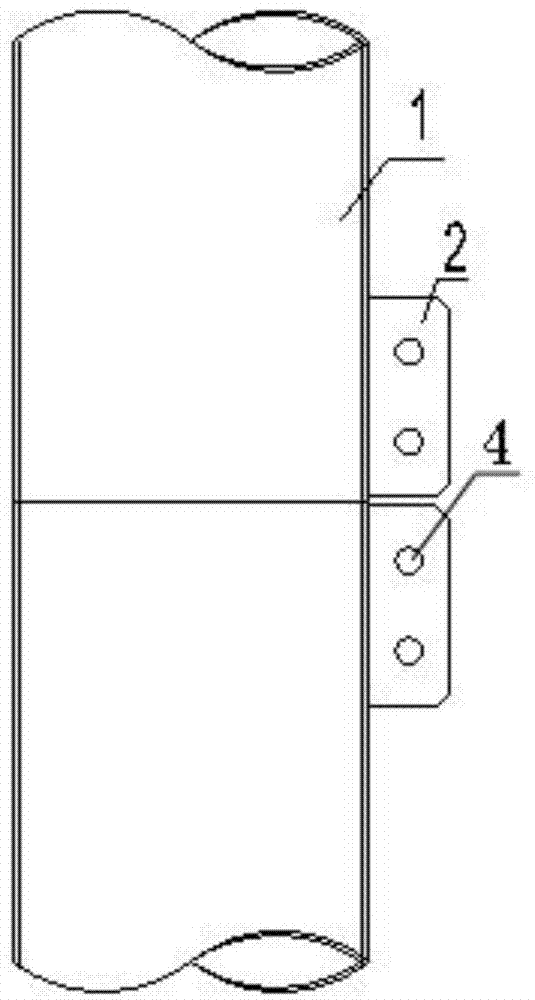

[0022] A new type of butt joint steel pipe connector, which is used in power transmission and transformation lines, and includes two main pipes 1 that need to be docked. Correspondingly arranged on the same horizontal plane respectively, the plugboards 2 are fixed by setting the connecting boards 3 .

[0023] The diameters of the above two connecting main pipes 1 are the same or different.

[0024] The flashboard 2 is vertically welded on the main pipe 1 .

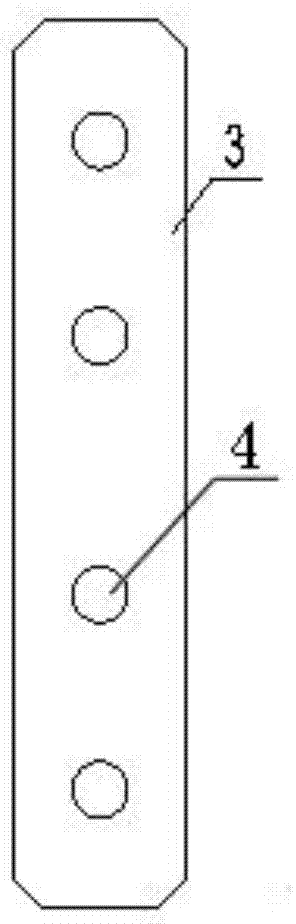

[0025] The above-mentioned plug-in plate is provided with bolt holes 4 .

[0026] Bolt holes 4 are provided on the above-mentioned connecting plate 3 .

[0027] The above-mentioned plug-in plate 2 and the above-mentioned connection plate 3 are fixedly connected by bolts.

[0028] The above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com