Fabricated stay bar prestressing sandwich pipe concrete combined member

A composite component and concrete technology, applied in the direction of building components, structural elements, building reinforcements, etc., can solve the problems of large wall thickness, high cost, and poor fire resistance of steel pipes, and achieve small thermal conductivity, large heat capacity, and improved The effect of strength and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

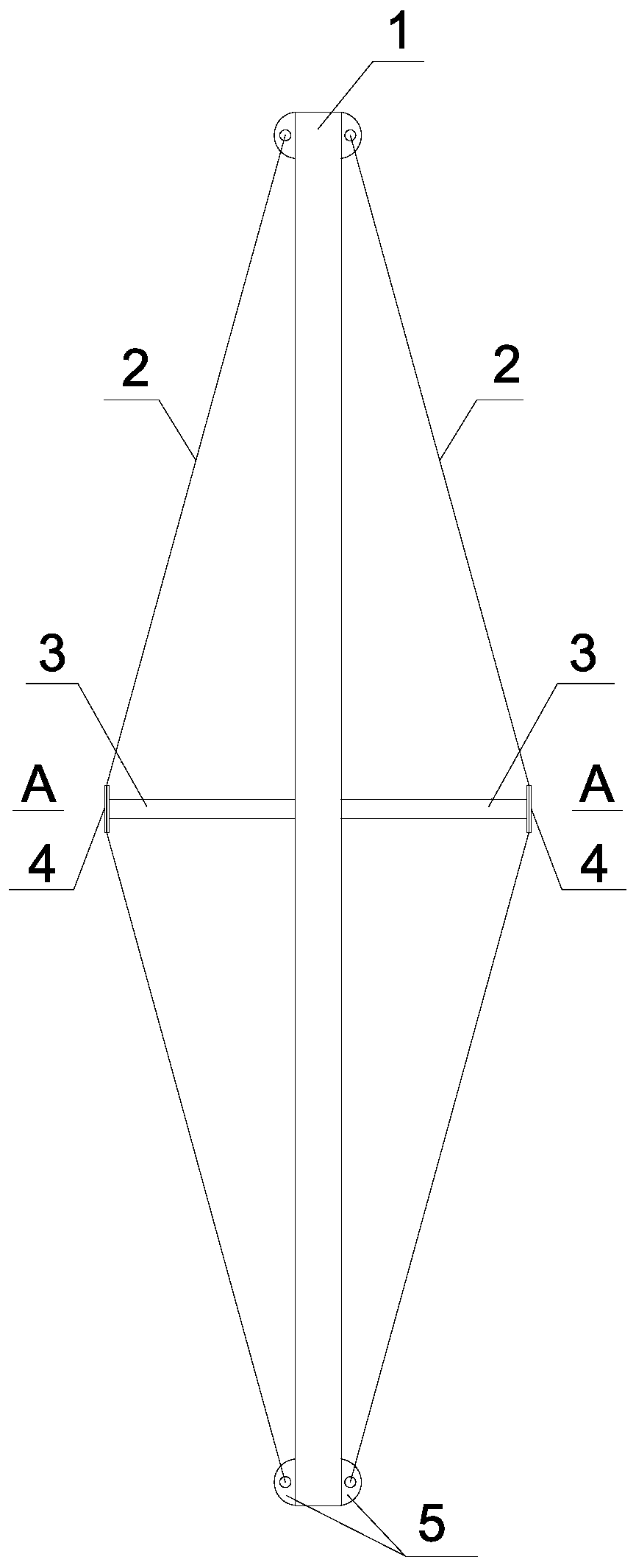

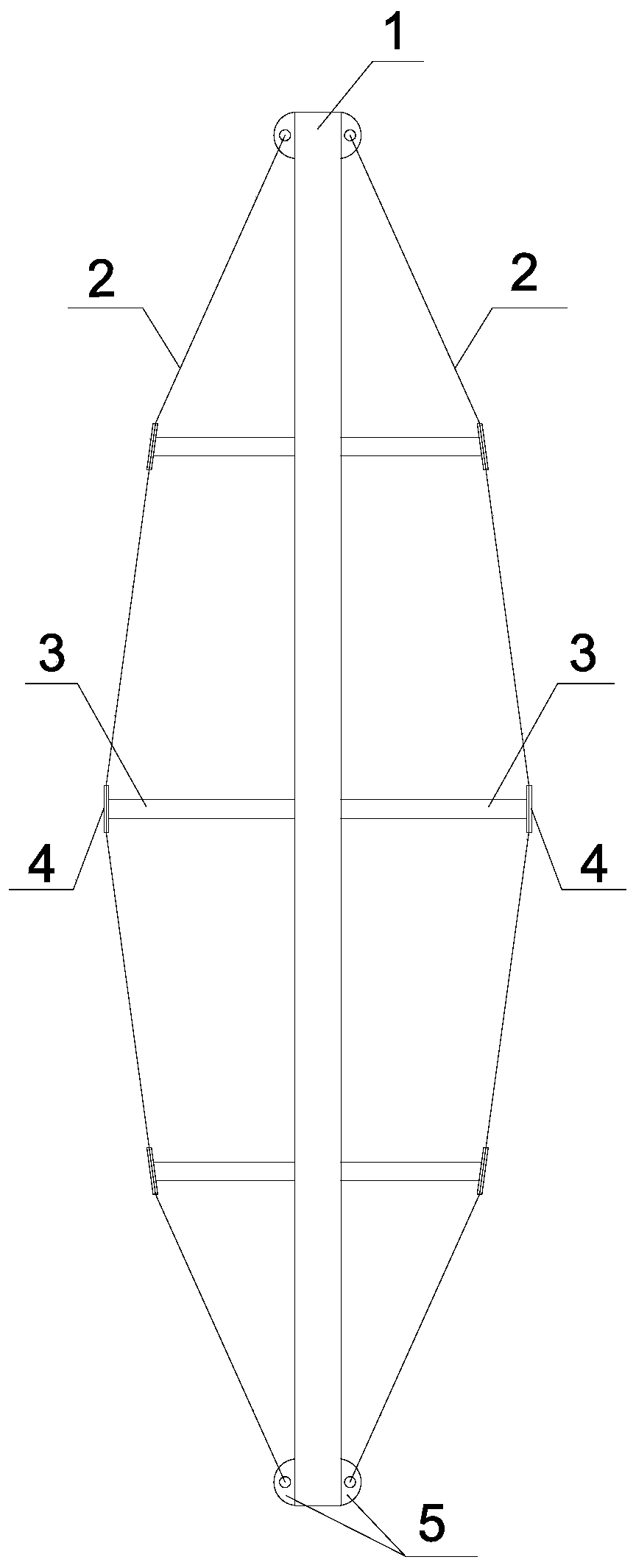

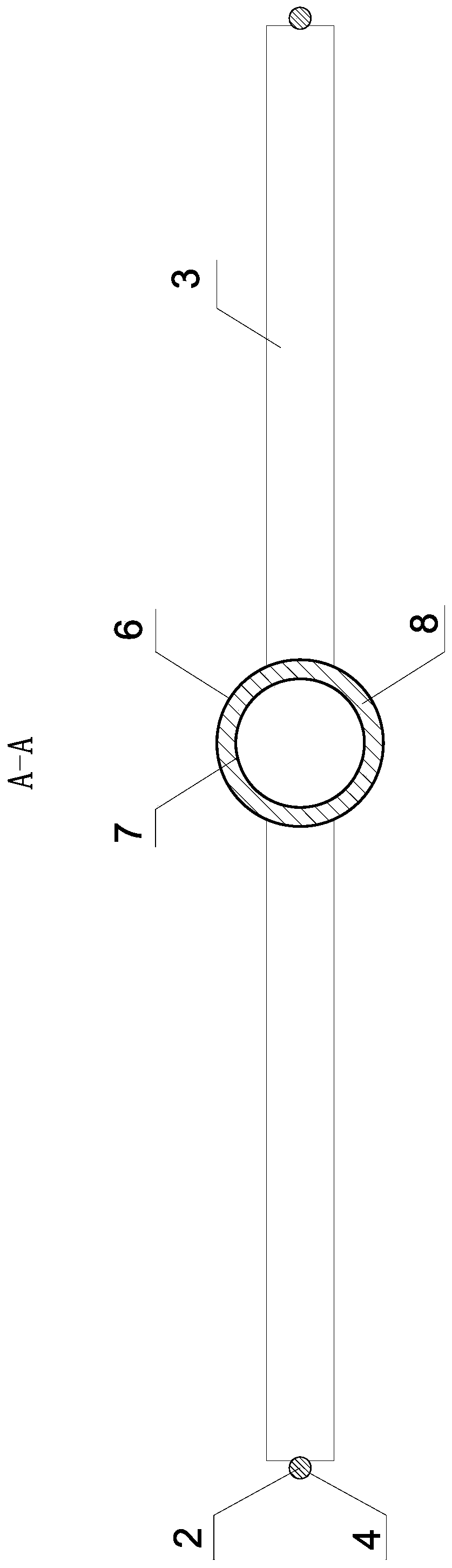

[0015] refer to Figure 1-Figure 3 As shown, an assembled strut prestressed sandwich tubular concrete composite member of this embodiment includes a sandwich tubular concrete column 1, a prestressed cable 2, a strut 3, a cableway 4 and a cable head 5; a sandwich tubular concrete column 1 N pairs of struts 3 are fixedly connected to the two sides of each pair of struts 3, and each pair of struts 3 is symmetrically arranged and perpendicular to the sandwich concrete column 1, and the ends of the struts 3 are fixedly connected to the cableway 4; wherein, N≥1 is a positive integer;

[0016] The prestressed cable 2 is threaded in the cableway 4, and its two ends are respectively fixed on the cable head 5 installed at the two ends of the sandwich concrete column 1, and the axes of the strut 3, the cableway 4 and the sandwich concrete column 1 are located on the same plane Inside, the two prestressed cables 2 on both sides of the sandwich tube concrete column 1 are symmetrically arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com