A fusiform constrained buckling-resistant brace

A buckling-resistant support and curved technology, which is applied in the direction of earthquake resistance and building components, can solve the problems of the overall transportation difficulties of buckling-resistant support components, affect the architectural effect, and the self-heaviness of components, so as to facilitate the architectural shape and reduce the calculation length , the effect of self-weight drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

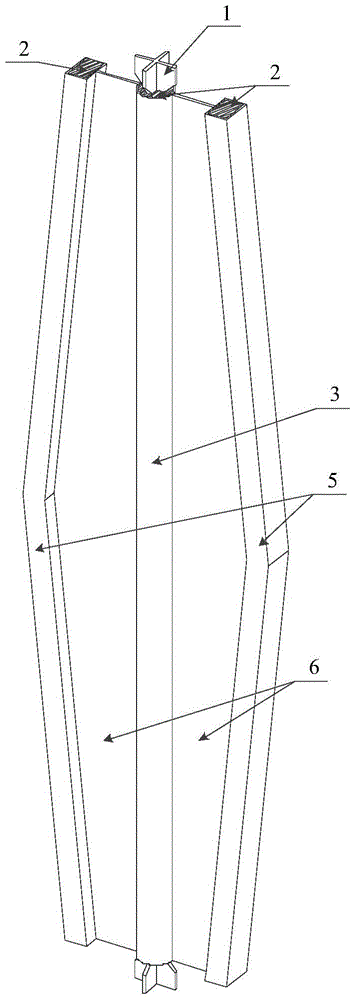

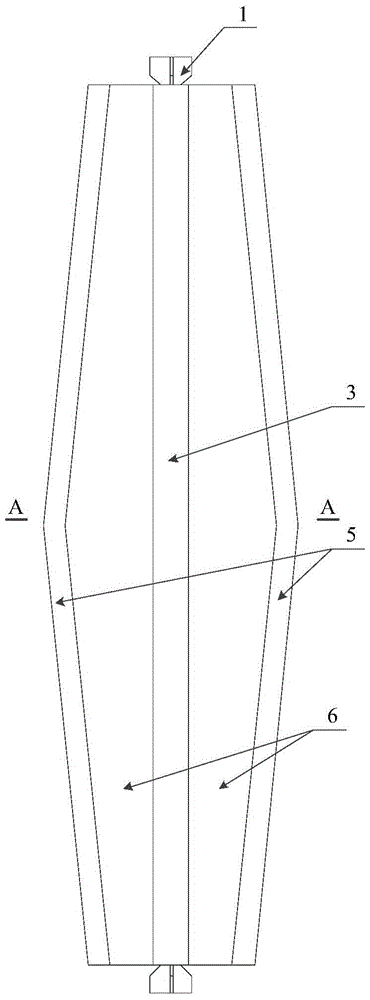

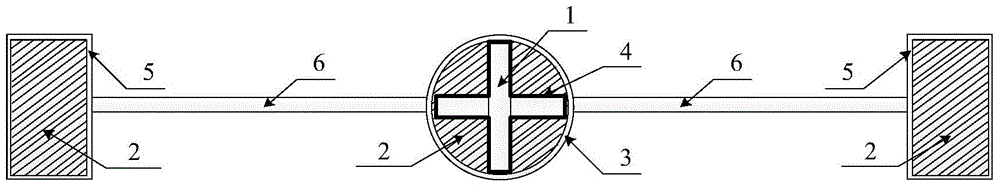

[0019] Attached below Figure 1-6 , detailing the implementation of this patent.

[0020] Such as Figure 1~5 As shown, a fusiform-constrained buckling-resistant bracing member includes the following components:

[0021] 1——cross core steel plate, including 1-1—narrow flat steel plate one; 1-2—narrow flat steel plate two; 1-3—wide flat steel plate;

[0022] 2 - filled with concrete;

[0023] 3—constrained steel pipe;

[0024] 4 - hard rubber;

[0025] 5—bent square steel pipe, including 5-1—rectangular steel pipe 1; 5-2—rectangular steel pipe 2;

[0026] 6——Connect the steel plate.

[0027] Such as Figure 4 As shown, the length of the cross core steel plate 1 is longer than that of the restraining steel pipe 3, and is composed of two narrower flat steel plates 1-1, 1-2 and one wider flat steel plate 1-3 by welding; as shown in Figure 3, Paste hard rubber 4 on the surface of the area where the cross core steel plate 1 is wrapped by the restrained steel pipe 3 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com