Patents

Literature

65 results about "Oblique Axis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hypothetical functional axis from the superior area of a sacroiliac articulation to the contralateral inferior sacroiliac articulation. It is designated as right or left relevant to its superior point of origin. 2. A term described by Fred Mitchell, Sr, DO.

Degenerative Valvular Disease Specific Annuloplasty Rings

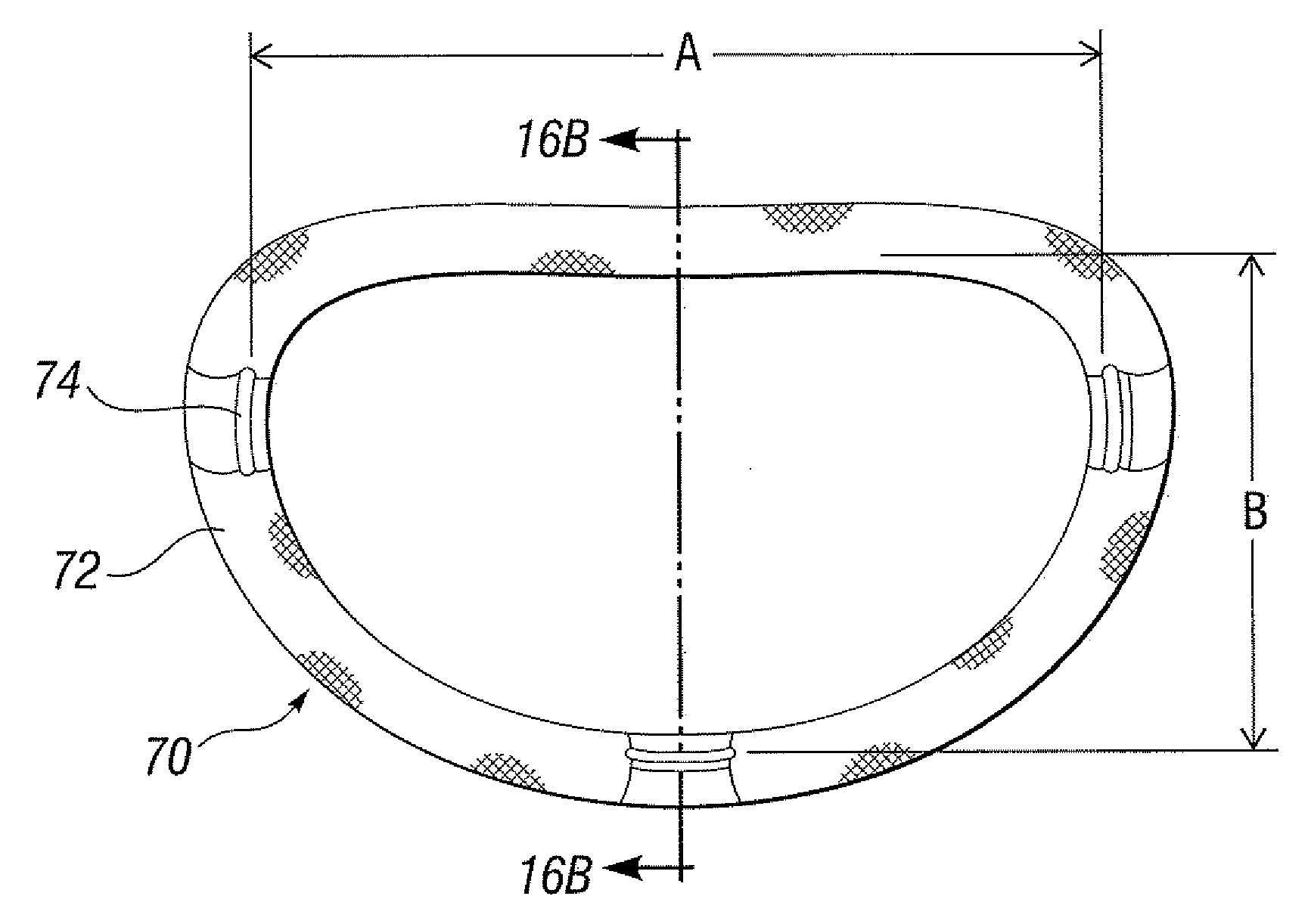

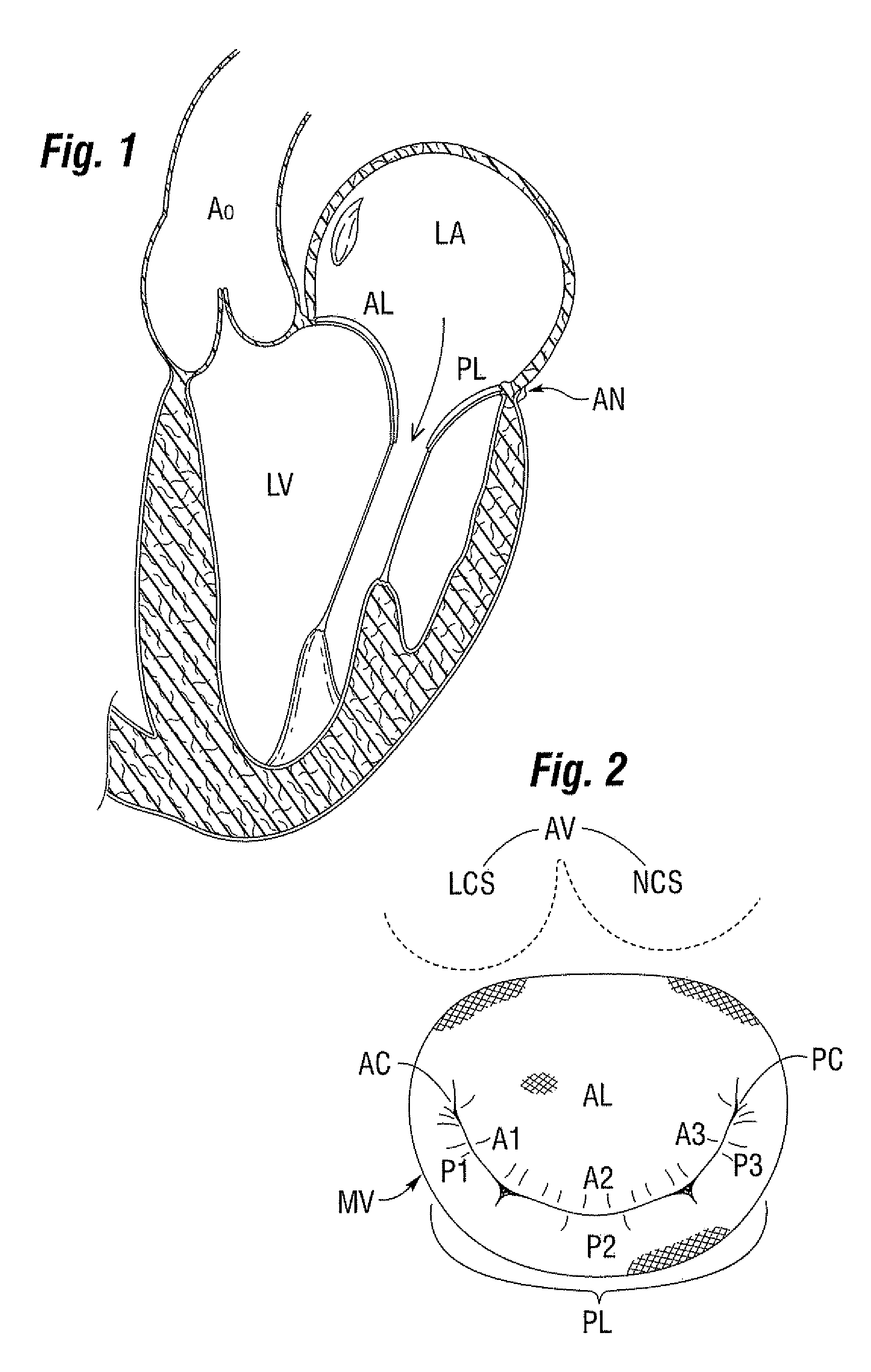

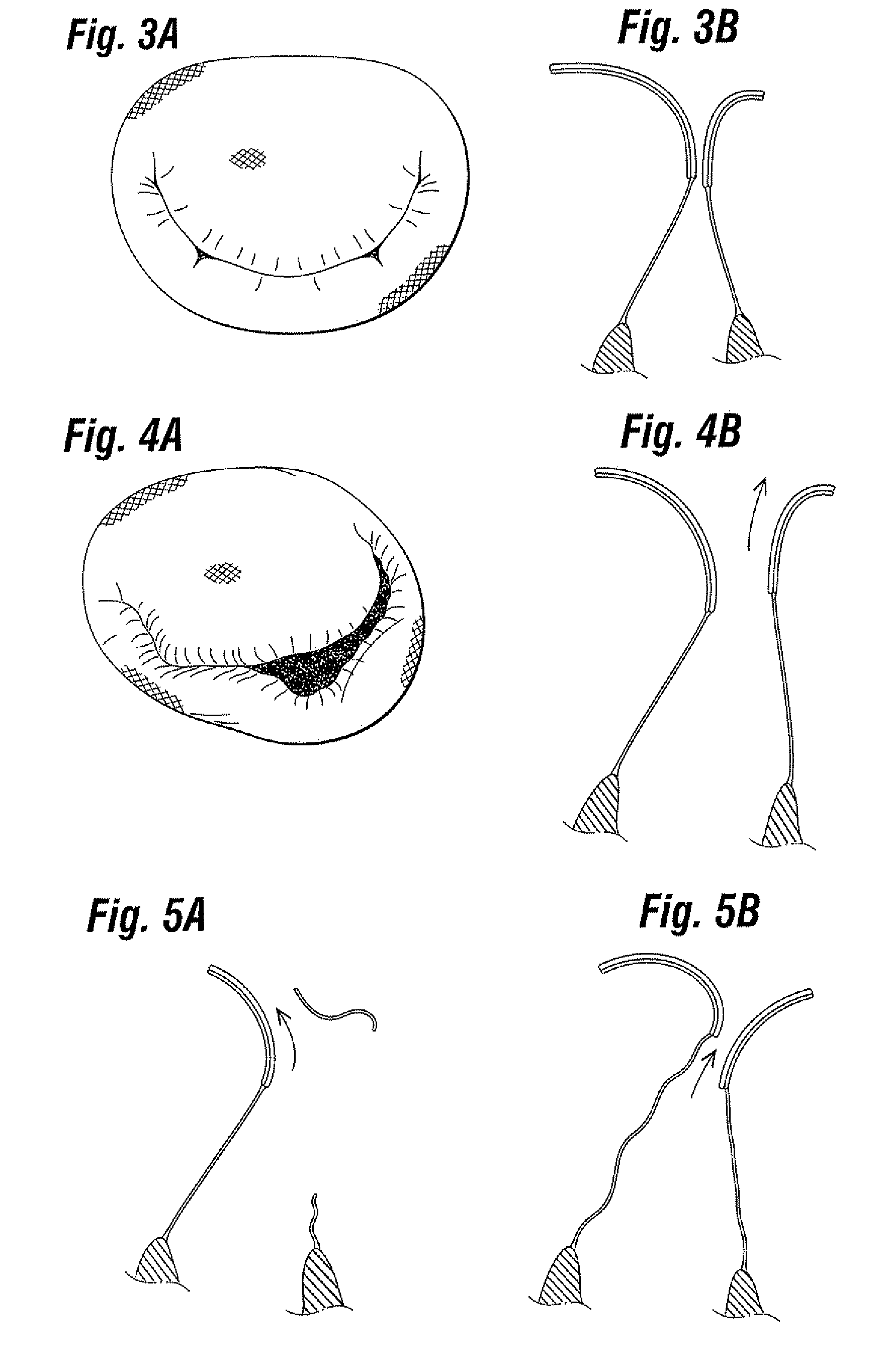

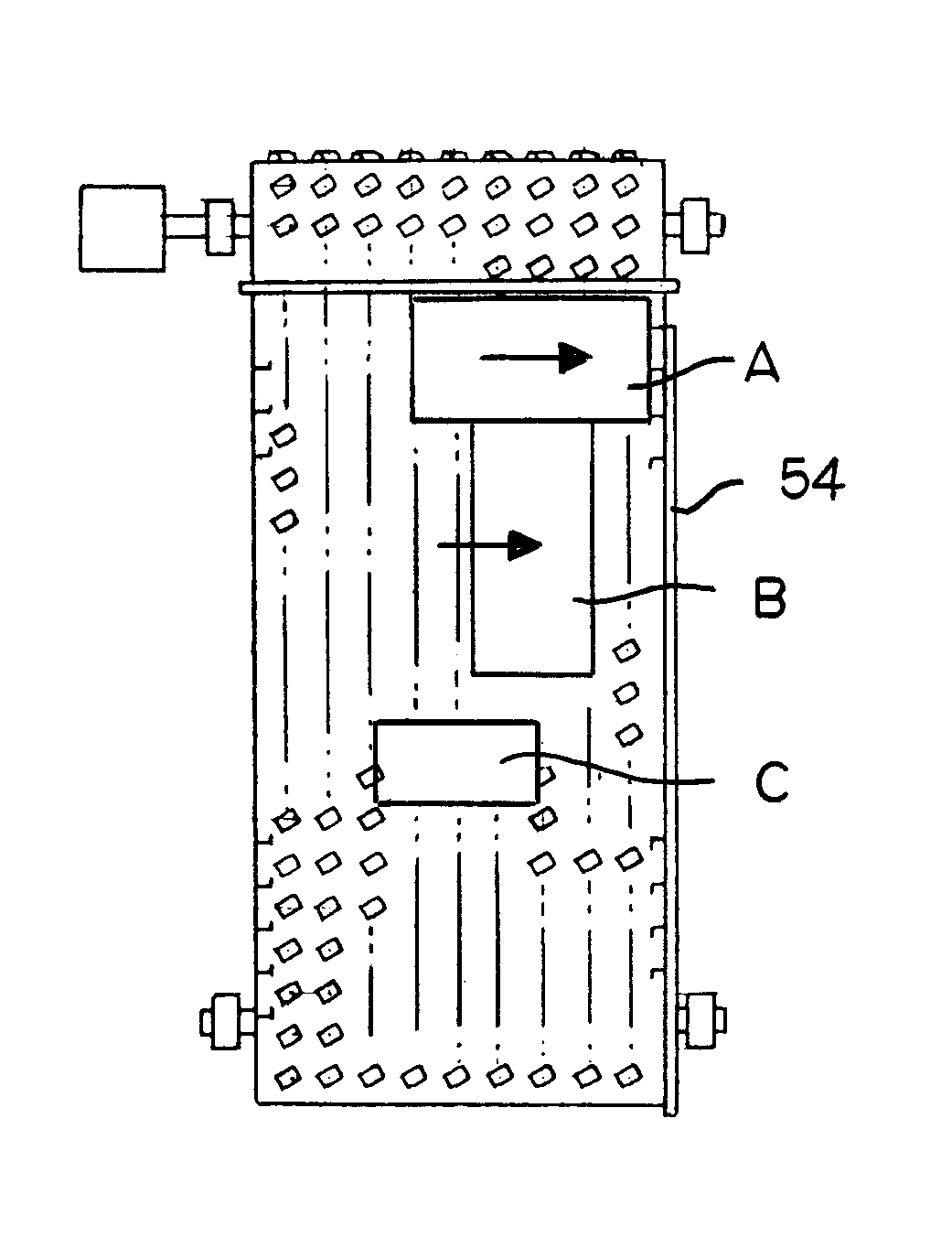

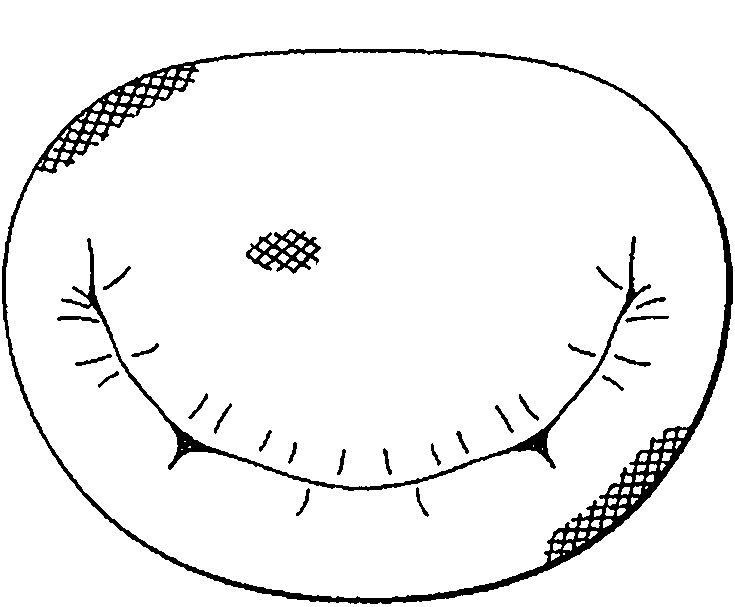

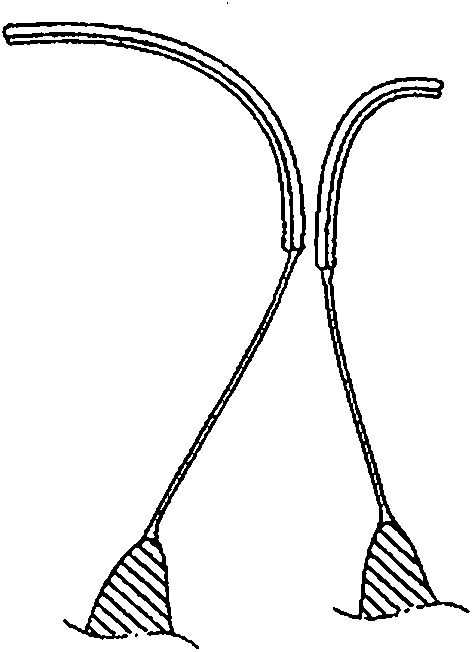

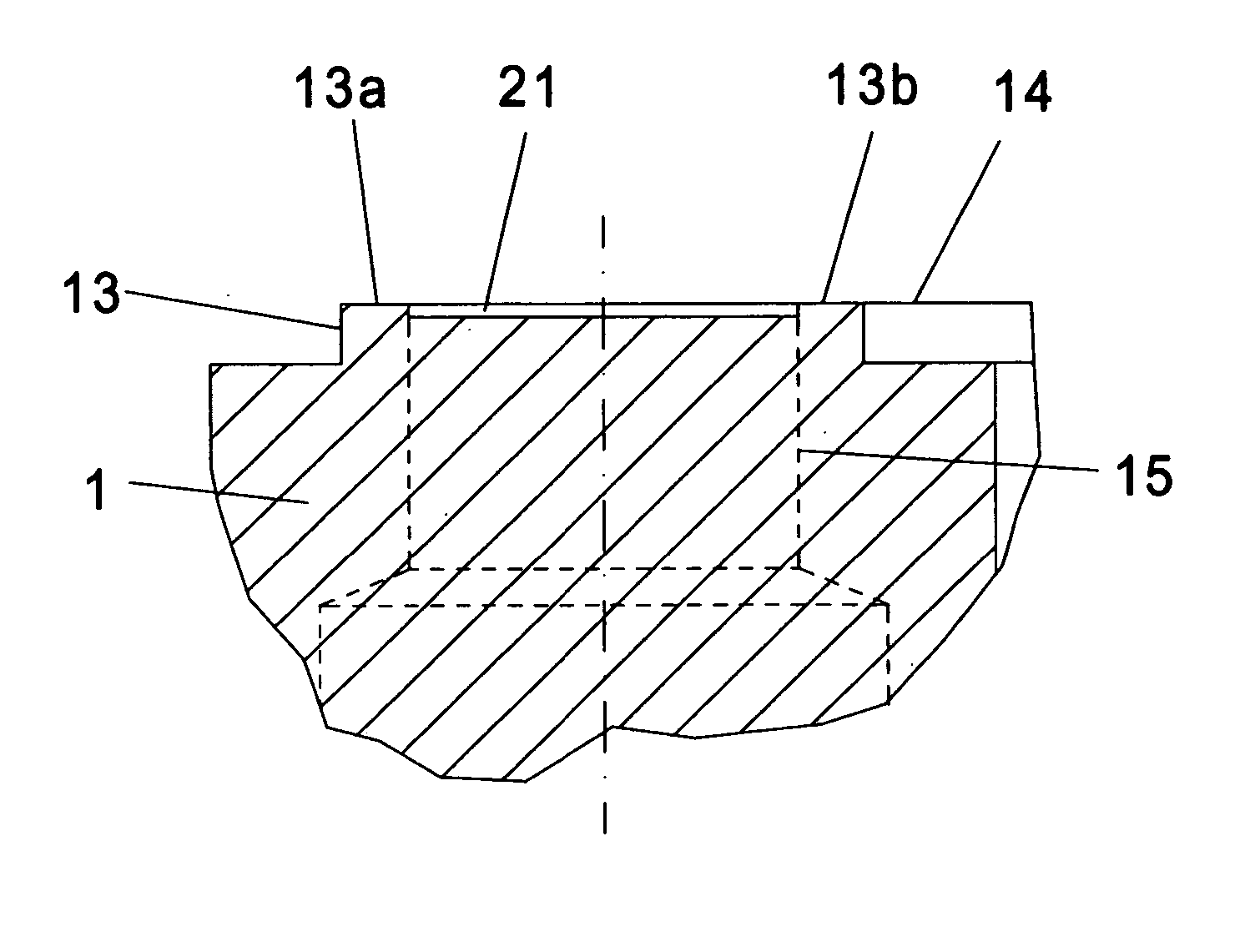

Annuloplasty rings optimally sized to take into account more of the common degenerative valve pathologies. Each ring has a structural ring body with a shape that complies with predicted shapes of degenerative valvular diseases, such as fibroelastic deficiency (FED), Marfan's or Barlow's. The predicted shapes are obtained through careful echocardiographic and intraoperative measurements, and often differ for different annulus orifice sizes. For instance, in mitral rings the larger rings have larger minor axis and oblique axis dimensions relative to their major axis dimensions, and are more circular as opposed to D-shaped. The rings may also be three-dimensional and the relative heights around the rings may change for different sized rings. A mitral ring may have a higher anterior saddle relative to a posterior saddle, with the relative heights varying across the ring sizes. The ring may have varying flexibility around the ring periphery which also changes for different ring sizes. A bulge on the sewing cuff forms a step on the outflow side for ease of suturing, which may be indicated by a suture line.

Owner:EDWARDS LIFESCIENCES CORP

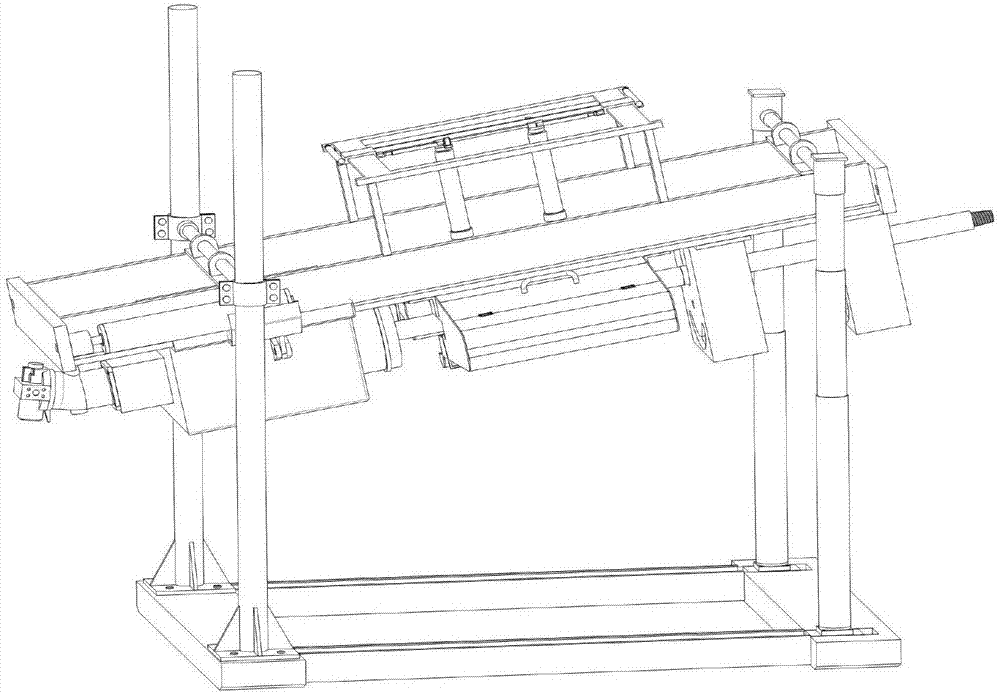

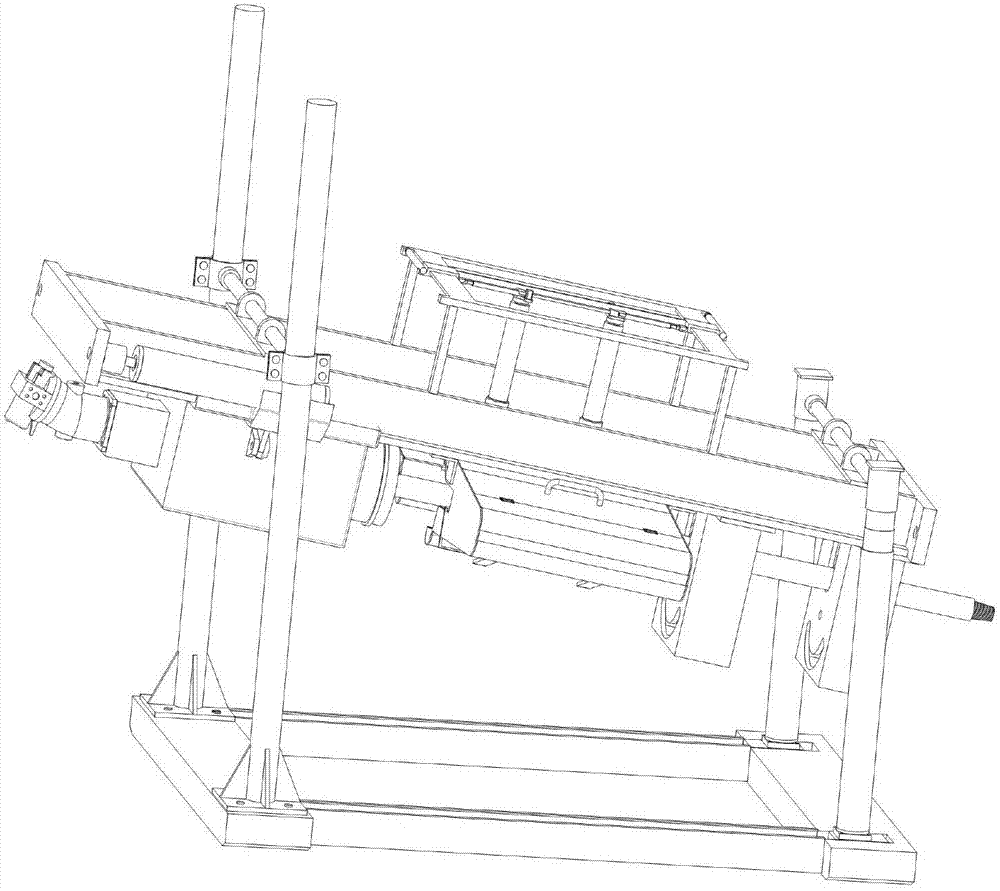

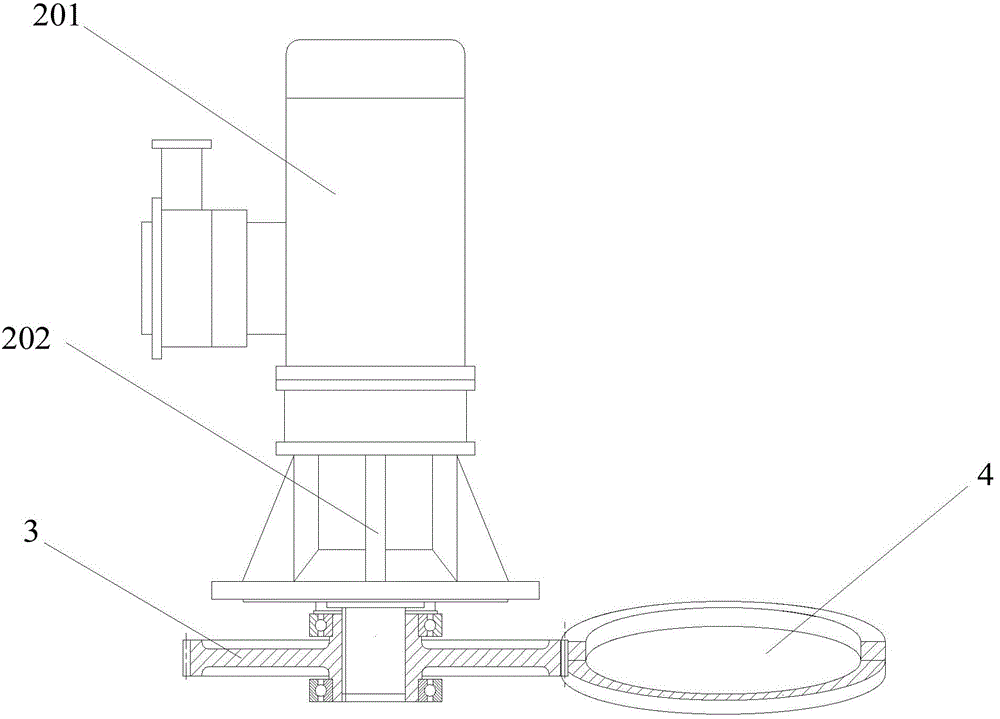

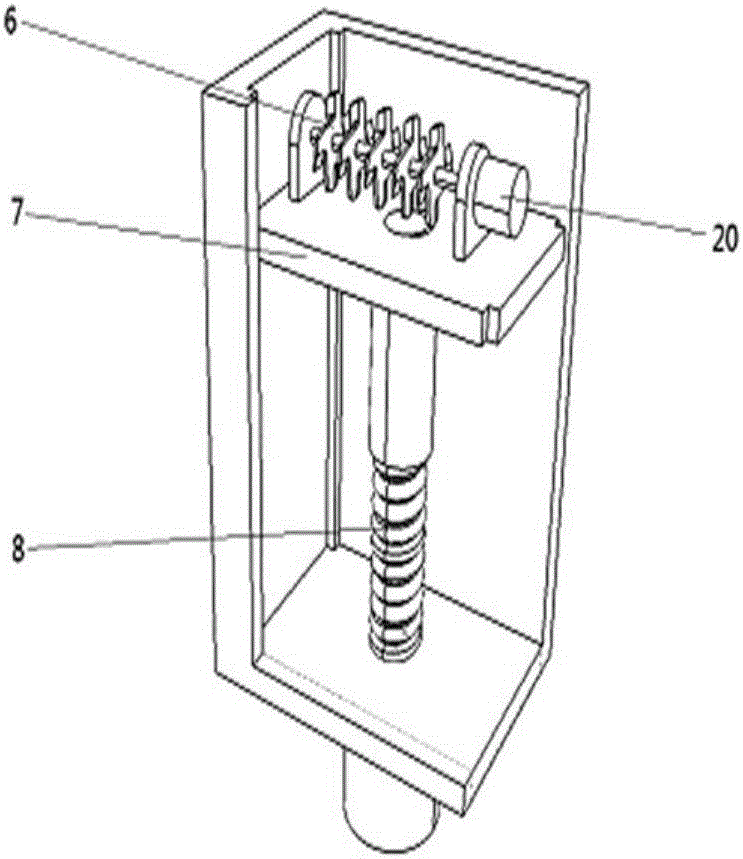

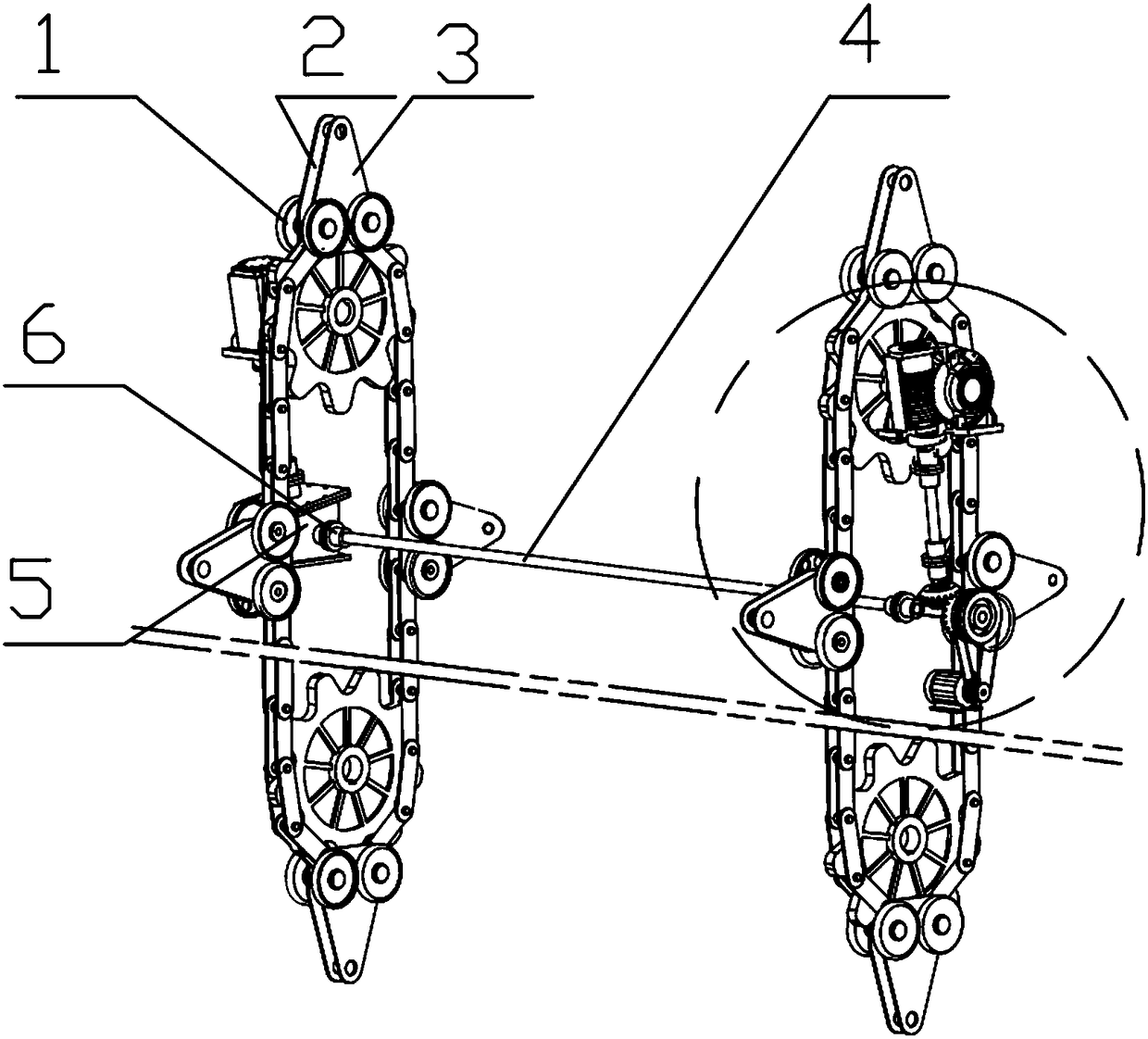

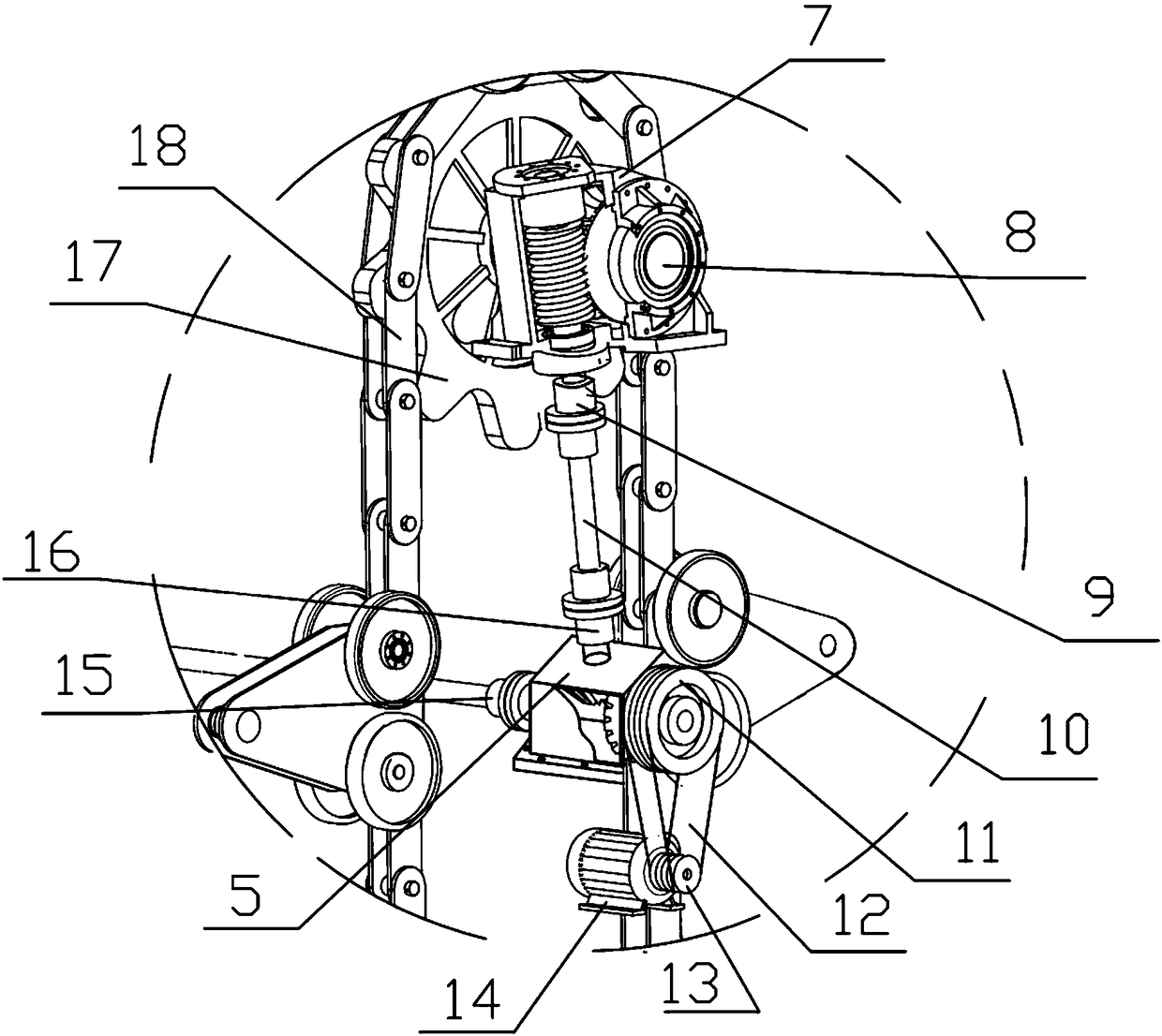

Ultralow pore continuous automatic rod assembling and disassembling hydraulic coal drill and rod assembling and disassembling method thereof

PendingCN107542416ARealize continuous continuous rodImprove work efficiencyDrilling rodsDrilling casingsManufacturing cost reductionOblique Axis

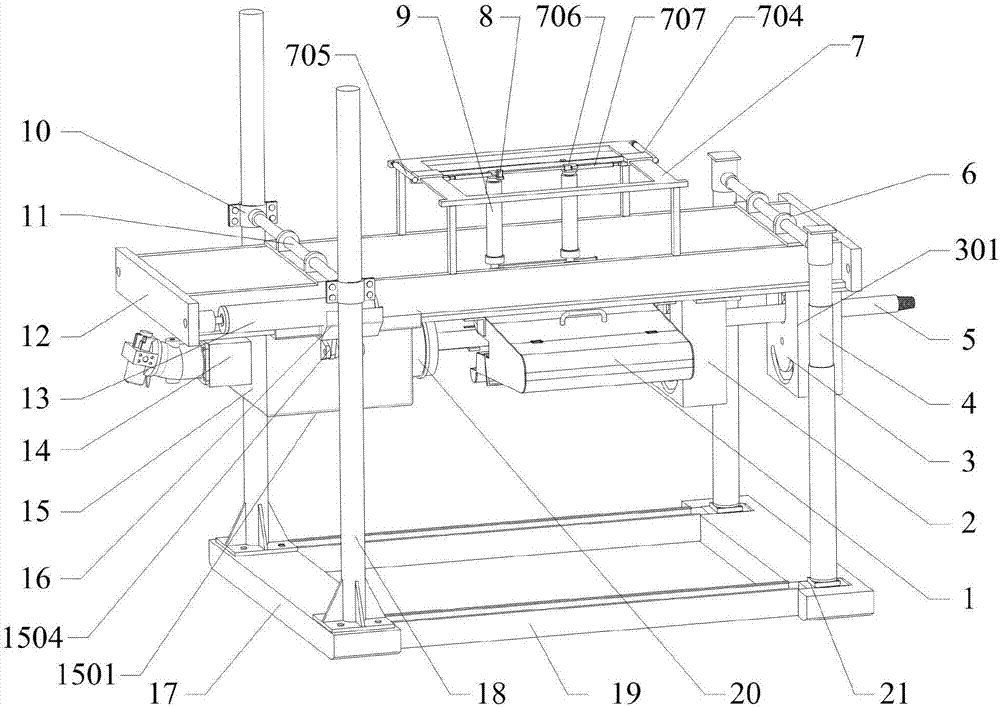

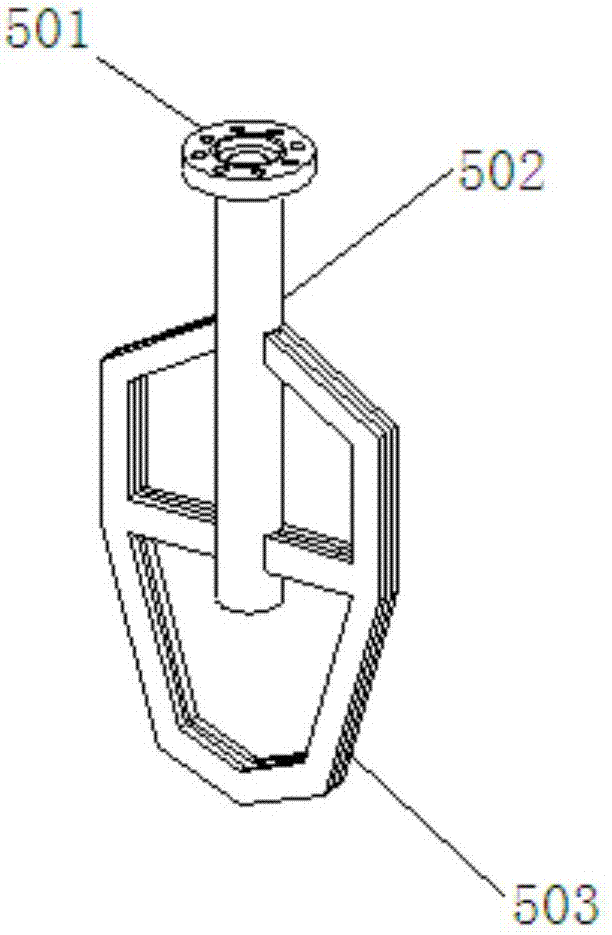

The invention discloses an ultralow pore continuous automatic rod assembling and disassembling hydraulic coal drill and a rod assembling and disassembling method thereof. The drill comprises two rod storing and disassembling boxes, a middle clamp, a front clamp, hydraulic telescopic support stand columns, a manipulator hydraulic support, hollow rotating platforms, manipulators, a working table, anoblique axis variable-displacement motor, a speed reducer, a rack base and a rubber sleeve hydraulic chuck. The oblique axis variable-displacement motor, the speed reducer, the rubber sleeve hydraulic chuck, the rod storing and disassembling boxes and the clamps are installed on the lower portion of the working table, the manipulator hydraulic support is installed on the upper portion of the working table, and a working method that the two rod storing and disassembling boxes act together, and the manipulators conduct rod assembling and disassembling from the bottom of the drill is adopted. The drill has the obvious advantages that structural arrangement is ingenious, the drill height is greatly lowered, operation is convenient, the continuous automatic rod assembling and disassembling functions are achieved, the work efficiency is improved, the security work is safe and stable, and the manufacturing cost is lowered; the problem that an existing drill cannot drill an ultralow pore, andcontinuous rod assembling and disassembling cannot be conducted is solved.

Owner:ANHUI UNIV OF SCI & TECH

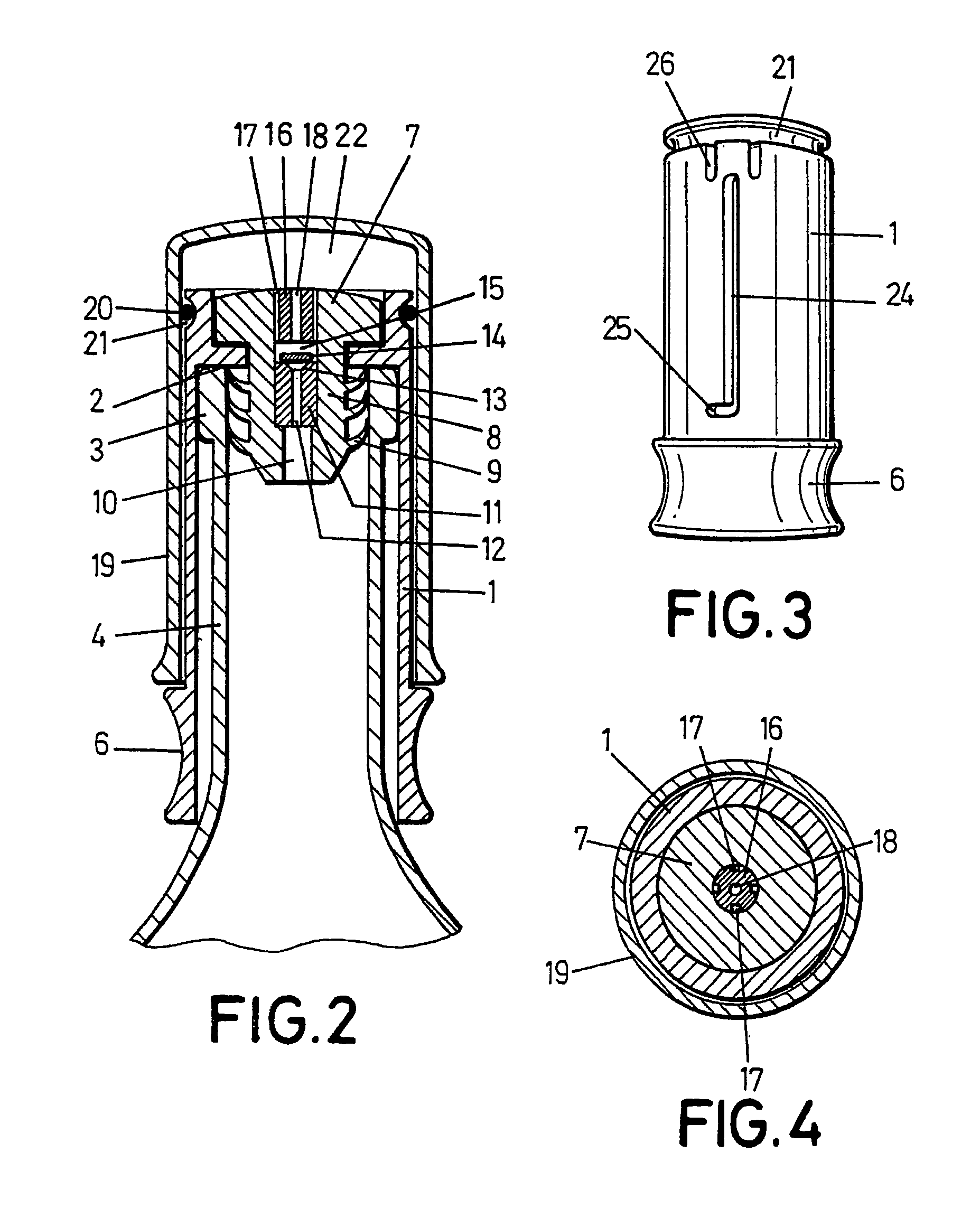

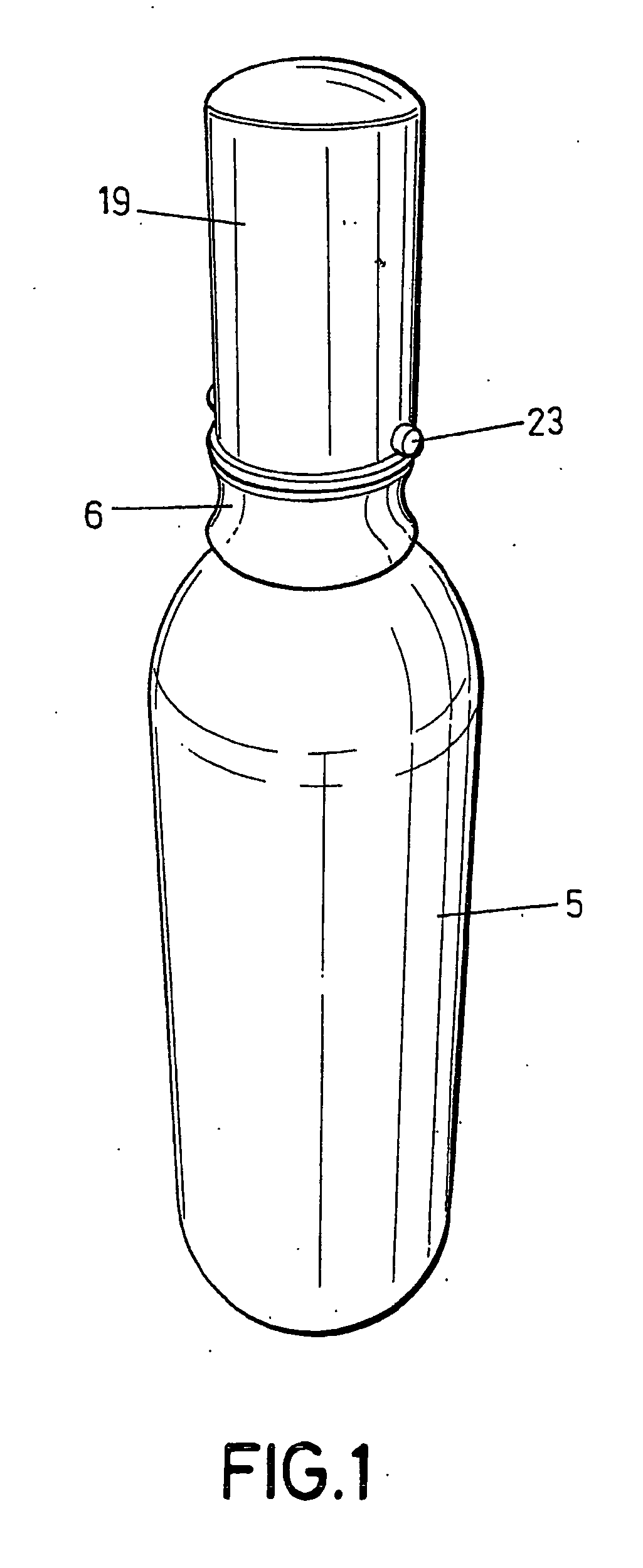

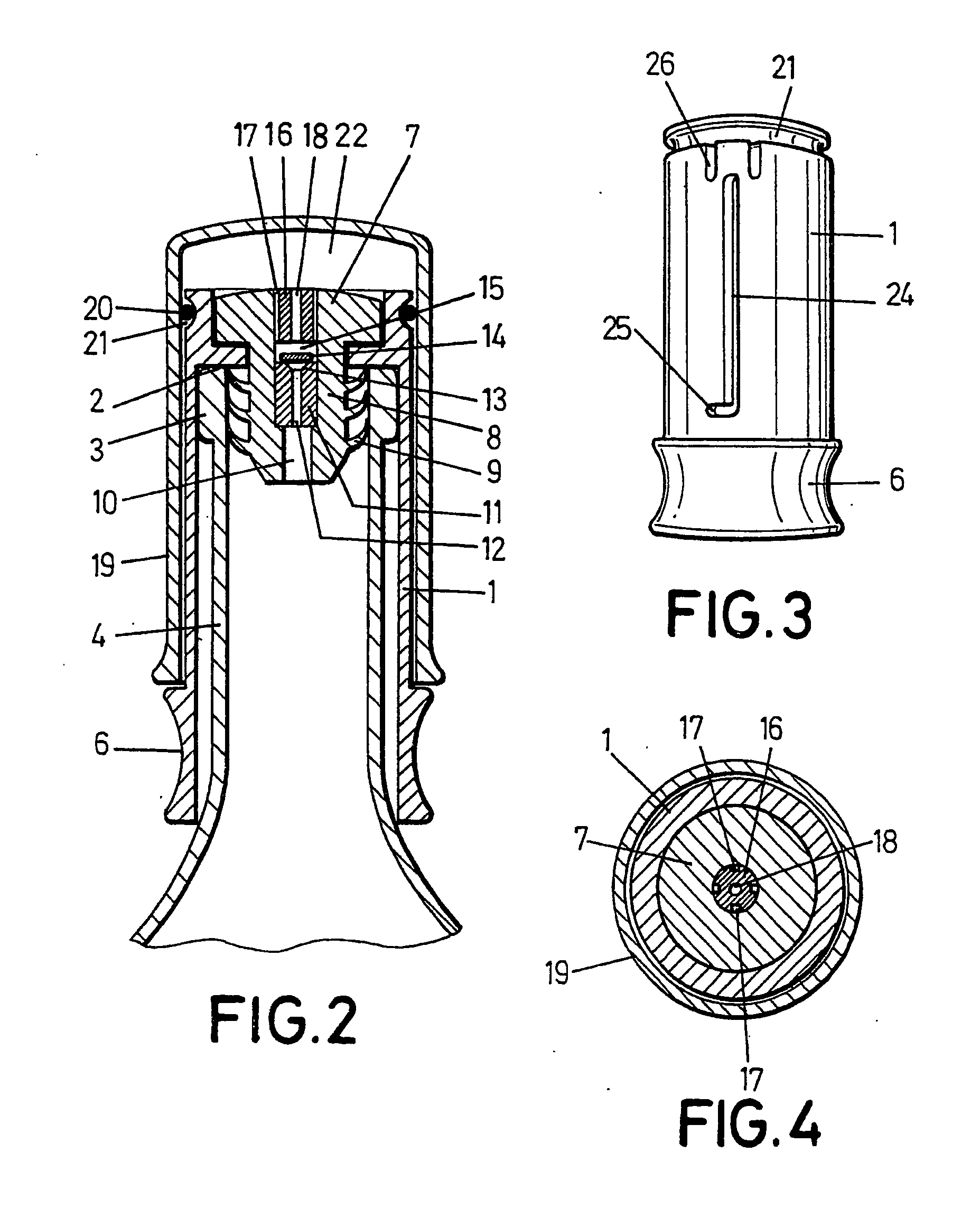

Vacuum pump for bottles

InactiveUS7086427B2Liquid fillingPackaging by pressurising/gasifyingTracheotomyTracheostomy tube insertion

The invention relates to a hemi-cannula for tracheotomy patients, comprising a main tubular body (1.1) which is made from a suitable flexible material and which comprises peripheral end fixing flanges (1.2 and 1.3). One of said flanges (1.2), which is intended to be disposed inside the trachea next to the inner face of same, takes the form of a wing comprising a cylindrical surface with an oblique axis in relation to an axis perpendicular to the main axis of the main body (1.1). The other flange (1.3) takes the shape of a truncated cone comprising a larger outer base. According to the invention, a conduit forming the main tubular body passes through the centre of both of said flanges. The invention is suitable for producing tracheotomy cannulas.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

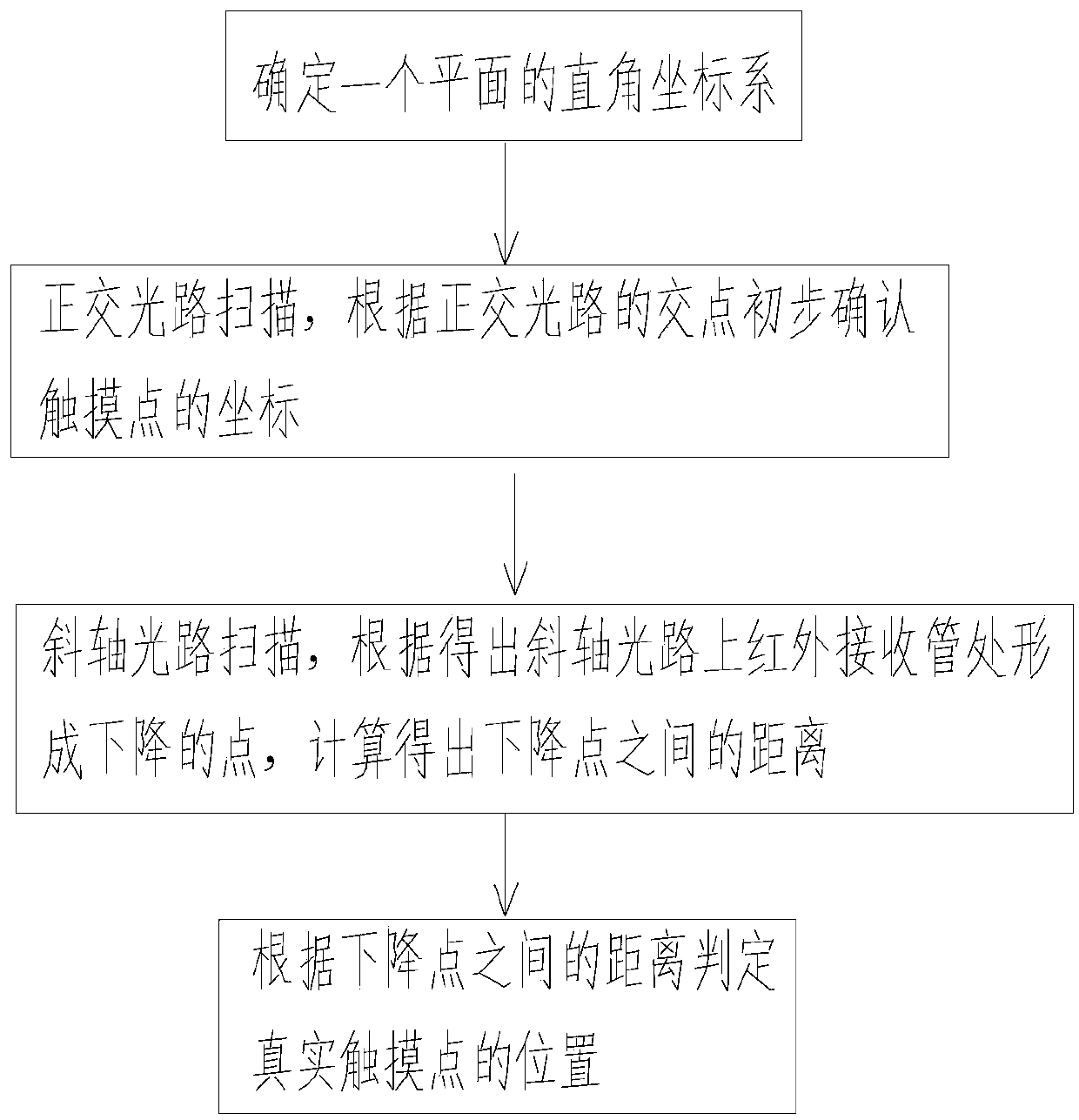

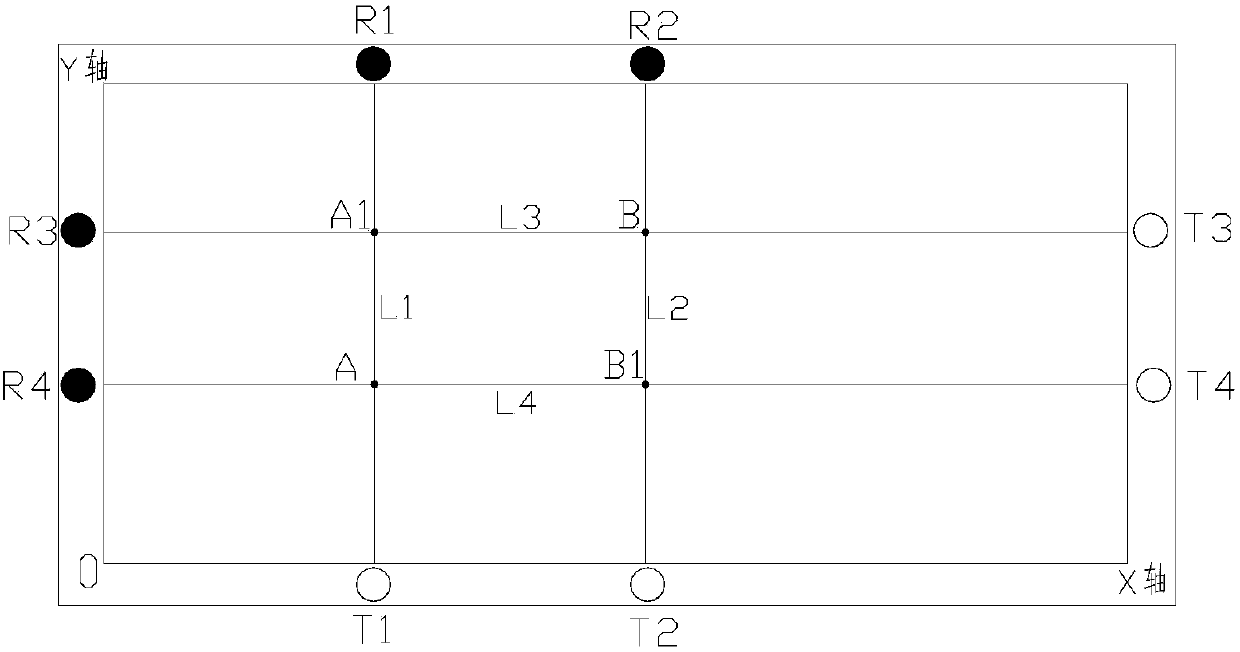

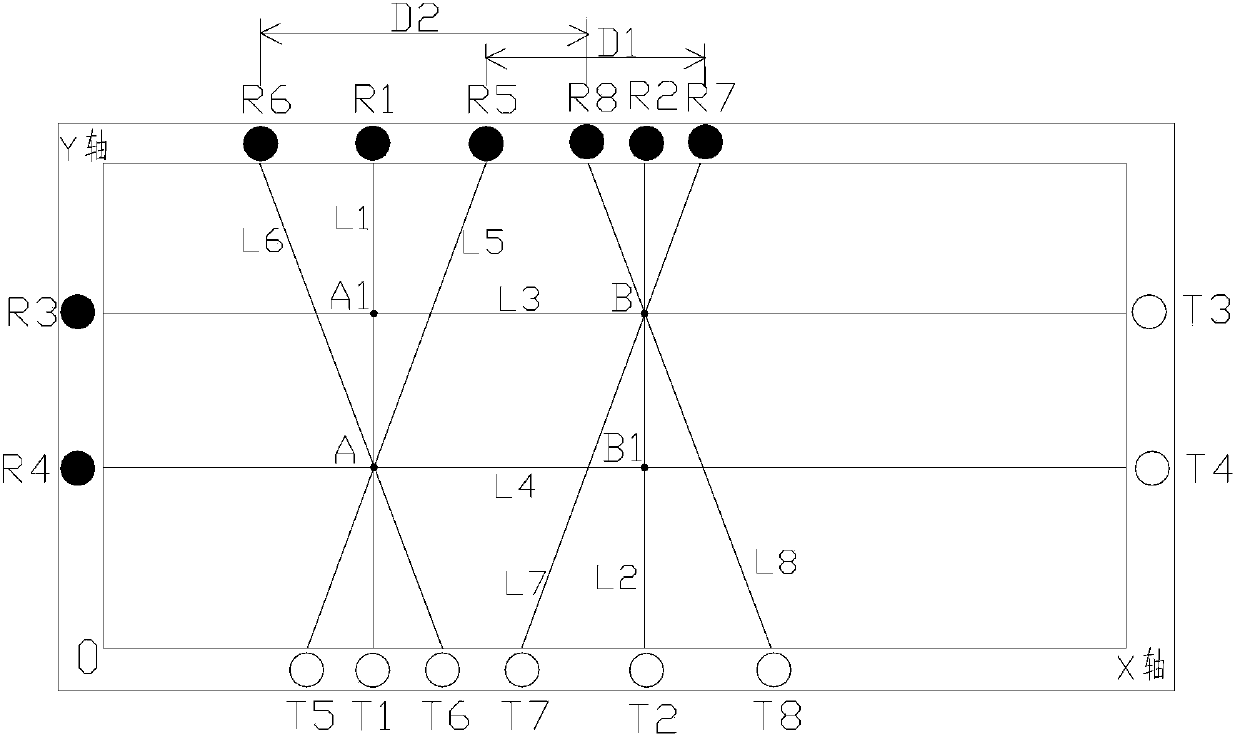

Multi-point touch identification method for infrared touch screen

InactiveCN103365492AAccurate confirmationFast operationInput/output processes for data processingOptical pathOblique Axis

The invention discloses a multi-point touch identification method for an infrared touch screen, which comprises the steps of determining a rectangular plane coordinate system by taking one corner of the touch screen as the origin of coordinates; scanning the infrared germinate transistors on the screen in the X axis and Y axis directions of the rectangular coordinate system, forming orthogonal light paths according to the shield signals of touch points, and primarily determining the touch point by the crossing point of the orthogonal light paths; performing oblique axis light path scanning in the X or Y axis, and calculating the linear distance between the lowering points, wherein crossing lines are formed by the oblique axis light path at the crossing point of the orthogonal light paths in the X or Y axis and the lowering points are formed by the crossing lines at an infrared receiving tube; and determining the position of the real touch point according to the crossing point of the orthogonal light paths and the linear distance between the lowering points. The multi-point touch identification method for the infrared touch screen has the advantages of accurately determining the real touch point by scanning the primarily determined point by an oblique axis light path scanning mode, and being fast in computing speed without causing errors due to the abnormity of a certain LED (light emitting diode) on the touch screen.

Owner:陈云波

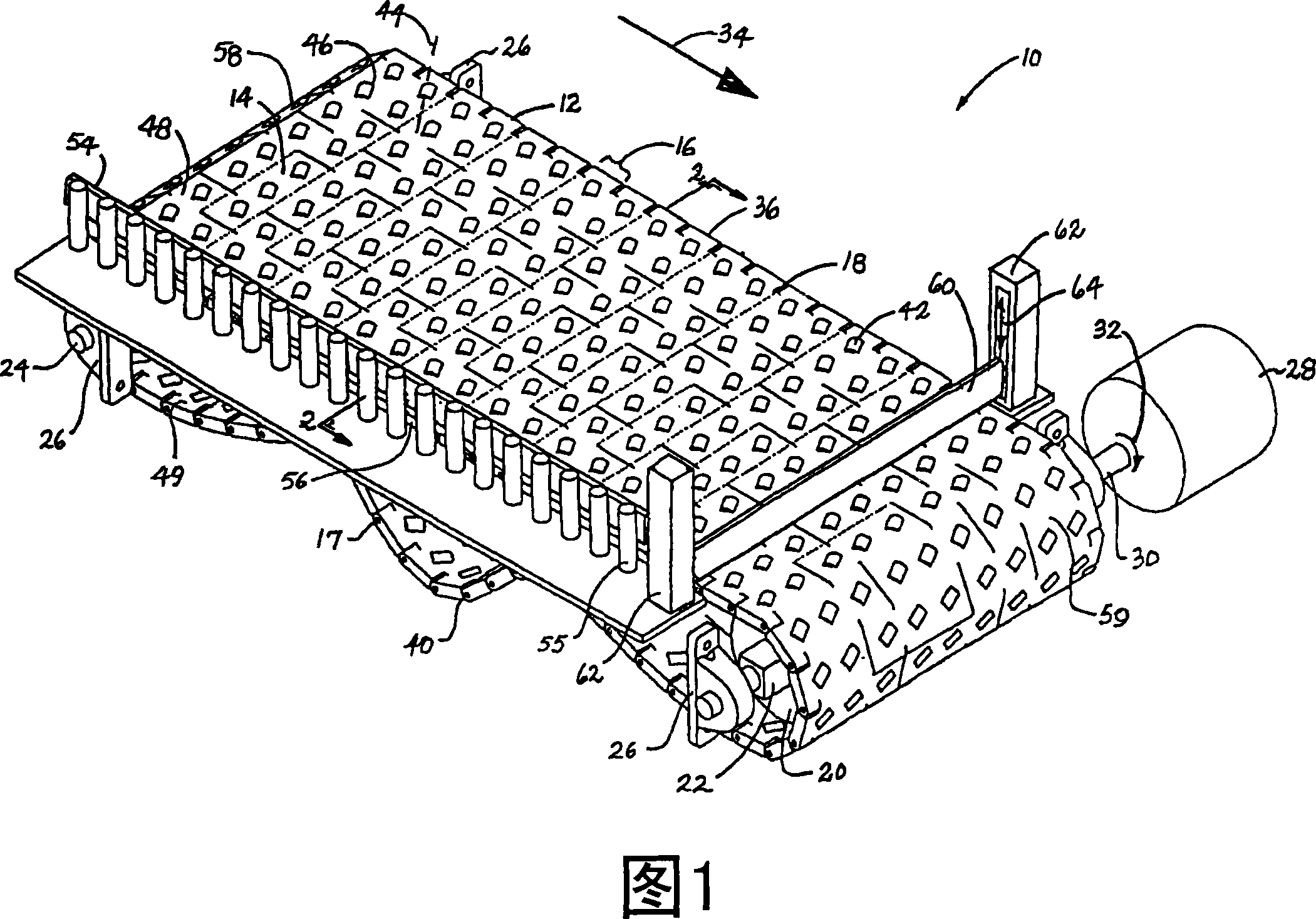

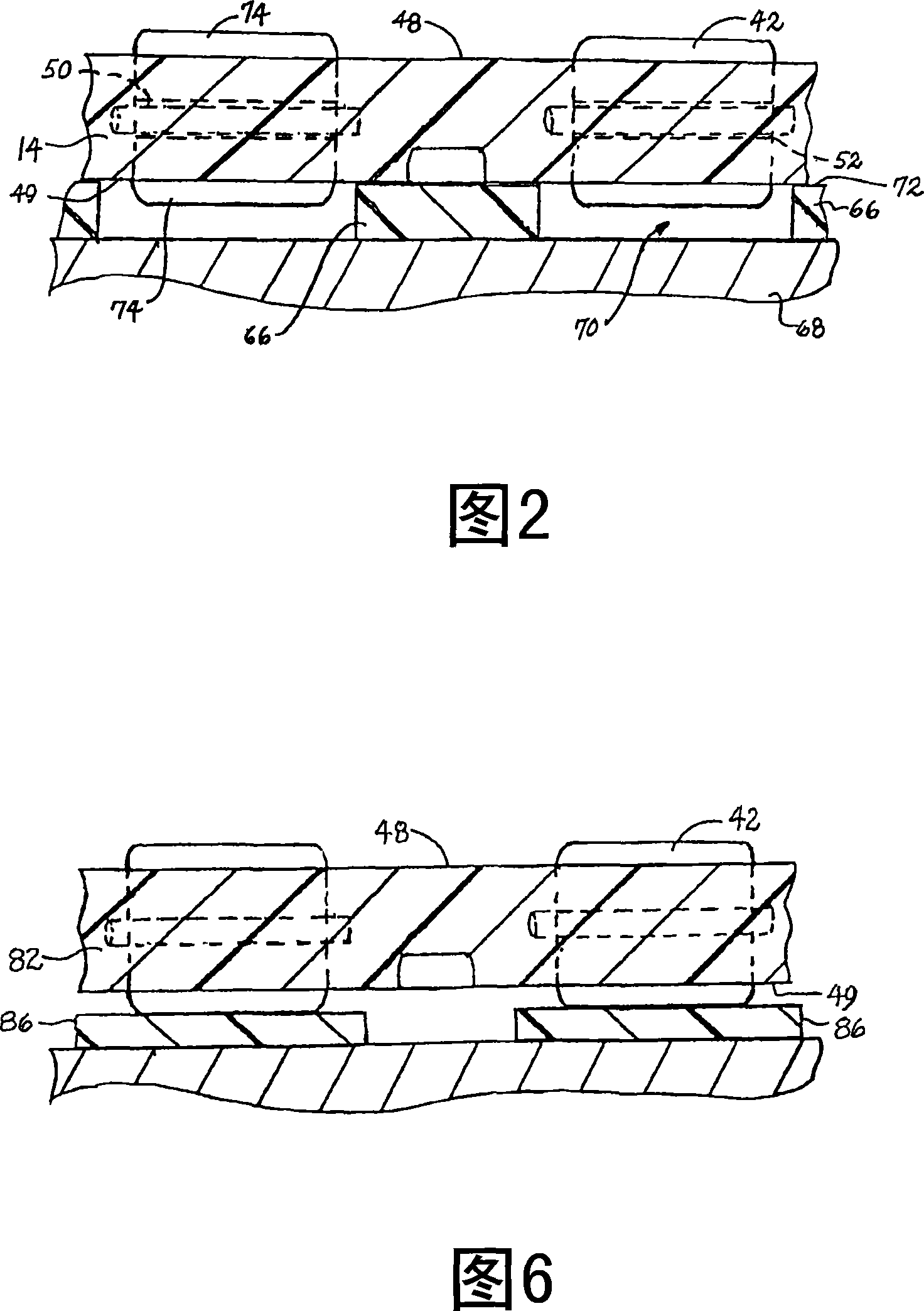

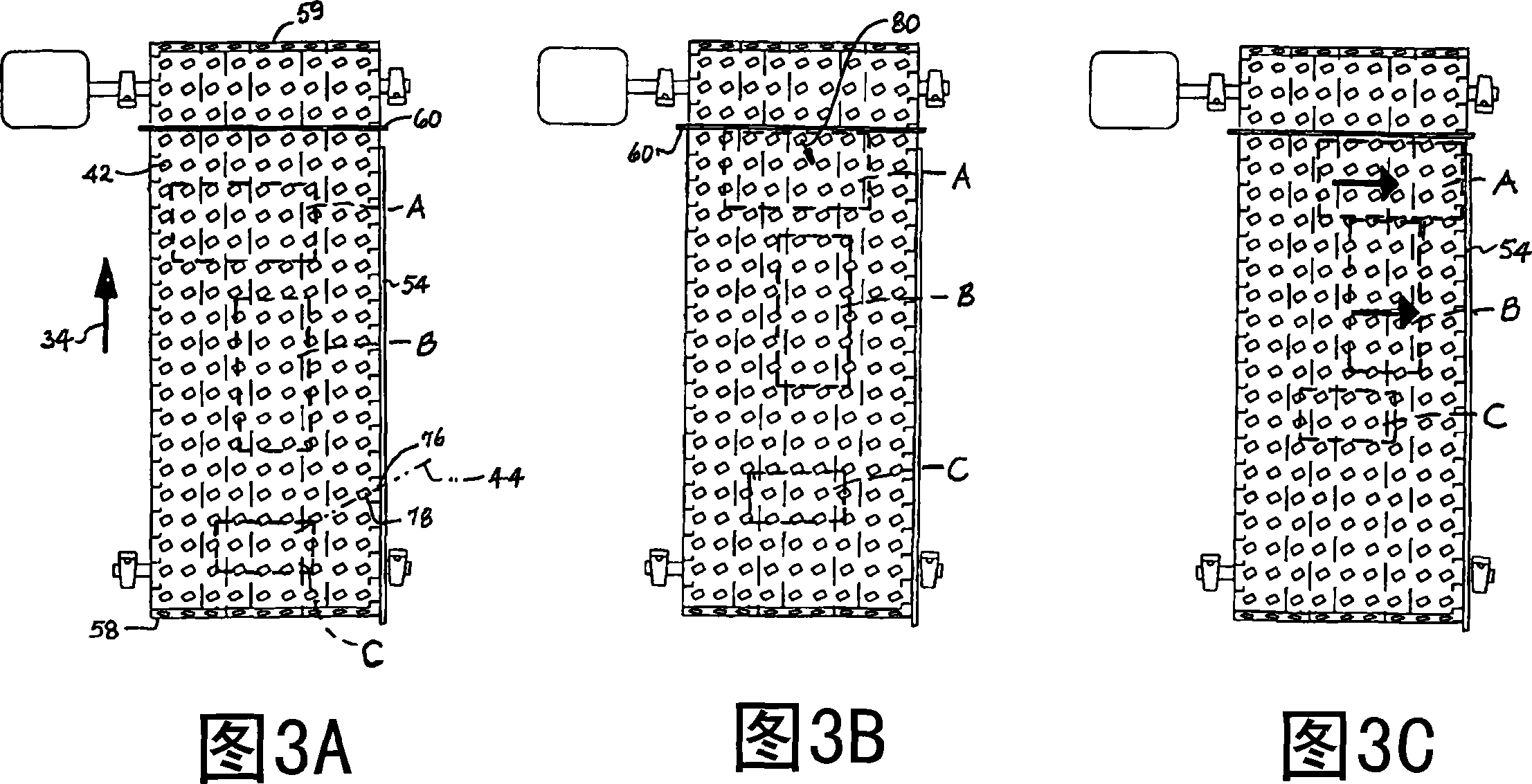

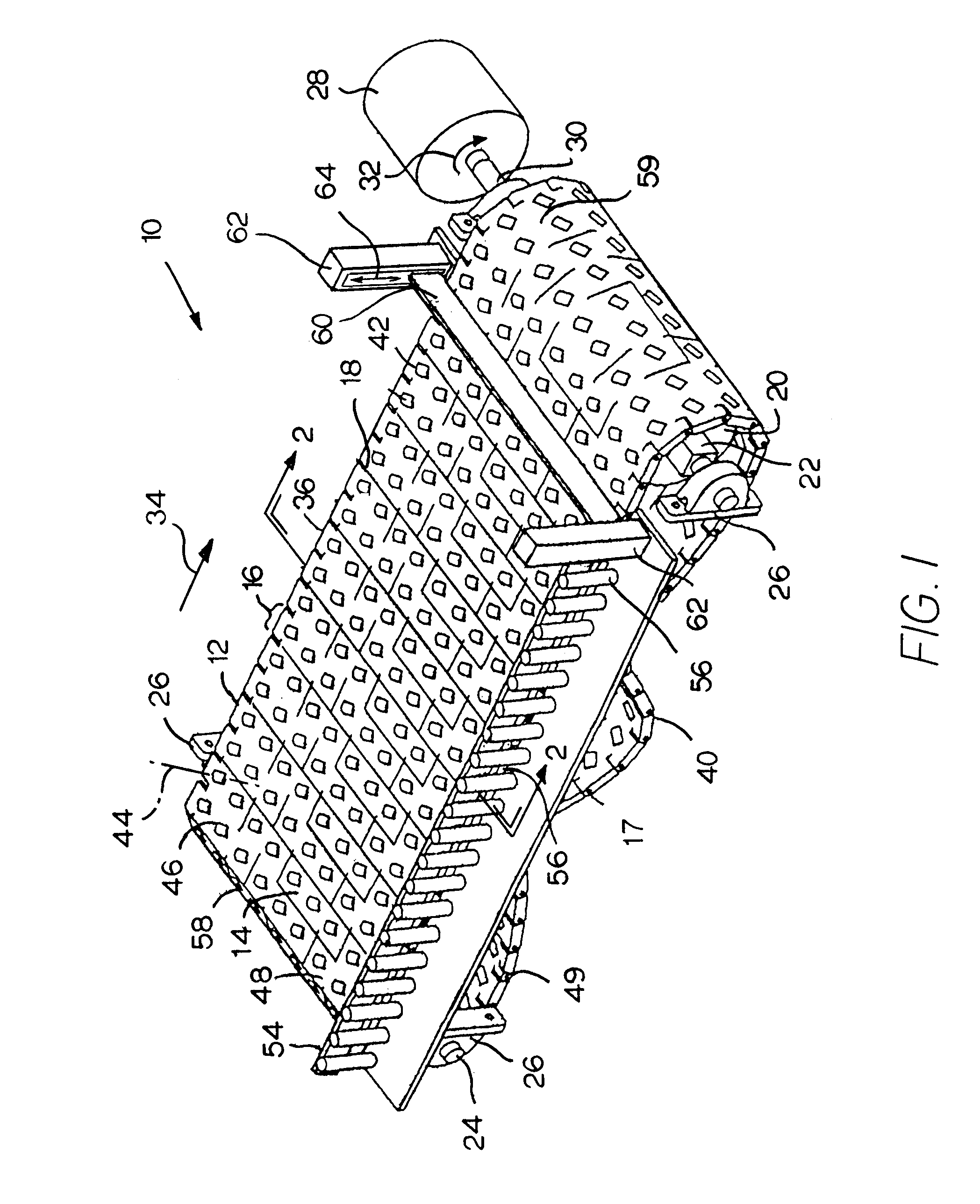

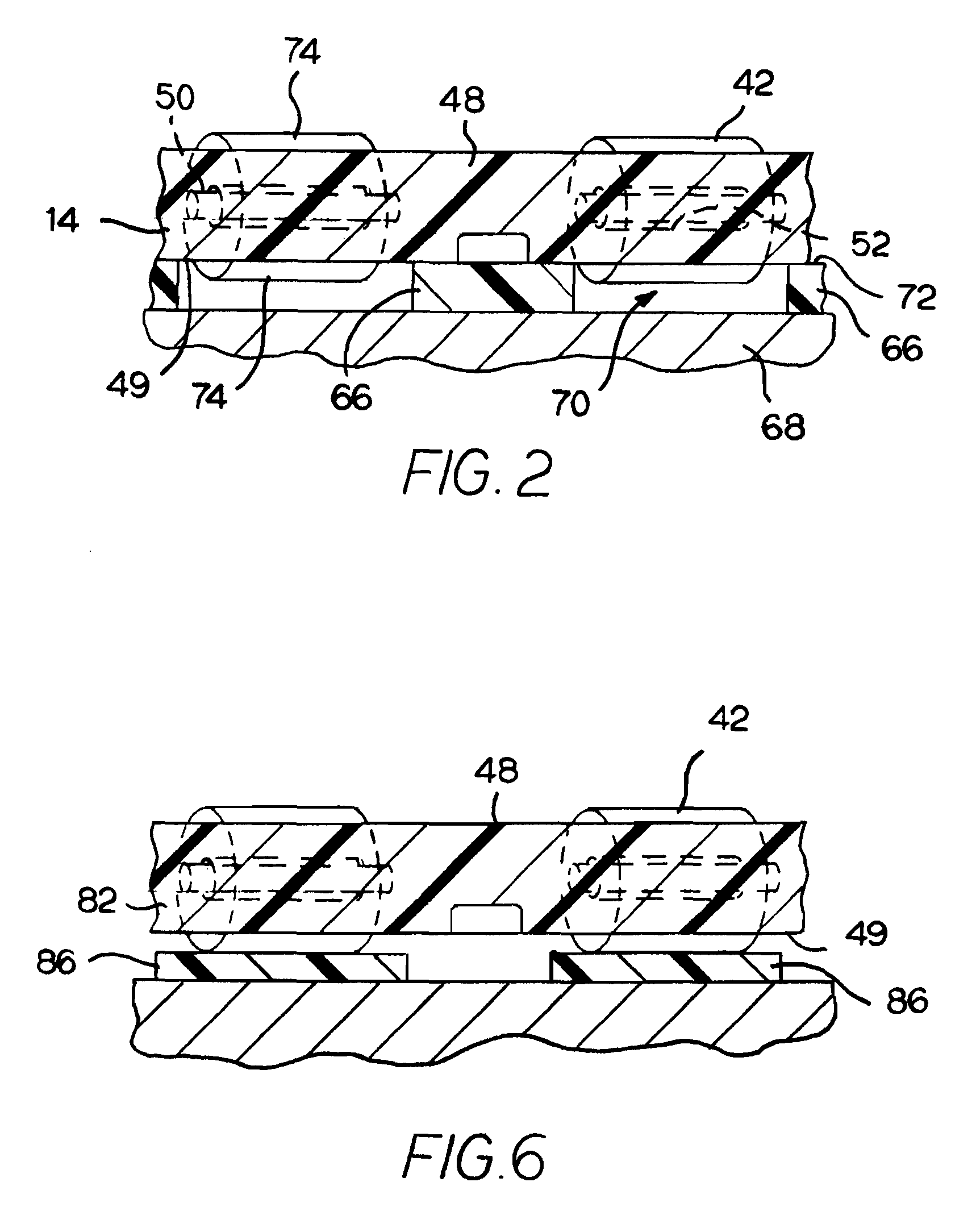

Roller-belt conveyor for accumulating and moving articles laterally across the conveyor

Owner:LAITRAM LLC

Axial piston machine having a device for the electrically proportional adjustment of its volumetric displacement

Owner:DANFOSS POWER SOLUTIONS INC

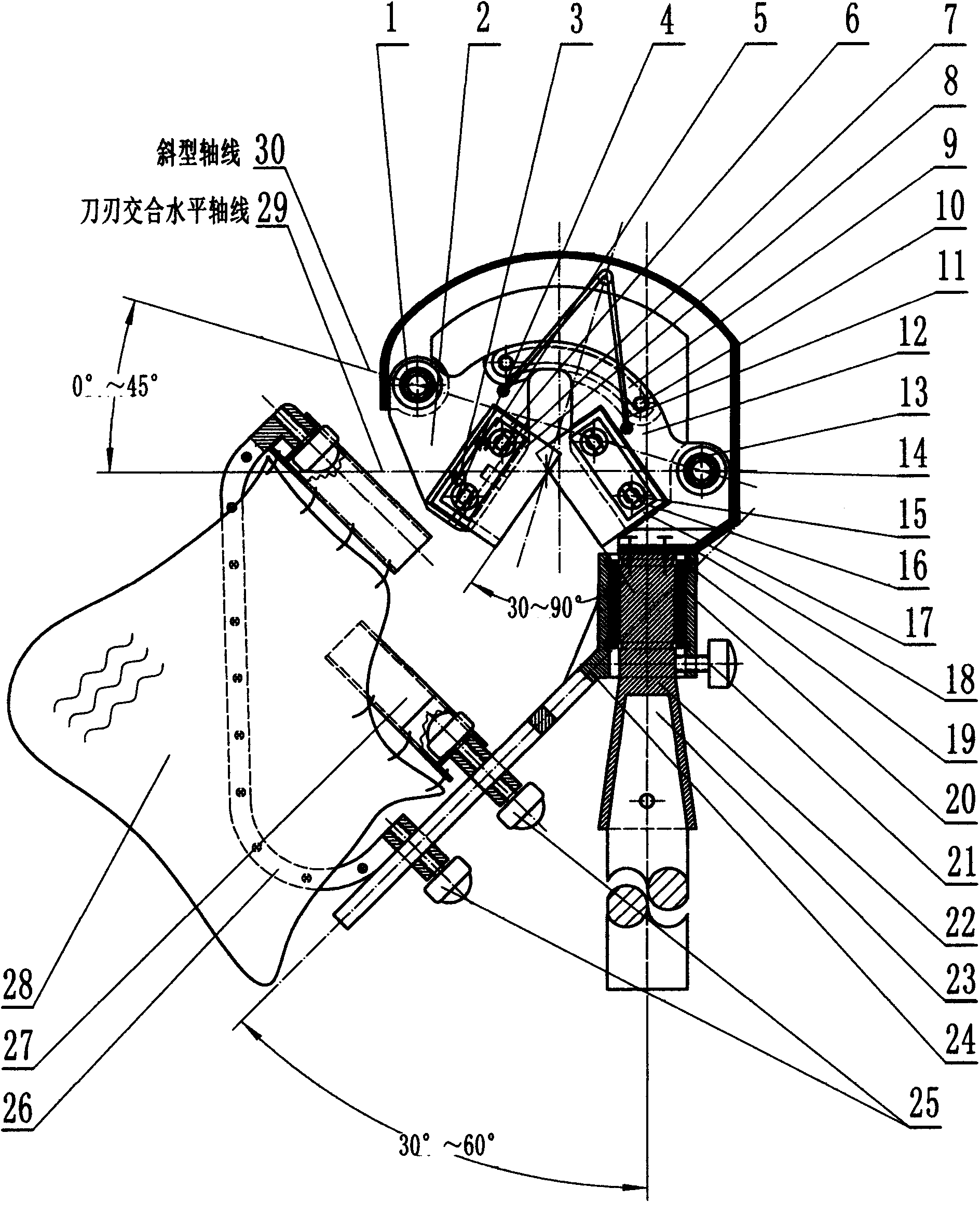

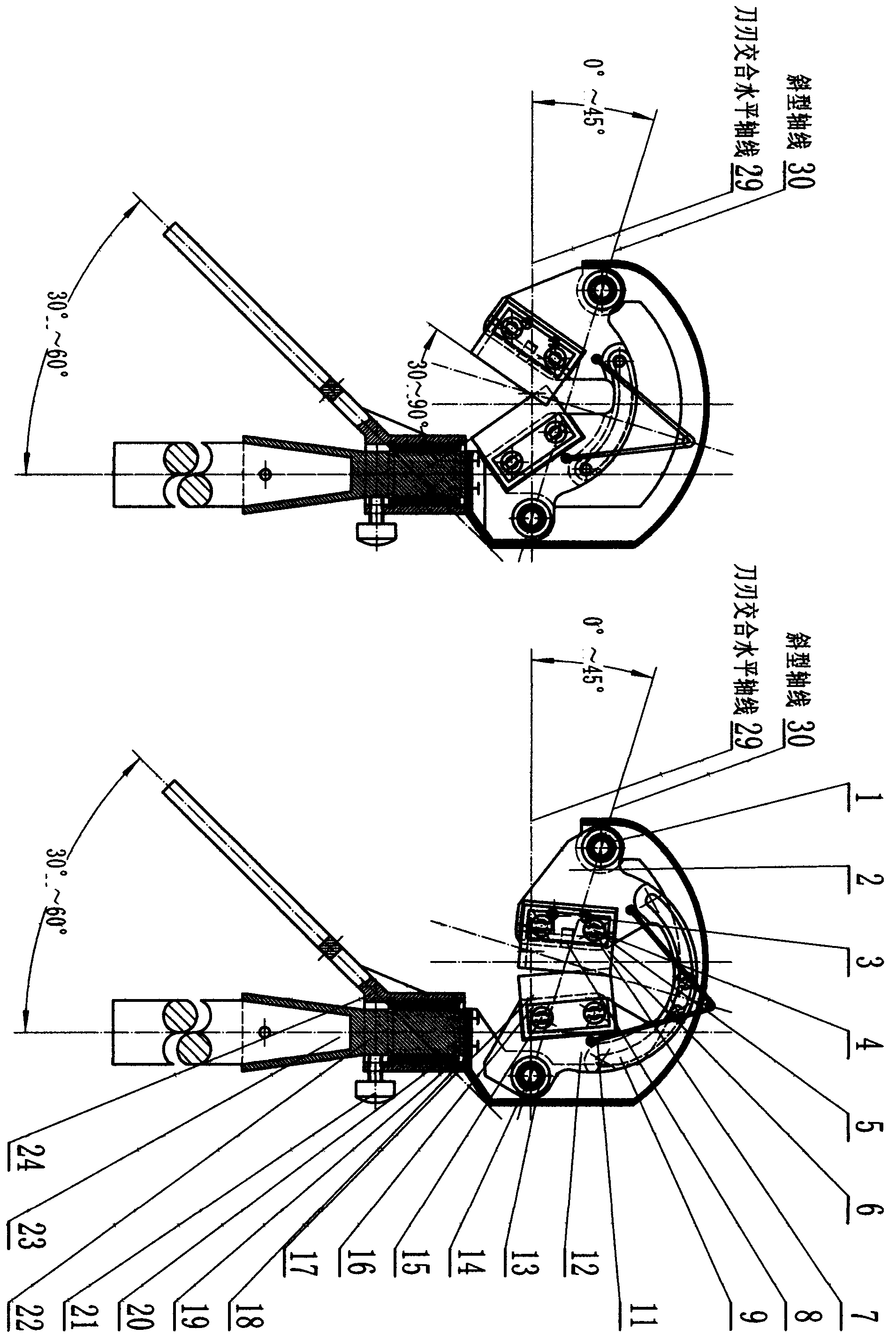

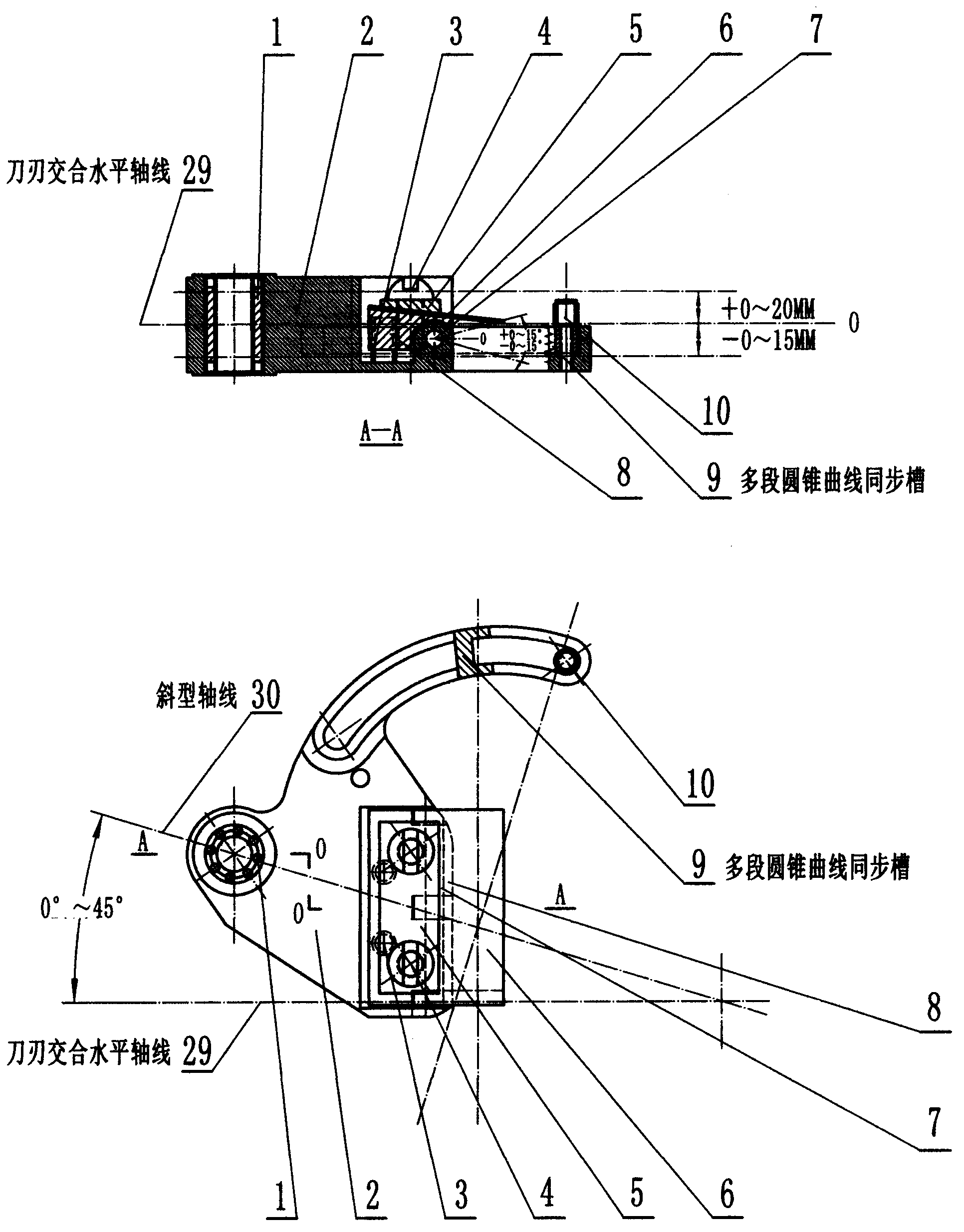

Oblique-axis horizontal-axis-knife automatic cutting-pulling harvester for fruits on high branches

The invention relates to an automatic cutting-pulling tool for manual harvesting of fruits on high branches (such as anise, haw, Chinese prickly ash, apple, apricot, longan and litchi) by orchard workers and provides an oblique-axis horizontal-axis-knife automatic cutting-pulling harvester for fruits on high branches. The harvester comprises a high-axle-hole automatic cutter seat assembly, a low-axle-hole automatic cutter seat assembly, an oblique axis seat handle assembly, an adjustable fruit receiving frame assembly and a return spring. Spare and accessory parts of the harvester are interchangeable, and supportive of standardized production. Through usage of the oblique-axis horizontal-axis-knife automatic cutting-pulling harvester for fruits on high branches, workers on the ground only need to roughly aim at fruits on high branches and pull back the fruits, so the fruits can be easily, conveniently, quickly, safely and automatically cut and harvested.

Owner:方孙典

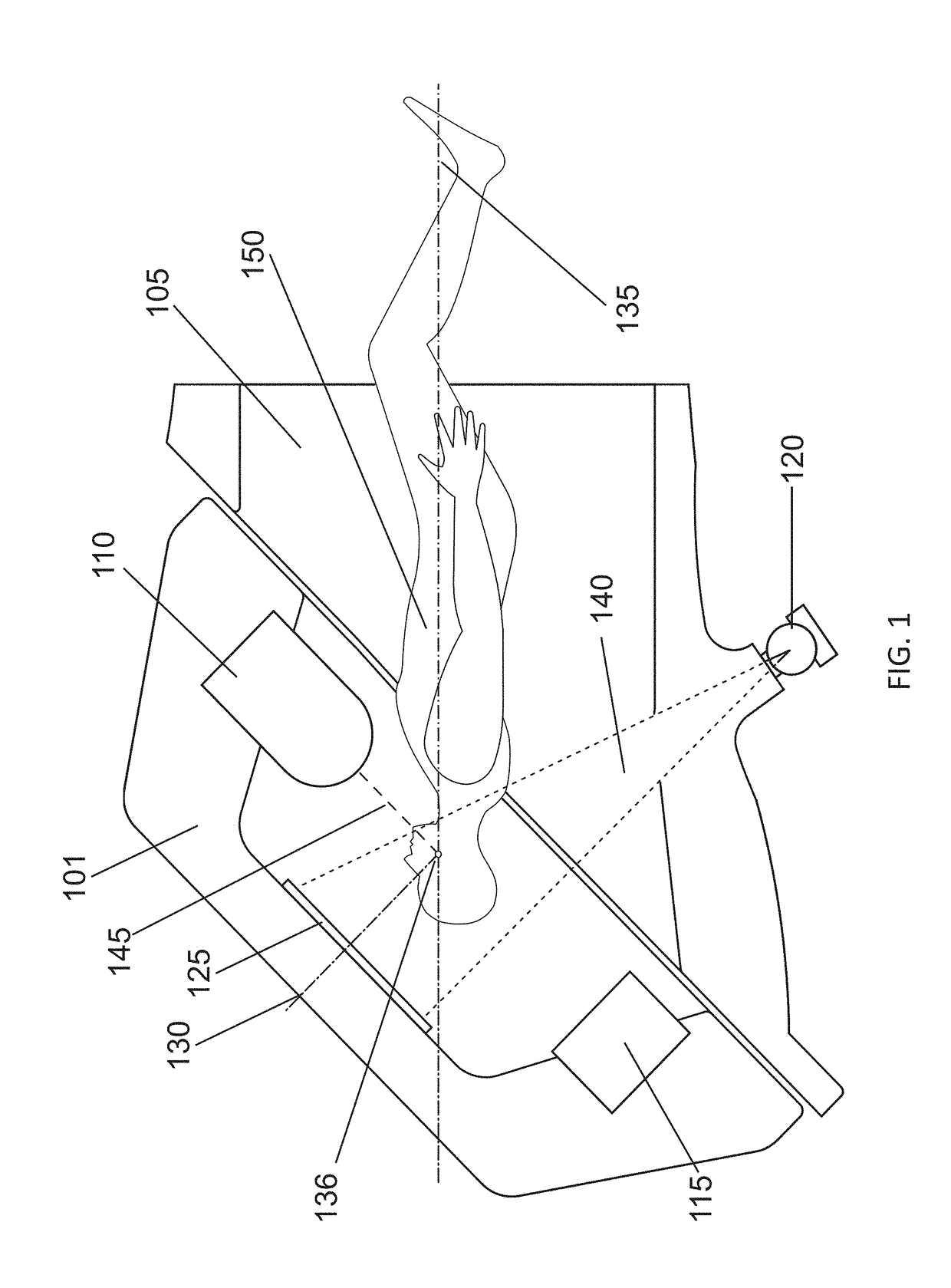

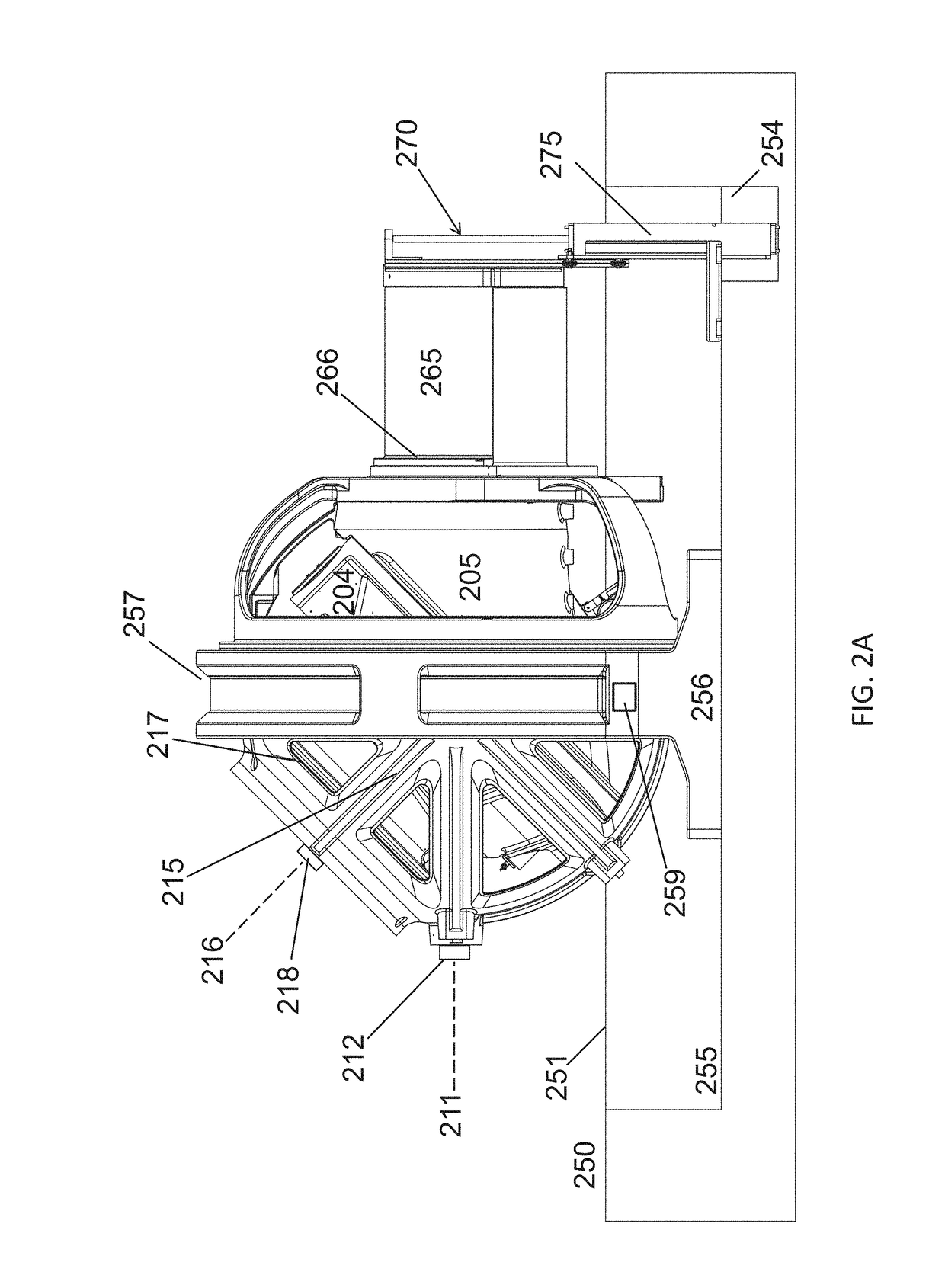

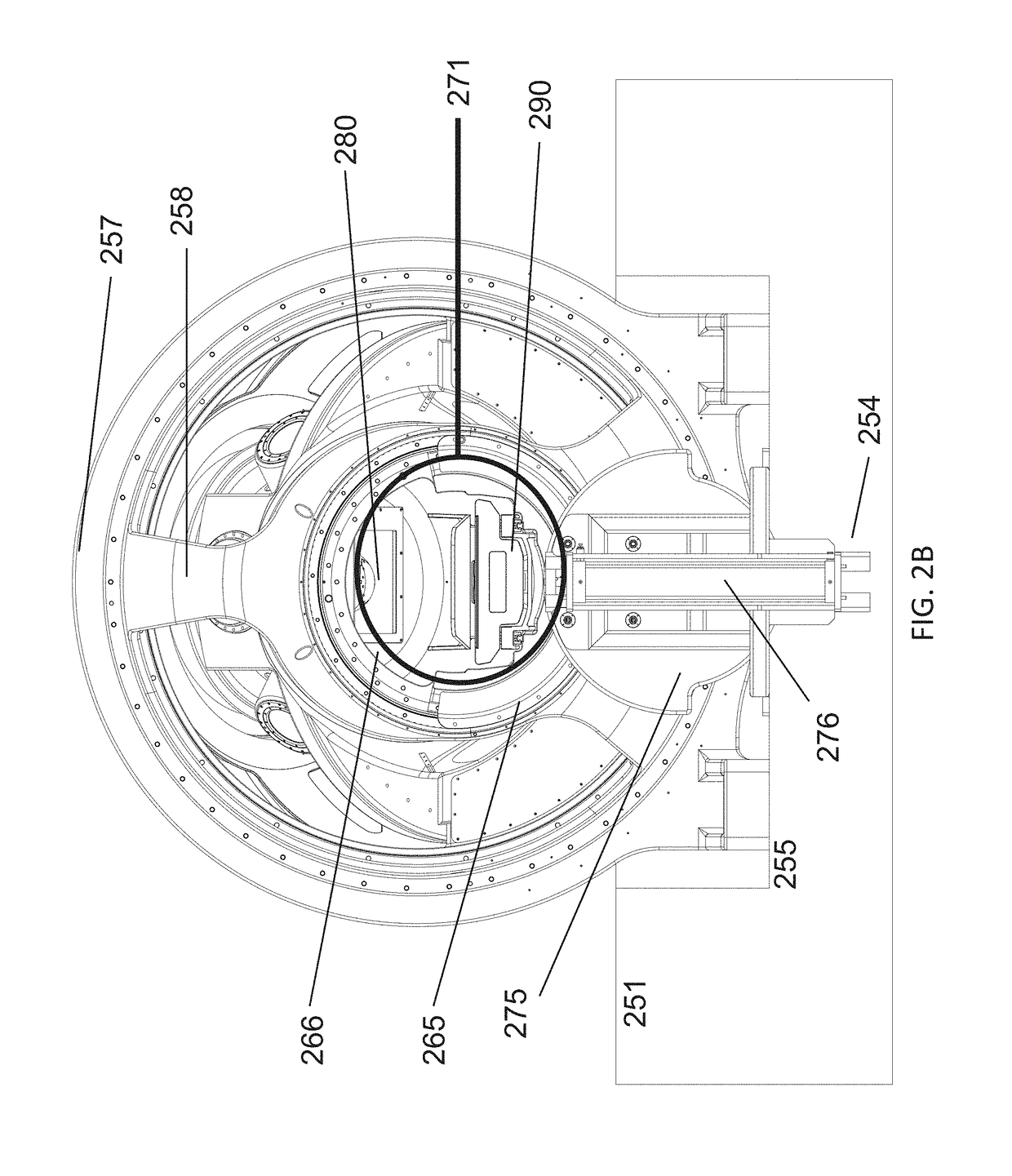

Self-shielded, integrated-control radiosurgery system

ActiveUS20190069856A1Small footprintHelp accuracyPatient positioning for diagnosticsSterographic imagingRadiosurgeryAutomatic control

A self-shielded and computer controlled system for performing non-invasive stereotactic radiosurgery and precision radiotherapy using a linear accelerator mounted within a two degree-of-freedom radiation shield coupled to a three-degree of freedom patient table is provided. The radiation shield can include an axial shield rotatable about an axial axis and an oblique shield independently rotatable about an oblique axis, thereby providing improved range of trajectories of the therapeutic and diagnostic radiation beams. Such shields can be balanced about their respective axes of rotation and about a common support structure to facilitate ease of movement. Such systems can further include an imaging system to accurately deliver radiation to the treatment target and automatically make corrections needed to maintain the anatomical target at the system isocenter. Various subsystems to automate controlled and coordinated movement of the movable shield components and operation of the treatment related subsystems to optimize performance and ensure safety are also provided.

Owner:ZAP SURGICAL SYST INC

Pallet-forming roller-belt conveyor

Owner:LAITRAM LLC

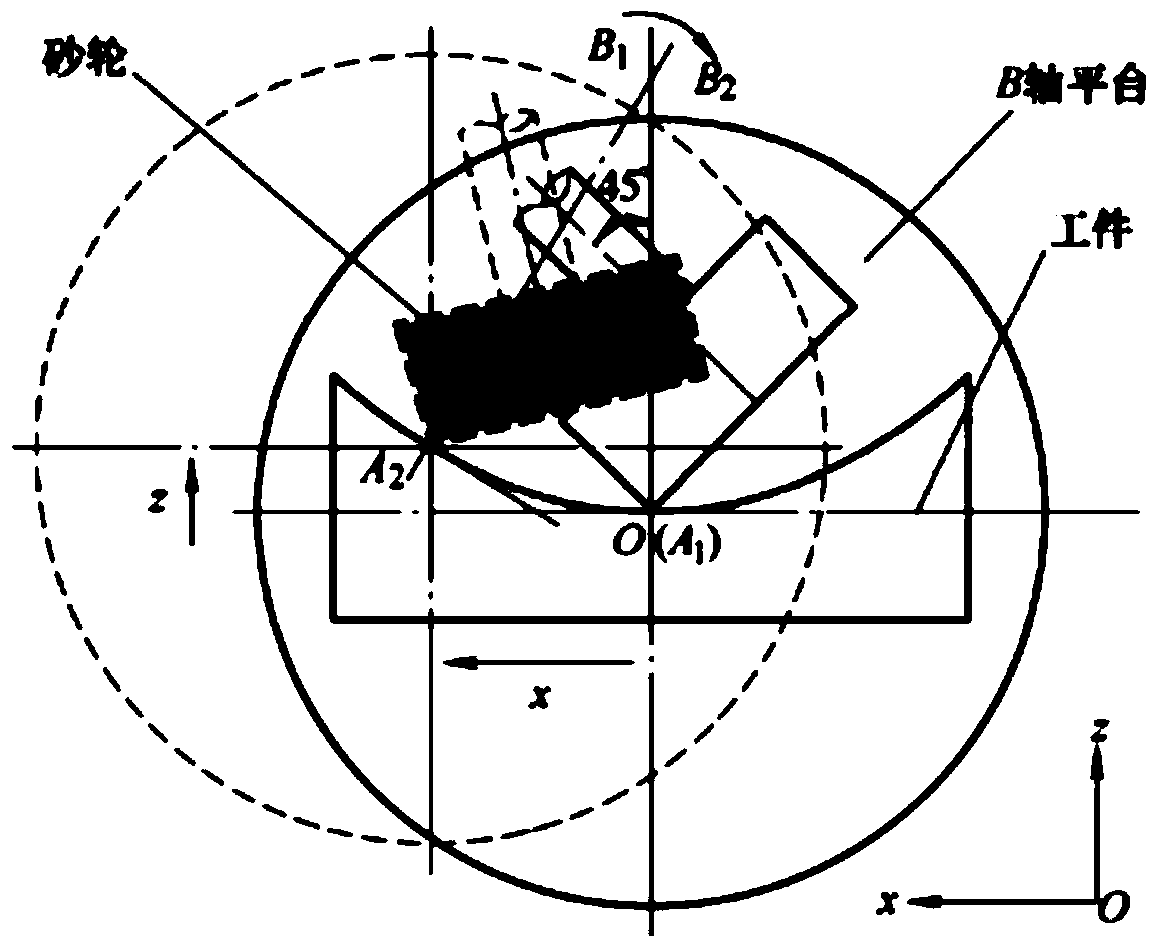

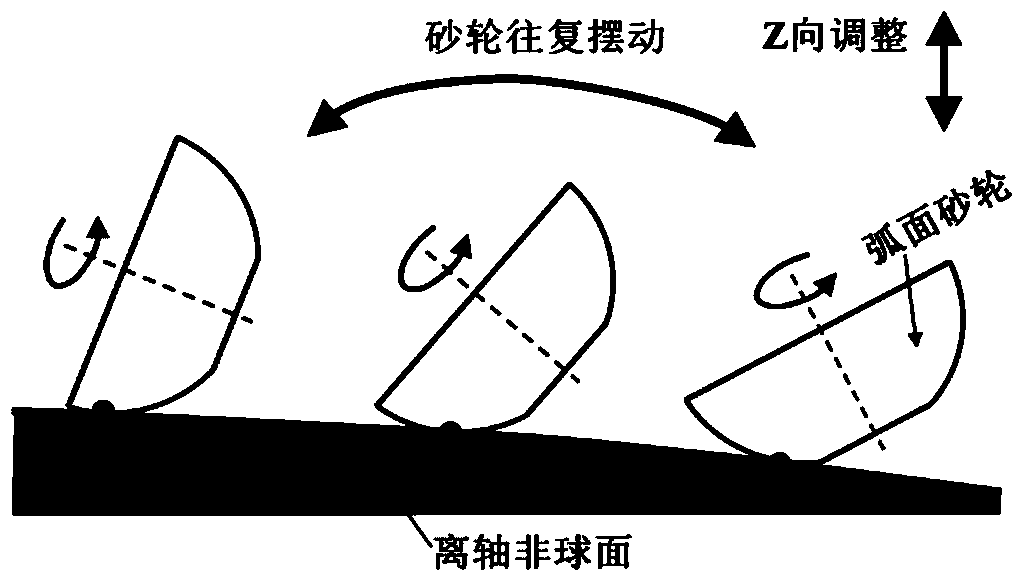

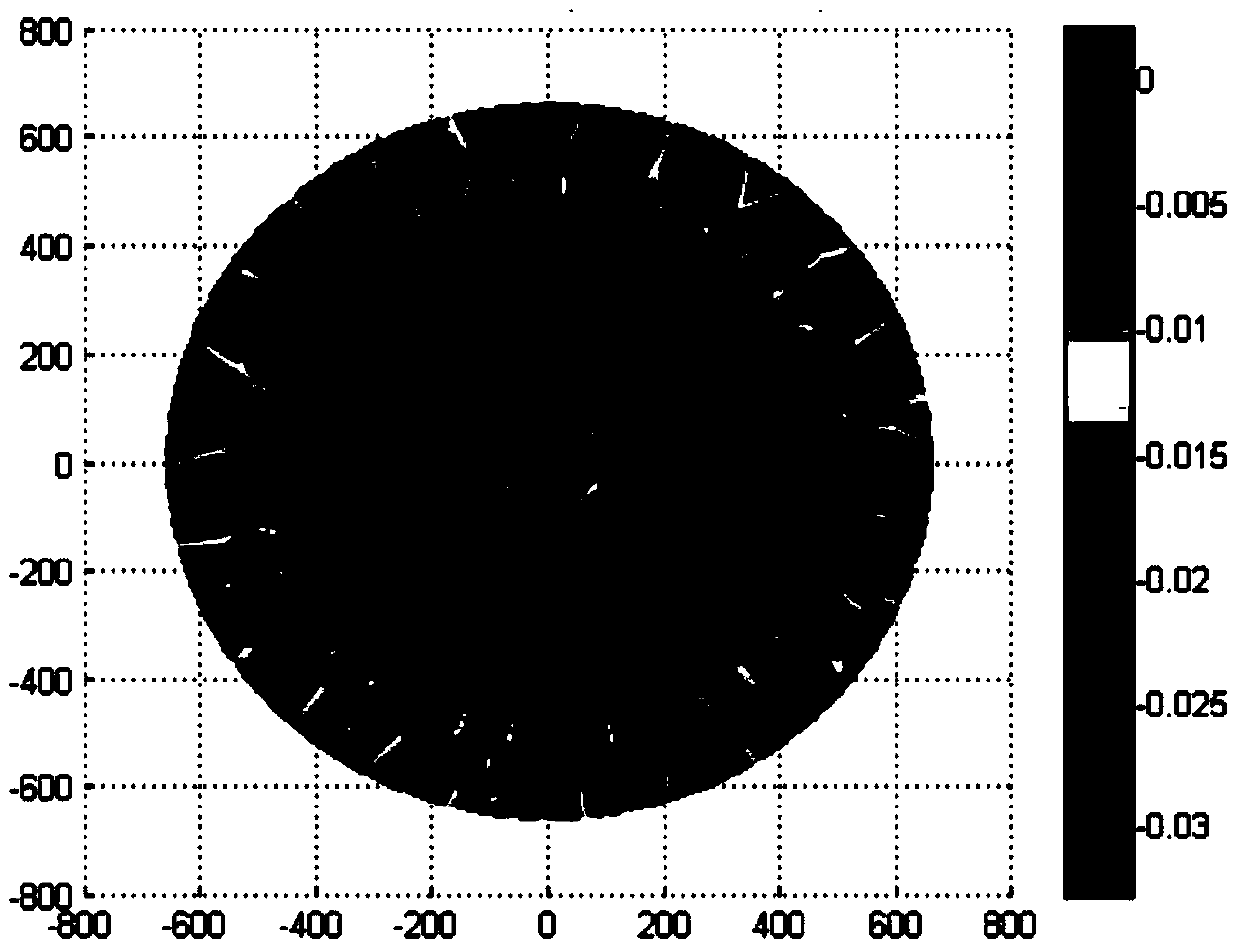

Grinding wheel home position automation shaping and milling processing method of off-axis aspheric reflector

ActiveCN103737451ARealize in-situ automatic shapingRealize functionOptical surface grinding machinesLensNumerical controlPost processor

The invention discloses a grinding wheel home position automation shaping and milling processing method of an off-axis aspheric reflector, and relates to the advanced manufacturing field of space optics systems. The grinding wheel home position automation shaping and milling processing method of the off-axis aspheric reflector solves the problem that an existing single point oblique axis grinding method is low in processing efficiency. The grinding wheel home position automation shaping and milling processing method of the off-axis aspheric reflector includes: establishing a computer aided design (CAD) analysis model of the off-axis aspheric reflector; calculating processing residence time and a processing path of a current grinding point on the surface of a cambered grinding wheel; calculating variable quantity of a current Z axis following coordinate of the cambered grinding wheel on the Z axis direction, which is caused by variation of the current grinding point on the surface of the cambered grinding wheel; producing a post processor file and converting the post processor file into a five axis linkage numerical control processing program; fixing a work piece at the center of a five axis linkage machine tool rotary table, and using ultrasonic vibration to assist the cambered grinding wheel in swing processing according to the five axis linkage numerical control processing program. The grinding wheel home position automation shaping and milling processing method of the off-axis aspheric reflector enables each point on the surface of the grinding wheel to participate in grinding through low speed reciprocating swings of the cambered grinding wheel, homogenizes total wearing capacity of the grinding wheel onto the whole cambered surface of the grinding wheel, achieves home position automation shaping and shape preserving functions of the cambered grinding wheel, and is low in cost and short in processing cycle.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

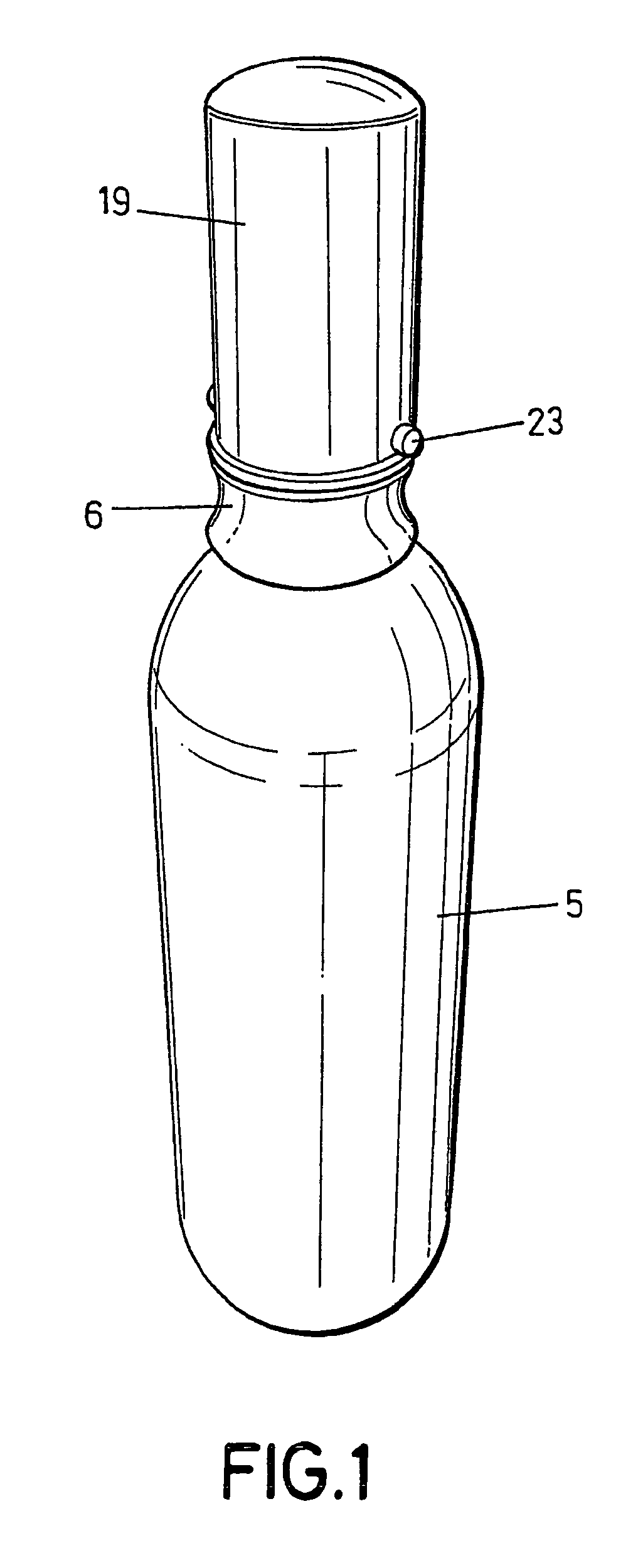

Vaccum pump for bottles

InactiveUS20050178094A1Packaging by pressurising/gasifyingPackaging under vacuum/special atmosphereTracheotomyOblique Axis

The invention relates to a hemi-cannula for tracheotomy patients, comprising a main tubular body (1.1) which is made from a suitable flexible material and which comprises peripheral end fixing flanges (1.2 and 1.3). One of said flanges (1.2), which is intended to be disposed inside the trachea next to the inner face of same, takes the form of a wing comprising a cylindrical surface with an oblique axis in relation to an axis perpendicular to the main axis of the main body (1.1). The other flange (1.3) takes the shape of a truncated cone comprising a larger outer base. According to the invention, a conduit forming the main tubular body passes through the centre of both of said flanges. The invention is suitable for producing tracheotomy cannulas.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

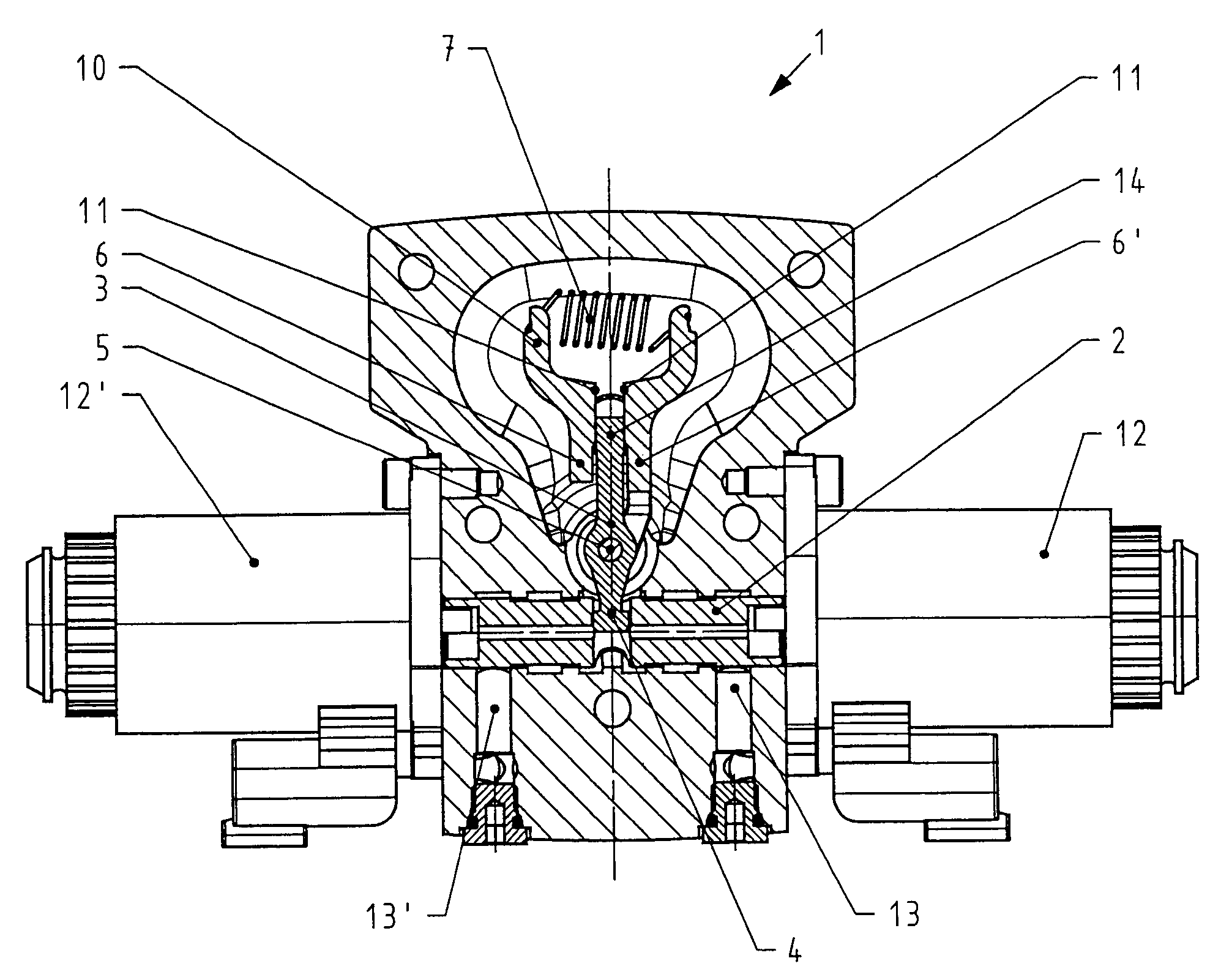

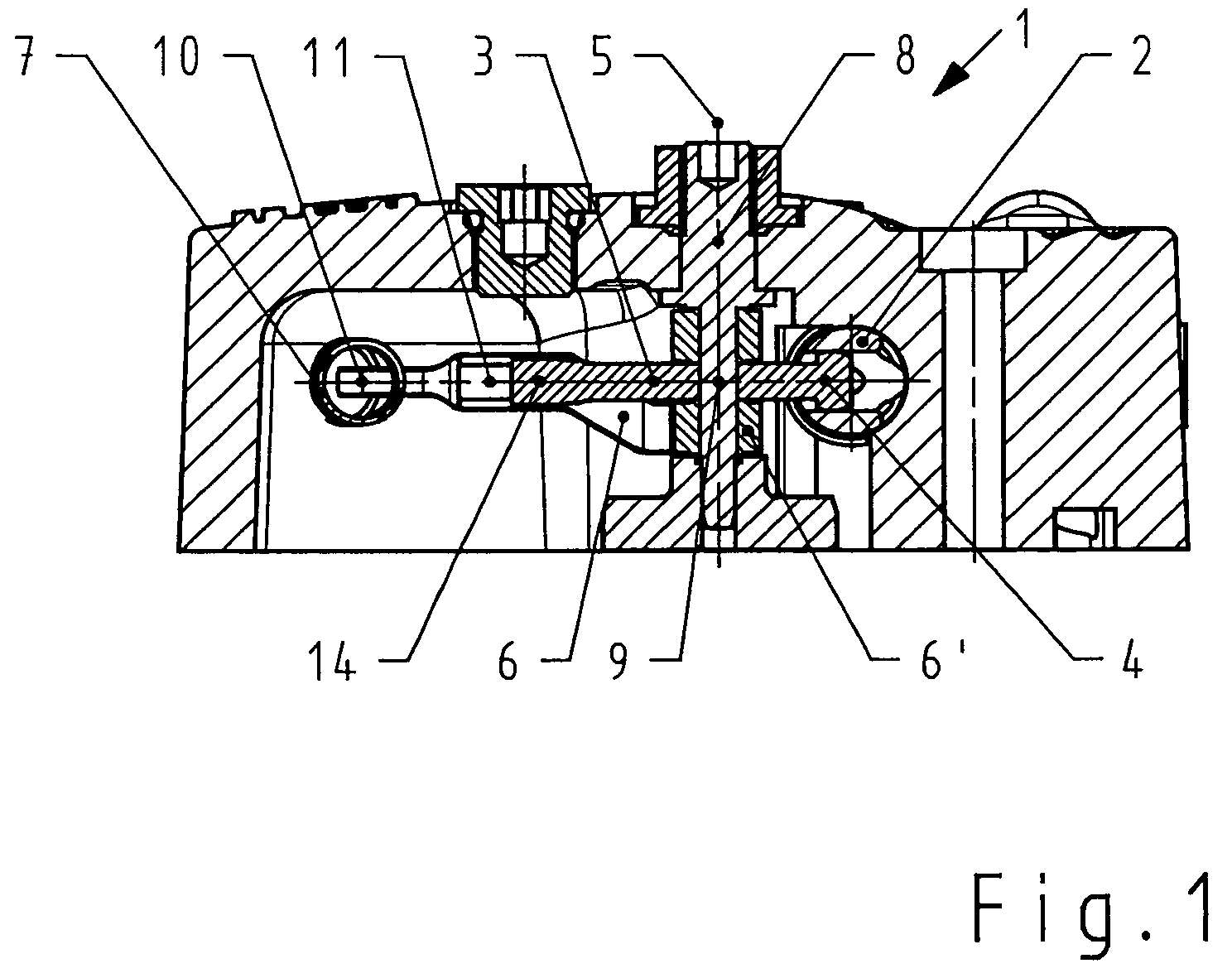

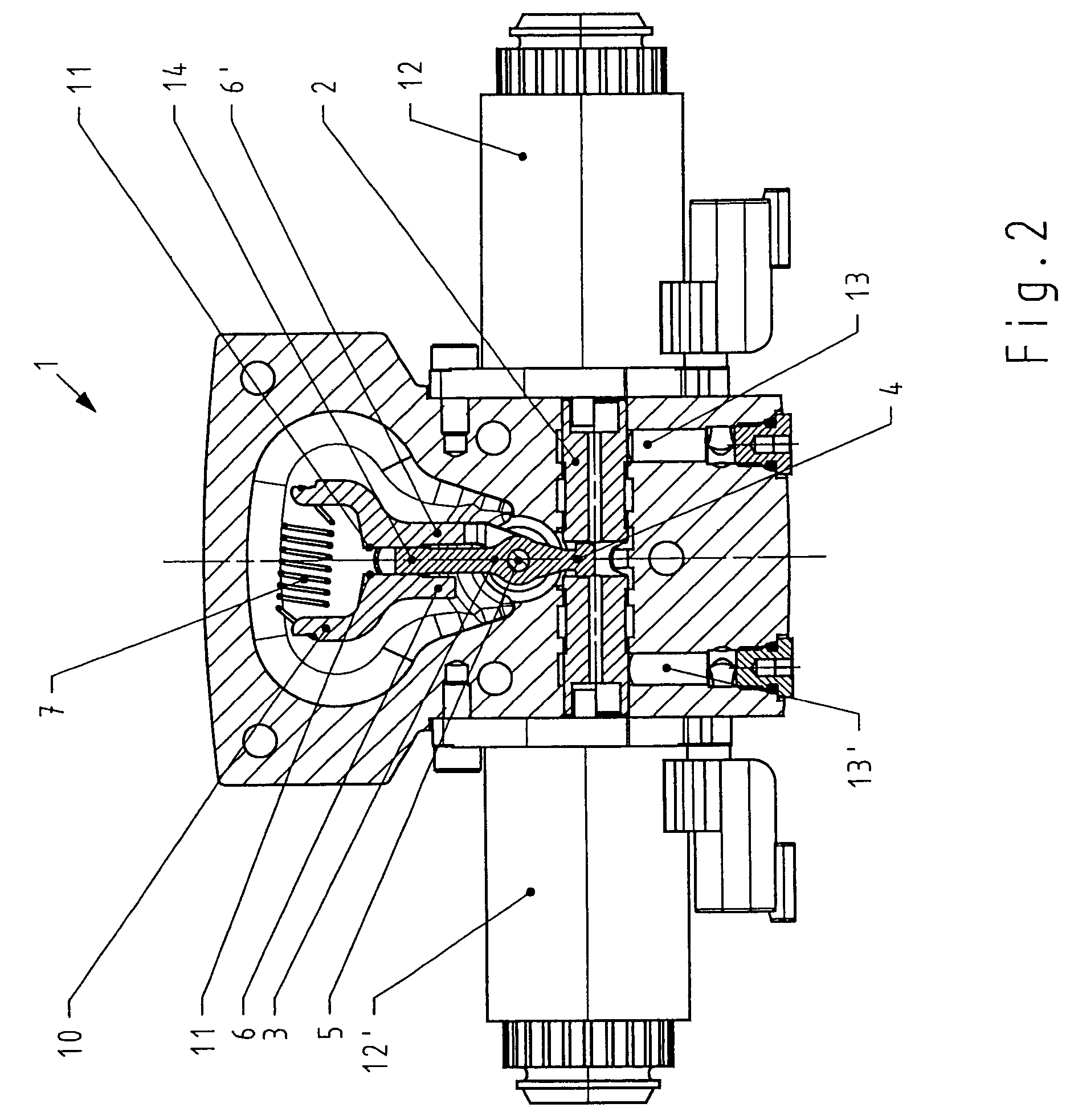

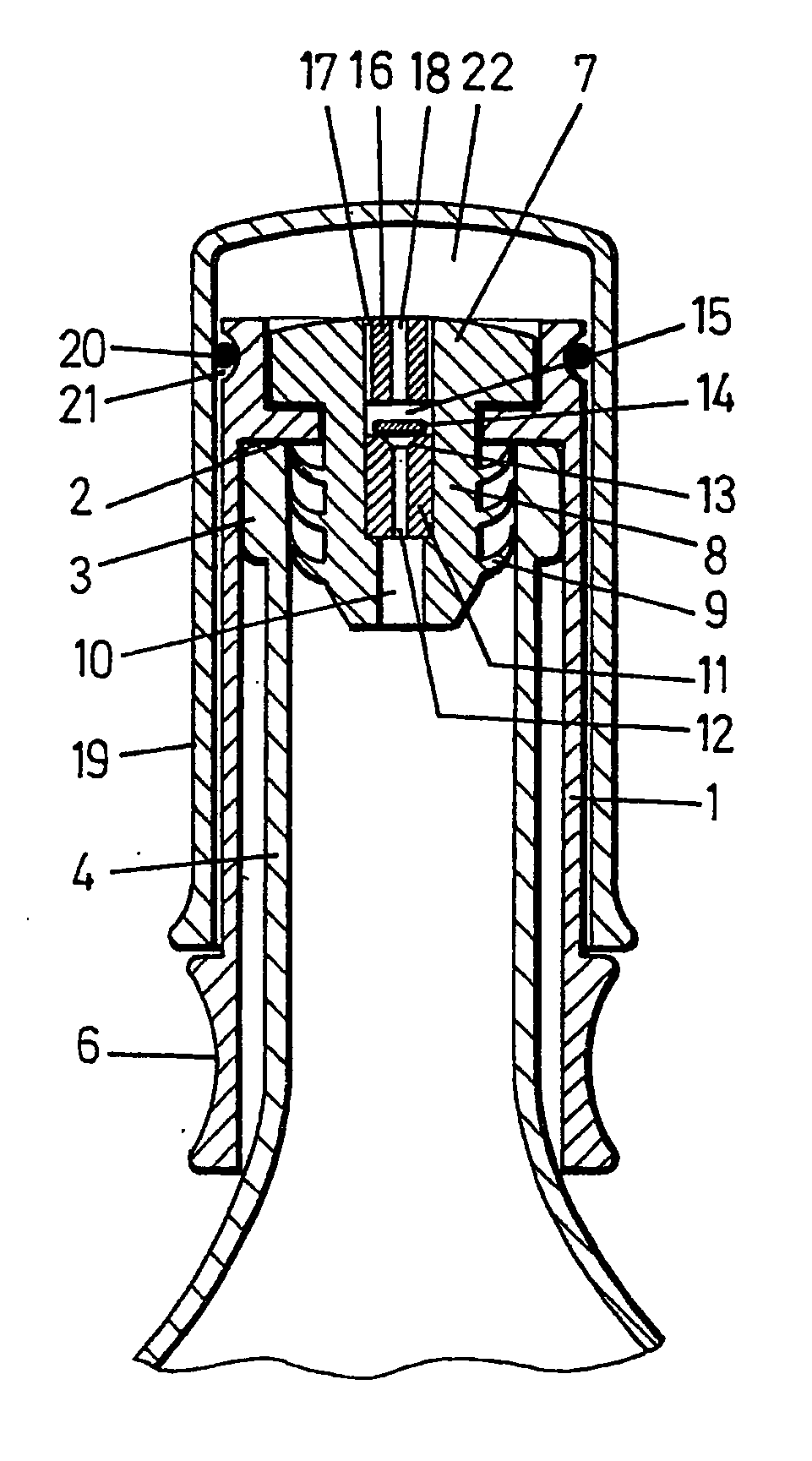

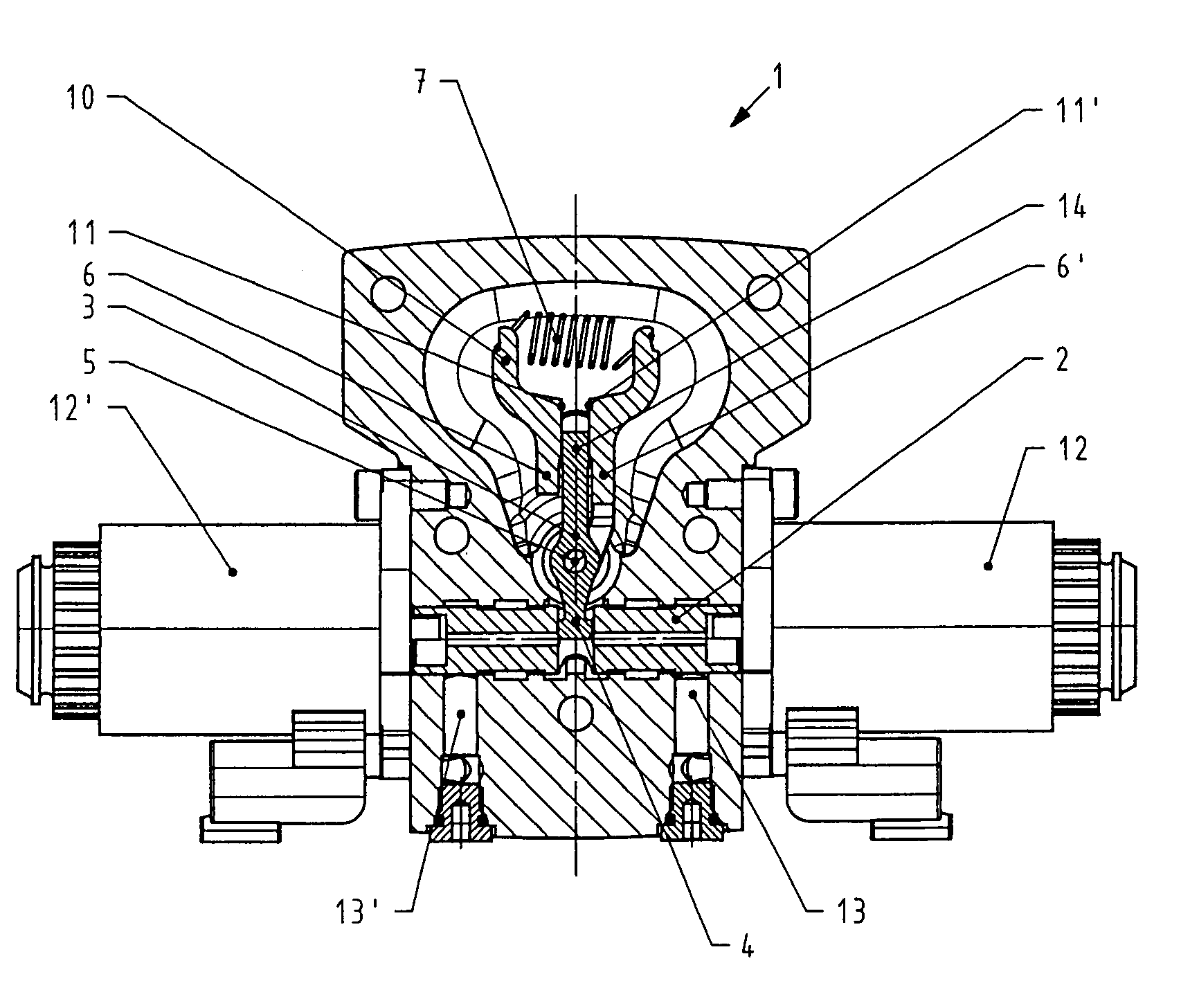

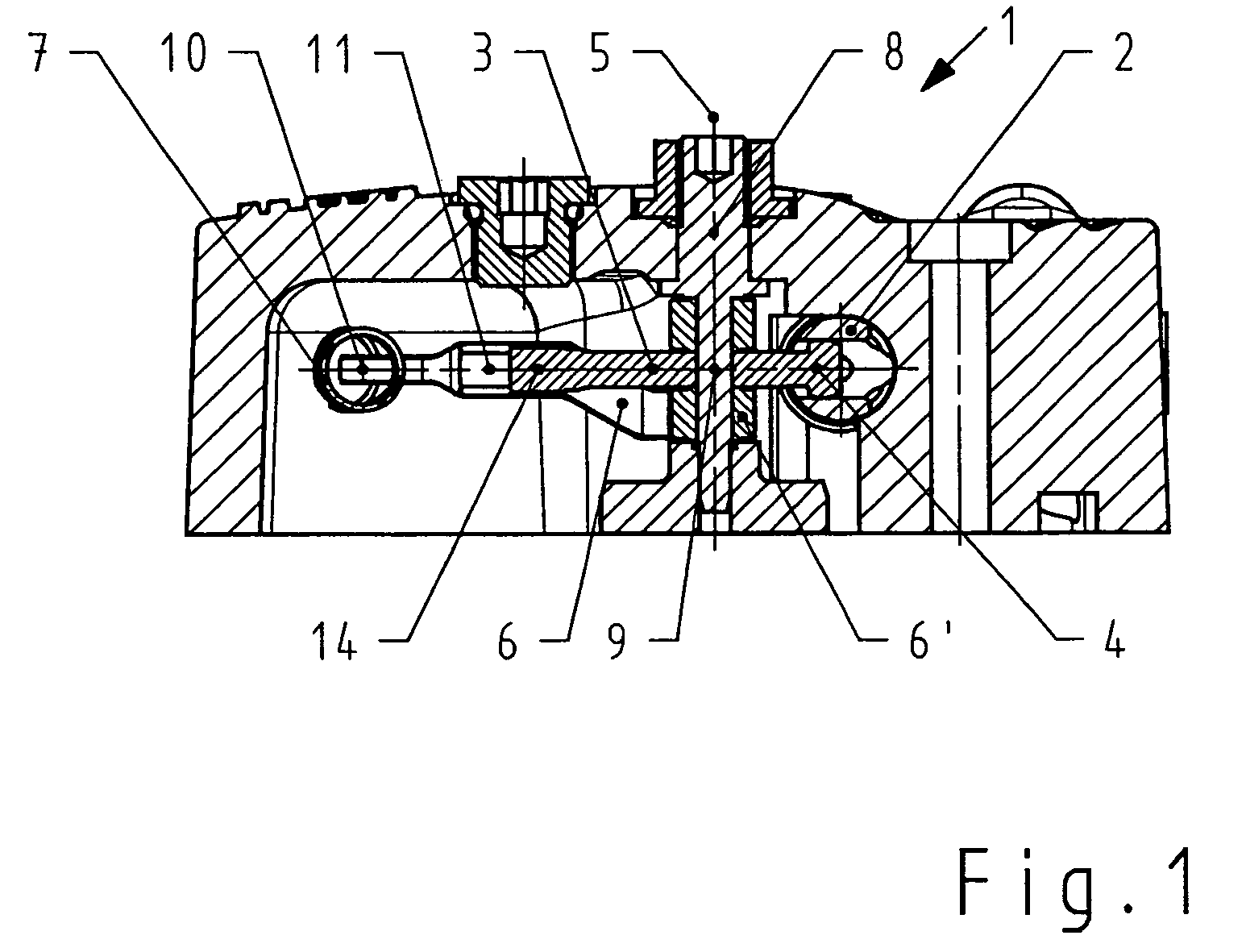

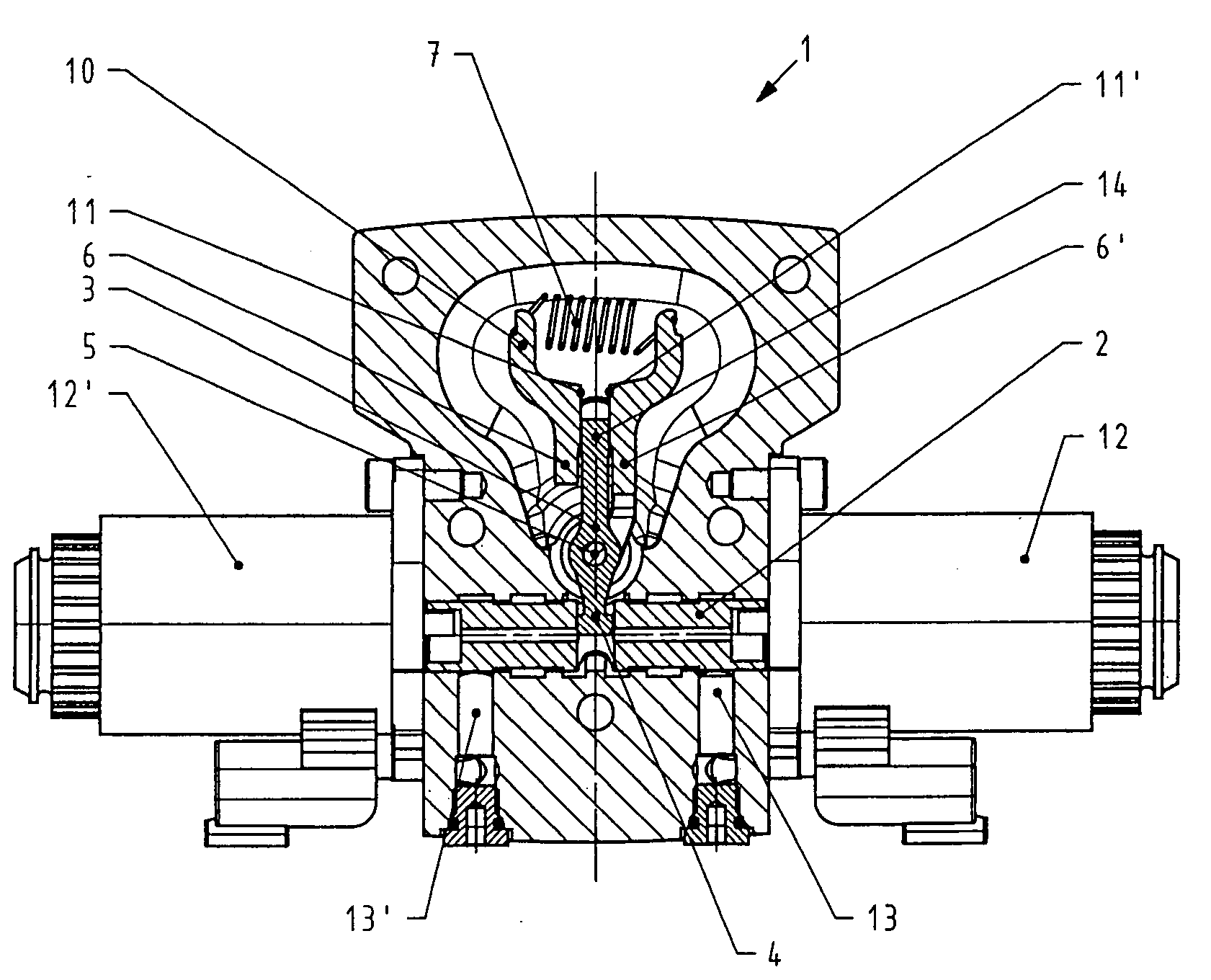

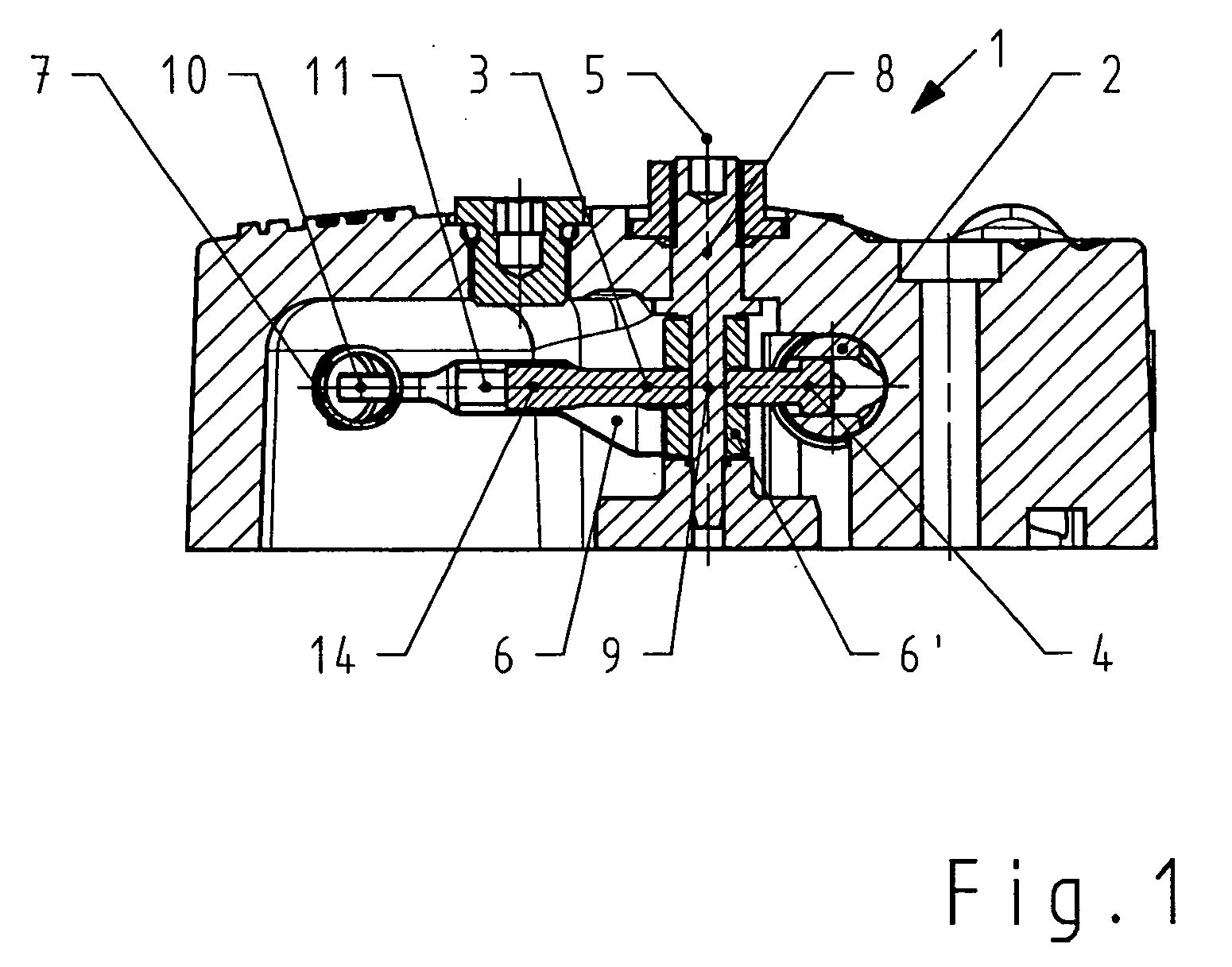

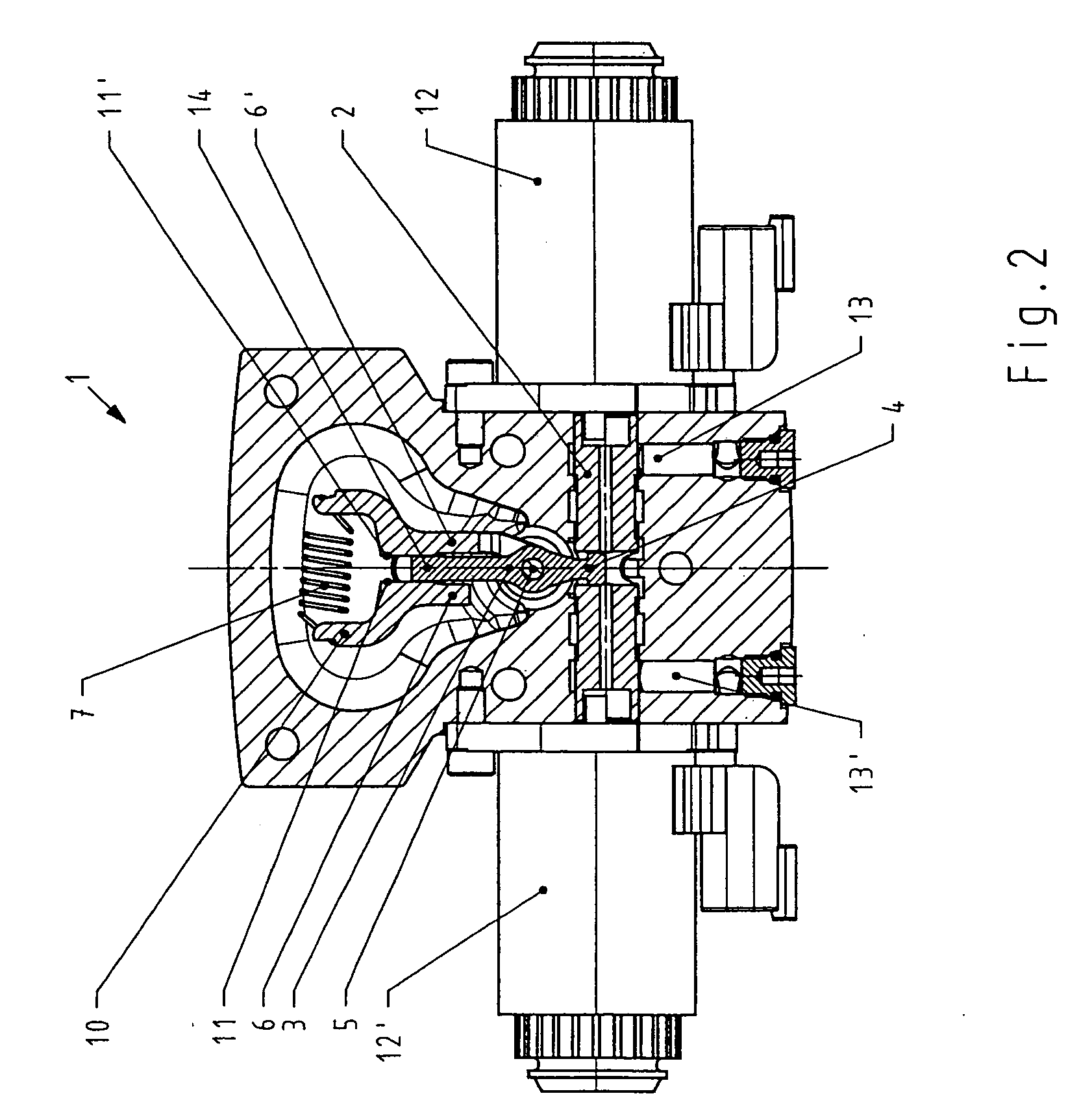

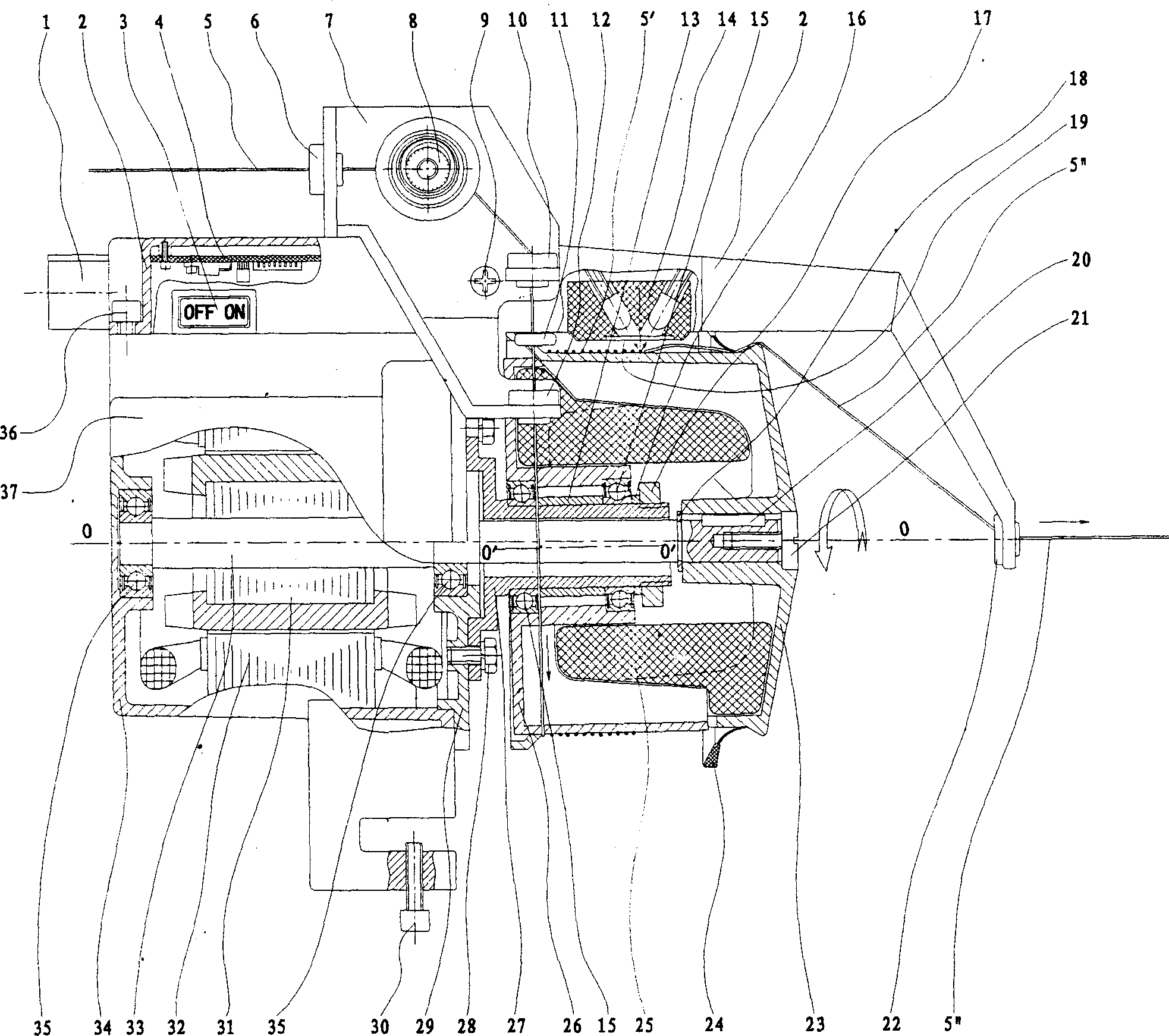

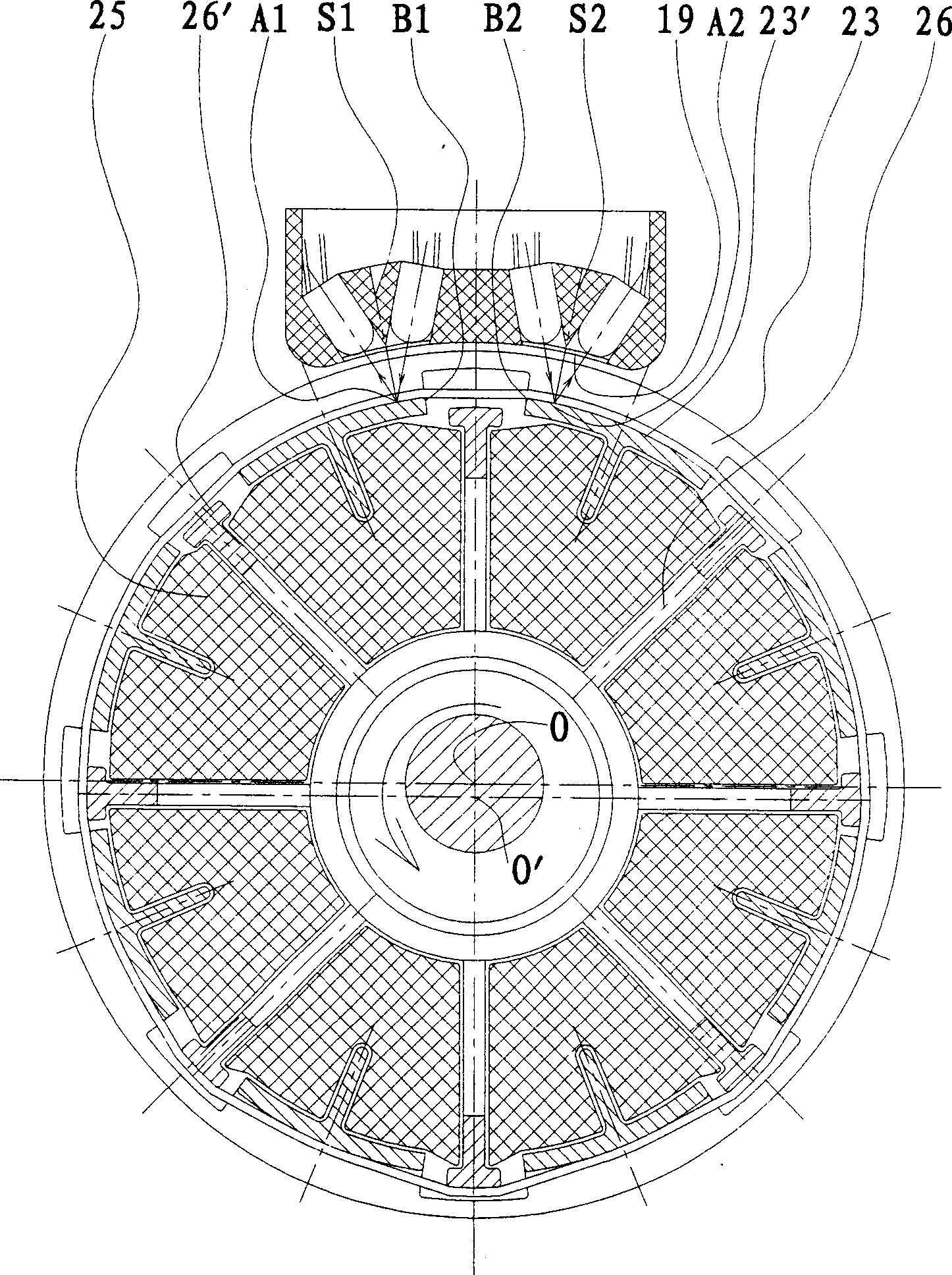

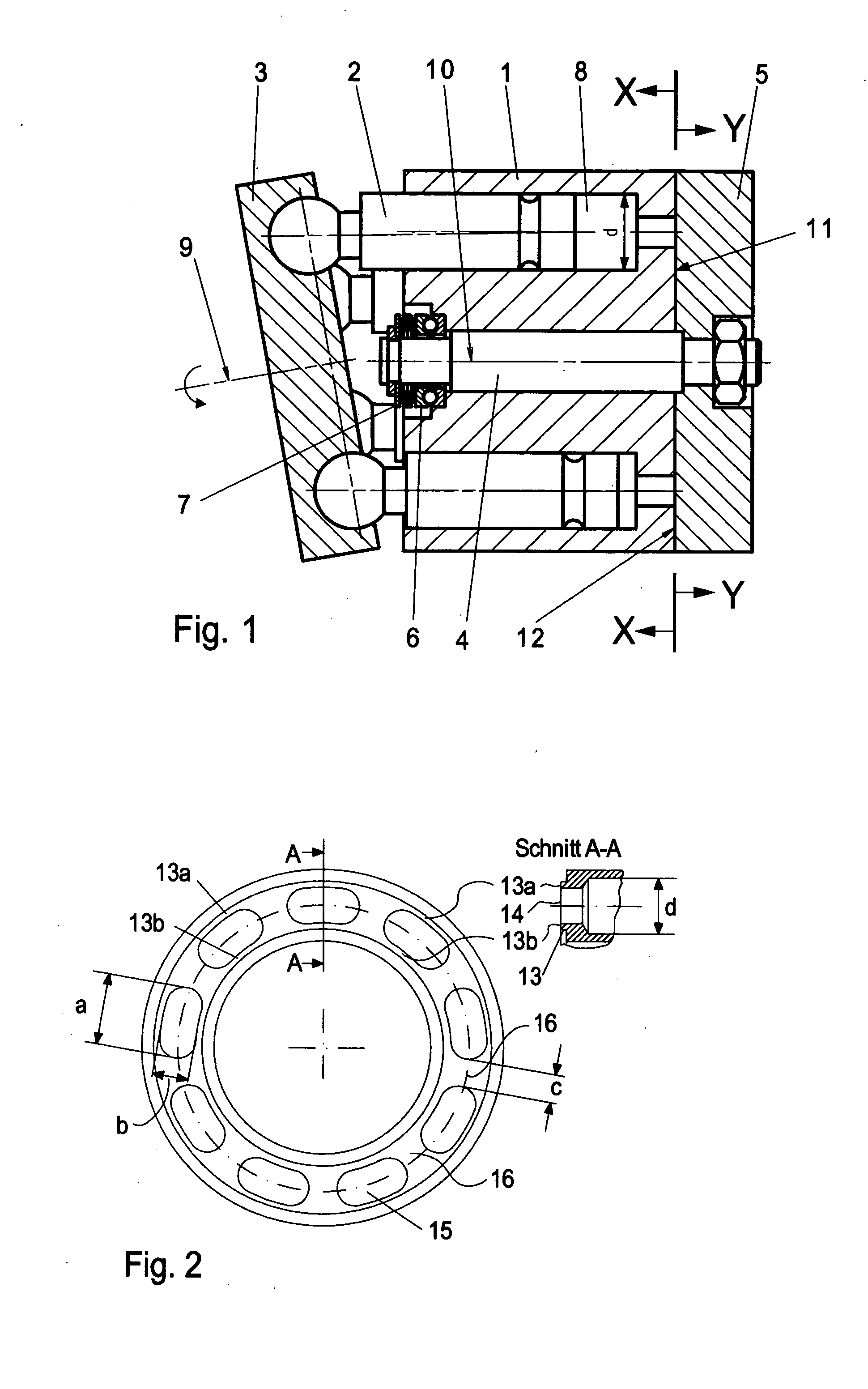

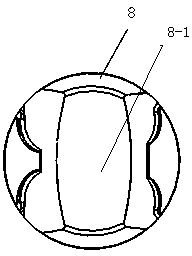

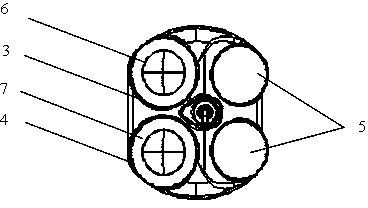

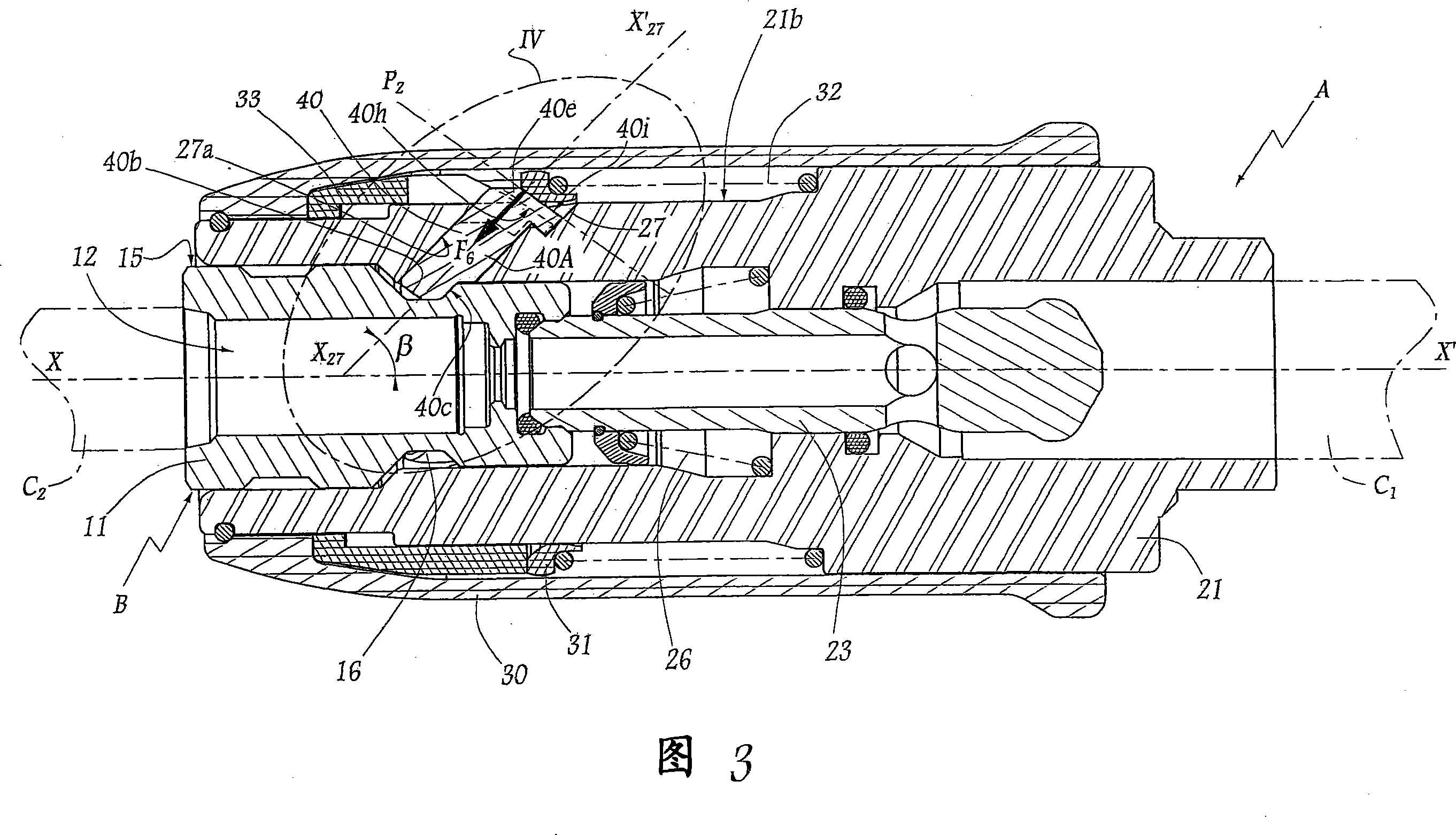

Axial piston machine having a device for the electrically proportional adjustment of the volumetric displacement

An axial piston machine having a swashplate or an oblique axis which can be adjusted by means of servopistons and has a valve segment and an adjustment unit for the electrically proportional adjustment of the volumetric displacement. The adjustment unit comprises proportional magnets which can be activated electrically, and a control piston for controlling the oil pressure which moves the servopistons. The proportional magnets act on the control piston along a common tappet axis, a feedback device for feeding back the current swashplate or oblique-axis valve-segment position to the control piston being provided. The feedback device comprises spring levers 6, 6′ which can pivot about an axis, the spring levers 6, 6′ each being mounted on the pivot axis 5 with a bearing shell 15, which are each composed of two component shells which support the spring lever 6, 6′ at separate locations on the pivot axis 5, and which each essentially enclose a half-space about the pivot axis 5.

Owner:DANFOSS POWER SOLUTIONS INC

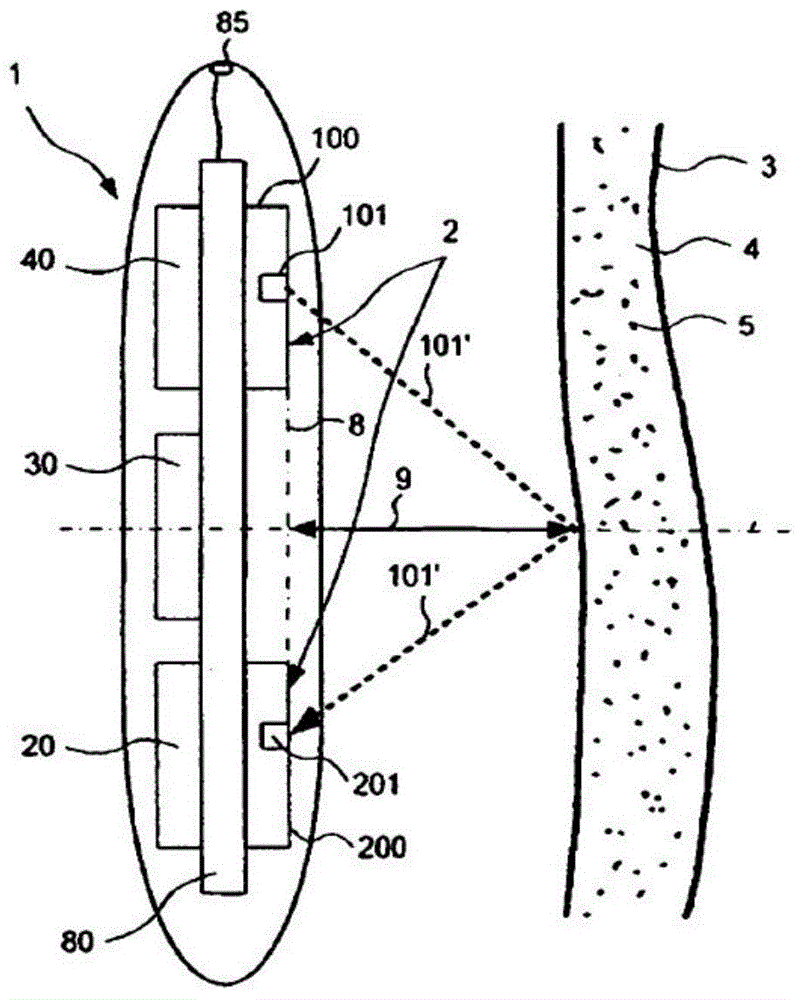

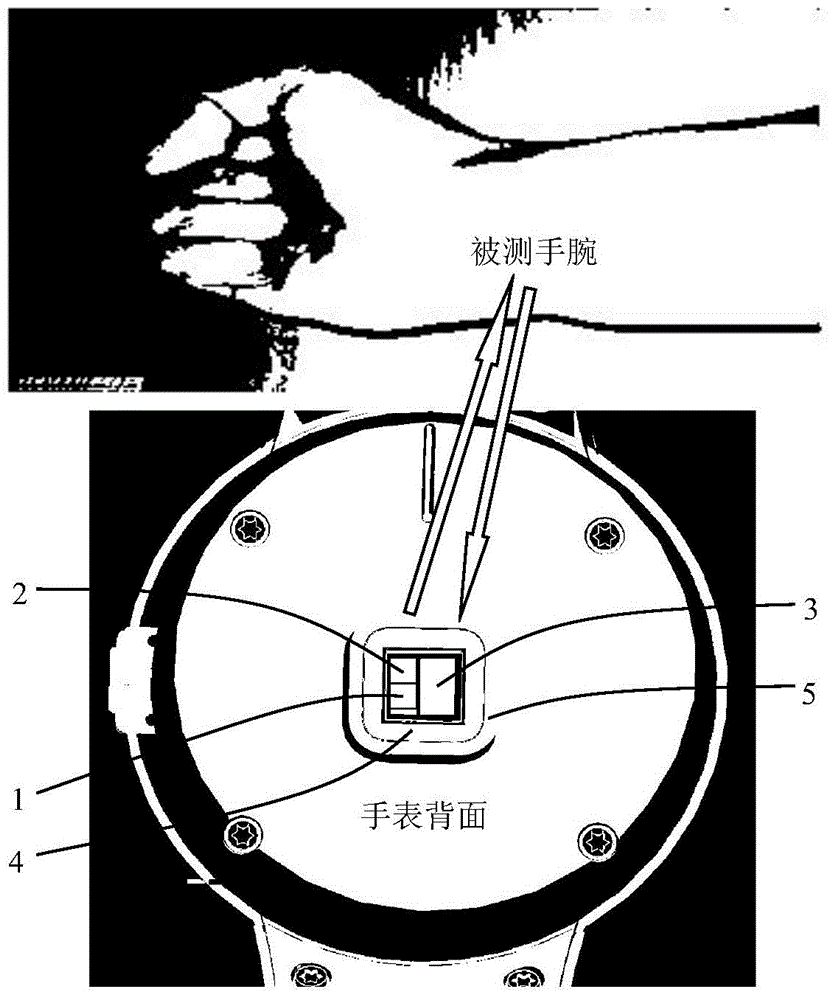

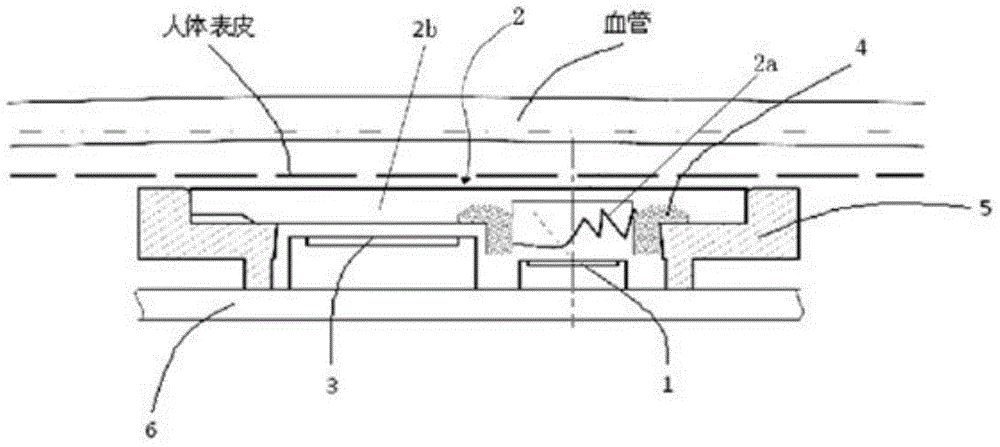

Optical sensing device for heart rate and blood pressure monitor

ActiveCN105982654AStrong signalReduce noiseEvaluation of blood vesselsAngiographyFresnel lensHigh heart rate

The invention discloses an optical sensing device for a heart rate and blood pressure monitor, comprising a light-emitting device, an optical lens, a photoelectric receiving tube and a light-shielding black frame, wherein the optical lens includes a light-gathering window above the light-emitting device and a photoelectric The light-transmitting window above the receiving tube; the light-shielding black frame is located above the light-emitting device and is set between the light-gathering window and the light-transmitting window; the light-gathering window adopts a Fresnel structure, which includes at least one transmission surface and one or more teeth composition of reflective surfaces. Due to the use of the oblique-axis Fresnel lens, it can achieve the purpose of concentrating and turning the light path with a relatively thin thickness. It concentrates the LED light and converges it to the measured point on the skin in an oblique direction, passing through the measured point. After being reflected by the blood vessels in the measuring point, it is received by the photoelectric receiving tube through the transparent window, thereby generating pulse and blood signals. The optical sensing device has the characteristics of strong signal, low noise, high sensitivity, accuracy, good reliability and the like.

Owner:MIKOLTA OPTICAL TECH CO

Axial piston machine having a device for the electrically proportional adjustment of the volumetric displacement

An axial piston machine having a swashplate or an oblique axis which can be adjusted by means of servopistons and has a valve segment and an adjustment unit for the electrically proportional adjustment of the volumetric displacement. The adjustment unit comprises proportional magnets which can be activated electrically, and a control piston for controlling the oil pressure which moves the servopistons. The proportional magnets act on the control piston along a common tappet axis, a feedback device for feeding back the current swashplate or oblique-axis valve-segment position to the control piston being provided. The feedback device comprises spring levers 6, 6′ which can pivot about an axis, the spring levers 6, 6′ each being mounted on the pivot axis 5 with a bearing shell 15, which are each composed of two component shells which support the spring lever 6, 6′ at separate locations on the pivot axis 5, and which each essentially enclose a half-space about the pivot axis 5.

Owner:DANFOSS POWER SOLUTIONS INC

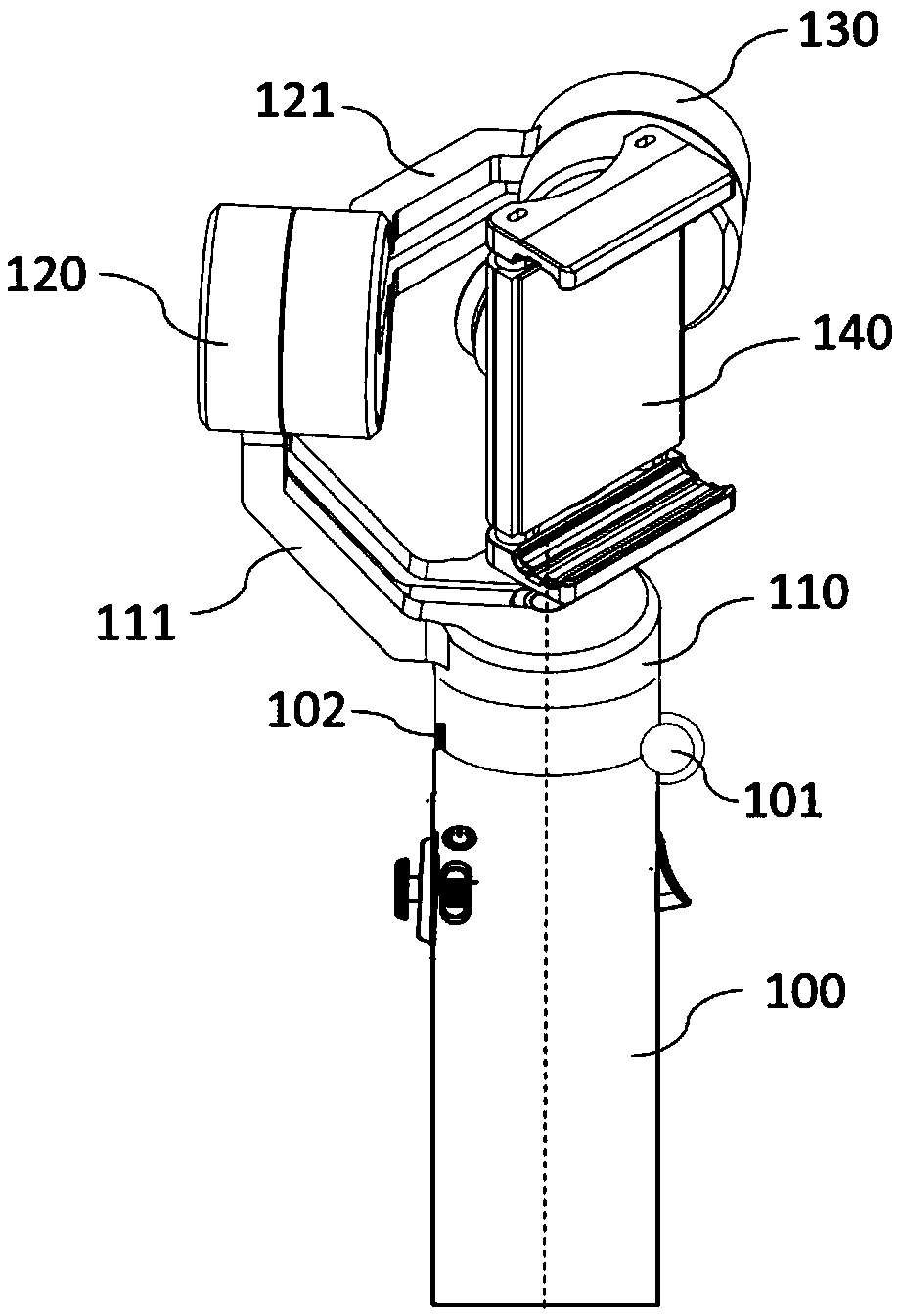

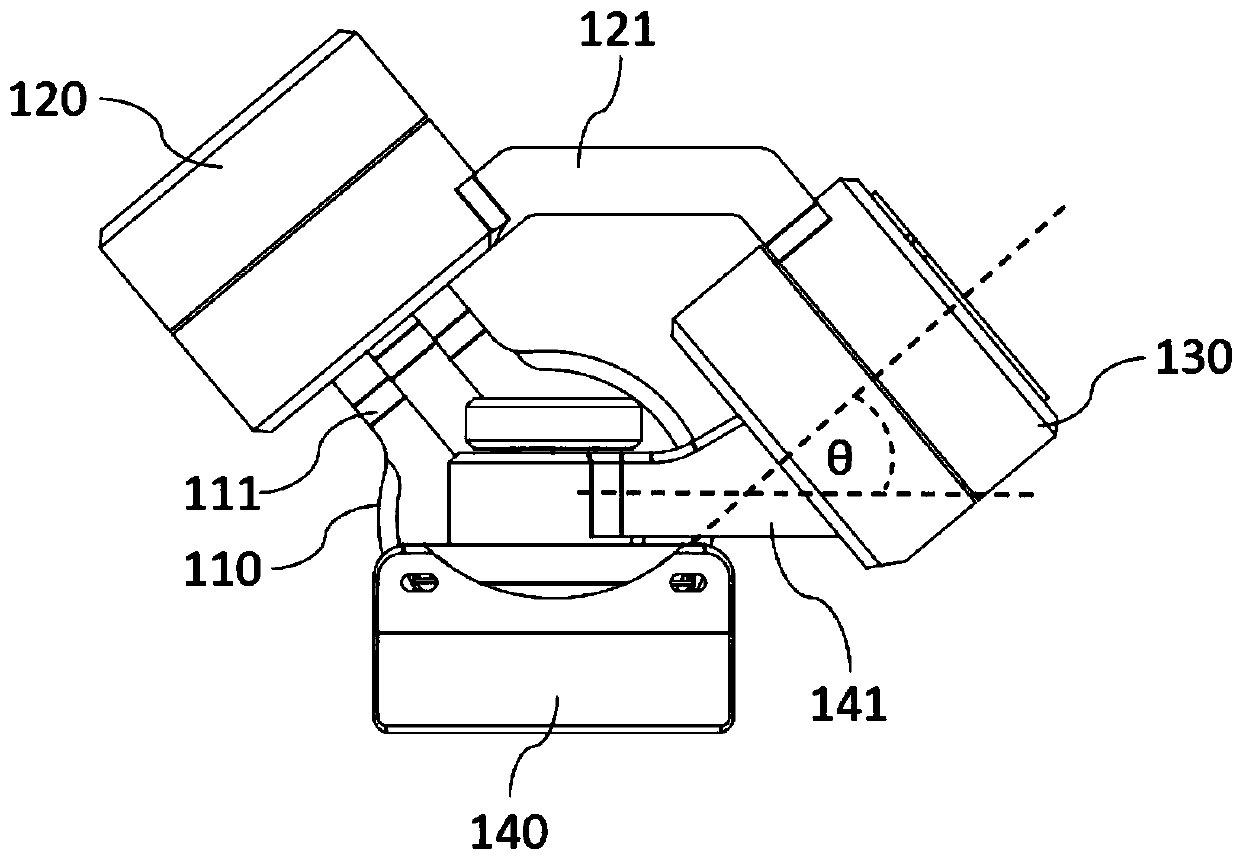

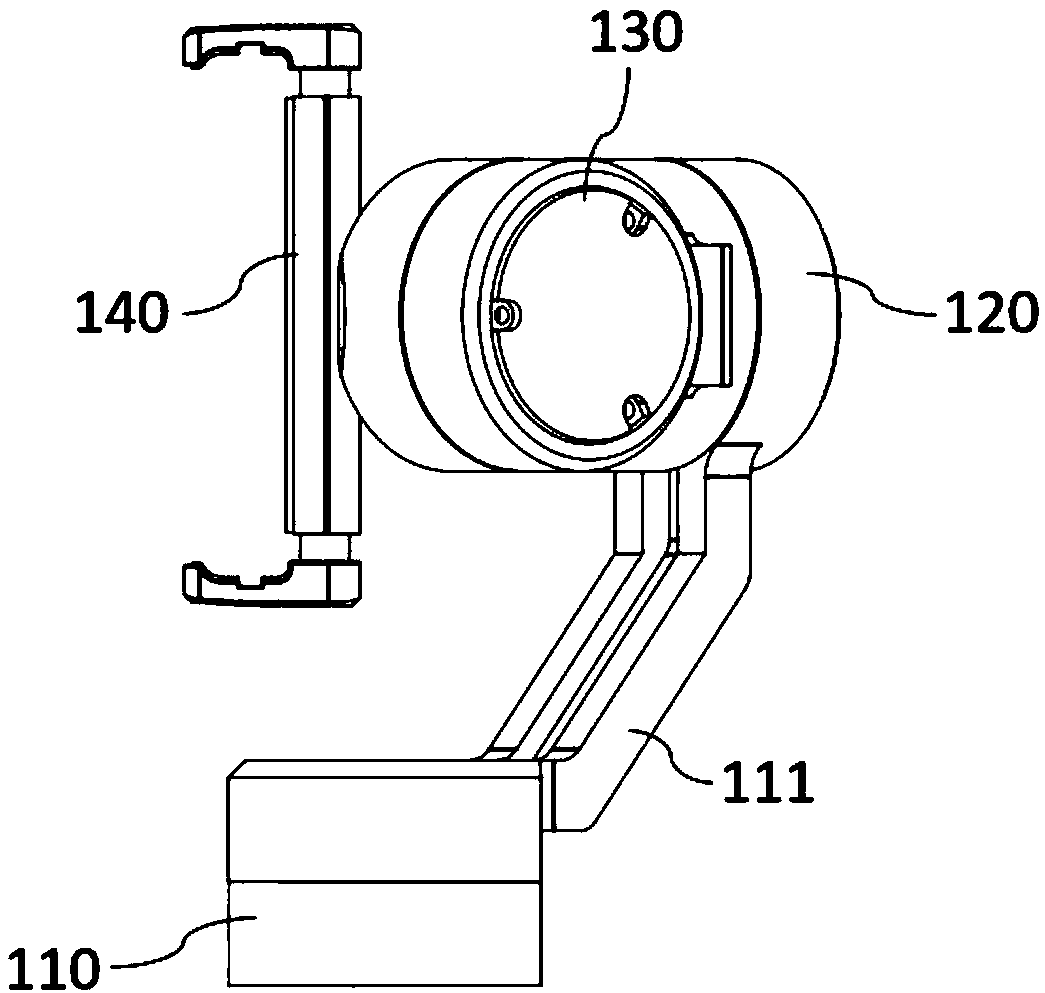

Foldable tilting axis hand stabilizer

InactiveCN109611675AMeet the center of gravity adjustment requirementsLow costStands/trestlesAcute angleOblique Axis

The invention provides a foldable tilting axis hand stabilizer which comprises a heading axis motor, a roll axis motor, a pitch axis motor, a clamp and a handle. The pitch axis motor is connected withthe clamp through a clamping arm, a first included angle formed between the pivot axis of the pitch axis motor and the axis of the clamping arm is an acute angle, the handle and the heading axis motor are pivotally connected through a pin shaft, and the handle and the heading axis motor are further provided with a matched buckle structure. According to the foldable tilting axis hand stabilizer, on the condition that the pivot axis of the heading axis motor, the pivot axis of the roll axis motor and the pivot axis of the pivot axis motor are pairwise orthogonal, a data line interface of shooting equipment is still not blocked by a pitch motor in the horizontal shooting process, and a folding function is achieved since the handle and the pitch axis motor are pivotally connected through thepin shaft.

Owner:GUILIN ZHISHEN INFORMATION TECH CO LTD

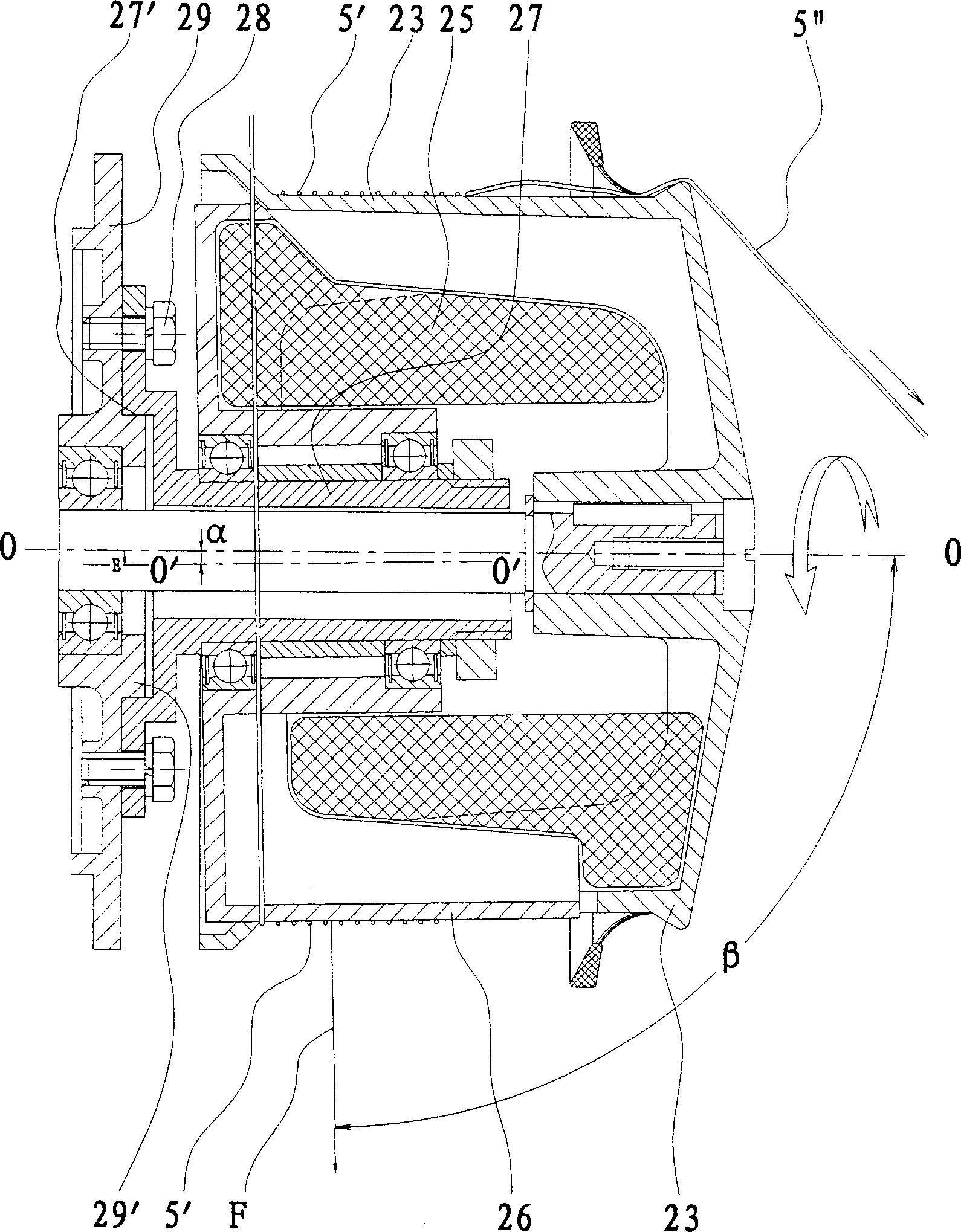

Rotating-drum yarn storing device for intermittent yarn storage and its manufacture

There is a device that stores thread for non-shuttle spinning machine, composed by electronic motor, inner-spinning drum, outer-spinning drum, hollow oblique axis, up-cover board, spinning tension machine, breaking spinning switch, electrical machinery controlling circuit board and spinning sensor and so on. The spinning cover of the outer-spinning drum is identical with the outside diameter of the inner-spinning drum. But each has different resolving axis. The resolving axis (O'-O') has a specified deviation distance to the outer-spinning axis and also has a specified angle of inclination, beta. So it can make the thread twined on the storing spinning cylinder, composed by outer-spinning drum and inner-spinning drum, move forward in a specified interval an ensure not overlapping spinning.

Owner:绍兴市联创电器有限公司

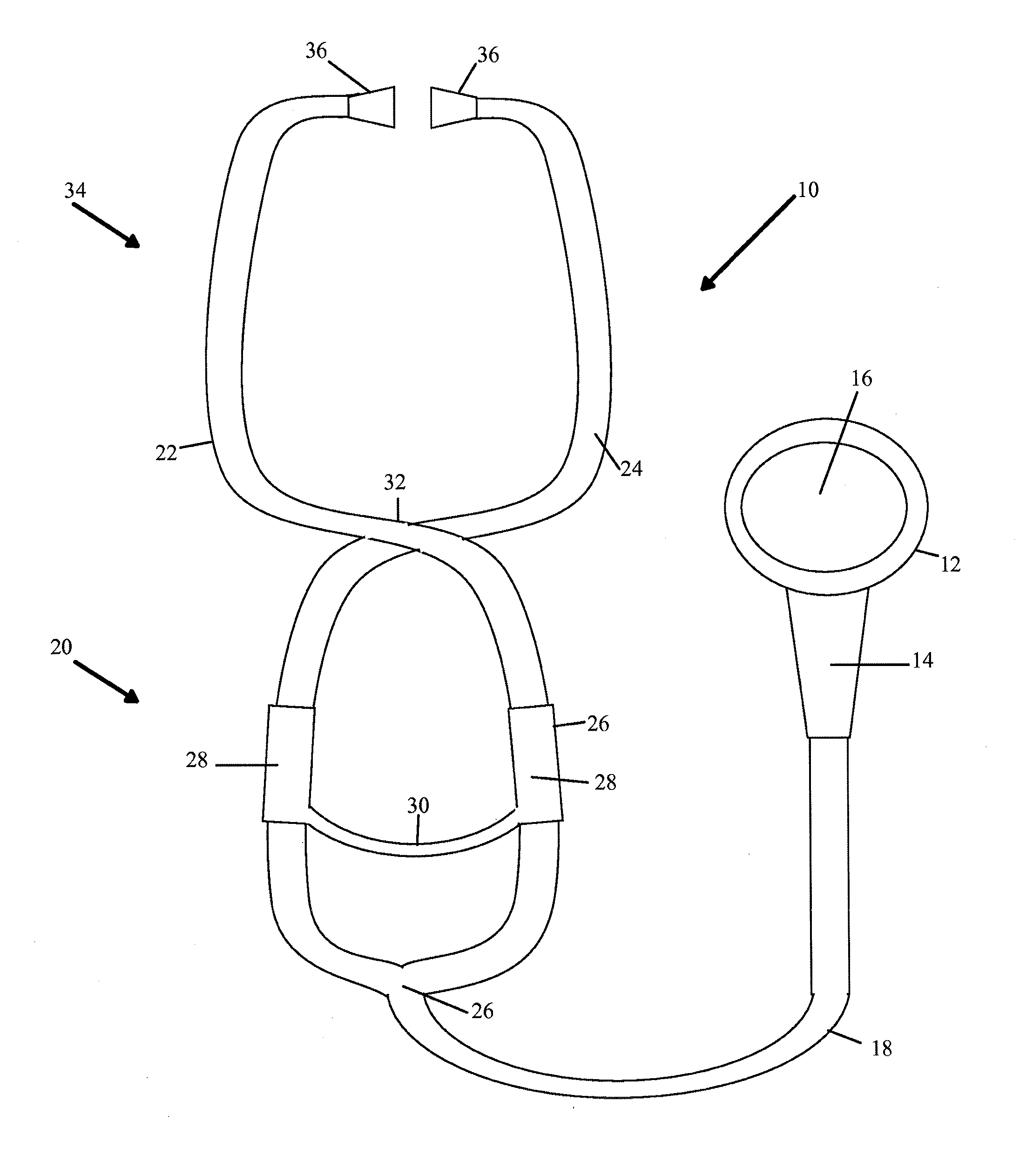

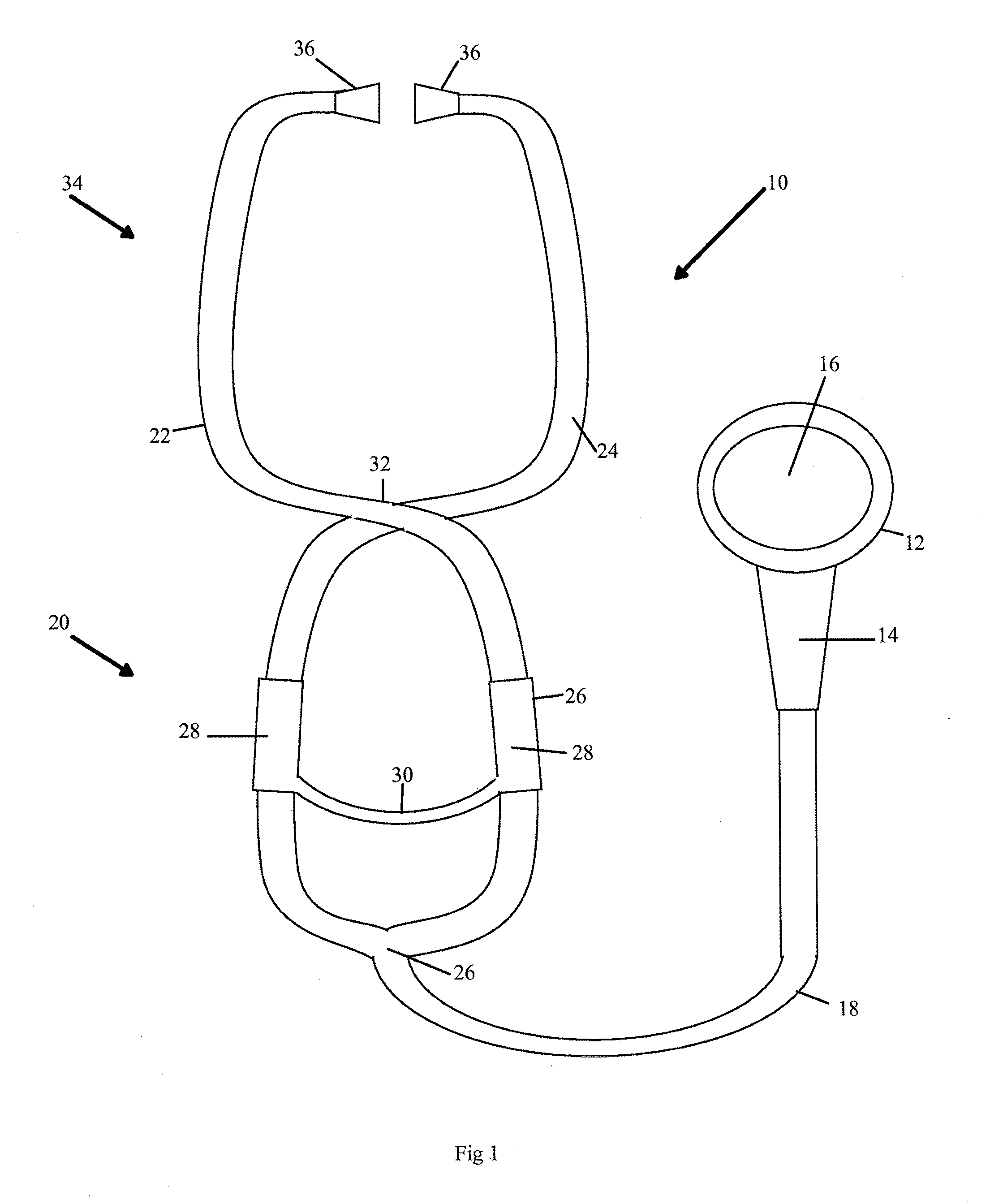

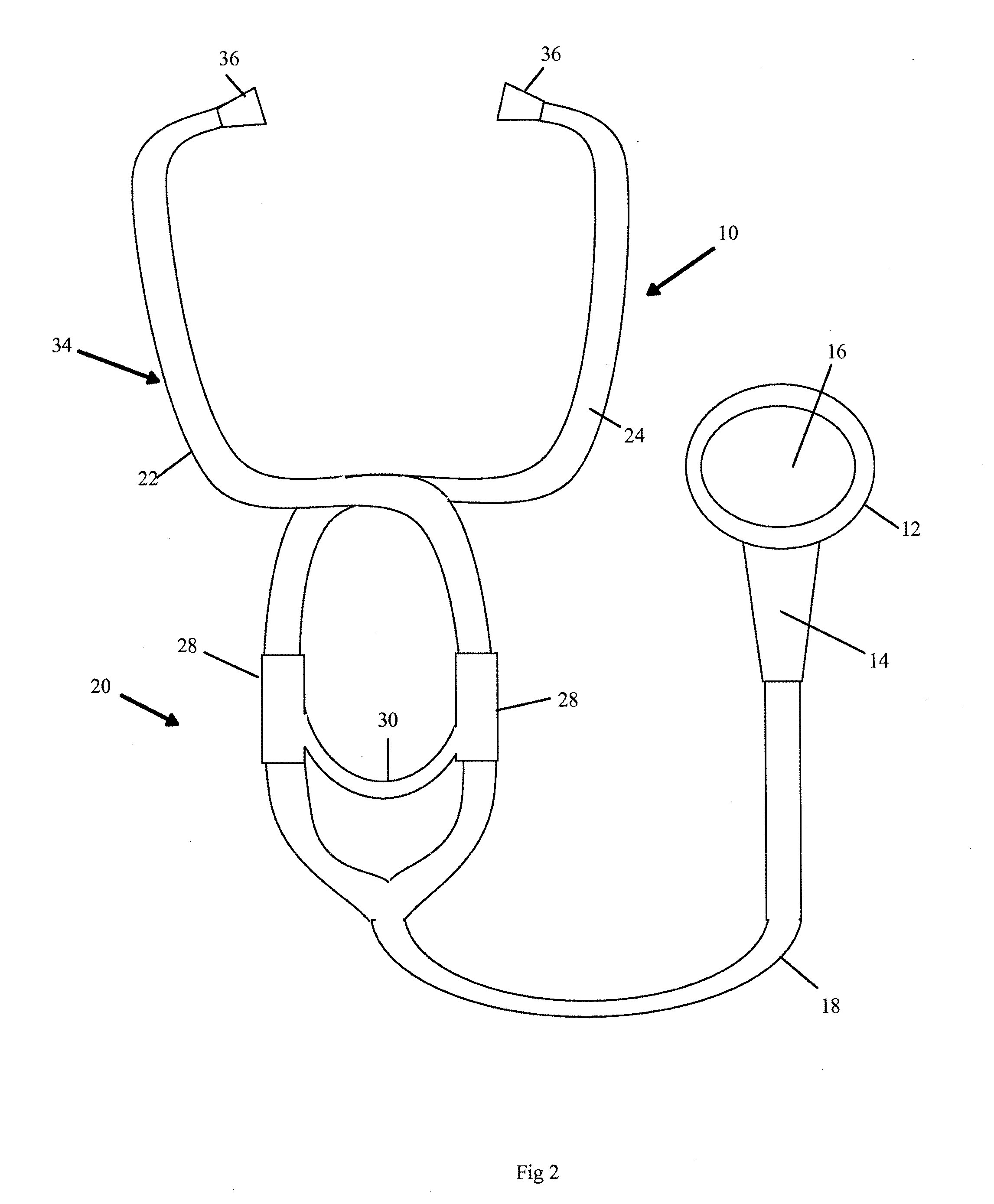

Stethoscope Having An Elliptical Headpiece And Amplified Earpieces

InactiveUS20110088964A1Improved manipulationImproved auscultationStethoscopeAudio power amplifierAcute angle

A stethoscope having a headpiece with a conical body extending uniformly along an oblique axis from a first circular opening of a first diameter to a second opening of a second diameter and having an elliptical cross-section perpendicular to said oblique axis, where the second diameter is smaller than the first diameter and the axis intersects the first opening at an acute angle. The stethoscope also includes first and second sound amplifiers removably interconnected to the ends of the ear tubes to allow a user to amplify sounds or listen normally as desired.

Owner:TGMDVM

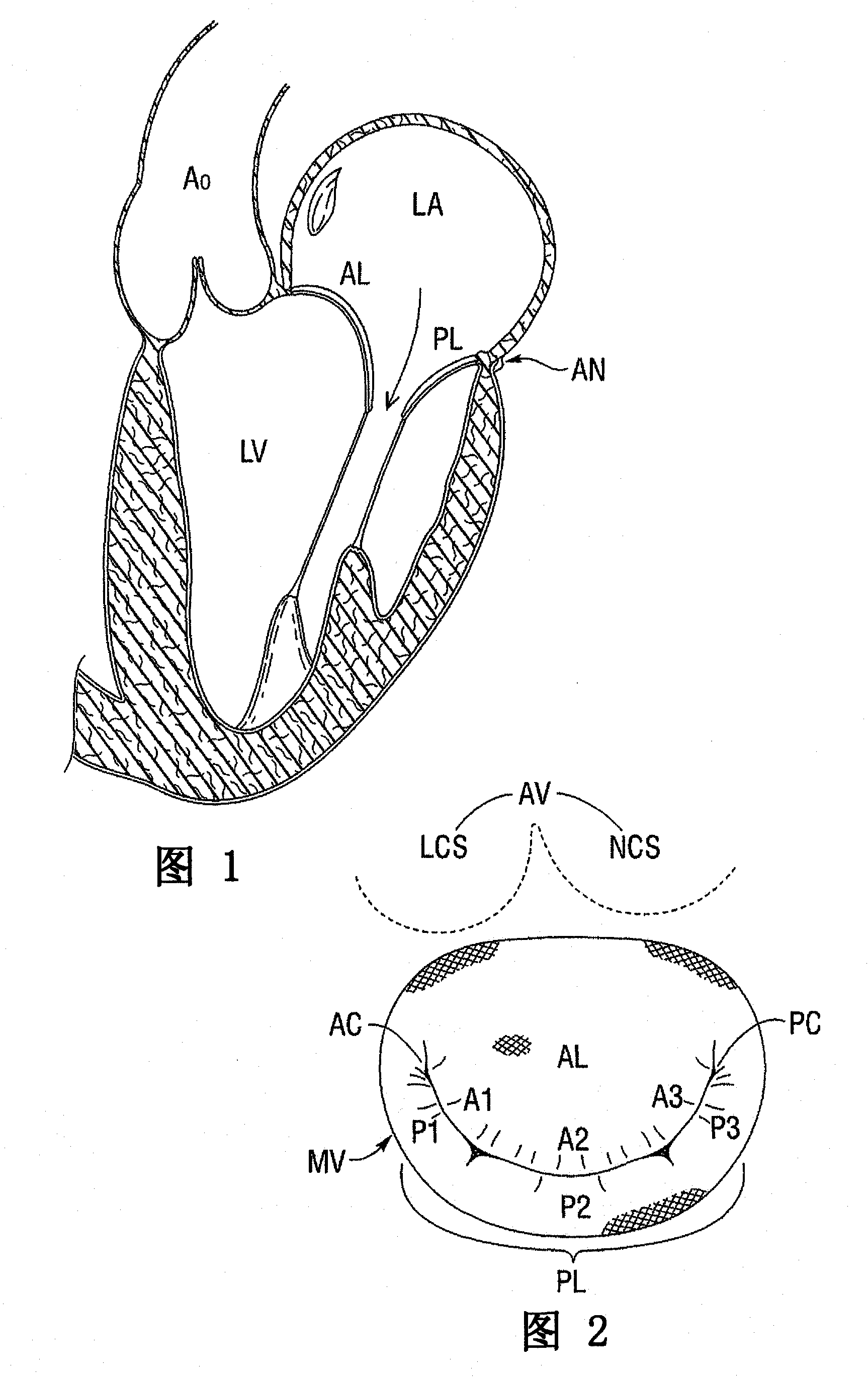

Degenerative valvular disease specific annuloplasty rings

Annuloplasty rings optimally sized to take into account more of the common degenerative valve pathologies. Each ring has a structural ring body with a shape that complies with predicted shapes of degenerative valvular diseases, such as Fibroelastic deficiency (FED), Marfan's or Barlow's. The predicted shapes are obtained through careful echocardiographic and intraoperative measurements, and often differ for different annulus orifice sizes. For instance, in mitral rings the larger rings have larger minor axis and oblique axis dimensions relative to their major axis dimensions, and are more circular as opposed to D-shaped. The rings may also be three-dimensional and the relative heights around the rings may change for different sized rings. A mitral ring may have a higher anterior saddle relative to a posterior saddle, with the relative heights varying across the ring sizes. The ring may have varying flexibility around the ring periphery which also changes for different ring sizes. A bulge on the sewing cuff forms a step on the outflow side for ease of suturing, which may be indicated by a suture line.

Owner:EDWARDS LIFESCIENCES CORP

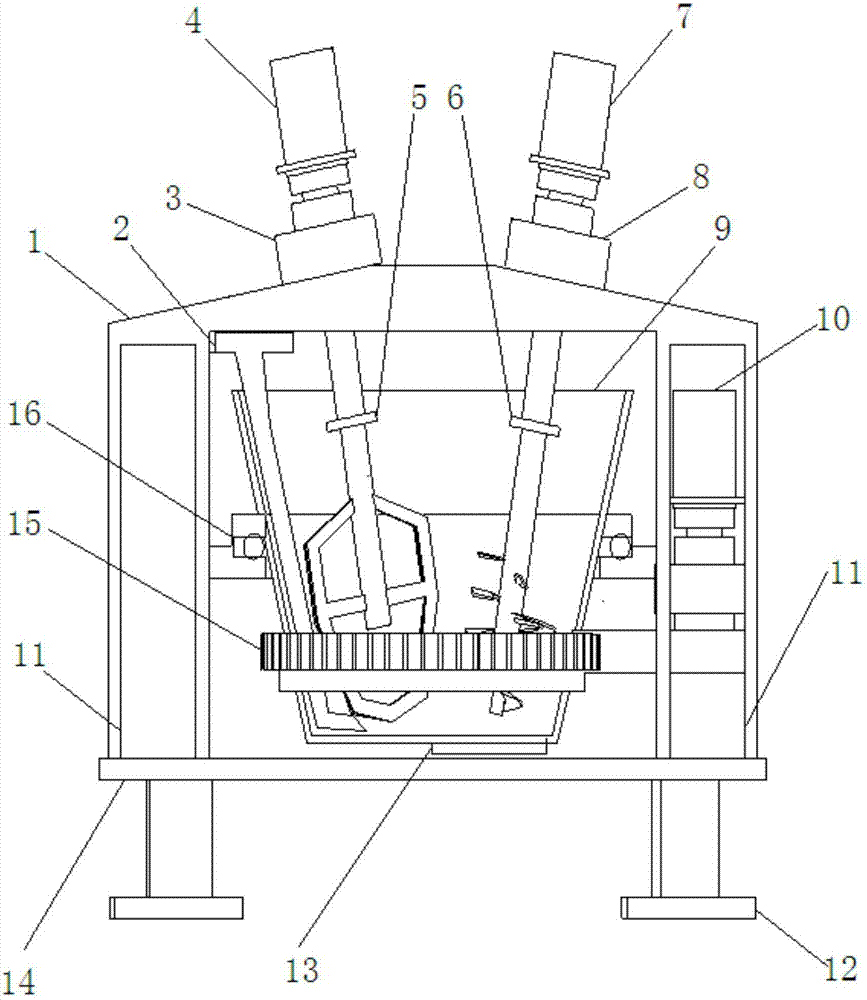

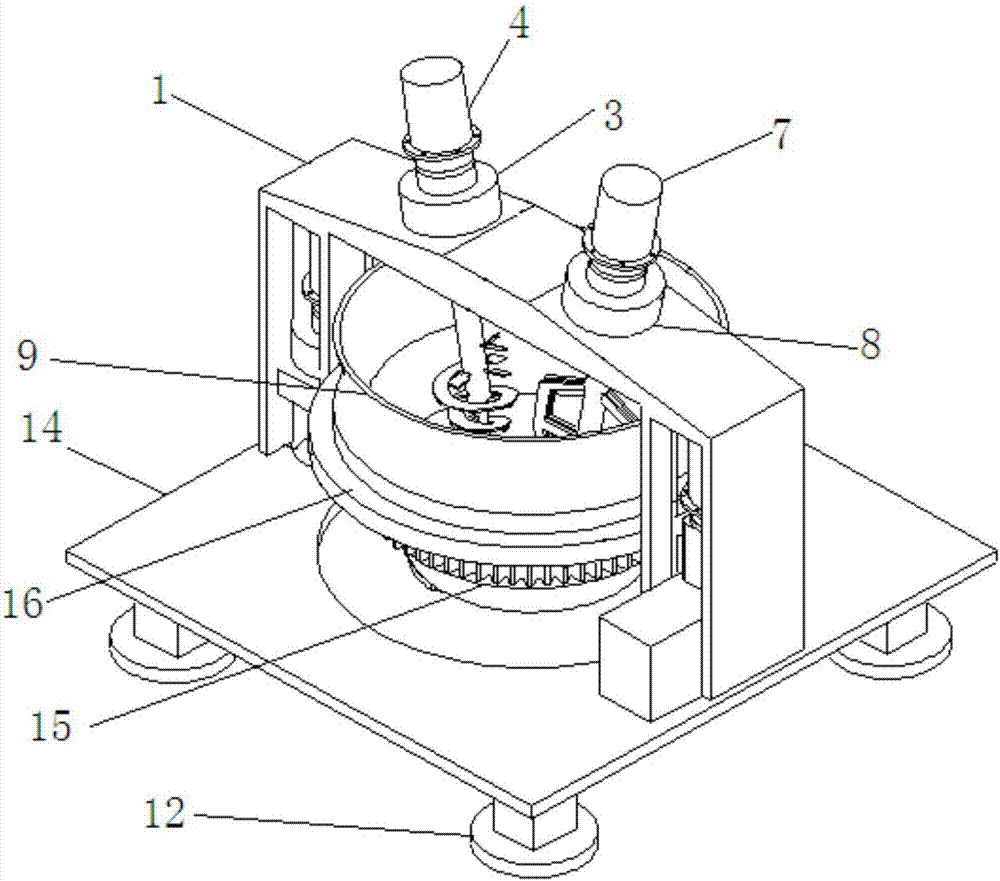

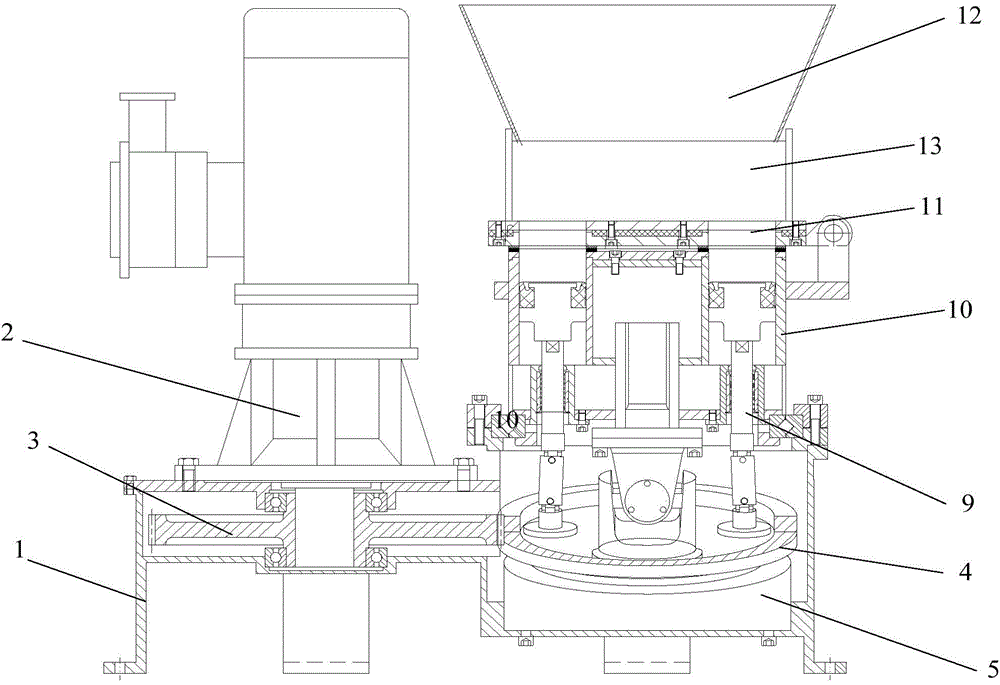

Vertical-type oblique-axis concrete mixer

The invention discloses a vertical-type oblique-axis concrete mixer. The vertical-type oblique-axis concrete mixer comprises a machine frame, a revolving drum drive motor, a cross beam, a stirring drive motor and a material lifting drive motor. A slewing bearing is arranged inside the machine frame, and a mixing drum is arranged inside the slewing bearing. An outer gear ring is arranged on the outer side wall of the mixing drum. The revolving drum drive motor is fixed to the machine frame, and a spindle of the revolving drum drive motor is connected with a driving gear engaged with the outer gear ring. The cross beam is provided with a stirring support and a material lifting support. A stirrer is assembled inside the stirring support in a rotating mode, and a material lifter is assembled inside the material lifting support in a rotating mode. One end of the stirrer and one end of the material lifter stretch into the mixing drum. The stirring drive motor is fixed to the stirring support, and a spindle of the stirring drive motor is connected with the stirrer. The material lifting drive motor is fixed to the material lifting support, and a spindle of the material lifting drive motor is connected with the material lifter. The vertical-type oblique-axis concrete mixer is simple in overall structure, easy to implement and capable of effectively improving the stirring quality and stirring efficiency of mixtures.

Owner:CHANGAN UNIV

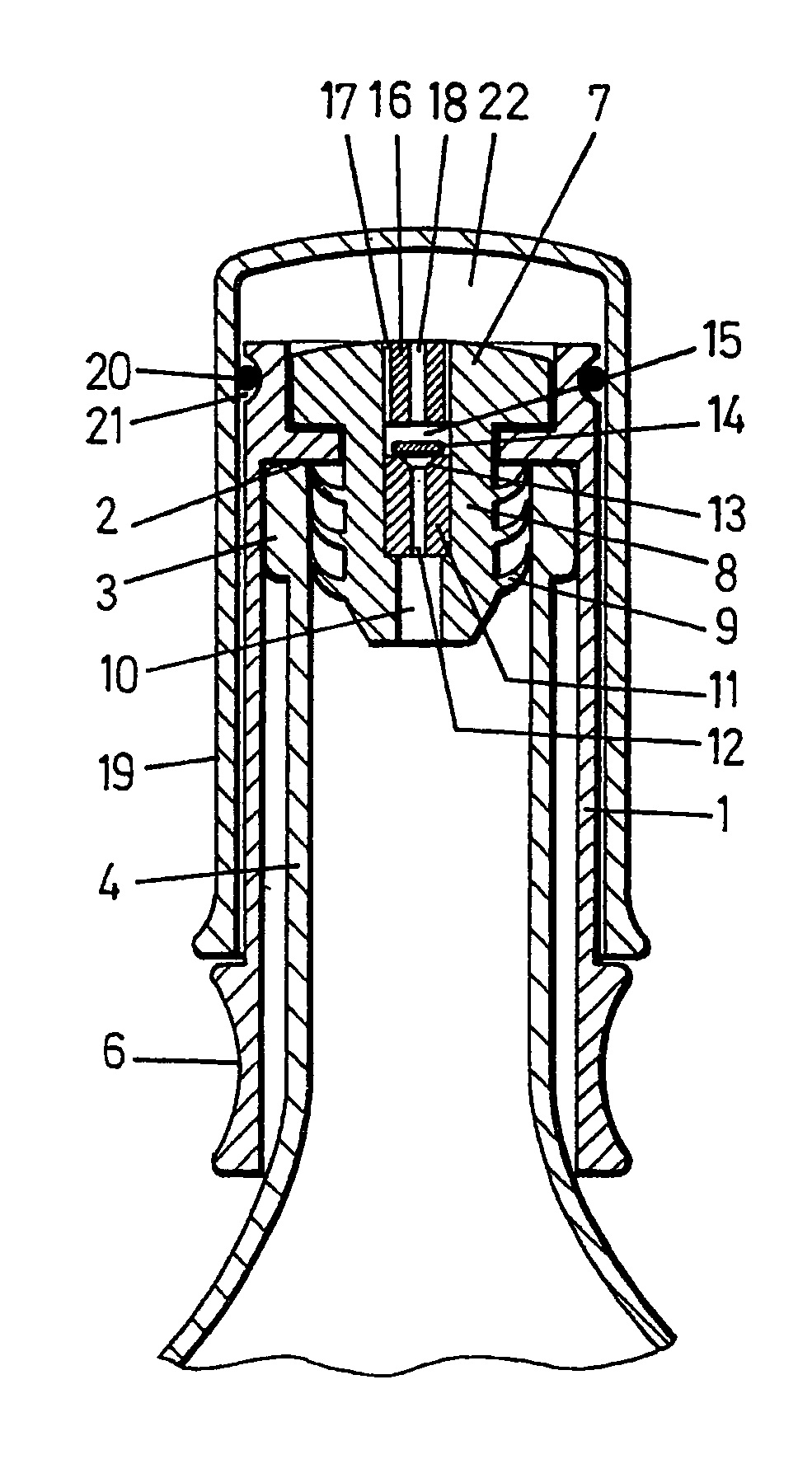

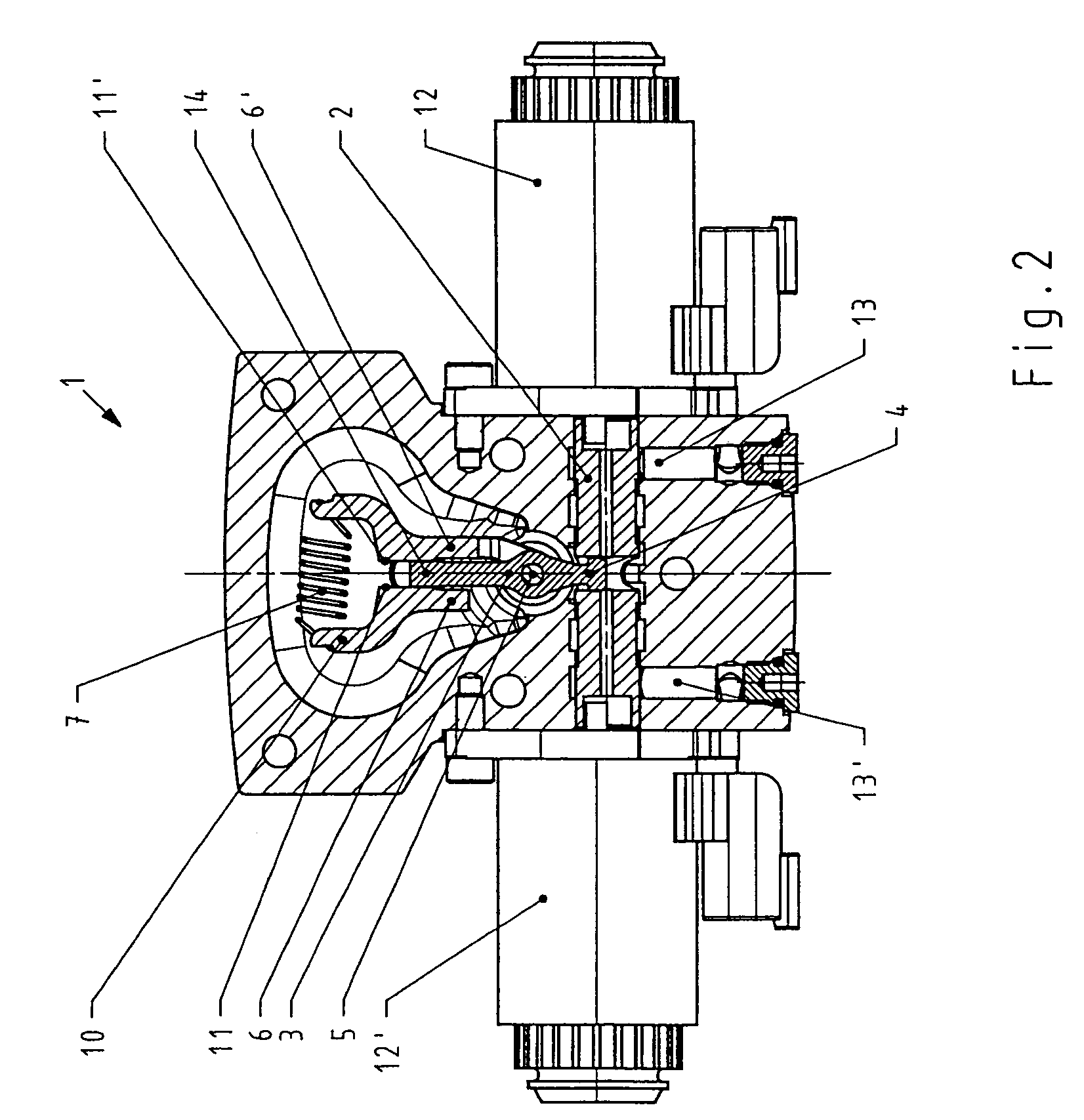

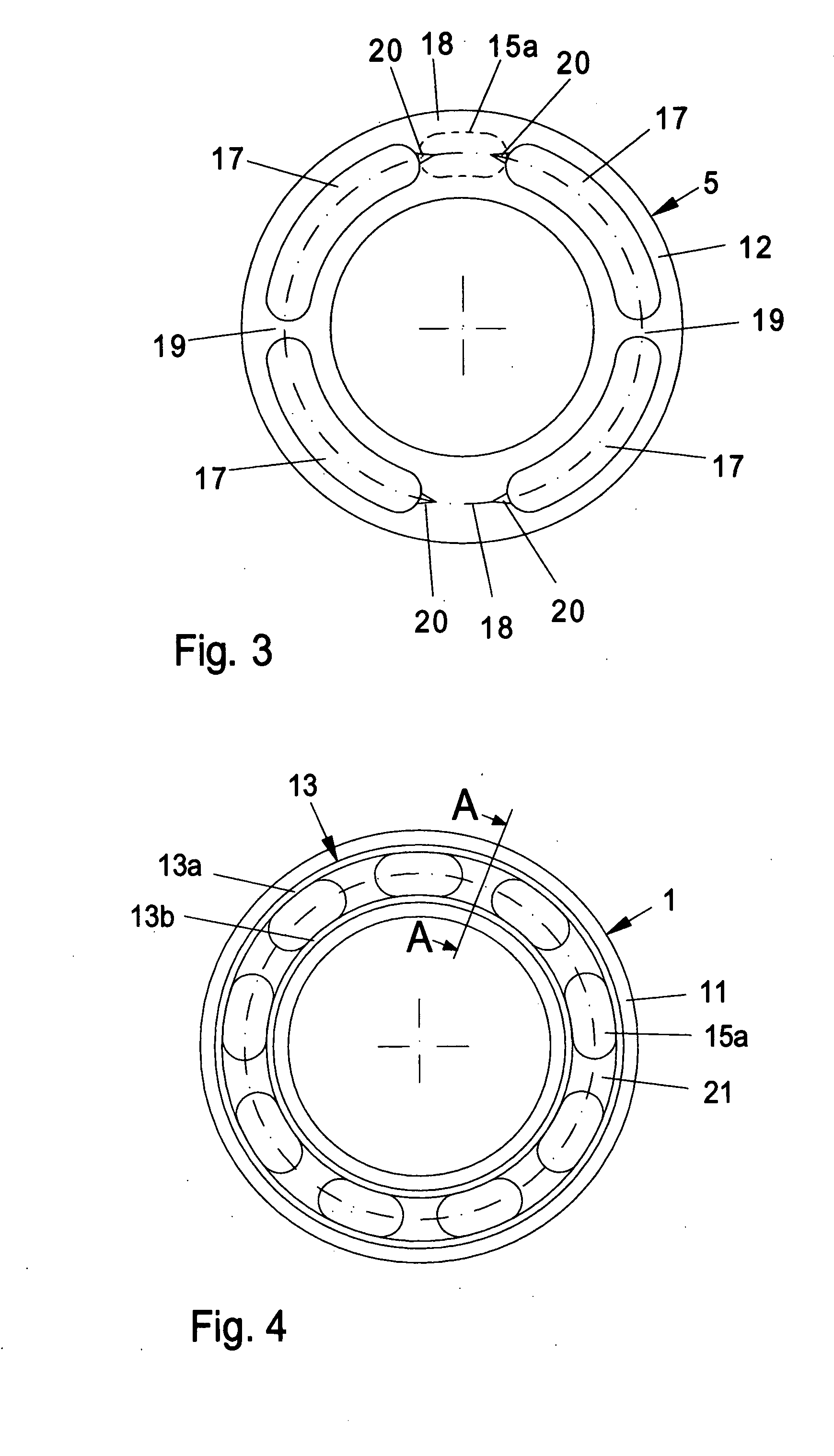

Axial-piston machine of the swashplate or oblique-axis type of construction

InactiveUS20050063834A1Made smallPrevent leakagePositive displacement pump componentsMulti-stage pumpsCylinder headOblique Axis

In an axial-piston machine of the swashplate or oblique-axis type of construction, a contact face of the cylinder head (1) is pressed against a stationary sealing face. The contact face has located in it transition orifices (15a) for the exchange of hydraulic fluid between the cylinder head (1) and the stationary part. The transition orifices (15a) are located on a raised annular collar (13) of the end face (11) of the cylinder head (1). Microgrooves (21) are recessed in the annular collar (13) between the individual transition orifices (15a), so that, of the supporting face, only two edge webs (13a, 13b) remain. The depth of the microgrooves (21) is only a few hundredths of a millimeter. This design prevents a hydrodynamic carrying effect between the cylinder head and the stationary part.

Owner:SAUER DANFOSS NORDBERG

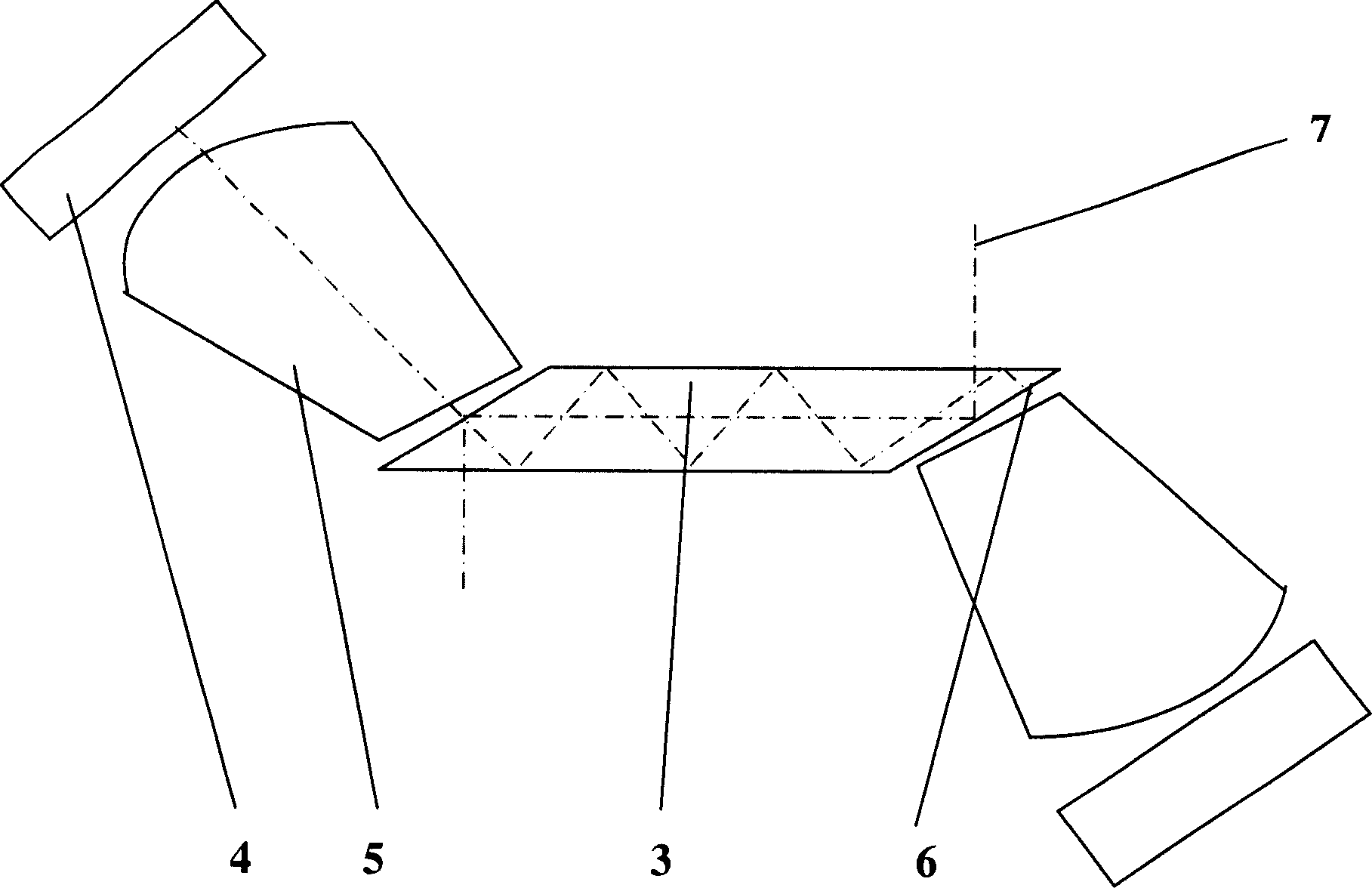

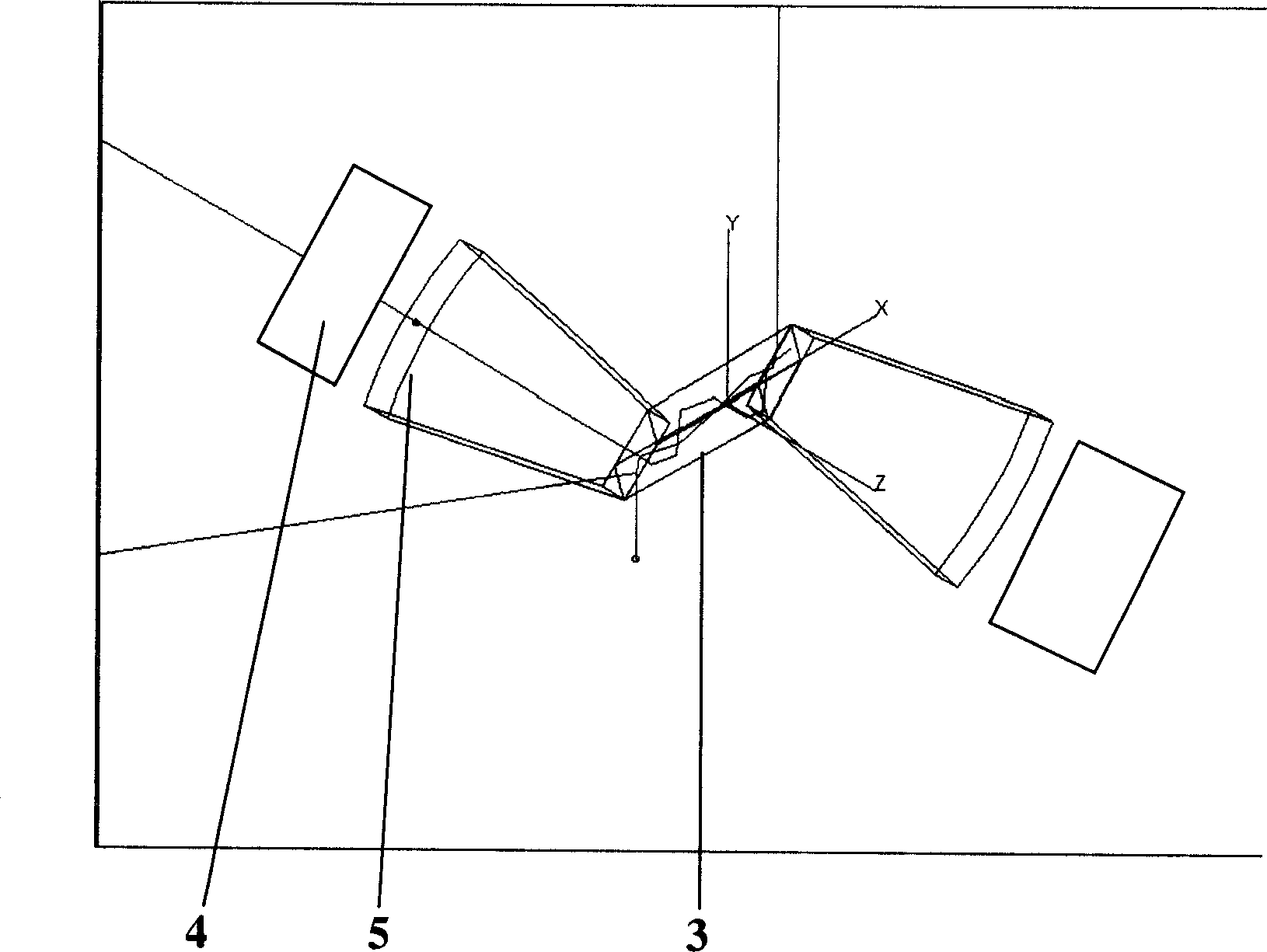

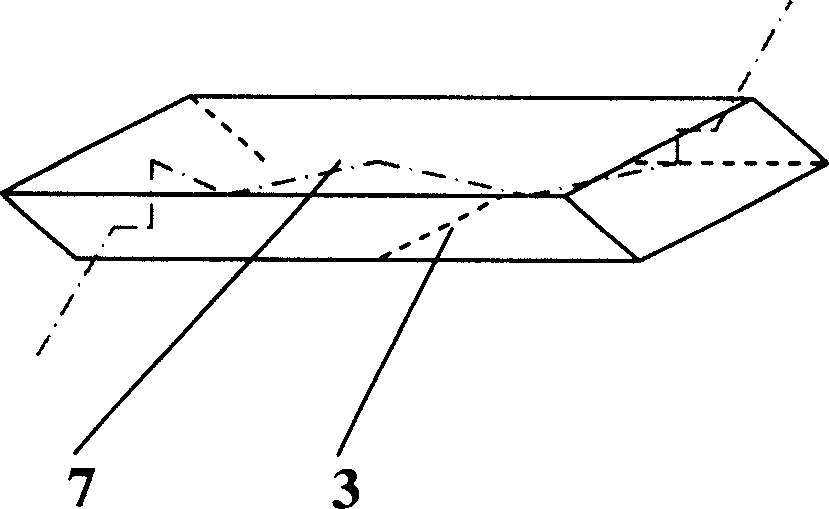

45 deg. oblique axis pumping method and pumping module for strip shaped laser crystal

InactiveCN1688070AGuaranteed uniformityImprove power densityActive medium materialActive medium shape and constructionLaser technologyReflection loss

This invention relates to a pumping method for a 45deg. clino-axis and a pump module, which combines the advantages of parallel optical axis pump and vertical optical axis pump and puts forward a 45deg.clino-axis pump method and a pump module. Since the pump light is transmitted in zigzag in the crystal, it ensures the uniformity of the pump and full absorption of the crystal to pump lights, it's more suitable for solid laser materials with low absorption coefficient and fine output beams, besides, the total reflection of the 45deg. can reduce the interface reflection loss and cost of a laser crystal, the coupled face of 45deg. cutting increases the coupled face by 1.4times, move pump lights are coupled in.

Owner:TSINGHUA UNIV

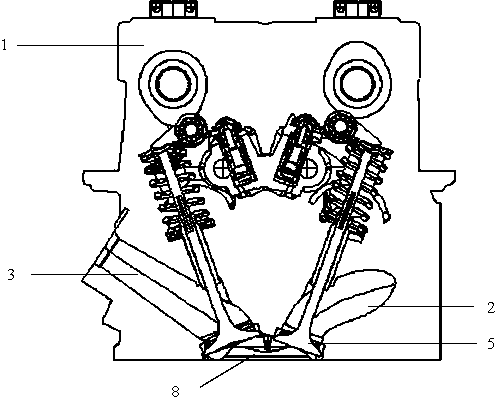

Atkinson cycle engine combustion system

ActiveCN103437897AStrong vortex motionImprove combustion efficiencyInternal combustion piston enginesCylinder headsCombustion systemCombustion chamber

The invention discloses an Atkinson cycle engine combustion system which comprises a cylinder cover and a piston. The design that the compression ratio of the piston is within the range from 4 to 12 is met, a top face of the piston is designed to be of a protruding structure, and the central area of the top face is designed to be in a concave spherical structure. Lift ranges of an exhaust valve, a first intake valve and a second intake valve are non-variable-valve lift ranges. The valve motion of the first intake valve and the valve motion of the second intake valve are driven by the same mechanism, the motion curves of the first intake valve and the second intake valve are not symmetrical and form an oblique axis vortex, the first intake valve and the second intake valve respectively comprises the lift range and a phase, vortex motion is formed in the air inside the cylinder due to the asymmetrical phase design, the asymmetrical design is combined with tumble and vortex and forms oblique axis vortex, and form much stronger turbulent motion at the ignition moment, and therefore the combustion efficiency is improved. According to the Atkinson cycle engine combustion system, on the premise that an original cylinder cover is not changed, due to the reasonable design of the valve motion and a combustion chamber, the combustion efficiency of the Atkinson cycle engine can be improved, therefore, a part of load oil consumption is reduced, and the low-speed torque is improved. The Atkinson cycle engine combustion system has the advantages of being simple in structure and easy to implement.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

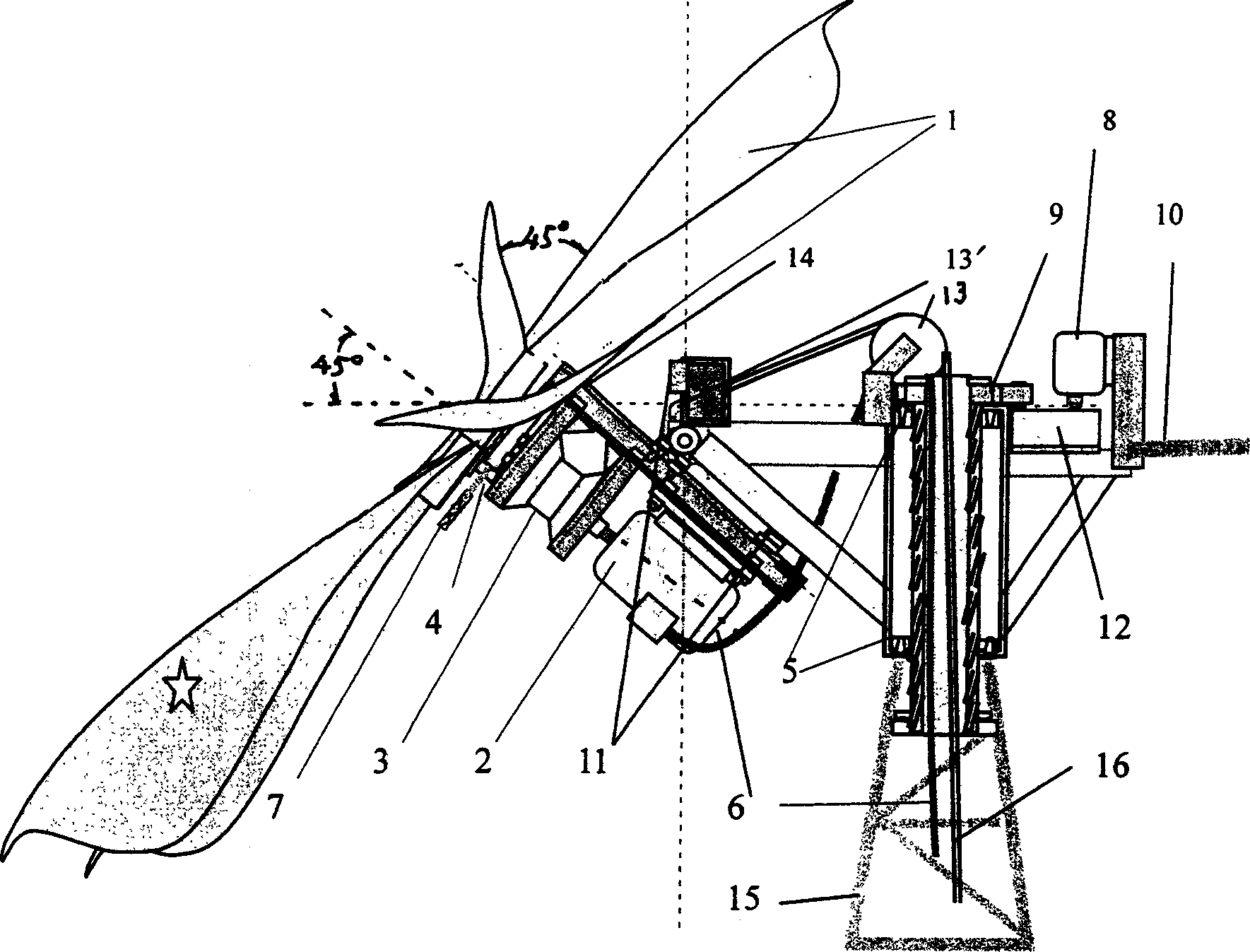

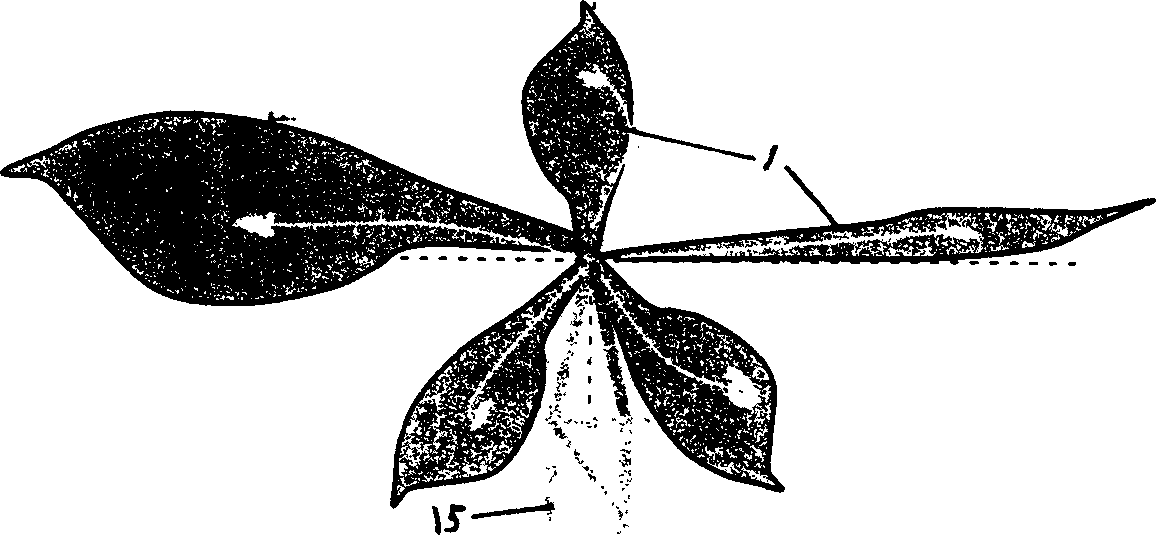

Oblique axis type windpower generating unit

InactiveCN1851258ATurn fasterBest angle of attackMachines/enginesWind motor combinationsRotational axisElevation angle

The invention relates to an angle-type wind-force generator, comprising vanes, generator, gear box, arrester, arrester link rod, inclined column bearing, cable, windward motor, windward gear, tail helm, gear box, machine seat and tower frame, where each vane is a petal-like, bucket ram-type vane whose section is wing-shaped, and plural vanes are integrally designed into a flower shape, and the machine set comprises a vane structure, inversely hanging on a windward frame on the front side of a transverse support rod tower and having a barycenter deviating from the hanging point and having a rotating shaft with a windward elevation angle of 10-89 deg.C, and the windward frame is provided with a pair of limit blocks. And the invention is also provided with a machine set lifting mechanism comprising two pulleys and steel wire rope. And it is convenient to electricity generation with breeze and able to make the vanes fast rotate to output higher power and carry out brake speed regulation and protection by the integral elevation of the machine set and vane structure, and the whole machine set is completely convenient to fall to the ground for maintaining. And it is a novel wind-force generator with certain ornamentality.

Owner:刘运超

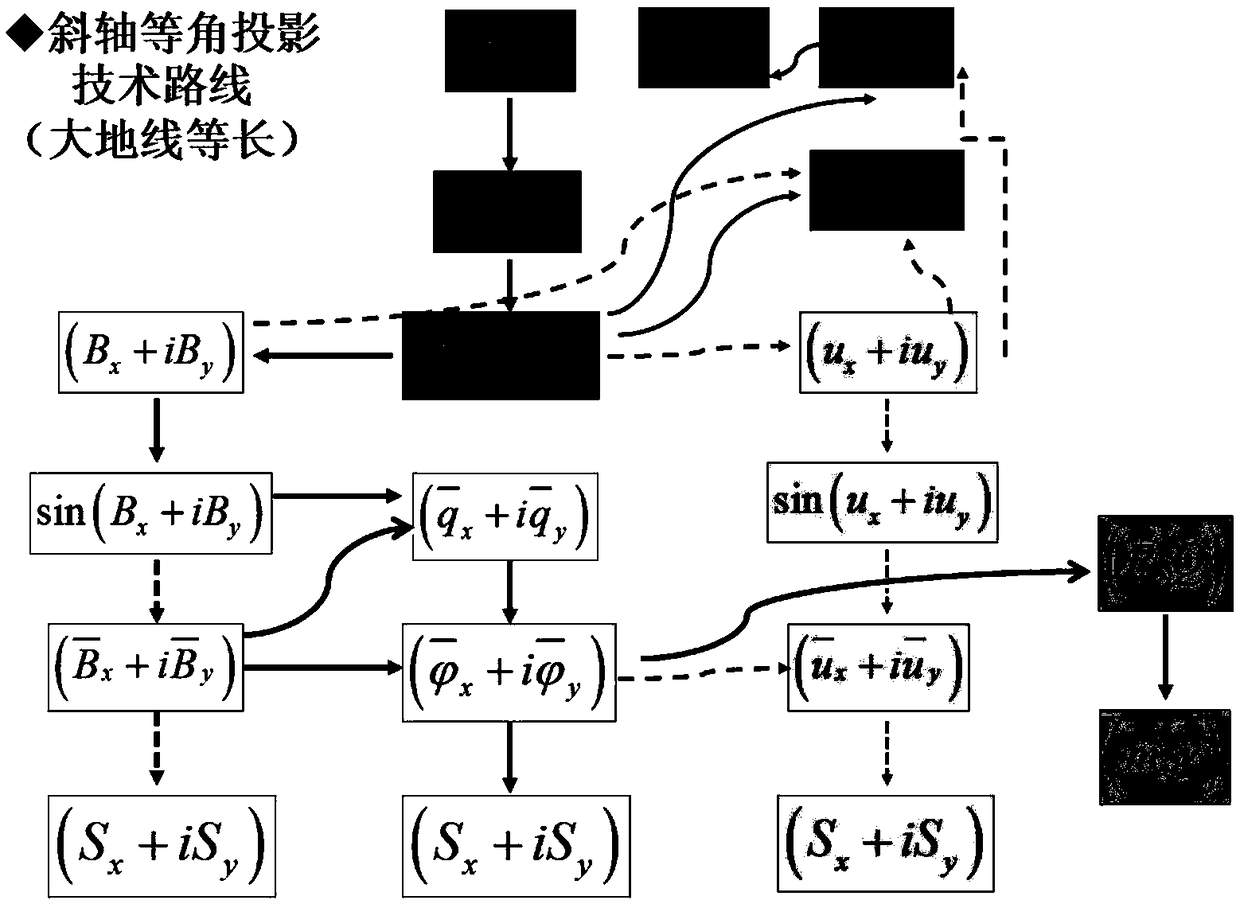

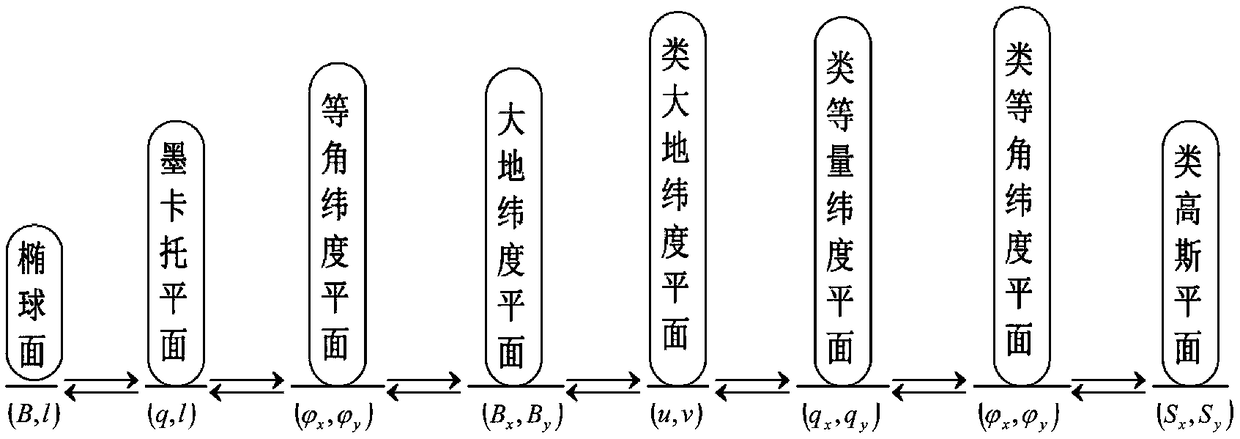

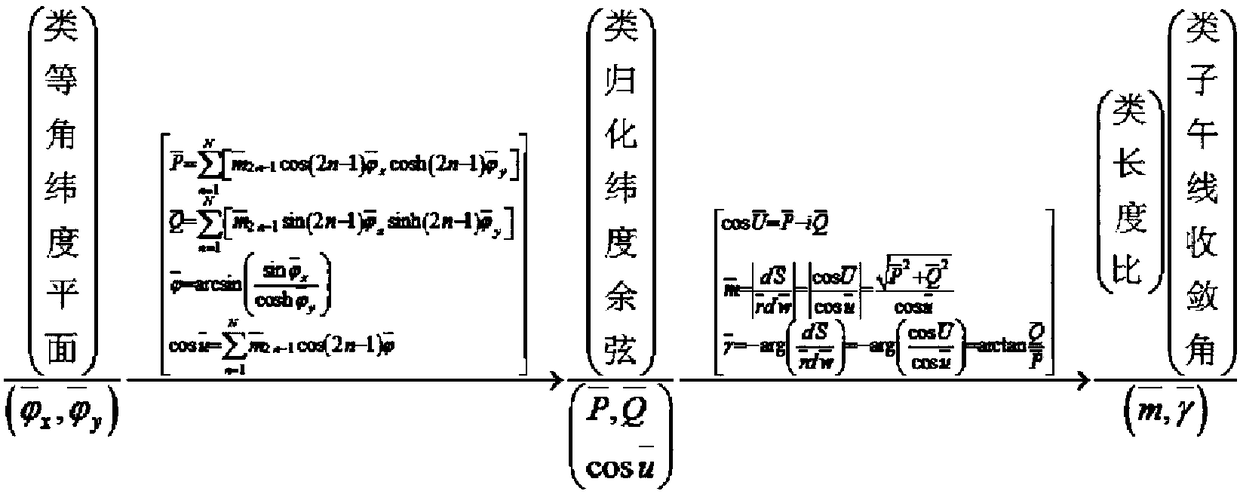

Calculation method of oblique axis gaussian projection based on equal length of geodesic

ActiveCN109344360AHigh precisionGuaranteed accuracyDesign optimisation/simulationComplex mathematical operationsHypothesisEllipse

The invention relates to an oblique axis Gaussian projection calculation method based on the equal length of a geodetic line, wherein a certain geodetic line is taken as a central meridian, projectedas a straight line, the length is kept constant, and the oblique axis Gaussian projection is realized. At the same time, it is agreed that the oblique Gaussian projection satisfies three basic conditions: the oblique Gaussian projection is a conformal projection, that is, an isometric projection; The geodesic line is a straight line after projection, and it is the symmetry axis of projection. Thelength remains unchanged after the geodesic line is projected. A line of earth is envisage as a central meridian, project as a straight line, With the help of geodetic-like latitude, normalized-like latitude, isometric-like latitude and isometric-like latitude, the hypothesis of geodetic mapping ellipse is put forward and proved. On the basis of the hypothesis, the expression of geodetic arc length and the complex and real formulas of oblique axis Gaussian projection based on a geodetic equilength are deduced. The real oblique axis Gaussian projection is realized and the deformation of lengthprojection is solved.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

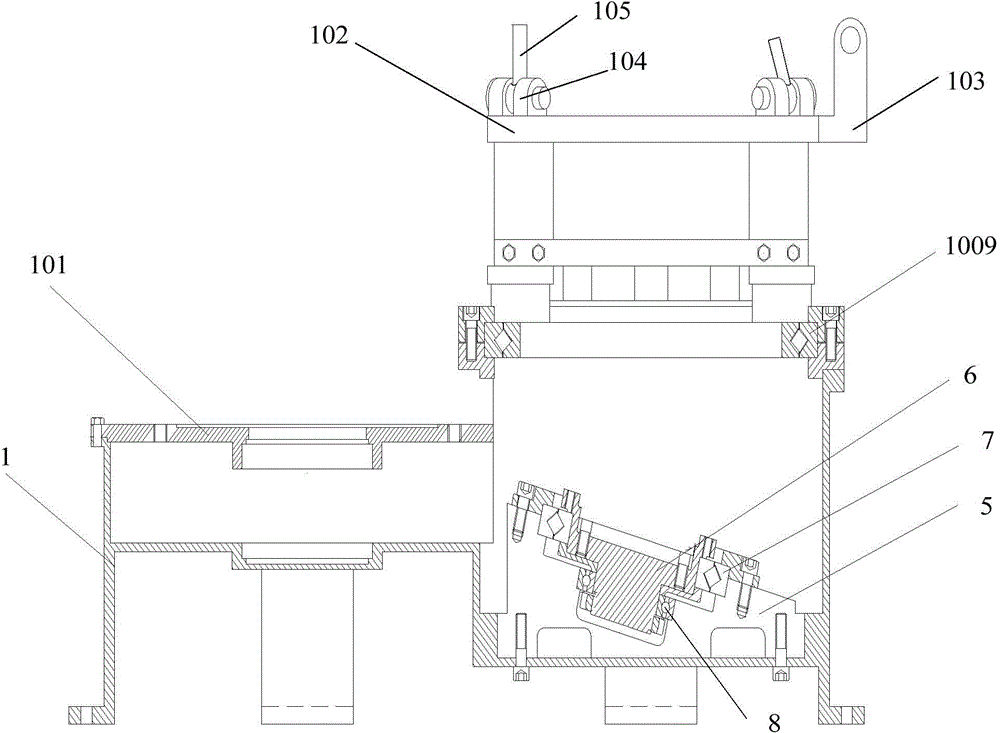

Mining pneumatic-conveying universal joint piston type concrete spraying machine

InactiveCN104564108AIncrease displacementIncrease output torqueUnderground chambersTunnel liningCouplingUniversal joint

The invention provides a mining pneumatic-conveying universal joint piston type concrete spraying machine. The problems of large size and low efficiency of an existing spraying machine are solved. The mining pneumatic-conveying universal joint piston type concrete spraying machine comprises a machine frame, wherein a rotor cylinder barrel is arranged on the machine frame, a plurality of material storage channels are formed in the rotor cylinder barrel, piston modules penetrate through the material storage channels, an oblique table base is arranged under the rotor cylinder barrel, a rotating seat rotating along the oblique axis is arranged on the oblique table base, a straight gear is fixedly connected to the top face of the rotating seat, the piston modules are connected with the straight gear through a double-cross universal coupling, a spline shaft penetrates into the central position of the rotor cylinder barrel and is connected with the rotating seat through a single-cross universal coupling, and an air distribution disc is arranged above the rotor cylinder barrel and is communicated with a hopper and an air box. A power mechanism is arranged on the machine frame, the driving end of the power mechanism is connected with a bevel gear, and the bevel gear is in meshed connection with the straight gear. The mining pneumatic-conveying universal joint piston type concrete spraying machine is small in size, simple in structure, capable of saving energy and protecting environment, abrasion-resistant, low in operation cost and high in efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

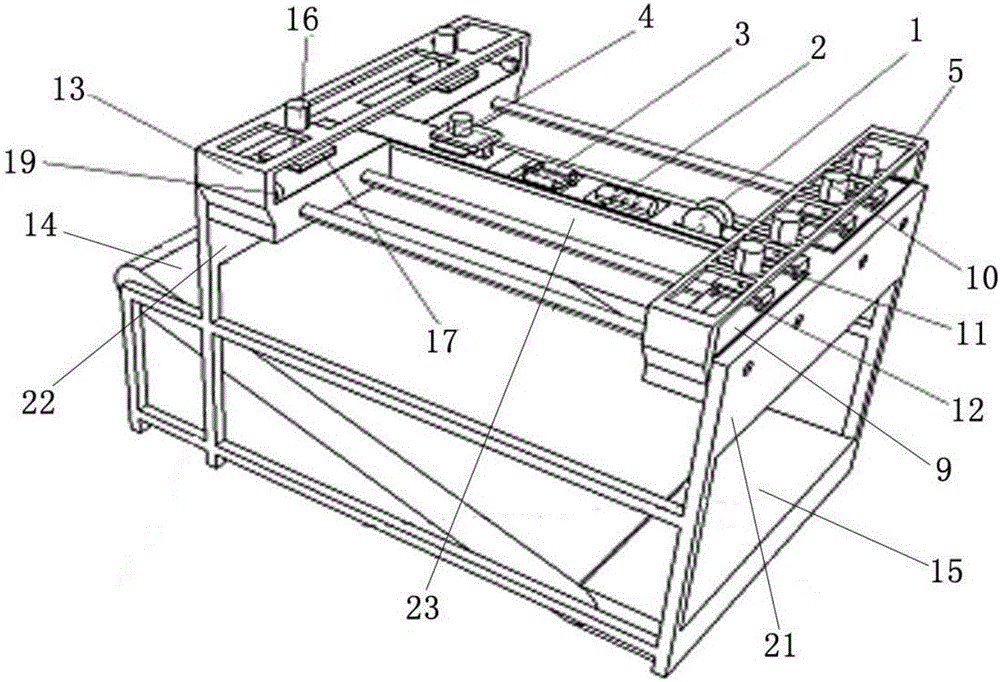

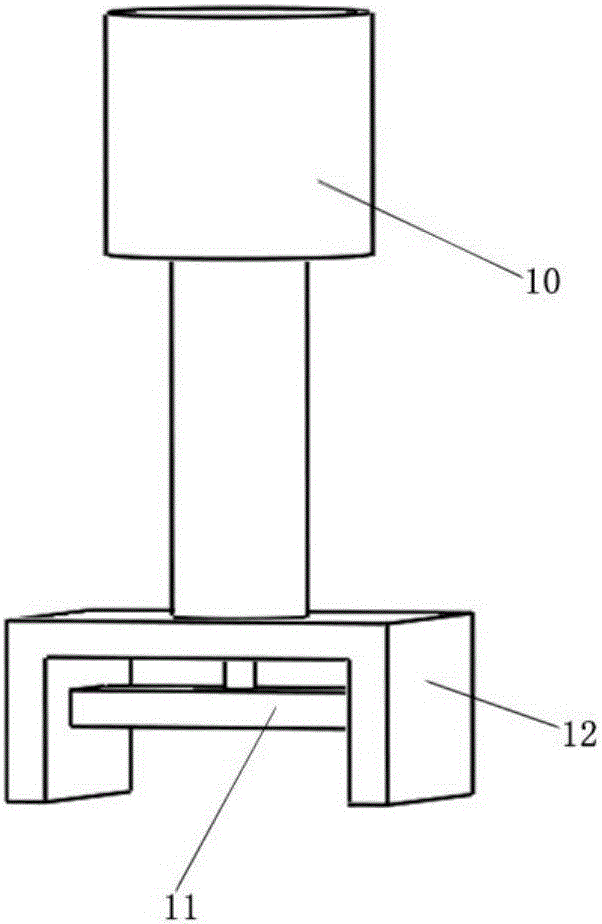

Automatic sled plate comb bonding machine and using method

InactiveCN106239641AGood adhesionGuaranteed StrengthPlywood pressesMulti-purpose machinesOblique AxisEngineering

The invention relates to an automatic sled plate comb bonding machine and a using method. The automatic sled plate comb bonding machine comprises a first mounting rack and a second mounting rack, wherein a worktable is fixedly arranged between the first mounting rack and the second mounting rack, a transporter is movably arranged at one end close to the first mounting rack; a bonding vehicle is movably arranged at one end close to the second mounting rack, and the transporter and the bonding vehicle respectively move along the axis direction of the worktable; the bonding vehicle comprises a pressing block which is obliquely mounted; the pressing block is used for crimping woods; a cutting device, a combing device, a gluing device and an adhesive pressing device are sequentially arranged along the axis of the worktable; the cutting device is arranged at one end close to the first mounting rack; the adhesive pressing device is arranged at one end close to the second mounting rack; and the combing device comprises a combing knife; and the combing knife reciprocates along the vertical direction. The automatic sled plate comb bonding machine combines functions such as cutting, combing, gluing and bonding into a whole, and the woods are pressed in an oblique axis manner by adopting vertical combs, so that bonding is firm.

Owner:SHANDONG UNIV

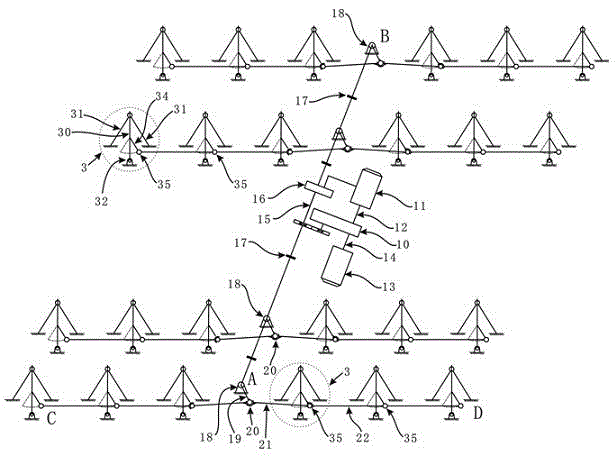

Array type solar oblique-axis tracking device

InactiveCN104656685AReduce in quantityReduced failure volumeControl using feedbackSufficient timeOblique Axis

The invention discloses an array type solar oblique-axis tracking device. The array type solar oblique-axis tracking device mainly comprises a reducer, a primary tracking motor, a secondary tracking motor, a tracking output shaft, a sensor, a longitudinal shaft rotating bracket, a primary tracking driving arm, a driving knuckle bearing, a primary connecting rod, a secondary connecting rod, and solar energy oblique single-axis tracking brackets, wherein secondary tracking driving arms and driven knuckle bearings are mounted on the solar energy oblique single-axis tracking brackets. When the primary tracking motor is broken, the secondary tracking motor provides tracking power, so that the photovoltaic power generation array can continuously work normally, and the maintenance personnel have sufficient time to maintain and replace the broken main tracking motor; both of the primary tracking motor and the secondary tracking motor with the redundant backup function are utilized to realize the purpose of using the tracking driving capability output by the same reducer to drive a plurality of solar energy oblique single-axis tracking bracket arrays, so as to reduce the number of motors in the former single-motor tracking situation, reduce the failure quantity and lower the tracking cost.

Owner:SHANGHAI JINXIN INVERTER

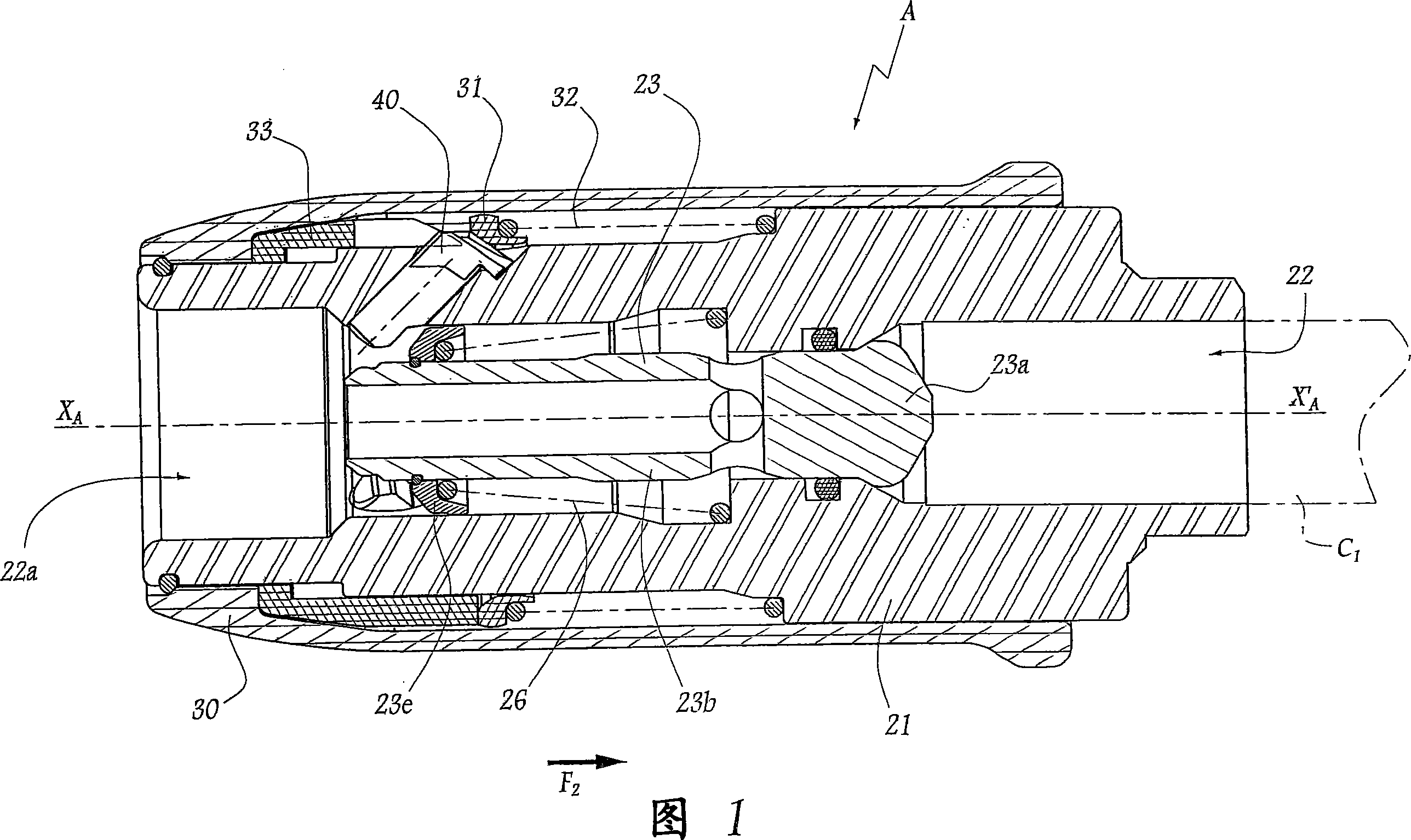

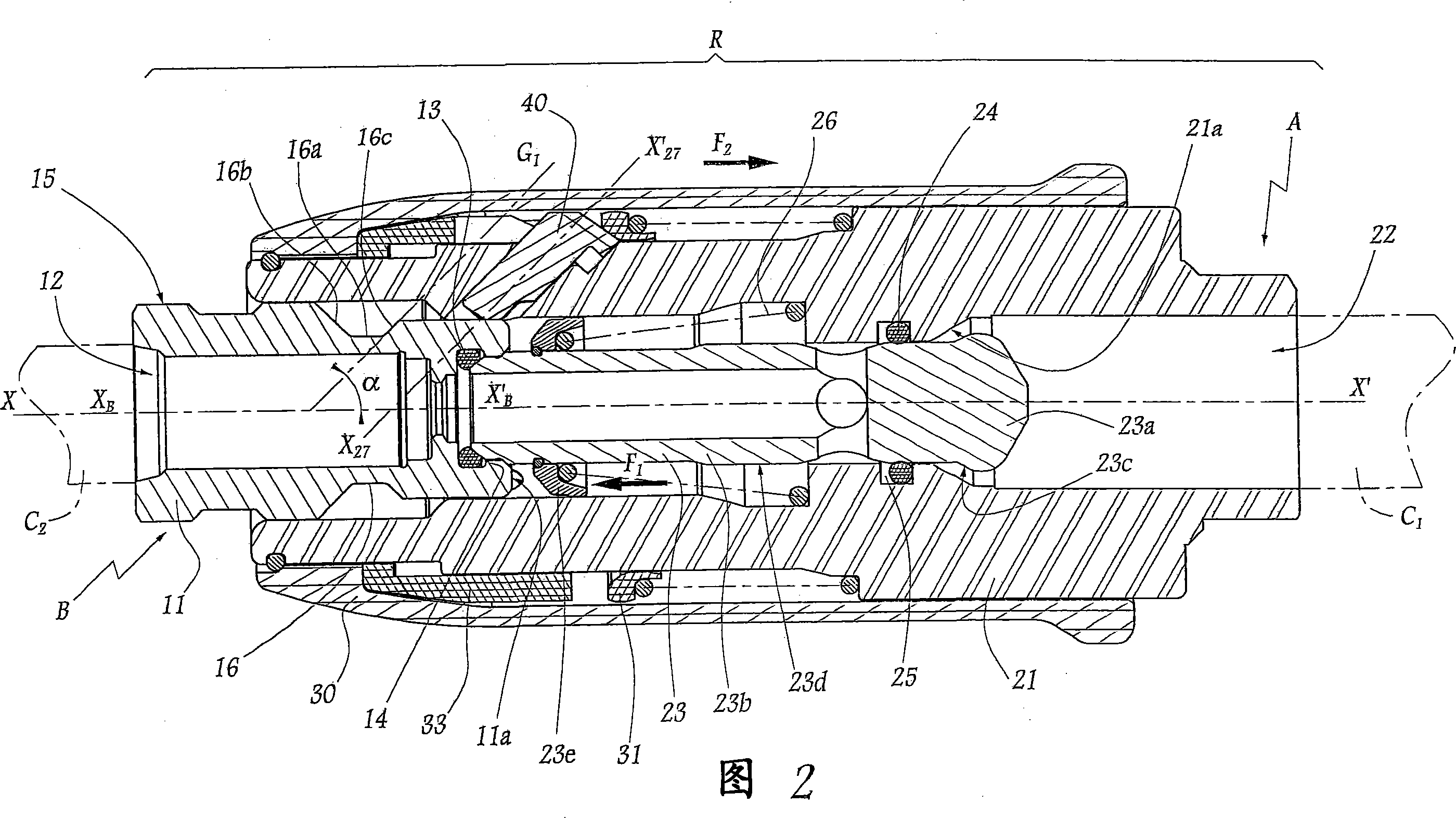

Female connection element and quick connection including such an element

The female rapid coupling element (A) is adapted to receive a male element (B) by insertion along a longitudinal axis (X-X'). It is equipped with at least one locking member ( 40 ), movable on an oblique axis (X27-X'27) and provided with an end ( 40 b) intended to be engaged in a groove ( 16 ) of a male element (B). A head ( 40 e) of the member is provided with at least one lug defining a first surface ( 40 h), oriented towards the end ( 40 b) and adapted to receive in sliding contact a corresponding surface ( 33 b) of a first component ( 33 ). The sliding plane (P1) between these surfaces ( 40 h , 33 b) is inclined at an angle of between around 75 DEG and 105 DEG with respect to the axis (X27-X'27) of translation of the member ( 40 ). According to the invention, the head ( 40 e) has two lugs arranged on either side of a rod for connection between the end ( 40 b) and the head.

Owner:STAUBLI FAVERGES SA

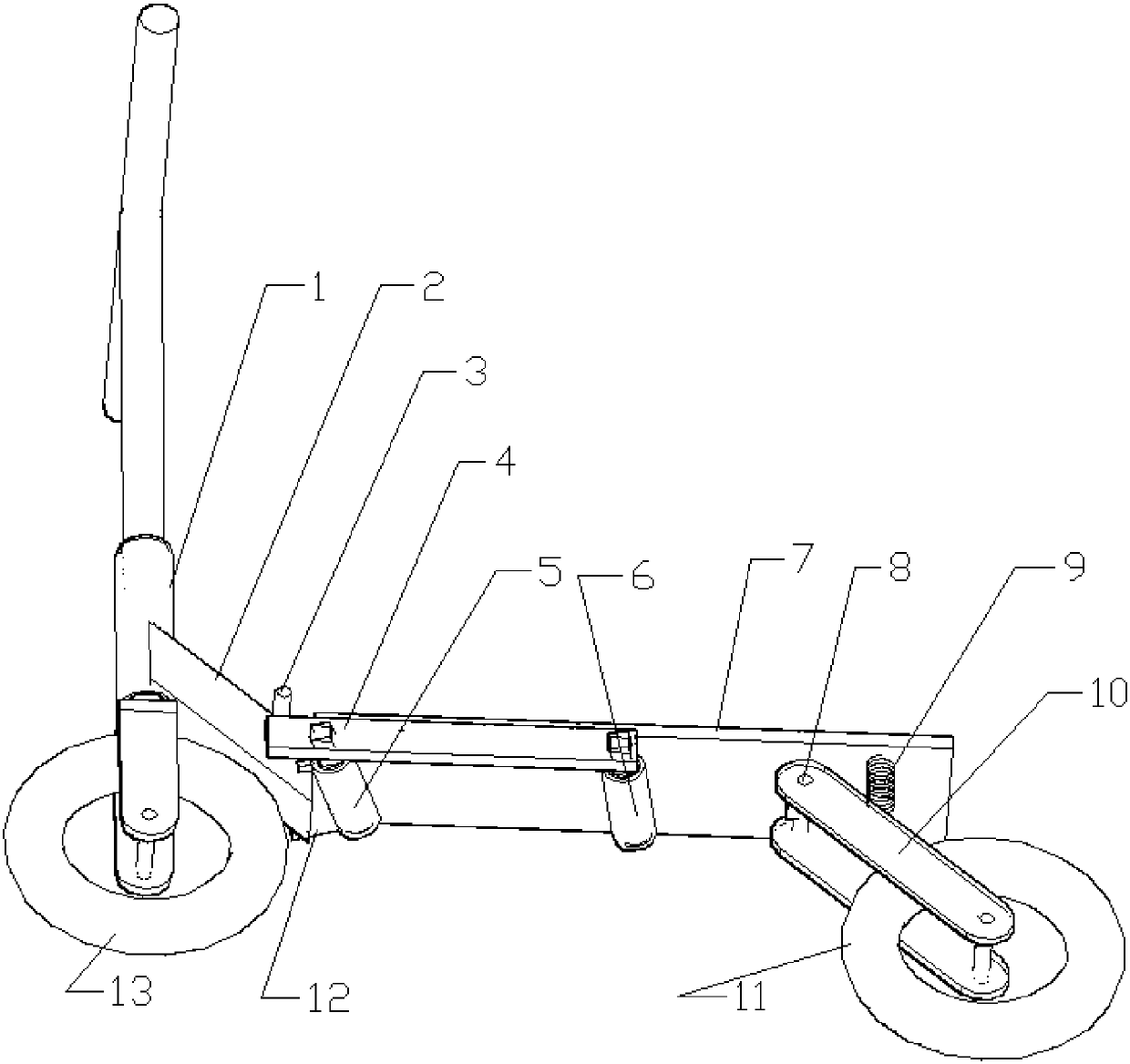

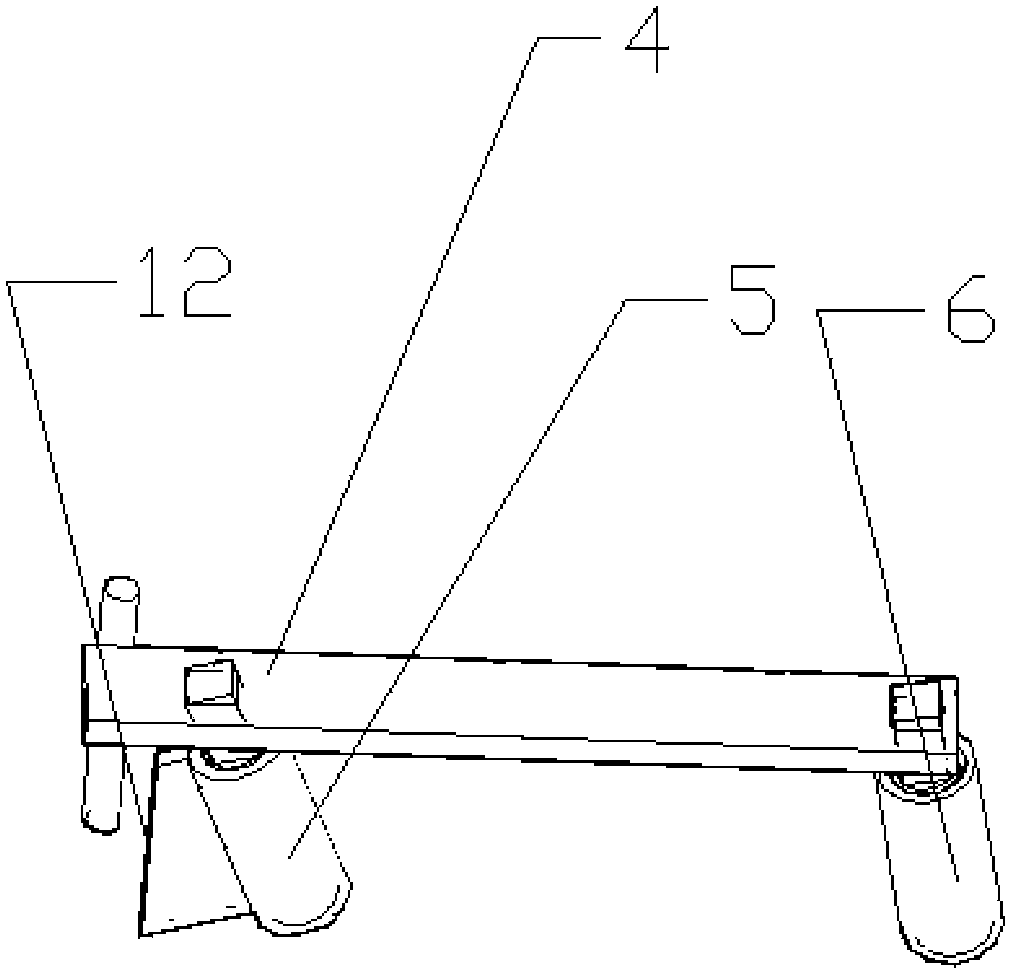

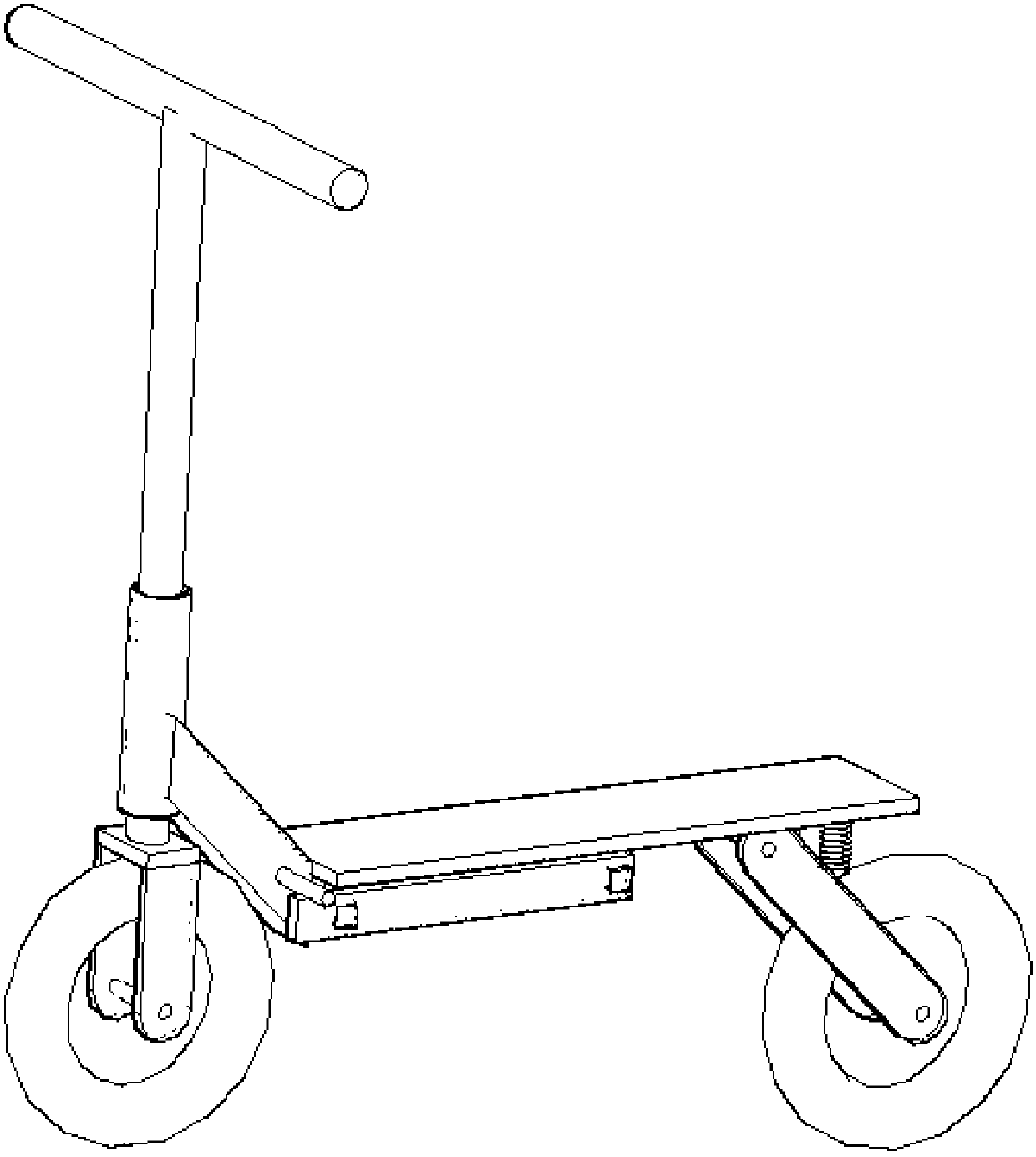

Folding scooter with oblique-shaft folder

The invention aims at providing an oblique-shaft folder and provides a folding scooter with the oblique-shaft folder. A front wheel and a rear wheel of the folding scooter with the oblique-shaft folder are gathered together at one end of the folding scooter with the oblique-shaft folder and are coaxially parallel to each other; a handlebar is at the other end of the folding scooter with the oblique-shaft folder; and while being carried, the folding scooter with the oblique-shaft folder is towed by holding the handlebar by hand and enabling the wheels to touch down so that clothes are preventedfrom getting dirty, the weight of the scooter can be overcome and the scooter is easy to carry. The folding scooter with the oblique-shaft folder mainly comprises a front folding part faucet assembly, the oblique-shaft folder, a rear folding part plate body and a rear wheel; an oblique-shaft folder front shaft bearing is connected with a faucet head tube oblique bar; a rear shaft bearing is connected with the middle part of a plate body; the rear wheel is mounted on a shock absorbing rear fork at the rear end of the plate body; and the horizontal position difference between a front wheel axleand an oblique-shaft folder front shaft is equal to the height difference between a rear wheel axle and an oblique-shaft folder rear shaft. By using the oblique-shaft folder, a folding part connectedwith the oblique-shaft folder is folded in different dimensions; and that is to say that the folding in the front and back dimensions and offset adjustment in the left and right positions are realized.

Owner:吴结华

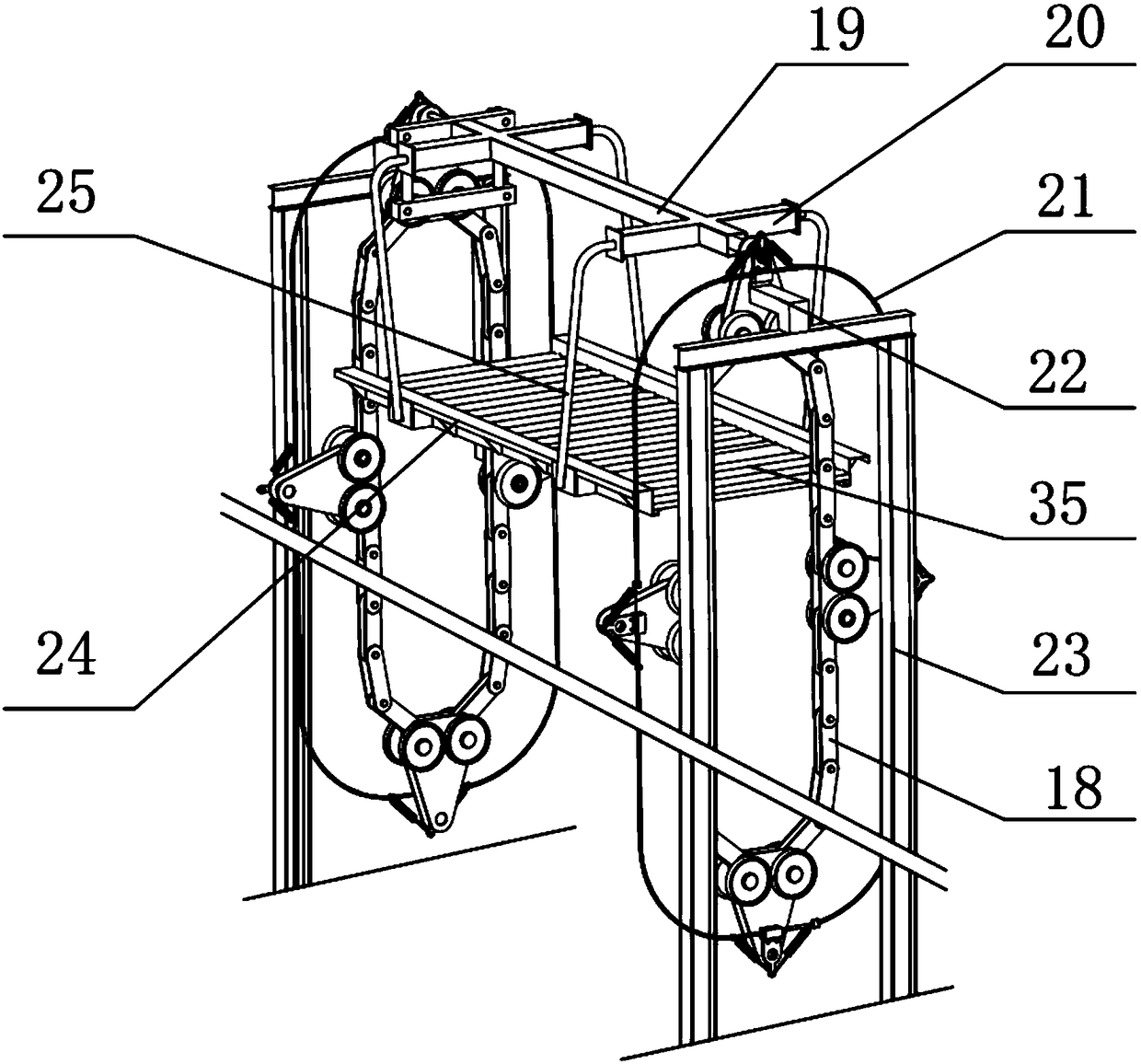

Safe driving device used for no-fall and no-slip vertical circulating stereo garage

The invention relates to a safe driving device used for a no-fall and no-slip vertical circulating stereo garage and belongs to the field of machinery. The safe driving device comprises a power transmission mechanism, a carrying mechanism and a safety protection mechanism, wherein a driving belt pulley is arranged on a shaft of a motor, a driven belt pulley is arranged on an input shaft of an oblique axis bevel gear speed reducer, a belt is connected with the driving belt pulley and the driven belt pulley, one output shaft of the oblique axis bevel gear speed reducer is connected with a lowercoupler, the other output shaft is connected with a transverse coupler, the lower coupler is connected with an upper coupler by virtue of an oblique axis, the upper coupler is connected with an inputshaft of an oblique axis worm and gear speed reducer, a grooved pulley is mounted on an output shaft of the oblique axis worm and gear speed reducer, and a carrying chain is connected end to end and is driven to operate annularly by virtue of the grooved pulley. Once the carrying chain or a carrying plate breaks due to various reasons in manufacturing or use, the condition that a car carrying plate falls down can not occur under the protection of a steel wire rope and a safety hook. No matter which transmission part breaks down, a vehicle can not slip or fall.

Owner:许继鲁

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com