Vertical-type oblique-axis concrete mixer

A technology of concrete mixer and inclined shaft, which is applied in the direction of cement mixing device, clay preparation device, chemical instrument and method, etc. It can solve the problems of poor uniformity of concrete mixing, prolonged mixing time, low mixing efficiency, etc., and achieves easy implementation and improved mixing Quality, improve the effect of stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

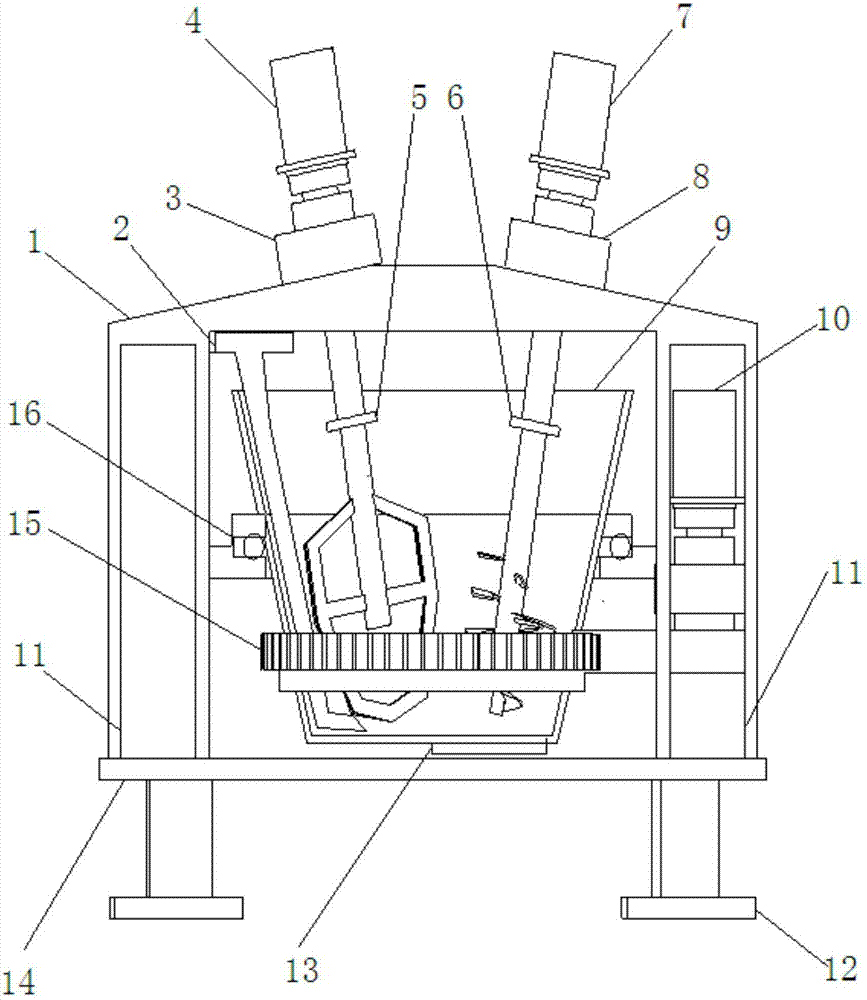

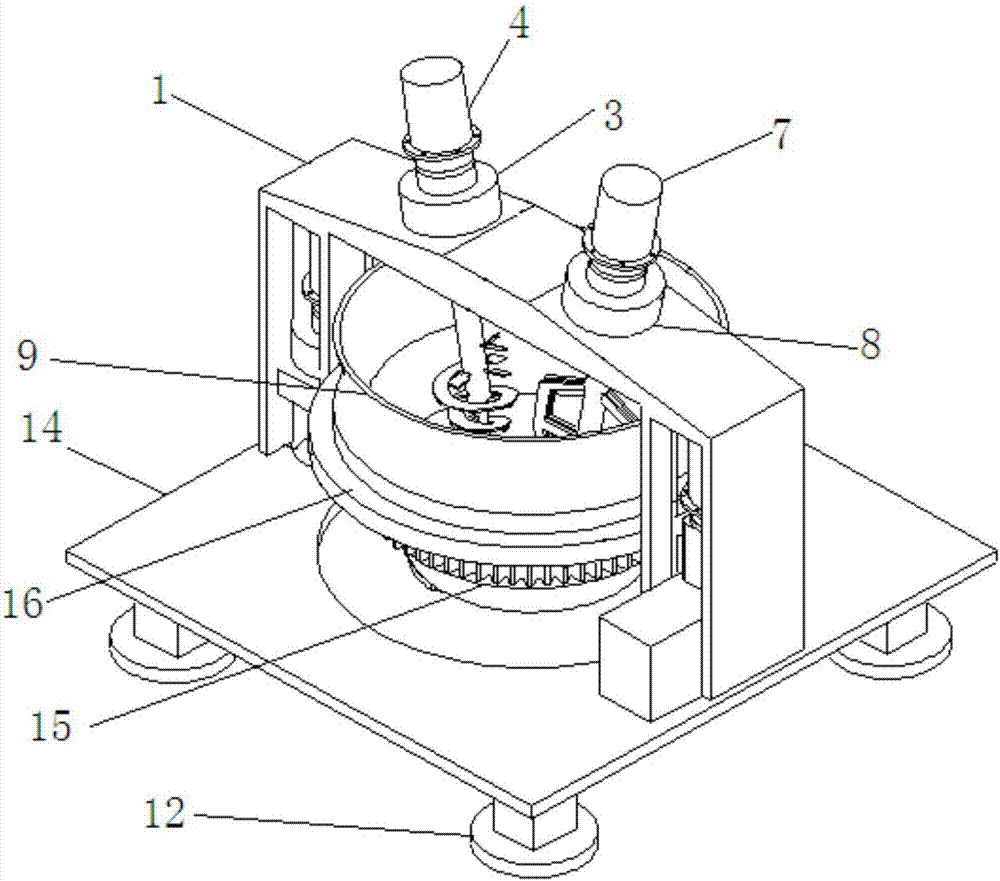

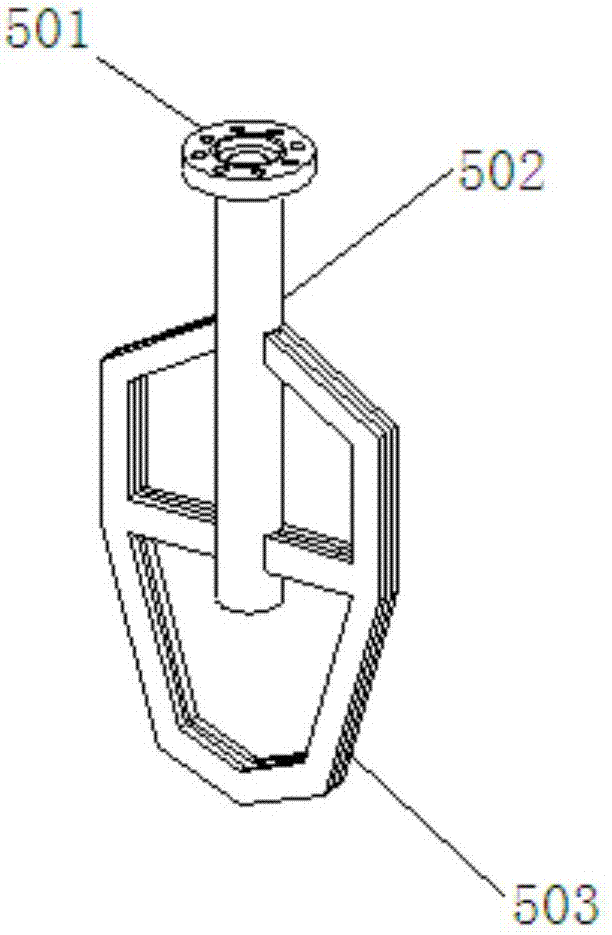

[0027] Such as figure 1 and figure 2 As shown, the embodiment of the present invention proposes a vertical inclined-axis concrete mixer, including: a frame, a drum drive motor 10, a beam 1, a stirring drive motor 4, and a material-lifting drive motor 7; a slewing bearing is arranged in the frame 16. A mixing drum 9 is arranged inside the slewing support 16, and an outer ring gear 15 is arranged on the outer wall of the mixing drum 9; the drum driving motor 10 is fixed on the frame, and the main shaft of the drum driving motor 10 is connected with a driving gear. The driving gear meshes with the outer ring gear 15; the crossbeam 1 is facing the port of the mixing drum 9, and the crossbeam 1 is provided with a stirring support 3 and a material lifting support 8, and the stirring support 3 is equipped with an agitator 5 for rotating and lifting. A material lifter 6 is rotated in the support 8, and one end of the stirrer 5 and one end of the material lifter 6 extend into the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com