Oblique axis type windpower generating unit

A wind power generation device and oblique axis technology, which is applied in the direction of wind power generation, wind power engine, wind power motor combination, etc., can solve the problems of low peak speed ratio, non-self-starting, low utilization rate of breeze, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

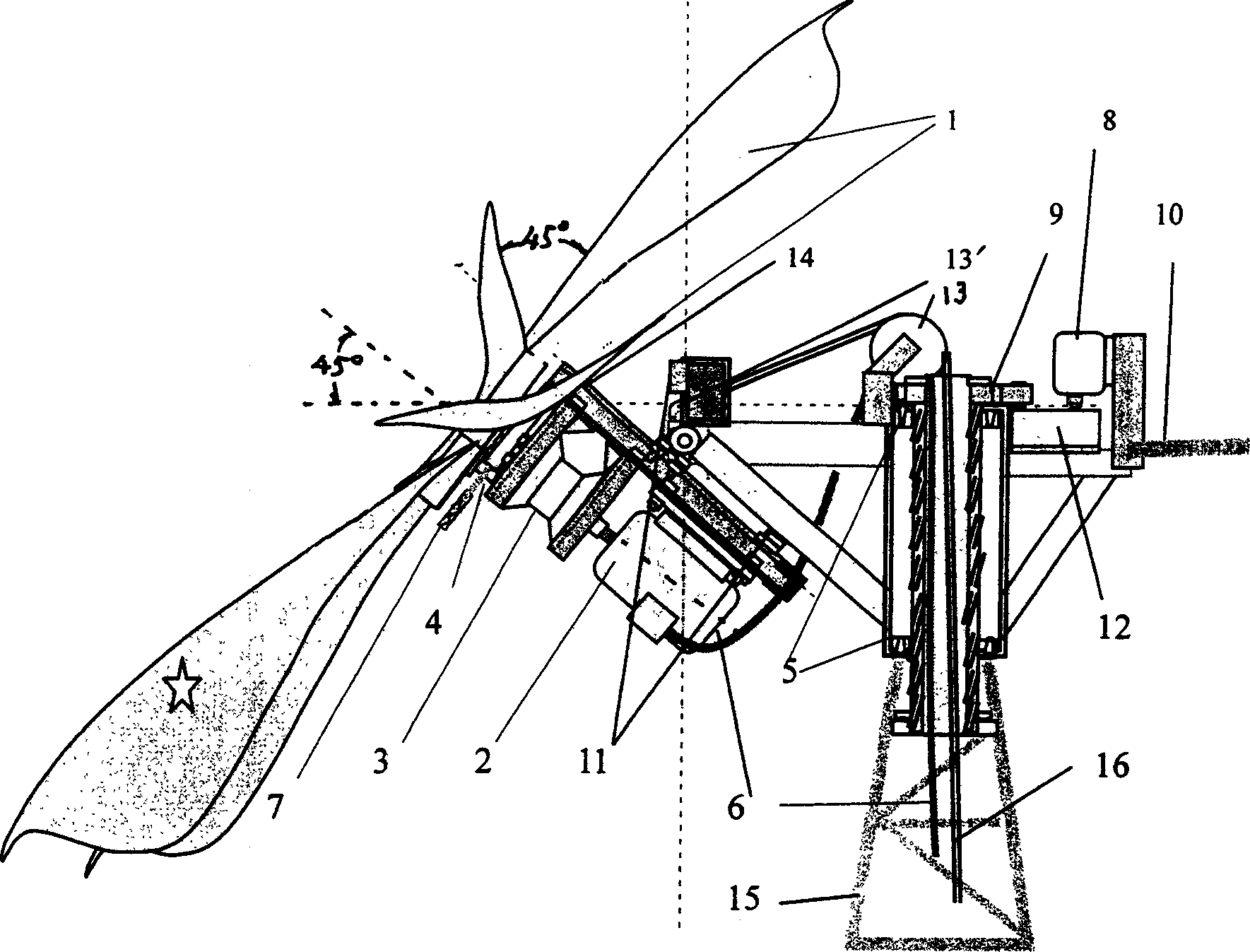

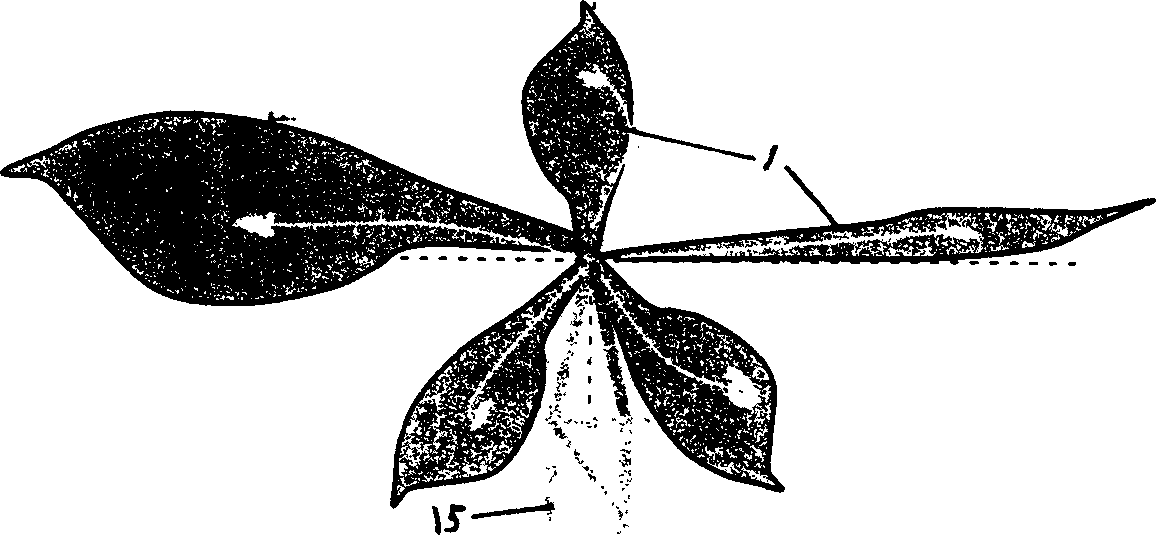

[0010] see figure 1 with figure 2 , the present embodiment has 5 fan blades, and the overall design is flower-shaped, and the unit includes an oblique axis wind power generation device with the overall rotation axis of the fan blade structure facing the wind up 45°, which includes fan blade 1, generator 2, variable speed Box 3, brake 4, inclined column bearing 5, cable 6, brake linkage lever 7, wind-facing motor 8, wind-facing gear 9, tail rudder 10, gearbox 12, machine base 14 and tower 15, and wind blade 1 is its Petal-shaped bucket-handled fan blades with wing-shaped cross-section; the unit including the fan blade structure is hung upside down on the wind-facing frame on the front side of the cross-arm support tower, and the center of gravity is offset from the suspension point; its rotation axis is raised by 45° against the wind.

[0011] In this device, a pair of limit blocks 11 are also provided on the wind-facing frame. Also be provided with center upward pulley 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com