Ultralow pore continuous automatic rod assembling and disassembling hydraulic coal drill and rod assembling and disassembling method thereof

A coal mine drilling rig, automatic technology, applied in the direction of drill pipe, drill pipe, earthwork drilling and mining, etc., can solve the problems that the drilling rig cannot be continuously and automatically up and down the rod, and cannot drill ultra-low holes, etc., and achieves the advantages of compact structure, simplified structure and reduced height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the technical means realized by the present invention, the creative features, the purpose and the effect achieved are easy to understand, the following in conjunction with specific illustrations, further elaborate the present invention:

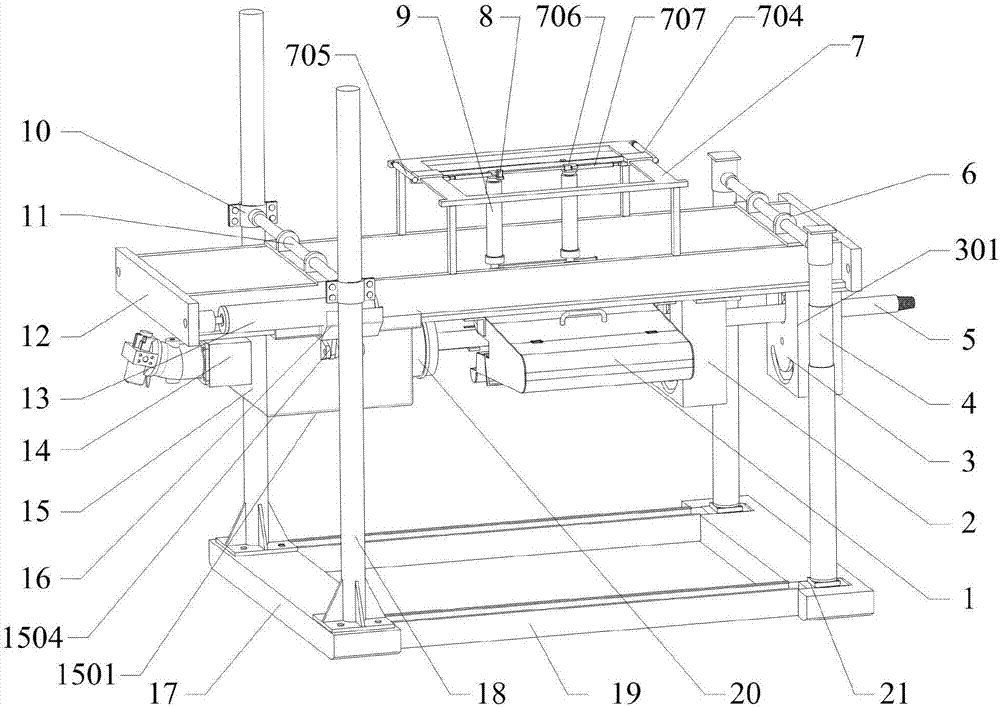

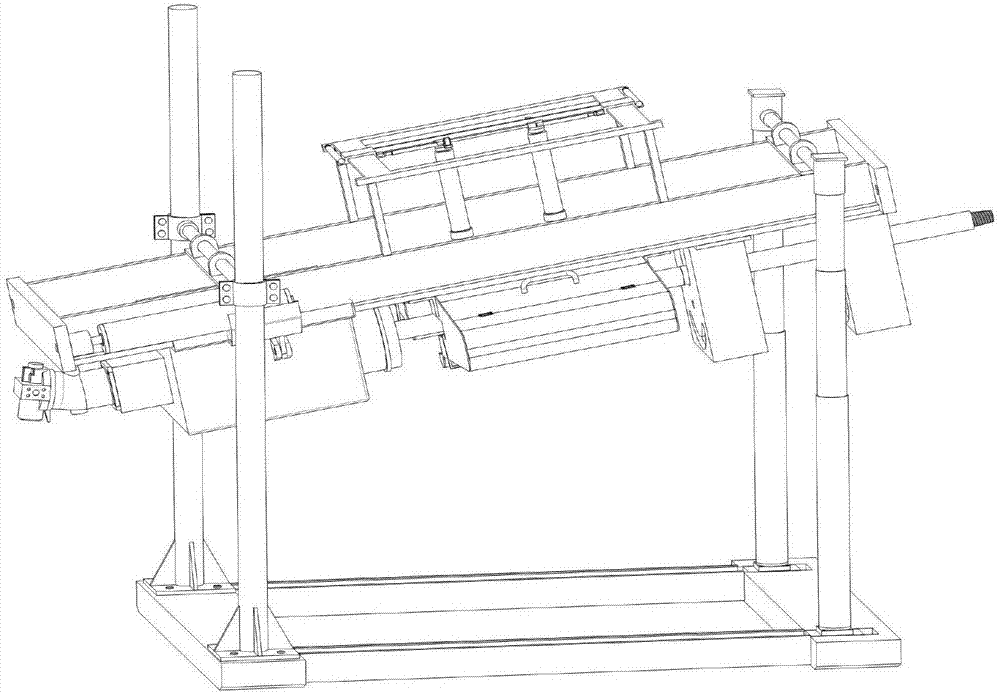

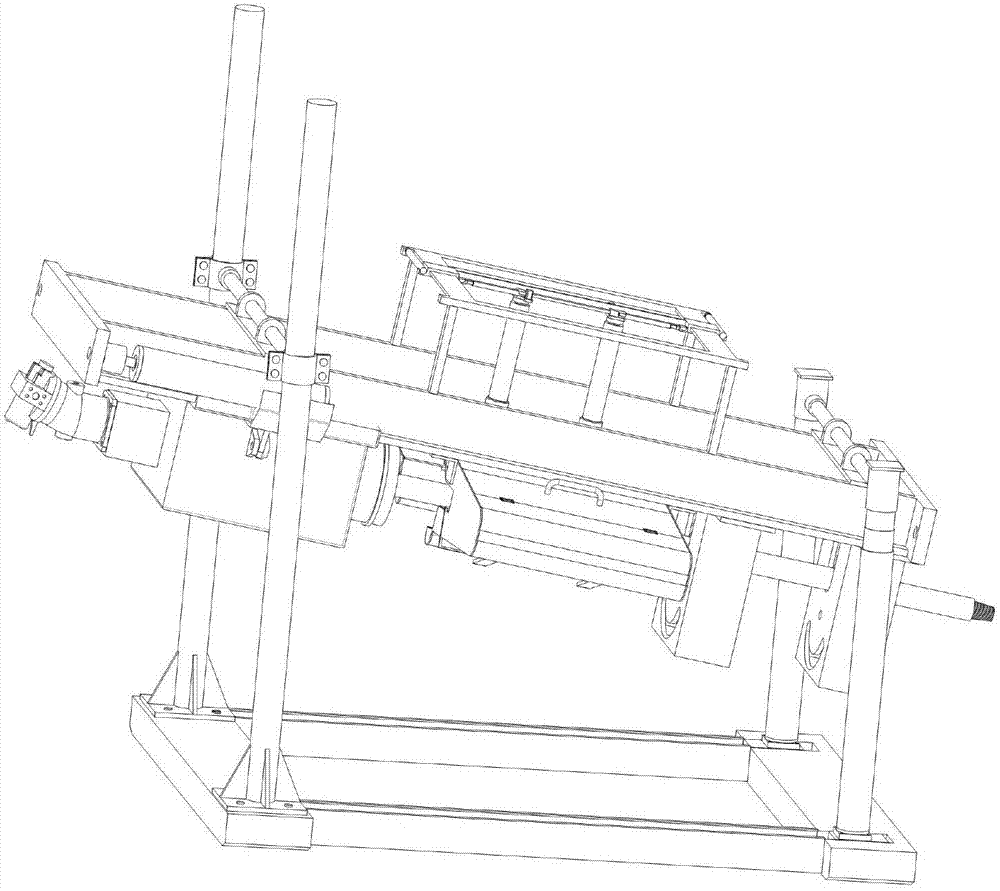

[0055] Such as figure 1 , figure 2 , image 3 and Figure 7 Shown: an ultra-low hole continuous automatic upper and lower pole hydraulic coal mine drilling rig includes a storage and unloading rod box 1, an intermediate gripper 2, a front gripper 3, a hydraulic telescopic support column 4, a drill pipe 5, a beam 6, and a manipulator hydraulic support 7. Hollow rotating platform 8, manipulator 9, frame pin 10, cross bar 11, workbench 12, gyrator propulsion hydraulic cylinder 13, inclined axis variable motor 14, reducer 15, pallet 16, frame seat 17, Support column 18, base guide rail 19, rubber cylinder type hydraulic chuck 20, slide block 21; Described base guide rail 19 has two, is welded on the both sides of frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com