Atkinson cycle engine combustion system

A combustion system, Atkinson's technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as thermal efficiency decline, low-speed torque deterioration, affecting the combustion of the in-cylinder mixture, to avoid adverse effects of combustion, improve Low-speed torque and improved combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

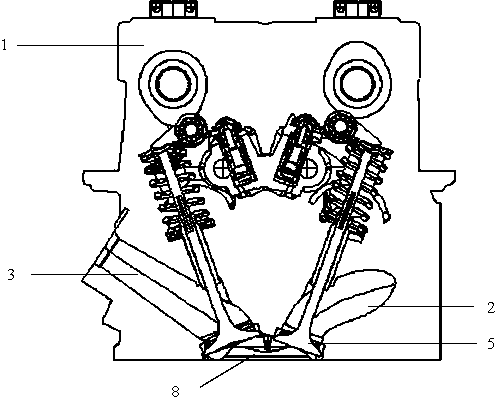

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

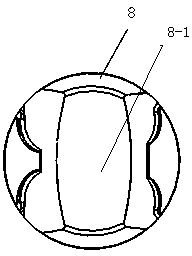

[0016] As shown in Figure 1, for the design of the piston (8), the piston is designed to meet the compression ratio between 12 and 14 without changing the cylinder head and cylinder body, and the top surface of the piston is designed as a protruding structure. The piston (8 ) The central area of the top surface is designed as a concave spherical shape to avoid the adverse effects of the high compression ratio protrusion structure on the tumble flow and flame propagation.

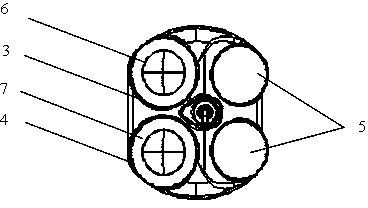

[0017] Further, the lifts of the exhaust valve (5), the first intake valve (6) and the second intake valve (7) are non-variable valve lifts; the intake valve 1 (6) and the intake valve 2 The valve movement of (7) is driven by the same mechanism, and the movement curve is designed as an asymmetric design, including lift and phase; one of the intake valve lifts is designed as a high lift, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com