Continuous extraction system for herbicide production

A herbicide and extraction technology, applied in the field of continuous extraction systems for herbicide production, can solve the problems of low extraction efficiency, inability to achieve continuous extraction, excessive time and labor consumption, etc., and achieve thorough, cleaner, and thorough extraction. , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

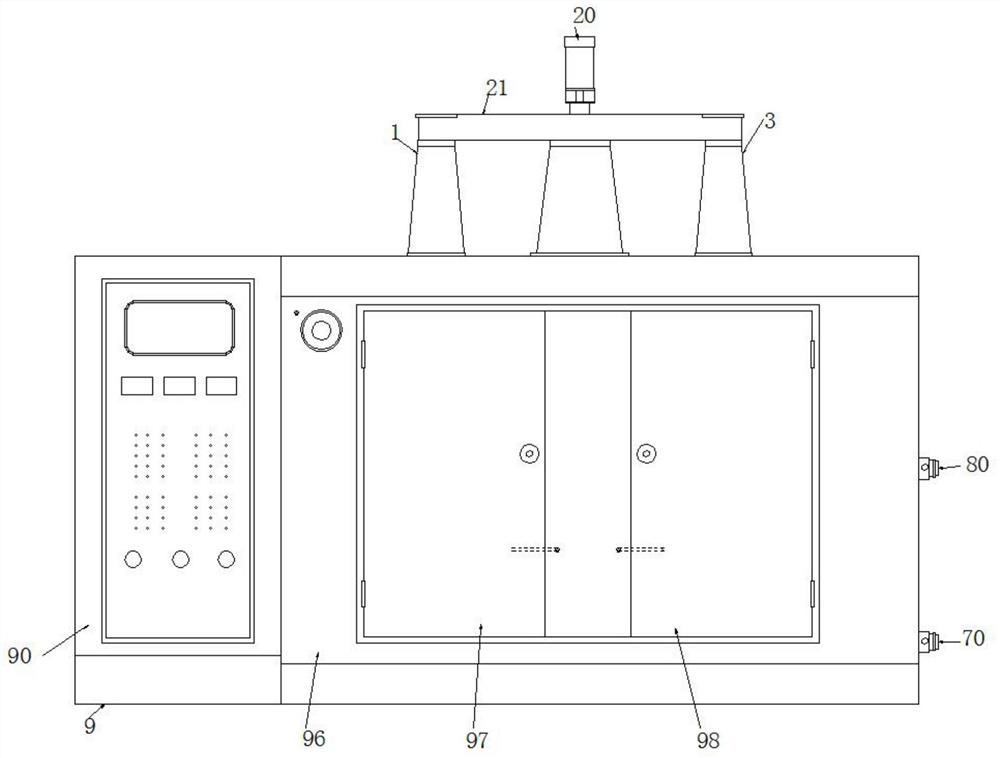

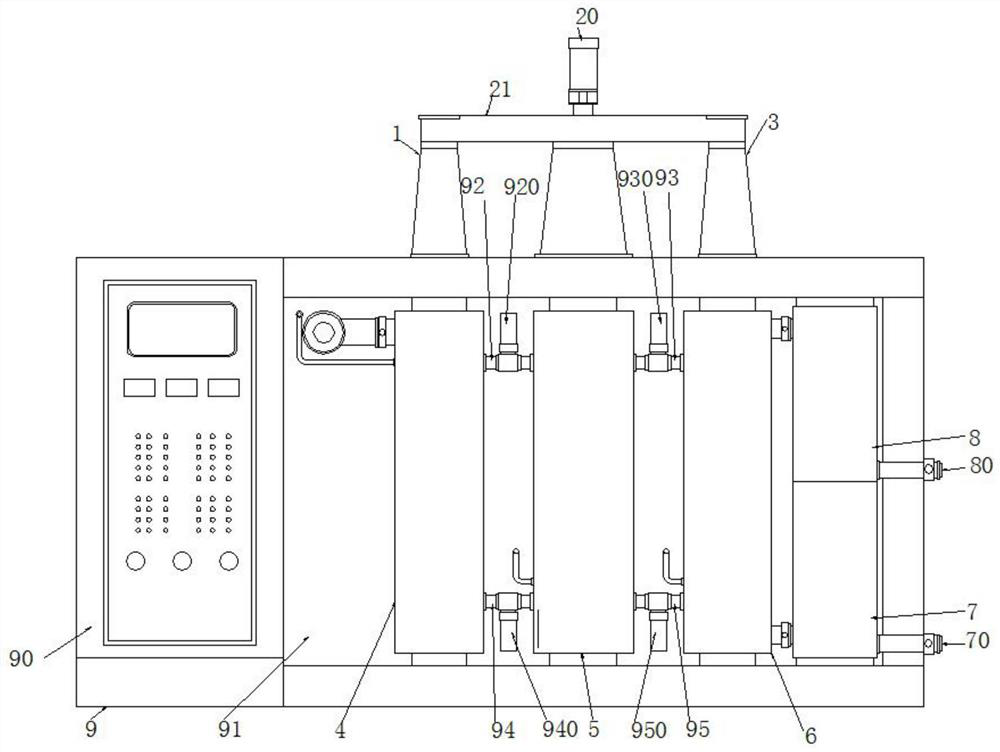

[0029] Specific implementation mode one, refer to Figure 1-9 , the present invention provides a technical solution: a continuous extraction system for herbicide production, comprising a first extraction tank structure 4, a second extraction tank structure 5, a third extraction tank structure 6 and a body 9, the left side of the body 9 The control cabinet 90 is arranged on the upper part, and the right part of the body 9 is provided with an extraction cabinet 96, and an installation cavity 91 is opened in the extraction cabinet 96, and the first extraction tank structure 4 is installed in the left part of the installation cavity 91, and the installation cavity The second extraction tank structure 5 is installed in the middle part of 91, and the third extraction tank structure 6 is installed in the right part of the installation cavity 91, and the light liquid collection tube 8 is installed on the upper right side of the third extraction tank structure 6, and the light liquid T...

specific Embodiment approach 2

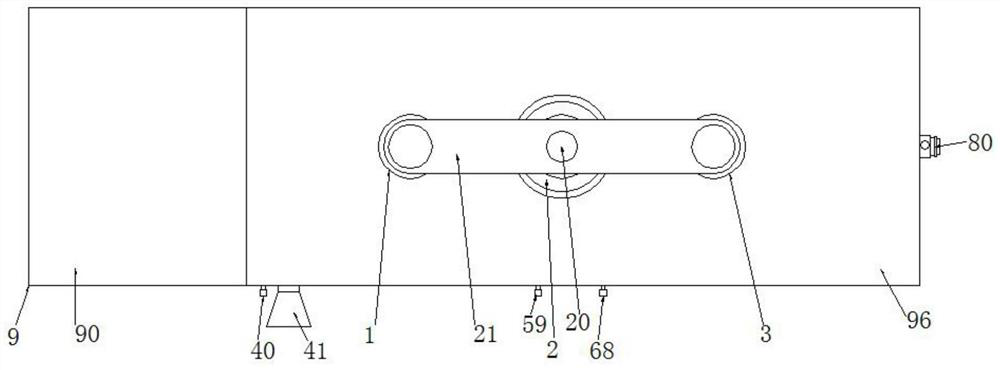

[0031] Specific embodiment 2. This embodiment is a further limitation of specific embodiment 1. In the present invention, the setting of the first protective cover 1 is used to protect the first rotating shaft 10, and the first rotating shaft 10 and the first extraction tank structure 4 in the first A stirring shaft 46 is connected together, so that the first stirring shaft 46 is driven to rotate together while the first rotating shaft 10 is rotating, so as to quickly stir the mixed liquid and the extracting liquid in the first extraction tank structure 4, so that they are evenly mixed together, It is helpful for rapid extraction and separation of the mixed liquid initially.

specific Embodiment approach 3

[0032] Specific embodiment 3, this embodiment is a further limitation of specific embodiment 1, the setting of the second protective cover 2 in the present invention is used to protect the second rotating shaft 22, the second rotating shaft 22 and the first extraction tank structure 5 in the second The two stirring shafts 51 are connected together, so that the second stirring shaft 51 is driven to rotate together while the second rotating shaft 22 is rotating, so as to quickly stir the mixed liquid and the extracting liquid in the second extraction tank structure 5 to make them evenly mixed together, It is helpful for rapid extraction and separation of the mixed solution for the second time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com