Patents

Literature

47results about How to "Thorough extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supported hydrophilic polyvinylidene fluoride microporous membrane and preparation method thereof

ActiveCN104667763AThorough extractionUniform pore size distributionSemi-permeable membranesPolyvinylidene difluorideSolvent

The invention relates to a supported hydrophilic polyvinylidene fluoride microporous membrane and a preparation method thereof. The pore size of the microporous membrane is 0.1-20 mu m, and the thickness of the microporous membrane is 90-200 mu m. The method comprises the following steps: 1)the preparation of a casting membrane solution, dissolving a polyvinylidene fluoride resin in a solvent firstly, adding hydrophilic components and an additive, and at temperature of 30-80 DEG C, fully stirring the obtained mixture so as to form the uniform and stable casting membrane solution; and 2) membrane formation by phase inversion: casting the casting membrane solution on a support layer, carrying out membrane wiping on the support layer saturating in the casting membrane solution by using a scraper under the condition that a gap between the scraper and the support layer is 15-40 mu m, standing for 10-400 seconds in the air, and after a membrane sequentially passes through a first coagulation bath, a second coagulation bath and a third coagulation bath, taking out the membrane, and drying the membrane,,and then the hydrophilic microporous membrane is obtained. Compared with the prior art, the membrane disclosed by the invention has the advantages of thorough extraction, uniform pore size distribution, better filtering accuracy and filtering efficiency, capability of being applied to continuous mass production, stable product performances, and the like.

Owner:上海一鸣过滤技术有限公司

Vacuum extraction brewing system

The invention discloses a vacuum extraction brewing system. The system includes a transparent glass brewing chamber, a pipe control system and a tea base. The transparent glass brewing chamber is sealed from top to bottom, an umbrella-shaped flow guiding sheet is contained in the top of the transparent glass brewing chamber, and the tea base comprises a detachable filtering net. Compared with other tea boiling machines, the system is more complicated in control; according to the brewing system, the water supply amount, the water temperature and the brewing time are controlled precisely; moreover, by adopting a unique vacuum extraction technology, the system can complete brewing of a cup of tea with strong fragrance in a short time. The brewing system has the advantages that the operation is simple, the brewing speed is high, the intelligentization is high, the extraction rate is high, installation and dismantling are convenient, convenience is provided for cleaning, and a high-qualityexperience can be provided for users. The vacuum extraction brewing system is not limited to brewing of tea and can also be used for preparation of different kinds of flower tea, healthcare tea and coffee.

Owner:深圳市恒帮康养科技有限公司

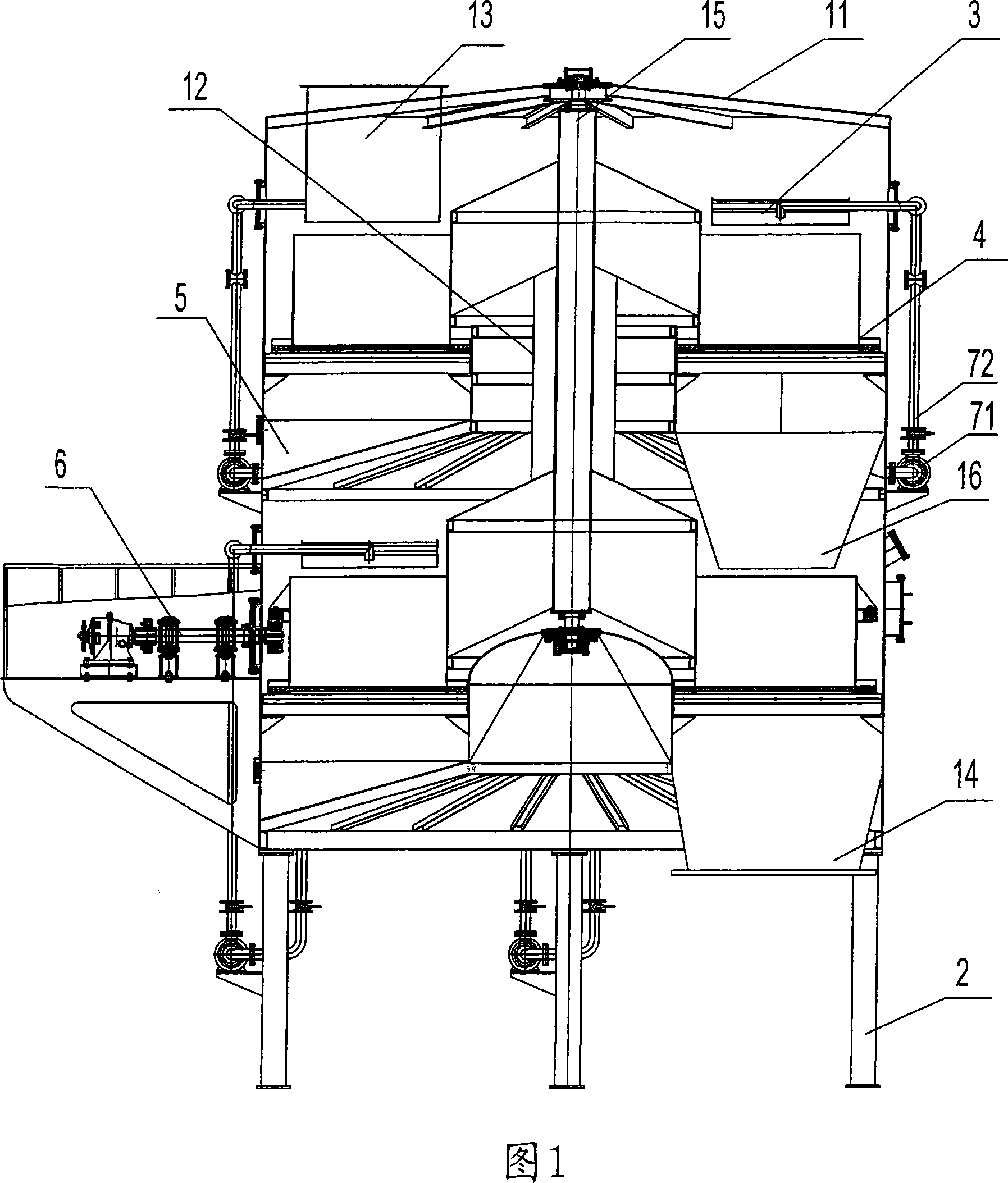

Continuous gradient counterflow extraction producing soybean concentrate protein method and equipment

InactiveCN101103761AAchieve continuous extractionReduce consumptionProtein composition from vegetable seedsSalty tasteLight white

The invention discloses a continuous gradient countercurrent extraction method for producing soybean protein concentrate, which takes low-temperature defatted soybean expeller or high-temperature defatted expeller as the raw materials, and ethanol solution as the extraction agent; a multilayer and continuous extraction equipment is adopted for extracting the defatted soybean expeller continuously with a completed closure operating technology, and a soybean molasses is obtained from the extraction liquid which is made by the extraction technology. The soybean protein concentrate made by the method of the invention has light white color and pure flavor without salty taste, which can eliminate the anti-nutritional factors, and can be widely used in the food industry, which also is an indispensable nutritional additive in high-grade feed. The soybean molasses production which is made by the method of the invention is the best raw materials for further processing soybean isoflavones, soybean saponins, soybean oligosaccharides and extracting trypsinase inhibitor.

Owner:黑龙江双河松嫩大豆生物工程有限责任公司

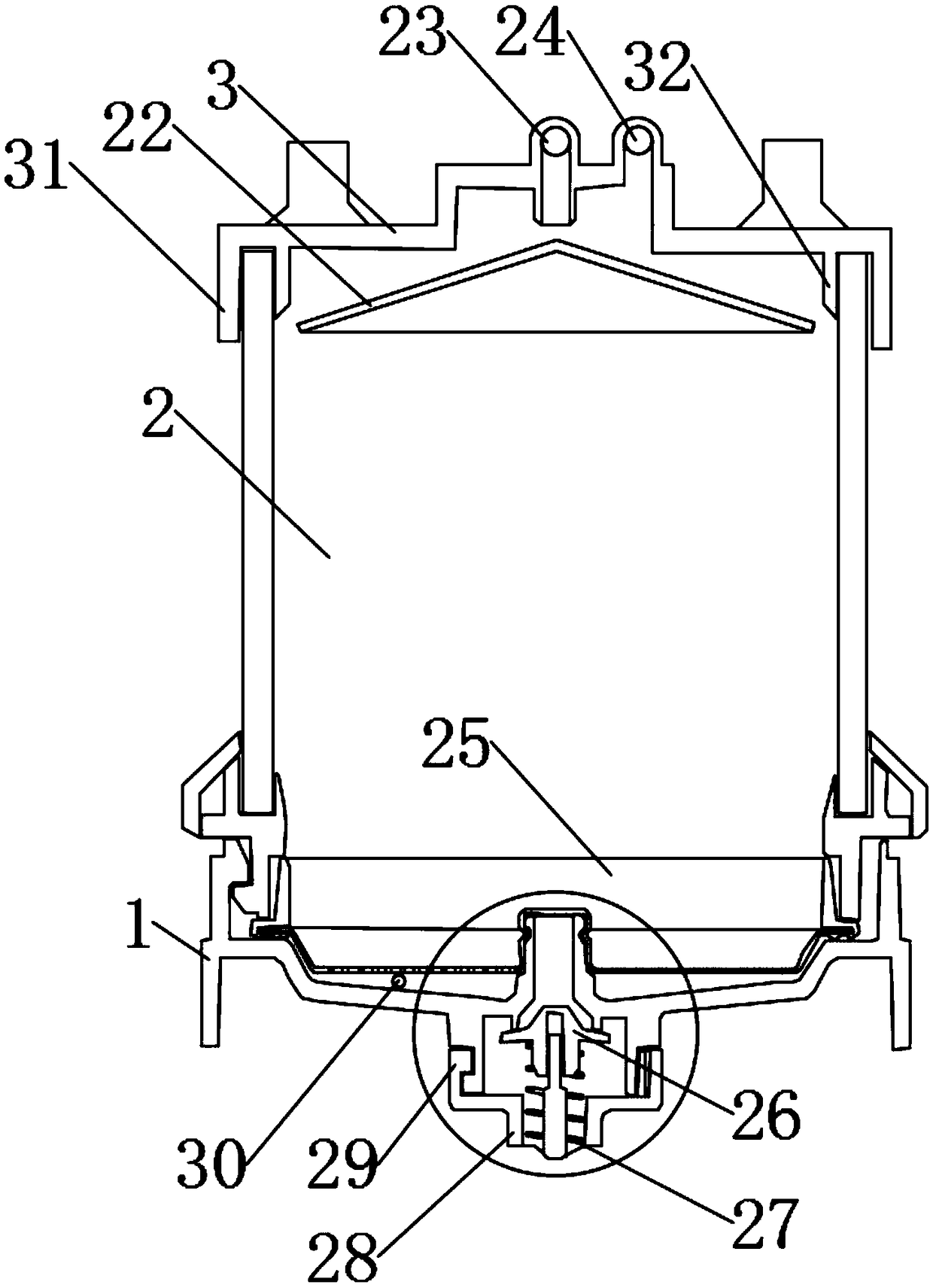

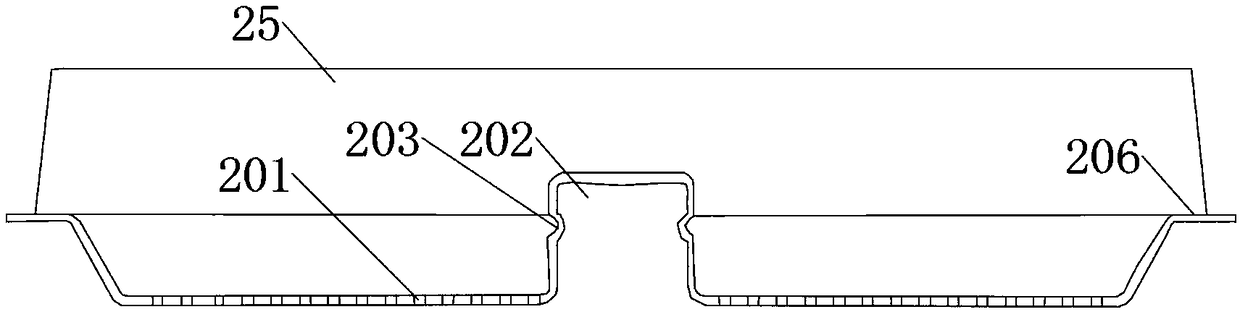

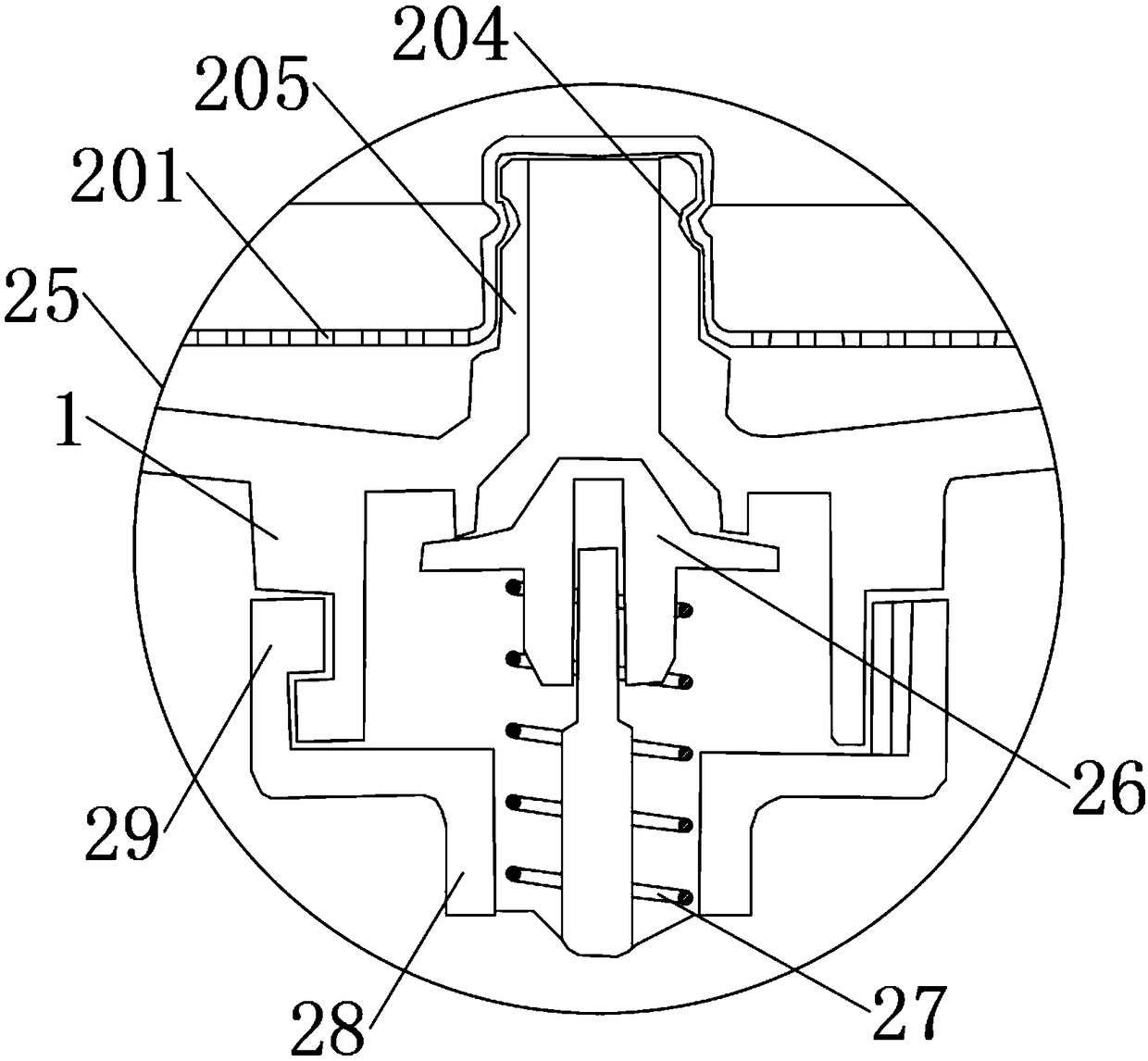

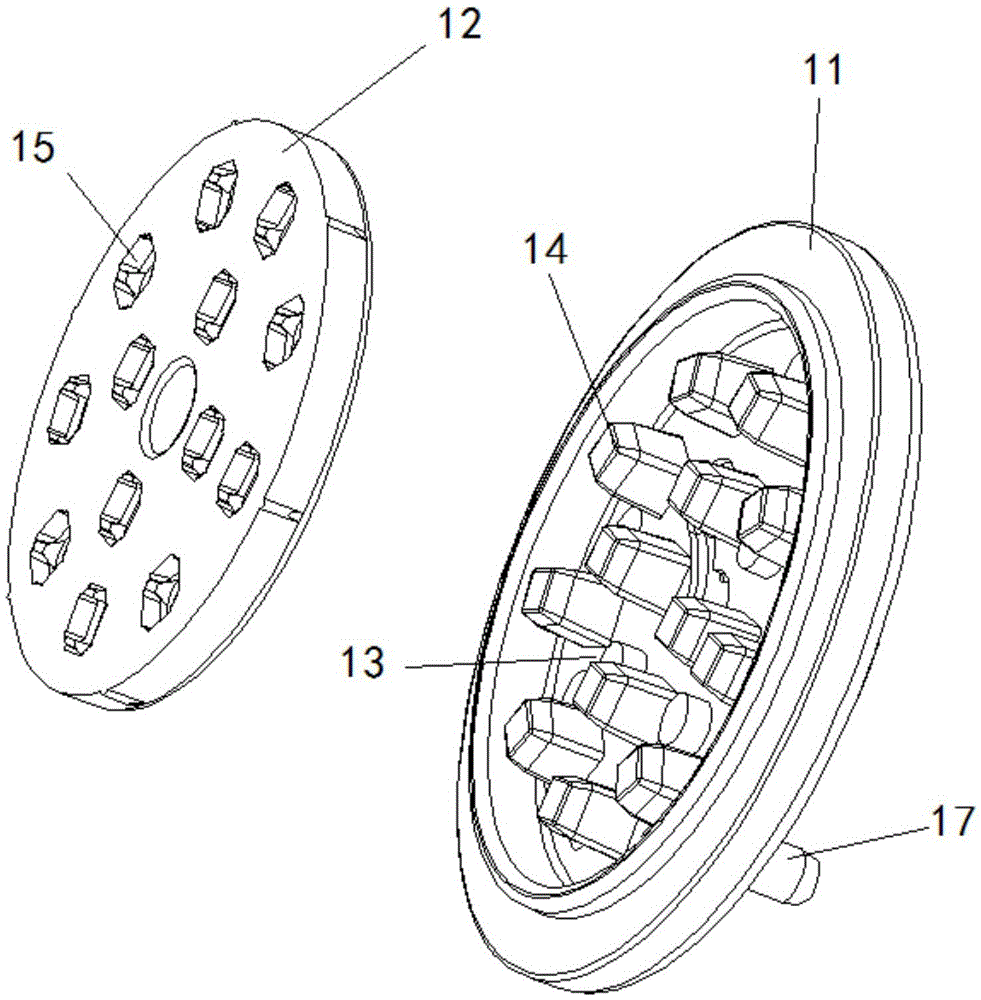

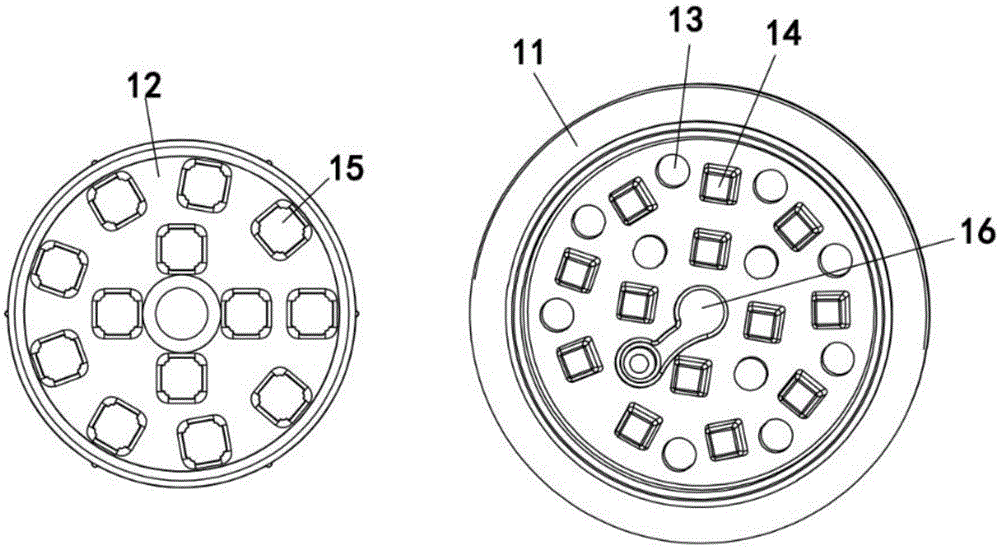

Brewing chamber for vacuum extraction brewing

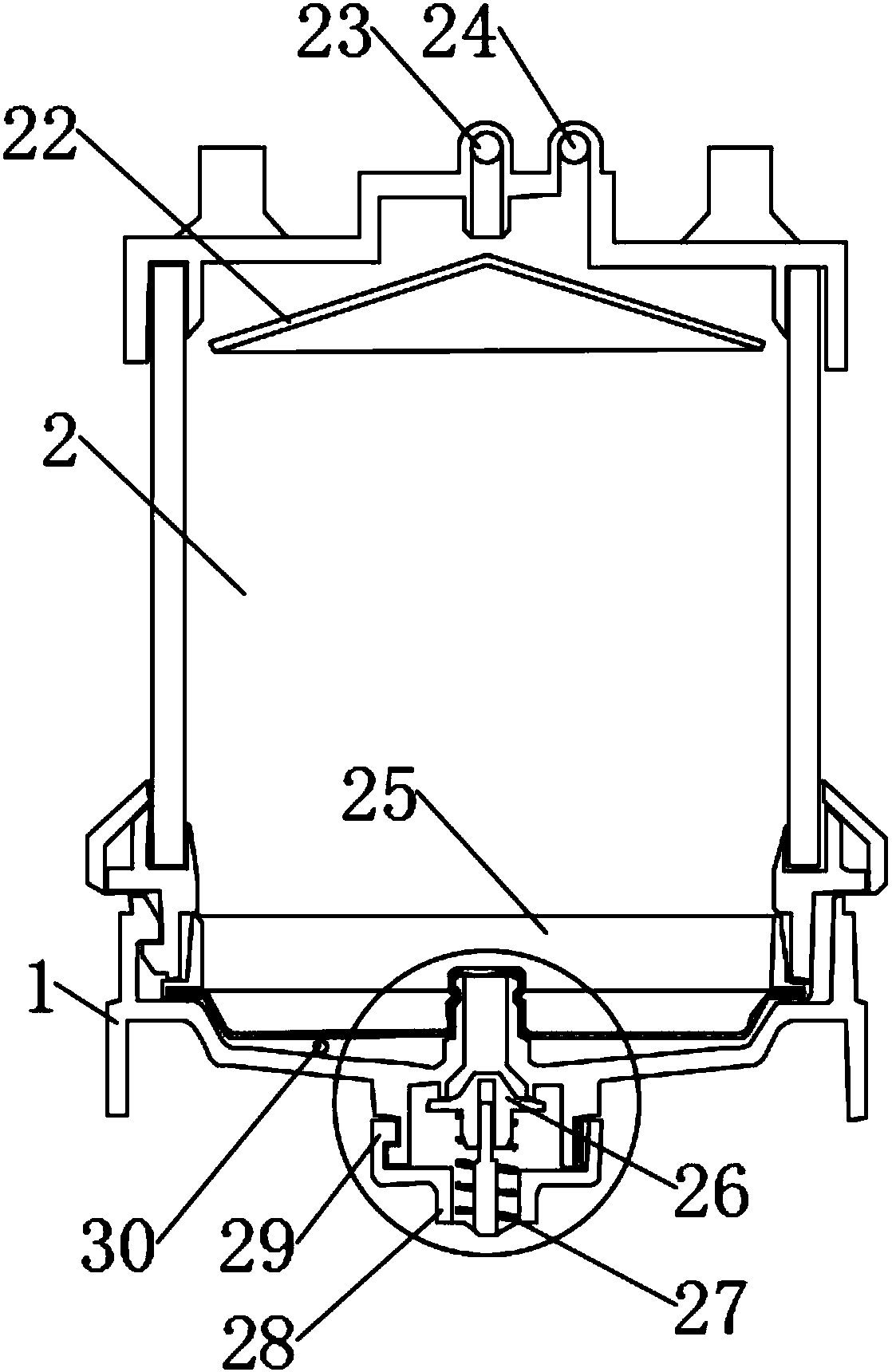

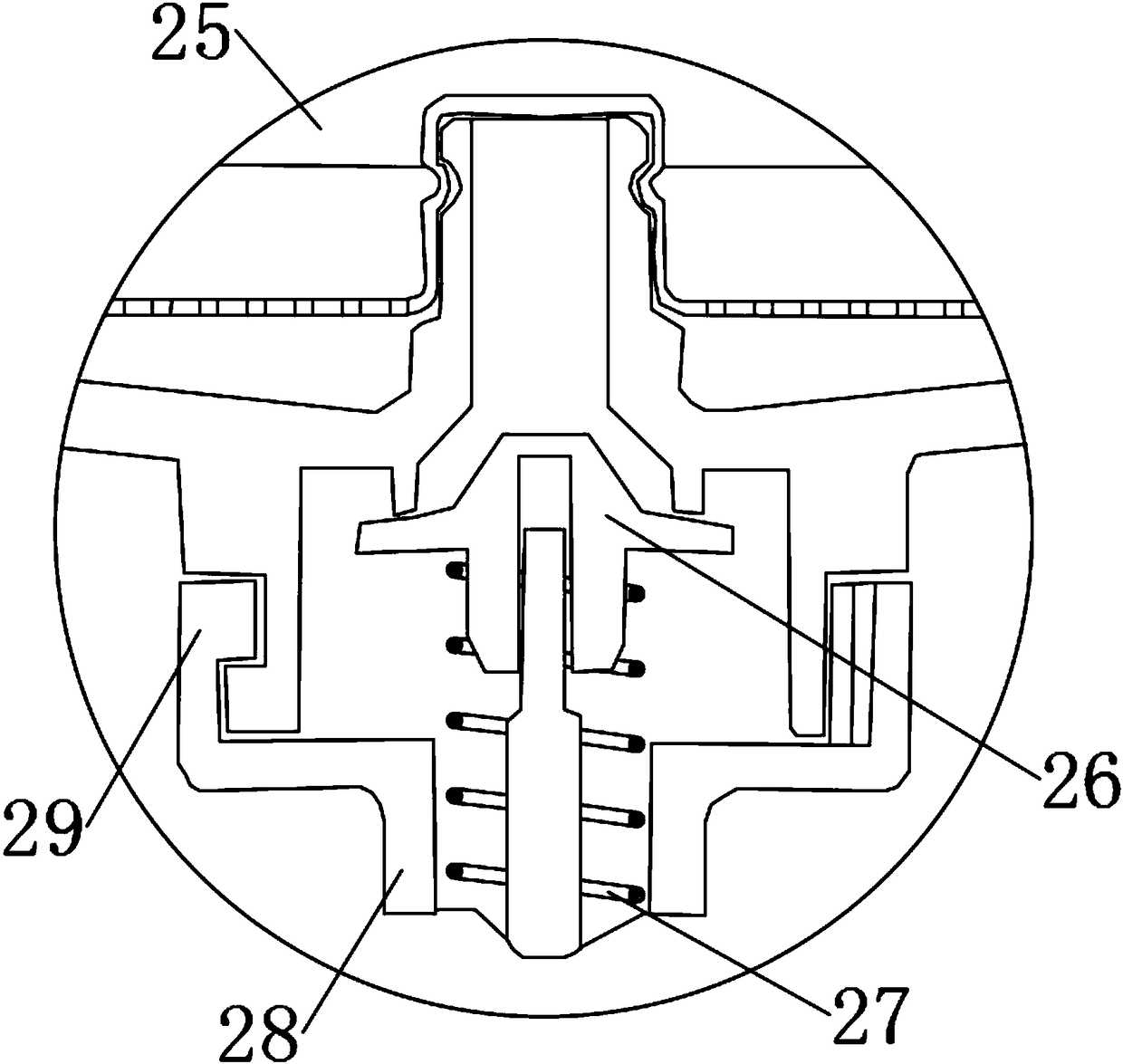

PendingCN108720603AIntuitive visualization of the brewing processRealize automatic cleaning functionBeverage vesselsInterference fitVacuum extraction

The invention discloses a brewing chamber for vacuum extraction brewing. The brewing chamber comprises a transparent glass brewing chamber, a close cover and a tea seat, wherein the upper part and thelower part of the transparent glass brewing chamber are sealed; an umbrella-shaped flow deflector is arranged at the top of the transparent glass brewing chamber; a detachable filter screen is connected with the tea seat in a clamping manner by a connecting clamping column and a clamping slot; a limiting slot and a limiting ring, which are clamped with each other, are arranged between the connecting clamping column and the clamping slot; the limiting slot is in interference fit with the limiting ring, so that the connection structure is stable; multiple groups of filter holes formed in the detachable filter screen serve the purpose of filtering tea leaves, and the tea leaves are not allowed to flow out with a water flow, so that the use is convenient; a clamped edge of an outer ring of the detachable filter screen is clamped between the tea seat and the transparent glass brewing chamber, and the tea seat is clamped at the lower end of the transparent glass brewing chamber, so that theconnection is convenient; and the transparent glass brewing chamber provided by the invention is simple in operation, high in brewing speed, high in intelligence, high in extraction rate, convenientto install and disassemble and easy to clean, and can bring high quality experience to users.

Owner:深圳市恒帮康养科技有限公司

Method for extracting honokiol and magnolol from mangnolia officinalis crude extract

ActiveCN103922899AEasy to separateFully extractedOrganic chemistryOrganic compound preparationBiotechnologyHonokiol

The invention discloses a method for extracting honokiol and magnolol from a mangnolia officinalis crude extract. In existing methods of separating the honokiol from the magnolol in the mangnolia officinalis crude extract, in some methods, the cost is too high, the production volume is low, and mass production is not easy to achieve. In the method disclosed by the invention, by means of the characteristic that the magnolol and the honokiol contained in the mangnolia officinalis crude extract can be completely separated in a weak polar solution under an alkaline condition with certain concentration, the magnolol is extracted from a mixed solution by using a weak alkaline solvent, the honokiol is left in the solution, the honokiol is extracted by a strong alkaline solution, some oily impurities are left in an organic solvent layer, then acid regulation and precipitate out are carried out respectively, at this time, the contents of the honokiol and the magnolol in the obtained coarse-grain are greatly improved. The method disclosed by the invention is simple and feasible in separation and purification process and is suitable for large-scale industrial production, and the prepared magnolol and honokiol can be used for developing new medicines with single components.

Owner:浙江得恩德制药股份有限公司

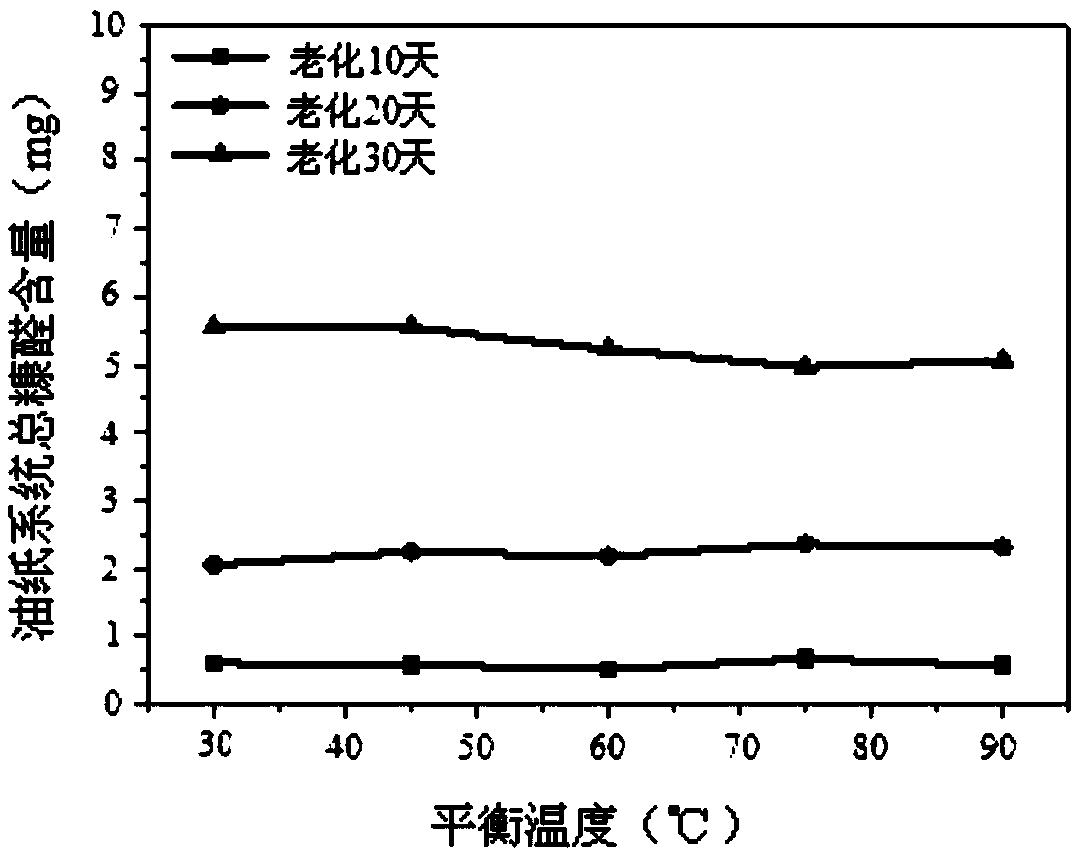

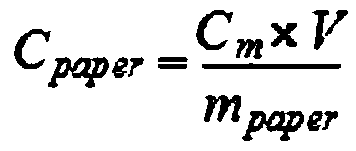

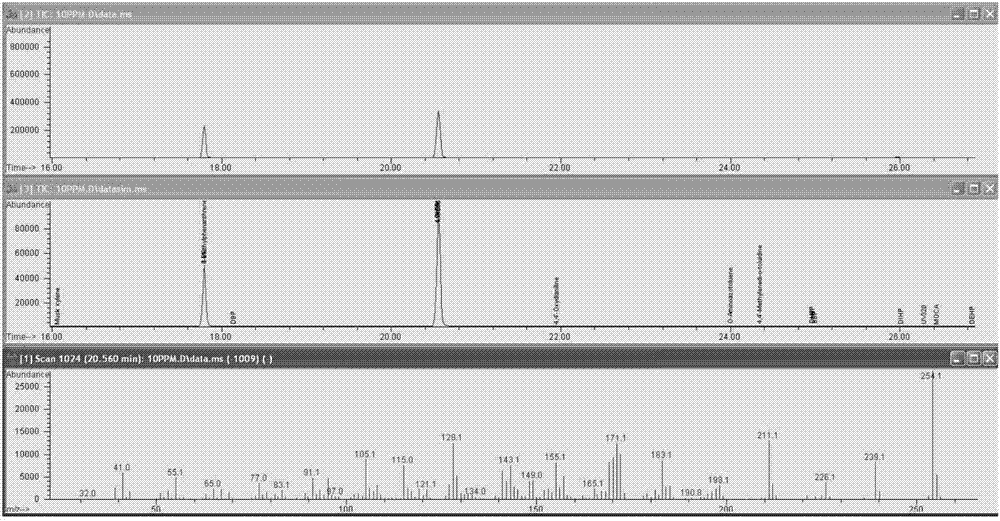

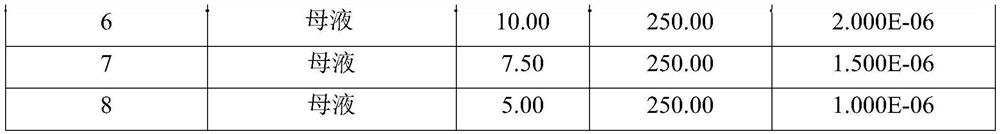

Detection method for content of furfural in transformer insulation paper

InactiveCN105510469AComprehensive basisThorough extractionComponent separationAlcoholPulp and paper industry

The invention discloses a detection method for the content of furfural in transformer insulation paper. The detection method mainly comprises the following operation steps that the insulation paper is sampled; the furfural in the insulation paper is extracted through methyl alcohol; the content of the furfural in the methyl alcohol is detected through a high performance liquid chromatography method; the content of the furfural in the insulation paper is calculated. The detection method for the content of the furfural in the transformer insulation paper is presented for the first time, and by simultaneously using the detection method and an existing detection method for the furfural in oil, the total furfural content in a transformer oil-paper insulation system can be obtained, and more comprehensive evaluation indexes can be supplied to transformer insulation remaining life prediction. Meanwhile, the detection method for the content of the furfural in the insulation paper has the advantages of being easy to operate and lower in cost and has the popularizing potential. In addition, the invention further provides a method for verifying the accuracy of detection on the content of the furfural in the insulation paper.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

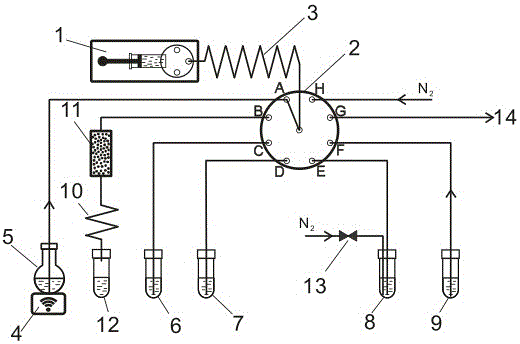

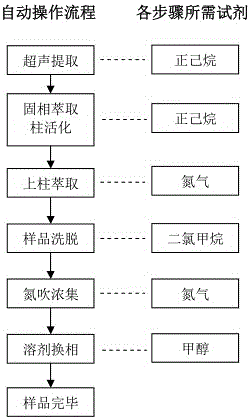

Automatic pretreatment device for PAH (polycyclic aromatic hydrocarbon) sample in PM2.5

ActiveCN106404965ASimple working processEnsure operational consistencyComponent separationPolycyclic aromatic hydrocarbonSystems design

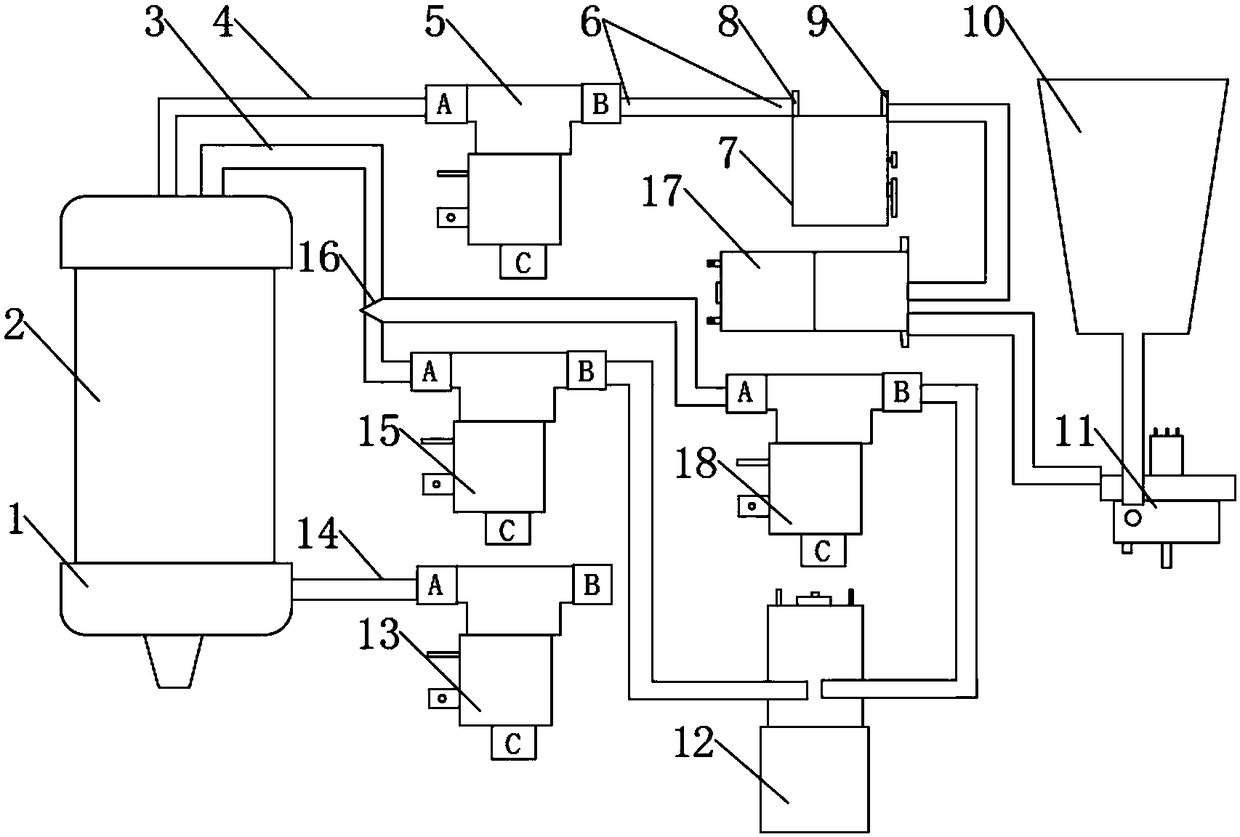

An automatic pretreatment device for a PAH (polycyclic aromatic hydrocarbon) sample in PM2.5 comprises an injection pump, an eight-position selection valve, a buffer coil, a liquid distribution pipe, solution utensils and a liquid chromatograph, wherein the injection pump is connected to the eight-position selection valve through the buffer coil, eight rotation positions including A, B, C, D, E, F, G and H are arranged on the eight-position selection valve and are connected to the corresponding solution utensils or the liquid chromatograph through the liquid distribution pipe, and the solution utensils comprise an extraction bottle, a waste liquid bottle, an extraction reagent bottle, an elution reagent bottle, a phase change bottle and a polar solvent bottle. With the combination of the system design including the injection pump, the buffer coil and the multi-position valve, automatic complex operation is realized, the operation consistency during solid-phase extraction is realized, and the analysis precision is improved.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

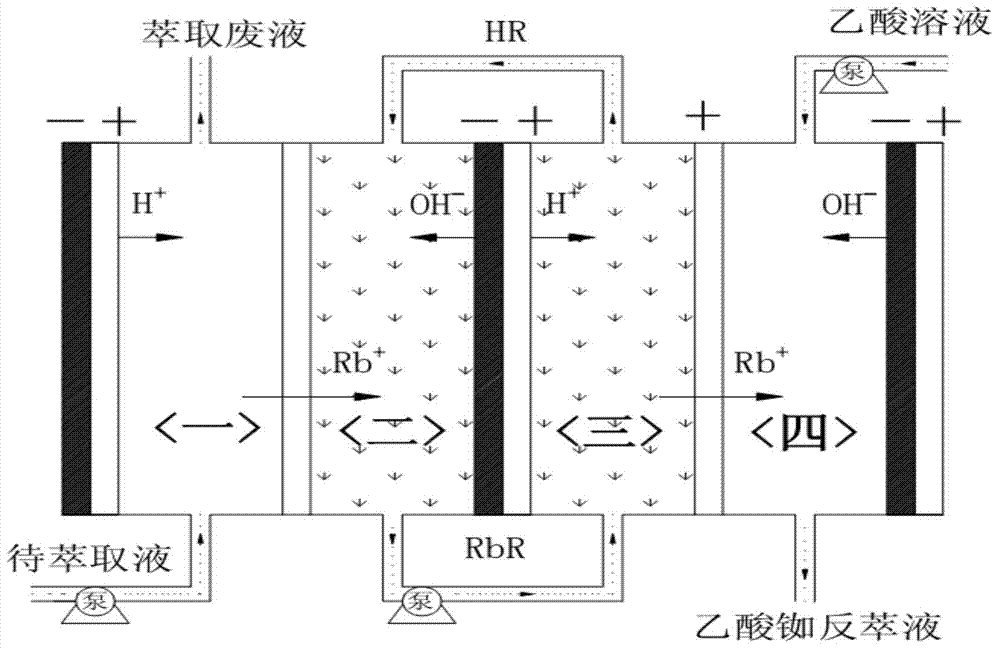

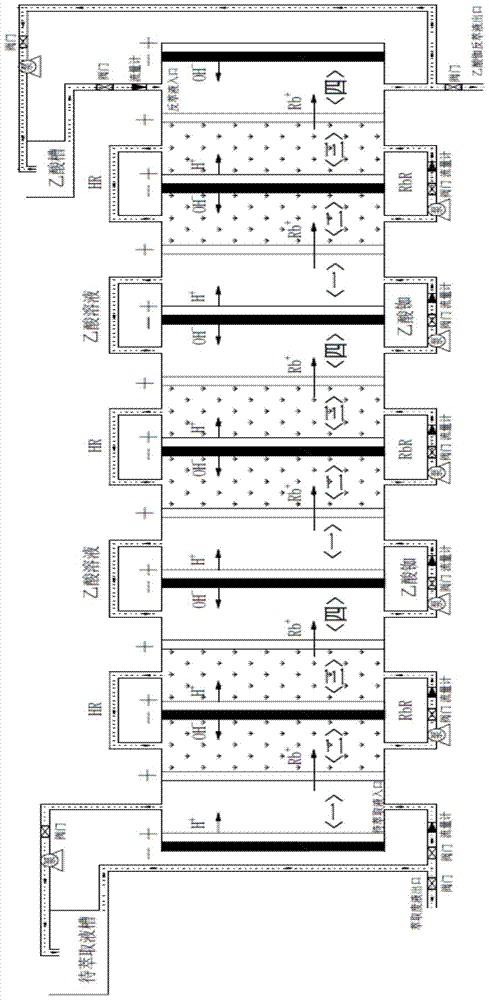

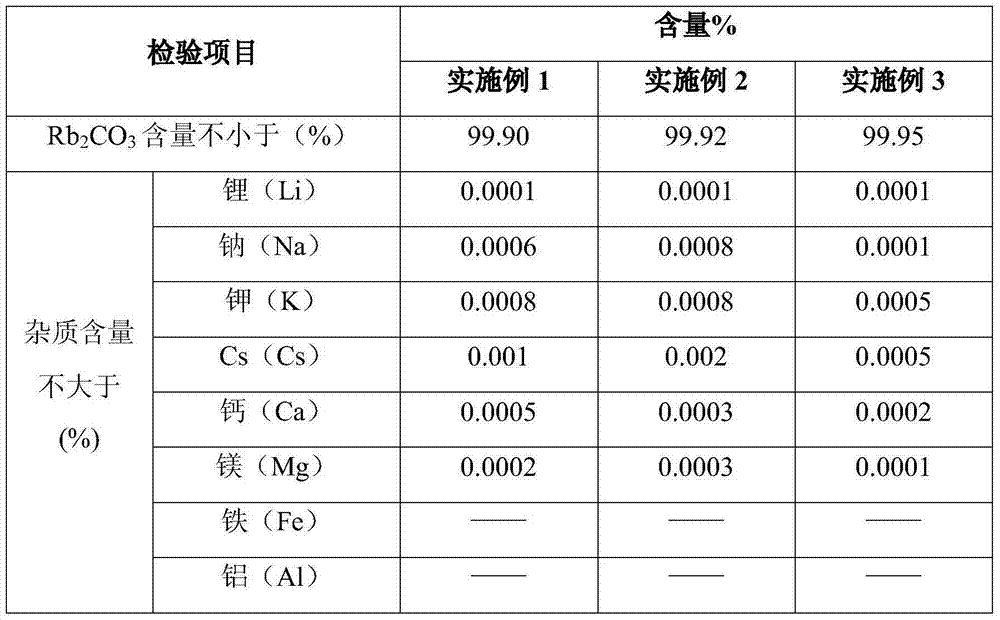

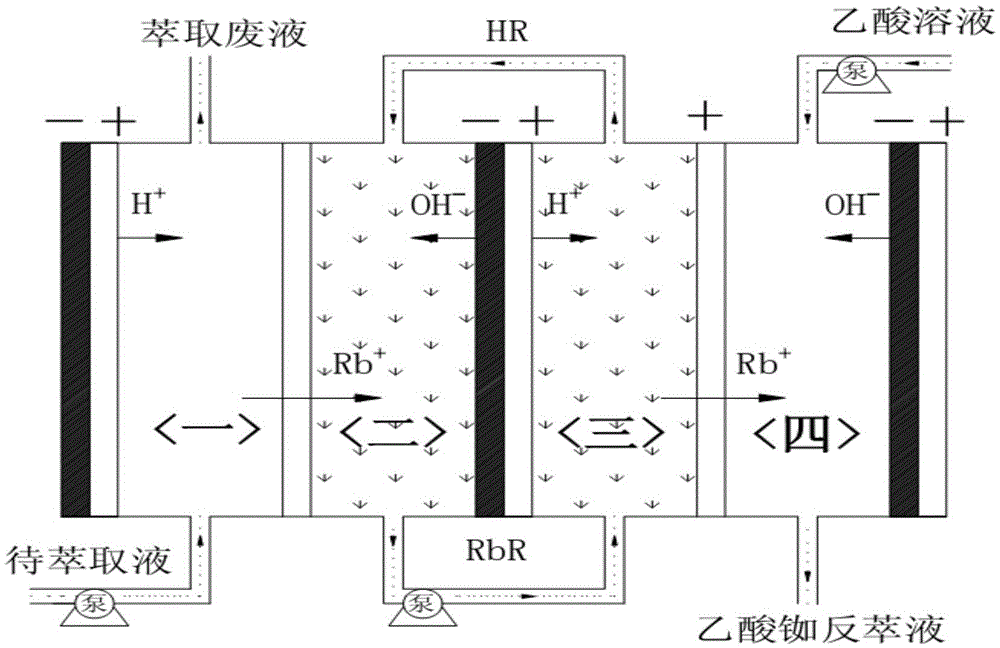

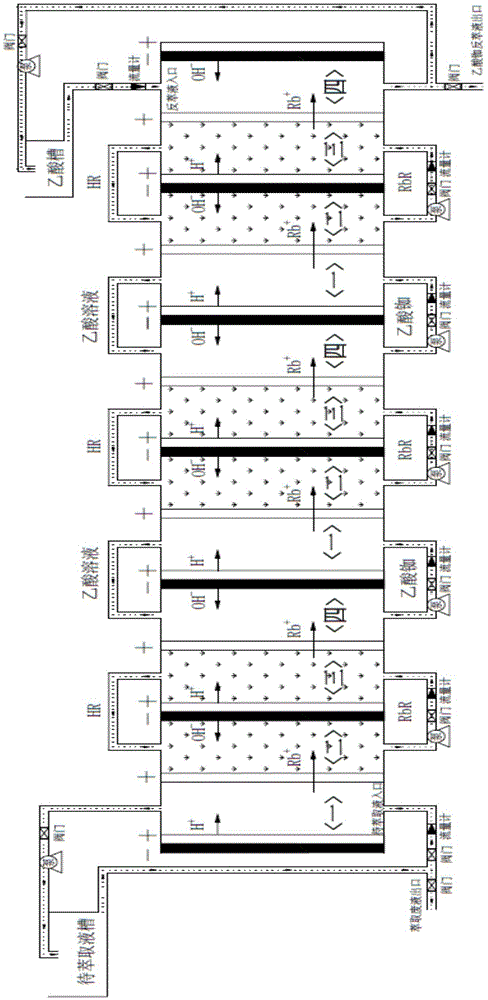

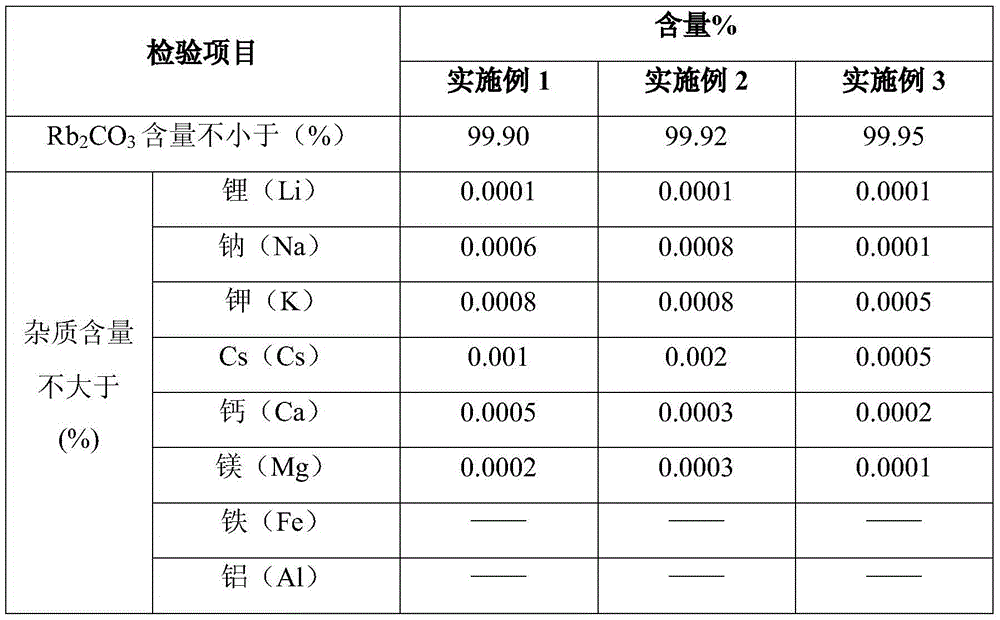

Method for preparing high-purity rubidium carbonate

The invention belongs to the technical field of methods for extracting metal ions by the aid of bipolar membrane electric osmosis technology and further generating a high-purity inorganic metal compound, and particularly relates to a method for preparing high-purity rubidium carbonate by the aid of the bipolar membrane electric osmosis technology by taking rubidium-containing waste liquor as a raw material. The method includes the steps: firstly, concentrating the rubidium-containing waste liquor, removing magnesium, iron, aluminum, calcium and barium; secondly, further removing calcium to obtain liquor to be extracted; thirdly, extracting rubidium from the liquor to be extracted by the aid of an electric extraction device to prepare rubidium acetate strip liquor; finally, concentrating, crystallizing and decomposing the rubidium acetate strip liquor at high temperature to obtain the rubidium carbonate. The method is efficient and environmentally friendly, and the obtained rubidium carbonate is excellent in quality and suitable for industrial popularization and application.

Owner:HUBEI BAIJIERUI ADVANCED MATERIALS

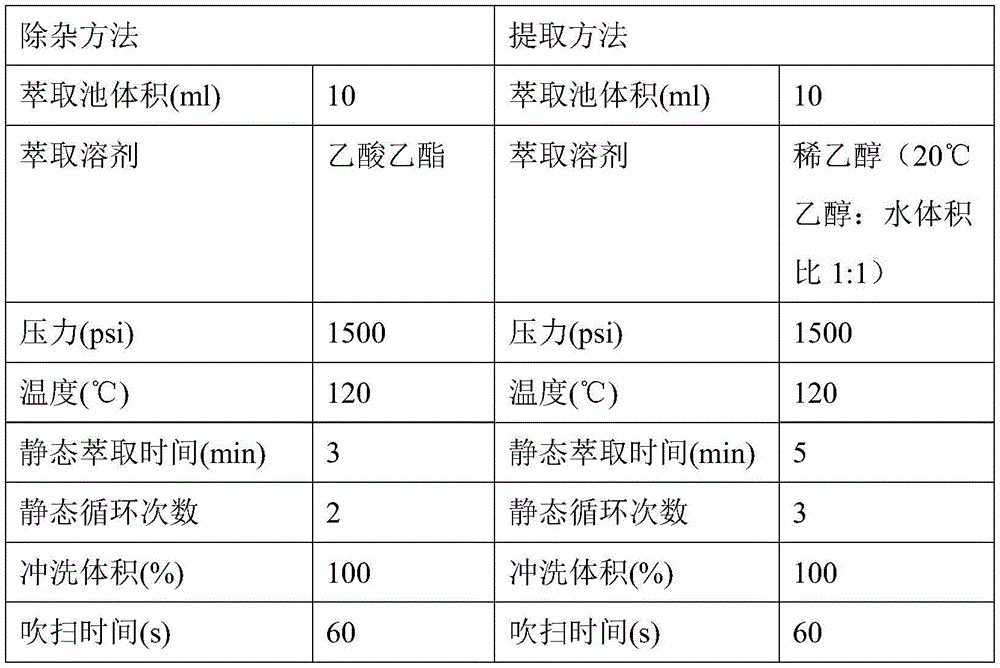

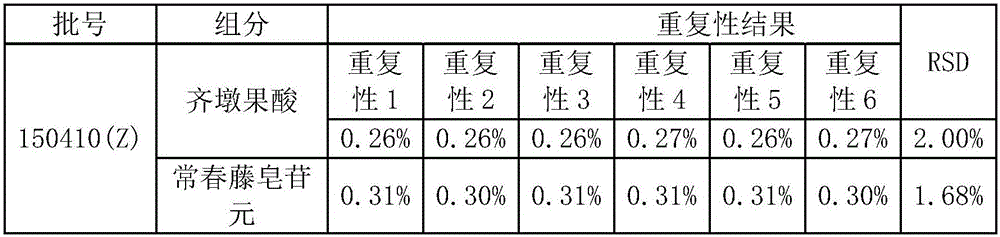

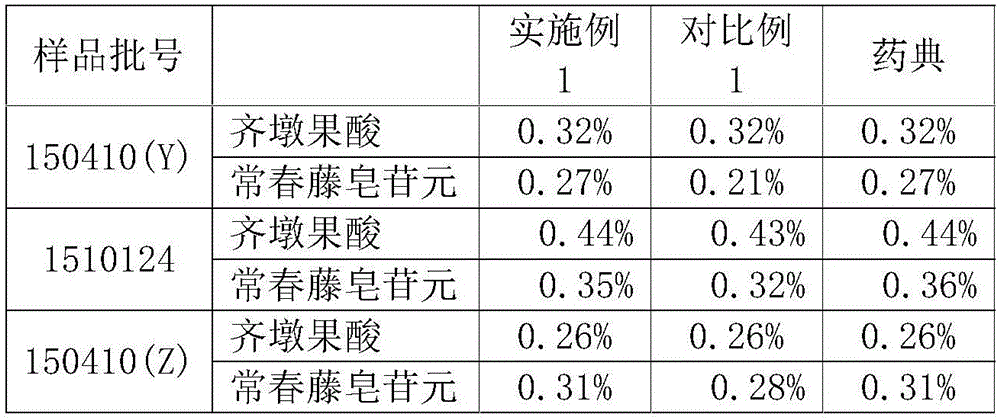

Method for extracting oleanolic acid and hederagenin in clematis root

InactiveCN105954385AAchieve the extraction effectThorough extractionComponent separationClematisTwo step

The invention discloses a method for extracting oleanolic acid and hederagenin in clematis root. The method comprises the following steps: step 1, crushing the clematis root and then mixing the crushed clematis root with a proper amount of quartz sand; step 2, adding the mixture obtained in the previous step into an extraction tank where diatomite is laid, adding quartz sand until solids in the extraction tank reach the mouth of the extraction tank, covering a cover of the extraction tank, carrying out extraction and collecting extract, wherein extraction is carried out in two steps, i.e., a degreasing step and an extraction step; and step 3, subjecting the extract to centrifugation so as to obtain supernatant. The method for extracting oleanolic acid and hederagenin in the clematis root in the invention can simultaneously extract oleanolic acid and hederagenin in the clematis root, is thorough in extraction and reaches extraction effect described in pharmacopeia.

Owner:WUZHOU INST FOR FOOD & DRUG CONTROL

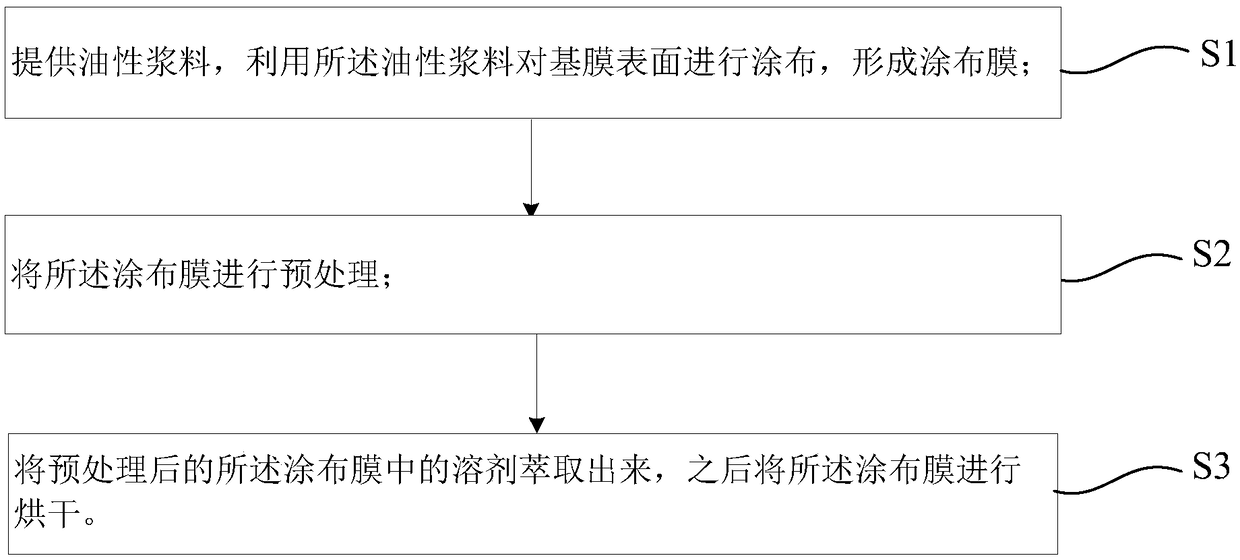

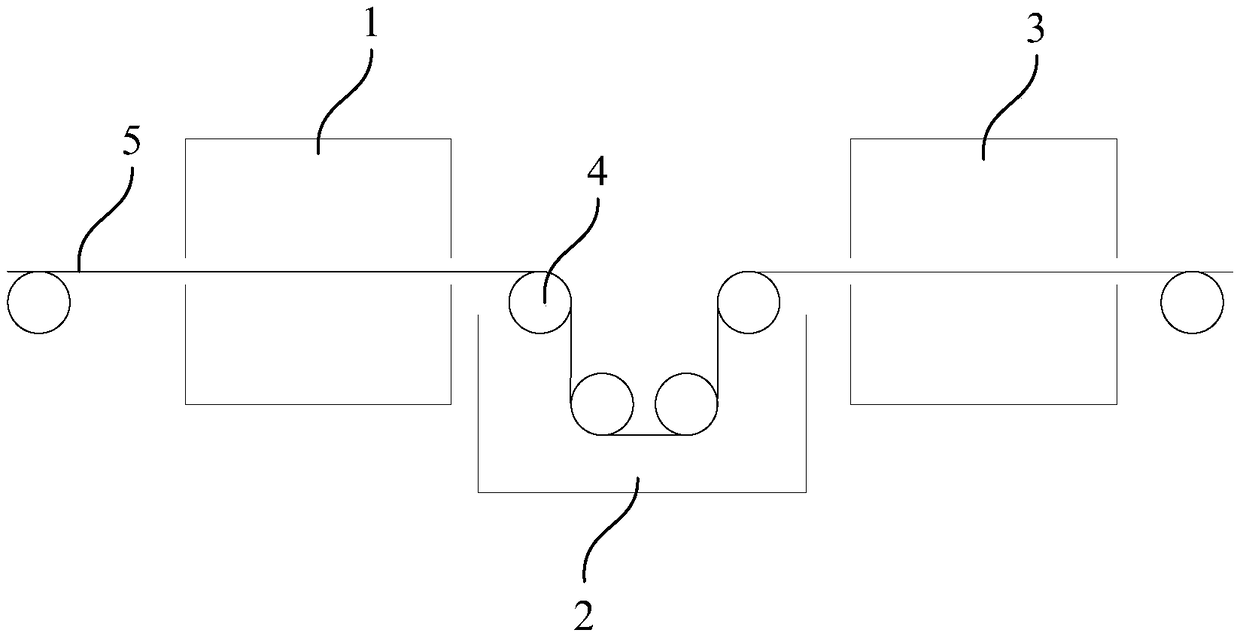

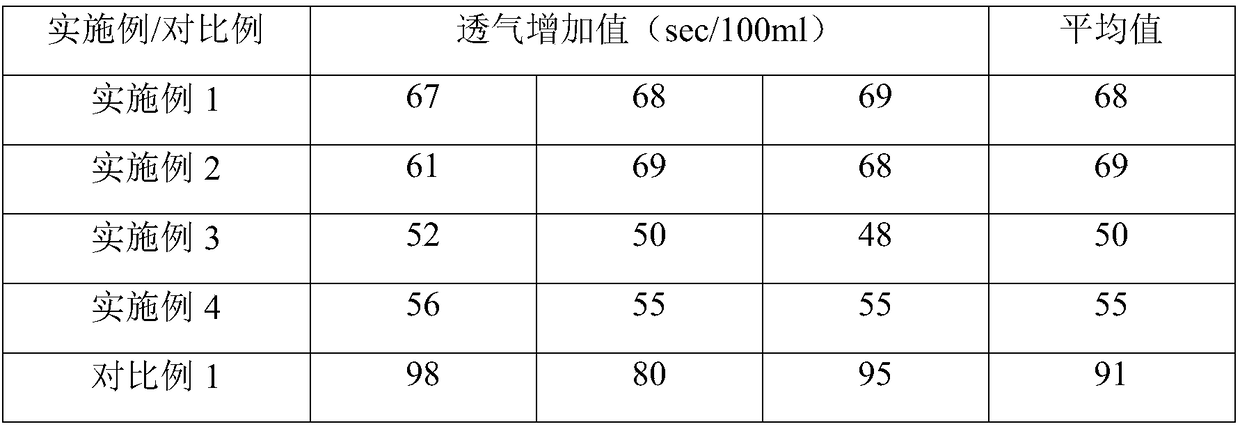

Oily lithium battery membrane coating treatment method and device

PendingCN109382291AImprove breathabilityImprove uniformityPretreated surfacesCoatingsCoated membranePhysical chemistry

The invention provides an oily lithium battery membrane coating treatment method and device. The coating treatment method at least comprises the steps that firstly, oily slurry is provided, and the surface of a base membrane is coated with the oily slurry to form a coated membrane; then, the coated membrane is placed in a constant-temperature and constant-humidity condition for pretreatment; finally, a solvent in the pretreated coated membrane is extracted, and then the coated membrane is dried. According to the method, the constant-temperature and constant-humidity pretreatment step is addedbefore the extraction process, by means of constant-temperature and constant-humidity pretreatment, a polymer in the slurry can be evenly dispersed in the solvent, the oily slurry can slowly move in amild environment, coating uniformity is achieved, and inherent defects of a coating are eliminated. Besides, the oily slurry can be pre-solidified and separated under the most uniform state, that is,the coated membrane can be preliminarily extracted under a constant-temperature and constant-humidity condition, so that extraction of the solvent in the subsequent extraction step is more thorough,the coated membrane is also easy to dry, and the performance of the coated membrane is greatly improved.

Owner:ZHUHAI ENERGY NEW MATERIALS TECH CO LTD

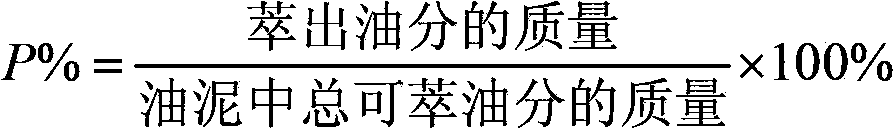

Resource treatment method of oil-containing sludge

ActiveCN103693825AGood compatibilityAchieving processing powerSludge treatment by de-watering/drying/thickeningSludgeWastewater

The invention relates to a resource treatment method of oil-containing sludge, and especially discloses a composite extracting agent for treating the oil-containing sludge produced in a wastewater treating process of an oil refinery. Oil-containing sludge having higher water content after centrifugal dehydration is mixed with the composite extracting agent under a condition of higher temperature to destroy a water, oil and solid stabilizing system of the oil-containing sludge, extraction treatment is carried out, the extracted mixture is subjected to solid-liquid separation, the separated solid phase is dried, the formed solid residue is mixed with coal and can be used as fuel of a coal-fired boiler, the separated-out oil and the extracting agent directly go into a crude oil processing system for recycling, and wastewater generated in the process can reach standards after biochemical treatment and is discharged. The treatment method is mainly characterized by having high extracting efficiency, short device procedures, and low equipment investment.

Owner:PETROCHINA CO LTD

Method for preparing high-purity magnolol and magnolol

InactiveCN102408314BHigh selectivityEasy to follow upOrganic chemistryOrganic compound preparationMagnololSolvent

Owner:GUANGXI UNIV

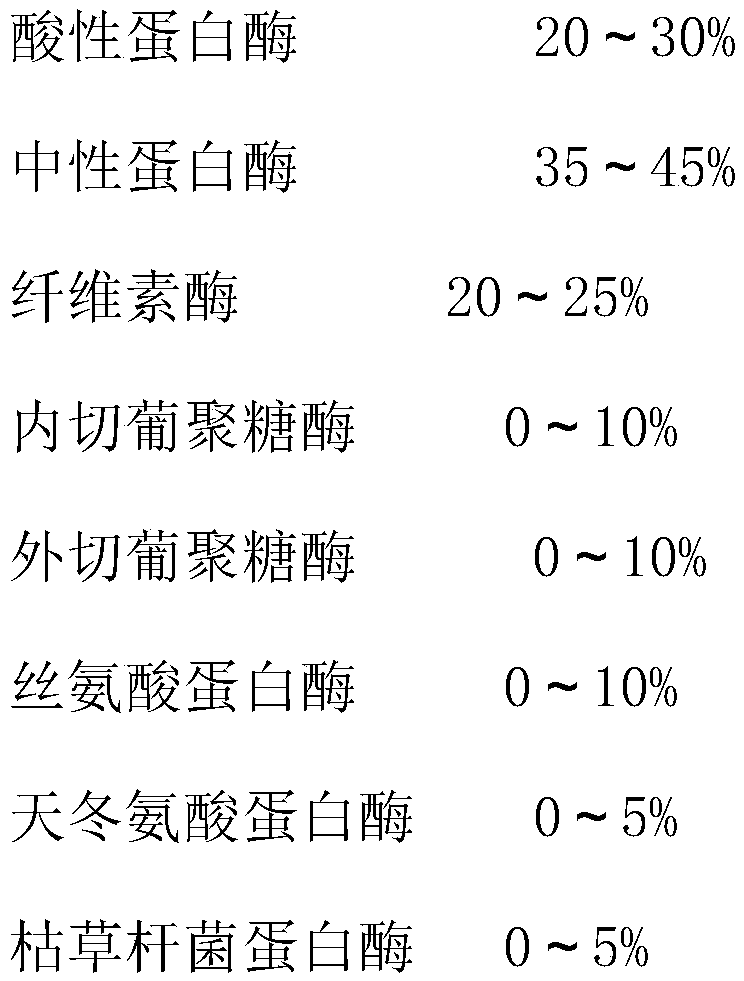

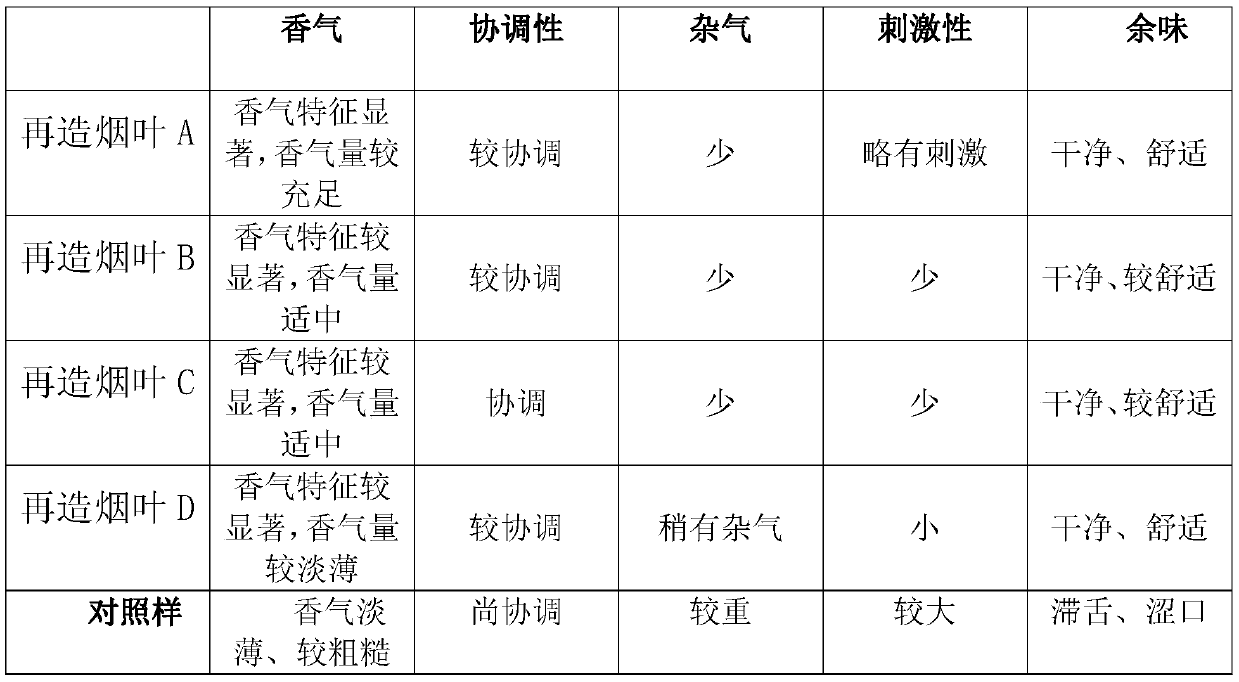

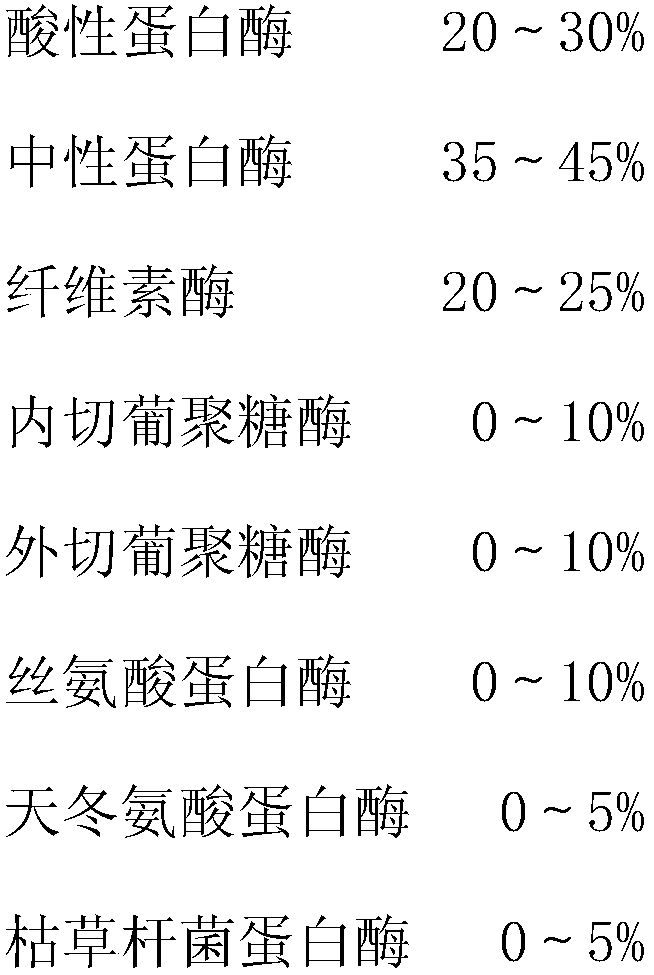

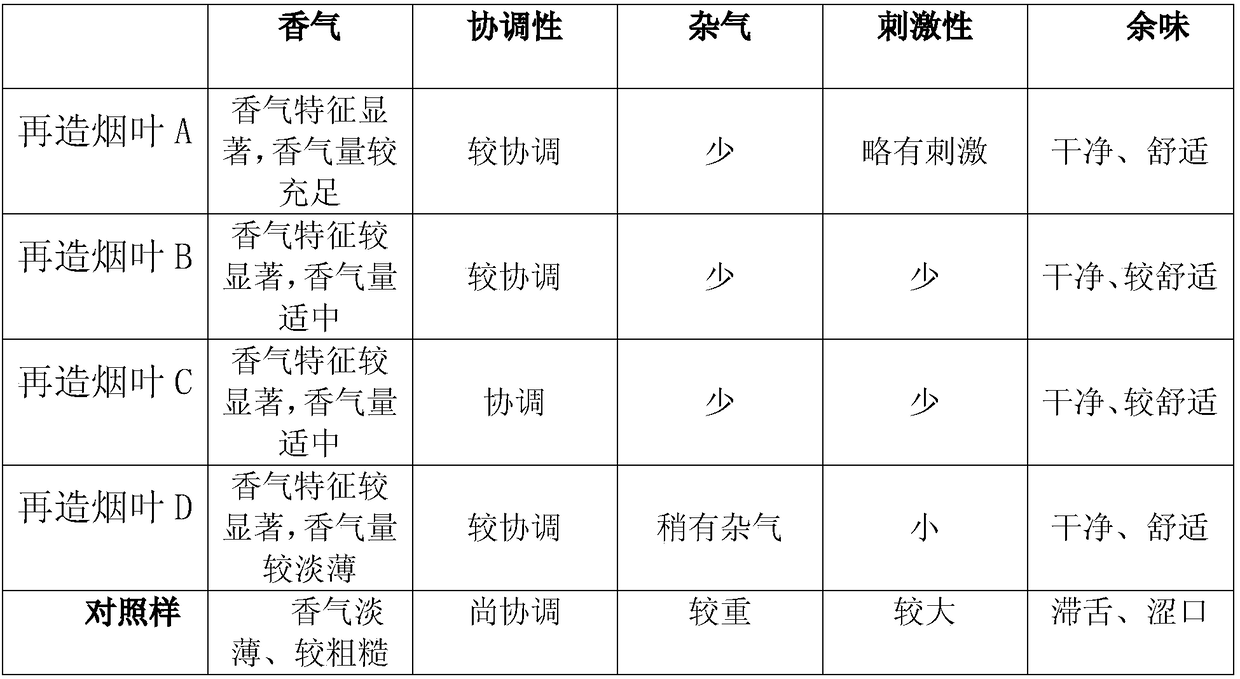

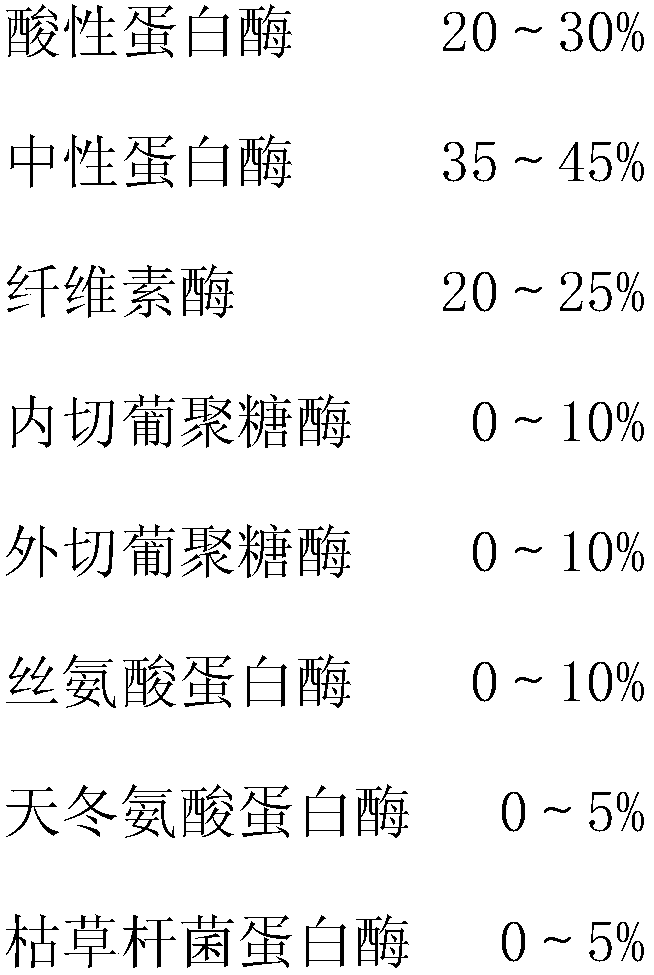

A manufacturing process of characteristic reconstituted tobacco leaves of Burley tobacco

ActiveCN108477662BIncrease profitPromote formationTobacco preparationTobacco treatmentBiotechnologyFructose

The invention provides a manufacture technique of burley characteristic reconstituted tobacco, comprising: adding burley material into a powder extraction tank, adding a composite enzyme and water, and extracting and separating by means of two-step backflow to obtain leaf solid material and leaf extract; adding water to burley stem material, and performing two-step backflow extract to obtain stemextract and stem solid; mixing the extracts to a proportion, adding a flocculating agent, stirring, sucking supernate, purifying, and concentrating to obtain concentrate; mixing the solids, beating toobtain slurry, adding fiber slurry with water, adding water to dilute the mixture, and making base sheet quantified to 58-60 g / m<2>; adding a tobacco flavor, fructose and glucose to the concentrate to obtain a coating liquid; applying the coating liquid to the base sheet, drying, and cutting to obtain the reconstituted tobacco. The manufacture technique can significantly improve the flavor characteristic of burley, reduced stimulus and reduce miscellaneous gas, and whole sensory comfort of the reconstituted tobacco is improved.

Owner:HUBEI CHINA TOBACCO IND

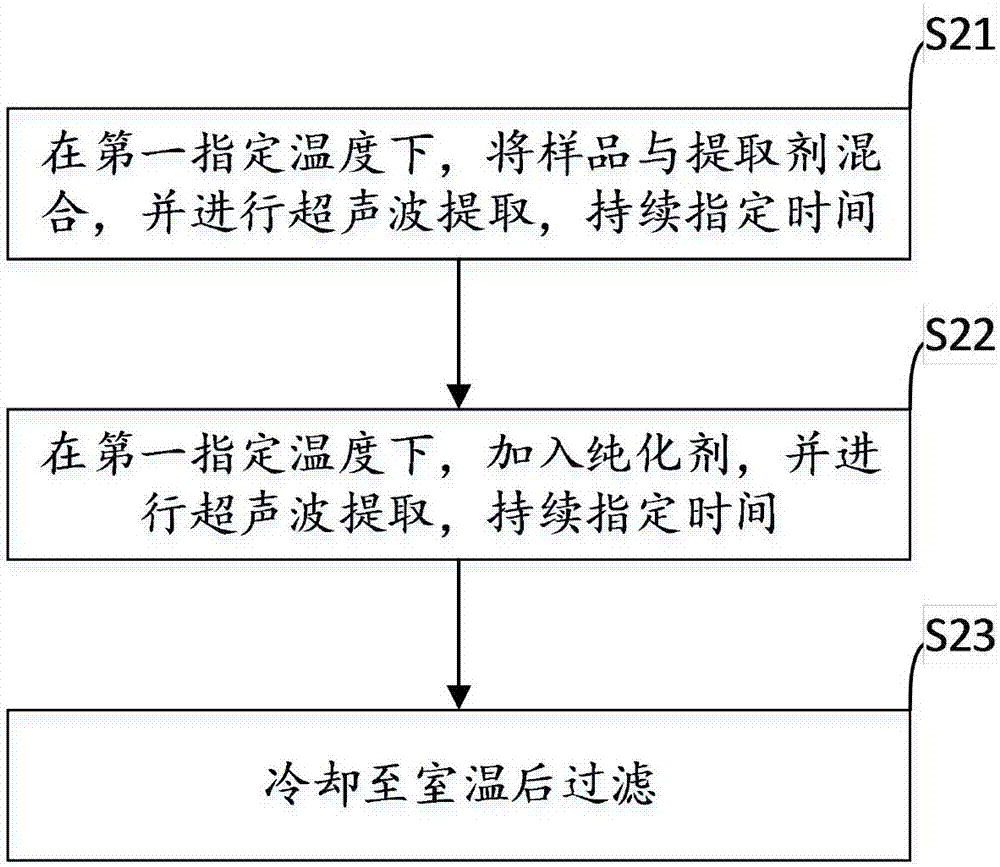

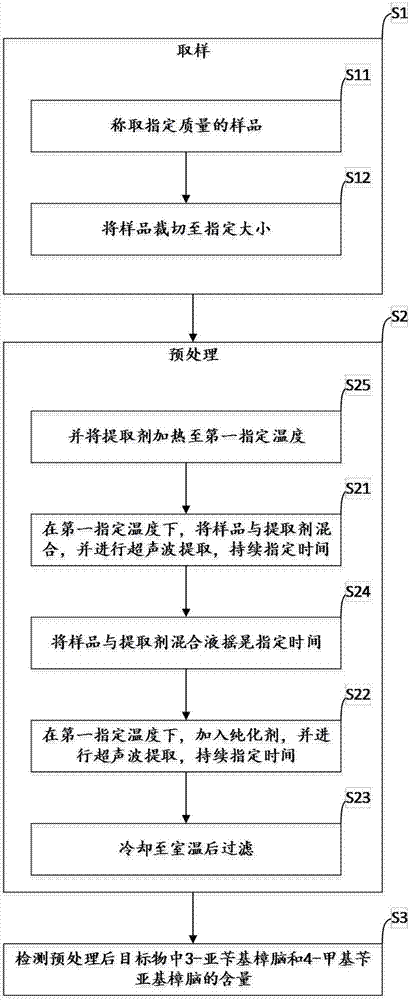

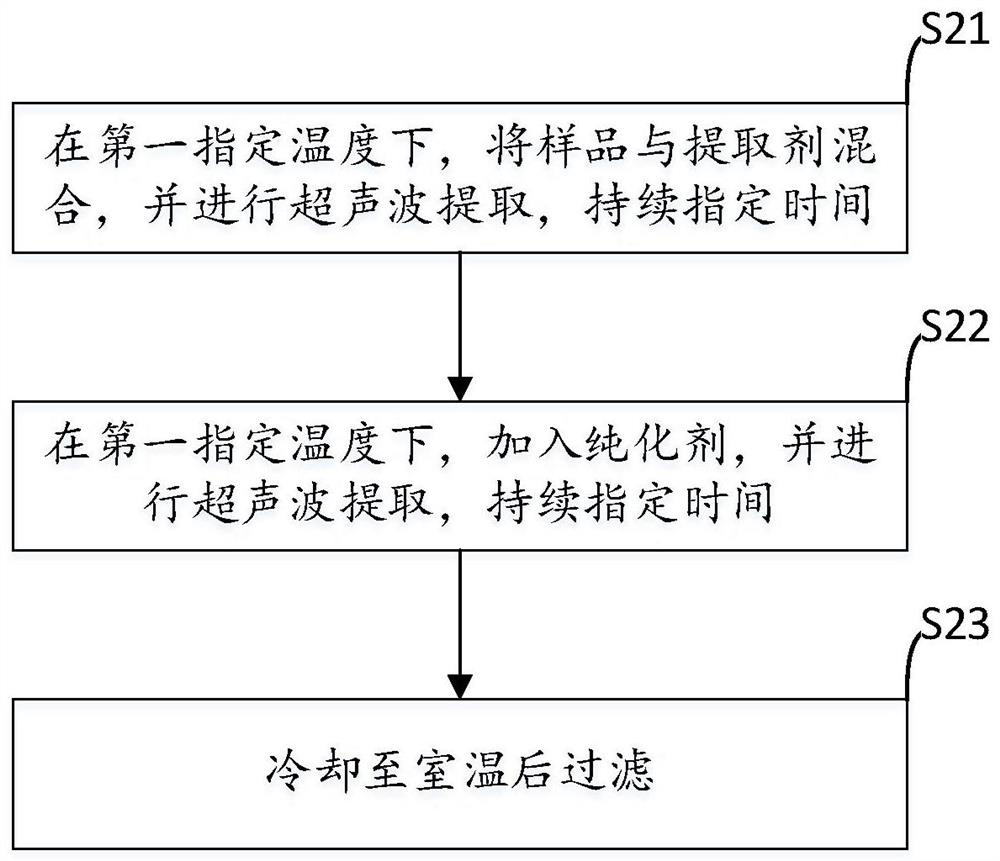

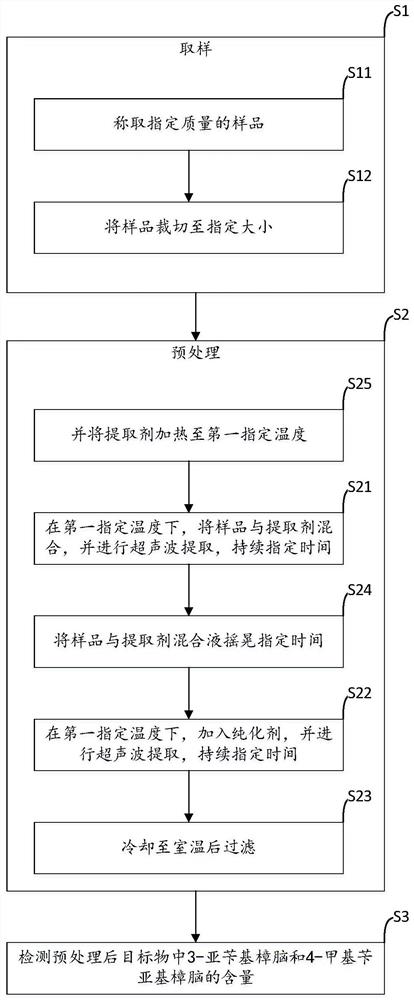

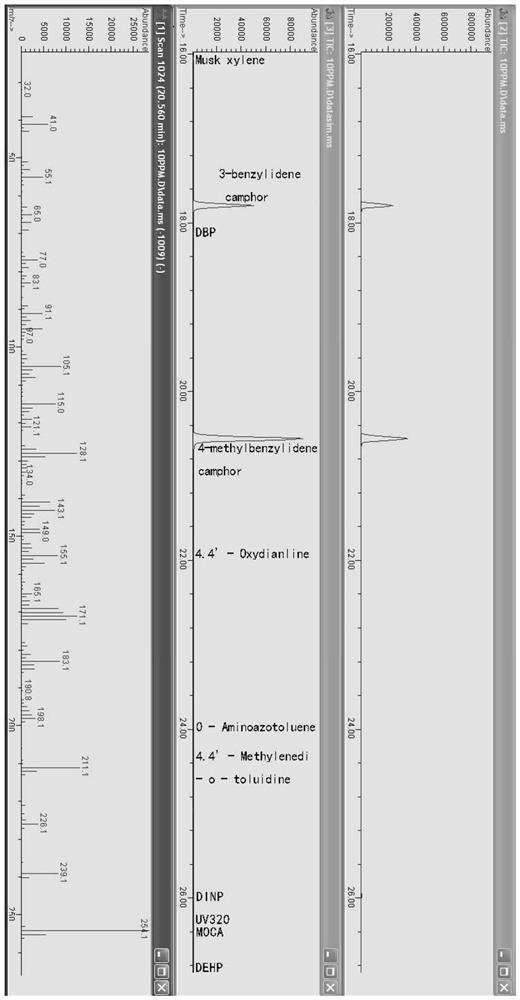

Method for detecting 3-benzylidene-camphor and 4-methyl benzyl subunit camphor in consumer goods

ActiveCN107255679AImprove test accuracyThorough extractionComponent separationRoom temperature3-benzylidene camphor

The invention discloses a method for detecting 3-benzylidene-camphor and 4-methyl benzyl subunit camphor in consumer goods. The method includes steps of carrying out sampling, to be more specific, pretreating targets and detecting the contents of the 3-benzylidene-camphor and the 4-methyl benzyl subunit camphor in the pretreated targets. Pretreatment steps include mixing samples and an extracting agent with one another at first specified temperatures and carrying out ultrasonic extraction for the specified time; adding a purifying agent into first extraction products at the first specified temperatures and carrying out ultrasonic extraction for the specified time; cooling second extraction products until the temperatures of the second extraction products reach the room temperature and then filtering the second extraction products. The method for detecting the 3-benzylidene-camphor and the 4-methyl benzyl subunit camphor in the consumer goods has the advantages that the detection limit can reach 0.003%; the test accuracy of the samples can be improved by the aid of the pretreatment steps; tetrahydrofuran and acetone mixed liquid is used as the extracting agent, acetonitrile is used as the purifying agent, accordingly, the targets can be thoroughly extracted from products, and extraction procedures are speedy owing to ultrasonic extraction.

Owner:深圳天祥质量技术服务有限公司

Manufacture technique of burley characteristic reconstituted tobacco

ActiveCN108477662AIncrease profitAdd characteristic aromaTobacco preparationTobacco treatmentFiberFlavor

The invention provides a manufacture technique of burley characteristic reconstituted tobacco, comprising: adding burley material into a powder extraction tank, adding a composite enzyme and water, and extracting and separating by means of two-step backflow to obtain leaf solid material and leaf extract; adding water to burley stem material, and performing two-step backflow extract to obtain stemextract and stem solid; mixing the extracts to a proportion, adding a flocculating agent, stirring, sucking supernate, purifying, and concentrating to obtain concentrate; mixing the solids, beating toobtain slurry, adding fiber slurry with water, adding water to dilute the mixture, and making base sheet quantified to 58-60 g / m<2>; adding a tobacco flavor, fructose and glucose to the concentrate to obtain a coating liquid; applying the coating liquid to the base sheet, drying, and cutting to obtain the reconstituted tobacco. The manufacture technique can significantly improve the flavor characteristic of burley, reduced stimulus and reduce miscellaneous gas, and whole sensory comfort of the reconstituted tobacco is improved.

Owner:HUBEI CHINA TOBACCO IND

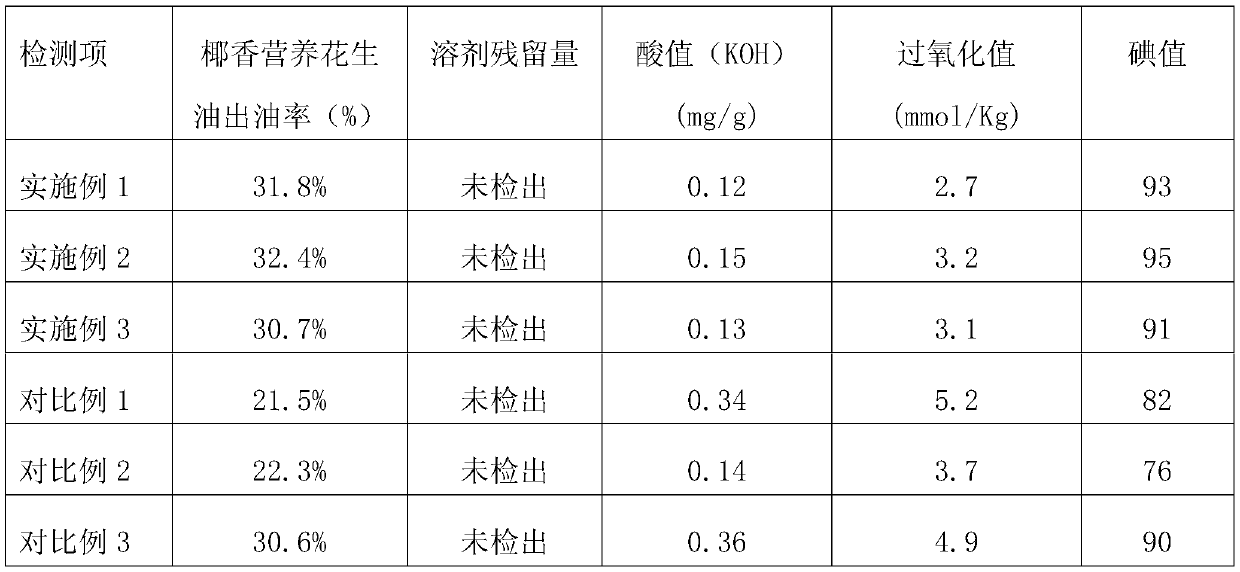

Preparation method of coconut nutrient peanut oil

InactiveCN109852469AEffective destructionImprove permeabilityFatty-oils/fats refiningFatty-oils/fats productionFreeze thawingFiltration

The invention discloses a preparation method of coconut nutrient peanut oil. The method comprises the following steps: (1) performing pretreatment on raw materials: uniformly mixing peanut kernels andcoconut meat according to a weight ratio of (2-5):1, adding a sodium chloride solution with a mass fraction of 0.5-1%, performing ultrasonic soaking for 2-3 h, taking out the soaked material, performing washing by using cold water, and performing draining for standby application; (2) performing repeated freeze thawing: placing the raw materials obtained by the pretreatment of the step (1) into crushing equipment, performing crushing, performing freezing on the crushed raw material to -15DEG C to -20 DEG C, placing the frozen material at 40 DEG C for rapid melting, and performing the repeatedfreeze thawing for 3-5 times; (3) performing low-temperature drying; (4) performing supercritical carbon dioxide extraction; and (5) performing filtration to remove impurities: performing vacuum filtration on crude coconut peanut oil obtained in the step (4) to remove the impurities to obtain the refined coconut nutrient peanut oil. The method provided by the invention improves the oil yield and quality of the product, has environmental protection and no pollution, and is suitable for large-scale promotion and use.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

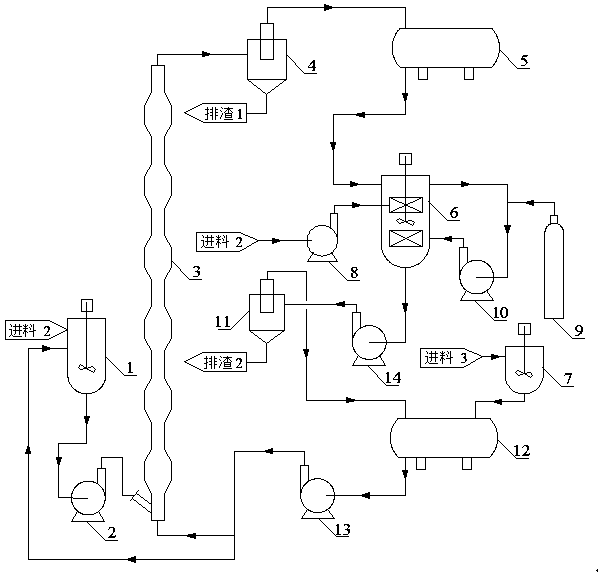

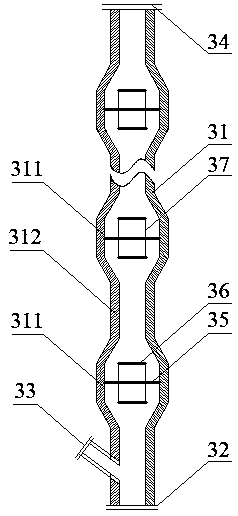

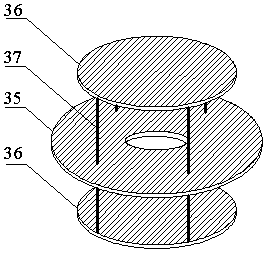

Pulse rising type system and process for continuously recovering mercury from mine tailings

InactiveCN109536743AEnhanced backmixingReduce pollution hazardsProcess efficiency improvementSolubilityDecomposition

The invention discloses a pulse rising type system for continuously recovering mercury from mine tailings. The system comprises a slurry preparation unit, a rising extraction unit, a flocculation separation unit and a solvent regeneration unit. The invention further comprises a pulse rising type process for continuously recovering the mercury from the mine tailings. The process comprises the following steps of slurry preparation, rising extraction, flocculation separation and solvent regeneration. According to the pulse rising type system and process for continuously recovering the mercury from the mine tailings, the pulse rising type system for continuously recovering the mercury from the mine tailings adopts a riser reactor for liquid-solid extraction for the first time, the riser reactor is composed of thick sections and fine sections in a staggered mode, so that the material backmixing degree is greatly enhanced, due to the fact that a baffle plate is arranged inside the riser reactor, the staying time is prolonged, the extraction is more thorough, the extraction efficiency is higher, and the pollution hazard of the mercury in the mercury-containing tailings to the environmentis greatly reduced; and a sodium thiosulfate solution for extracting the mercury is subjected to heating and bubbling of carbon dioxide, so that decomposition is enhanced, and thiosulfate after mercury decomposition is converted into a mercury sulfide precipitation form which is low in solubility, high in stability and low in toxicity.

Owner:SHANDONG UNIV OF SCI & TECH

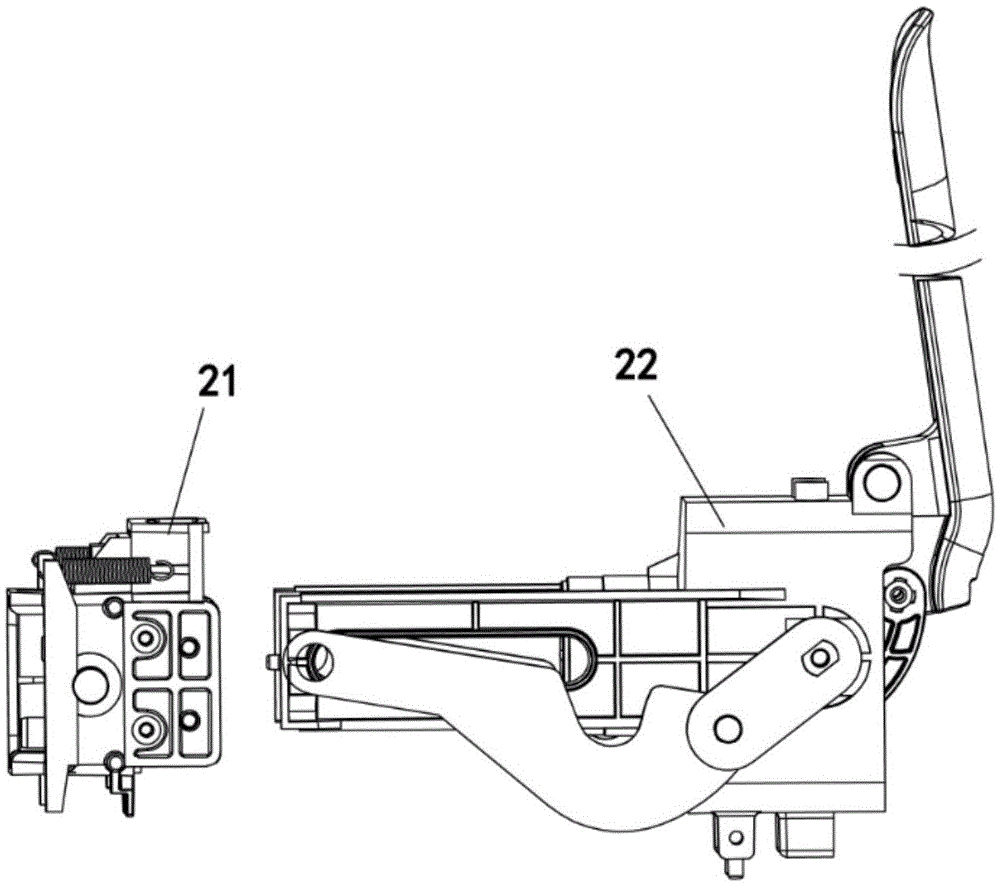

Filtering assembly and capsule coffee making device

InactiveCN105455648ASimple production processThe production process is simpleBeverage vesselsEngineeringManufacturing technology

The invention relates to the technical field of coffee machines, in particular to a filtering assembly. The filtering assembly comprises a filtering screen provided with a plurality of filtering holes. A plurality of bosses are further arranged on the filtering screen. The filtering assembly further comprises a screen cover matched with the filtering screen. The screen cover is provided with a plurality of assembly holes matched with the bosses in shape and in position. The bosses are inserted into the assembly holes in a one-to-one correspondence mode so that the screen cover can be connected with the filtering screen in a matched mode. Besides, gaps exist between the assembly holes and the bosses after the assembly holes and the bosses are rotationally assembled, and the bosses will be higher than the plane of the screen cover. The invention further provides a capsule coffee making device using the filtering assembly. The filtering assembly has the advantages of being simple in manufacturing technology and small in hole diameter, and large making pressure can be provided while it can be guaranteed that coffee liquid output is smooth.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

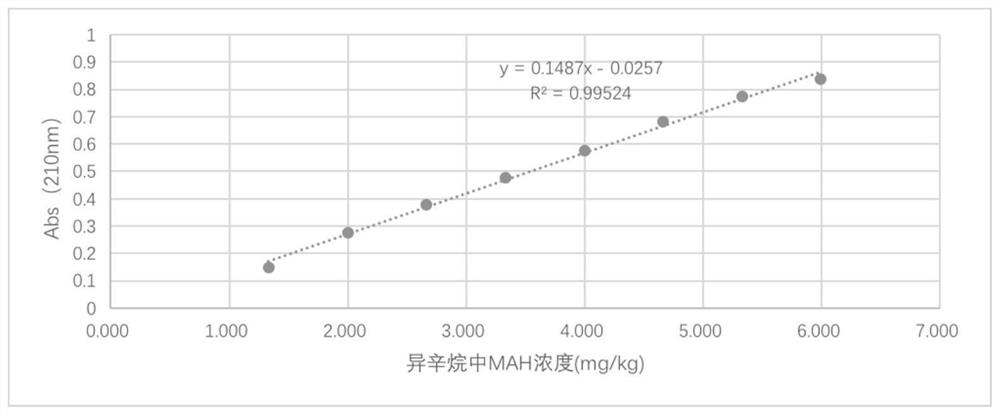

A method for detecting the migration of mah residues in pp-g-mah materials

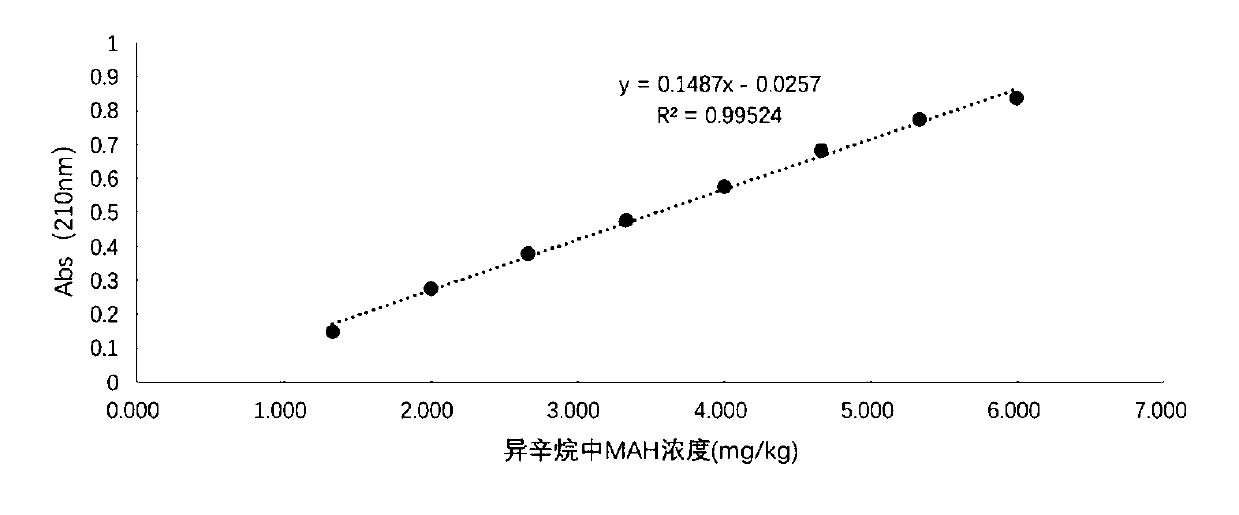

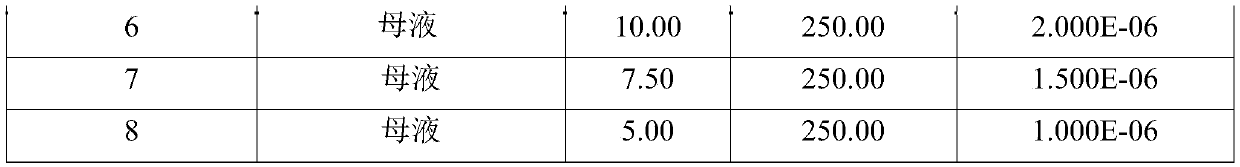

ActiveCN110296950BThorough extractionReliable test resultsPreparing sample for investigationColor/spectral properties measurementsUv absorbancePhysical chemistry

The invention provides a method for detecting the migration amount of MAH residues in PP-g-MAH materials, the method comprising the following steps: Step 1, establishing a standard working curve, carrying out ultraviolet spectrum testing to the standard working solution; using the concentration of the standard working solution is the abscissa; with its corresponding UV absorbance at the appropriate reference wavelength as the ordinate, draw a standard working curve; step 2, detect the migration of MAH residues in the PP-g-MAH sample material, and the sample sheet is placed in the oil Extract from the base food simulant to obtain the migration extract; take the migration extraction and deionized water to react in the autoclave; take out the mixed liquid in the autoclave, separate the liquid, and take the water phase; Phase UV spectrum test, read the absorbance value, and calculate the migration amount of MAH residual single in the sample according to the standard working curve established in step 1.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

Environment-friendly recovering treatment technology based on foamed plastic

ActiveCN113500721AEasy post-processingReduce device power consumptionPlastic recyclingMechanical engineeringRaw material

The invention discloses an environment-friendly recovering treatment technology based on foamed plastic. The technology comprises the following steps that Step 1, waste foamed plastic is cut, specifically, the waste foamed plastic is placed into a cutting box from the right side and is pushed leftwards through a pushing structure until one layer of the bottom surface is cut off by a bottom surface cutting assembly; and the left waste foamed plastic is pushed out from the left side, then the waste foamed plastic is inserted from the right side again in the other direction, and one layer of the other surface is cut off. The invention relates to the technical field of environmental protection. According to the environment-friendly recovering treatment technology based on the foamed plastic, a driving mechanism is arranged, so that the bottom surface cutting assembly and three sets of cutting assemblies can be driven to operate at the same time, a first steel wire of the bottom surface cutting assembly can cut off one layer of the dirty surface of the waste foamed plastic, after multiple surfaces are cut off, the rest is the clean foamed plastic, the foamed plastic can be directly recycled through simple cleaning in the later period, only a small amount of foamed plastic on the dirty surfaces needs to be cleaned and bleached, and the raw material consumption is low.

Owner:湖南隆铼新材料科技有限公司

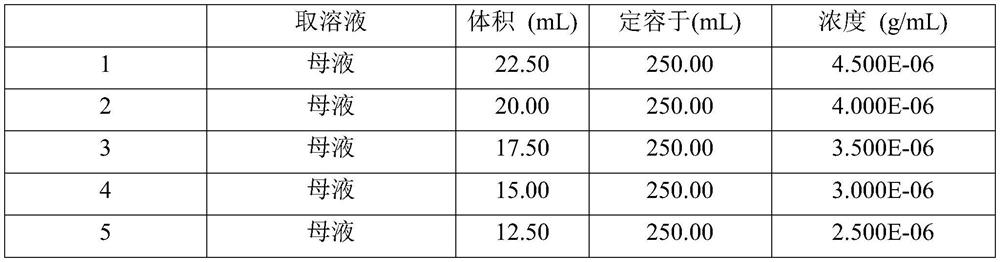

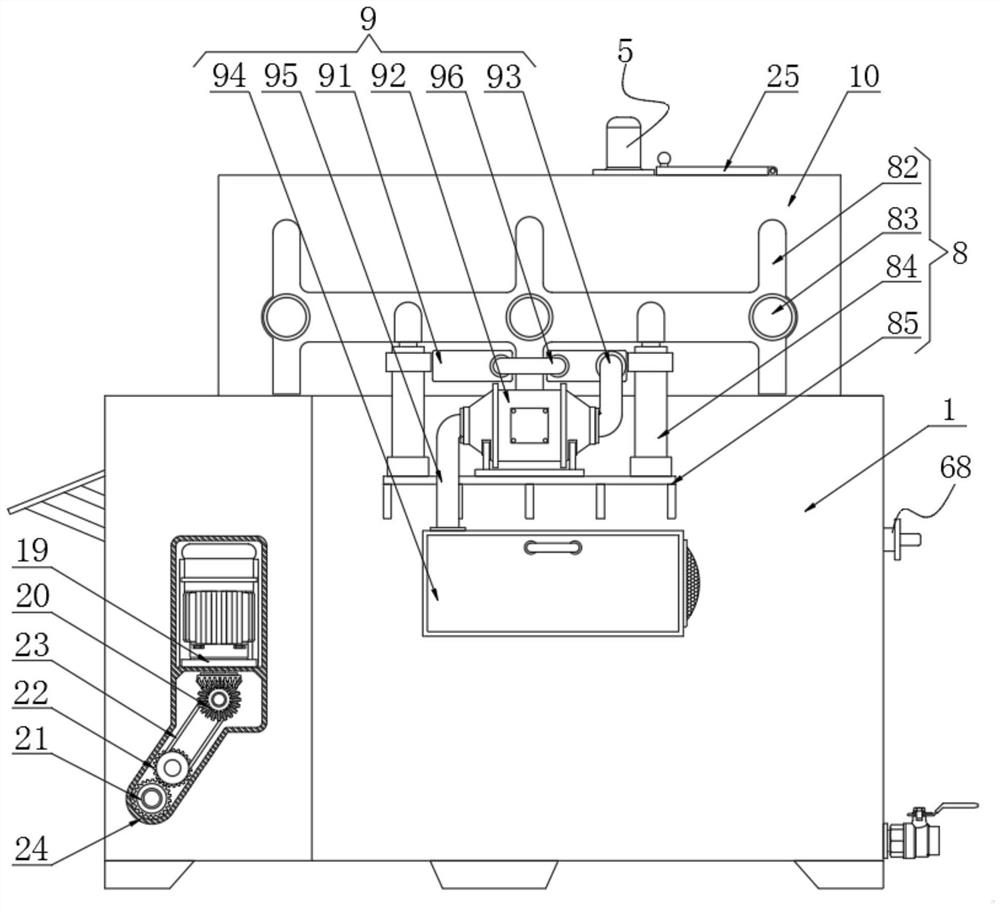

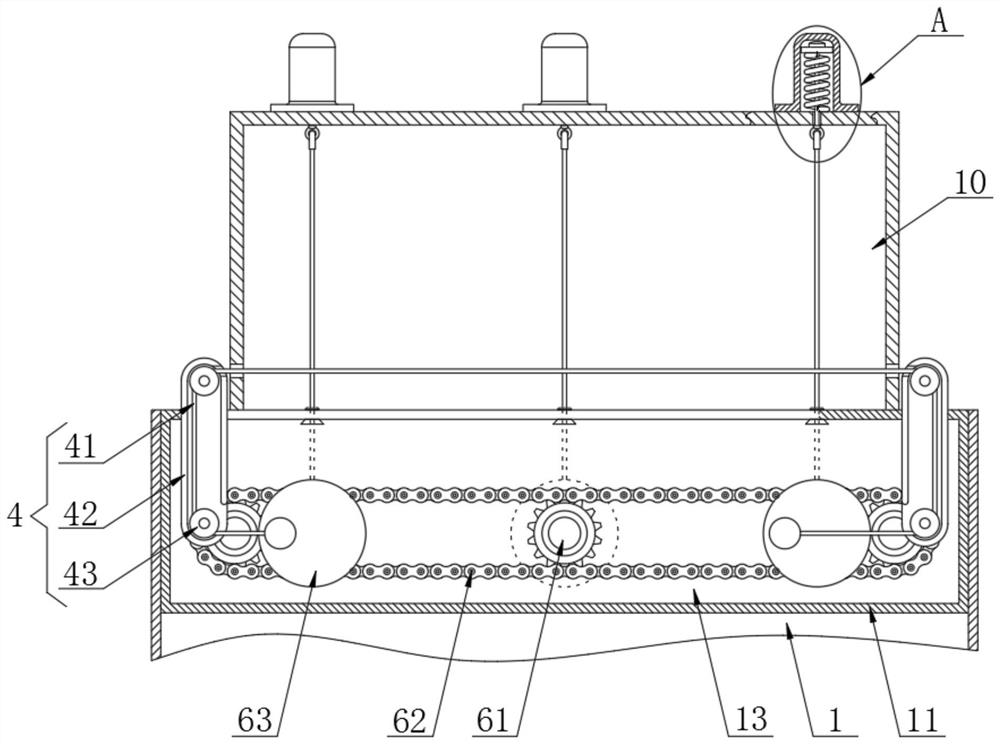

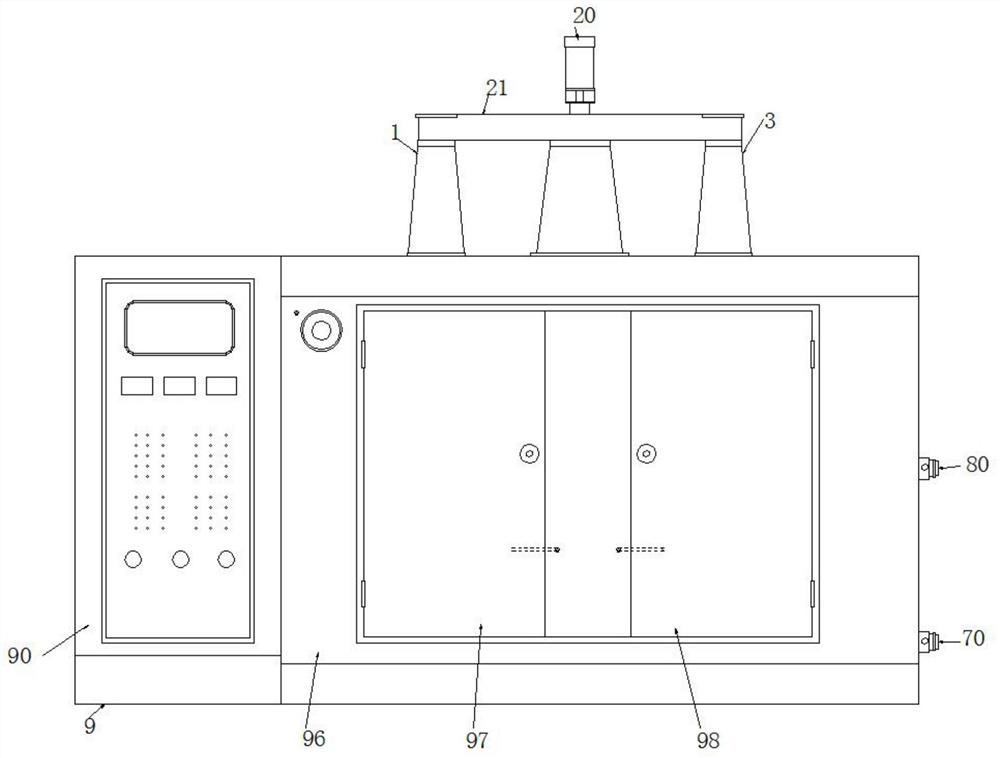

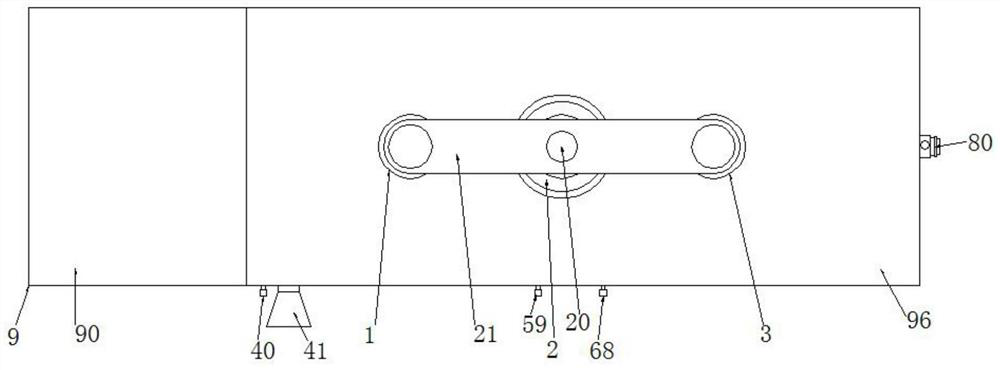

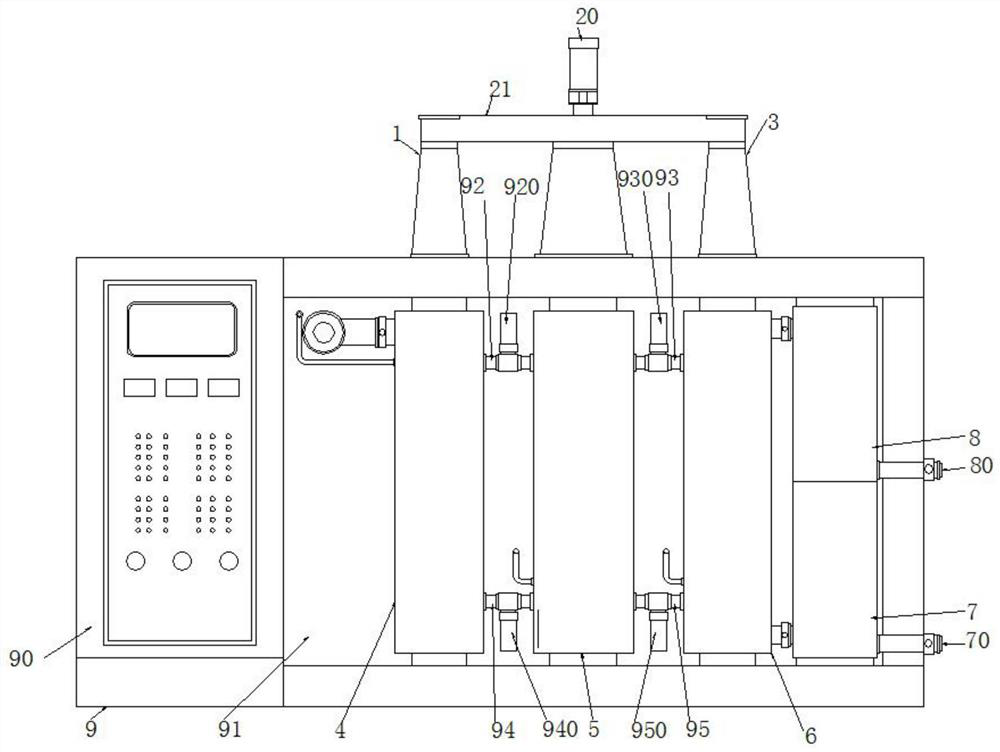

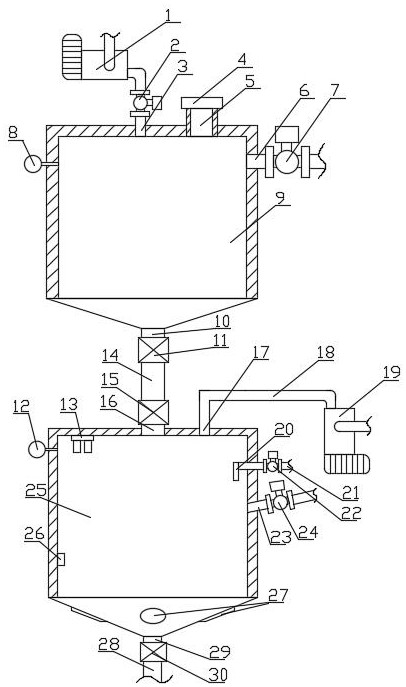

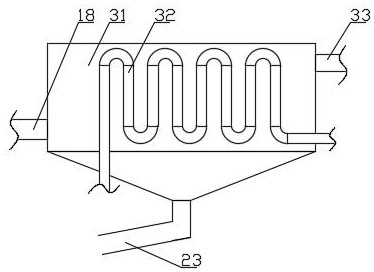

Continuous extraction system for herbicide production

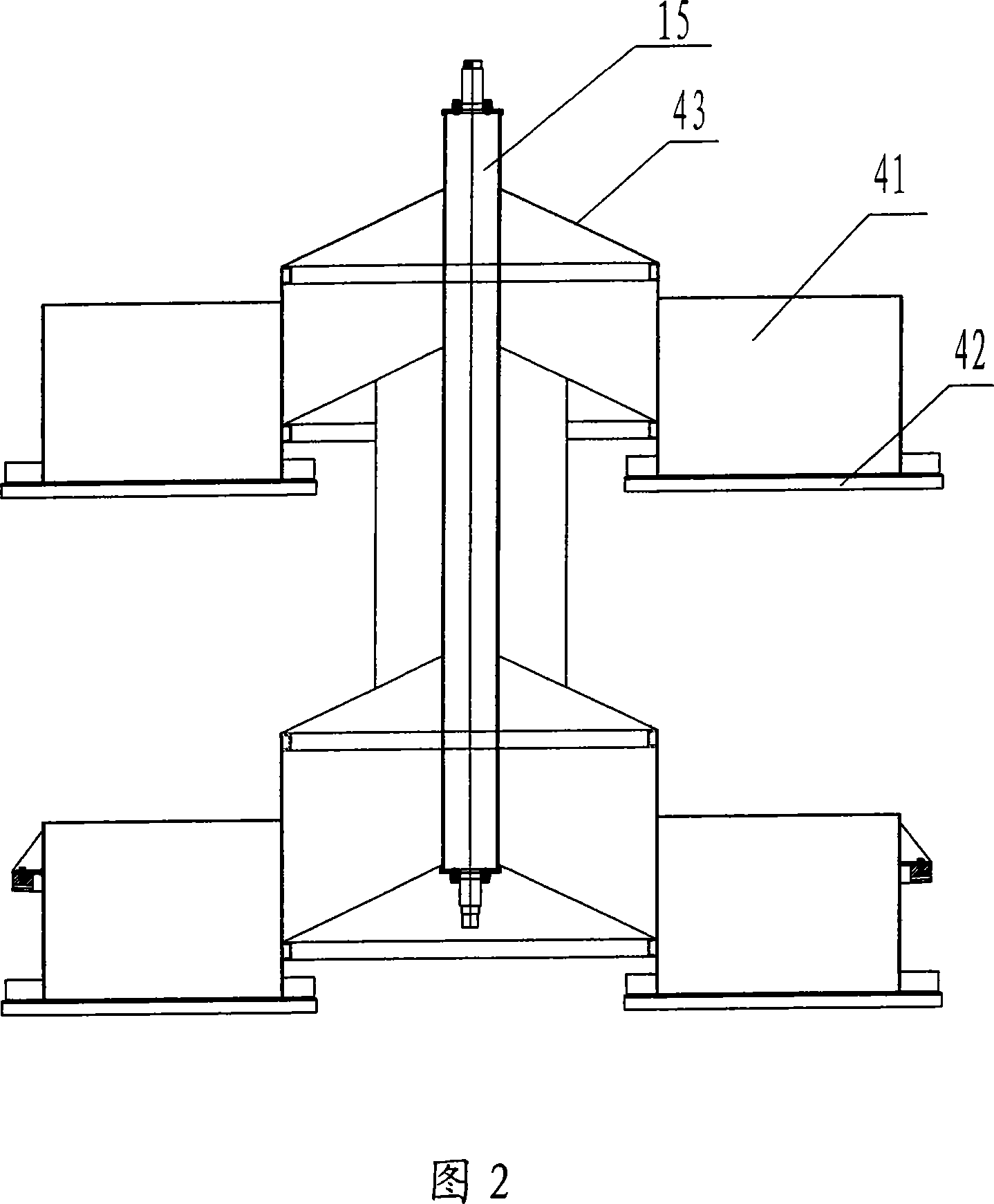

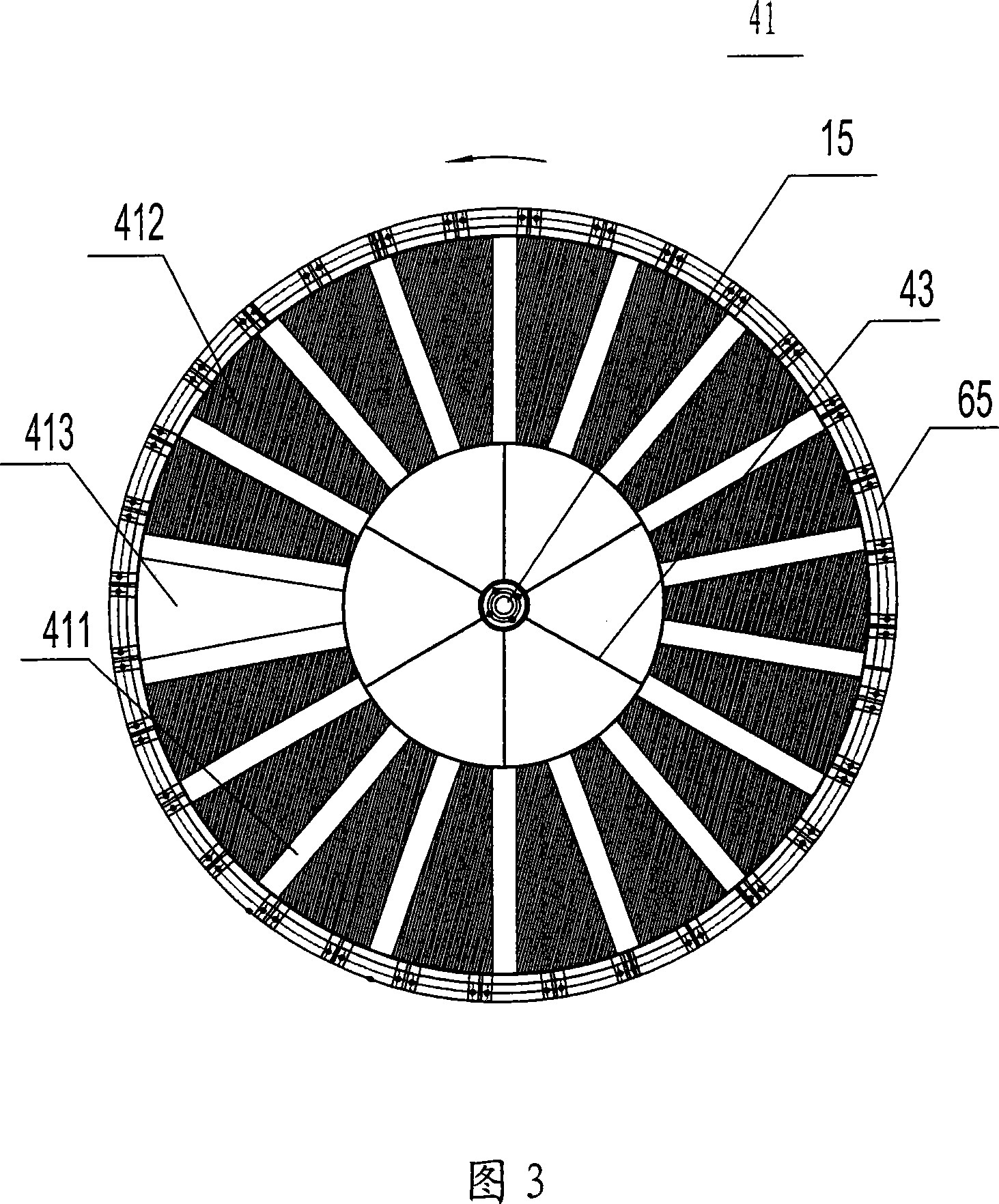

InactiveCN113101698AEasy drive transmissionIncrease contact areaLiquid solutions solvent extractionProcess engineeringMechanical engineering

A continuous extraction system for herbicide production, disclosed in the invention, comprises a first extraction tank structure, a second extraction tank structure, a third extraction tank structure and a machine body, the first extraction tank structure is installed at the left part in a mounting cavity, the second extraction tank structure is installed at the middle part in the mounting cavity, and the third extraction tank structure is installed at the right part in the mounting cavity; and a light liquid collecting cylinder is mounted above the right side of the third extraction tank structure, and a heavy liquid collecting cylinder is mounted below the right side of the third extraction tank structure. According to the continuous extraction system for herbicide production, a rotating shaft is used for rapidly rotating a stirring shaft, so that shearing force generated by a mixed liquid and an extraction agent in the tank enables the mixed liquid to be broken into a plurality of fine liquid drops, strong vortex motion is generated in the mixed liquid, meanwhile, the contact area of the extraction agent and a stock solution is increased, and the split fine liquid drops are extracted in the tank, therefore, the mixed liquid can be continuously extracted for multiple times, the purpose of continuous extraction is achieved, and the extraction is more thorough and cleaner.

Owner:安徽省圣丹生物化工有限公司

Method for detecting MAH residual monomer migration volume in PP-g-MAH material

ActiveCN110296950AThorough extractionReliable test resultsPreparing sample for investigationColor/spectral properties measurementsUltravioletLength wave

The invention provides a method for detecting the MAH residual monomer migration volume in a PP-g-MAH material, and the method comprises the following steps: Step 1, establishing a standard working curve, and carrying out ultraviolet spectrum test on a standard working solution; taking the concentration of the standard working solution as a horizontal ordinate; drawing a standard working curve bytaking the corresponding ultraviolet absorbance at a proper reference wavelength as a vertical coordinate; and Step 2, detecting the MAH residual monomer migration volume in a PP-g-MAH sample material, placing a sample sheet in an oil-based food simulant for extraction, and preparing a migration extracting solution; taking the migration extracting solution and deionized water to react in a high-pressure reaction kettle; taking out the mixed liquid of the high-pressure reaction kettle, separating the liquid, and taking a water phase; and performing ultraviolet spectrum test on the taken water phase, reading the absorbance value, and calculating the MAH residual monomer migration volume in the sample according to the standard working curve established in the Step 1.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

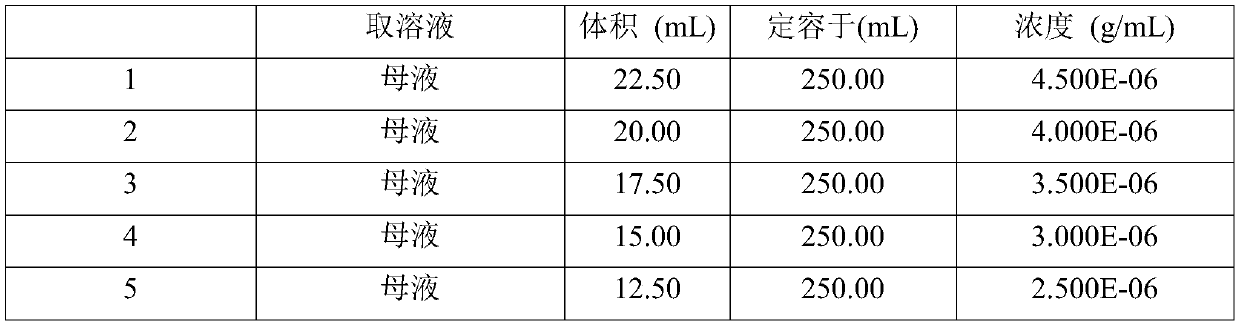

Process for extracting and concentrating dilute aqueous formaldehyde solution by using composite solvent

PendingCN113511965AEasy to operateImprove extraction capacityChemical industryCarbonyl compound separation/purificationCo solventAqueous solution

The invention relates to a process for extracting and concentrating a dilute aqueous formaldehyde solution by using a composite solvent. A process device comprises a recovery extraction tower, a concentration extraction tower, a desolventizing rectifying tower and a plurality of heat exchangers, wherein tower equipment in the process is a plate type tower in which a plurality of sieve plates are arranged, a solvent is selected as a continuous phase during operation, and the aqueous formaldehyde solution is a dispersed phase. The process comprises the following specific steps: completely extracting formaldehyde in a dilute formaldehyde solution into a composite solvent phase in a recovery extraction tower, allowing the composite solvent phase to flow out from the top of the tower, removing most of a cosolvent through heating and evaporating, enabling the composite solvent phase to enter the bottom of a concentration extraction tower, and allowing the content of formaldehyde in the solvent phase to be continuously increased under the action of adding concentrated formaldehyde into the tower top until a concentration requirement is met. The composite solvent adopted by the process can obviously improve the partition coefficient of formaldehyde under the condition of a low concentration, and a concentrated product is obtained by further concentration through fractional extraction, so efficient purification and phase separation are realized, and an energy-saving and effective production method is provided for concentration of the low-concentration aqueous formaldehyde solution.

Owner:潍坊惠丰化工有限公司

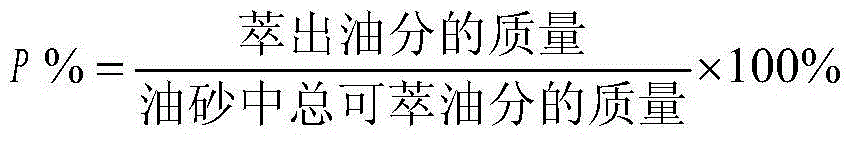

Method for treating oil sand by using composite extractant

ActiveCN104449796AReduce usageEasy extractionLiquid hydrocarbon mixture productionHydrocarbon oils treatmentGas phaseSolvent

The invention relates to a method for treating oil sand by using a composite extractant, particularly an extraction method for treating natural oil sand by using a composite extractant. The method provided by the invention is as below: breaking oil sands under different temperature conditions, extracting twice, conducting centrifugal separation on the material after extraction, conducting solvent regeneration on a separated liquid phase and recovering a thickened oil product, conducting destructive distillation on the separated solid phase under certain temperature, and condensing the gas phase from destructive distillation as an extraction agent, wherein the content of oil substances in the residue after destructive distillation is less than 0.3%, so as to achieve standard reached discharge. The invention has the main characteristics of high extraction efficiency, short process device and low equipment investment.

Owner:PETROCHINA CO LTD

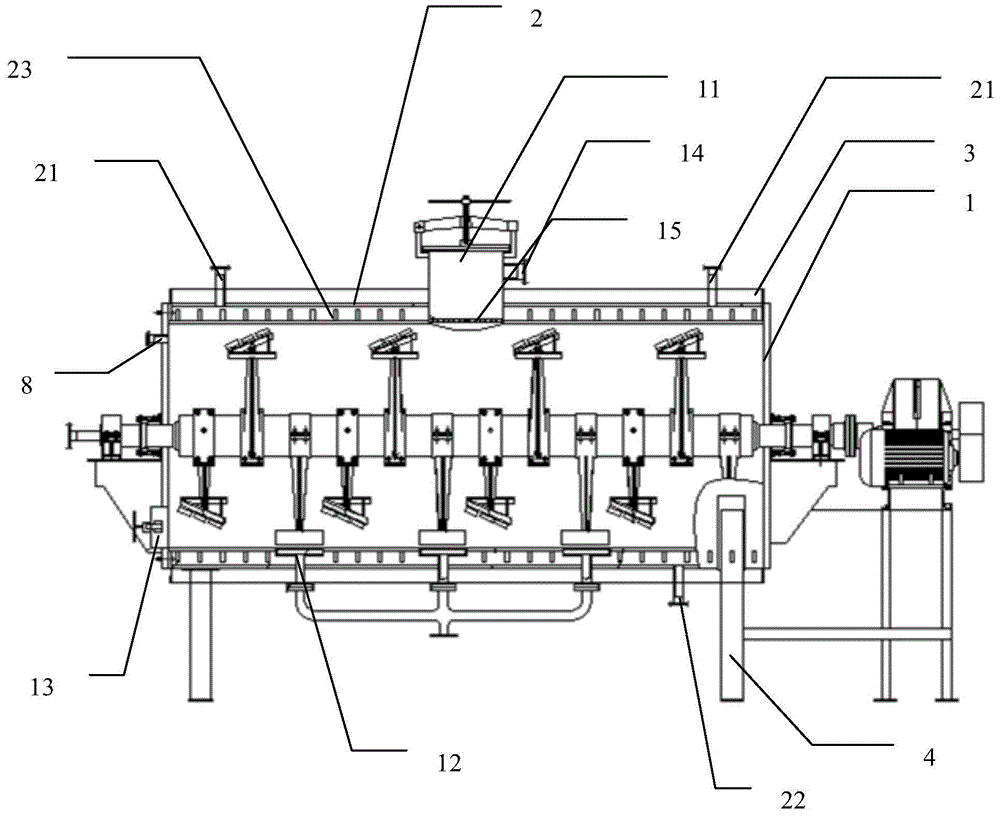

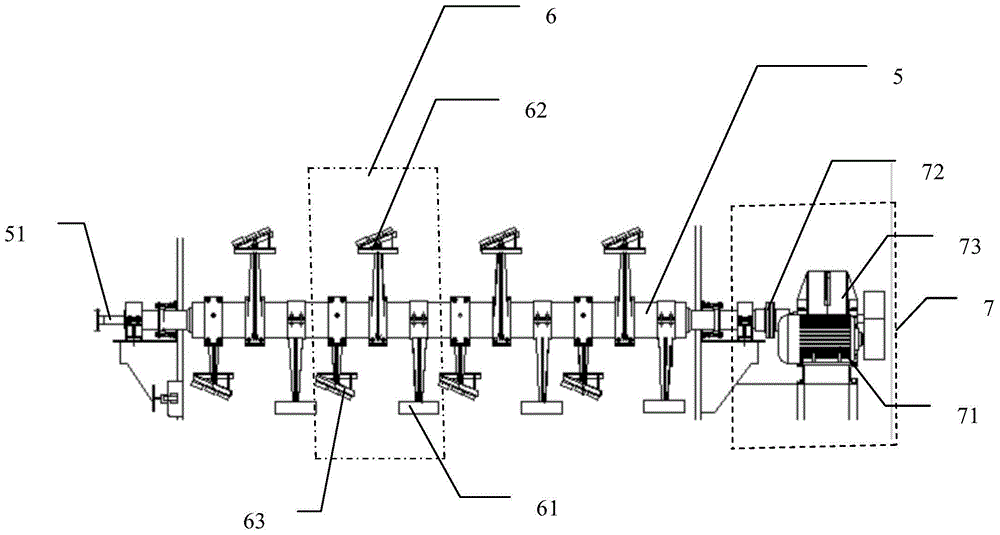

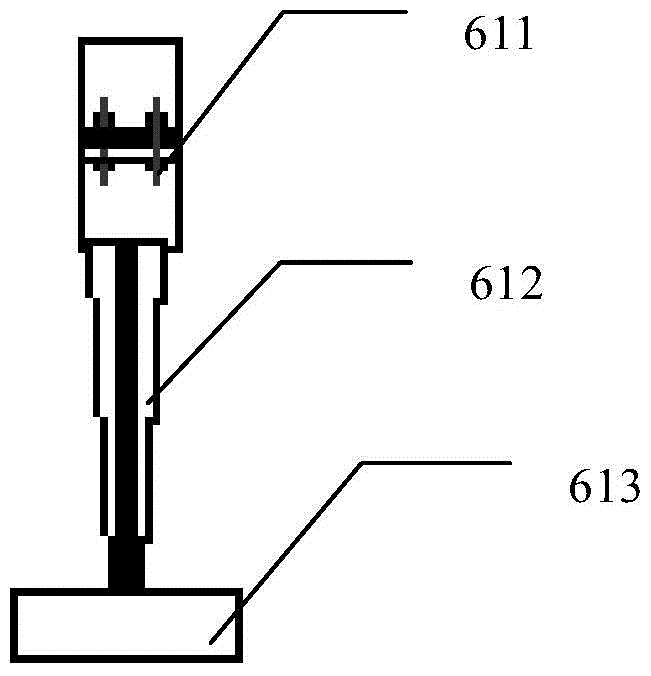

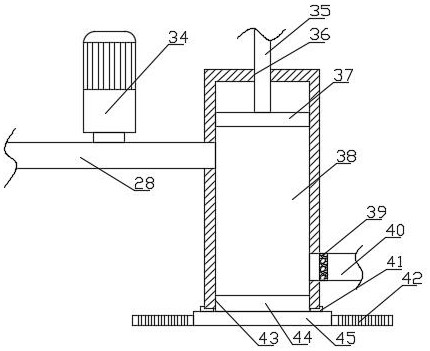

Self-unloading hot-press extraction device based on compound stirring

ActiveCN105107227BEfficient mixingAvoid stickinessFatty-oils/fats productionSolid solvent extractionSlagHot press

The invention discloses a self-unloading hot-pressing extraction device based on combined stirring, comprising an extraction tank, a jacket, a stirring shaft, a driving device and multiple stirring sets, wherein a feeding hole, a discharge hole and a slag discharge hole are formed in the extraction tank; the jacket sleeves the outside of the extraction tank; the stirring shaft is arranged inside the extraction tank; the driving device is connected with the stirring shaft and drives the stirring shaft to rotate; each stirring set comprises three stirring arms, and each stirring arm is provided with a shaft sleeve, a connecting rod and a stirring blade; the shaft sleeve sleeves the stirring shaft, two ends of the connecting rod are respectively fixedly connected with the stirring blade and the shaft sleeve, the multiple stirring sets are arranged at certain intervals three stirring arms in each stirring set are arranged at certain intervals, an included angle between two adjacent connecting rods in each stirring set is 120 degrees, and each stirring set comprises a rectangular stirring blade and two triangular stirring blade. According to the invention, the problems of conventional extraction tanks that extraction is not thorough, grease is not easy to separate, the universality is poor, and requirement for workshop and auxiliary equipment is high are solved.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

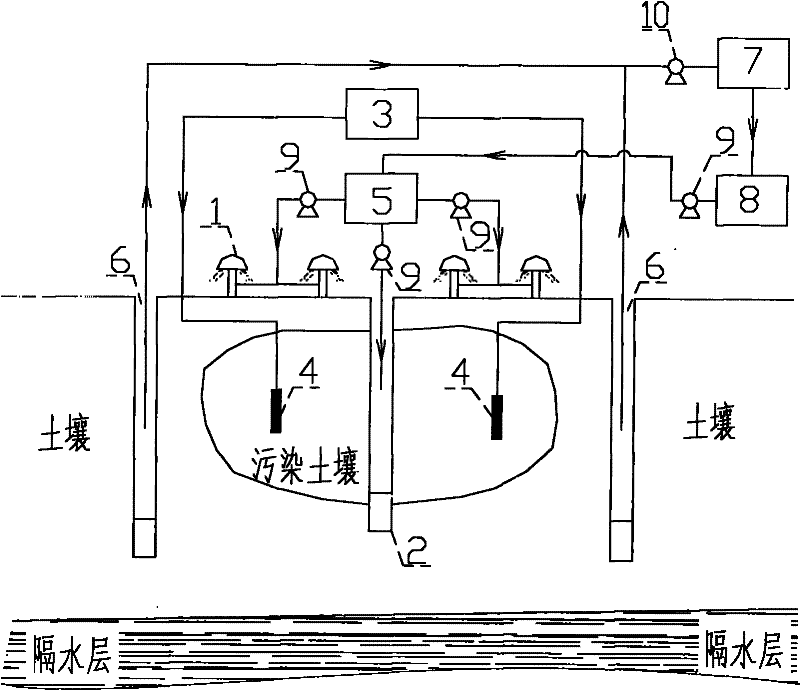

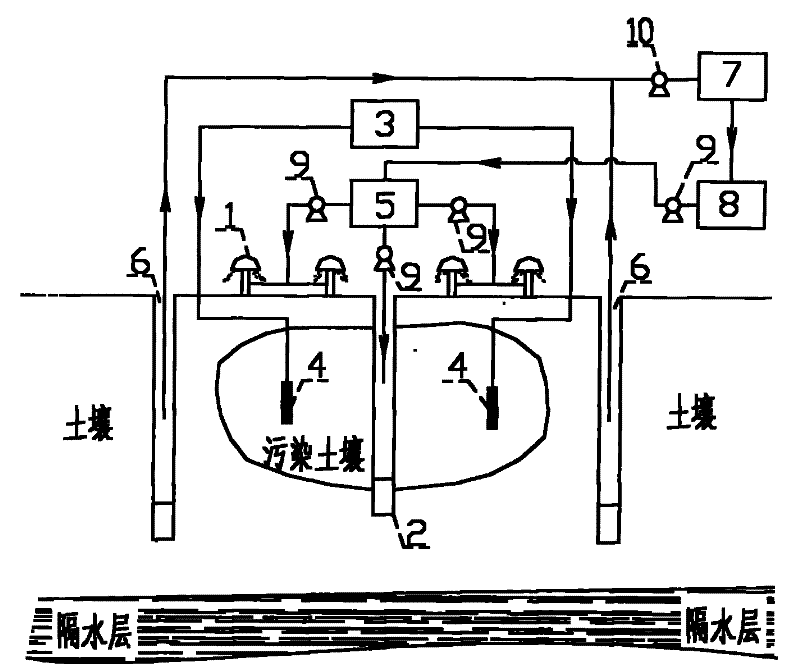

Ultrasonic in situ extraction process for remediating heavy metal-polluted soil

InactiveCN101879519BImprove extraction efficiencyThorough extractionContaminated soil reclamationSurface layerUltrasound - action

Owner:长春联创水质工程有限公司

Continuous extraction device and extraction method for traditional Chinese medicine raw materials

ActiveCN114870430AIncrease contact areaThorough extractionSolid solvent extractionMedicinal herbsProcess engineering

The invention provides a continuous extraction device and method for traditional Chinese medicine raw materials, the continuous extraction device comprises a pretreatment mechanism for breaking holes in medicinal materials and at least one group of extraction units, and each extraction unit comprises a high-pressure infiltration mechanism and a low-pressure extraction mechanism located below the high-pressure infiltration mechanism; a first discharge port of the high-pressure soaking mechanism is communicated with a second feed port of the low-pressure extraction mechanism through a first pipeline, a first valve is arranged at the first discharge port of the high-pressure soaking mechanism, and a second valve is arranged at the second feed port of the low-pressure extraction mechanism. The device can better extract non-powdery herbs at a lower temperature, in addition, due to the control of the temperature and the time, the extraction temperature does not reach 100 DEG C in the extraction process, and pasteurization is performed on liquid medicine while more medicine properties are kept.

Owner:XINYANG AGRI & FORESTRY UNIV

A method for preparing high-purity rubidium carbonate

ActiveCN104843746BSave waterNo lossRubidium/caesium/francium compoundsStrontium carbonateRubidium carbonate

The invention belongs to the technical field of methods for extracting metal ions by the aid of bipolar membrane electric osmosis technology and further generating a high-purity inorganic metal compound, and particularly relates to a method for preparing high-purity rubidium carbonate by the aid of the bipolar membrane electric osmosis technology by taking rubidium-containing waste liquor as a raw material. The method includes the steps: firstly, concentrating the rubidium-containing waste liquor, removing magnesium, iron, aluminum, calcium and barium; secondly, further removing calcium to obtain liquor to be extracted; thirdly, extracting rubidium from the liquor to be extracted by the aid of an electric extraction device to prepare rubidium acetate strip liquor; finally, concentrating, crystallizing and decomposing the rubidium acetate strip liquor at high temperature to obtain the rubidium carbonate. The method is efficient and environmentally friendly, and the obtained rubidium carbonate is excellent in quality and suitable for industrial popularization and application.

Owner:HUBEI BAIJIERUI ADVANCED MATERIALS

Health-care wine and preparation method thereof

InactiveCN101948730BImprove immunityRelieve fatigueAlcoholic beverage preparationBifidus factorRhizome

The invention is comprehensive heath-care wine. Based on the mixture of fermented grape juice distilled wine and millet vinegar, Chinese herbal medicines including hawthorn, burdock root, cassia seed, cynomorium songaricum, Chinese angelica, eucommia bark, medicinal cyathula root, codonopsis pilosula, dried longan pulp, liquoric root, astragalus, cinnamon, south dodder seed, common curculigo rhizome, Chinese wolfberry, mint safflower, Chinese date, desertliving cistanche, raspberry, epimedium herb, rehmanniae vaporata and prepared tuber of multiflower knotweed are added with water and decocted by the conventional decocting method to prepare decoction; bifidus factor, zinc gluconate, citric acid and cooked white sugar are added into the dectoction; and the finished product is obtained by settling, clarifying, coarsely filtering, fining, finely filtering, stabilizing by freezing and filtering by a membrane. The product has overall health-care functions, excellent taste and high stability and adopts a simple and easy-to-implement process.

Owner:QINGDAO JINNAN DRINK

Method for the detection of 3-benzylidene camphor and 4-methylbenzylidene camphor in consumer products

ActiveCN107255679BImprove test accuracyThorough extractionComponent separationBiochemical engineeringBenzyl group

The invention discloses a method for detecting 3-benzylidene-camphor and 4-methyl benzyl subunit camphor in consumer goods. The method includes steps of carrying out sampling, to be more specific, pretreating targets and detecting the contents of the 3-benzylidene-camphor and the 4-methyl benzyl subunit camphor in the pretreated targets. Pretreatment steps include mixing samples and an extracting agent with one another at first specified temperatures and carrying out ultrasonic extraction for the specified time; adding a purifying agent into first extraction products at the first specified temperatures and carrying out ultrasonic extraction for the specified time; cooling second extraction products until the temperatures of the second extraction products reach the room temperature and then filtering the second extraction products. The method for detecting the 3-benzylidene-camphor and the 4-methyl benzyl subunit camphor in the consumer goods has the advantages that the detection limit can reach 0.003%; the test accuracy of the samples can be improved by the aid of the pretreatment steps; tetrahydrofuran and acetone mixed liquid is used as the extracting agent, acetonitrile is used as the purifying agent, accordingly, the targets can be thoroughly extracted from products, and extraction procedures are speedy owing to ultrasonic extraction.

Owner:深圳天祥质量技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com