Ultrasonic in situ extraction process for remediating heavy metal-polluted soil

A technology of polluted soil and ultrasonic wave, applied in the direction of restoration of polluted soil, etc., to achieve the effect of reducing energy consumption, shortening extraction time, and wide range of types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

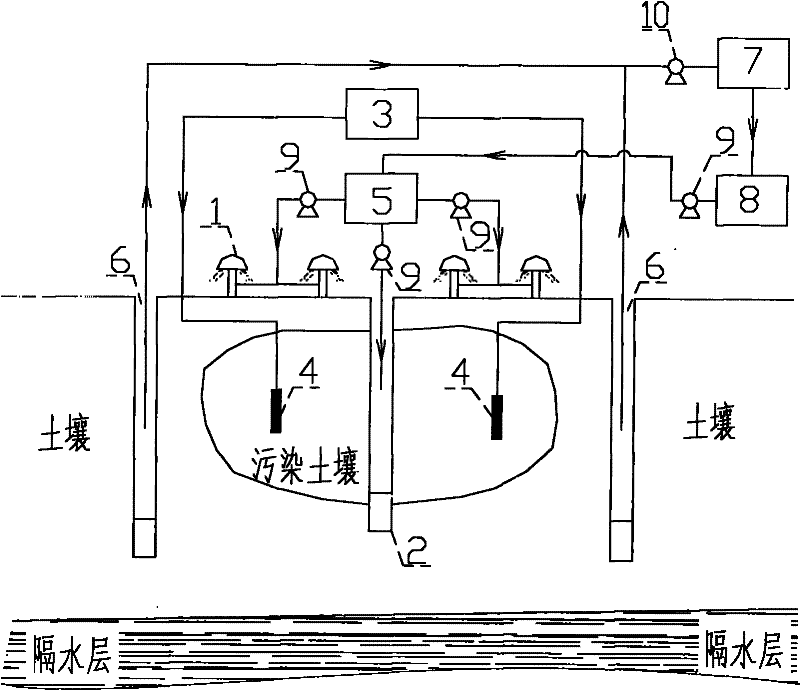

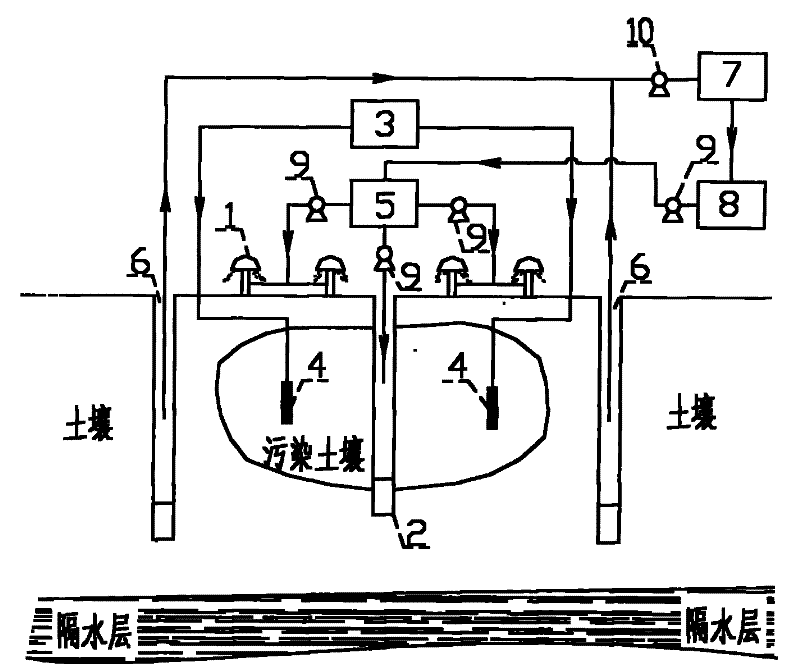

[0015] combine figure 1 The embodiment of the present invention is specifically described as follows: the prepared extractant is stored in the extractant storage tank (5), and after the sprinkler irrigation device (1) and the injection well (2) are evenly infiltrated into the surface layer and the inside of the polluted soil, the ultrasonic generator is opened (3) and adjust the power, through the transducer vibrator box (4) to emit ultrasonic waves to the soil for ultrasonic extraction, after extraction for a certain period of time, under the action of the pump (10), the extraction agent is extracted from the extraction well (6) Transport to the extractant collection tank (7), then flow into the extractant regeneration tank (8), where the extractant and heavy metals are separated in the extractant regeneration tank (8), and the regenerated extractant flows into the extractant storage tank (5) reuse in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com