Patents

Literature

104results about How to "Uniform extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

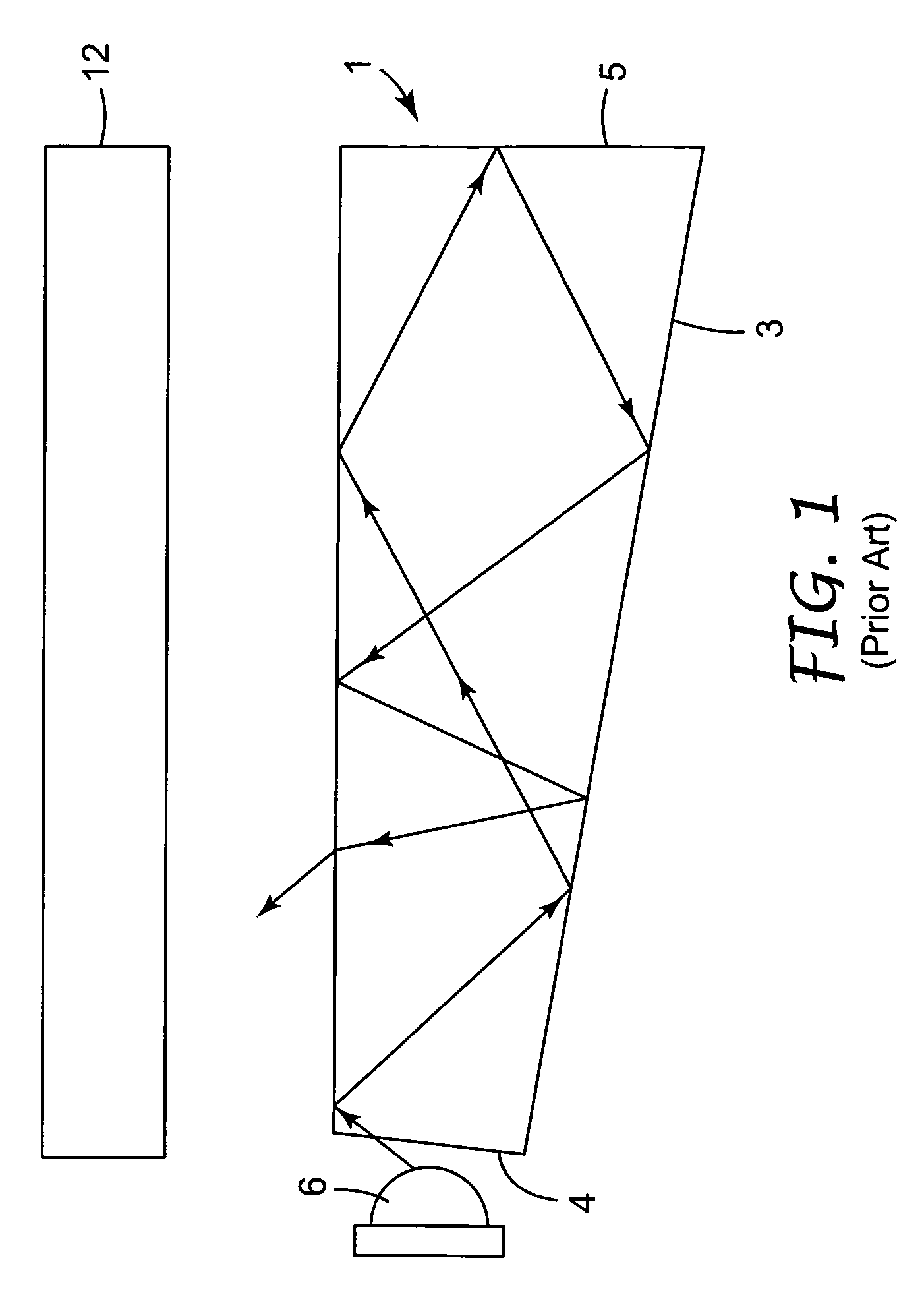

Illumination device

InactiveUS7052168B2Improve uniformityUniform extractionMechanical apparatusLight guides for lighting systemsLight guideLighting system

An illumination system includes a light guide for distributing light. Extraction structures are provided to uniformly extract light from the light guide. The structures extract more light out of the light guide when light is propagating in the light guide in a direction toward the light input area than when light is propagating in the light guide in a direction away from the light input area.

Owner:3M INNOVATIVE PROPERTIES CO

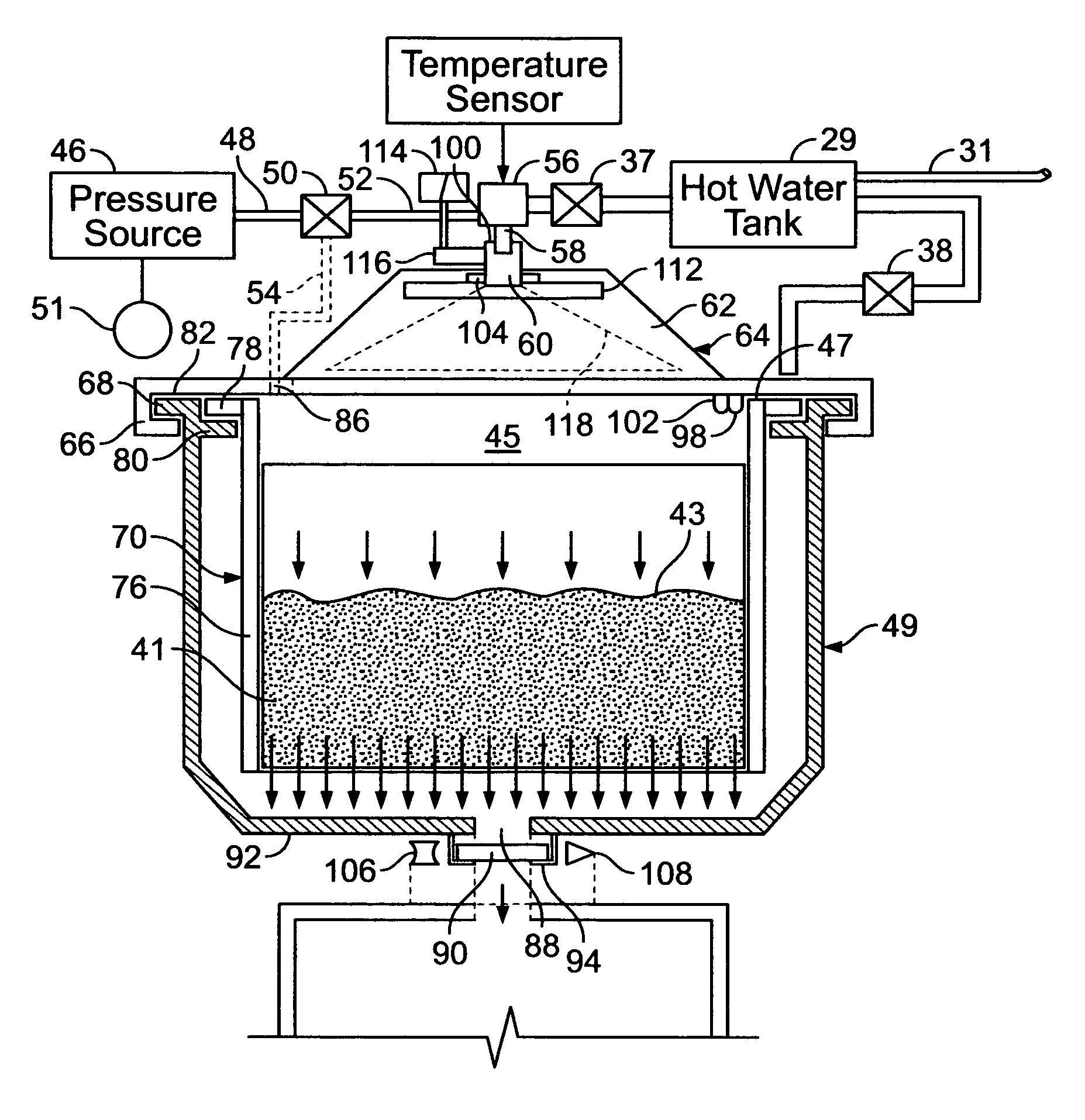

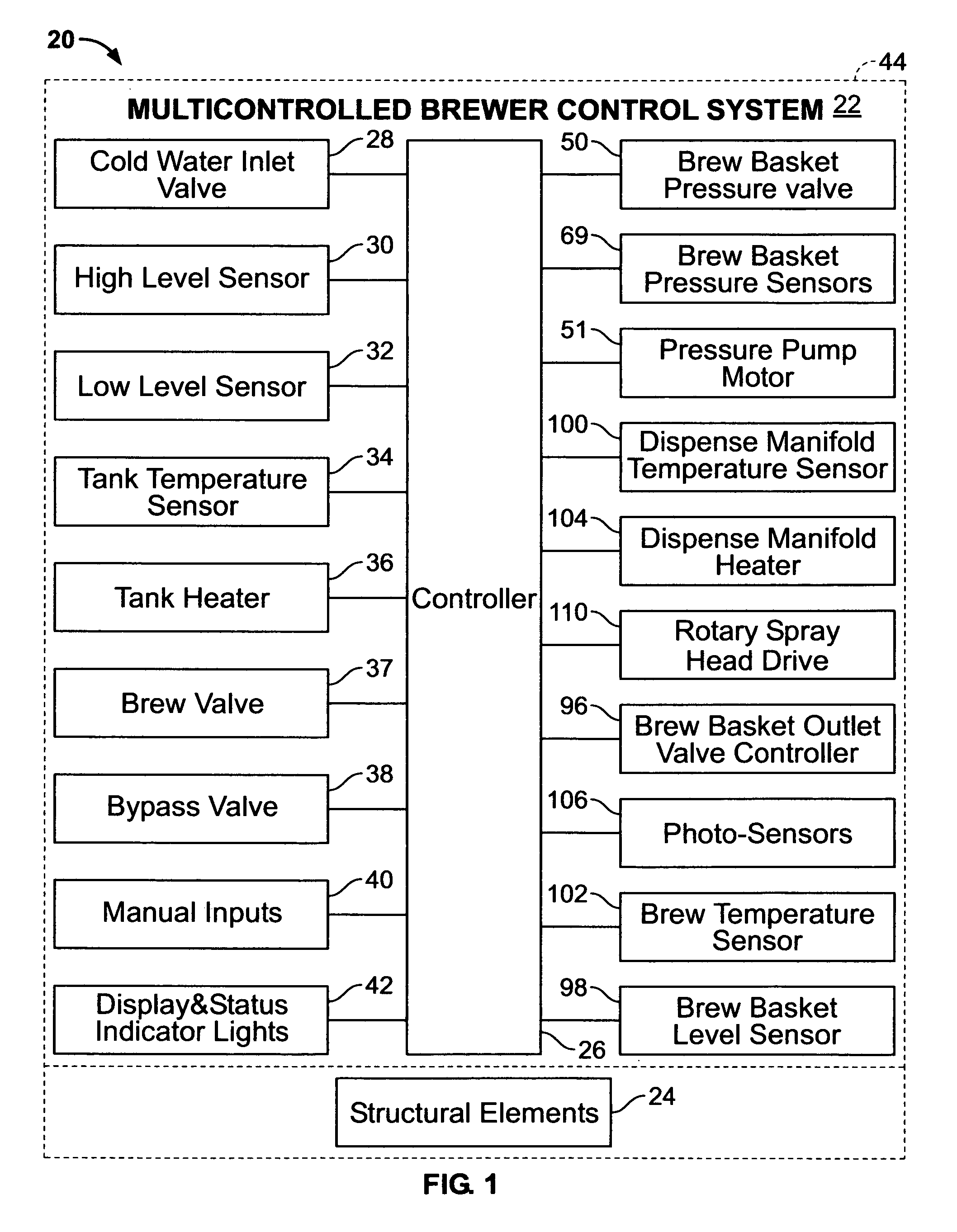

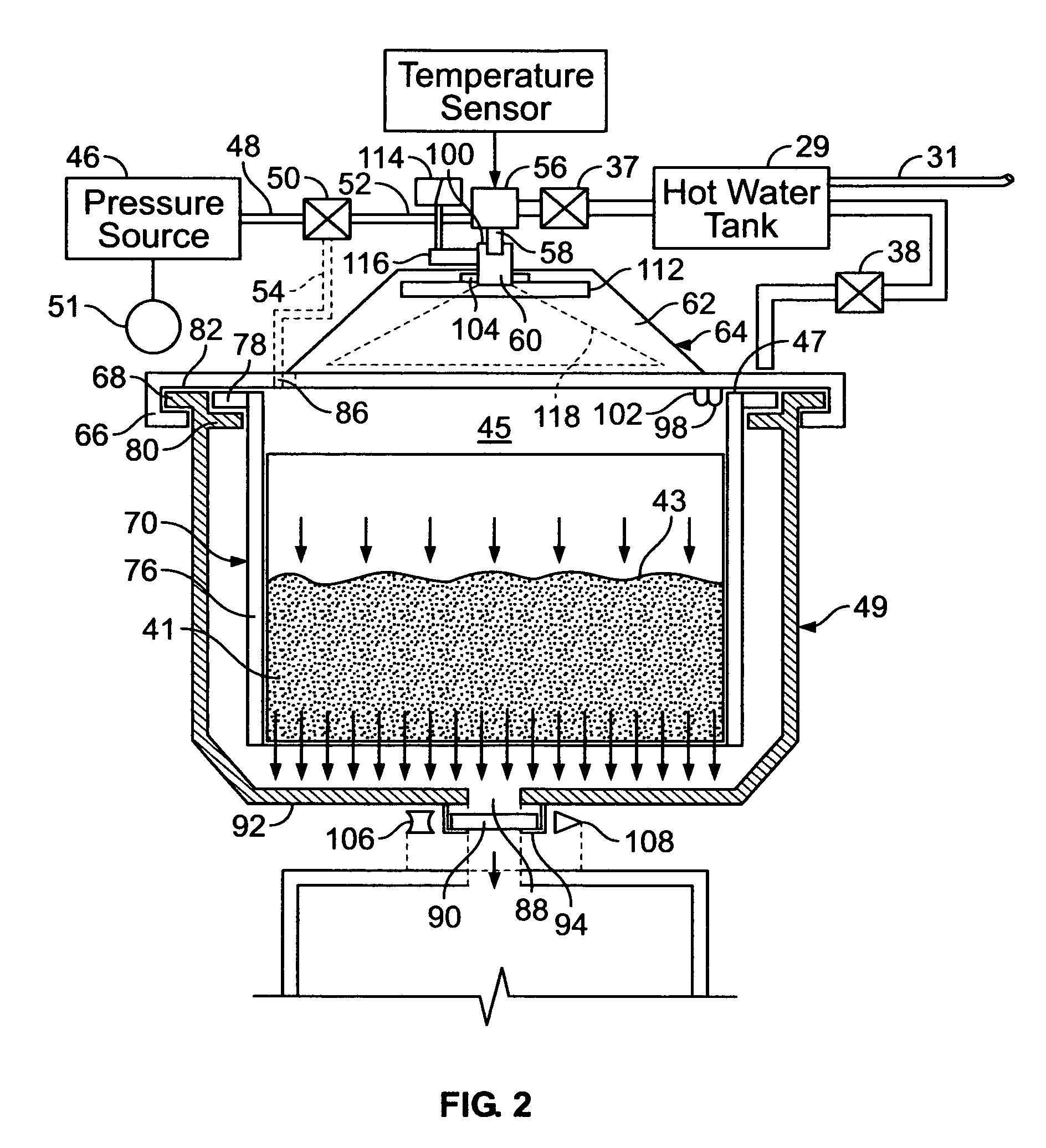

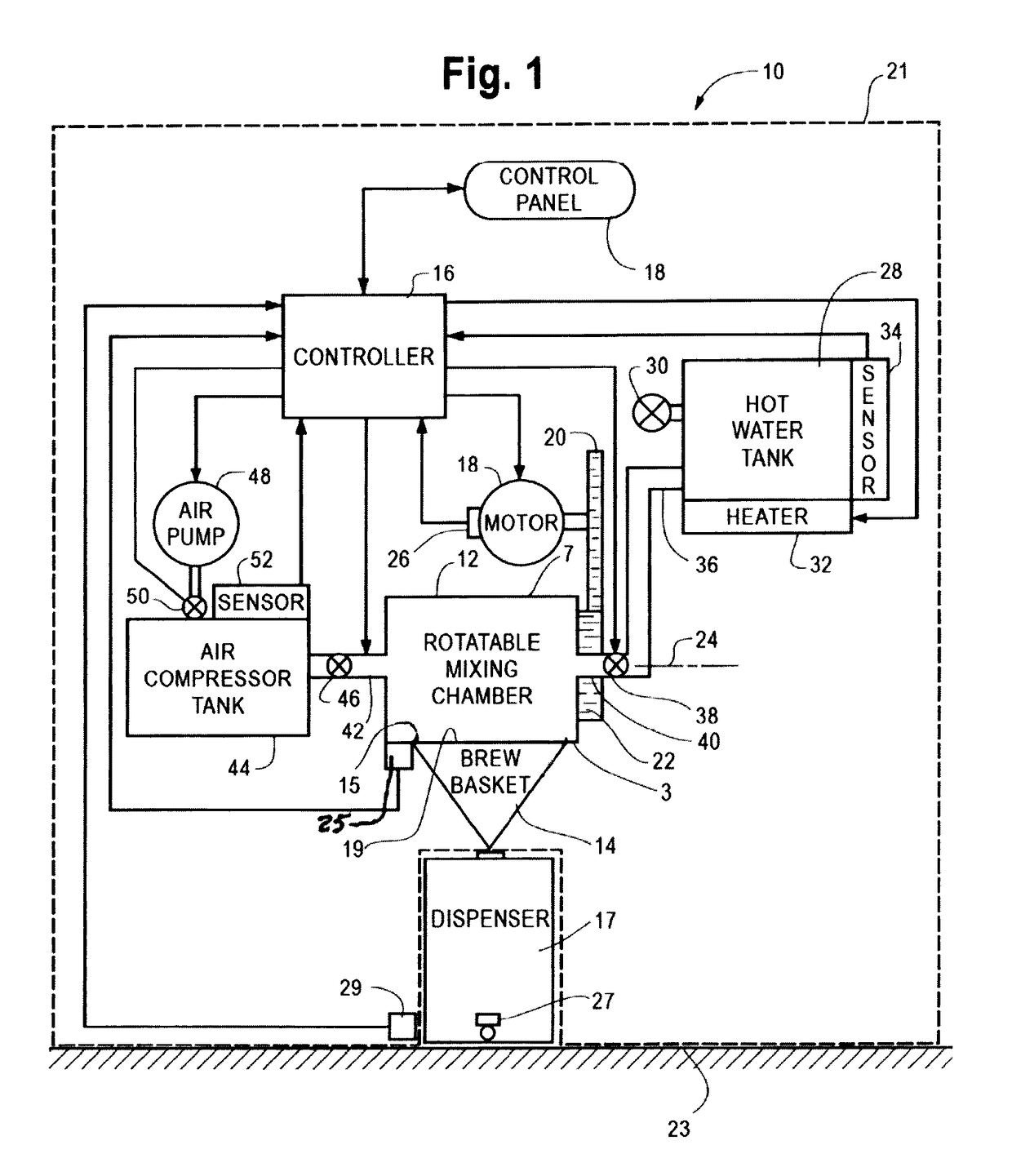

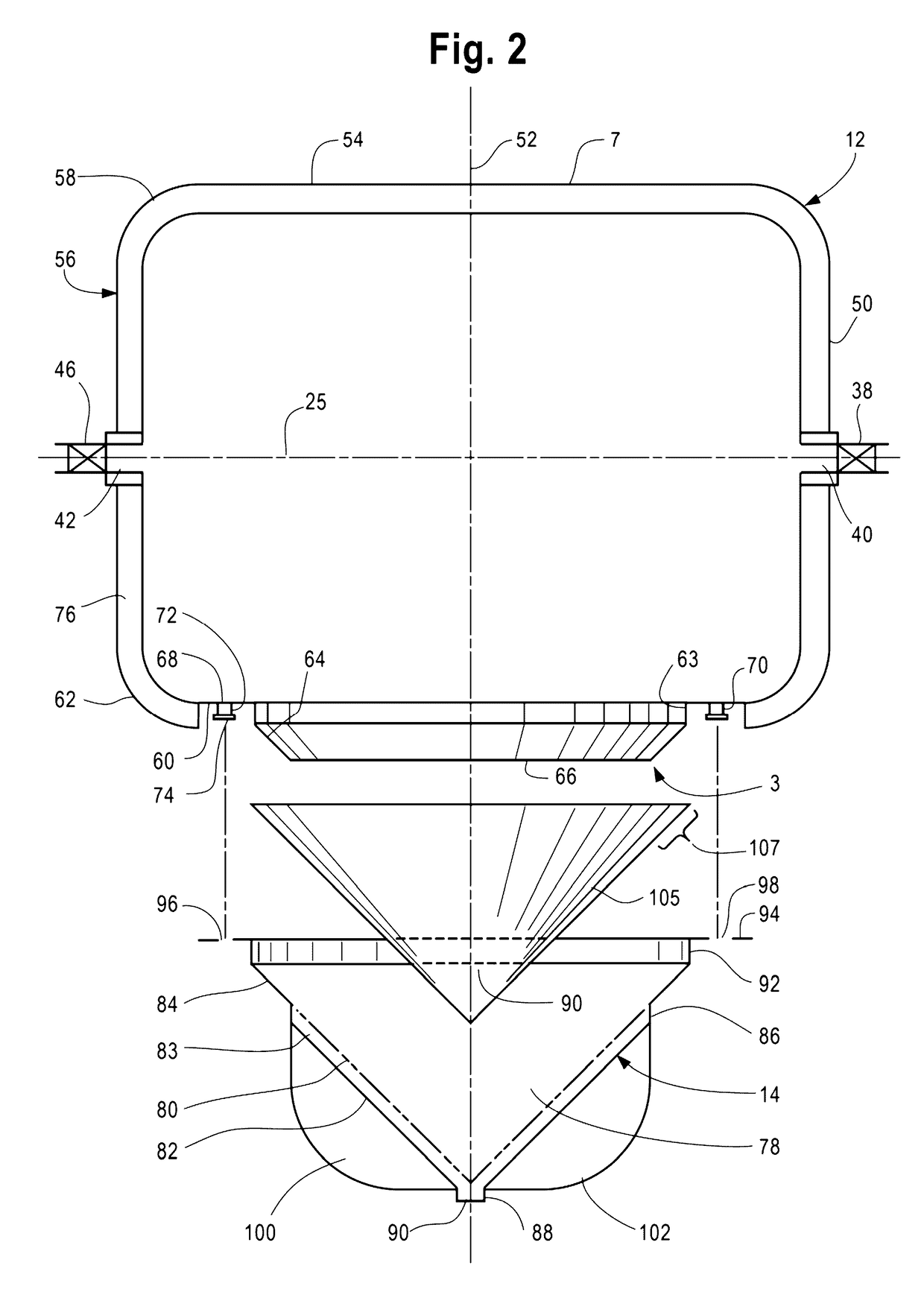

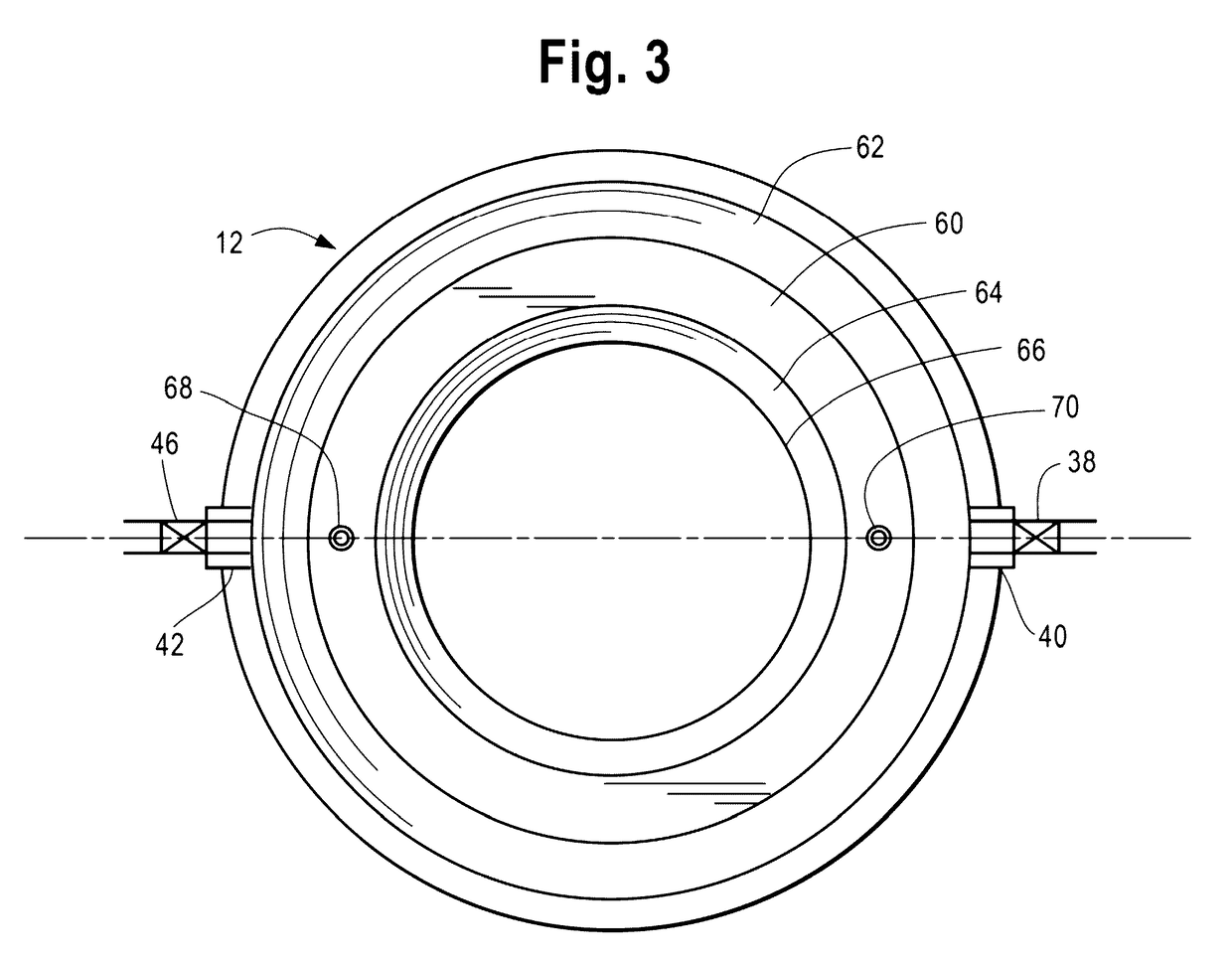

Multicontrolled brewer for optimum flavor extraction

A multicontrolled, fresh beverage brewer (20) with a dispense manifold heater (104) for selectively instantaneously heating pre-heated hot water from a hot water tank (29) immediately before the preheated hot water is dispensed into the brew basket (49) in sensed temperature of the beverage within the brew basket the preheated water immediately prior to being added to the brew basket, a photosensor (106) for sensing a level of light conductance of the beverage for controlling at least one of a brew dispense valve (37), a bypass valve (38) and a brew basket drain hole closure (94) in response to photosensor sensing a level of light conductance level of the beverage, and brew basket pressurization system (50, 69, 51) for selectively pressurizing the brew basket (49) to selectively accelerate the flow rate of hot water though an ingredient within the brew basket. A rotary spray head drive (110) rotates a rotating spray assembly to provide an even distribution of hot water over the surface of the ingredient, and a spray distribution plate employs open channels of differing length (156) to channel the water to different desired location are open for easy cleaning and elimination of clogging from lime residue. A brew basket filter holder (72) insert for insertion into the filter holder has a cylindrical, water impervious wall to prevent side passage of the hot water through the layer of beverage ingredient.

Owner:FOOD EQUIP TECH

Method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing, and permeability increasing

InactiveCN101644166AImprove flow statusEasy to extractUnderground miningSurface miningHigh pressure waterHigh pressure

The invention discloses a method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing and permeability increasing, comprising the following steps: whena drill is drilled into a predetermined position of the coal seam, coal bodies at both sides of a drill hole are cut in the drill hole by high pressure water jet with a certain pressure and flow; a flat slot is formed at both sides of the drill hole; the cut coal bodies is led out the hole by the high pressure water jet. The exposed area of the coal body at the slotted part in the drill hole aregreatly increased, namely that an extremely thin protective layer is exploited with local scope of the flat slot, which enlarges effective influential range of pressure releasing, permeability increasing and gas discharging of the coal bodies in the drill hole, thus the air permeability of the coal bodies is increased about 200-300 times, the average amount of single-hole gas extraction reaches 0.3m<3> / min, the concentration of the gas extraction is 30-60%, gas drainage rate of working face of coal extraction is more than 50%, the number of drill holes for gas drainage is reduced by 10-20% after slotting, pressure releasing and permeability increasing. The method realizes the safety, high efficiency and uniform extraction of the gas from the high gas low permeability outburst coal seam, and changes high gas coal seam with outburst danger into low gas coal seam without outburst danger.

Owner:CHINA UNIV OF MINING & TECH

Method for increasing permeability of inert gas and extracting gas

A method for increasing the permeability of an inert gas and extracting gas under the coupling action between temperature and pressure, belongs to a method for extracting the gas. A permeability increasing hole is formed in the middle of a workface coal bed; gas extraction holes are formed on vertexes of an equilateral triangle with the permeability increasing hole as a center; after the gas extraction holes are sealed, the gas is extracted; the inert gas under the coupling action between temperature and pressure is injected into the permeability increasing hole one by one; under the coupling action of temperature and pressure of the nitrogen, a small-size clearance of a coal body is pressed by the inert gas to be opened, so that an original crack in the coal body is stretched, the stretched crack further extends and no protrusion by induction occurs; 90 percent of adsorption gas in the coal body absorbs energy and the separating speed of the gas from the coal body is increased, so that gas which is difficult to desorb in the coal body is converted into free gas which is convenient to quickly extract in a large flow; and a permeability increasing medium is gas, and the gas subjected to permeability increase can be exhausted from a crack channel without blocking the gas flowing channel, so that the conditions for the extraction of the gas is provided. The method has the advantages of simplicity in operation, favorable effect, high extraction efficiency of the gas and applicability.

Owner:CHINA UNIV OF MINING & TECH

Gridding type layer-through drilling pore group permeability-increasing gas pumping method

InactiveCN101144389AImprove breathabilityIncrease pre-pumping rateUnderground miningSurface miningHigh pressure waterHigh pressure

The invention relates to a grid type across-seam drilling hole multi-hole anti reflection gas extraction method. Grid type across-seam drilling hole positions are set in the coal seal area where the gas extraction is performed; the grid type across-seam drilling hole positions set are drilled with holes one by one, forming a hole group; when the hole drilling construction enters the coal seam, hole punching is performed by using high pressure water with 5 to10MPa water pressure and 10 m3 / h flow quantity to cause the drilling hole to spray holes, to form a crack between the coal seam hole and the hole, and to increase the coal seam permeability; after the drilling hole is penetrated through the coal seam of 0.5 m, the drilling hole is escaped from a drilling rod, and is inserted into a sealing tube for hole sealing. The drilling hole is connected with an extraction tube mesh through a sealing tube, a collecting tube, a gas collection tank and a branch tube, to perform gas extraction for the coal seam. The method leads the coal seam pre-drainage efficiency to be improved to over 40 percent from the original 20 percent, realizes safe, efficient and even extraction for the sole low permeability outburst coal seam, a high gas outburst dangerous coal seam is changed to be a low gas non-outburst dangerous coal seam, and the invention has a wide practicability.

Owner:CHINA UNIV OF MINING & TECH +1

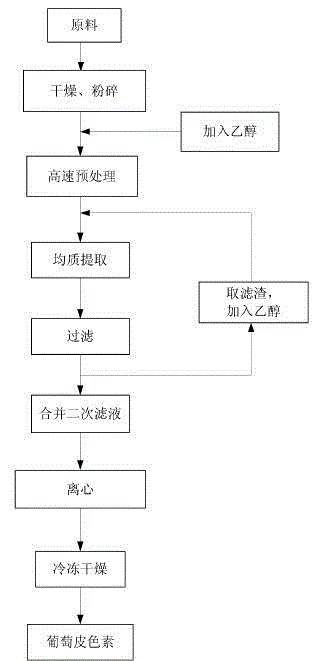

Extraction method for natural pigment

The invention discloses an extraction method for a natural pigment. The extraction method for a natural pigment comprises the following steps of: (1) washing, drying and crushing raw materials, then passing through a 100-mesh sieve, performing homogeneous extraction in the mixed solution of ethanol aqueous solution in the percentage of 60-95% by volume and hydrochloric acid aqueous solution in the concentration of 0.1 mole per litre, and filtering after the extraction, so as to obtain a filtrate, wherein the pH value of the obtained mixed solution is 2.0-5.0; and the homogeneous extraction comprises a high-speed pre-treatment phase and a homogeneous extraction phase; (2) neutralizing, centrifuging and deslagging the filtrate obtained in the step (1), so as to obtain a supernatant; and (3) concentrating and drying the supernatant obtained in the step (2), so as to obtain the natural pigment, wherein the raw materials are chestnut shells, black soya bean skins, dragon fruit peels, lychee exocarps, grape seeds, hickory exocarps, acorn shells, orange peels, hazelnut shells, nectarine peels and purple sweet potato or purple-black broomcorn shells. The extraction method disclosed by the invention is simple in process, low in requirements on production equipment, not easy to break pigment substances, and high in extraction rate.

Owner:SHANGHAI LAMP BIOLOGICAL SCI & TECH

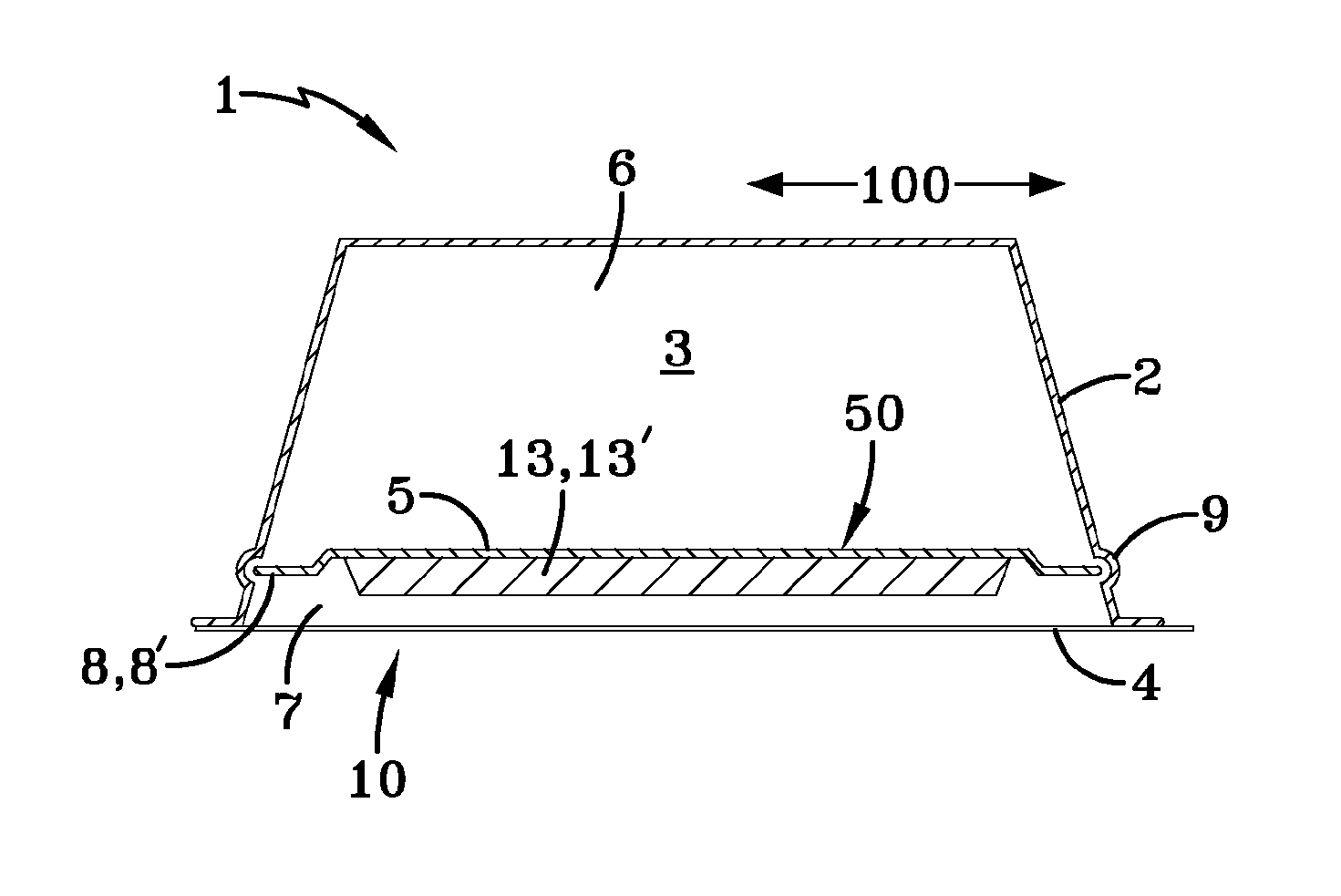

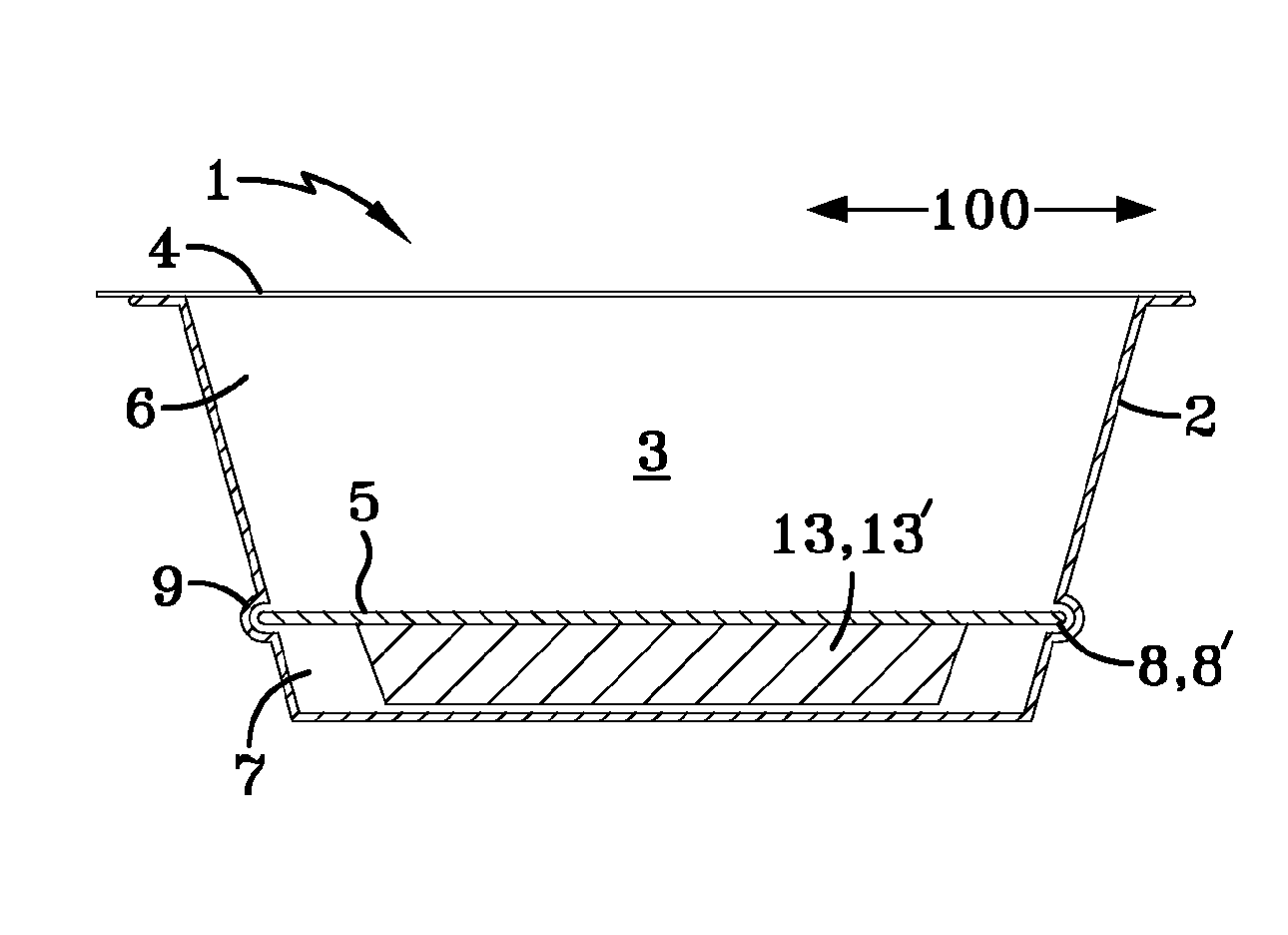

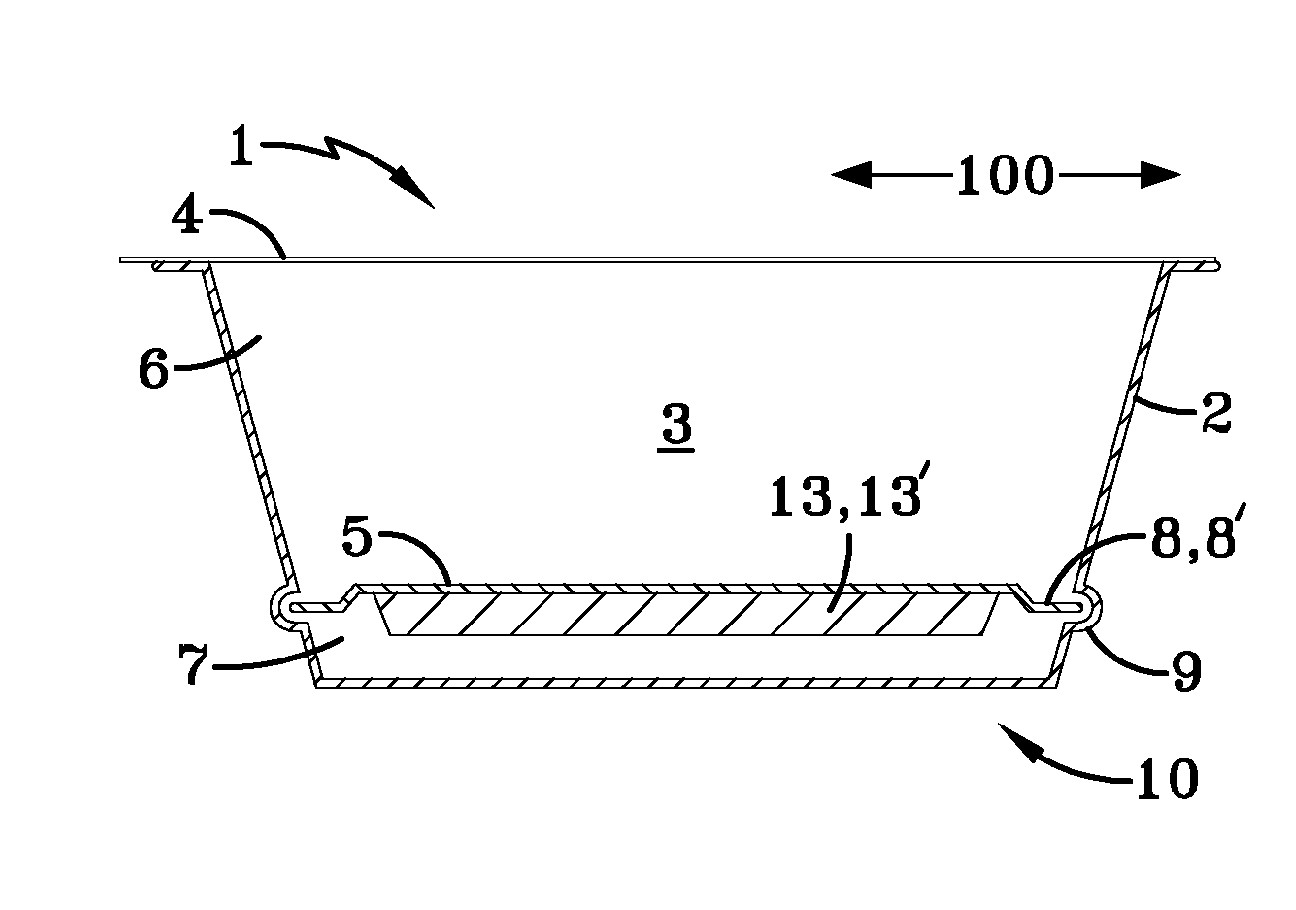

Portion capsule and use of a portion capsule

The invention relations to a portion capsule for producing a beverage, having a substantially truncated cone-shaped or cylindrical base element (2) that has a hollow space (3) and a membrane (4) sealing the hollow space, wherein within the hollow space a filter element (5) is disposed, which subdivides the hollow space into a first region (6) for receiving a raw beverage material and into a second region (7) for receiving a beverage extract, wherein the filter element is fastened to the base element by means of at least one fastening means (8) that is arranged substantially in the region of a face of the base element lying opposite the membrane.

Owner:K FEE SYST

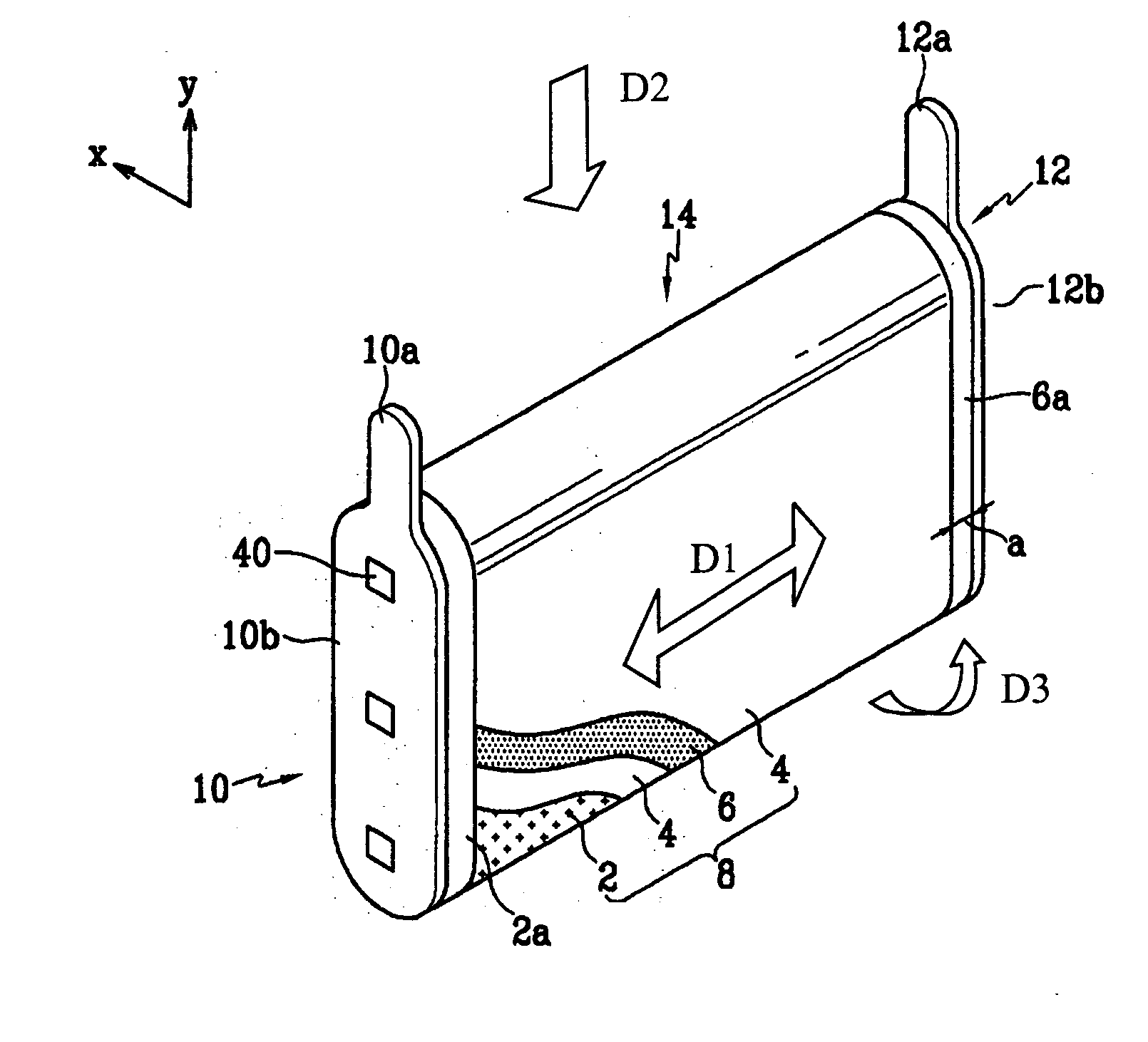

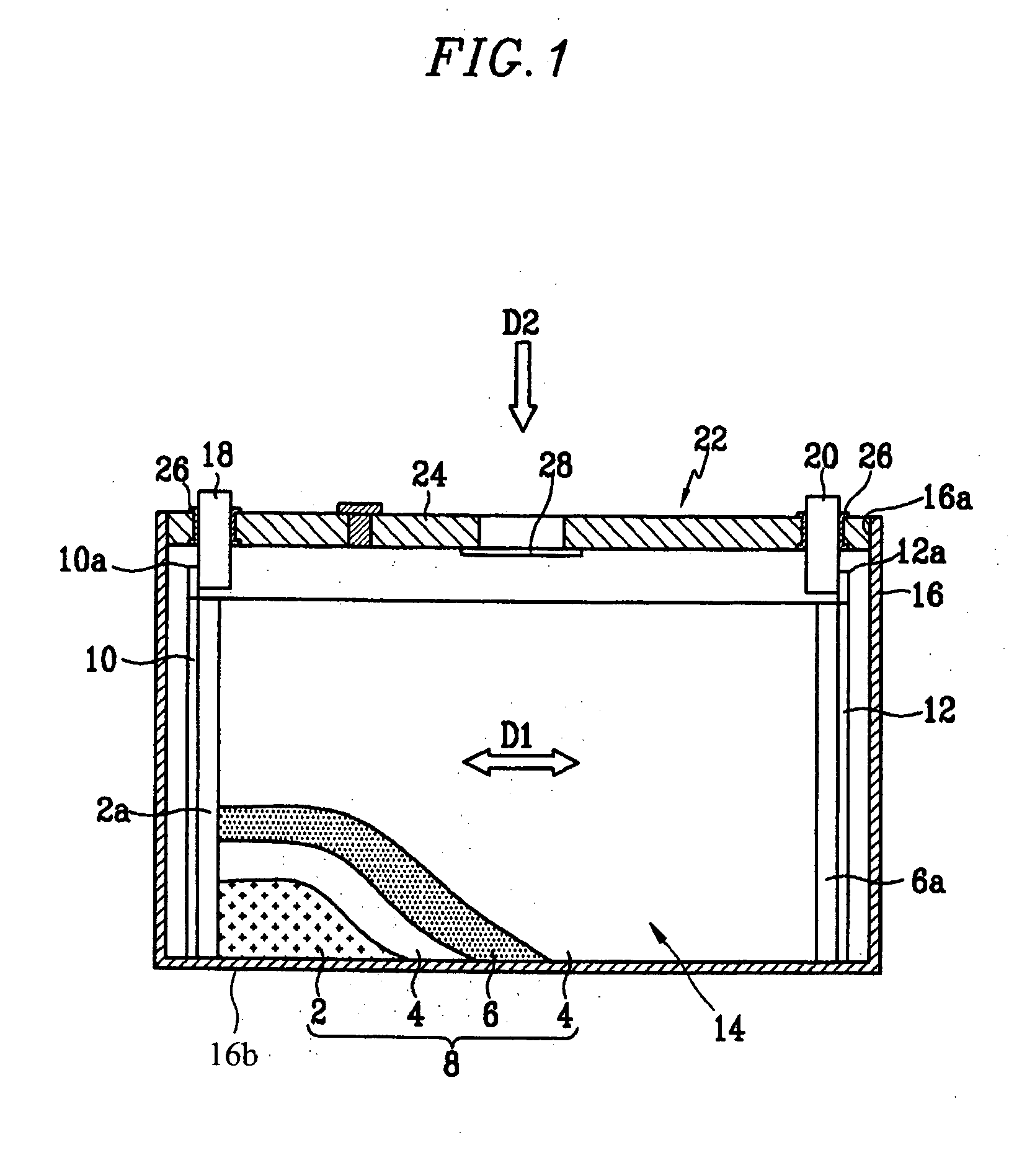

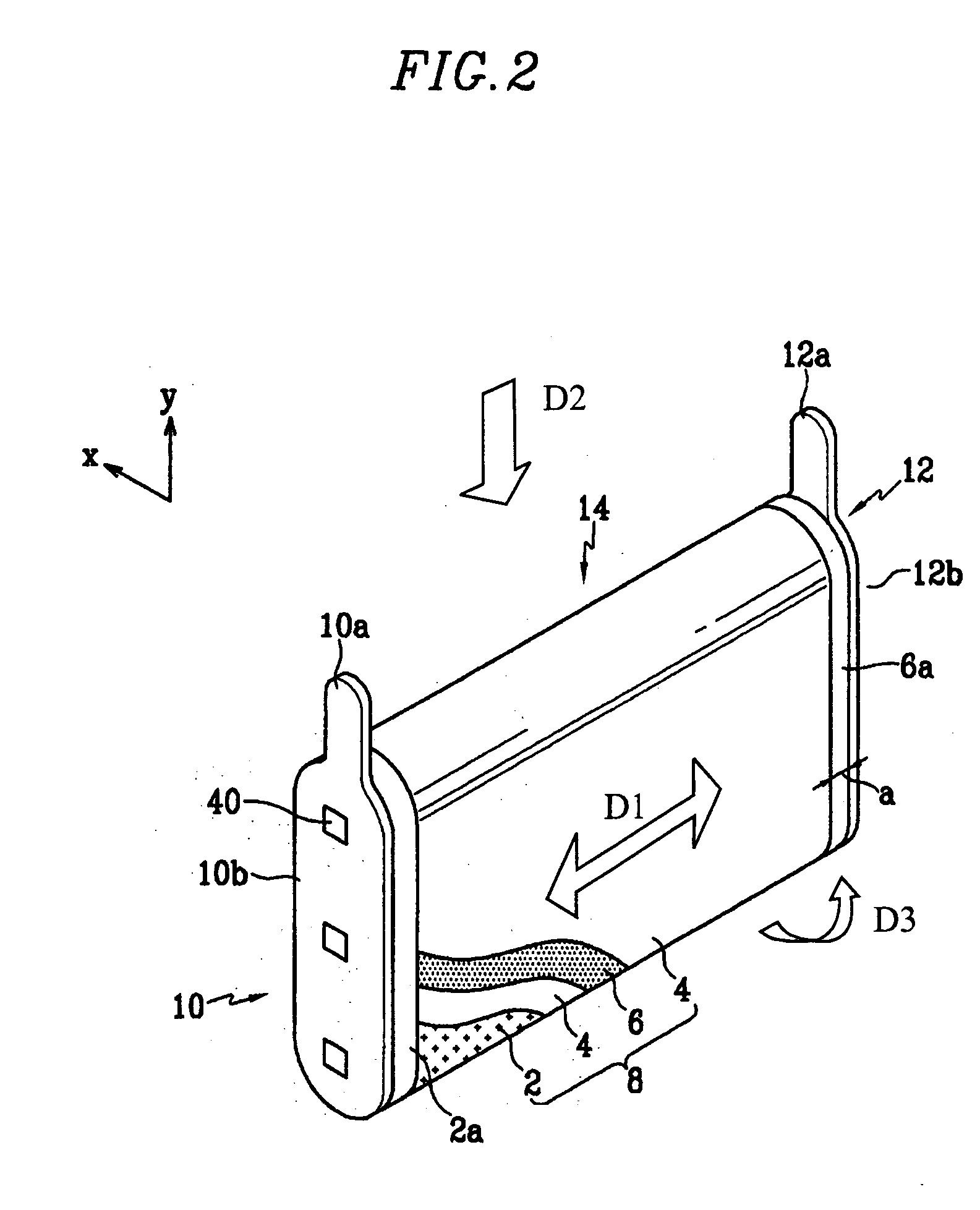

Electrode package and secondary battery using the same

InactiveUS20050221178A1Improved electrode packageImproved secondary batteryFinal product manufactureElectrode carriers/collectorsEngineeringElectrical and Electronics engineering

The electrode package for a secondary battery with an electrode assembly including a positive electrode, a negative electrode, and a separator interposed between those two electrodes, each of the positive and negative electrodes having an uncoated region along the edge thereof, a positive collector plate covering the front end of the uncoated region of the positive electrode to be electrically connected to the uncoated region of the positive electrode, the positive collector plate having a portion disposed outside the electrode assembly, and a negative collector plate covering the front end of the uncoated region of the negative electrode to be electrically connected to the uncoated region of the negative electrode, the negative collector plate having a portion disposed outside the electrode assembly.

Owner:SAMSUNG SDI CO LTD

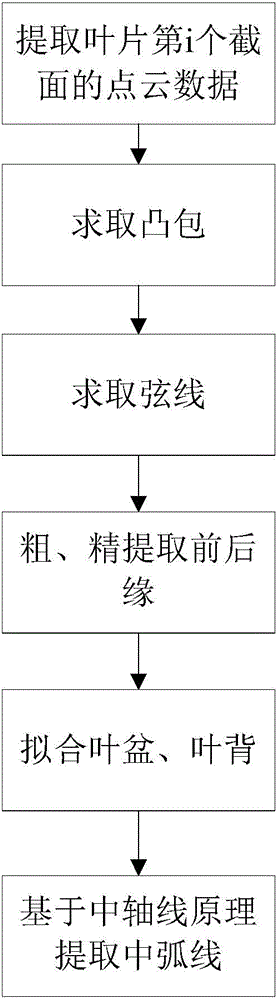

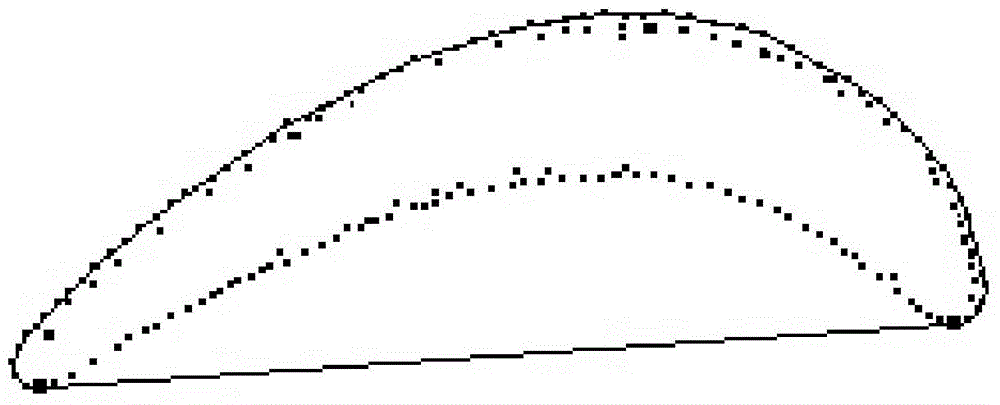

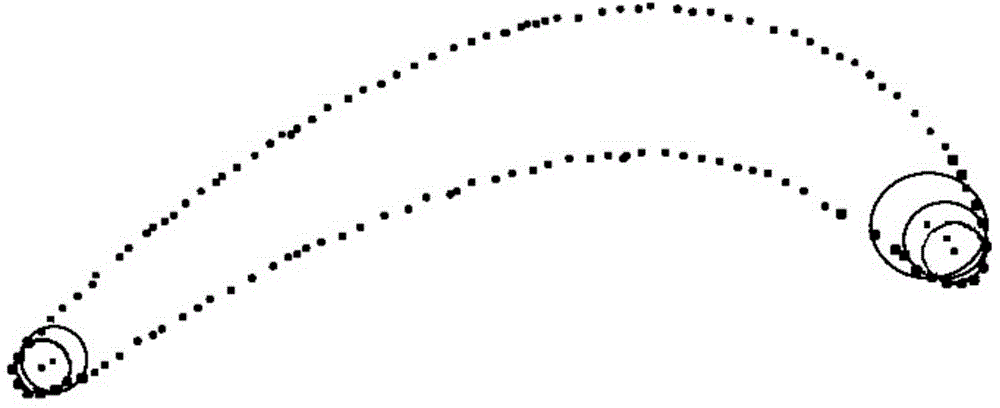

Method for extracting profiling feature parameters of aeronautical blade based on central axis

The invention discloses a method for extracting profiling feature parameters of an aeronautical blade based on a central axis. The method comprises the steps of intercepting section of a blade measuring model and generating corresponding point cloud data; acquiring a convex hull and obtaining two points pL and pR which are in the maximum distance away from each other; roughly extracting data point sets of the front edge of the blade and the rear edge of the blade; finely extracting data point sets of the front edge and the rear edge of the blade; acquiring the front curve Xp (t) and the back curve Xb (t) of the blade; extracting a central arc line of the section of the blade according to the central axis theory. According to the method, the front edge and rear edge parameters are respectively roughly extracted and finely extracted bys steps; the central arc parameters are extracted based on the central axis theory, so that the operation efficiency is high and the result accuracy is improved; the processing parameters of the blade in processing can be correspondingly adjusted according to the obtained parameters of the central arc line of the section of the blade and the front edge and the rear edge, and therefore, the blade processing quality can be improved.

Owner:武汉克诺德智能科技有限公司

Method of brewing a beverage with an electric, automatic beverage maker

ActiveUS9668496B1Uniform extractionSame qualityBeverage vesselsUnwanted substance removalAdditive ingredientMixing chamber

Owner:FOOD EQUIP TECH

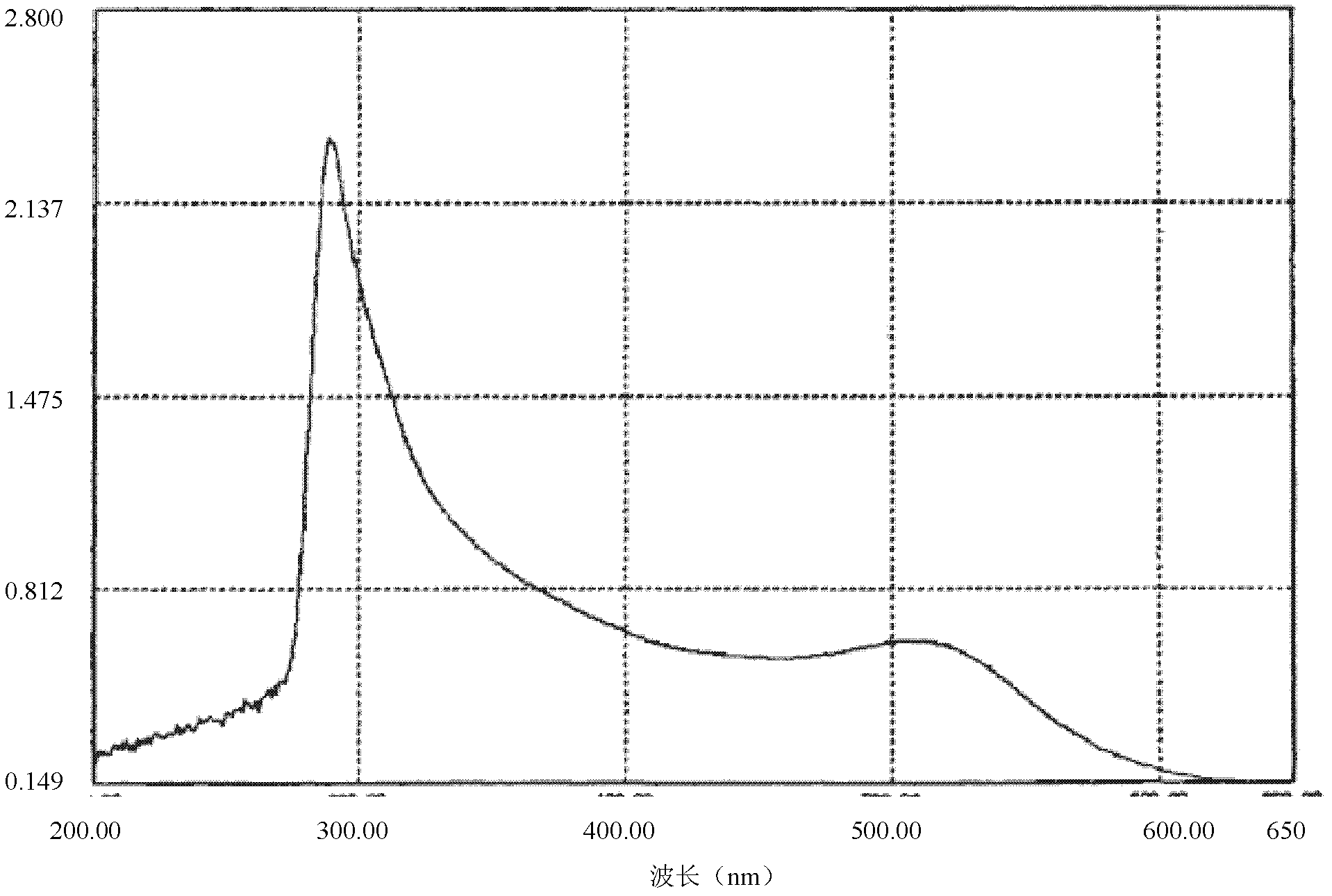

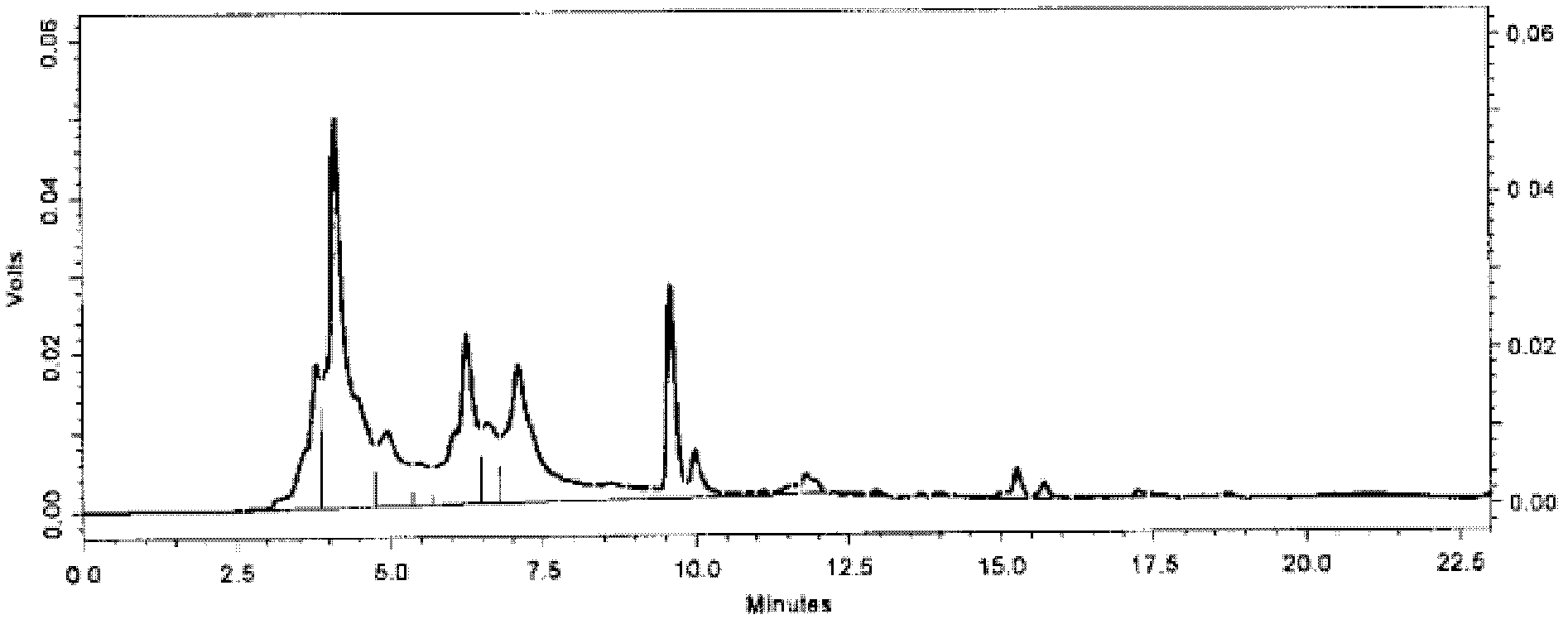

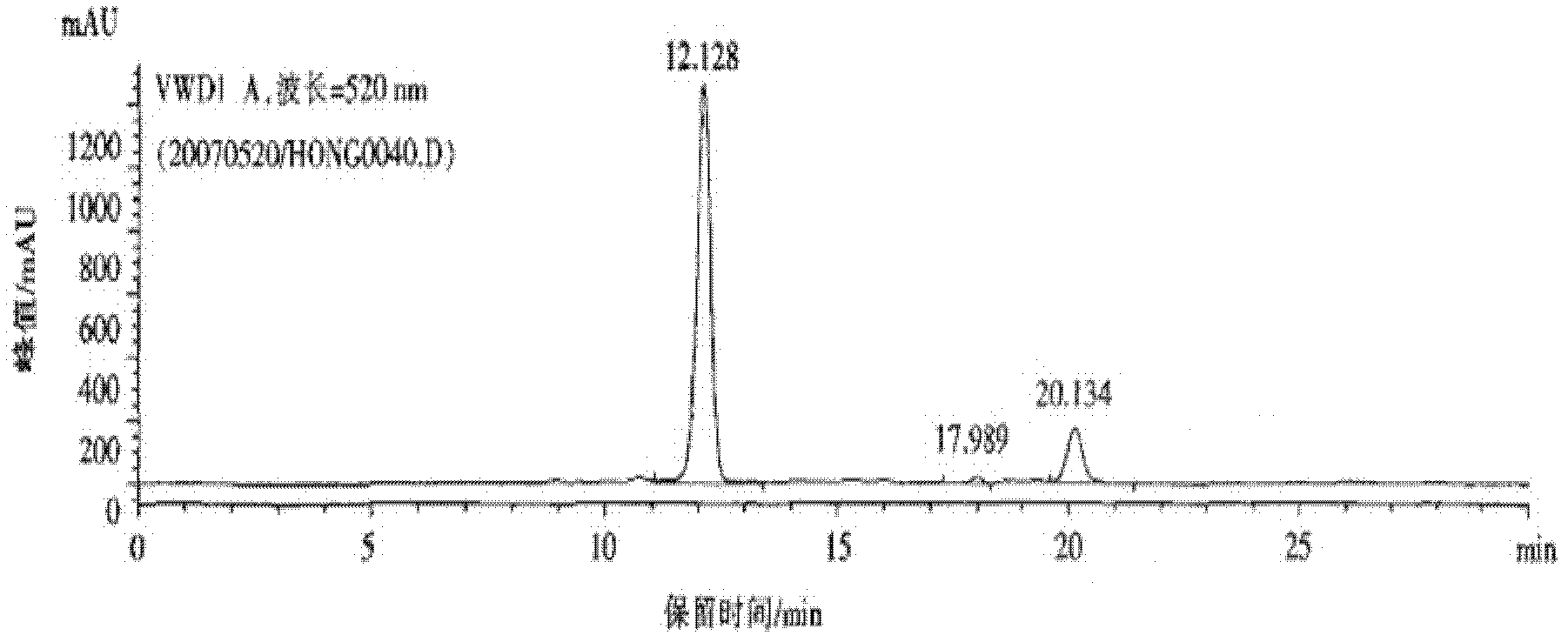

Process for extracting ginkgo biloba flavone, ginkgo biloba lactone and ginkgo biloba phenolic acid from ginkgo biloba leaves

ActiveCN102727538AQuick contactAccelerated leaching extractionNervous disorderGinkgophyta medical ingredientsAfter treatmentBULK ACTIVE INGREDIENT

The present invention discloses a process for extracting ginkgo biloba flavone, ginkgo biloba lactone and ginkgo biloba phenolic acid from ginkgo biloba leaves. The process comprises the following steps: (1) carrying out a pretreatment on ginkgo biloba leaves; (2) carrying out extraction by an ultrasonic device; (3) carrying out reduced pressure concentration; (4) loading the resulting solution on a macroporous resin to carry out a treatment; (5) collecting the resulting eluate; (6) carrying out reduced pressure concentration; (7) detecting the resulting extract; and (8) carrying out drying and storing on the extract. With the process of the present invention, the ginkgo biloba flavone content and the ginkgo biloba lactone content in the extract prepared by the process of the present invention are high, the loss of active ingredients are avoided, the production process is simplified, the production cycle is shortened, and the ginkgo biloba phenolic acid content after treatment is substantially reduced.

Owner:JIANGSU EHAI PHARMA CORP

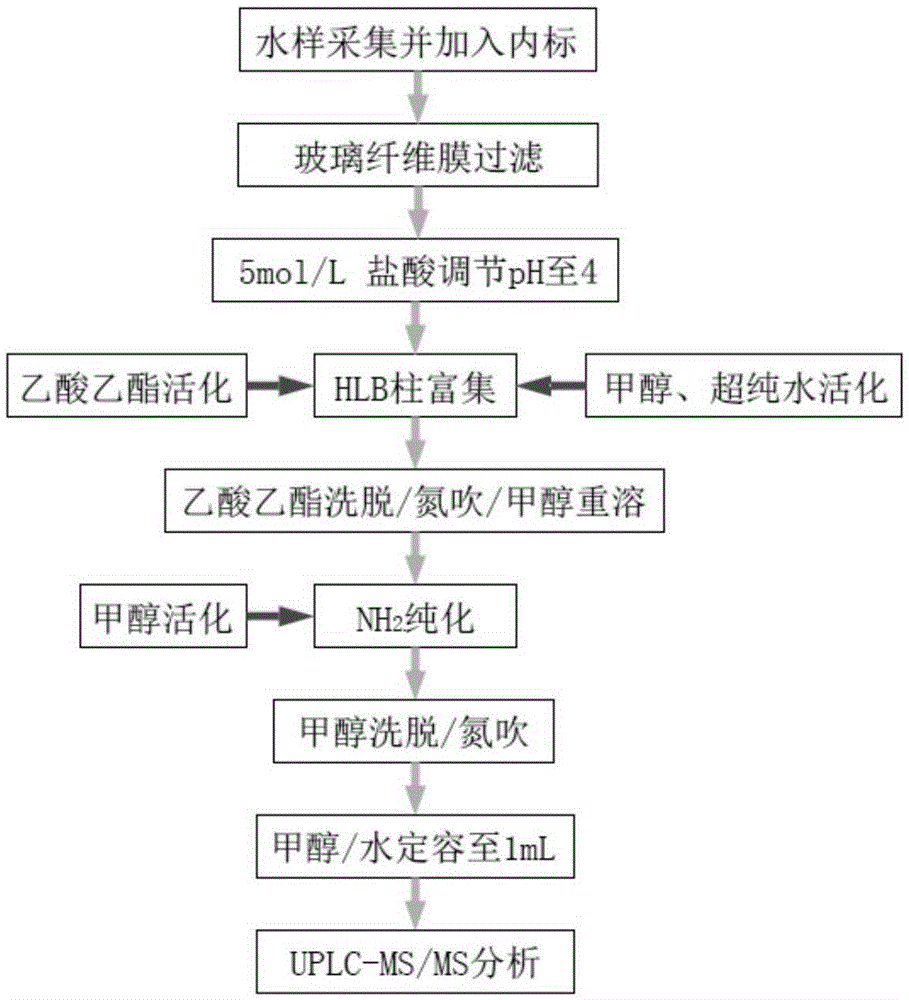

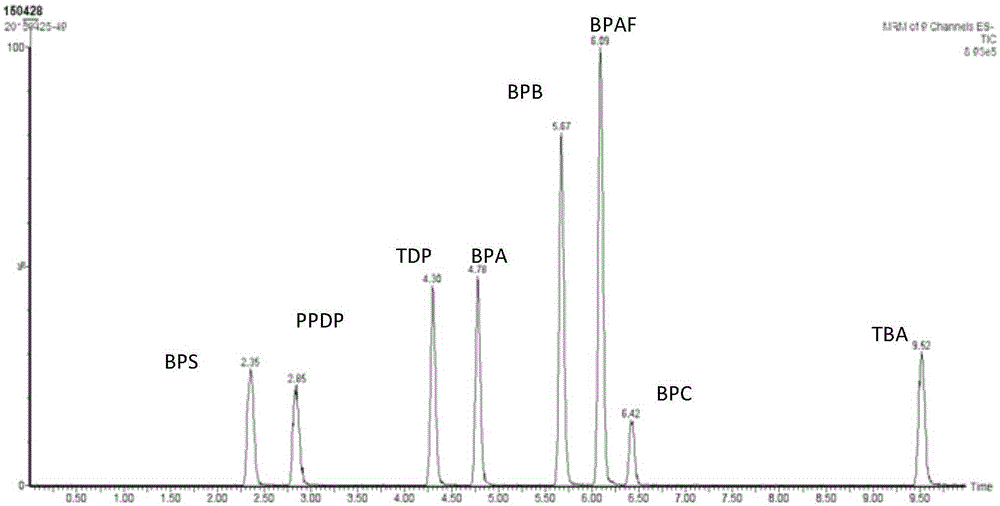

Second-order mass spectrometric detection method for bisphenol substances in water environment

InactiveCN105259287AUniform extractionReduce dosageComponent separationSolid phase extractionMass spectrometric

The invention relates to a second-order mass spectrometric detection method for bisphenol substances in a water environment, and belongs to the field of bisphenol substance detection. The problems that an existing analysis method for bisphenol pollutants is low in accuracy and precision due to interference of a natural water body matrix are solved. According to the second-order mass spectrometric detection method for the bisphenol substances in the water environment, an HLB column is adopted for solid-phase extraction, an amino column is purified, a full scanning mode is selected and used for qualitative and quantitative detection, all target objects used in a sample can be detected out at the same time by means of the mode, the mode is used for analyzing trace substances in a complex matrix, and for each substance, only one or two specific pairs of parent ions and daughter ions are selected to be detected. Matrix interference can be effectively removed, and sensitivity of detection and accuracy of qualitation and quantitation are improved.

Owner:HARBIN INST OF TECH

Method for preparing cooked pepper resin

The invention relates to a method for preparing cooked pepper resin. Pepper is cooked and crushed to corresponding particle size; the pepper resin is prepared by supercritical extraction; the extracted pepper resin is pollution-free, has strong cooked pepper aroma and effectively improves the raw smell characteristic of the pepper resin.

Owner:天津双星食品有限公司

Process method for microwave assistant supercritical extraction of active ingredients of curcuma

InactiveCN102100875AIncrease polarityAvoid multi-stage extractionMetabolism disorderAntinoxious agentsFiltrationBULK ACTIVE INGREDIENT

The invention discloses a process method for microwave assistant supercritical extraction of active ingredients of curcuma. In the method, the active ingredients, namely curcumin and fat soluble curcuma oil, of curcuma are extracted by the synergistic action of the microwave technology and the supercritical technology. The process method mainly comprises the following steps of: performing microwave intermittent sudden heating and then carbon dioxide (CO2) supercritical extraction; separating CO2 and curcuma oil in an analyzing kettle; and adding water or ethanol into curcuma residue in a solid-to-liquid weight ratio of 1:7-14, and performing microwave action, twice soaking, filtration, condensation and spray drying to obtain the curcumin. The process method solves the problem that in the prior art, only single active ingredient can be extracted or the compositions of the extract are not balanced, and realizes the extraction of two main active ingredients, namely curcuma oil and curcumin, of the curcuma at the same time, and the yield is over 8 percent and 13 percent respectively. The process method is the physical method and has the advantages of no product pollution, high purity, low cost, simple process and easy mass production.

Owner:GUANGZHOU RZN BIOTECH CO LTD

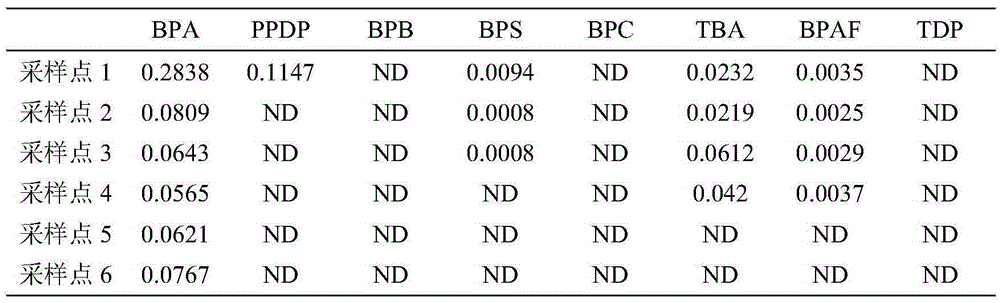

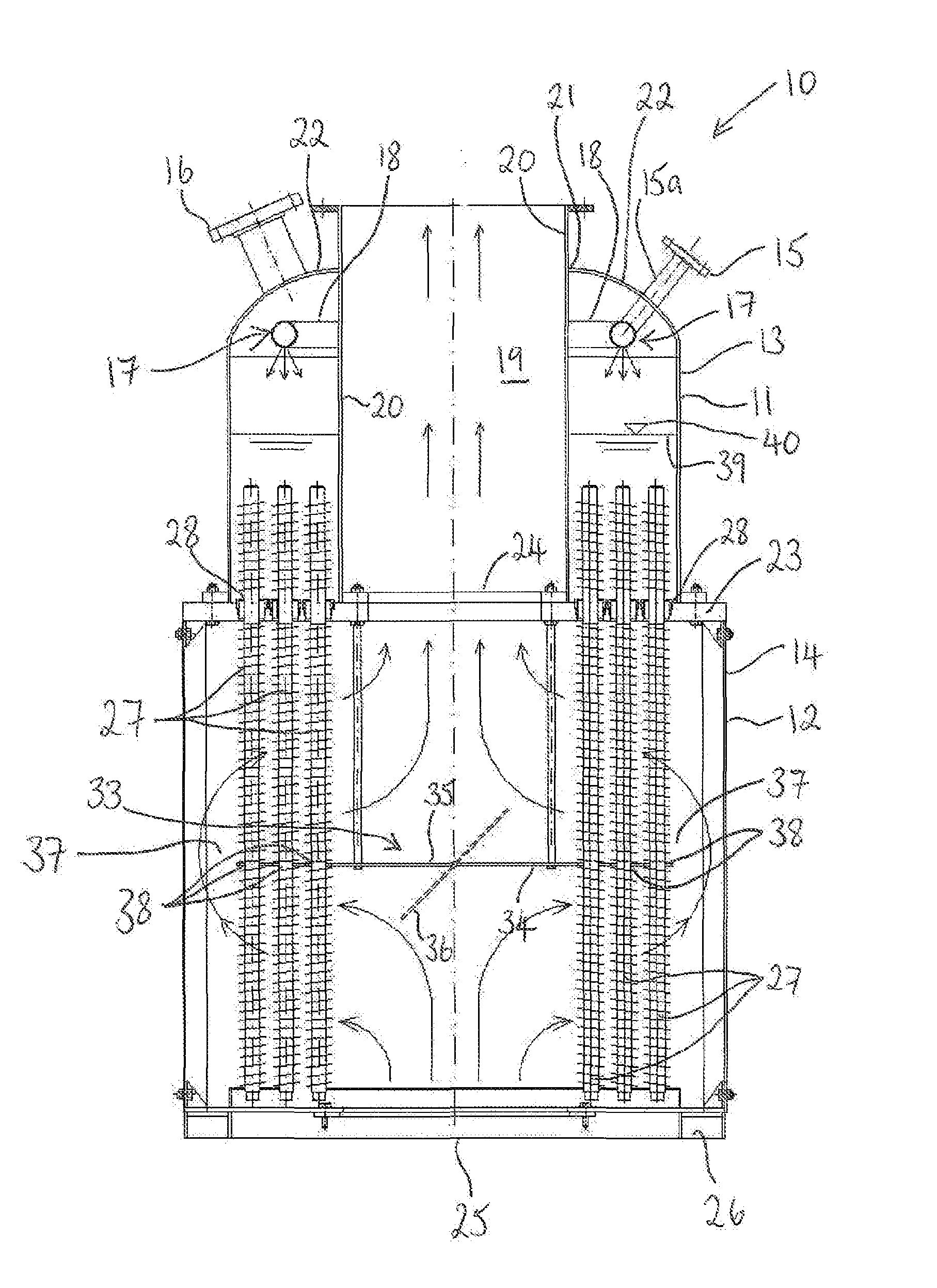

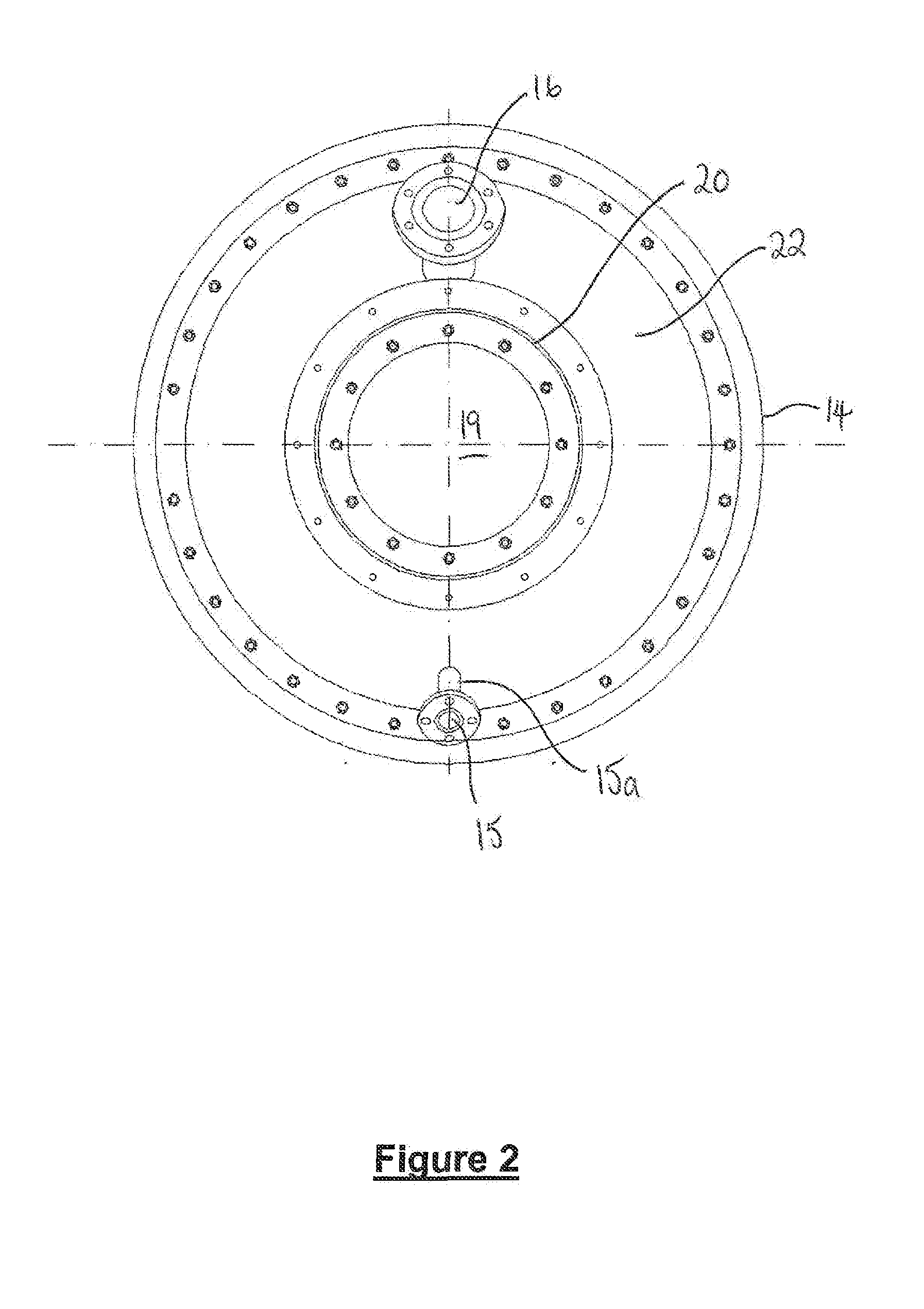

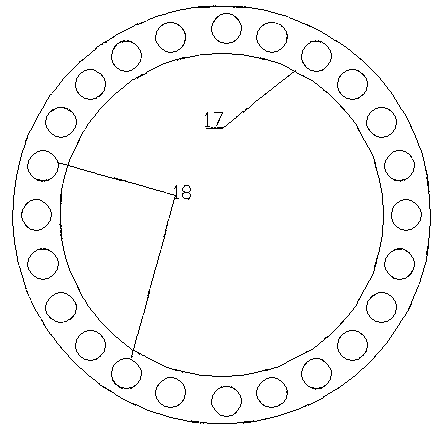

Steam-to-gas heat exchanger

InactiveUS20130269907A1Cool evenlyMinimizes localized heatingAir-treating devicesSteam generation heating methodsPlate heat exchangerEngineering

A heat exchanger for generating steam from water is disclosed. The exchanger comprises a first heat exchanging chamber, a second heat exchanging chamber and an array of heat pipes which are arranged to extend from within the first heat exchanging chamber to within the second heat exchanging chamber. The first heat exchanging chamber comprises a distributed inlet for passing the water into the first chamber from a distributed position around the chamber and an outlet through which the steam can exit the first chamber, the water being arranged to pass over the portion of the heat pipes which extend within the first chamber. The second heat exchanging chamber comprises an inlet for receiving a gas into the chamber and an outlet through which the gas can exit the second chamber, the gas being arranged to pass over the portion of the heat pipes which extend within the second chamber.

Owner:FETCU DUMITRU

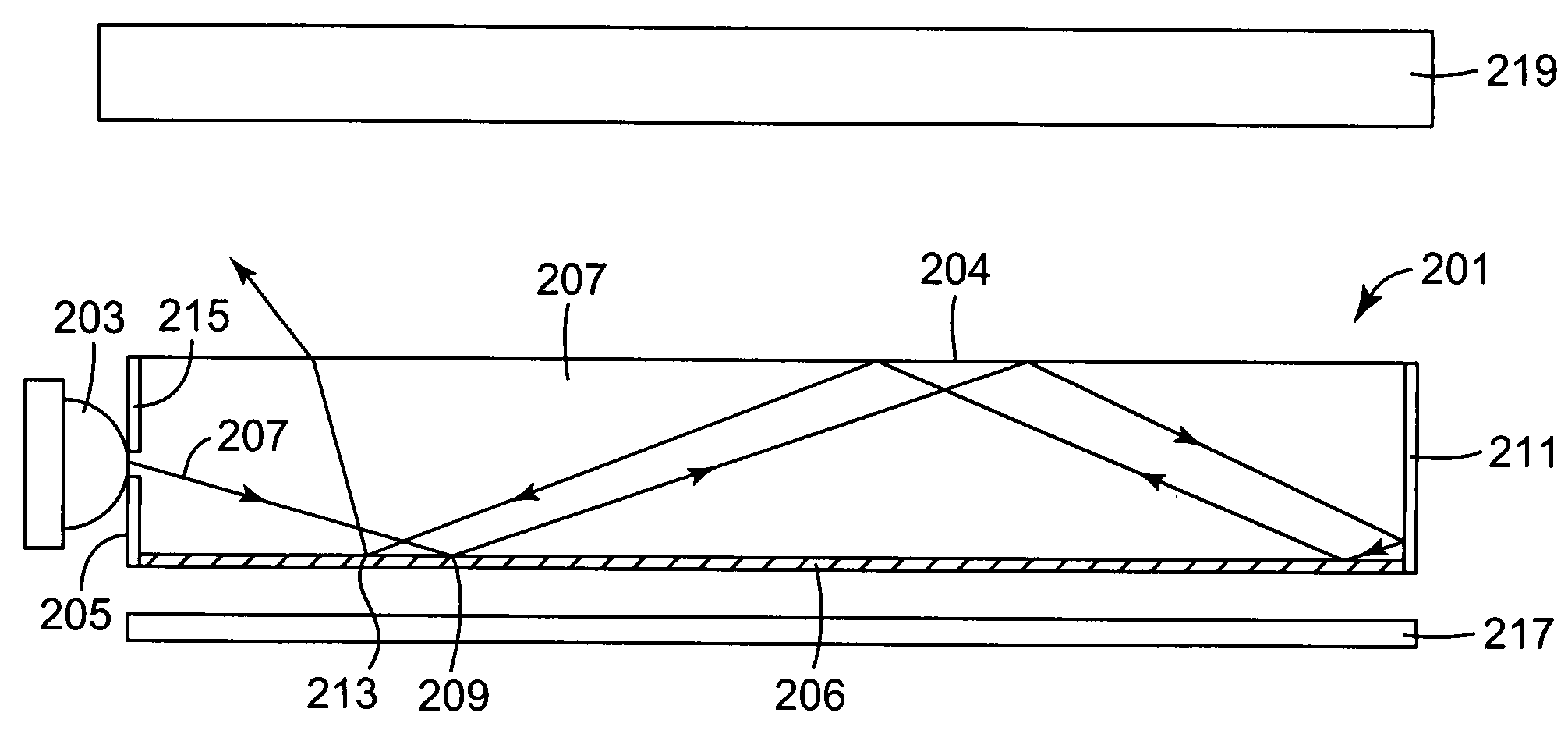

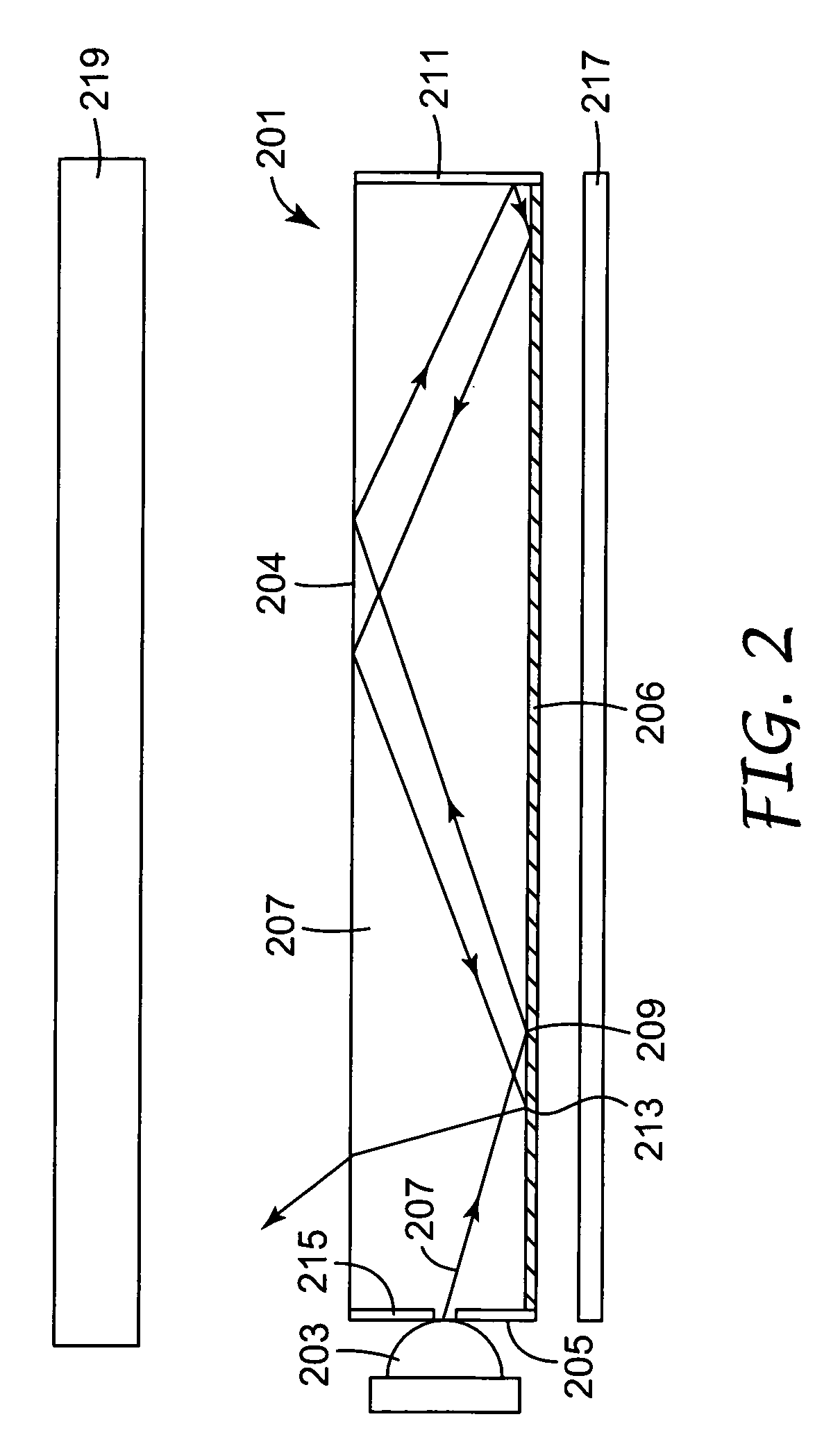

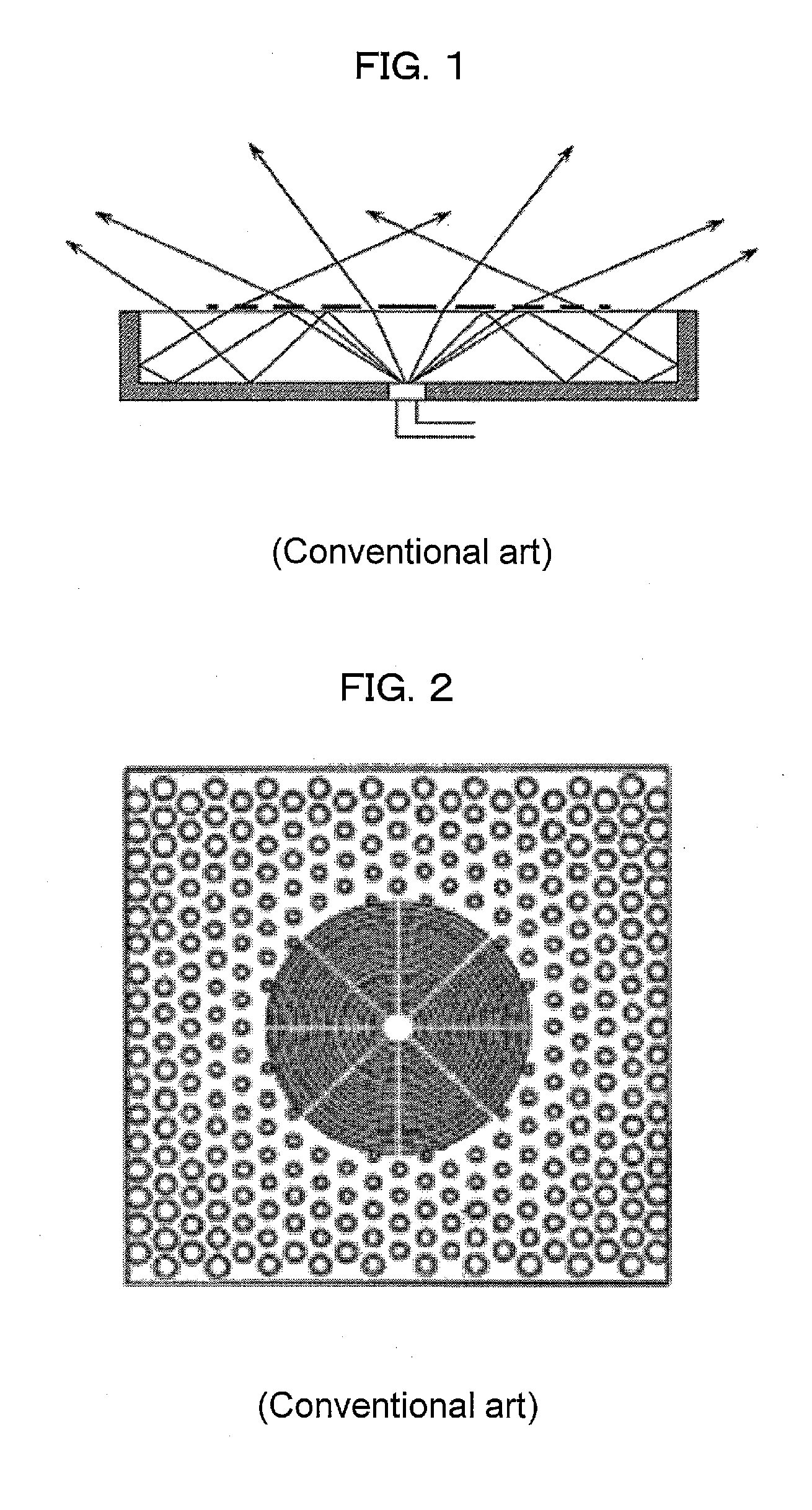

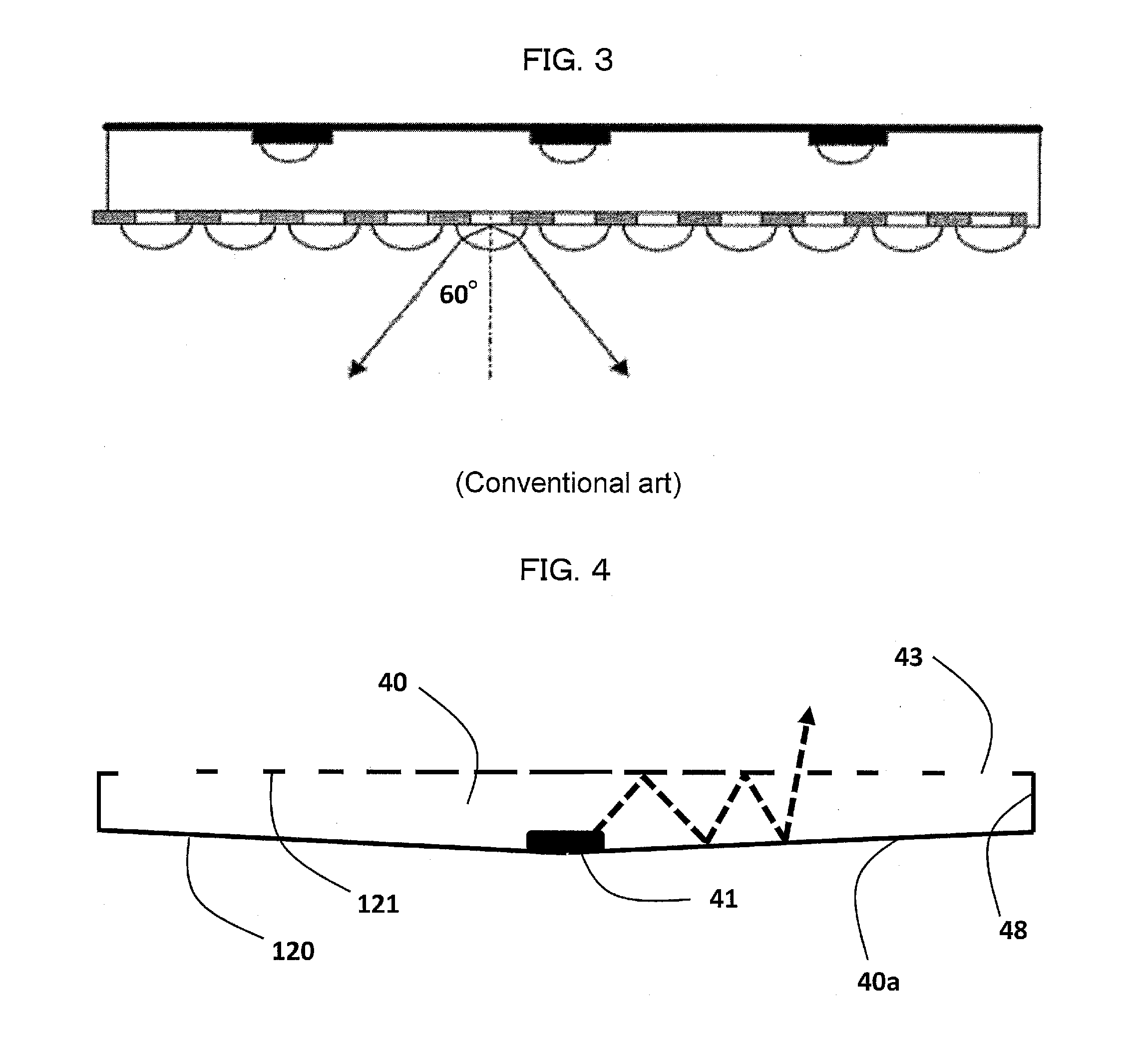

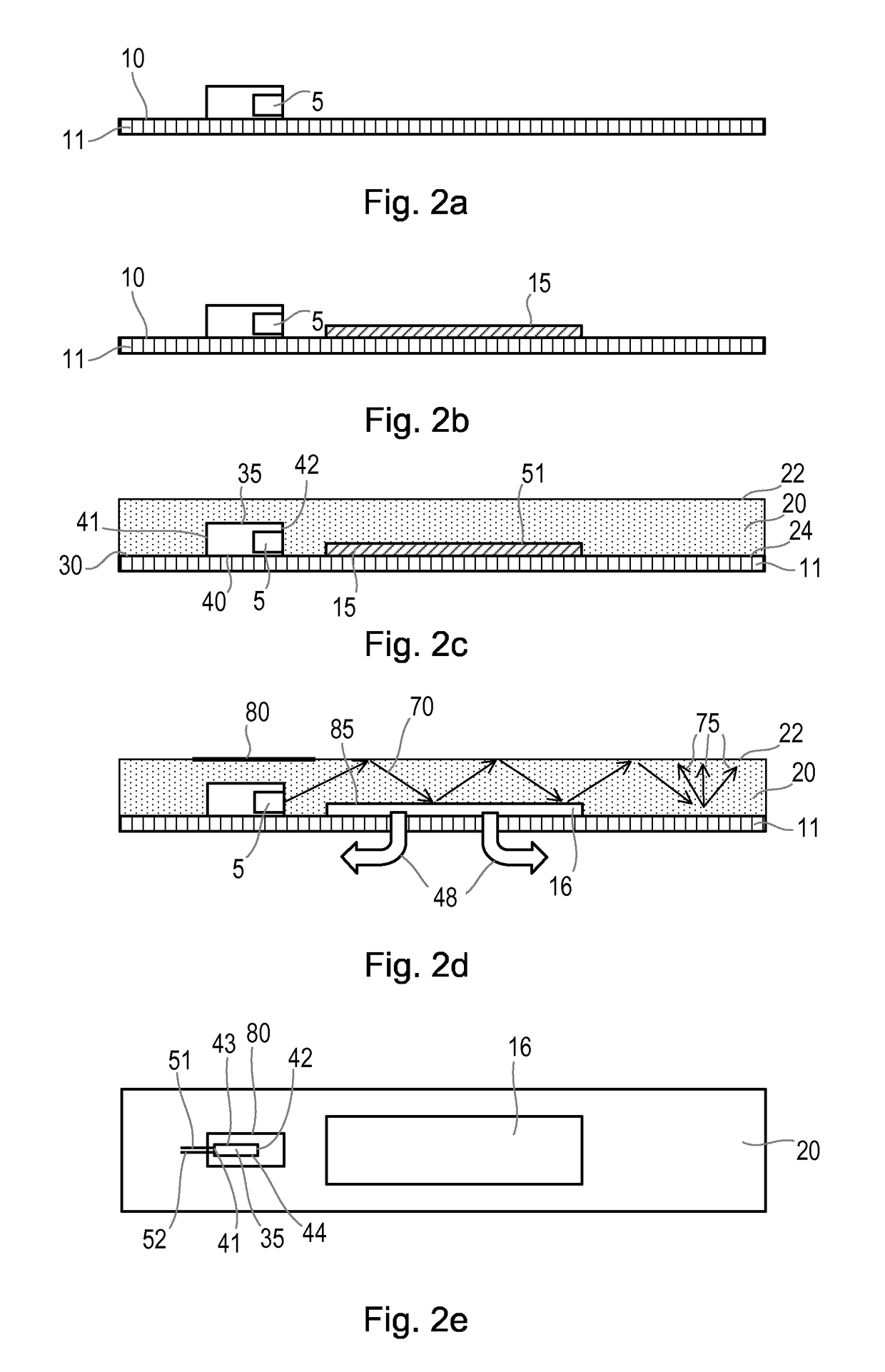

Lighting device and method for providing light

InactiveUS20150176810A1Maximize characteristicMaximize efficiencyLighting applicationsPlanar light sourcesExit surfaceSpecular reflection

A lighting device includes a transparent optical cavity having an exit surface including a specularly reflective material arranged to reflect light into the cavity, the exit surface having a plurality of apertures formed therein, a base surface including a specularly reflective material arranged to reflect light into the cavity, and at least one light receiving surface arranged relative to the base surface and configured to receive light from a light source. The plurality of apertures are arranged to maximize at least one of uniformity, angular distribution, efficiency or luminous intensity of light exiting the exit surface, and a distribution of light received at the light receiving surface is altered by at least one of a combination of the exit surface and the base surface, or the light receiving surface.

Owner:SHARP KK

Method for producing bayberry polyphenol capsules by sectional dielectric heating combined extraction

InactiveCN101703216AAvoid wastingPromote exudationFood shapingFood preparationFreeze-dryingRadio frequency

The invention provides a method for producing bayberry polyphenol capsules by sectional dielectric heating combined extraction, and belongs to the technical field of the processing of fruit and vegetable food. The method comprises the steps of: under radio frequency of 50MHz, low frequency microwave of 915MHz and high frequency microwave of 2,450MHz, preparing the bayberry polyphenol capsules by using raw juice or fresh fruits of bayberries through sectional leaching, centrifugation, concentration, freeze-drying, grinding, capsule filling, packaging and storage. The method has the advantages that: firstly, by the radio frequency treatment with good penetrability, the internal leaching is made more effective; secondly, by the re-treatment of the low frequency microwave, a crude extract internally leached is accelerated to seep; and finally, by the treatment of the high frequency microwave, the crude extract leached to the surface is accelerated to seep, and thus the whole quick combined leaching is completed. By the combination of three extraction methods, the advantages of the three extraction methods are mutually complemented; polyphenol substances in the juice or the fresh fruits of the bayberries are combinedly extracted, which further improves the extraction ratio; and the extraction ratio of the sectional dielectric heating combined auxiliary leaching is as high as 23.17 percent.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

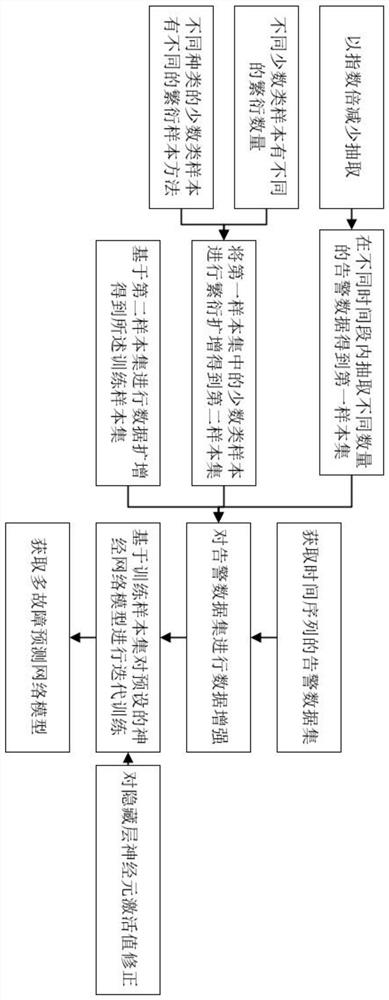

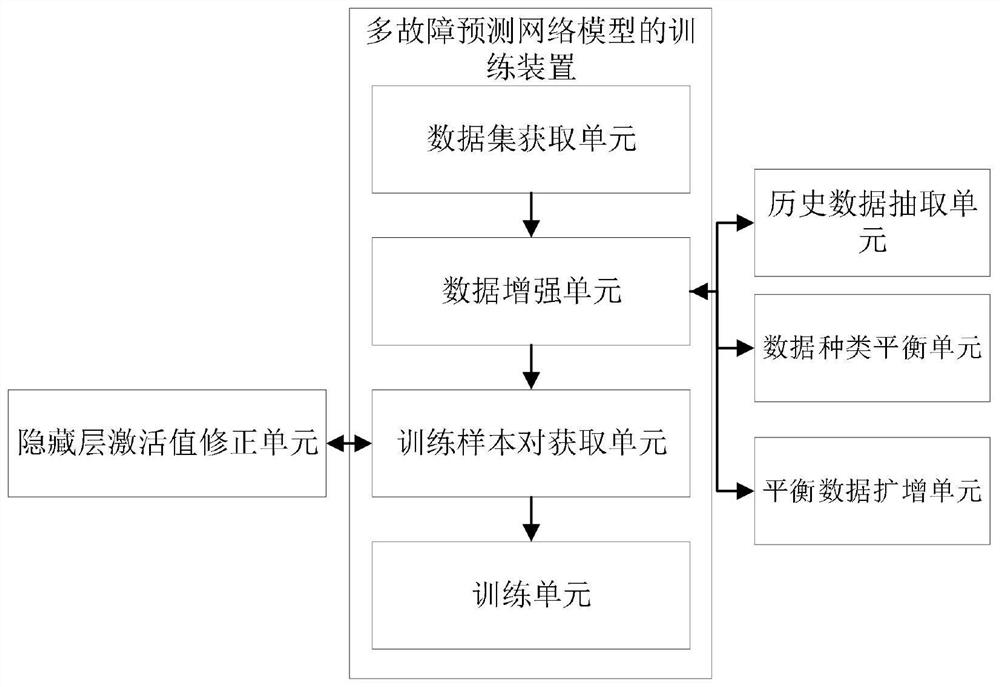

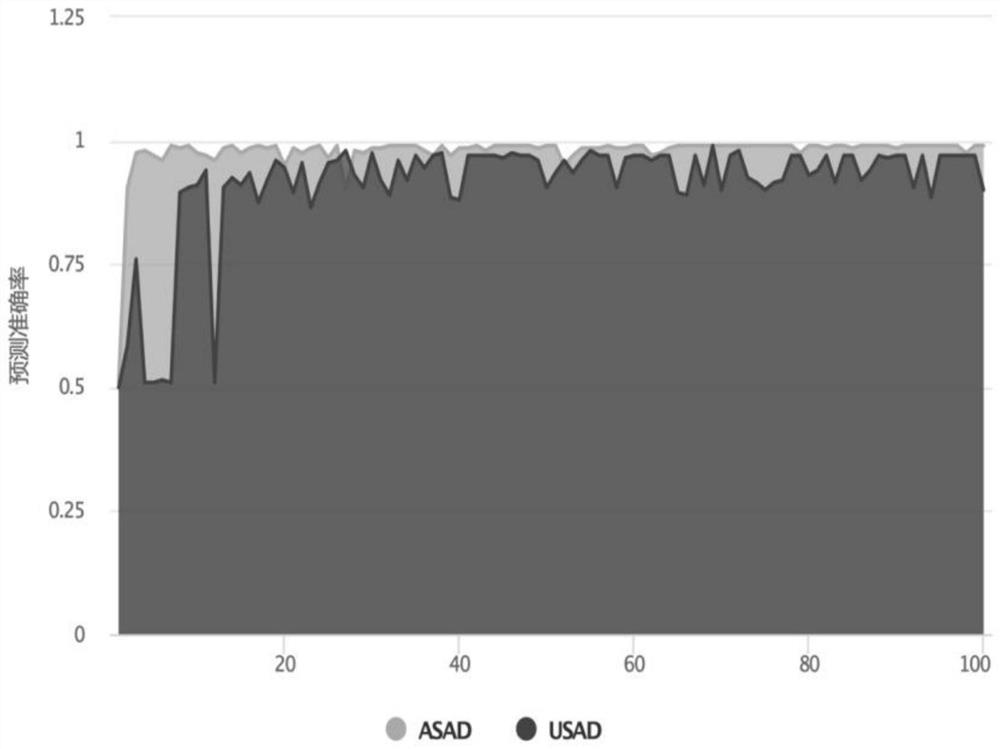

Training method and device for multi-fault prediction network model of power information system

ActiveCN112508243AImprove forecast accuracyStable prediction effectDigital data information retrievalForecastingData setOriginal data

The invention discloses a training method and device for a multi-fault prediction network model of a power information system, and the method comprises the steps: obtaining an alarm data set of a timesequence, carrying out the data enhancement of the alarm data set, and obtaining an enhanced training sample set; obtaining an input sample for model training and a target output sample correspondingto the input sample based on the training sample set; and performing iterative training on a preset neural network model based on the input sample, the target output sample and a preset network modelloss function to obtain a multi-fault prediction network model. According to the method, data feature equalization is realized by performing data enhancement processing on the original data set, andthe multi-fault prediction network model obtained by performing model training fitting based on the training sample set after data enhancement has higher prediction precision and a more stable prediction effect.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +3

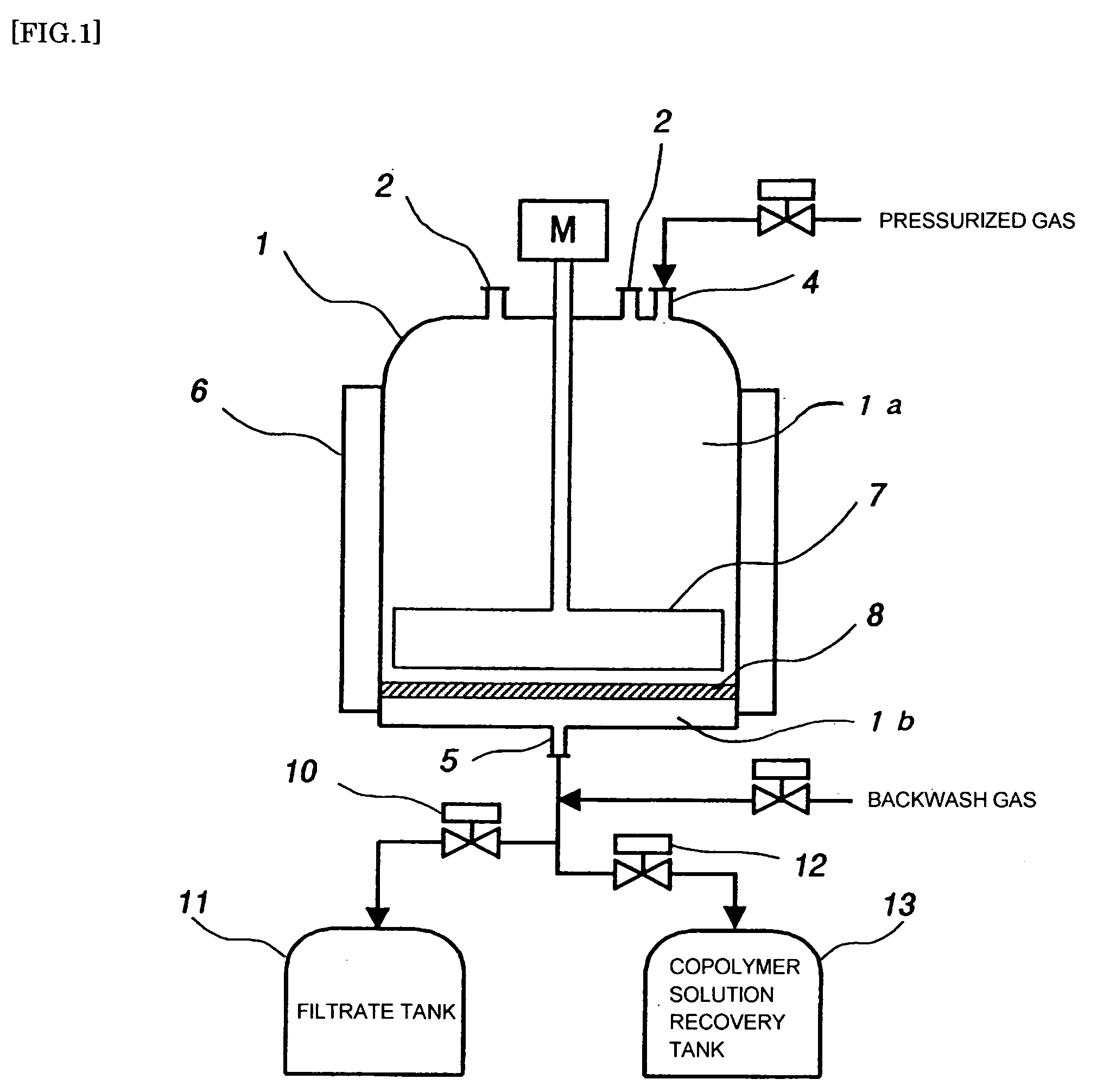

Production process of copolymer for semiconductor lithography

ActiveUS20050096447A1Efficiently performImprove efficiencyPhotosensitive materials for photomechanical apparatusSolventDouble bond

Efficient and reproducible production of a copolymer for lithography, which has stable quality, with little lot-to-lot variations, and is suited for film-forming and coating compositions. Radical polymerization of a monomer, which contains at least one ethylenic double bond, with an initiator, in a solvent, and purification of the reaction mixture by precipitation and filtration, in a hermetically-closable single vessel divided by a filter medium, into a first section provided with fluid feeding means and agitating means, and a second section with fluid drawing means. Feeding the reaction mixture from the fluid feeding means into the first section of the vessel, containing a poor solvent, and contacting the reaction mixture with the poor solvent to precipitate a solid; and filtering the resulting fluid, containing the precipitated solid, through the filter medium, drawing the resultant filtrate through the fluid drawing means, and then separating the precipitated solid.

Owner:MARUZEN PETROCHEMICAL CO LTD

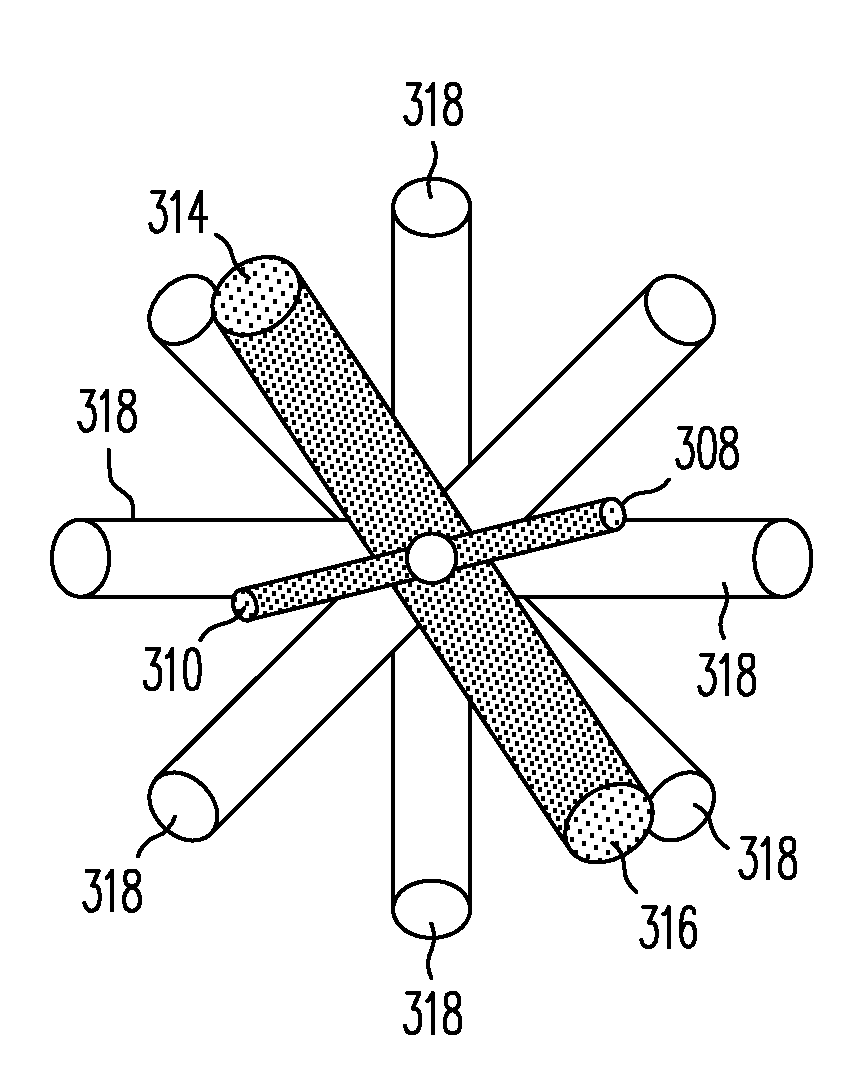

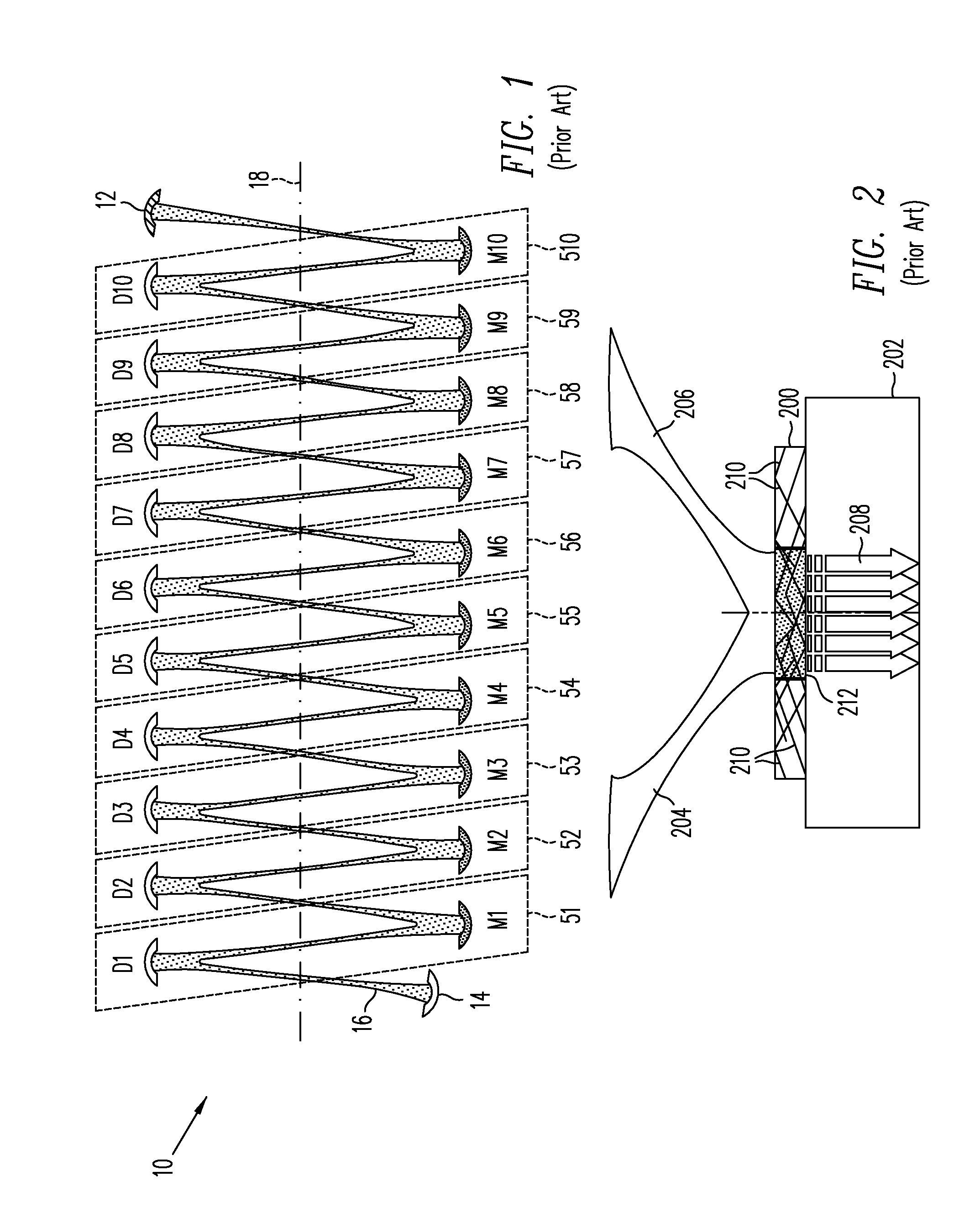

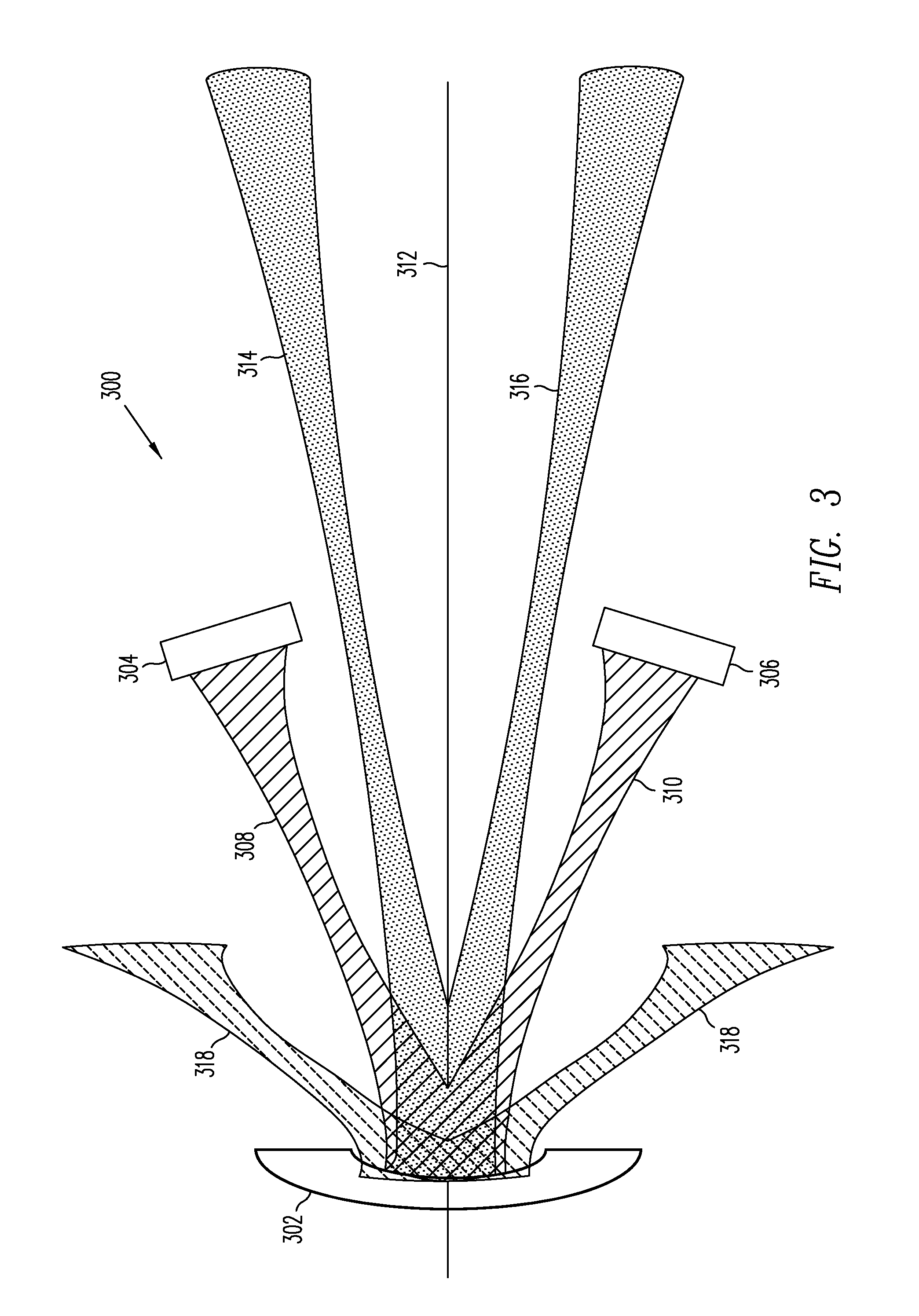

Reliable startup of high power thin-disk laser resonators

ActiveUS20100254424A1Mitigate problematic aberrationReduce probabilityOptical resonator shape and constructionActive medium shape and constructionPre-conditionPre conditioning

Helper resonators useful for the reliable, controlled startup of an associated high power multidisk unstable imaging thin disk laser (TDL) main resonator each includes one of the thin disk gain elements (TDGEs) of the associated main resonator and a pair of helper reflectors disposed on opposite sides thereof. The helper resonators act to prevent the buildup of undesirable amplified spontaneous emission (ASE) during startup of the main resonator, pre-condition the TDGEs so as to enable efficient power transfer from the helper resonators to the main resonator when the main resonator reaches a selected feedback ratio (FBR) and provide a rapidly acting shunt for disk power in the event of a cessation of lasing of the main resonator.

Owner:THE BOEING CO

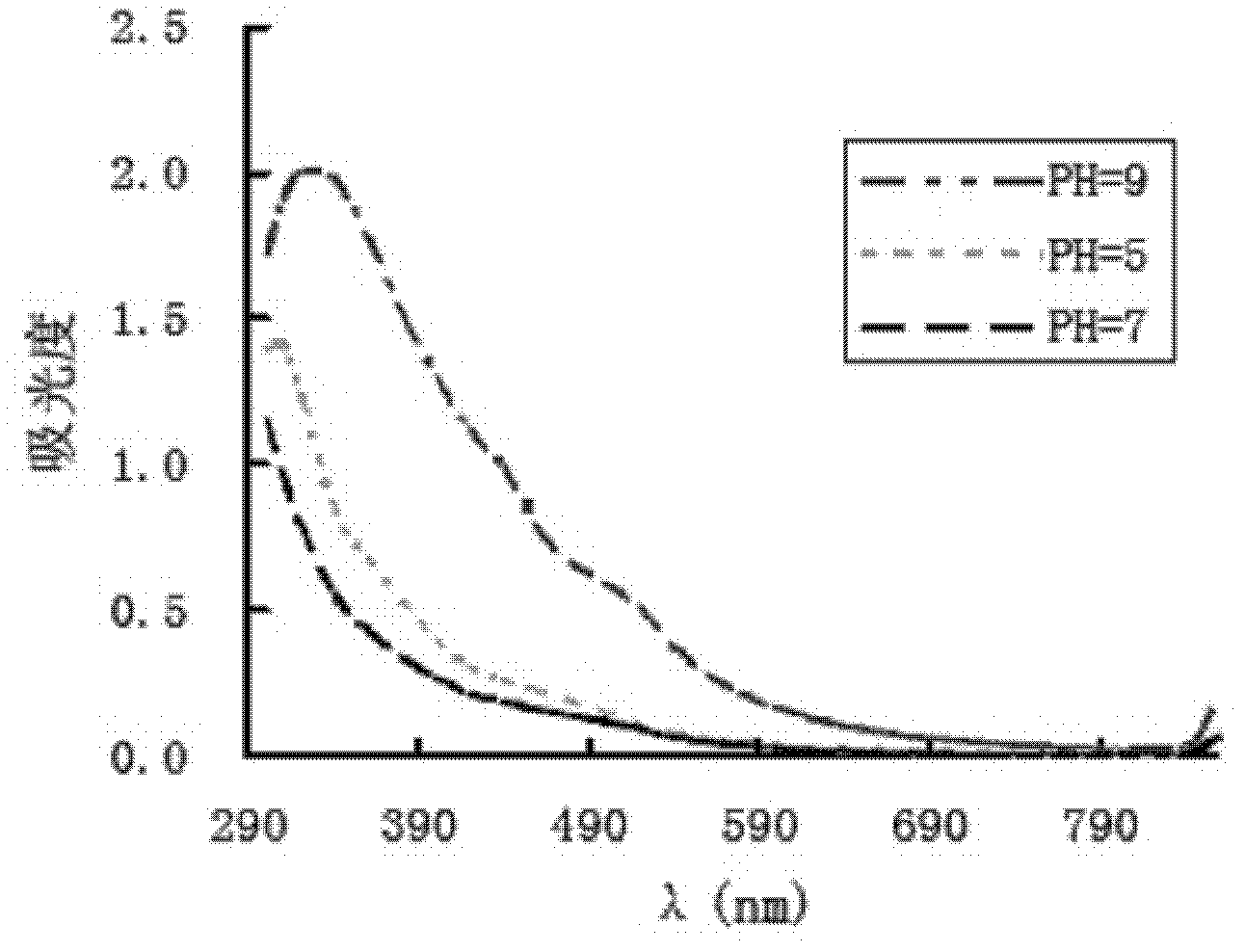

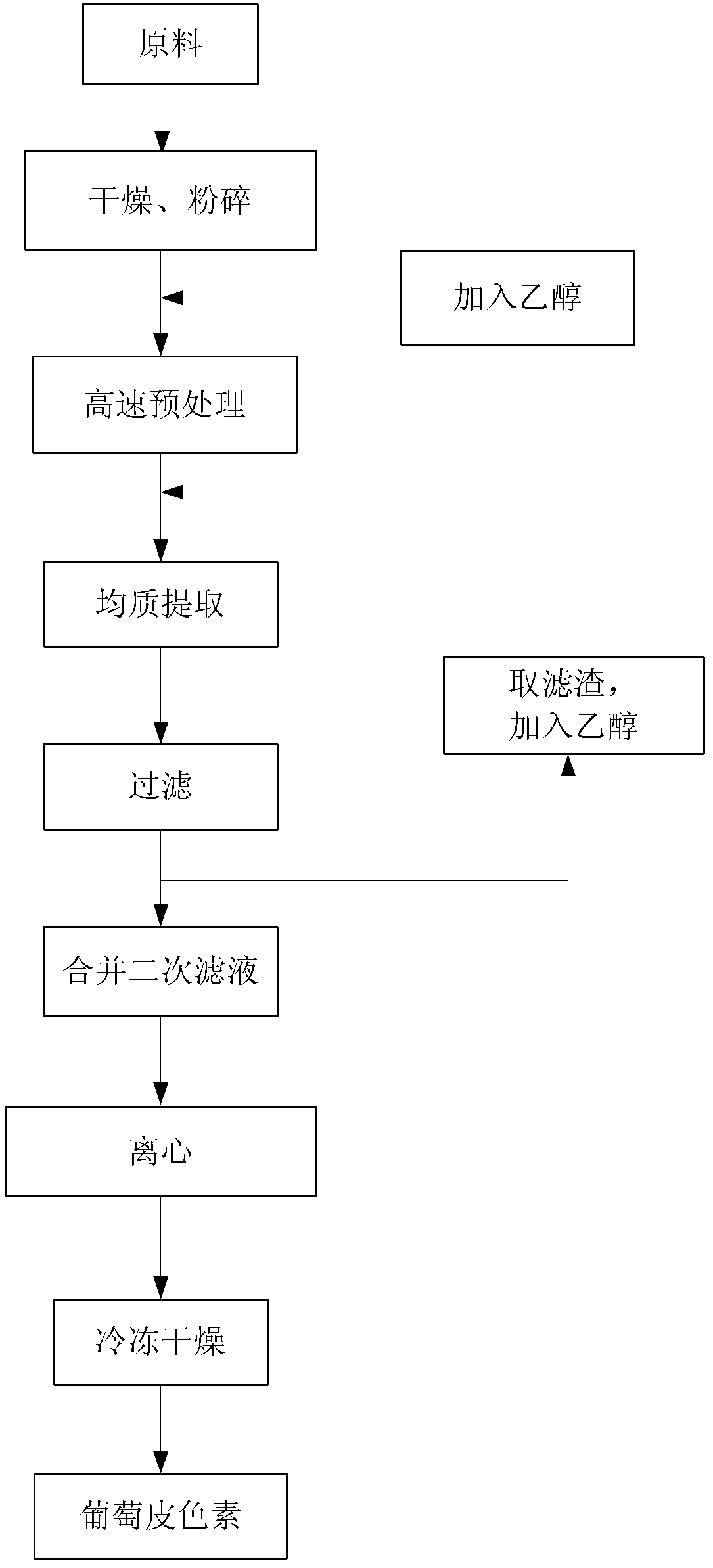

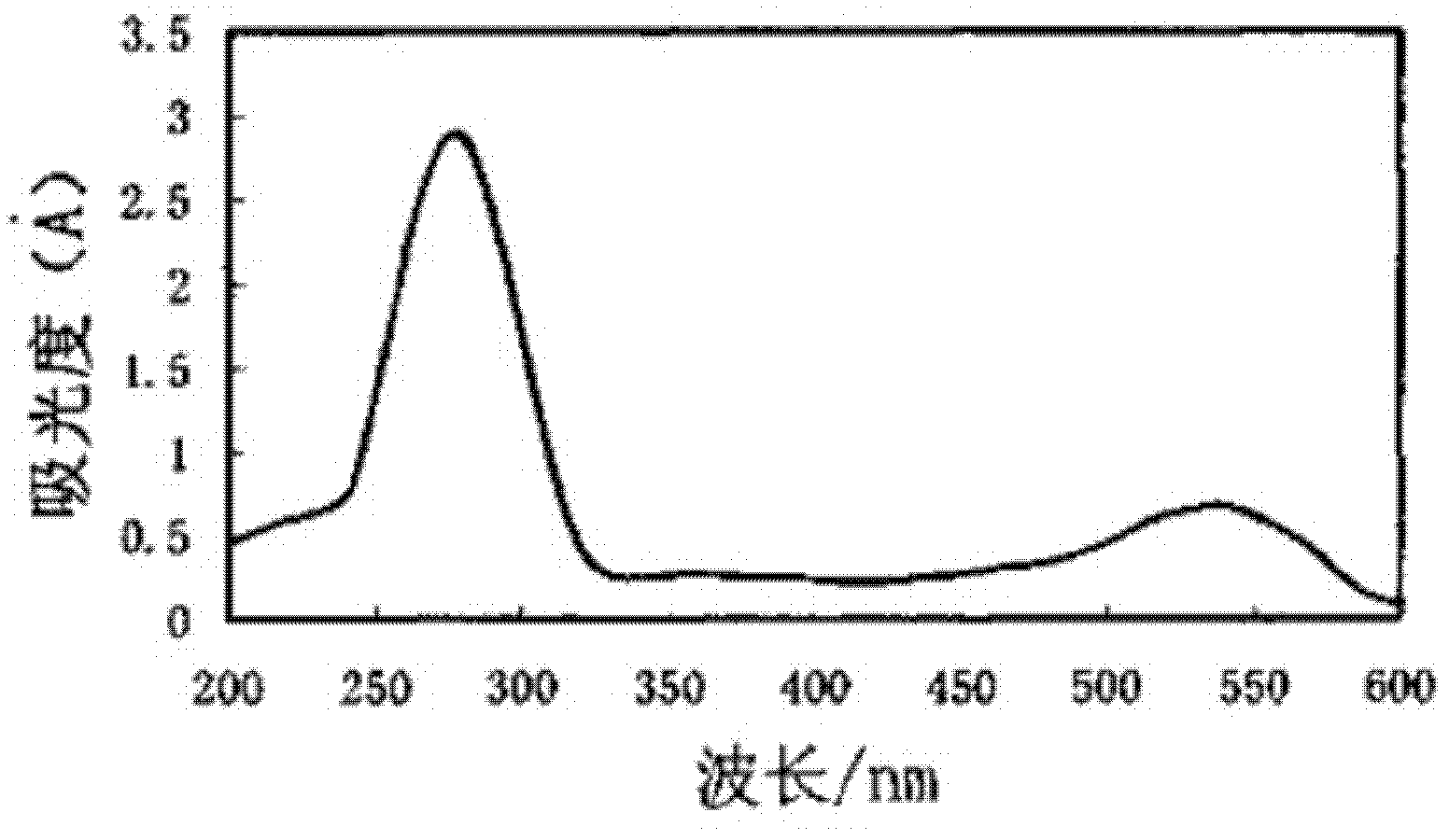

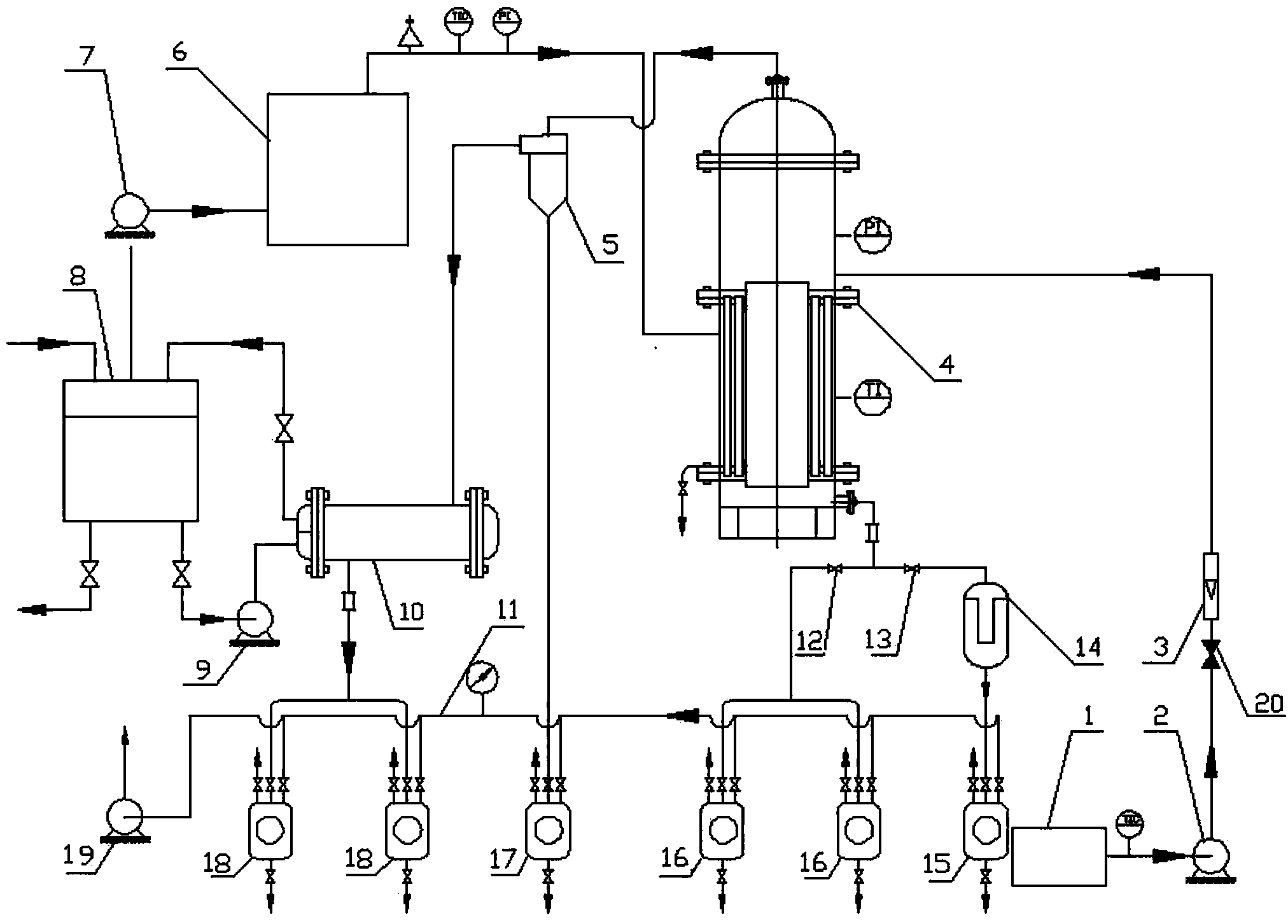

Grape-skin pigment and extraction process for same

InactiveCN103160137AHigh pigment extraction rateEvenly distributedNatural dyesSolubilityFood additive

The invention discloses an extraction process for grape-skin pigment. The extraction process for grape-skin pigment comprises the following steps of: (1) mixing dried grape-skin powder with 95 wt% ethanol, adjusting the pH value to 2-4 by citric acid aqueous solution, performing high-speed pre-treatment and homogeneous extraction at a room temperature, and filtering; (2) mixing the filter residue obtained after filtering with 95 wt% ethanol, adjusting the pH value to 2-4 by citric acid aqueous solution, performing homogeneous extraction again, and filtering; and (3) centrifuging the filtrate, collecting the supernatant, freeze-drying the supernatant into a powder, namely, the grape-skin pigment, wherein the high-speed pre-treatment is performed for more than 5 minutes at a speed of 5000-10000 r / min; and the homogeneous extraction is performed for more than 10 minutes at a speed of 1000-4000 r / min. The invention further discloses the grape-skin pigment prepared by the process. The extraction process disclosed by the invention is simple, low in requirements on production equipment, high in extraction efficiency, greatly shortened in extraction time, and obviously superior to the traditional solvent extraction method. The obtained grape-skin pigment is good in water solubility, good in appearance colour, stable in character, and suitable for use as a food additive or a healthcare food raw material.

Owner:SHANGHAI LAMP BIOLOGICAL SCI & TECH

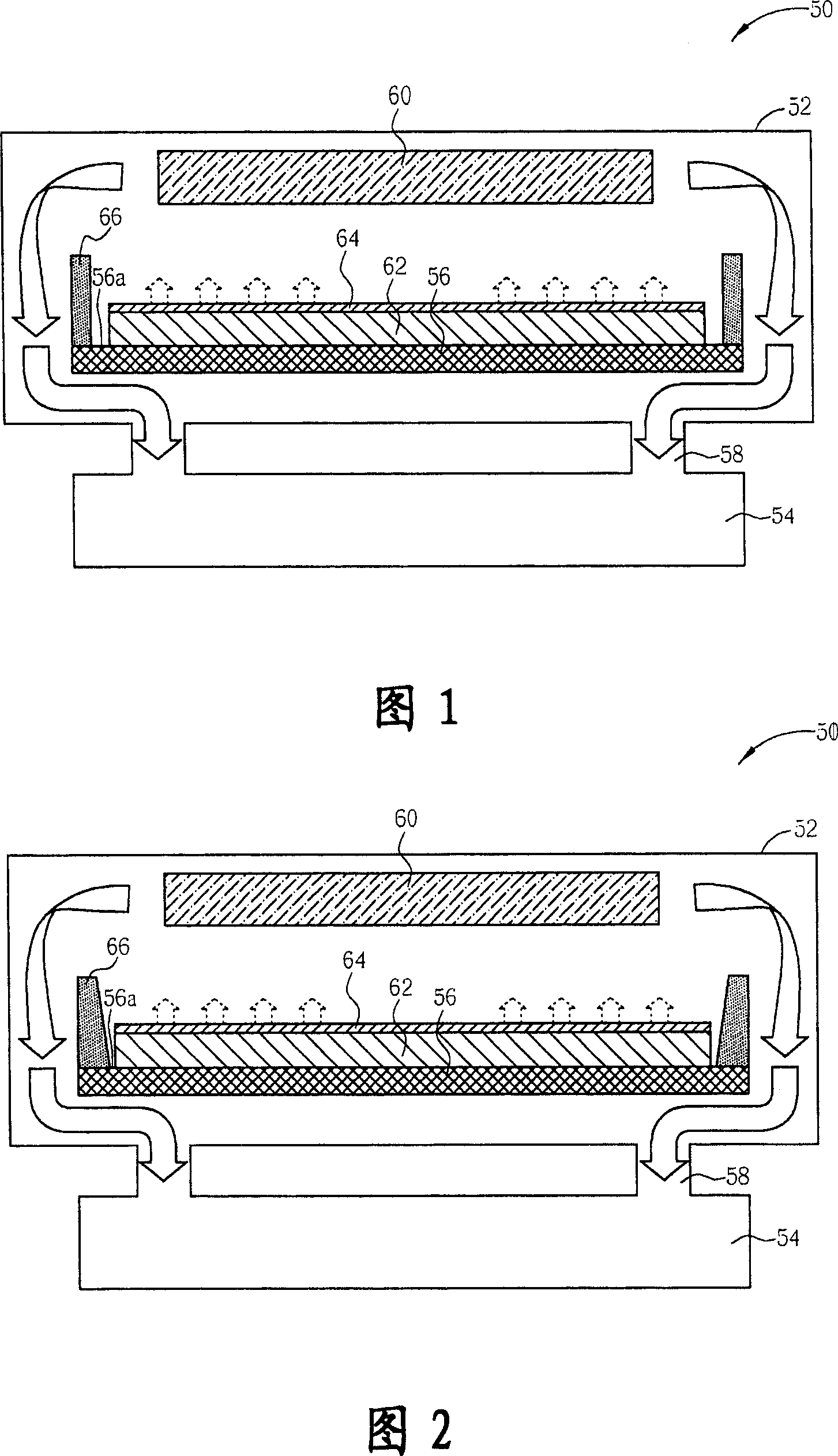

Coating drier with regulating air flow path function

ActiveCN1945437AUniform extractionExtended Airflow PathPhotomechanical coating apparatusOptical elementsResistEngineering

The invention discloses a coating drying equipment with function of adjusting the flow path, including: a reaction chamber, a vacuum system that connects the chamber to extract gas in the chamber, a loading platform that is set in the chamber and includes a loading surface to load a base plate, and a baffle plate structure that is set on the loading surface surrounding the base plate, and its height is more than the thickness of the base plate. Accordingly, when extracting the gas in the chamber, the vacuum system can uniformly extract the solvent in the photoresist layer.

Owner:AU OPTRONICS CORP

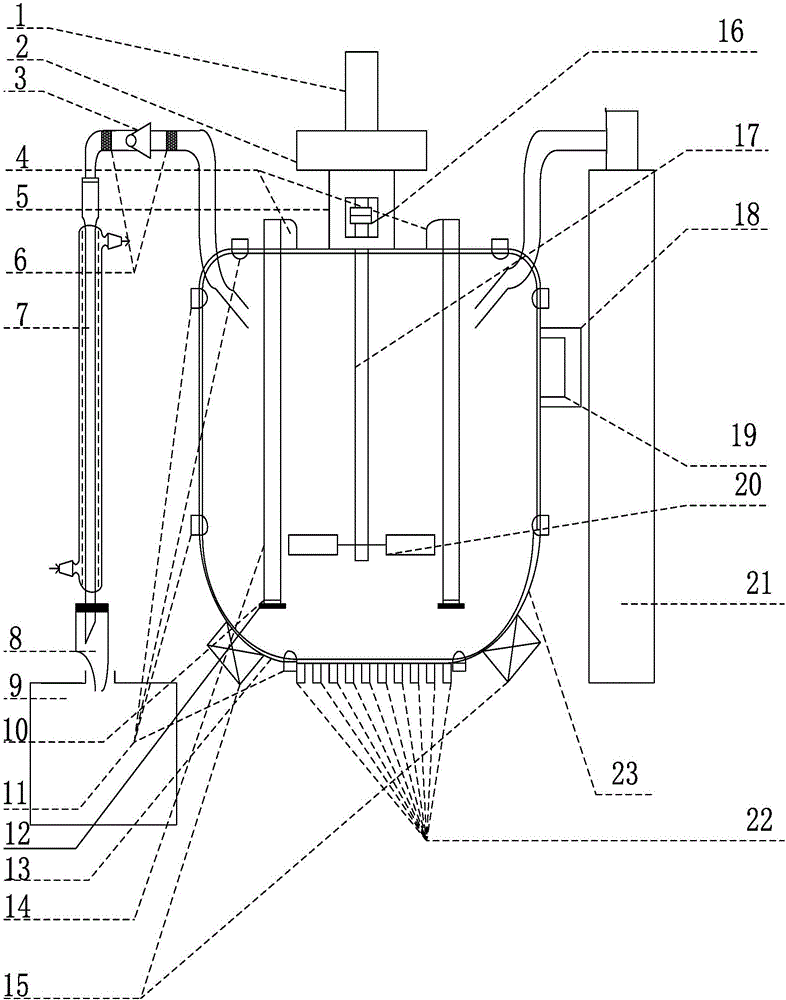

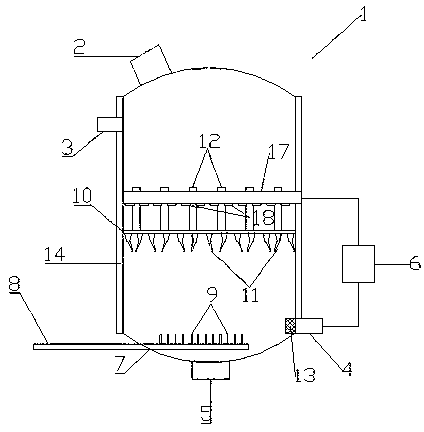

Single chip microcomputer intelligent control microwave pyrolysis microalgae directional oil-making device

ActiveCN106000254AImprove conversion rateControl reaction temperatureProcess control/regulationEnergy based chemical/physical/physico-chemical processesMicrocontrollerThermal insulation

The invention discloses a single chip microcomputer intelligent control microwave pyrolysis microalgae directional oil-making device. The device comprises a motor, a speed reducer, an air pump, microwave sources, a bracket, filter screens, a condenser pipe, an ox horn pipe, a liquid collection bottle, a microwave burst, temperature inductors, a seal structure, a thermal insulation layer, waveguide pipes, residue outlets, a connecting sleeve, a stirring shaft, an electrical bin, a single chip microcomputer control system, stirring fins, an N2 bottle, and a pressure sensor array. The device also comprises a tank body. The single chip microcomputer intelligent control microwave pyrolysis microalgae directional oil-making device provided by the invention adopts a metal tank, has high strength, can bear a lot of reaction materials, the microwave sources irradiate microwave evenly into the metal tank through the four uniformly disposed waveguide pipes to heat the reaction materials. The single chip microcomputer controls the reaction through the temperature in the tank and the weight change of the reaction materials, can well improve the material conversion rate, and saves energy.

Owner:GUANGXI UNIV

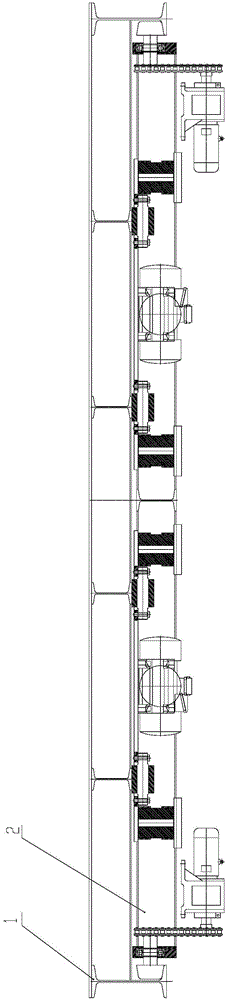

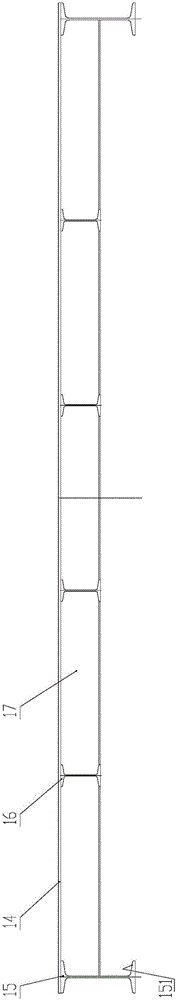

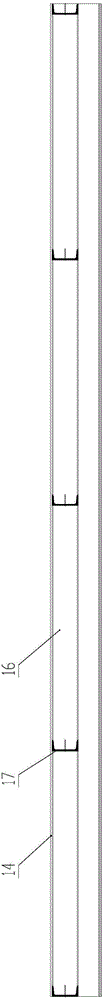

PC prefabricated component forming equipment

ActiveCN106217589AReduce handling workEasy to carry outCeramic shaping apparatusEngineeringProduction quality

The invention provides PC prefabricated component forming equipment. The PC prefabricated component forming equipment comprises two parts of a mold table and a vibration platform, and is characterized in that the mold table is a fixed platform; a guide rail is arranged on the fixed platform; the vibration platform is a mobile vibration platform; a vibration mechanism and a walk driving mechanism are arranged on the mobile vibration platform; the walk driving mechanism is positioned on the guide rail, so that the mobile vibration platform is movably arranged on the fixed platform along the guide rail corresponding to the fixed platform. The PC prefabricated component forming equipment adopts a working mode of fixed mold table and automatic moving vibration platform, improves the working efficiency, reduces the cost, improves the prefabricated component production quality, and reduces the working intensity of operators.

Owner:ANHUI XINGHUA FORKELEVATOR

Preparation method of mulberry red pigment

The invention discloses a preparation method of a mulberry red pigment. The preparation method comprises the following steps: (1) mixing dried mulberry powder with ethanol (95 wt%), adjusting the pH value of the solution to 2-4 by a critic acid water solution, carrying out high speed pretreatment at a room temperature, homogenizing, extracting, and filtering; (2) after filtering, mixing the dregs with ethanol (95 wt%), adjusting the pH value to 2-4 by a critic acid water solution, homogenizing, extracting, and filtering; (3) subjecting the filtrate to centrifugation, collecting the supernate, and freeze-drying the supernate to obtain powder, namely the mulberry red pigment. The preparation method is simple, the requirements on equipment are low, the extraction efficiency is high, the extraction time is largely shortened, and the provided method is obviously better than the conventional solvent extraction method. Moreover, the obtained mulberry red pigment has the advantages of high water solubility, beautiful appearance and luster, and stable property, and can be used as food additive and raw material of healthcare product.

Owner:CHONGQING SANLINGSAN TECH CO LTD

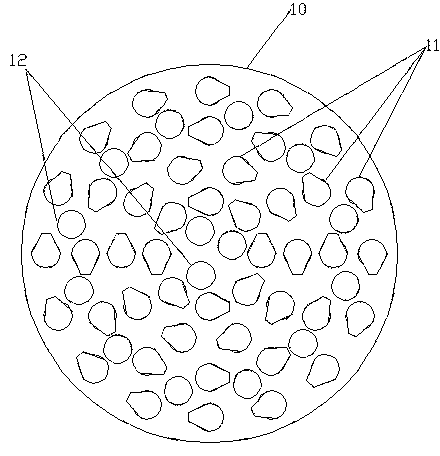

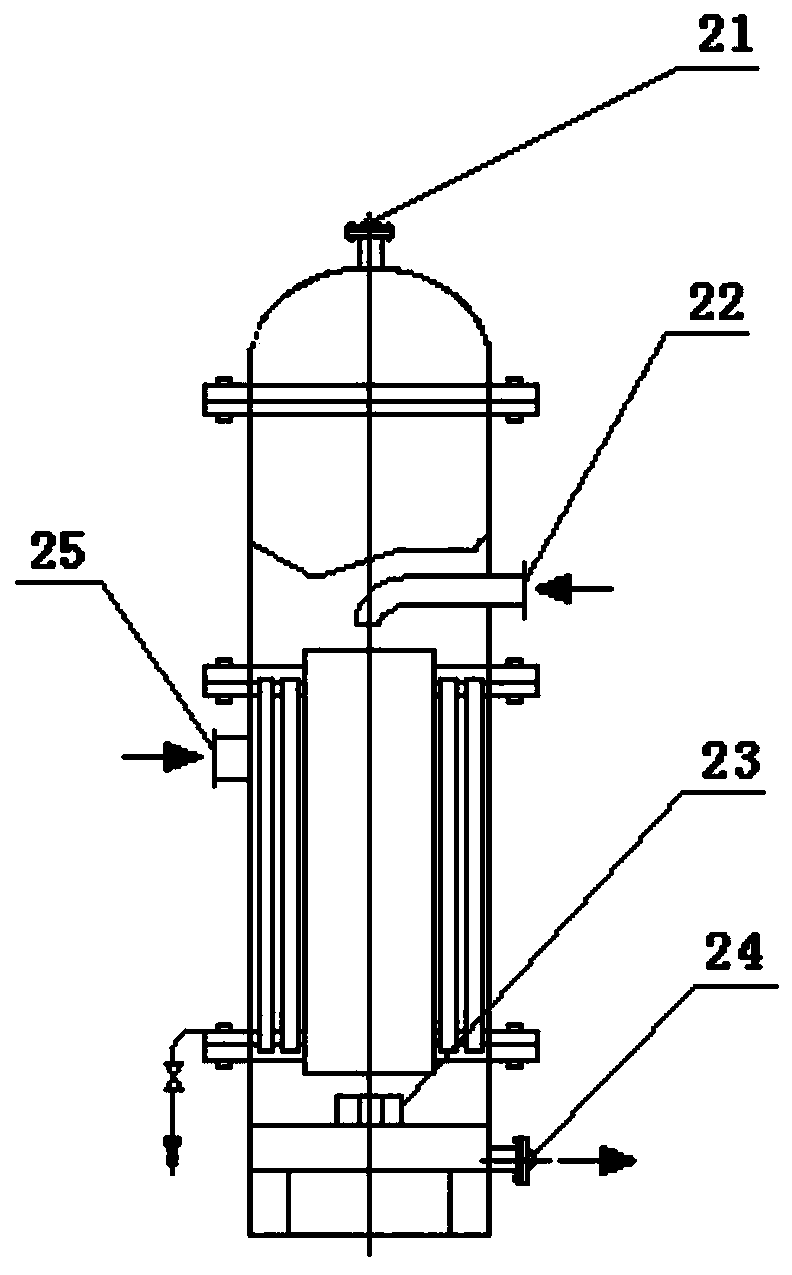

Extracting tank with built-in partition plate

InactiveCN103212216AUniform extractionImprove extraction efficiencySolid solvent extractionMedicinal herbsEngineering

The invention discloses an extracting tank with a built-in partition plate. The extracting tank is characterized in that the middle part of a tank body is provided with the partition plate for dividing an inner cavity of the tank body into upper and lower parts, downward liquid spraying pipes are distributed on the partition plate along the circumference, and air passing pipes are arranged at the other positions of the partition plate; the inner diameters of the liquid spraying pipes are gradually reduced from an inlet to an outlet, the outlets of the liquid spraying pipes on the same circumference and the clockwise rotation tangential speed along the circumference are obliquely downward in a 45-degree angle, or the outlets of the liquid spraying pipes on the same circumference and the anticlockwise rotation tangential speed along the circumference are obliquely downward in the 45-degree angle, and the outlet directions of the liquid spraying pipes on the adjacent circumferences are opposite; a coil is arranged above the partition plate, is close to the partition plate and is arranged along the inner circumference of the tank boy, and the bottom of the coil is provided with downward spraying holes; and a circulating pump comprises a pump inlet and a pump outlet, the pump inlet is connected with a liquid outlet, and the pump outlet passes through the side wall of the tank body so as to be communicated with the interior of the coil. A turbulence liquid medicine is formed in the extracting tank, the uniformly mixing degree of a liquid medicine and a medicinal material at each part in the tank is promoted, and effective active ingredients in the medicinal material are rapidly fully extracted.

Owner:汪振朴

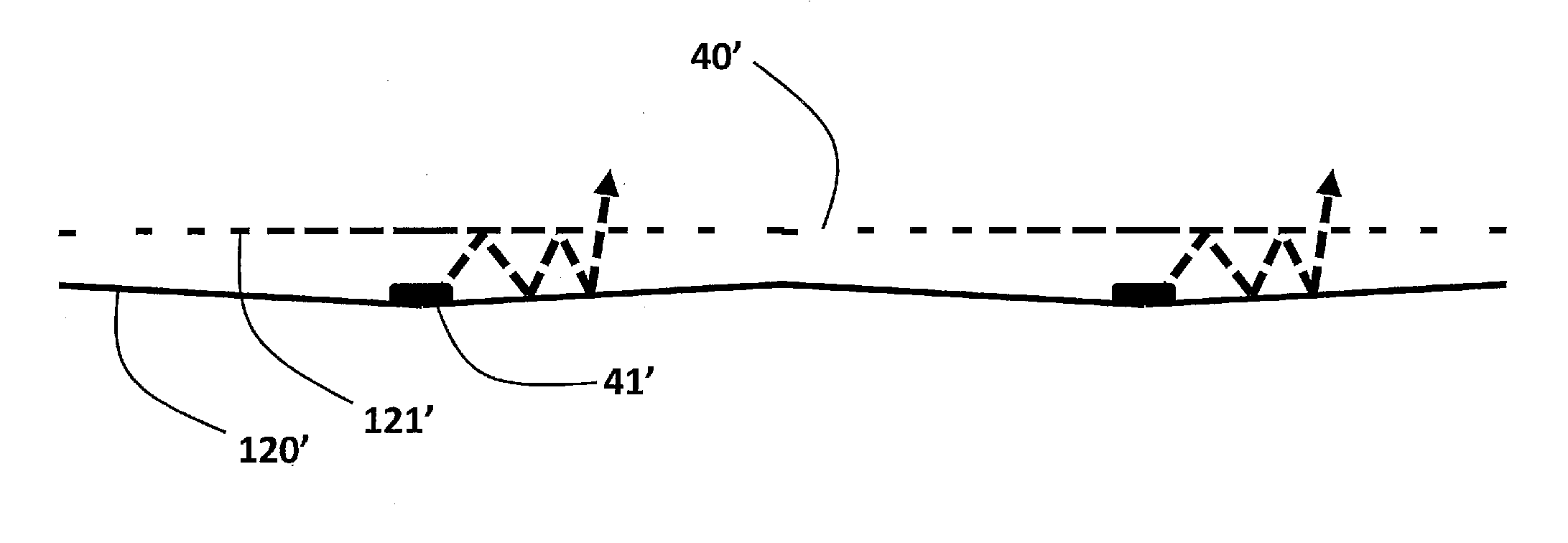

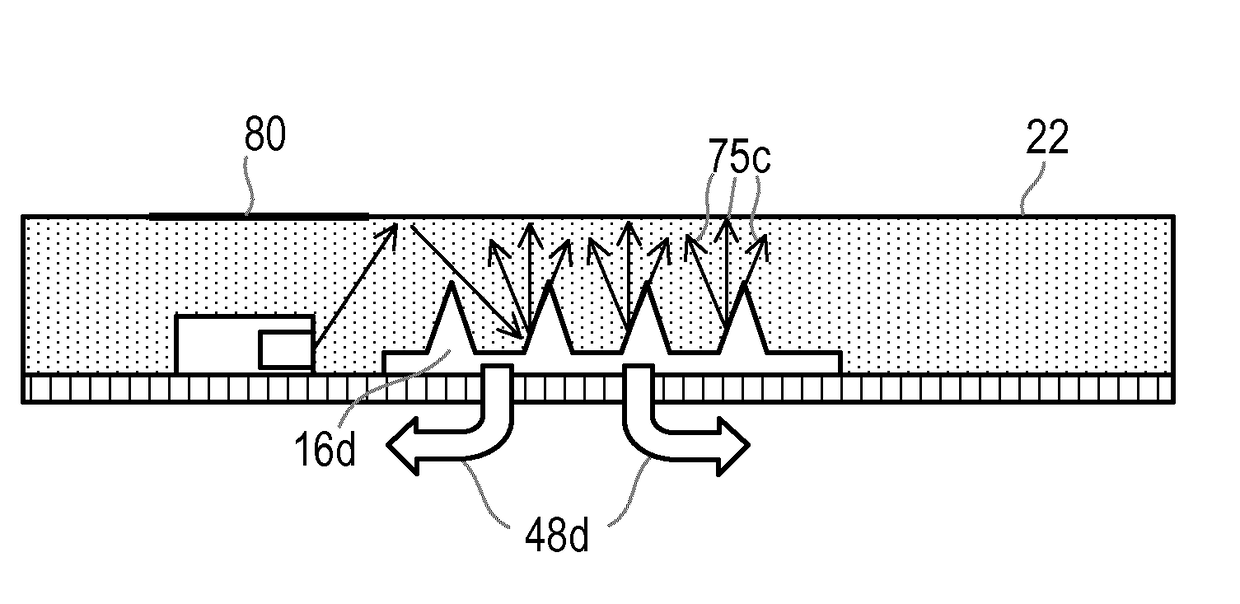

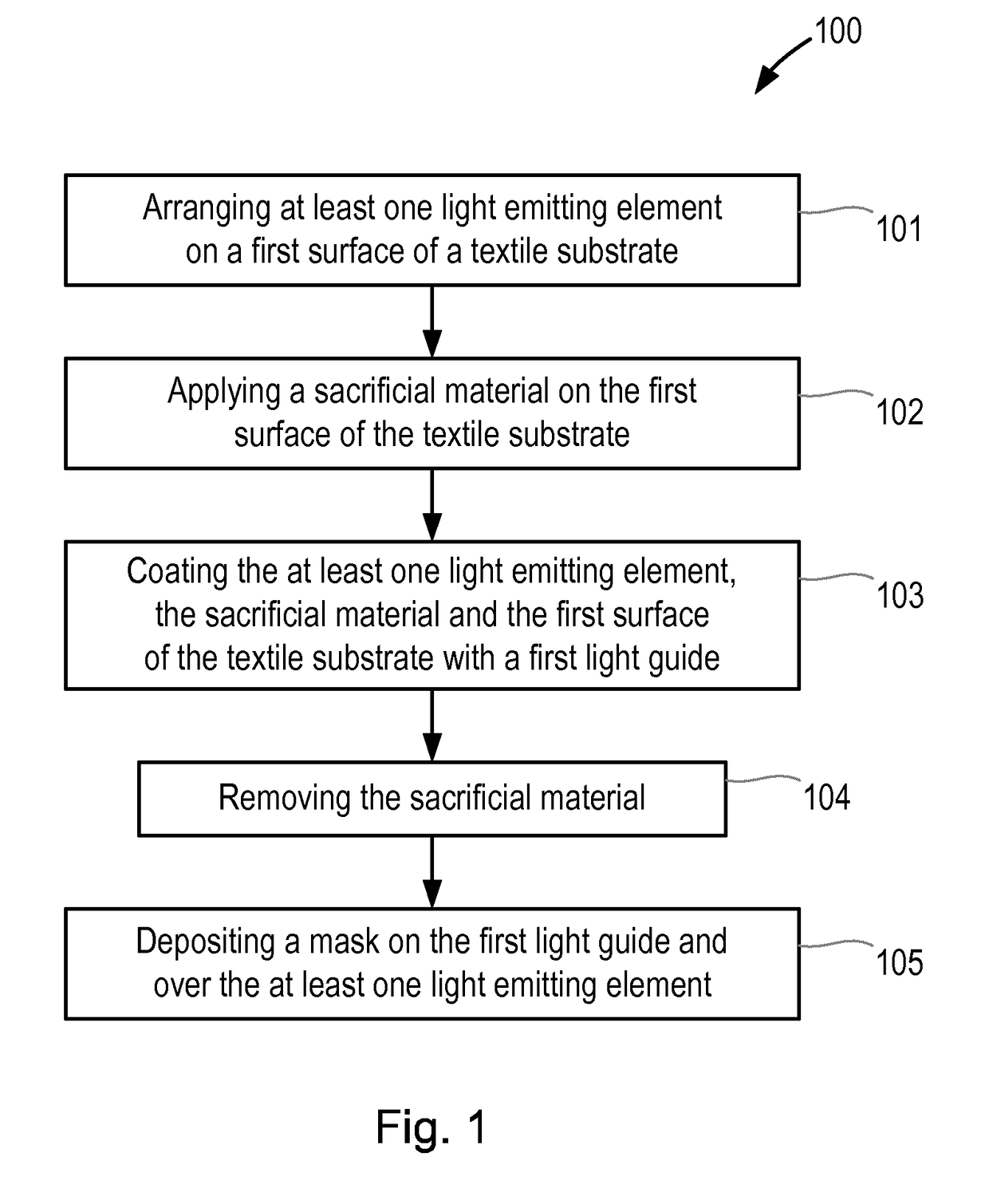

Light spreading in textiles

InactiveUS20180052272A1Improve the level ofMinimal/decreased bright spotsMechanical apparatusPlanar/plate-like light guidesLight guideLight emitting device

The present invention relates to a light emitting device comprising a light emitting element and a light guide arranged on a textile substrate and wherein one or more air gaps are present in the light guide at the interface with the textile substrate. The method also relates to a method of making the light emitting device and to various uses of the light emitting device.

Owner:SIGNIFY HLDG BV

Process for extracting and concentrating total flavone in hawthorn

InactiveCN104138670AShorten extraction and concentration timeIncrease concentrationEvaporationEnergy based chemical/physical/physico-chemical processesHigh concentrationEvaporation

The invention relates to a process for extracting and concentrating total flavone in hawthorn. The process comprises a process for extracting total flavone in hawthorn and a process for evaporating and concentrating total flavone in hawthorn. The process is characterized in that the process for extracting total flavone in hawthorn and the process for evaporating and concentrating total flavone in hawthorn are respectively completed in integrated ultrasonic extraction, evaporation and concentration equipment. The process is scientific and reasonable in design, has the advantages of simplicity in operation, short extraction and concentration time, high concentration degree, uniformity in extraction, high circulation speed, good solution property, small possibility of scaling, convenience in equipment washing and repair and simplicity, and is relatively high in innovativeness.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

Process for extracting ginkgo biloba flavone, ginkgo biloba lactone and ginkgo biloba phenolic acid from ginkgo biloba leaves

ActiveCN102727538BPlay brokenEfficient crushingNervous disorderGinkgophyta medical ingredientsBiotechnologyGinkgolide

The present invention discloses a process for extracting ginkgo biloba flavone, ginkgo biloba lactone and ginkgo biloba phenolic acid from ginkgo biloba leaves. The process comprises the following steps: (1) carrying out a pretreatment on ginkgo biloba leaves; (2) carrying out extraction by an ultrasonic device; (3) carrying out reduced pressure concentration; (4) loading the resulting solution on a macroporous resin to carry out a treatment; (5) collecting the resulting eluate; (6) carrying out reduced pressure concentration; (7) detecting the resulting extract; and (8) carrying out drying and storing on the extract. With the process of the present invention, the ginkgo biloba flavone content and the ginkgo biloba lactone content in the extract prepared by the process of the present invention are high, the loss of active ingredients are avoided, the production process is simplified, the production cycle is shortened, and the ginkgo biloba phenolic acid content after treatment is substantially reduced.

Owner:JIANGSU EHAI PHARMA CORP

Grape skin pigment extraction technology

InactiveCN104448902ASmall particlesHigh pigment extraction rateNatural dyesFood additiveFreeze-drying

The invention discloses a grape skin pigment extraction technology. The technology comprises the following steps: 1, mixing dried grape skin powder with 95wt% ethanol, adjusting the pH value of the above obtained solution to 2-4 by using an aqueous citric acid solution, carrying out high speed pretreatment at room temperature, homogeneously extracting, and filtering; 2, mixing filter residues obtained after the filtration with 95wt% ethanol, adjusting the obtained solution to 2-4 by using the aqueous citric acid solution, homogeneously extracting, and filtering; and 3, centrifuging the obtained filtrate, collecting the obtained supernatant, and freeze-drying to obtain powder in order to obtain a grape skin pigment. The high speed pretreatment is carried out under 5000-1000rpm for above 5min, and the homogeneous extraction is carried out under 1000-4000rpm for above 10min. The invention also discloses the grape skin pigment obtained through the technology. The extraction technology has the advantages of simplicity, low requirements on a production device, high extraction efficiency, and great shortening of the extraction time, is obviously better than traditional solvent extraction methods. The obtained grape skin pigment has the advantages of good water solubility, good appearance color and stable properties, and is suitable for being used as a food additive and a health food raw material.

Owner:QINGDAO ZHONGREN ZHIYE BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com