Patents

Literature

331results about How to "Same quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

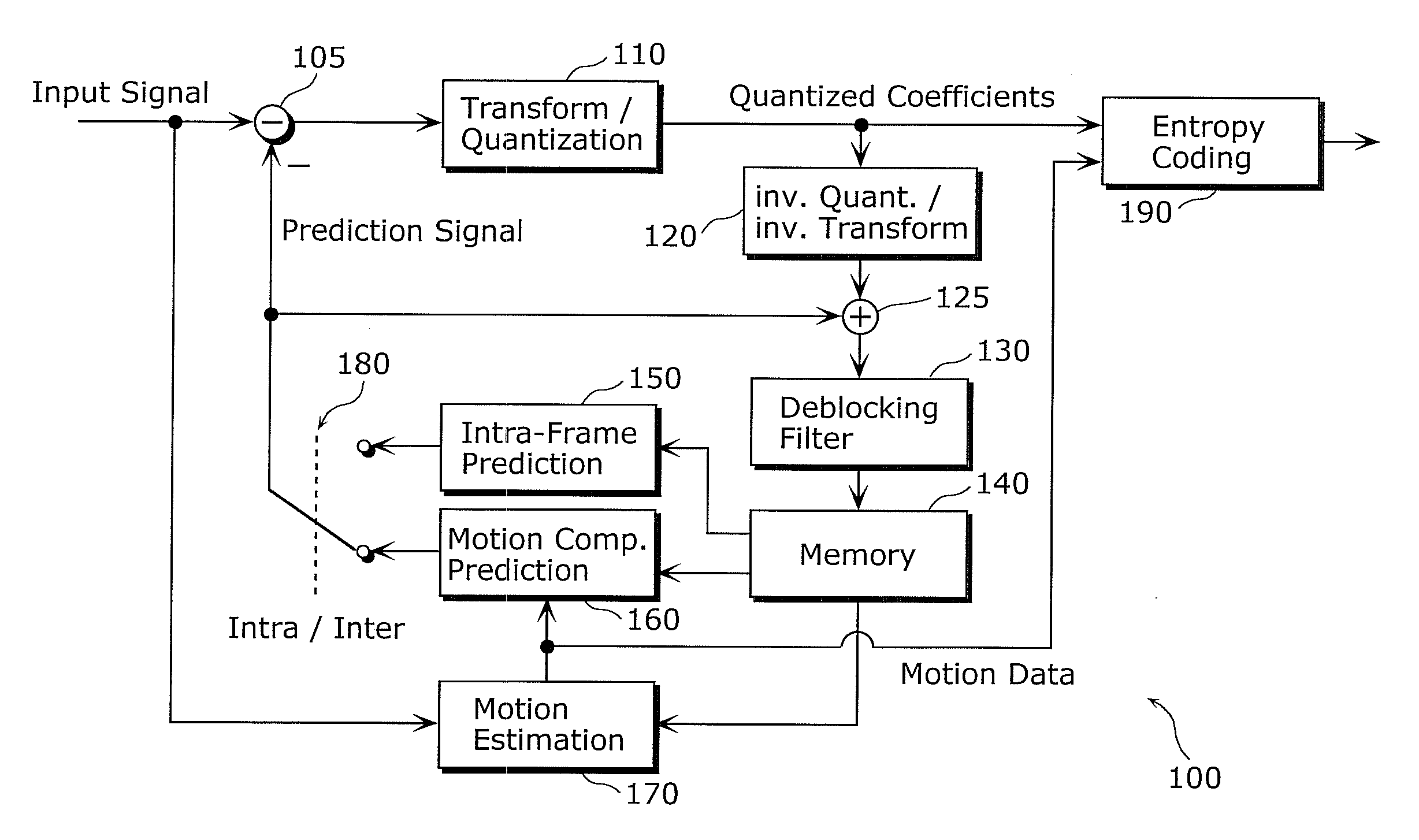

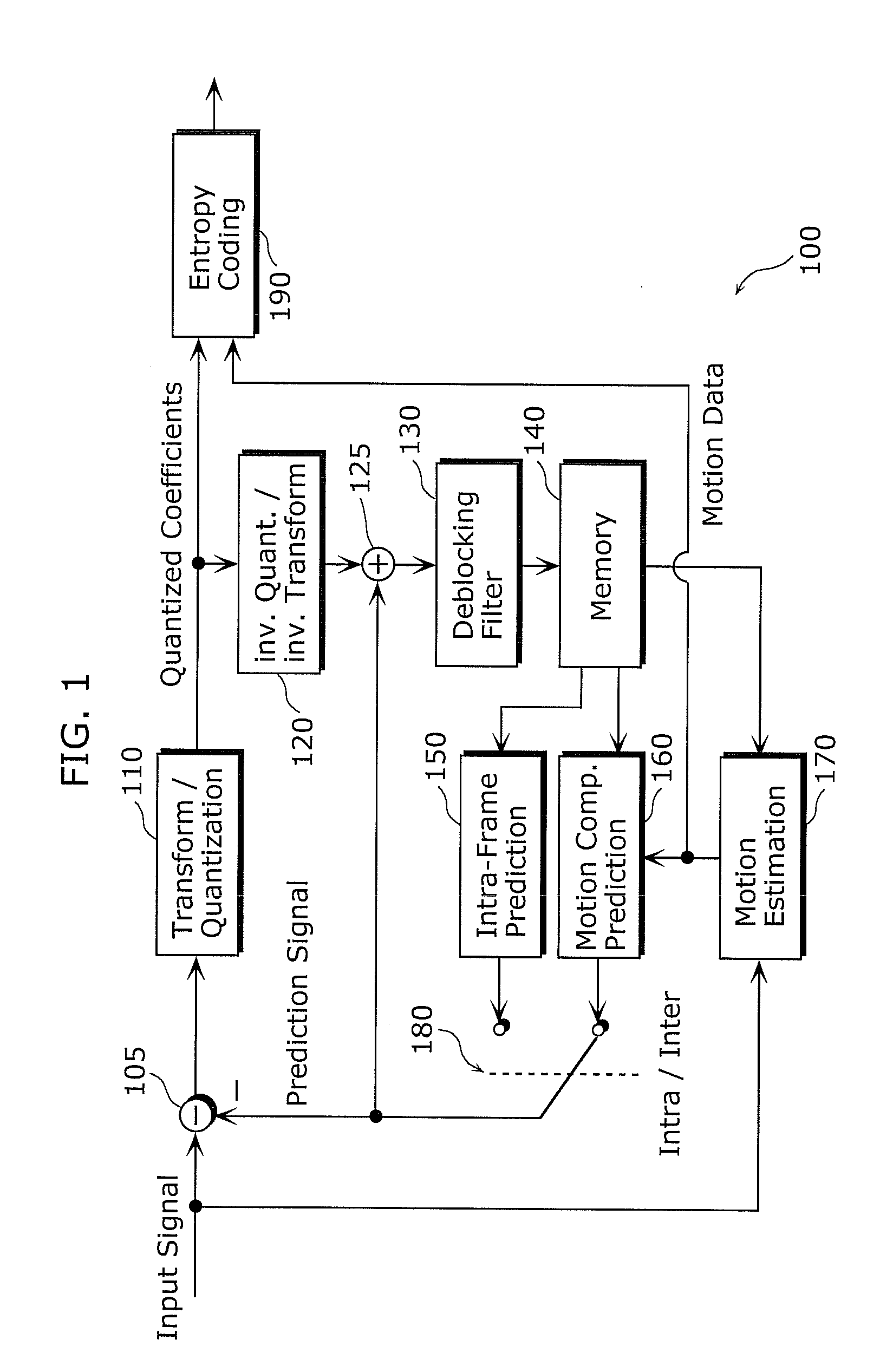

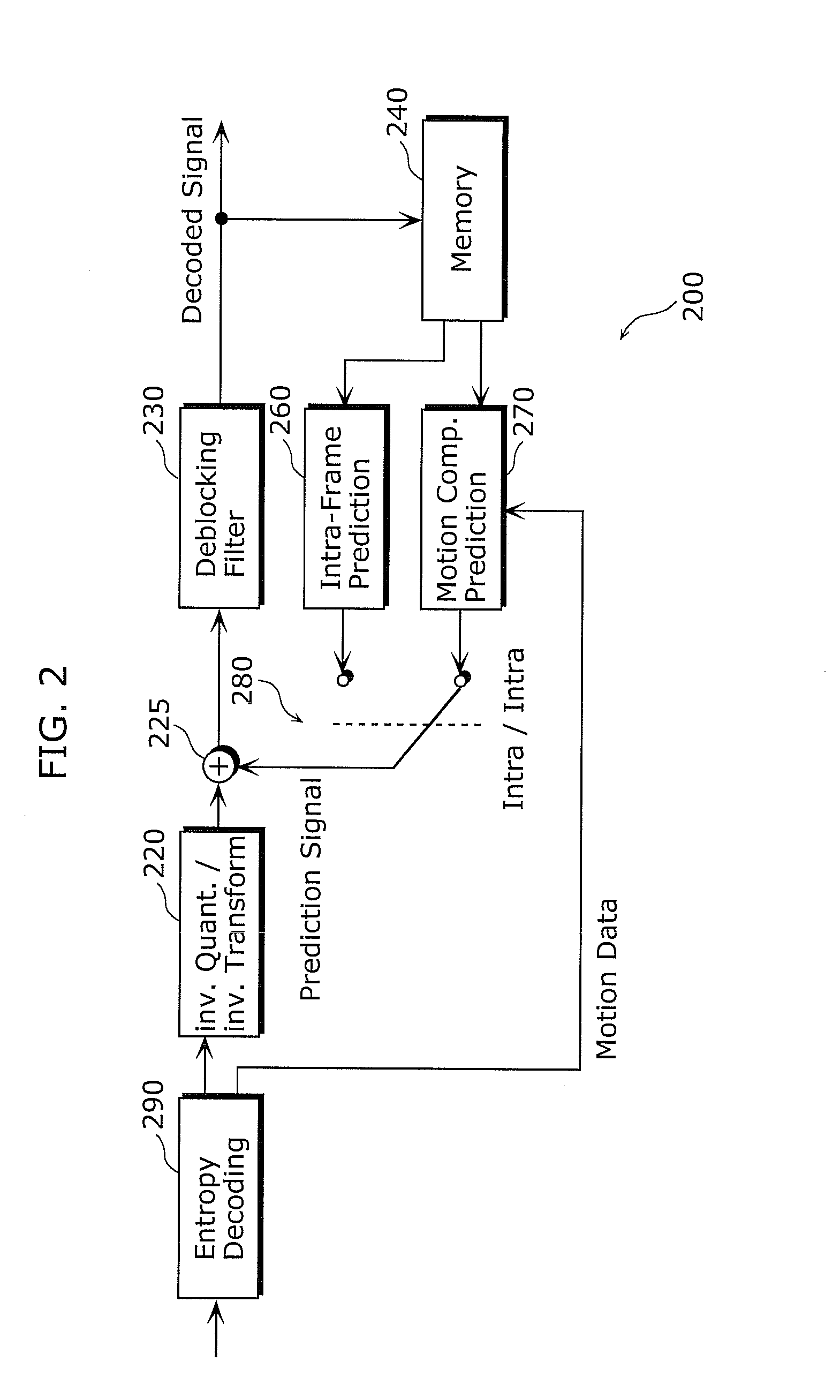

Image coding method, image decoding method, image coding apparatus, image decoding apparatus, integrated circuit and program

InactiveUS20110206135A1Efficient decodingSame qualityColor television with pulse code modulationColor television with bandwidth reductionComputer hardwareDecoding methods

Images are coded with higher efficiency while maintaining the same image quality. An image coding method of coding an image on a block basis, including: transforming (S1201) a two-dimensional array of pixel values of a current block to be encoded, into a two-dimensional array of transform coefficients; determining (S1202), depending on the two-dimensional array of the transform coefficients, a scan order for scanning the transform coefficients of the two-dimensional array; scanning (S1203) the transform coefficients of the two-dimensional array sequentially according to the scan order, to generate a one-dimensional array of the transform coefficients; and coding (S1204) the transform coefficients of the one-dimensional array.

Owner:PANASONIC CORP

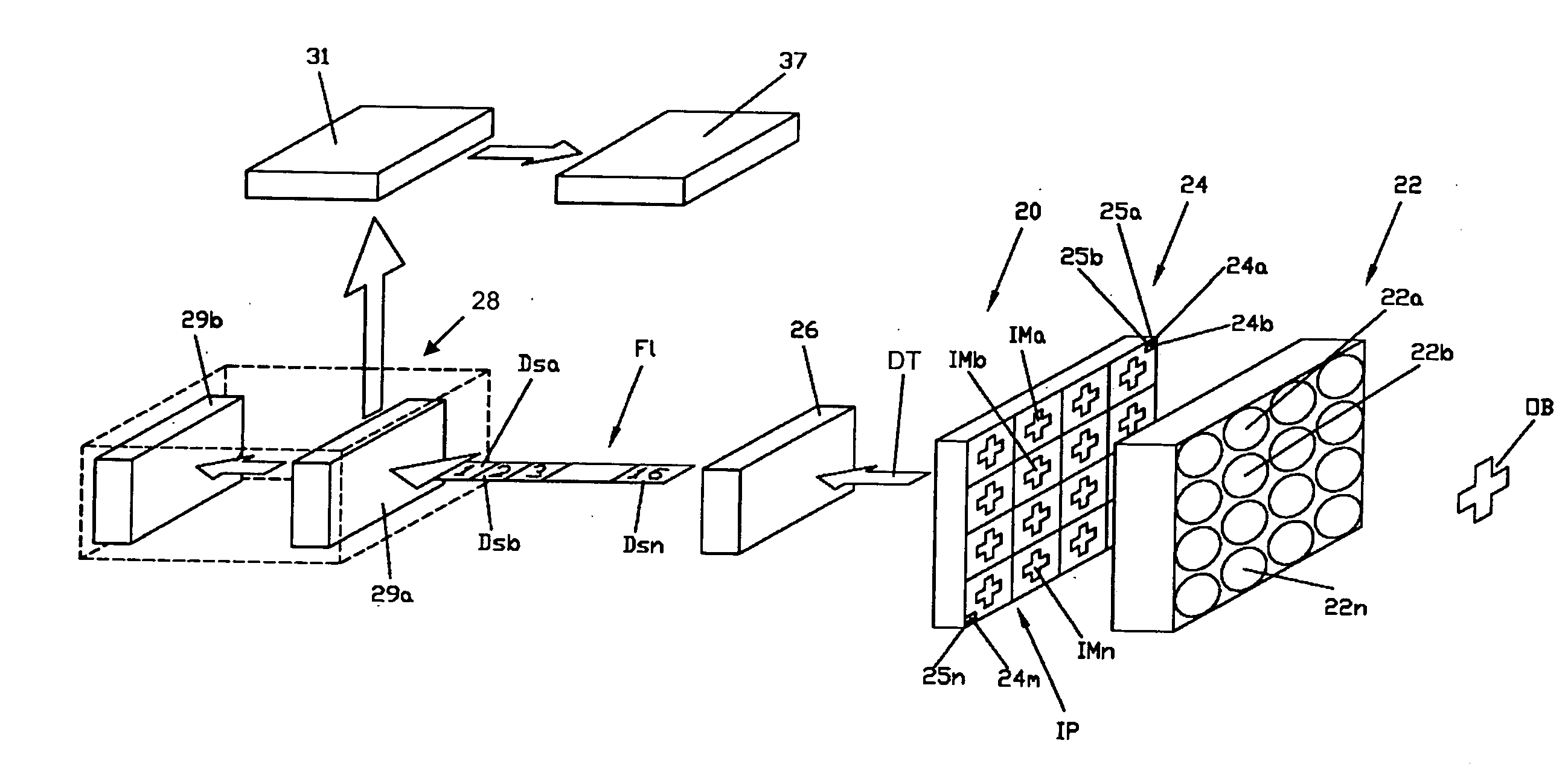

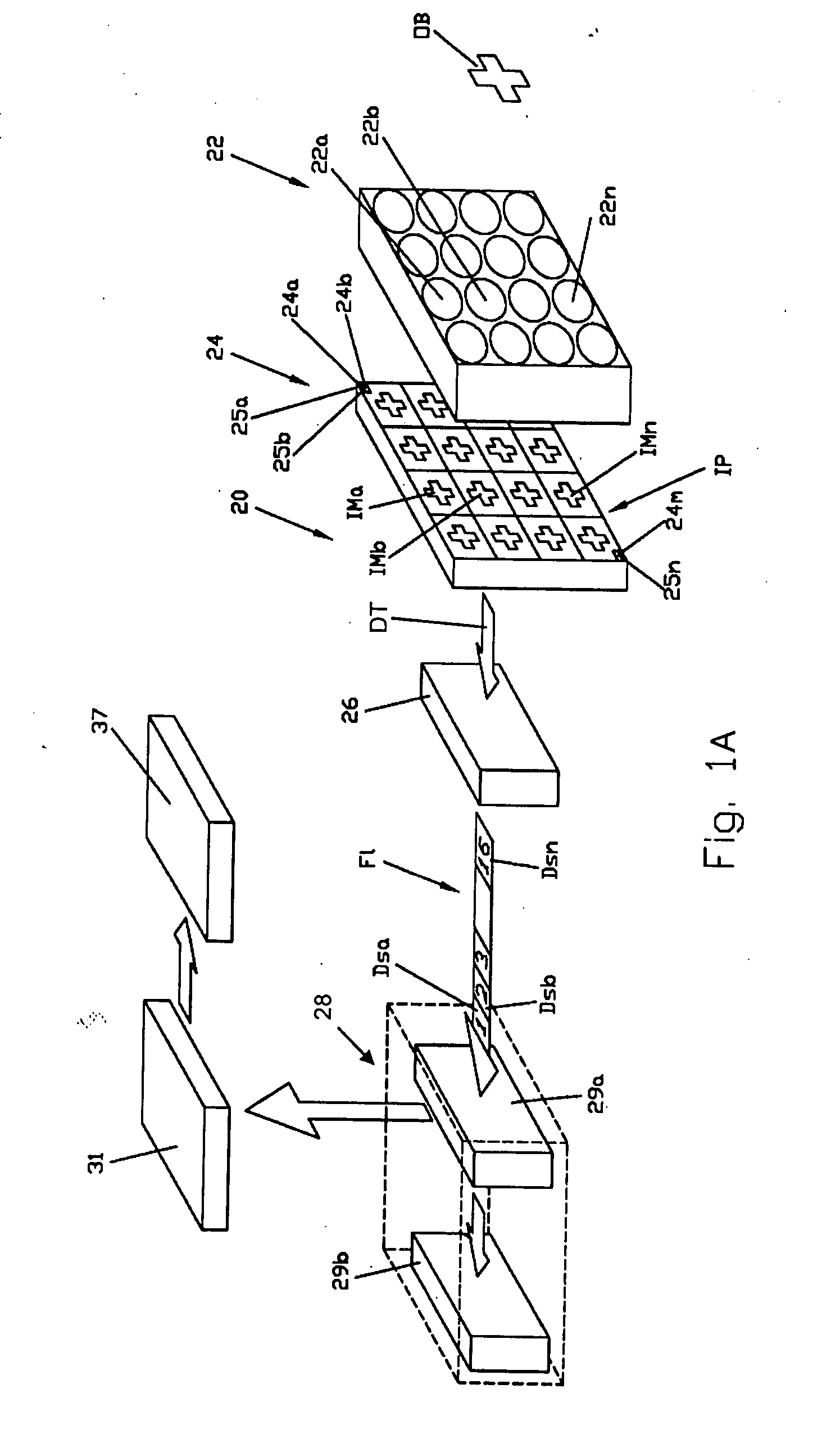

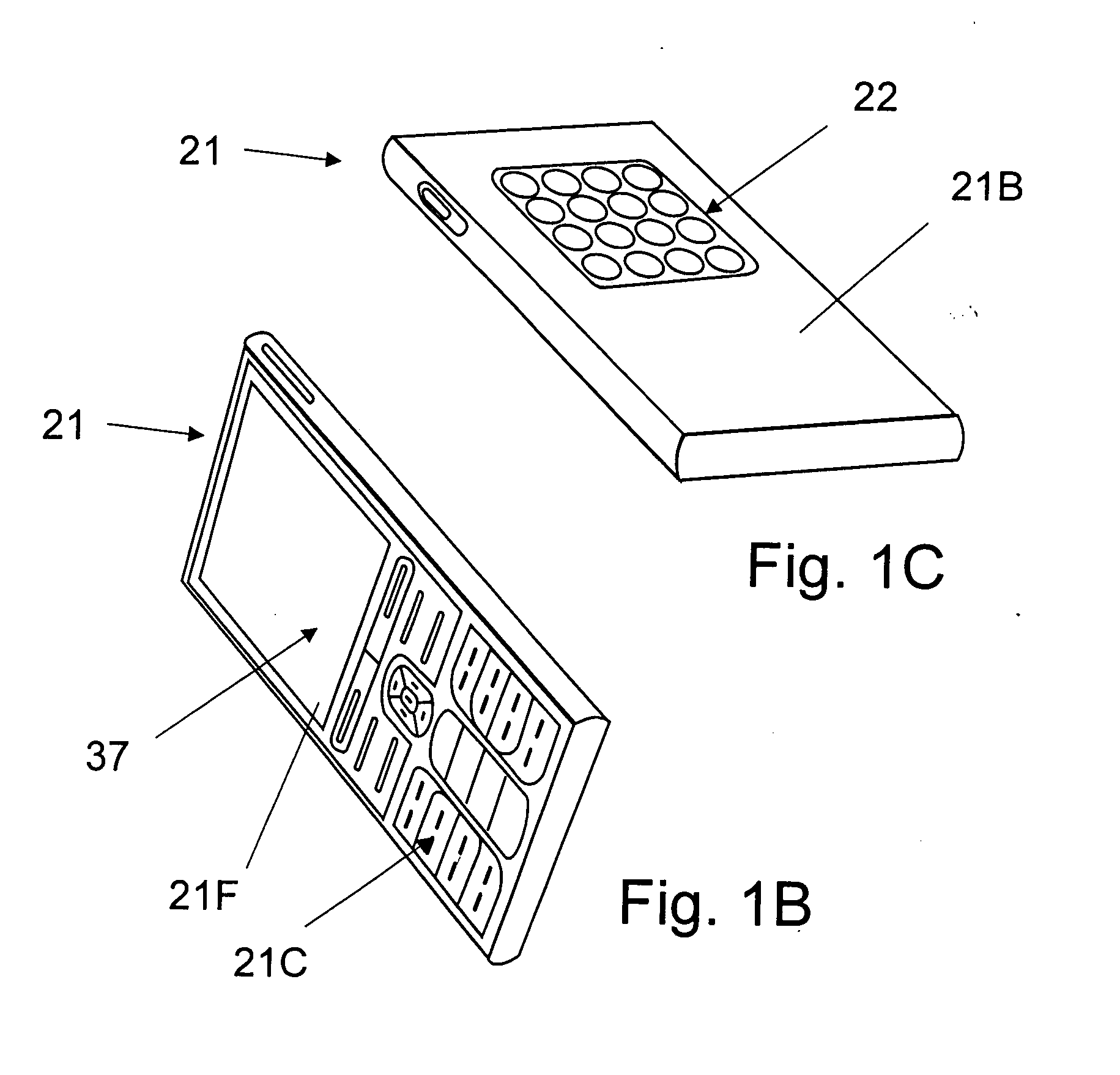

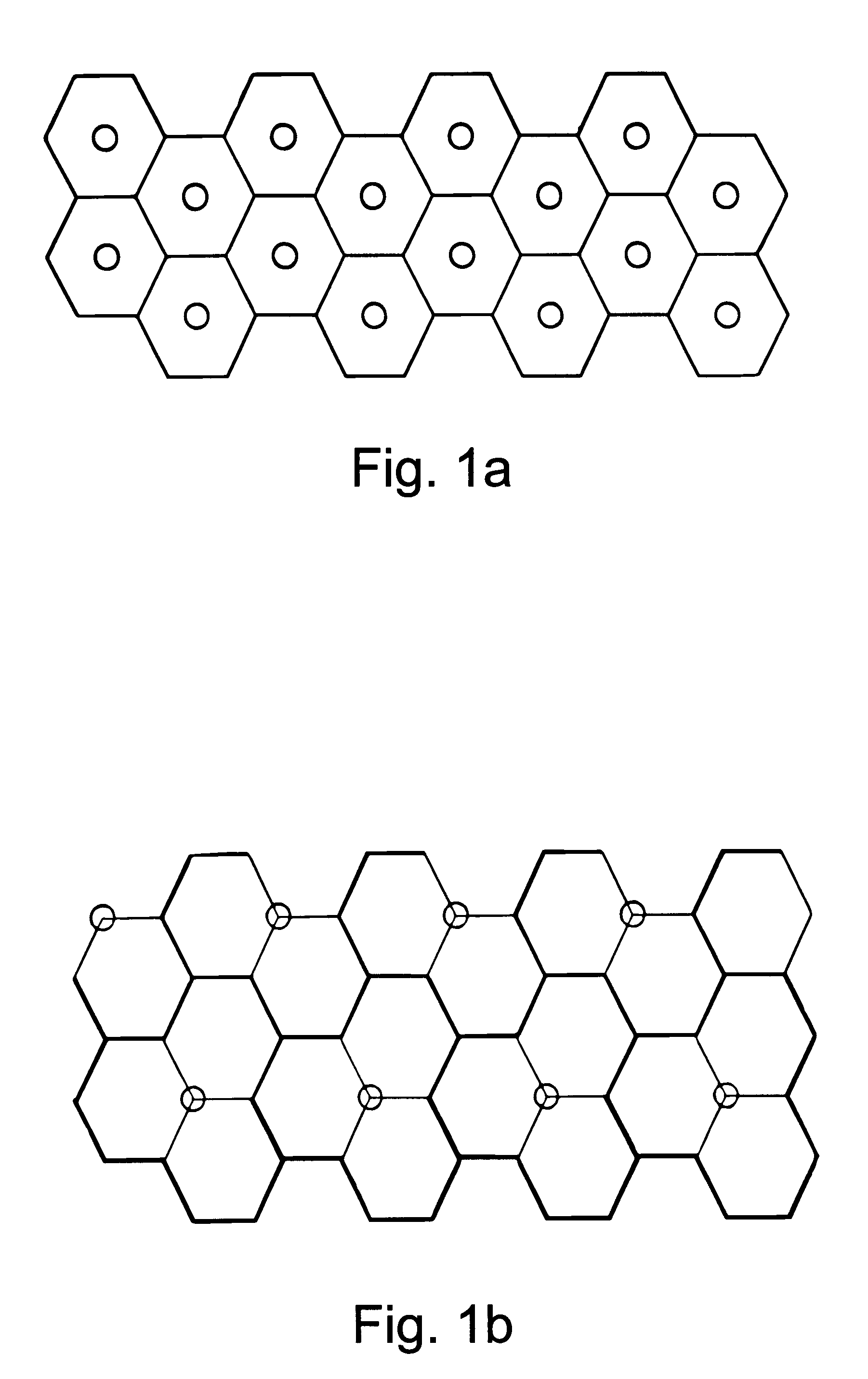

Ultra-thin digital imaging device of high resolution for mobile electronic devices and method of imaging

InactiveUS20070263114A1Enhance the imageCompact integrationTelevision system detailsColor television detailsDigital imagingData set

An ultra-thin digital imaging device has a thickness of several millimeters and is capable of producing data for creating images of 3 Mp and higher. The device comprises a multi-channel imaging unit that contains a plurality of optical channels formed by microlens objectives and a pixilated image sensor unit with a plurality of sensing elements. Each individual identical image obtained through each optical channel is pixilated and converted into electrical signals that are processed into data sets which can be stored in the imaging device and either reproduced on the display of the device or transmitted to an external image-reproducing device where the obtained data of individual images are transformed into a single, high-resolution megapixel image by means of a technique known in the art.

Owner:MICROALIGN TECH

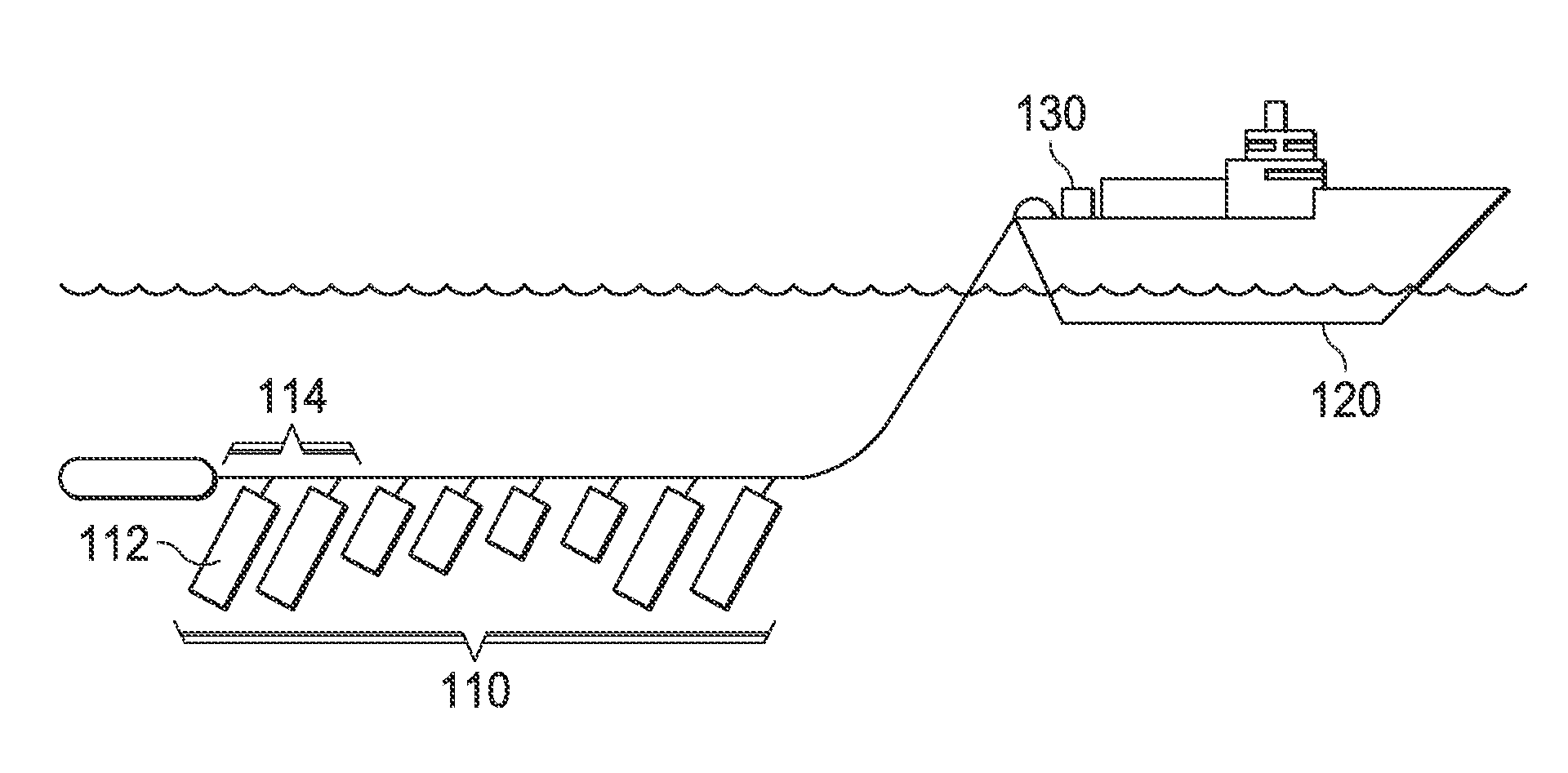

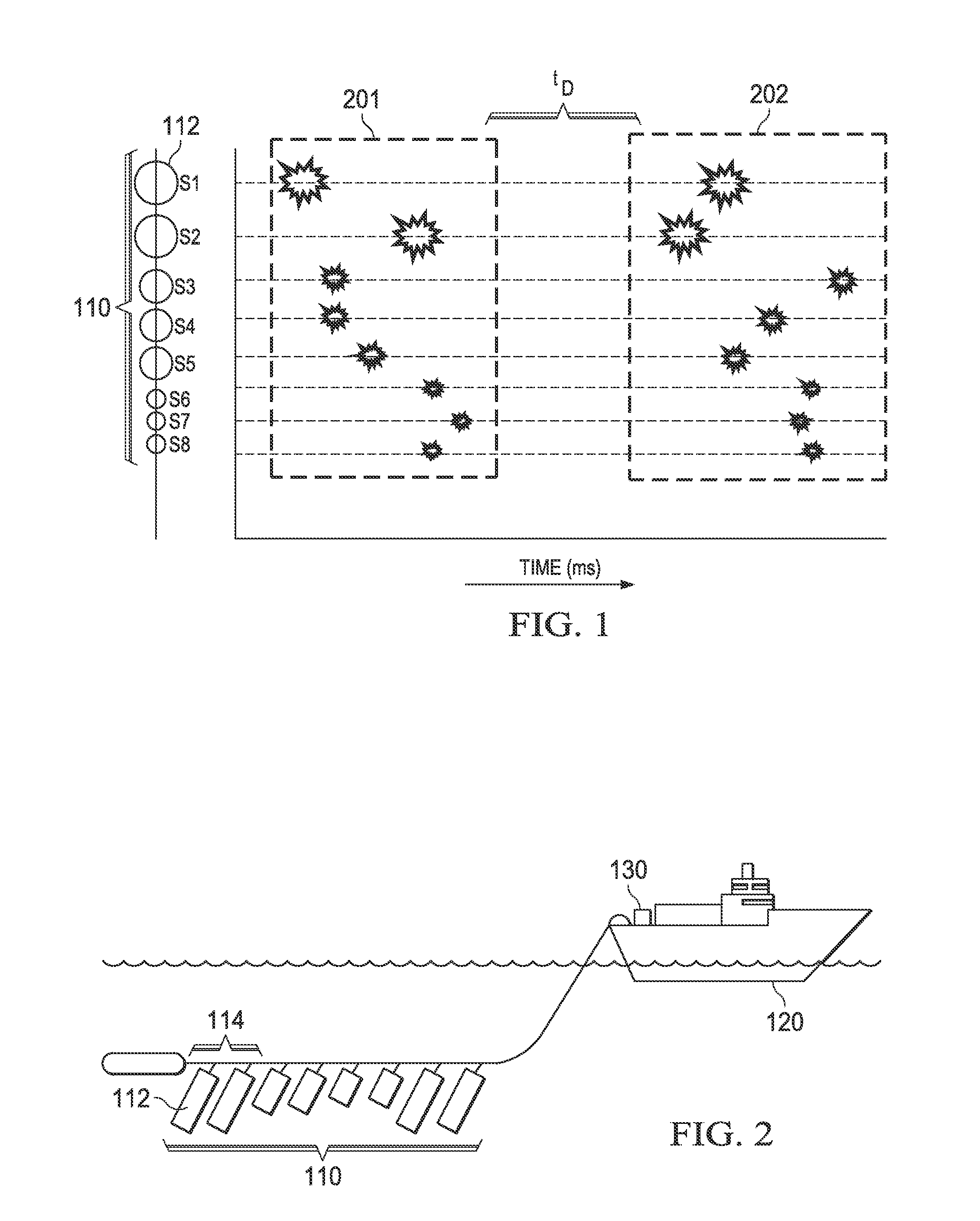

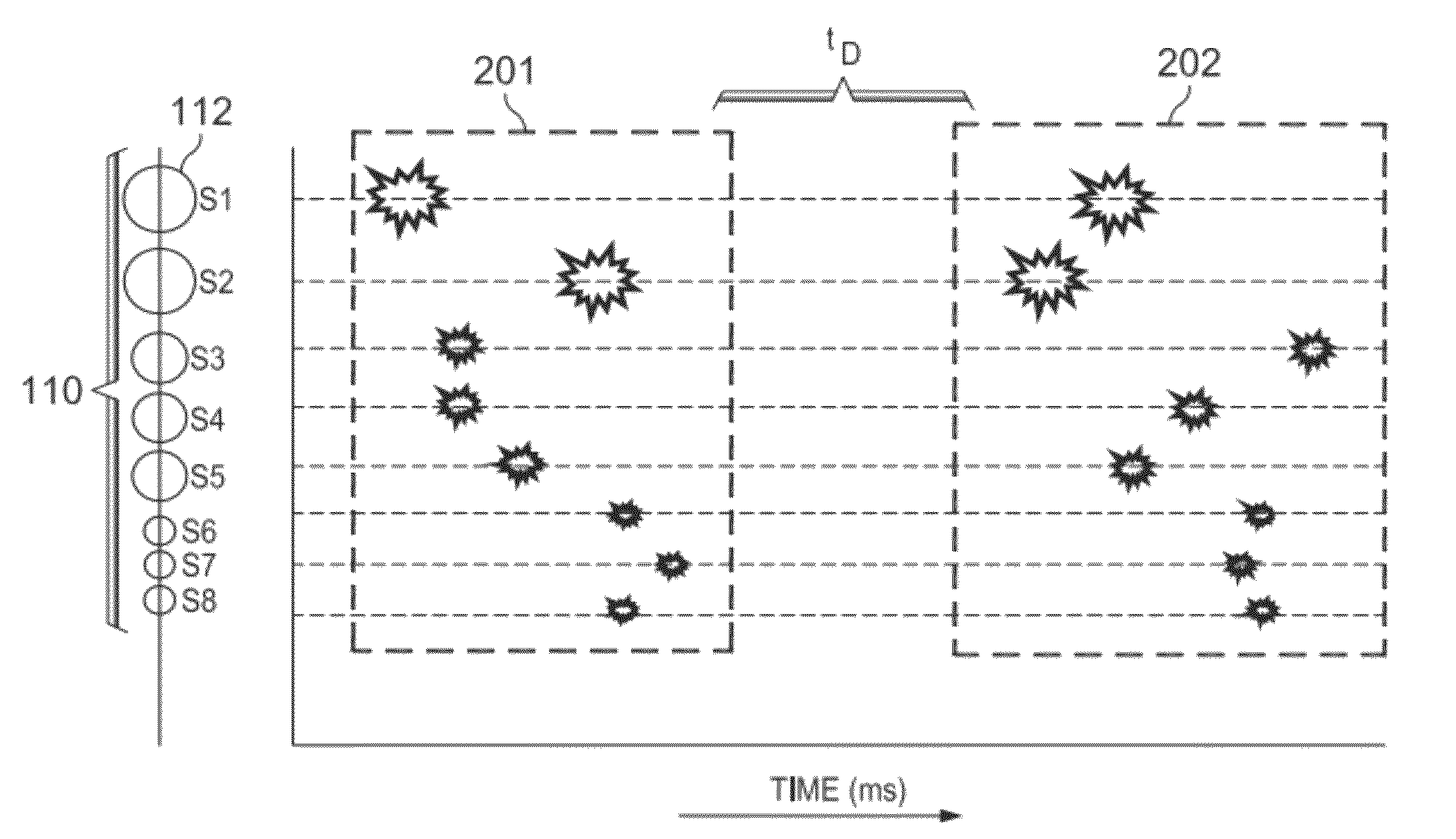

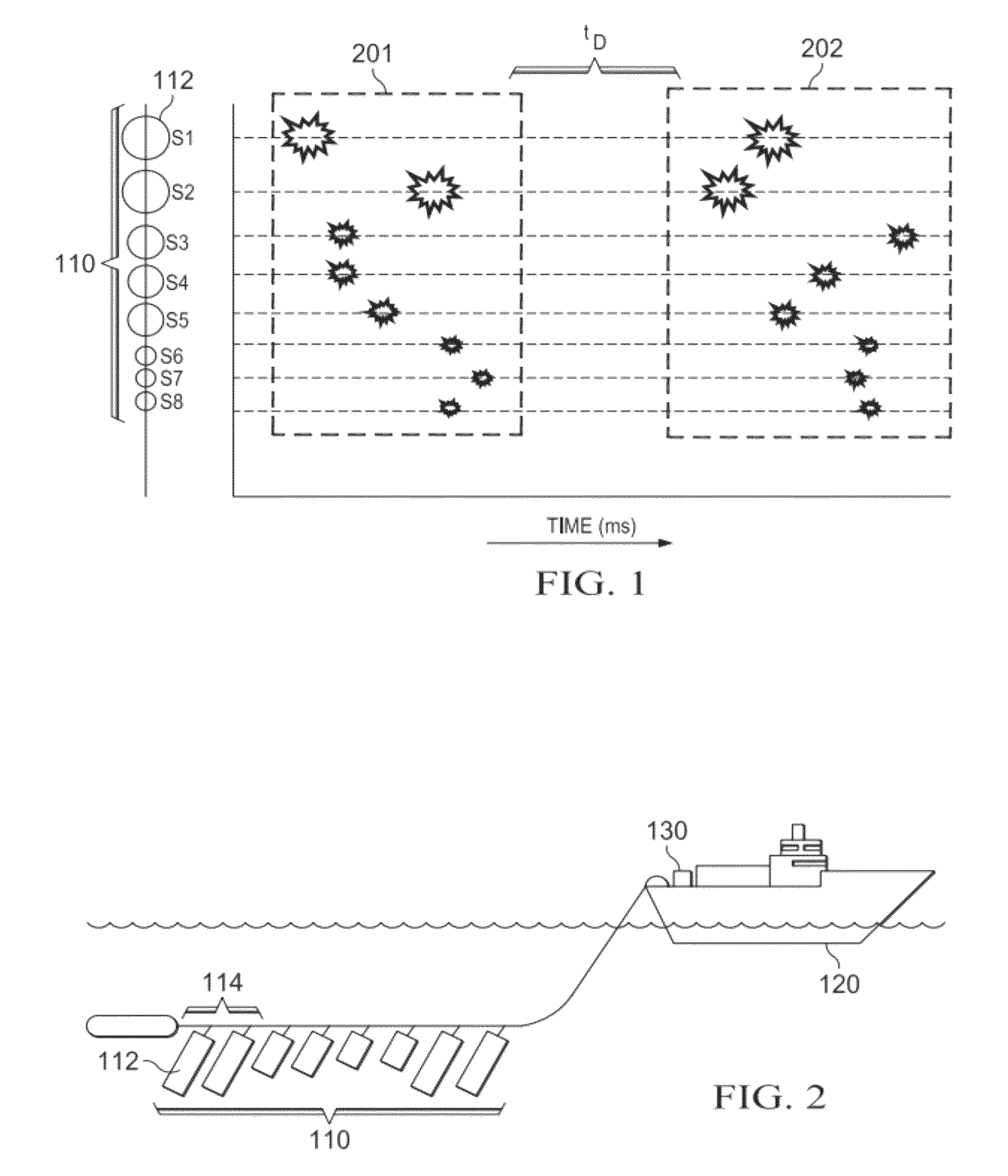

Seismic acquisition method and system

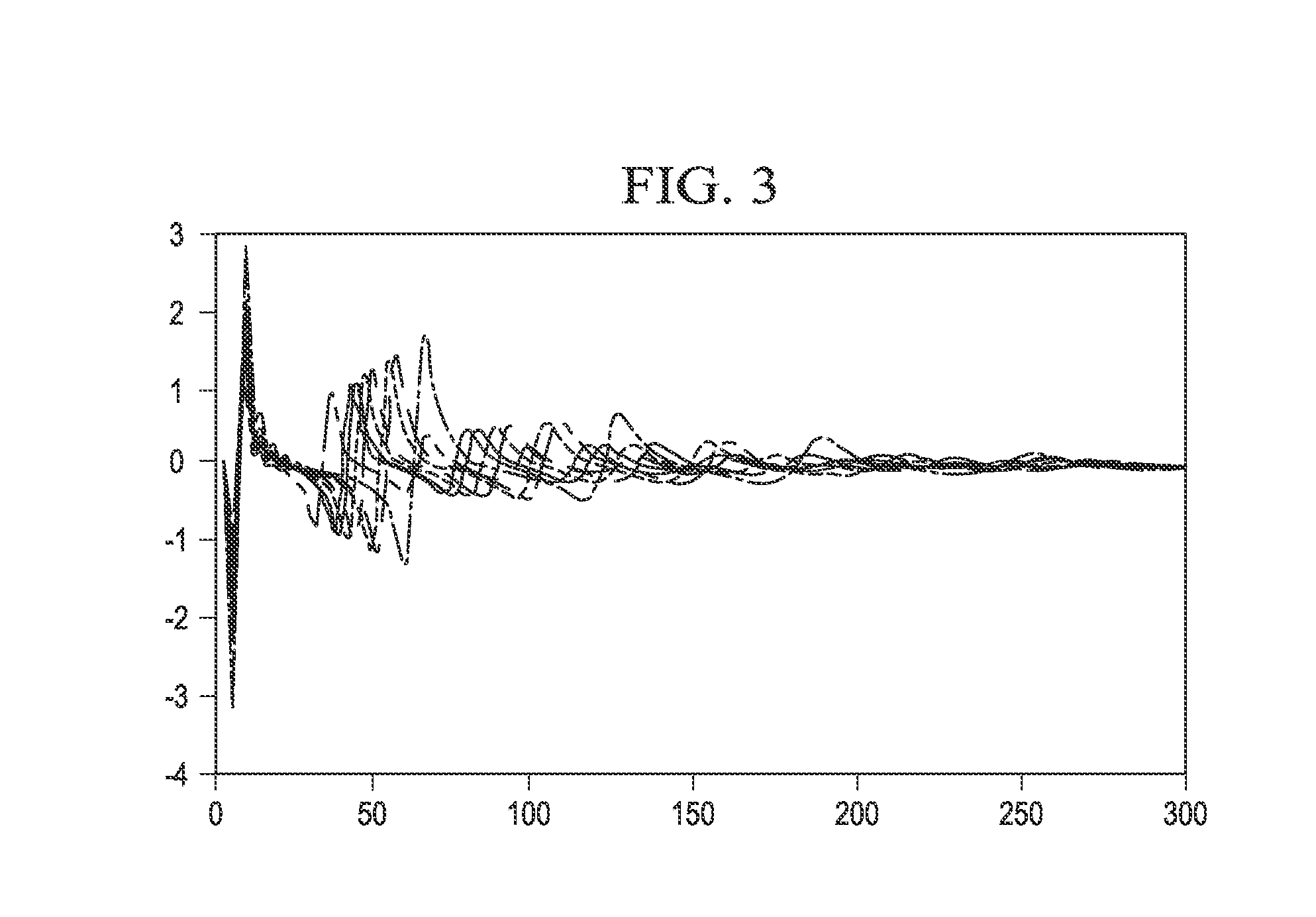

ActiveUS20120147701A1Reduce impactReduce outputSeismic data acquisitionSeismic energy generationImaging qualityBiological activation

The maximum output of a seismic source array may be reduced by activating the individual seismic sources within these seismic source array in a pattern that is extended in time rather than by the presently employed conventional simultaneous activation of a large number of individual seismic sources. Methods are disclosed which take data shot with patterned sources and may use a sparse inversion method to create data with the about same image quality as that of conventional sources. In this manner the output of the maximum impulse of a seismic source array may be reduced by an amplitude factor of about 10 in the examples shown here, corresponding to a reduction of about 20 dB while maintaining virtually the same seismic image quality. The disclosed methods may be used in combination with any simultaneous sourcing technique. In addition, the disclosed methods may be used with a plurality of source arrays.

Owner:BP CORP NORTH AMERICA INC

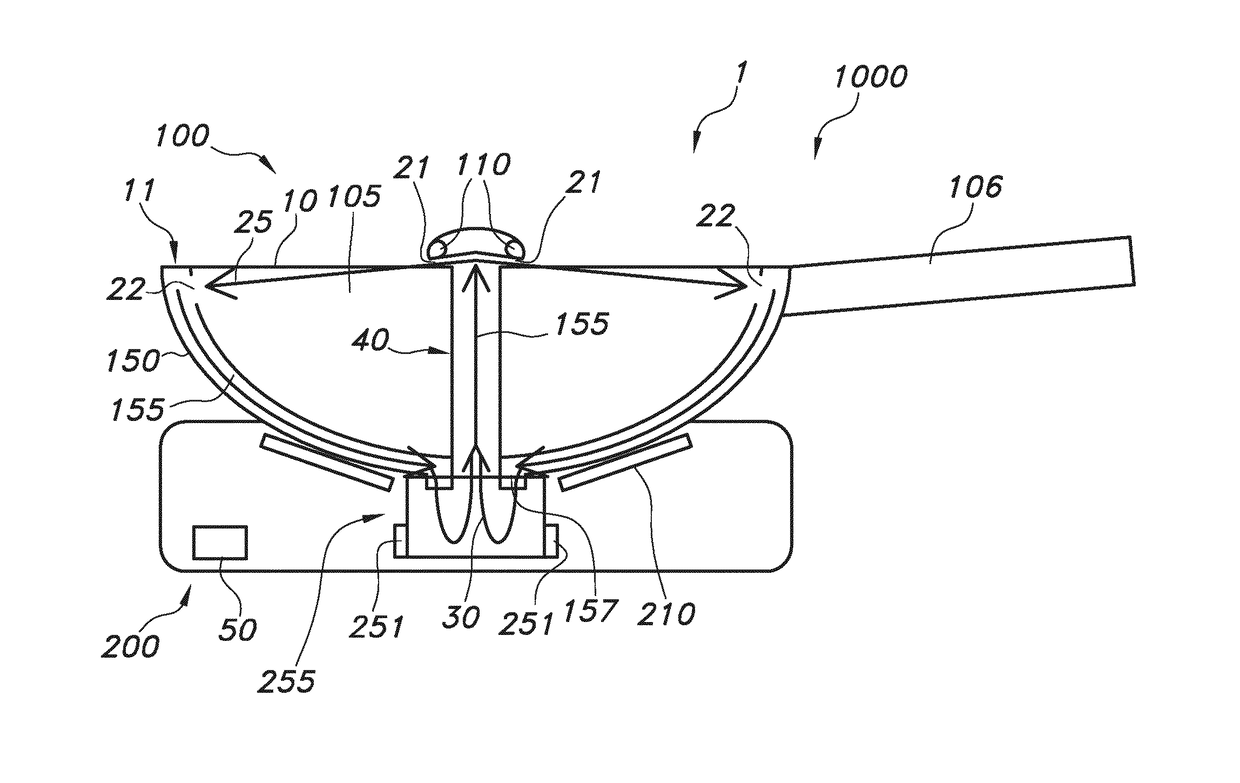

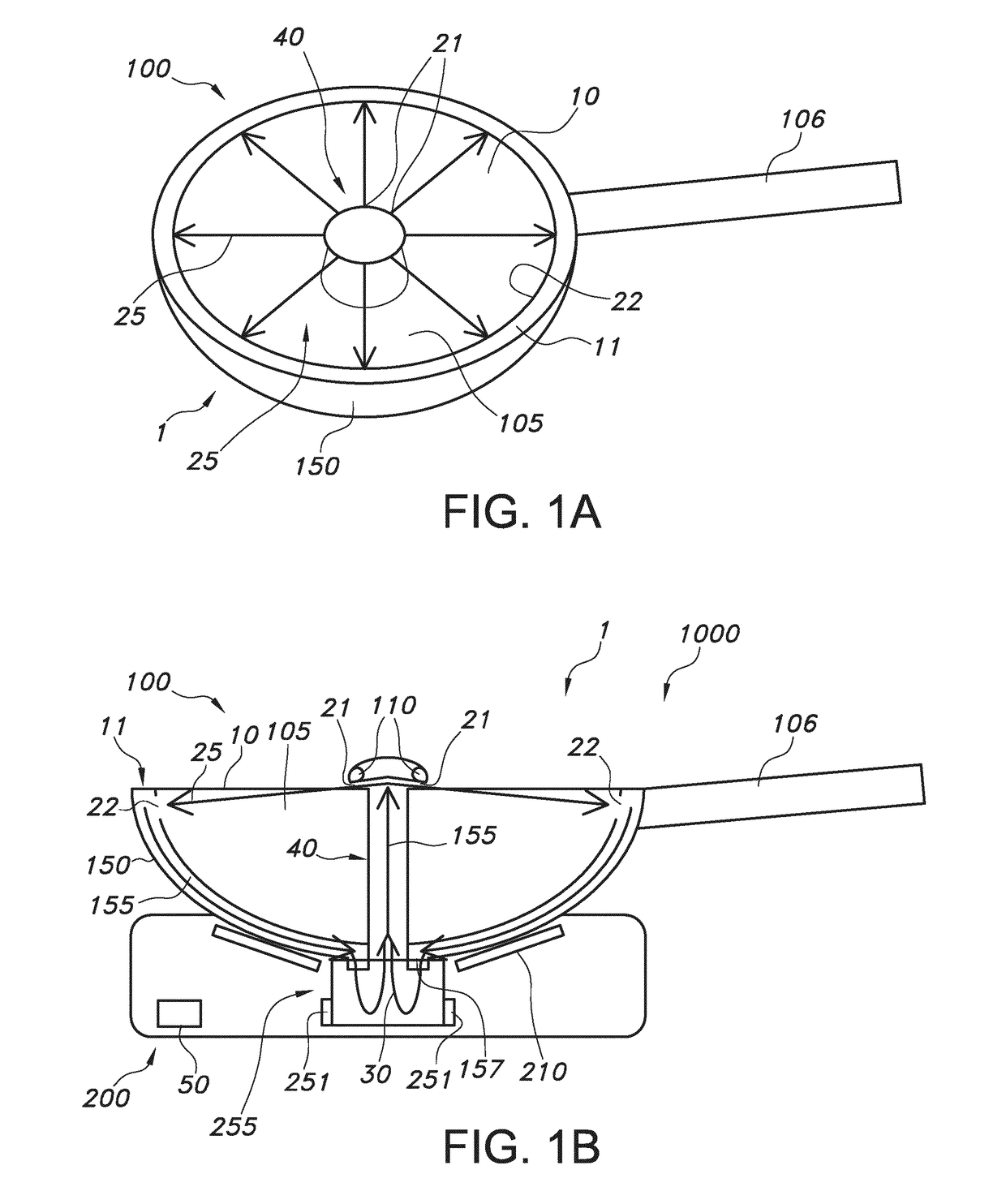

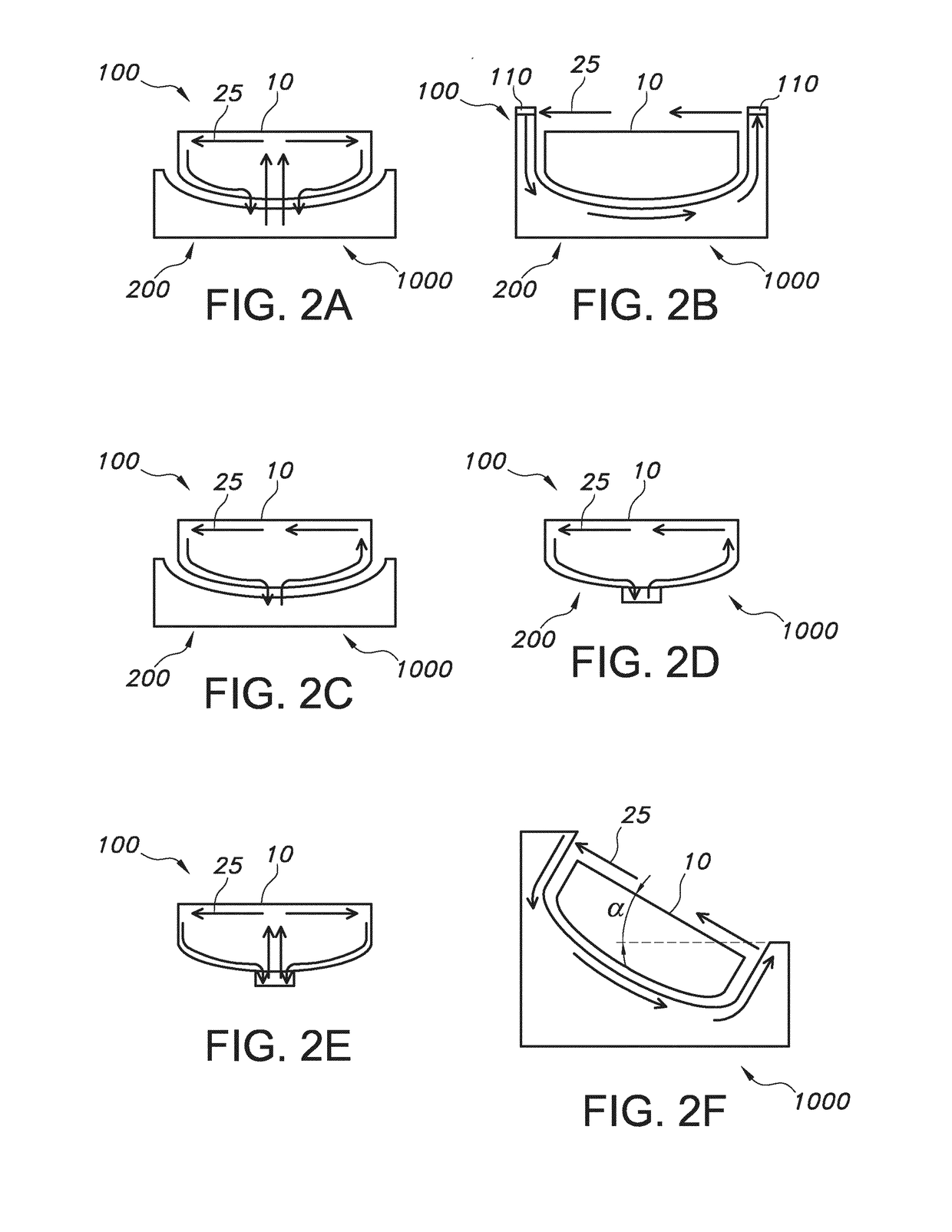

Smokeless air blade wok

InactiveUS20170367514A1Reduce escapeImprove efficiencyFood scienceCooking vessel constructionsEngineeringFood preparation

The invention provides a food preparation vessel (100) comprising a main inlet (10) for introduction of a food material into the food preparation vessel (100), wherein the food preparation vessel (100) comprises a gas flow generator outlet (21) and a gas flow receiver inlet (22), wherein the gas flow generator outlet (21) is configured to provide a gas flow (25) in the direction of the gas flow receiver inlet (22) and having a component parallel to the main inlet (10) when the gas flow generator outlet (21) is functionally coupled with a gas flow generator in operation.

Owner:KONINKLJIJKE PHILIPS NV

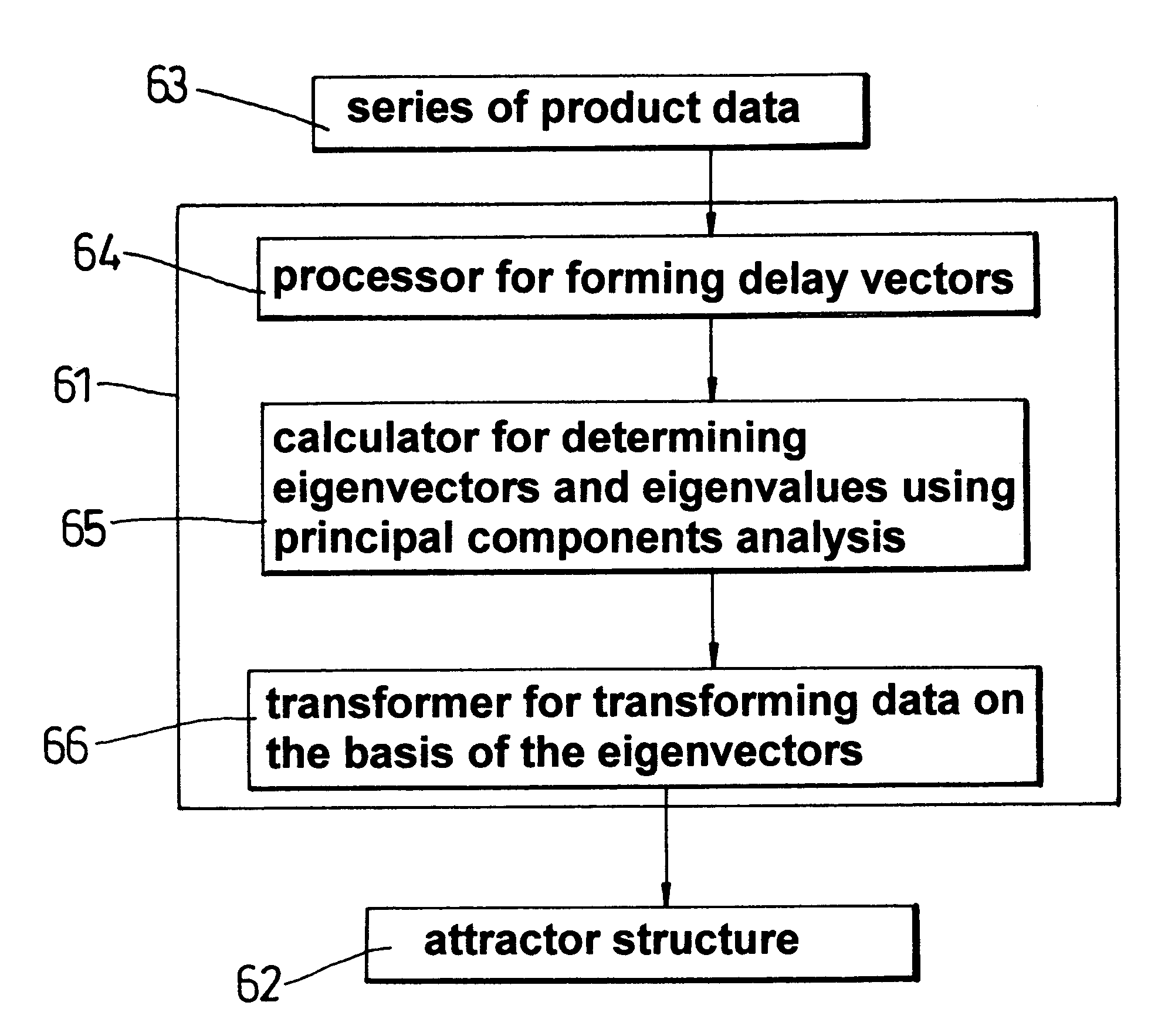

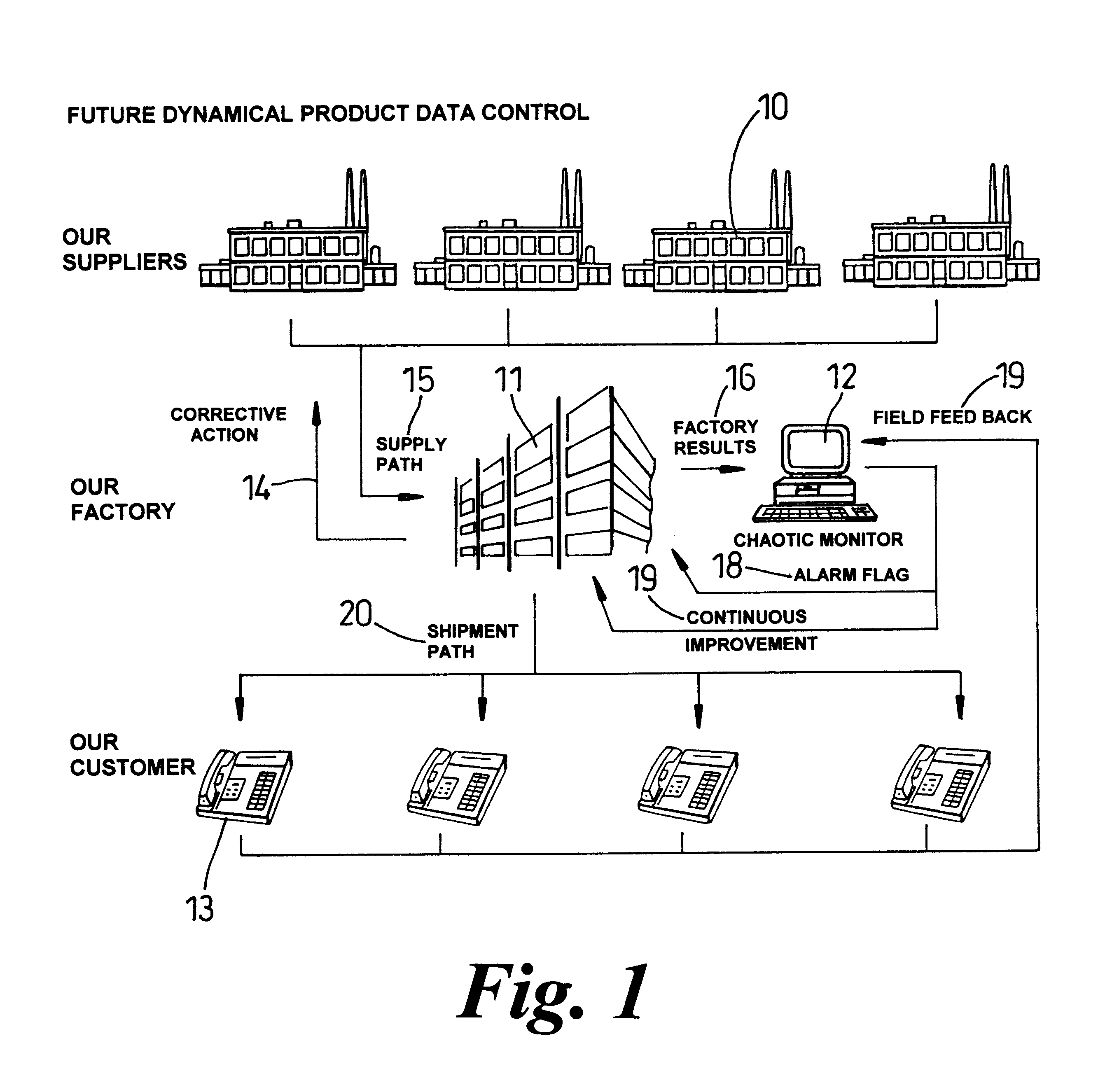

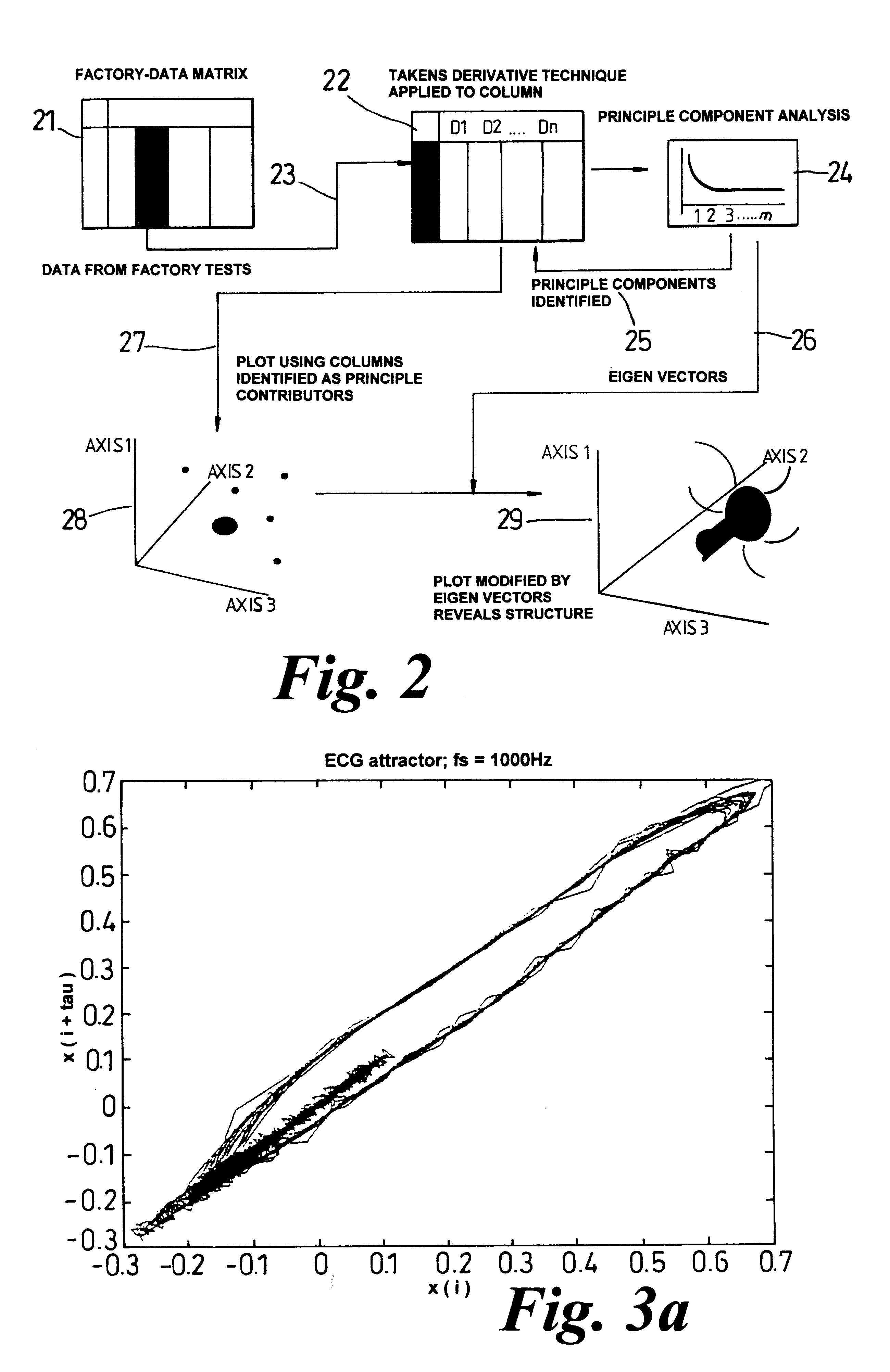

Dynamic prediction for process control

InactiveUS6370437B1Eliminate timeReduce wasteDigital computer detailsAnti-hunting elementsMotion estimationProcess control

Product data from a manufacturing process is analysed using techniques adapted from the study of chaos. Future values of a series of product data are predicted and an attractor structure is determined from the product data. This enables the manufacturing process to be monitored, controlled and analysed. Action can be taken to modify the manufacturing process using the results from the prediction and attractor structure to reduce costs and improve performance and efficiency.

Owner:CALLSTAT SOLUTIONS LLC

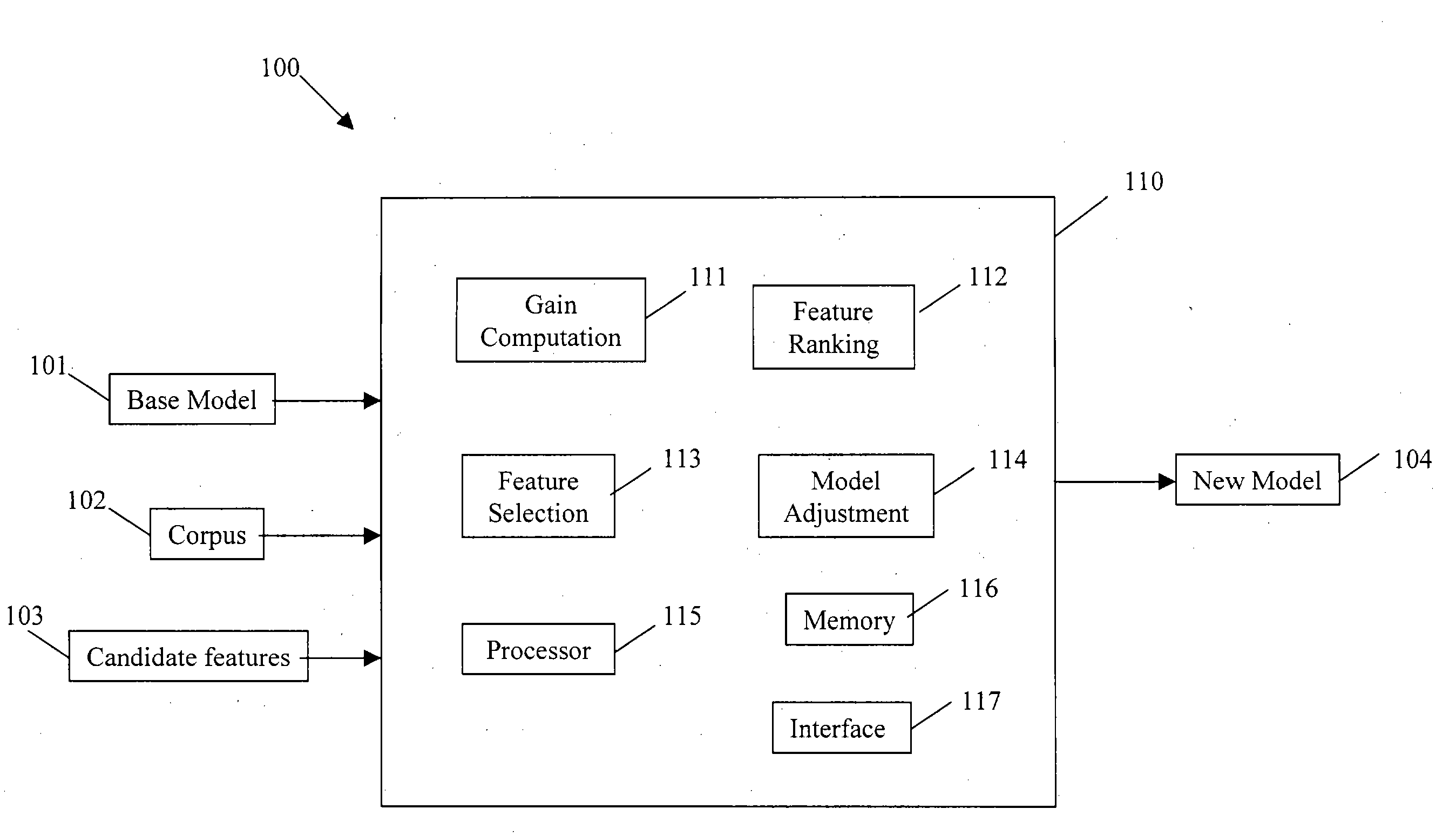

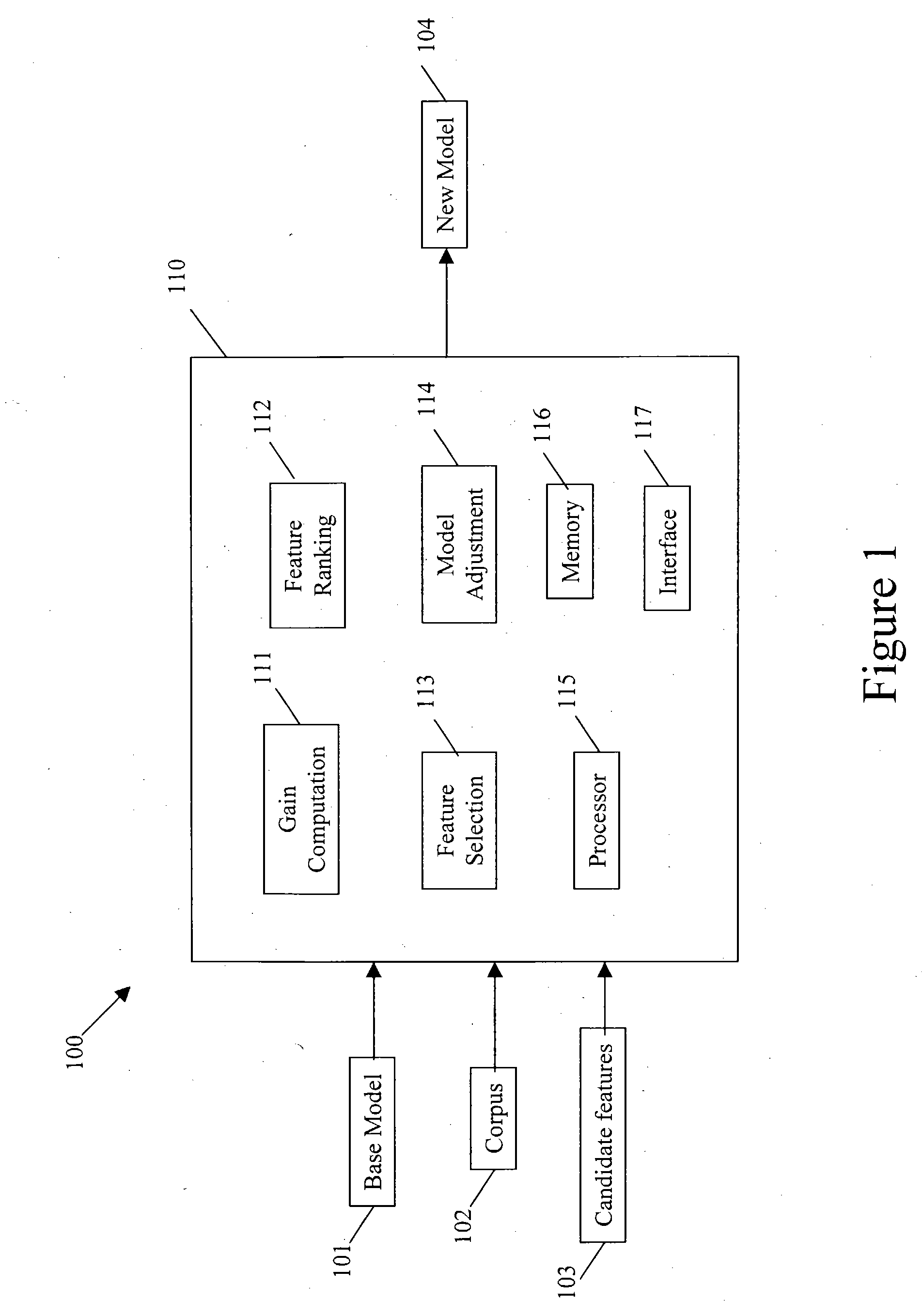

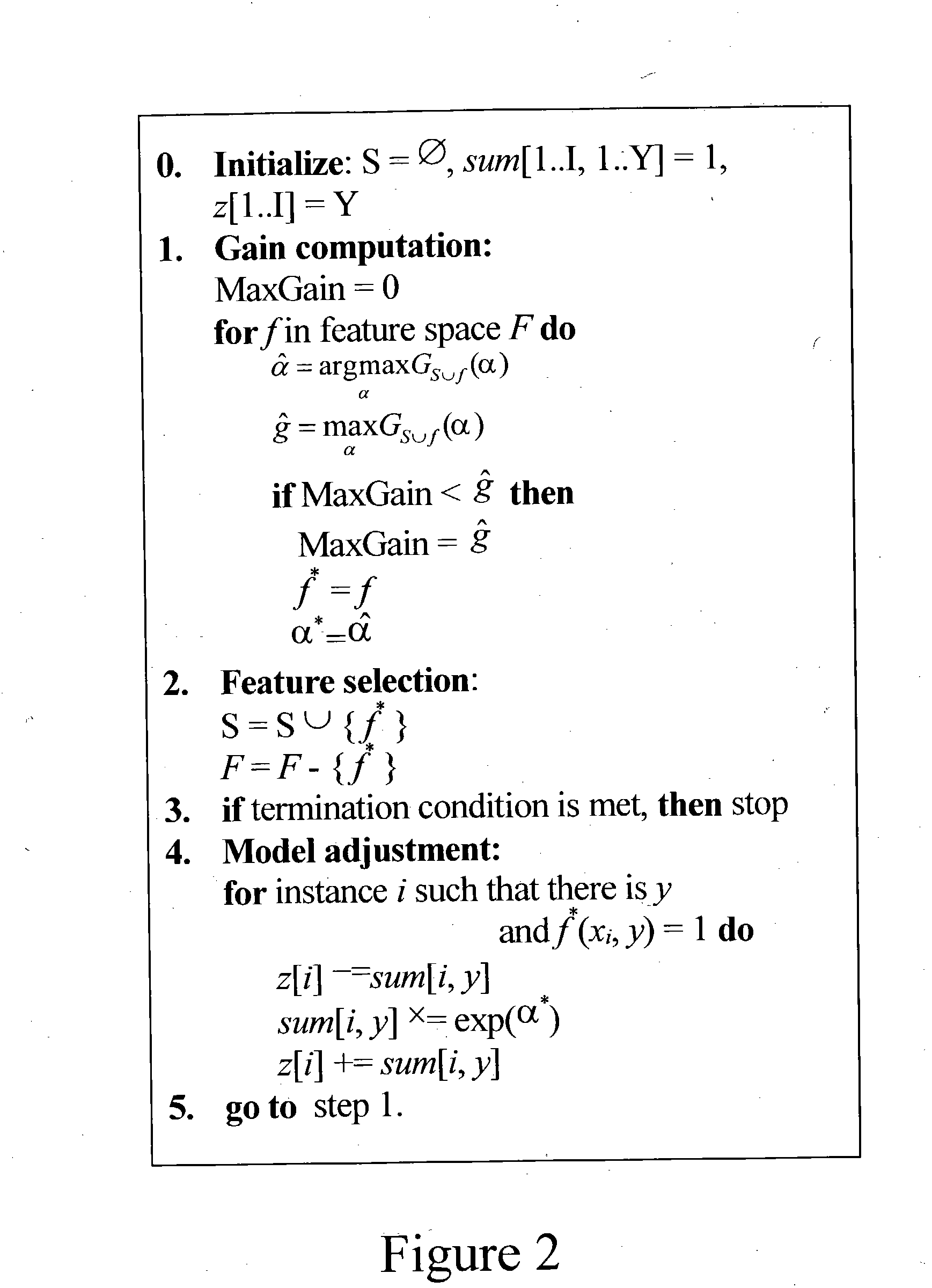

Fast feature selection method and system for maximum entropy modeling

ActiveUS20050021317A1Quick selectionIncrease choiceDigital computer detailsCharacter and pattern recognitionFeature selectionSelection method

A method to select features for maximum entropy modeling in which the gains for all candidate features are determined during an initialization stage and gains for only top-ranked features are determined during each feature selection stage. The candidate features are ranked in an ordered list based on the determined gains, a top-ranked feature in the ordered list with a highest gain is selected, and the model is adjusted using the selected using the top-ranked feature.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

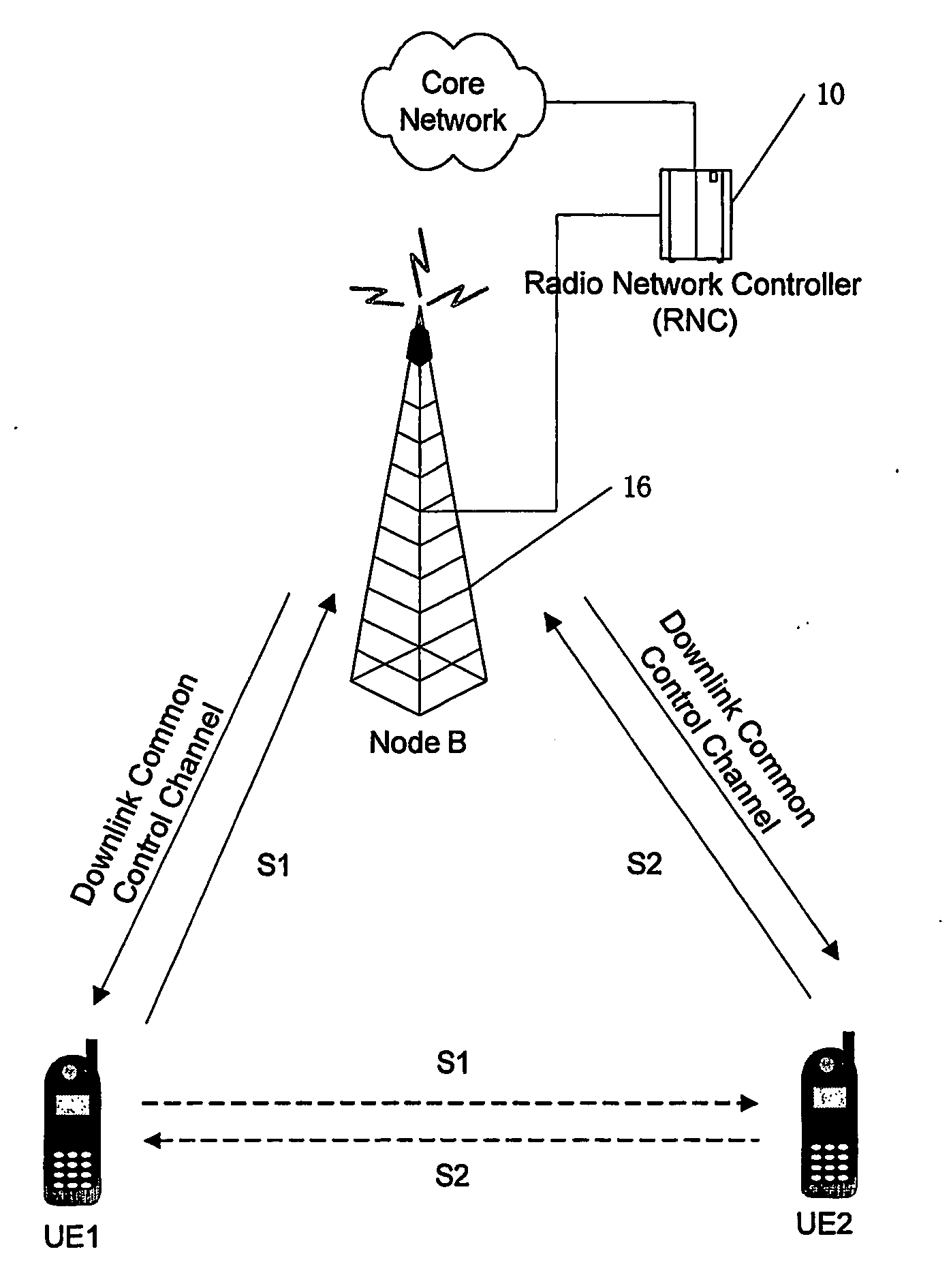

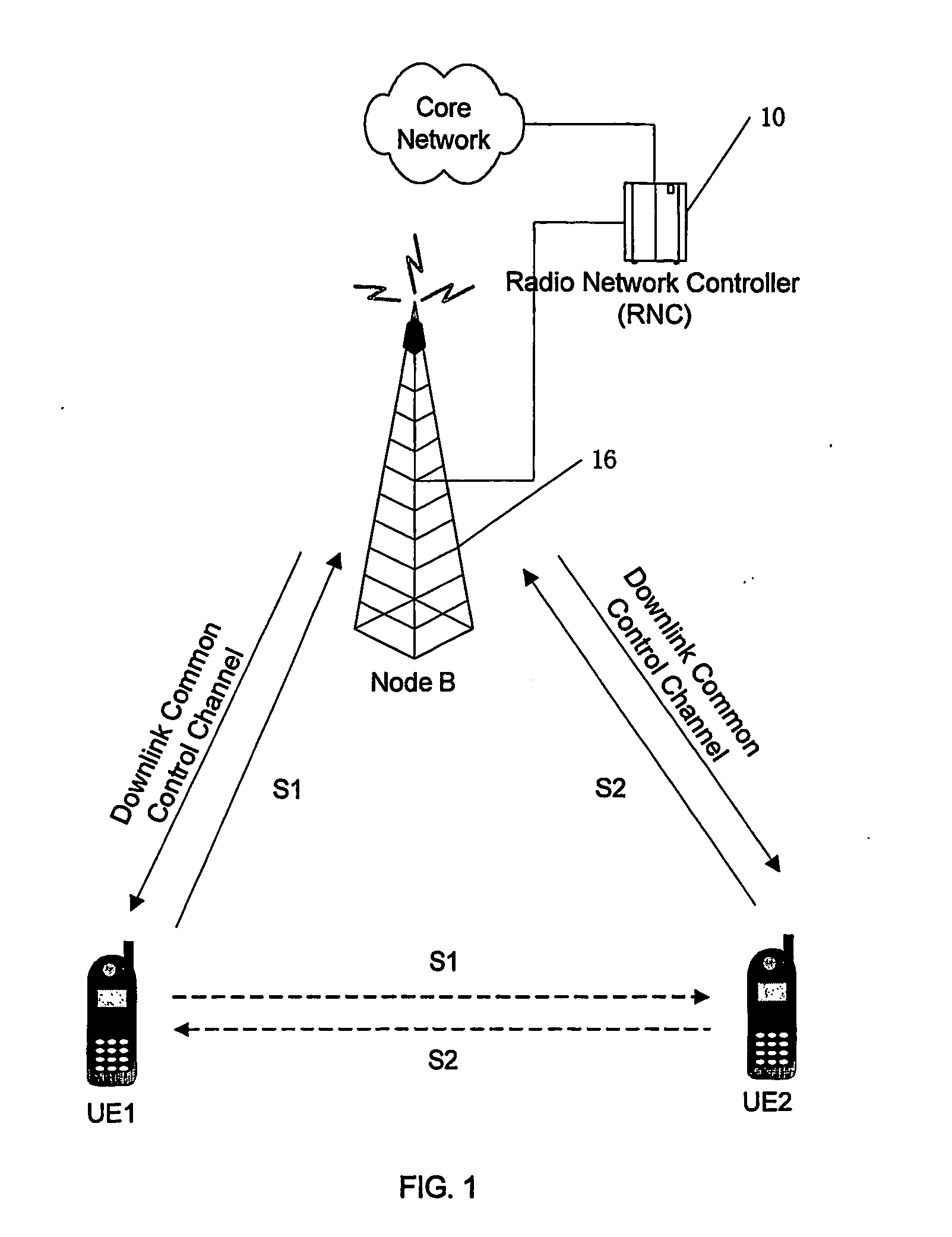

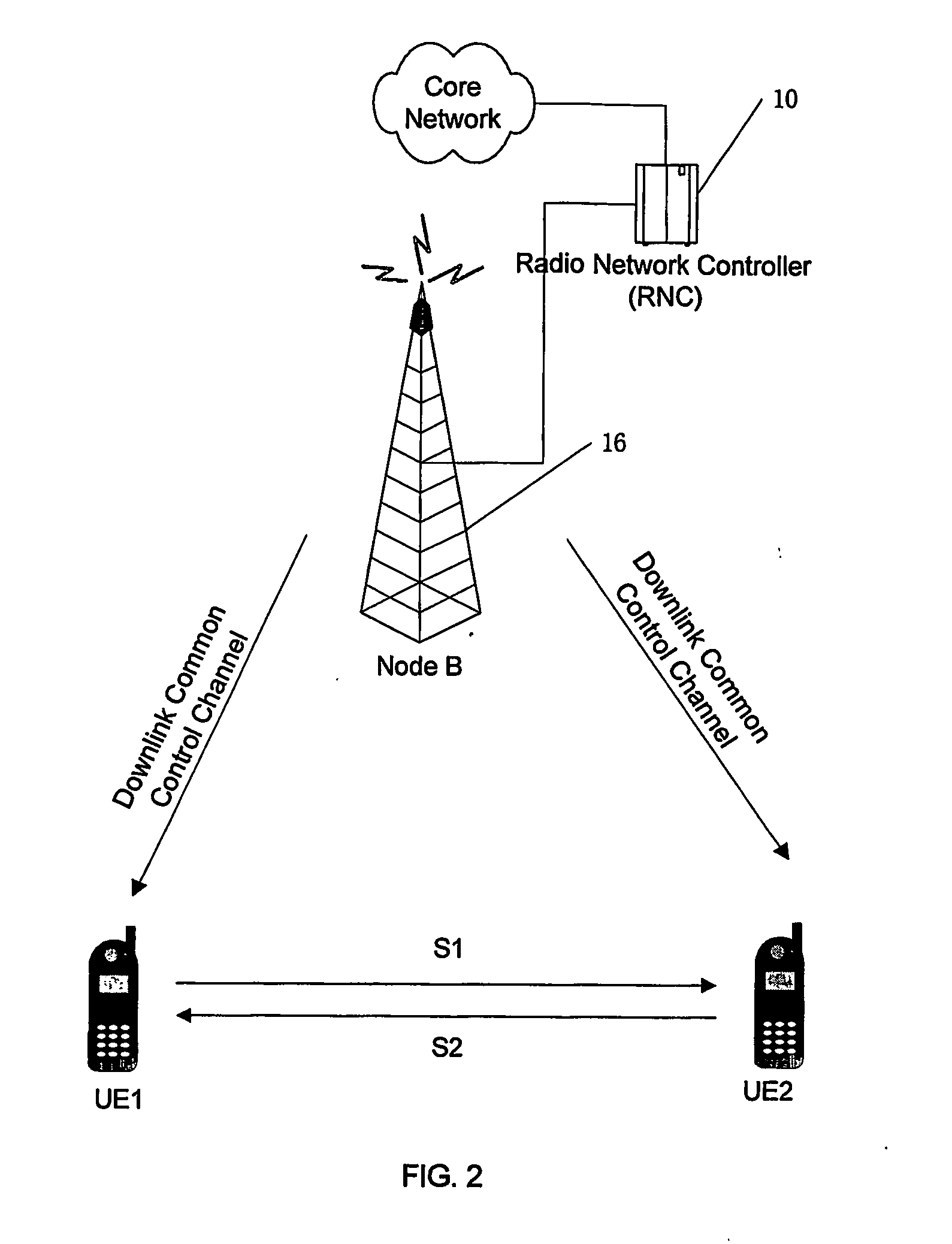

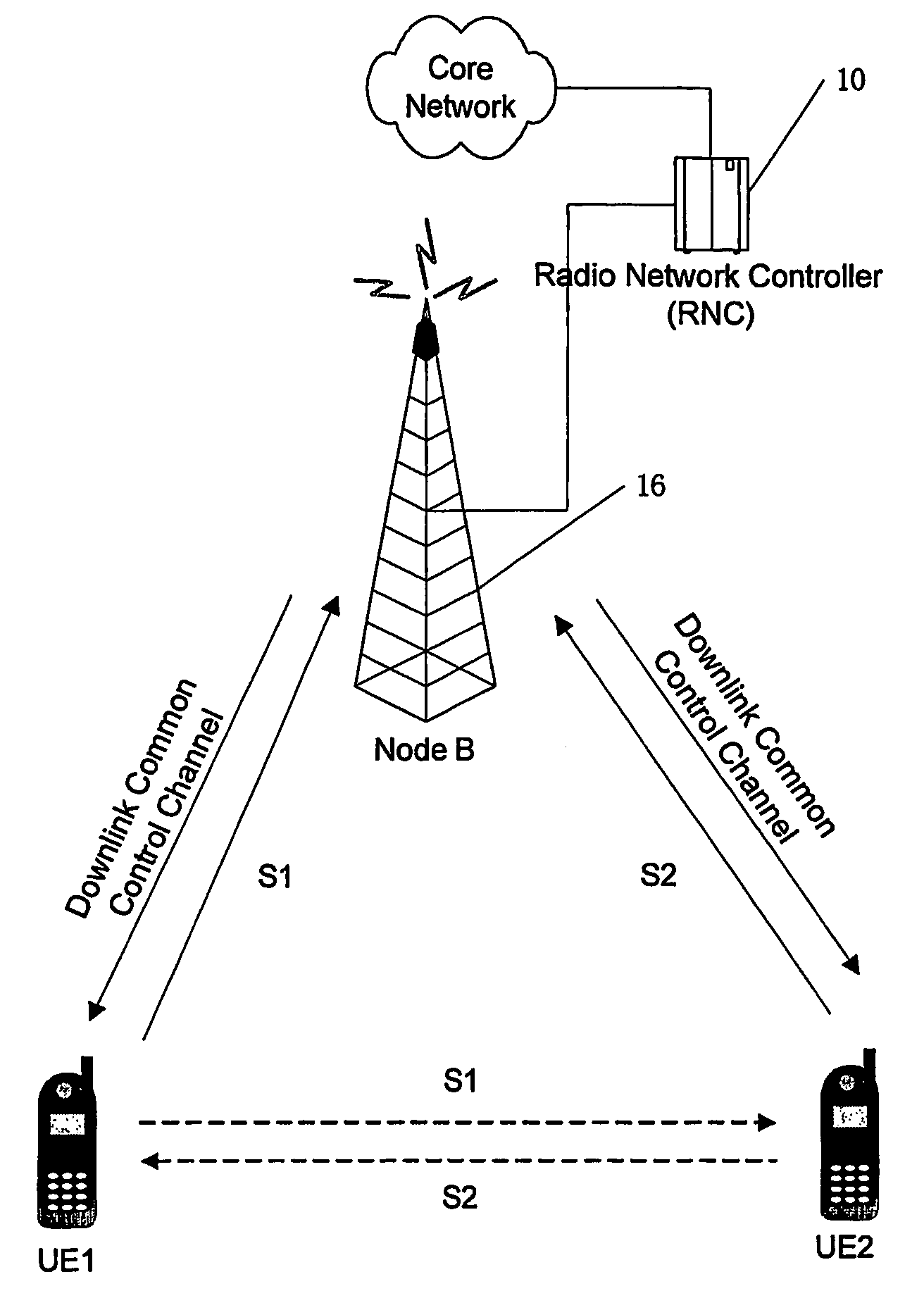

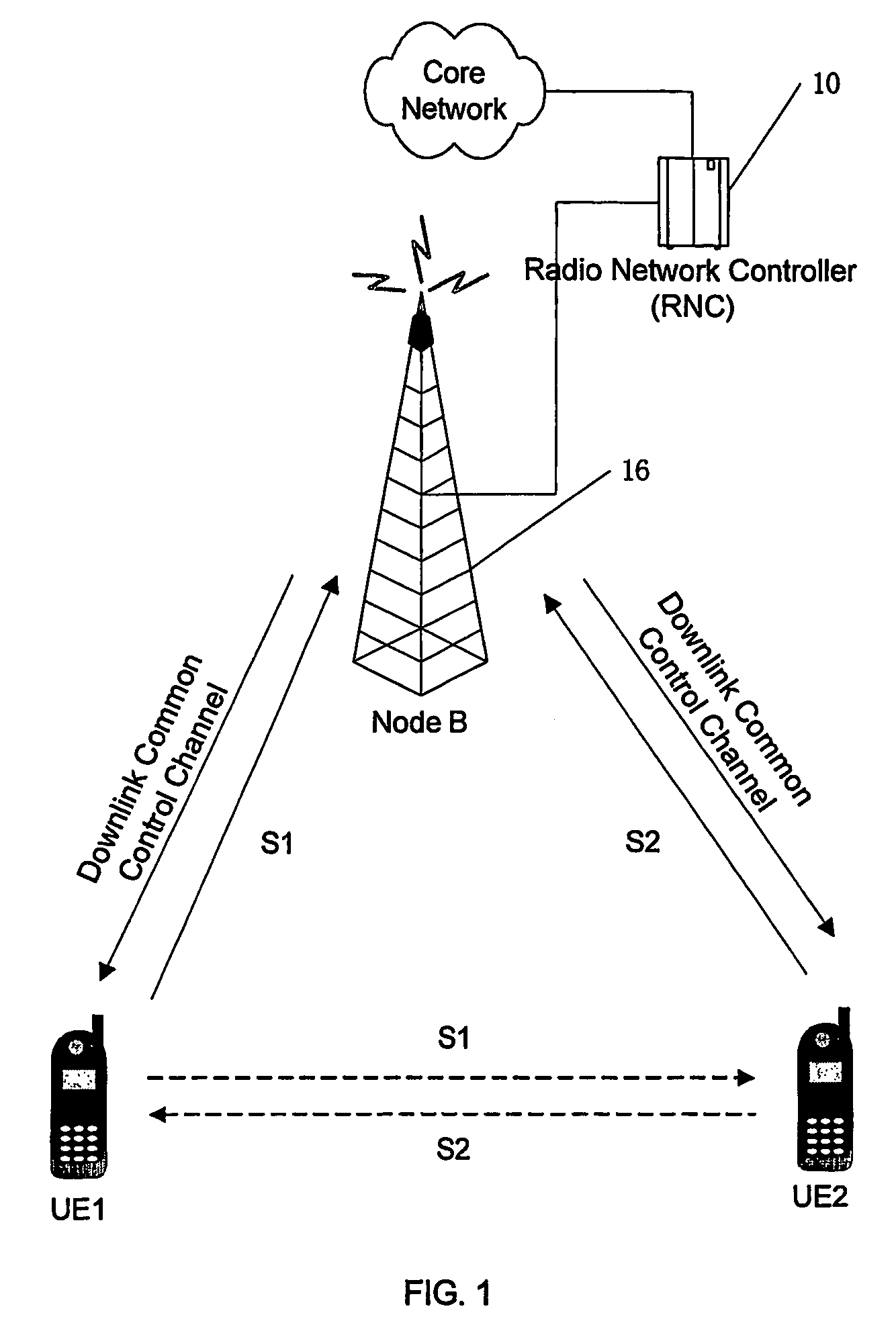

Method and system for establishing wireless peer-to-peer communications

ActiveUS20060229092A1The process is simple and effectiveSimplifying the radio resources re-allocation schemeAssess restrictionTransmission control/equalisingTelecommunicationsNetworked system

The present invention provides a wireless network system for establishing peer-to-peer communication between mobile terminals. Upon determining that peer-to-peer communication can be established between two mobile terminal, the wireless network system transmits to each of the mobile terminals information about radio resources used by the other one of the mobile terminals. Each mobile terminal then uses the radio resources information to test the characteristics of a dedicated uplink channel between the other one of the mobile terminals and the network system. Thus, no separate radio channel needs to be allocated for the channel testing. Furthermore, each mobile terminal uses the same radio resources to establish a dedicated radio channel in the peer-to-peer communication with the other one of the mobile terminals, which were previously used by itself for communication with the network system on the dedicated uplink channel. In this way, the network system does not need to allocate additional radio resources for establishing the peer-to-peer communication, thus simplifying the radio resources re-allocation scheme, while ensuring that the quality of the channels is the same as tested.

Owner:ATREUS LABS LLC

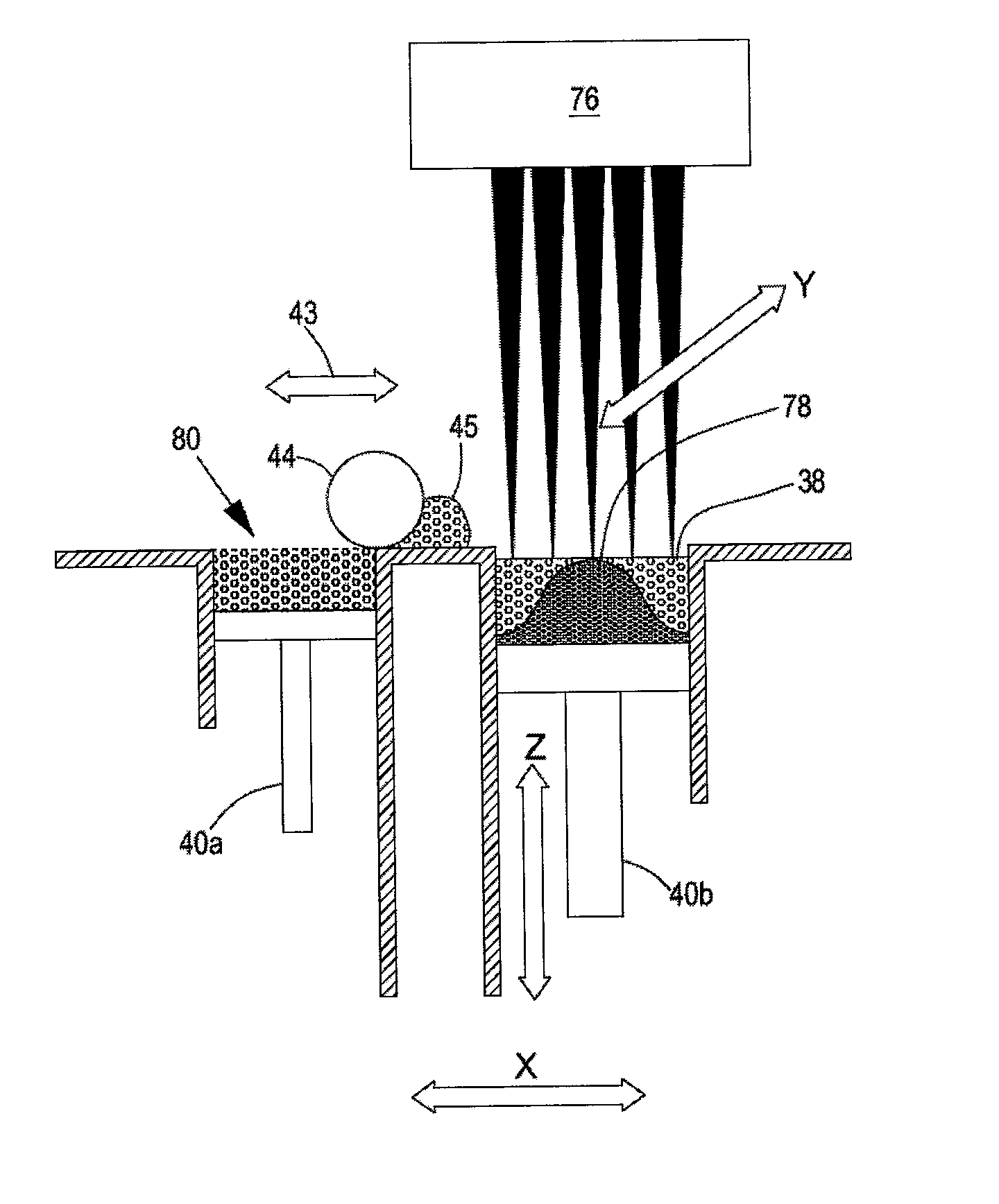

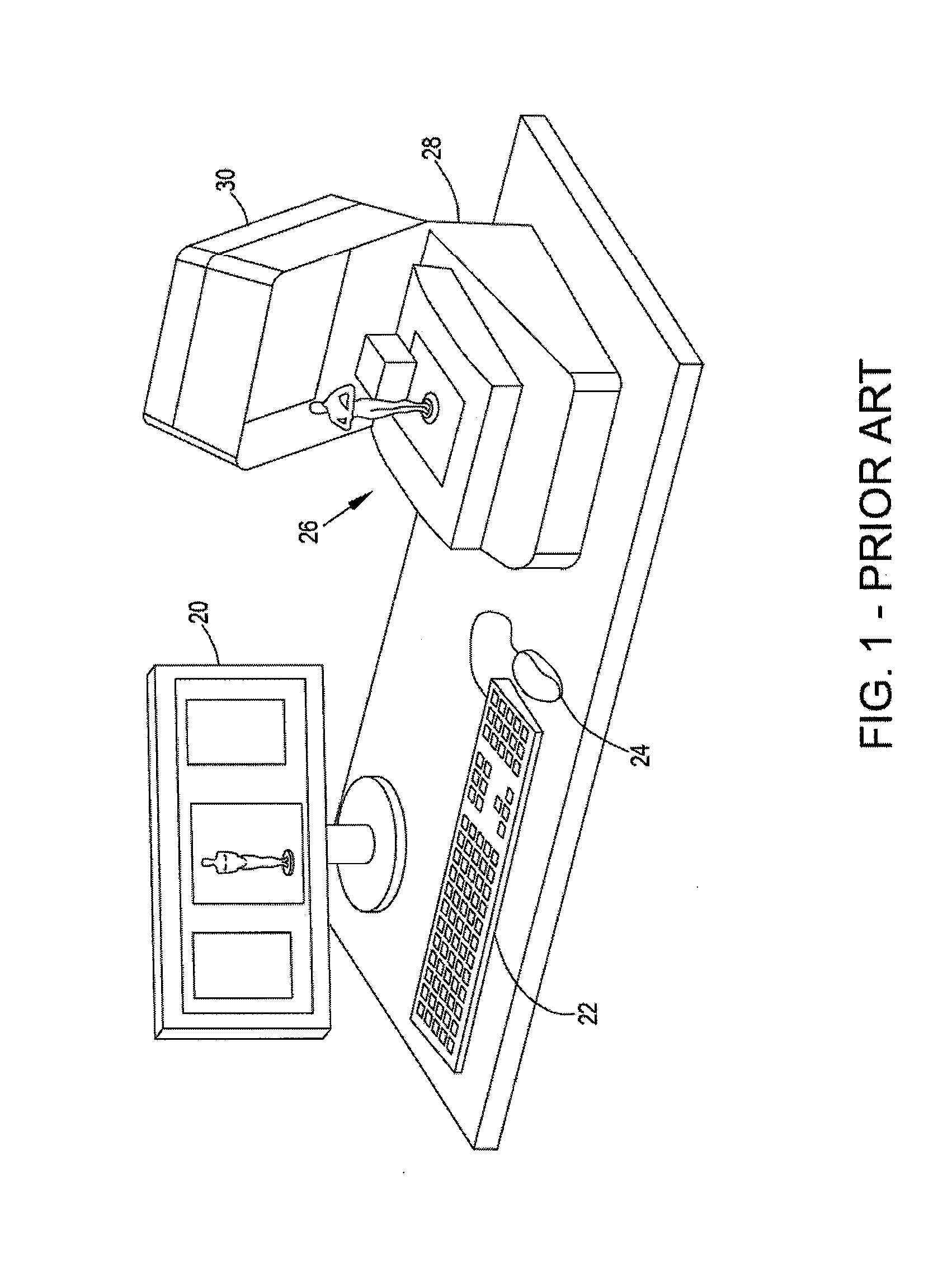

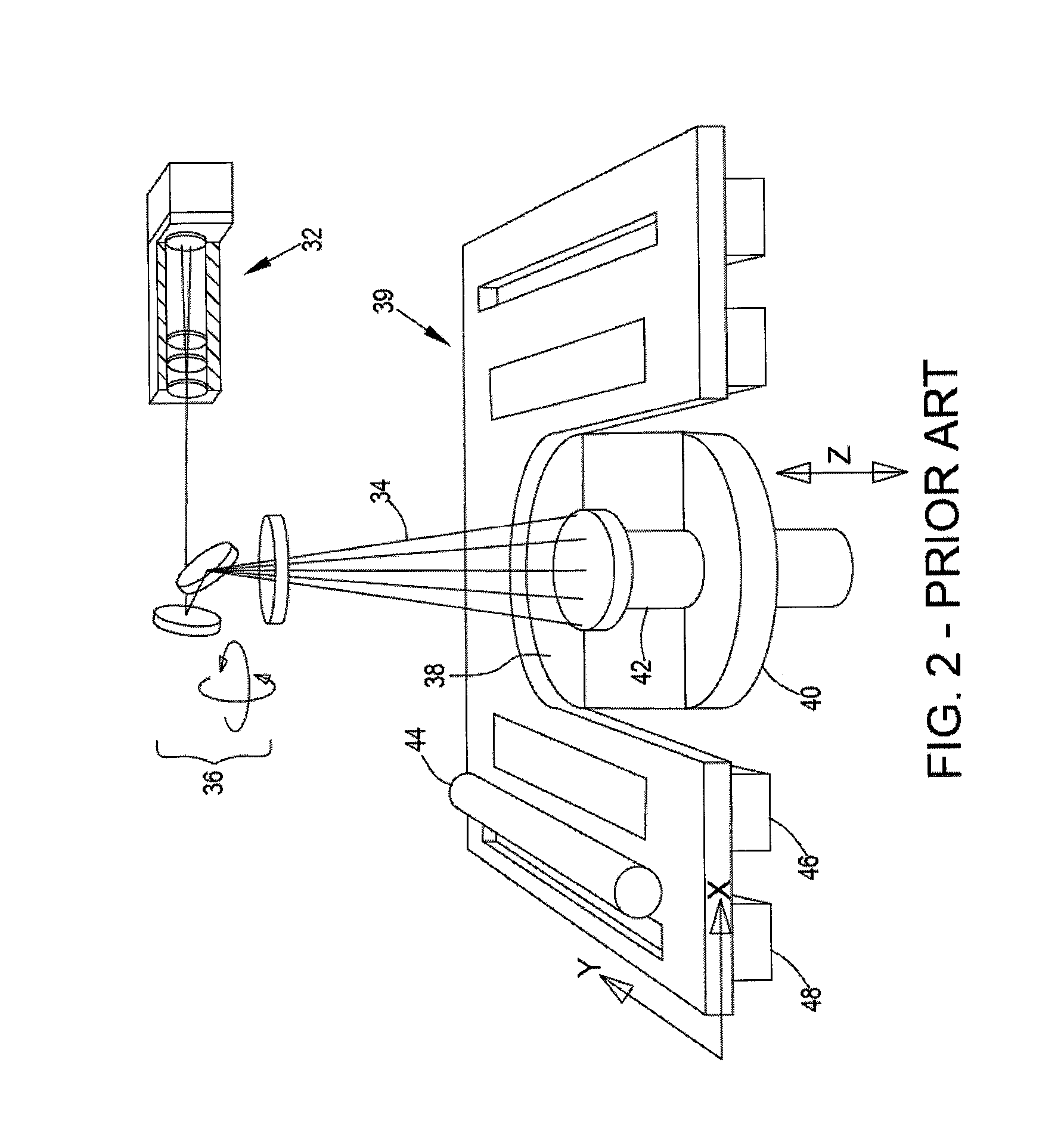

Device and a method for 3D printing and manufacturing of materials using quantum cascade lasers

ActiveUS20160082662A1More compact in sizeAbsorption of radiant energyAdditive manufacturing apparatusSemiconductor laser arrangementsChannel powerEngineering

A 3D printer device utilizing at least one Quantum Cascade Laser (QCL) image head having at least one beam focused in a focal plane of the device for building on a surface of the device a 3D model of a target object from a digital image. The inventive 3D printer is more compact in size due to the use of QCL image heads, which provides focused wavelengths of QCLs matching the absorption properties in plastics for more efficient absorption of the radiant energy. Each QCL channel power in the inventive 3D printer can be doubled by combining two lasers with a polarization beam splitter. The QCL image head is provided with Pulse Width Modulation (PWM) for compensating for imaging speed. The invention includes a method for scaling up the building speed of 3D printing regardless of detail level. The invention discloses an affordable 3D printer using QCL technology while maintaining high standards of resolution, use of quality materials, and rapid building speeds.

Owner:3DM DIGITAL MFG LTD

Method and system for establishing wireless peer-to-peer communications

ActiveUS7283832B2The process is simple and effectiveSimplifying the radio resources re-allocation schemeTransmission control/equalisingAssess restrictionTelecommunicationsNetworked system

The present invention provides a wireless network system for establishing peer-to-peer communication between mobile terminals. Upon determining that peer-to-peer communication can be established between two mobile terminal, the wireless network system transmits to each of the mobile terminals information about radio resources used by the other one of the mobile terminals. Each mobile terminal then uses the radio resources information to test the characteristics of a dedicated uplink channel between the other one of the mobile terminals and the network system. Thus, no separate radio channel needs to be allocated for the channel testing. Furthermore, each mobile terminal uses the same radio resources to establish a dedicated radio channel in the peer-to-peer communication with the other one of the mobile terminals, which were previously used by itself for communication with the network system on the dedicated uplink channel. In this way, the network system does not need to allocate additional radio resources for establishing the peer-to-peer communication, thus simplifying the radio resources re-allocation scheme, while ensuring that the quality of the channels is the same as tested.

Owner:ATREUS LABS LLC

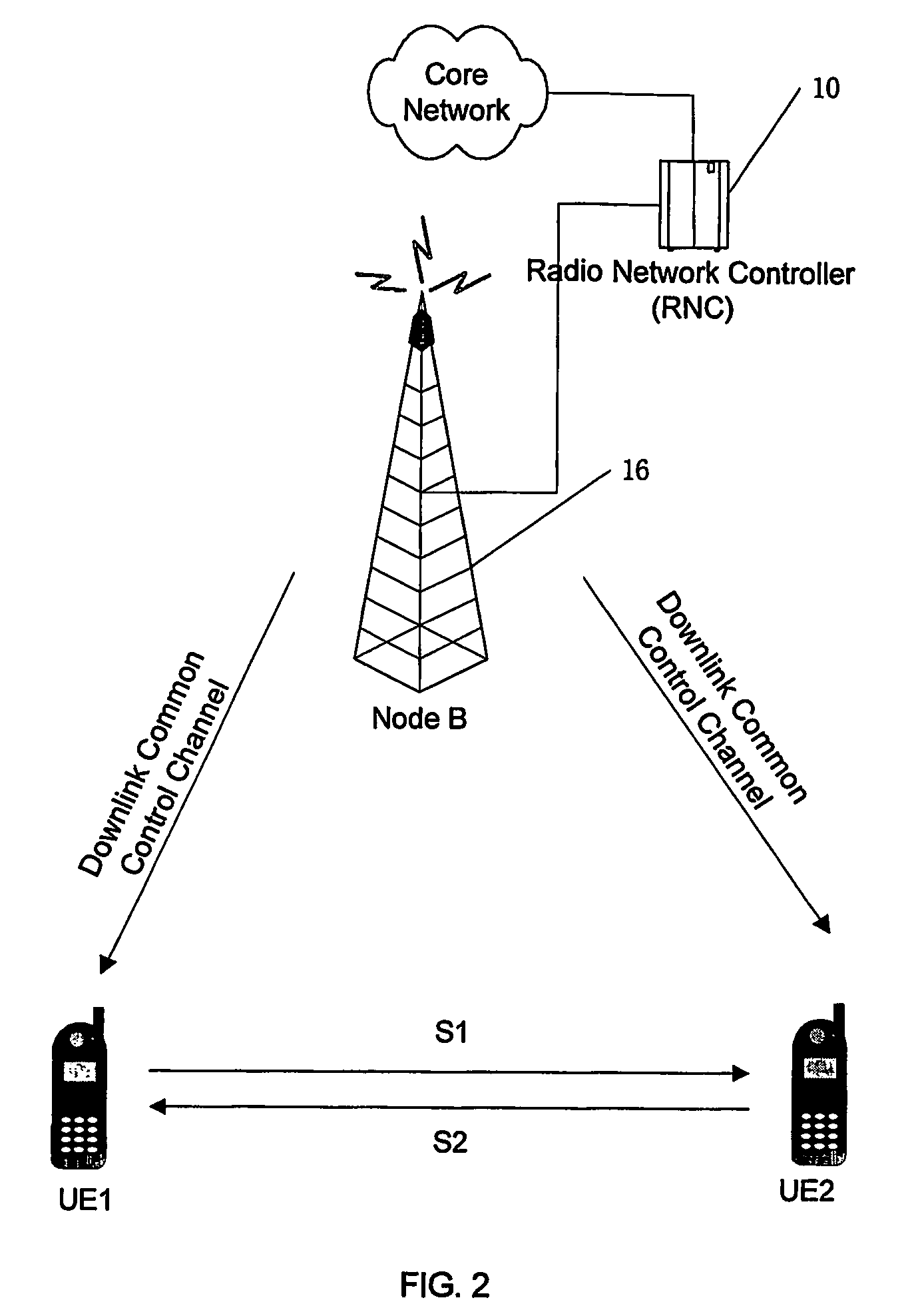

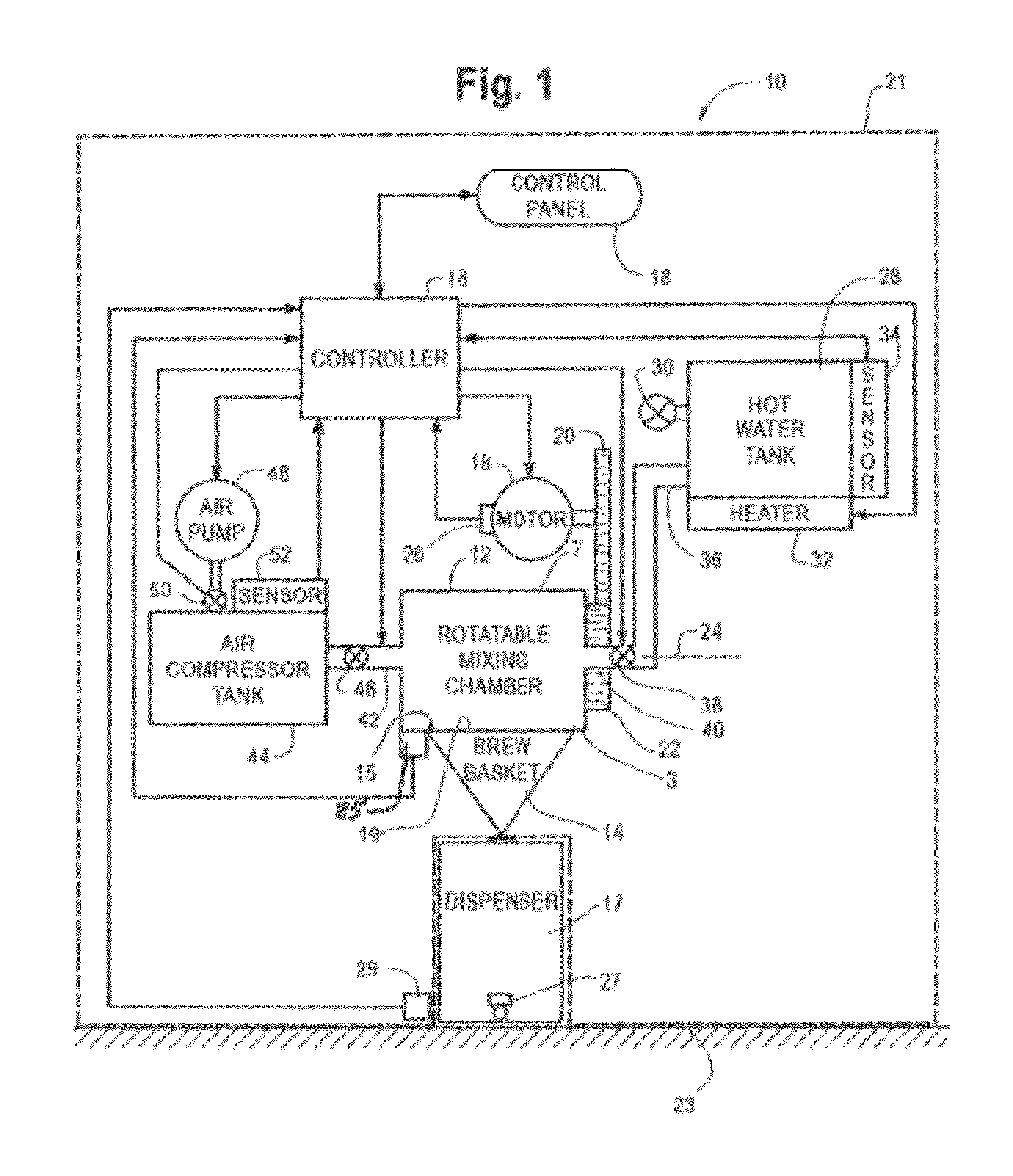

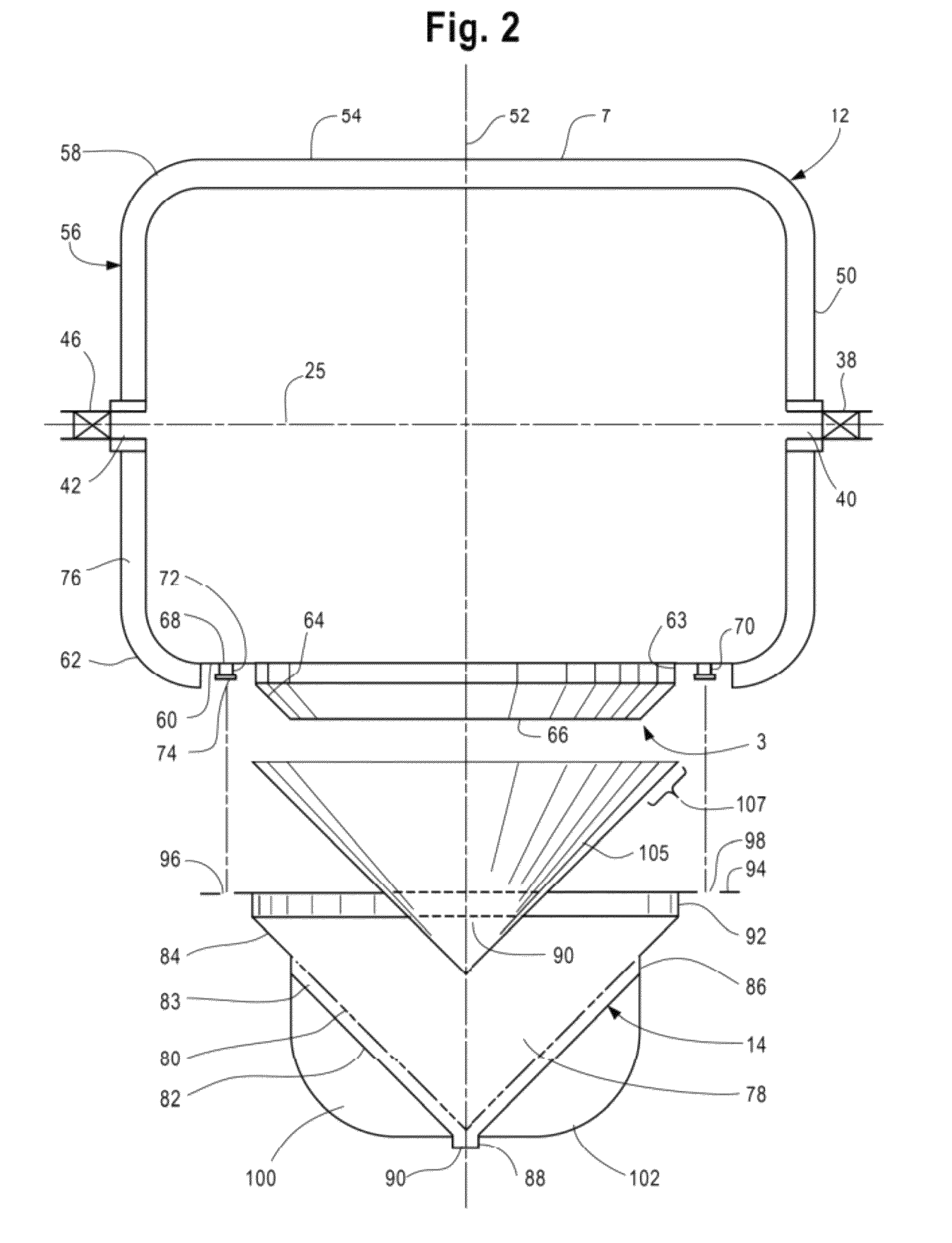

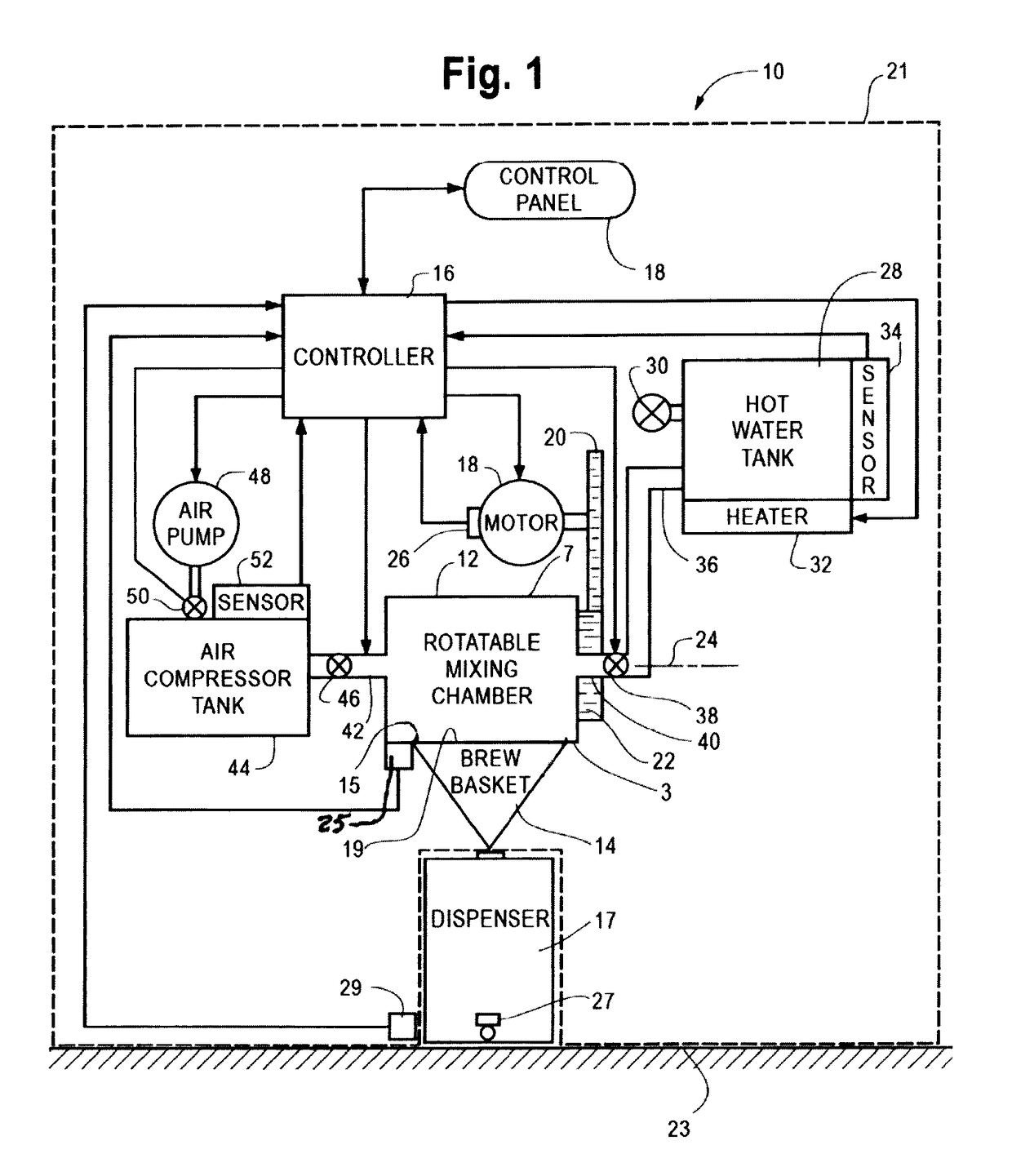

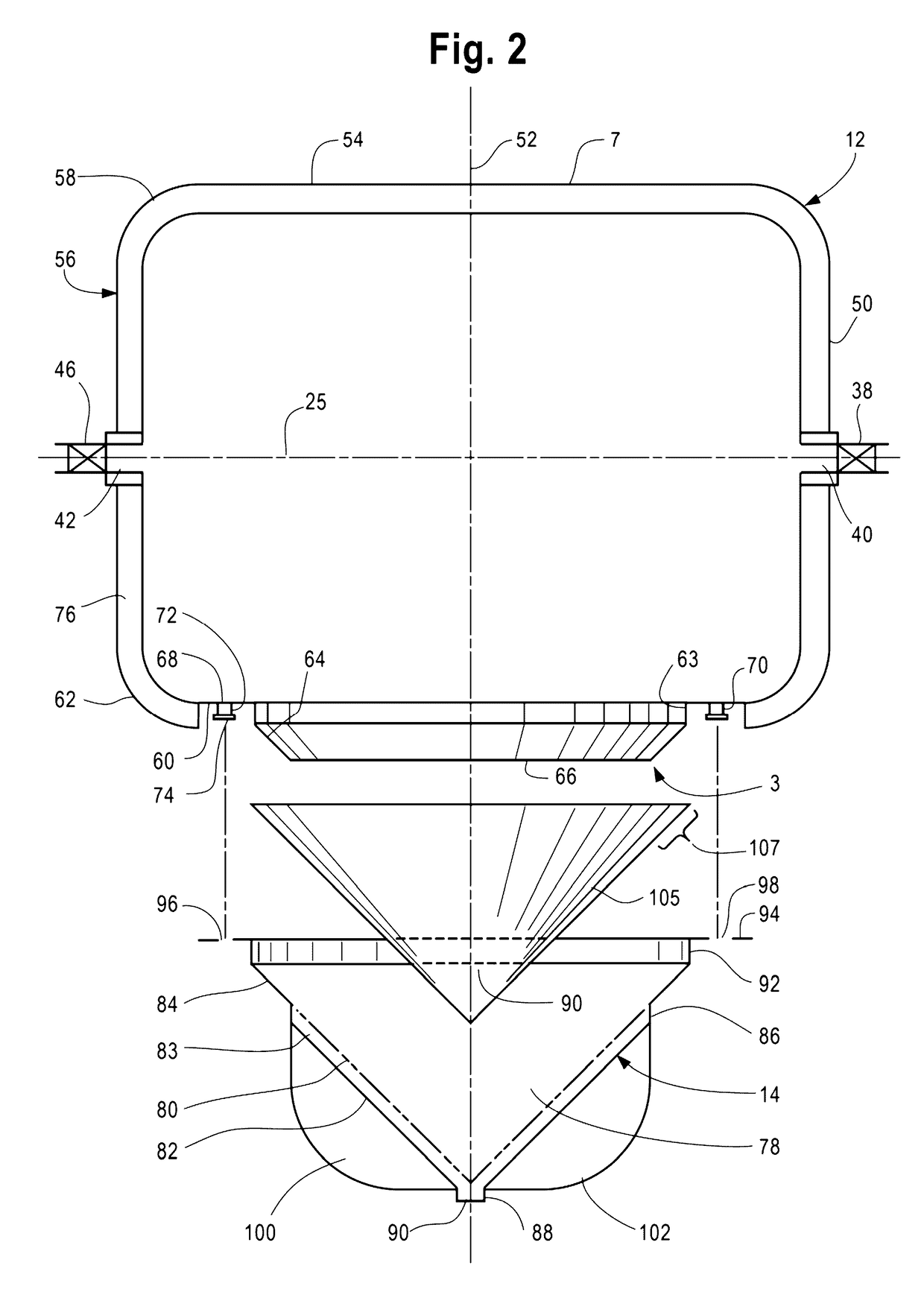

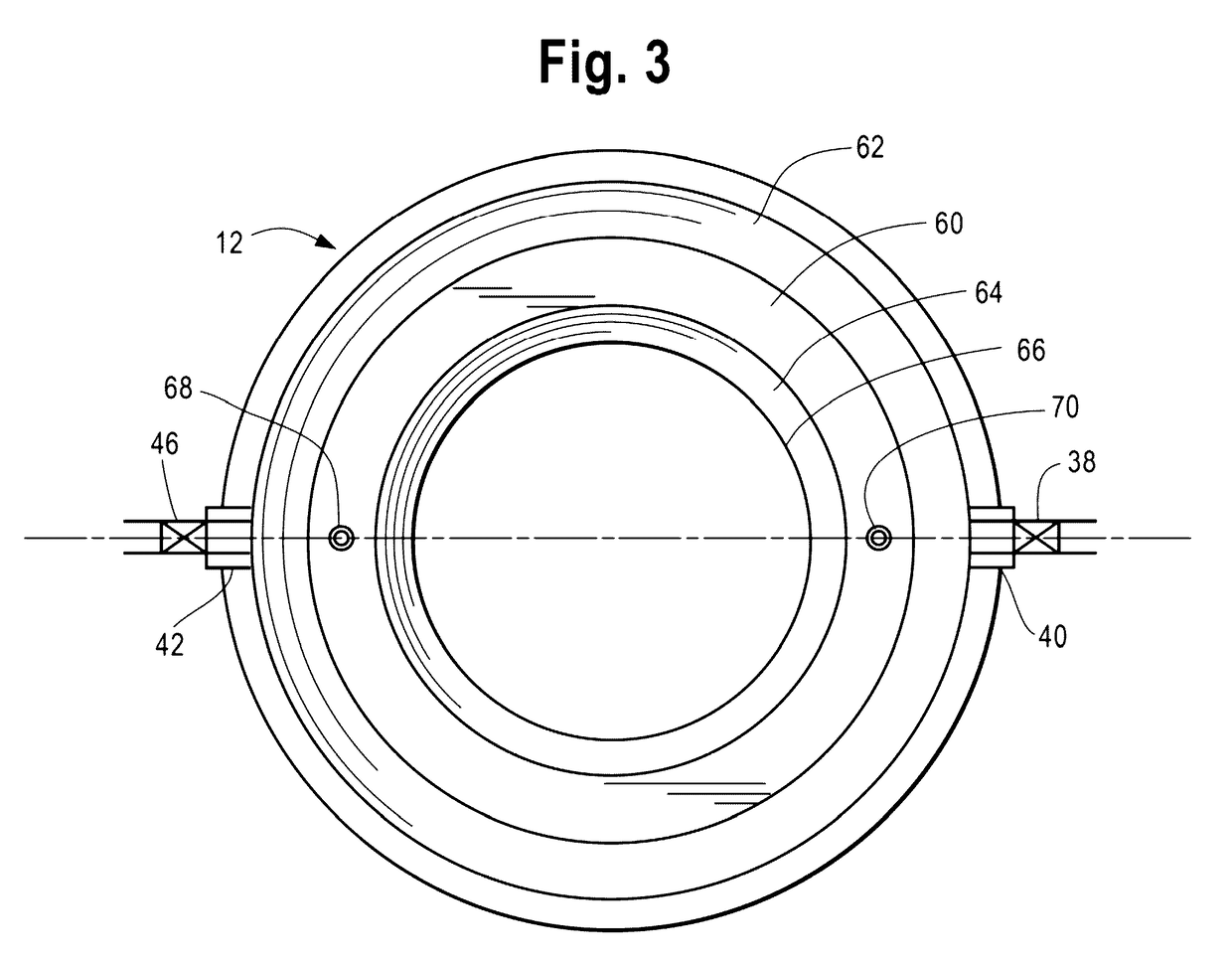

Automated french press-like quality producing, high volume, automated, electric beverage maker

ActiveUS8286547B1Uniform extractionReduce batch sizeBeverage vesselsUnwanted substance removalAdditive ingredientMixing chamber

A French press-like quality high volume, electrical, automatic beverage brewer (10) with a rotatable mixing chamber (12) for mixing water (109) from a hot water tank (28) with dry beverage ingredient (108) having a closed top (7) and an open bottom (3, 66) to which is releasably mounted a brew basket (14) with an open top (19) for fluid communication with the mixing chamber (12) through the open bottom (3, 66). Before mounting, the brew basket (14) is loaded with a filter (105) and dry beverage ingredient (109). The mixing chamber (12) with the brew basket (14) attached is then automatically turned upside down (FIG. 6) to dump the dry beverage ingredient (109) out of the filter (105) and onto the closed top (7) of the rotatable mixing chamber (12). A preselected amount of water (109) is then infused into the mixing chamber (12) to a level beneath the open bottom (3) and filter (105) and onto the dry beverage ingredient (109) for mixing therewith. After a preselected mixing time period is passed the mixing chamber (12) and mounted brew basket (14) is automatically turned right side up to pass the beverage (110) through the filter (105) and out of the drain hole (90) of the brew basket (14). After the mixing chamber (12) has been returned to an upright position, pressurized air (44,46,48) is automatically injected into the mixing chamber (12) to hasten the passage of beverage (110) through the filter (105) and out of the drain hole (90).

Owner:FOOD EQUIP TECH

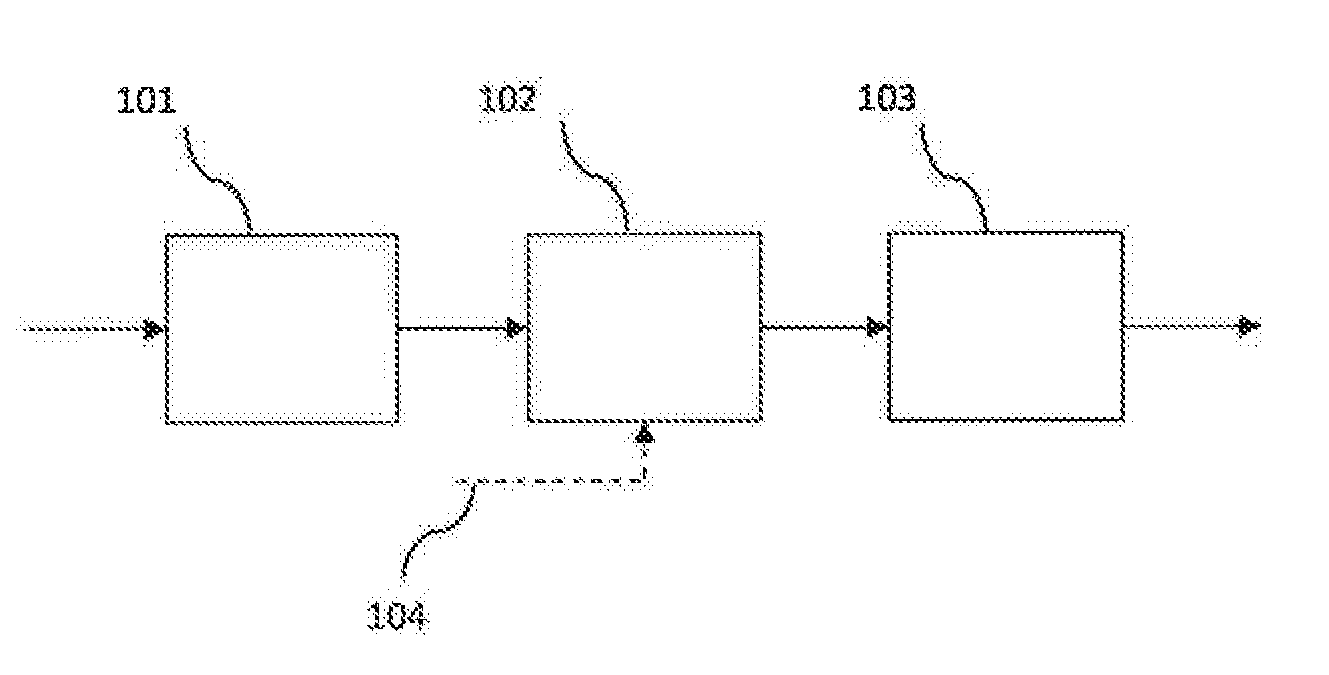

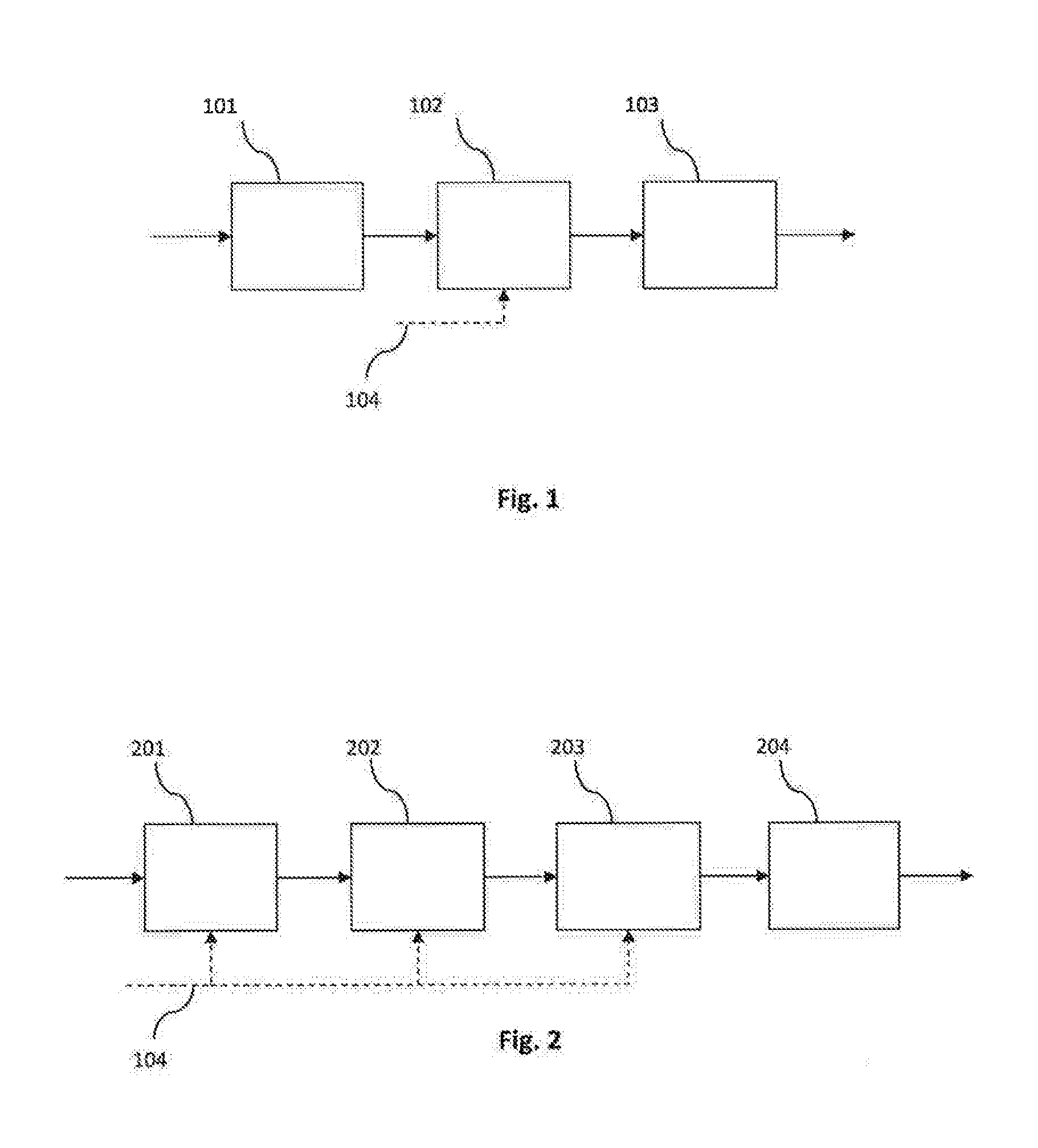

Cross product enhanced subband block based harmonic transposition

ActiveUS20130182870A1Promote resultsLow intermodulationGain controlSpeech analysisHarmonicImage resolution

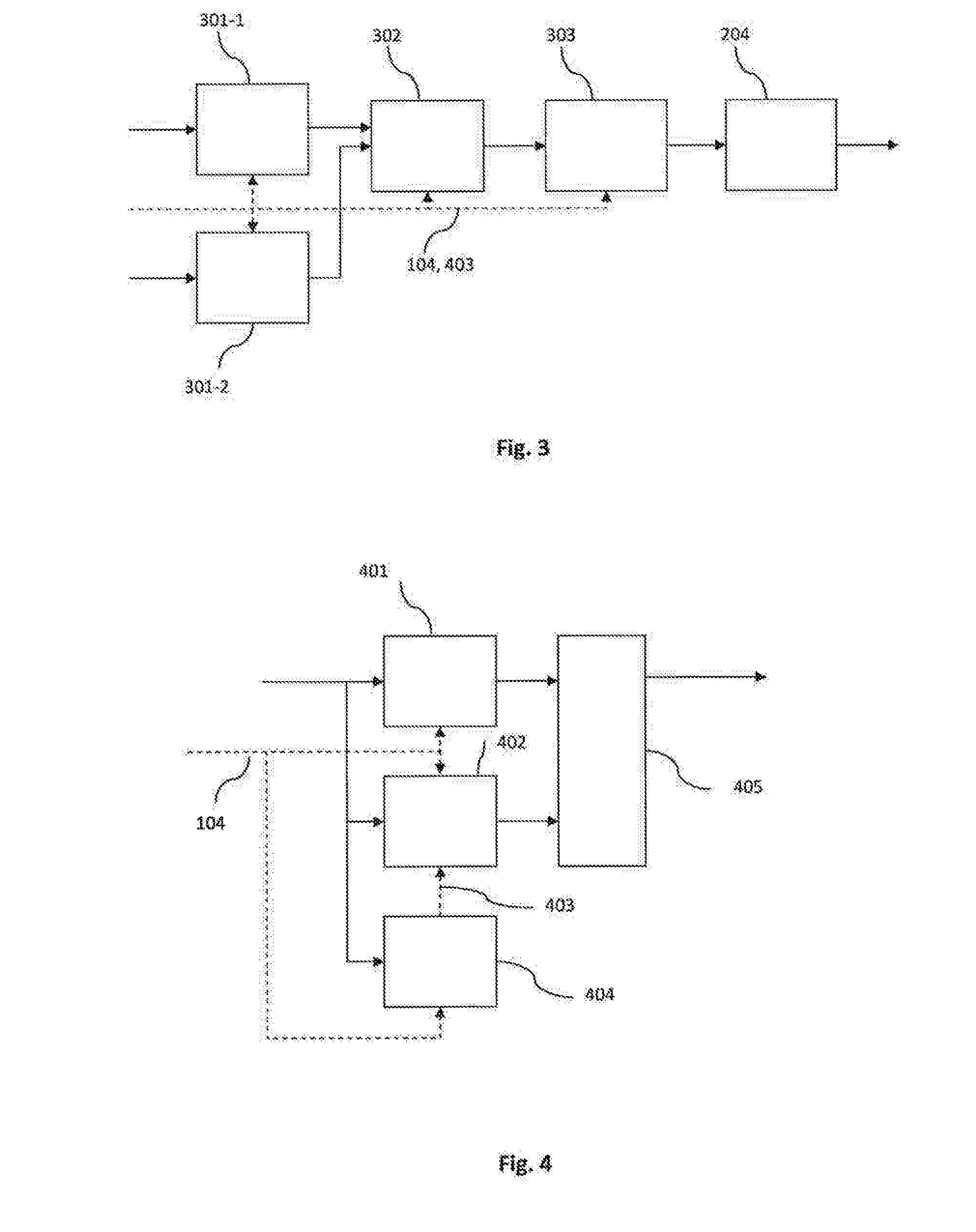

The invention provides an efficient implementation of cross-product enhanced high-frequency reconstruction (HFR), wherein a new component at frequency QΩ+Ωq is generated on the basis of existing components at Ω and QΩ+Ωq. The invention provides a block-based harmonic transposition, wherein a time block of complex subband samples is processed with a common phase modification. Superposition of several modified samples has the net effect of limiting undesirable intermodulation products, thereby enabling a coarser frequency resolution and / or lower degree of oversampling to be used. In one embodiment, the invention further includes a window function suitable for use with block-based cross-product enhanced HFR. A hardware embodiment of the invention may include an analysis filter bank (101), a subband processing unit (102) configurable by control data (104) and a synthesis filter bank (103).

Owner:DOLBY INT AB

Communication relay apparatus and communication receiver

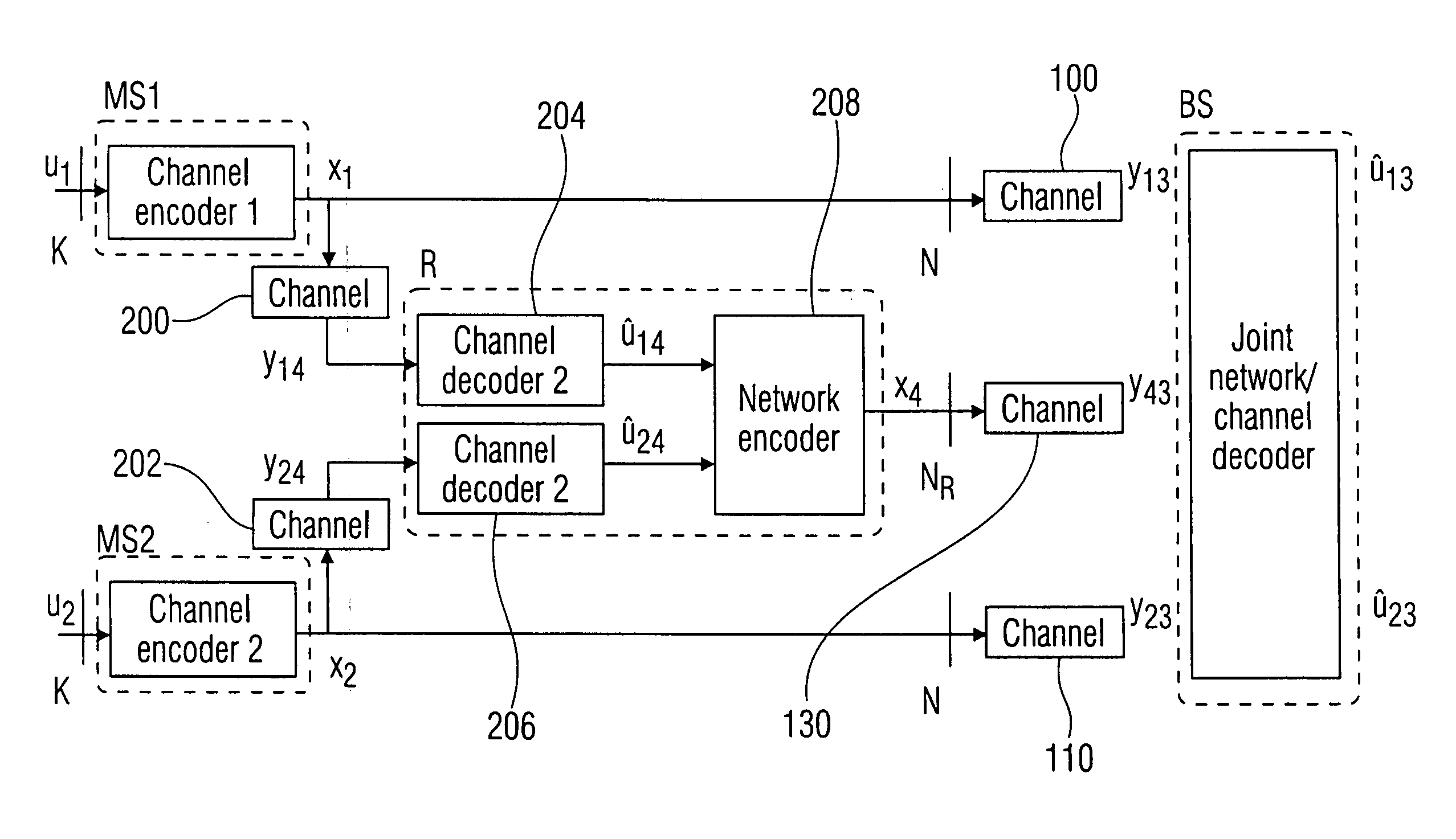

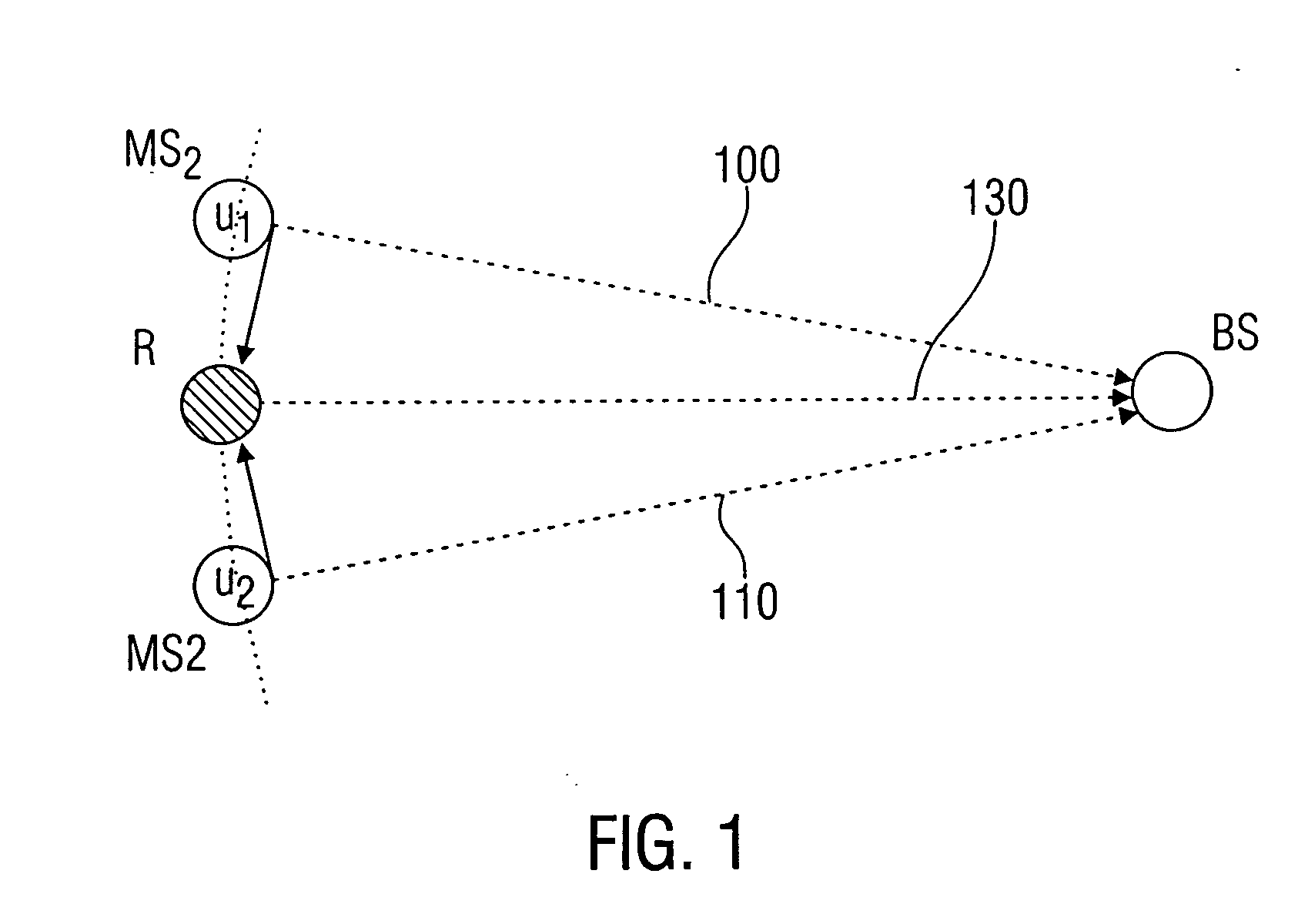

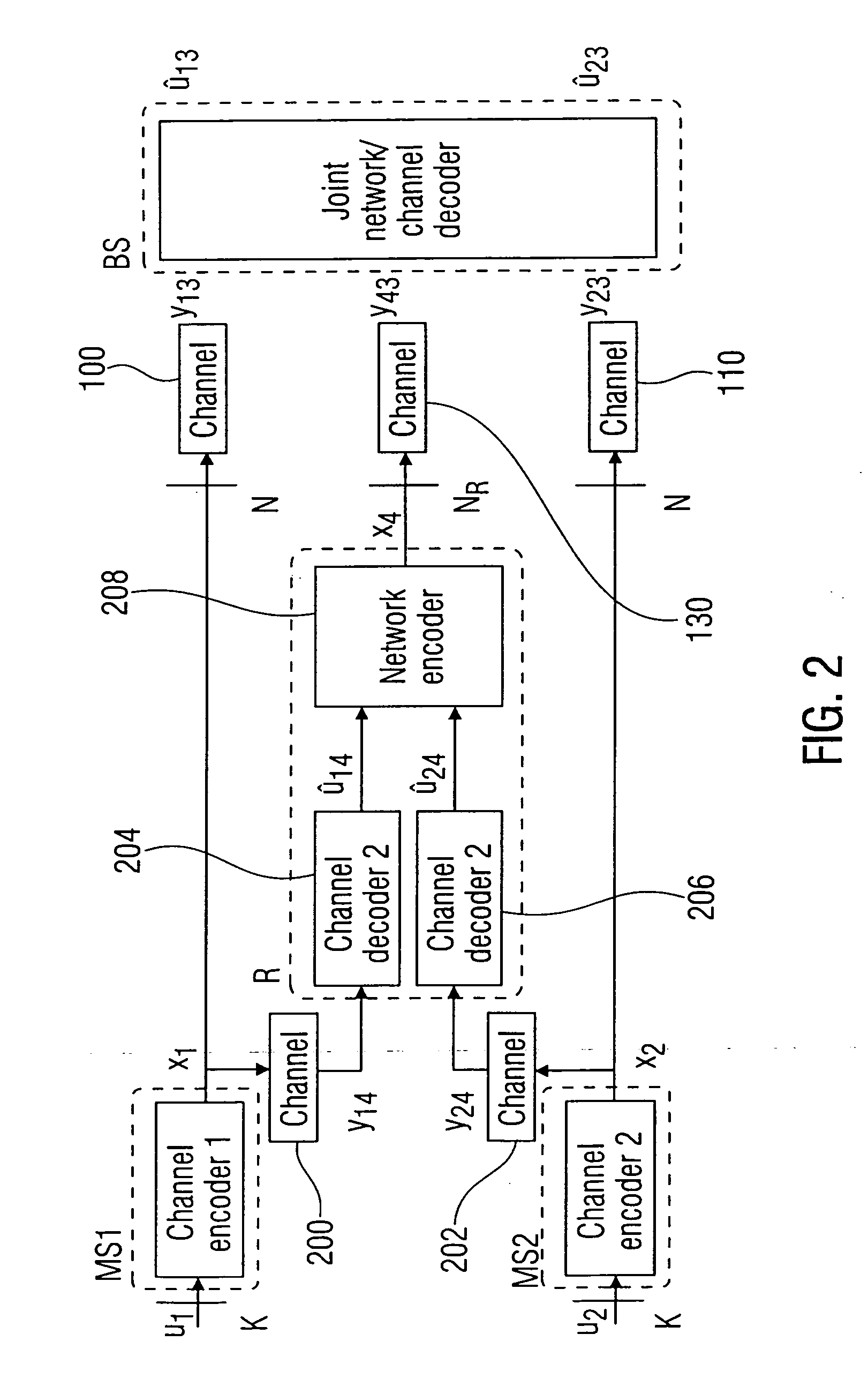

InactiveUS20060291440A1Improve featuresReduce bit error rateError prevention/detection by using return channelCode conversionWireless transmissionData source

A communication relay apparatus for providing a network-encoded information unit sequence comprises a first channel decoder which is configured to supervise a first wireless channel, to receive a first channel-encoded sequence of information units from a first data source via the first wireless channel and to decode the first channel-encoded sequence of information units to obtain a first decoded sequence of information units. Furthermore, the communication relay apparatus comprises a second channel decoder which is configured to supervise a second wireless channel, to receive a second channel-encoded sequence of information units from a second data source via the second wireless channel and to decode the second channel-encoded sequence of information units to obtain a second decoded sequence of information units, the first and second wireless channels being different from each other. Finally, the communication relay apparatus comprises a network-encoder which is configured to encode information of the first and second decoded sequences of information units into the network-encoded information unit sequence and wherein the network-encoder is further configured to wirelessly transmit the network-encoded information unit sequence to a data sink.

Owner:NTT DOCOMO INC

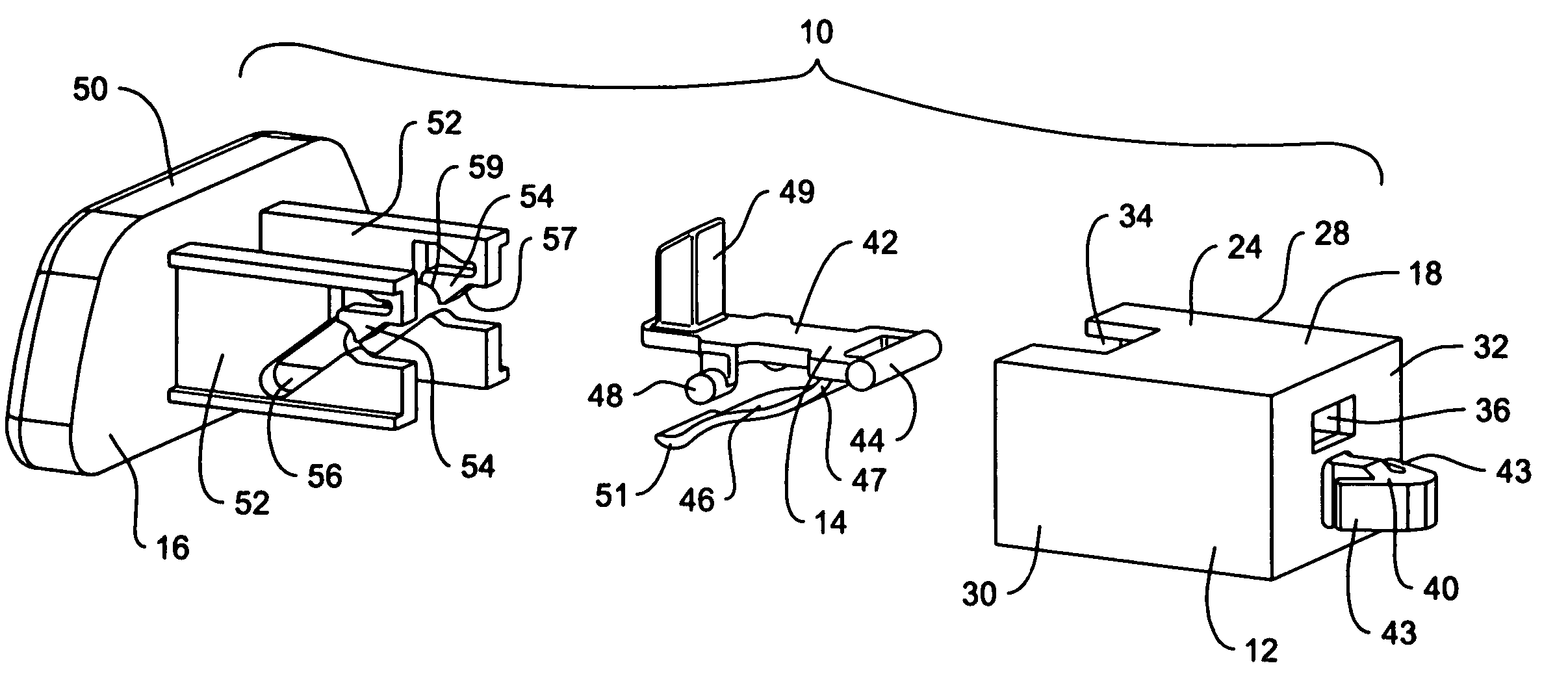

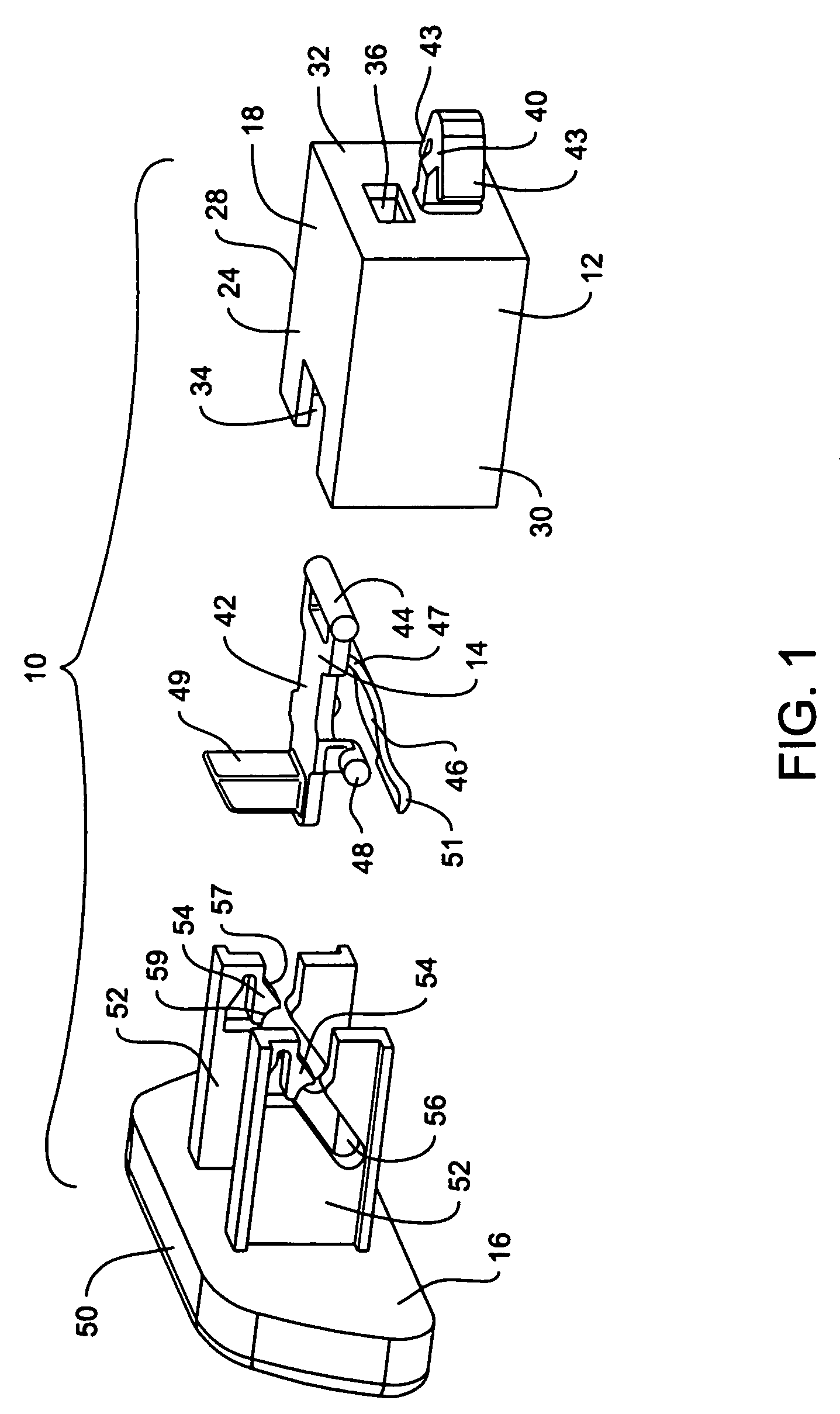

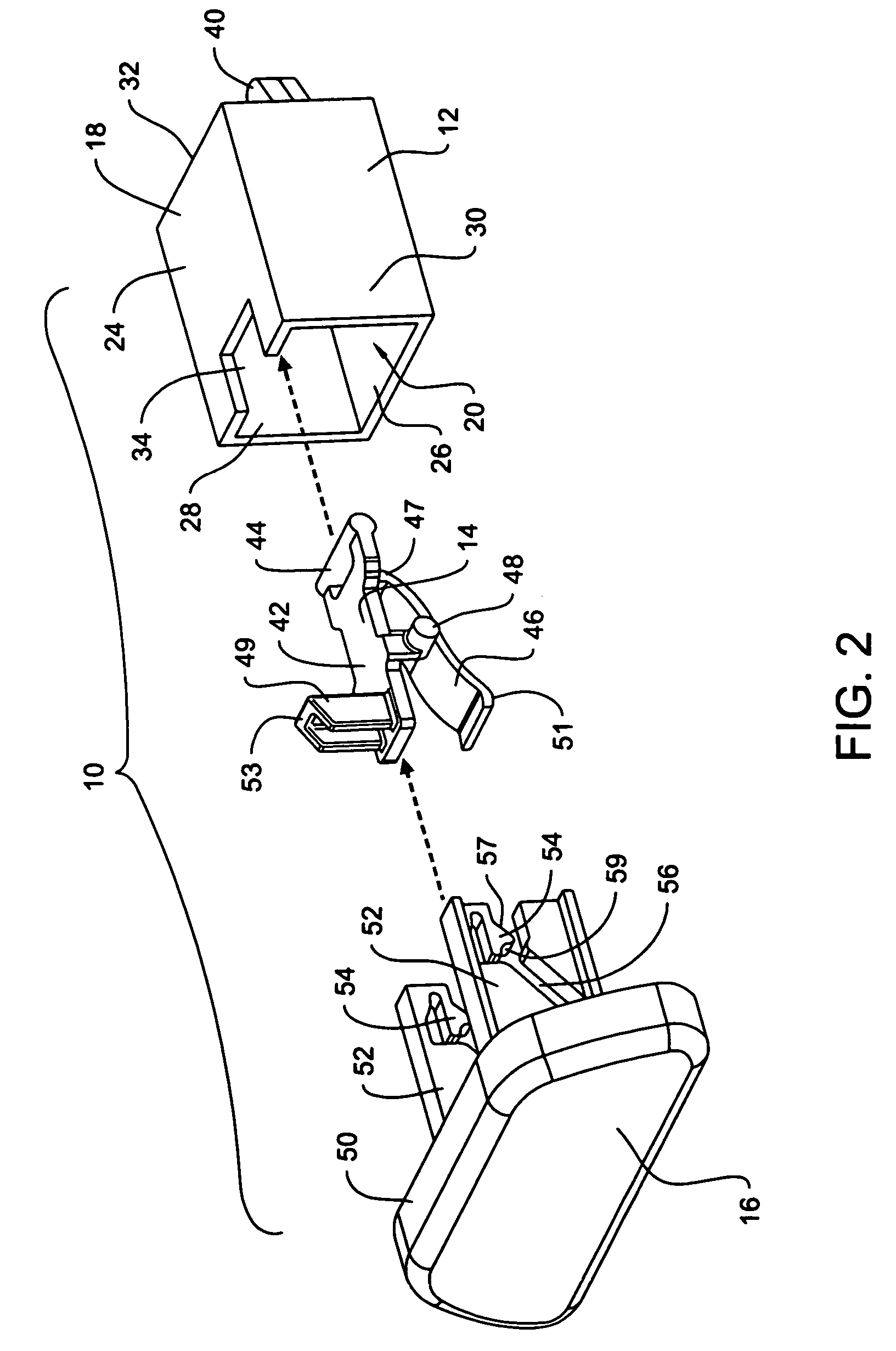

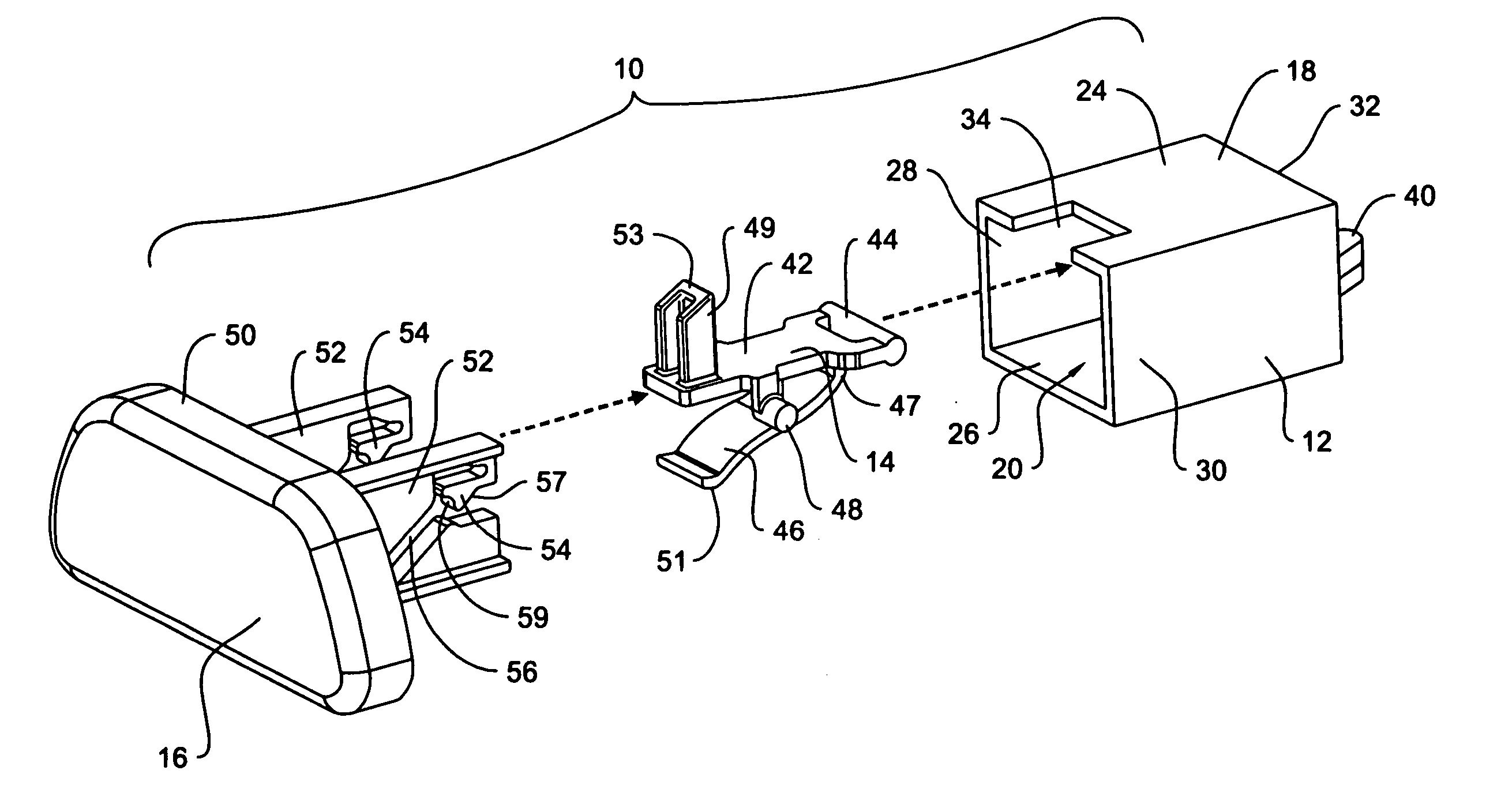

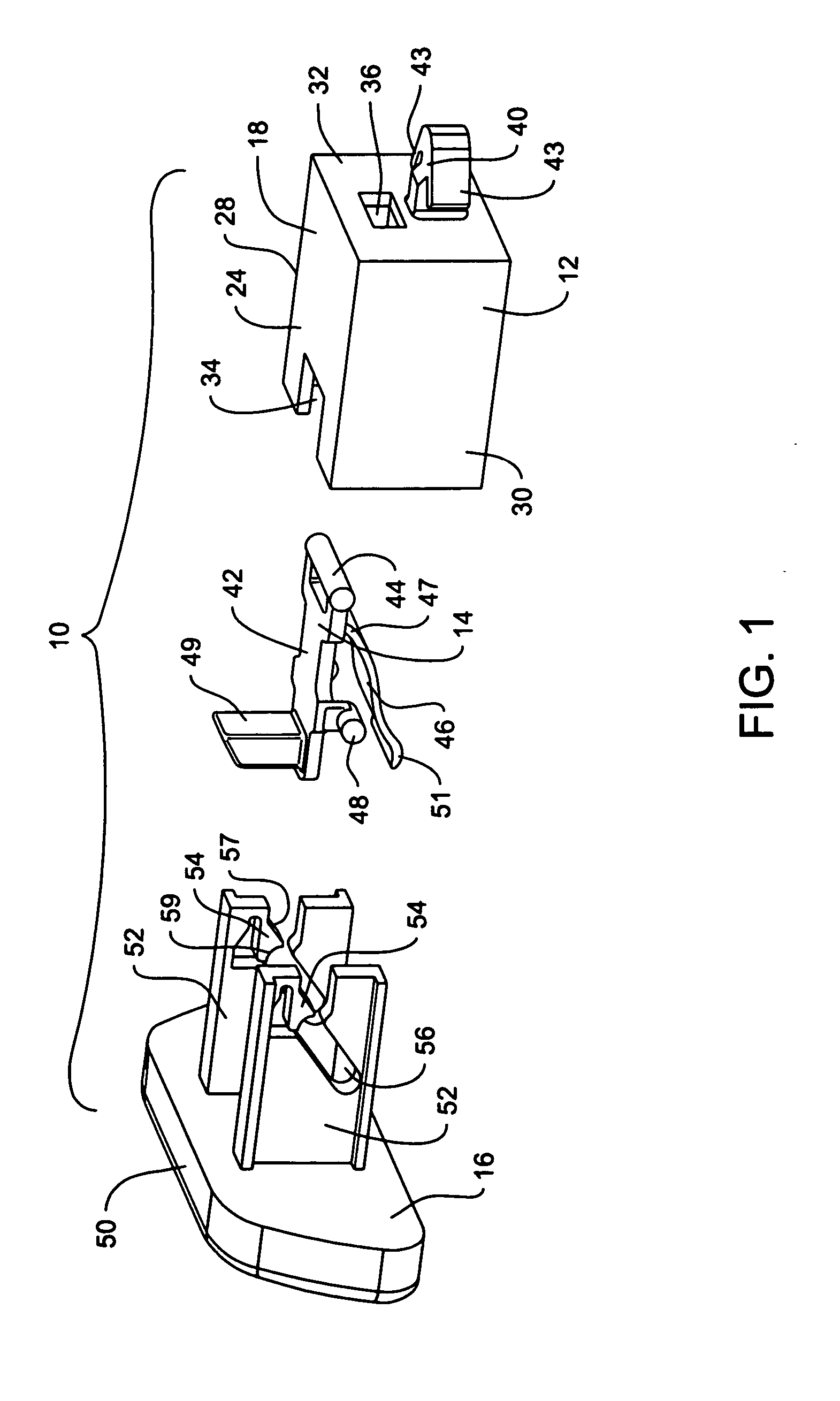

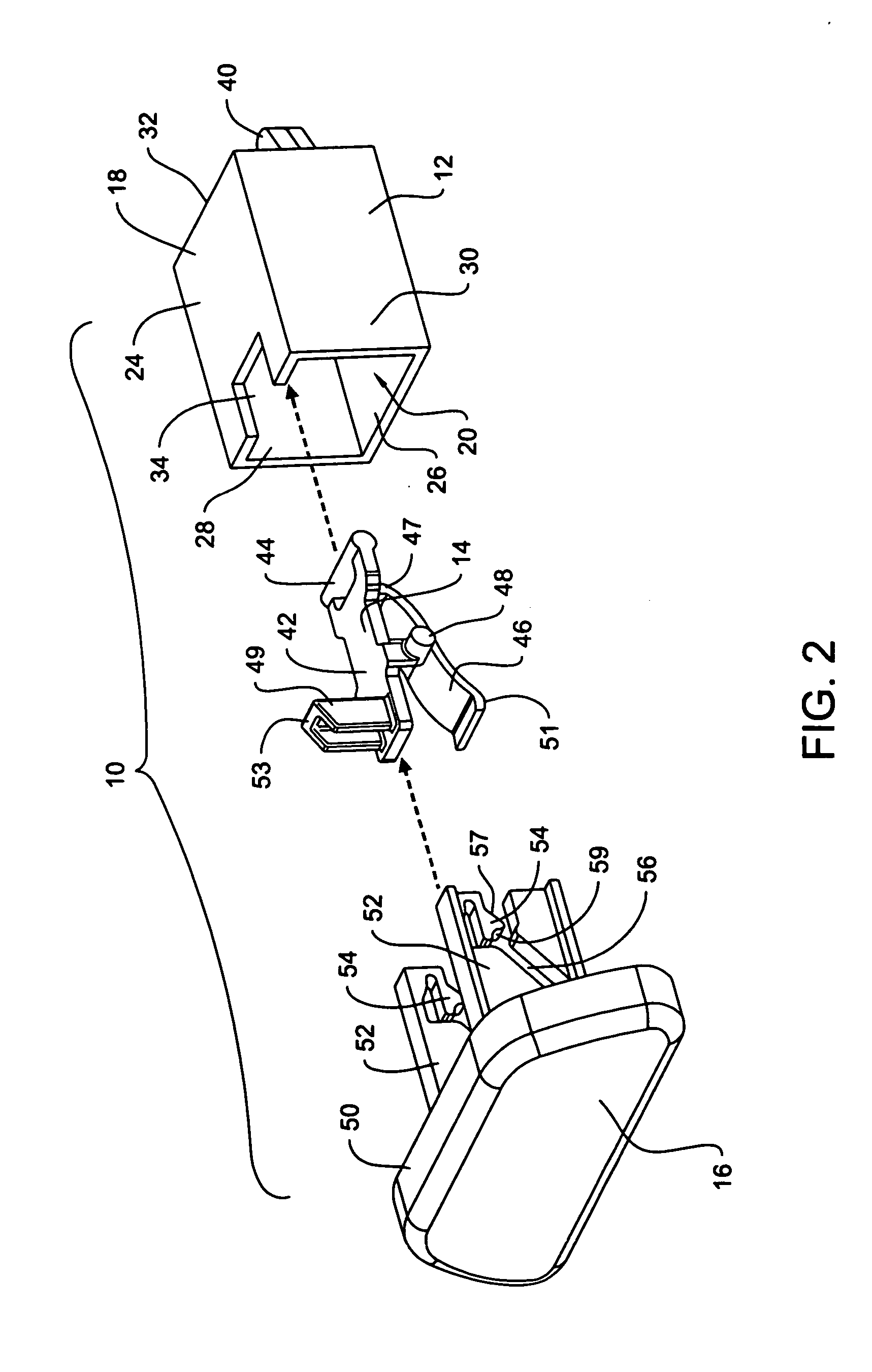

Push latch

ActiveUS7201411B2Reduce in quantitySame functionBuilding locksWing fastenersEngineeringButton pressing

Owner:ILLINOIS TOOL WORKS INC

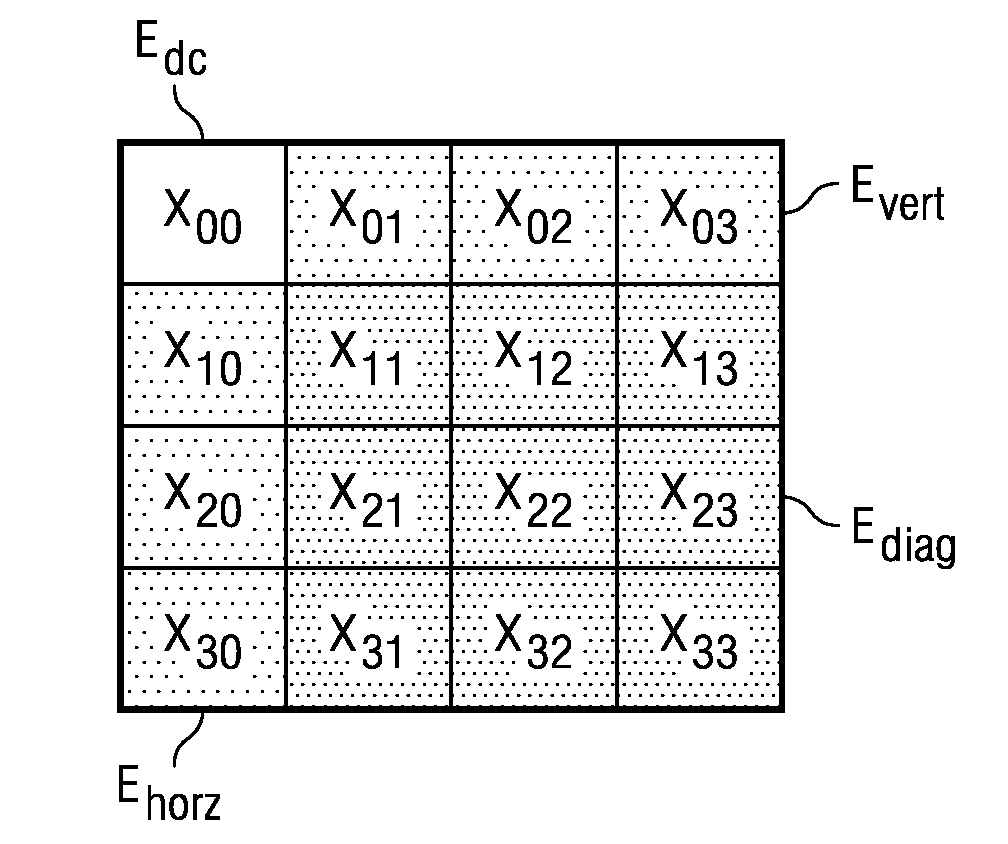

Transform Domain Fast Mode Search for Spatial Prediction in Advanced Video Coding

ActiveUS20080304763A1Reduce complexityMaintaining same qualityColor television with pulse code modulationColor television with bandwidth reductionFrequency domainFast mode

This invention is method for determining direction mode for an image block in intra prediction of video frames. The method calculates a plurality of energy terms from the spatial frequency domain image block, then determines a coarse classification from these energy terms. For at least some coarse classifications the method searches from among a subset of less than all possible direction modes. The method also searches a most likely direction mode determined from neighbor blocks when available.

Owner:TEXAS INSTR INC

Push latch

ActiveUS20060103140A1Reduce in quantityEasy to assembleBuilding locksWing fastenersManufacturing cost reductionBody compartment

A push latch that may be used in automobile applications to open and close compartment doors or bins reduces the number of components typically found in prior art designs while retaining the same quality and function. The push latch of the invention further eliminates the use of metal pins and springs, provides an assembly that is easier to assemble and reduces the cost to manufacture. In one embodiment, the push latch generally includes the use of a housing, lock and button. The lock includes the use of a flexible spring arm and bosses, which will engage with cam slots in the button. In operation, when the button is pushed, the cam slots will force the bosses and the lock downward causing the release of the compartment door. When the button is released, the flexible spring arm forces the cylindrical bosses upward in the cam slots thus forcing the button and lock back to their original positions.

Owner:ILLINOIS TOOL WORKS INC

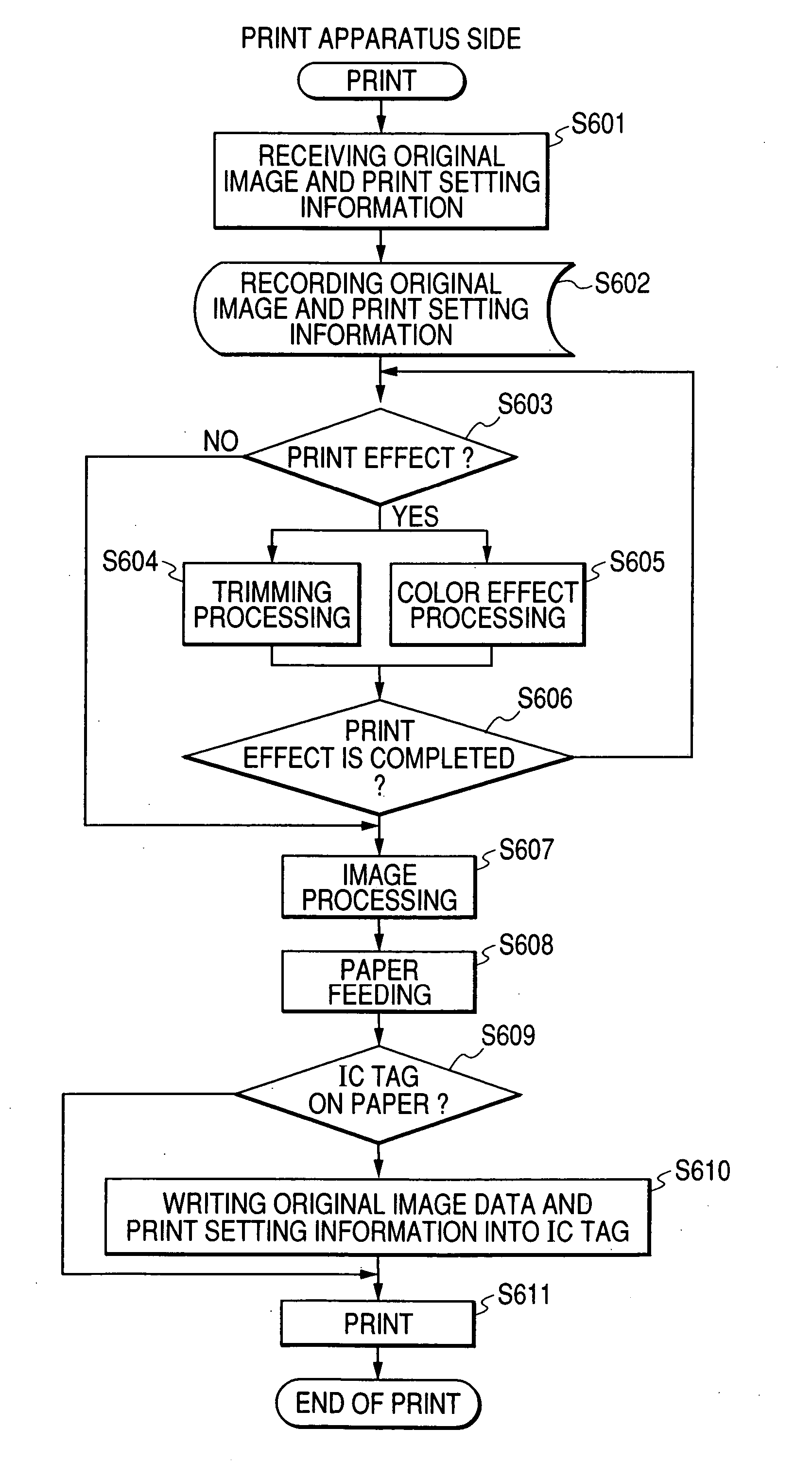

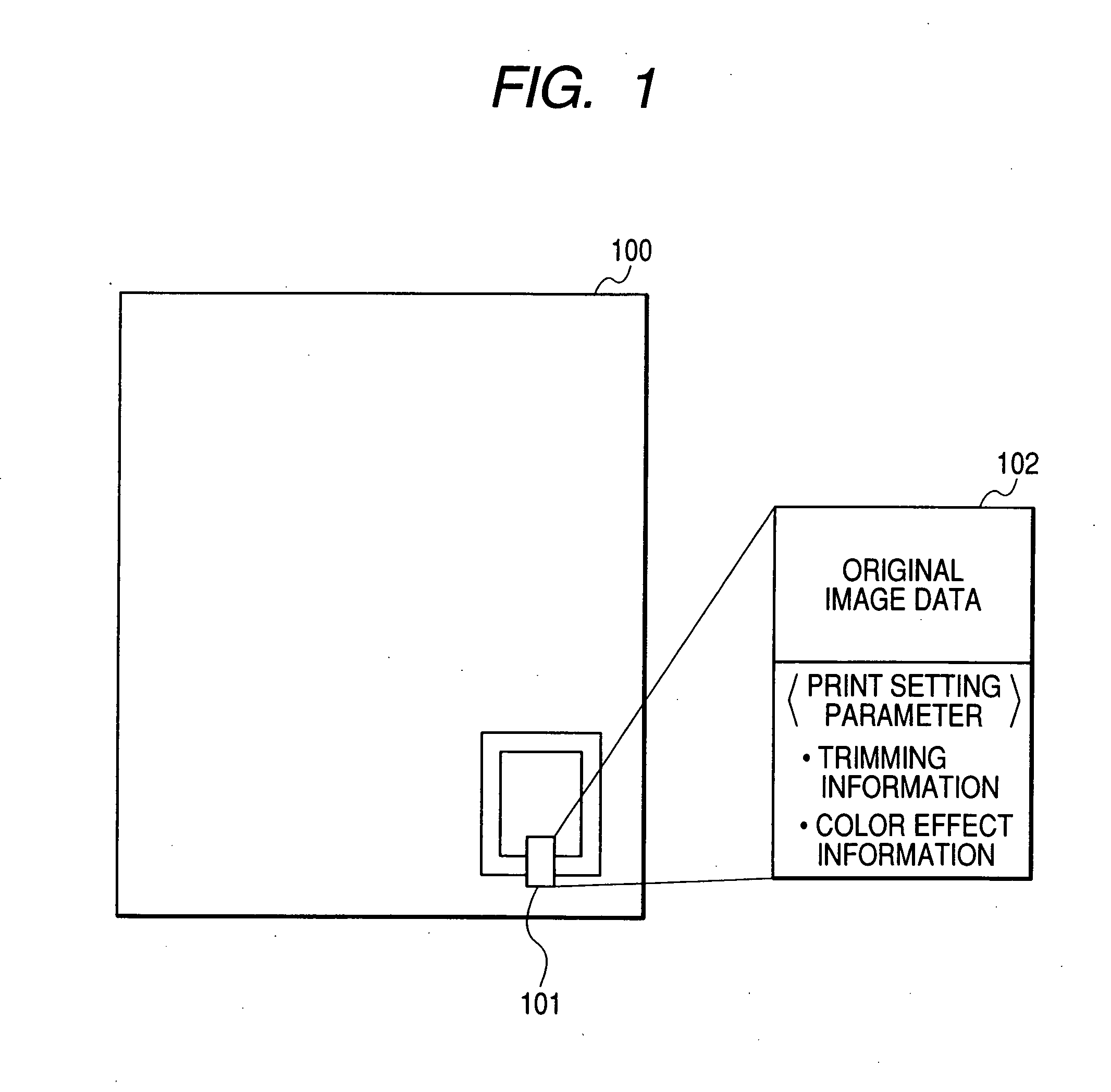

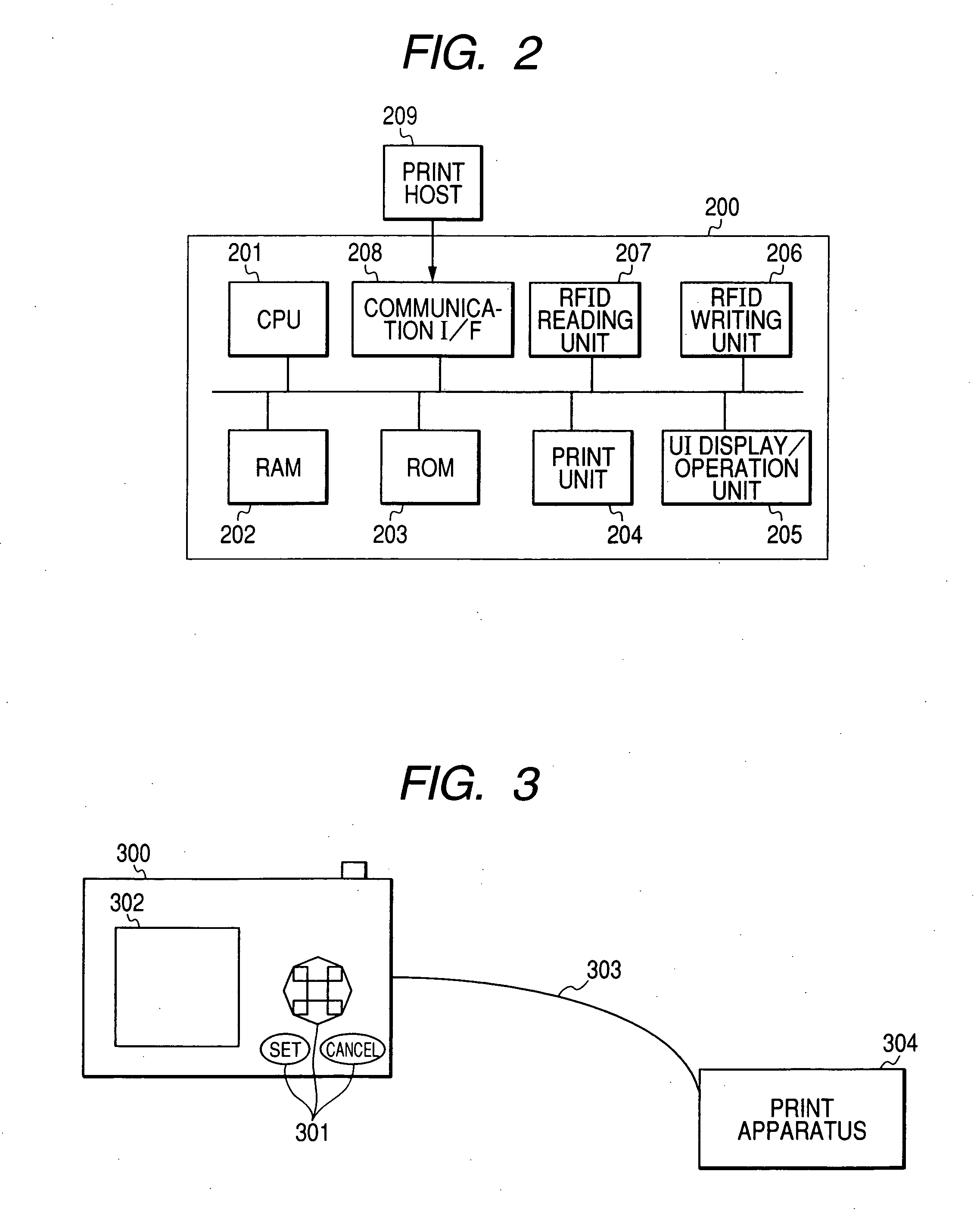

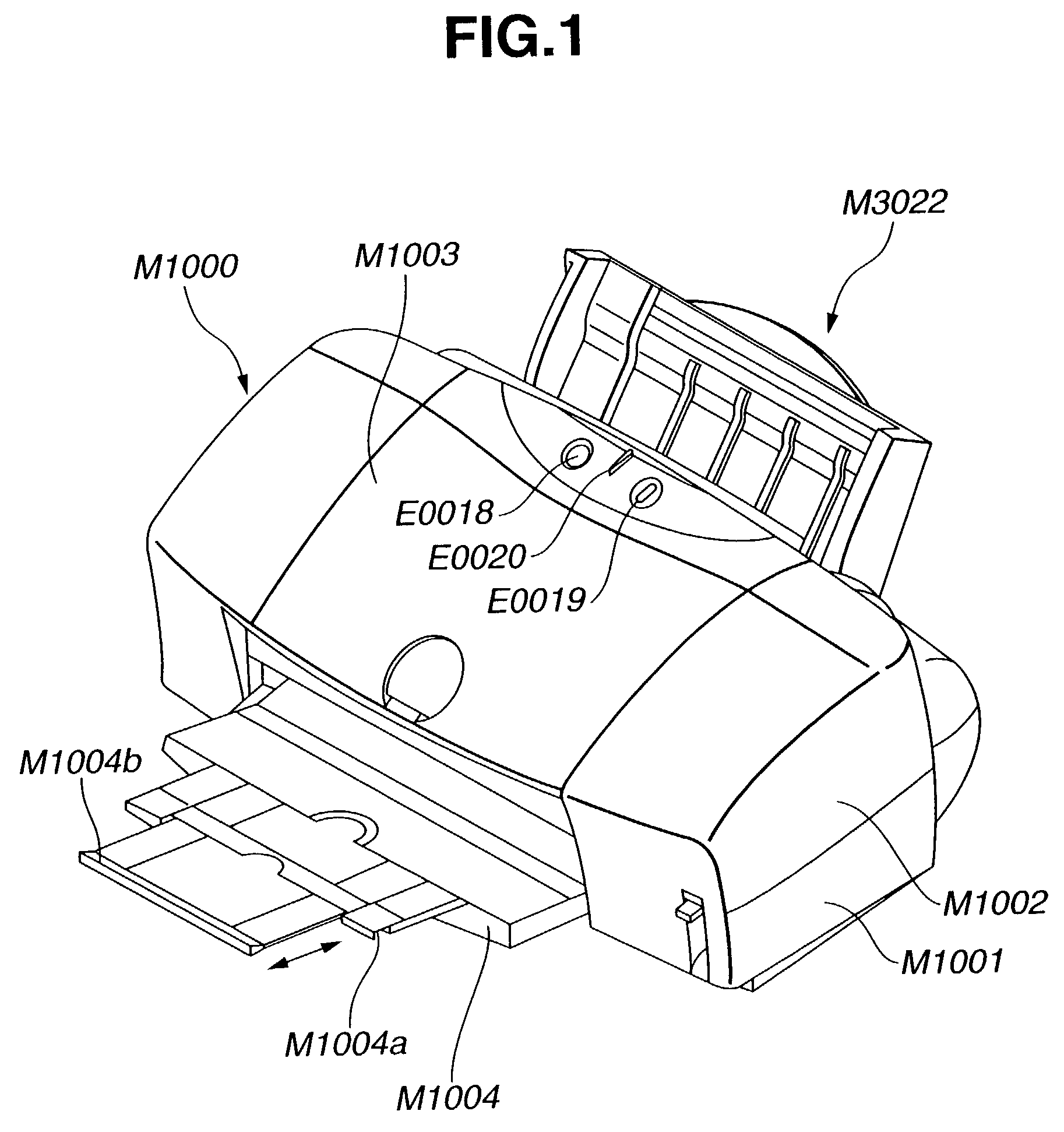

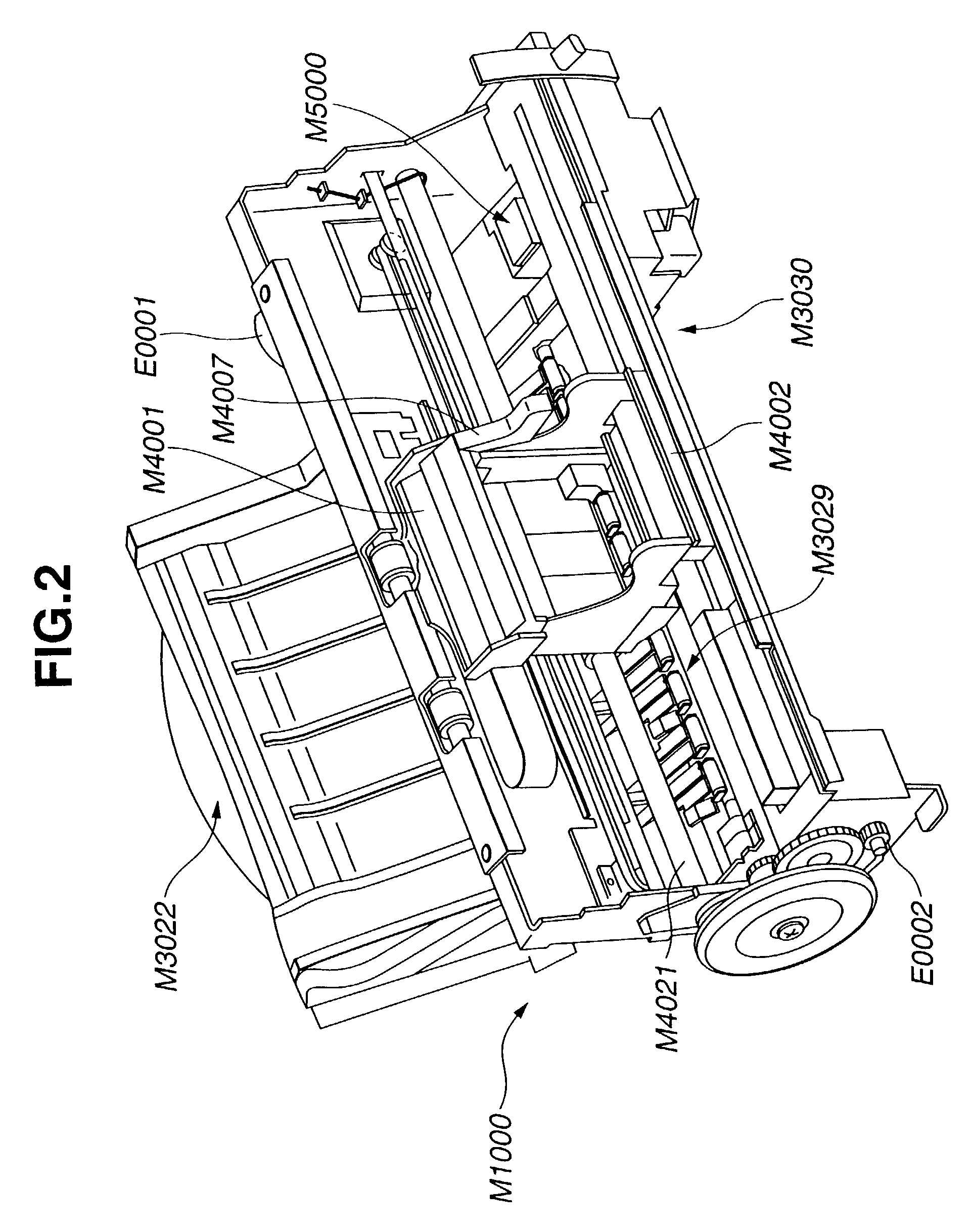

Recording medium and print apparatus

InactiveUS20060061814A1Easy to reprintSame qualityPictoral communicationDigital output to print unitsComputer hardwareImaging data

A recording medium such as paper on which an image can be printed by a print apparatus includes an RFID (Radio Frequency Identification) tag such as an IC tag for recording data comprising original image data and print setting information used upon printing. A print apparatus reads out the original image data and the print setting information from the RFID tag and executes the printing on the basis of them. Even in the case of an image subjected to a print effect processing, reprinting with the same picture quality can be easily performed and a trouble of searching for the image can be saved.

Owner:CANON KK

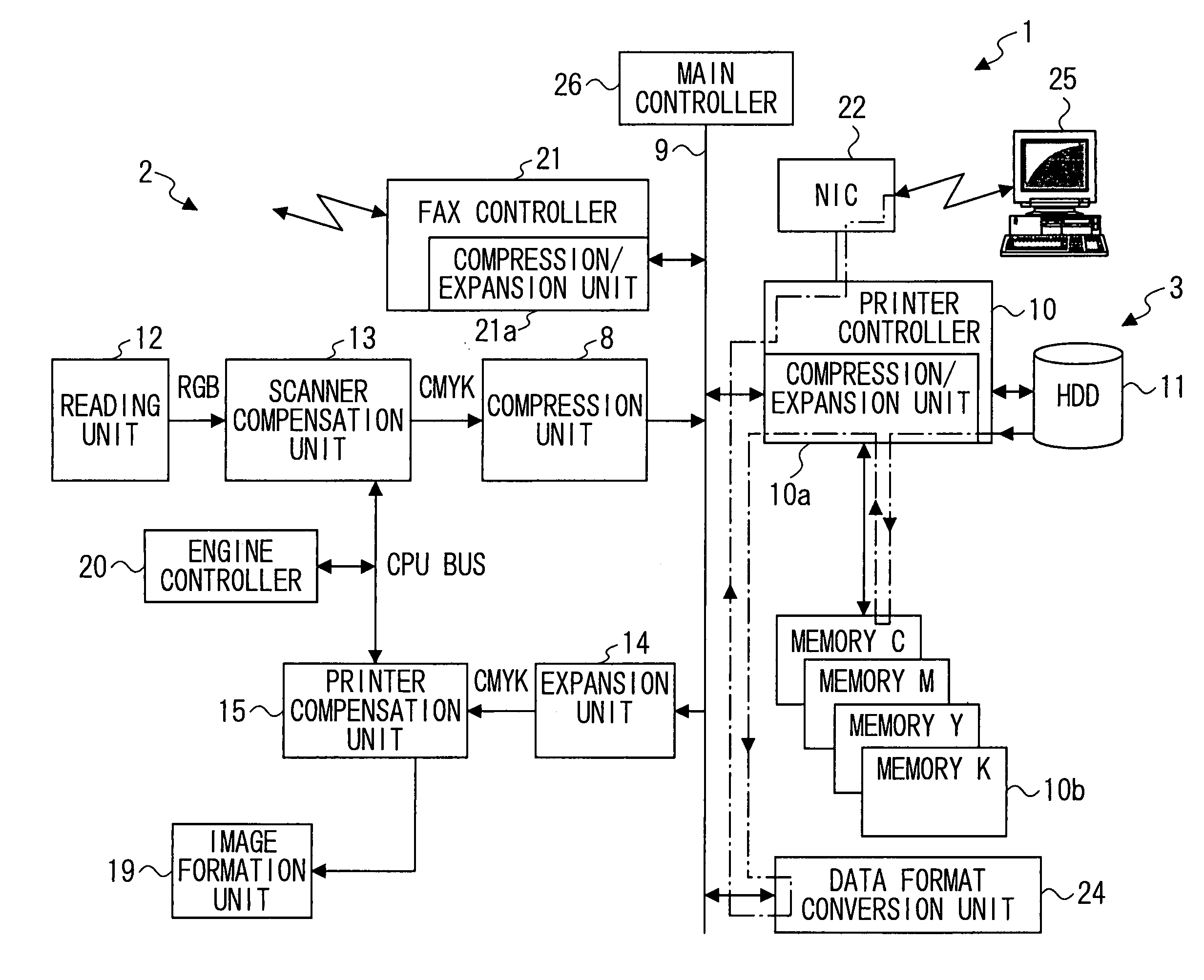

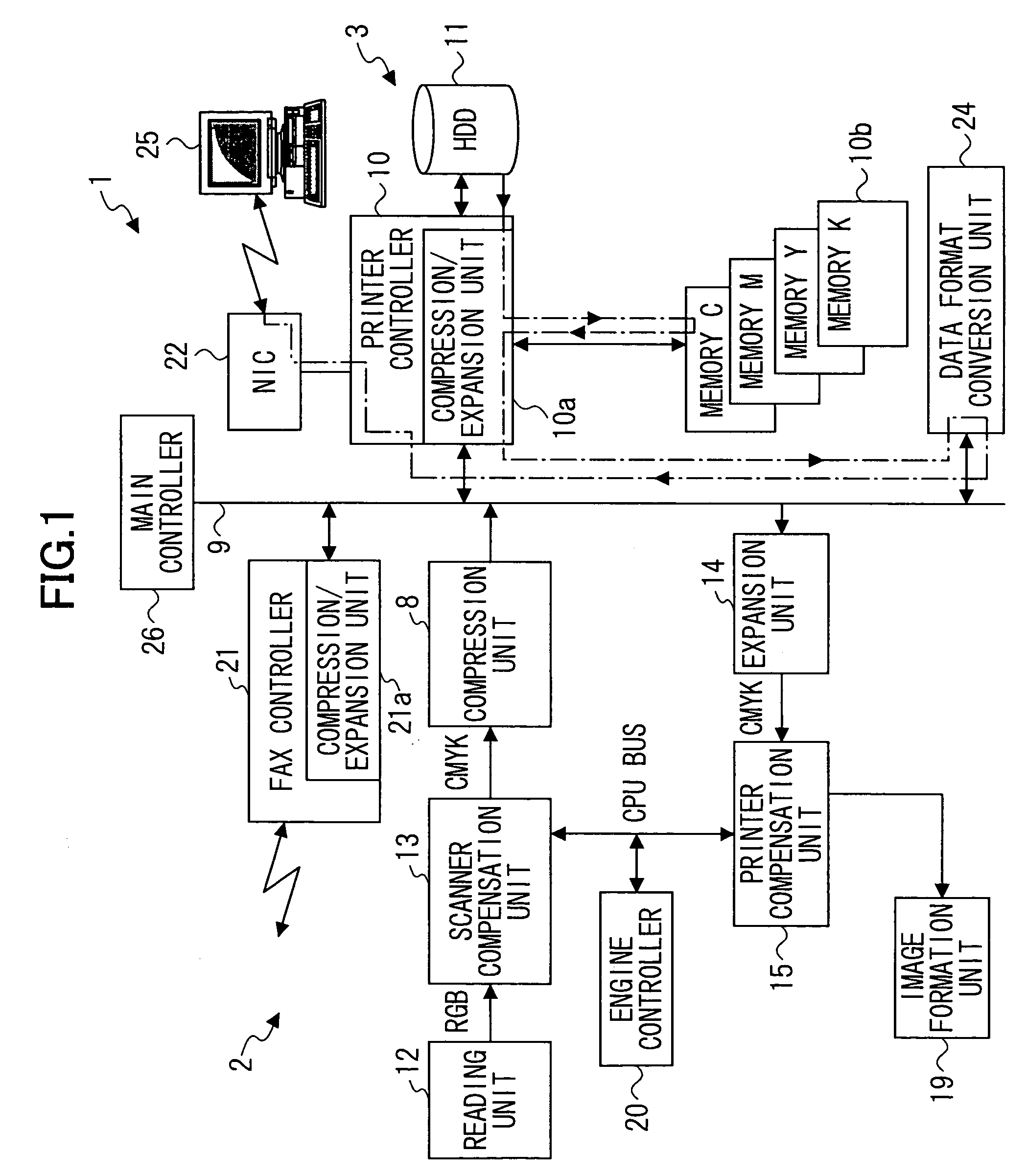

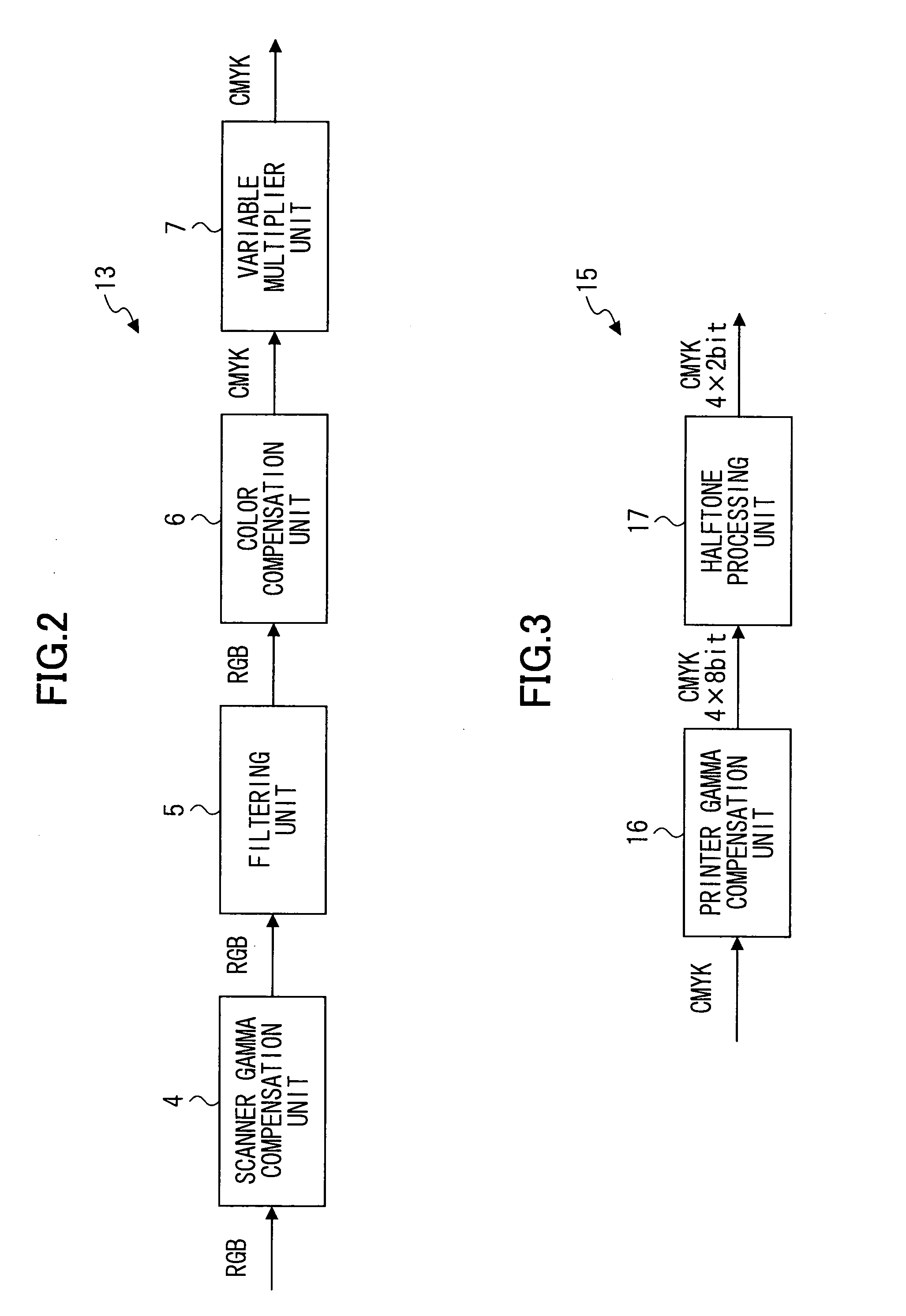

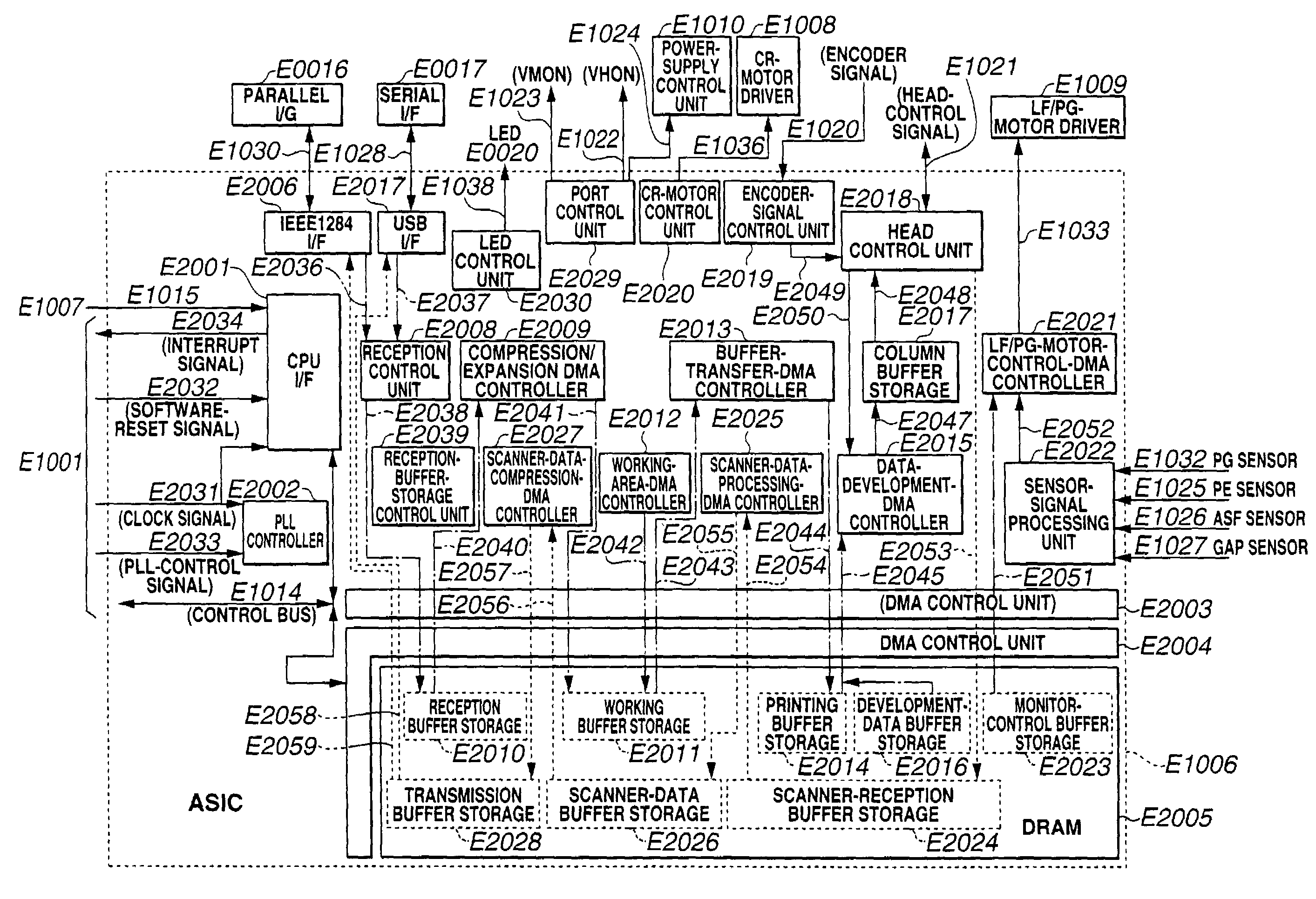

Copying apparatus, a program, and a storage medium

InactiveUS20050024666A1Same qualityDigital computer detailsDigital video signal modificationCommunication interfaceComputer printing

A copying apparatus, a computer-readable program, and a storage medium are disclosed. The copying apparatus is equipped with a reader for reading original image data, a communication interface for transmitting the read image data to a predetermined network and receiving image data from the network, and a printer engine for forming an image on a medium based on the received image data. The copying apparatus further includes storing means for storing the image data in a first data format; receiving means for receiving a request that the image data be sent to a predetermined transmission destination; data format conversion means for converting the stored image data from the first data format into a second data format; and transmitting means for transmitting the converted image data to the requested transmission destination.

Owner:RICOH KK

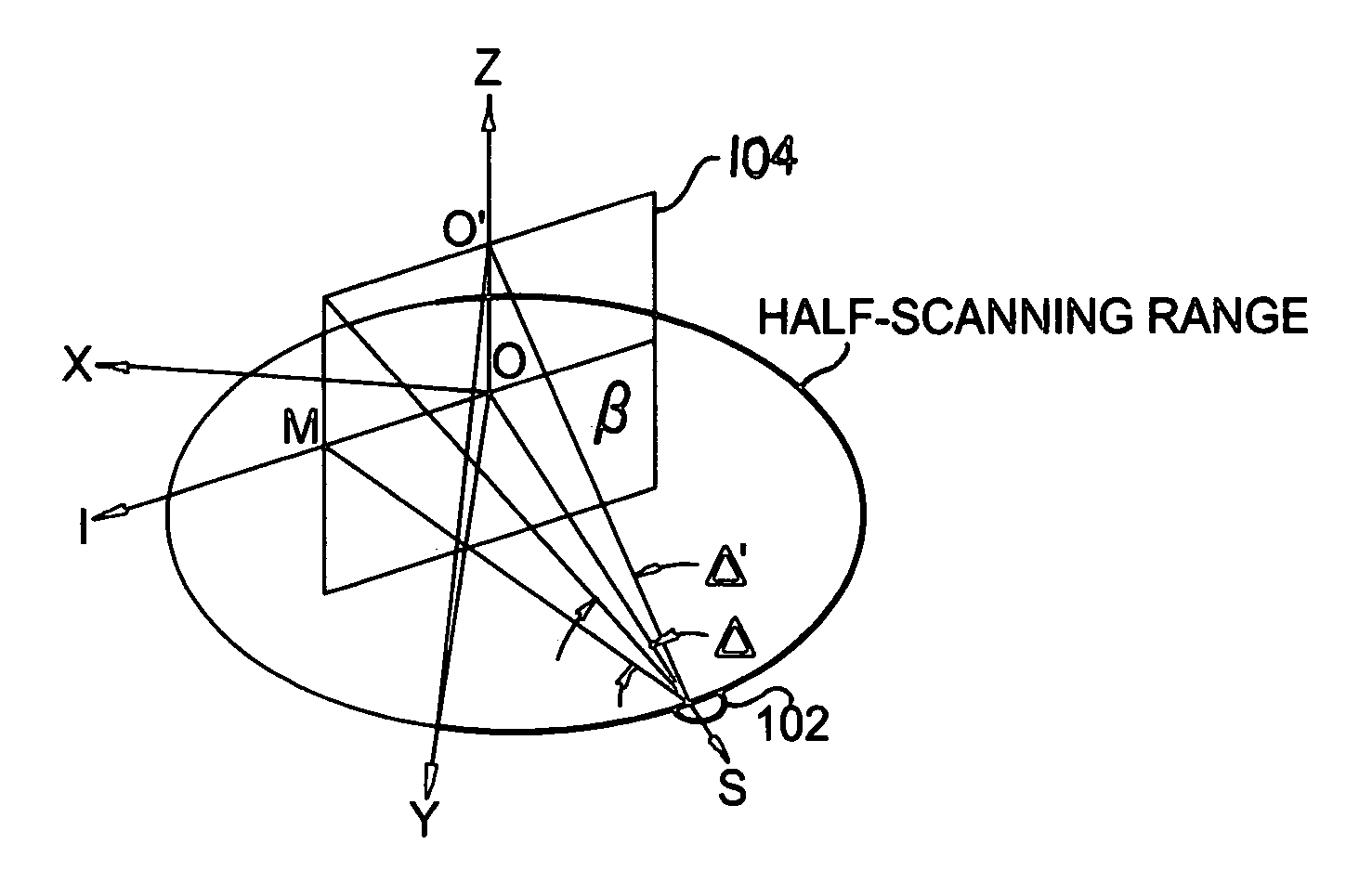

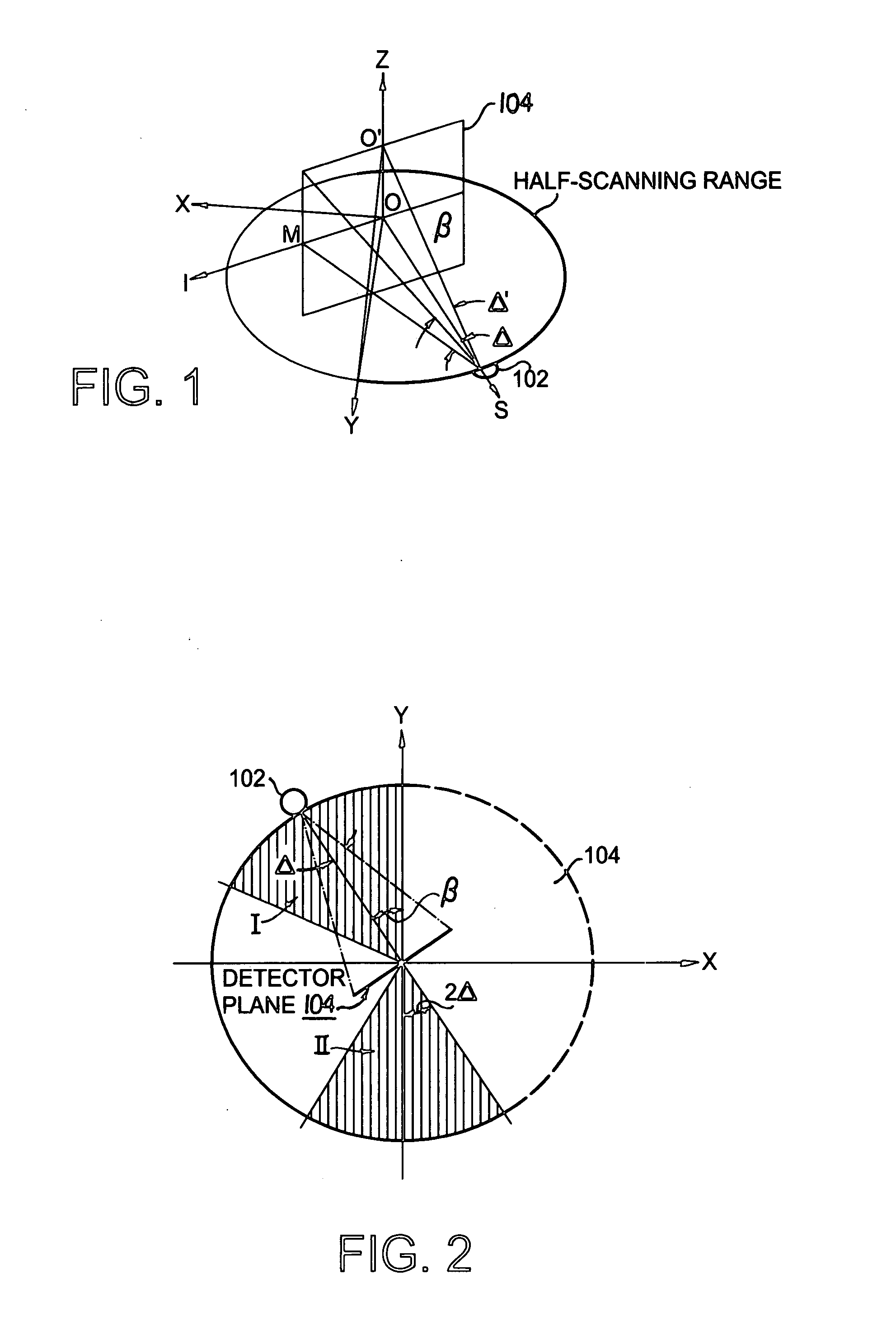

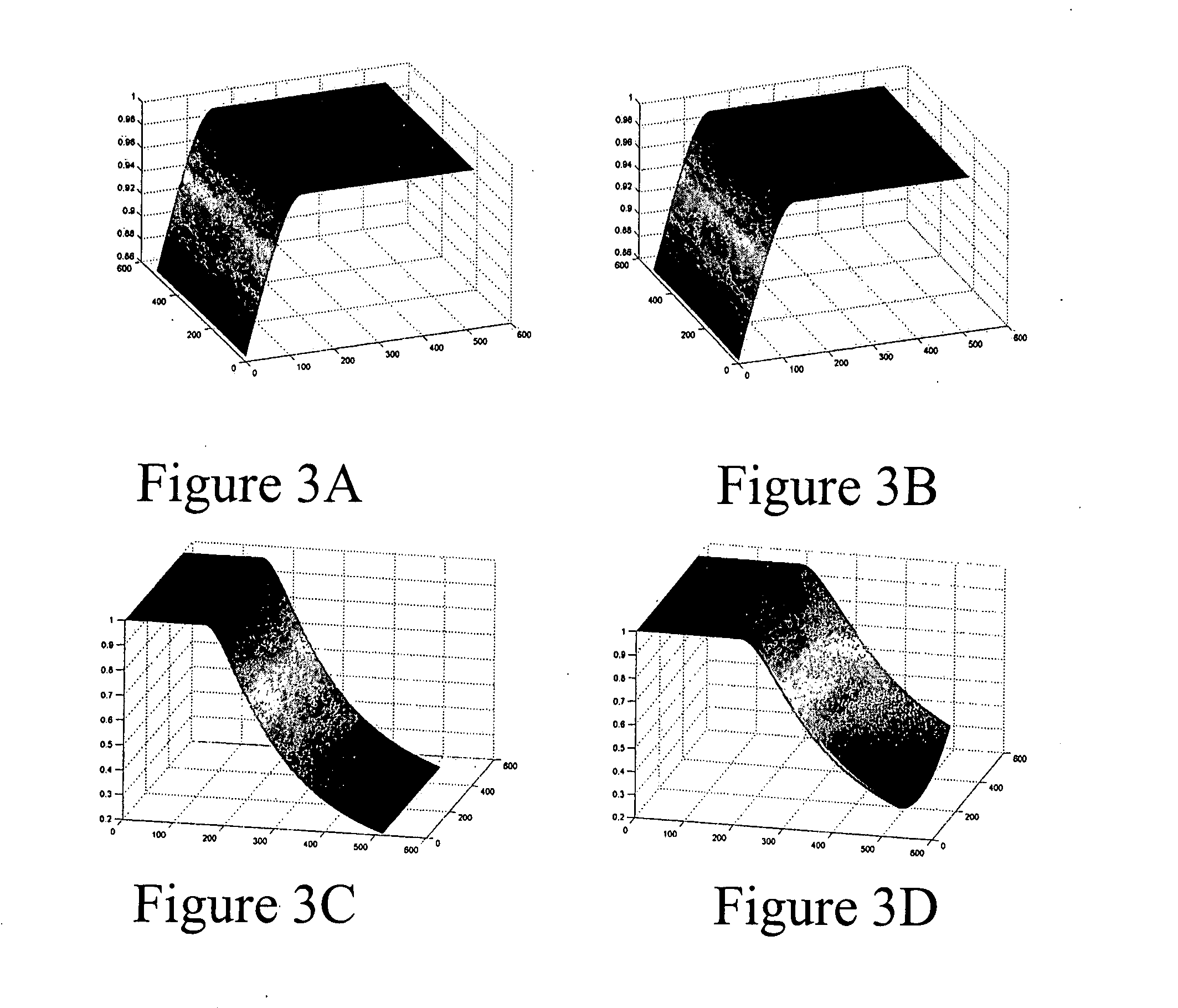

Method and apparatus for cone beam CT dynamic imaging

ActiveUS20070253528A1Same image qualityLess timeReconstruction from projectionMaterial analysis using wave/particle radiationA-weightingDynamic imaging

A cone-beam scanning system scans along a half circle. The reconstruction uses a weighting function which decreases for rows farther from the scan plane to take the redundancy of the projection data into account. Another embodiment uses a circle plus sparse helical scan geometry. Image data can be taken in real time.

Owner:UNIVERSITY OF ROCHESTER

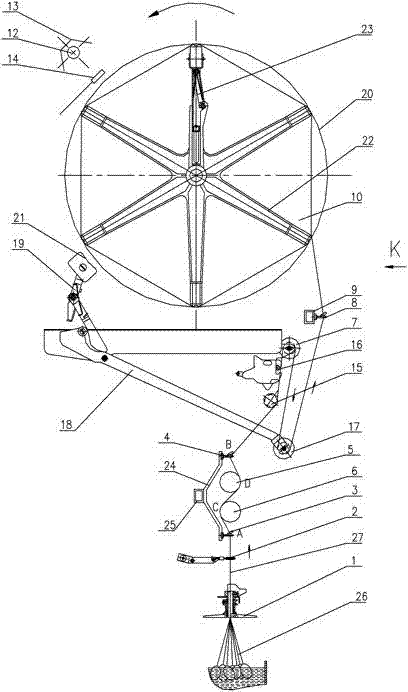

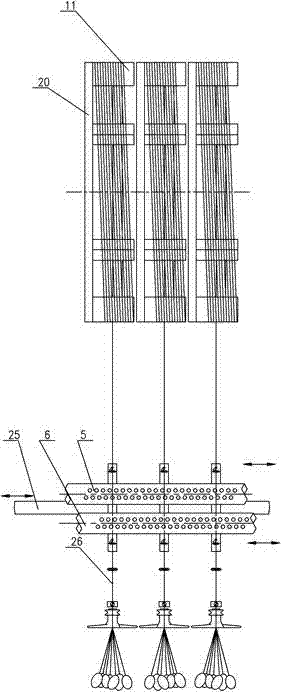

Silk reeling method and exclusive device for reeling raw silk

The invention relates to a silk reeling method and device, particularly to a silk reeling method and an exclusive device for reeling raw silk, which aim to solve the technical problems in the prior art that the energy consumption is large, the technological process is long, and more workers are needed all caused by silk reeling, rereeling and repeated drying; more time and labors are consumed because the bore diameter of a filament guide button is small; during the silk reeling process, the manual manner is adopted to form a silk sheath structure, and the hygrometric state raw silk is gathered by the function of the silk sheath in the method of gathering hygrometric state raw silk, the operation is complicated and the labor productivity is low. According to the invention, bave is processed by a hygrometric state raw silk gathering device after passing through an end feeding wing and a leading-in type filament guide button so as to enable the hygrometric state raw silk to be closely gathered, and moisture in a silk strip to be emitted by extrusion, tiny fouls on the bave surface are eliminated through kneading in a rotary manner, then, the bave is directly wound on a large shade and forms large flourishing yarn sheets through infra-red heating and drying, and the yarn sheets become reeled raw silk after silk falling arrangement.

Owner:ZHEJIANG SCI-TECH UNIV

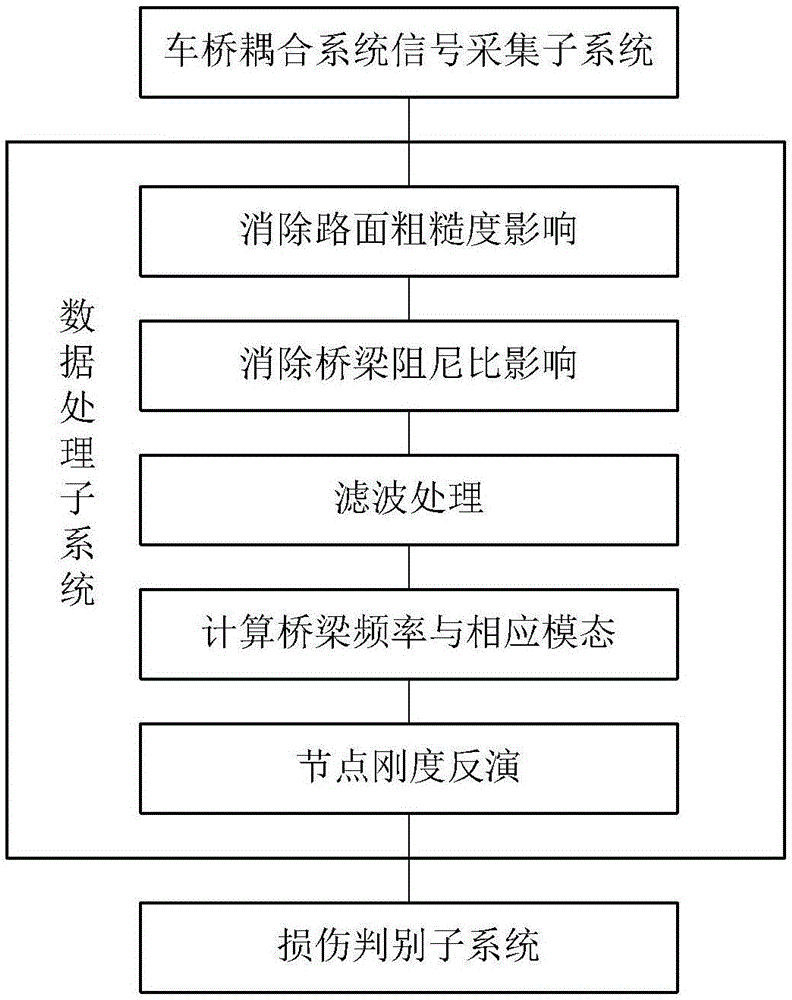

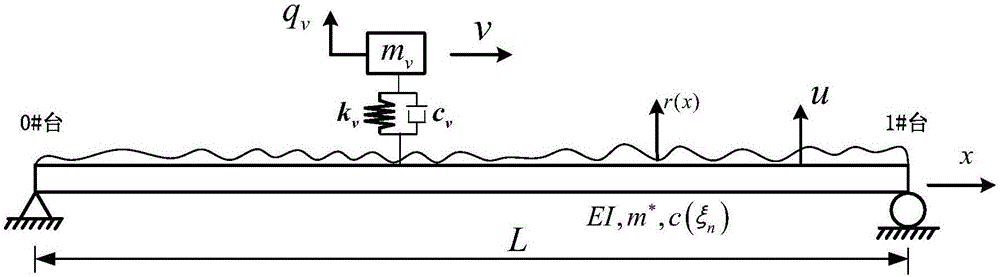

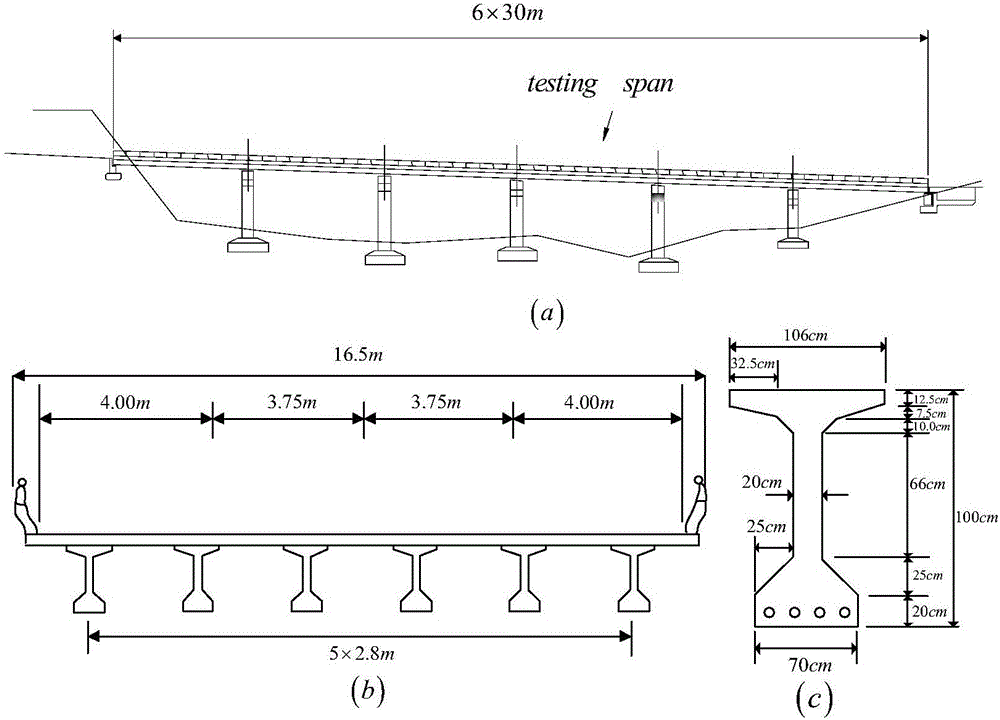

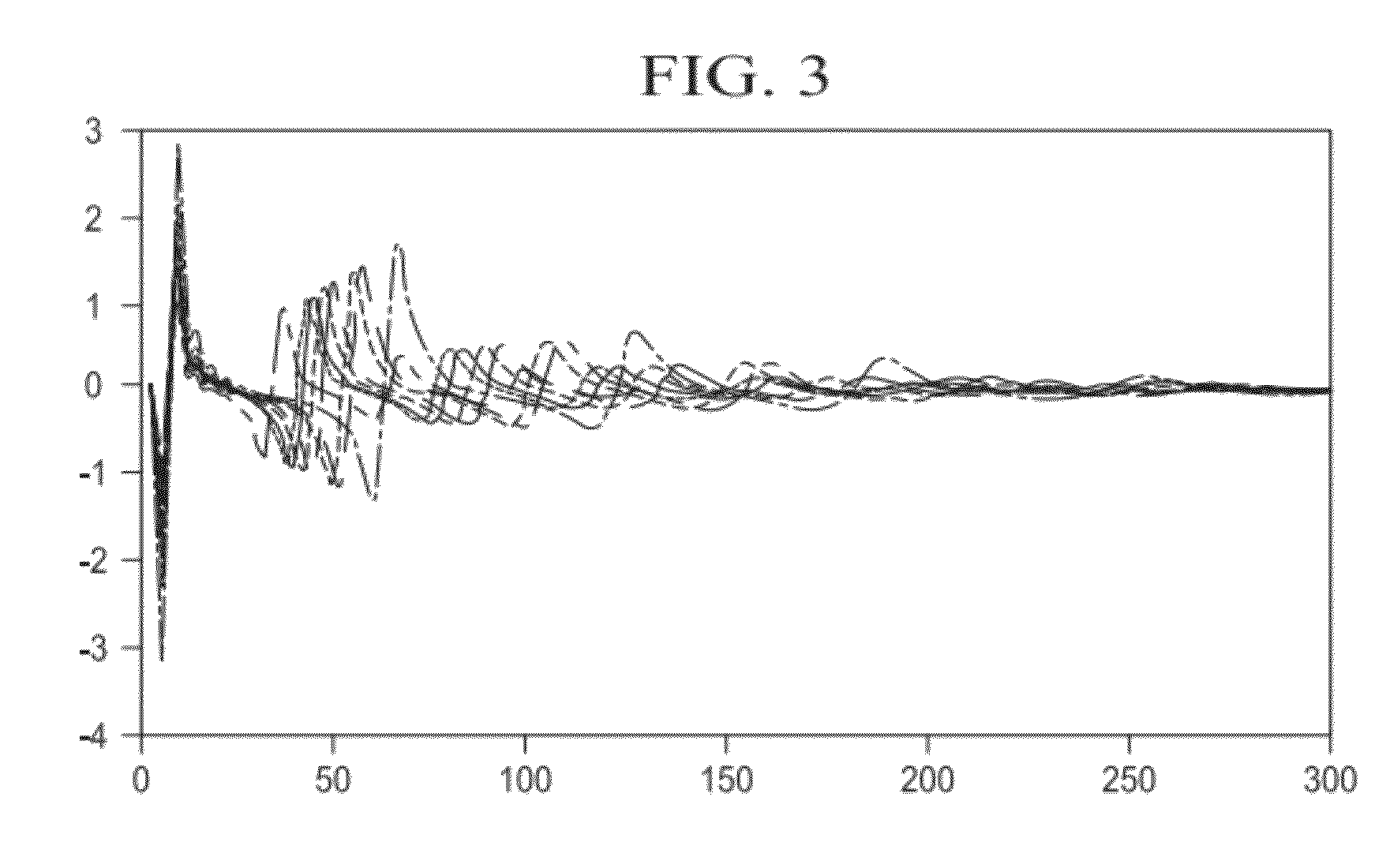

Bridge damage diagnosis method based on axle coupling system

InactiveCN106802222ADiscover hidden dangers in timeLow impact on normal traffic operationsElasticity measurementCoupling systemEngineering

The invention relates to the field of bridge engineering detection, specifically to a bridge damage diagnosis method based on an axle coupling system. The bridge damage diagnosis method includes the following specific steps: a. two detection vehicles depart from different positions of a bridge towards a 1# abutment direction to pass the bridge, and a signal acquisition subsystem synchronously acquires vertical acceleration response in the process of trolleys passing the bridge each time; b. the two detection vehicles depart from different positions of the bridge towards a 0# abutment direction to pass the bridge, and the signal acquisition subsystem synchronous acquires vertical acceleration response in the process of the trolleys passing the bridge each time; and c. using the vertical acceleration response of the trolleys measured in Step a and Step b to perform secondary integration processing on time t separately, thereby obtaining approximate vertical displacement response of the corresponding trolleys. Through the bridge damage diagnosis method based on the axle coupling system, detection signals can be obtained on the bridge to be detected through the detection vehicles, damage information of the bridge can be obtained through corresponding processing conversion according to the detection signals, the approximate position of bridge damage does not need to be known in advance, the operation is simple and easy, and the efficiency is high.

Owner:CHONGQING UNIV

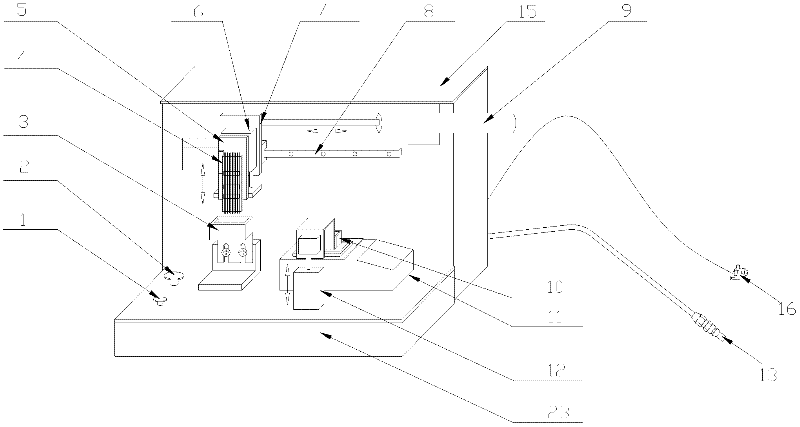

Semi-automatic tin dipping machine

InactiveCN102259223AGuaranteed levelConsistent immersion tin depthSolder feeding devicesSemi automaticEngineering

The invention discloses a semi-automatic wicking machine comprising a workbench, a fixing plate and a tin melting furnace. The semi-automatic wicking machine is characterized by further comprising a wicking groove, a soldering flux groove, a wiring plate, a guide rail, a first up-and-down moving device, a horizontal driving device and a second up-and-down moving device. The wicking groove is arranged above an opening of the tin melting furnace, the first up-and-down moving device is connected with the wicking groove, the soldering flux groove is arranged above the workbench, the second up-and-down moving device is connected with the wiring plate, the back end of the second up-and-down moving device is connected with the guide rail arranged on the fixing plate, and the horizontal driving device arranged on the fixing plate is connected with the second up-and-down moving device. The invention solves the problem that woven flare opening and bulging usually generate, the wicking length isinconsistent, and the sizes of finished produces are unstable due to the hard guarantee of the appearance and the quality of products because wire rods are wicked manually in prior art, and provides a semi-automatic wicking machine with unity in wicking, order appearance and good size consistency.

Owner:雷特威连接系统(苏州工业园区)有限公司

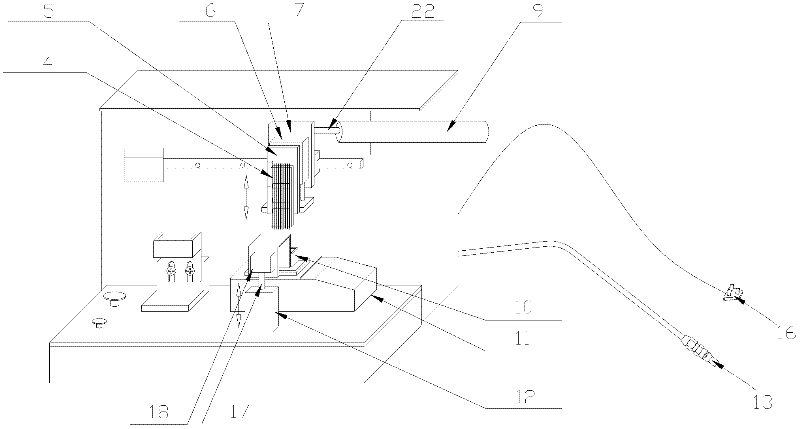

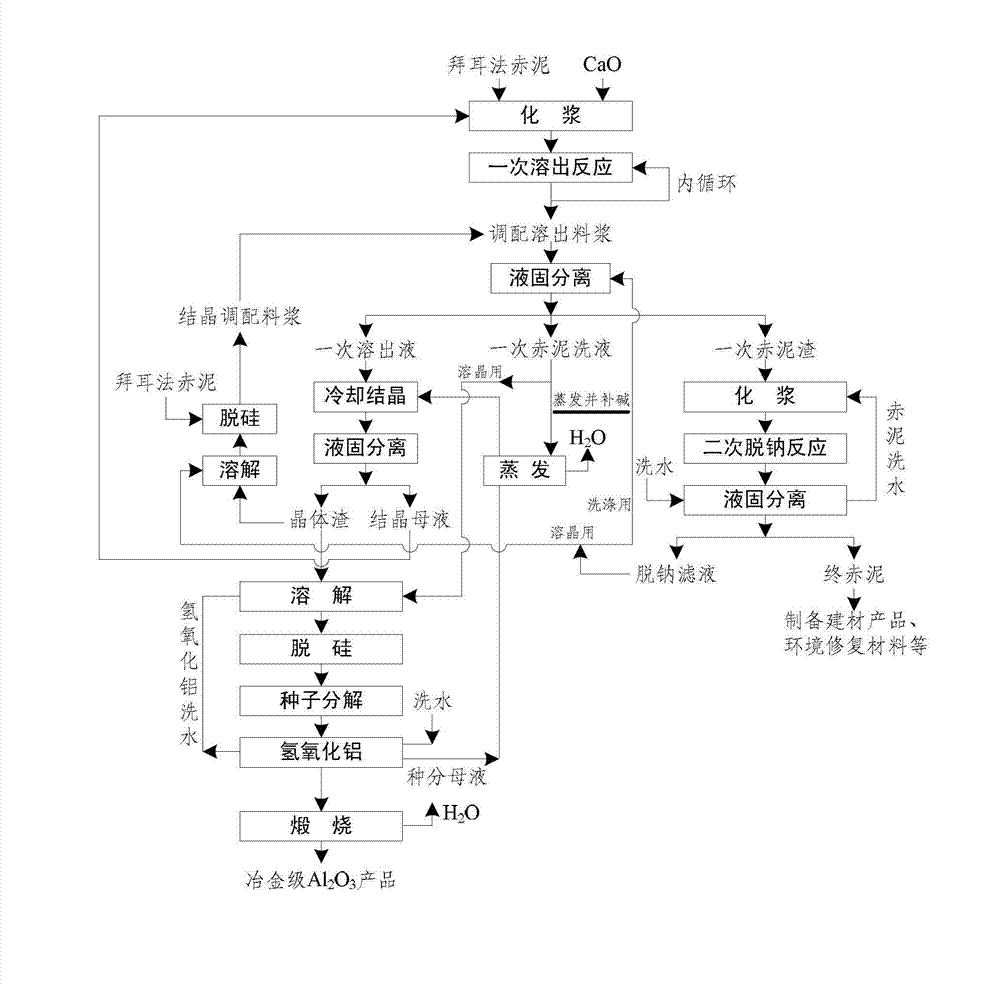

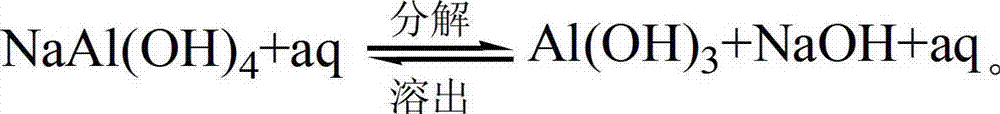

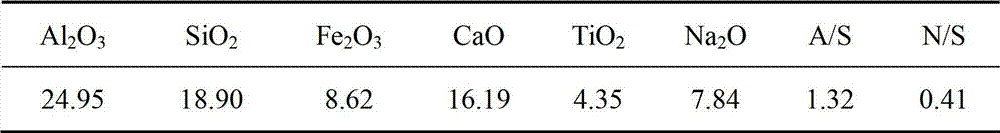

Method for recycling alumina and sodium oxide from bayer process red mud

ActiveCN103030160AHigh dissolution rateEfficient cycleAlkali metal oxidesAluminium oxides/hydroxidesBrickRed mud

The invention relates to a method for recycling alumina and sodium oxide from bayer process red mud. In the method, by adopting a high molecular ratio and high alkali concentration sodium aluminate solution, aluminum extracting reaction can be rapidly carried out under mild operating conditions, so that the recovery rate of alumina in the red mud reaches more than 85%, and the defects, such as equipment scabbing and the like can be effectively prevented and even eliminated; by implementing an efficient crystallization process of an intermediate product of hydrated sodium aluminate, the cycle efficiency of a dissolution medium is greatly improved; due to complete transformation of a phase in the aluminum extracting reaction, a reaction process of recycling sodium oxide can be performed at low temperature and normal pressure; and after secondary sodium removal reaction, the sodium oxide content in final red mud is not more than 1% and is far less than 6-8% of the bayer process red mud. Therefore, the red mud can be doped in large proportion for preparing cement, brick and roadbed materials, concrete additives, environmental remediation materials and other fillers, and the problems such as resource utilization of the red mud, potential environment hazard and the like are hopefully solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method of brewing a beverage with an electric, automatic beverage maker

ActiveUS9668496B1Uniform extractionSame qualityBeverage vesselsUnwanted substance removalAdditive ingredientMixing chamber

Owner:FOOD EQUIP TECH

Image processing apparatus, image processing method, and printing apparatus and printing system using the image processing apparatus

InactiveUS7385730B2Reduce memory capacityReduce capacityDigitally marking record carriersVisual representation by matrix printersImaging processingImage resolution

In an apparatus for performing printing using a color ink-jet head having a plurality of ink-discharge-port strings corresponding to ink materials having different color tones, a high-quality image having excellent gradation can be recorded, while reducing the cost of the apparatus and increasing the data processing speed by reducing the capacity of a memory for storing dot arrangement patterns. For that purpose, as a plurality of dot arrangement patterns for determining dot arrangement at output within a M×N-dot region for one input pixel, (1) patterns having a large number of gradation levels that can be represented (for example, nine gradation levels) and a high recording resolution (for example, 1,200 dpi (dots per inch)×2,400 dpi) are used for colors in which uneven stripes tend to be pronouncedly observed (for example, light cyan and light magenta), and (2) patterns having a small number of gradation levels that can be represented (for example, five gradation levels) and a low recording resolution (for example, 1,200 dpi×1,200 dpi) are used for colors in which uneven stripes tend to be less pronouncedly observed (for example, black, cyan, magenta and yellow).

Owner:CANON KK

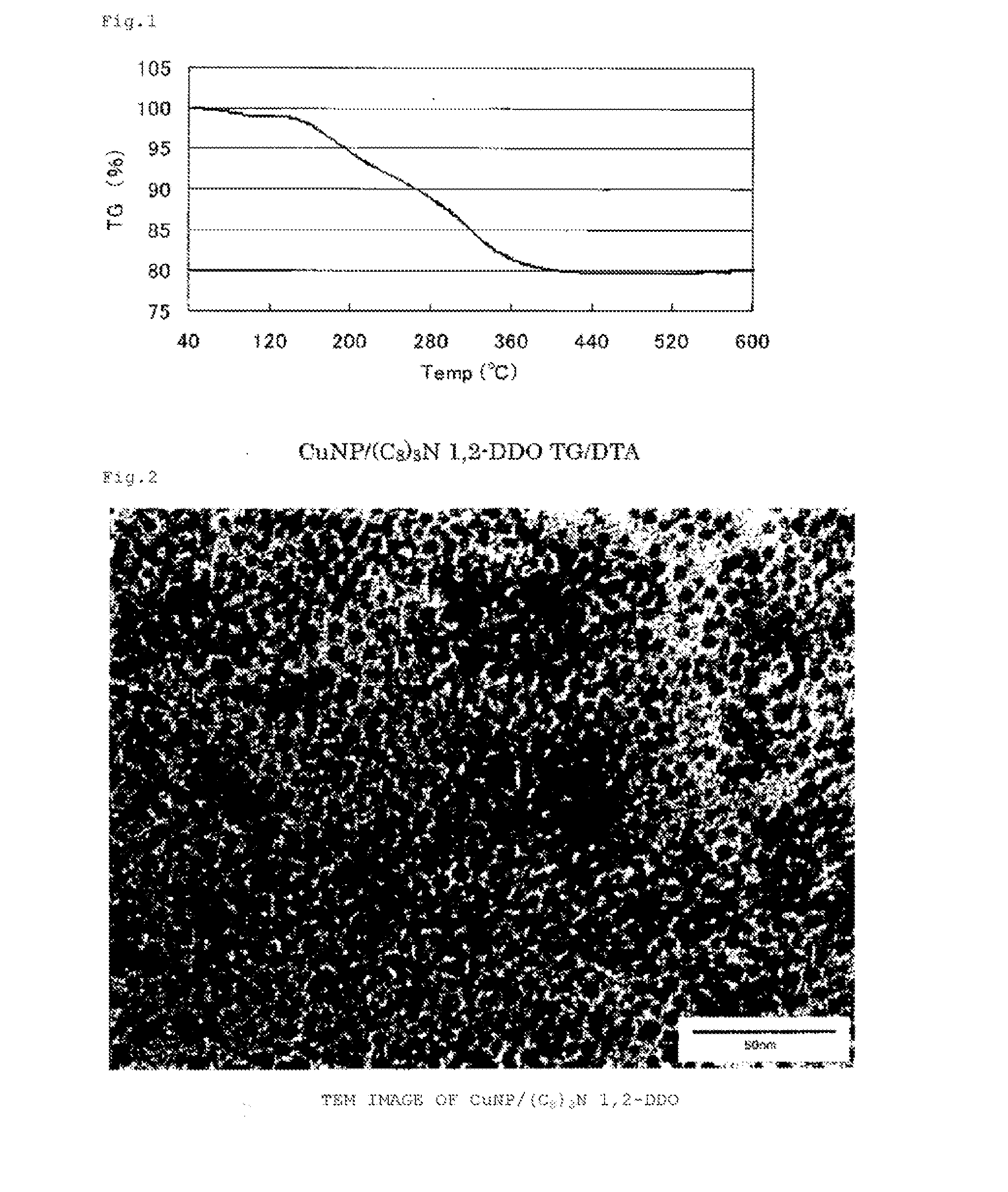

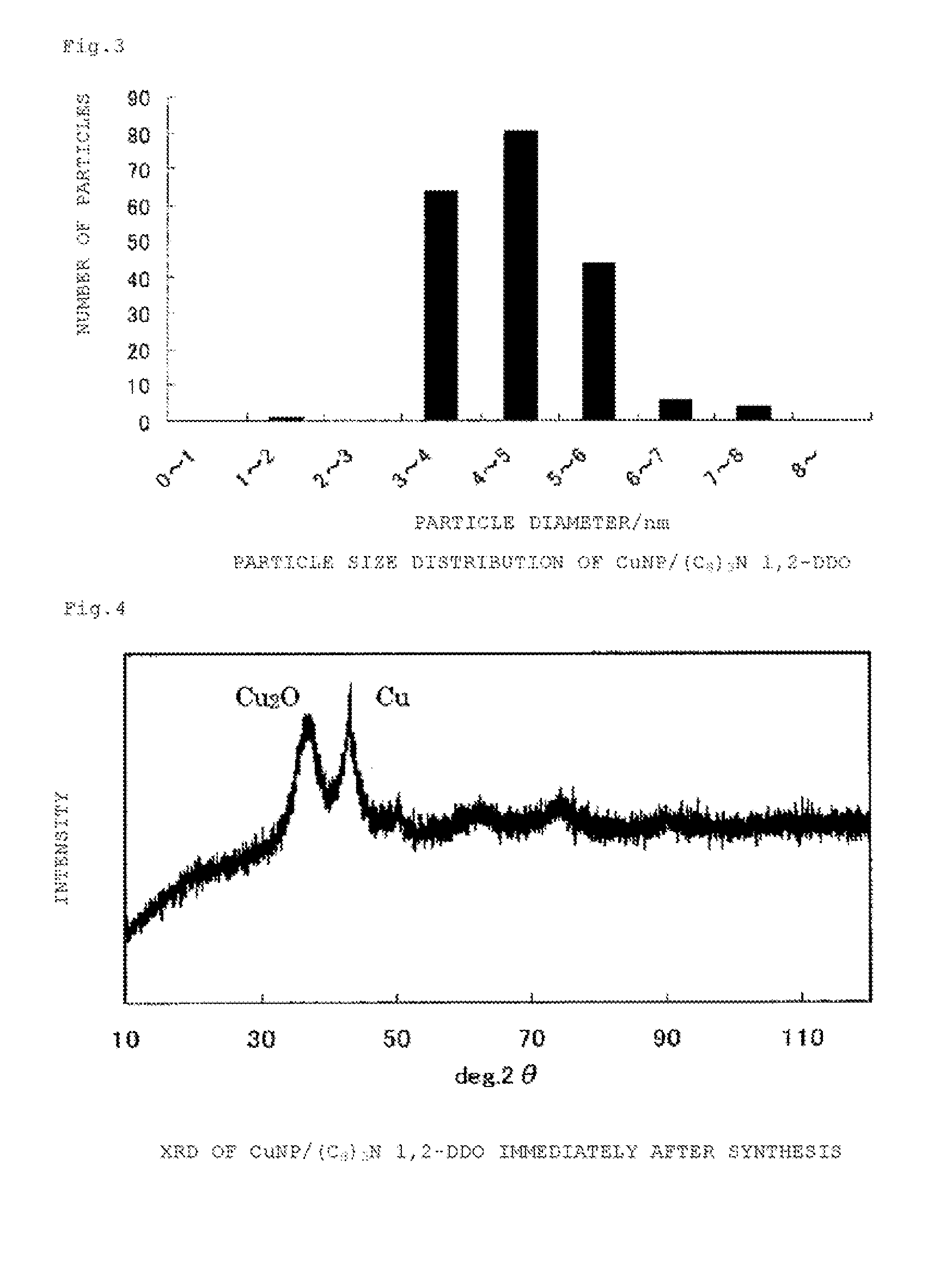

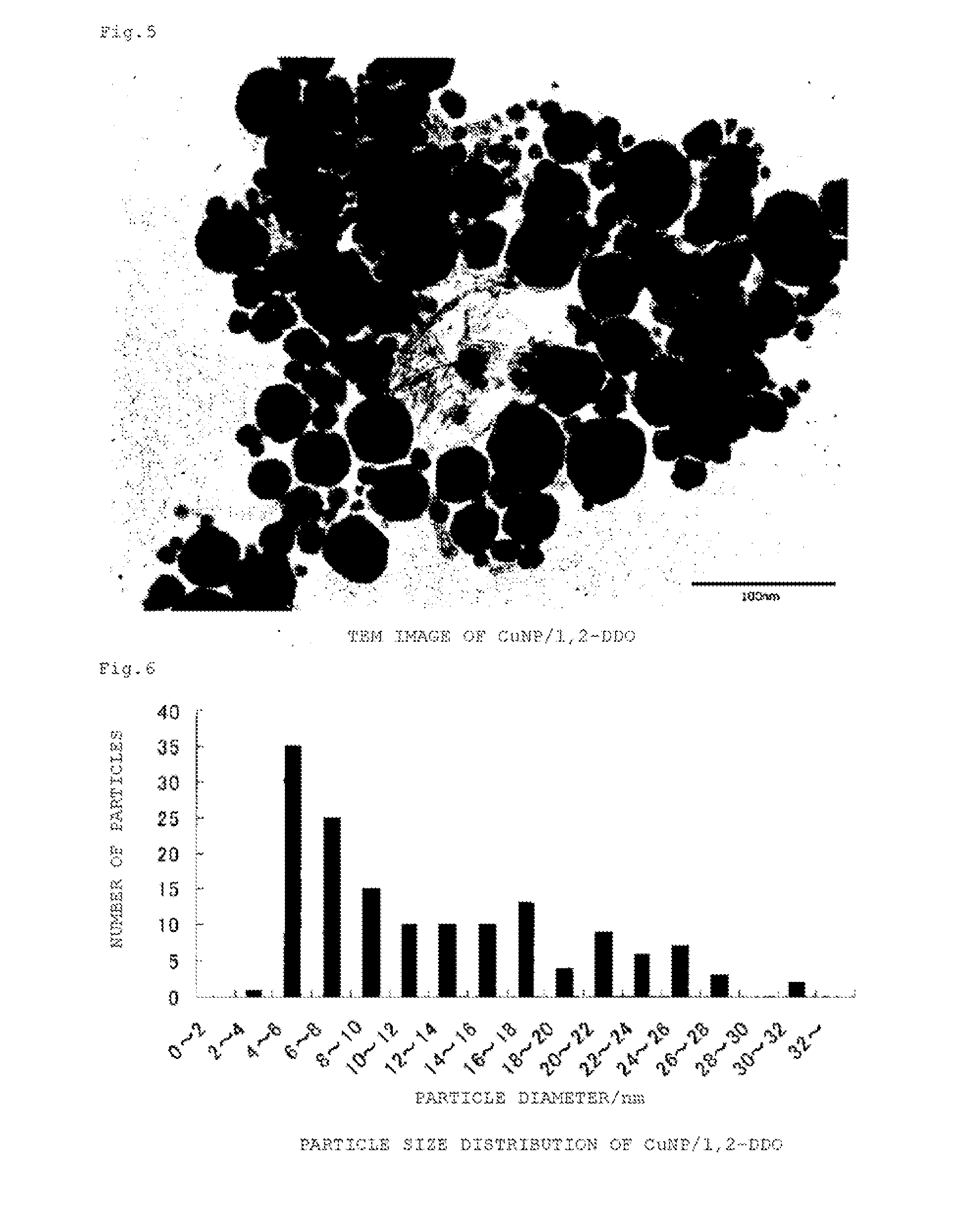

Copper-containing nanoparticles and manufacturing method therefor

InactiveUS20110193034A1Efficient preparationGood dispersionGroup 1/11 organic compounds without C-metal linkagesPigmenting treatmentDecompositionCompound (substance)

Copper-containing nanoparticles with excellent oxidation resistance is provided. The present invention relates to a method for manufacturing copper-containing nanoparticles including obtaining copper-containing nanoparticles that contain an organic component by heat treating an organic copper compound at a temperature equal to or higher than a decomposition initiation temperature of the compound and lower than a complete decomposition temperature of the compound in a non-oxidative atmosphere in the presence of an organic material containing a 1,2-alkanediol having 5 or more carbon atoms and / or a derivative thereof.

Owner:DAIKEN CHEM +1

Seismic acquisition method and system

ActiveUS8837255B2Reduce impactReduce outputSeismic data acquisitionSeismic energy generationImaging qualityBiological activation

The maximum output of a seismic source array may be reduced by activating the individual seismic sources within these seismic source array in a pattern that is extended in time rather than by the presently employed conventional simultaneous activation of a large number of individual seismic sources. Methods are disclosed which take data shot with patterned sources and may use a sparse inversion method to create data with the about same image quality as that of conventional sources. In this manner the output of the maximum impulse of a seismic source array may be reduced by an amplitude factor of about 10 in the examples shown here, corresponding to a reduction of about 20 dB while maintaining virtually the same seismic image quality. The disclosed methods may be used in combination with any simultaneous sourcing technique. In addition, the disclosed methods may be used with a plurality of source arrays.

Owner:BP CORP NORTH AMERICA INC

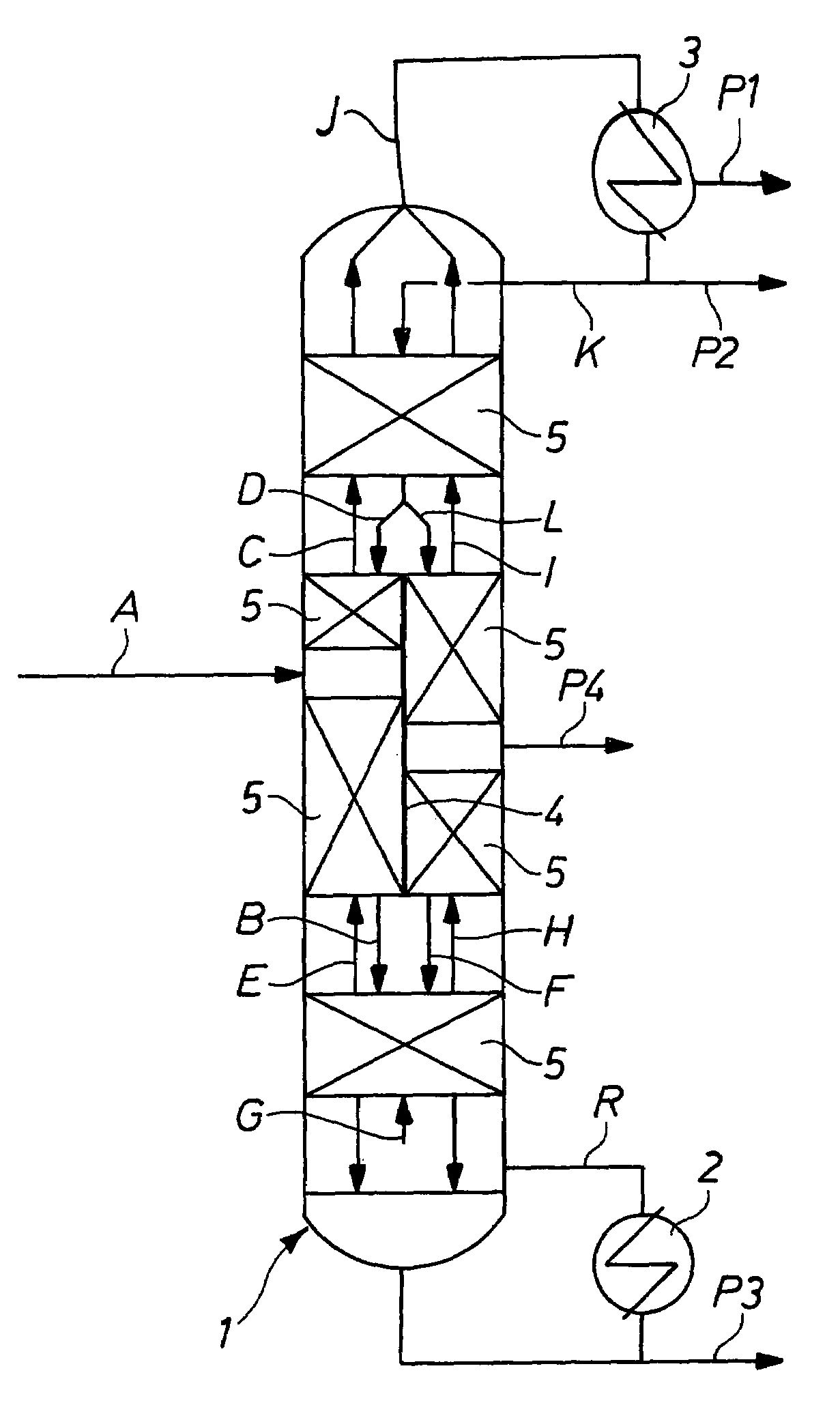

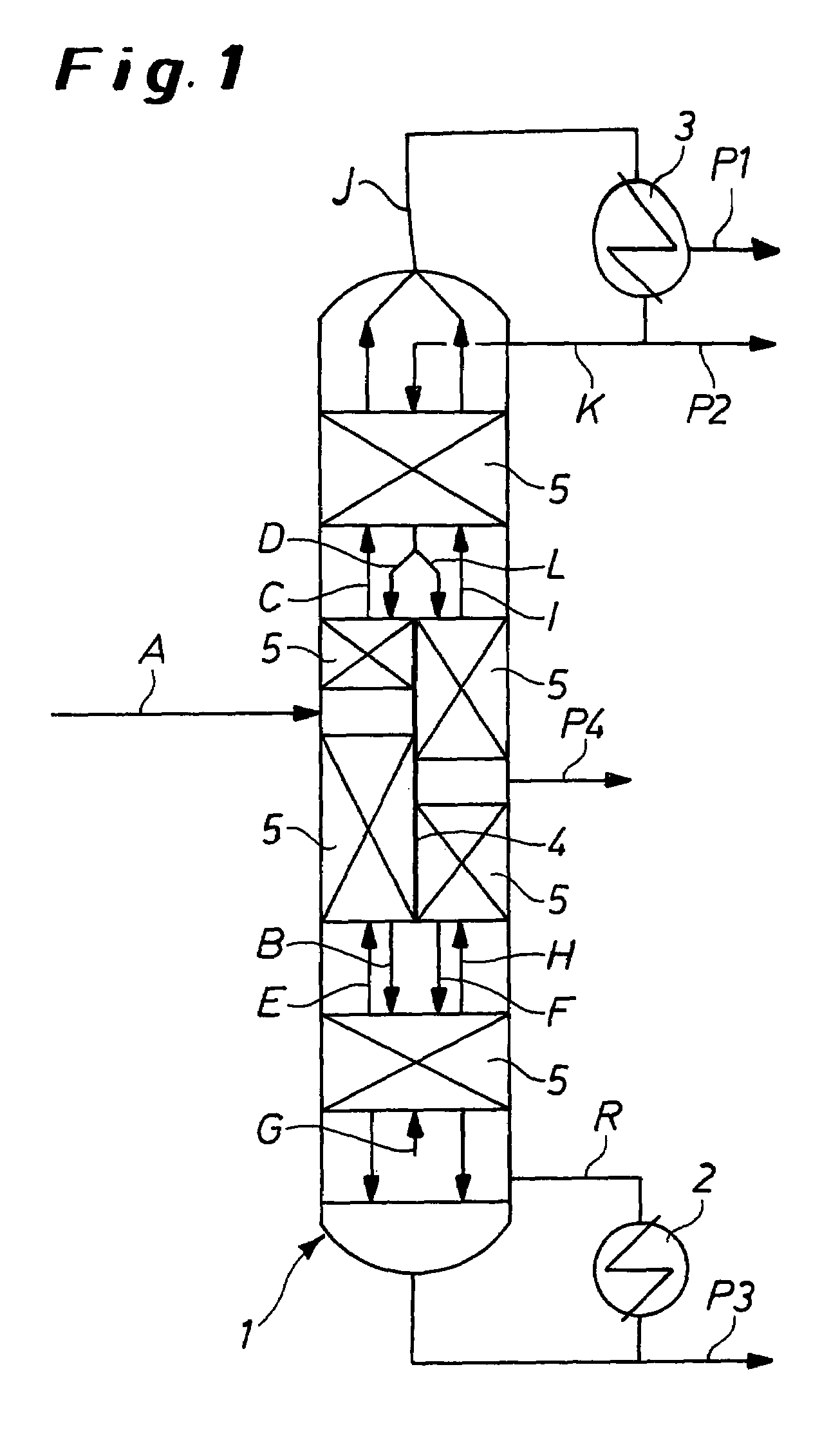

Process for the purification of toluene diisocyanate incorporating a dividing-wall distillation column for the final purification

InactiveUS7108770B2Improvement in TDI purityLower energy requirementsOrganic compound preparationIsocyanic acid derivatives purification/separationPurification methodsGas phase

Toluene diisocyanate is recovered from a crude distillation feed containing less than 2% by weight of phosgene by(a) fractionating the crude distillation feed containing less than 2% by weight of phosgene to remove the solvent and optionally the reaction residues to produce a crude toluene diisocyanate feed containing less than 20% by weight of solvent and(b) separating the crude toluene diisocyanate feed containing less than 20% by weight of solvent in a divided-wall distillation column into four product fractions P1–P4. P1 is a vapor phase low-boiler and solvent-enriched gas stream, P2 is a low-boiler and solvent-enriched product, P3 is a high boiler-enriched bottoms product containing toluene diisocyanate and P4 is a toluene diisocyanate product stream lean in low-boilers, high-boilers and reaction residues.

Owner:COVESTRO DEUTSCHLAND AG

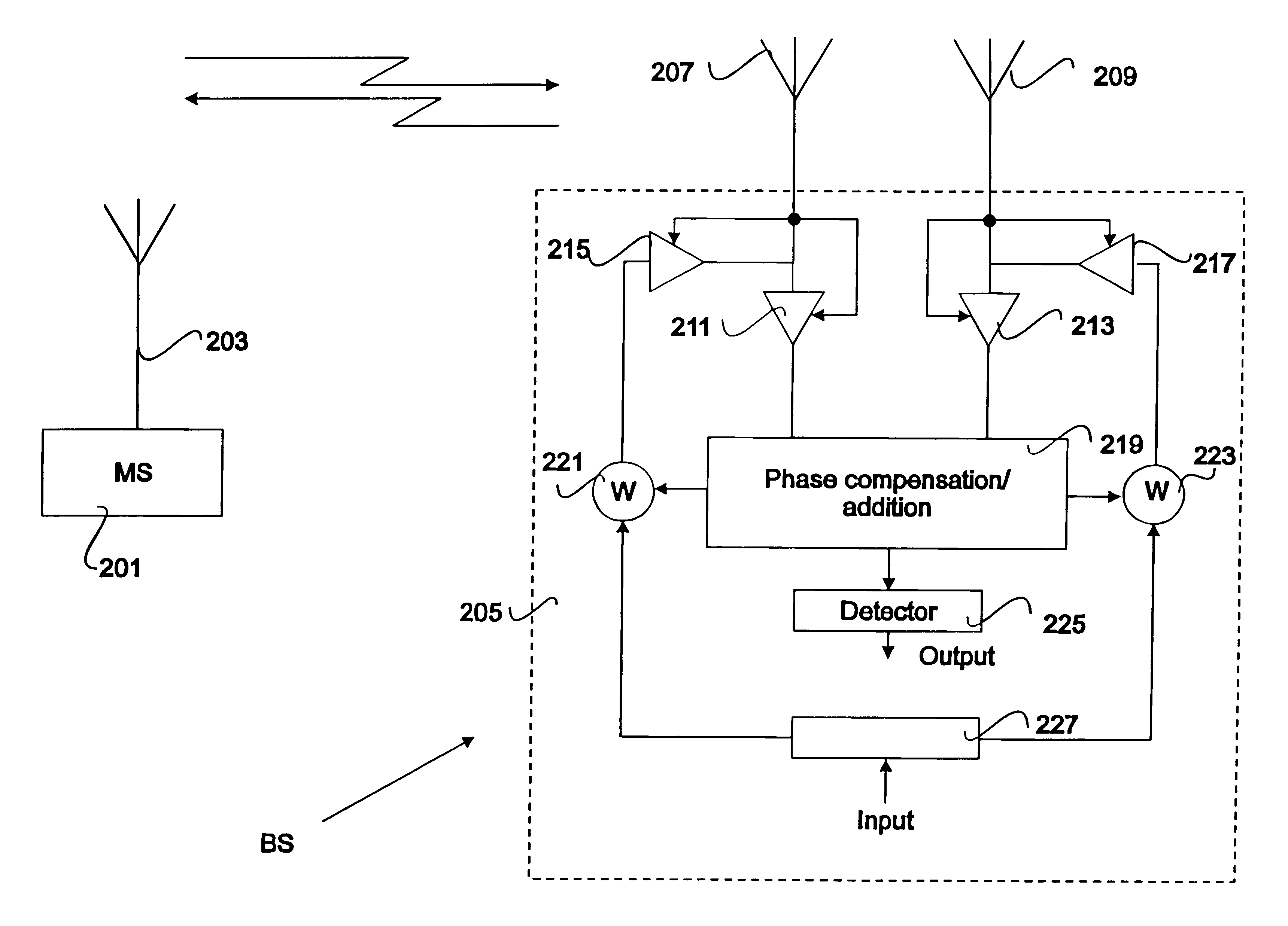

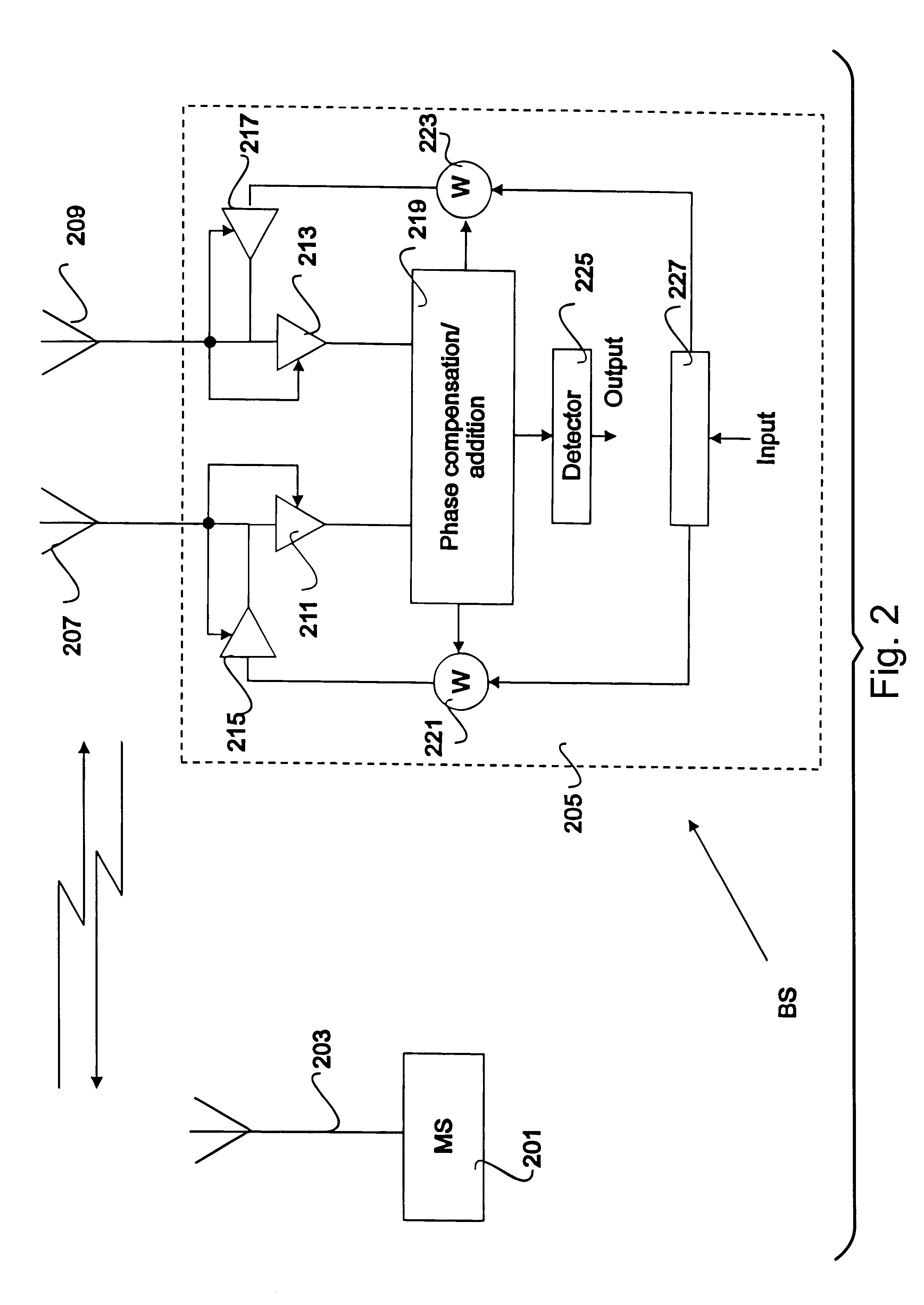

Method and a system for radio transmission

InactiveUS6526291B1Less powerSmall sizeSpatial transmit diversitySubstation equipmentCellular radioEngineering

In a cellular radio system down-link diversity is provided. The system has means in a base station (BS) for receiving signals from a mobile station (MS) using a diversity reception arrangement, in particular an antenna diversity arrangement (207, 209). Information regarding the current reception conditions is extracted from the reception diversity system and is used for improving the transmission. Thereby the transmitted signals can have less signal power, which in turn makes it possible to provide smaller cluster sizes and thereby increase the channel capacity in the cellular radio system.

Owner:TELEFON AB LM ERICSSON (PUBL)

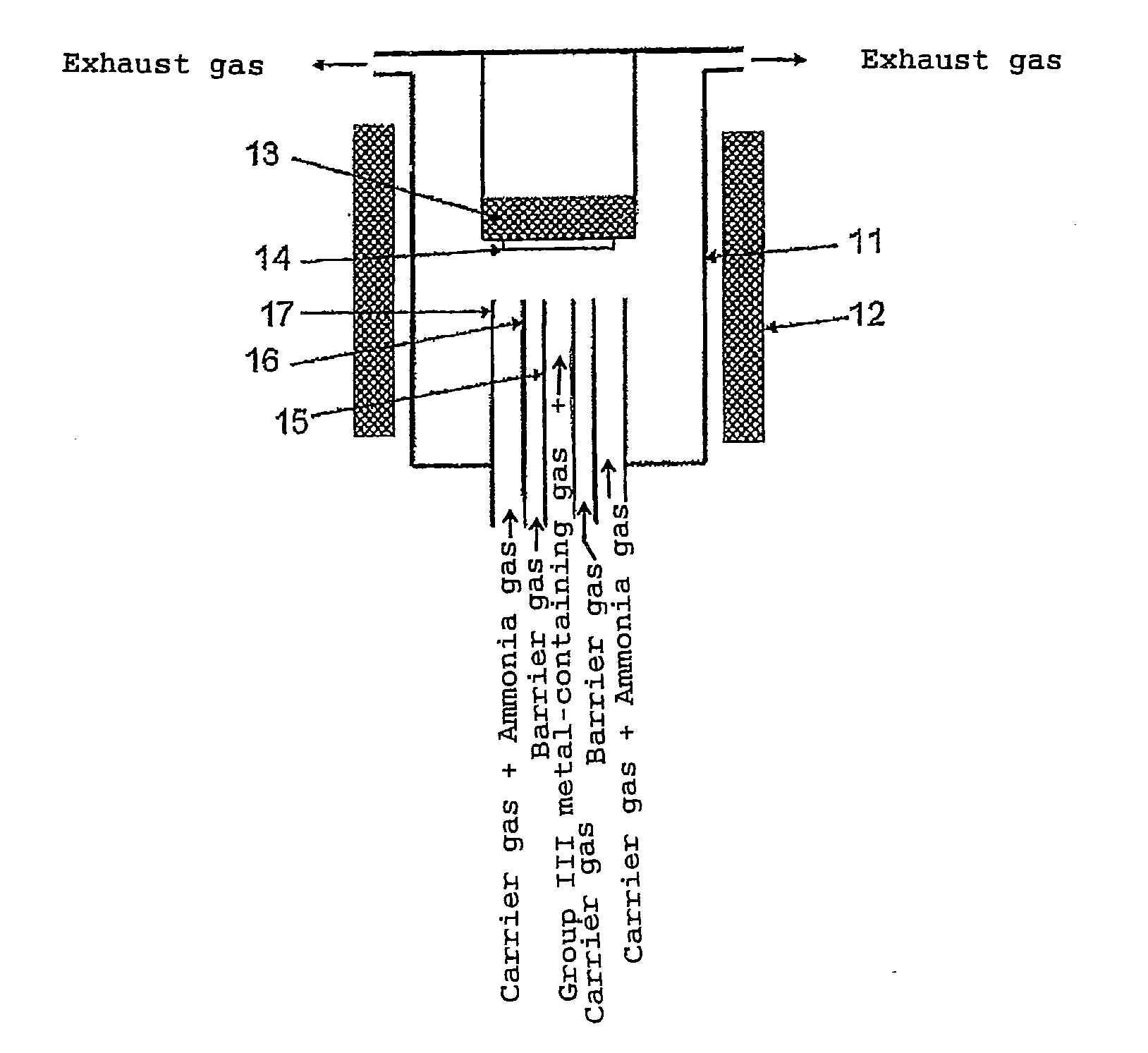

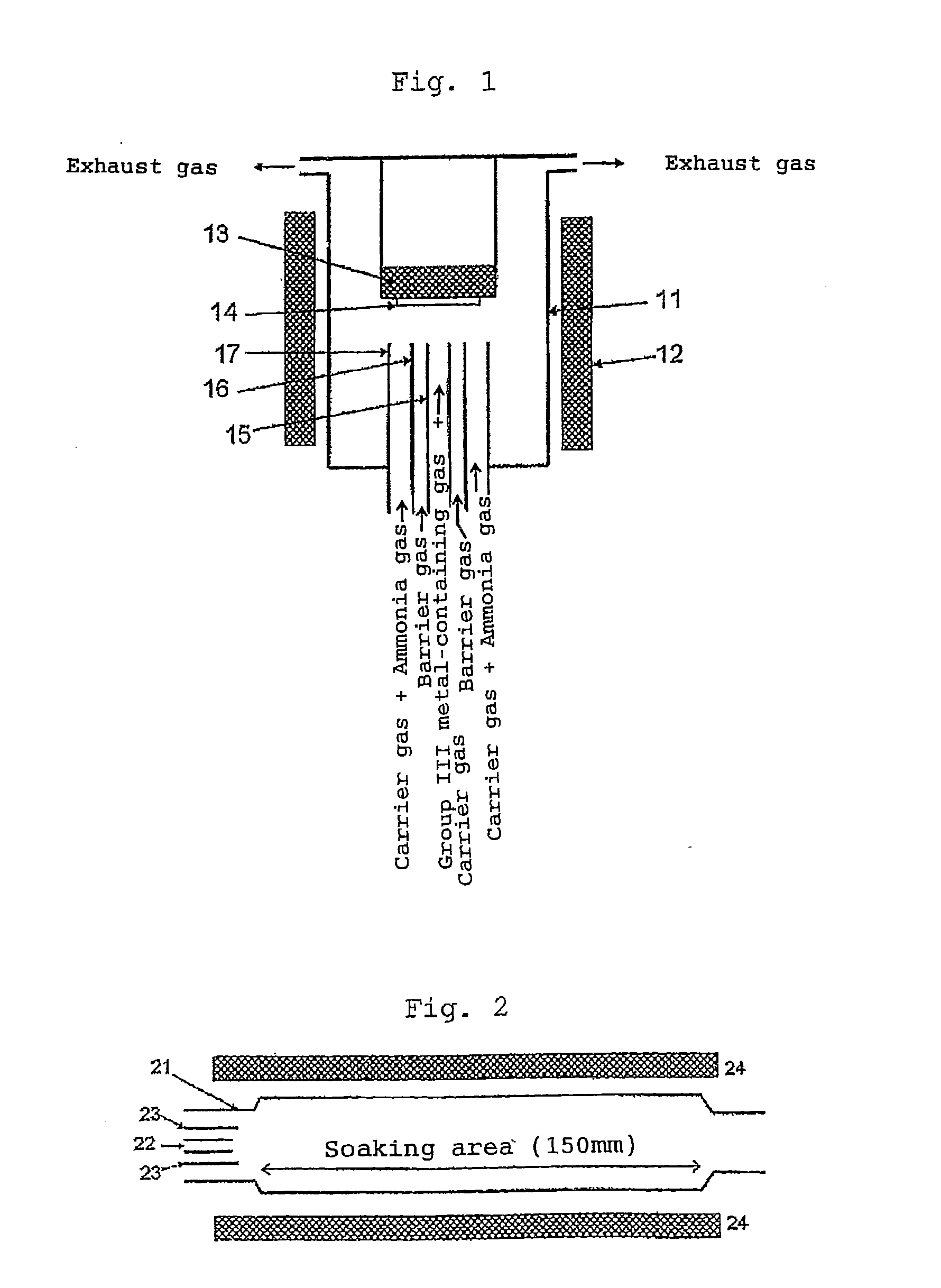

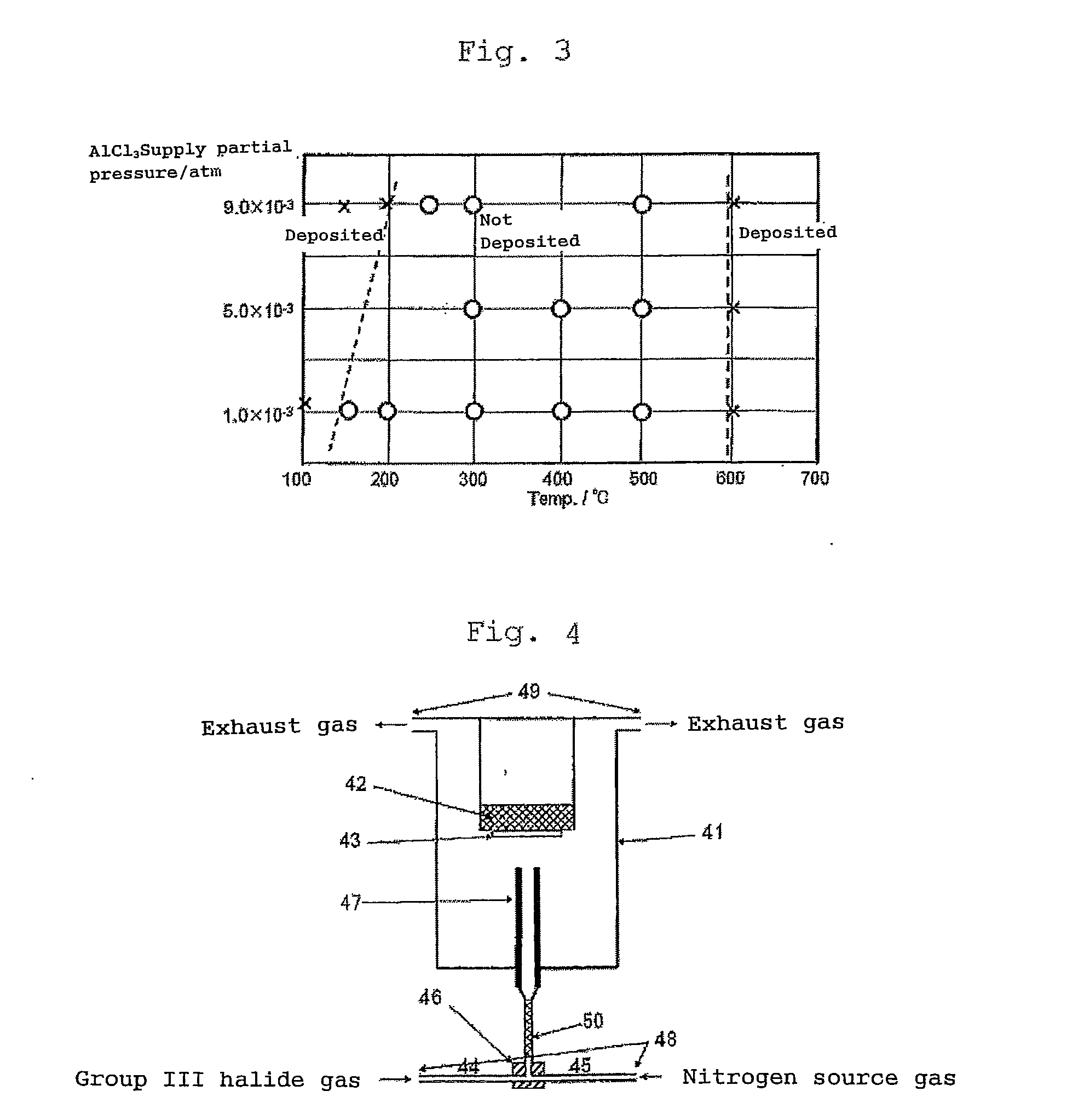

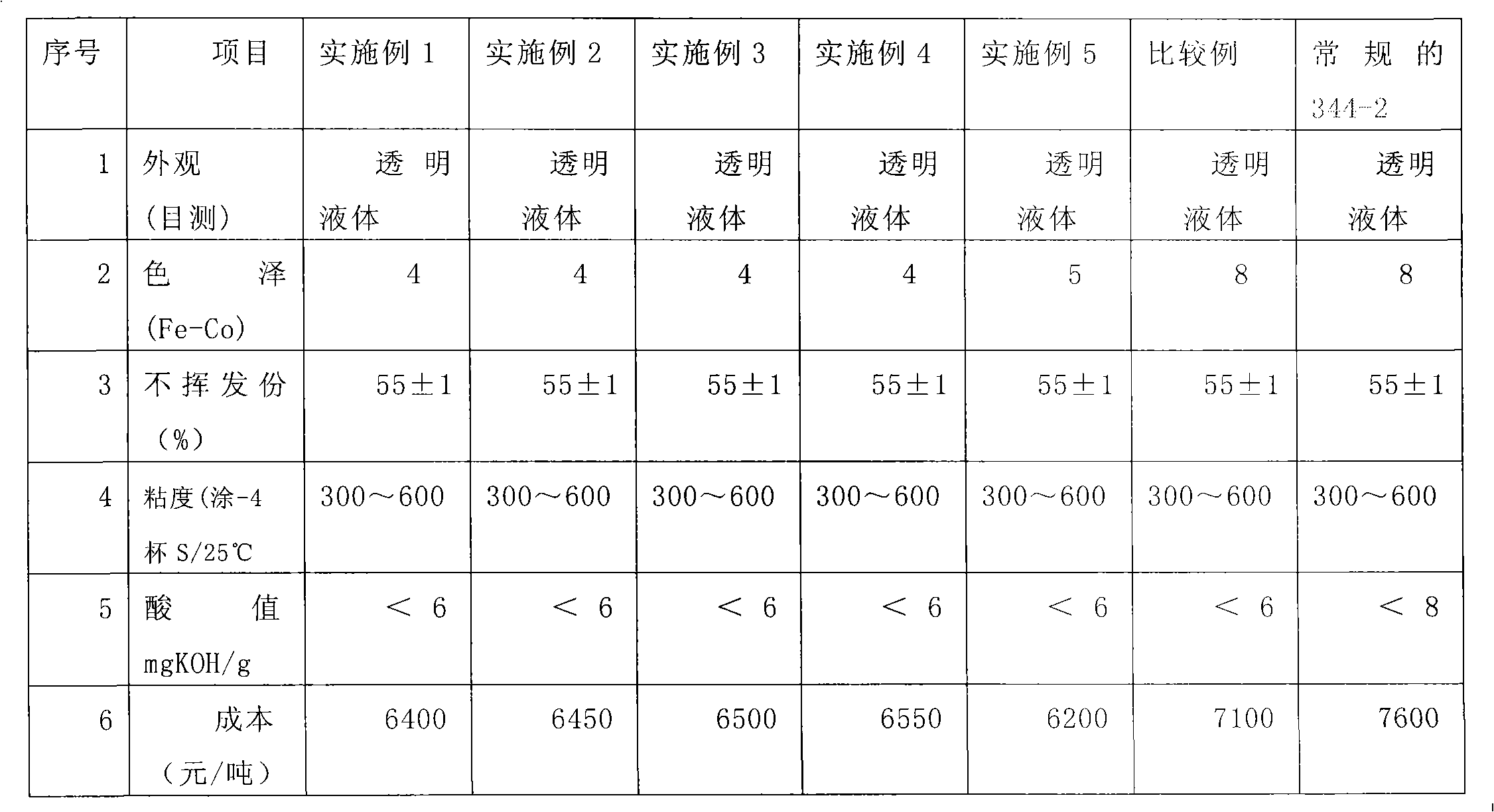

Method and apparatus for producing group iii nitride

InactiveUS20100029065A1High yieldSame qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingNitrogen sourceNitride

A method of producing a group III nitride such as aluminum nitride, comprising the step of reacting a group III halide gas such as aluminum trichloride gas with a nitrogen source gas such as ammonia gas in a growth chamber to grow a group III nitride on a substrate held in the growth chamber, wherein the method further comprises premixing together the group III halide gas and the nitrogen source gas to obtain a mixed gas and then introducing the mixed gas into the growth chamber without forming a deposit in the mixed gas substantially to be reacted each other.For the growth of a group III nitride such as an aluminum-based group III nitride by HVPE, there are provided a method of producing the group III nitride having as high quality as that obtained by the method of the prior art at a high yield and an apparatus used in the method.

Owner:TOKUYAMA CORP

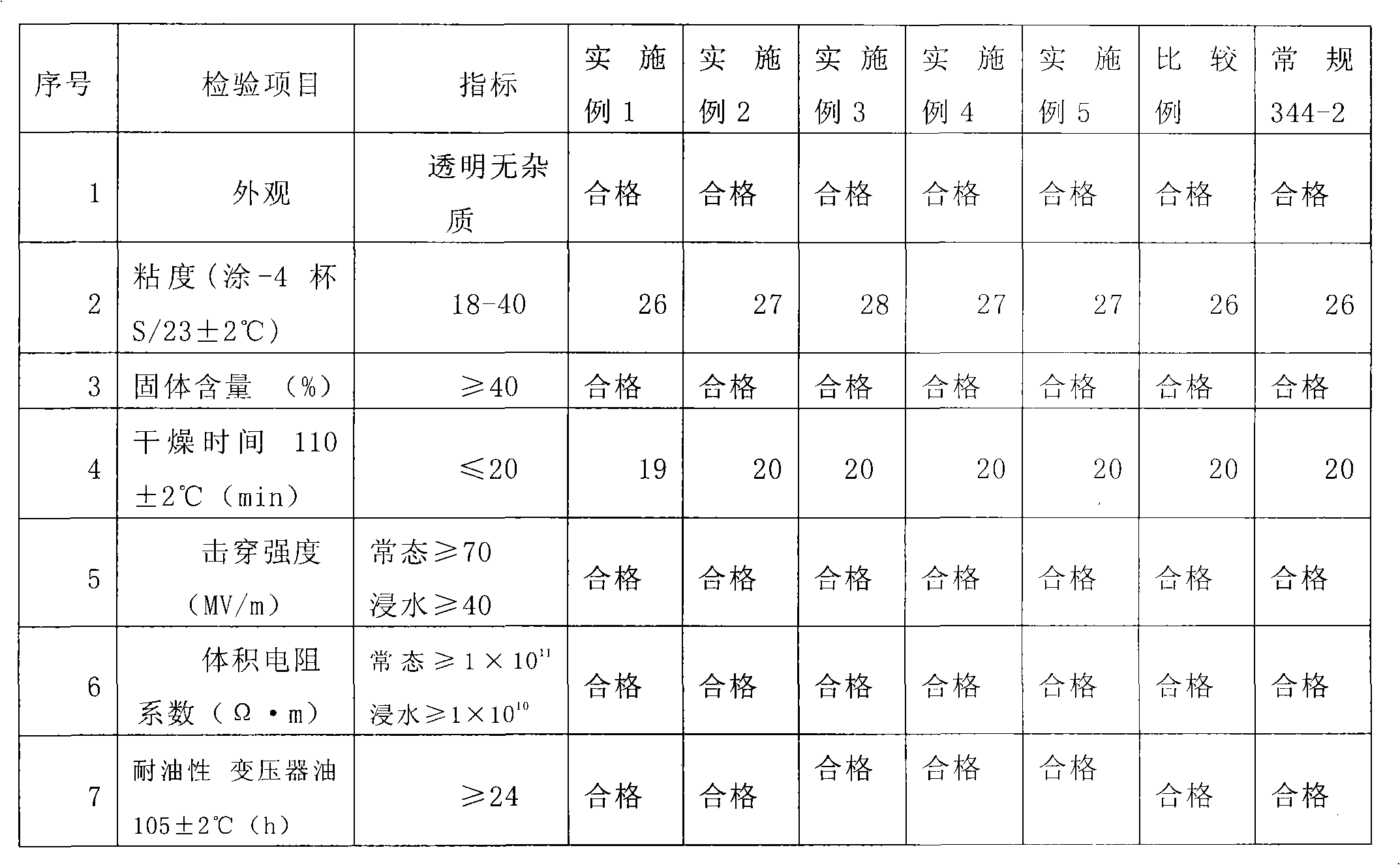

Alkyd resin for insulating paints and preparation method of alkyd resin

The invention discloses an alkyd resin for insulating paints and a preparation method of the alkyd resin. The alkyd resin for insulating paints is prepared by esterfying the following raw materials in parts by weight: 21-29 parts of glycerol, 10-16 parts of stearic acid, 16-24 parts of oleic acid, 15-25 parts of crude terephthalic acid, 0.06-0.1 part of hypophosphorous acid, 10-21 parts of phthalic anhydride and 4-7 parts of benzoic acid. Under the condition of ensuring that the final product quality is not reduced compared with that of similar products, the production cost of the alkyd resin for insulating paints is significantly reduced.

Owner:山东奔腾漆业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com