Silk reeling method and exclusive device for reeling raw silk

A special device and raw silk technology, applied in the direction of silk reeling, etc., can solve the problems of time-consuming and labor-intensive collection, affecting the quality of raw silk, and low labor productivity, so as to reduce the number of workers, shorten the time to deal with silk failures, and shorten the production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

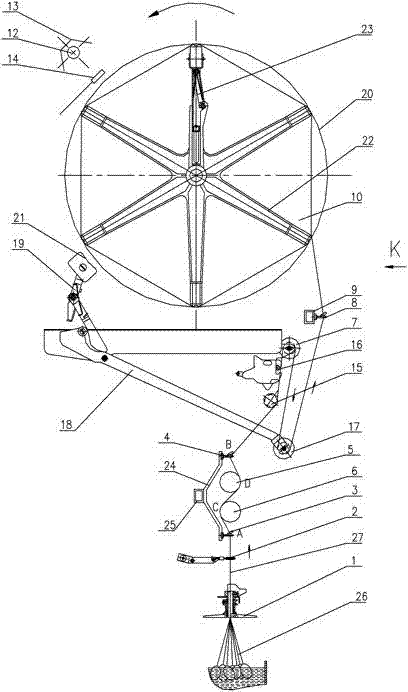

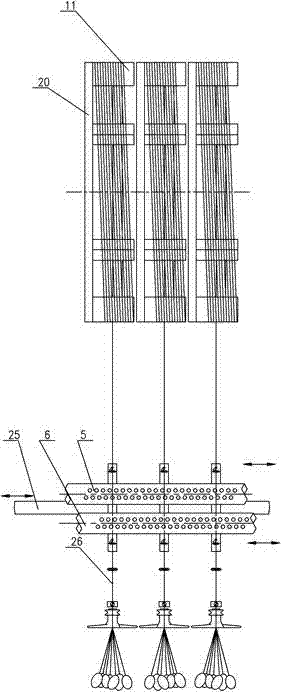

[0029] Embodiment: a kind of twisted raw silk reeling method of this example: according to raw silk specifications, such as figure 1 , figure 2 A plurality of cocoon threads 26 are assembled into wet raw silk 27 by high-speed rotation through the connecting wing 1, and the wet raw silk containing a large amount of water passes through the lead-in thread collector 2, passes through the lower guide wire hook 3 and the upper guide wire hook 4, The wet raw silk is in close contact with the lower godet roller 6 and the upper godet roller 5 in turn to form a certain wrap angle, and the wet raw silk is in close contact with the upper and lower godet rollers. After the godet rollers are heated, the raw silk strips are The godet rollers can be dried when in contact, reducing the moisture content of the raw silk. The wet raw silk and the godet roller move relative to each other. When the godet roller moves left and right and rotates slowly, the wet raw silk between the upper guide hoo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com