Patents

Literature

31results about How to "Hug tightly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

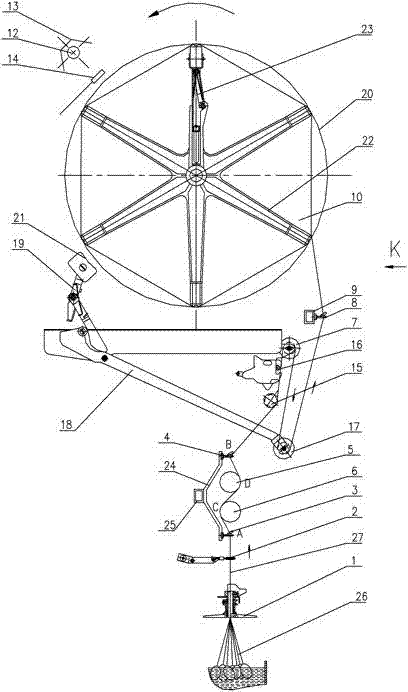

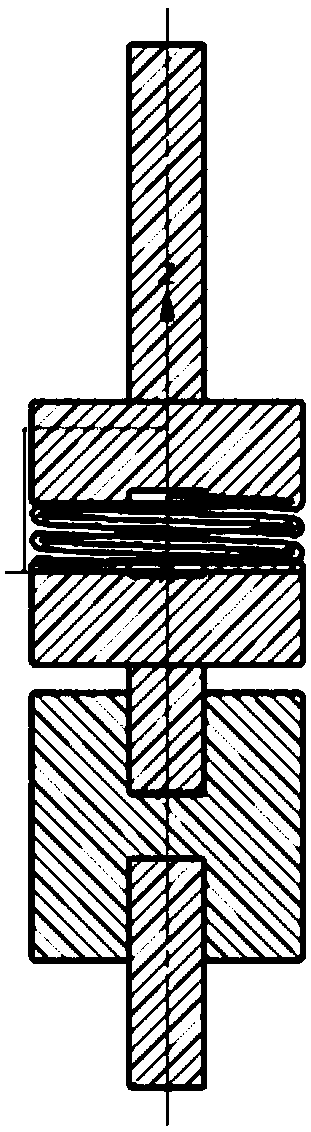

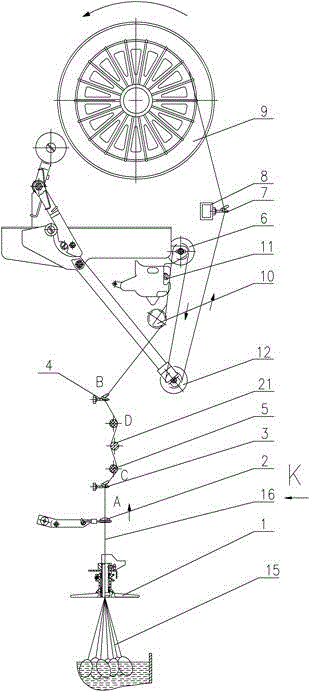

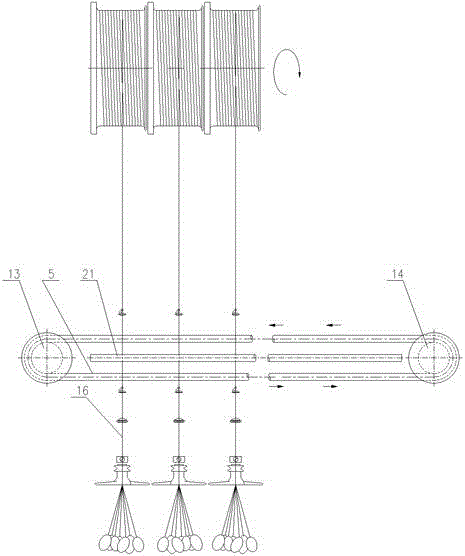

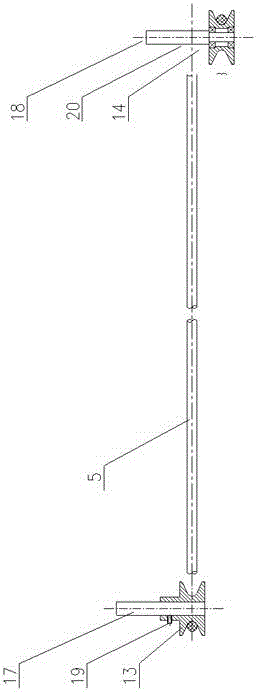

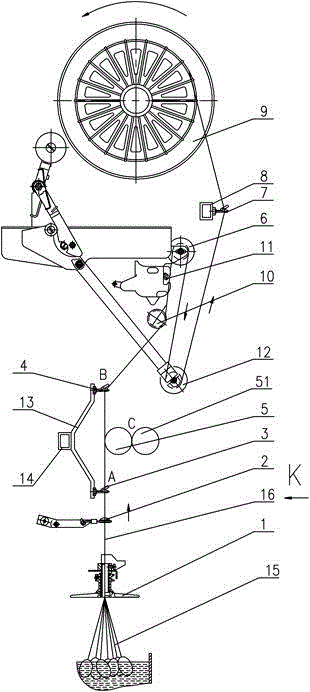

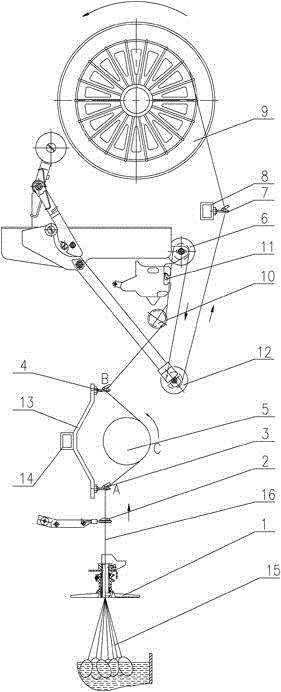

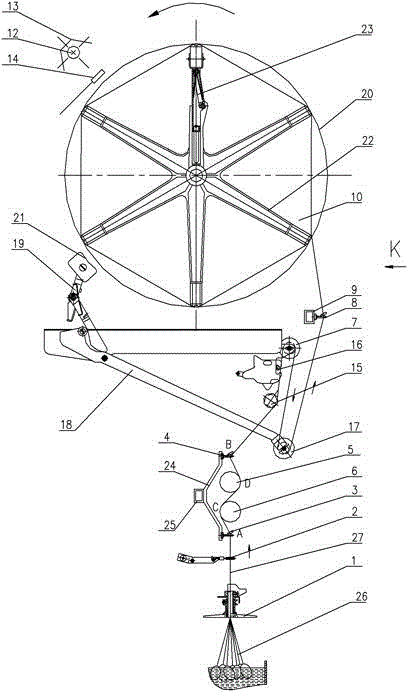

Silk reeling method and exclusive device for reeling raw silk

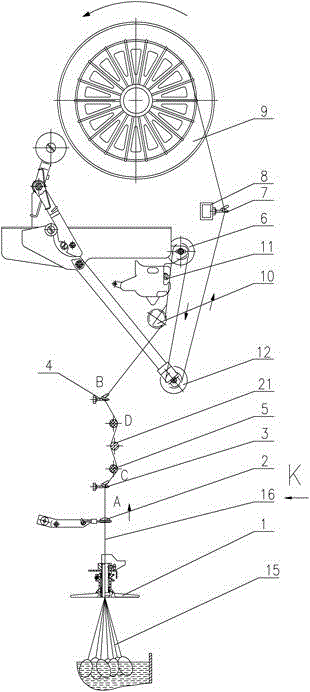

The invention relates to a silk reeling method and device, particularly to a silk reeling method and an exclusive device for reeling raw silk, which aim to solve the technical problems in the prior art that the energy consumption is large, the technological process is long, and more workers are needed all caused by silk reeling, rereeling and repeated drying; more time and labors are consumed because the bore diameter of a filament guide button is small; during the silk reeling process, the manual manner is adopted to form a silk sheath structure, and the hygrometric state raw silk is gathered by the function of the silk sheath in the method of gathering hygrometric state raw silk, the operation is complicated and the labor productivity is low. According to the invention, bave is processed by a hygrometric state raw silk gathering device after passing through an end feeding wing and a leading-in type filament guide button so as to enable the hygrometric state raw silk to be closely gathered, and moisture in a silk strip to be emitted by extrusion, tiny fouls on the bave surface are eliminated through kneading in a rotary manner, then, the bave is directly wound on a large shade and forms large flourishing yarn sheets through infra-red heating and drying, and the yarn sheets become reeled raw silk after silk falling arrangement.

Owner:ZHEJIANG SCI-TECH UNIV

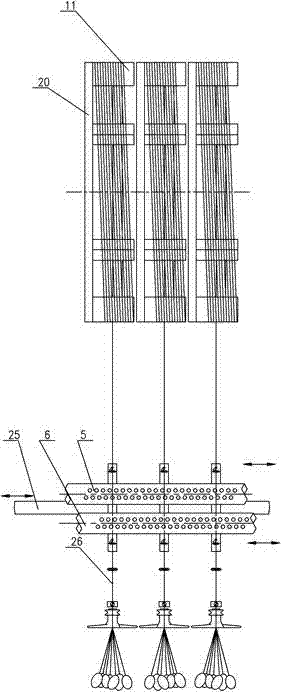

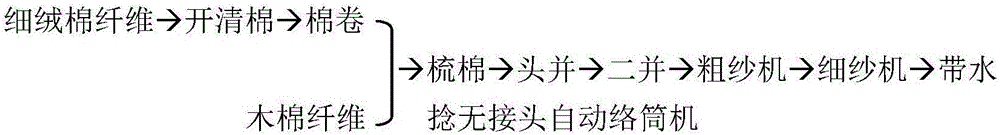

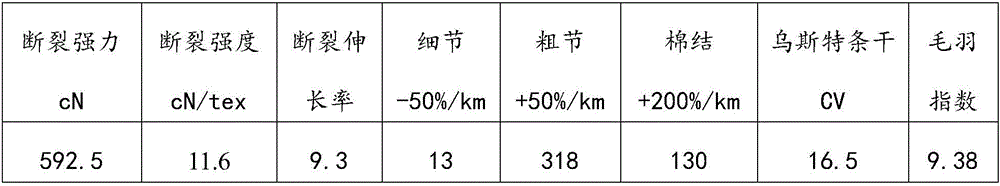

Kapok/fine staple cotton ring spinning blended yarn and production method and use thereof

The invention relates to a Kapok / fine staple cotton ring spinning blended yarn and a production method and application thereof. The production method of the blended yarn includes: performing humidifying, weight-increasing, and heath care treatment on kapok fibers in a warm water at the temperature of 40-50 DEG C so as to solve the problem of flying of the kapok fibers in spinning and improve the spinnability of the kapok fibers; performing grabbing, mixing, opening, dust removing, and rolling on fine staple cotton fibers to form cotton rolls; mixing the simple opened kapok fibers and the fine staple cotton rolls to form slivers in a cotton carding process by adoption of a cotton layer even mixing feeding manner; performing two-drawing, roving, spinning and spooling to finally acquire the Kapok / fine staple cotton ring spinning blended yarn having high strength. The Kapok / fine staple cotton ring spinning blended yarn is high in strength, is hairless, and is even; the kapok fiber is excellent in straightness and is tight in cohesion, and is soft and smooth in hand feeling, and has a golden light effect; and the blended yarn can be used in jeans wear and has good prospect.

Owner:WUHAN TEXTILE UNIV +1

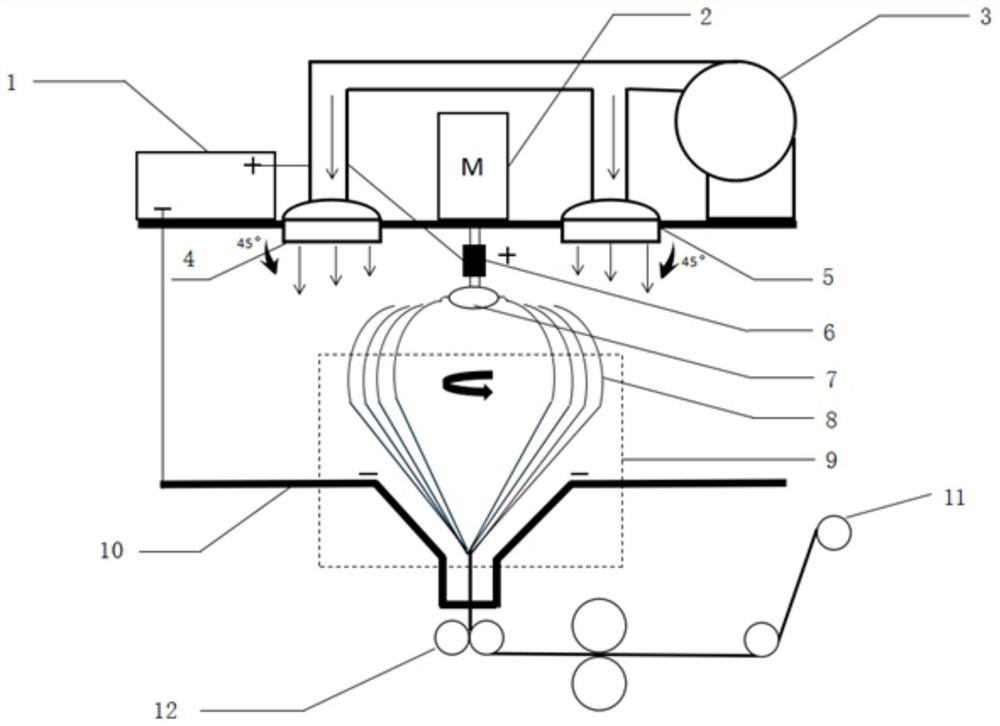

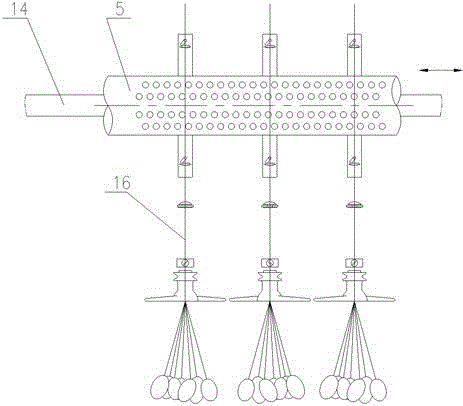

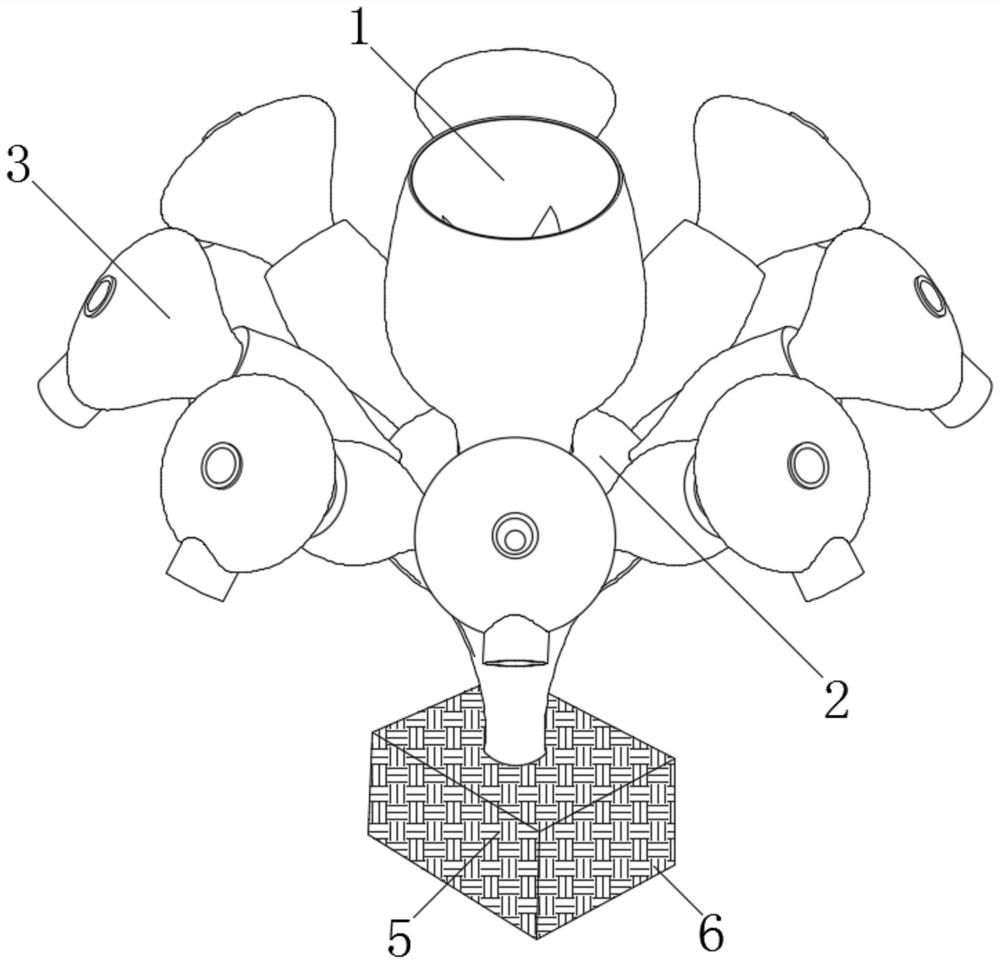

Continuous preparation device and method for self-twisting nanofiber yarn

ActiveCN108796687AIncrease productivityWide range of choicesElectro-spinningContinuous wound-up machinesYarnFiber

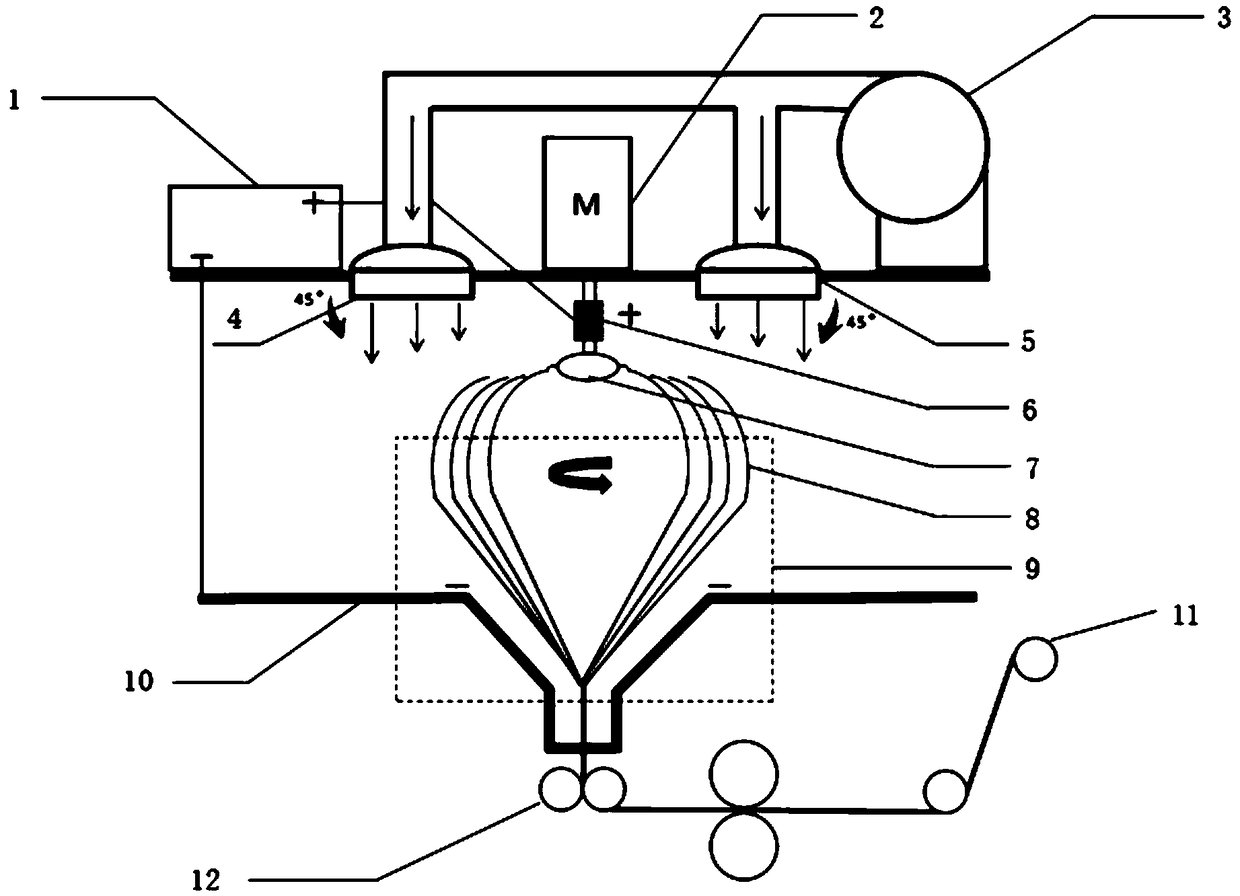

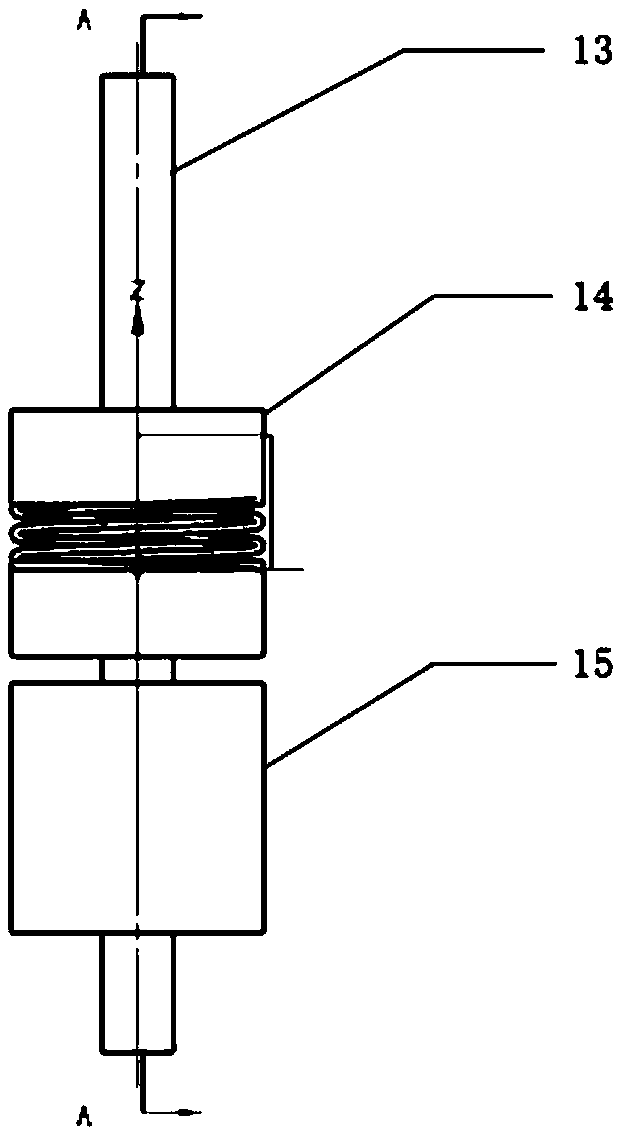

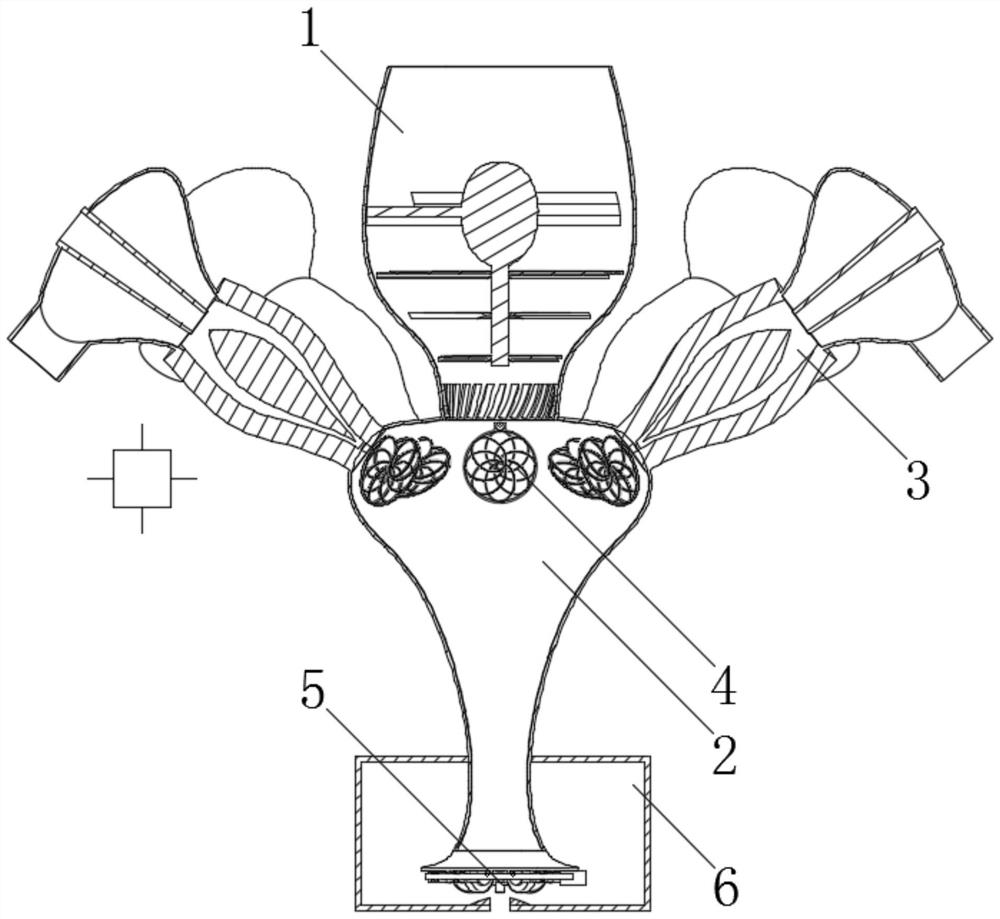

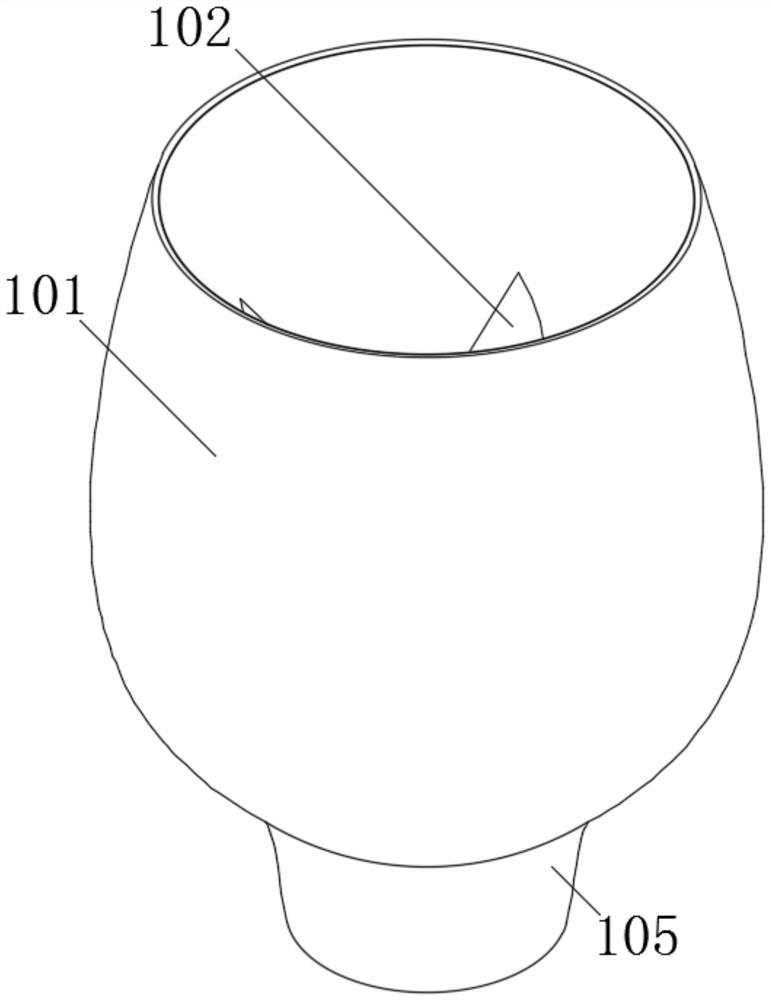

The invention relates to the technical field of textile processing and aims at providing a continuous preparation device and method for self-twisting nanofiber yarn. The device comprises a verticallymounted motor, and a rotating shaft at the bottom of the motor is connected to a metal spinneret through a coupler; a plurality of filament spraying holes are uniformly formed in a circumferential direction of the spinneret; a bundling system comprises a funnel-shaped bundling apparatus, a fan and at least two air spraying heads; the funnel-shaped bundling apparatus is connected to a negative electrode of an electrostatic generator through a cable; a through hole is formed in the center of a sinking part, and the through hole, the spinneret and the rotating shaft of the motor are located on the same vertical axis; the plane where the filament spraying holes in the spinneret are located is arranged in parallel with a planar part of the funnel-shaped bundling apparatus; a winding collectionsystem comprises a yarn guide roller and a winding roller, and the yarn guide roller is located below the through hole of the funnel-shaped bundling apparatus. According to the device and method, nanofibers are prepared by electrostatic centrifugal spinning, the production efficiency is high, and raw materials are soluble and meltable; the nanofiber yarn has the advantages of high orientation degree, good continuity, simultaneous twisting, high efficiency and a short flow.

Owner:ZHEJIANG SCI-TECH UNIV

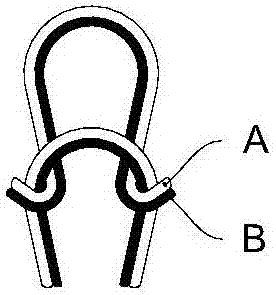

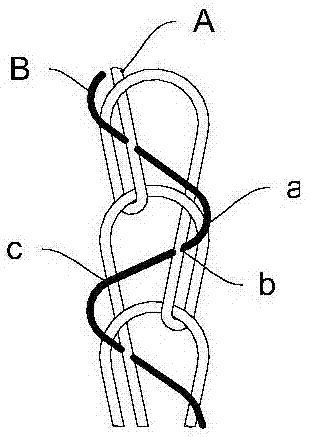

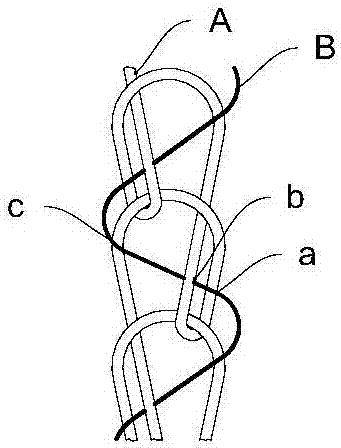

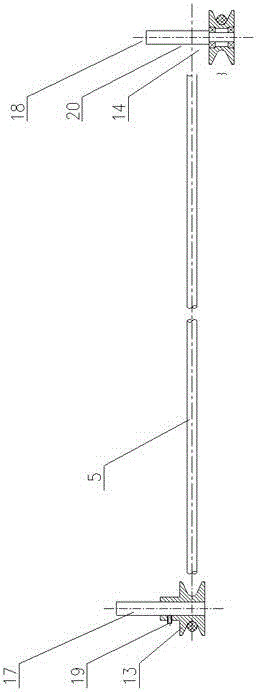

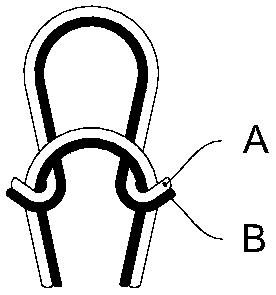

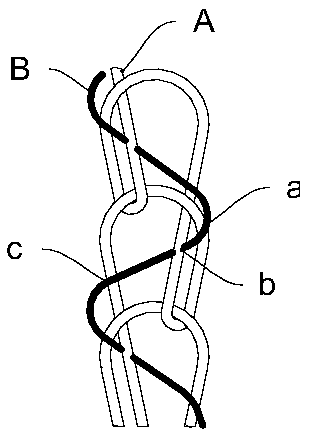

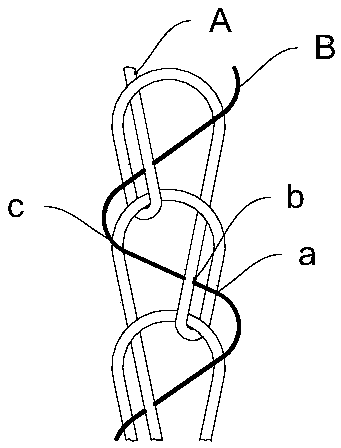

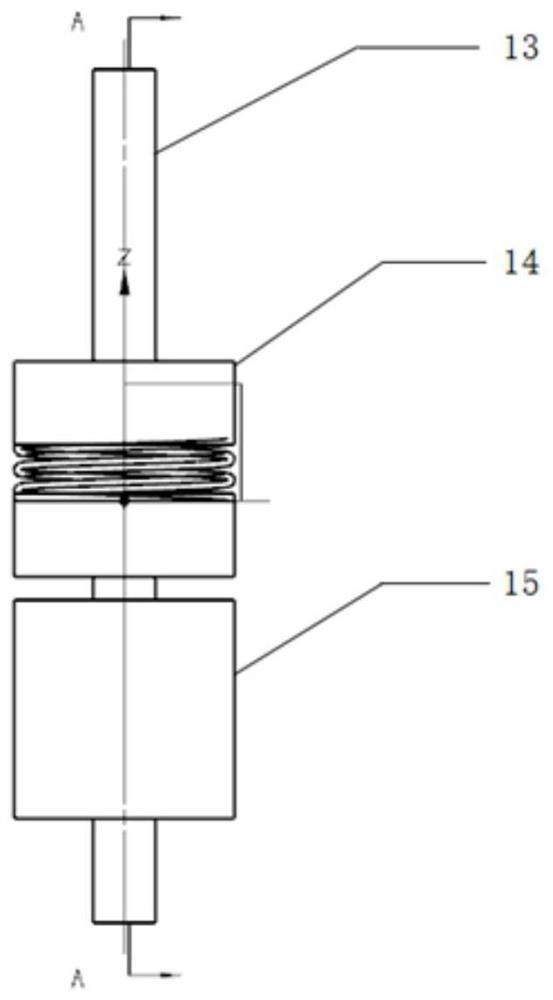

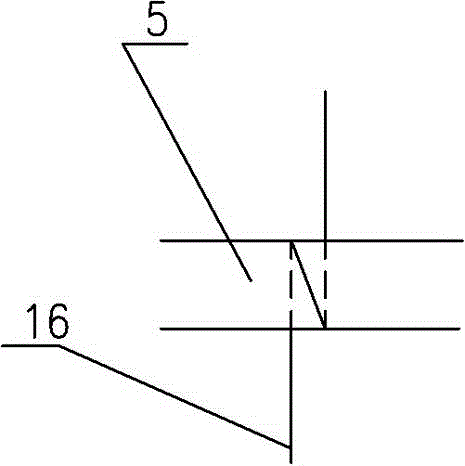

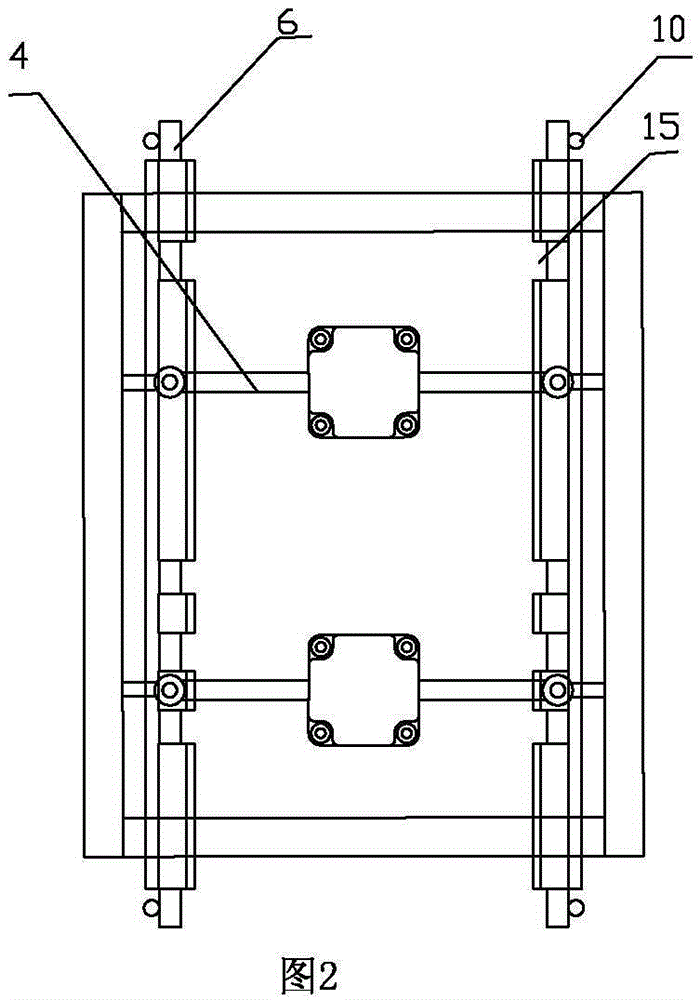

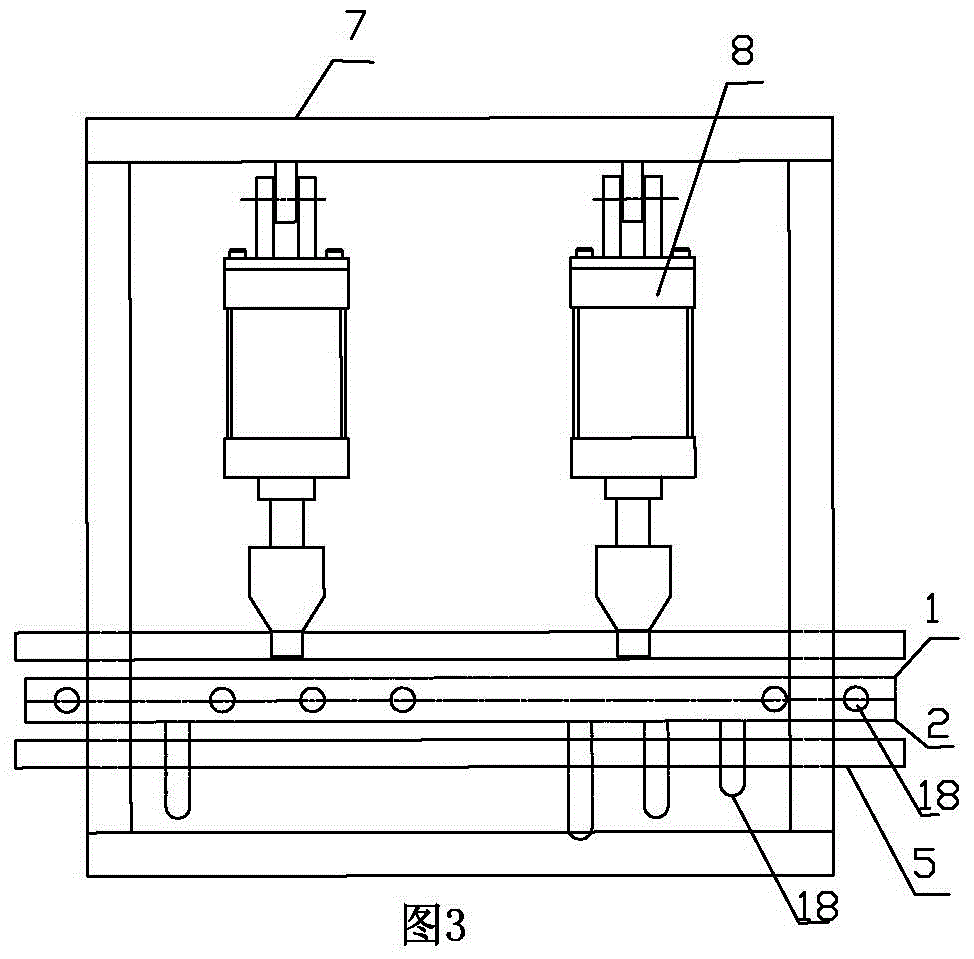

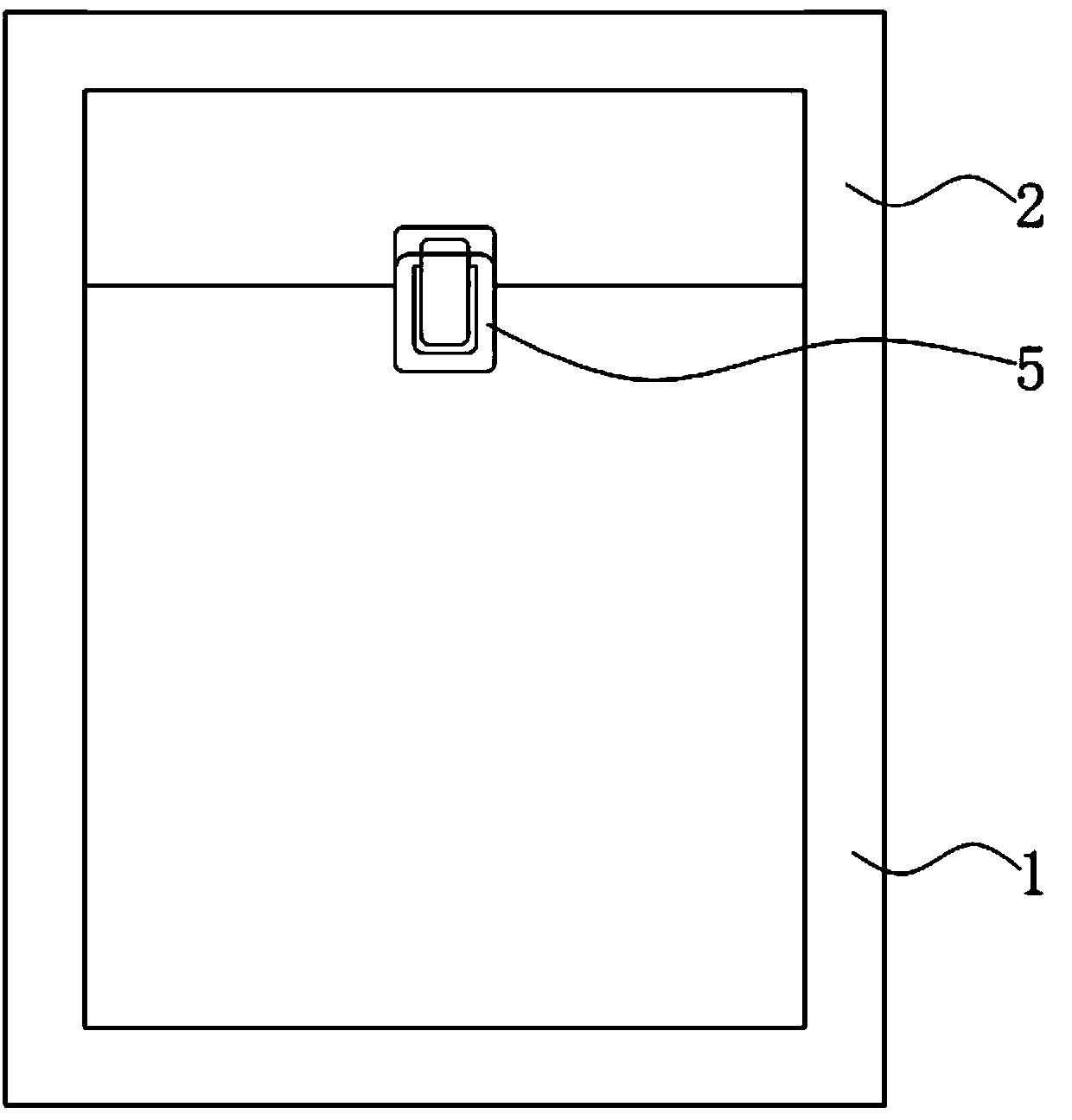

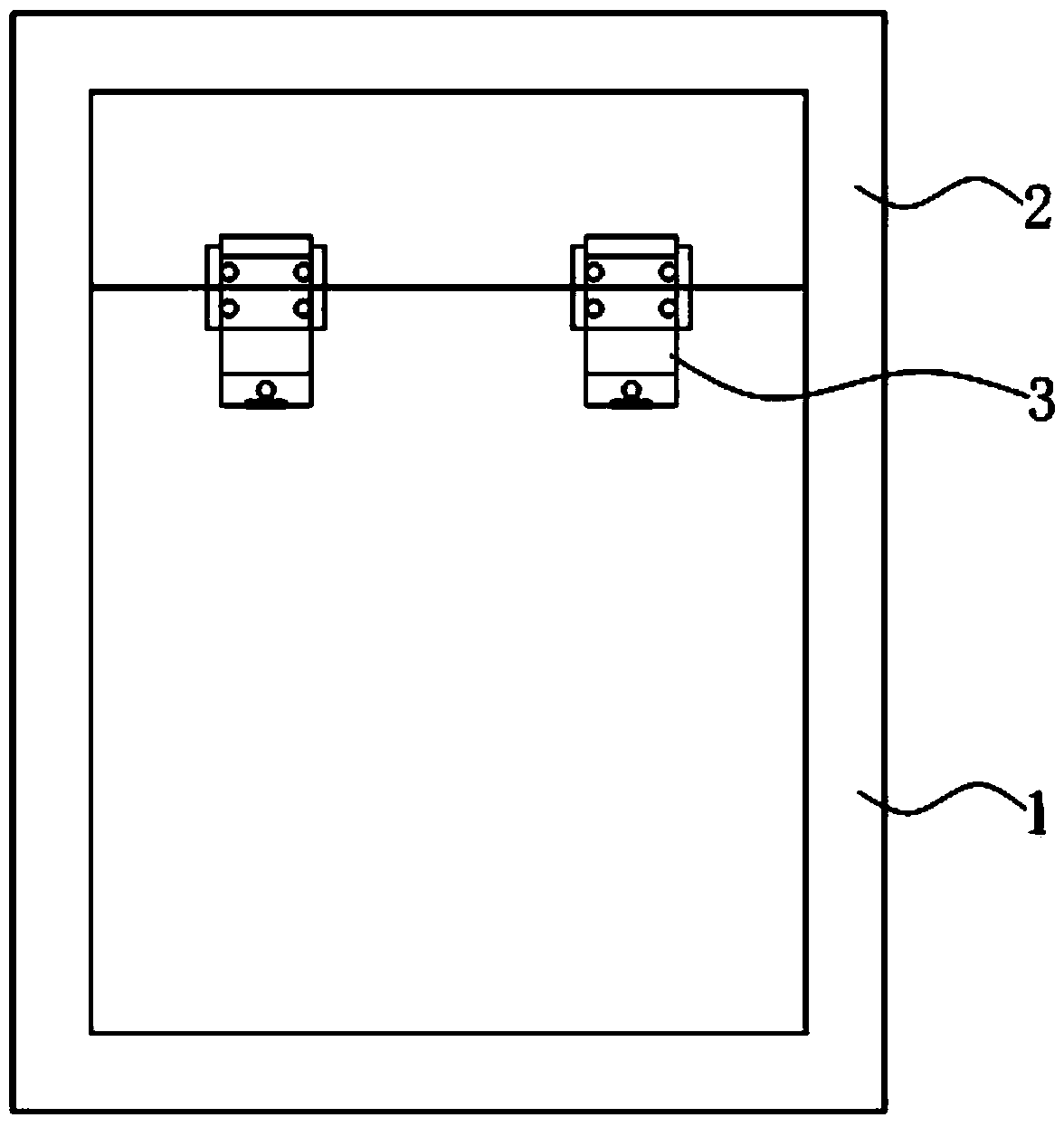

Wet raw silk double-twisting gathering method and special device

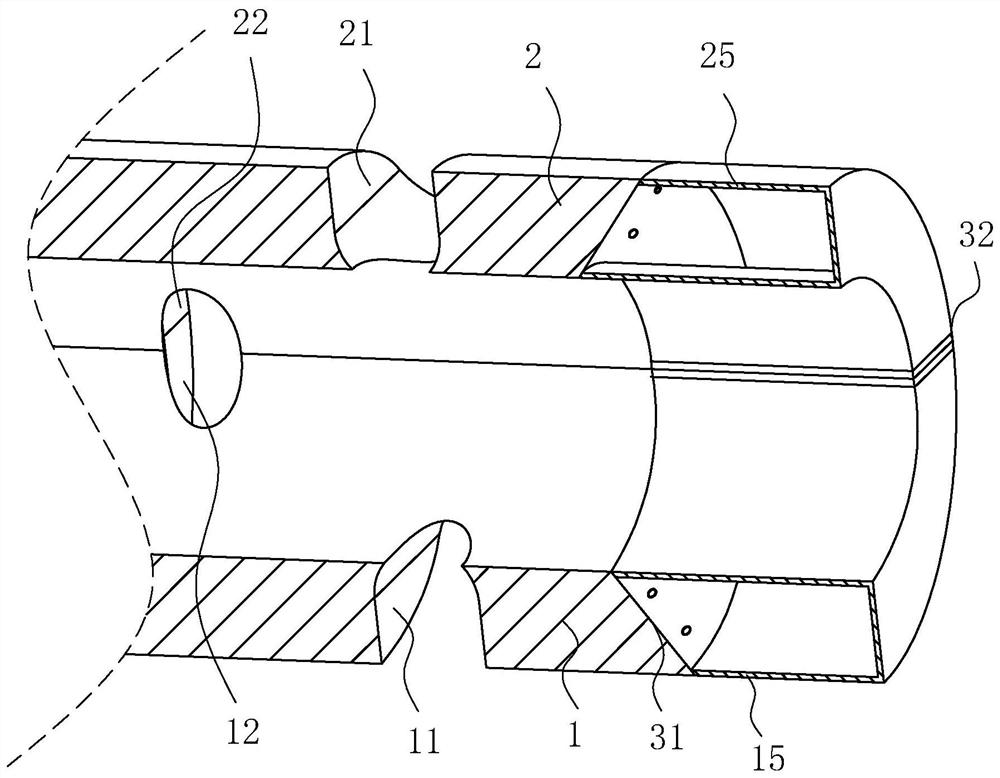

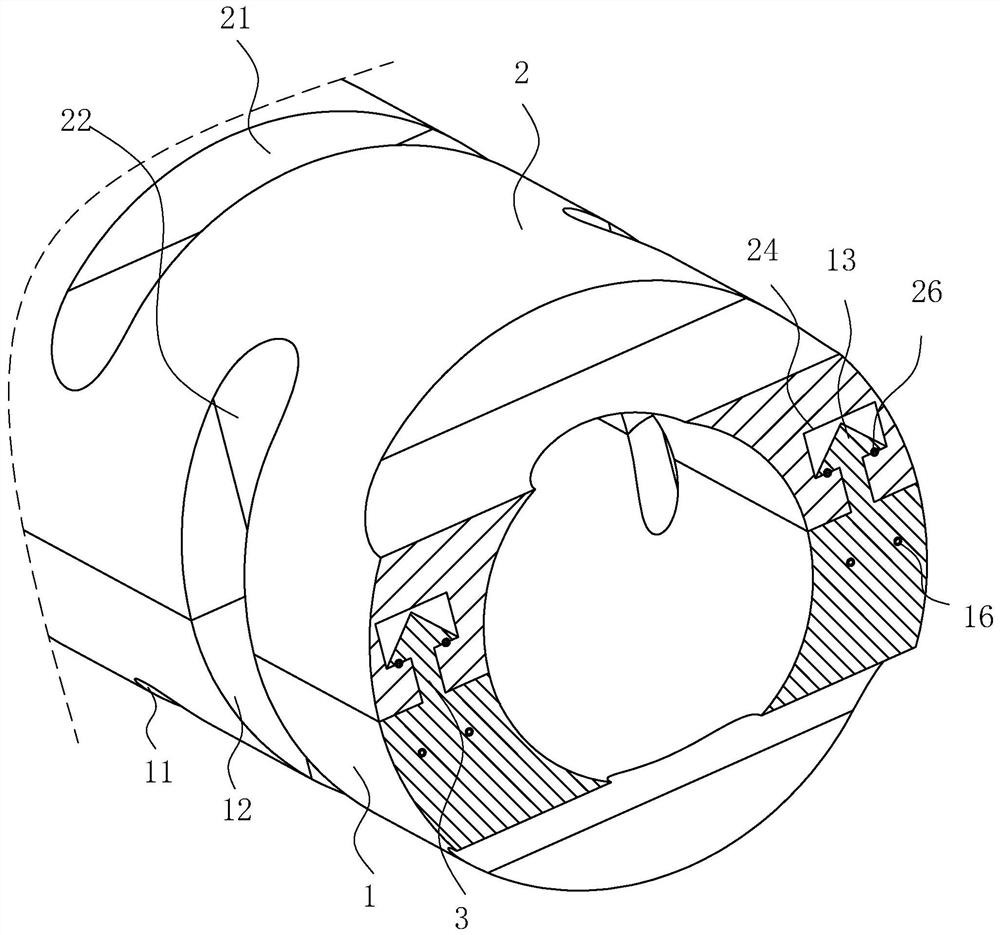

The invention relates to a silk reeling method and device, in particular to a wet raw silk double-twisting gathering method and a special device, and mainly solves the technical problems that croisure structures of silk ends are not uniform and the qualities of the raw silk are influenced due to the fact that croisure structures are manually formed and the wet raw silk is gathered under the action of croisures with a wet raw silk gathering method existing in the prior art. According to the wet raw silk gathering method and the special device, the wet raw silk reciprocates linearly relative to an upper godet and a lower godet, the wet raw silk and the godets create friction, and a plurality of pieces of cocoon silk glue forming the raw silk are kneaded to the periphery of the raw silk, so that the wet raw silk is closely gathered; and at the same time, strand silk rotates, an upper section of strand silk and a lower section of strand silk which are contacted with the upper and lower godets rotate in different directions, a lower section of raw silk rotates reversely after bypassing the godets, moisture in the strand silk is squeezed to be removed, and small knots on the surface of cocoon silk can be removed through rotating and kneading.

Owner:ZHEJIANG SCI-TECH UNIV

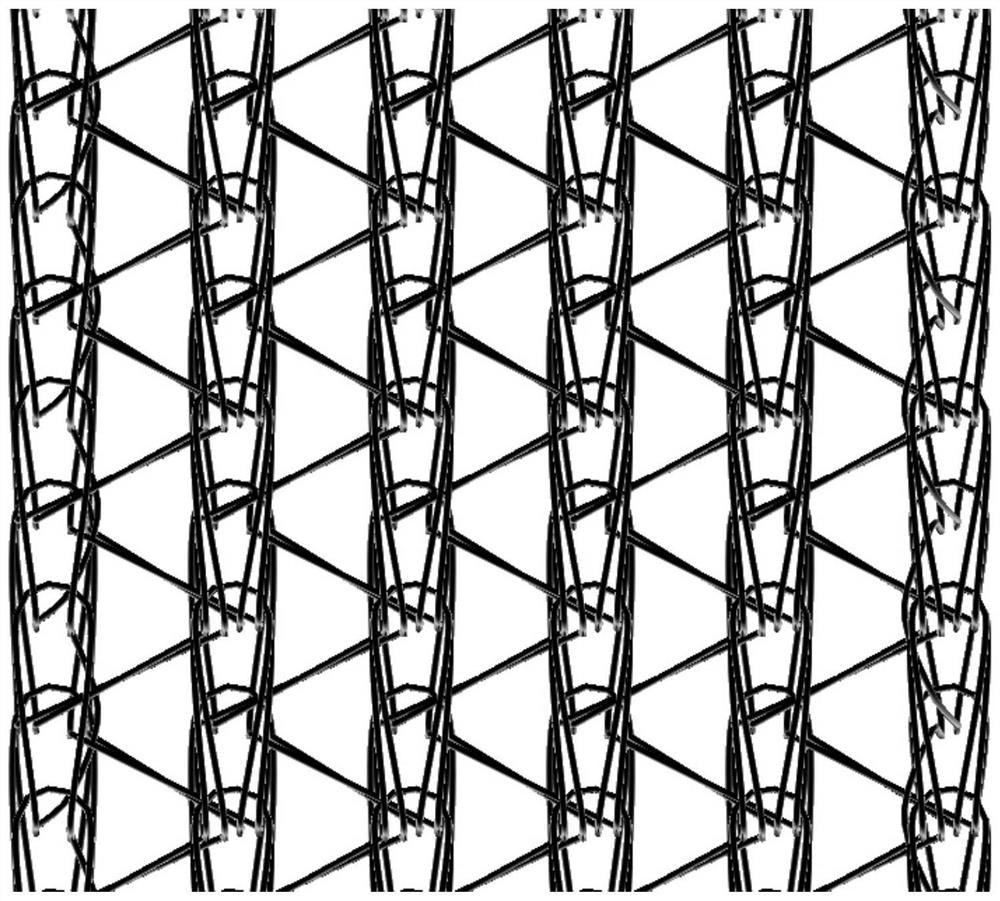

Knitting method of multi-bar warp-knitting machine

The invention provides a knitting method of a multi-bar warp-knitting machine. The method includes the following steps of firstly, preparing a raw material wire; secondly, feeding the raw material wire into a looping ground bar; thirdly, making the looping ground bar start knitting, wherein the raw material wire is composed of N yarns, N is larger than or equal to 1, and at least one of the N yarns is a raveling-resistant yarn. Raveling-resistant yarn loops are added on the basis of existing loops, the tightness of the existing loops is increased, joints of all the loops are staggered or overlapped, ground net yarn loops are made to have quite strong cohesive force and more closely cohered to fancy yarns forming a pattern, and even no chain stitch transfer transverse yarn or thermofuse yarn is added, the ground yarn loops and the fancy yarns are not prone to raveling after damage.

Owner:TIANHAI LACE CO LTD

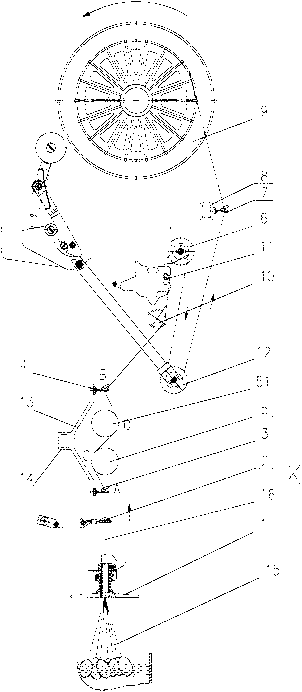

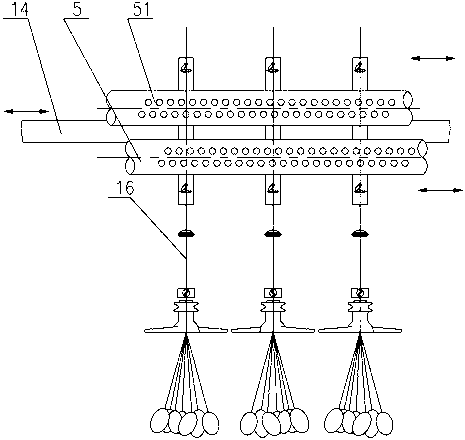

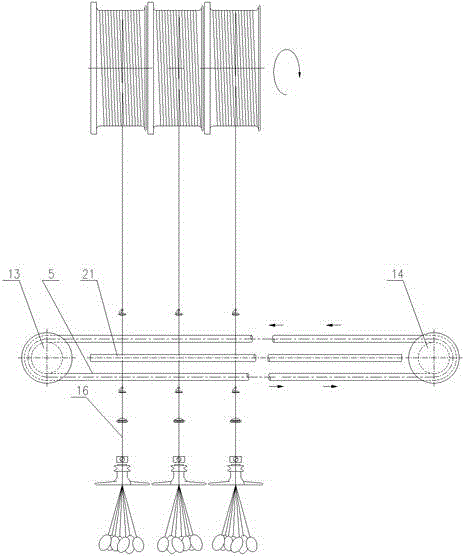

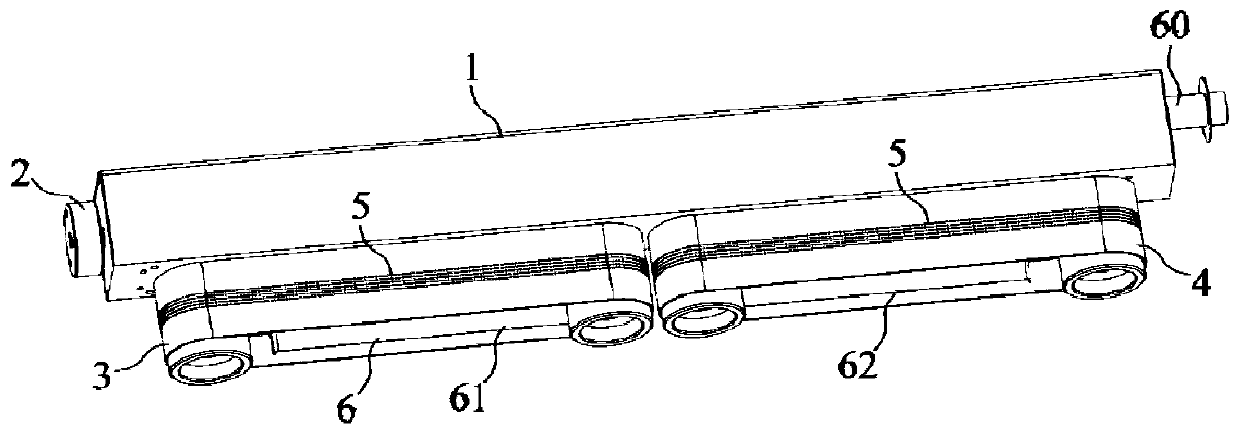

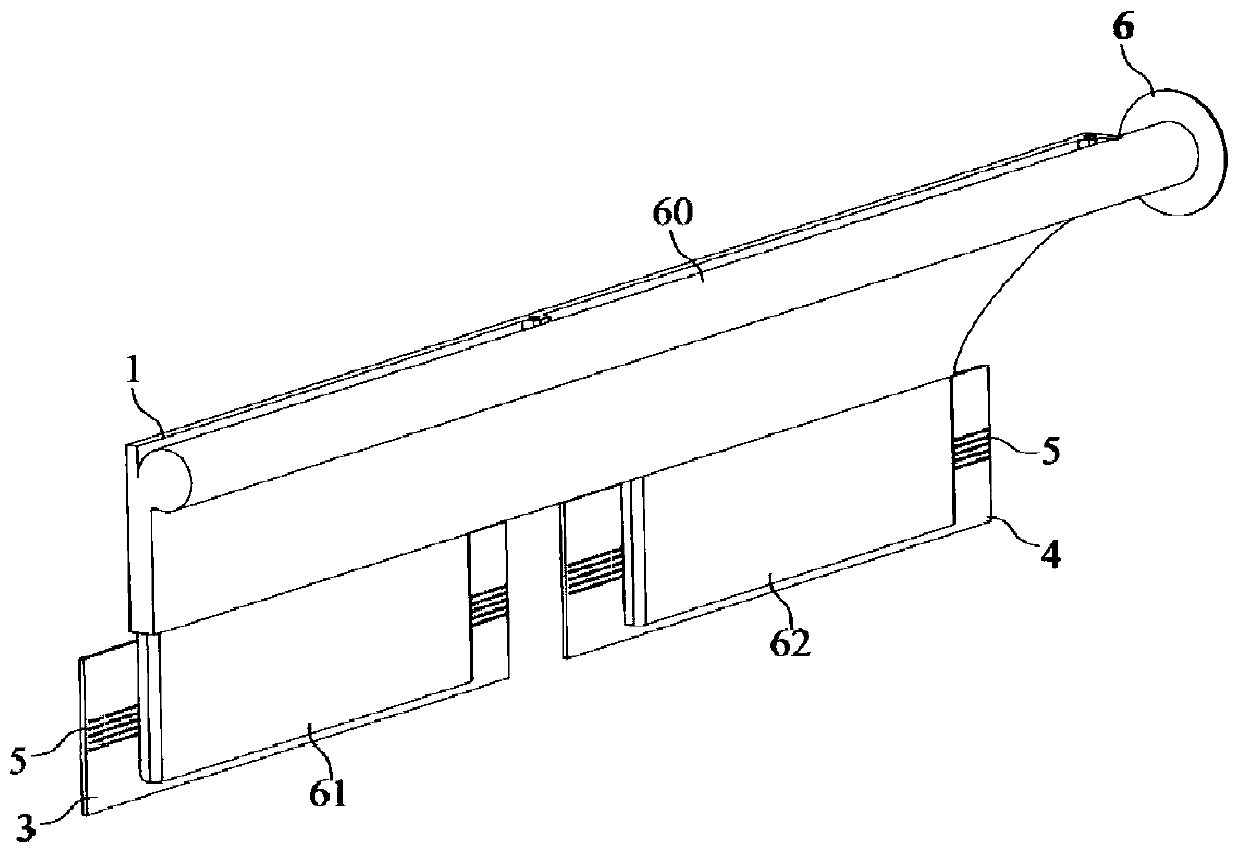

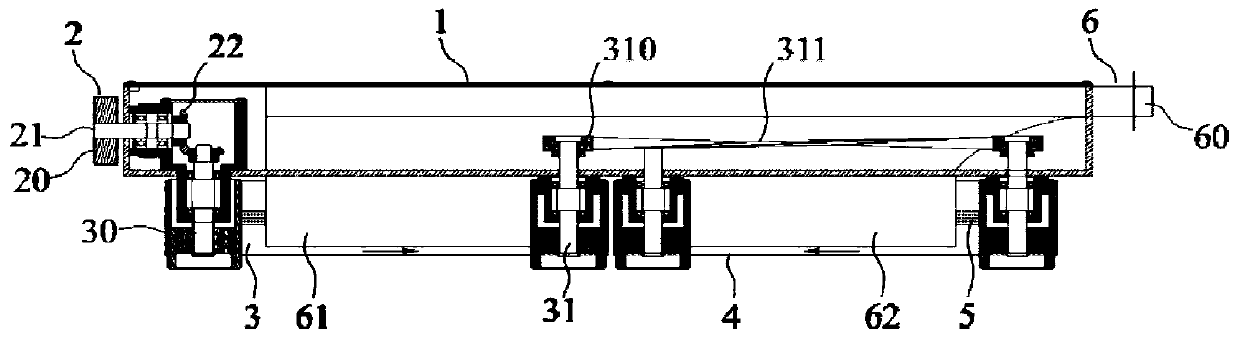

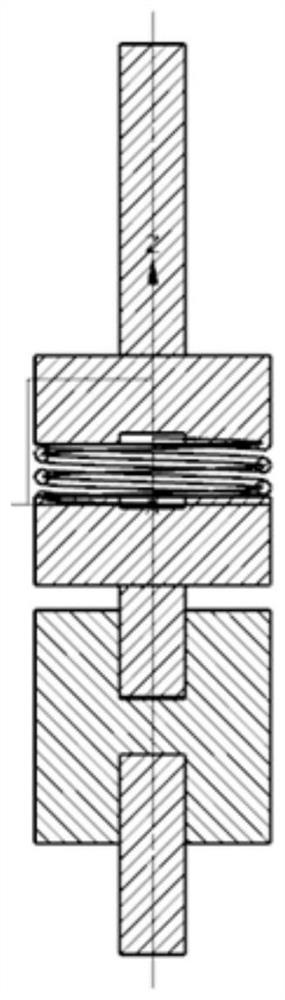

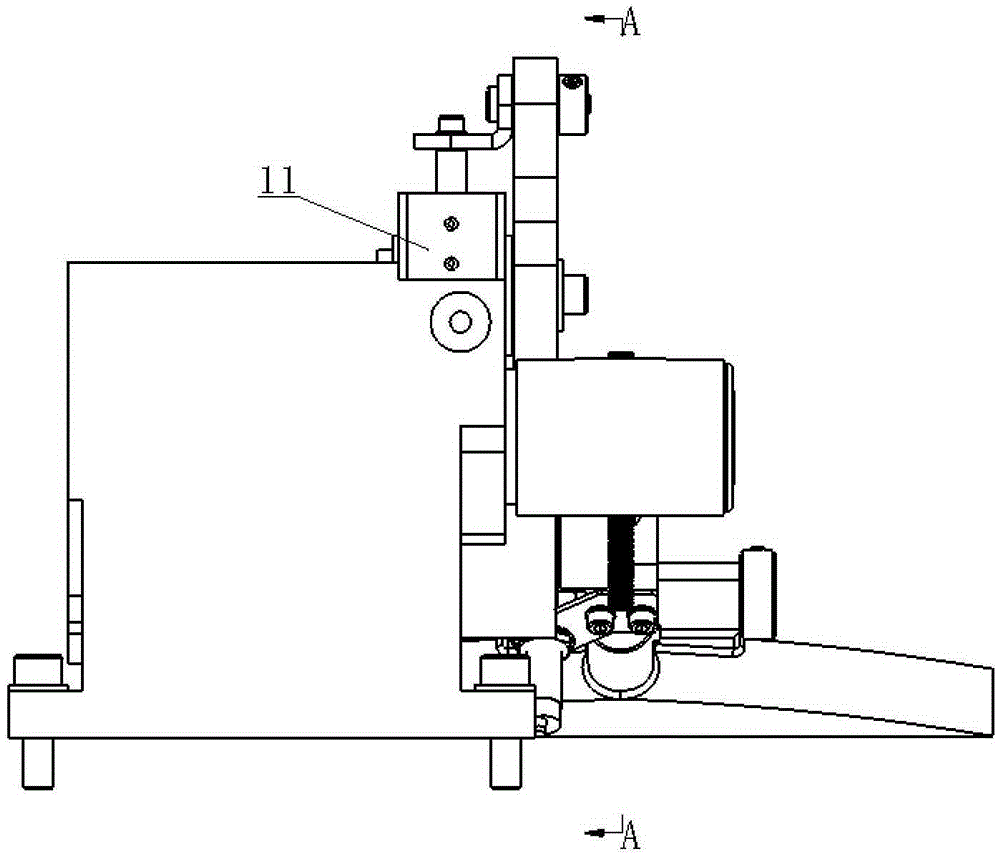

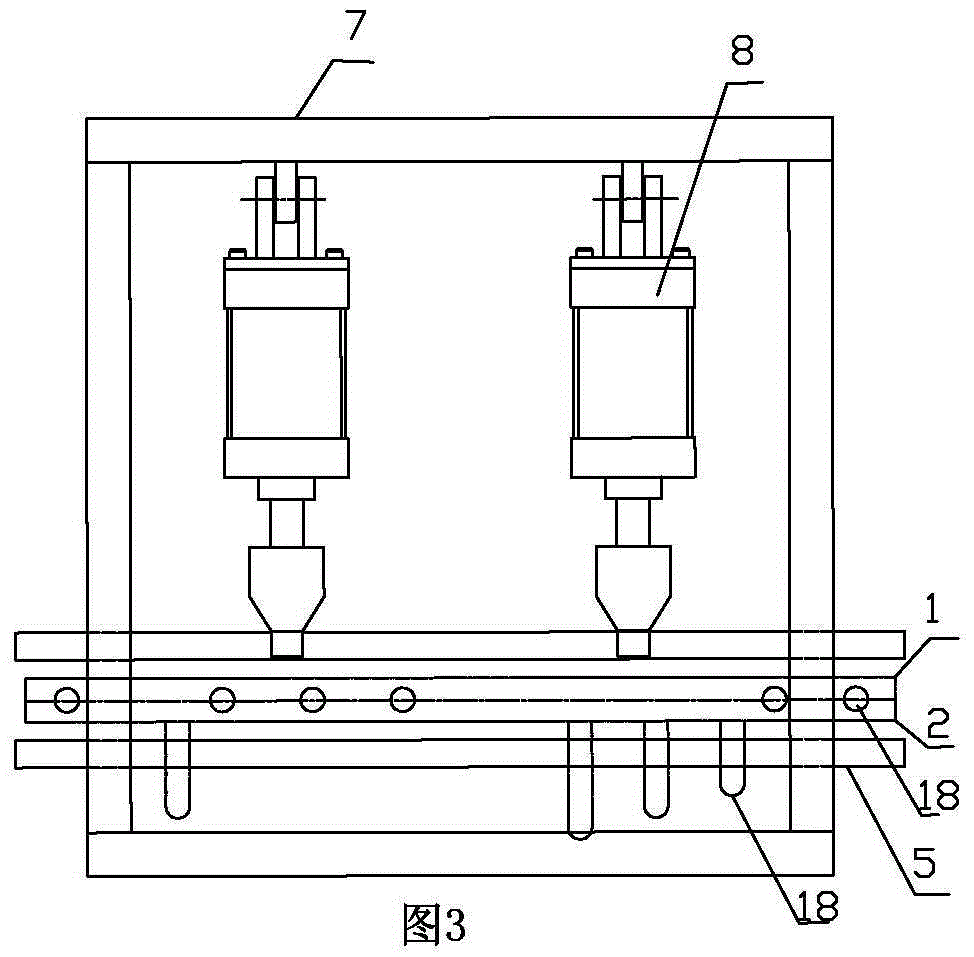

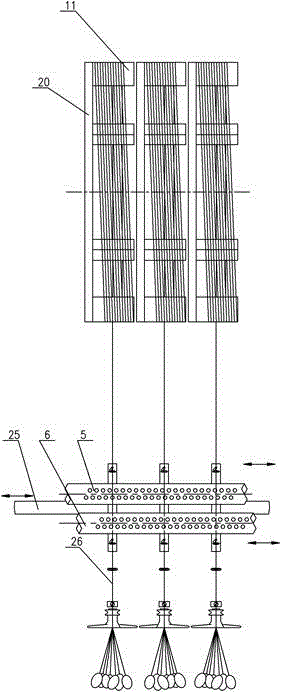

Band friction method and band friction device for replacing silk sheath

InactiveCN103334161AKnead continuously and evenlyFlat surfaceSilk reelingState of artBiomedical engineering

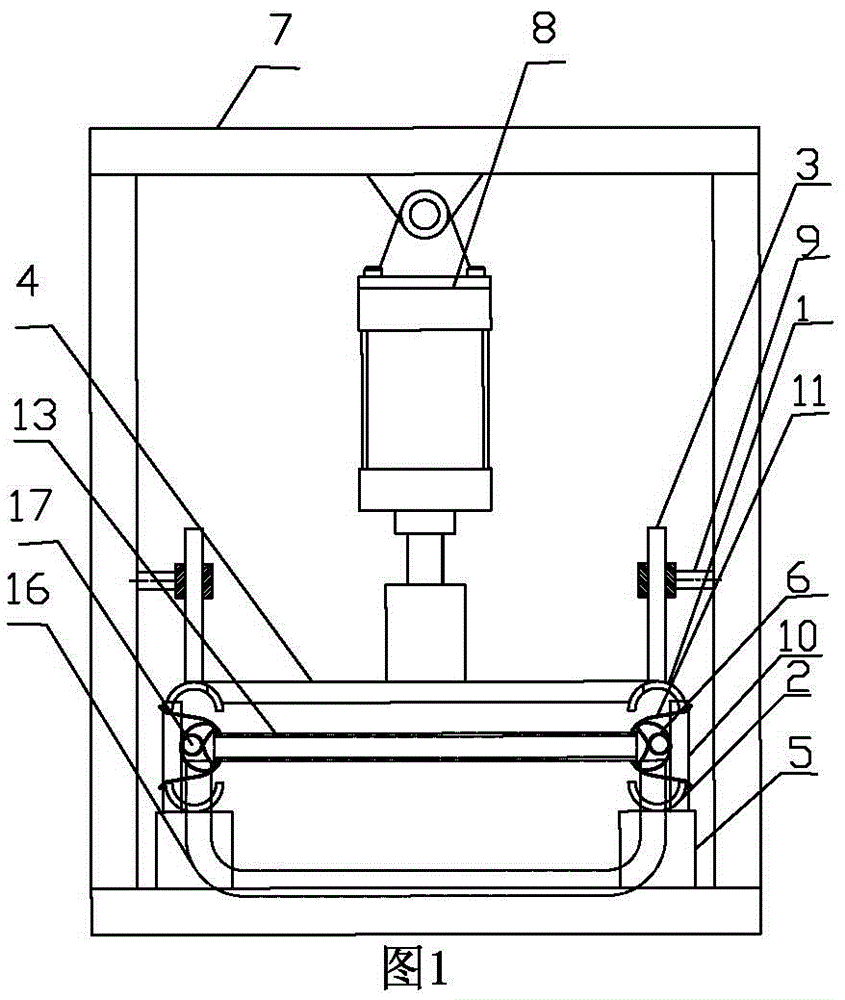

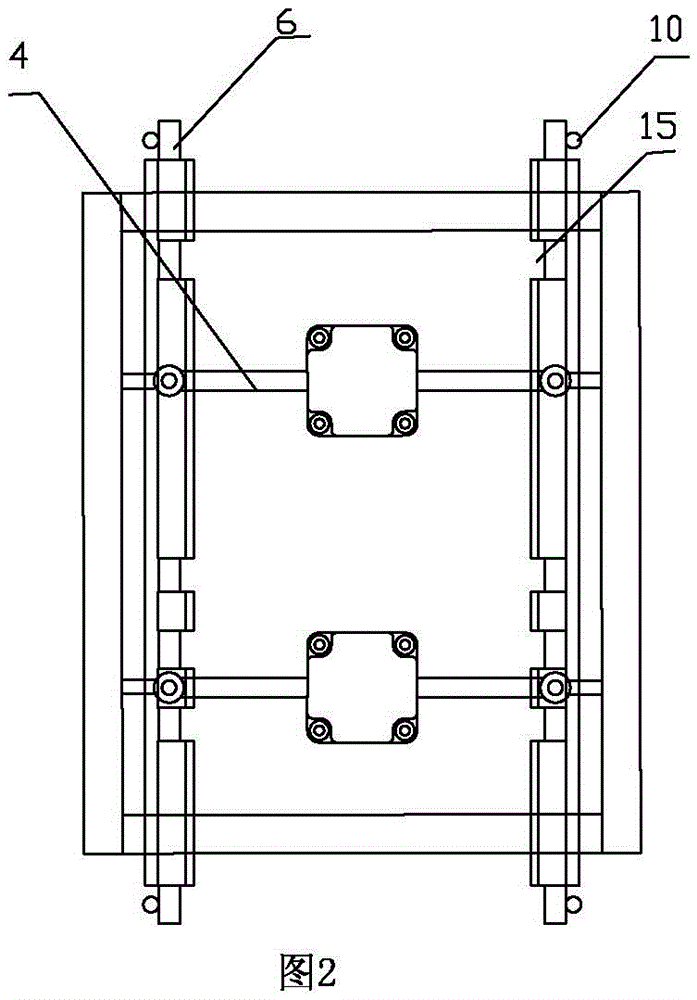

The invention relates to a silk reeling method and a silk reeling device, in particular to a band friction method and a band friction device for replacing a silk sheath. The method and the device mainly solve the technical problems that a wet raw silk gathering method during silk reeling production in the prior art forms a silk sheath structure by adopting a manual mode, and gathers wet raw silk through a silk sheath effect, and the quality of the raw silk is influenced, operation is complicated, and labor productivity is low due to the nonuniformity of the silk sheath structure between threads brought by the method, or solve the technical problem that gathering is nonuniform due to periodical change of the speed when back-and-forth friction is conducted by adopting reciprocating movement. According to the method and the device, upper and lower layers of driving bands which can be used for replacing silk sheath gathering cocoon silk and move reversely are wound with the wet raw silk; silk pressing guide rolls are arranged between the driving bands; a winding movement direction of the wet raw silk is perpendicular to movement directions of the driving bands relative to the raw silk; friction is generated between the wet raw silk and the driving bands; and tiny sections on the surface of the cocoon silk can be removed after rotation and kneading.

Owner:ZHEJIANG SCI-TECH UNIV

The knitting method of multi-bar warp knitting machine

Owner:TIANHAI LACE CO LTD

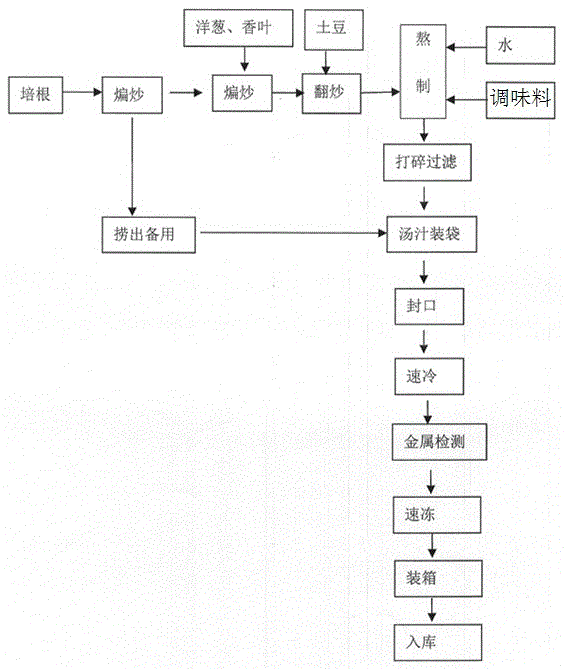

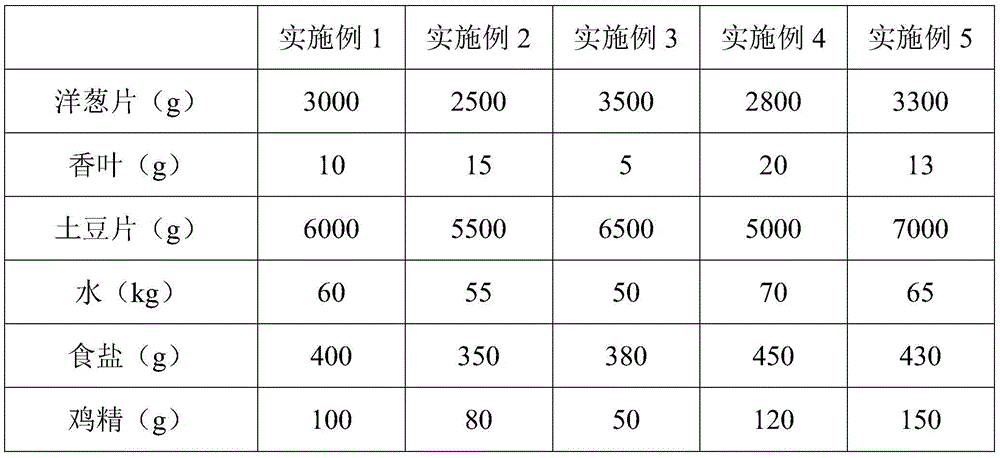

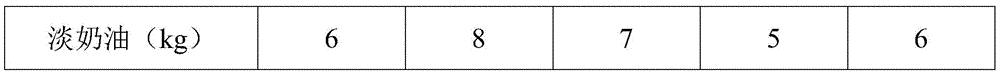

Processing process of potato thick soup

The invention provides a processing process of potato thick soup. The processing process comprises the following steps: (1) pre-treating raw materials; (2) frying bacons; (3) stirring and frying; (4) bagging; (5) sealing; (6) cooling; (7) carrying out metal detection; (8) instantly freezing; and (9) packaging in boxes, labeling and storing. The processing process provided by the invention is used for preparing aviation catering foods; the potato thick soup prepared by the process is simple in processing process, high in dish quality and long in guarantee period; after the potato thick soup is heated, the mouth feel is good; and the aviation catering varieties are effectively enriched.

Owner:NANJING WEIZHOU FOOD CO LTD

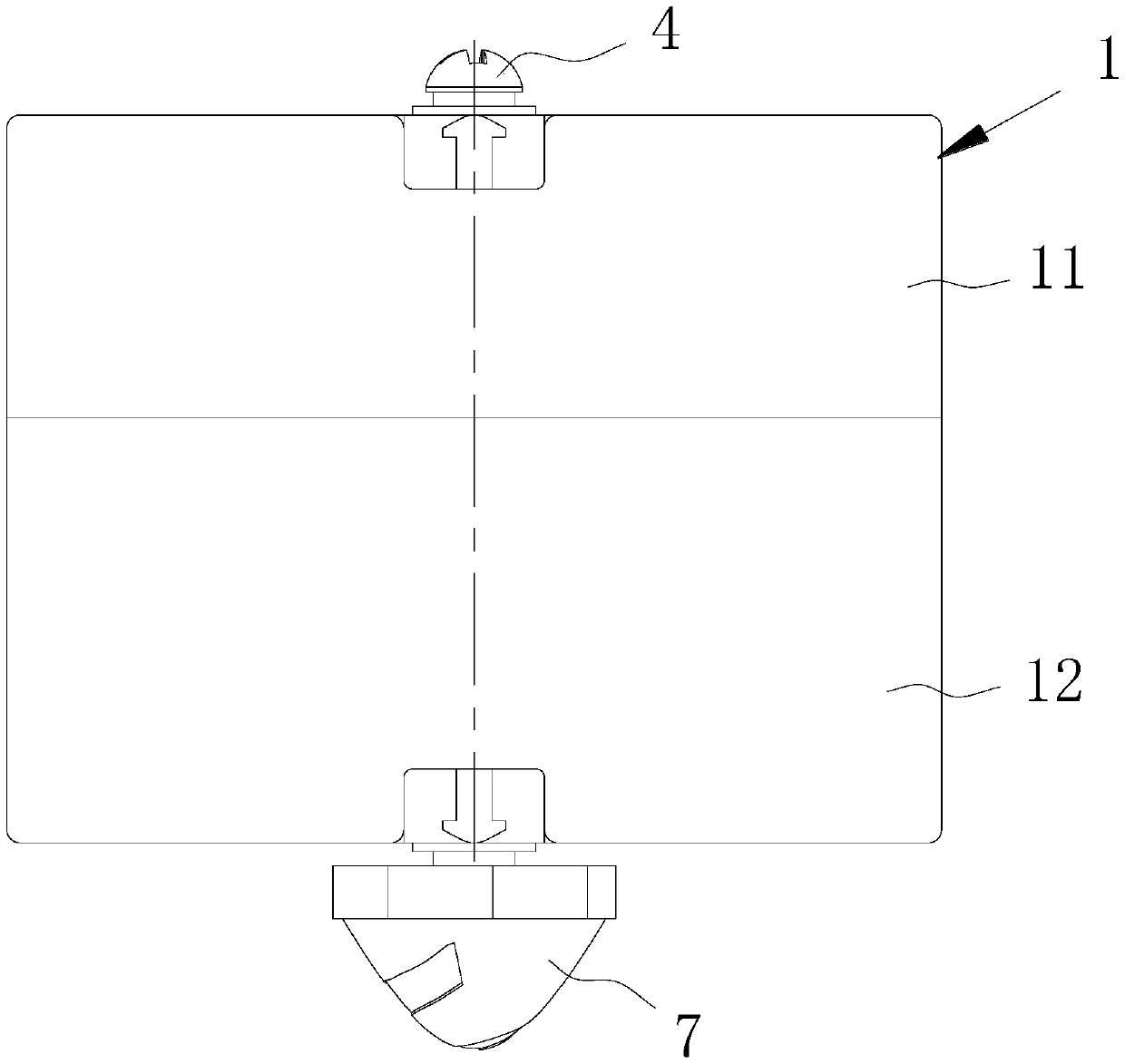

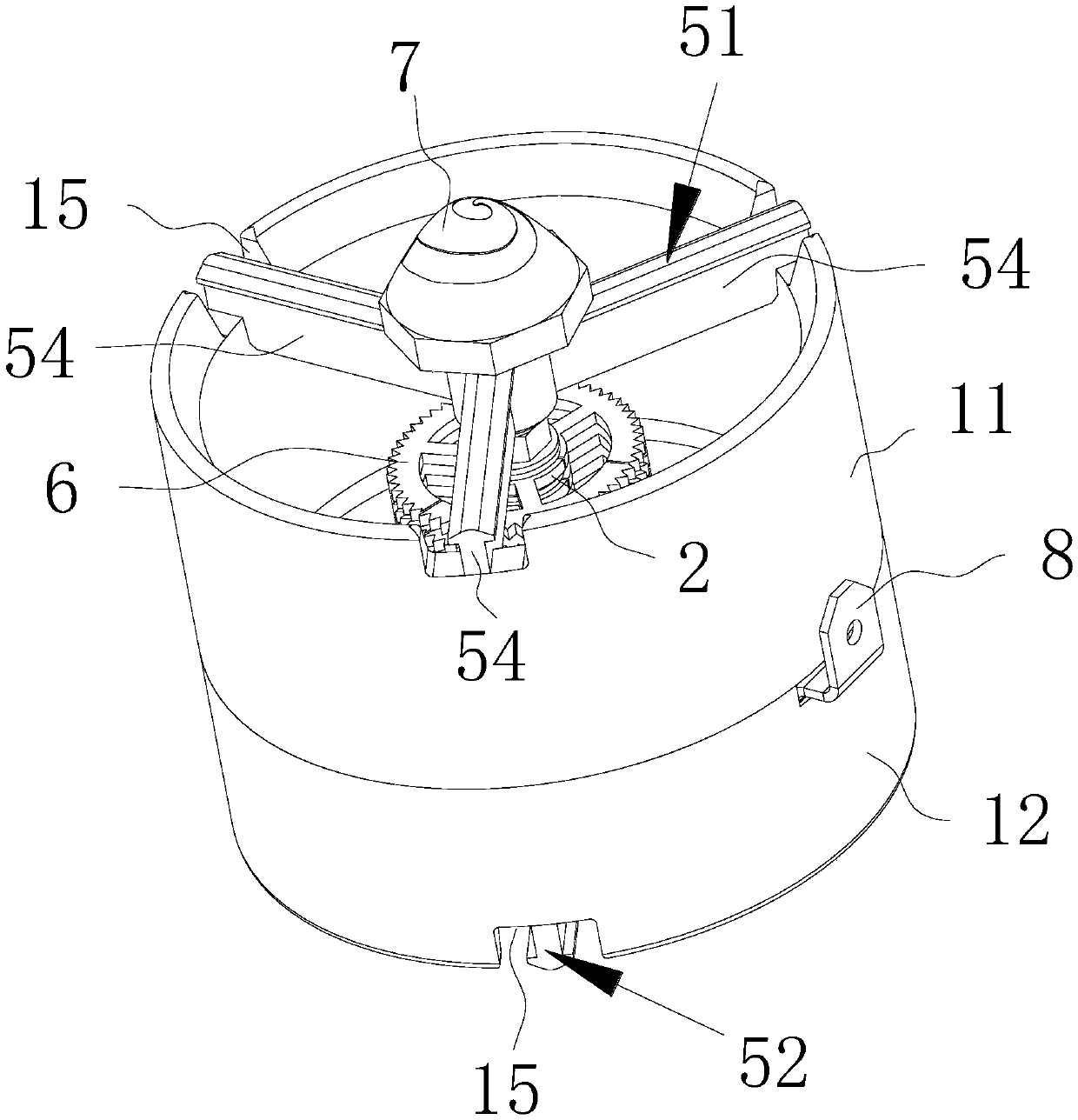

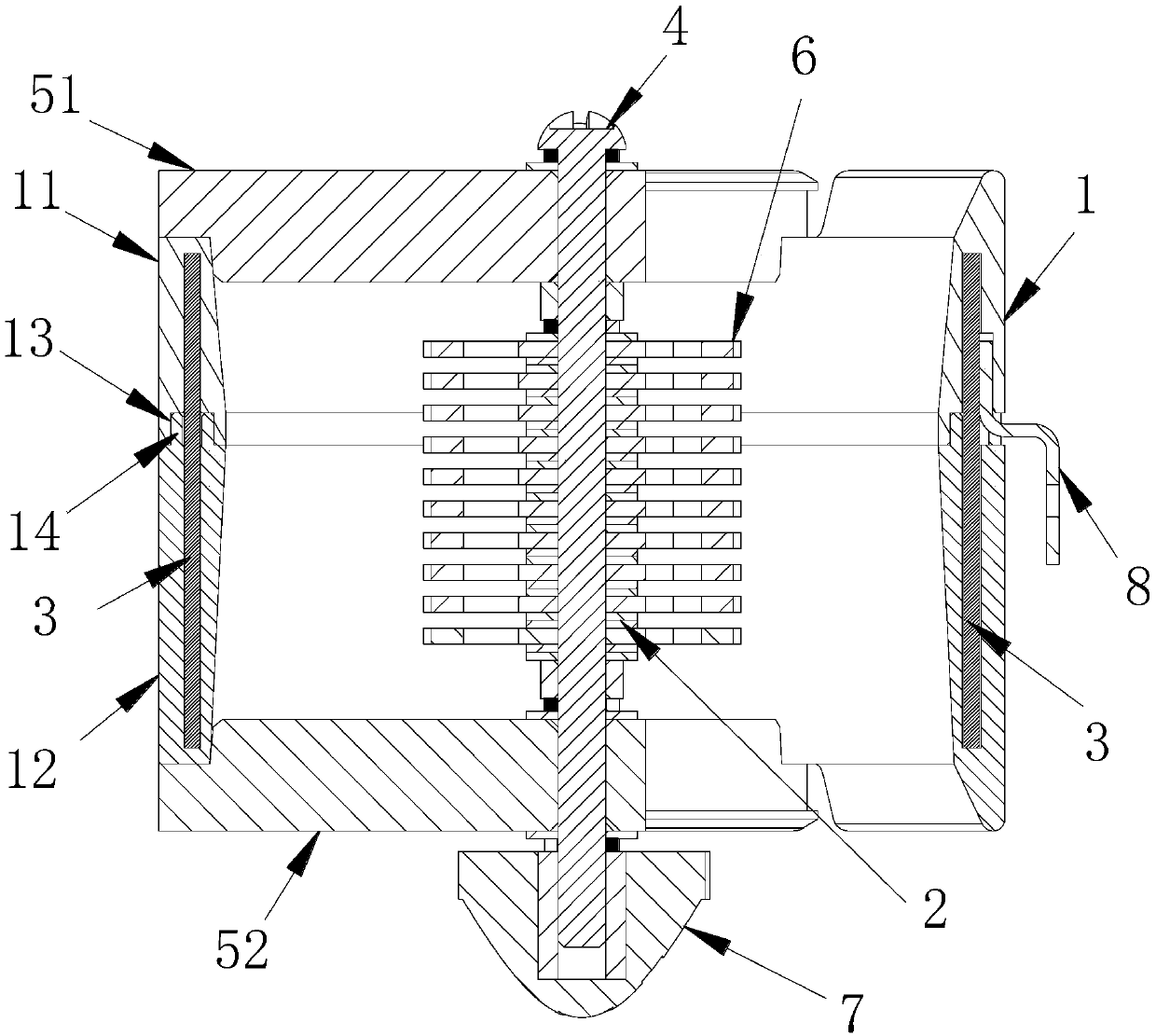

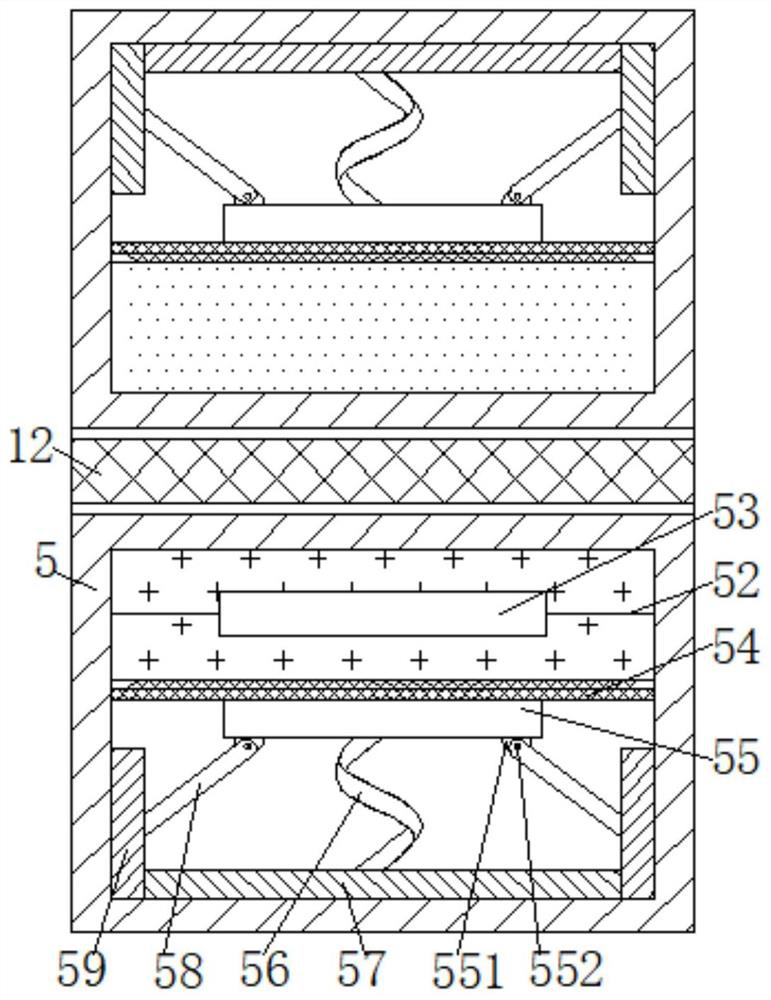

Engine combustion-supporting energy-saving device and vehicle

PendingCN109519308AWell mixedBurn fullyCombustion-air/fuel-air treatmentMachines/enginesFuel oilElectricity

The embodiment of the invention discloses an engine combustion-supporting energy-saving device and a vehicle. The engine combustion-supporting energy-saving device comprises a shell, a first electrode, a second electrode, a conductive shaft, a support and a toothed ring, wherein the conductive shaft is fixed into the shell through the support; the toothed ring is fixed onto the conductive shaft; one end of the conductive shaft stretches out of the shell; the first electrode is arranged on the conductive shaft and is located in the shell; the second electrode is embedded into the wall of the shell; and the first electrode and the second electrode are electrically connected with an output end of a high-voltage power supply and are made of carbon fiber materials. According to the engine combustion-supporting energy-saving device, static charges in air and oil gas are effectively eliminated, and air and a fuel are sufficiently mixed uniformly, so that the combustion efficiency of the fuelis improved, the utilization rate of the fuel oil is improved, and the emission load is reduced.

Owner:正道新能源科技有限公司

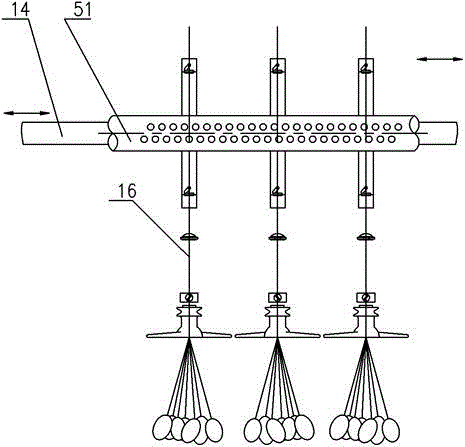

Cotton guiding device and cotton guiding method of cotton carding machine leather ring

PendingCN111235706ADoes not increase footprintLow modification costCarding machinesFiberMechanical engineering

The invention discloses a cotton guiding device and a cotton guiding method of a cotton carding machine leather ring, and belongs to the technical field of textile machinery. The cotton guiding devicecomprises a cross beam, a driving unit, a left leather ring, a right leather ring and an air suction system, wherein the driving unit is arranged at one end of the cross beam; the left leather ring is in transmission connection with the driving unit, and the setting direction of the left leather ring is the same as the length direction of the beam; the right leather ring is in transmission connection with the left leather ring, and the right leather ring is arranged on the extension line in the length direction of the left leather ring; the rotating directions of the left leather ring and theright leather ring are opposite; mesh holes are formed in the middle parts of the left leather ring and the right leather ring, and the mesh holes are arranged in the rotating direction of the corresponding leather ring; and the air suction system can form negative pressure on the outer surface of the leather ring mesh hole area. The cotton guiding device provided by the invention has the advantages that the air suction system is arranged, the mesh holes in the surfaces of the left and right leather rings are matched, the cotton net on an upper roller and a lower roller can be better stripped, the cotton guiding efficiency is improved, the straightening degree and the parallelism of the cotton net fibers are not affected, and finally the cotton net fibers are folded into bundles, and thecotton guiding quality is high.

Owner:ANHUI RIFA TEXTILE MACHINERY

Device and method for continuous preparation of self-twisting nanofiber yarn

ActiveCN108796687BIncrease productivityWide range of choicesElectro-spinningContinuous wound-up machinesYarnFiber

The invention relates to the technical field of textile processing and aims to provide a continuous preparation device and method for self-twisting nanofiber yarns. Including: a vertically installed motor, the rotating shaft at the bottom of which is connected to a metal spinneret through a coupling; multiple spinneret holes are evenly arranged along the circumference of the spinneret; the cluster system includes a funnel-shaped cluster, a fan and at least Two air shower heads; the funnel-shaped cluster is connected to the negative electrode of the electrostatic generator through a cable; a through hole is arranged in the center of the sinking part, and the through hole, the spinneret and the motor shaft are located on the same vertical axis; the spinneret The plane where each spinneret hole is located is arranged parallel to the plane part of the funnel-shaped cluster; the winding collection system includes a yarn guide roller and a winding roller, and the yarn guide roller is located below the through hole of the funnel-shaped cluster. In the present invention, the nanofibers are prepared by electrostatic centrifugal spinning, the production efficiency is high, and the raw materials are soluble and fusible; the nanofiber yarns integrate high degree of orientation, good continuity, synchronous twisting and efficient short process.

Owner:ZHEJIANG SCI-TECH UNIV

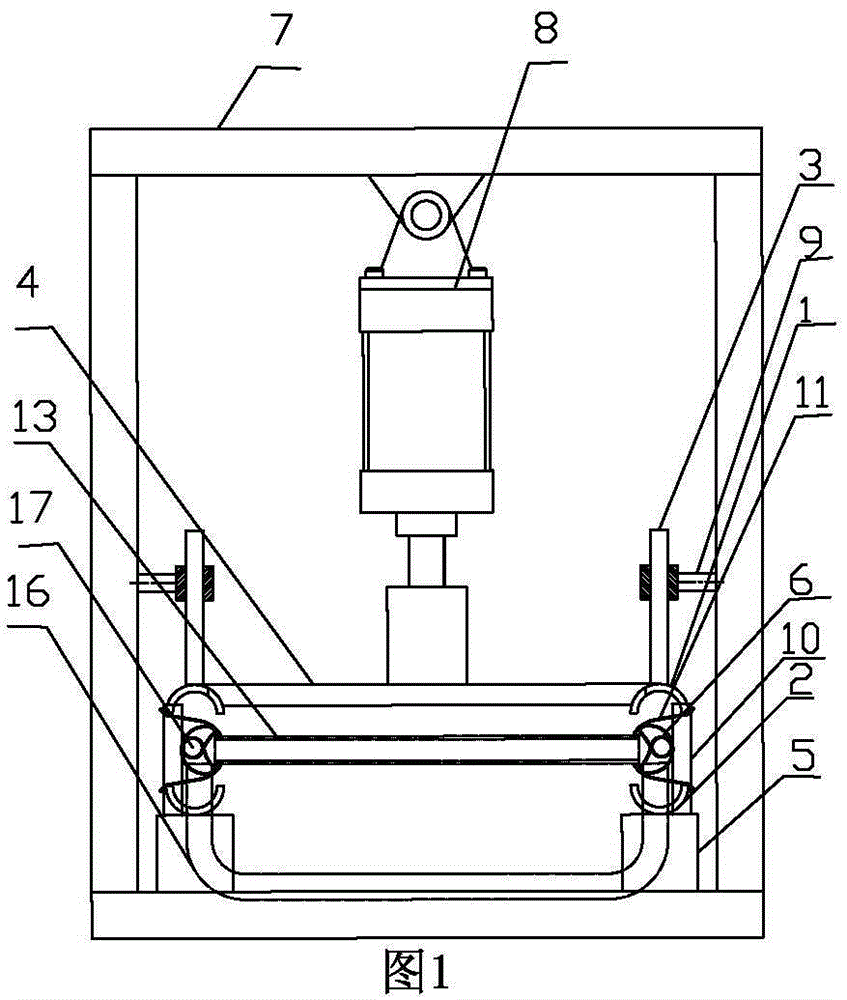

Cotton web bundling mechanism of intelligent comber

The invention discloses a cotton web bundling mechanism of an intelligent comber. The cotton web bundling mechanism adopts the structure that a first press roller and a second press roller on a supporting seat of the intelligent comber are mutually meshed for transmission; a driving device drives the first pressure roller to rotate; the inlet of a gathering pipe is just positioned behind a drafting output roller; the inlet of a conveying pipe is fixedly communicated with the outlet of the gathering pipe; a bundling horn mouth is fixedly mounted on the supporting seat of the intelligent comber; the inlet of the bundling horn mouth can be communicated with the outlet of the conveying pipe; a horn hole of which the outlet diameter is smaller than the inlet diameter is formed in the inner side of the bundling horn mouth; the meshing point between the first and second press roller just faces the outlet of the bundling horn mouth; a flat groove is formed in the side wall positioned at the outlet end of the bundling horn mouth; the mutually meshed ends of the first and second press rollers are just inserted into the flat groove; the meshing point between the first and second press roller is just positioned in the flat groove. Through adoption of the cotton web bundling mechanism, the cohesive force of gathered cotton slivers is remarkably improved, so that the cotton slivers are not easy to loosen when being conveyed on a conveying belt and not easy to break at a turning point, and then high-speed conveying and convenient maintenance of the cotton silvers are facilitated.

Owner:JIANGSU KAIGONG MACHINERY

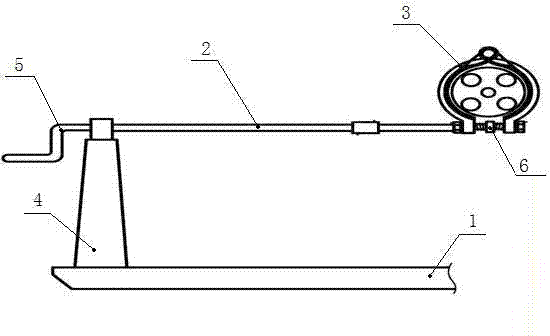

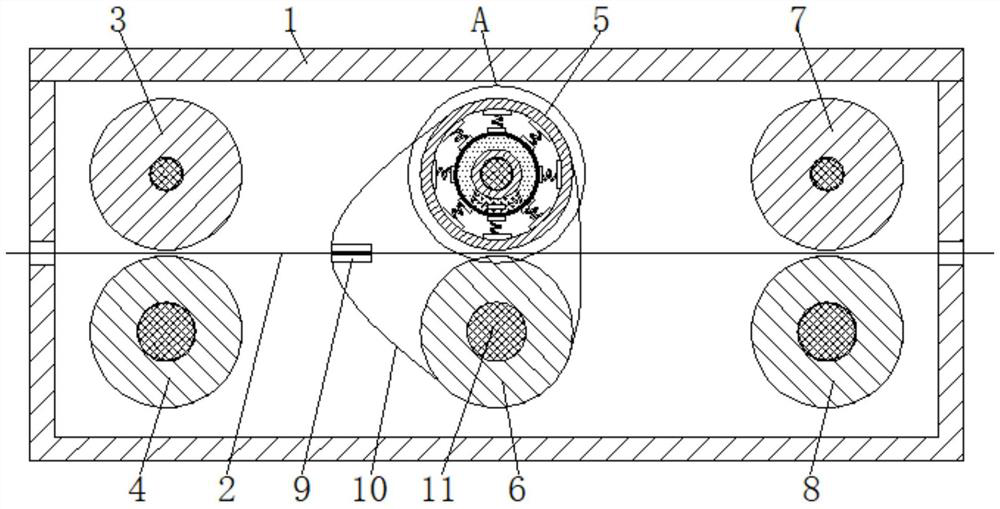

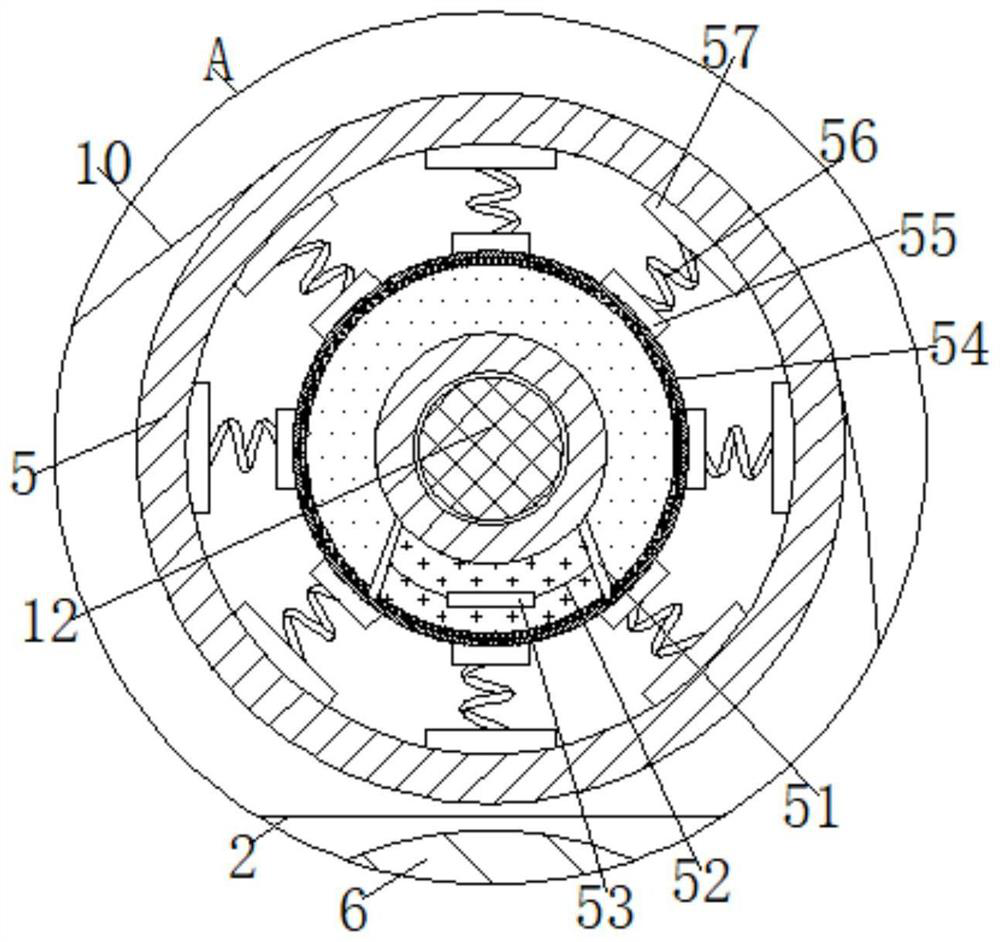

Brake device of pumping unit

InactiveCN104514823ABrake effortHug tightlyBraking membersDrum brakesEngineeringMechanical engineering

The invention discloses a brake device of a pumping unit. The brake device comprises a supporting seat, a rocking bar and a brake hoop, wherein the rocking bar is arranged on a rocking bar support of the supporting seat; the brake hoop has an arch structure; two ends of the arch structure are provided with reverser inner threads; one end of the rocking bar is provided with a rocking handle, and the other end of the rocking bar is provided with a positioning ring; the rocking bar on two sides of the positioning ring is provided with reverse threads; the rocking bar rotates to drive two ends of the arch structure to shrink or expand along the reverse inner threads; and the brake hoop has the arch structure which consists of two movably-hinged arch pieces. Compared with the traditional two brake devices in the prior art, the novel brake device is provided with an arch-shaped brake hoop, and the arch brake is depended on when the pumping unit is started, so that the braking is labor-saving, compact in cohesion, safe and reliable.

Owner:秦浩宇

Water-soluble fiber and high-count cashmere yarn spinning process

The invention relates to a water-soluble fiber and high-count cashmere yarn spinning process. The process comprises the following specific steps of (1) firstly opening cashmere, adding oil and water,then preliminarily mixing the cashmere and water-soluble fibers, and feeding a mixture into a mixing willow for full mixing; (2) processing the mixture obtained in the step (1) into rough yarns by using a carding machine, and controlling the temperature of a carding workshop to be 24-26 DEG C and the humidity to be 60-65%; (3) drafting and twisting the rough yarns obtained in the step (2) by a spinning frame to form spun yarns, winding the spun yarns into yarn ears, controlling the temperature of the carding workshop to be 20-30 DEG C and the humidity to be 60-65%, and controlling the draft multiple of the spun yarns to be 1.30-1.35; and (4) performing bobbin replacement and winding on the spun yarns by using a bobbin winder, and removing relatively thin or thick slivers at the same time.According to the process, on one hand, the spinning process is improved, and on the other hand, the water-soluble fibers are modified, so that the cashmere and the water-soluble fibers can be uniformly mixed in the wool mixing stage, after the water-soluble fibers are removed through water washing, the slivers can be uniform, and the wearability of a product is good.

Owner:ZHEJIANG MAGLIA CASHMERE FAMILY CO LTD

Spinning frame for yarn production

The invention relates to the technical field of textile equipment, and discloses a spinning frame for yarn production. The spinning frame comprises a cradle shell, three pairs of drafting assemblies are arranged in the cradle shell and comprise a first drafting assembly, a second drafting assembly and a third drafting assembly, the first drafting assembly comprises a front leather roller and a front roller, the front leather roller and the front roller movably sleeve one side of the interior of the cradle shell, and the front leather roller is located above the front roller. The surface of theouter ring of a middle leather roller is supported by thrust of a spring, a lower base, a movable rod and a side base to the outer ring of the middle leather roller, so that the outer ring of the middle leather roller is always kept in a flat state; and meanwhile, the gravity action direction of liquid oil is always downward, furthermore, the bottom end of the outer ring of the middle leather roller is kept in a horizontal state when the middle leather roller and a rough yarn are pressed, the middle roller can be always jacked, friction deformation of the middle roller and the middle leatherroller is always changed evenly, and the phenomenon that the middle leather roller sinks due to uneven friction force generated by the middle leather roller and the rough yarn is avoided.

Owner:张敏

Belt friction method and device for replacing silk sheath

InactiveCN103334161BKnead continuously and evenlyFlat surfaceSilk reelingConveyor beltBiomedical engineering

The invention relates to a silk reeling method and a silk reeling device, in particular to a band friction method and a band friction device for replacing a silk sheath. The method and the device mainly solve the technical problems that a wet raw silk gathering method during silk reeling production in the prior art forms a silk sheath structure by adopting a manual mode, and gathers wet raw silk through a silk sheath effect, and the quality of the raw silk is influenced, operation is complicated, and labor productivity is low due to the nonuniformity of the silk sheath structure between threads brought by the method, or solve the technical problem that gathering is nonuniform due to periodical change of the speed when back-and-forth friction is conducted by adopting reciprocating movement. According to the method and the device, upper and lower layers of driving bands which can be used for replacing silk sheath gathering cocoon silk and move reversely are wound with the wet raw silk; silk pressing guide rolls are arranged between the driving bands; a winding movement direction of the wet raw silk is perpendicular to movement directions of the driving bands relative to the raw silk; friction is generated between the wet raw silk and the driving bands; and tiny sections on the surface of the cocoon silk can be removed after rotation and kneading.

Owner:ZHEJIANG SCI-TECH UNIV

A Wet Raw Silk Extrusion Aggregation Method and Special Device

The invention relates to a silk reeling method and device, in particular to a squeezing type wet raw silk gathering method and a special device, and mainly solves the technical problems that croisure structures of silk ends are not uniform and the qualities of the raw silk are influenced due to the fact that croisure structures are manually formed and the wet raw silk is gathered under the action of croisures with a wet raw silk gathering method existing in the prior art. According to the squeezing type wet raw silk gathering method and the special device, a silk wrapping godet is wound by wet raw silk, a pushing godet is tightly attached to the silk wrapping godet and squeezes the wet raw silk, the two godets perform relative and linear reciprocating motion, the wet raw silk and the godets create friction, and a plurality of pieces of cocoon silk glue forming the raw silk are kneaded to the periphery of the raw silk, so that the wet raw silk is closely gathered; and at the same time, strand silk rotates an upper section of strand silk and a lower section of strand silk in different directions, moisture in the strand silk is squeezed to be removed, and small knots on the surface of cocoon silk can be removed through rotating and kneading.

Owner:ZHEJIANG SCI-TECH UNIV

Die tool of small pack basket heating radiator

ActiveCN105414874AReliable service lifeNice appearanceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStainless steel welding

The invention belongs to the technical field of civil radiator processing and manufacturing, and discloses a stainless steel welding structure member die tool of a small pack basket heating radiator. Inner core pipes are respectively placed in two vertical communicating pipes. A concave arc surface of the inner core pipe contacts with two end faces of a straight horizontal pipe. The left side of the inner core pipe is in an annular arc-shaped surface, and contacts with two edges of the profiles of the two vertical communicating pipes when being extruded and closed, and under the action of a pressure strut of a cylinder, the inner core pipe and the two edges of the profiles of the two vertical communicating pipes move relatively to clamp, so that the two edges of the profiles of the two vertical communicating pipes are kneaded tightly. A moon shape in the inner core pipe is divided into a plurality of sections. A space distance is between the end faces of the sections. The end faces on two ends of a bended horizontal pipe are inserted into the space distance. A cylindrical pipe is arranged on the upper part of the middle position of the moon shape of the inner core pipe. The bottom of the cylindrical pipe contacts with two end faces of the bended horizontal pipe. When the pressure strut of the cylinder contracts and exits, the inner core pipes on the two ends respectively rotate inward for 90 DEG, and the inner core pipes are pulled out.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

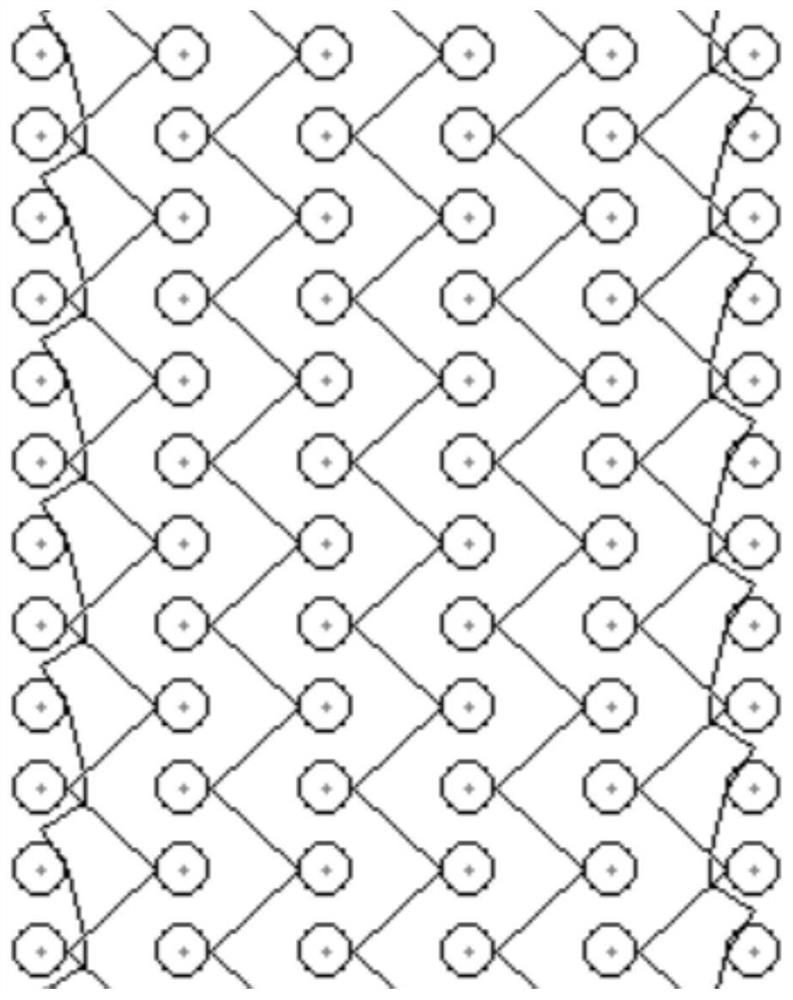

Suture tape for surgical operation and production method thereof

The invention discloses a production method for a suture tape for surgical operation. The production method comprises the following steps: adopting two guide bars for knitting yarns into two layers oftapes of warp flat structures on a double-needle bar warp knitting machine, and utilizing two guide bars to connect left sides and right sides of the tapes, thereby forming a flat structure with twosealed ends. Specifications of the yarns are separately 40D, 80D, 120D or 200D, the double-needle bar warp knitting machine separately adopts a two-needle process, a three-needle process, a four-needle process, a five-needle process or a six-needle process, and the flat structure is shrunk under a high-temperature high-pressure water bath environment after knitting is accomplished. The suture tapefor surgical operation provided by the invention is prepared by the production method. According to the suture tape for surgical operation and the production method provided by the invention, suturetape thicknesses are various, so that the suture tape for surgical operation and the production method thereof selected according to a practical condition can be met; and the suture tape thicknesses are adjustable, so that damage on tissues or organs pulled by the suture tape are avoided. Fibers are not liable to scatter and drop, and incisions are orderly.

Owner:JIANGSU BIODA LIFE SCI CO LTD

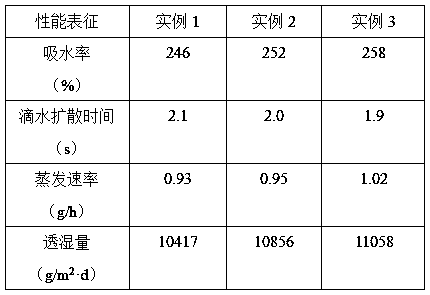

Transparent vitreous surface wiping material preparation method

InactiveCN110735329AStrong water absorptionStrong dust abilityCarding machinesCleaning equipmentPolymer chemistryPolylactic acid

The invention relates to a transparent vitreous surface wiping material preparation method, which belongs to the technical field of wiping materials. Silica sols coat the surfaces of polyvinyl alcoholfibers, viscose fibers and polylactic acid fibers as raw materials, and a transparent vitreous surface wiping material is prepared through a needling non-woven process. In the needling reinforcementprocess, needles with triangular or other shapes in cross section and barbs on edges are adopted to repeatedly needle fluffy fiber webs; hooks on the needles take some fibers on the surface and innerlayers of the fiber webs to pass through the fiber web layers along with the needles, so that the fibers are entangled with each other in the movement process, and meanwhile, due to the friction forceand the upward and downward displacement of the fibers, the fiber webs are compressed, and some fiber bundles become 'pins' to nail into the fiber webs, so that the transparent vitreous surface wiping material with certain thickness and strength is obtained.

Owner:李炳其

A Wet Raw Silk Aggregation Method and Special Device

The invention relates to a silk reeling method and device, in particular to a wet raw silk gathering method and a special device, and mainly solves the technical problems that croisure structures of silk ends are not uniform and the qualities of the raw silk are influenced due to the fact that croisure structures are manually formed and the wet raw silk is gathered under the action of croisures with a wet raw silk gathering method existing in the prior art. According to the wet raw silk gathering method and the special device, the wet raw silk reciprocates linearly relative to a godet, the godet rotates slowly, the wet raw silk and the godet create friction, and a plurality of pieces of cocoon silk glue forming the raw silk are kneaded to the periphery of the raw silk, so that the wet raw silk is closely gathered; and at the same time, strand silk rotates, an upper section of strand silk and a lower section of strand silk which are contacted with the godet rotate in different directions, a lower section of the raw silk rotates reversely after bypassing the godet, moisture in the strand silk is squeezed to be removed, and small knots on the surface of cocoon silk can be removed through rotating and kneading.

Owner:ZHEJIANG SCI-TECH UNIV

Polyester filament, composite yarn and fabric, and preparation method thereof

InactiveCN1297696CEvenlyLess exposedFilament/thread formingDyeing processColour fastnessPolymer science

The present invention produces one kind of polyester filament in conventional polyester filament spinning apparatus via control of the spinning speed and tension during melt spinning. The polyester filament has strength of 3-5 CN / dtex, elongation at breaking of 30-50 %, boiling water shrinkage of 8-20 %, and initial modulus of 50-70 % of conventional polyester filament. The polyester filament may be wrapped with natural cotton, wool, cashmere and other natural fiber in a conventional spinning frame to obtain embedded composite polyester yarn in multiple-dimensional structure. The fabric of the composite polyester yarn in multiple-dimensional structure may be co-dyed at normal temperature and normal pressure in high dyeing ability, deep color and high color fastness. The fabric has high evenness, soft hand feeling, bright color, comfortable wearing, appearance similar to natural fiber fabric and performance superior to natural fiber fabric.

Owner:张学军 +1

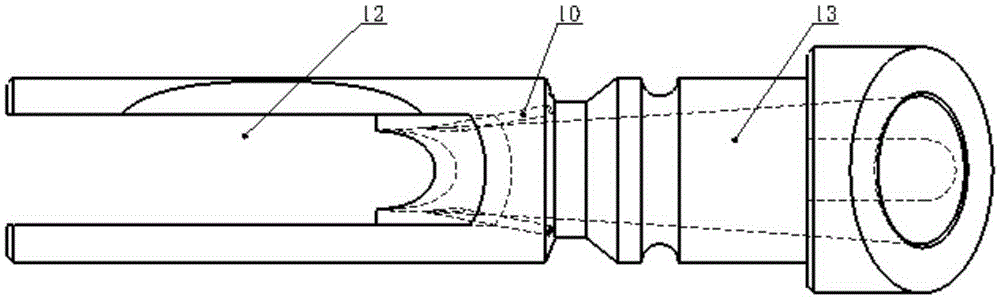

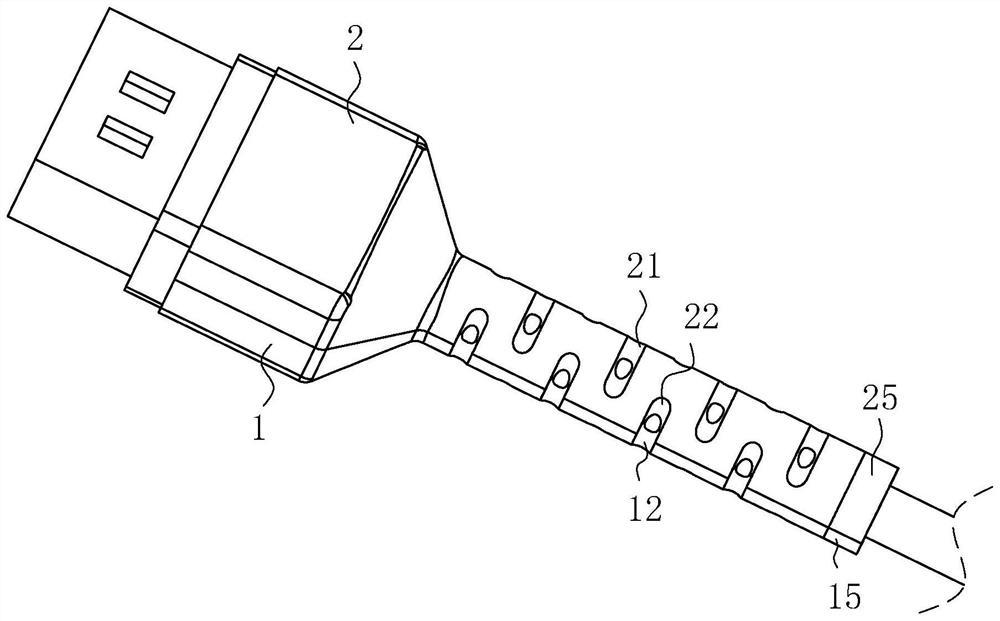

Bending-resistant data line protection sleeve

InactiveCN112768994AImprove stabilityNot easy to damageCoupling device detailsEngineeringStructural engineering

Owner:SHENZHEN TARGE IND CO LTD

Mold Tooling for Small Backpack Heating Radiator

ActiveCN105414874BHug tightlyPlay a role in shapingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStainless steel welding

The invention belongs to the technical field of civil radiator processing and manufacturing, and discloses a stainless steel welding structure member die tool of a small pack basket heating radiator. Inner core pipes are respectively placed in two vertical communicating pipes. A concave arc surface of the inner core pipe contacts with two end faces of a straight horizontal pipe. The left side of the inner core pipe is in an annular arc-shaped surface, and contacts with two edges of the profiles of the two vertical communicating pipes when being extruded and closed, and under the action of a pressure strut of a cylinder, the inner core pipe and the two edges of the profiles of the two vertical communicating pipes move relatively to clamp, so that the two edges of the profiles of the two vertical communicating pipes are kneaded tightly. A moon shape in the inner core pipe is divided into a plurality of sections. A space distance is between the end faces of the sections. The end faces on two ends of a bended horizontal pipe are inserted into the space distance. A cylindrical pipe is arranged on the upper part of the middle position of the moon shape of the inner core pipe. The bottom of the cylindrical pipe contacts with two end faces of the bended horizontal pipe. When the pressure strut of the cylinder contracts and exits, the inner core pipes on the two ends respectively rotate inward for 90 DEG, and the inner core pipes are pulled out.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

Liquor storage box

Owner:北京汤家老坊贸易有限公司

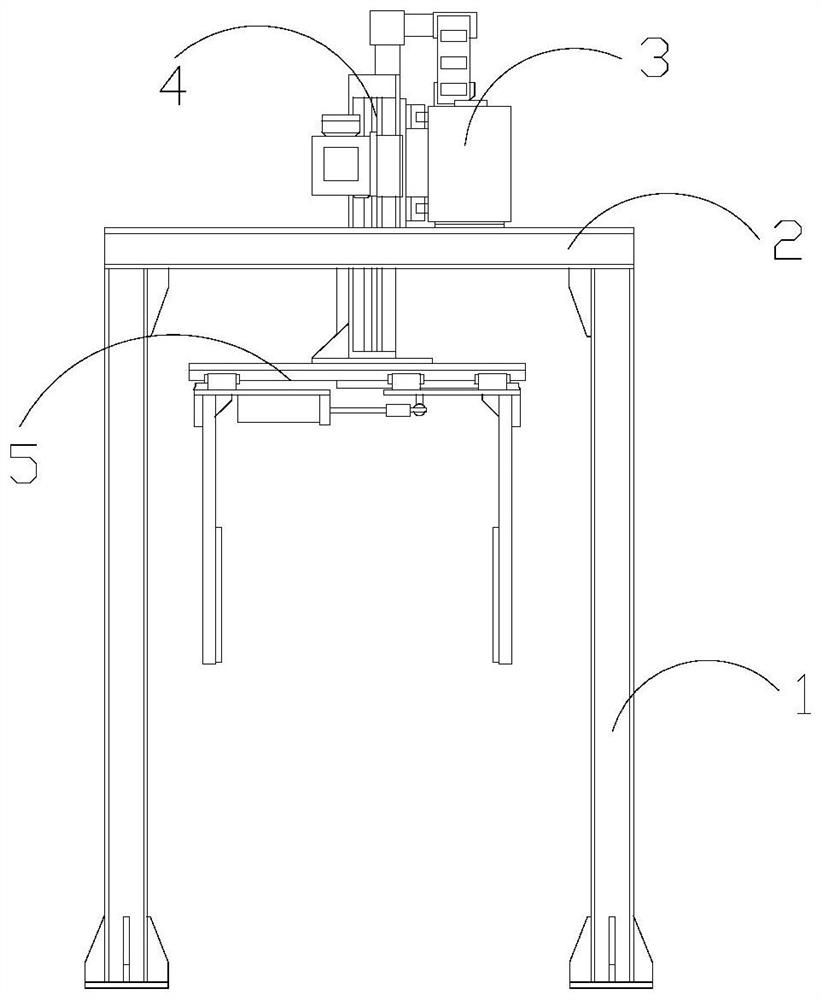

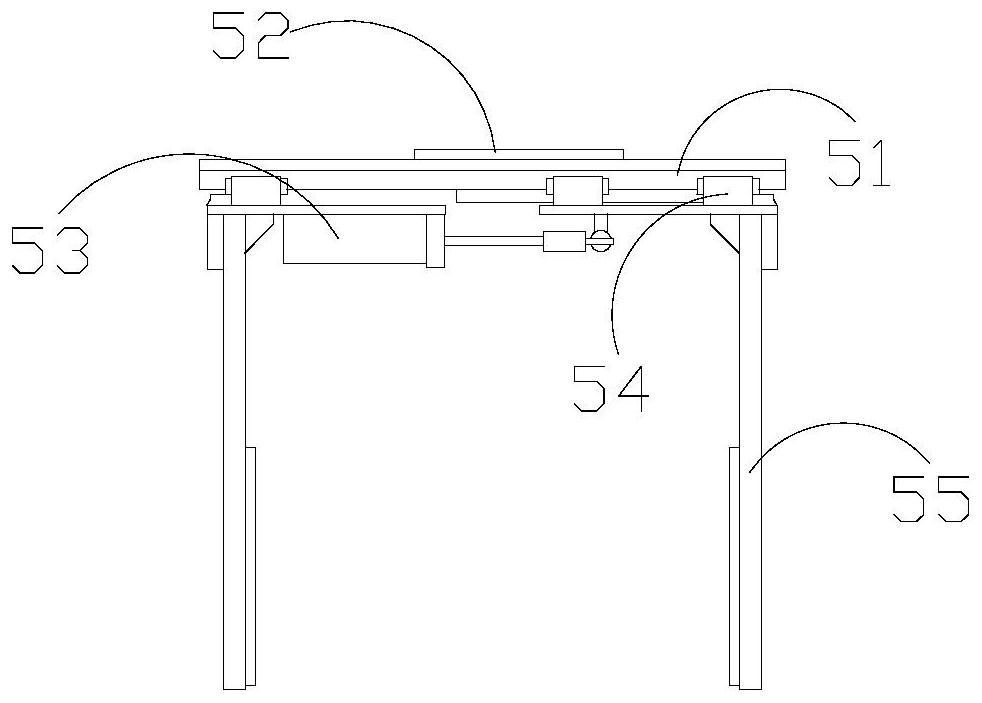

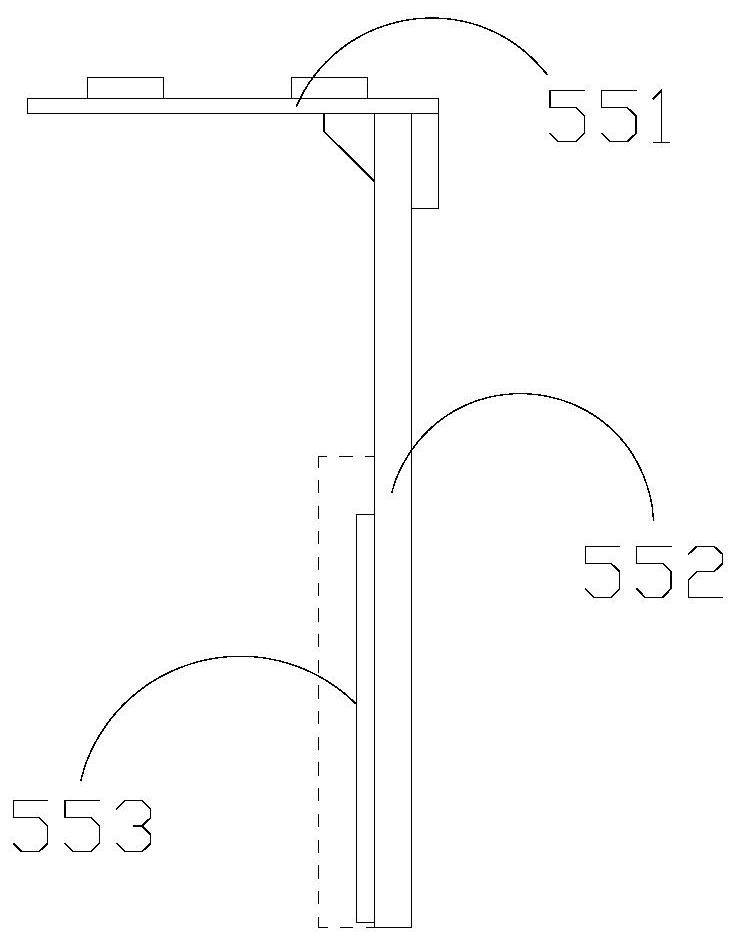

Logistics clamping holding machine

The invention discloses a logistics clamping holding machine. The machine structurally comprises a machine frame, a transverse guide rail, a driving box, a longitudinal guide rail and a clamping holding structure, wherein the transverse guide rail is horizontally installed at the upper end of the machine frame, the driving box is installed between the transverse guide rail, the longitudinal guiderail is vertically embedded into the inner sides of the driving box, and the clamping holding structure is vertically installed at the lower end of the longitudinal guide rail; and the clamping holding structure comprises a sliding rail, a supporting frame, an air cylinder, a sliding block and clamping holding plates, wherein the sliding rail is horizontally installed at the lower end of the supporting frame, the sliding block sleeves the outer side of the sliding rail, the air cylinder is installed between the clamping holding plates, and the clamping holding plates are vertically and fixedlyarranged at the lower end of the sliding block. According to the logistics clamping holding machine, the clamping holding plates are arranged at the lower end of the sliding block, so that right-angle limitation is better formed for the outer side of a carton, the situation that the carton is deviated due to uneven stress is prevented, and the integrity of the outer side smooth surface of the carton is guaranteed; and meanwhile, a suction cup structure is arranged on the inner side of an exhaust structure so that the outer side of the carton can be sucked, and the carton can be further clamped and held more tightly, thereby preventing deviation.

Owner:刘兆喜

High-speed spinning device capable of reducing hairiness

PendingCN113322551AIncrease spinning speedGuaranteed twisting qualityContinuous wound-up machinesOpen-end spinning machinesPhysicsYarn

The invention discloses a high-speed spinning device capable of reducing hairiness. The high-speed spinning device comprises a top air supply device; a blending chamber is arranged below the top air supply device; twisting devices are arranged on the outer wall of the upper portion of the blending chamber in the circumferential direction; pinch twisting adjusting devices are arranged on the inner wall of the upper portion of the blending chamber in the circumferential direction; the pinch twisting adjusting devices and the twisting devices are arranged in a one-to-one correspondence mode; a pinch twisting traction device is arranged at the bottom of the blending chamber; and a dust collection box is arranged outside the lower portion of the blending chamber. The invention relates to the technical field of textile equipment. According to the high-speed spinning device capable of reducing the hairiness, through the arrangement of the blending chamber, the twisting devices, the pinch twisting adjusting devices and the pinch twisting traction device, continuous cotton slivers subjected to drawing are fed from the outer end of the twisting devices and twisted through the twisting devices, two-way pinch twisting of preliminary spun yarn is conducted through the pinch twisting adjusting devices, and twisting or blending is conducted in the blending chamber, so that the problems that most mechanical spinning is relatively low in spinning speed and generates more floating dust, and yarn spun by air-flowing spinning is relatively low in strength and relatively long in hairiness can be solved.

Owner:王明远

Production process of nylon flame-retardant anti-infrared camouflage braid

PendingCN114836979AIncreased reflective refractionGood flexibilityFilament/thread formingHeat resistant fibresPolymer scienceSpinning

The invention discloses a nylon flame-retardant infrared-resistant camouflage braid production process which comprises the following steps: spinning, braid weaving, braid washing, ground color dyeing, printing, high-temperature color development, post-treatment and flame-retardant treatment. The invention has the beneficial effects that: 1, the cross section of the monofilament ejected from the spinneret orifice is Y-shaped by transforming the spinneret orifice, so that the surface brightness of the monofilament is increased, and the reflective refraction of the surface of a nylon braid woven by nylon yarns consisting of the monofilament is improved, and the color and luster of the nylon braid are saturated; 2, the spinning temperature of a spinning melt is increased, the content of cooling master batches is increased, the stretching ratio is increased, the softness of monofilaments is improved, the monofilaments can be tightly cohered together without being dispersed after being fully stretched, and therefore the nylon yarn is not prone to fuzzing; and 3, the air pressure during padding is improved, and the stability of the pressure is ensured, so that the nylon braid is fully padded, the moisture content of the nylon braid during secondary dip dyeing is consistent, and the dyeing uniformity of the nylon braid is improved.

Owner:四川鑫敬业化纤织带有限公司

Silk reeling method and special device for skeining raw silk

The invention relates to a silk reeling method and device, particularly to a silk reeling method and an exclusive device for reeling raw silk, which aim to solve the technical problems in the prior art that the energy consumption is large, the technological process is long, and more workers are needed all caused by silk reeling, rereeling and repeated drying; more time and labors are consumed because the bore diameter of a filament guide button is small; during the silk reeling process, the manual manner is adopted to form a silk sheath structure, and the hygrometric state raw silk is gathered by the function of the silk sheath in the method of gathering hygrometric state raw silk, the operation is complicated and the labor productivity is low. According to the invention, bave is processed by a hygrometric state raw silk gathering device after passing through an end feeding wing and a leading-in type filament guide button so as to enable the hygrometric state raw silk to be closely gathered, and moisture in a silk strip to be emitted by extrusion, tiny fouls on the bave surface are eliminated through kneading in a rotary manner, then, the bave is directly wound on a large shade and forms large flourishing yarn sheets through infra-red heating and drying, and the yarn sheets become reeled raw silk after silk falling arrangement.

Owner:ZHEJIANG SCI-TECH UNIV

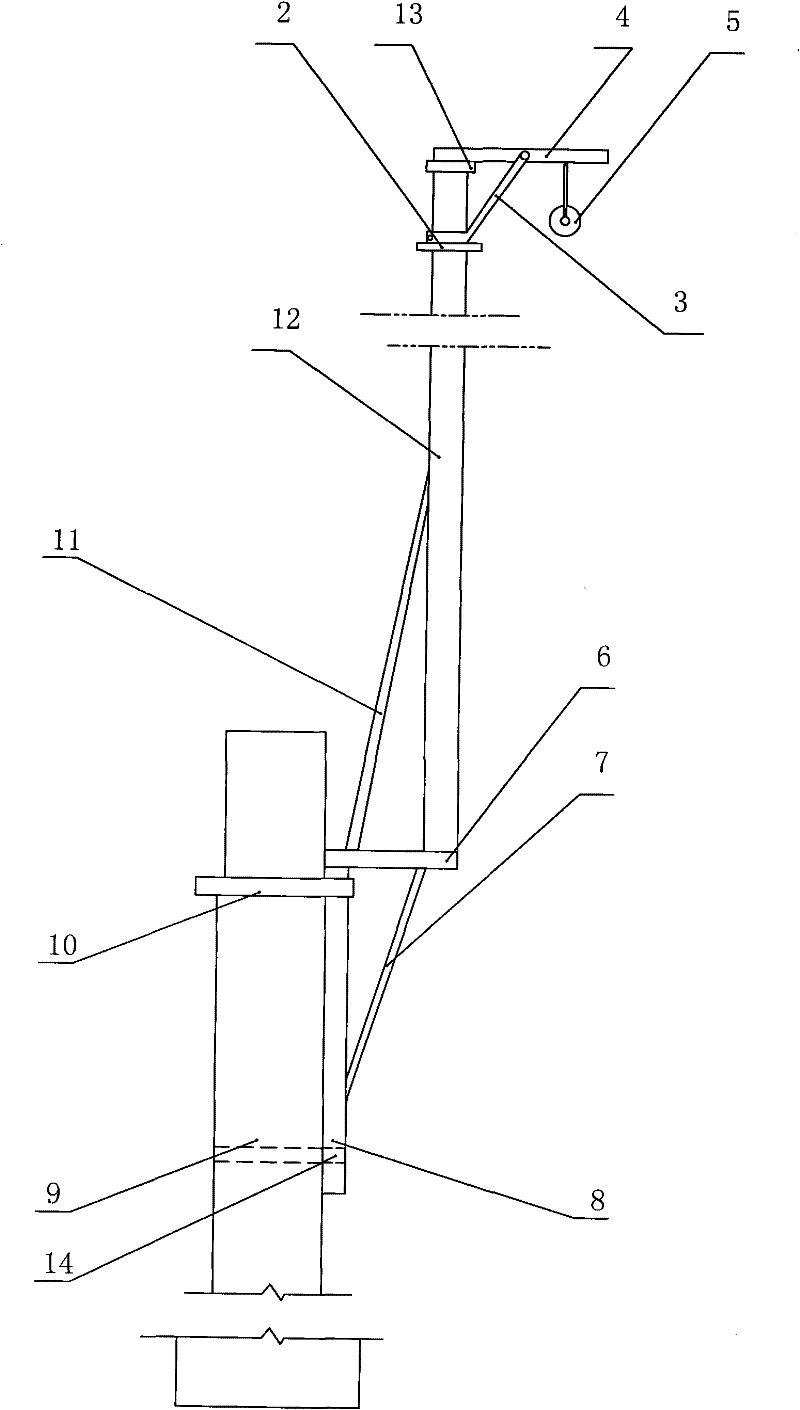

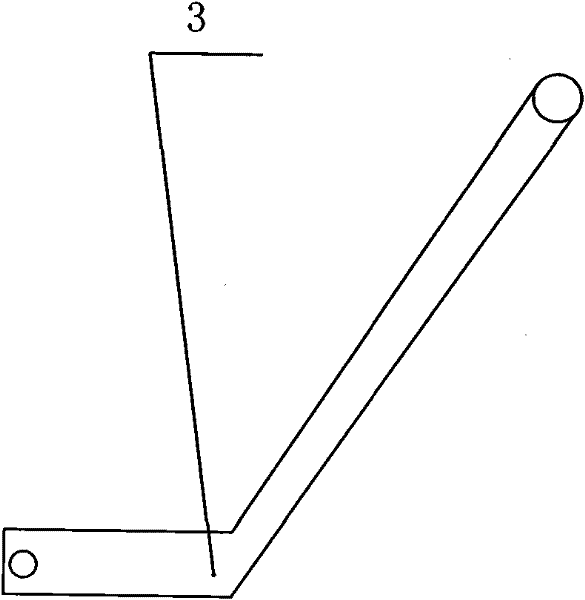

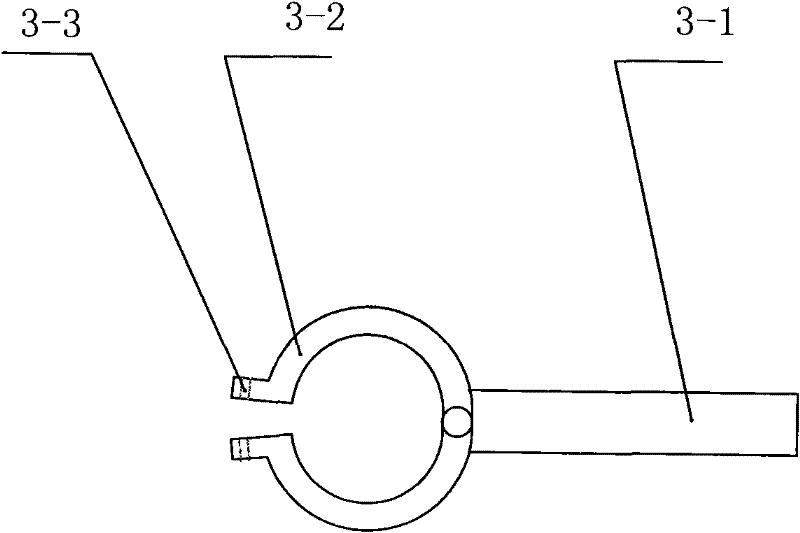

Hoisting tool for power distribution network overhead line

The invention relates to a hoisting tool for a power distribution network overhead line. The hoisting tool for a power distribution network overhead line comprises a steel pipe I. The steel pipe I is connected to a left end of a steel pipe III. A right end of the steel pipe III is connected to a lower end of a steel pipe II. An upper end of the steel pipe II is provided with a pulley support. The pulley support is provided with a fixed pulley. The steel pipe I is hinged to one or two climbers. The steel pipe is provided with an installing hole connected with an electric pole. Compared with the prior art, the hoisting tool for a power distribution network overhead line has the characteristics that the steel pipe I is hinged to the one or two climbers, so that during use, the one or two climbers are stuck on the electric pole and the cohesion between the one or two climbers and the electric pole is tighter and tighter with increasing of a force applied to the steel pipe I; and the one or two climbers can easily form the cohesion with a tower without slipping.

Owner:JIAOZUO POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com