Patents

Literature

47results about How to "Eliminate quality differences" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

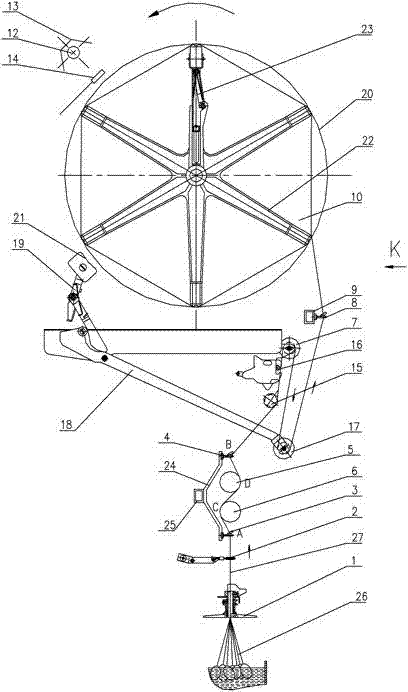

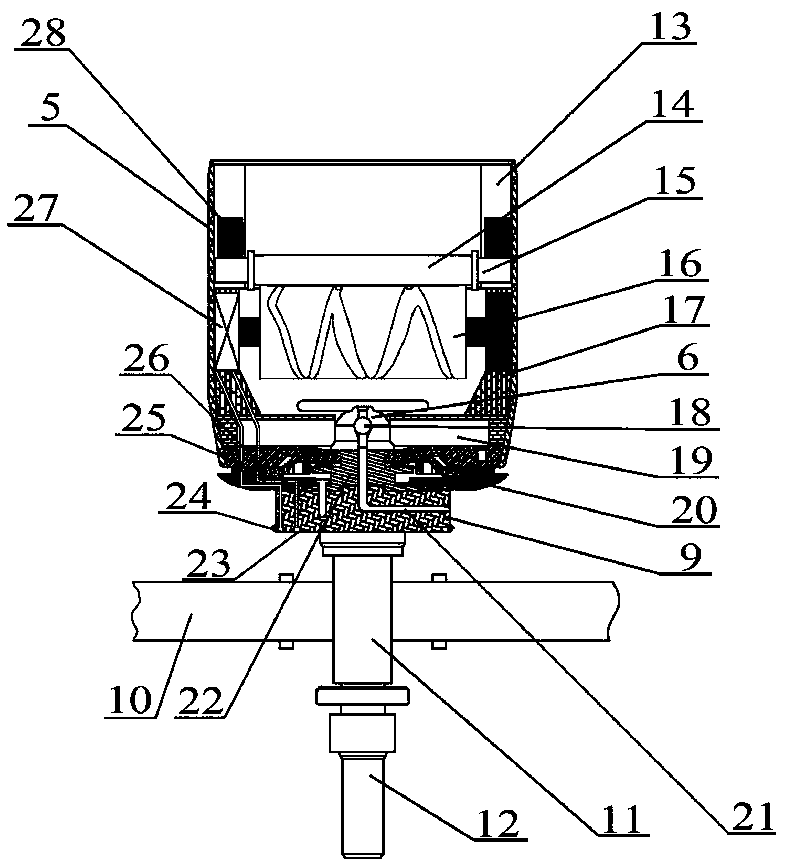

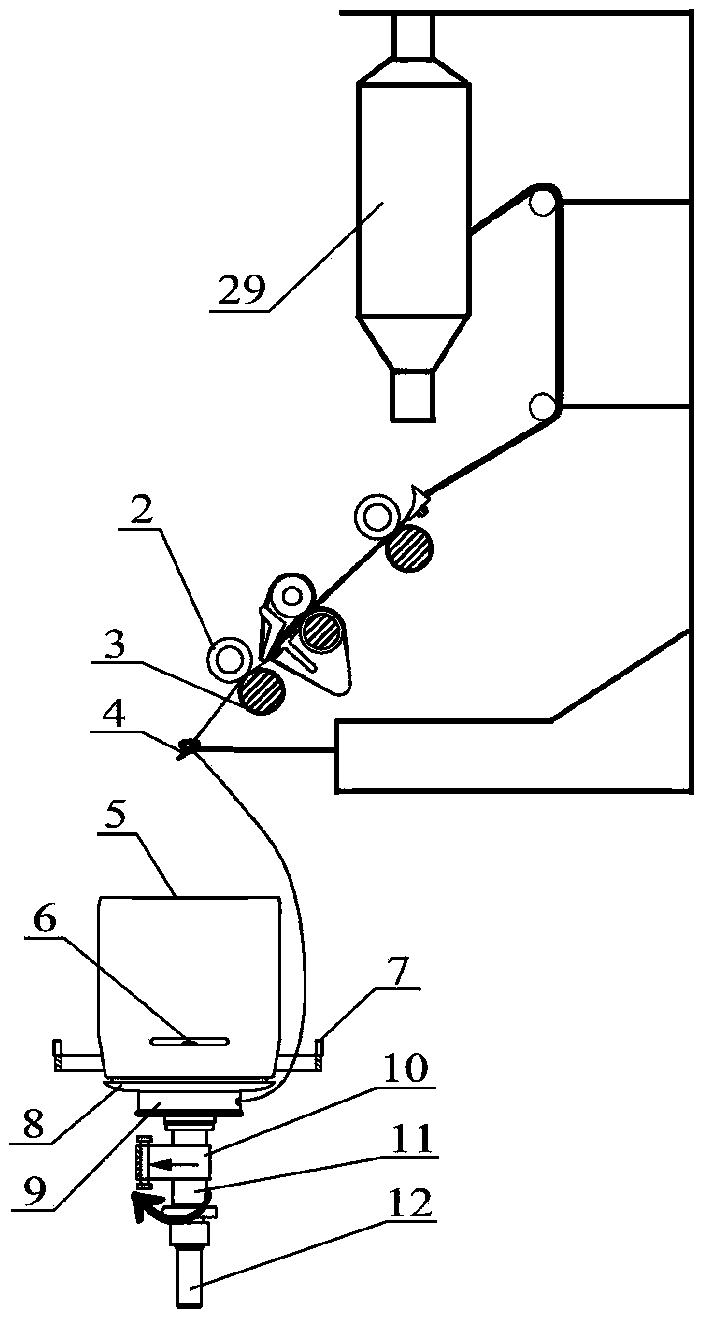

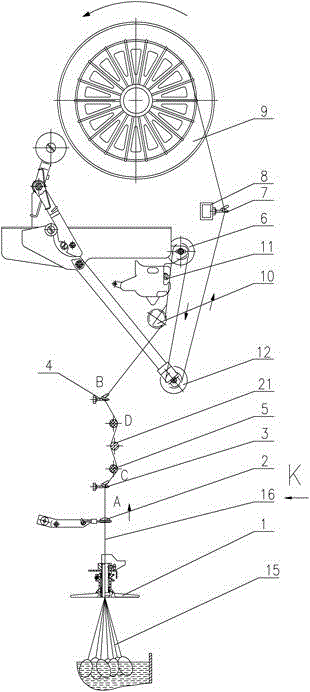

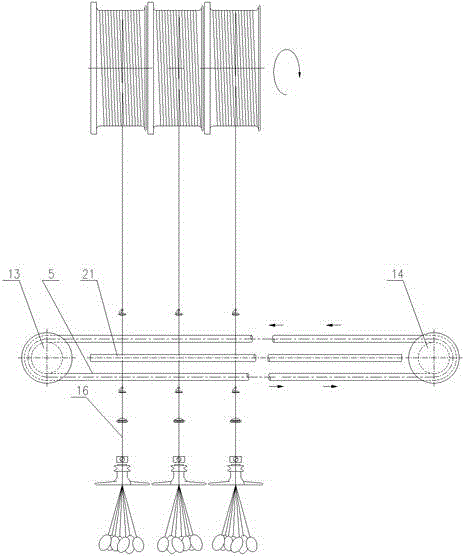

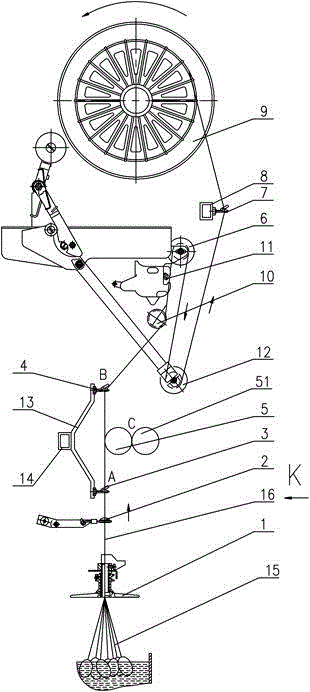

Silk reeling method and exclusive device for reeling raw silk

The invention relates to a silk reeling method and device, particularly to a silk reeling method and an exclusive device for reeling raw silk, which aim to solve the technical problems in the prior art that the energy consumption is large, the technological process is long, and more workers are needed all caused by silk reeling, rereeling and repeated drying; more time and labors are consumed because the bore diameter of a filament guide button is small; during the silk reeling process, the manual manner is adopted to form a silk sheath structure, and the hygrometric state raw silk is gathered by the function of the silk sheath in the method of gathering hygrometric state raw silk, the operation is complicated and the labor productivity is low. According to the invention, bave is processed by a hygrometric state raw silk gathering device after passing through an end feeding wing and a leading-in type filament guide button so as to enable the hygrometric state raw silk to be closely gathered, and moisture in a silk strip to be emitted by extrusion, tiny fouls on the bave surface are eliminated through kneading in a rotary manner, then, the bave is directly wound on a large shade and forms large flourishing yarn sheets through infra-red heating and drying, and the yarn sheets become reeled raw silk after silk falling arrangement.

Owner:ZHEJIANG SCI-TECH UNIV

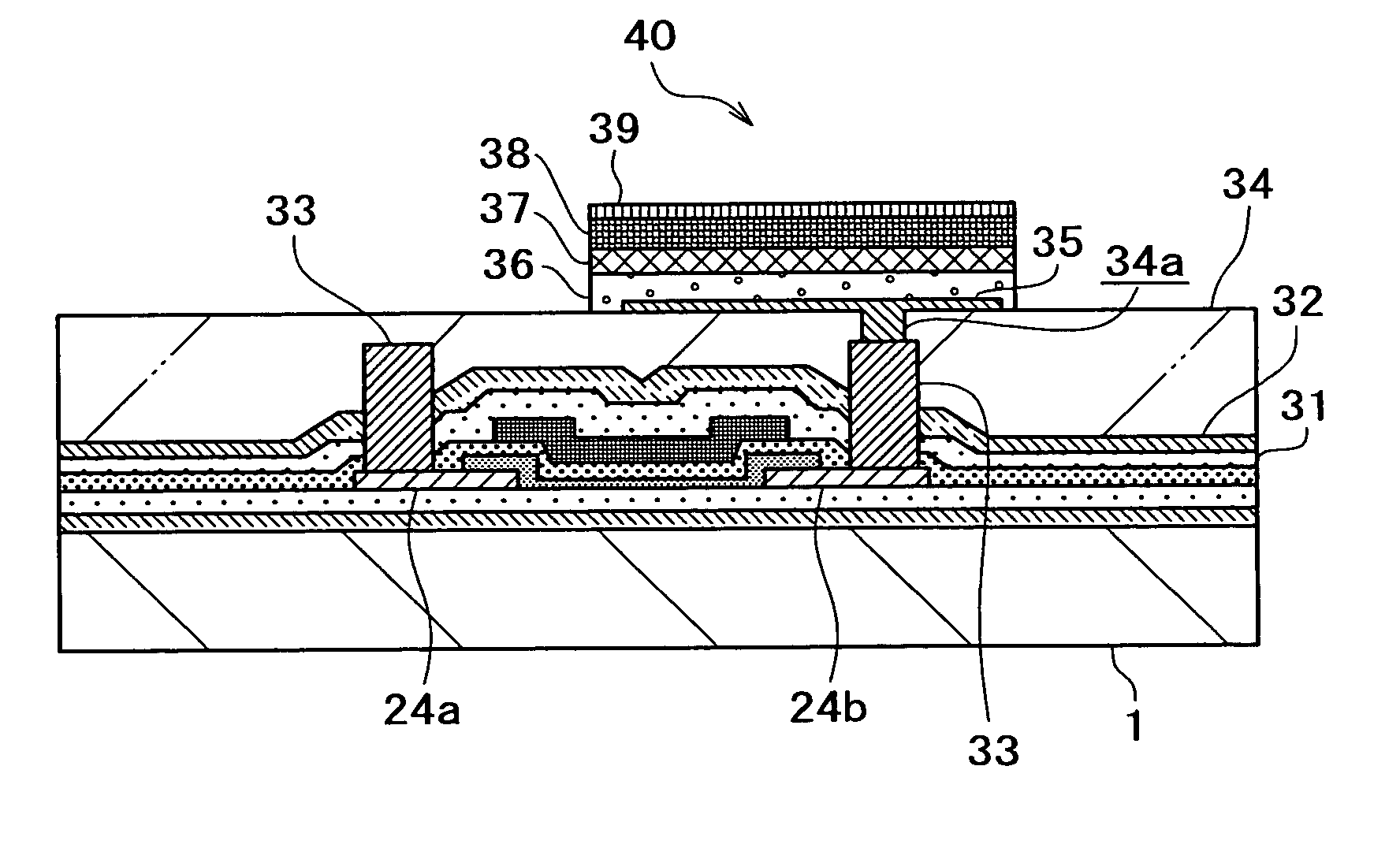

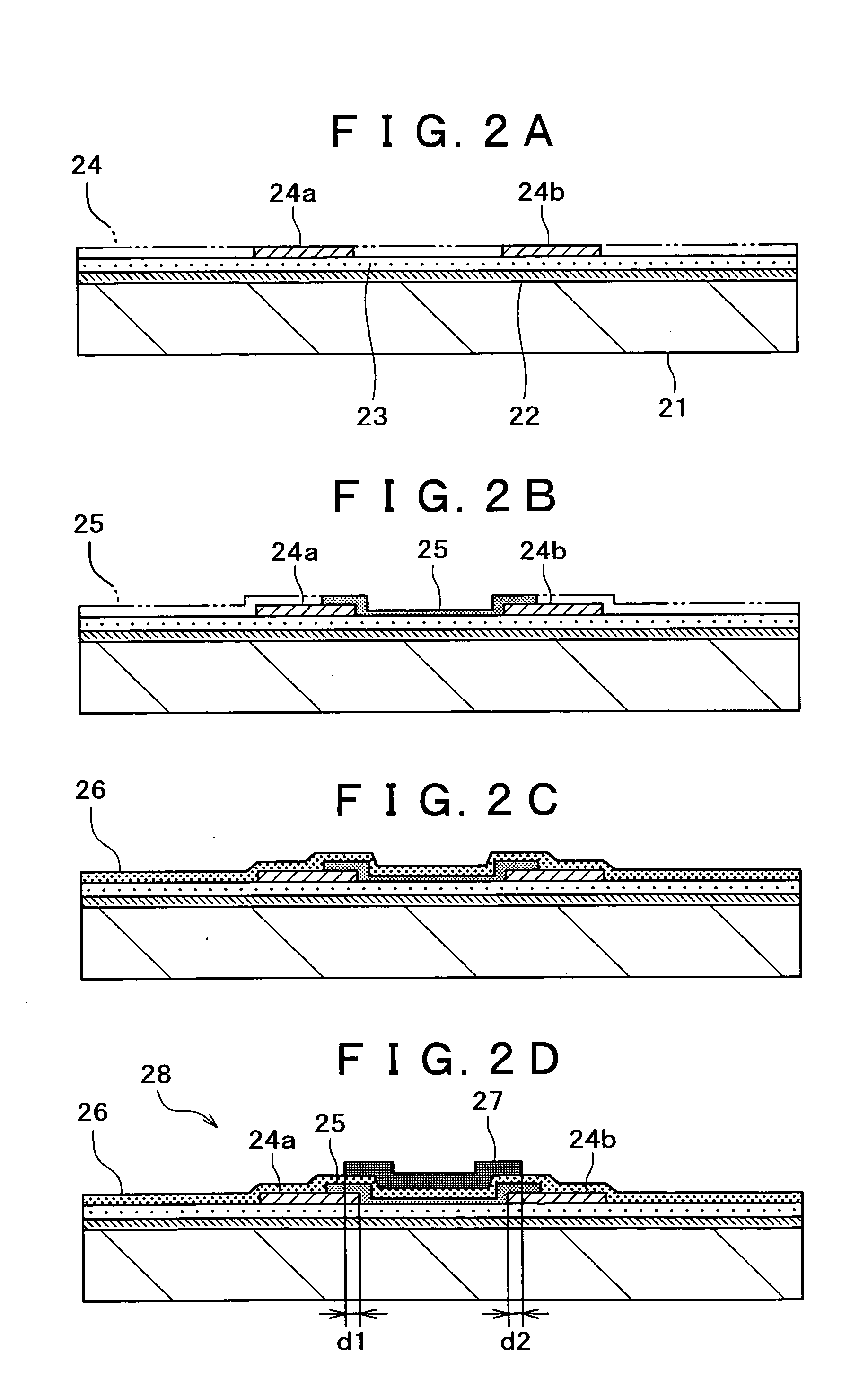

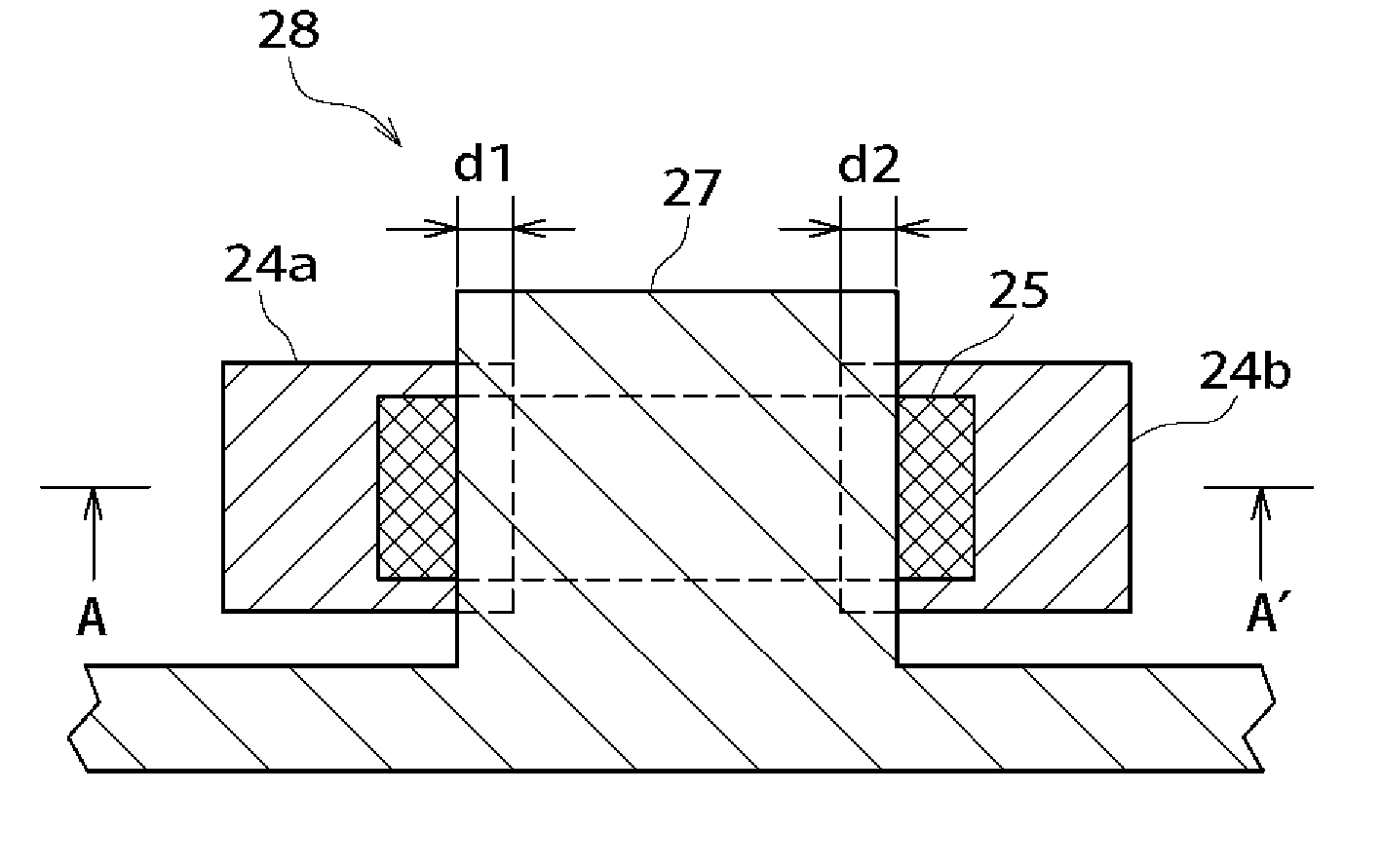

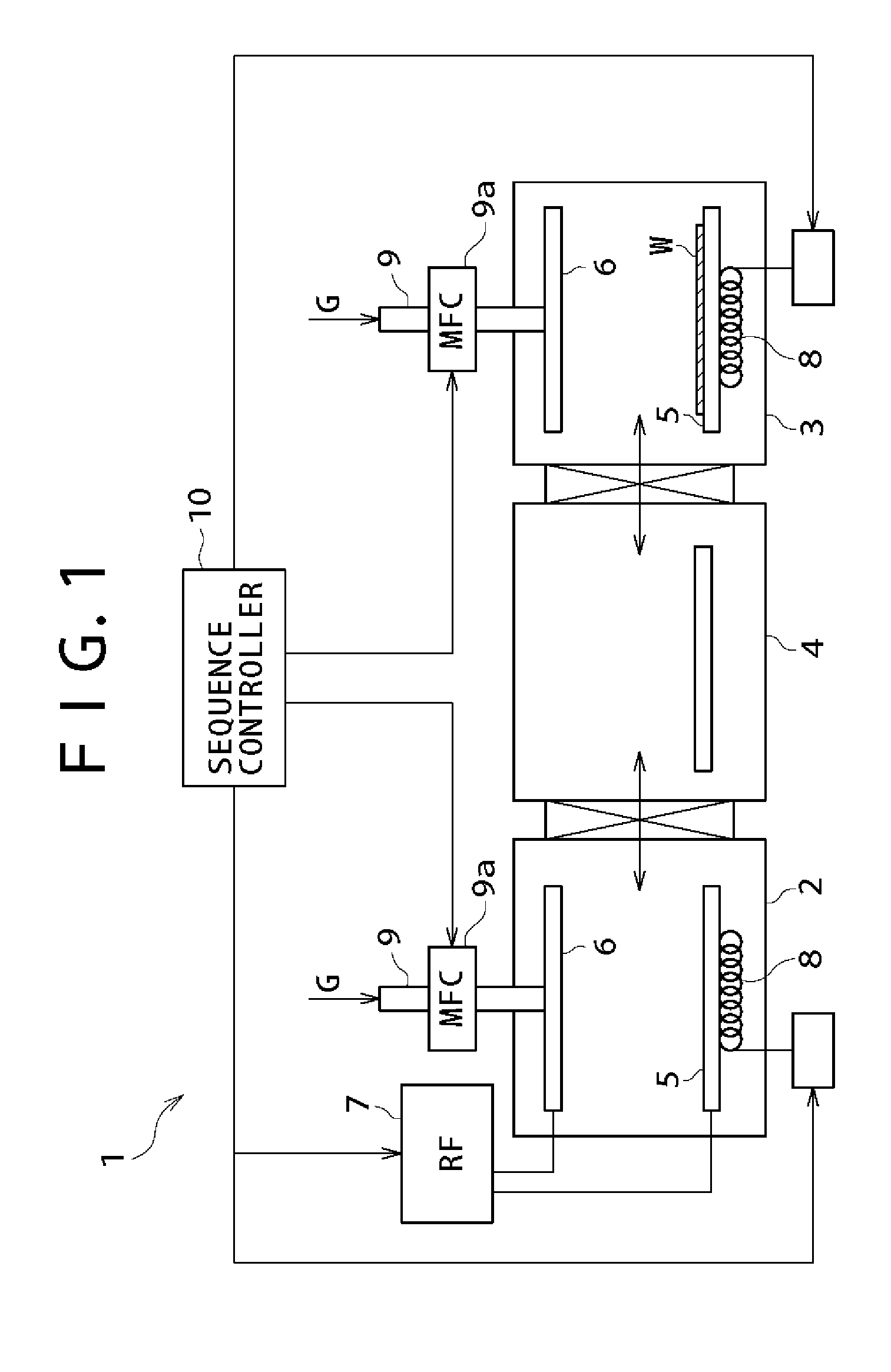

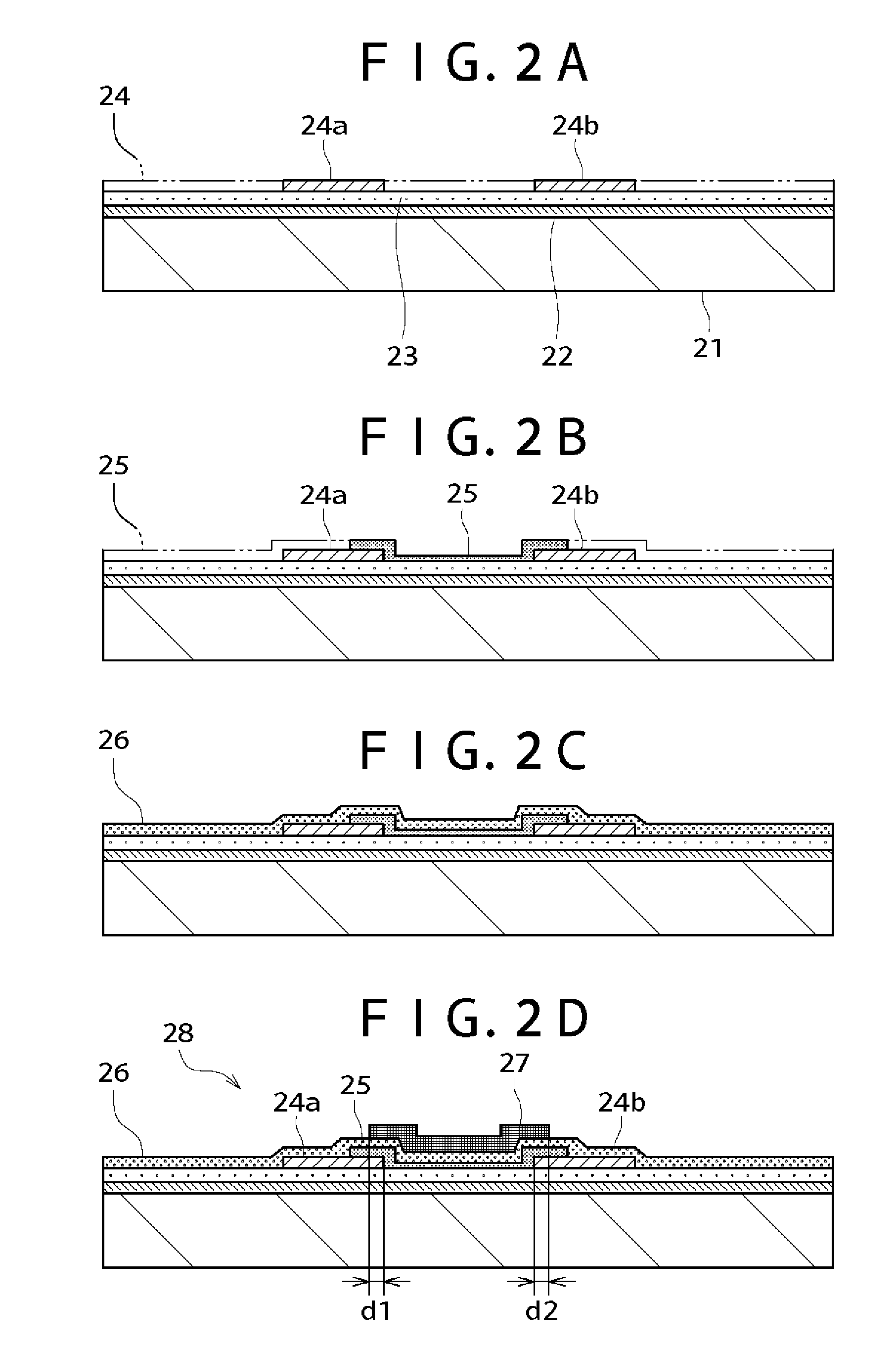

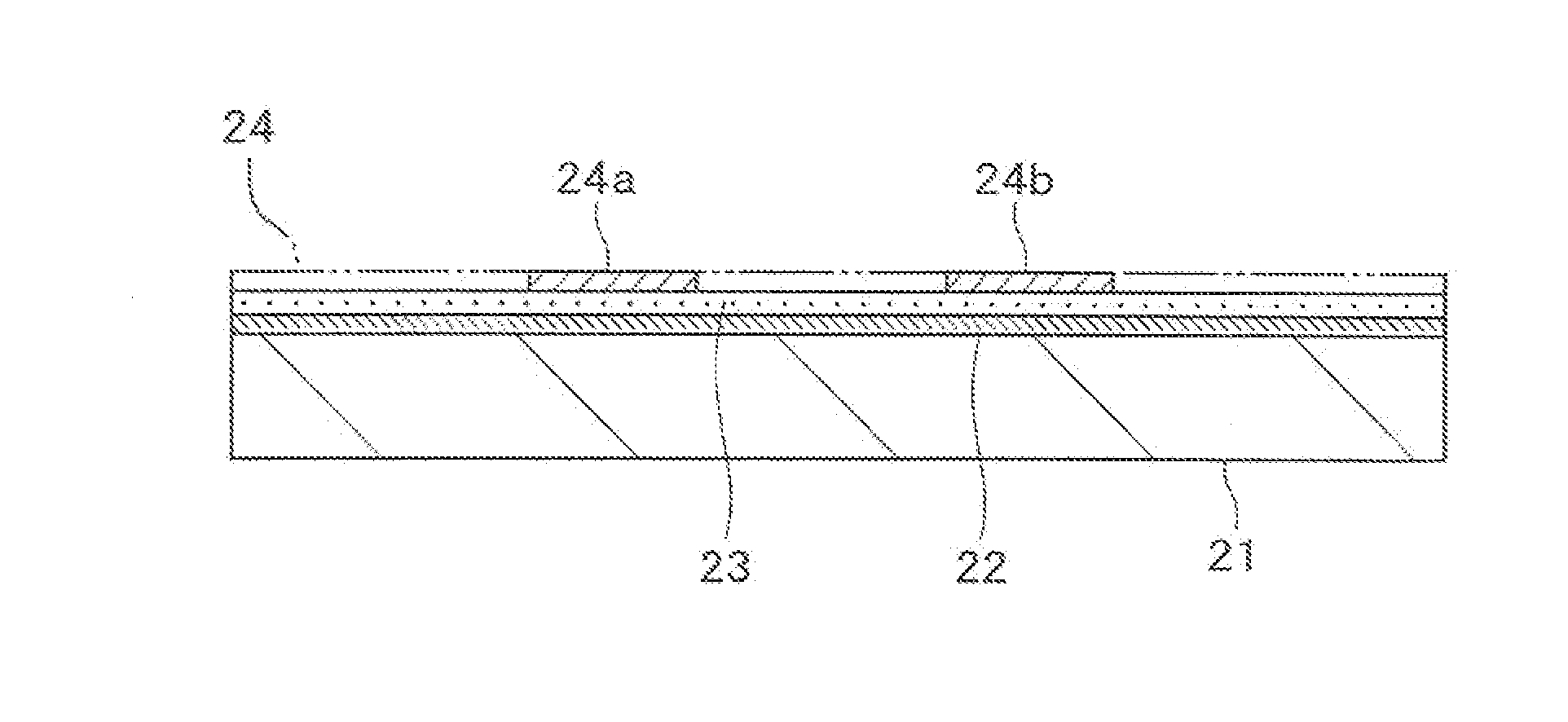

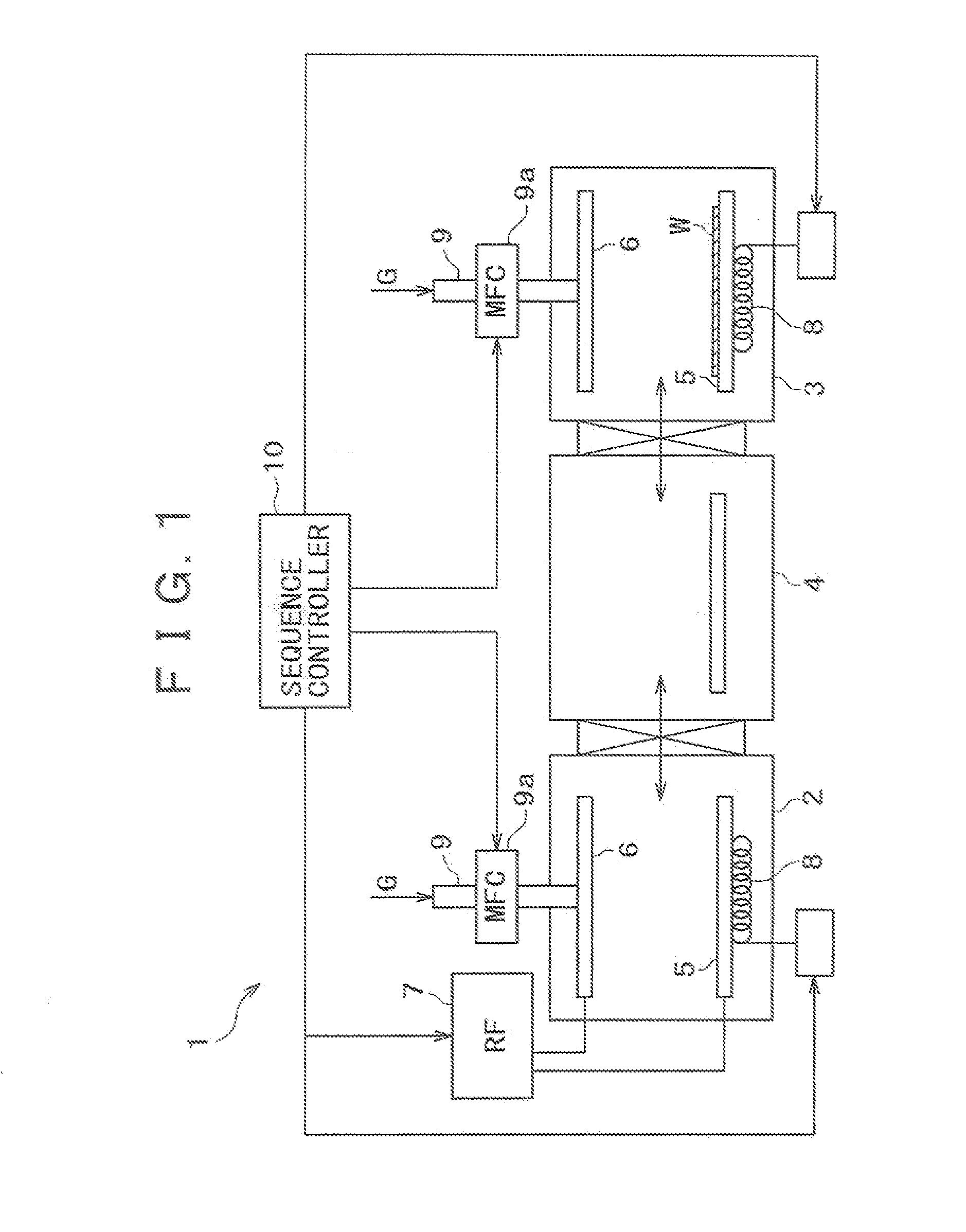

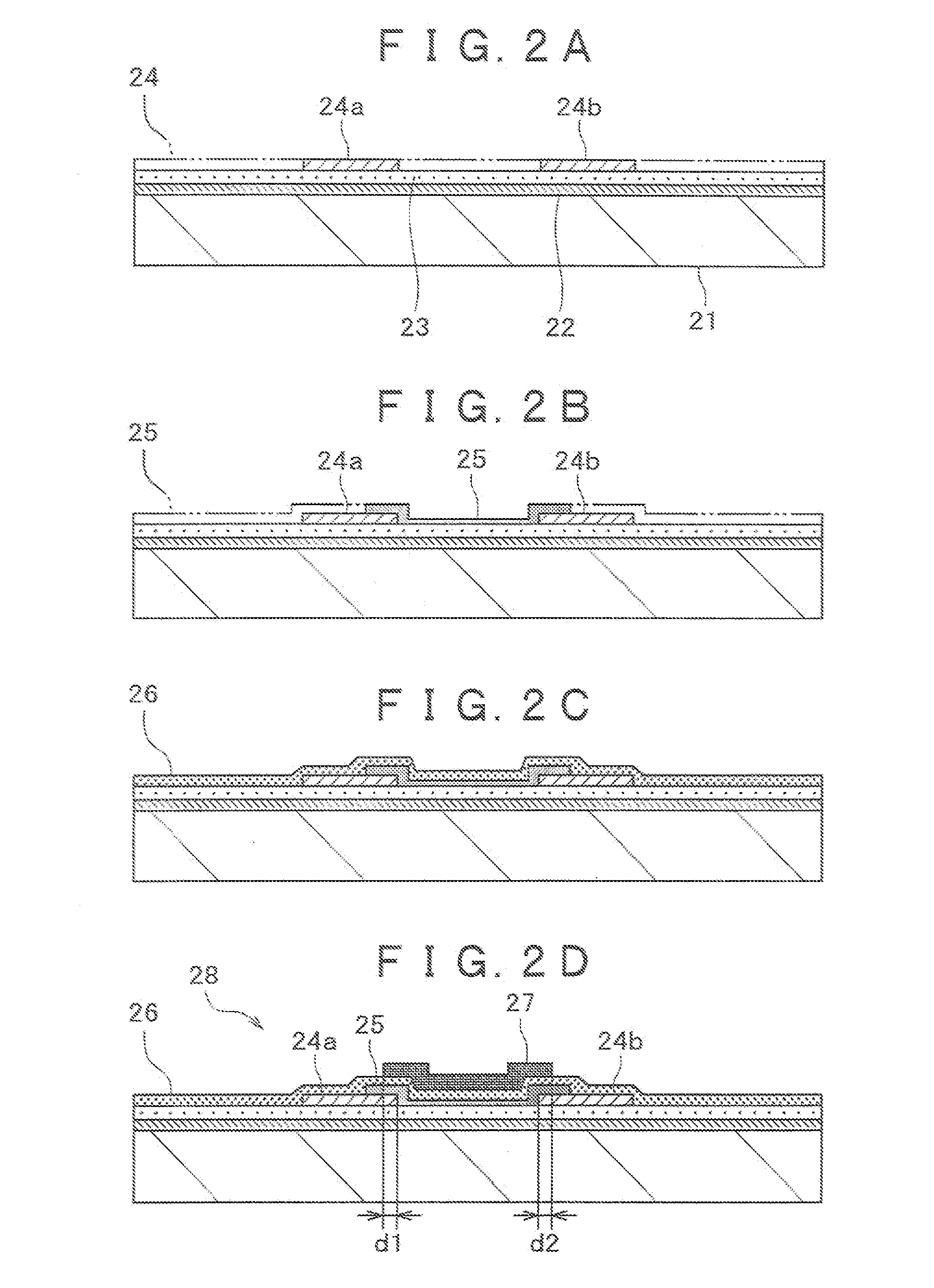

Thin film transistor and method for production thereof

InactiveUS20050070055A1High speedIncrease currentTransistorElectroluminescent light sourcesAmorphous semiconductorsUniform - quality

The production method of the thin film transistor according to the present invention involves the reactive heat CVD process to form the active layer and the source-drain layer. This offers the advantage of eliminating additional steps to crystallize the semiconductor thin film. The resulting stacked thin film transistor is composed of originally crystalline semiconductor thin films. Having the active layer and the source-drain layer formed from crystalline semiconductor thin film, the stacked thin film transistor has a faster working speed than the one formed from amorphous semiconductor thin film. Another advantage of eliminating steps for crystallization is uniform quality which would otherwise be adversely affected by crystallization. In addition, the fact that the source-drain layer is formed from a previously doped crystalline semiconductor thin film means that there is no need for any step to introduce impurities after film formation.

Owner:SONY CORP

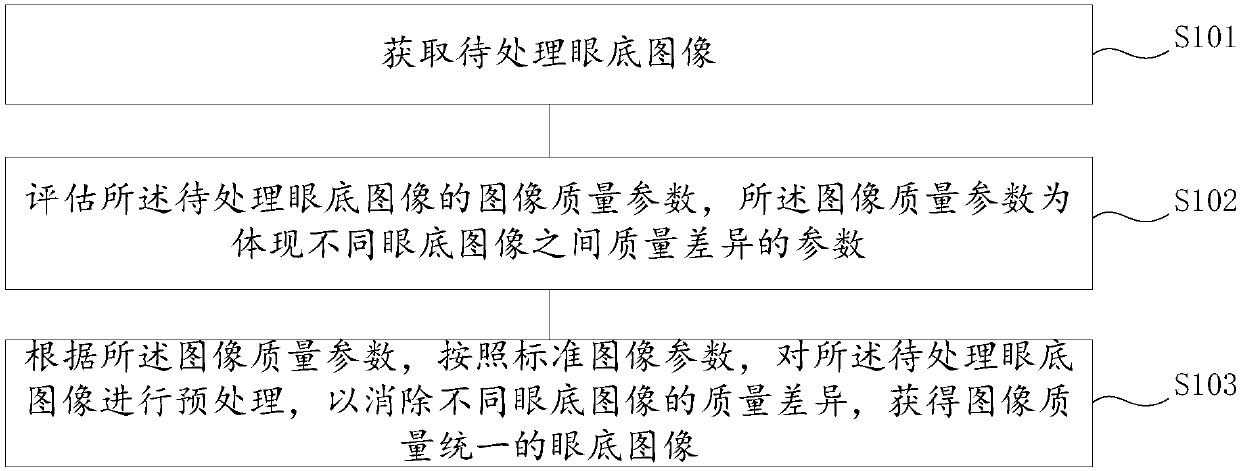

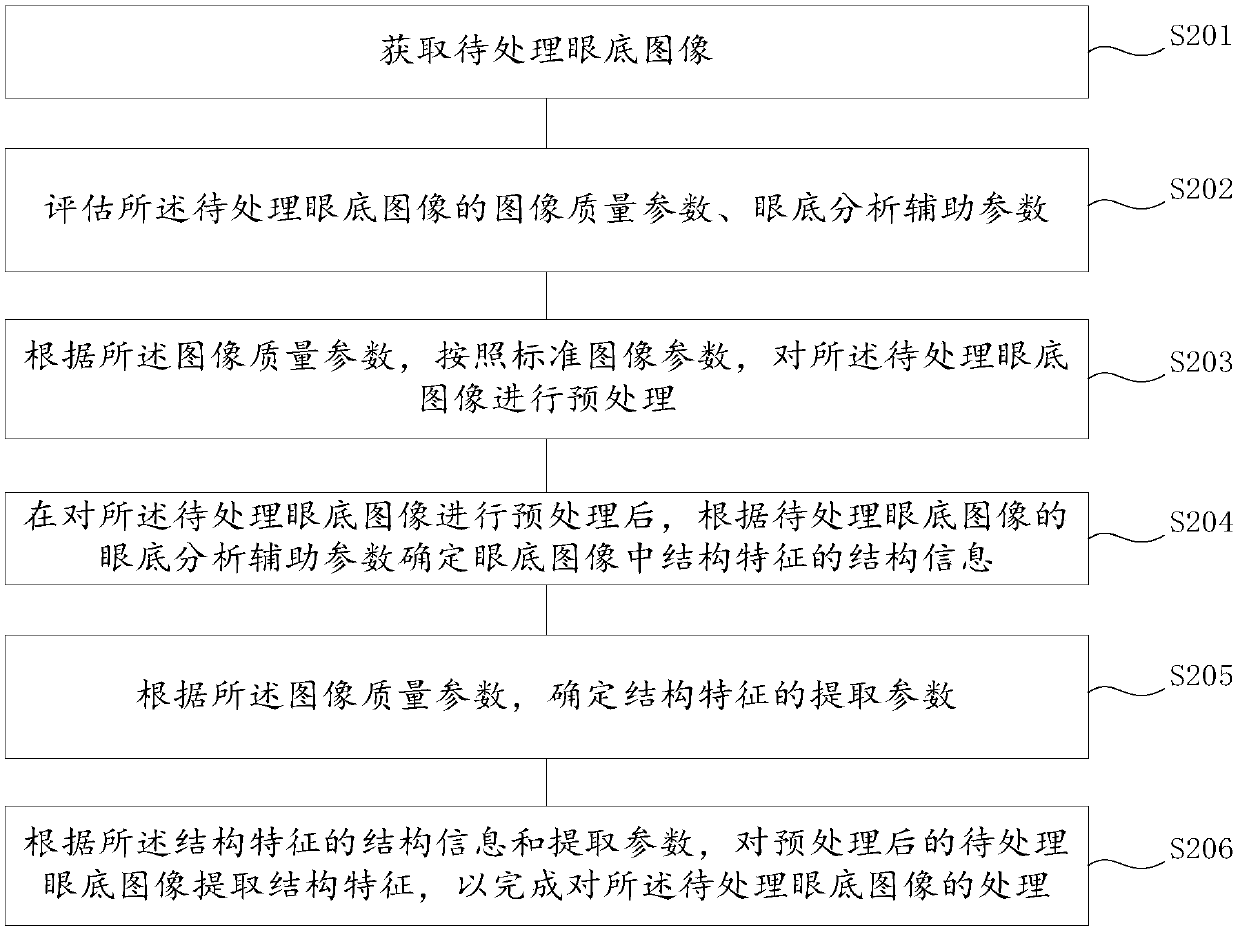

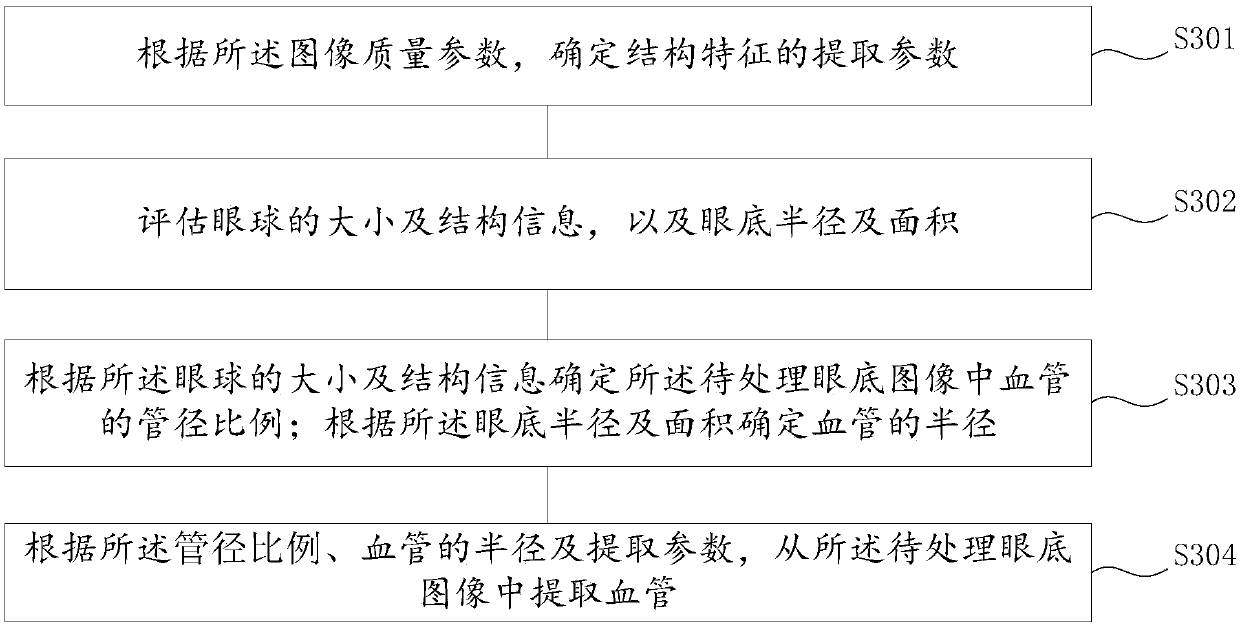

Method and device for processing eye fundus images

ActiveCN108272434AEliminate quality differencesReduce running timeOthalmoscopesImaging qualityFundus image

The invention discloses a method and device for processing eye fundus images. The method includes the steps of obtaining to-be-processed eye fundus images; evaluating image quality parameters of the to-be-processed eye fundus images, wherein the image quality parameters are the parameters reflecting the quality differences among different eye fundus images; conducting preprocessing on the to-be-processed eye fundus images according to the image quality parameters and standard image parameters to remove the quality differences among different eye fundus images to obtain the eye fundus images with uniform image quality. By conducting preprocessing on the to-be-processed eye fundus images, not only are the quality differences among different eye fundus images removed, but also the calculationamount of structural feature extraction and lesion analysis in the later period is reduced, so that the running time for analyzing the to-be-processed eye fundus images is shortened, and the purposeof processing the great quantity of to-be-processed eye fundus images at the same time can be achieved. Finally, the accuracy of the structural feature extraction and lesion judgement is improved.

Owner:柯鑫

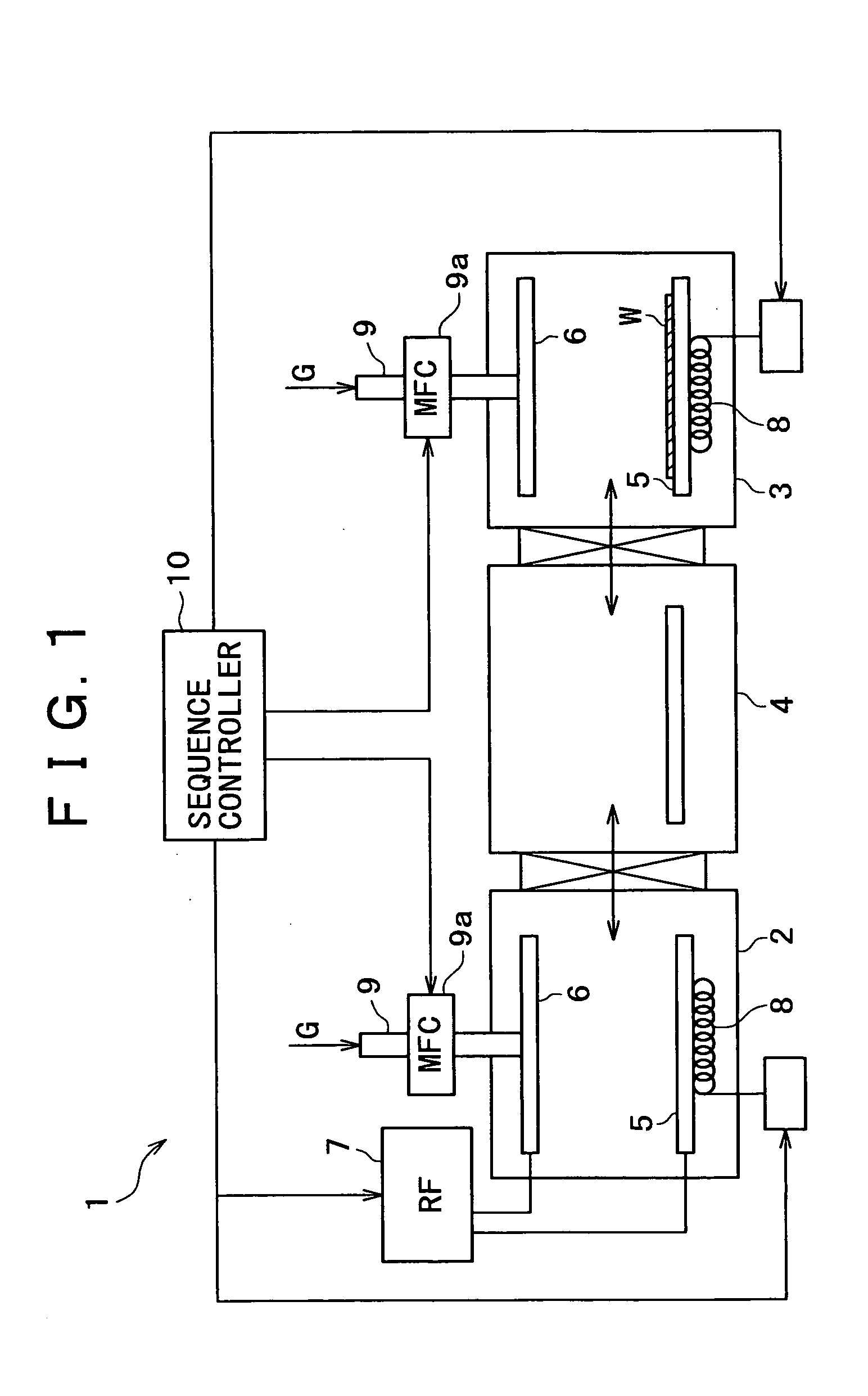

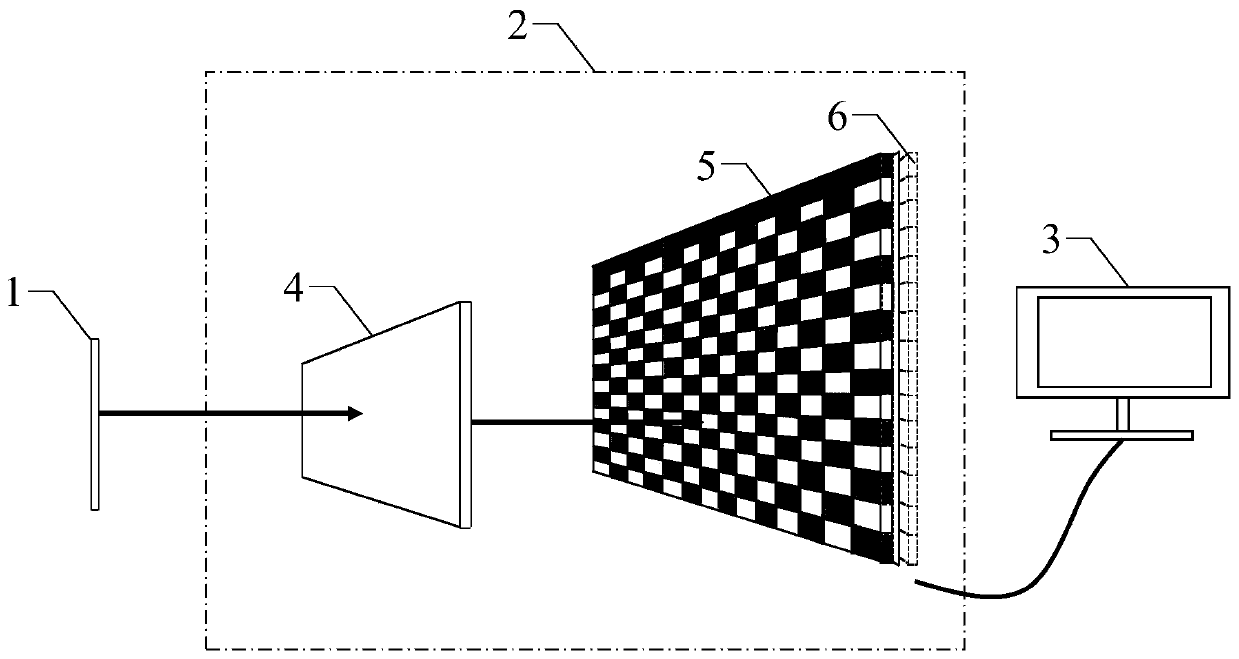

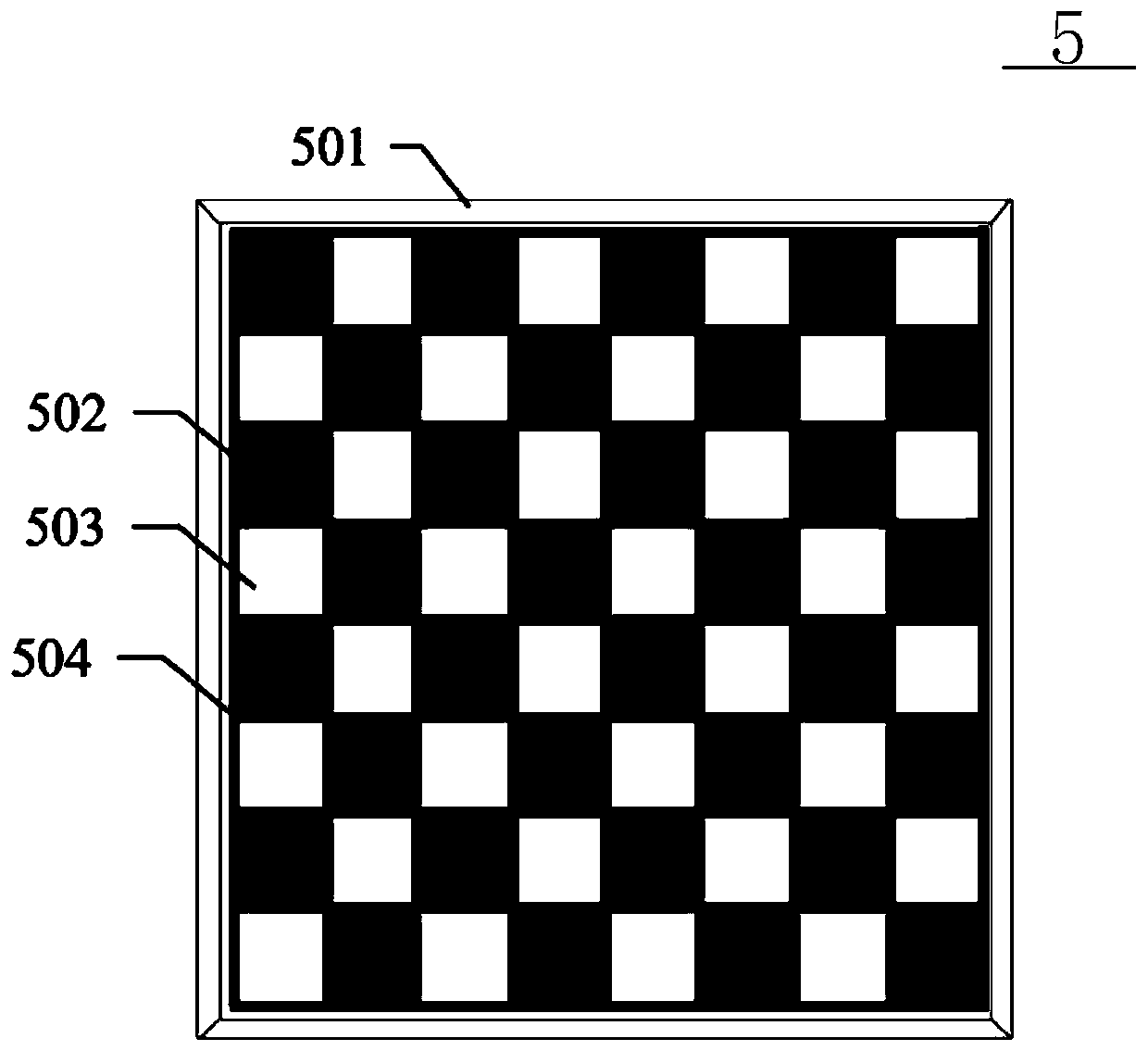

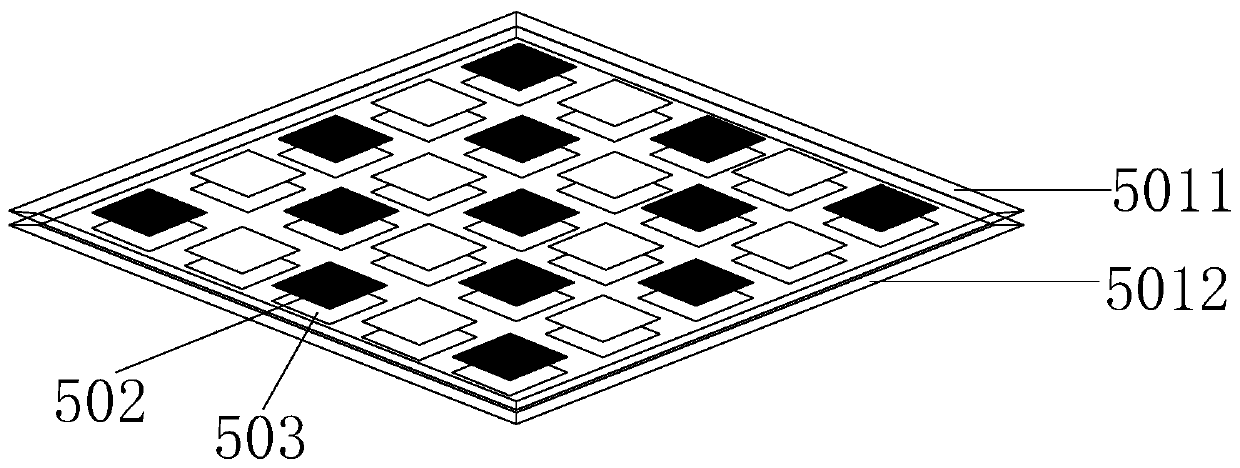

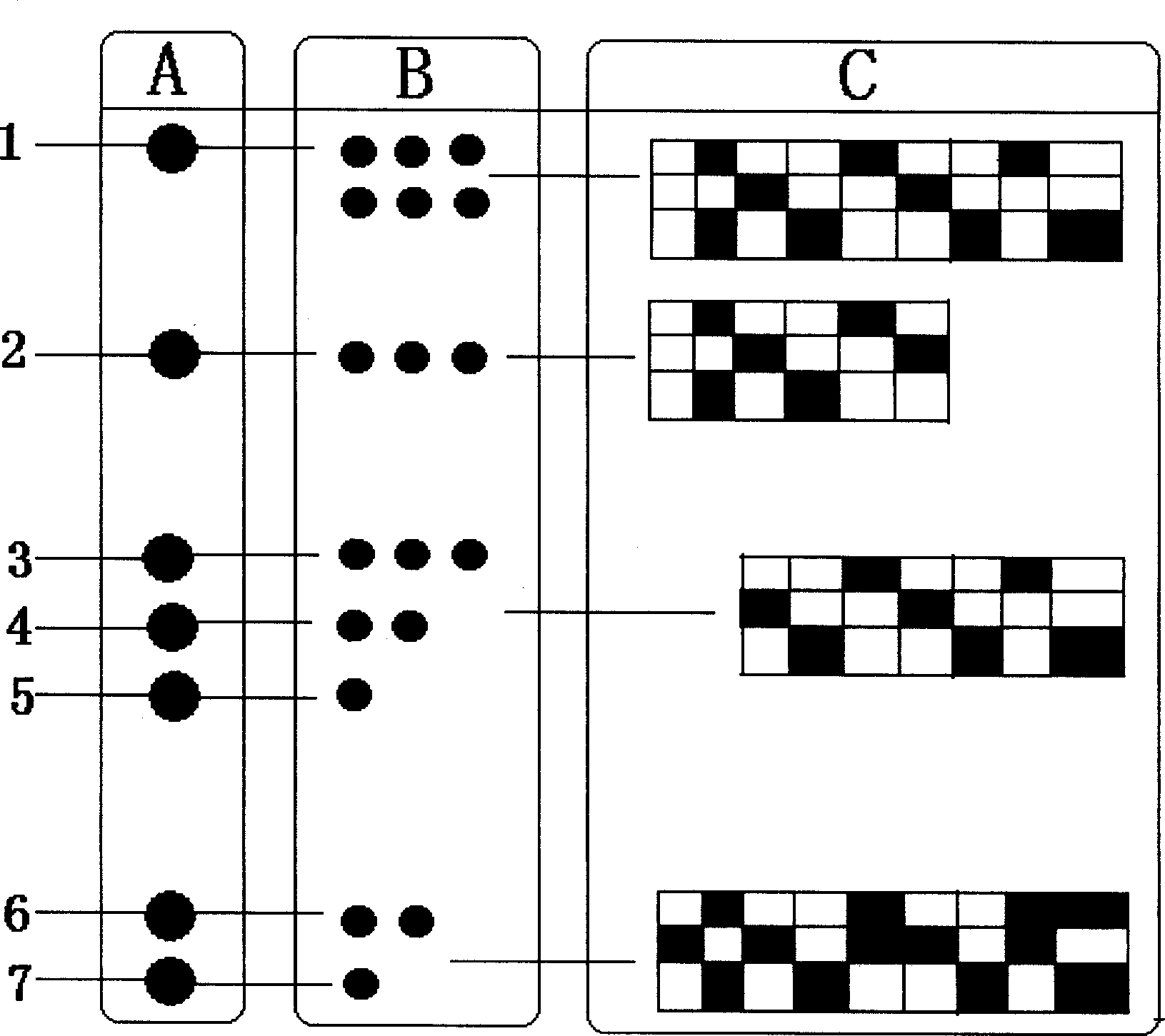

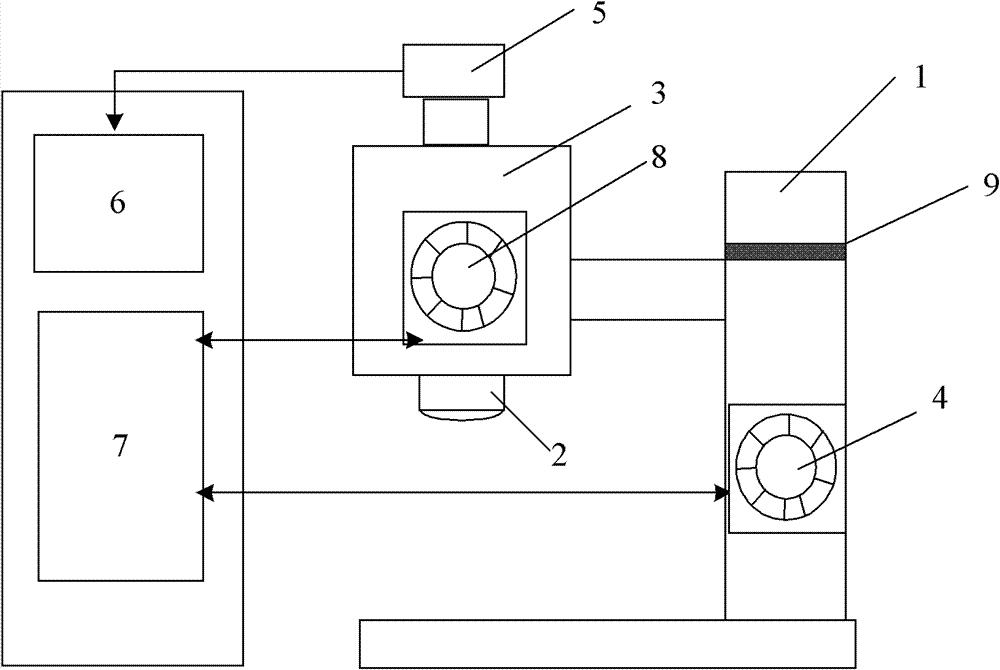

Temperature measurement system and method based on pixelated dual-band narrow-band optical filter array

ActiveCN111351578AIncrease flexibilityHigh precisionRadiation pyrometryImage analysisLight filterPixel based

The invention discloses a temperature measurement system and method based on a pixelated dual-band narrow-band optical filter array, and relates to the technical field of infrared light side mechanics. The temperature measurement system comprises a dual-band array image acquisition device and a calculation device; in the calibration stage, the dual-band array image acquisition device is used for acquiring a gray scale array image of dual-band radiation light in a calibration area of the high-temperature calibration device, and the calculation device is used for acquiring a correction parametermatrix and a system response parameter matrix; in a measurement stage, the dual-band array image acquisition device is used for acquiring a gray scale array image of dual-band radiation light of an object to be measured, and the calculation device is used for correcting the gray scale array image of the object to be measured, extracting data and calculating a temperature field of the object to bemeasured. According to the invention, the common influence caused by the quality difference of each filtering unit, the lens distortion, the chromatic aberration, the integration error of the filtering units and the pixels and the like is eliminated in the temperature measurement system and the temperature measurement method for the first time, and the precision of the temperature measurement system and method is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

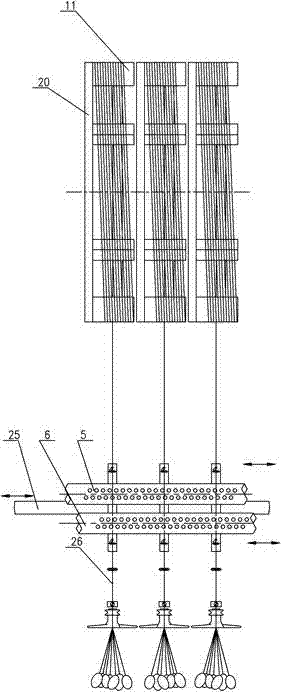

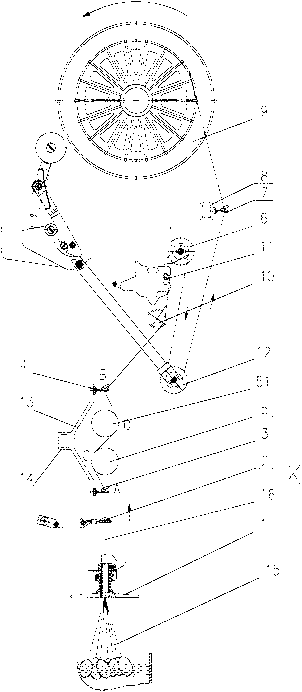

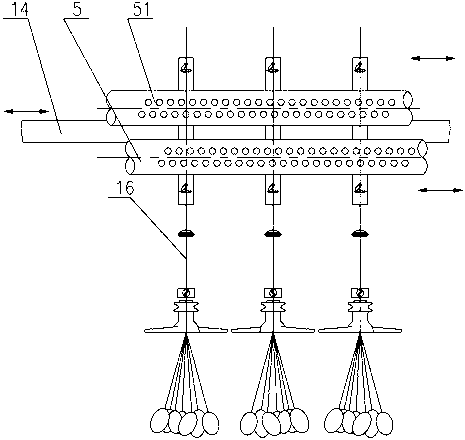

Two-for-one twisting type spinning frame

ActiveCN109554784AImprove twisting efficiencyDestroy qualityDrafting machinesContinuous wound-up machinesYarnWind component

The invention relates to a two-for-one twisting type spinning frame, and belongs to the technical field of textile. The two-for-one twisting type spinning frame has the advantages that a twisting andspinning mechanism of an ordinary ring spinning frame is changed into a two-for-one twisting winding mechanism, the two-for-one twisting winding mechanism comprises a two-for-one twisting mechanism and a winding mechanism, a twisting disc can rotate by a circle for silver operated in zones from jaws of a front roller to a tension device, accordingly, two-twist two-for-one twisting effects can be realized for the silver, and the twisting efficiency can be improved; the winding mechanism is positioned in a yarn storage tank of the two-for-one twisting mechanism, twisting components and winding components are substantially separated from one another, twisting and winding can be separately individually controlled, the twisting and winding mechanism, by which twisting and winding can be simultaneously carried out and are constrained by each other, of the ordinary ring spinning frame is thoroughly changed, large-package spun yarns of cheese can be formed, the shortcomings of great winding balloon and tension difference of the traditional spinning frame mechanisms and high fluctuation of the quality of existing resultant yarns can be overcome, and accordingly the quality and the uniformity of resultant yarns can be improved; the two-for-one twisting type spinning frame is reasonable in structure and convenient to operate, and popularization can be facilitated.

Owner:WUHAN TEXTILE UNIV

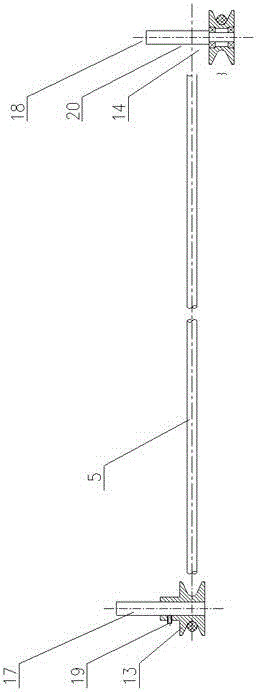

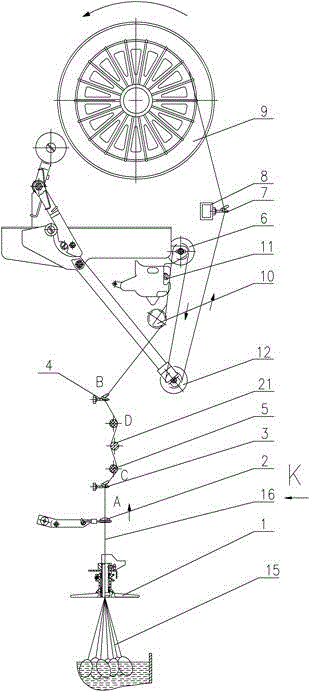

Wet raw silk double-twisting gathering method and special device

The invention relates to a silk reeling method and device, in particular to a wet raw silk double-twisting gathering method and a special device, and mainly solves the technical problems that croisure structures of silk ends are not uniform and the qualities of the raw silk are influenced due to the fact that croisure structures are manually formed and the wet raw silk is gathered under the action of croisures with a wet raw silk gathering method existing in the prior art. According to the wet raw silk gathering method and the special device, the wet raw silk reciprocates linearly relative to an upper godet and a lower godet, the wet raw silk and the godets create friction, and a plurality of pieces of cocoon silk glue forming the raw silk are kneaded to the periphery of the raw silk, so that the wet raw silk is closely gathered; and at the same time, strand silk rotates, an upper section of strand silk and a lower section of strand silk which are contacted with the upper and lower godets rotate in different directions, a lower section of raw silk rotates reversely after bypassing the godets, moisture in the strand silk is squeezed to be removed, and small knots on the surface of cocoon silk can be removed through rotating and kneading.

Owner:ZHEJIANG SCI-TECH UNIV

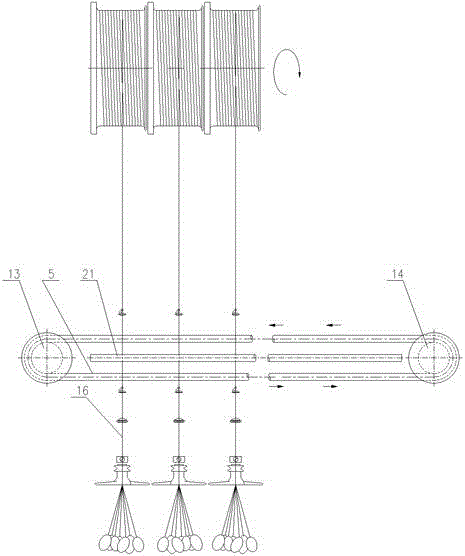

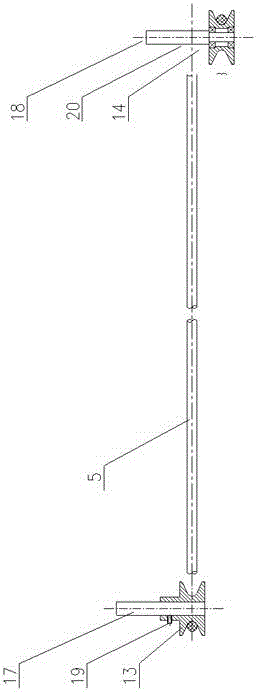

Band friction method and band friction device for replacing silk sheath

InactiveCN103334161AKnead continuously and evenlyFlat surfaceSilk reelingState of artBiomedical engineering

The invention relates to a silk reeling method and a silk reeling device, in particular to a band friction method and a band friction device for replacing a silk sheath. The method and the device mainly solve the technical problems that a wet raw silk gathering method during silk reeling production in the prior art forms a silk sheath structure by adopting a manual mode, and gathers wet raw silk through a silk sheath effect, and the quality of the raw silk is influenced, operation is complicated, and labor productivity is low due to the nonuniformity of the silk sheath structure between threads brought by the method, or solve the technical problem that gathering is nonuniform due to periodical change of the speed when back-and-forth friction is conducted by adopting reciprocating movement. According to the method and the device, upper and lower layers of driving bands which can be used for replacing silk sheath gathering cocoon silk and move reversely are wound with the wet raw silk; silk pressing guide rolls are arranged between the driving bands; a winding movement direction of the wet raw silk is perpendicular to movement directions of the driving bands relative to the raw silk; friction is generated between the wet raw silk and the driving bands; and tiny sections on the surface of the cocoon silk can be removed after rotation and kneading.

Owner:ZHEJIANG SCI-TECH UNIV

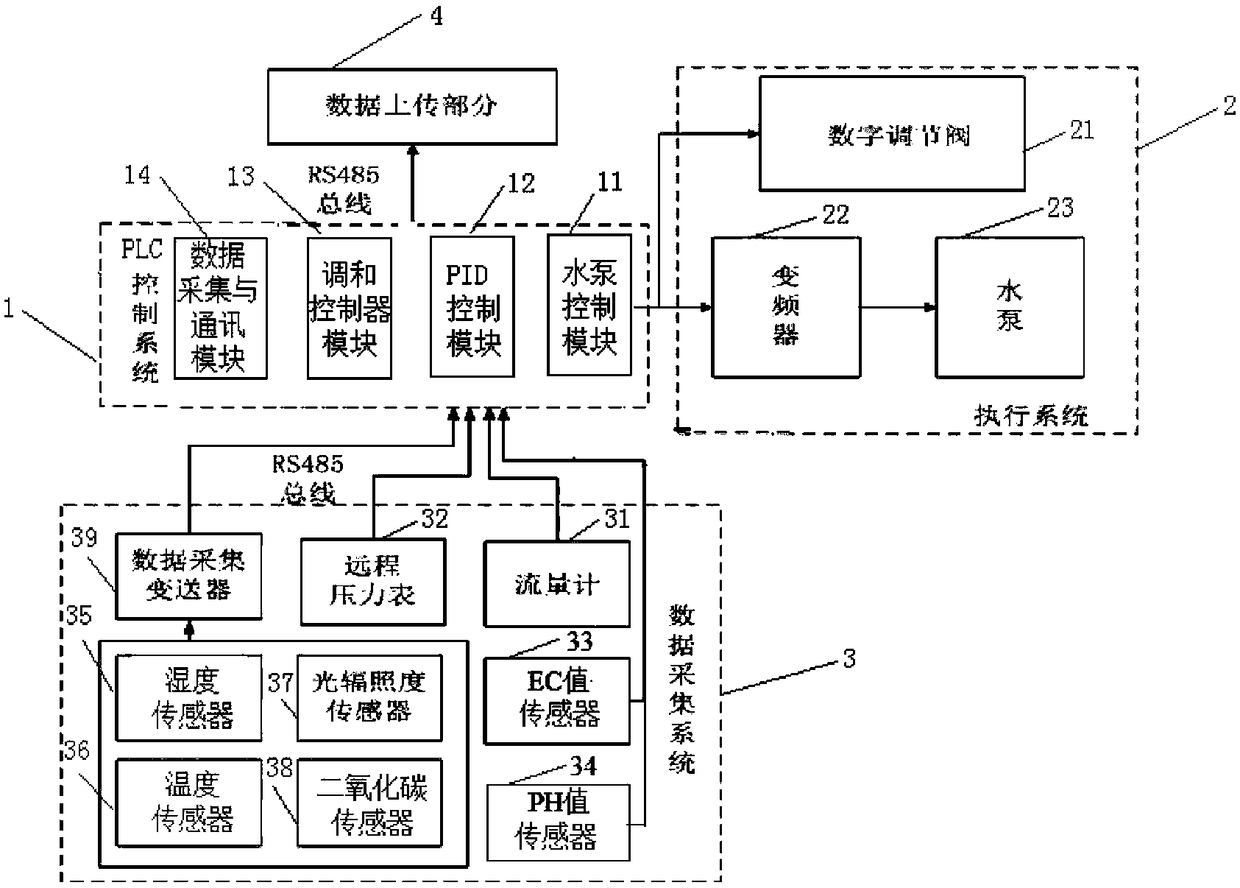

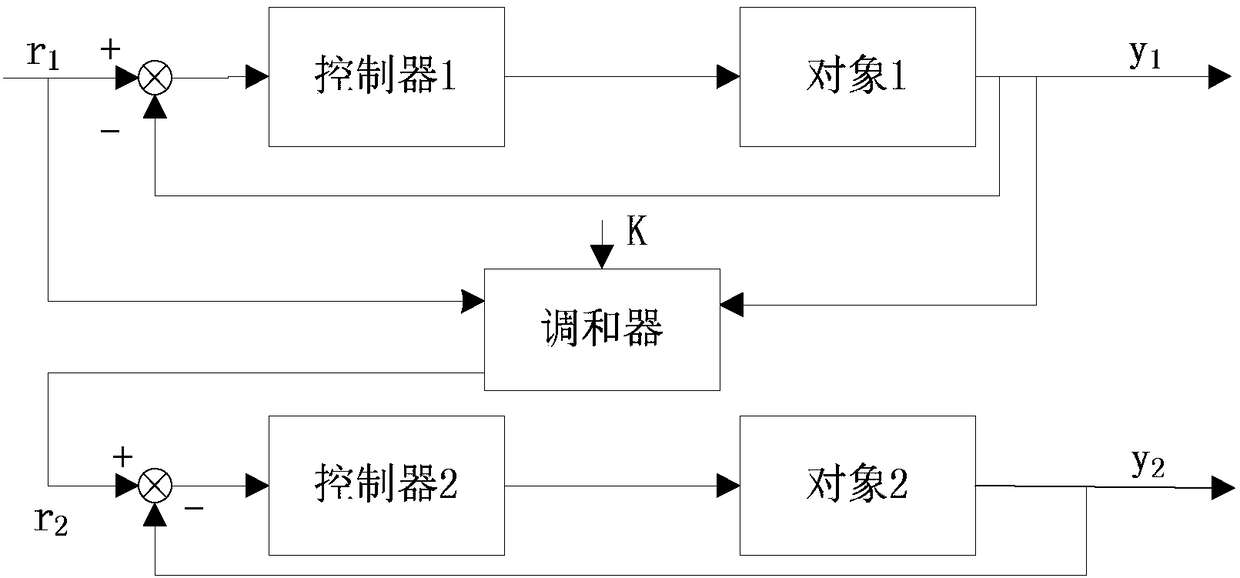

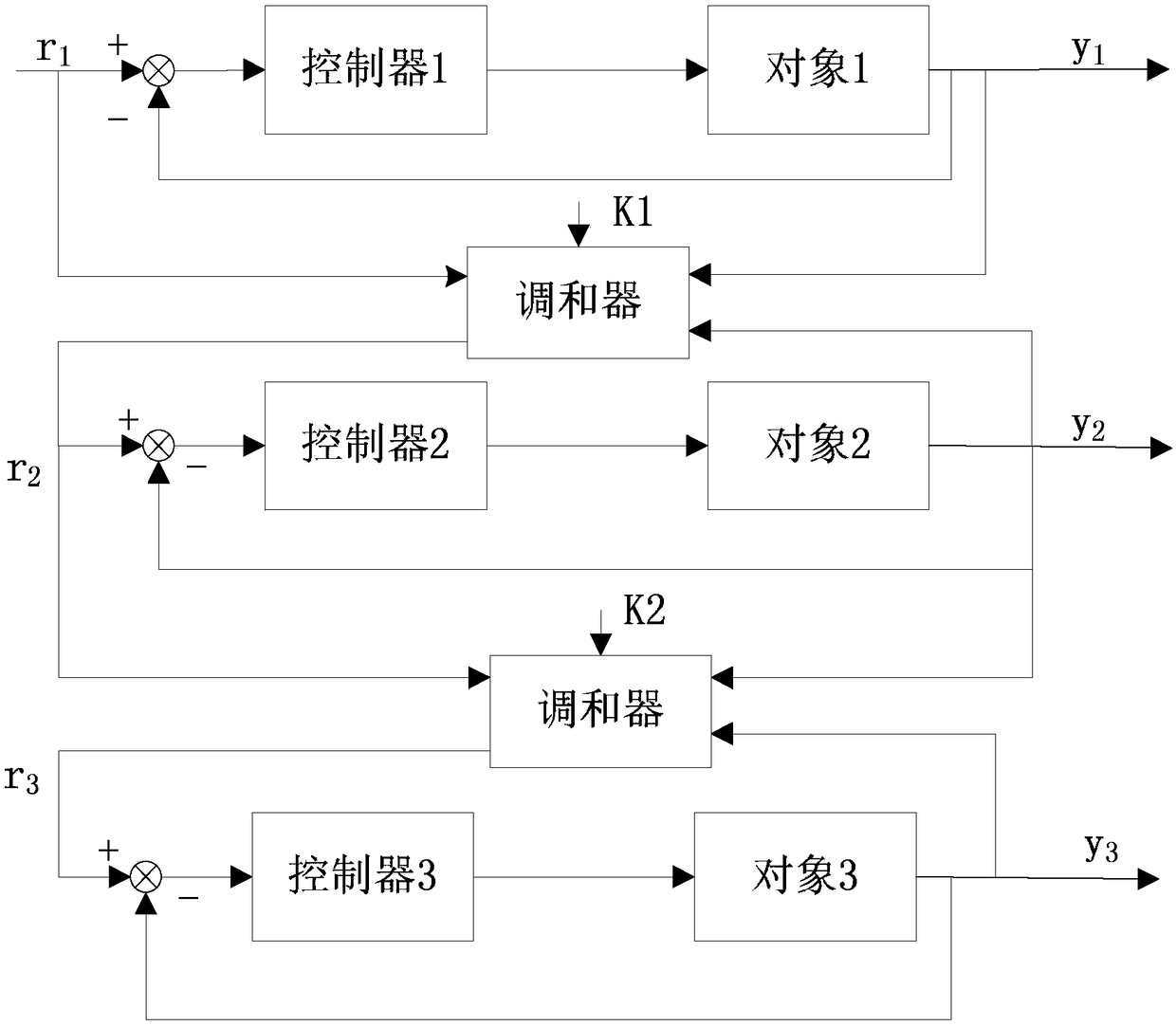

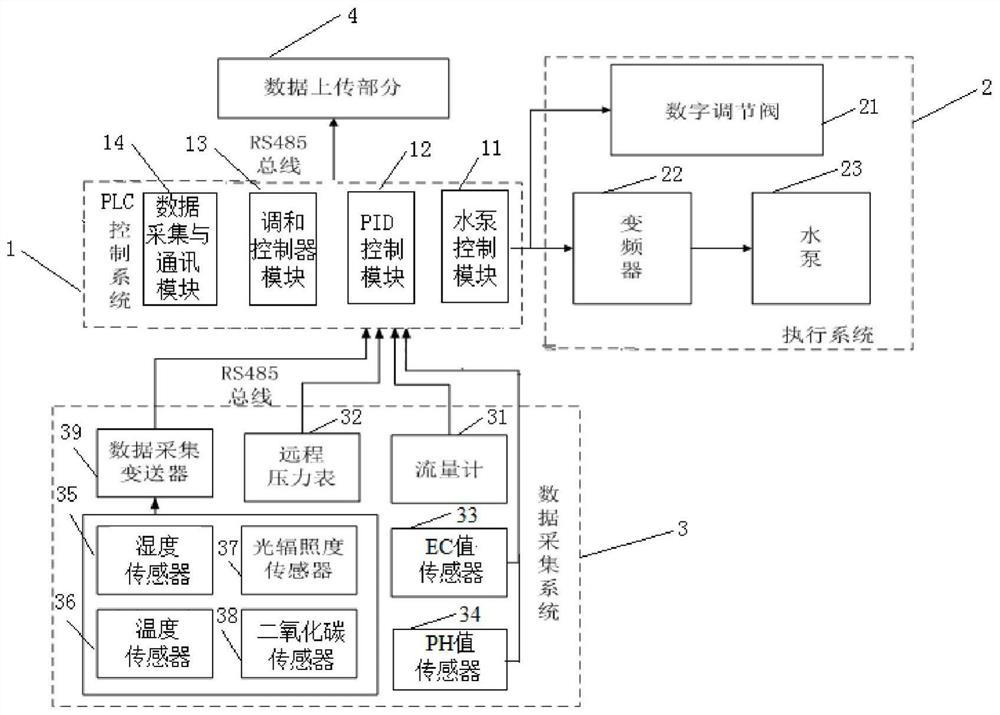

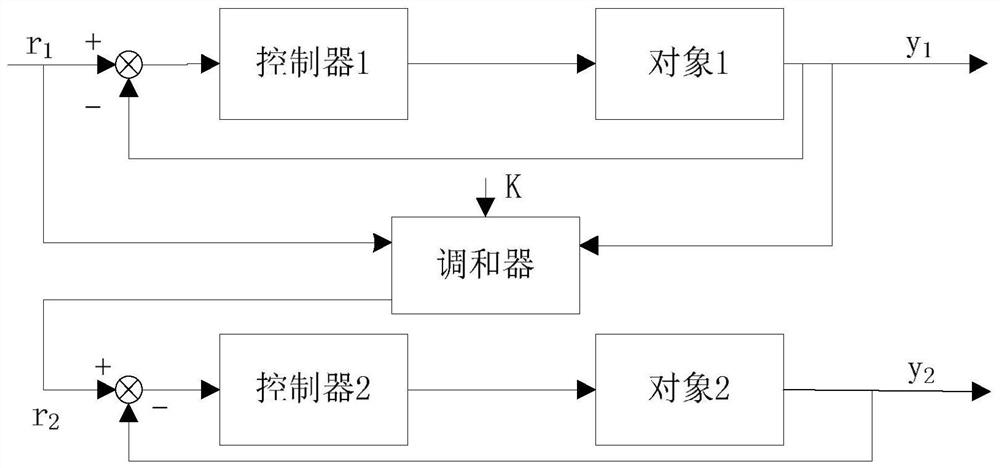

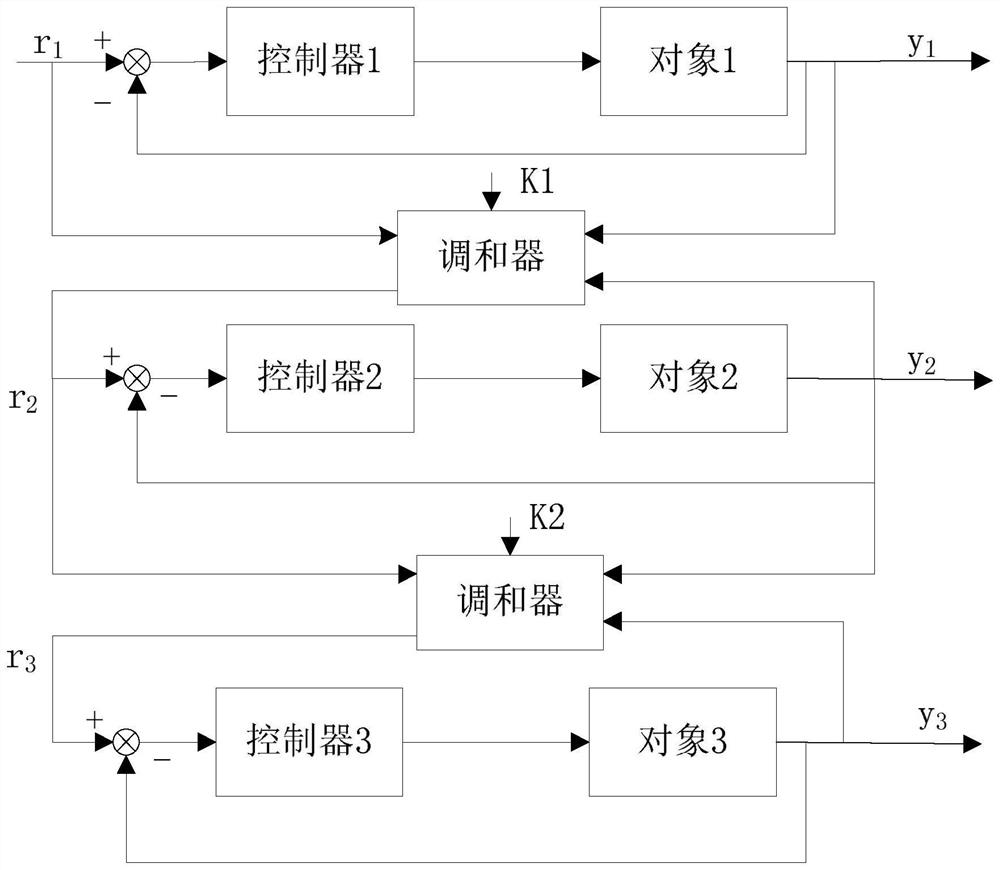

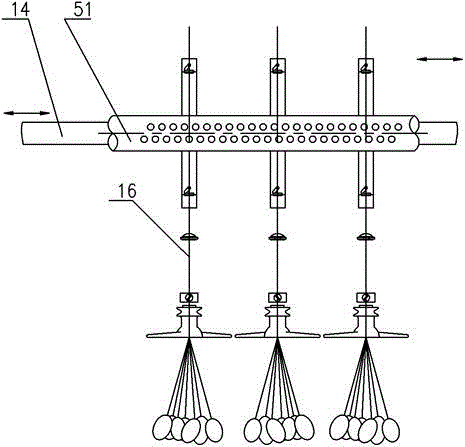

Integrated water and fertilizer machine based on multi-channel flow control and flow control method thereof

ActiveCN108450115AImprove fertilization efficiencyShort time spentClimate change adaptationWatering devicesFertilizerWater soluble

The invention discloses an integrated water and fertilizer machine based on multi-channel flow control and a flow control method thereof. The flow is controlled by digital regulating valves of variouswater channel, so that the fertilizer preparation ratio is controlled. Water and multi-channel water-soluble fertilizers simultaneously enter a water pump, are uniformly mixed in the water pump and finally reach plant roots by virtue of a drip irrigation zone. The structure has high fertilization efficiency, and spent time is short. Multiple types of fertilizers are simultaneously applied, so that the fertilizers are fully and uniformly mixed to reach the crop roots, and the fertilizer absorption efficiency of the crops is improved. Non-uniformity of different plant fertilizers in the fertilization process is avoided, and the condition that quality differences of crops are caused due to non-uniform growth vigor of different plants is avoided. An adaptive harmonic ratio control algorithm is adopted, and the control algorithm is capable of realizing unity of flow control rapidness and following performance. When flow of a main pipeline is subjected to disturbance, flow of branch pipelines rapidly follows, and the condition that the flow ratio of mismatched can be effectively avoided.

Owner:NORTHEASTERN UNIV

Thin film transistor and method for production thereof

InactiveUS20060199317A1Uniform characteristic propertyIncrease speedTransistorElectroluminescent light sourcesOptoelectronicsUniform - quality

The production method of the thin film transistor according to the present invention involves the reactive heat CVD process to form the active layer and the source-drain layer. This offers the advantage of eliminating additional steps to crystallize the semiconductor thin film. The resulting stacked thin film transistor is composed of originally crystalline semiconductor thin films. Having the active layer and the source-drain layer formed from crystalline semiconductor thin film, the stacked thin film transistor has a faster working speed than the one formed from amorphous semiconductor thin film. Another advantage of eliminating steps for crystallization is uniform quality which would otherwise be adversely affected by crystallization. In addition, the fact that the source-drain layer is formed from a previously doped crystalline semiconductor thin film means that there is no need for any step to introduce impurities after film formation.

Owner:KUNII MASAFUMI

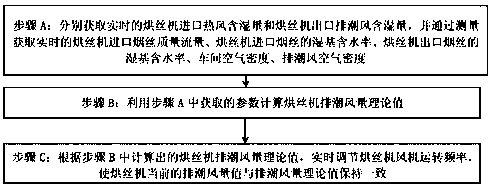

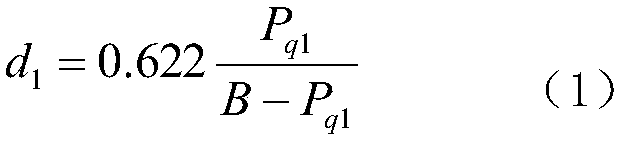

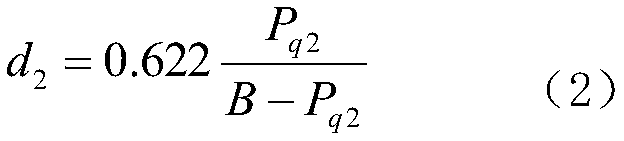

Moisture balance based cut tobacco moisture content control method for drum-type cut tobacco drier

ActiveCN108669616AEliminate quality differencesQuick responseTobacco preparationAir volumeControl system

The invention discloses a moisture balance based cut tobacco moisture content control method for a drum-type cut tobacco drier. According to the method, real-time moisture content of hot blast at an inlet of the cut tobacco drier and moisture content of moisture eliminating air at an outlet of the cut tobacco drier are obtained respectively, and real-time mass flow rate of cut tobacco at the inletof the cut tobacco drier, wet-based moisture content of the cut tobacco at the inlet of the cut tobacco drier, wet-based moisture content of the cut tobacco at the outlet of the cut tobacco drier, air density of a workshop and air density of the moisture eliminating air are obtained by measuring. A theoretical value of moisture eliminating air volume of the cut tobacco drier is calculated on thebasis of the moisture balance principle according to the obtained data, and fan operation frequency of the cut tobacco drier is adjusted in real time to enable current moisture eliminating air volumevalue of the cut tobacco drier to be consistent with the theoretical value of the moisture eliminating air volume. The adjusting and reaction speeds are higher, response speed of a control system is increased effectively, and quality difference of cut tobacco in the same batch in processing is avoided to a greater extent.

Owner:CHINA TOBACCO HENAN IND

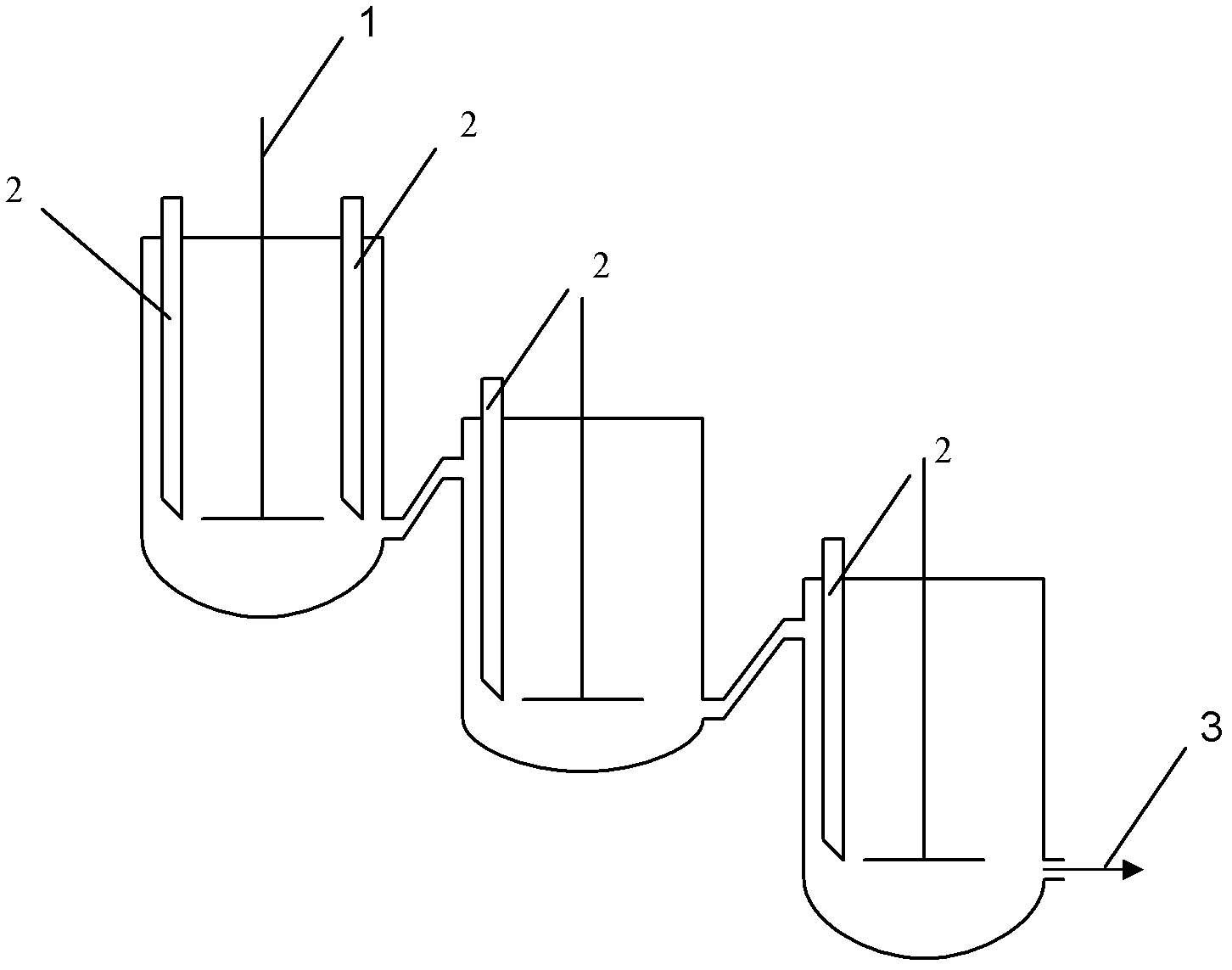

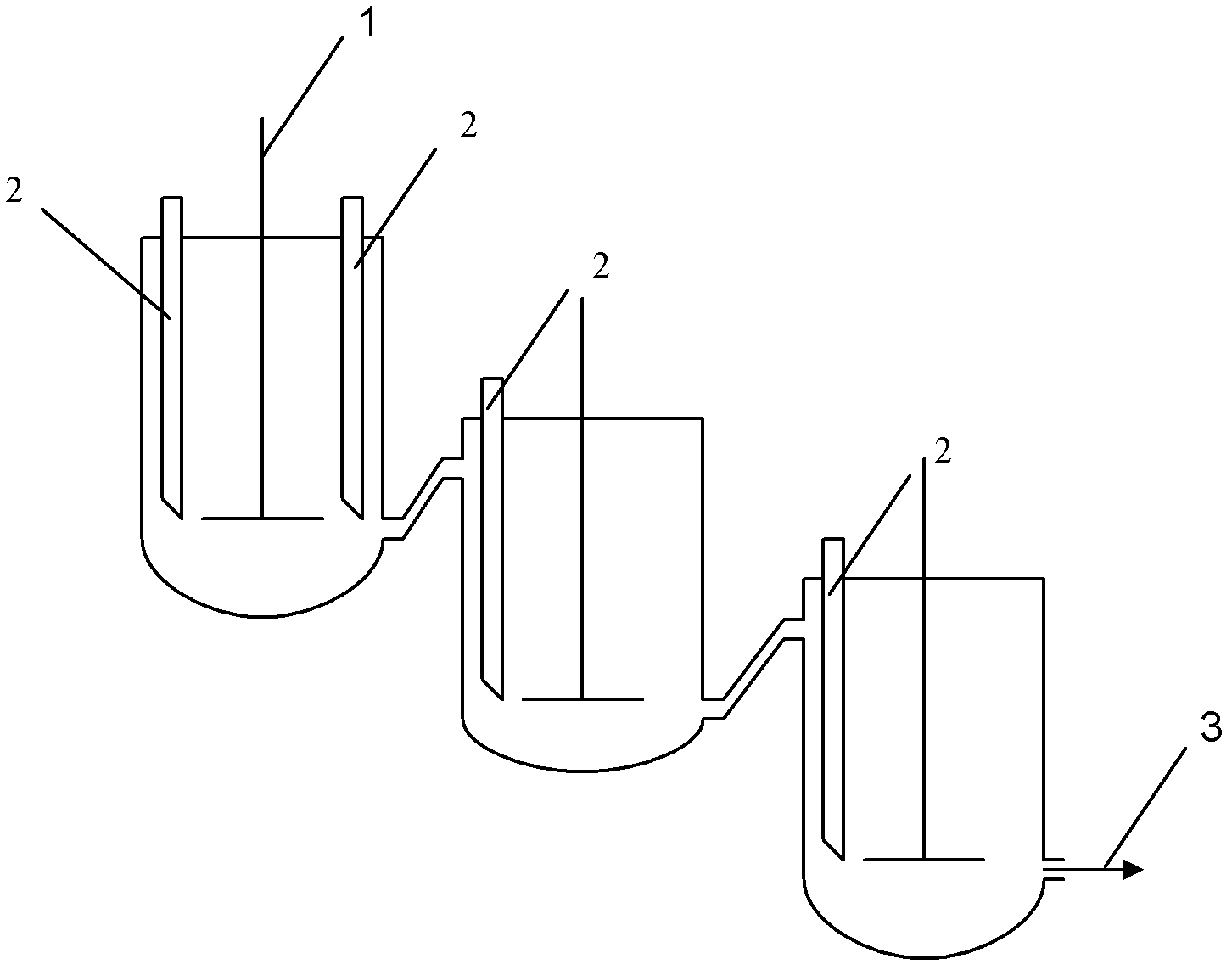

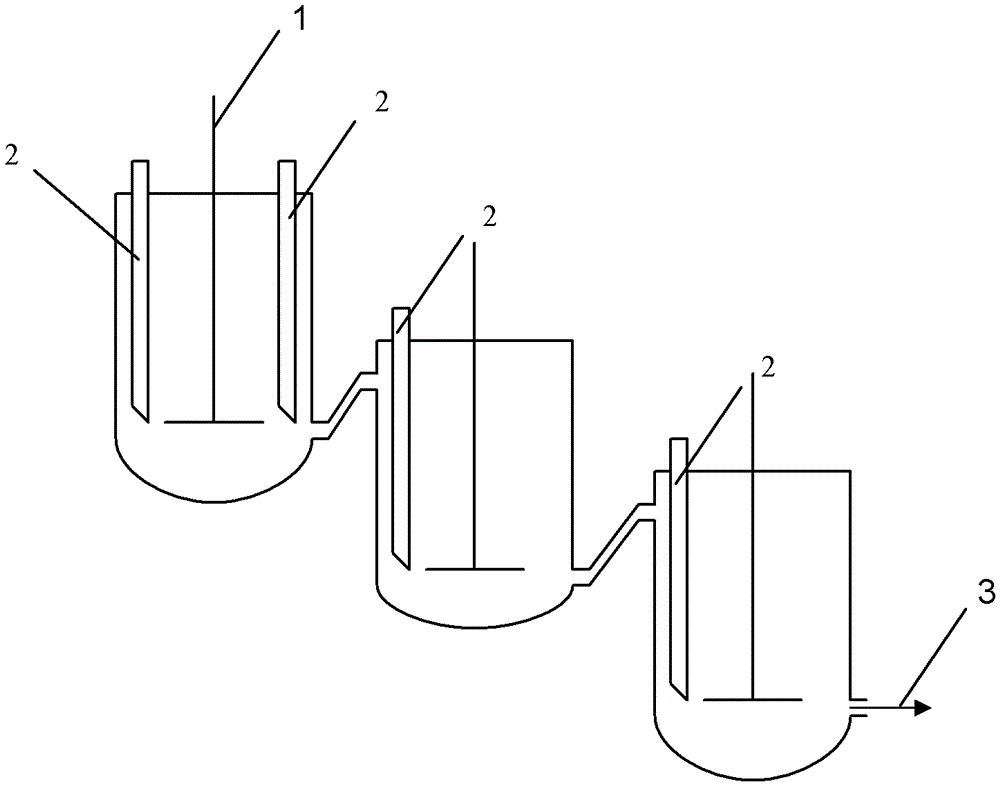

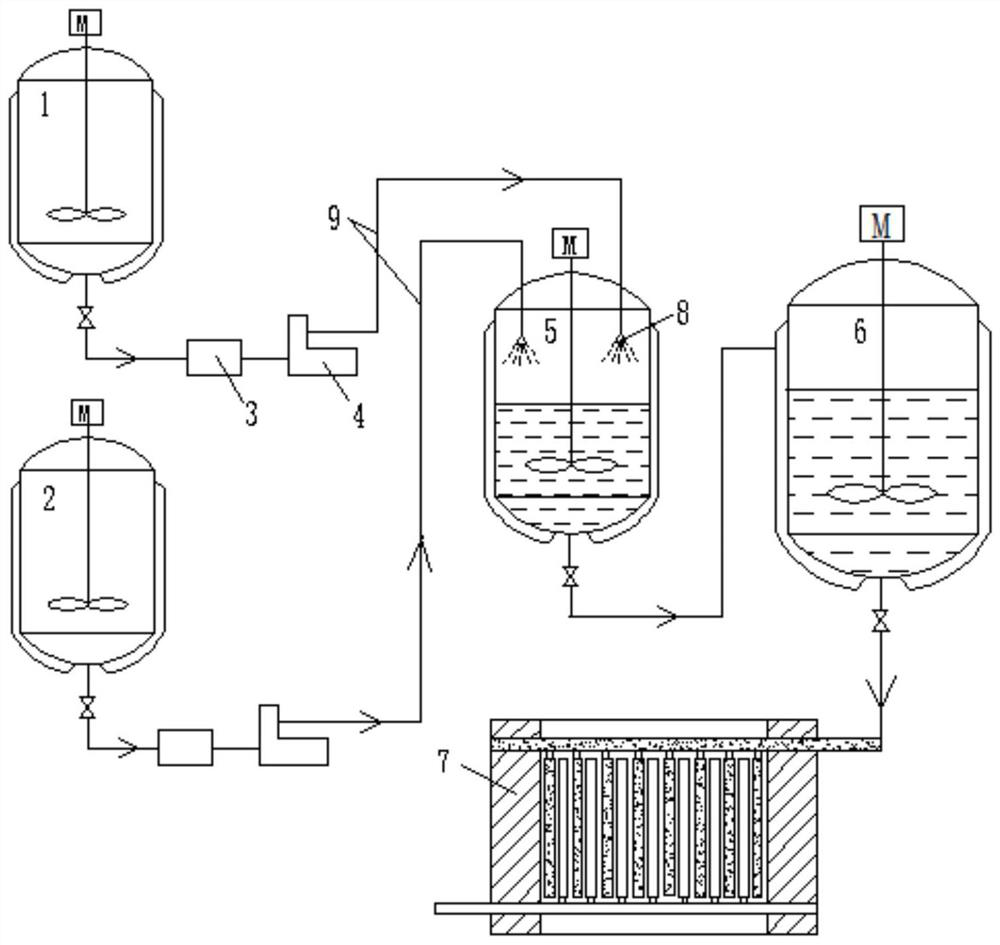

Process for continuously producing azodicarbonamide (ADC) foaming agents in multi-kettle serial-connection mode

The invention relates to a process for continuously producing azodicarbonamide (ADC) foaming agents in multi-kettle serial-connection mode, which includes a hydrazine hydrate and urea blending into biurea process and a biurea and chlorine oxidizing into ADC foaming agent process. In the biurea and chlorine oxidizing into ADC foaming agent process, two and more than two reaction kettles are adopted to be connected in series, and continuous reaction is achieved by continuously feeding and continuously stirring. Furthermore, in the hydrazine hydrate and urea blending into biurea process, two and more than two reaction kettles are adopted to be connected in series, and continuous reaction is achieved by continuously feeding and continuously stirring. The process has the advantages that by adopting the process for continuously producing ADC foaming agents in multi-kettle serial-connection mode, continuous production can be achieved, yield can be improved, uniformity of product quality can be achieved, reaction is controllable, and quality difference of products caused by multi-kettle reaction is avoided.

Owner:HANGZHOU HI TECH FINE CHEM

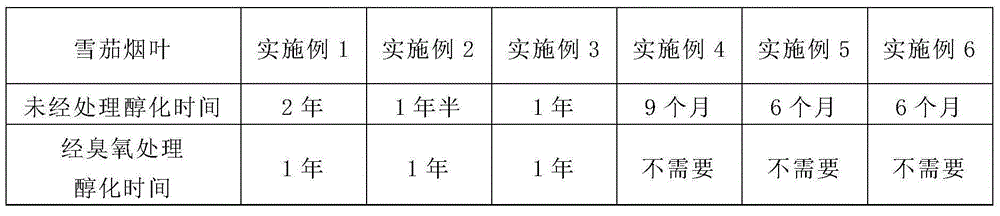

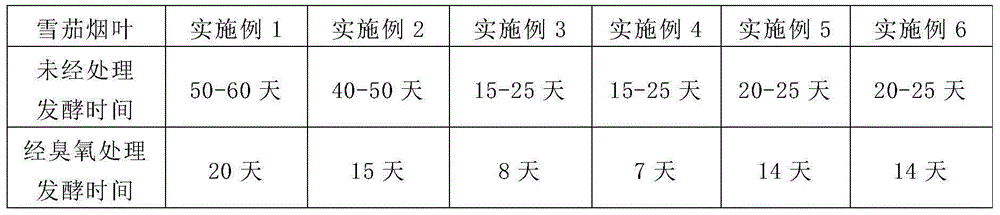

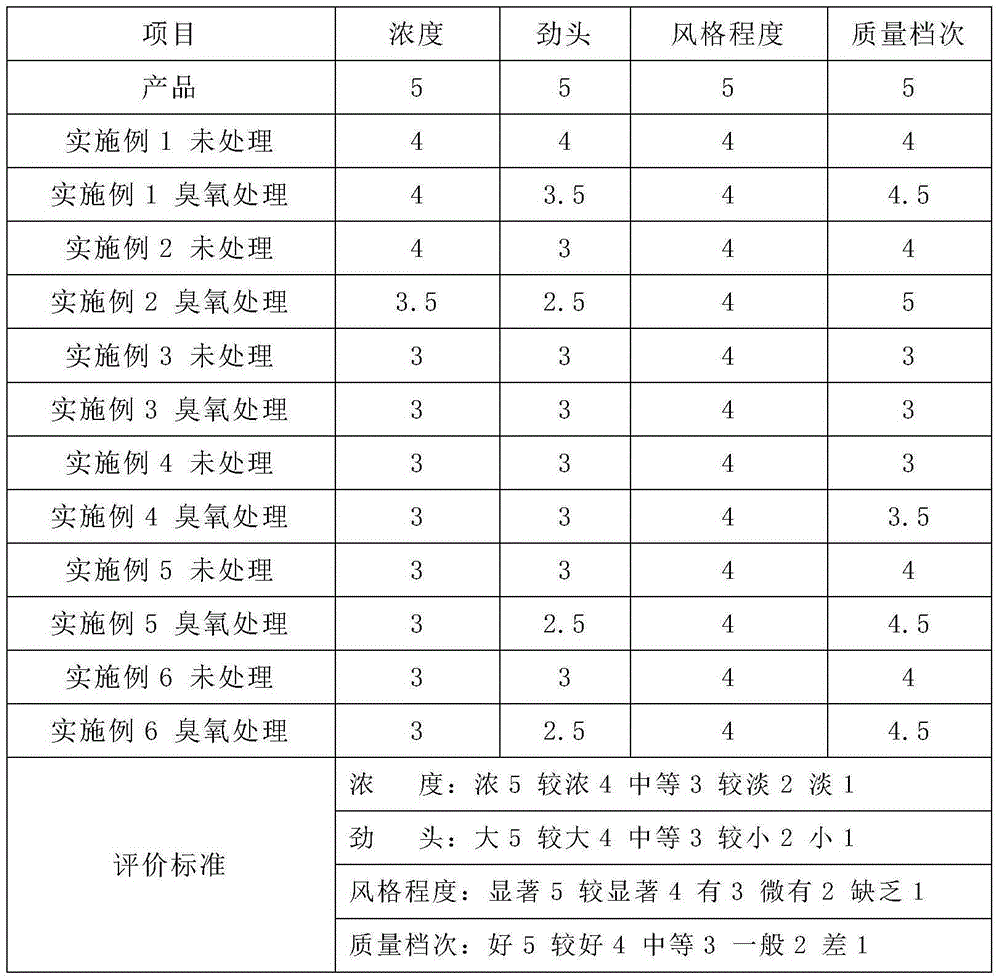

Application of ozone treatment in fermentation and quality improvement of cigar

The invention discloses an ozone treatment process for fermentation and quality improvement of a cigar. The ozone treatment process is characterized by comprising the following steps: humidifying a cigar leaf to improve the moisture of the cigar leaf until the water content of the cigar leaf is 18 to 22 percent, and then charging ozone, namely charging 0.5 to 3mg of ozone into 1kg of the cigar leaves. According to the ozone treatment process, the own fragrance of the cigar leaf is retained, and meanwhile, the defects of heavy bitterness, heavy offensive odor, strong irritation, high strength and uncomfortable remaining taste of the cigar leaf before processing treatment are overcome; the inherent quality of the cigar leaf is improved, the mellowing period of the cigar leaf is shortened, and the problem of over-large stock of the cigar leaves is mitigated.

Owner:HUBEI CHINA TOBACCO IND

Be hospitalized procedure node key element management method

InactiveCN1619603AEliminate differences in management levelsEliminate quality differencesMaps/plans/chartsProcess optimizationComputerized system

The present invention relates to a hospitalization process note factor management method, belonging to the field of medical management method research. It is mainly characterized by utilizing a computer system to implement optimum management for every procedure of hospitalization process.

Owner:CENTURY RONGSHENG ENTERPRISE MANAGEMENT CONSULTATIVE BEIJING

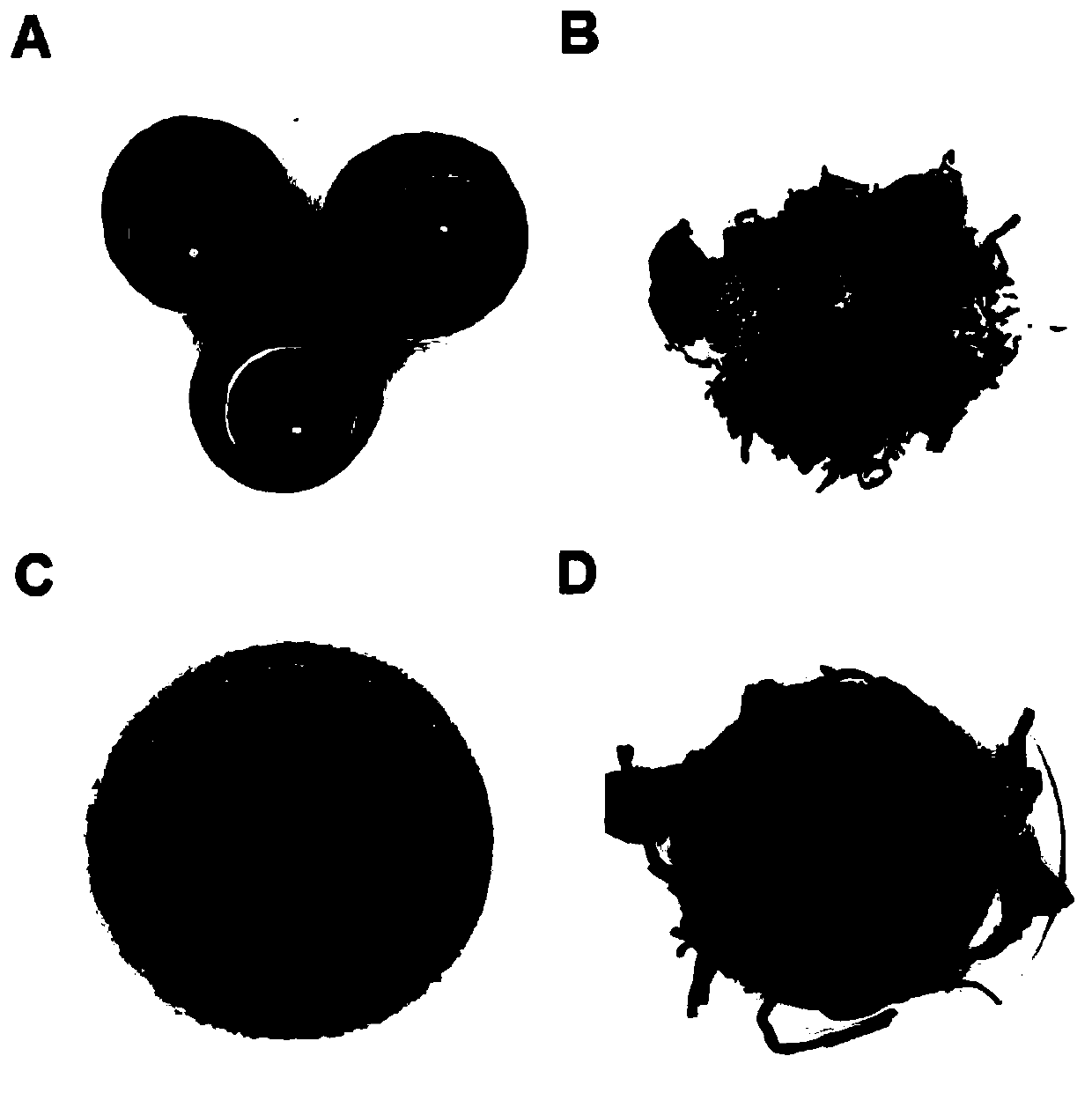

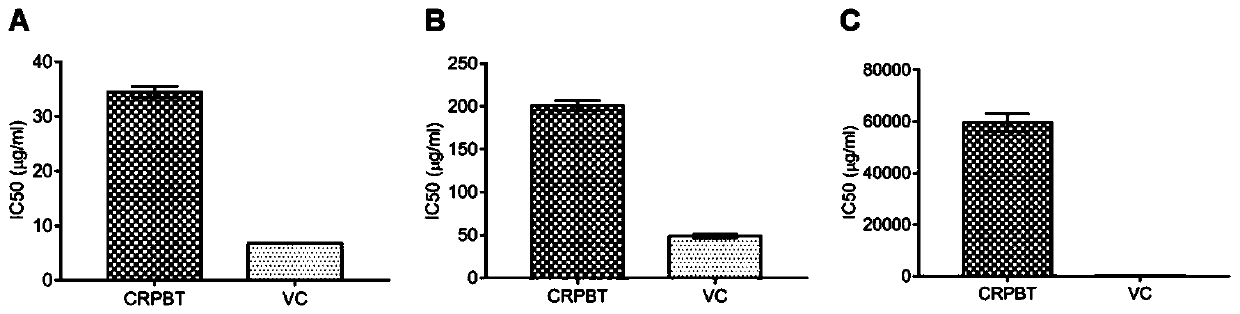

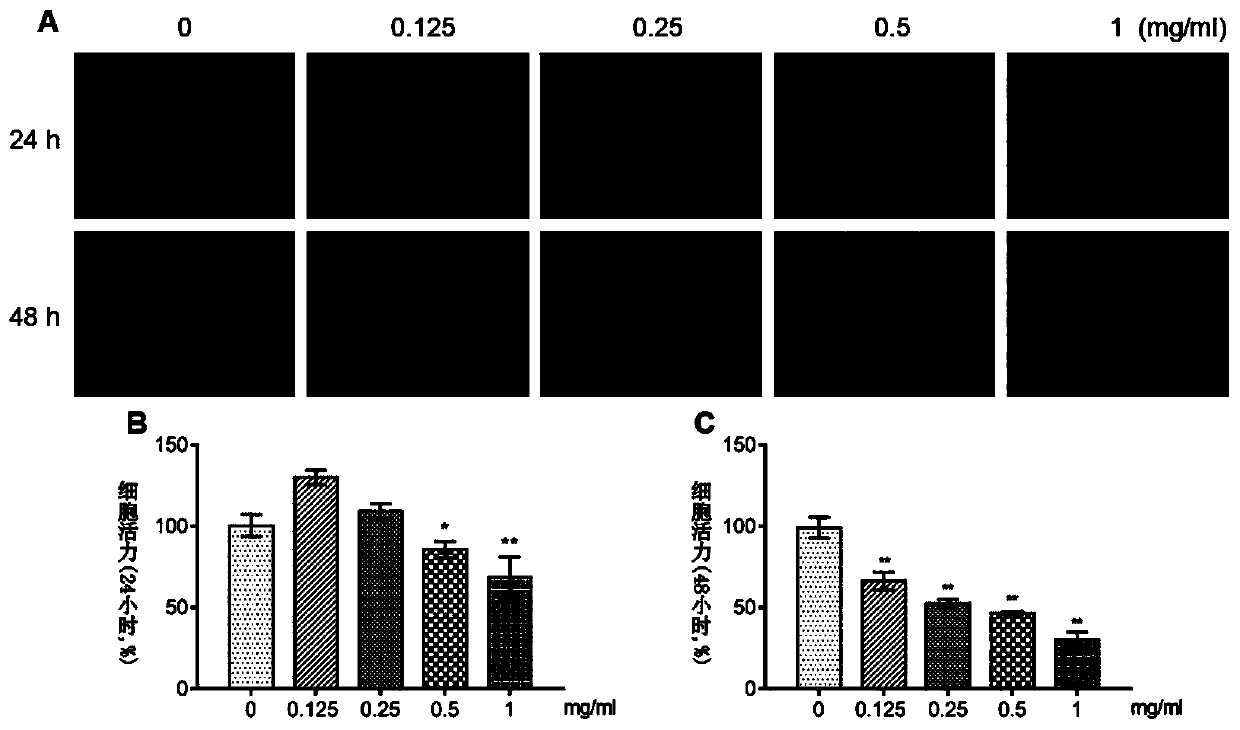

Citrus black tea extract

InactiveCN109700026AHealth function directly reflectsDigAntineoplastic agentsPlant ingredientsTheaflavinBLACK TEA EXTRACT

The present application relates to a citrus black tea extract. The citrus black tea extract comprises tea polyphenols, free amino acids, flavonoid compounds, soluble sugars, theaflavins, thearubiginsand theabrownin.The citrus black tea extract has relatively strong anti-oxidation, anti-cell proliferation-and-migration activities, and can be used to prepare PI3K signaling pathway inhibitors or MMPs signaling pathway inhibitors.

Owner:WUYI UNIV +1

Thin Film Transistor and Method For Production Thereof

InactiveUS20070298553A1Uniform characteristic propertyIncrease speedTransistorElectroluminescent light sourcesUniform - qualityActive layer

The production method of the thin film transistor according to the present invention involves the reactive heat CVD process to form the active layer and the source-drain layer. This offers the advantage of eliminating additional steps to crystallize the semiconductor thin film. The resulting stacked thin film transistor is composed of originally crystalline semiconductor thin films. Having the active layer and the source-drain layer formed from crystalline semiconductor thin film, the stacked thin film transistor has a faster working speed than the one formed from amorphous semiconductor thin film. Another advantage of eliminating steps for crystallization is uniform quality which would otherwise be adversely affected by crystallization. In addition, the fact that the source-drain layer is formed from a previously doped crystalline semiconductor thin film means that there is no need for any step to introduce impurities after film formation.

Owner:SONY GRP CORP

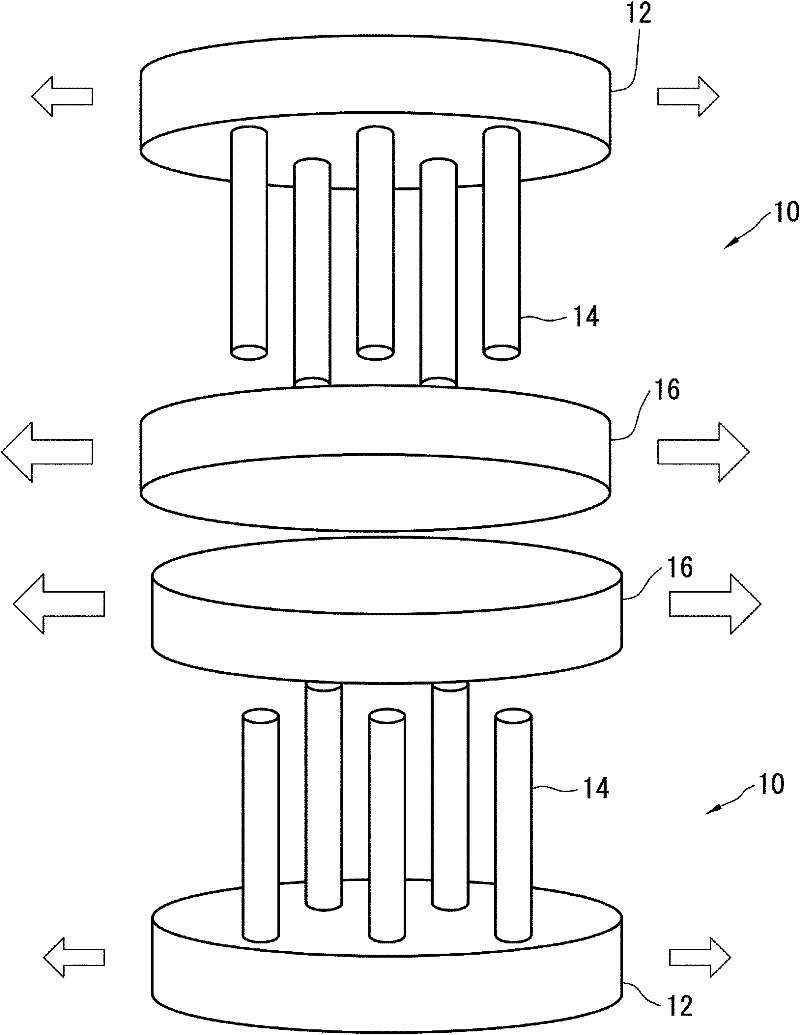

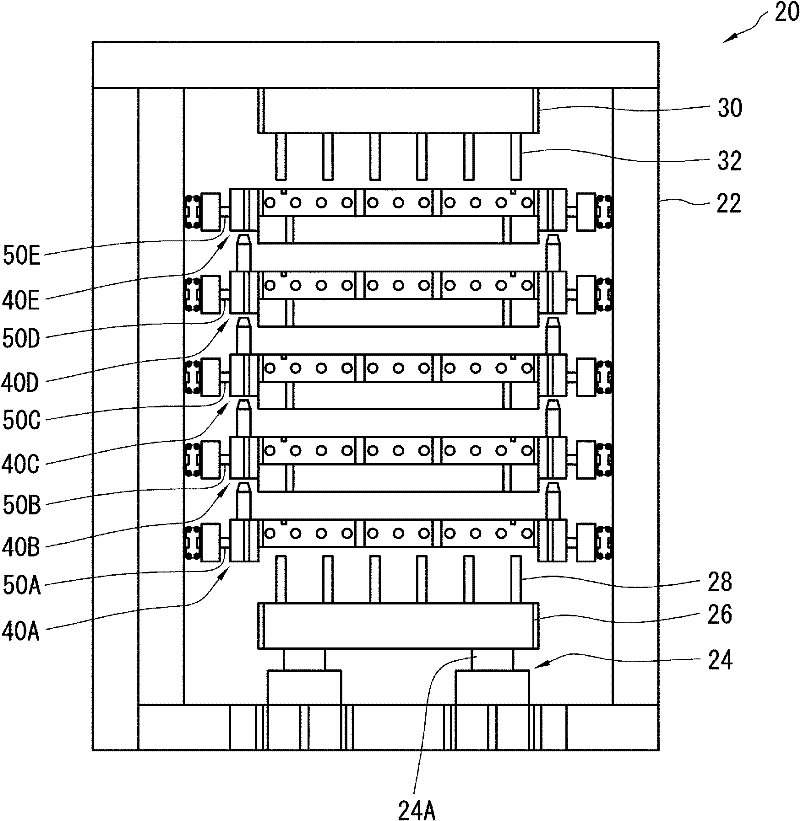

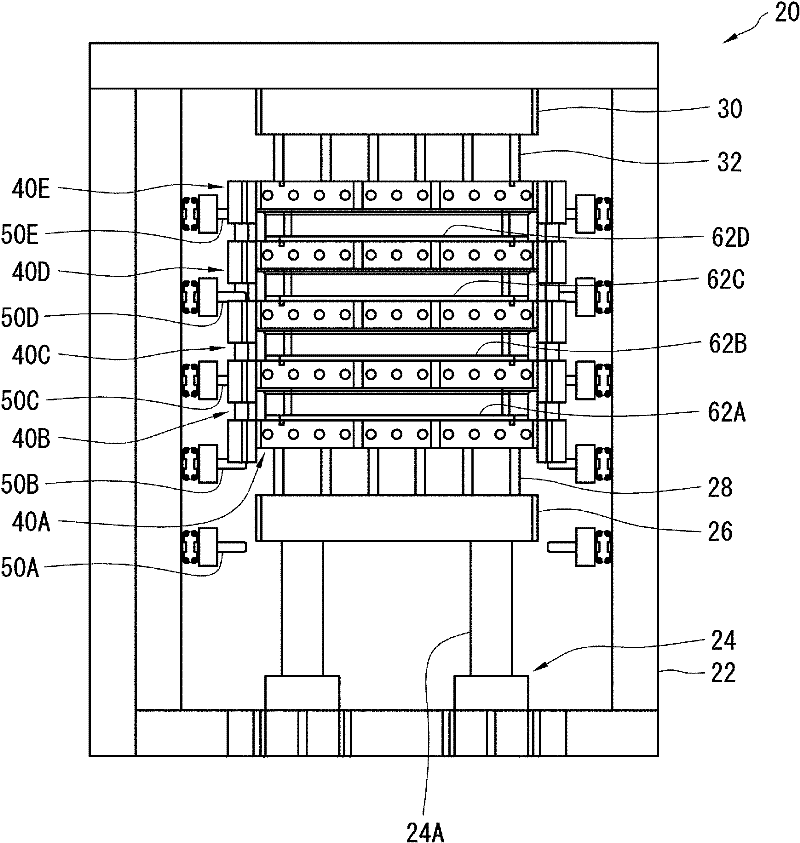

Press mechanism and bonding apparatus

The invention provides a press mechanism and a bonding apparatus improving treatment efficiency of a composite substrate and capable of preventing quality difference. A joint device (20) in the press mechanism and bonding apparatus is provided with: a base part (26, 30) with specified load applied by a press device (24), heat disc parts (40A-40E) provided with a heating device, and a supporting part (28, 32), the supporting part (28, 32) makes the load applied upon the base part (26, 30) be transmitted to the heat disc parts (40A-40E) as a press force, the top part of the supporting part is a free end no fixed with the heat disc part (40A-40E). Wherein, a plurality of heat disc parts (40A-40E) are disposed in the acting direction of the press force, via mutual press joint of the adjacent heat disc parts along the acting direction of the press force, vacuum chambers (62A-62D) are made to form between the heat disc parts, and base materials for adhesion are in heat press and joint in the vacuum chambers (62A-62D).

Owner:MURATA MFG CO LTD

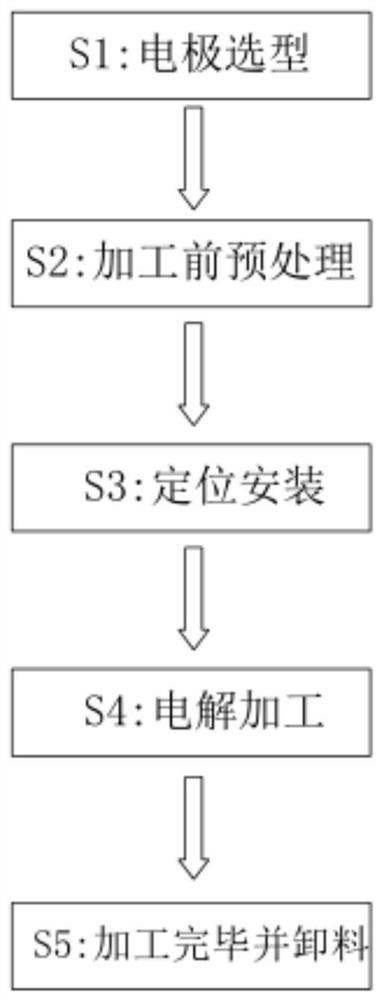

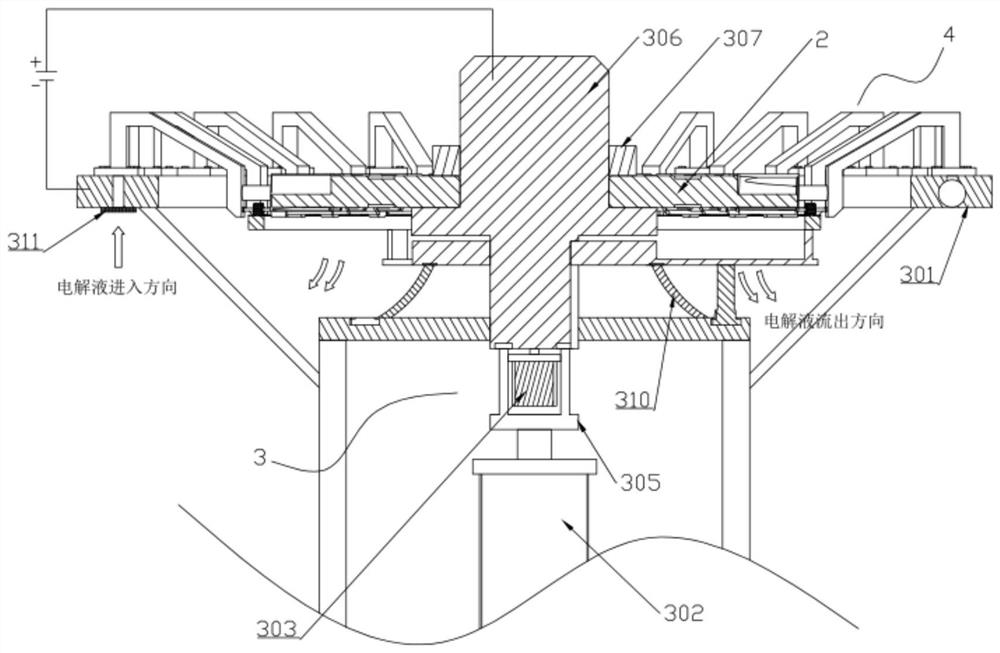

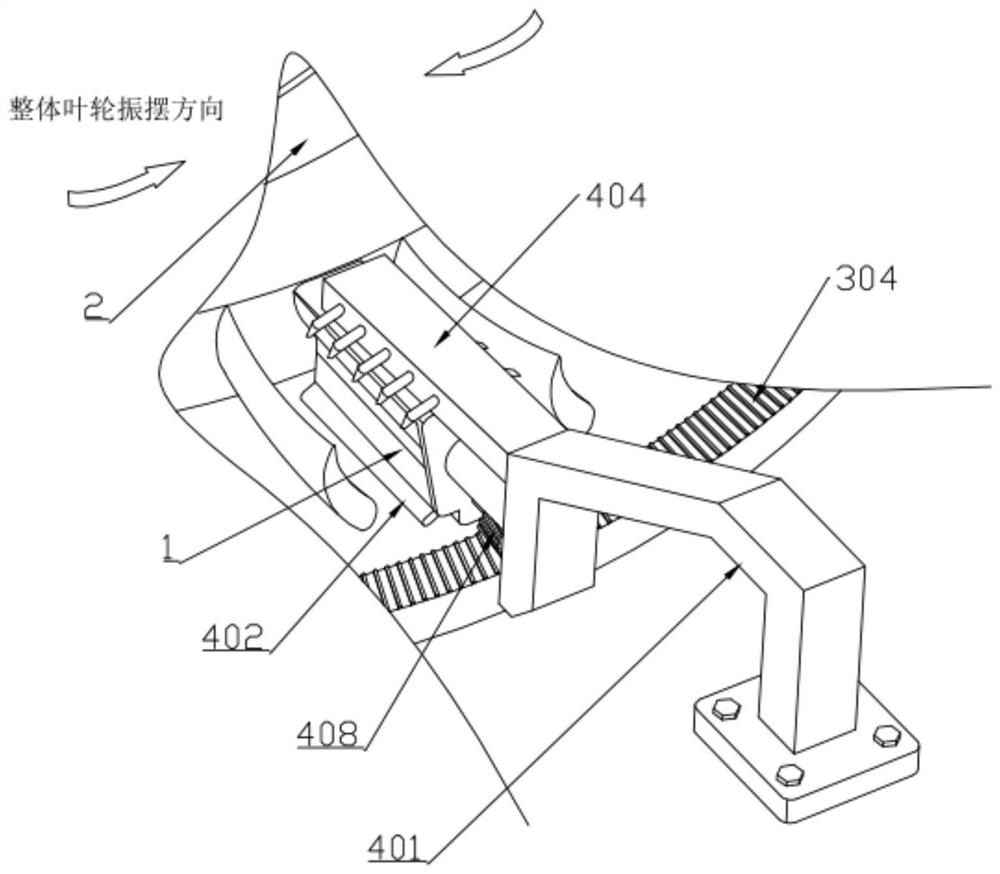

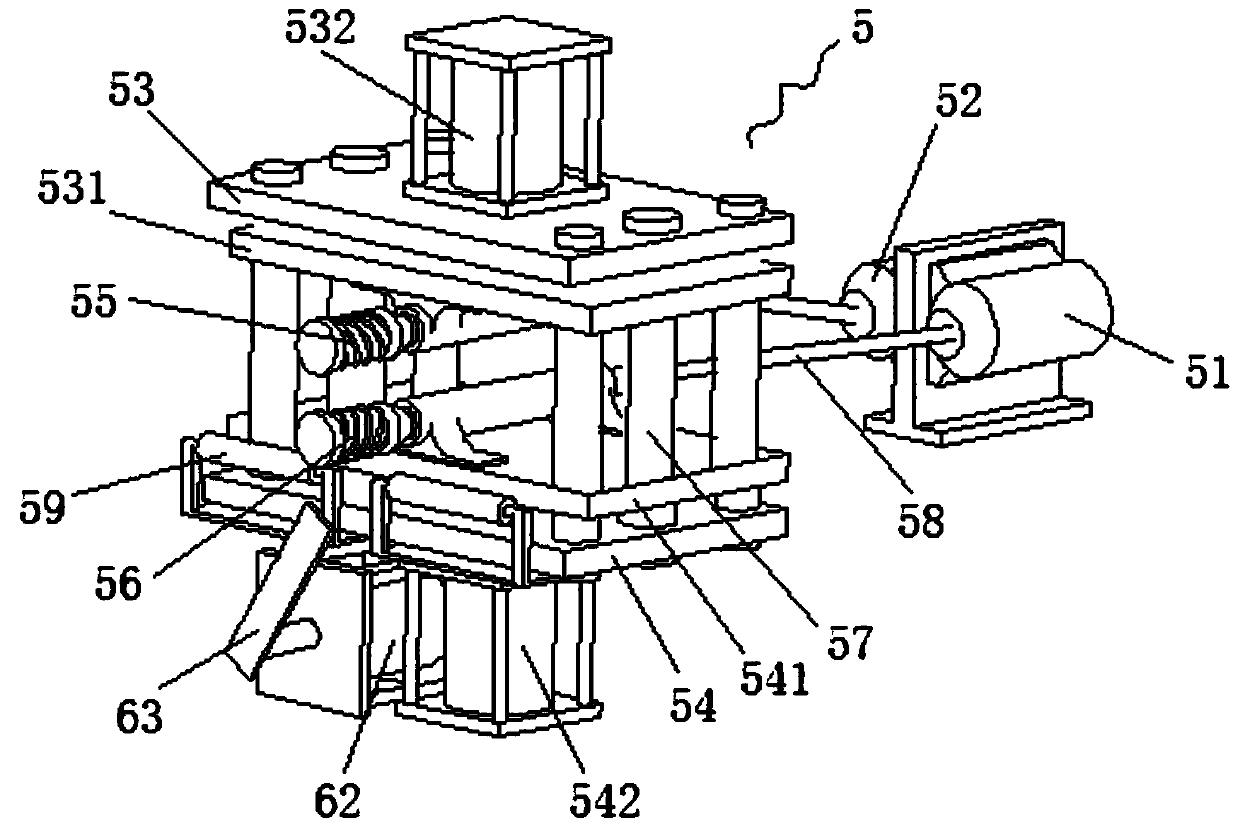

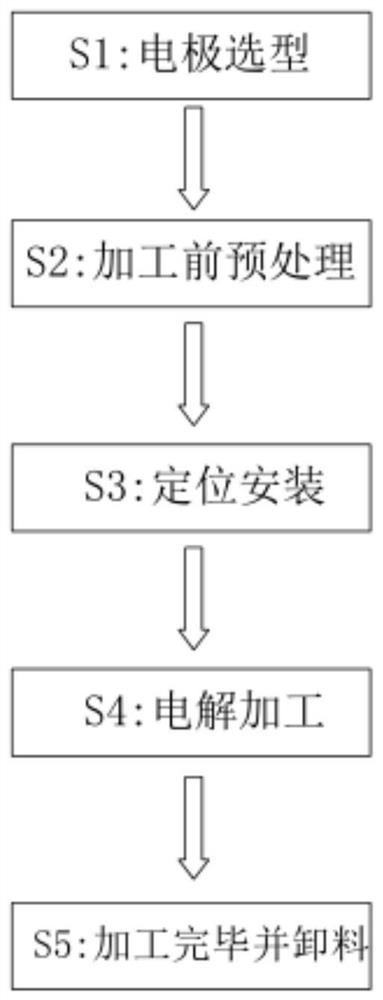

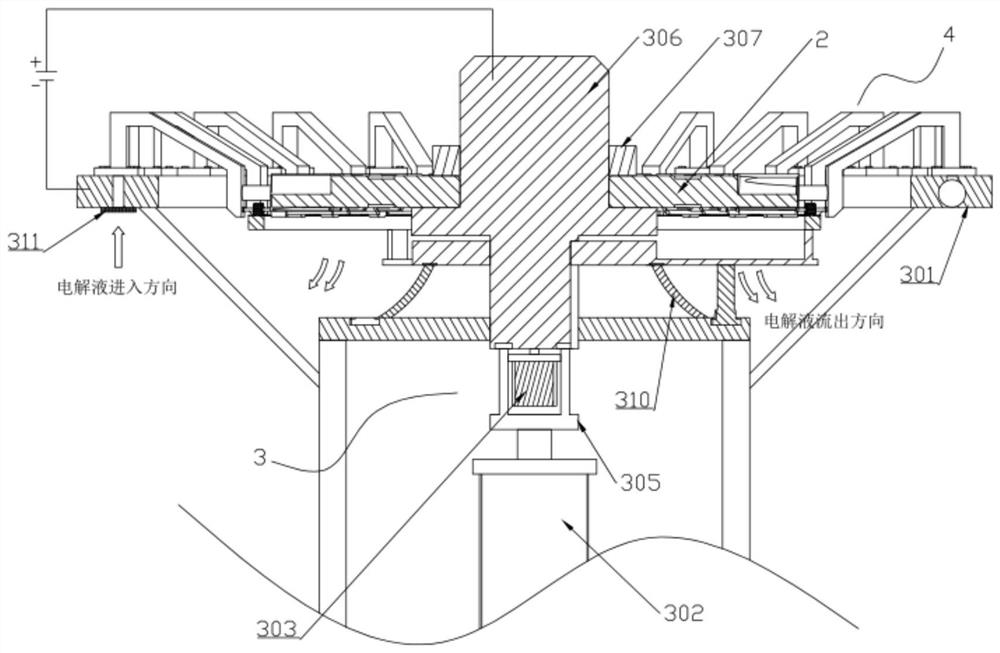

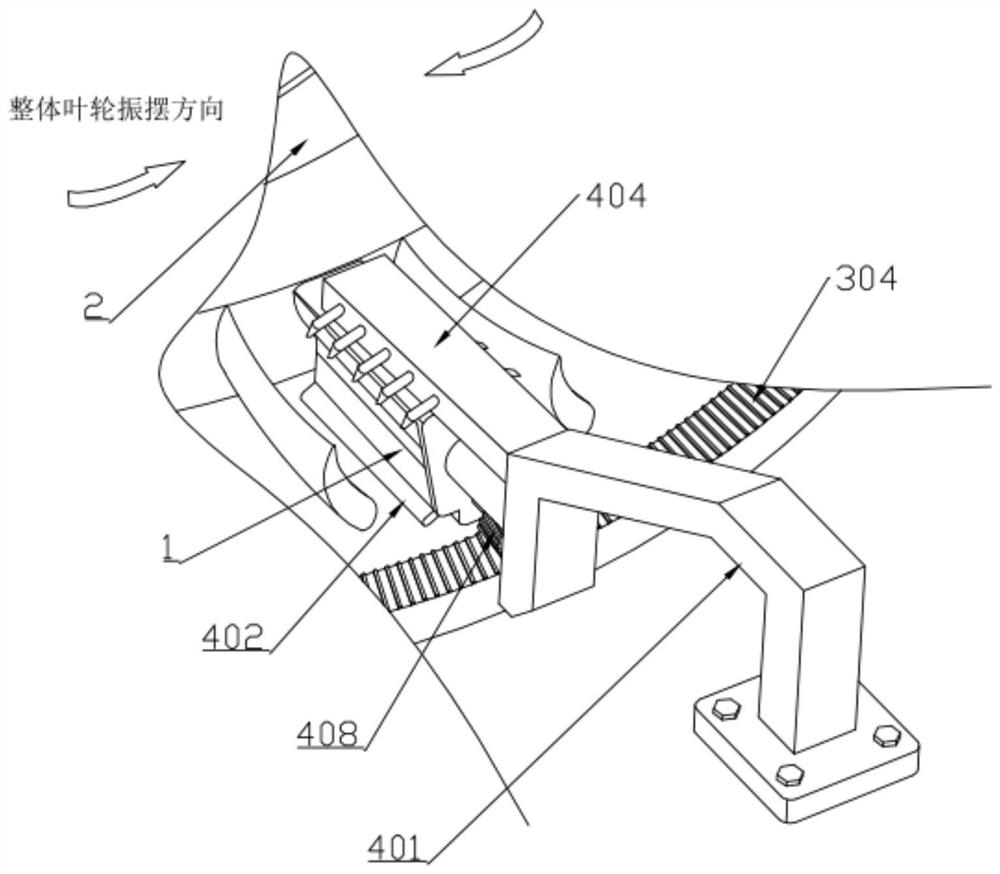

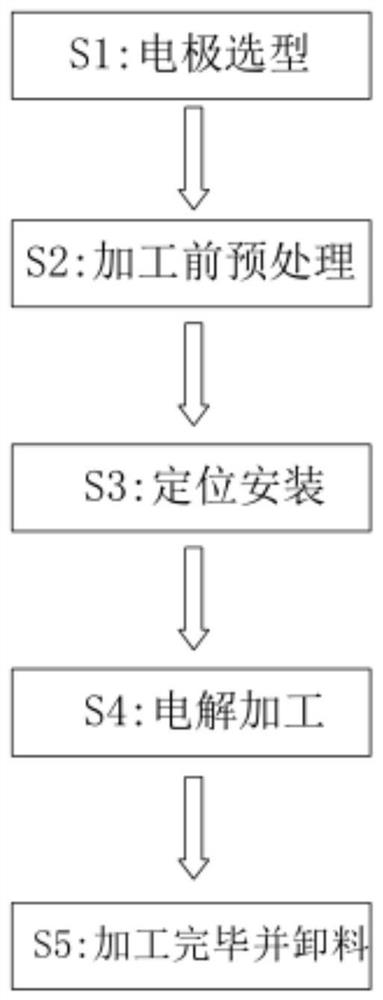

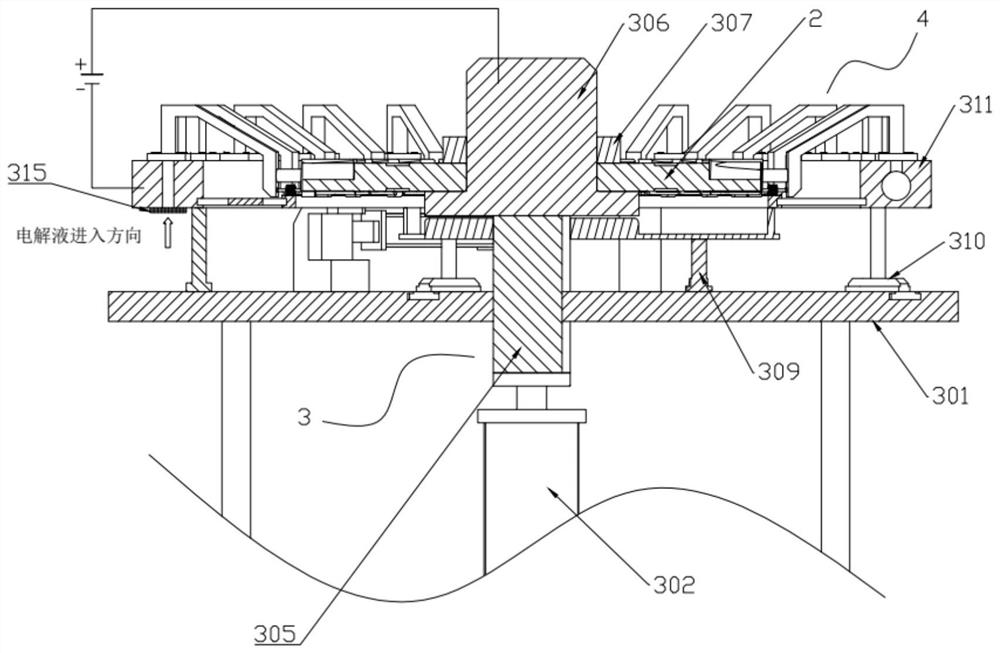

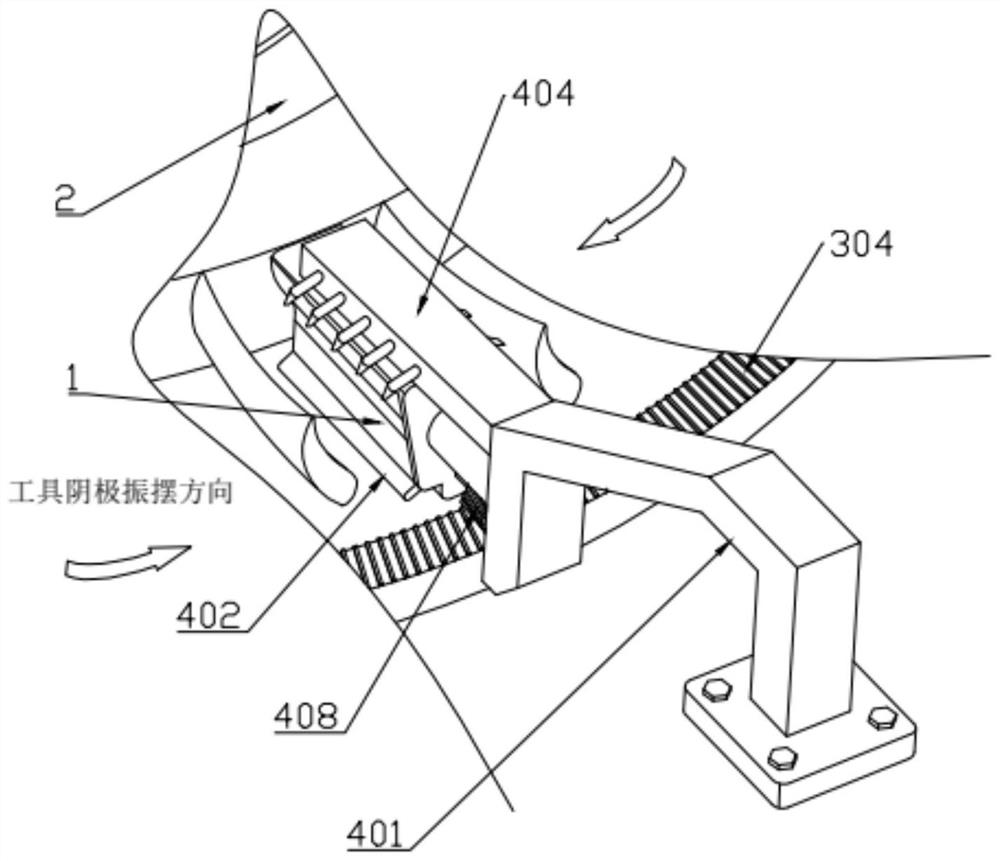

Precise electrolytic machining process for blade profile

ActiveCN113333880AGuarantee processing qualityFlow field stabilityMachining electrodesMachining working media supply/regenerationImpellerElectrolysis

The invention discloses a precise electrolytic machining process for a blade profile, and relates to the technical field of electrolytic machining. The process comprises the following steps of electrode type selection, pretreatment before machining, positioning installation, electrolytic machining and discharging after machining is finished. According to the process, a plurality of uniformly distributed follow-up mechanisms are arranged on a swing mechanism, and a blade basin part of a blade at one side and a blade back part of the other blade on two adjacent blades on an integral impeller are processed jointly by a tool cathode and a front edge cathode I and a front edge cathode II which are arranged in the tool cathode, a flow field is stable, the front edges of all the blades on the integral impeller are subjected to covering type electrolytic machining while short-circuit ablation is prevented, and the blade machining quality is guaranteed; and intermittent vibration electrolysis is carried out on the integral impeller which is horizontally placed, precise electrolytic machining of all blades on the integral impeller is synchronously completed within the rotating angle between blade channels, the precise electrolytic machining efficiency is greatly improved, and meanwhile the quality difference of the machined blades can be eliminated.

Owner:JIANGSU JIANGHANGZHI AIRCRAFT ENGINE COMPONENTS RES INST CO LTD

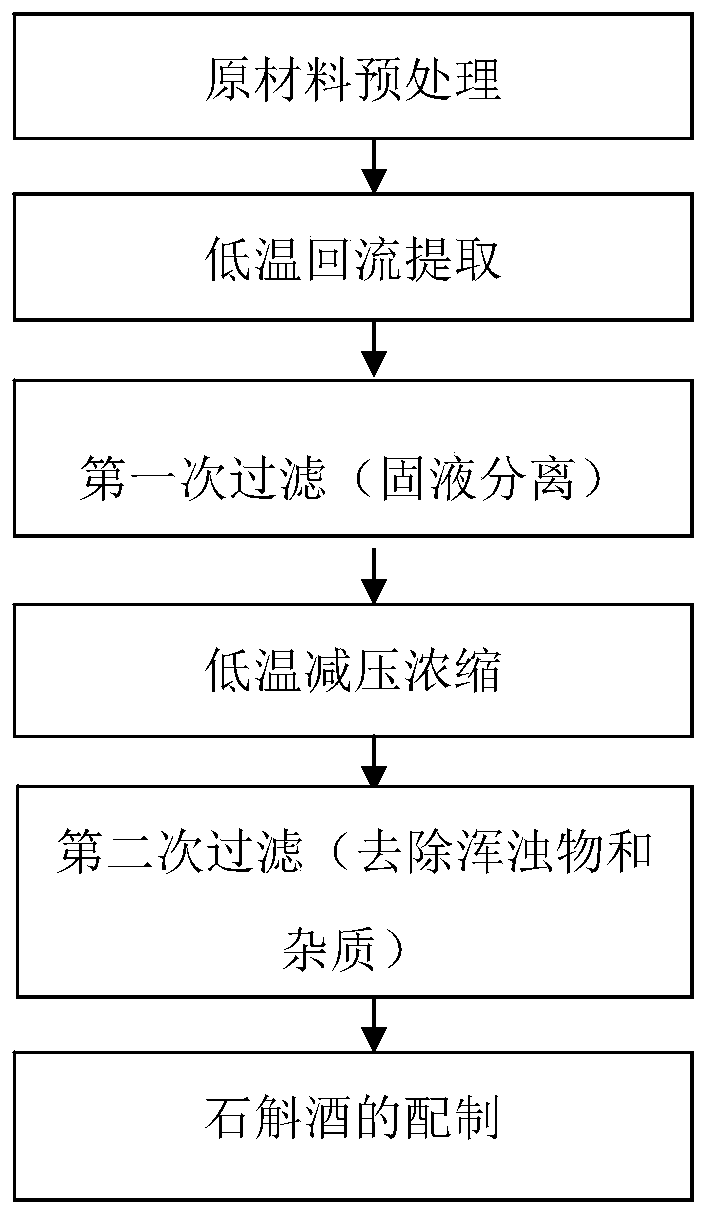

Dendrobium wine using dendrobium alcohol extractive as raw material and preparation method of dendrobium wine

PendingCN110484414AReduce qualityQuality improvementAlcoholic beverage preparationReflux extractionAlcohol

The invention provides a preparation method of dendrobium wine using a dendrobium alcohol extractive as a raw material. The preparation method comprises the specific steps of pretreatment of the dendrobium raw material, low temperature reflux extraction, first filtration, low temperature decompression concentration, second filtration, preparation of the dendrobium wine and other steps. The invention further provides the dendrobium wine prepared by the preparation method. According to the preparation method, the dendrobium alcohol extractive is used as the dendrobium raw material, the problem of mutual integration of dendrobium effective components and dendrobium base wine is effectively solved, occurrence of sediment and turbid objects is avoided, low temperature reflux extraction and lowtemperature concentration and other technologies are used, and the dendrobium effective components are obtained to the utmost extent. In addition, time is short, the cost can be obviously lowered, theprepared and obtained dendrobium wine is mellow and clean, and has obvious dendrobium flavour.

Owner:SHAOGUAN COLLEGE

A water and fertilizer integrated machine based on multi-channel flow control and its flow control method

ActiveCN108450115BConstant pressureImprove fertilizer absorption efficiencyClimate change adaptationWatering devicesPlant rootsAgricultural engineering

The invention discloses an integrated water and fertilizer machine and a flow control method based on multi-channel flow control. The flow is controlled through digital regulating valves in each water channel, thereby controlling the proportion of fertilizer. Water and multiple water-soluble fertilizers enter the water pump at the same time, are mixed evenly in the water pump, and finally reach the plant roots through the drip irrigation belt. This structure has higher fertilization efficiency and shorter time. Multiple types of fertilizers are applied at the same time, so that the fertilizers are fully mixed and reach the roots of the crops, improving the fertilizer absorption efficiency of the crops. It prevents uneven fertilizers for different plants during the fertilization process and avoids differences in crop quality caused by uneven growth of different plants. The invention adopts an adaptive harmonic ratio control algorithm, which can achieve the unification of flow control speed and following performance. When the main pipeline flow is greatly disturbed, the branch pipeline flow follows quickly, which can effectively avoid the occurrence of flow ratio mismatch.

Owner:NORTHEASTERN UNIV LIAONING

A kind of technology of continuous production of ADC foaming agent in multi-tank series

ActiveCN102584640BUniform qualityEliminate quality differencesOrganic chemistryContinuous reactorBiurea

The invention relates to a process for continuously producing an ADC foaming agent in series with multiple reactors. The process for producing the ADC foaming agent includes the process of condensing hydrazine hydrate and urea to form a biurea, and the process of oxidizing biurea and chlorine to form an ADC foaming agent; In the process of oxidizing biurea and chlorine to ADC foaming agent, two or more reactors are connected in series, with continuous feeding and stirring to realize continuous reaction. Furthermore, in the process of condensing hydrazine hydrate and urea to form biurea, two or more reactors are connected in series, with continuous feeding and stirring to realize continuous reaction. The beneficial effect of the present invention is: adopt multi-tank serial continuous production ADC blowing agent process, can realize continuous production, improve production capacity; Adopt multi-tank serial continuous production ADC foaming agent process, can realize the uniformity of product quality, and The reaction is controllable, which prevents the quality difference of the product caused by the multi-pot reaction.

Owner:HANGZHOU HI TECH FINE CHEM

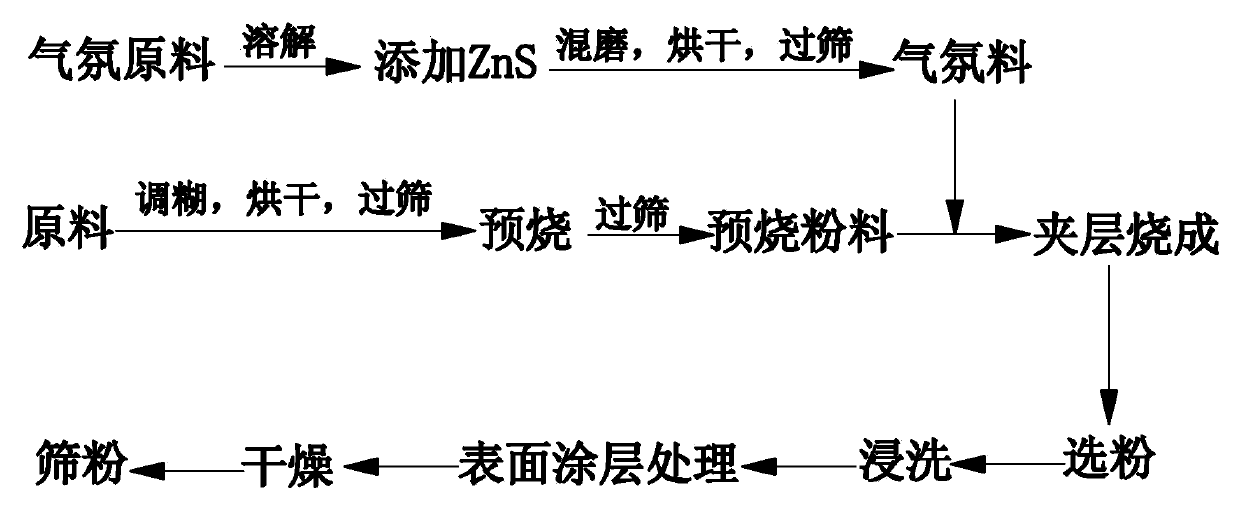

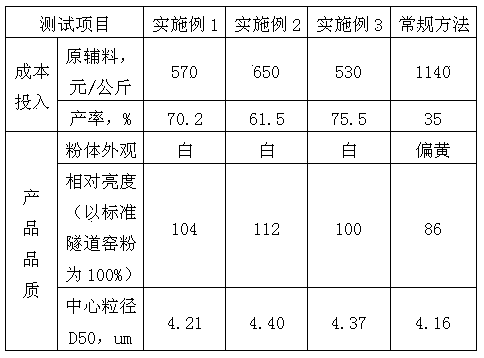

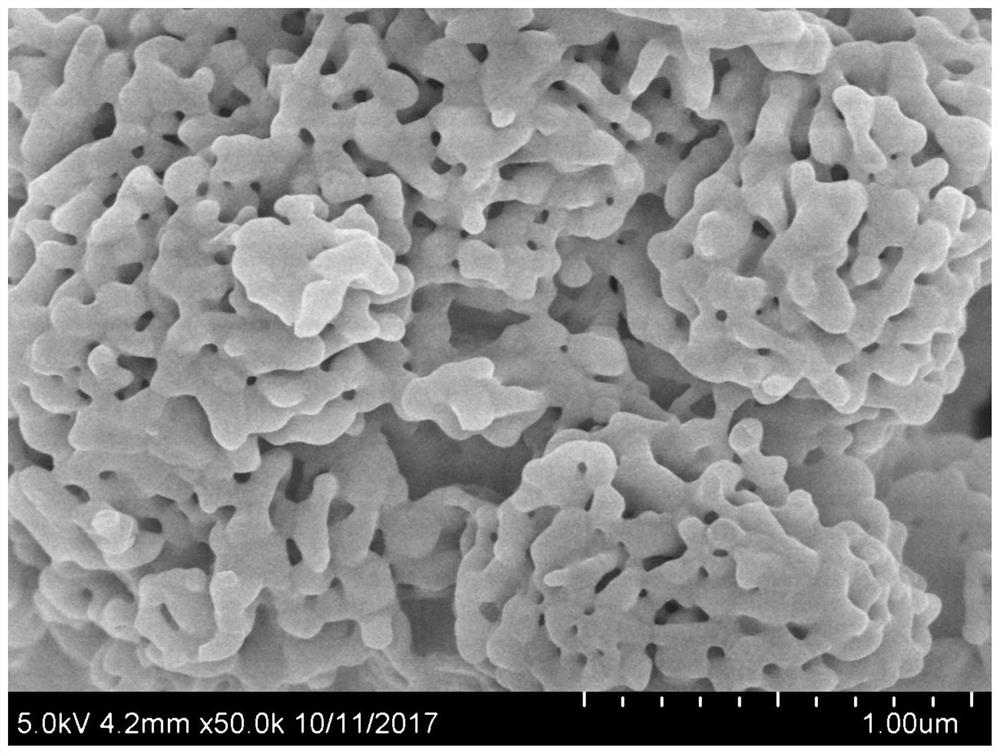

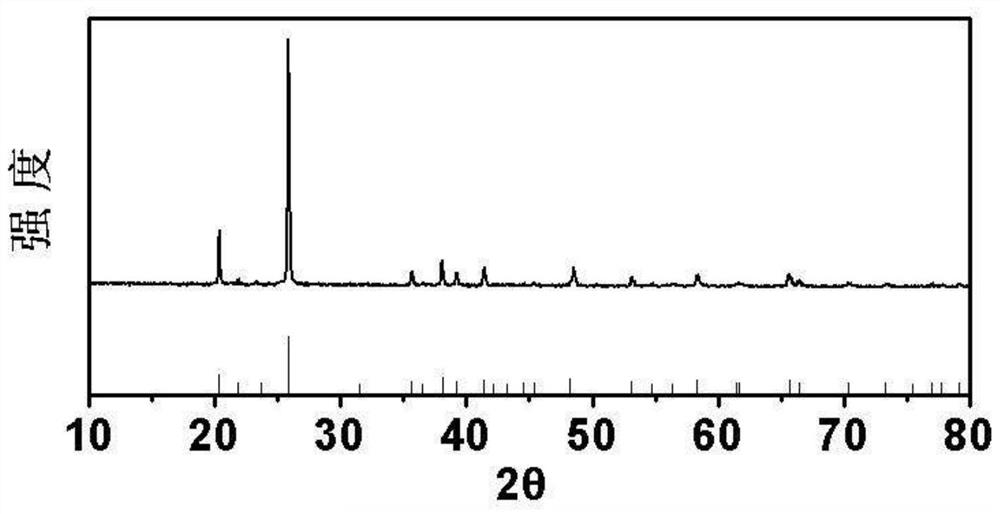

Method for preparing green fluorescent powder for VFD (Vacuum Fluorescent Display)

InactiveCN104194779AEliminate quality differencesGuaranteed stabilityLuminescent compositionsSemiconductor devicesDisplay deviceFluorescent light

The invention relates to a method for preparing green fluorescent powder for a VFD (Vacuum Fluorescent Display) and belongs to the technical field of preparation of fluorescent powder. The method comprises the following steps: by taking zinc oxide, zinc sulfide and sulfur as raw materials, blending the raw materials into a paste, grinding, drying, screening, isolating air and presintering, thereby obtaining presintered powder; by taking zinc sulfide or sulfur as an atmosphere material, performing laminated burning on the presintered powder, performing powder concentration and immersion cleaning based on absolute ethyl alcohol on the burnt powder, adding pure water, mixing and stirring, adding a stock solution of potassium silicate, performing surface coating treatment, dehydrating, drying and screening, thereby obtaining a finished product. The preparation method disclosed by the invention has the advantages of simple process, simple equipment, preparation safety and the like, and the prepared green fluorescent powder for the VFD has the characteristics of high brightness, uniform particle size, narrow particle size distribution and the like.

Owner:WUHE TONGSHIFU FOOD

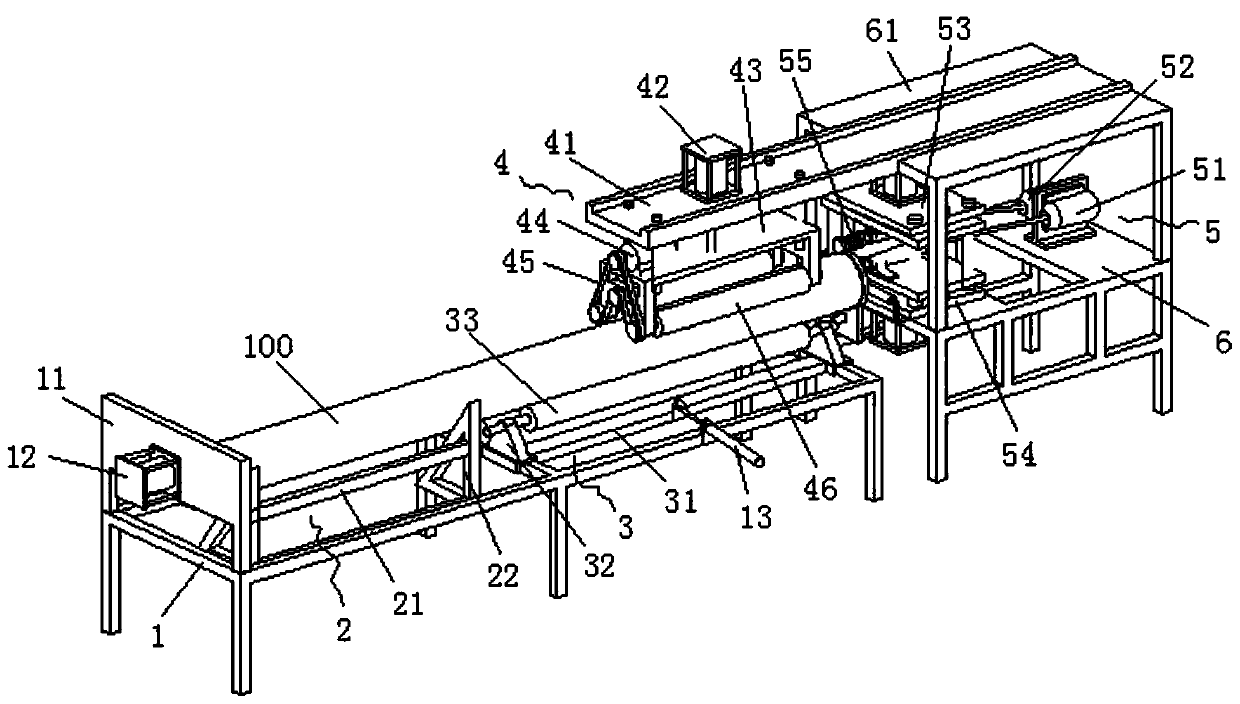

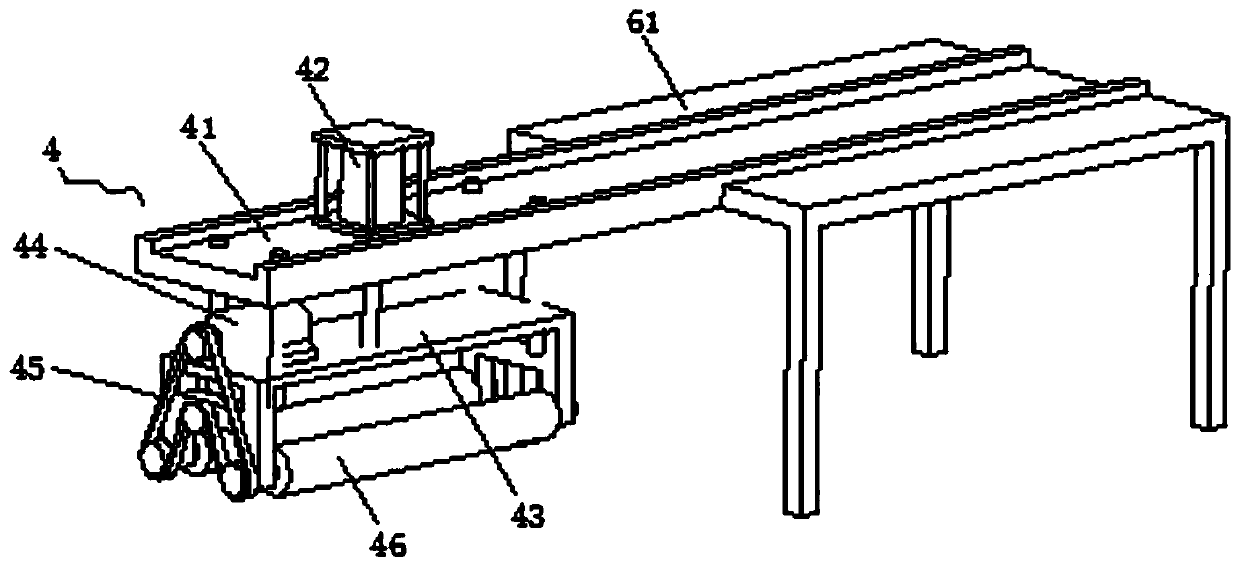

Opening flattening device for polishing composite pipe opening seal ring

InactiveCN111001865AIncrease productivitySolve quality differencesMilling machinesFeeding apparatusPolishingEngineering

The invention discloses an opening flattening device for polishing a composite pipe opening seal ring. The opening flattening device for polishing the composite pipe opening seal ring comprises a holding machine frame arranged on the front side, a work machine frame bench arranged on the back side and a top machine frame fixed to the work machine frame bench. A front end side plate is arranged atthe front end of the holding machine frame and provided with a front end pushing telescopic rod. A group of supporting rack assemblies which are symmetrical in the left-right direction and a group ofsupporting roller assemblies which are symmetrical in the left-right direction are sequentially installed on the holding machine frame and used for supporting a pipe. A back end pushing telescopic rodis fixedly installed on the lower side of the work machine frame platform. The telescopic end of the back end pushing telescopic rod is fixedly provided with a locating plate. A pipe rotating drive mechanism is installed at the front end of the top machine frame. A polishing mechanism used for polishing the inner and outer walls of the opening sealing ring is installed on the work machine frame platform. The opening flattening device for polishing the composite pipe opening seal ring replaces manual opening flattening with mechanical opening flattening, so that efficiency is improved; and theinstability problem of manual polishing and opening flattening can be effectively solved.

Owner:ANHUI YONGGAO PLASTIC IND DEV CO LTD

A kind of blade profile precision electrolytic machining process

ActiveCN113333880BGuarantee processing qualityFlow field stabilityMachining electrodesMachining working media supply/regenerationImpellerElectrolysis

The invention discloses a precision electrolytic machining process for a blade profile, which relates to the technical field of electrolytic machining and includes the following steps: electrode selection, preprocessing before machining, positioning and installation, electrolytic machining, and discharging after machining. In the present invention, a plurality of evenly distributed follower mechanisms are arranged on the swing mechanism, and the tool cathode and the leading edge cathode 1 and the leading edge cathode 2 arranged inside jointly complete the blade basin part of the blade on one side of the two adjacent blades on the integral impeller. And the processing of the blade back part of the other blade, the flow field is stable, and the short-circuit ablation is prevented. At the same time, all the leading edges of the blades on the integral impeller are covered by electrolytic machining to ensure the processing quality of the blades; intermittently through the horizontally placed integral impeller Vibration electrolysis, within the rotation angle between an inter-blade channel, synchronously completes the precision electrolytic machining of all the blades on the integral impeller, which greatly improves the precision electrolytic machining efficiency and eliminates the difference in the quality of the processed blades.

Owner:JIANGSU JIANGHANGZHI AIRCRAFT ENGINE COMPONENTS RES INST CO LTD

Belt friction method and device for replacing silk sheath

InactiveCN103334161BKnead continuously and evenlyFlat surfaceSilk reelingConveyor beltBiomedical engineering

The invention relates to a silk reeling method and a silk reeling device, in particular to a band friction method and a band friction device for replacing a silk sheath. The method and the device mainly solve the technical problems that a wet raw silk gathering method during silk reeling production in the prior art forms a silk sheath structure by adopting a manual mode, and gathers wet raw silk through a silk sheath effect, and the quality of the raw silk is influenced, operation is complicated, and labor productivity is low due to the nonuniformity of the silk sheath structure between threads brought by the method, or solve the technical problem that gathering is nonuniform due to periodical change of the speed when back-and-forth friction is conducted by adopting reciprocating movement. According to the method and the device, upper and lower layers of driving bands which can be used for replacing silk sheath gathering cocoon silk and move reversely are wound with the wet raw silk; silk pressing guide rolls are arranged between the driving bands; a winding movement direction of the wet raw silk is perpendicular to movement directions of the driving bands relative to the raw silk; friction is generated between the wet raw silk and the driving bands; and tiny sections on the surface of the cocoon silk can be removed after rotation and kneading.

Owner:ZHEJIANG SCI-TECH UNIV

Adaptive machining method for leading and trailing edges of aero-engine turbine blades

ActiveCN113333881BGuarantee processing qualityFlow field stabilityMachining electrodesMachining working media supply/regenerationImpellerTurbine blade

Owner:JIANGSU JIANGHANGZHI AIRCRAFT ENGINE COMPONENTS RES INST CO LTD

A Wet Raw Silk Extrusion Aggregation Method and Special Device

The invention relates to a silk reeling method and device, in particular to a squeezing type wet raw silk gathering method and a special device, and mainly solves the technical problems that croisure structures of silk ends are not uniform and the qualities of the raw silk are influenced due to the fact that croisure structures are manually formed and the wet raw silk is gathered under the action of croisures with a wet raw silk gathering method existing in the prior art. According to the squeezing type wet raw silk gathering method and the special device, a silk wrapping godet is wound by wet raw silk, a pushing godet is tightly attached to the silk wrapping godet and squeezes the wet raw silk, the two godets perform relative and linear reciprocating motion, the wet raw silk and the godets create friction, and a plurality of pieces of cocoon silk glue forming the raw silk are kneaded to the periphery of the raw silk, so that the wet raw silk is closely gathered; and at the same time, strand silk rotates an upper section of strand silk and a lower section of strand silk in different directions, moisture in the strand silk is squeezed to be removed, and small knots on the surface of cocoon silk can be removed through rotating and kneading.

Owner:ZHEJIANG SCI-TECH UNIV

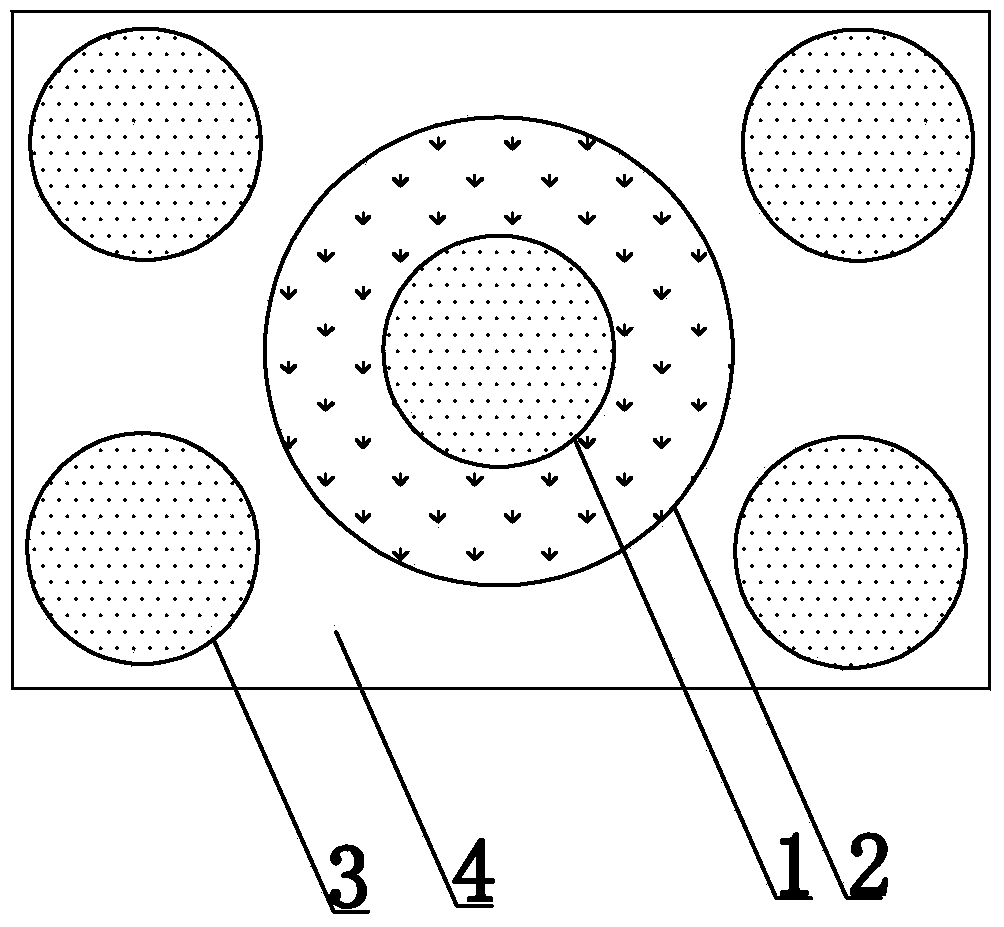

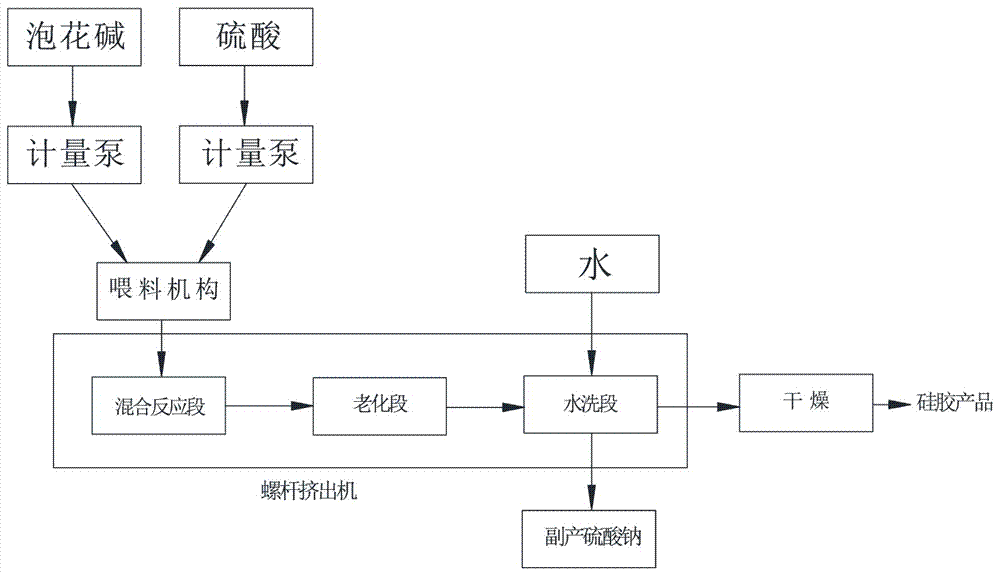

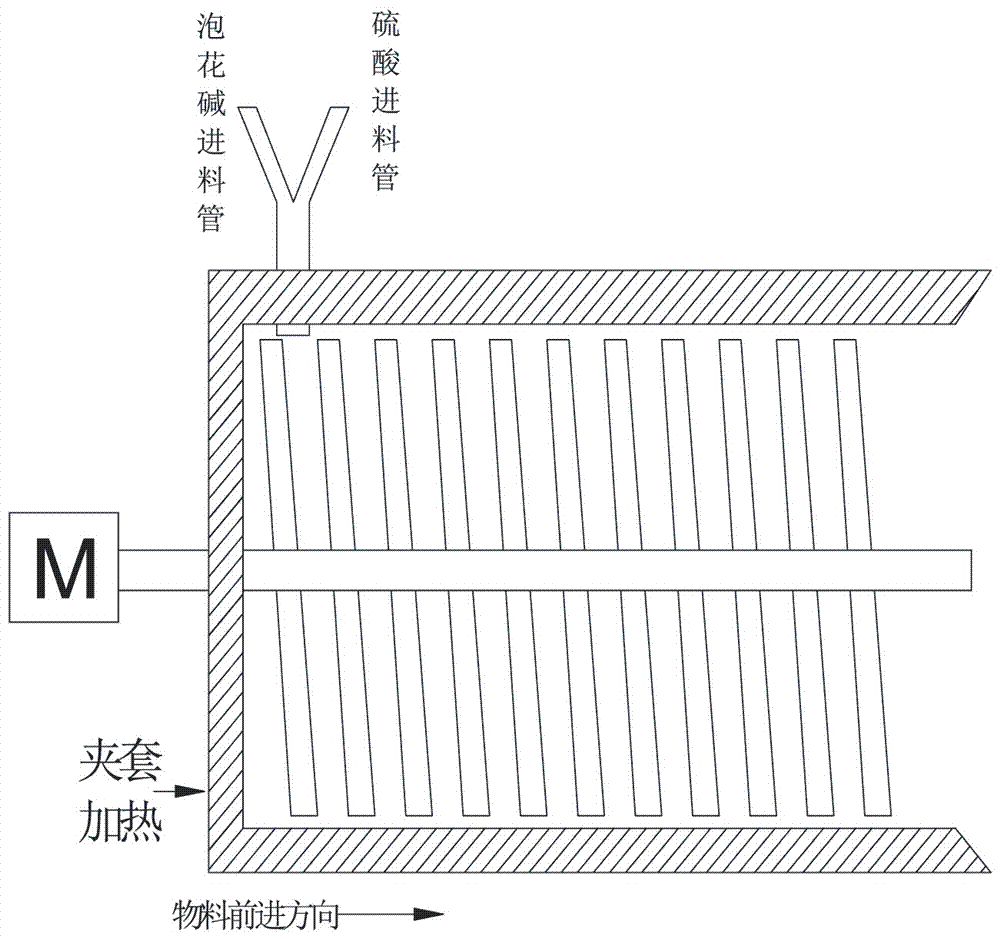

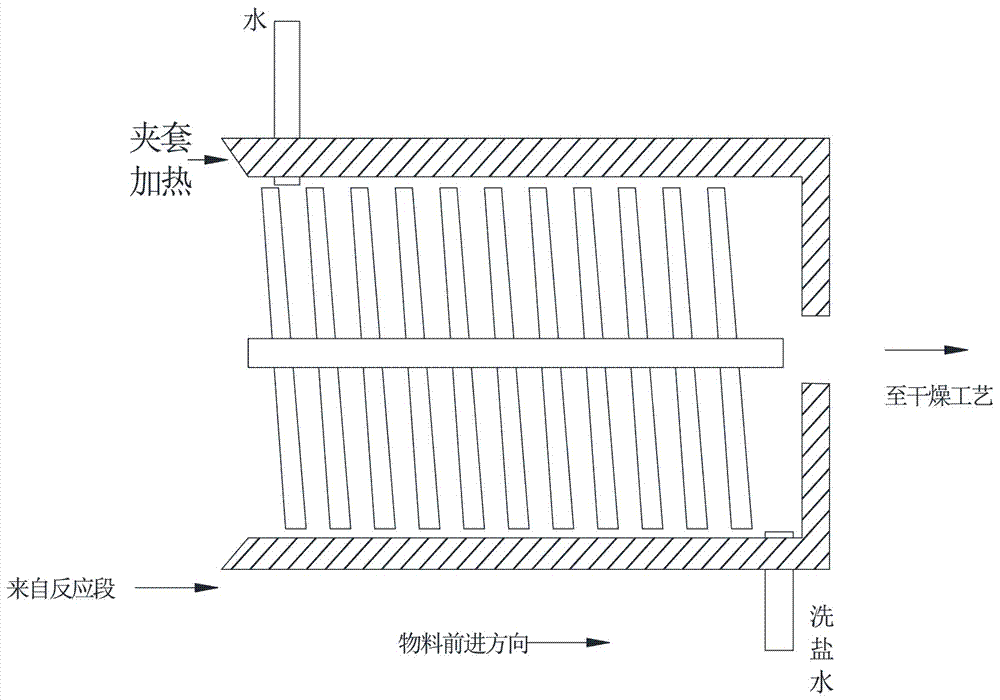

Continuous production device of amorphous silica gel and production method

PendingCN107055555AIncrease productivityEliminate quality differencesSilicaSodium silicateSulfuric acid

The invention belongs to the technical field of amorphous silica gel production, and relates to achieving continuous production of amorphous silica gel by using a screw-rod extrusion machine. A continuous production device of the amorphous silica gel is characterized in that the outlet of a sodium silicate tank and the outlet of a sulfuric acid tank are connected with inlet pipelines of a feeding mechanism at the front end of the screw-rod extrusion machine through a metering pump separately; an inner cavity of a cylinder of the screw-rod extrusion machine is provided with a reaction segment, an aging segment and a water-washing extrusion segment in the flow direction of materials; in the reaction segment, sodium silicate and sulfuric acid are rapidly mixed and subjected to reaction to generate initial products which are white silica-gel pieces; in the aging segment, the initial products are soaked in hot water, aged and shaped; in the water-washing extrusion segment, a large amount of salt generated when sodium silicate reacts with sulfuric acid is washed away, and an product outlet at the extrusion end is connected and communicated with a product drying chamber. The continuous production device of the amorphous silica gel has the advantages that in combination with a traditional batch-type silica-gel preparation process, the steps of reaction, aging, water washing and the like are achieved in one screw-rod extrusion machine, during production, it is only necessary to observe whether or not various mechanical parts work normally, and it is unnecessary to adjust the continuous production device of the amorphous silica gel again. The continuous production device of the amorphous silica gel is conductive to continuous production in industries, and the production efficiency is improved.

Owner:上海华震科技有限公司

A preparation method and production device of battery-grade iron phosphate

ActiveCN108117055BGuaranteed batch stabilityImprove securityPhosphorus compoundsIron saltsElectrical battery

A method for preparing battery-grade iron phosphate, comprising the following steps: preparing an iron salt solution, preparing a phosphorus source solution, and performing an oxidation precipitation reaction; the reacted feed liquid is filtered through a plate and frame; the filter cake is washed and sintered to finally obtain an iron phosphate product . The production device includes an iron salt storage tank, a phosphate storage tank, a reaction kettle, a retention kettle and a plate frame, and the iron salt storage tank and the phosphate storage tank are respectively connected to the top of the reaction kettle through a feeding pipeline. Connected to the board and frame in turn. The above preparation process adopts a continuous feeding and discharging production device, so that the oxidation precipitation reaction is in a state of dynamic equilibrium, the reaction time is short, the quality of the produced iron phosphate is stable, and the particle size is controllable, realizing the continuous industrial production of iron phosphate.

Owner:山东彩客新材料有限公司 +1

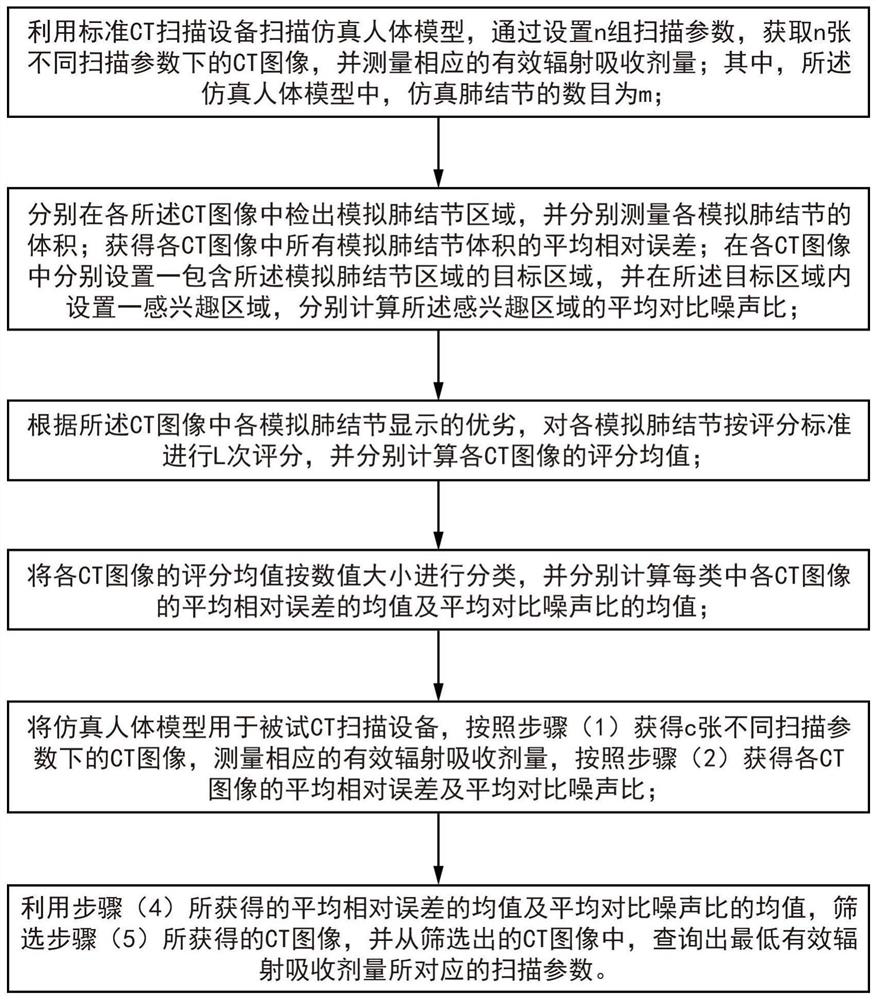

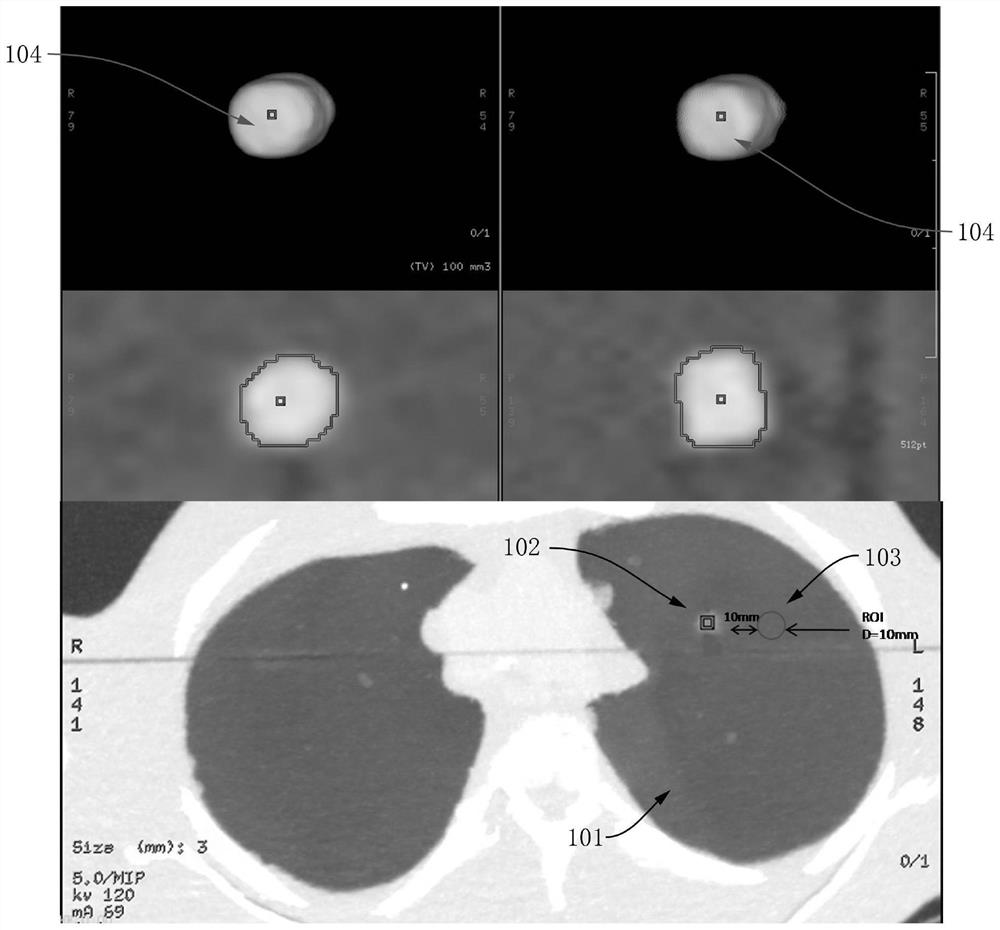

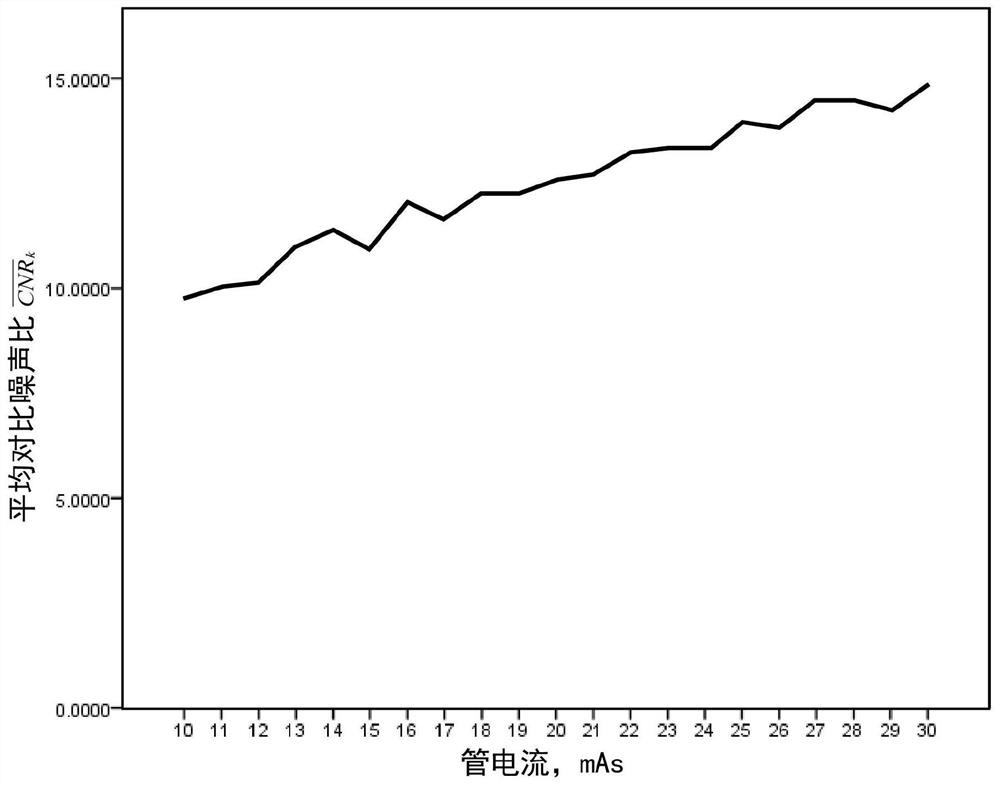

A Method for Optimizing the Parameters of Chest Low-dose CT Scanning

ActiveCN109646036BMeet diagnostic requirementsUniversalComputerised tomographsTomographyCt screeningPulmonary nodule

The invention relates to a method for optimizing chest low-dose CT scanning parameters, which is characterized in that, using standard CT scanning equipment, the CT images of the simulated human body model are obtained multiple times by setting the scanning parameter gradient, and the objective image quality index and subjective image quality evaluation are obtained index, and establish a corresponding relationship; use the tested CT scanning equipment to obtain the CT image of the simulated human body model, and according to the corresponding relationship, screen out the scanning parameters corresponding to the lowest effective radiation absorbed dose; the optimization method provided by the present invention, Simple, effective, and universal, it can obtain the optimal combination of scanning parameters that meet the diagnostic requirements on any CT scanning equipment, and minimize the absorbed radiation dose of the subject, thus effectively solving the problems in the existing technology. There is a lack of consistency and reliability in the selection of CT screening scan parameters, especially for the optimization of scan parameters for lung nodule screening in high-risk groups of lung cancer.

Owner:SICHUAN CANCER HOSPITAL

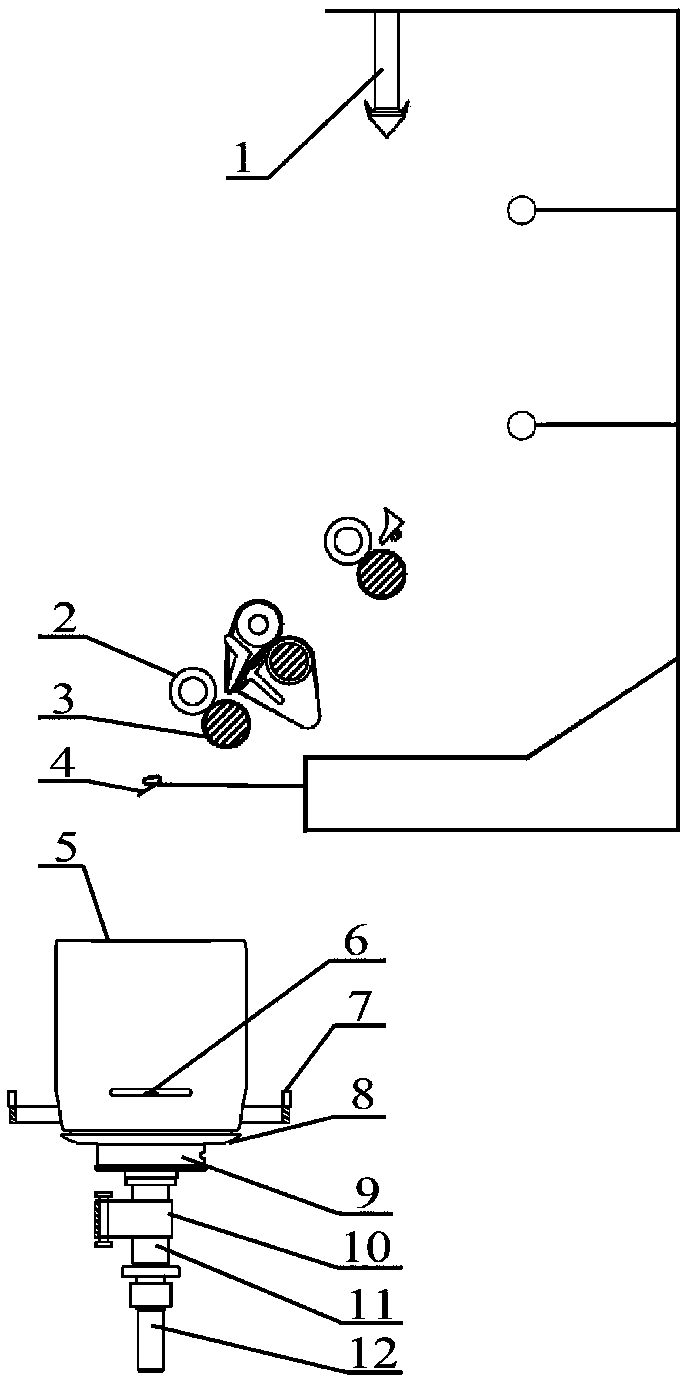

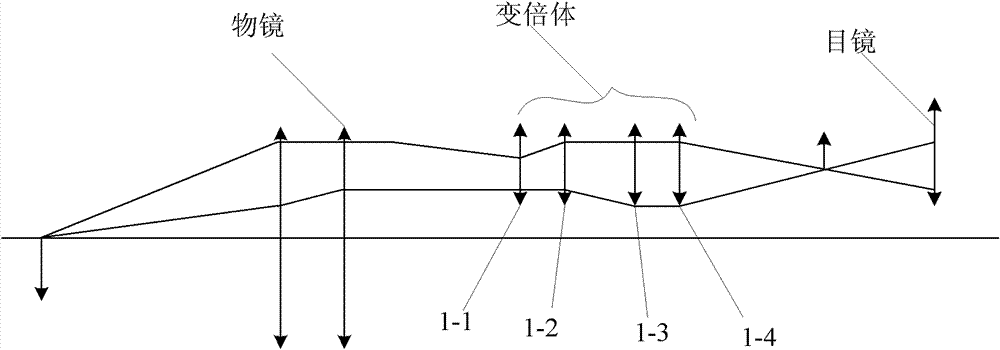

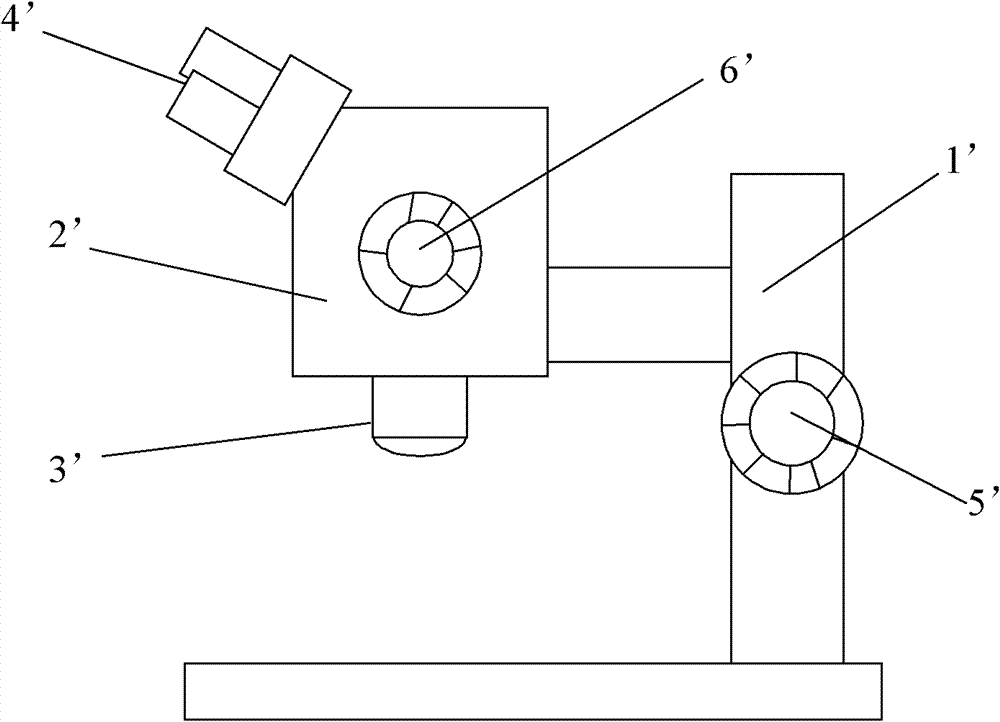

Zoom-stereo microscope detection device and method

ActiveCN102261986BNot affected by fatigueSelf-requirement loweredTesting optical propertiesOphthalmologyEngineering

The invention relates to a zoom-stereo microscope detection device for detecting the parfocalization property of a stereo microscope. The zoom-stereo microscope detection device comprises a frame, a stereo loading mechanism, an objective lens, a focusing control mechanism, an image acquisition device, a precision judgment device and a motion control module, wherein the stereo loading mechanism can move upwards and downwards along the frame; the focusing control mechanism is used for adjusting the position of the stereo loading mechanism on the frame; the image acquisition device is matched with the objective lens; the precision judgment device is connected with the image acquisition device and used for acquiring the quality evaluation information of an image; and the motion control moduleis connected with a stereo control motor and a focusing control motor and used for controlling the stereo control motor and the focusing control motor to operate. Compared with the prior art, the zoom-stereo microscope detection device provided by the invention has the advantages that by using the device, the human errors arising from visual qualitative detection can be avoided so as to facilitate the adjustment and detection of the assembling personnel, thereby greatly improving the production efficiency and the production automation degree. By using the zoom-stereo microscope detection device, the focal length deviations can be adjusted precisely.

Owner:NINGBO YONGXIN OPTICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com