Process for continuously producing azodicarbonamide (ADC) foaming agents in multi-kettle serial-connection mode

A technology of ADC foaming agent and multi-tank series, which is applied in the field of multi-tank series continuous production of ADC foaming agent, can solve problems such as operation difficulty and product quality difference, achieve controllable reaction, realize product quality, and continuous production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

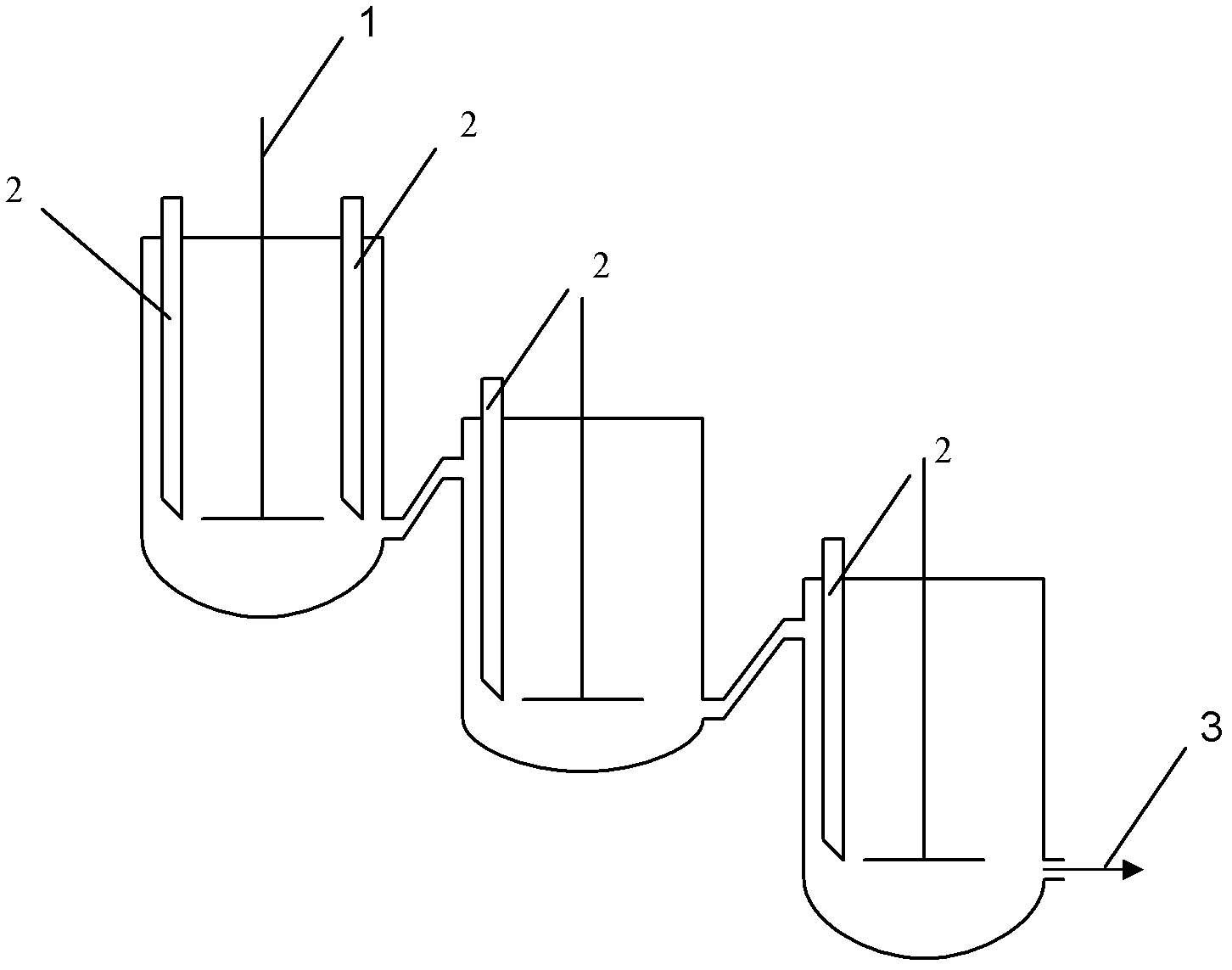

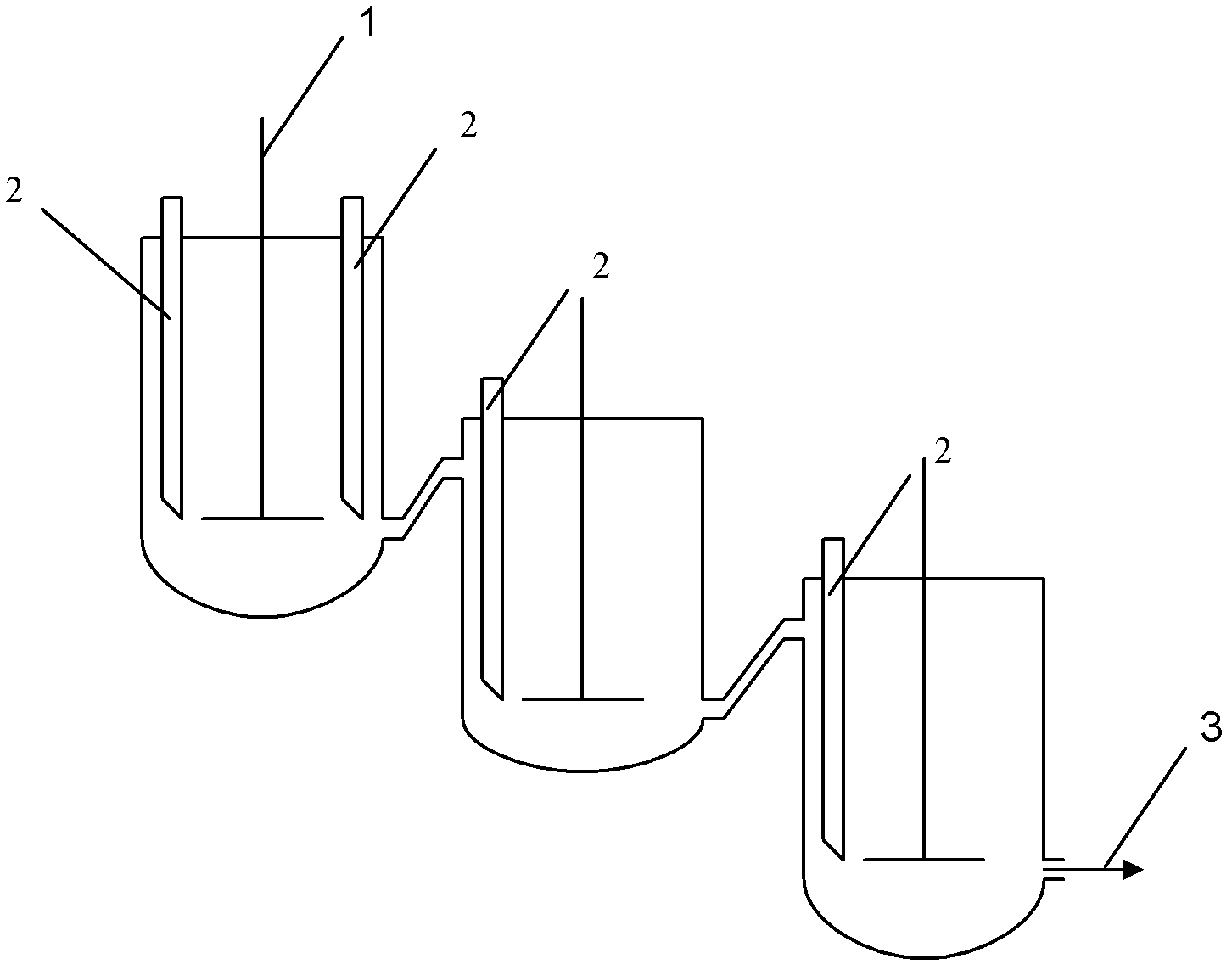

[0017] The volume of three series-connected reaction tanks is 100L. Using this process, biurea is oxidized into ADC foaming agent by chlorine gas. First, 50kg of biurea slurry (containing 50% of biurea, percentage by weight) is added to the first In the reaction kettle, turn on the chlorine gas switch, add 5.18L of chlorine gas, turn on the agitator 1 to stir, and after stirring for 1 hour, control the flow rate of biurea to 20kg / h, the flow rate of chlorine gas to 5L / h, and the flow rate of chlorine gas in the second reactor to control 2L / h, the third reactor controls the urea flow rate of 2L / h, and the product from the third reactor is filtered, washed and dried to obtain the ADC foaming agent. After determination, under the same output, the continuous method can produce ADC foaming agent. The consumption of chlorine gas is saved by 30%, and the obtained ADC foaming agent has a uniform particle size and high product quality.

Embodiment 2

[0019] The biurea that adopts in embodiment 1, utilizes this technology to condense hydrazine hydrate and urea reaction into biurea, and the volume of three series-connected reactors is 100L, and the concentration of hydrazine hydrate is 40% (percentage by weight), at first Put 50kg of hydrazine hydrate into the first reactor, control the urea flow rate at 10kg / h, keep stirring for two hours, open the hydrazine hydrate control valve, control the hydrazine hydrate flow rate to 25kg / h, and control the urea flow rate in the second reactor 8kg / h, the third reactor controls the flow of urea to 6kg / h, and the product from the third reactor is filtered, washed and dried to obtain biurea. It has been determined that the operation of this continuous method can be more than that of the intermittent method every day. With a yield of 40%, the urea consumption can be saved by 30% under the same yield. The obtained biurea has uniform particle size and high purity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com