A Wet Raw Silk Extrusion Aggregation Method and Special Device

A special device and extruding technology, applied in the direction of silk reeling, etc., can solve the problems of non-uniform silk sheath structure between threads, affecting the quality of raw silk, and low labor productivity, so as to achieve smooth surface of silk strips, improve the quality of raw silk in batches, The effect of eliminating quality differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

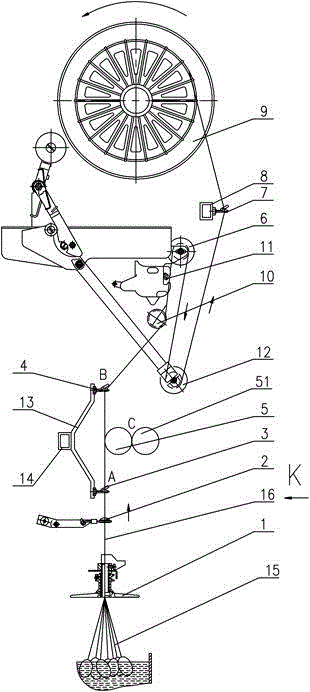

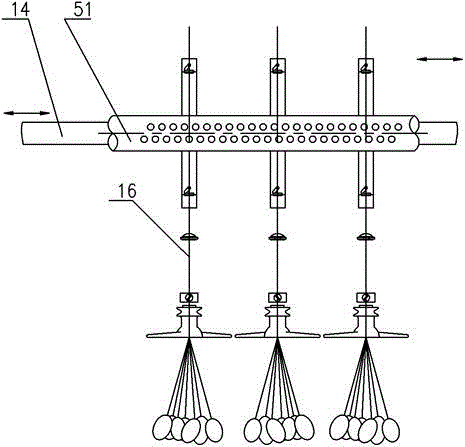

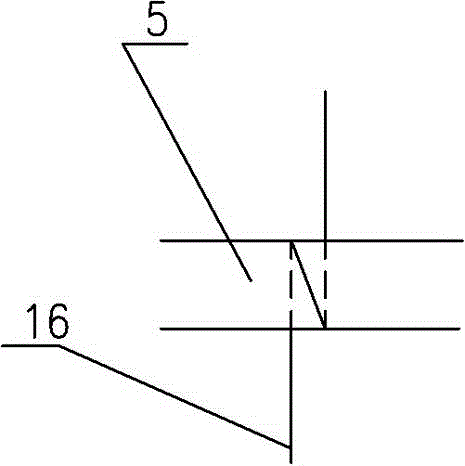

[0021] Embodiment: A kind of wet state raw silk extruding type aggregation method and special device of this example, according to raw silk specification requirements, such as figure 1 , figure 2 , image 3 A plurality of cocoon silks 15 are assembled into wet raw silks 16 through the high-speed rotation of the threading wing 1, and the wet raw silks 16 containing a large amount of water pass through the thread collector 2, and pass through the lower guide wire hook 3 and the upper guide wire hook 4, so that Wet state raw silk 16 is wound on the winding godet roller 5, pushes godet roller 51 to be close to winding godet roller, when two godet rollers move relative to each other, under the effect of frictional force, drive raw silk thread to rotate, and to Moisture in the sliver is extruded, and the godet roller is heated so that the raw silk sliver can be dried when in contact with the godet roller, reducing the moisture content of the raw silk. The wet raw silk and the god...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com