Temperature measurement system and method based on pixelated dual-band narrow-band optical filter array

A narrow-band filter and temperature measurement technology, applied in optical radiation measurement, radiation pyrometry, measurement devices, etc., can solve the problems of large measurement error, low spatial resolution and spatial resolution, and inconvenient integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

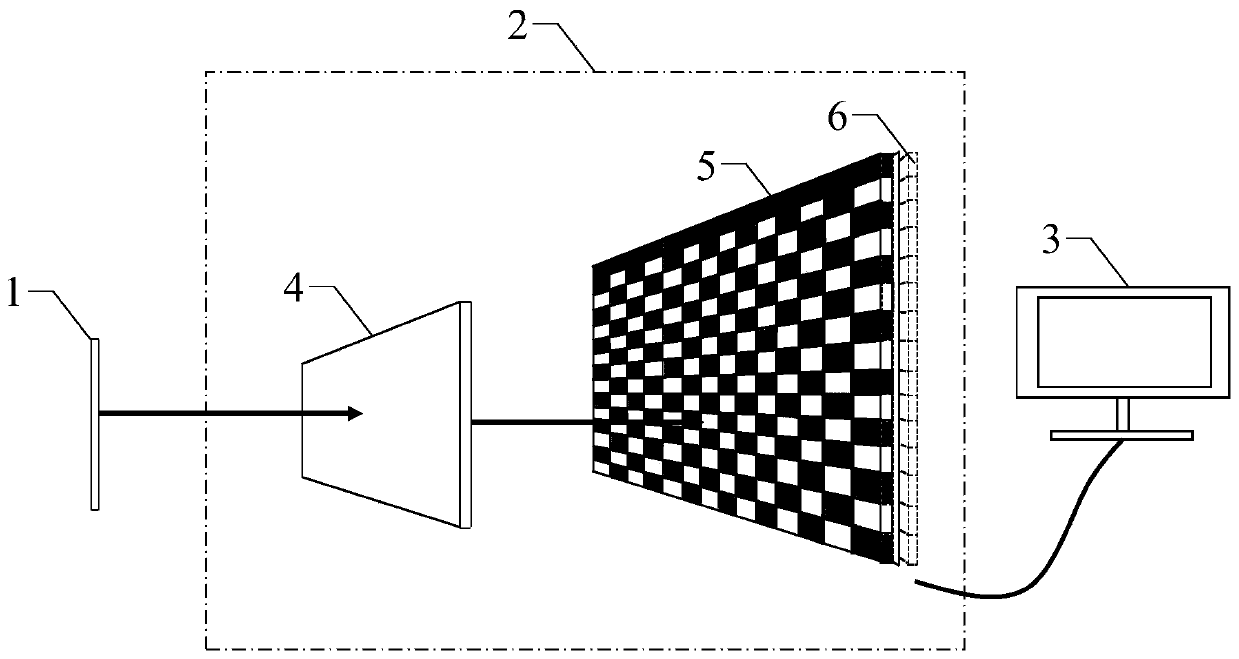

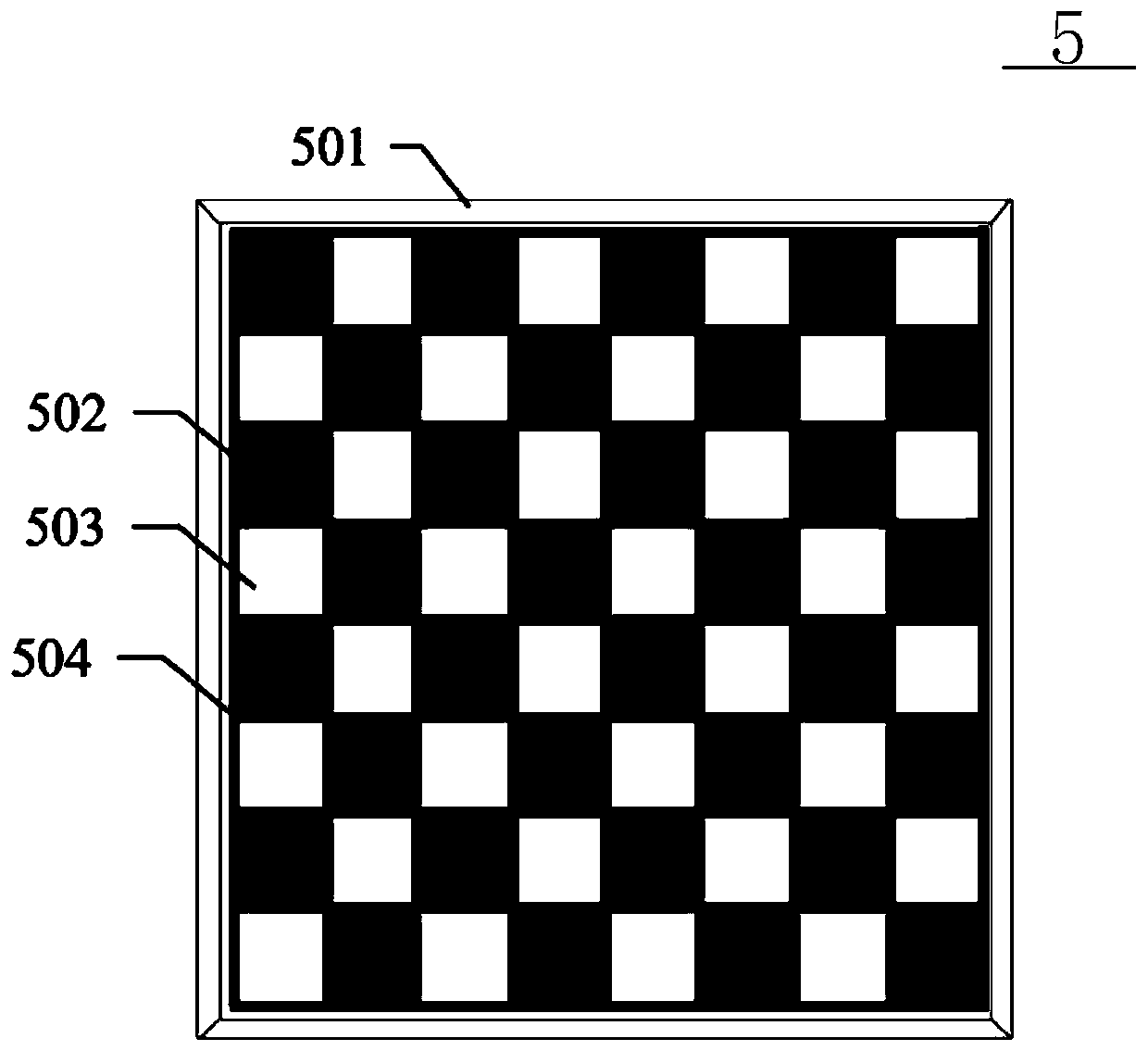

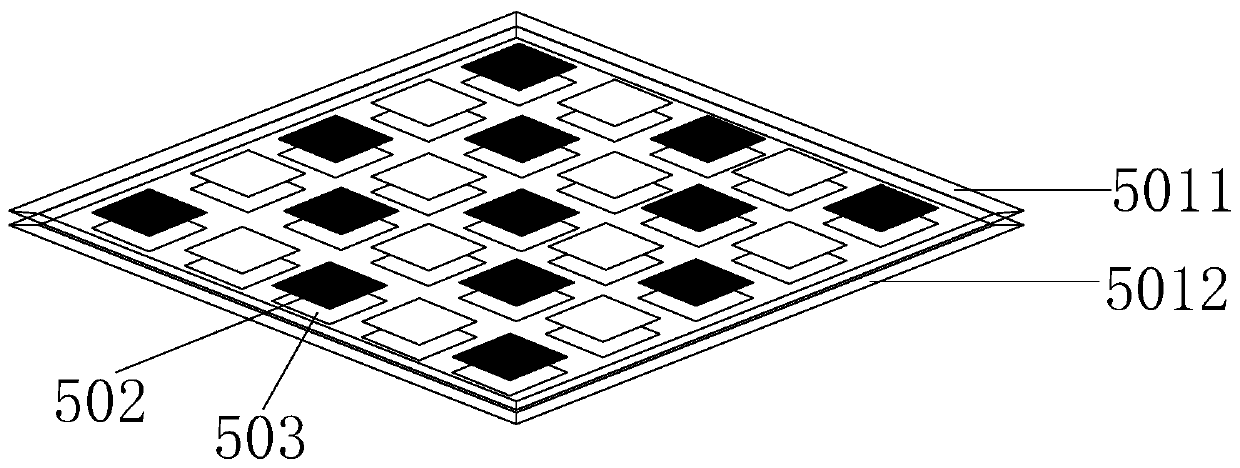

[0060] figure 1 It is a structural schematic diagram of a temperature measurement system based on a pixelated dual-band narrowband filter array in this embodiment, as figure 1 As shown, the present embodiment provides a temperature measurement system based on a pixelated dual-band narrow-band filter array, the temperature measurement system includes a dual-band array image acquisition device 2 and a computing device 3, and the dual-band array image acquisition device 2 and computing device The device 3 is electrically connected;

[0061] In the calibration stage, the dual-band array image acquisition device 2 is used to acquire the grayscale array image of the calibration area of the high-temperature calibration device including the radiation light in the first band and the second band, and the computing device 3 is used to acquire and record the correction parameter matrix and system response parameters matrix;

[0062] In the measurement phase, the dual-band array image ...

Embodiment 2

[0087] This embodiment provides a temperature measurement method based on a pixelated dual-band narrowband filter array, the method includes a calibration phase and a measurement phase performed by a temperature measurement system based on a pixelated dual-band narrowband filter array, and the temperature measurement system Calibration is then used for temperature measurement.

[0088] Figure 6Shown is the flow chart of the calibration stage based on the pixelated dual-band narrowband filter array in this embodiment, as Figure 6 shown, combined with Figure 1-5 , the calibration phase includes:

[0089] Step 2011, direct the dual-band array image acquisition device 2 to the calibration area of the high-temperature calibration device, and use the dual-band array image acquisition device 2 and the image receiving module 101 to acquire the single-band grayscale array image and the dual-band array image of the calibration area of the high-temperature calibration device gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com