Method for preparing green fluorescent powder for VFD (Vacuum Fluorescent Display)

A green fluorescent powder and manufacturing method technology, applied in chemical instruments and methods, luminescent materials, semiconductor devices, etc., can solve problems such as complex operation, high risk of mixed atmosphere reaction, poor product stability, etc., and achieve quality stability Improve, avoid quality differences, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

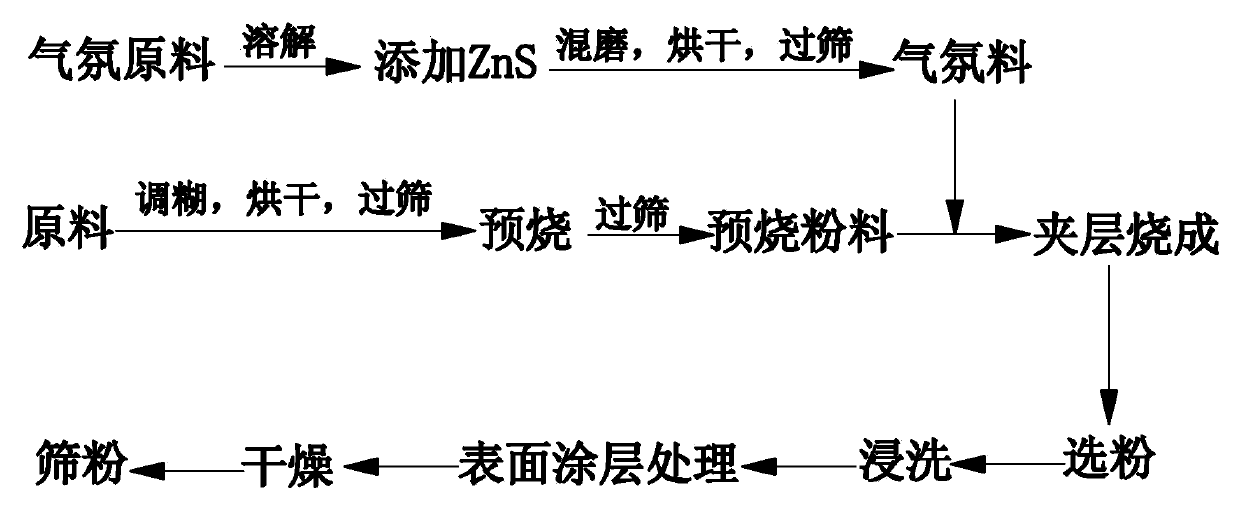

[0024] A kind of manufacturing method of green phosphor powder for vacuum fluorescent display of this embodiment, combines figure 1 , mainly consists of the following steps:

[0025] (1) Ingredients: Weigh 1kg of zinc oxide, 15g of zinc sulfide, and 5g of sulfur, mix them; adjust to paste with absolute ethanol, put them into a ball mill for mixing and grinding, dry at 80°C, and sieve through a 200-mesh nylon sieve to obtain Raw material.

[0026] (2) Pre-burning: put the prepared raw material into a quartz crucible, make it slightly solid, and evenly cover the surface with a layer of zinc sulfide to isolate the air, cover the crucible tightly with a quartz cover, and keep it warm at 500°C for 60 minutes; After cooling, remove the zinc sulfide layer on the surface, and sieve the lower layer powder with 200 mesh to obtain pre-fired powder.

[0027] (3) Prepare atmosphere material: weigh aluminum chloride hexahydrate (AlCl 3 .6H 2 O) 7g, sodium chloride (NaCl) 1.5g, aluminum ...

Embodiment 2

[0036] A kind of manufacturing method of green phosphor powder for vacuum fluorescent display of this embodiment, combines figure 1 , mainly consists of the following steps:

[0037] (1) Ingredients: Weigh 1kg of zinc oxide and 15g of sulfur, mix them; adjust to a paste with absolute ethanol, put them into a ball mill for mixing and grinding, dry at 80°C, and sieve through a 200-mesh nylon sieve to obtain raw meal.

[0038] (2) Pre-burning: put the prepared raw material into a quartz crucible, make it slightly solid, and evenly cover the surface with a layer of zinc sulfide to isolate the air, cover the crucible tightly with a quartz cover, and keep it warm at 650°C for 30 minutes; After cooling, remove the zinc sulfide layer on the surface, and sieve the lower layer powder with 200 mesh to obtain pre-fired powder.

[0039] (3) Prepare atmosphere material: weigh aluminum chloride hexahydrate (AlCl 3 .6H 2 O) 6g, sodium chloride (NaCl) 1.0g, aluminum sulfate octadecahydrate ...

Embodiment 3

[0048] A kind of manufacturing method of green phosphor powder for vacuum fluorescent display of this embodiment, combines figure 1 , mainly consists of the following steps:

[0049] (1) Ingredients: Weigh 1 kg of zinc oxide and 25 g of zinc sulfide, mix them; use absolute ethanol to make a paste, put them into a ball mill for mixing and grinding, dry at 80°C, and sieve through a 200-mesh nylon screen to obtain raw meal.

[0050] (2) Pre-burning: put the prepared raw materials into a quartz crucible, make it slightly solid, and evenly cover the surface with a layer of zinc sulfide to isolate the air, cover the crucible tightly with a quartz cover, and keep it warm at 600°C for 60 minutes; After cooling, remove the zinc sulfide layer on the surface, and sieve the lower layer powder with 200 mesh to obtain pre-fired powder.

[0051] (3) Prepare atmosphere material: weigh aluminum chloride hexahydrate (AlCl 3 .6H 2 O) 8.5g, aluminum sulfate octadecahydrate (Al 2 (SO 4 ) 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com