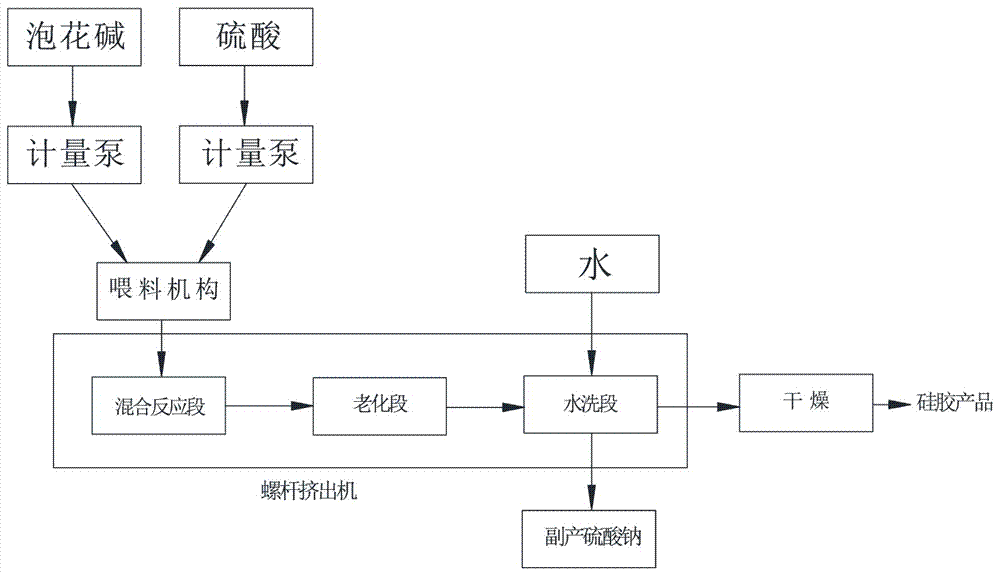

Continuous production device of amorphous silica gel and production method

A production device and amorphous technology, applied in chemical instruments and methods, silicon oxide, silicon dioxide, etc., can solve the problems of long production cycle, high energy consumption, unstable product quality, etc., to eliminate quality differences and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

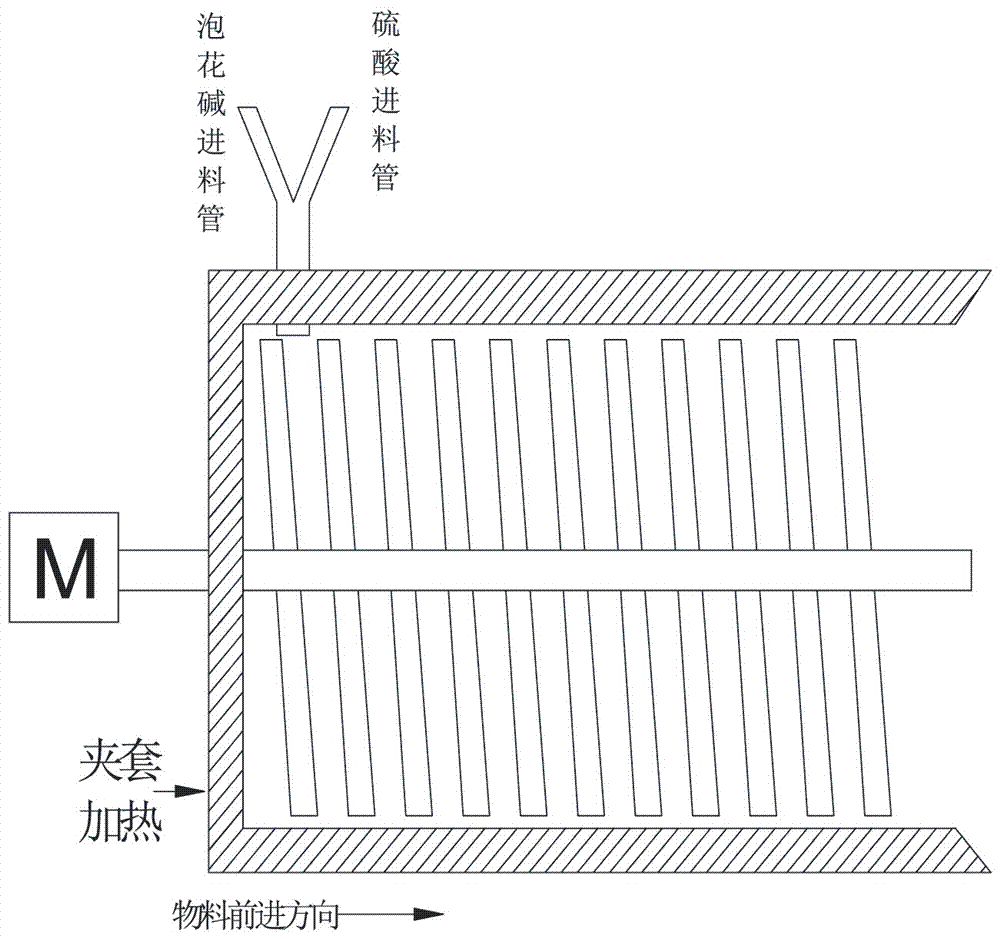

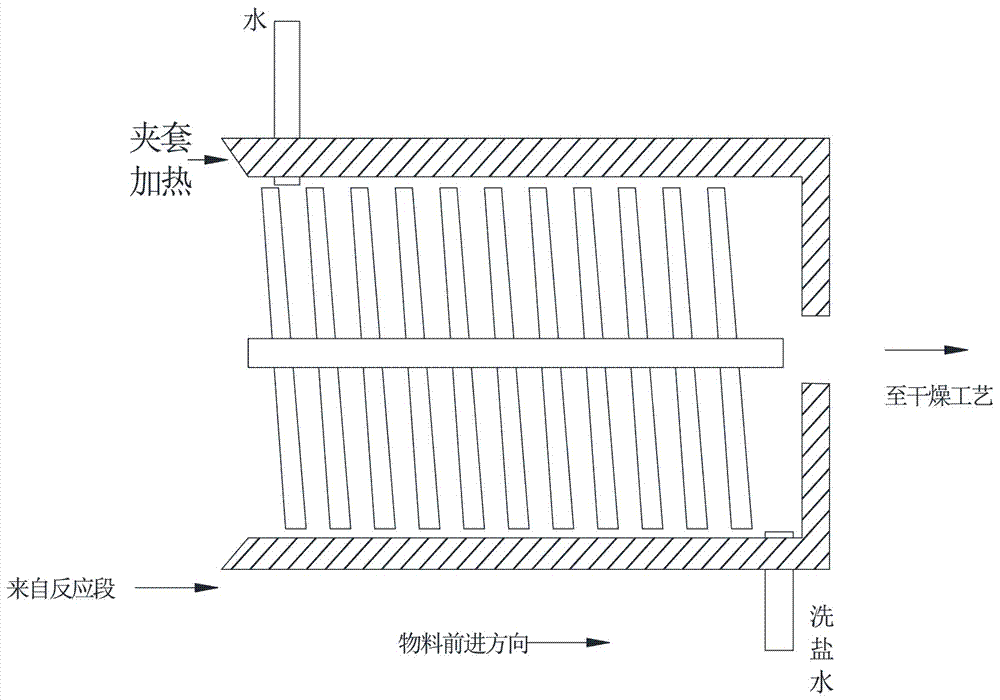

Embodiment 1

[0023] First, adjust the screw extruder according to the process requirements for the preparation of amorphous silica gel; adjust the temperature of the mixing reaction section to 30°C, the temperature of the jacket of the aging section to 90°C, and the temperature of the washing section to 60°C, and then adjust the temperature of the 8% Sodium natrium and 18% sulfuric acid are preheated to 30°C in a storage tank and then continuously added to the screw extruder at a mass ratio of 1:0.75. The screw speed is controlled at 1 R / min, and the material is kept in the mixing reaction section for 2 hours. The aging section is kept for 4 hours, and then 60°C water is added to the screw extruder to rinse the material after the material advances to the water washing section. When the sodium ion at the outlet of the rinse water is less than 50ppm, the washing is stopped, and the product extrusion end of the screw extruder The extruded product was sent to a drying room at 400°C for drying, ...

Embodiment 2

[0025] According to the process conditions of Example 1, the screw speed is adjusted to 4.5R / min, so that the material is retained in the mixing reaction section for 1h, and the aging section is reserved for 1h. When the sodium ion concentration of the washing water outlet in the washing section is less than 50ppm, the washing is suspended. All the other conditions are not changed. The pore structure of the final silica gel product is: specific surface area: 150m 2 / g; Pore volume: 0.35ml / g; Pore diameter: 5.2nm.

Embodiment 3

[0027] Set the jacket temperature of the mixing reaction section and the aging section to 90°C, adjust the temperature of the water washing section to 80°C, and then add 10% sodium bicarbonate and 22% sulfuric acid to the screw extruder continuously at a mass ratio of 1:1.5 , control the screw speed to 0.7R / min, keep the material mixing reaction section for 3h, and the aging section for 6h, and then add 80°C water to the screw extruder to rinse the material after the material advances to the water washing section, and wait for the water at the outlet When the sodium ion concentration is less than 50ppm, the product is sent to a drying room at 600°C for drying. After crushing and screening, the pore structure of the silica gel product is: specific surface area: 220m 2 / g; Pore volume: 1.47ml / g; Pore diameter: 29.8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com