Belt friction method and device for replacing silk sheath

A technology of silk sheath and special device, applied in the direction of silk reeling, etc., can solve the problems of non-uniform silk sheath structure between threads, low labor productivity, affecting the quality of raw silk, etc. The effect of batch raw silk quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

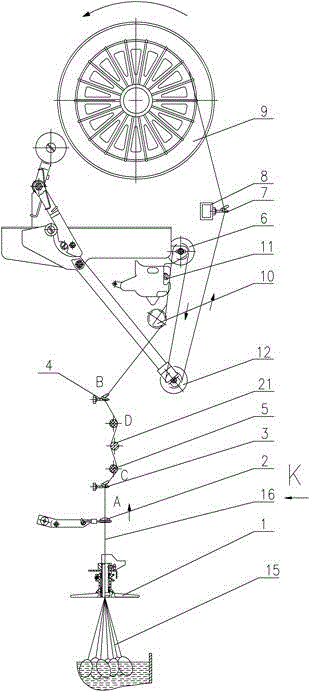

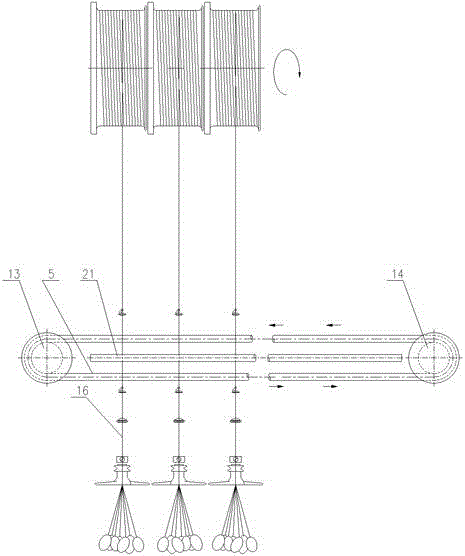

[0022] Embodiment 1: A kind of belt type rubbing method that replaces silk sheath in this example, according to raw silk specification requirements, such as figure 1 , figure 2 , image 3 A number of cocoon threads 15 are assembled into wet raw silk 16 by high-speed rotation through the jointing wing 1, and the wet raw silk 16 containing a large amount of water passes through the thread collector 2, passes through the lower guide wire hook 3 and the upper guide wire hook 4, and wraps around On the upper and lower two-layer reverse-moving transmission belt 5 that can be used to replace the silk sheath to gather cocoon silk, a pressing wire guide roller 21 is set in the middle of the upper and lower two-layer reverse-movement transmission belt, and the wet state raw silk 16 that is wound on the transmission belt Play the role of pressing and increasing the wrap angle. The wet raw silk and the transmission belt produce relative motion. When the transmission belt is driven at a...

Embodiment 2

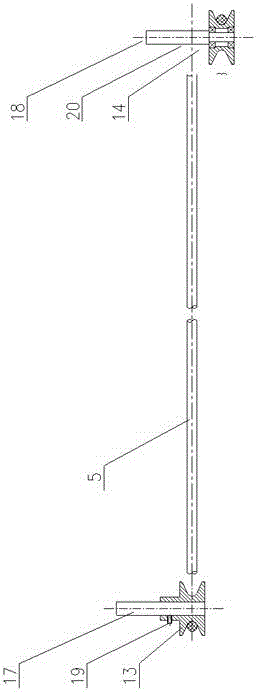

[0026] Embodiment 2: a kind of belt type friction device that replaces silk sheath of this example, as Figure 4 , Transmission belt 5 is positioned at the outside of wet state raw silk 16, and pressing guide roller is positioned at the inboard of wet state raw silk 16, and all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com