Patents

Literature

295results about "Machining working media supply/regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

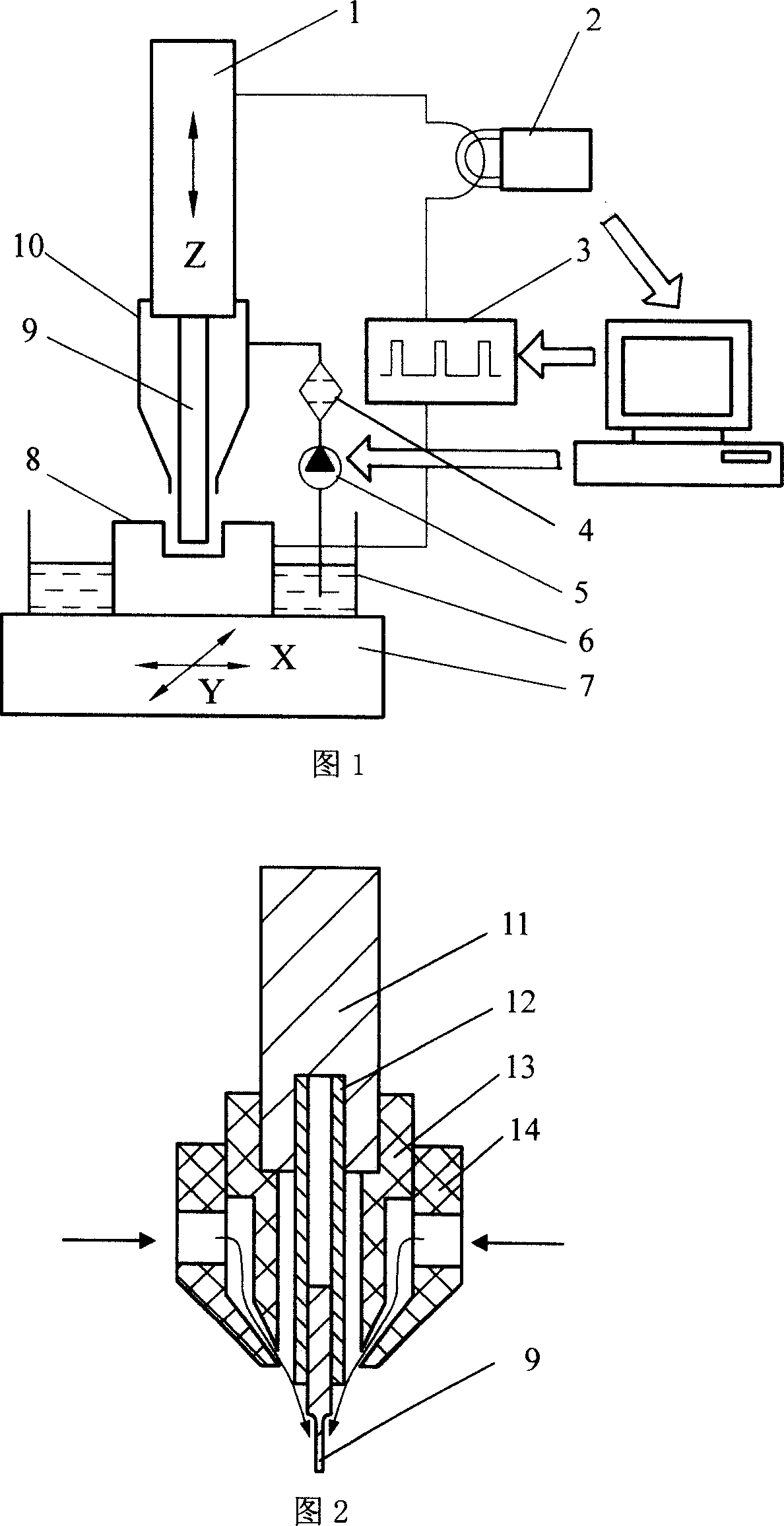

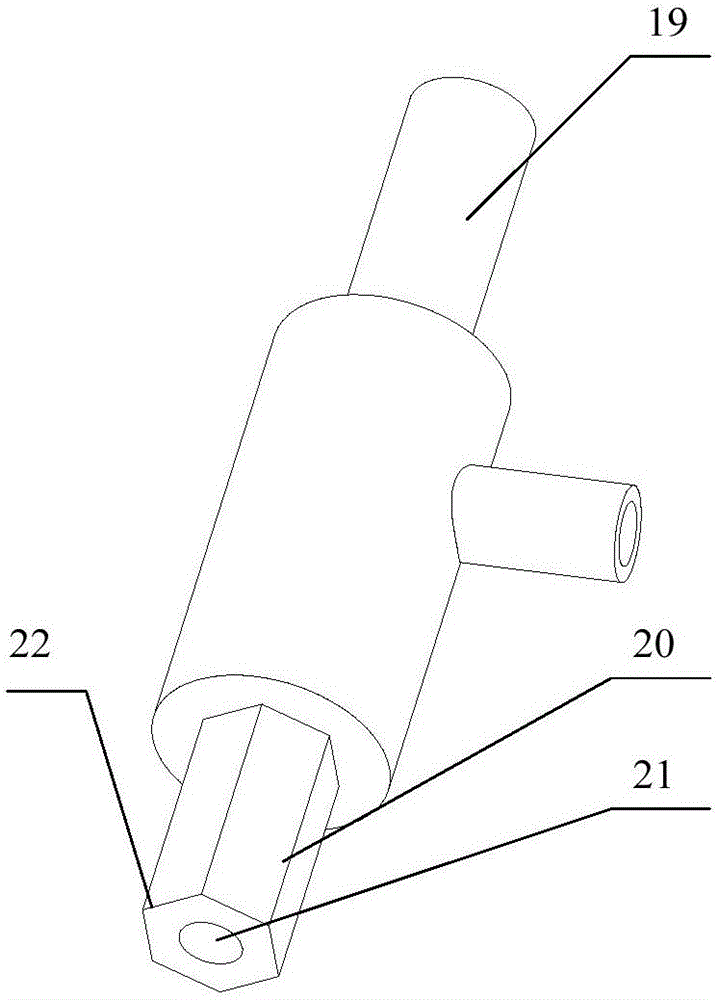

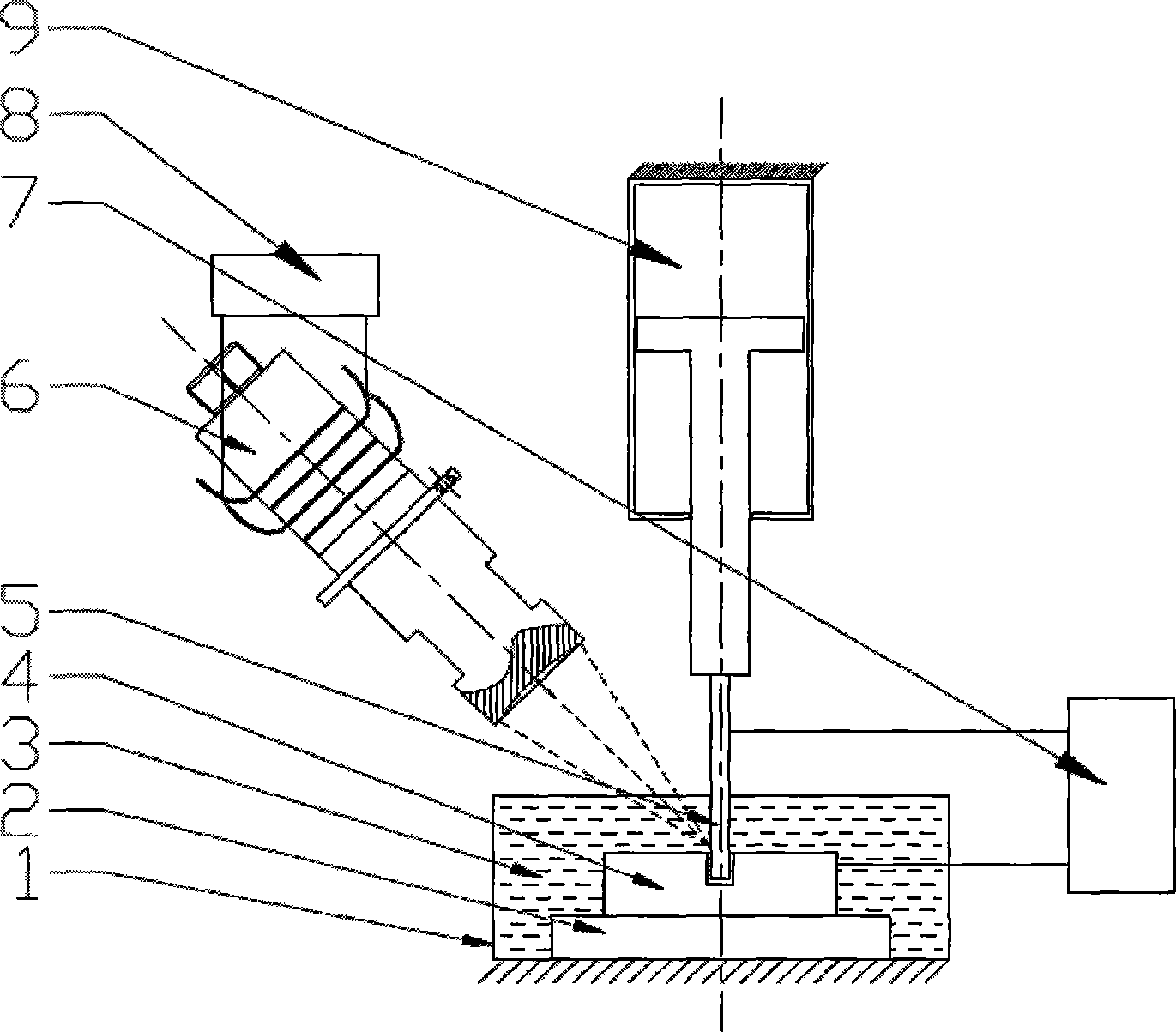

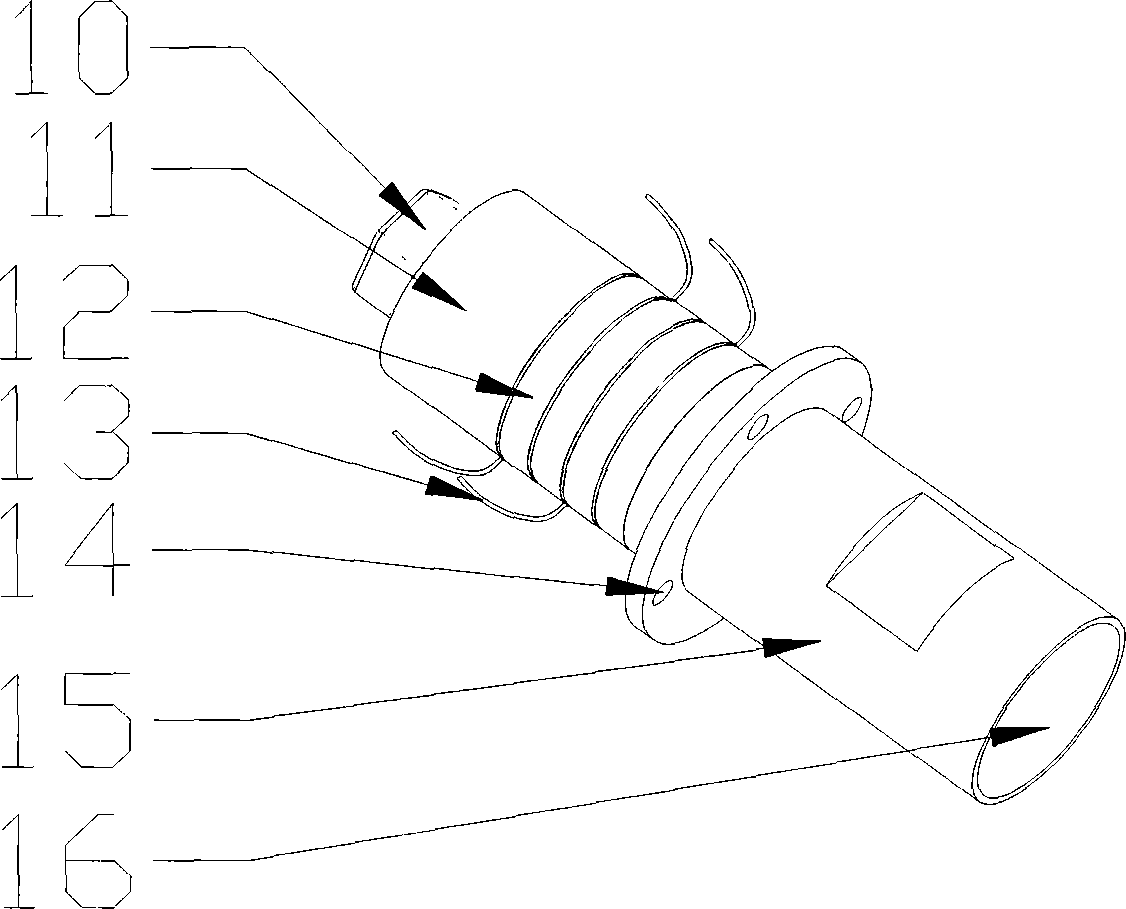

Subtly processing method of electrolyte axial flow and special electrode nozzle therefor

InactiveCN101011765AShorten the timeReduced areaMachining working media supply/regenerationElectrolysisEngineering

The invention relates to trickle electrochemical machining. The liquid level of the electrolyte cell is lower than the machining surface, extracting electrolyte form the cell using its pump, using special electrode nozzle to introduce the electrolyte flowing slowly to the machining area along the radial of the tool electrode and finally returning back to the electrolyte cell from the machining area. The special electrode is made of nozzle clamper, electrode annular tube, nozzle liner and nozzle bushing. It can improve the machining stability, machining precision and micro degree.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

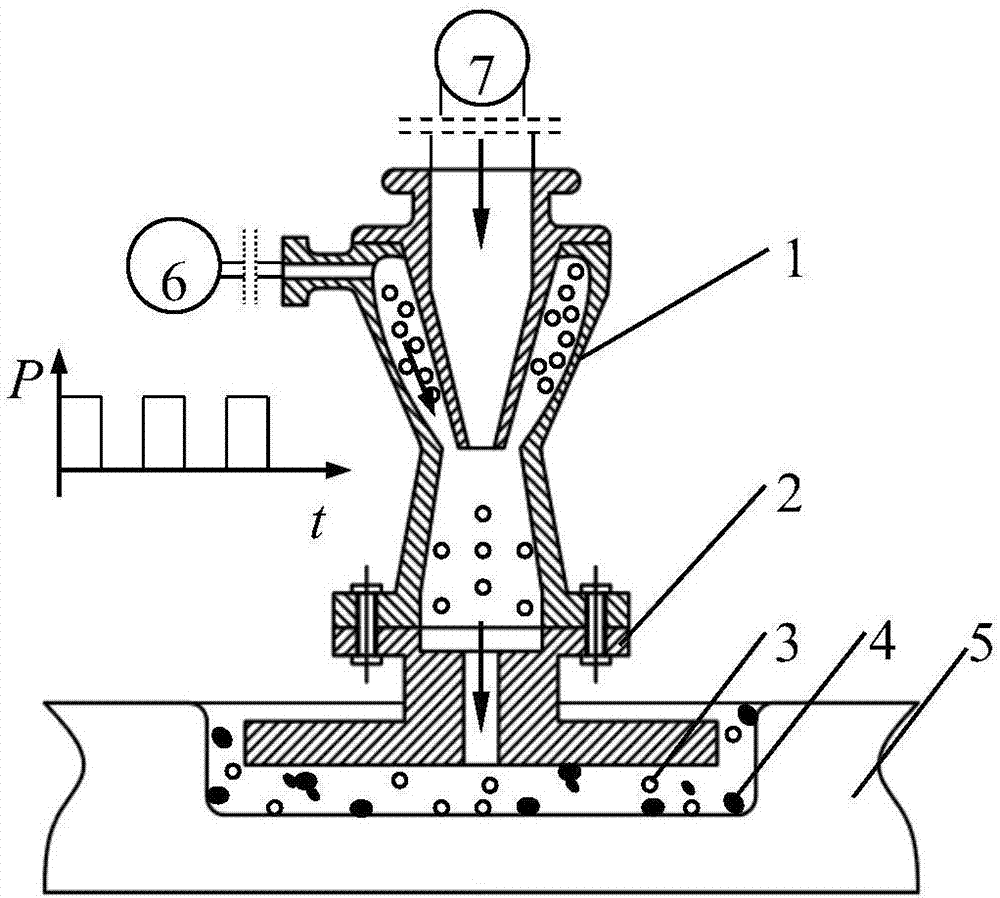

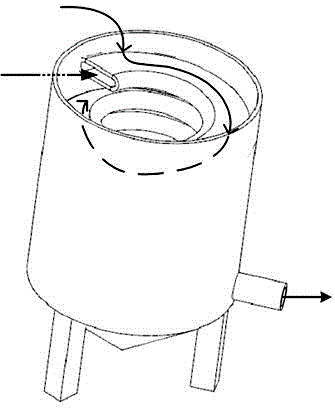

Microscale pulse electrolysis jet processing system and processing method thereof

InactiveCN101633065AEffective filteringEliminate pulsationMachining working media supply/regenerationNumerical controlElectrolysis

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

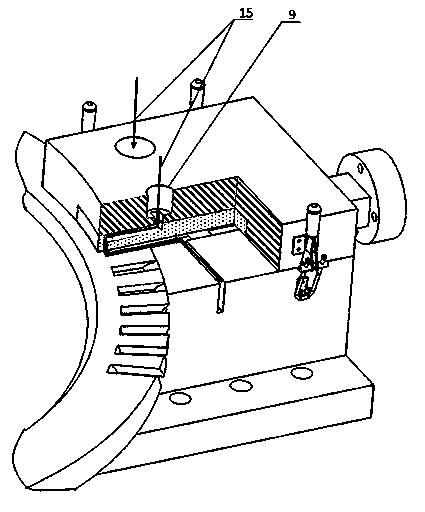

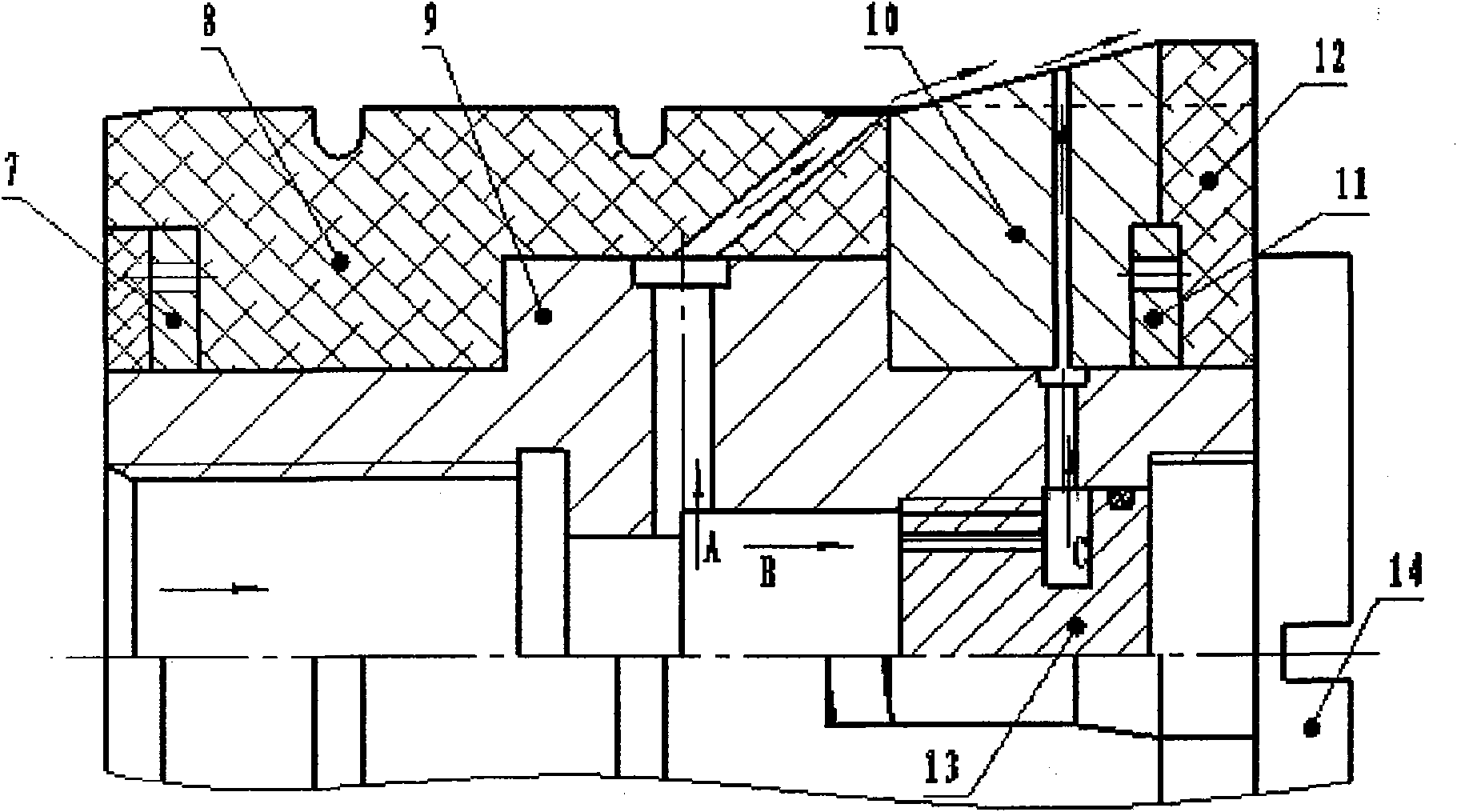

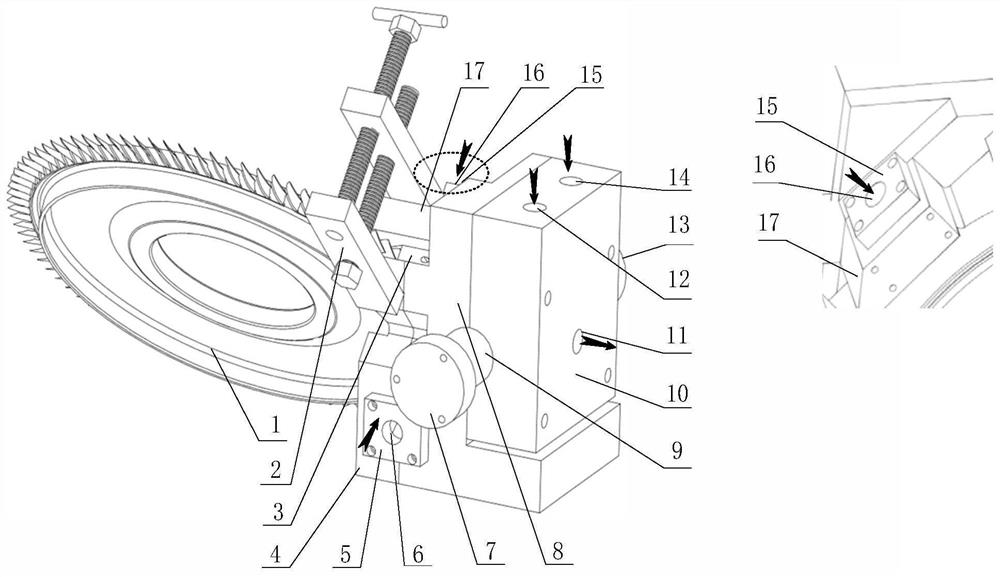

Dynamic auxiliary electrolyte feeding clamp and electrolyte feeding way for electrolytic machining of vane cascade channel of blisk

ActiveCN104001996AMachining working media supply/regenerationElectrical-based auxillary apparatusElectrolysisEngineering

The invention relates to a dynamic auxiliary electrolyte feeding clamp and an electrolyte feeding way for electrolytic machining of a vane cascade channel of a blisk, which belong to the field of electrolytic machining. A clamp body comprises a main electrolyte inlet (8) and an auxiliary electrolyte inlet (9), wherein a first path of electrolyte flows from the main electrolyte inlet (8) to a first side face (18) of a tool cathode, and then enters from the side face to a machining clearance on a front end face (20) of the tool cathode; a second path of electrolyte enters from the auxiliary electrolyte inlet (9) to a supplementary electrolyte elongated slot (12) on following supplementary electrolyte, enters from the supplementary electrolyte elongated slot (12) to an outlet of the following supplementary electrolyte, and then enters the machining clearance on the front end face (20) of the tool cathode; the two paths of electrolytes are intersected at the machining clearance on the front end face (20) of the tool cathode; the electrolytes after intersection flow to a second side face (16) of the tool cathode, and then pass by a root portion (17) of the tool cathode, and flow out of an electrolyte outlet (13) of a clamp base. According to the dynamic auxiliary electrolyte feeding clamp and the electrolyte feeding way disclosed by the invention, a flow field of the machined electrolytes is improved, and a machining stability is enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

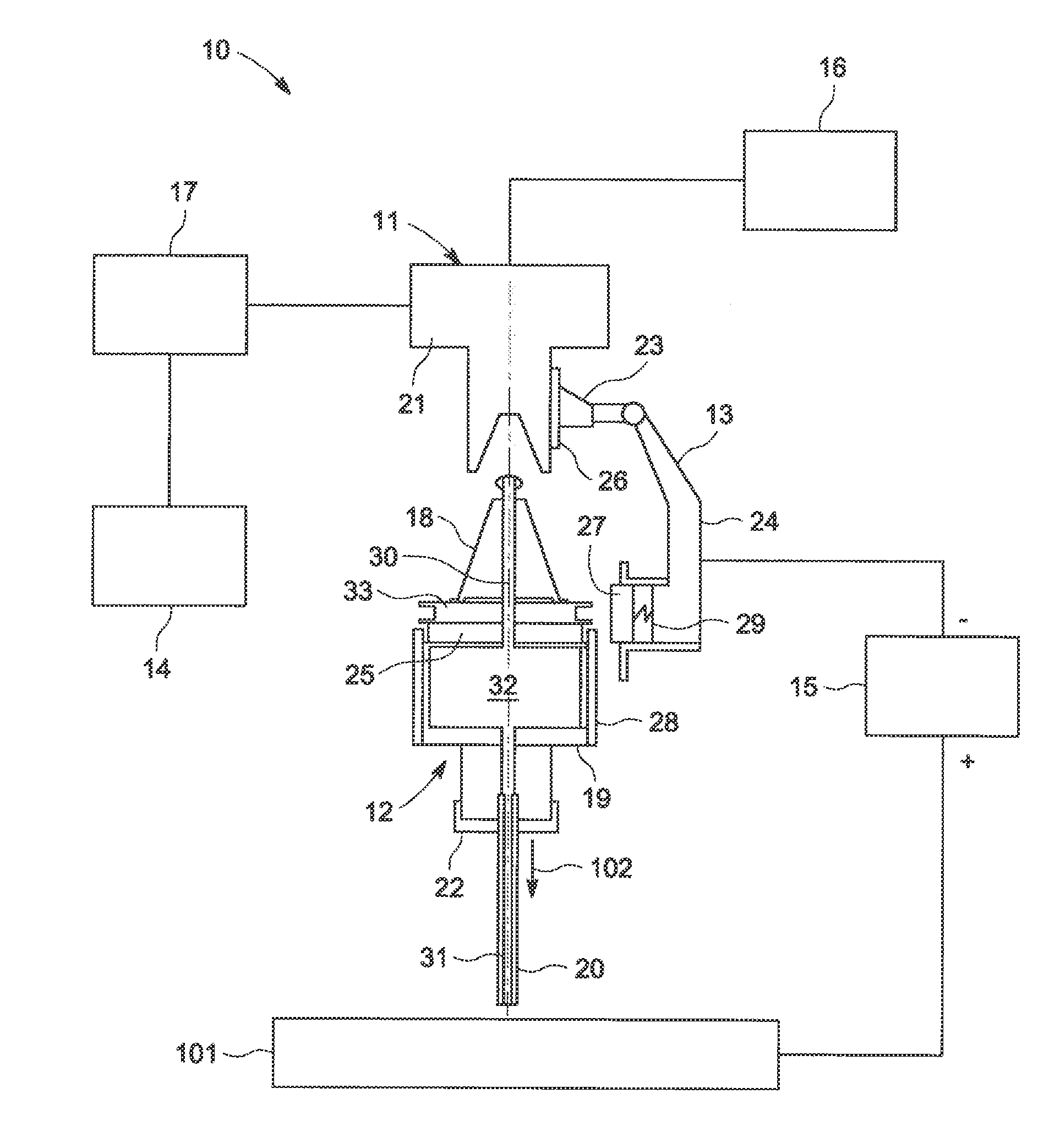

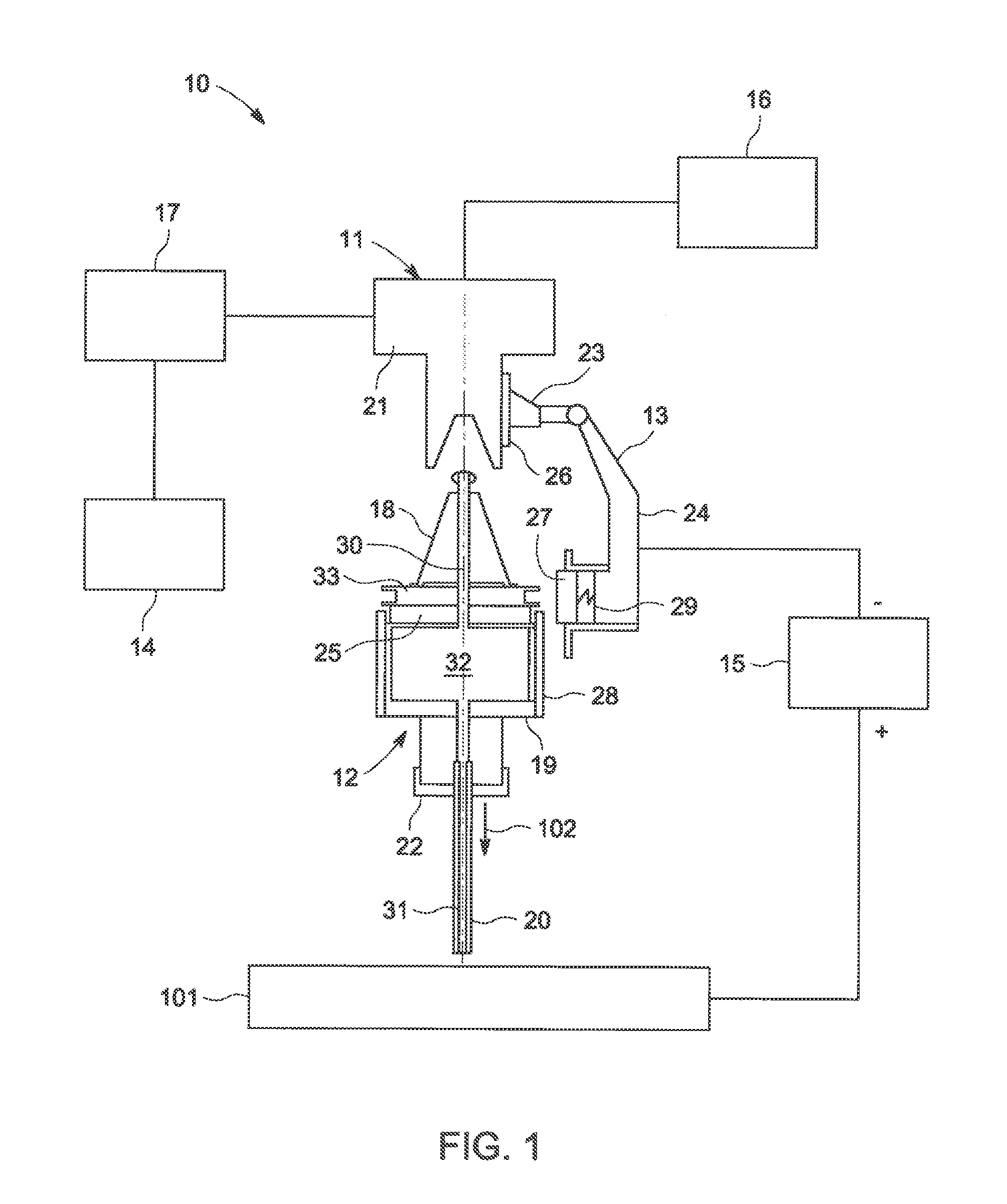

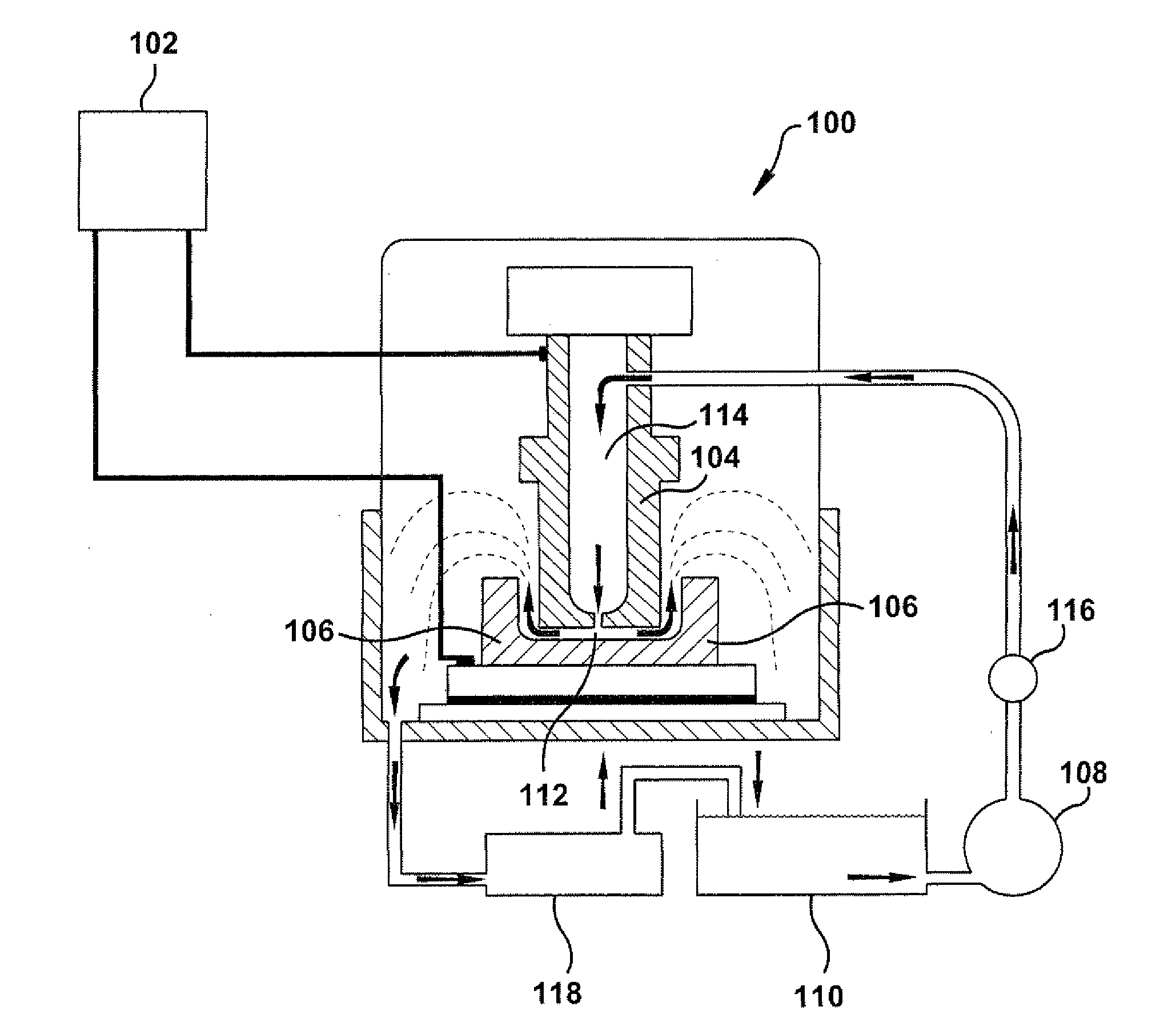

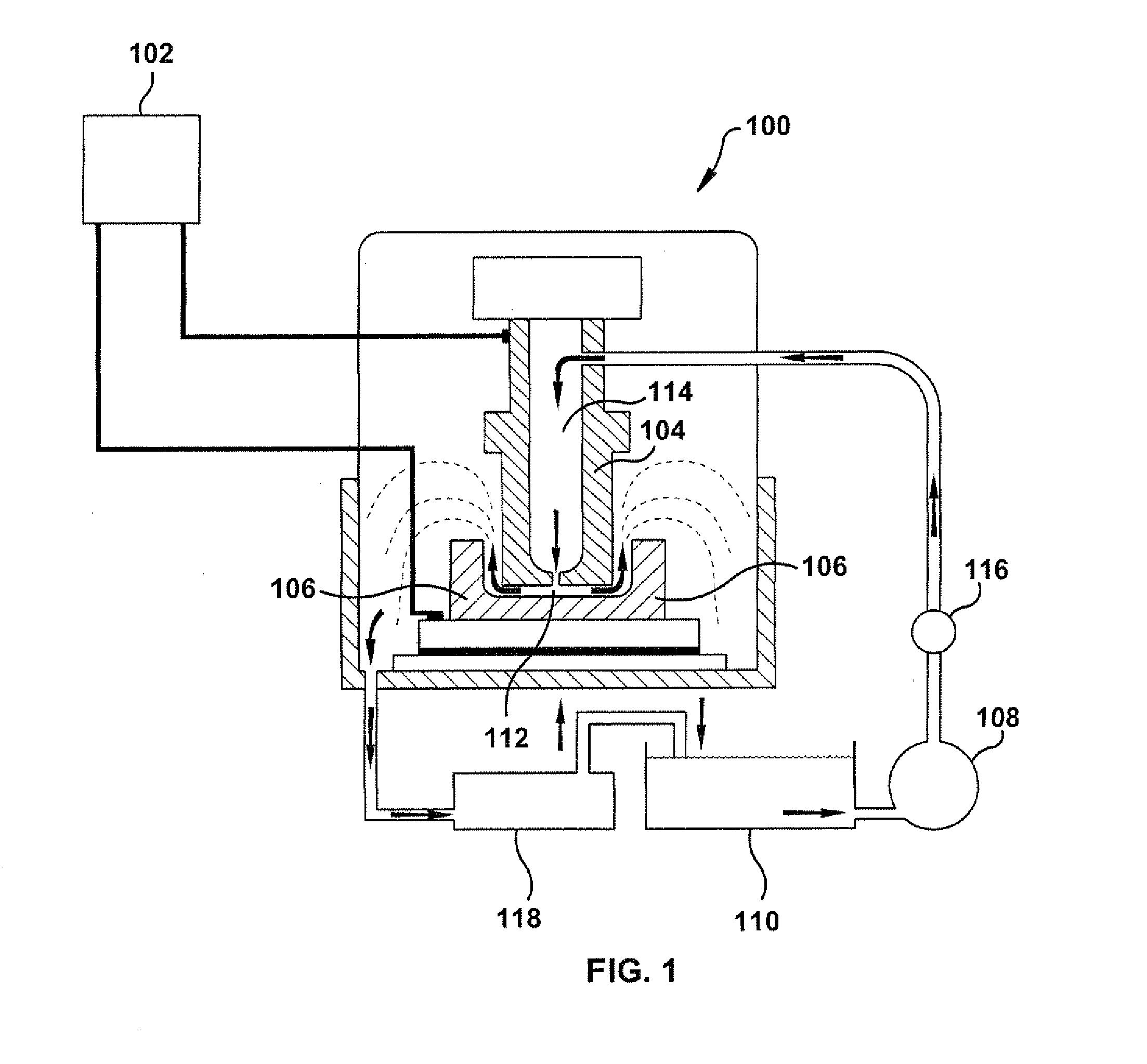

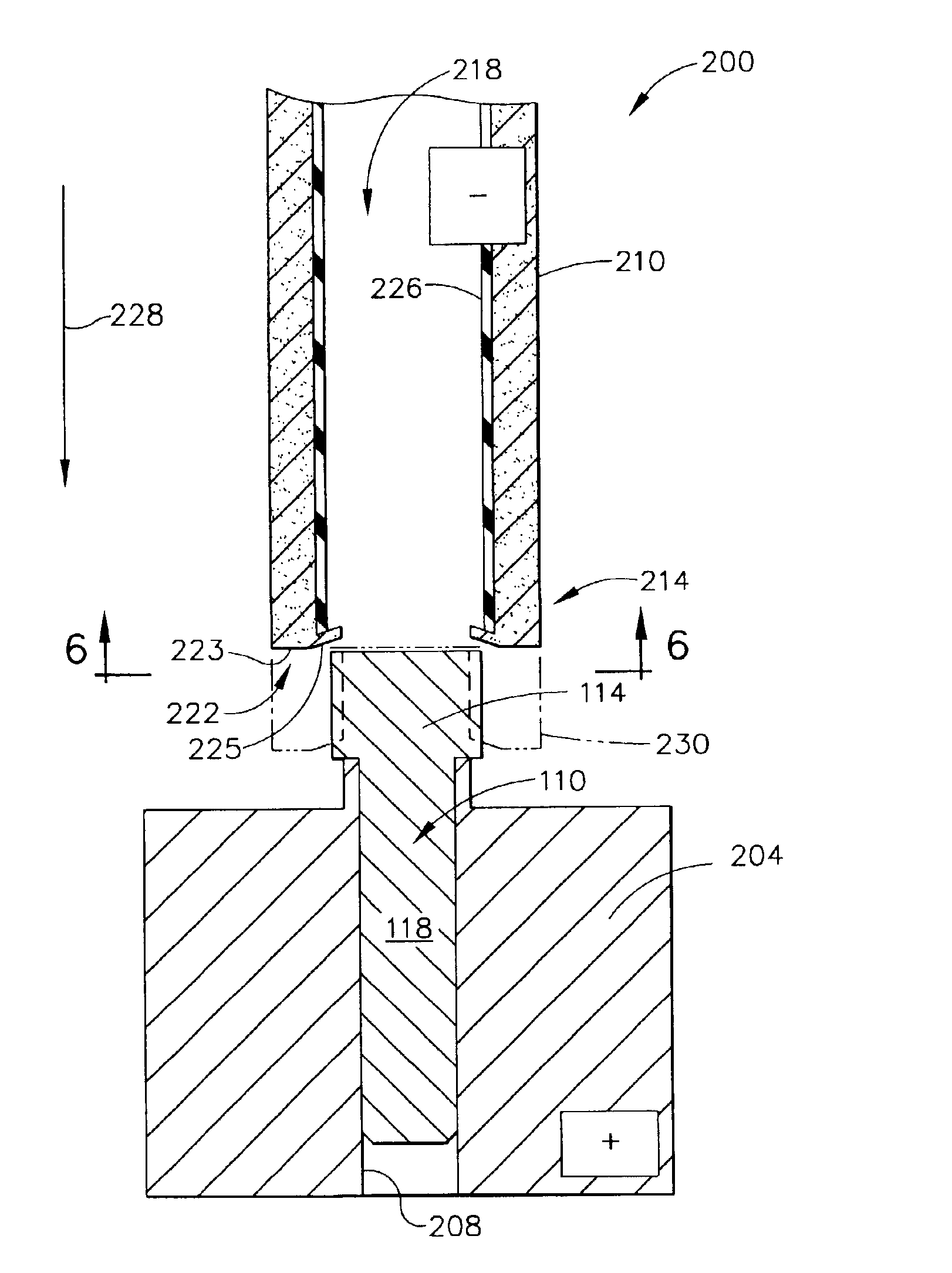

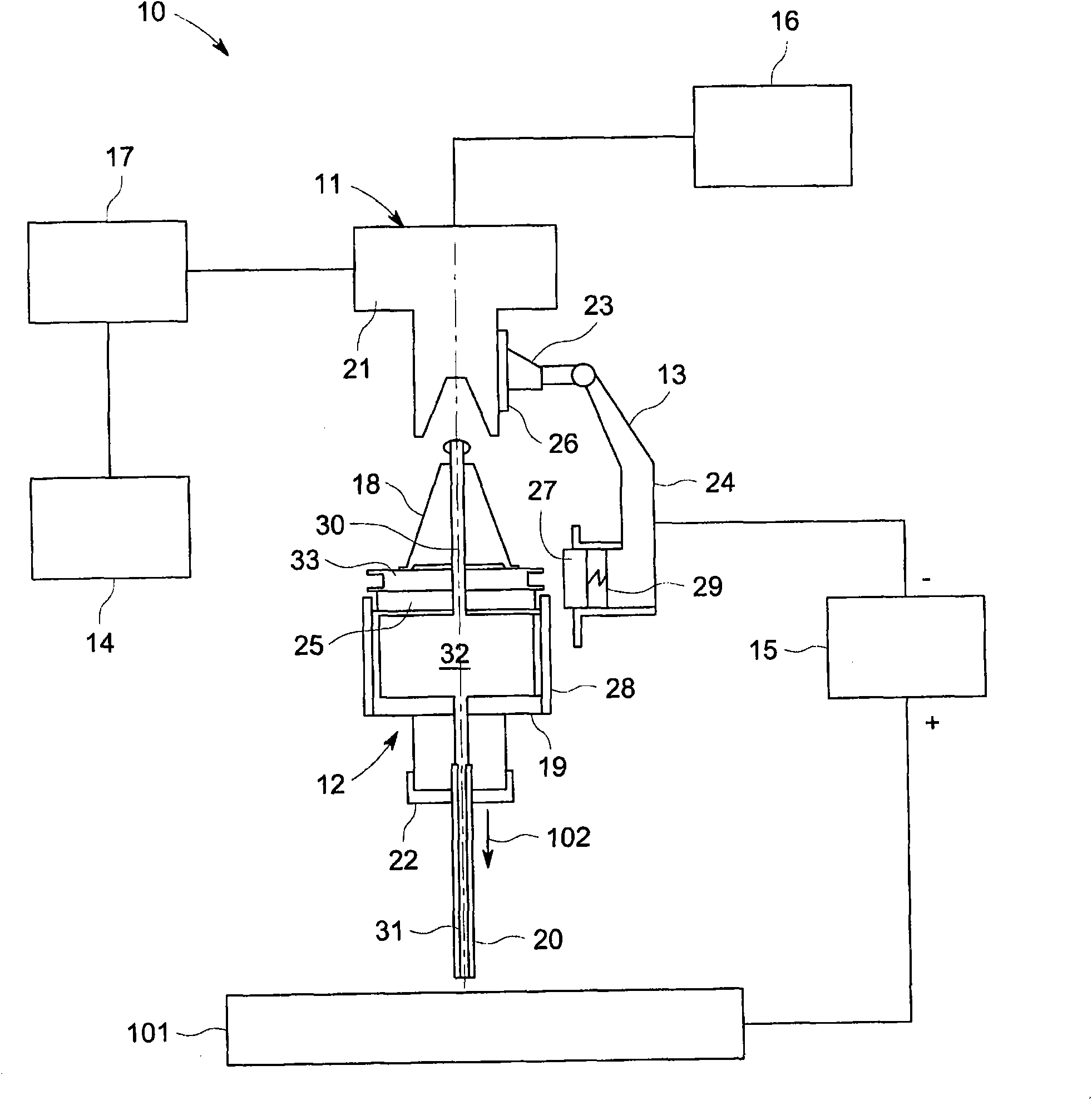

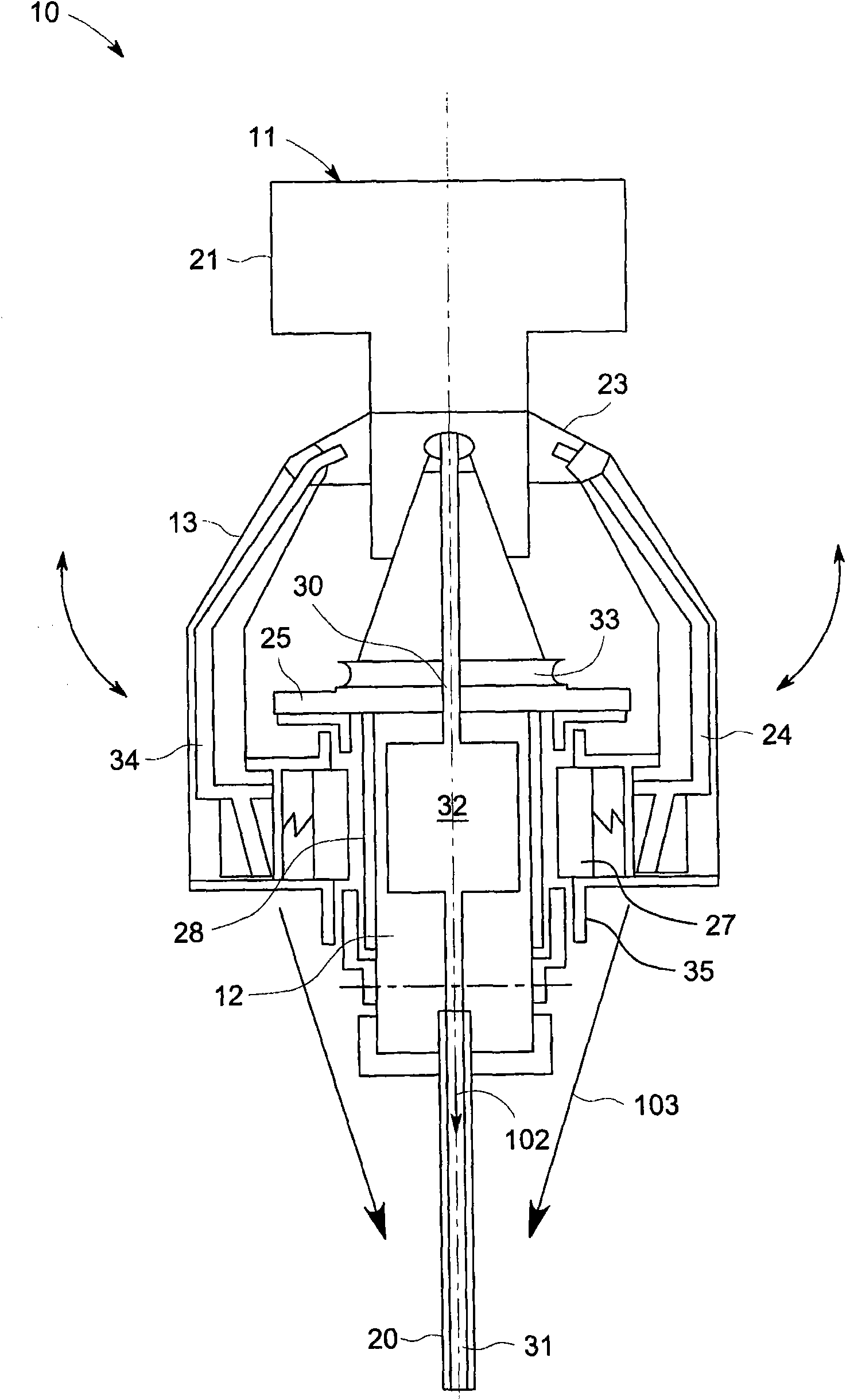

Tool adapter assembly and machining system

A machining system is provided and includes a machining tool comprising a spindle, one or more electrodes configured to perform the electromachining, and one or more tool holding elements configure to conductively hold the respective one or more electrodes and be assembled onto the spindle of the machining tool. The machining system further comprises one or more adapters and one or more power sources configured to electrically connect to the respective one or more adapters and the workpiece. The one or more adapters are configured to conductively contact the respective one or more tool holding elements. Further, the machining system comprises one or more machining solution sources provided to pass one or more machining solutions between the workpiece and the respective one or more electrodes. A tool adapter assembly is also presented.

Owner:GENERAL ELECTRIC CO

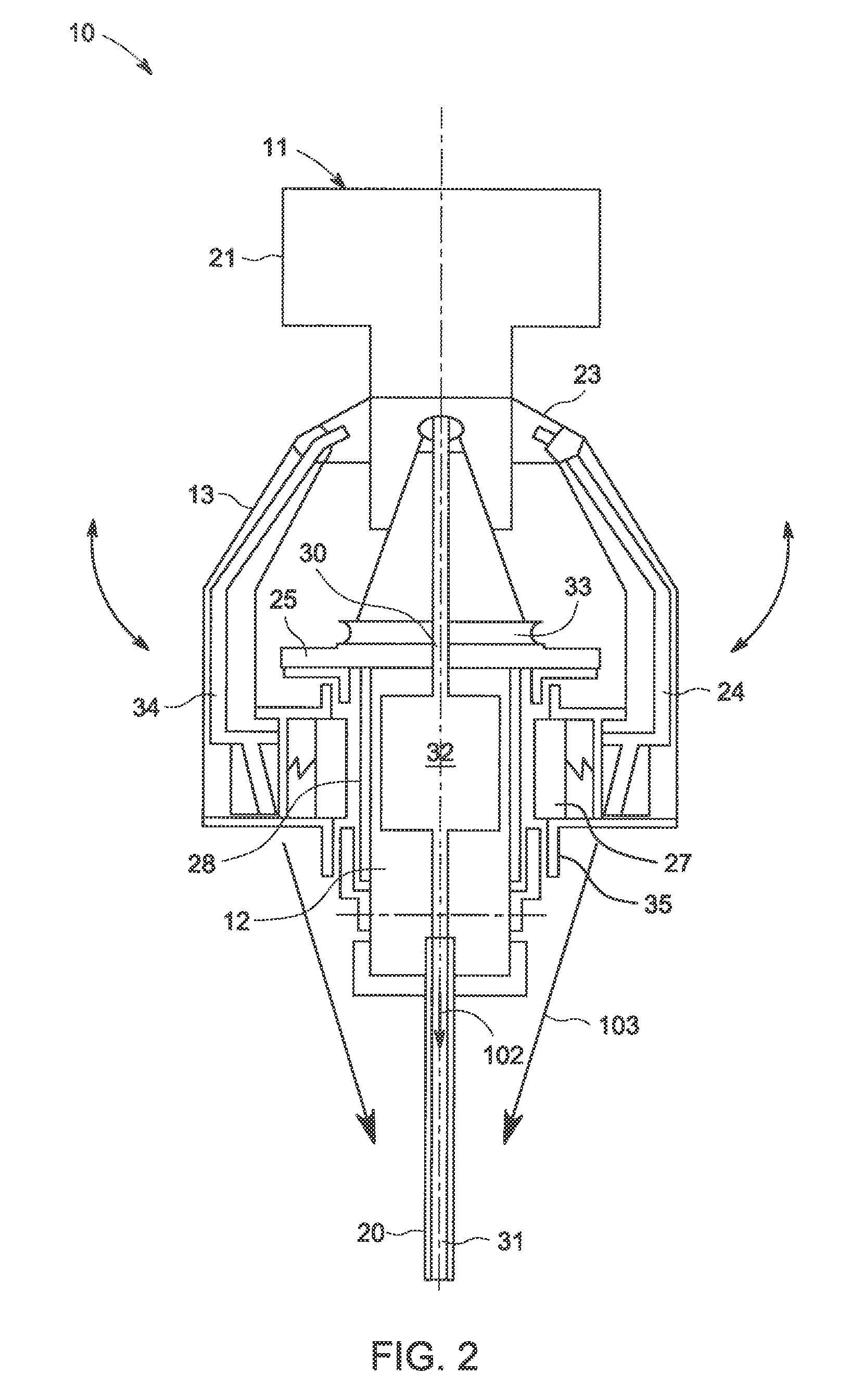

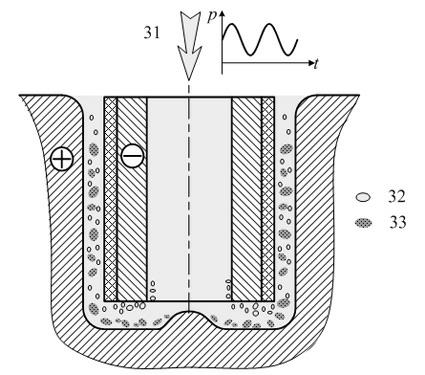

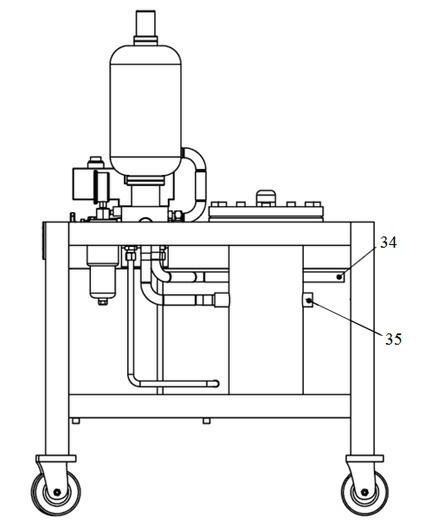

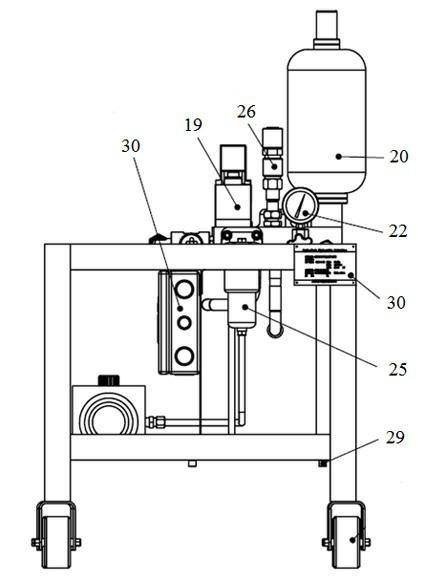

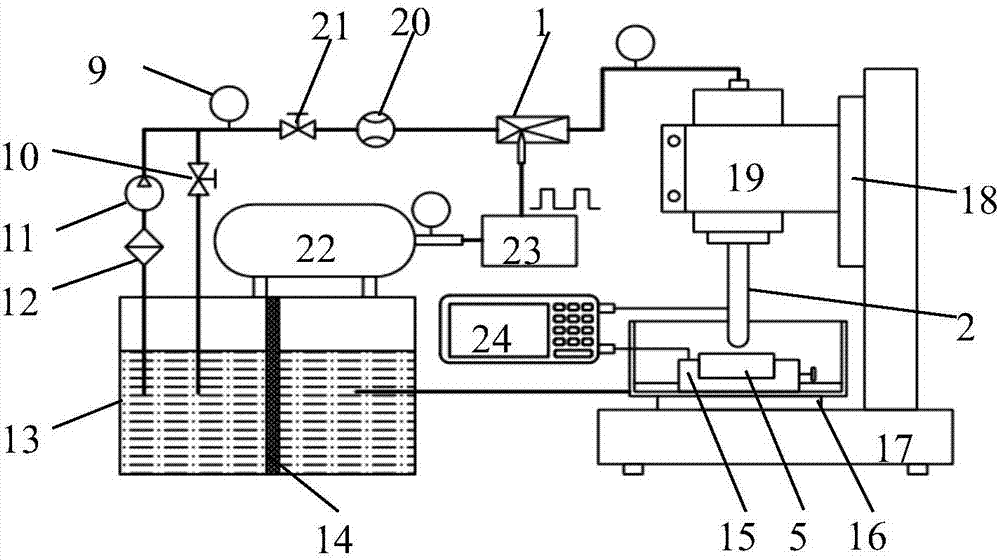

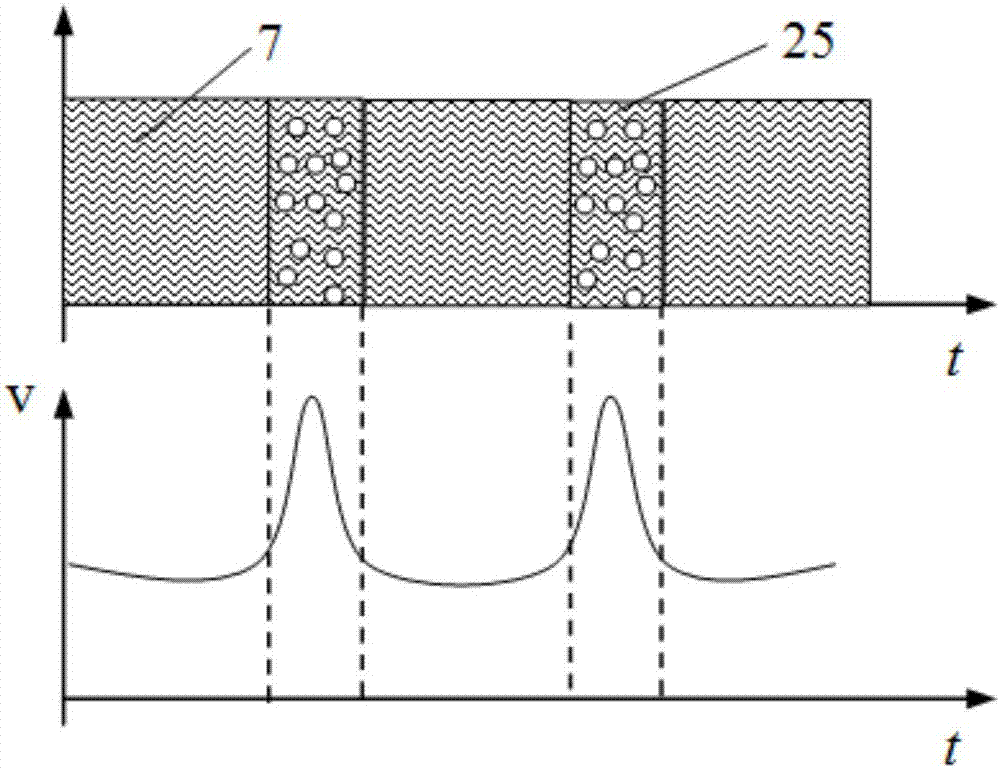

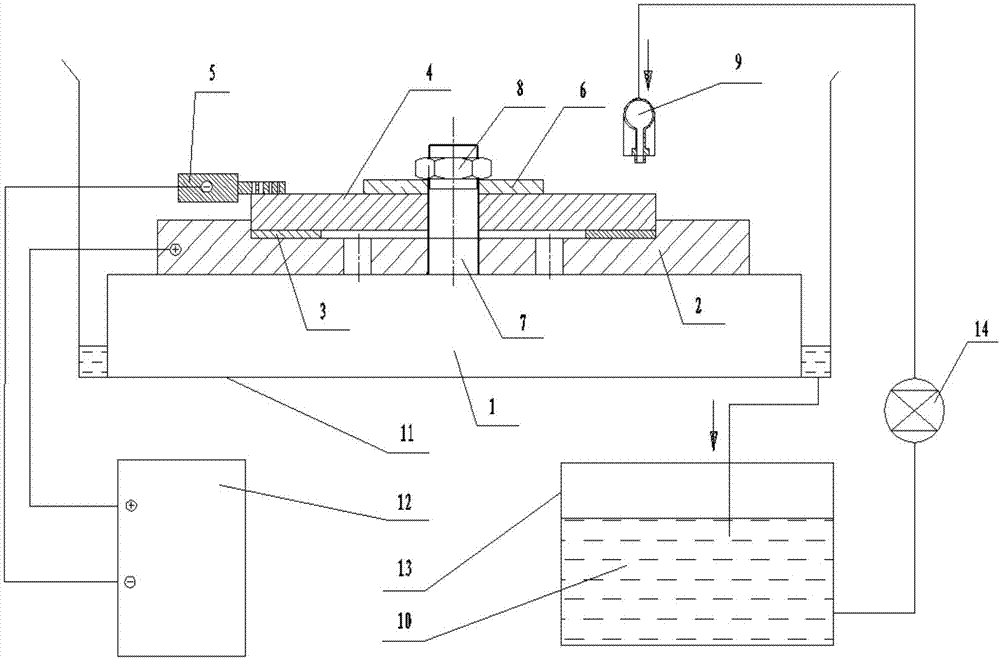

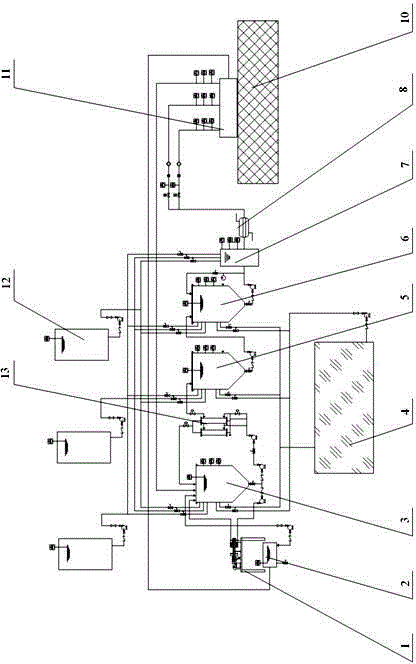

Electrochemical machining method and device for pulsating flow field tube electrode

ActiveCN102198549AReduce the "holding effect"Reduce the "squeeze effect"Machining working media supply/regenerationVoltage pulseElectrolysis

The invention relates to an electrochemical machining method and an electrochemical machining device for a pulsating flow field tube electrode, and belongs to the technical field of electrochemical machining. The method comprises the following steps of: 1, adjusting the flow and the pressure by controlling an action of a spool of a servo valve (9) by a pressure servo execution module (4), and outputting a pulsating electrolyte solution to an electrochemical machining area; 2, modulating a control instruction phase by using a control system of an electrochemical machining machine tool according to a pressure and voltage feedback signal, so that the pressure of the machining area is matched with the voltage pulse rhythm; and 3, dynamically adjusting a feeding speed and the machining voltage by using the control system of the electrochemical machining machine tool so as to machine a hole with a variable section in regular change. The method and the device provided by the invention have important meaning for increasing the flocculent product discharge rate and the machining stability of the electrochemical machining of a neutral saline solution deep hole tube electrode.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

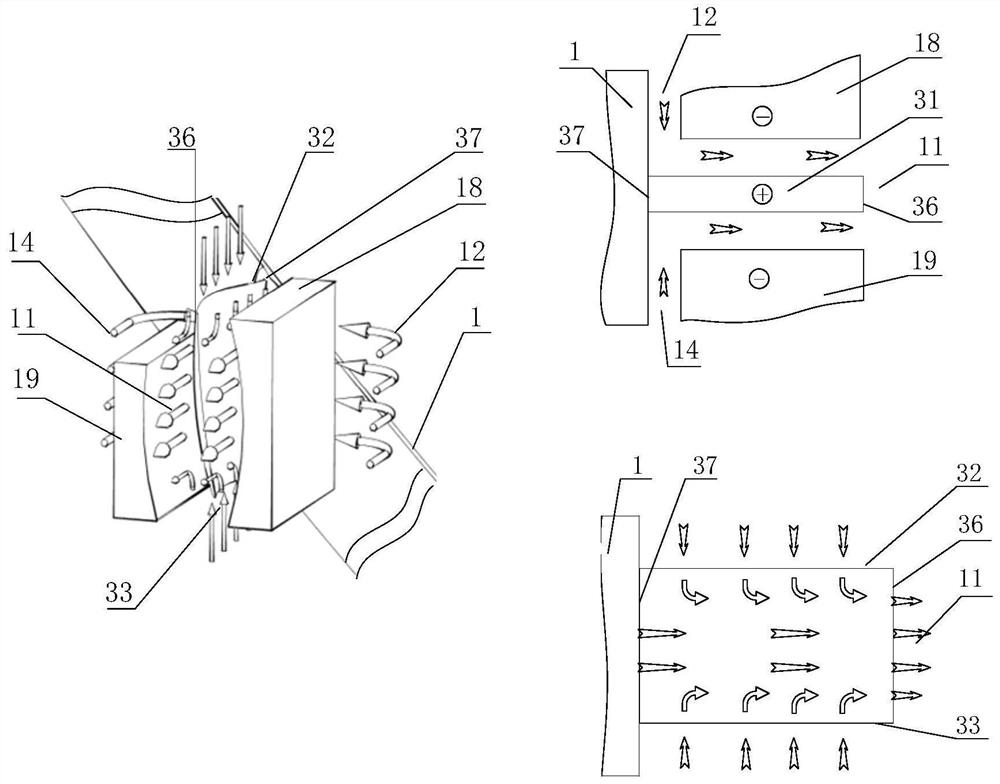

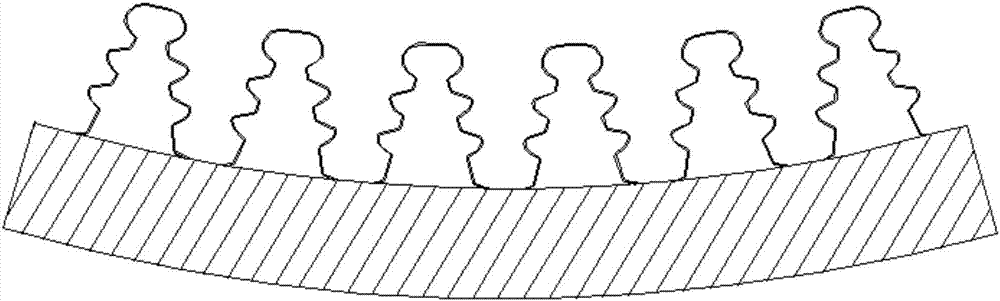

Method, apparatus and system for flexible electrochemical processing

Conventional electrochemical machining process requires fixed shaped tool cathodes, which makes retooling time consuming and expensive. Flexible tool cathodes include elastically deformable cathodes that can deform in two or three dimensions and can adapt to the contour of the workpiece while the workpiece is moving relative to the flexible tool cathode. That is, the flexible tool cathode can perform tracing. Certain flexible tool cathodes can be also used for special configurations such corners and edges. The flexible tool cathodes can be used to polish, finish, or shape the workpiece through electrochemical processes.

Owner:GENERAL ELECTRIC CO

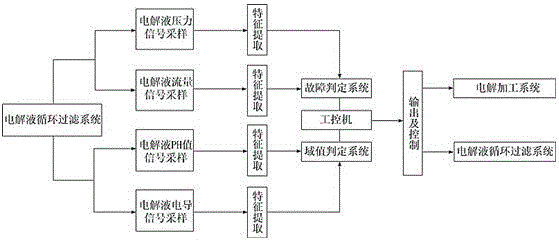

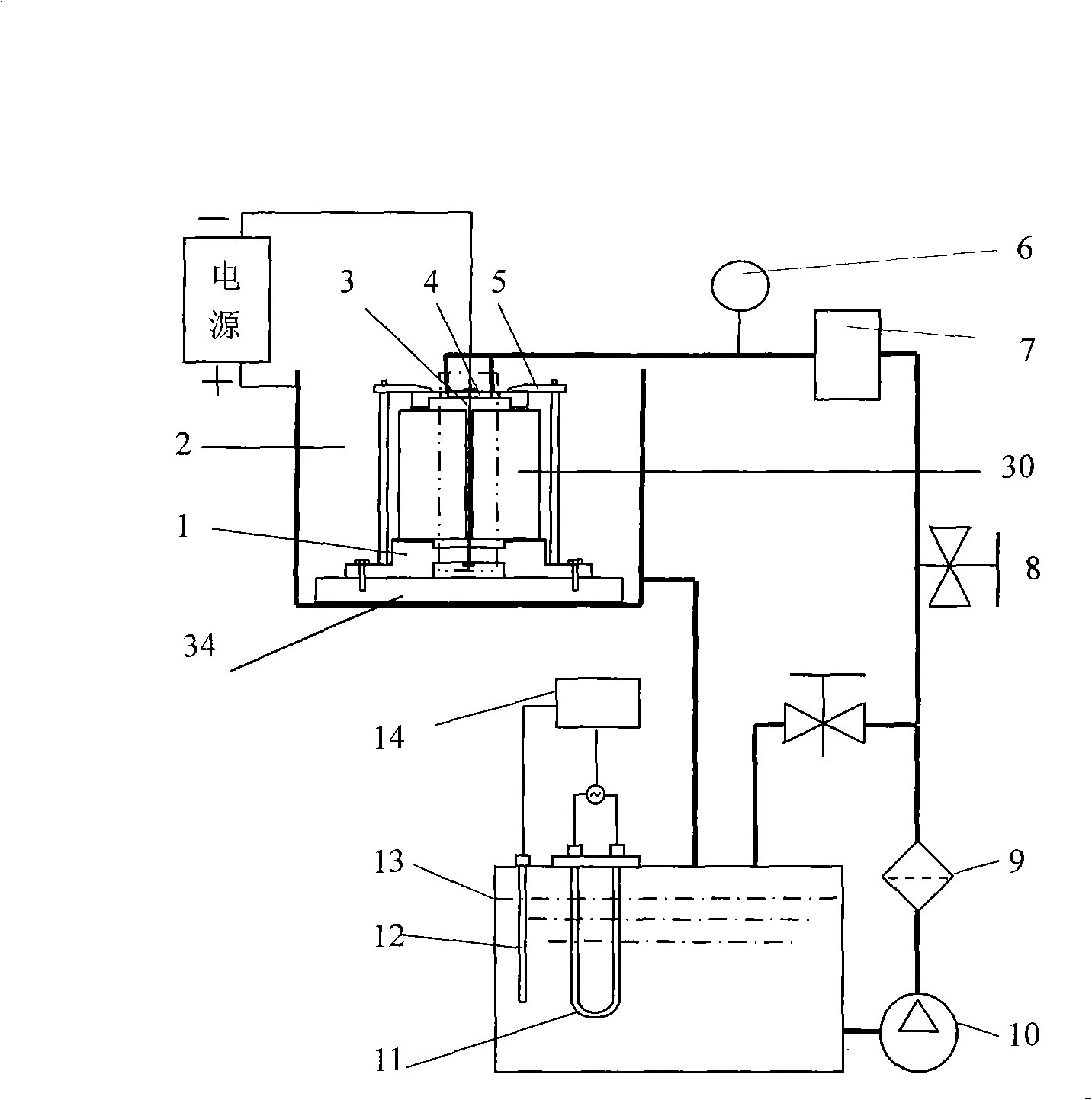

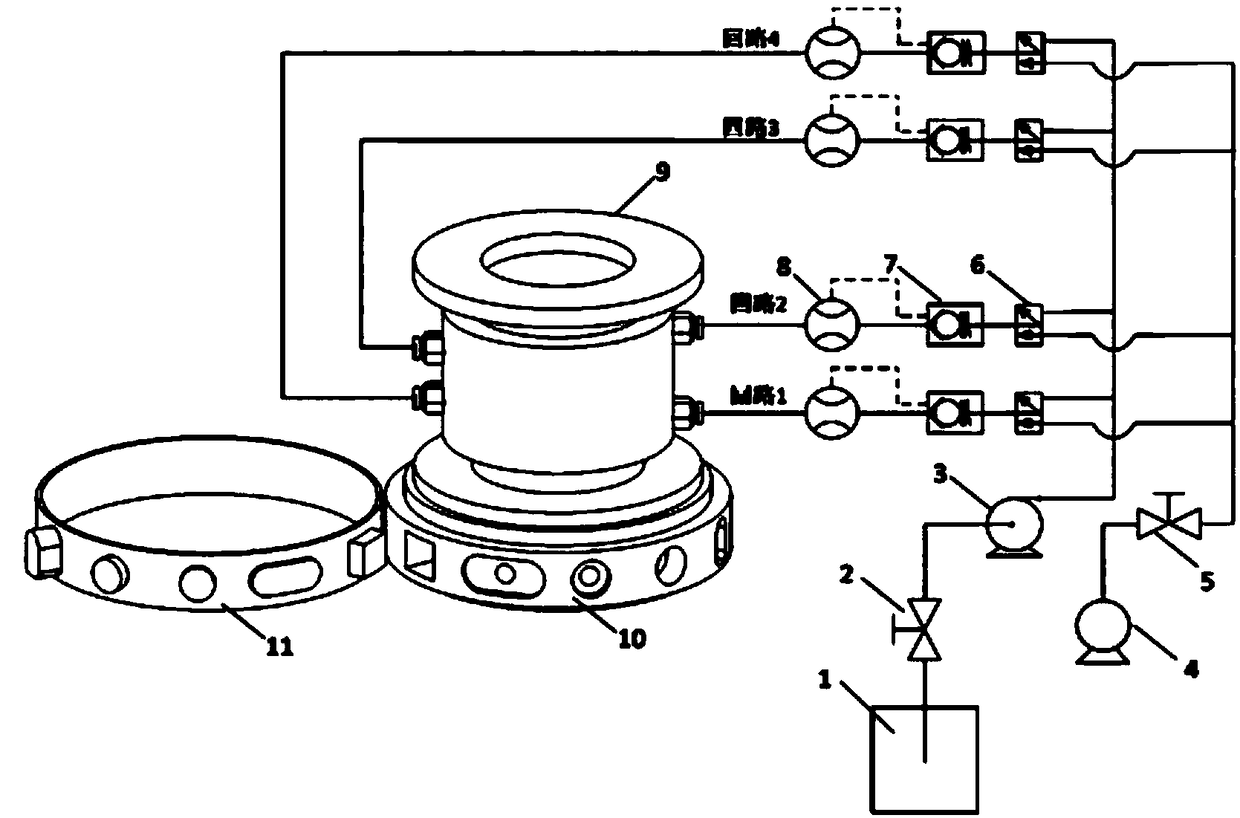

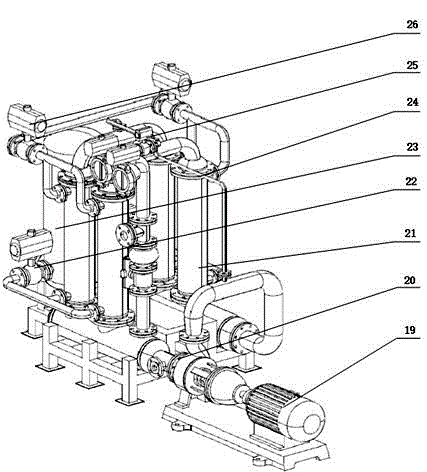

Circulating filtration system for electrochemical machining electrolyte and control method thereof

InactiveCN102873418AImprove cleanlinessImprove operational reliabilityMachining electric circuitsMachining working media supply/regenerationElectrolytic agentSolenoid valve

The invention discloses a circulating filtration system for electrochemical machining electrolyte and a control method thereof, and belongs to the technical field of electrochemical machining. The circulating filtration system for the electrochemical machining electrolyte comprises an electrolyte tank, an electrolyte circulating device, an electrolyte filtering device, an electrolyte filtering and monitoring device and an electrolyte component control device. According to the circulating filtration system for the electrochemical machining electrolyte, which is disclosed by the invention, two loops are connected in parallel to filter the electrolyte, the electrolyte input to a processing area has a high cleanliness; the electrolyte filtering and monitoring device is adopted to monitor a secondary filter and a plate-and-frame filter press in real time; in an electrolysis processing process, the circulating filtration system for the electrolyte has a high reliability; the electrolyte component control device is used for monitoring the pH (potential of hydrogen) value and the conductivity of the electrolyte in real time; and an industrial personal computer controls a liquid regulation tank to correspond to the on and off of a solenoid valve so as to guarantee the stability of the pH value and the conductivity of the electrolyte in the electrolysis processing process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

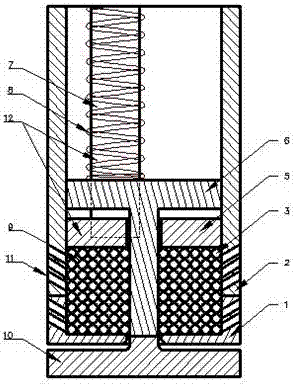

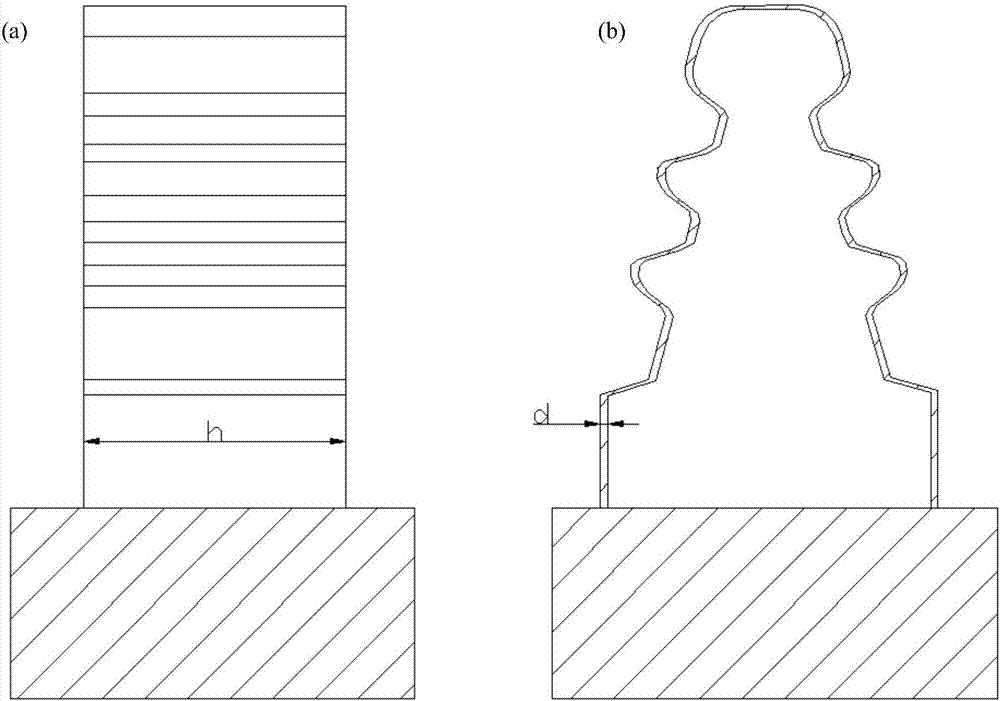

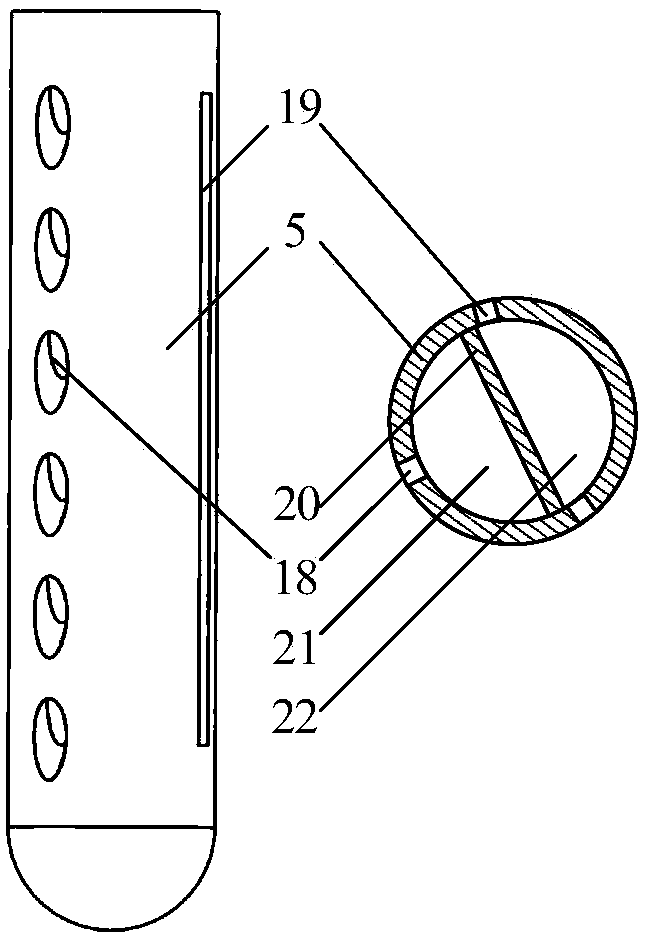

Electrolytic machining technique and device for small bore diameter inner wall surface fine groove

InactiveCN101259549AFast curingImprove curing effectMachining electrodesMachining working mediaElectrolysisEngineering

The invention discloses an electrolytic machining technique of a micro-groove on an inner wall surface of a small aperture and a device. The technique is that: a cathode of a forming tool of a variable cross-section structure which is provided with insulation sections and conductive sections at intervals and is made of conductive metal wires of 200 to 1000 mum is positioned in an unthreaded hole of a workpiece which is processed in advance by utilizing the electrolytic machining device of the invention, the workpiece is taken as an anode, then electrolytic solution is radially flowed along an electrode wire, the electrolytic machining is carried out in the unthreaded hole, the pressure of the electrolytic solution is maintained at 1 to 5 MPa, and the micro-groove structure is obtained at the inner wall surface of the unthreaded hole by flushing the products after the processing. The diameter size of the cathode of the forming tool which is prepared by adopting the ultra-violet light masking solidification technology and the electroforming process can be as small as a few hundred microns, and a rib cooling hole structure with the hole diameter size of about 1mm can be obtained by combining the electrolytic machining technique. The adopted technical process of the invention is easy to master and has small investment, the minimal hole diameter which can be processed is small, and the processing precision is high.

Owner:ZHEJIANG UNIV OF TECH

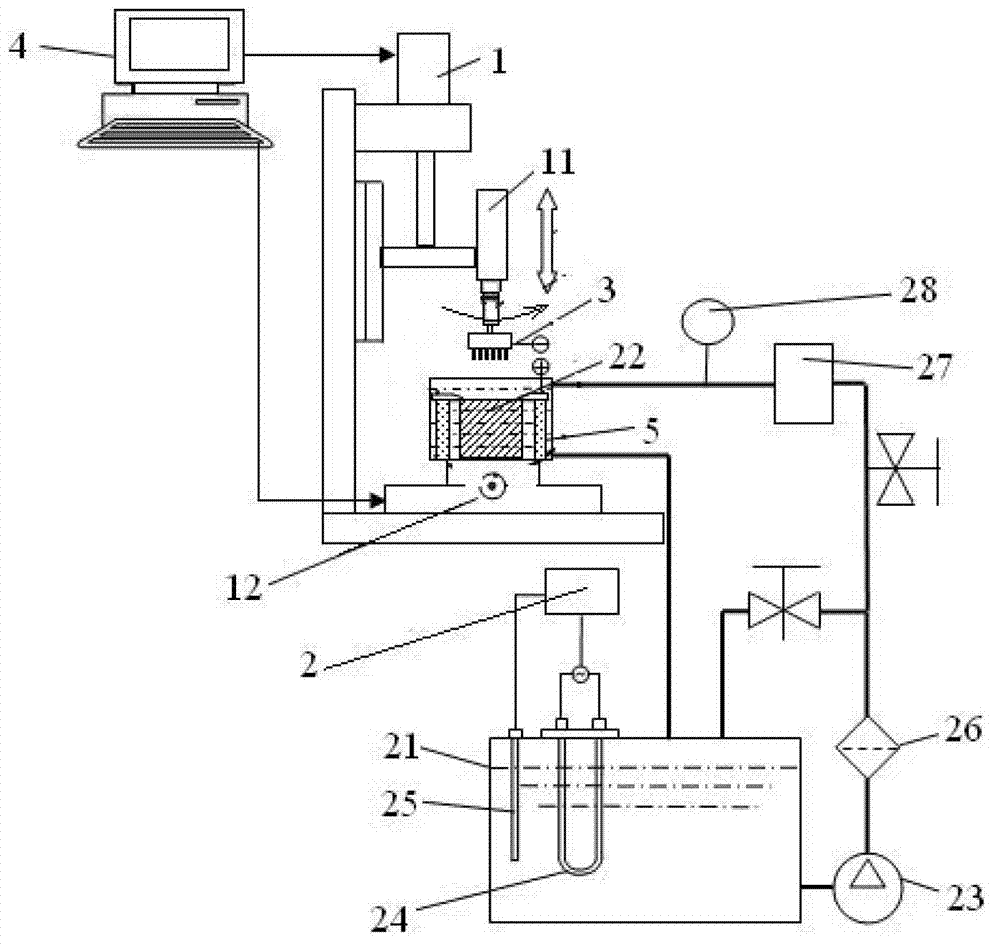

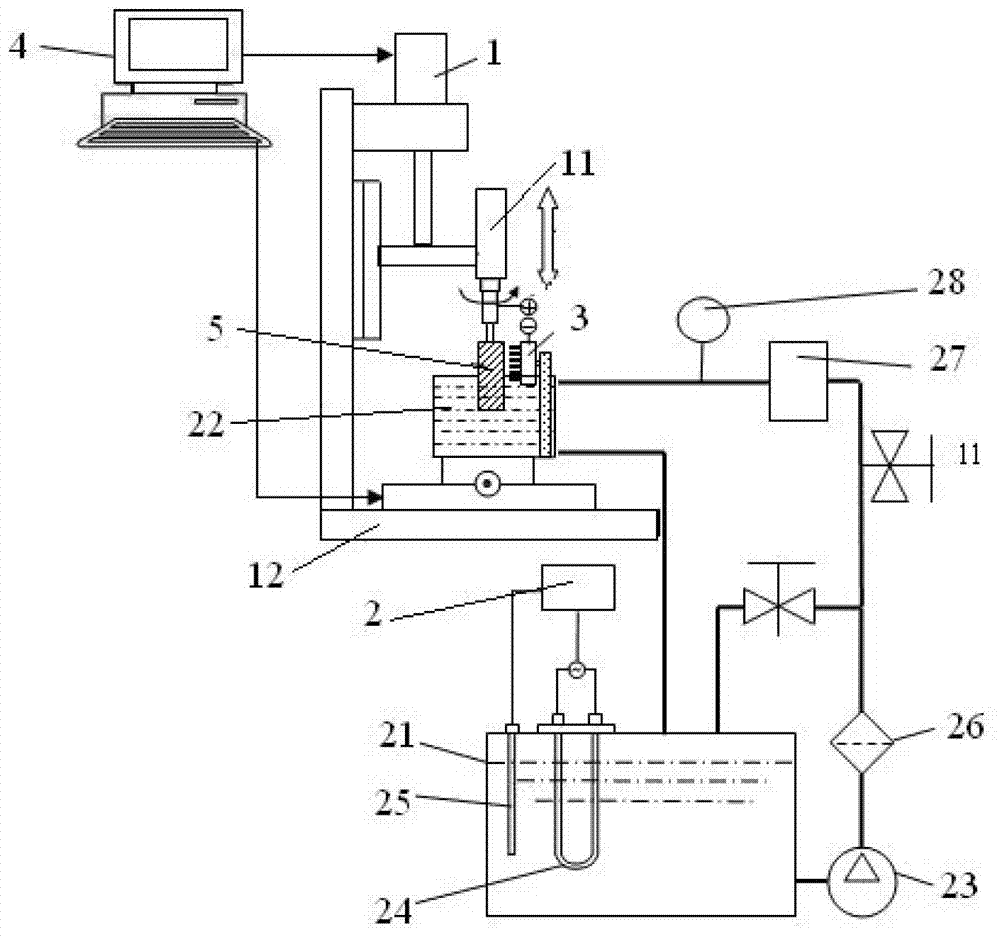

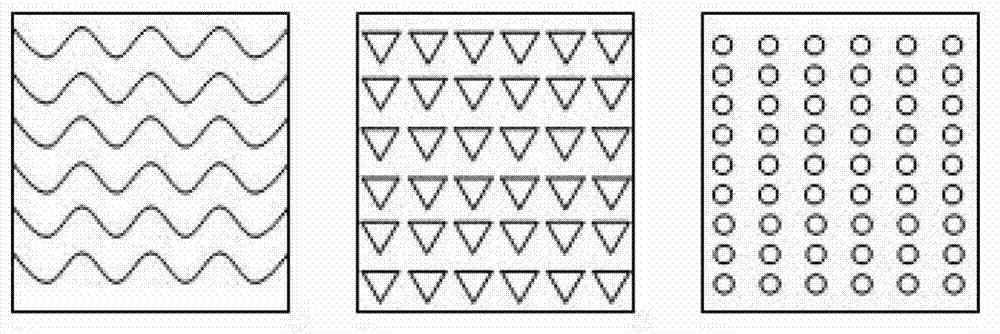

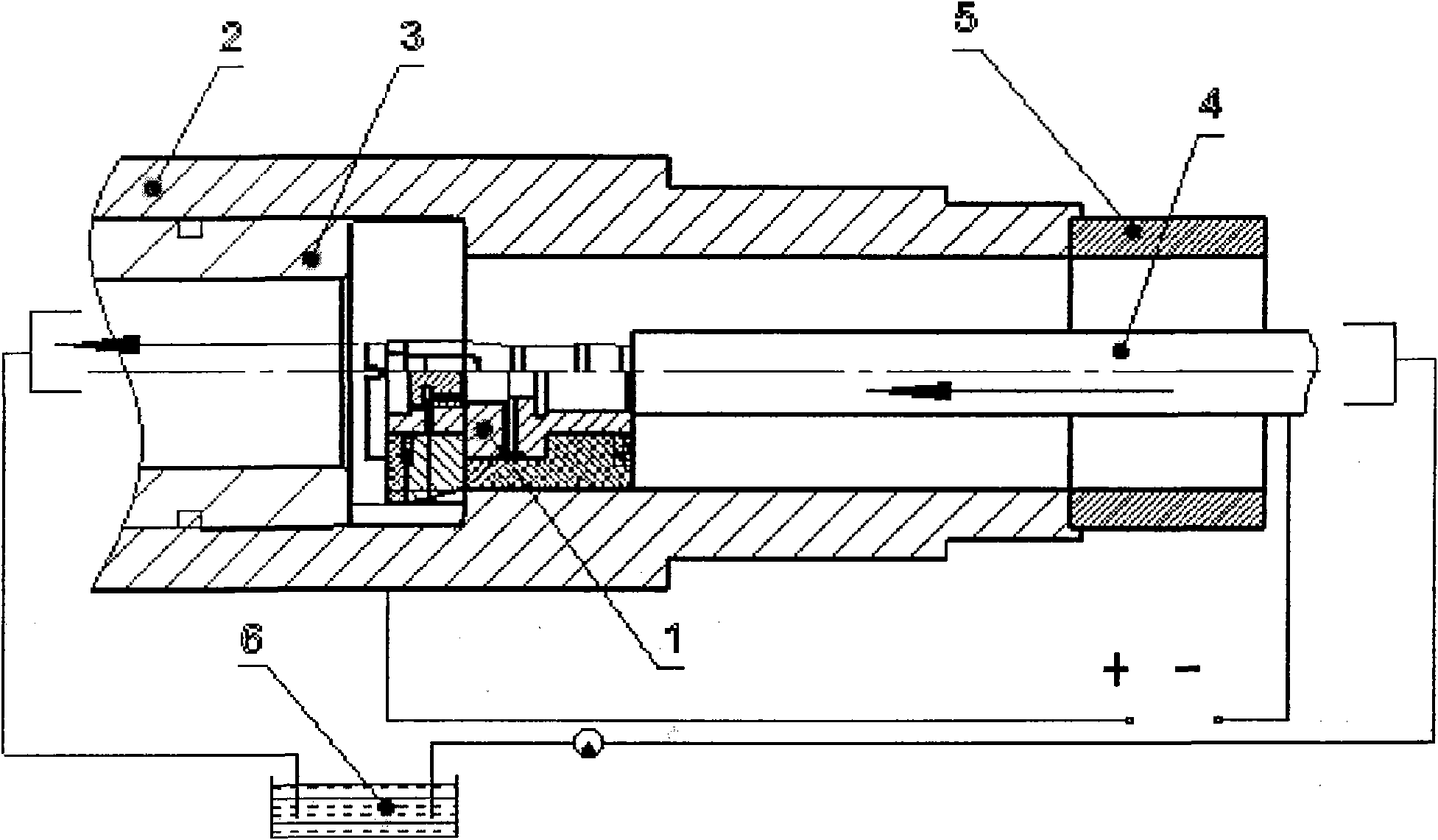

Metal surface micro texture group electrode direct writing micro electrolysis processing method and dedicated device

InactiveCN103111696AAvoid deformationReduce processing stepsMachining working media supply/regenerationElectrolysisDirect writing

Provided is a metal surface micro texture array electrode direct writing micro electrolysis processing method and a dedicated device. The processing method includes a first step of processing metal surface micro texture of workpieces to be processed by adopting line-shaped array electrodes, and a second step of enabling the array electrodes to conduct relative movement with the workpieces to be processed under the control of a machine tool numerical control system and processing the micro texture out of the surfaces of the workpieces to be processed under the conditions of flow of electrolyte and power-on of a processing power supply. The dedicated device comprises a machine tool, an electrolyte circulating device, a line-shaped array electrodes, a computer and a power supply provided with an anode and a cathode, the electrolyte circulating device and the line-shaped array electrodes are respectively in electric connection with the computer and meanwhile controlled by the machine numerical control system matched with the computer. The metal surface micro texture group electrode direct writing micro electrolysis processing method and the dedicated device has the advantages of being capable of processing complicated texture structure with the electrodes in simple shapes, free from need to manufacture a mask plate, short in processing cycle, high-efficiency, capable of avoiding deformation of the surfaces of the workpieces and 'secondary processing' and good in quality.

Owner:ZHEJIANG UNIV OF TECH

Insulation shielding sleeve material electrolytic machining cathode system and machining method

ActiveCN107052483AReduce the impactImprove surface qualityMachining electrodesMachining working media supply/regenerationMachine partsPower flow

The invention provides an insulation shielding sleeve material electrolytic machining cathode system and a machining method. The cathode system mainly comprises a sleeve material cathode body, a sleeve material cathode head, an insulation auxiliary block and insulation particles. In the electrolytic method, the flowing mode of electrolyte is side flowing. A workpiece gradually extends into a machined profile protection cavity and pushes the insulation auxiliary block to move synchronously, the surface of the machined part of the workpiece is coated with the insulation particles in the protection cavity in a particle film form. High-pressure gas is blown into the protection cavity from a gas blowing channel and is blown to the machined area at the root of the workpiece. According to the insulation shielding sleeve material electrolytic machining cathode system and the machining method, the electrolyte between gaps of the machined areas of the workpiece can be reduced, a power line on the machined surface of the workpiece is shielded, secondary corrosion of stray currents to the surface of the workpiece is reduced effectively, and the surface quality of the machined profile is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

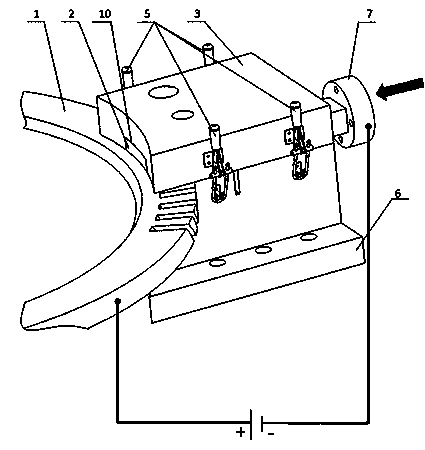

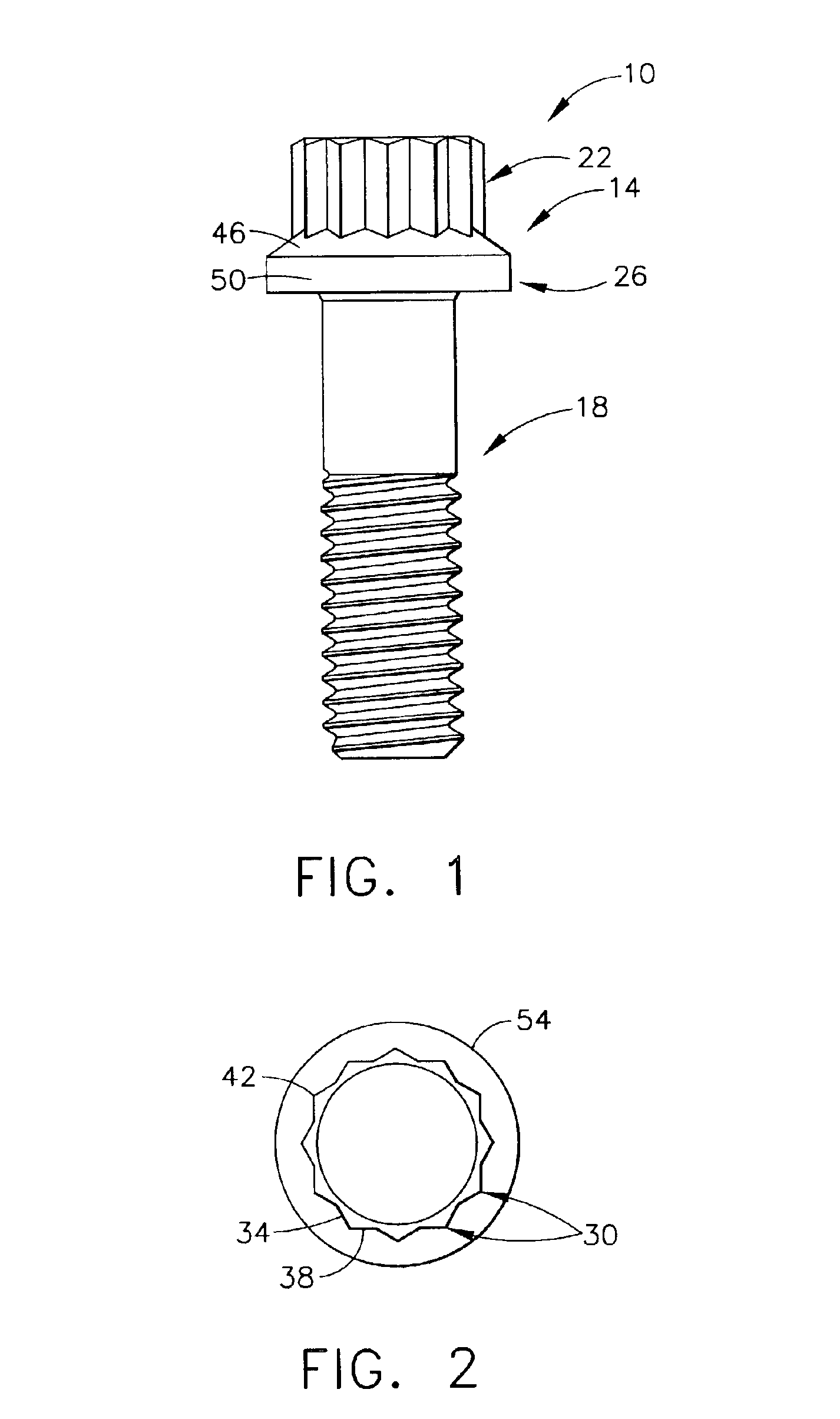

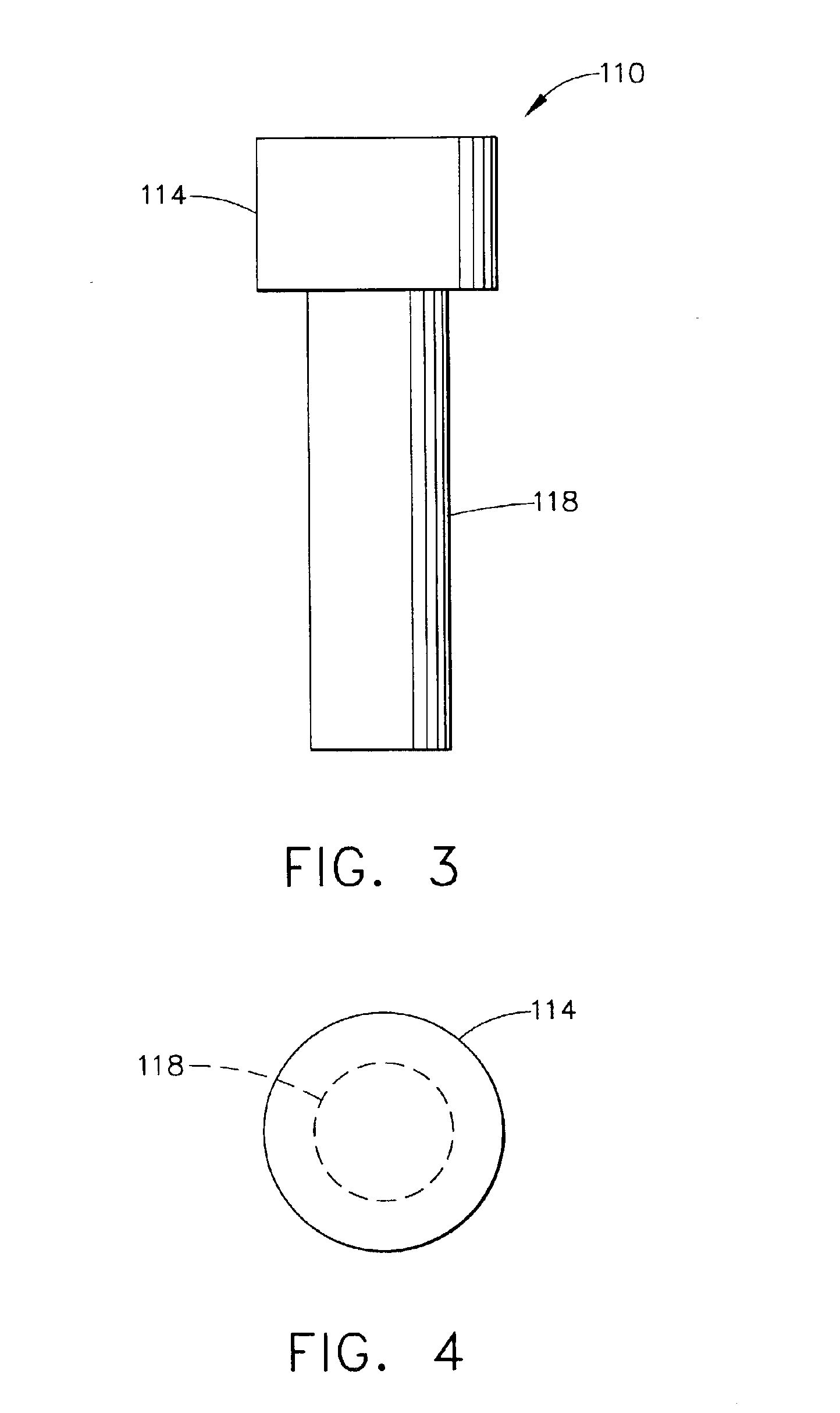

Drive head and ECM method and tool for making same

InactiveUS6866769B2Increase supplyReduced fatigue lifeMachining electrodesMachining working mediaCouplingEngineering

A drive head for a bolt, fastener, coupling, nut or other driveable head made from a less malleable metal such as a powder metal nickel alloy. The drive head has an upper drive portion having at least six convex corners spaced around the outer periphery thereof, each corner terminating in an edge. The drive head also has a lower flange portion adjacent to the drive portion and having an edge extending radially outwardly to at least the edge of each corner. The drive portion and the flange portion of the drive head is formed by subjecting a blank having a generally circular head to electrochemical machining (ECM). A tool is also provided for the ECM method to form the drive portion and flange portion of the drive head.

Owner:LEHR PRECISION +1

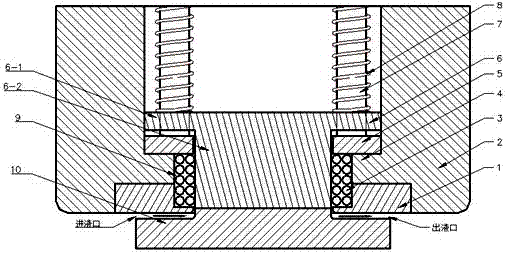

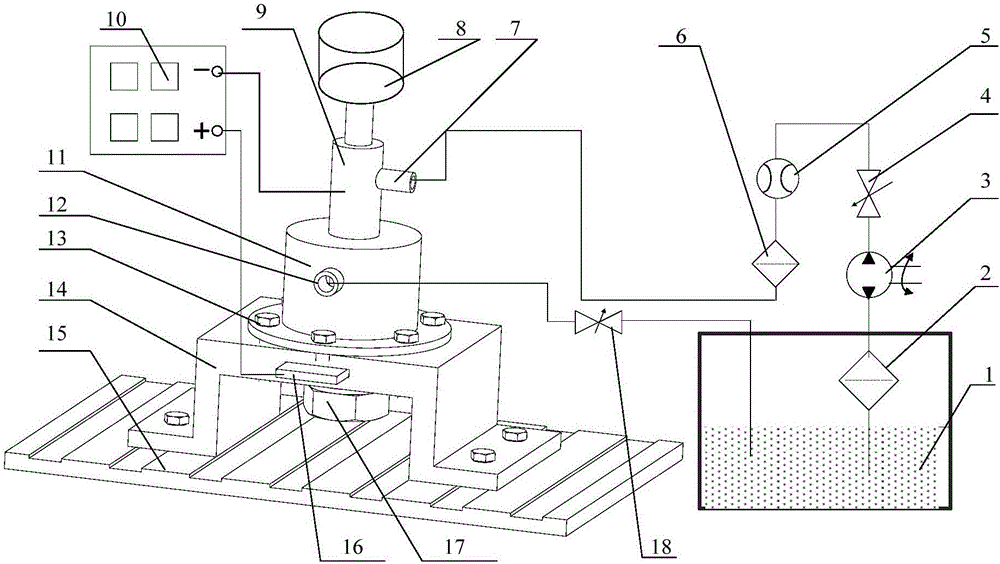

Hexagon-hole electrolytic machining device

InactiveCN106541192ASimple structureReduce economic costsMachining working media supply/regenerationElectrolysisEngineering

The invention discloses a hexagon-hole electrolytic machining device, and belongs to the field of electrolytic machining. The device provided by the invention comprises a tool cathode device, an electrolysis tooling fixture device, a workpiece, a machine tool system and an electrolyte circulation system. The tool cathode device is connected with a main shaft of the machine tool system; the workpiece is connected and fixed by the tooling fixture device; one end of the electrolyte circulation system is connected to the tool cathode device, and the other end of the electrolyte circulation system is connected to the tooling fixture device. An electrolyte flows through a gap formed by a tool cathode and the workpiece at high speed under the action of a pulsed power supply, thus completing the hexagon electrolytic machining; the flow field stability is guaranteed by a sealed electrolyte cavity and the regulation of an electrolyte outlet valve, and a series of hexagon-hole electrolytic machining is realized through the movement of the workpiece in a tooling slot. The hexagon-hole electrolytic machining device has the characteristics that the flow field stability is realized, the flow field uniformity of the electrolyte is guaranteed, the electrolytic machining efficiency and electrolytic machining quality are improved, short circuit is not easy to generate during the electrolytic machining, and the practical value is extensive.

Owner:CHANGZHOU INST OF TECH

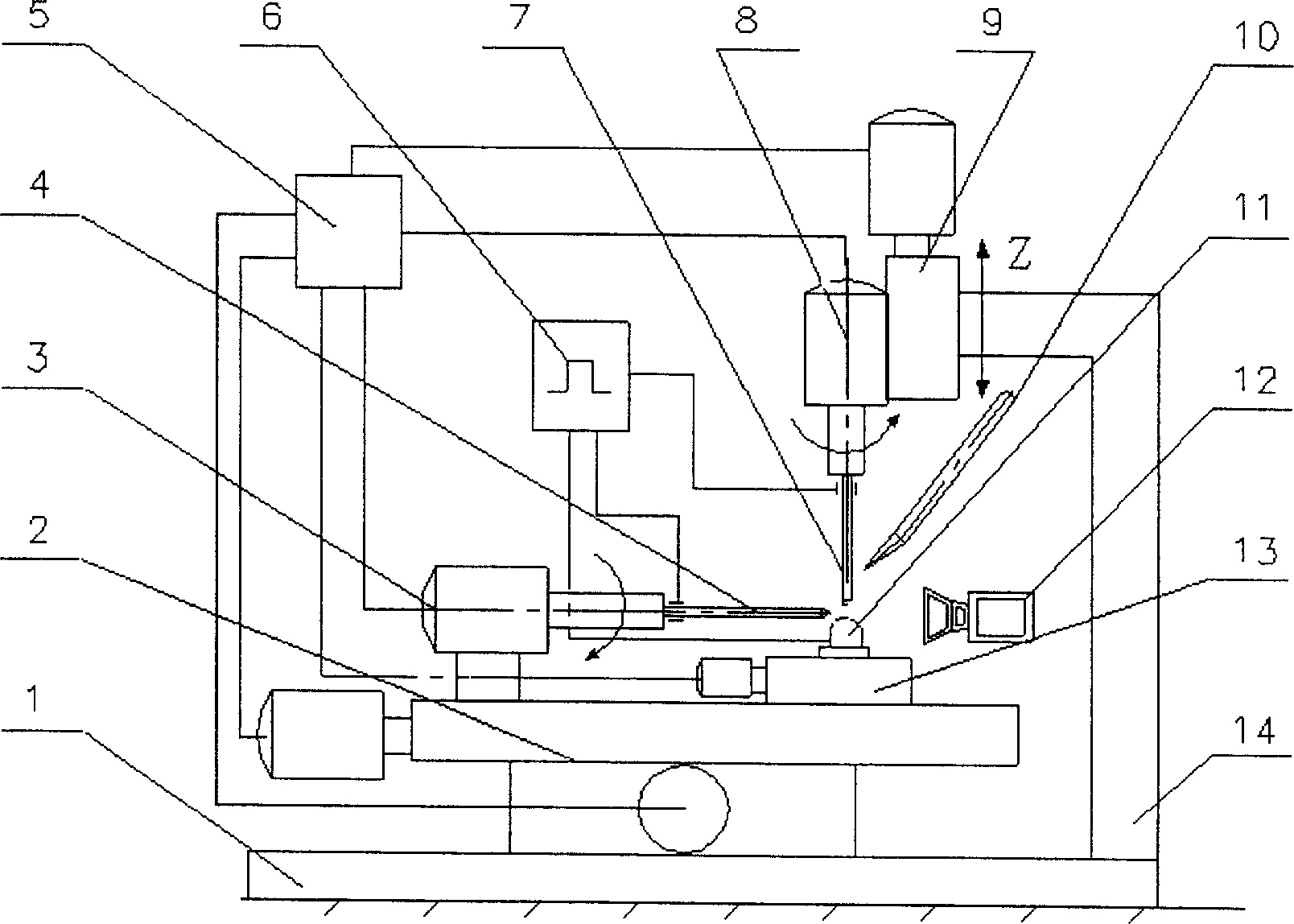

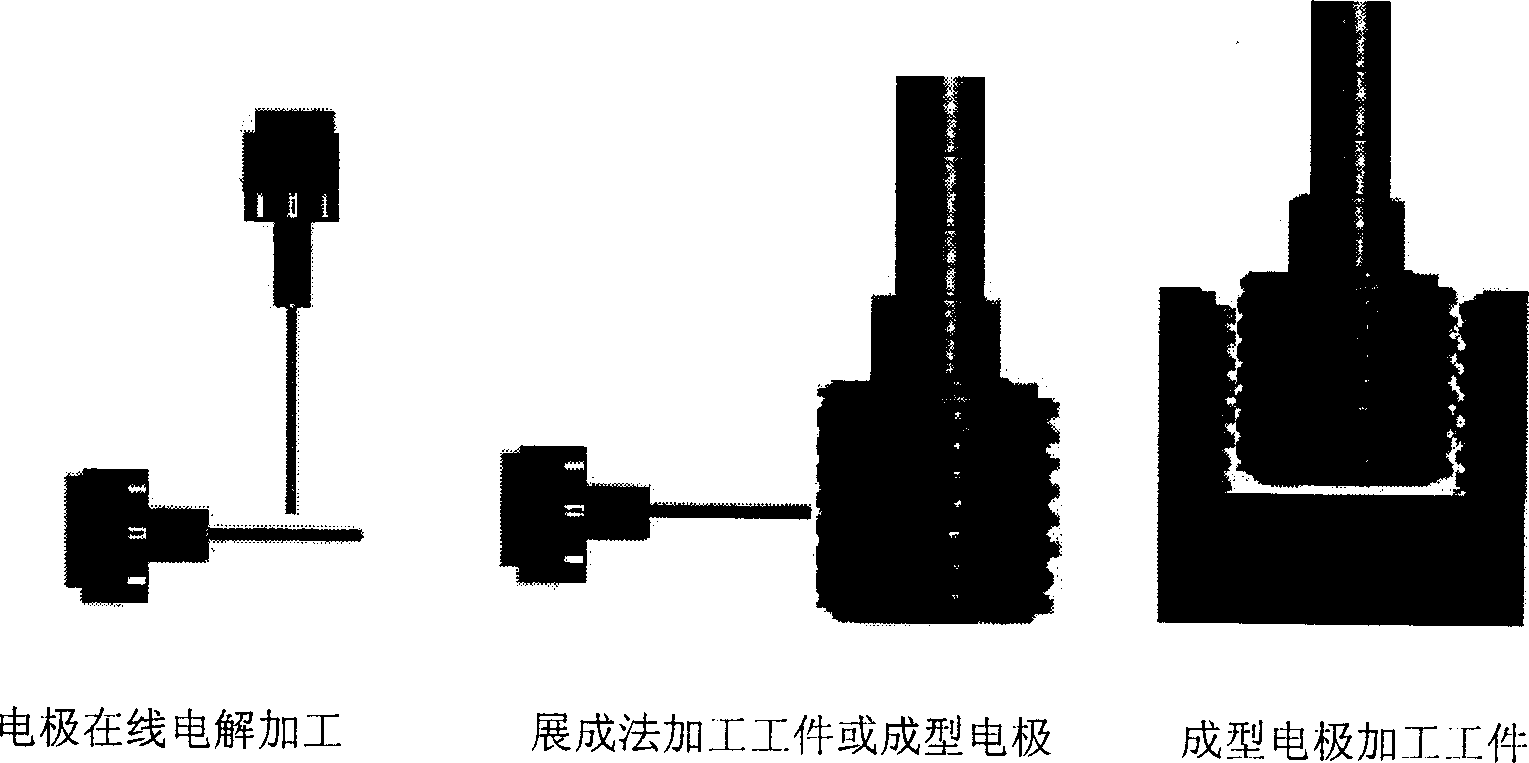

Three-dimension micro-expansion electrolysis processing method and apparatus

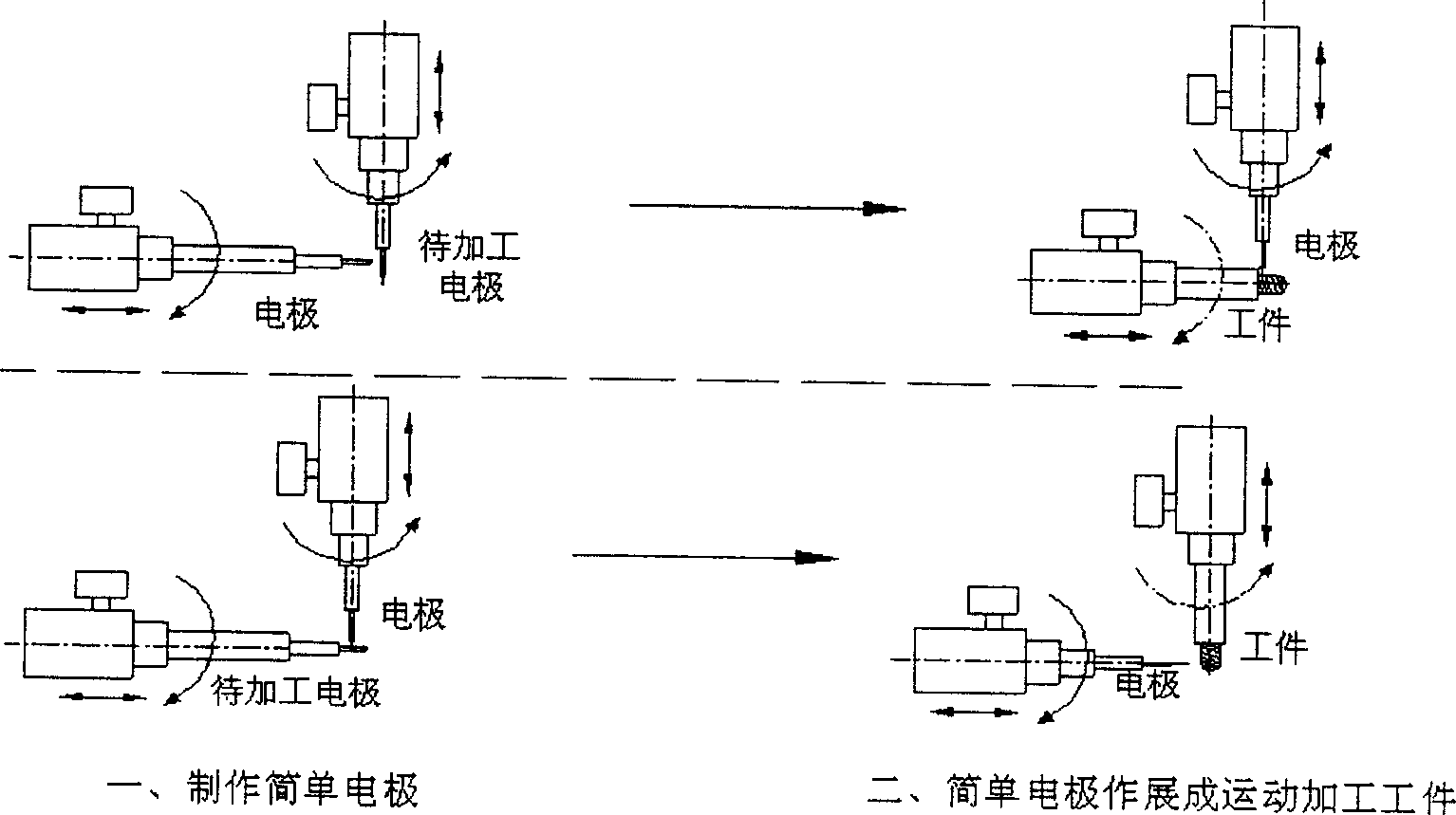

InactiveCN1676257AHigh precisionStrong leveling abilityMachining electric circuitsMachining working media supply/regenerationElectrolysisControl system

The present invention discloses a 3-D microfine generating electrolytic processing method and its processing equipment. Said method utilizes the generating electrolytic processing of one electrode to another electrode or mutually-alternative generating electrolytic processing of two electrodes to implement on-line precision manufacture of electrode. Said processing equipment comprises mechanical motion mechanism, control system, pulse power supply, observation device and electrolyte supply system. Besides, said invention also provides the concrete application of said electrode.

Owner:GUANGDONG UNIV OF TECH

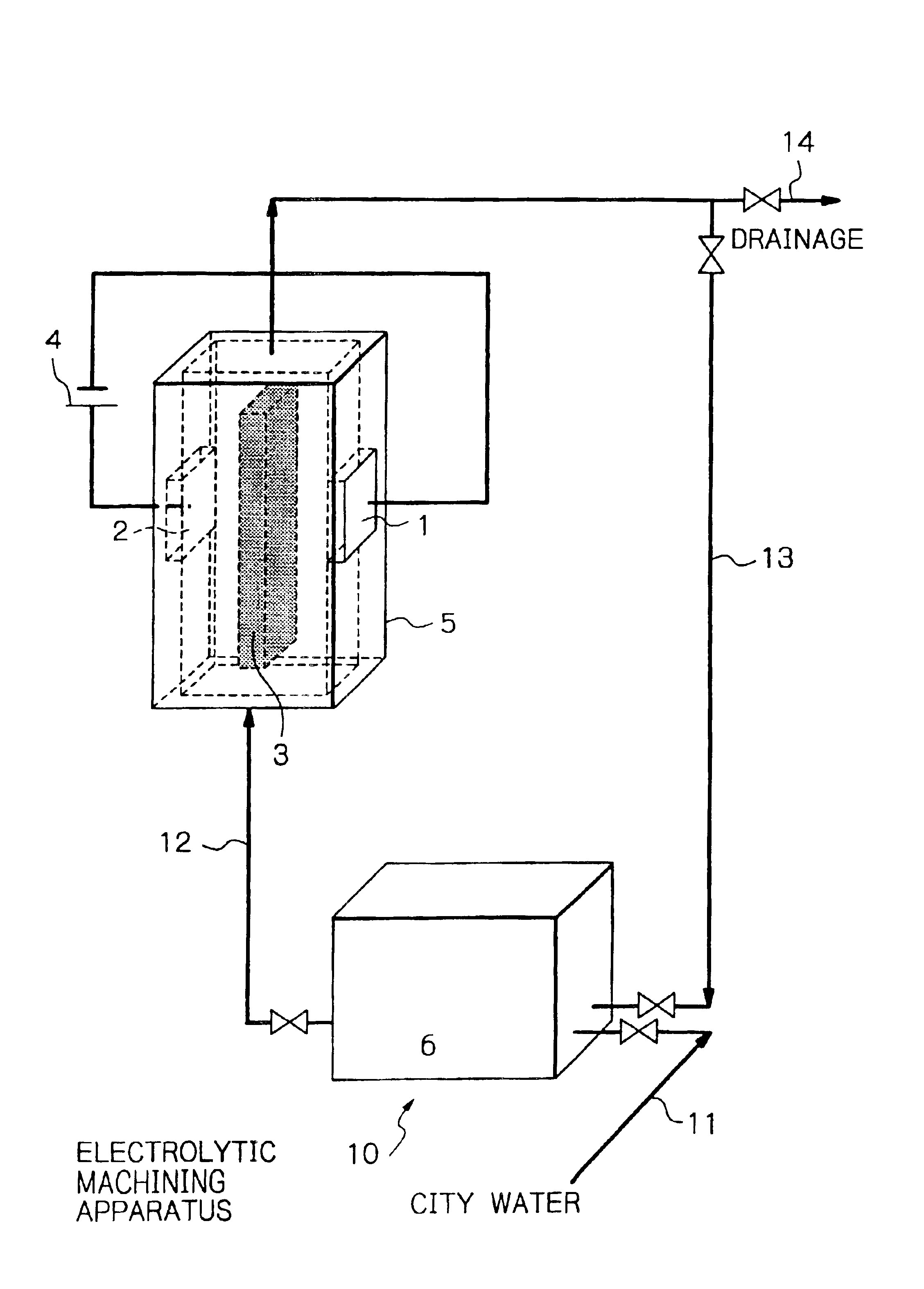

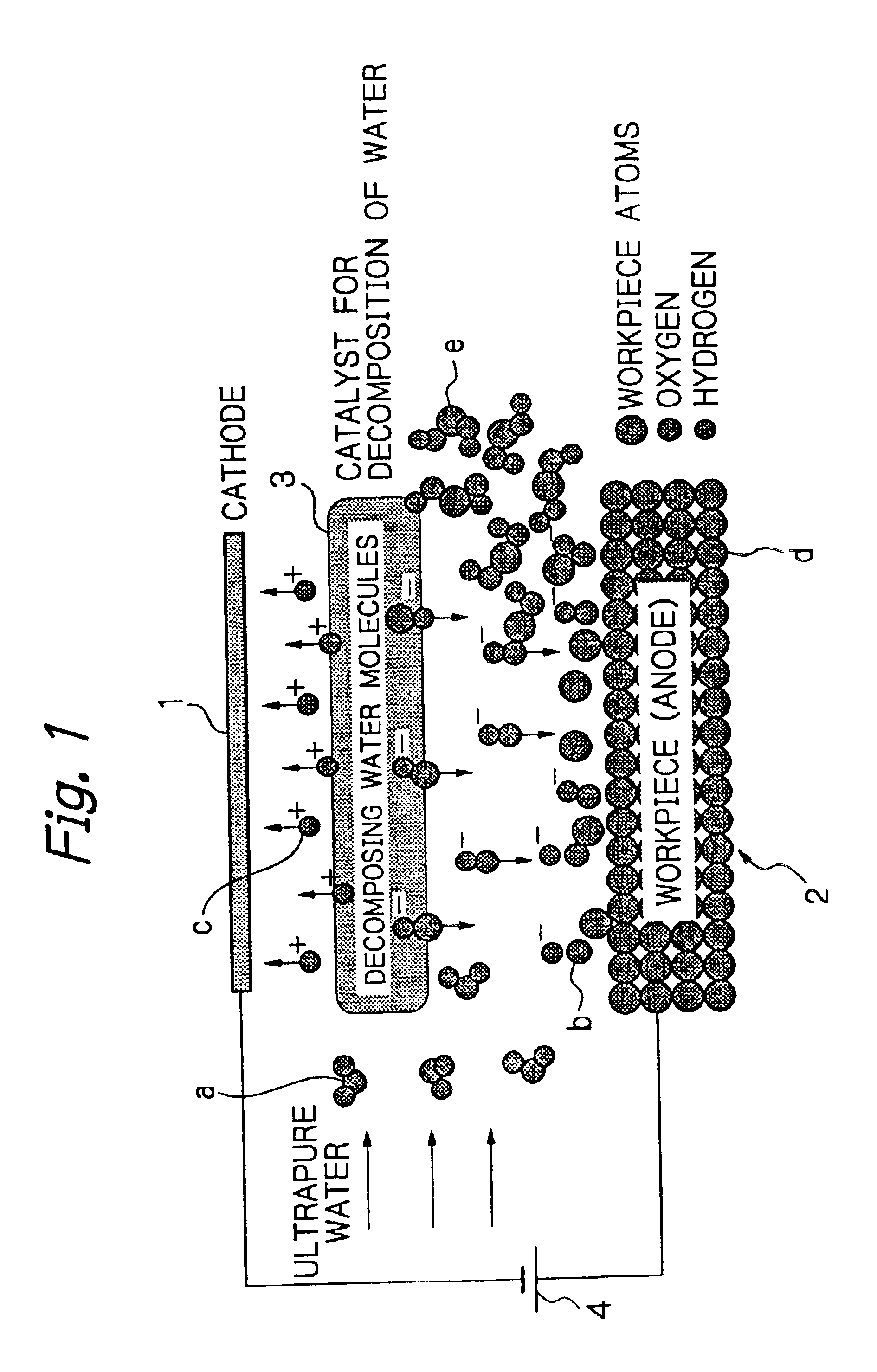

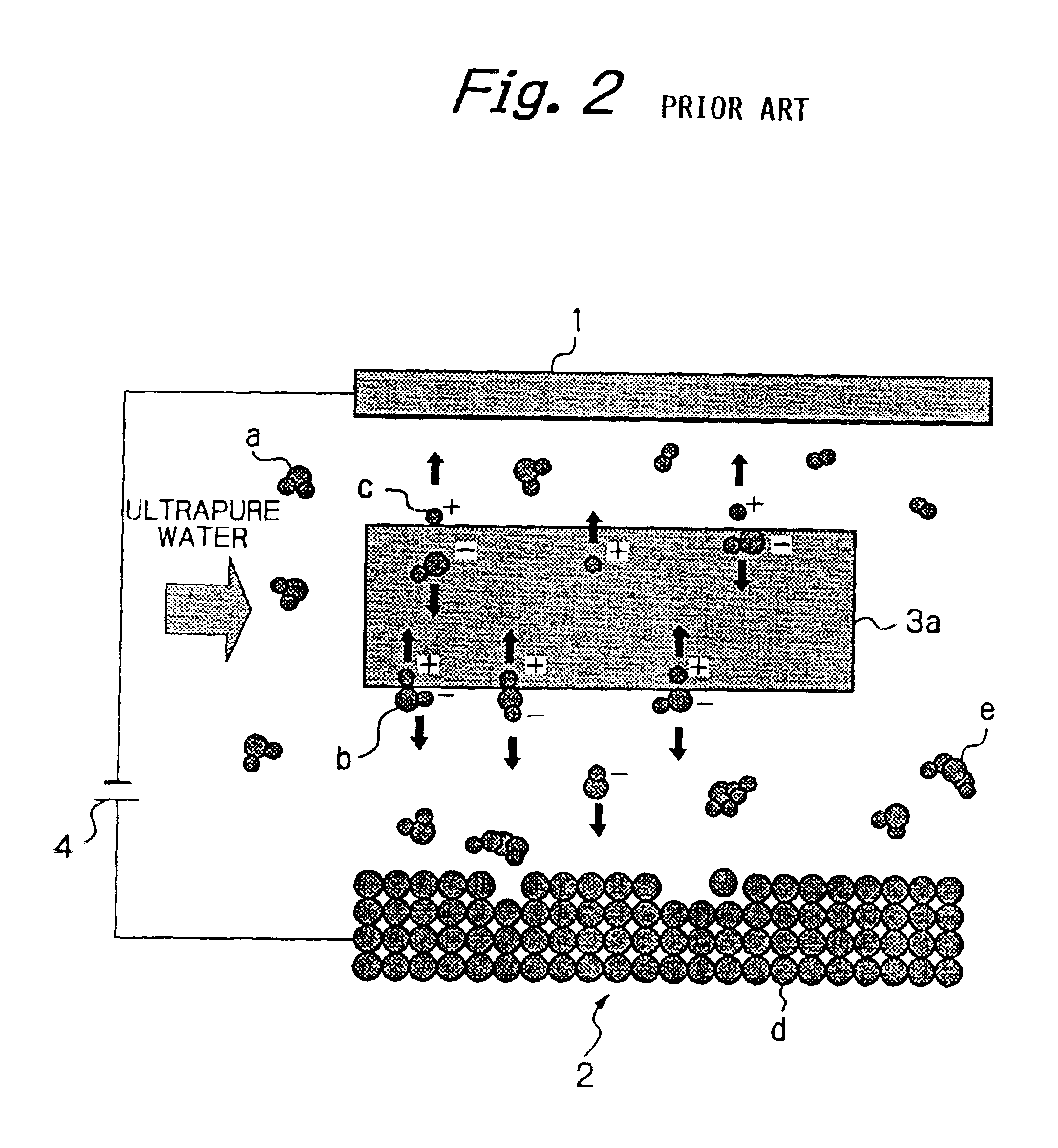

Electrolytic machining method and apparatus

An anode as a workpiece, and a cathode opposed to the anode with a predetermined spacing are placed in ultrapure water. A catalytic material promoting dissociation of the ultrapure water and having water permeability is disposed between the workpiece and the cathode. A flow of the ultrapure water is formed inside the catalytic material, with a voltage being applied between the workpiece and the cathode, to decompose water molecules in the ultrapure water into hydrogen ions and hydroxide ions, and supply the resulting hydroxide ions to a surface of the workpiece, thereby performing removal processing of or oxide film formation on the workpiece through a chemical dissolution reaction or an oxidation reaction mediated by the hydroxide ions. Thus, clean processing can be performed by use of hydroxide ions in ultrapure water, with no impurities left behind on the processed surface of the workpiece.

Owner:MORI YUZO +1

Deep hole internal spline electrolytic machining device

InactiveCN101590552AReduce processing difficultyIncrease productivityMachining working media supply/regenerationComposite cathodeElectrolysis

Owner:CHONGQING WANGJIANG IND

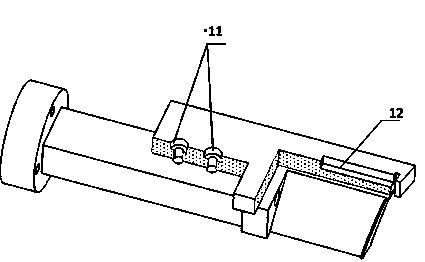

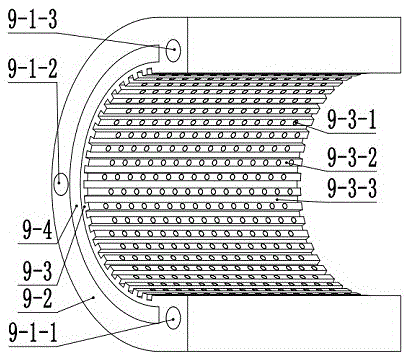

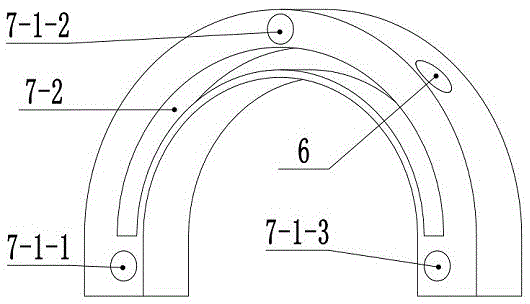

Apparatus for electrochemical machining of mask on cylindrical surface

InactiveCN105921831AFit tightlyExclude smoothlyMachining working media supply/regenerationEngineeringPorous medium

The invention patent discloses an apparatus for electrochemical machining of a mask on a cylindrical surface. The apparatus includes a liquid matching body, a front seal end cover and a rear seal end cover. The liquid matching body includes an external structure layer, a semicircle arc structure layer, an axially through diversion trench disposed between the outer structure layer and the semicircle arc structure layer. The arc surface of the semicircle arc structure is provided with liquid outlet grooves and bosses distributed in a staggered and uniformly toward an axial direction. The adjacent liquid outlet grooves and the bosses have a central angle of 3-10 degrees. The bosses are provided with liquid inlets at equal distances (d) along the axial direction. The front seal end cover and the rear seal end cover are in detachable sealing coupling with two axial ends of the liquid matching body respectively. A drainage groove communicates with the diversion trench. The apparatus in the invention is conducive to the discharge of an electrolytic product in an inter-electrode porous medium filled type mask electrolytic machining method, can improve the flow field uniformity at an anode surface of a cylindrical workpiece, further improves the quality of the electrochemical machining, is especially suitable for electrochemical machining of cylindrical surfaces, and is simple in structure, easy to operate and low in process cost.

Owner:HENAN POLYTECHNIC UNIV

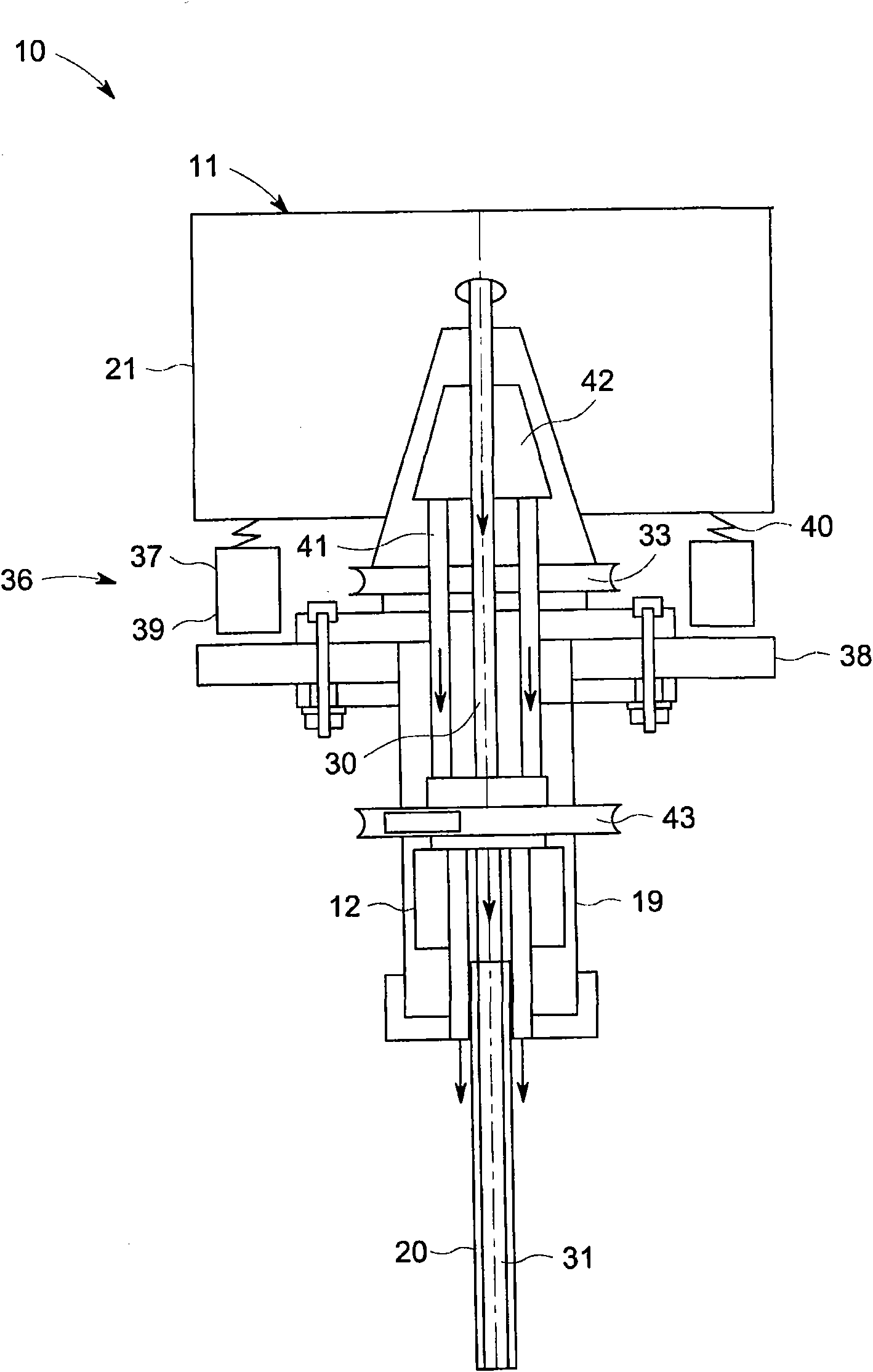

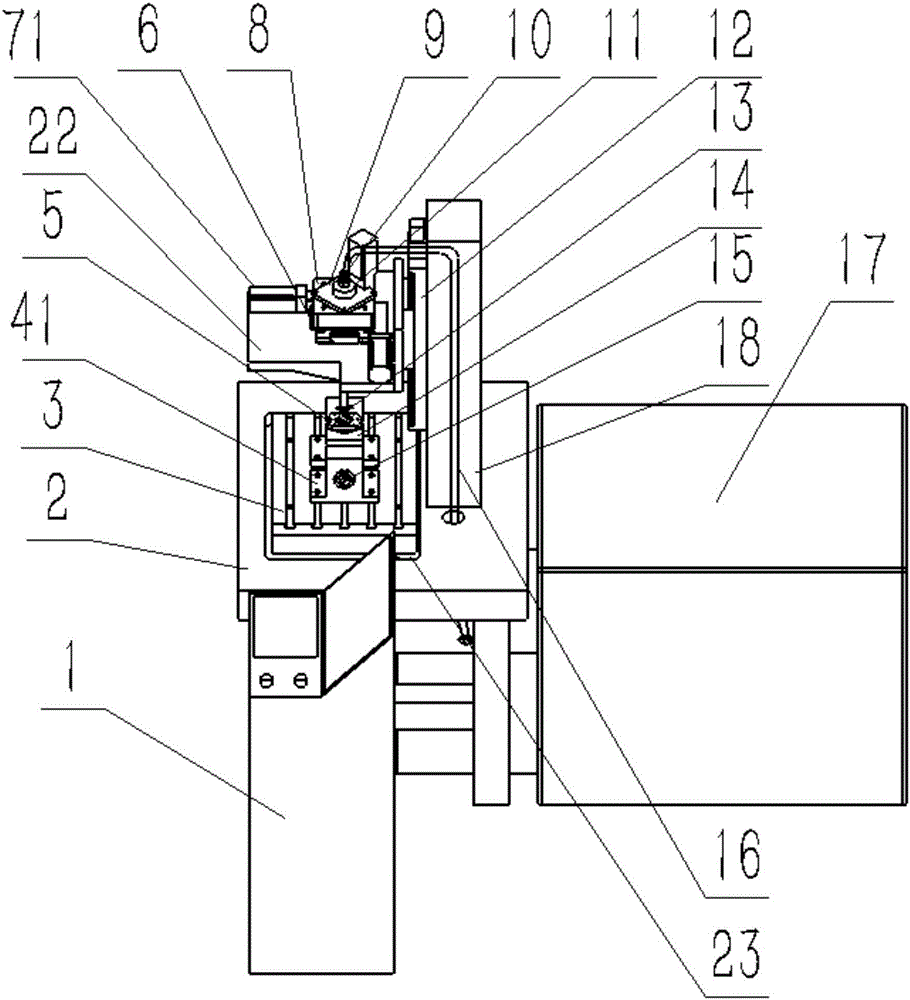

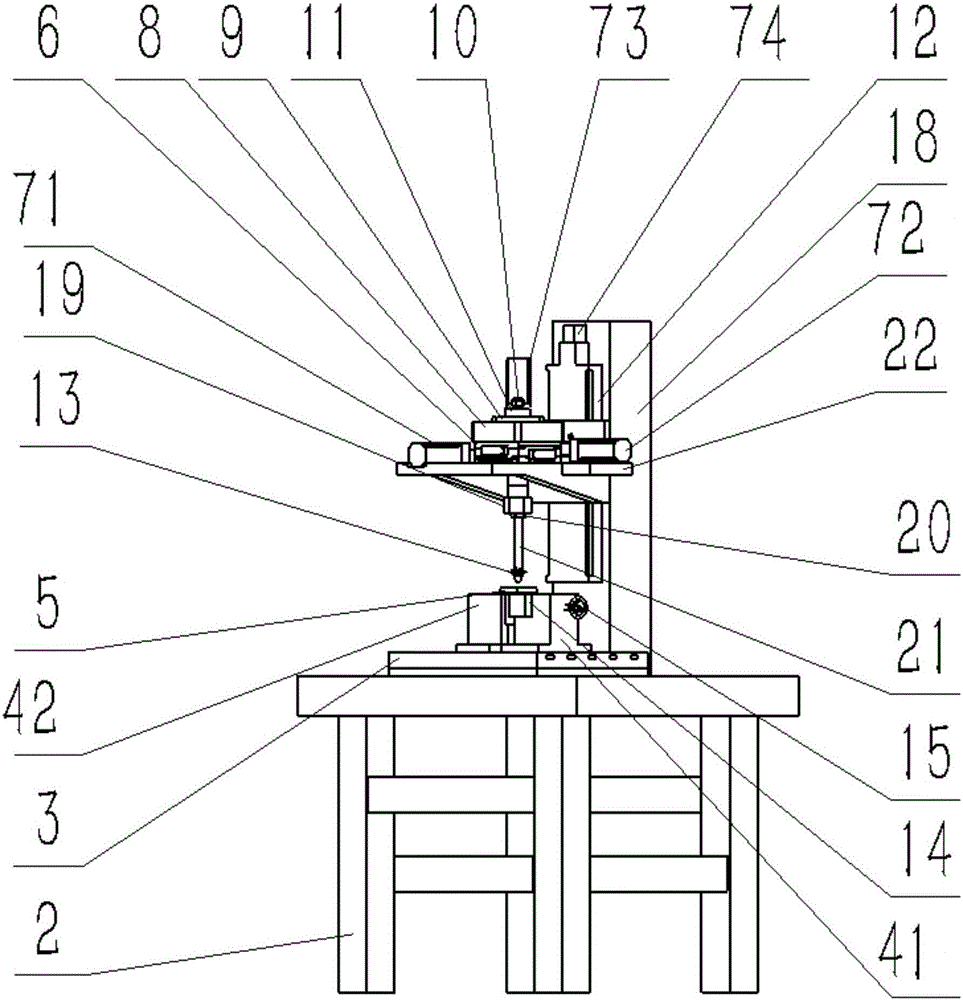

Cutter joint assembly and processing system

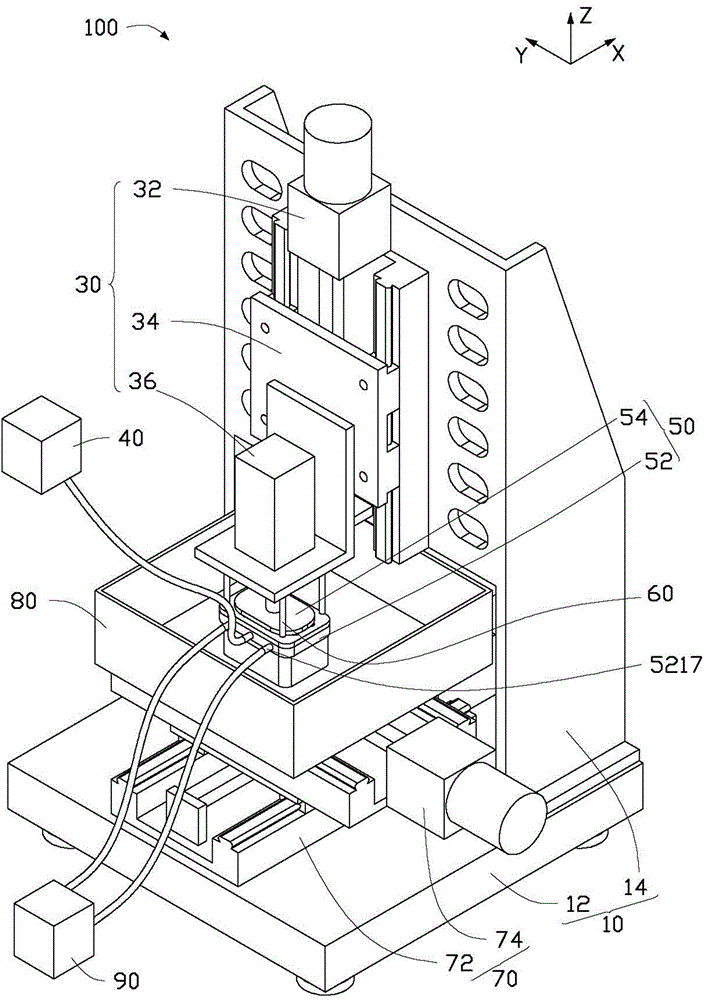

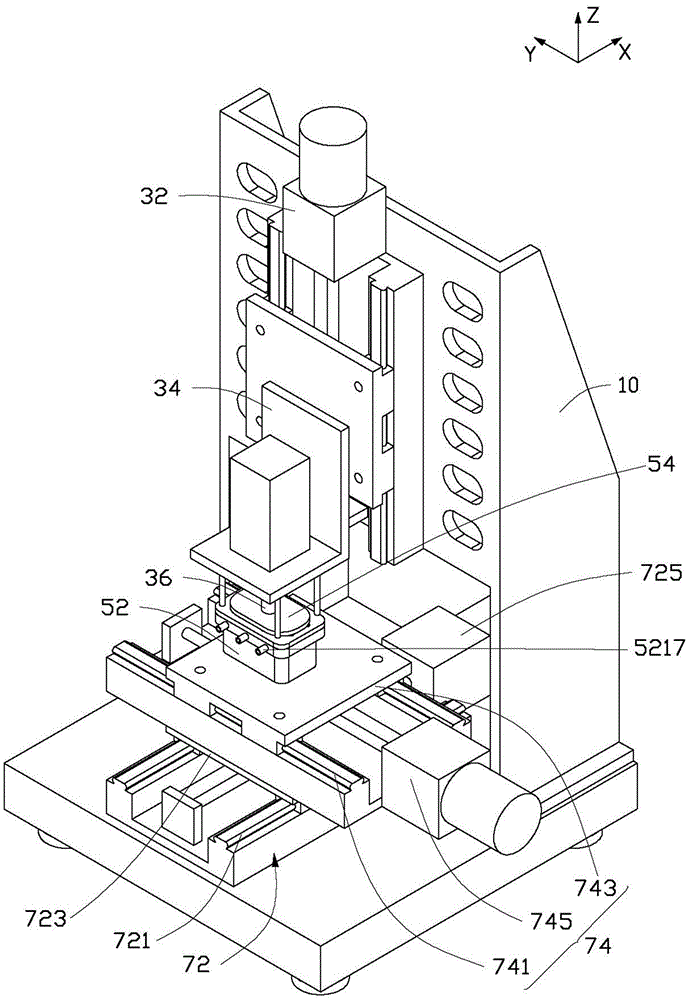

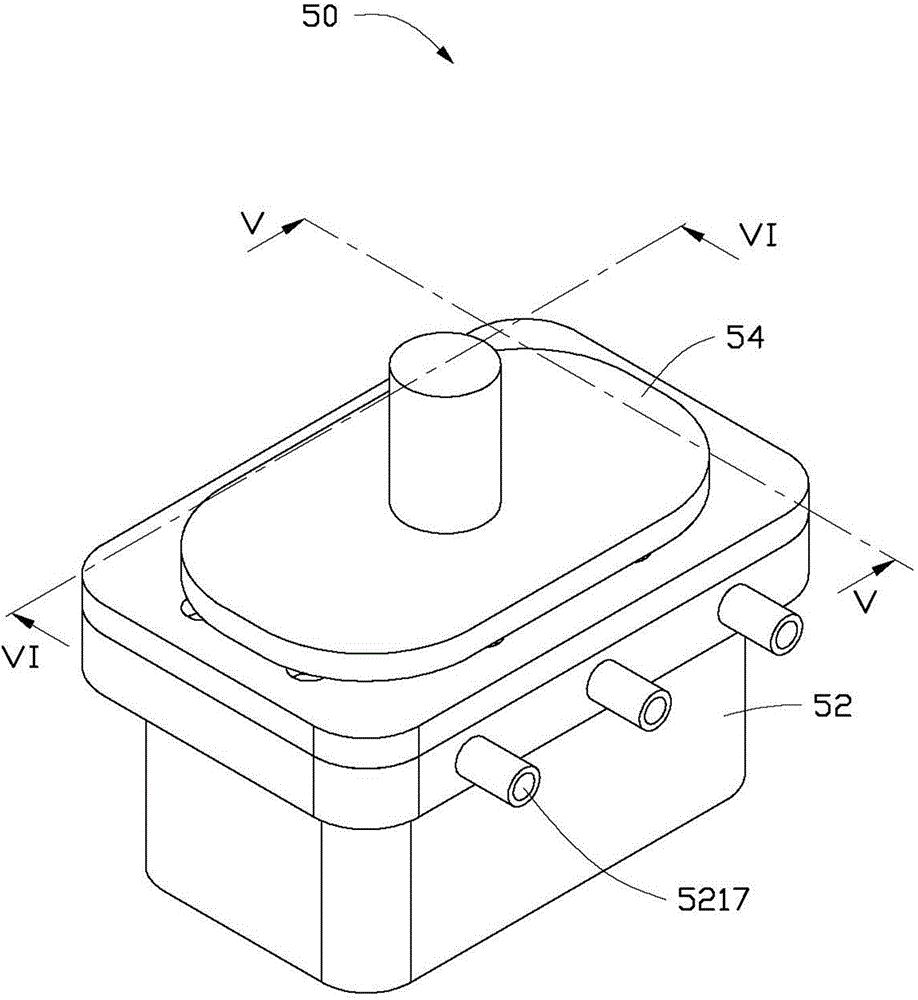

ActiveCN102133666AMachining electric circuitsMachining working media supply/regenerationMachine toolElectrode

The invention discloses a cutter joint assembly and a processing system. The processing system for electrically processing a workpiece comprises a machine tool, an electrode, a cutter holding device and an adapter. The machine tool comprises a main shaft. The electrode can be used for electrical processing. The cutter holding device is arranged on the main shaft of the machine tool and conductively holds the electrode. The adapter is conductively contacted with the cutter holding device. The processing system further comprises a power supply and a processing liquid source. The power supply can be connected with the adapter and the workpiece so that the workpiece and the electrode have opposite polarities. The processing liquid source can provide processing liquid passing through the place between the electrode and the workpiece. Moreover, the invention also relates to the cutter joint assembly.

Owner:GENERAL ELECTRIC CO

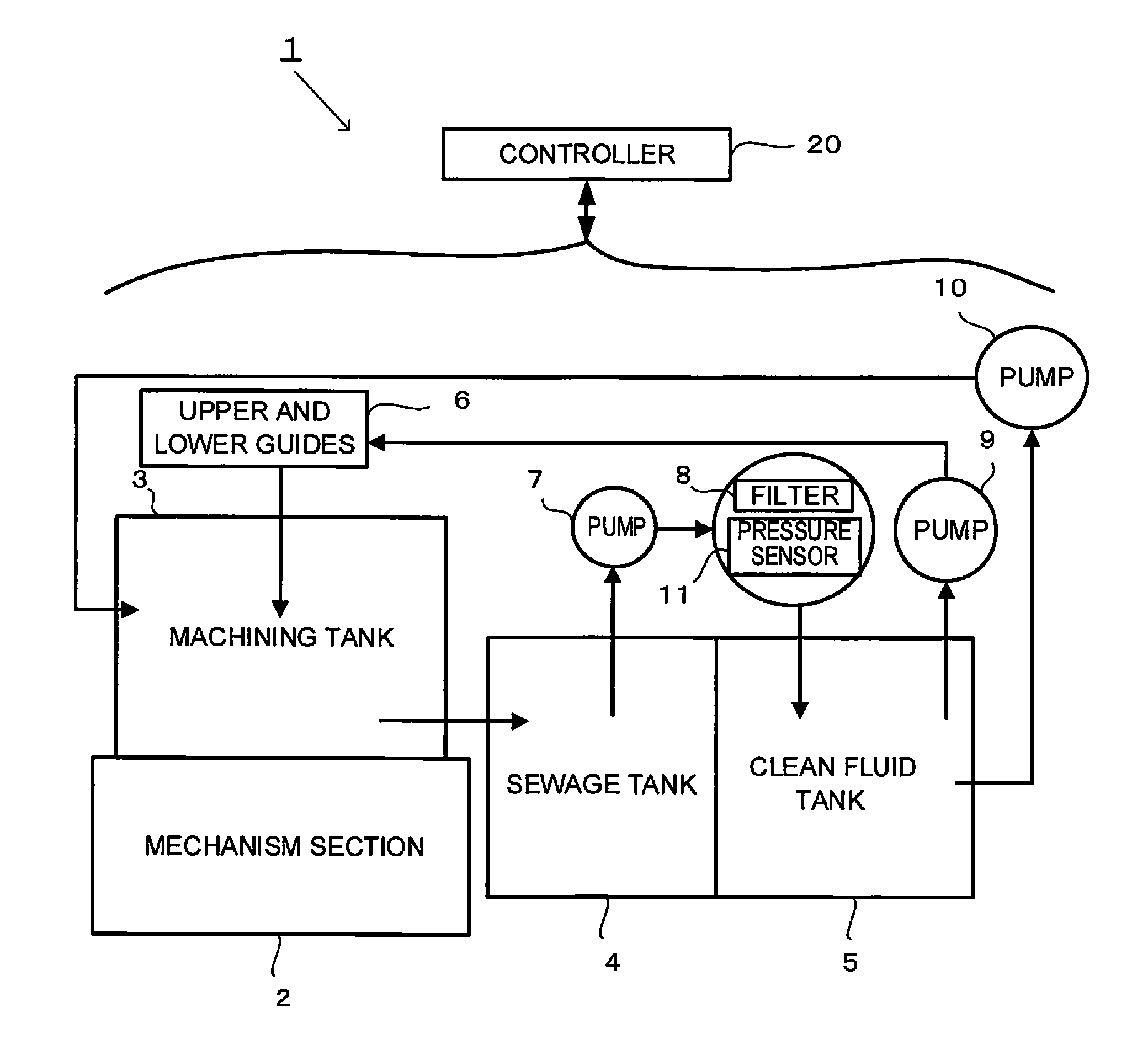

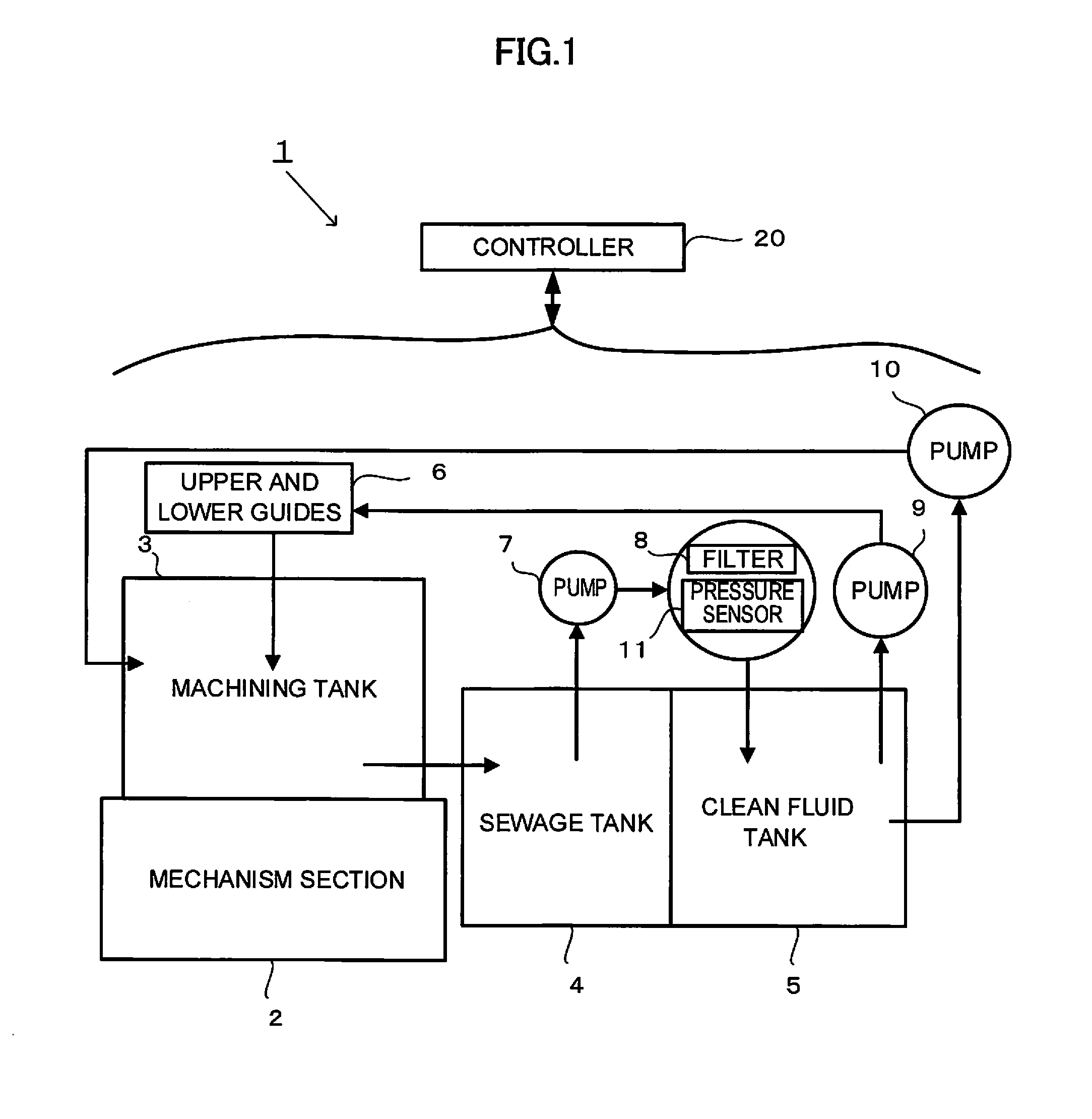

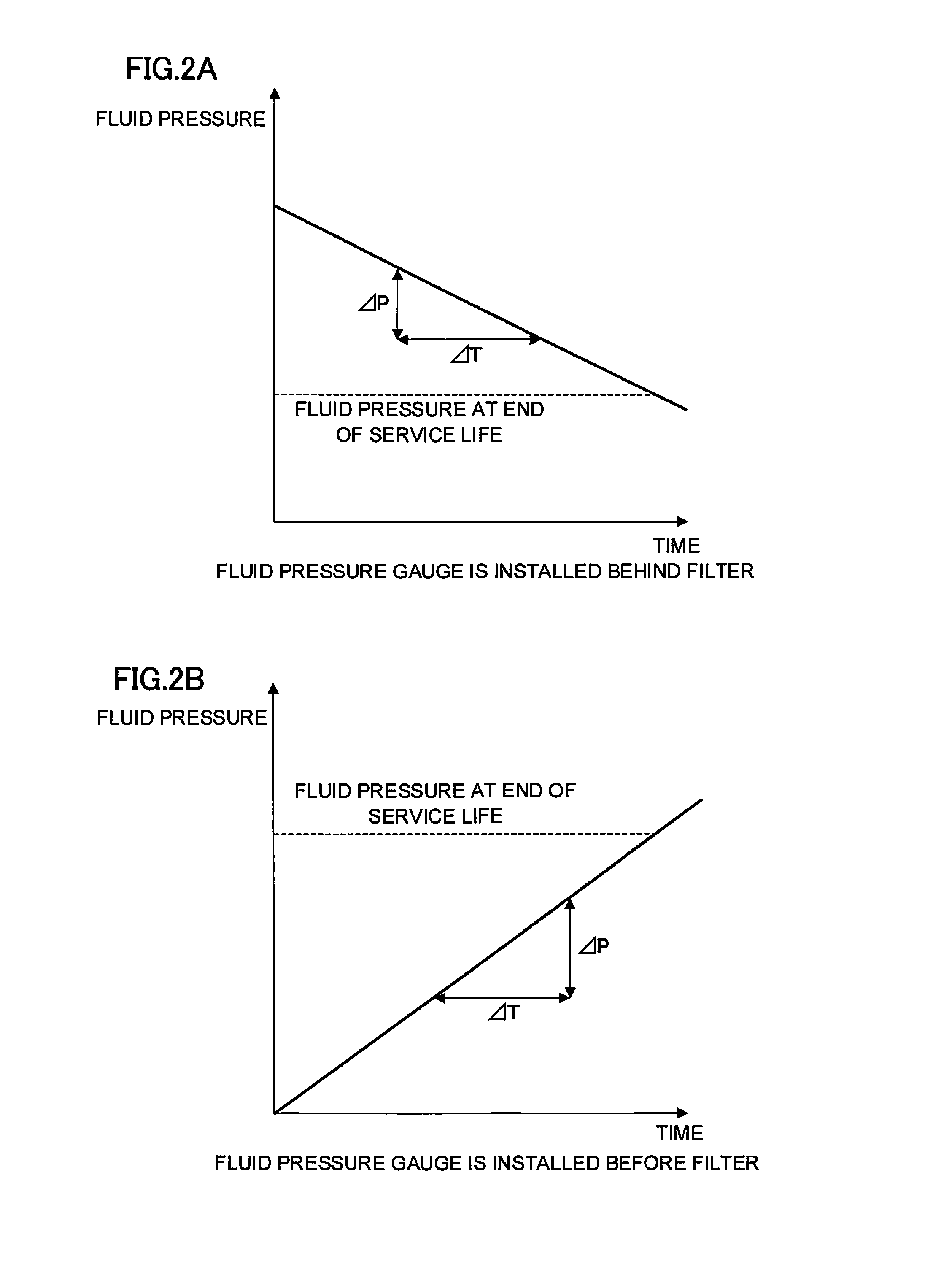

Wire electric discharge machine having estimation function for filter replacement timing

ActiveUS20160096231A1Water treatment parameter controlMachining working media supply/regenerationElectric dischargeReliability engineering

A wire electric discharge machine has a function of estimating the time for replacement of a filter based on a use situation for the machine. A time Tr during which the filter is serviceable is calculated according to an equation, Tr=|(Pd−Pn) / ΔP|, based on a fluid pressure variation amount ΔP, a current filter fluid pressure Pn, and a filter life pressure. A remaining available time Td for the filter which takes into account the operation rate of the machine is calculated according to an equation, Td=Tr / W.

Owner:FANUC LTD

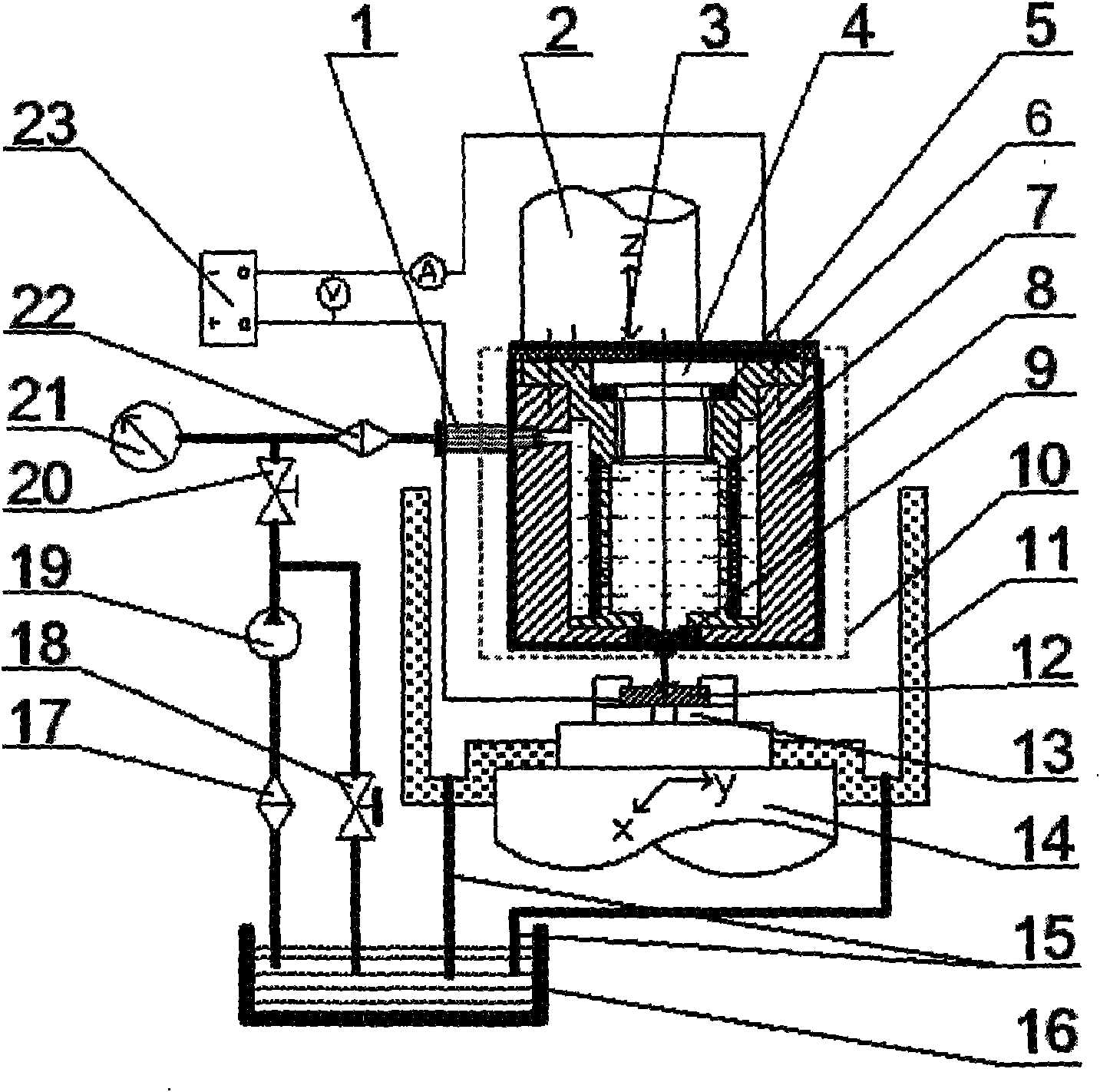

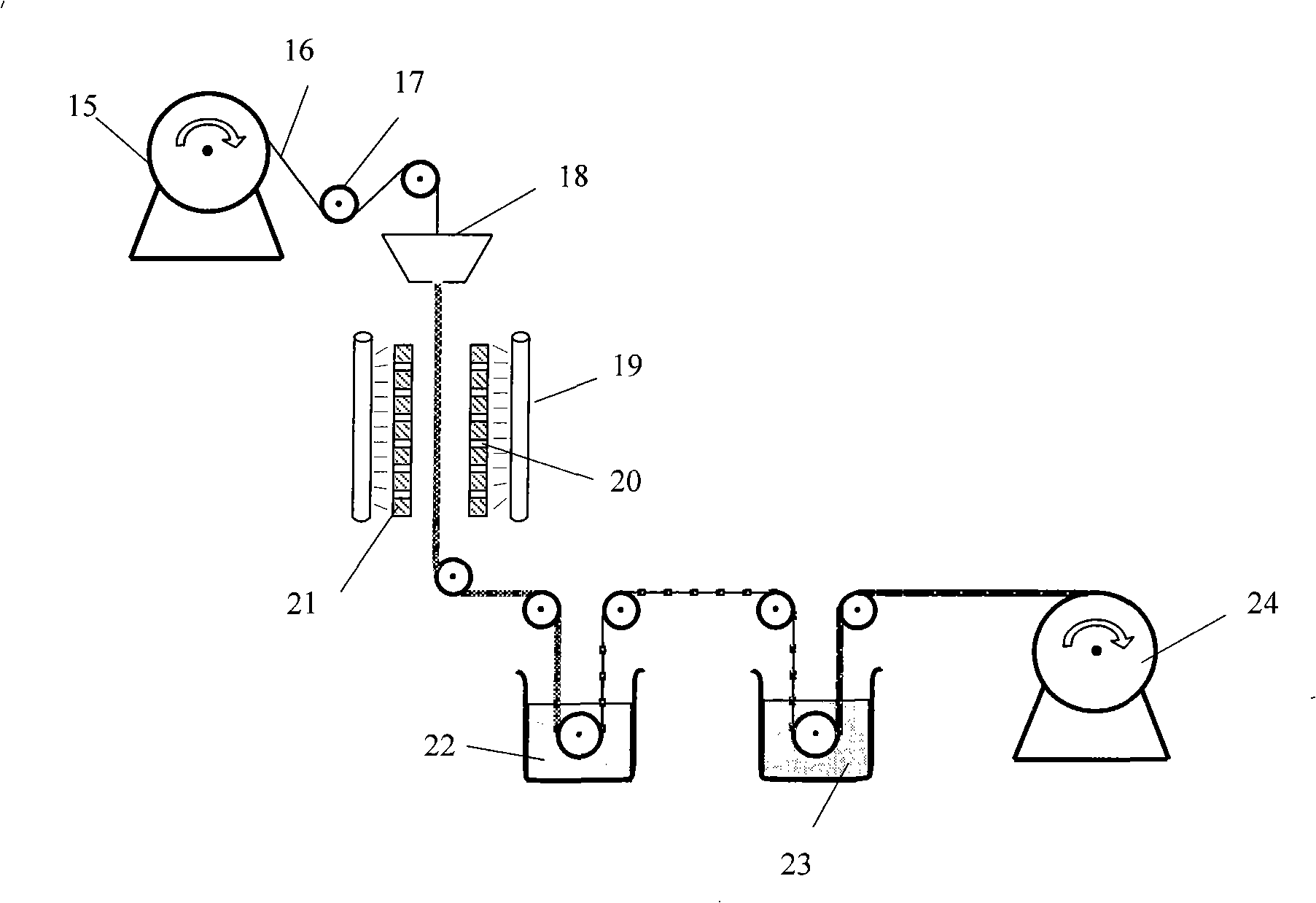

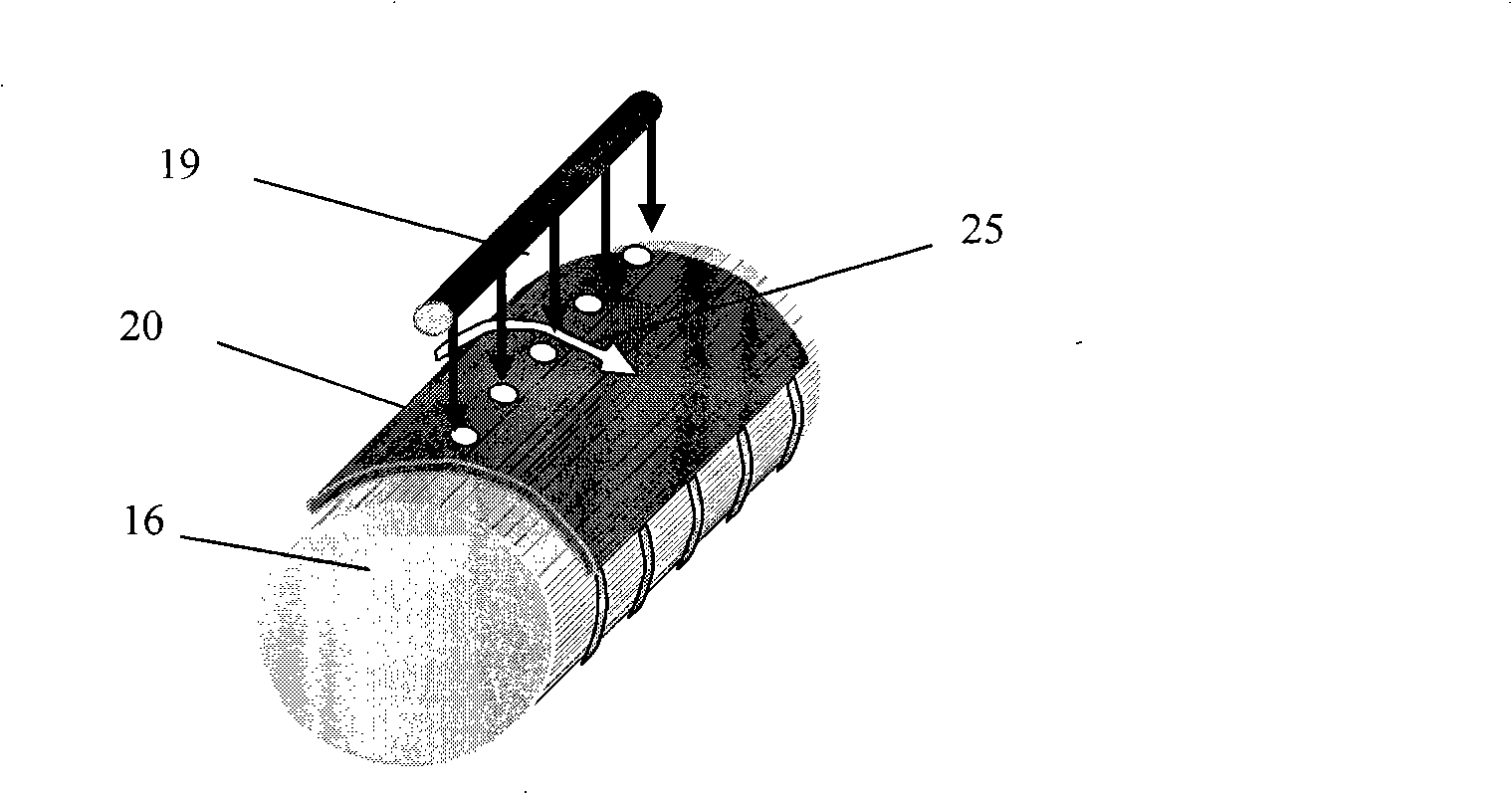

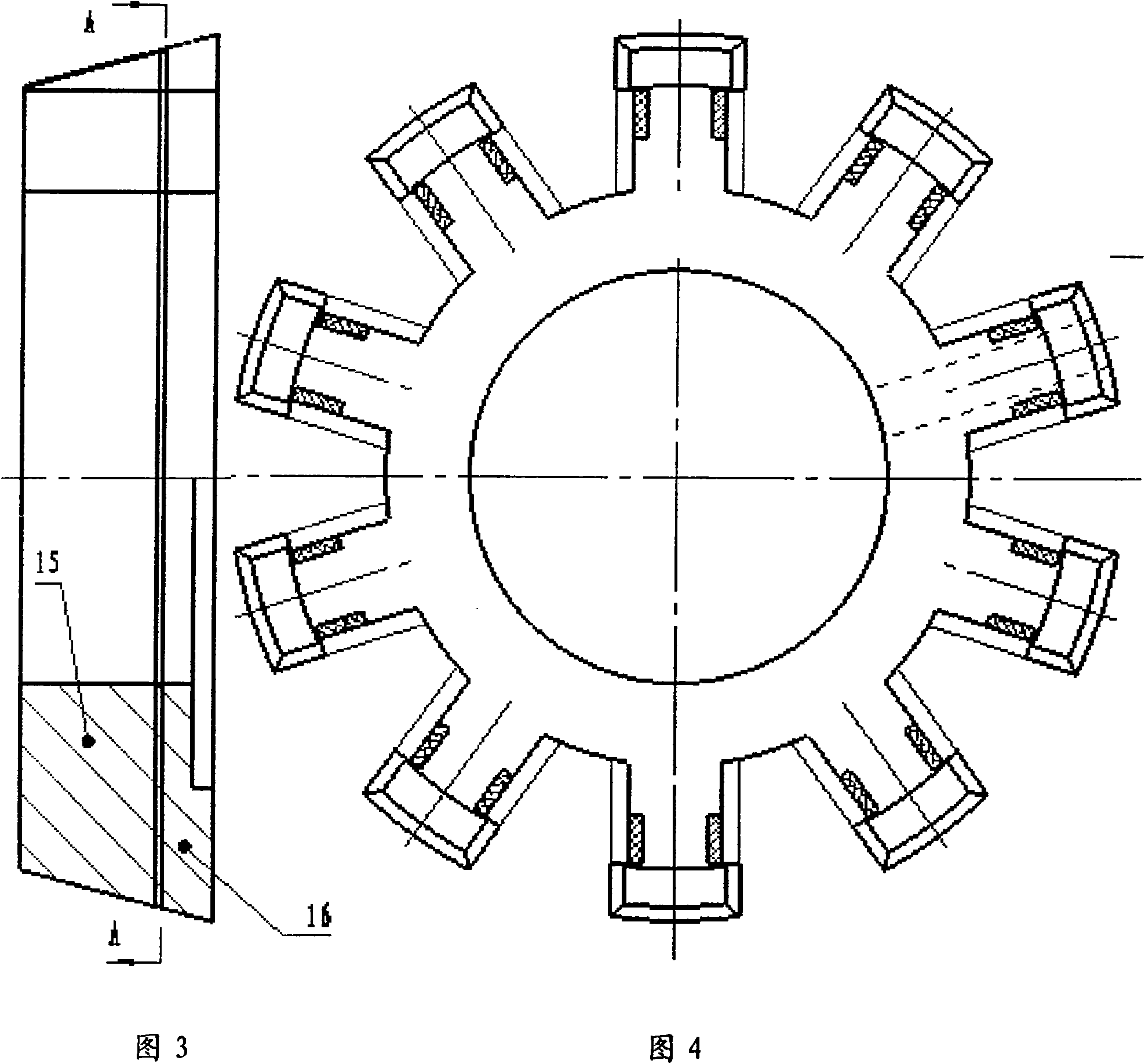

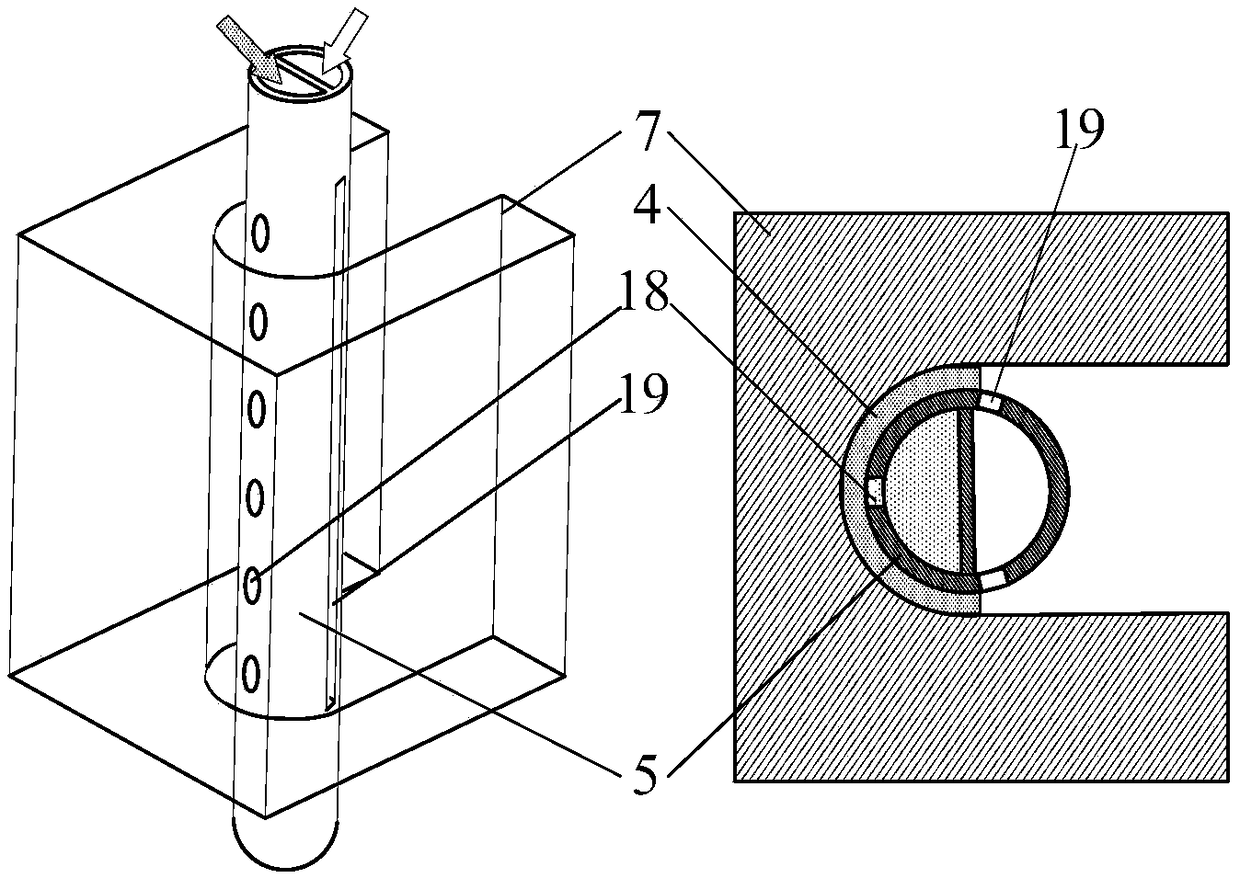

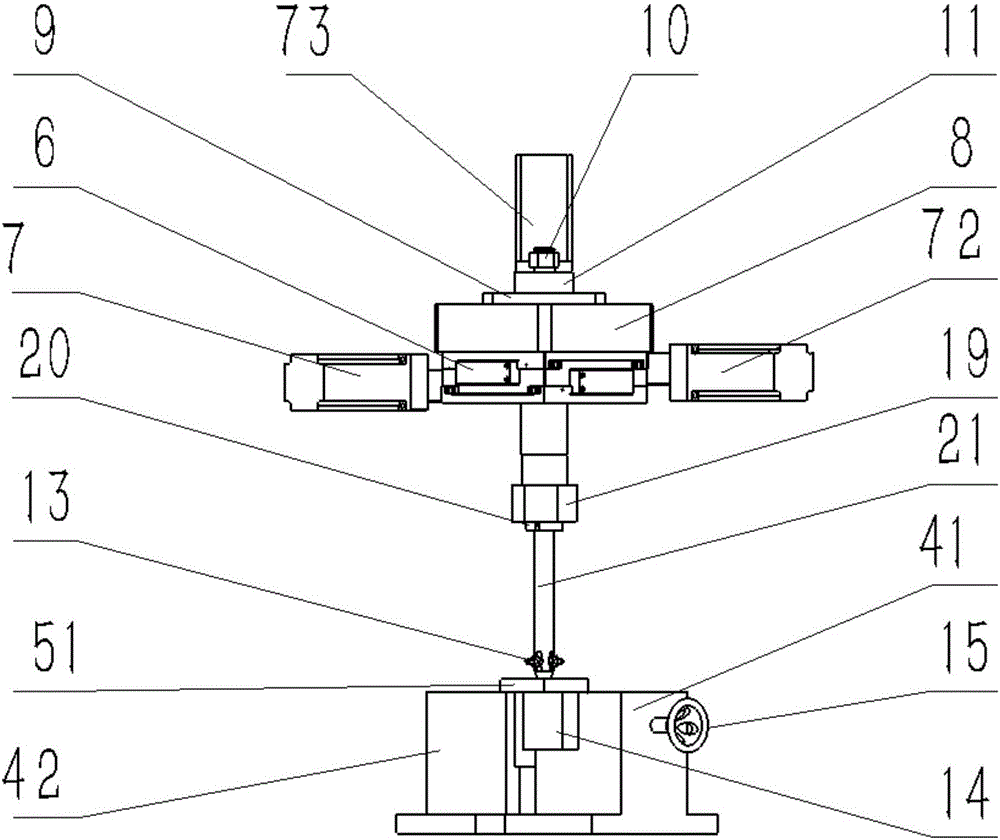

Machining device and method for polishing blade profile of integrated bladed disk

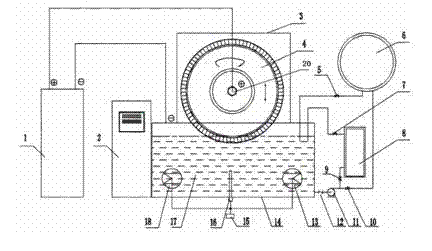

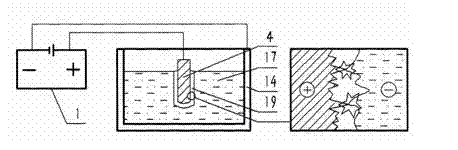

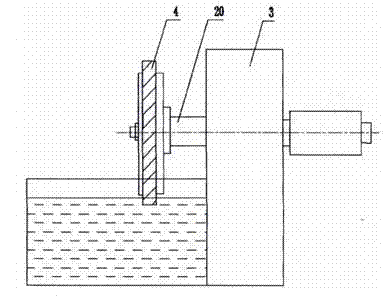

InactiveCN102489797ARealize the automation of polishing processQuality improvementMachining working media supply/regenerationMachine toolMachining

The invention provides machining device and method for polishing the blade profile of an integrated bladed disk by applying electrolyte-plasma machining technology, which is characterized in that: an integrated bladed disk work-piece 4 is located and clamped on a machine tool spindle 20, and the integrated bladed disk work-piece 4 is connected with the positive pole of a power supply; a blade part is soaked in an electrolyte 17 in a machine tool working pool 14, and the electrolyte is connected with the negative pole of the power supply; the spindle 20 starts to rotate with a rotational speed N and drives the bladed disk to rotate; and process parameters are set and then polishing machining for the blade profile is performed. The machining device and method for polishing the blade profile of an integrated bladed disk has the following advantages that: continuous machining, efficiency increasing and uniform machining surface can be realized; as well as the automation of polishing machining for the blade profile of integrated bladed disk and batch production with high efficiency and low cost can also be realized.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

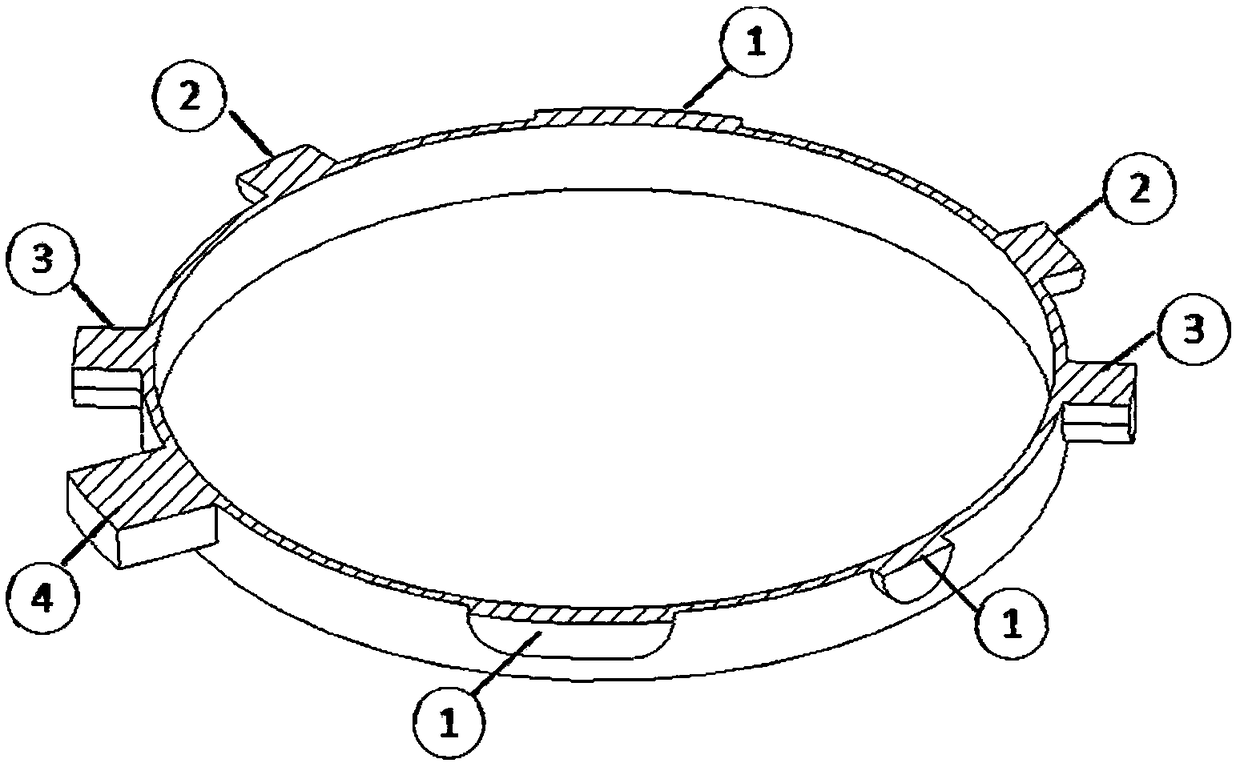

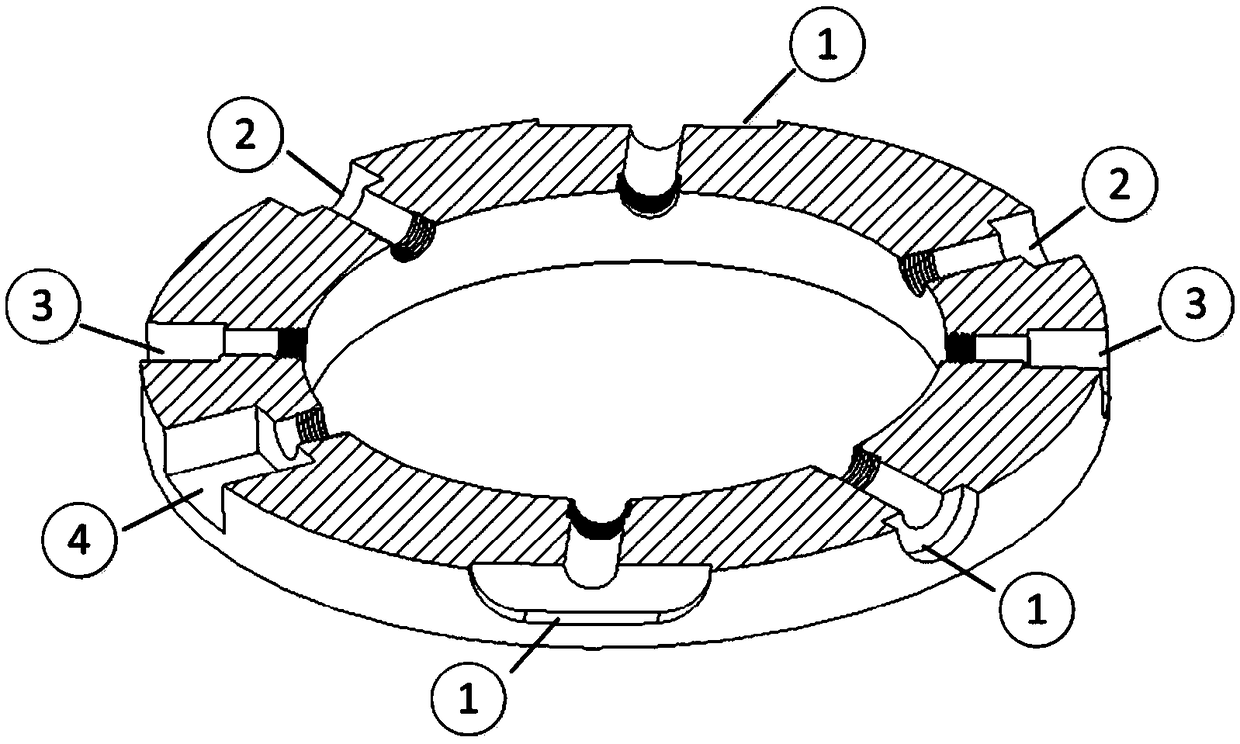

Rotary marking electrolysis method of different-height bosses on surface of revolved body, and cathode system

ActiveCN108788345APrecise control of processing heightRealize one-time processing and moldingMachining electrodesMachining working media supply/regenerationElectrolysisMachining process

The invention relates to a rotary marking electrolytic machining method of different-height bosses on the surface of a revolved body, and a cathode system, and belongs to the field of electrolytic machining. The method comprises the following steps that a revolved body tool cathode is adopted, grooves in different depths are formed in the surface of the cathode, and only the side walls of the interiors of the grooves are insulated; the bosses with the identical heights are sequentially divided into I type, II type, III type and the like from small to large according to the heights of the bosses machined on the surface of a workpiece; in the machining process, an electrolyte rushes into a machining area from the side surface, all the cathode grooves are filled with gas simultaneously, and the end surfaces of the bosses are prevented from being corroded; when the feeding amount of the cathode meets the machining requirement of the I type of the boss, a reversing valve in circuit I is switched, the groove corresponding to the I type of the boss is filled with the electrolyte, the end surface of the I type of the boss is continuously dissolved with the feeding of the cathode, and the heights of the bosses tend to be constant; and similarly, with the increase of the feeding amount, reversing valves in other circuits are sequentially switched, and one-time machining on the different-height bosses on the surface of the whole part is completed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

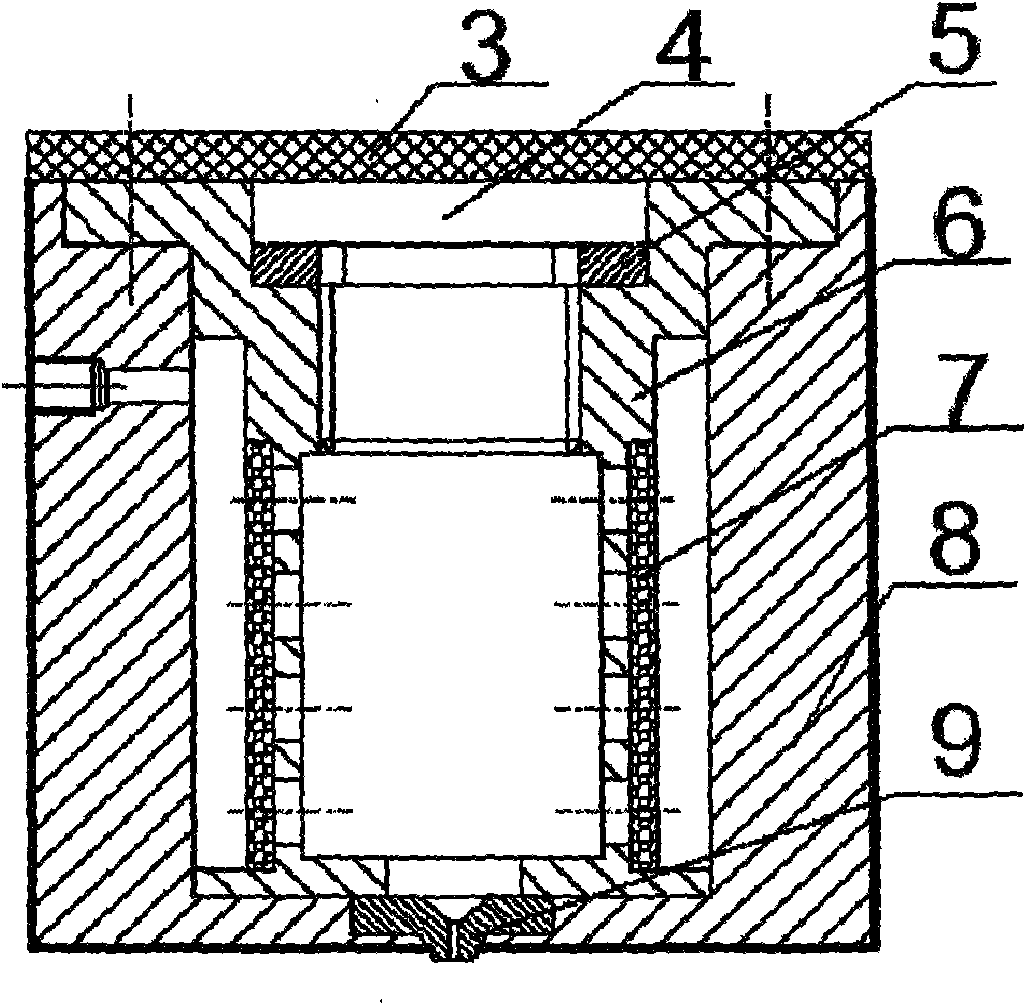

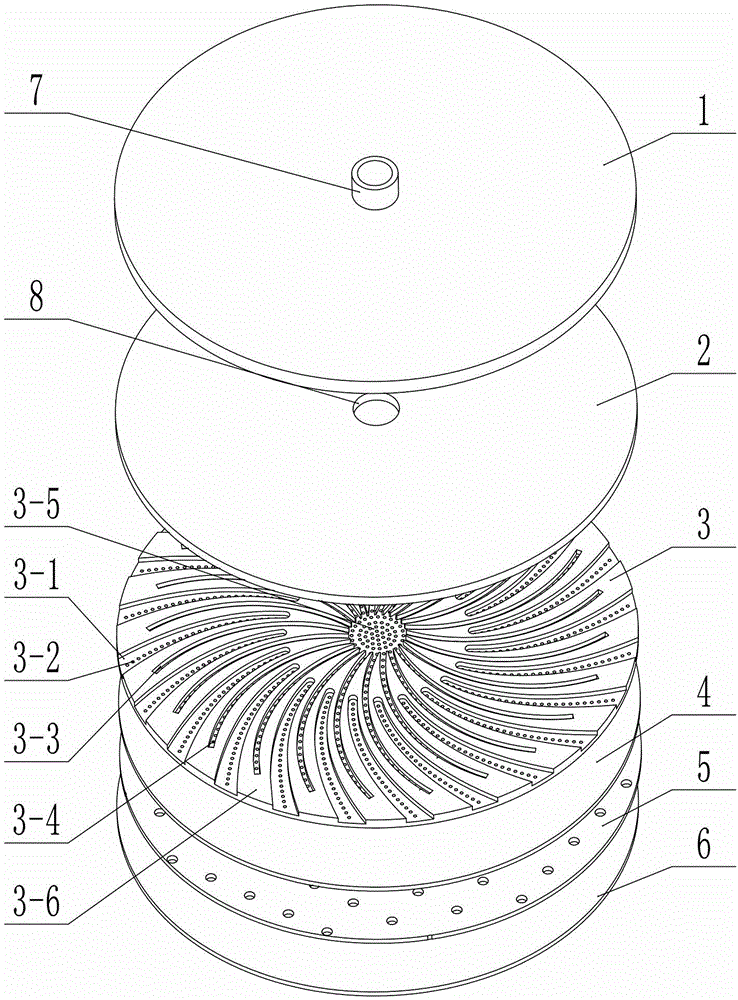

Liquid drainage device used for electrochemical machining of interelectrode porous medium filling type mask

InactiveCN104785872AShort discharge routeReduce resistanceMachining working media supply/regenerationElectrolysisPorous medium

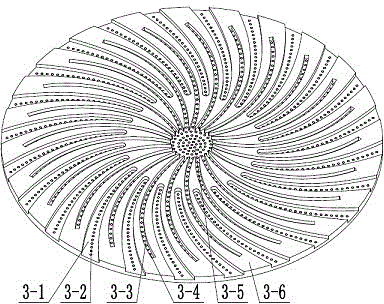

The invention discloses a liquid drainage device used for electrochemical machining of an interelectrode porous medium filling type mask. The liquid drainage device comprises a top cover, a sealing pad, a cathode, a non-metal flexible porous medium, the mask and a workpiece anode, wherein the front face of the cathode is flat, evenly distributed grooves and bosses formed between every two adjacent grooves are formed on the back face of the cathode; the grooves include a round liquid gathering groove located in the center of the cathode, arc drainage grooves located in the other areas except the liquid gathering groove and distributed in a windmill shape, and liquid outlet grooves formed between every two adjacent drainage grooves; the drainage grooves are not communicated with the liquid outlet grooves; liquid inlet holes are formed inside the liquid gathering groove and the drainage grooves; liquid outlet holes are formed inside the liquid outlet grooves; the top cover, the sealing pad, the cathode, the porous medium and the mask are tightly attached to the workpiece anode in sequence from top to bottom, and therefore a core machining unit is formed. The liquid drainage device enables electrolysate to be discharged more easily by directly changing the shape of the cathode, and enables a flow field on the surface of the workpiece anode to be distributed more evenly, thereby improving electrochemical machining quality.

Owner:HENAN POLYTECHNIC UNIV

Electrolytic machining device

ActiveCN104625260AEfficient dischargeMachining electrodesElectrolysis componentsEngineeringVacuum pump

An electrochemical machining apparatus includes a fastening bracket, a first drive member positioned on the fastening bracket, a connecting member, a first electrode connected to the connecting member, a second driving member, a second electrode connected to the second driving member, a moving assembly positioned on the fastening bracket, an electrolytic cell positioned on moving assembly, a pump, and a vacuum pump. The first electrode defines a plurality of liquid collecting grooves spaced from each other. Each liquid collecting grooves defines a plurality of second through holes. At least one liquid collecting groove is connected to the pump, and the other liquid collecting grooves are connected to the vacuum pump. The portion of the second electrode can be inserted into and depart from the second through holes.

Owner:富联精密电子(郑州)有限公司

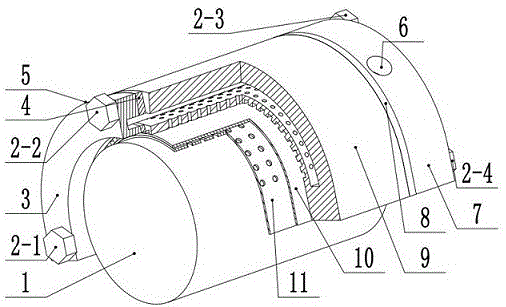

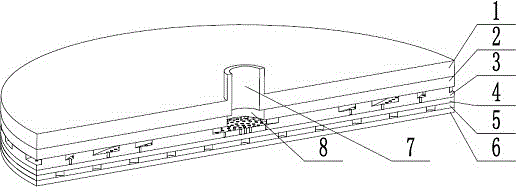

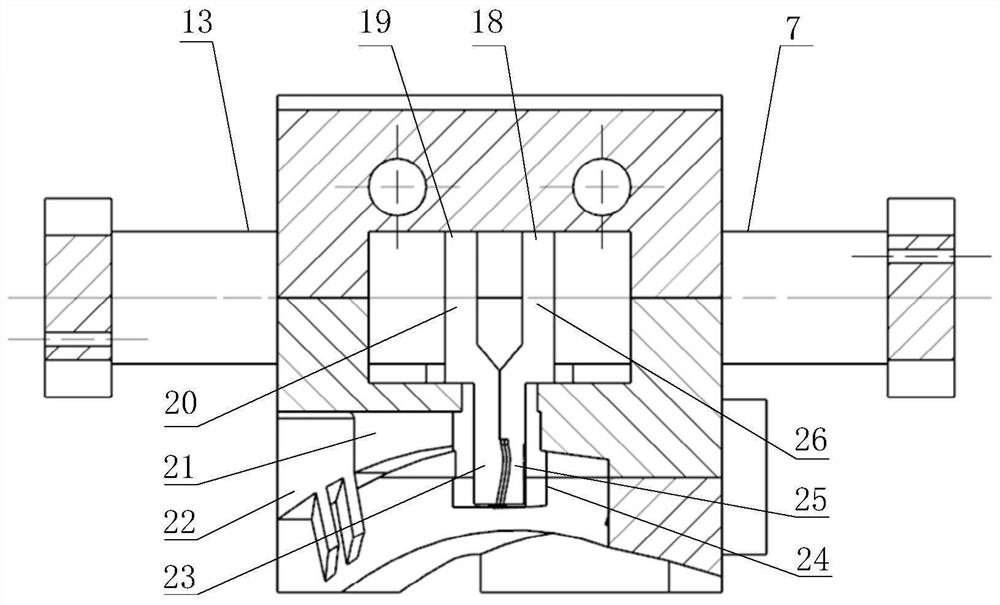

Blisk electrolytic machining device and method for blade full-profile liquid supply

ActiveCN112059333AEasy to shapeMake up for the uncontrollable defect of the flow fieldMachining working media supply/regenerationElectrolytic agentEngineering

The invention relates to a blisk electrolytic machining device and a method for blade full-profile liquid supply, and belong to the field of electrolytic machining. The blisk electrolytic machining device are used for correspondingly supplying electrolyte to a blade basin, a blade back, an air inlet edge and an air outlet edge of a blade. The clamp body is provided with a main liquid supply flow channel and an auxiliary liquid supply flow channel; the main liquid supply flow channel comprises a blade back flow channel and a blade basin flow channel which are used for supplying the electrolyteto the blade back and the blade basin machining area correspondingly, and liquid inlets of the main liquid supply flow channel are formed in the back surface of a blade back cathode and the back surface of a blade basin cathode; the auxiliary liquid supply flow channel comprises an air inlet side flow channel and an air outlet side flow channel which are used for supplying the electrolyte to the blade air inlet side machining area and the blade air outlet side machining area correspondingly, and liquid inlets of the auxiliary liquid supply flow channel are formed above the blade blank air inlet side and below the blade blank air outlet side; and the blade back cathode, the blade basin cathode, the blisk workpiece and the clamp body form a closed flow field mode in which the electrolyte ineach flow channel is independently controlled. The method is characterized in that liquid is supplied to the whole profile of the blade, the uniformity of a flow field of a machining area is improved,the machining stability and repeated precision of air inlet and outlet edges are improved, and the whole-profile molded surface of the blisk is machined.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

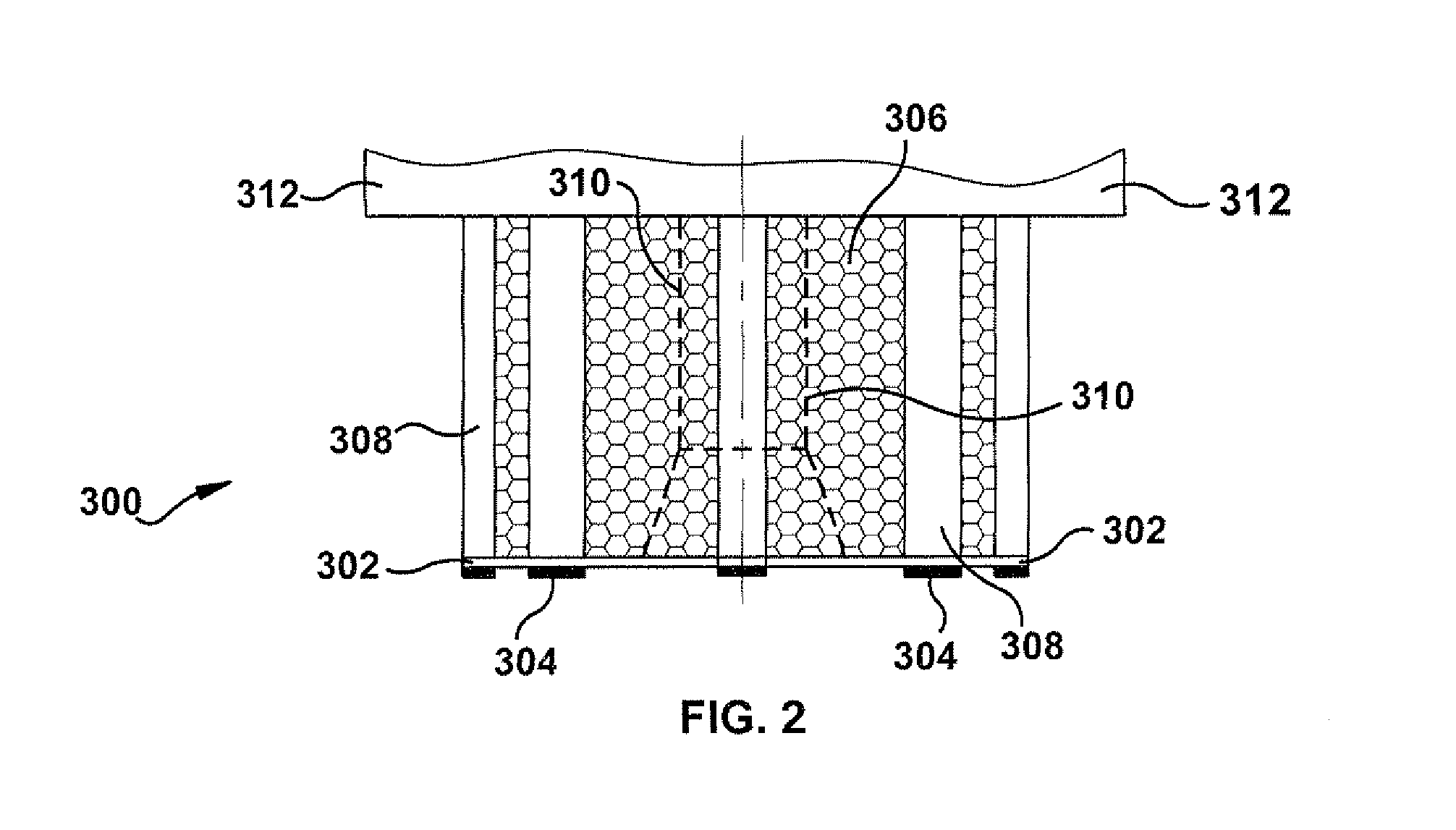

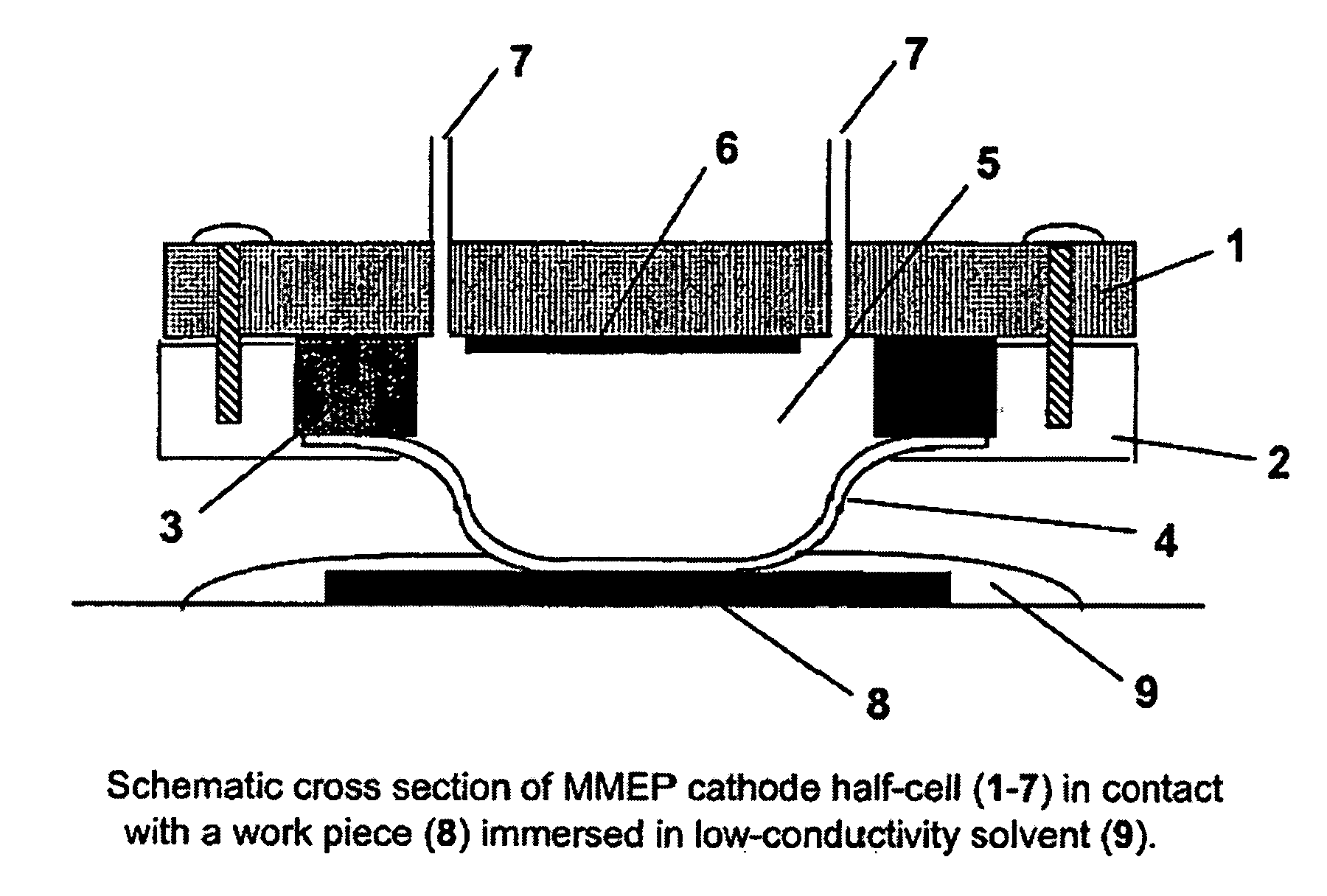

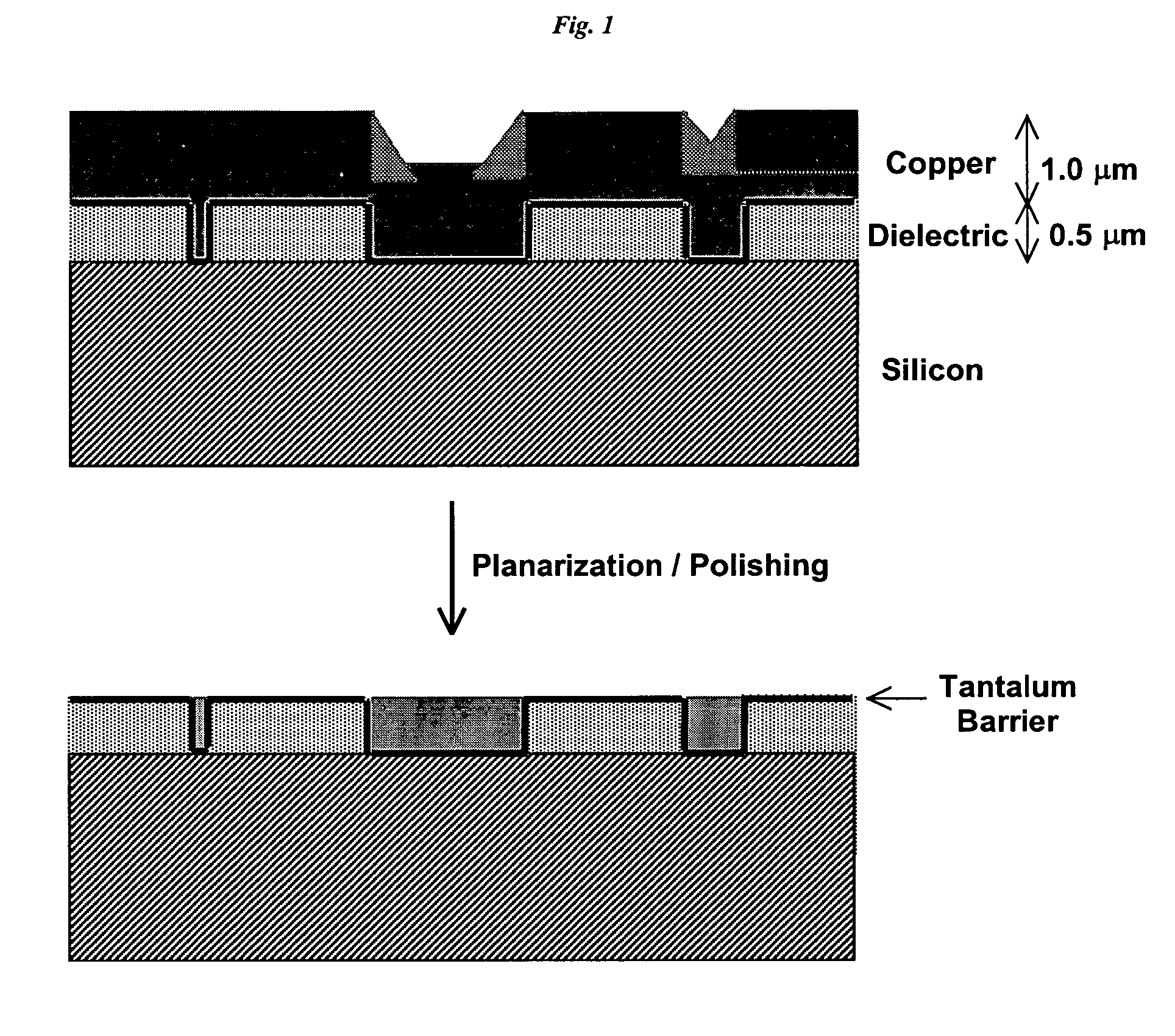

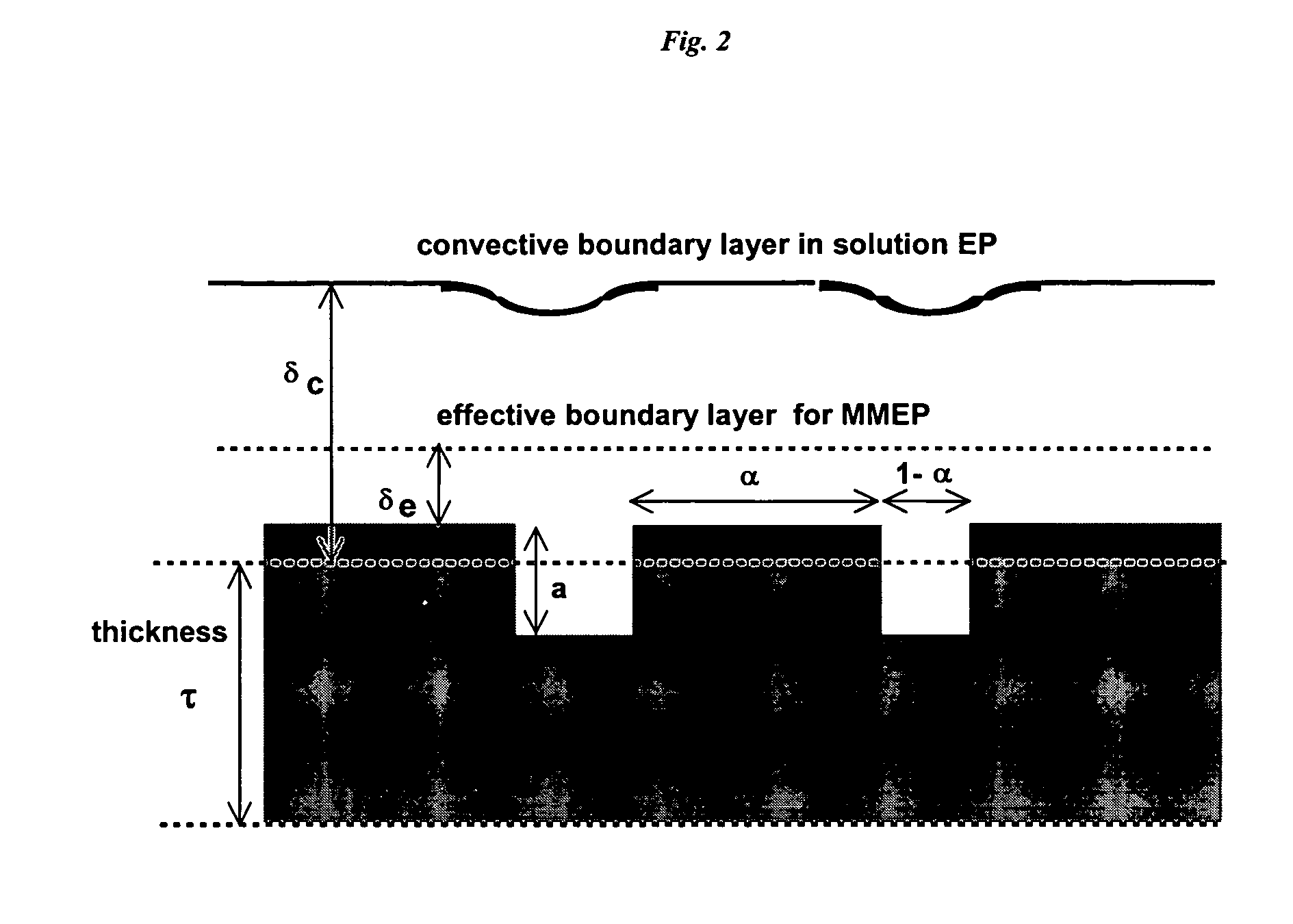

Membrane-mediated electropolishing

InactiveUS7422677B2Efficiently planarizedElectrolysis componentsSemiconductor/solid-state device manufacturingElectrolysisPower flow

Owner:EI DU PONT DE NEMOURS & CO

Electrochemical machining device

InactiveCN107116275AEfficient removalImprove stabilityMachining working media supply/regenerationElectrolysisMachined surface

The invention discloses an electrochemical machining device comprising a machine tool and a solution supplying system, wherein the machine tool is used for clamping a workpiece and driving a workpiece cathode to move relative to the workpiece in the X-axis direction, the Y-axis direction and the Z-axis direction, and the solution supplying system is used for supplying solution to the workpiece. The electrochemical machining device further comprises a pressure pulse system. The pressure pulse system comprises an air compressor, a gas pulse generator and a gas-liquid mixer, wherein the air compressor, the gas pulse generator and the gas-liquid mixer are sequentially connected. The gas-liquid mixer is connected with the liquid supplying system, mixes gas and liquid intermittently and outputs the gas and liquid mixture to the workpiece cathode. By the adoption of the electrochemical machining device, the pressure pulse system is arranged, and gas is intermittently input and mixed with the work solution, a liquid-state working solution and a gas-liquid two-phase work solution alternately perform; and when the gas-liquid two-phase work solution fills a machining interval, fine bubbles in the electrolytic solution approaches a machined surface and crack due to blockage, in the crack process, quite high pressure and micro-jet are generated, a metallic oxide attached layer prone to generation during electrochemical machining is effectively removed, and therefore the stability of electrochemical machining is improved.

Owner:GUANGDONG UNIV OF TECH

Electrode and machining device and method for electrolytic cutting rapid forming of turbine disc mortise

ActiveCN107962262ASolve technical problems such as high processing precisionReduce labor intensityMachining electrodesMachining working media supply/regenerationElectrolysisEngineering

The invention relates to an electrode and machining device and method for electrolytic cutting rapid forming of a turbine disc mortise, and belongs to the technical field of aero-engine turbine disc mortise electric machining. The electrode is a cutting electrode and is used for serving as a tool cathode on an electrolytic machine tool to carry out rapid cutting forming machining on the turbine disc mortise. The machining device adopting the electrode as the cutting electrode comprises a power source, a work box, a turbine disc part, the cutting electrode, a workpiece clamping and locating system and an electrolyte circulating system. The method adopting the device for cutting machining comprises the steps that equipment is mounted, alignment is carried out, a machining gap is adjusted, cutting machining is carried out, machining parameters are controlled in the machining process, after machining is completed, the turbine disc part is rotated to the next station in an indexing manner,and the process is repeated till electrolytic cutting machining of the whole turbine disc mortise is completed. The method adopts the cutting electrode for electrolytic cutting rapid forming, and through the electrolytic cutting rapid forming machining technological process, high-efficiency and high-quality machining of the turbine disc mortise is completed.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Double-channel tube electrode and electrolytic cutting method thereof

ActiveCN108890053AReduced turbulent diffusionImprove uniformityMachining electrodesMachining working media supply/regenerationElectrolysisEngineering

The invention relates to a double-channel tube electrode and an electrolytic cutting method thereof and belongs to the technical field of electrochemical processing. The double-channel tube electrodeand the electrolytic cutting method thereof are mainly characterized in that a double-channel metal tube with one end closed is adopted as a tool cathode for electrolytic cutting, wherein arrayed small holes are obliquely formed downward in the wall surface of the outer side of a liquid conveying channel of the double-channel tube electrode, and slightly elongated seams are formed in both sides ofthe wall surface of the outer side of an air conveying channel. During electrolytic cutting, an electrolyte is obliquely ejected from the arrayed small holes downward to increase the downward flow rate of the electrolyte and promote the discharge of electrolysis products, and the efficiency of electrolytic cutting is improved; at the same time, high-pressure gas is ejected from the slightly elongated seams to close the electrolyte in a front-end machining gap, the turbulent diffusion range of the electrolyte in the machining gap is reduced, the electrolytic machining area is reduced, and theelectrolytic cutting precision is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

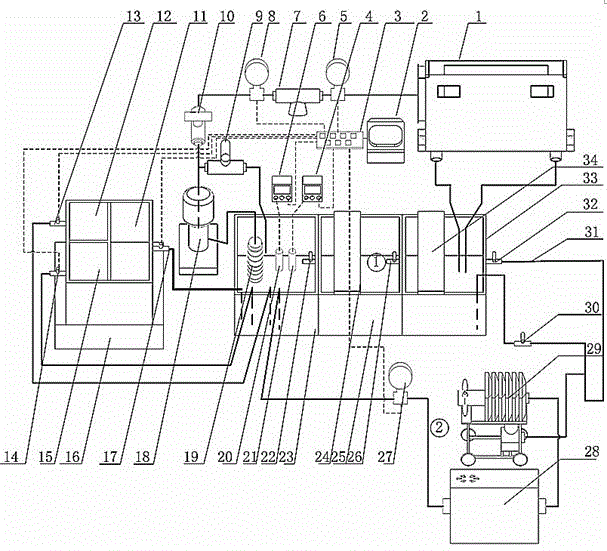

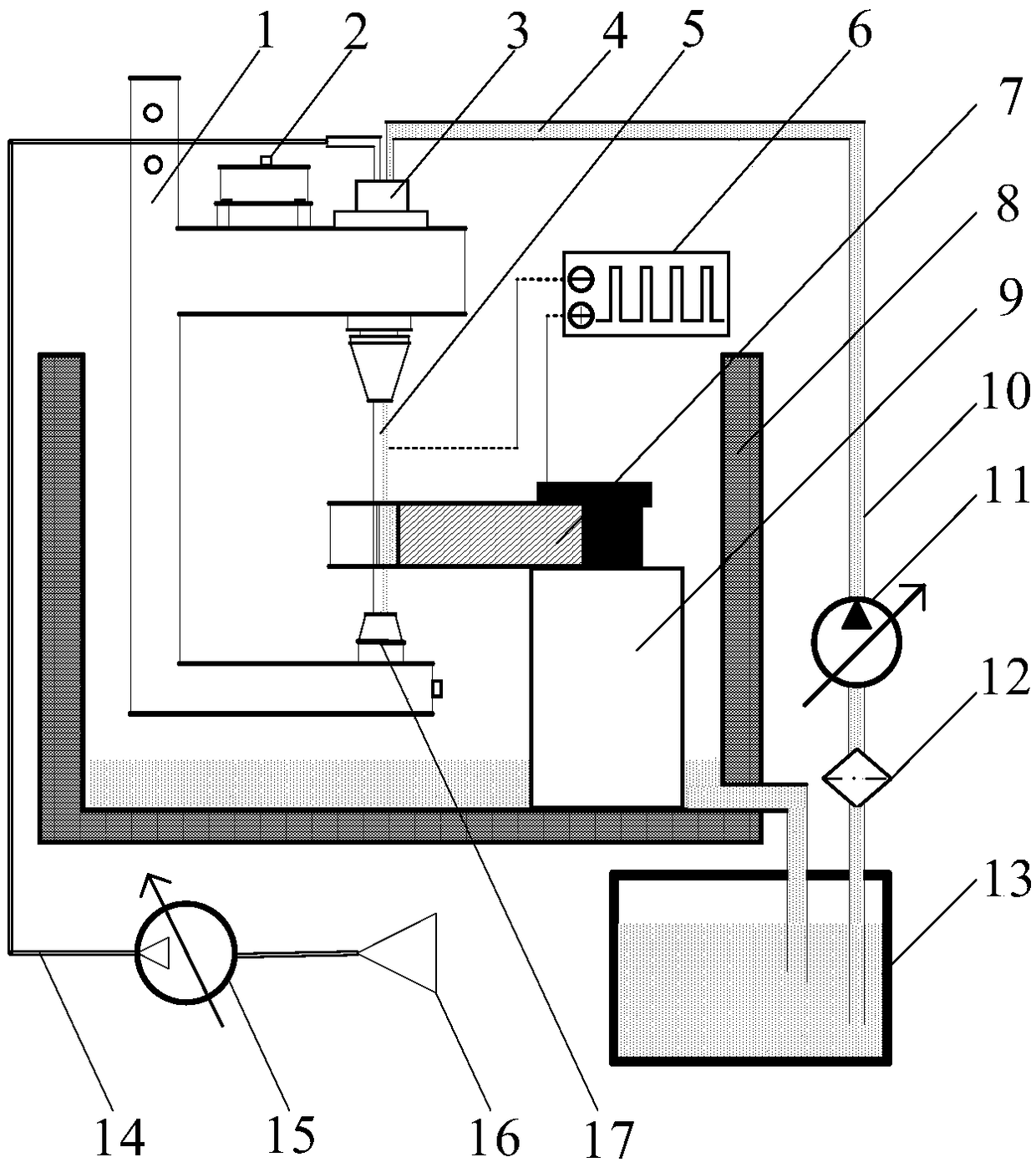

Electrolyte precise control system with real-time adjustable parameters and working method thereof

ActiveCN104801796AStable temperatureImprove stabilityMachining working media supply/regenerationWater bathsAutomatic control

The invention relates to an electrolyte precise control system with real-time adjustable parameters and a working method thereof; and the invention belongs to the technical field of electrolytic machining. The system substantially comprises a turbid fluid tank (3), a buffer tank (5), a clear fluid tank (6), a sample regulating tank (7), a ceramic membrane filter (13), a solid-liquid separation device (1), a cold-heat exchanging device (4), a constant-temperature water bath device (8), a machine tool backflow water tank (2), and a plurality of automatic regulating valves, pumps, sensors, or the like. The system can achieve the automatic control to the turbidity of the electrolyte, can accurately control the temperature of the electrolyte and the flow speed of the electrolyte, can stabilize the ion concentrations of the electrolyte or regulate each ion concentration of the electrolyte as need during the machining process. The electrolyte precise control system with the real-time adjustable parameters can be used in association with a universal electrolytic machine tool, with the requirements to an electrolyte system in the electrolytic machining being substantially satisfied.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electrolytic machining machine tool for large-lead multi-roller-path rolling ball nut circular-arc spiral groove

ActiveCN106363263AImprove coaxialitySolve the rotation accuracyMachining working media supply/regenerationElectrical-based auxillary apparatusRotational axisElectrolysis

The embodiment of the invention discloses an electrolytic machining machine tool for a large-lead multi-roller-path rolling ball nut circular-arc spiral groove. A hollow rotary platform and an XY precise sliding table are arranged above a workbench; a cathode guide rod with a cathode ball head is driven to carry out electrolytic machining on a rolling ball nut semi-finished product piece, so that the technical problem that rotation precision and sealing effect of a rotary shaft are reduced due to the fact that the XY sliding table or a rotating mechanism is arranged under the workbench, and a workpiece is mounted on the rotary shaft which is guided out from the XY sliding table or the rotary mechanism in the prior art. According to the embodiment of the invention, the electrolytic machining machine tool comprises a machine tool body, an electrolyte circulating box, a power supply and a control cabinet.

Owner:GUANGDONG UNIV OF TECH

Focused ultrasonic vibration working solution electrochemical machining device and method

InactiveCN103962661ASpeed up the cycleImprove update speedMachining working media supply/regenerationElectrical-based auxillary apparatusElectrolysisHigh energy

The invention discloses a focused ultrasonic vibration working solution electrochemical machining device. The device comprises an electrochemical machining unit and an ultrasonic vibration unit. The electrochemical machining unit comprises an electrolyte box, a workpiece fixture and a power supply, wherein the electrolyte box is filled with an electrolyte, the workpiece fixture is arranged in the electrolyte box, a workpiece is fixed to the upper portion of the workpiece fixture and submerged into the electrolyte, a tool is arranged above the workpiece, a feeding mechanism is connected to the upper portion of the tool, and the positive electrode and the negative electrode of the power supply are connected with the workpiece and the tool respectively. The ultrasonic vibration unit can generate high-energy focused ultrasound gathering near the lower end of the tool. According to the device, the circulation and update speed of the electrolyte in electrochemical machining can be increased, electrolysis products between the workpiece and the tool can be discharged and prevented from depositing on the surface of the tool, and the machining efficiency and accuracy can be improved. The invention further discloses a method for carrying out focused ultrasonic vibration working solution electrochemical machining through the device.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com