Deep hole internal spline electrolytic machining device

A processing device and internal spline technology, which is applied in the field of deep hole internal spline electrolytic processing devices, can solve the problems of long exploration time for the number of liquid-increasing holes, complex cathode structure, and long initial feeding time, etc., and achieve shortening of auxiliary ineffective processing time, reduce the difficulty of cathode processing, and improve the effect of processing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

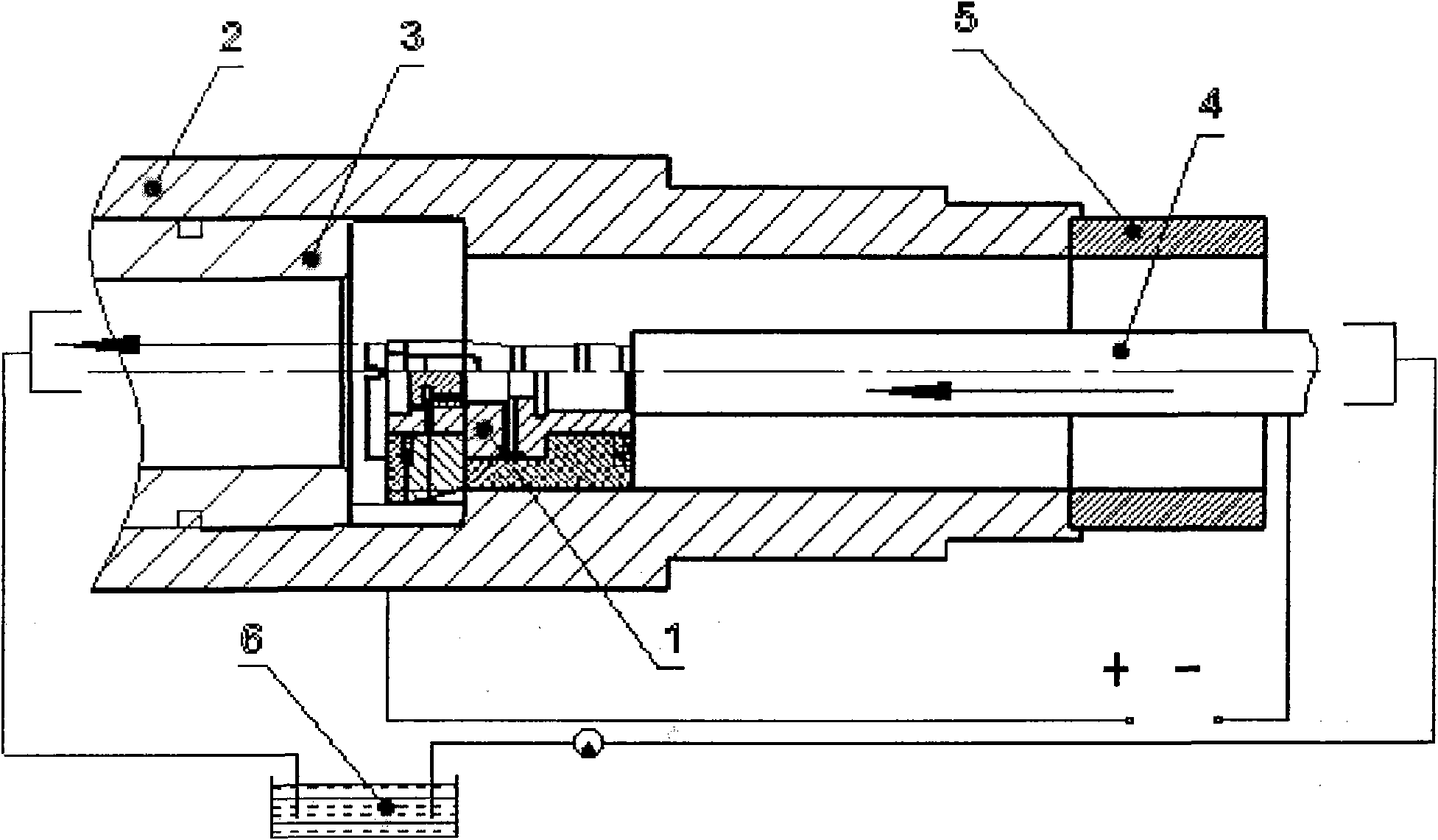

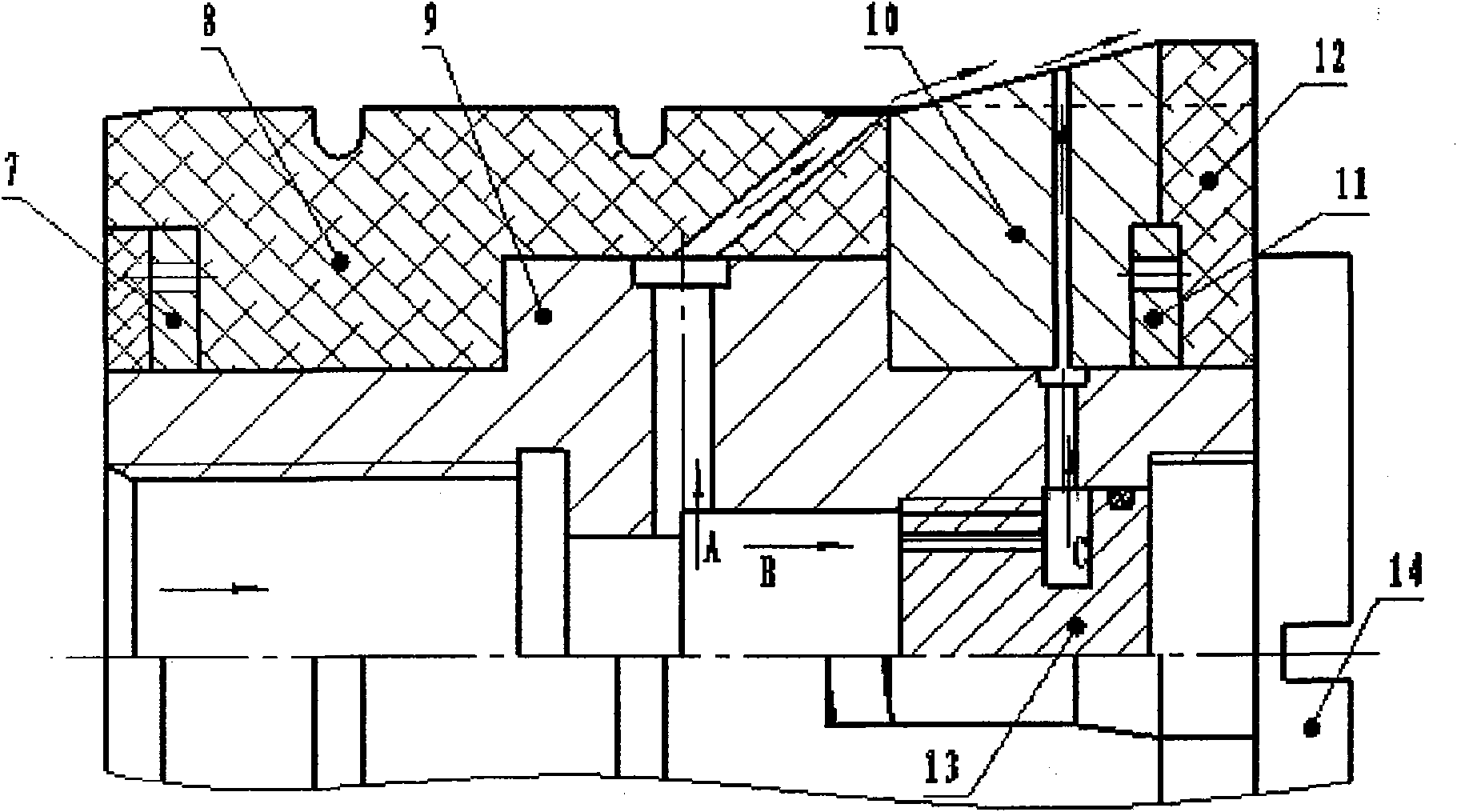

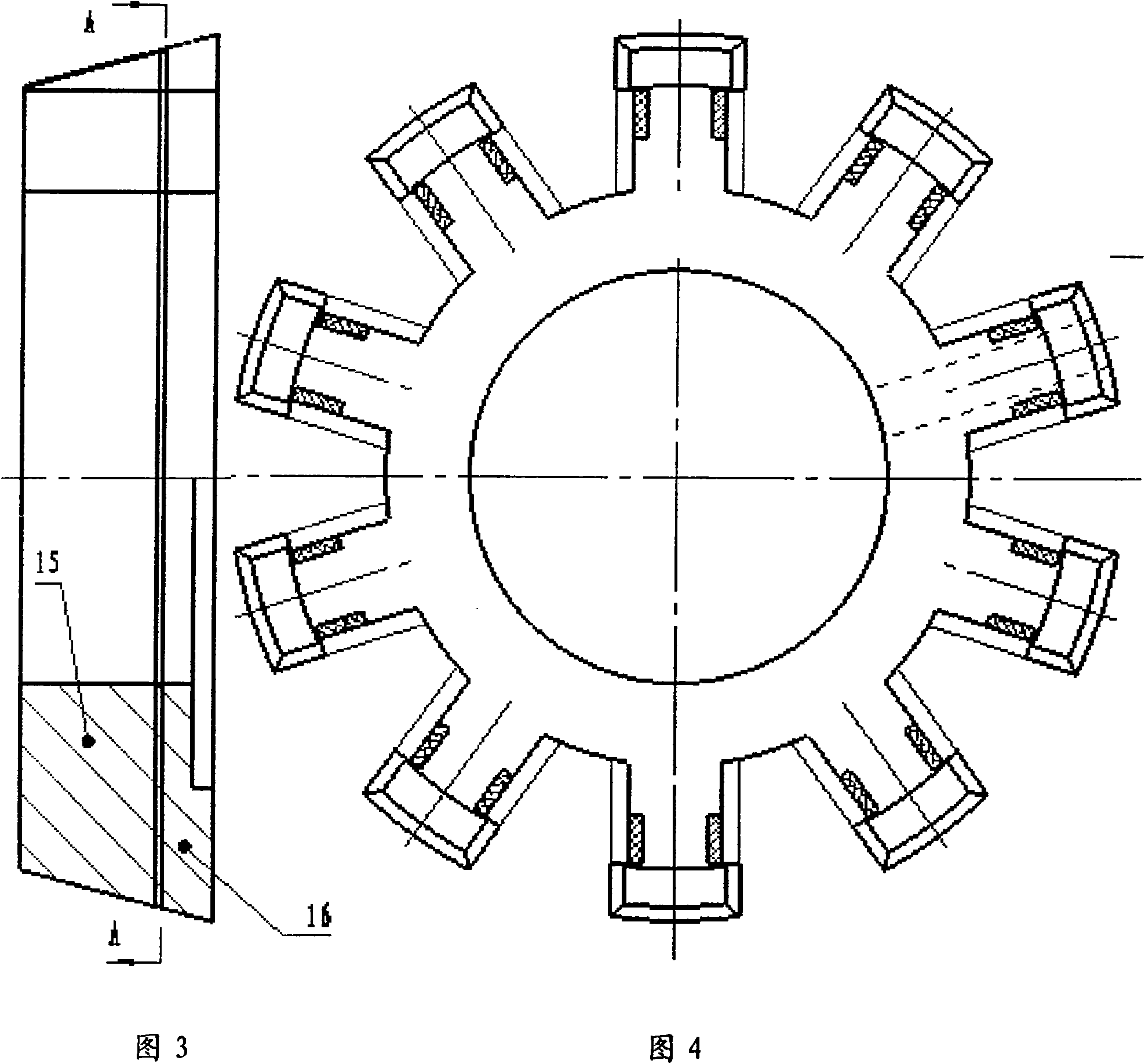

[0022] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , the spline electrolytic processing device in the deep hole of the present invention, its cathode 1 is installed in the middle part of the pre-hole of the workpiece 2 to be processed, the liquid guide auxiliary tool 3 is installed in the left part of the pre-hole of the workpiece to be processed, and the conductive liquid guide rod 4 Installed on the right part of the pre-hole of the workpiece 2 to be processed, one end of the conductive liquid guiding rod is connected to the cathode 1, and the other end passes through the process material head 5, and the process material head is connected to the right end of the processed workpiece; the liquid guiding aid 3 and the conductive The liquid guide rods 4 are communicated with the electrolyte pool 6 respectively; the positive pole of the power supply is connected with the processed workpiece 2, and the negative pole of the power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com