Liquid drainage device used for electrochemical machining of interelectrode porous medium filling type mask

A porous medium and filling technology, which is applied in the direction of electrochemical processing equipment, processing working medium supply, metal processing equipment, etc., can solve the problem of large flow resistance of electrolyte, uneven distribution of flow field between electrodes, and affect the effect of electrolytic processing and speed to achieve the effect of small resistance and short discharge route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

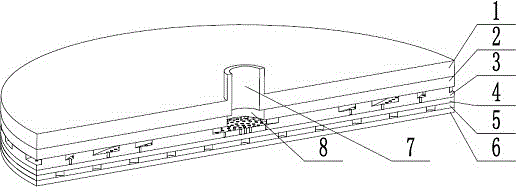

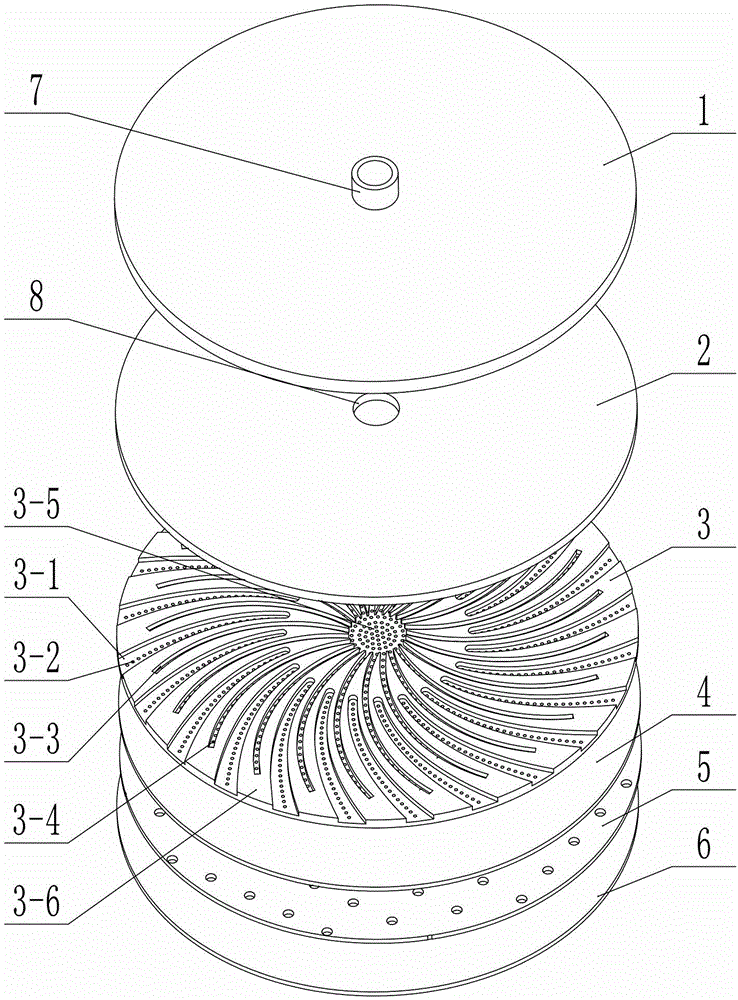

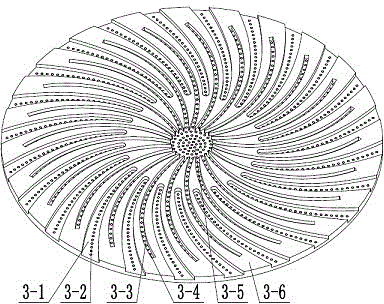

[0023] Attached below Figures 1 to 5 The implementation of the present invention is further described.

[0024] Such as Figures 1 to 5 As shown, a liquid introduction device for inter-electrode porous medium filled mask electrolytic processing, including a flat top cover 1 with a liquid inlet 7, a sheet-shaped gasket 2 with a central through hole 8 , a cathode 3 with through holes, a non-metallic flexible porous medium 4, a mask 5 and a workpiece anode 6; the front side of the cathode 3 is flat; the back side of the cathode 3 contains evenly distributed grooves and formed between two adjacent grooves The boss 3-6; the groove includes a circular sink 3-5 located in the center of the cathode 3, an arc-shaped drainage groove 3-3 evenly distributed in a windmill shape located in other areas except the sink 3-5, and The liquid outlet tank 3-1 installed between two adjacent drainage tanks; the drainage tank 3-3 is not connected to the liquid outlet tank 3-1; one end of the drain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com