Electrochemical machining method and device for pulsating flow field tube electrode

A processing method and technology of electrolytic processing machine tools, which are applied in the direction of electrochemical processing equipment, metal processing equipment, and the supply of processing working media, can solve the problems of inability to popularize fixed cathodes, poor processing stability, and complex device structures, etc., and achieve Improve electrochemical reaction efficiency, improve flow field, simple effect of pulsating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

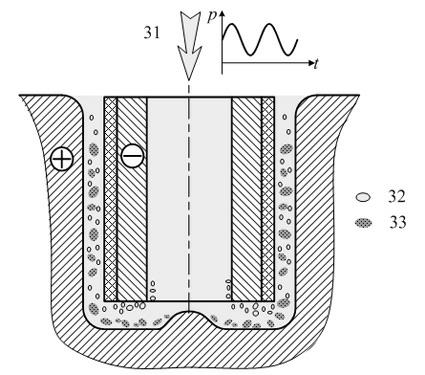

[0024] figure 1 In the process, the electrolyte enters the tube electrode 9 with a certain pressure, injects into the processing gap at a high speed, takes away the electrolysis product and Joule heat, and completes the renewal of the electrolyte between the electrodes. The localization of the electrolytic machining can be improved through the insulation of the side wall of the tube electrode 9 .

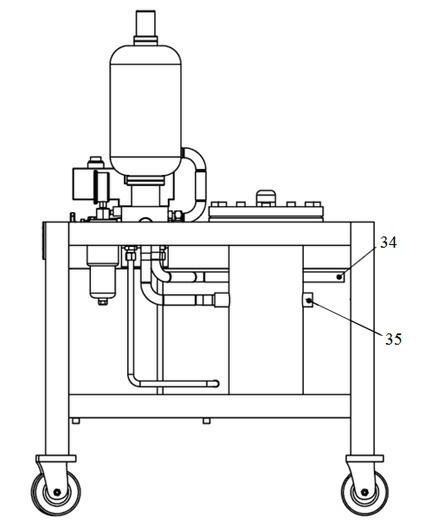

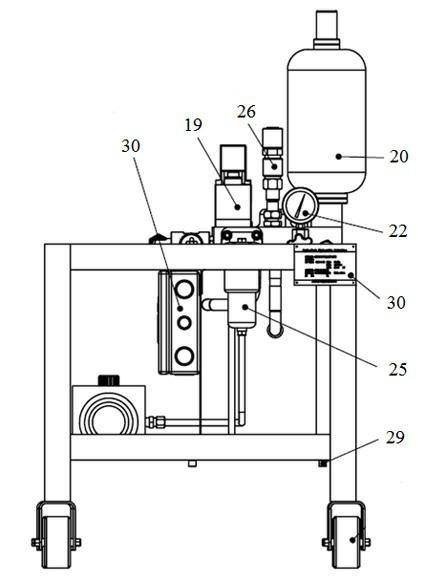

[0025] figure 2 In the shown pulsating flow field tube electrode electrolytic machining system, the pulse power supply 15, the spindle feed device 7, the electrode fixture 6, the machine tool body 8, the working box 12 and the workbench 10 form the electrolytic machining machine tool hardware system; the motion control card 14, The data acquisition card 17, the current sensor 16, the industrial computer 18 and related circuits constitute the control system of the electrolytic machining machine tool; the electrolytic liquid storage tank 1, the one-way valve 2, the pressure pump 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com