PDC bit rock breaking tool

A tool and rock-breaking technology, which is applied in the field of PDC drill bit rock-breaking tools, can solve the problems of reducing the service life of the drill bit, short action time of the drill bit, and low energy utilization rate, so as to improve the service life, rock-breaking efficiency, and energy utilization rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following non-limiting examples serve to illustrate the invention.

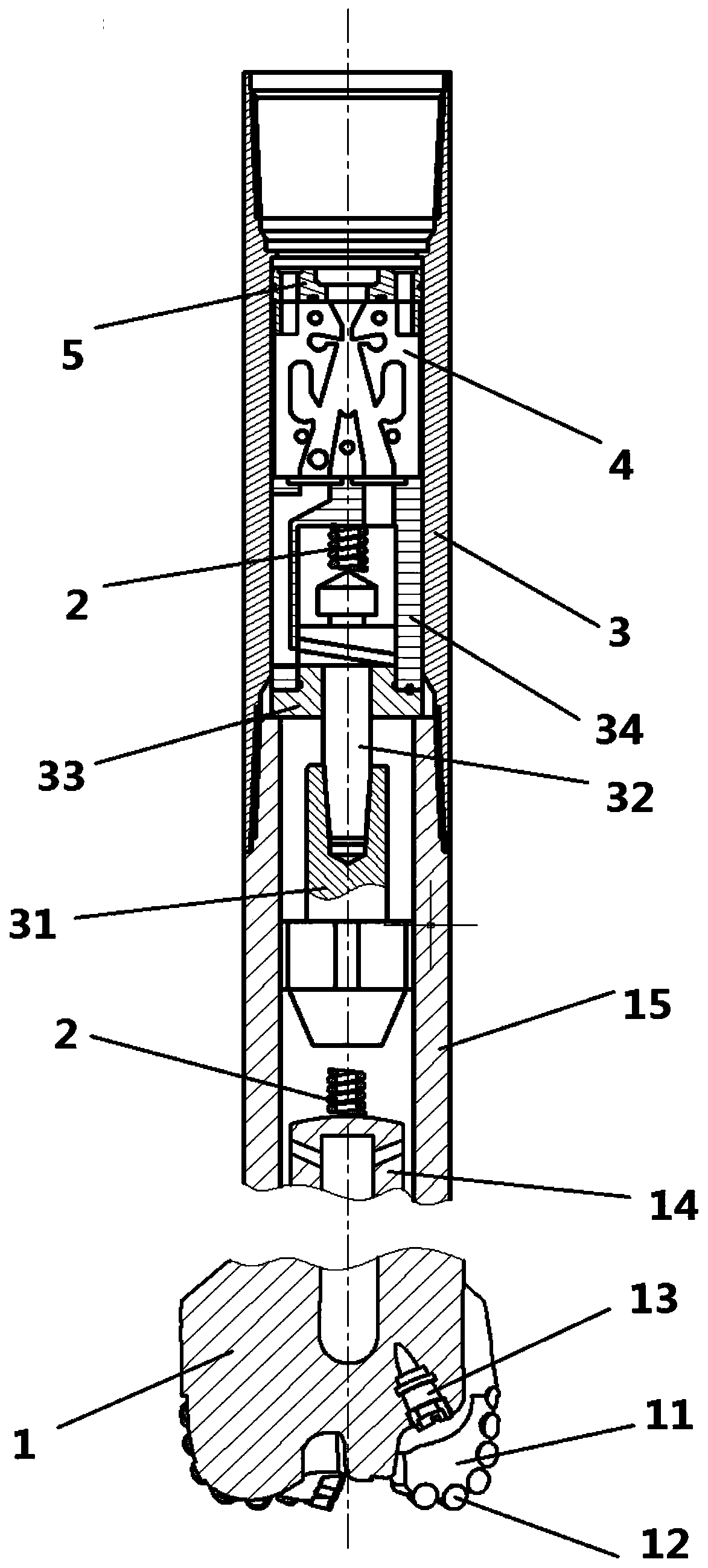

[0025] A PDC bit rock breaking tool, comprising a bit body 1, a blade 11, a PDC tooth 12, and a nozzle 13. The rock breaking tool is provided with a tool housing 3, a diverter 5, a jet element 4, and a piston from top to bottom. The cylinder 34, the piston 32, the hammer 31, the anvil 14, the drill body 1, the anvil 14 is arranged inside the drill body 1, the anvil 14 is provided with an elastic element 2, and the piston cylinder 34 is provided with an elastic element 2. Such as figure 1 Shown.

[0026] Preferably, the elastic element in the rock breaking tool is a leaf spring, a coil spring, a gas spring, or a rubber spring.

[0027] Preferably, the disturbance frequency of the rock breaking tool is controlled within the range of 5Hz-50Hz.

[0028] Preferably, the perturbation amplitude of the rock breaking tool to the drill bit is controlled by 3mm-10mm.

[0029] Preferably, the ratio of the axial force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com