Subtly processing method of electrolyte axial flow and special electrode nozzle therefor

A technology of axial flow and processing methods, which is applied in the direction of electrochemical processing equipment, metal processing equipment, and the supply of processing working media, etc., can solve the problems that the electrolyte cannot be updated in time and has poor stability, so as to reduce time and area and enhance The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

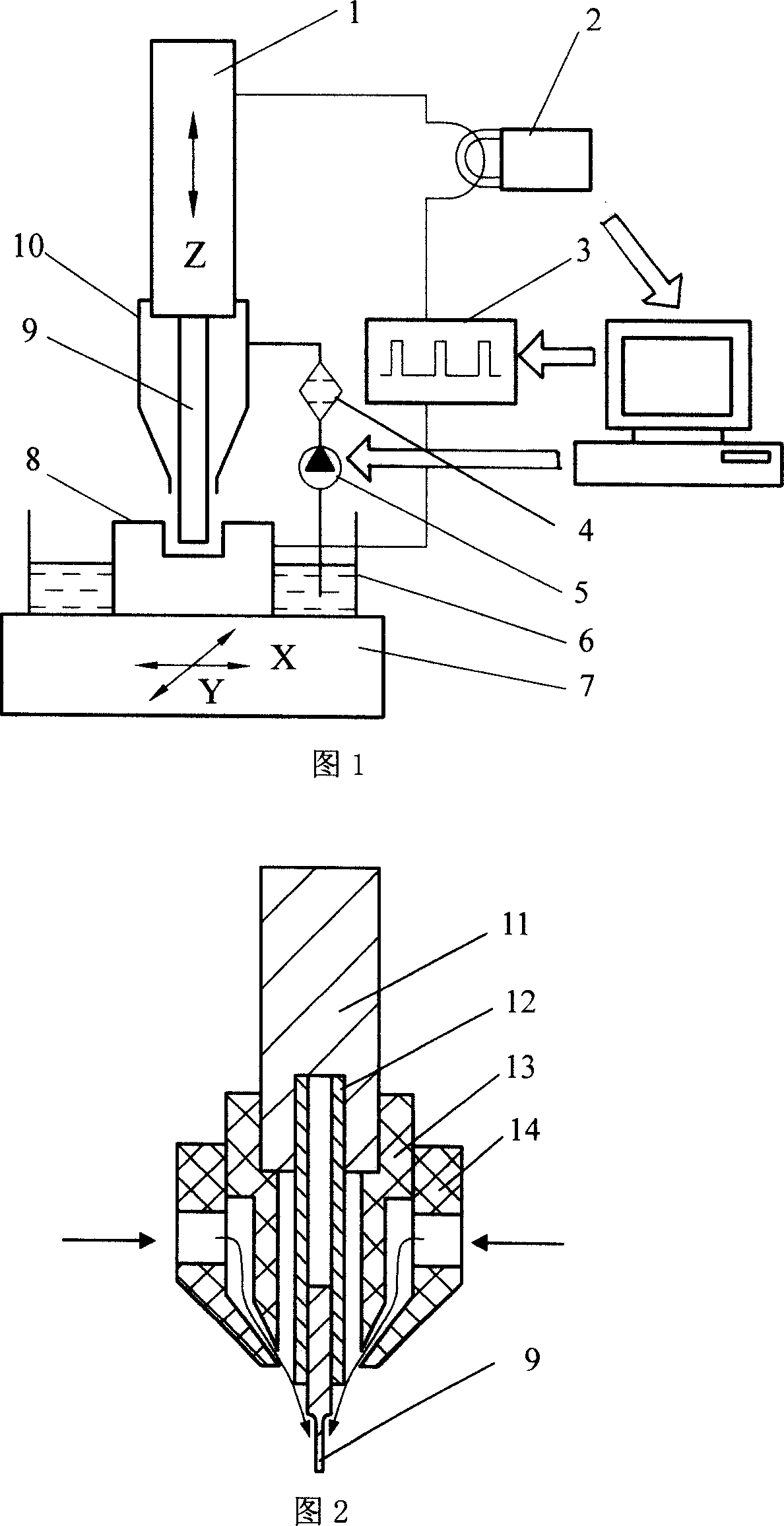

[0015] The device for implementing the "microelectrolytic machining method with axial flow of electrolyte" of the present invention is shown in Figure 1. Including the spindle 1 and workbench 7 of the micro electrolytic machining machine tool, the current sensor 2, the micro electrolytic machining pulse power supply 3, the electrolyte filter 4, the acid and alkali resistant micro pump 5, the electrolyte tank 6, the workpiece anode 8 to be processed, the micro Tool cathode 9 and electrode nozzle 10. Wherein the electrode nozzle is composed of a nozzle chuck 11 , an electrode sleeve 12 , a nozzle inner sleeve 13 and a nozzle outer sleeve 14 .

[0016] Concrete implementation steps of the present invention are as follows:

[0017] 1. The electrode nozzle is installed on the spindle of the machine tool with a spring collet and connected to the electrolyte circulation pipeline. The micro tool electrode is inserted into the electrode sleeve, and the anode of the workpiece is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com