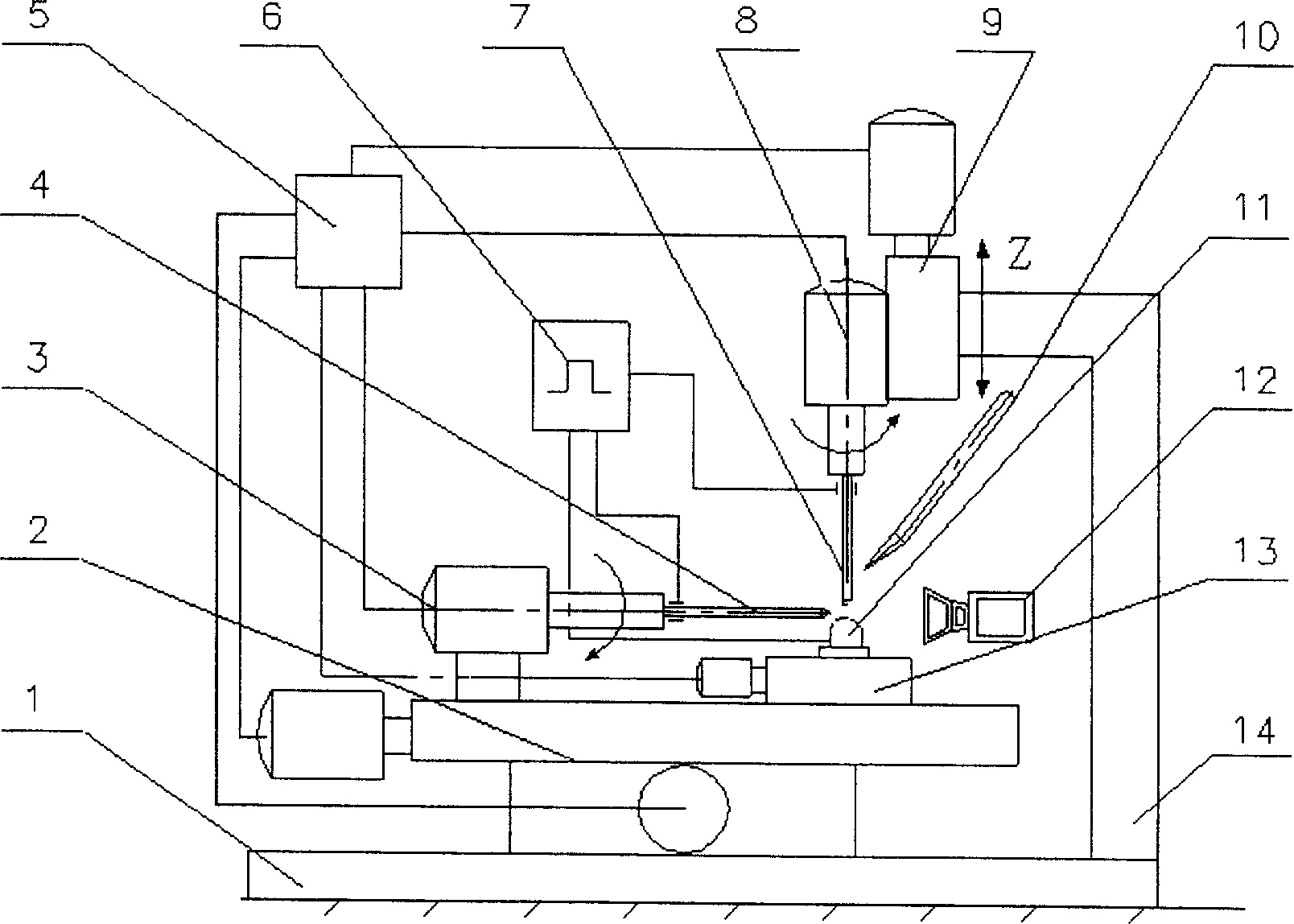

Three-dimension micro-expansion electrolysis processing method and apparatus

A technology of generating electrolysis and processing devices, which is applied in the field of three-dimensional micro-generating electrolytic processing methods and processing devices, which can solve the problems of difficult electrode processing and long electrode processing cycles, and achieve high forming precision, self-adaptive control, and leveling powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

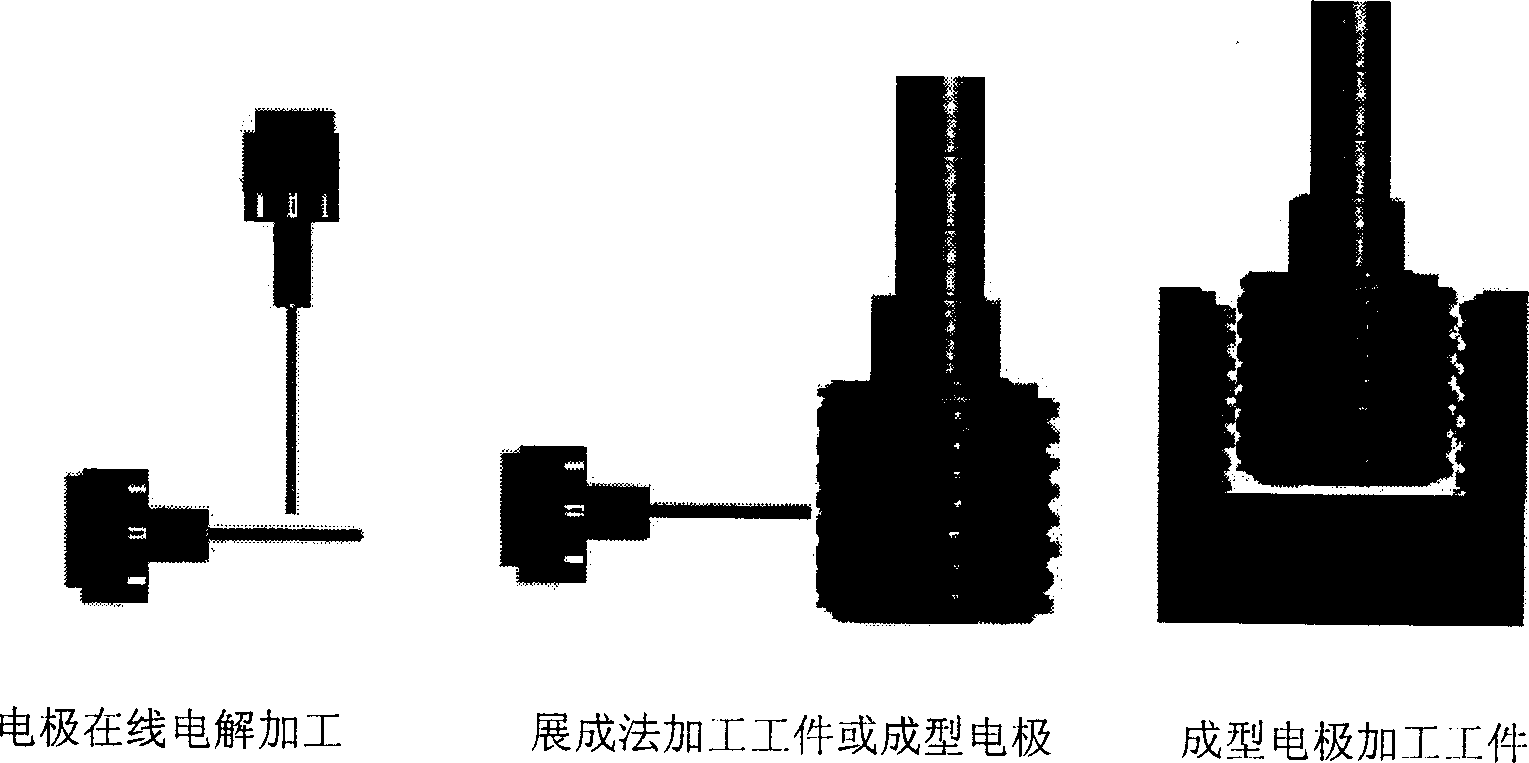

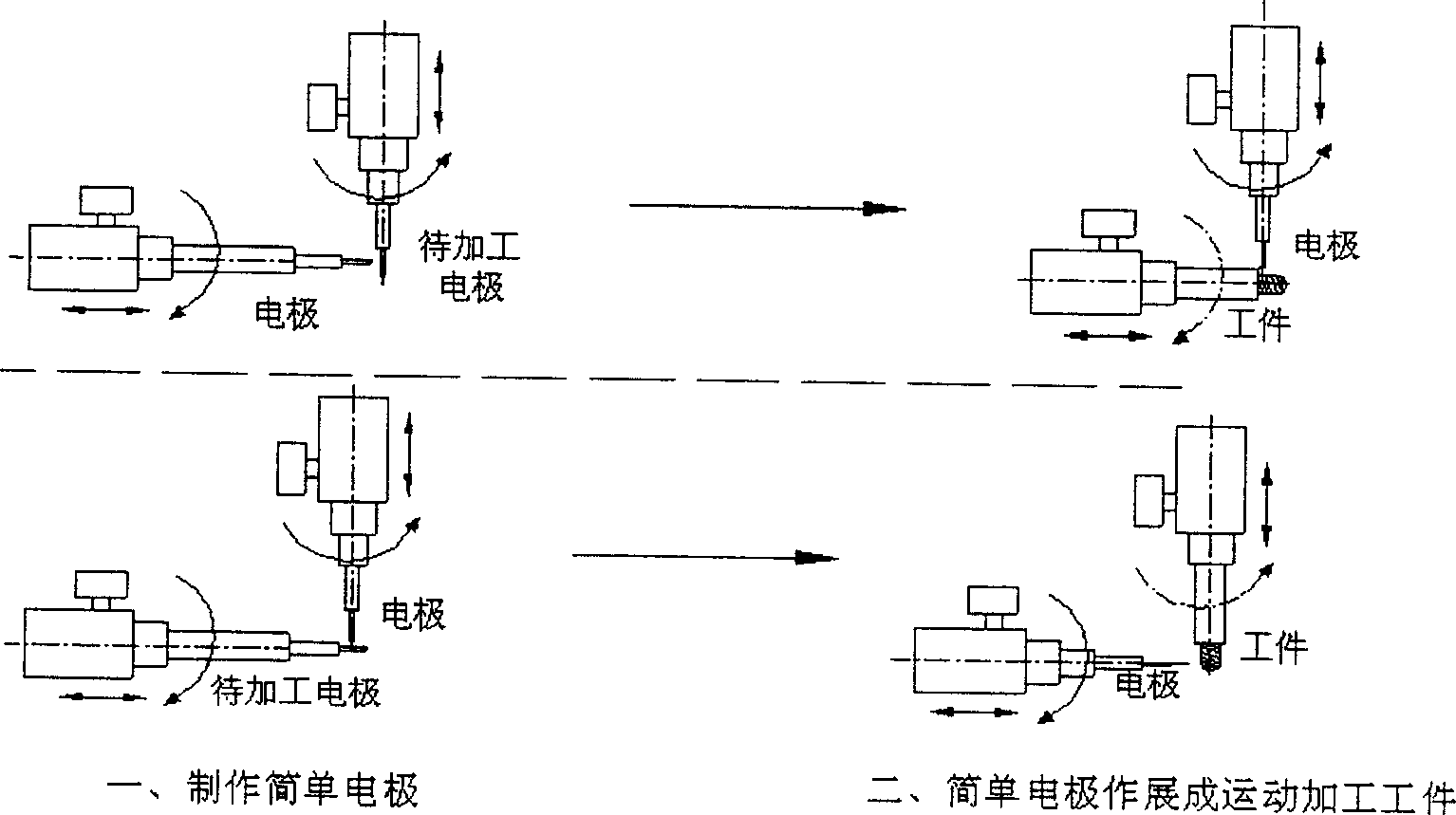

[0054] 1. If using image 3 In the processing method shown, a simple tool electrode with a certain shape at the tip can be used to process tiny screws, drills, etc., and it can also be used to process small, pointed probes with a certain shape. Firstly, the tool electrode is designed and manufactured, and the process is as follows: image 3 Shown in the two left figures. One electrode is connected to the negative electricity of the pulse power supply as the tool electrode; the other is connected to the positive electricity as the electrode to be processed. According to the processing situation, the two can also exchange positive and negative electrical connections during the processing process to carry out interactive processing. Design the shape of the electrode to be processed according to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com