Electrolytic machining machine tool for large-lead multi-roller-path rolling ball nut circular-arc spiral groove

An electrolytic machining machine tool and ball nut technology, which is applied in the direction of electric processing equipment, electrochemical processing equipment, metal processing equipment, etc., can solve the problems such as the rotation accuracy of the rotating shaft and the reduction of sealing effect, so as to facilitate the flow collection and reduce the processing accuracy requirements , the effect that is conducive to collection and supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

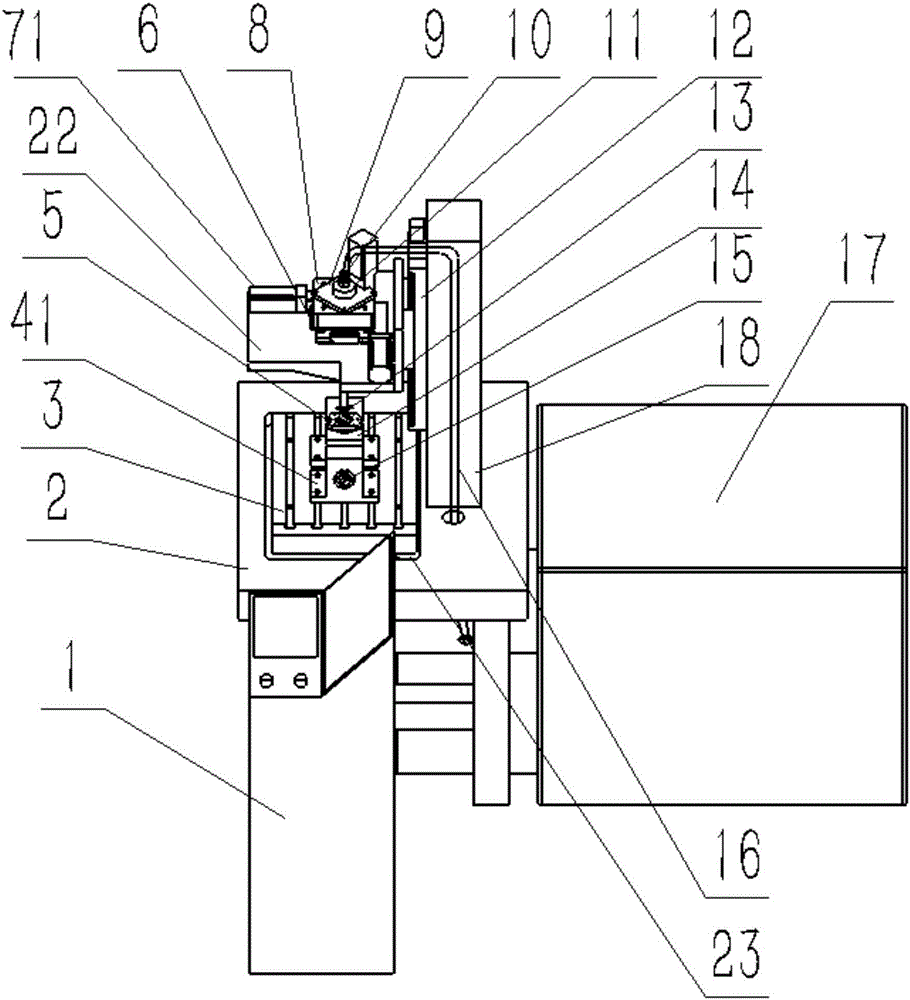

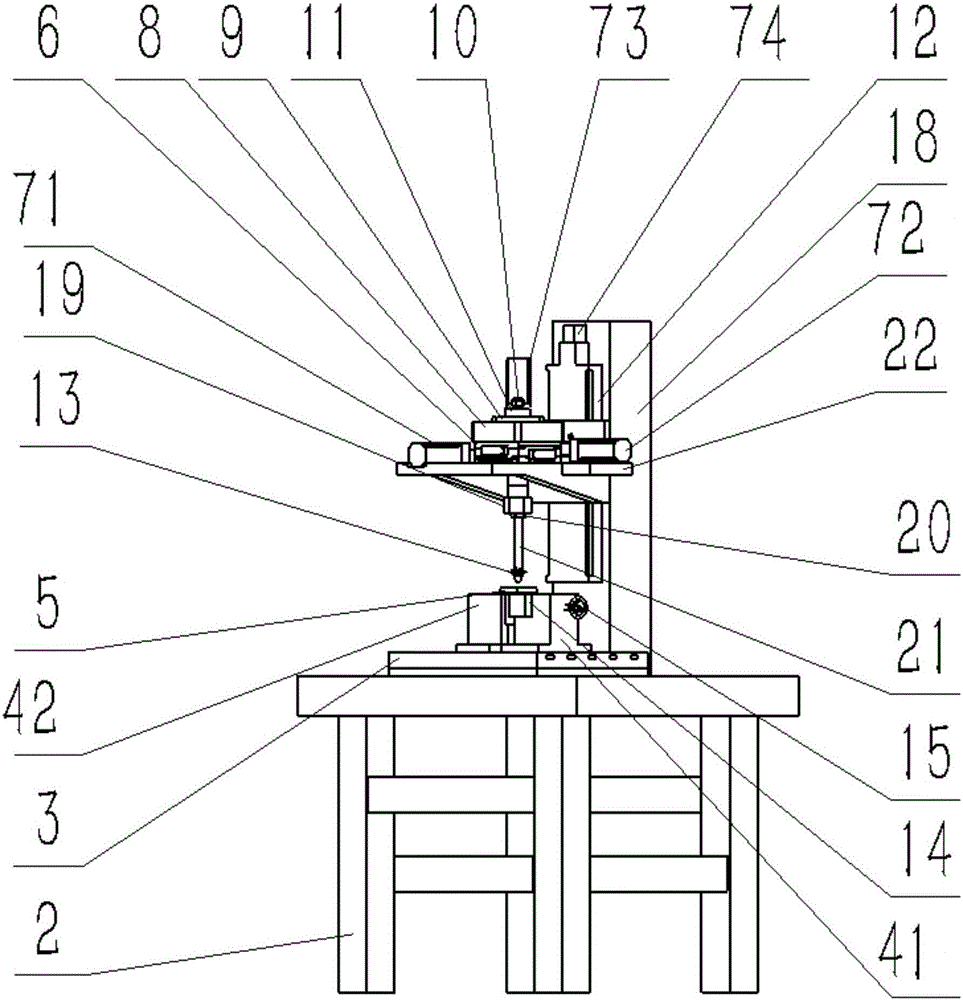

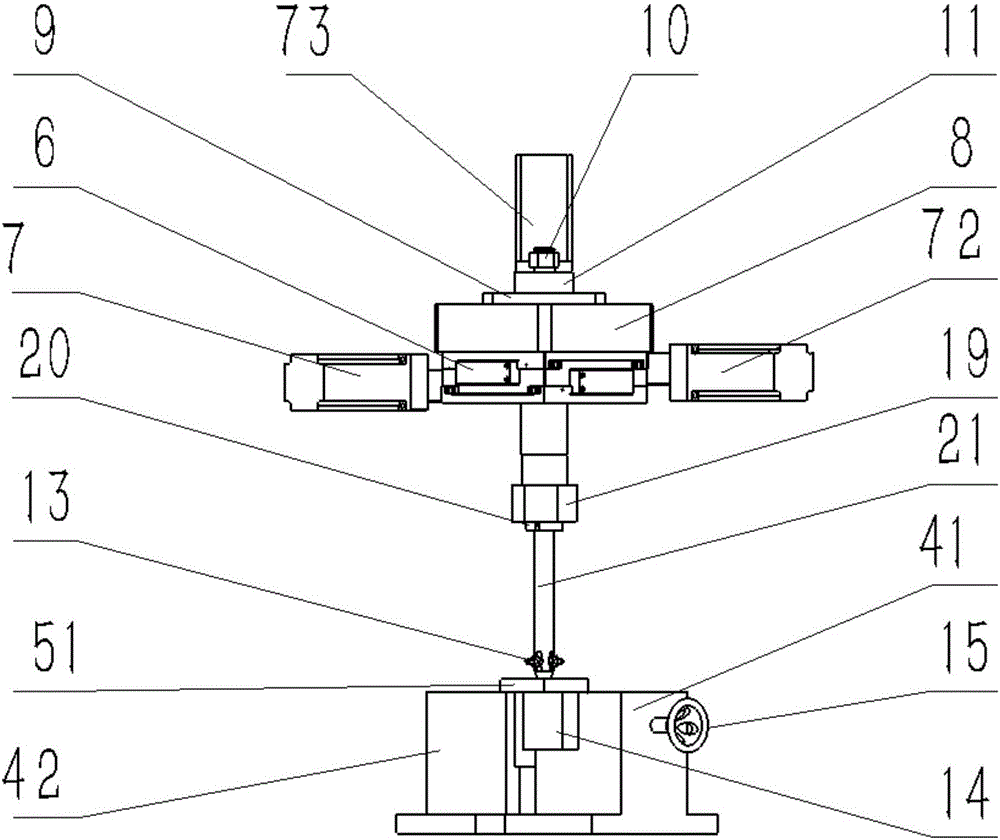

[0043] The embodiment of the present invention provides an electrolytic machining machine tool with a large-lead multi-raceway ball nut arc spiral groove. By setting the hollow rotating platform and the XY precision slide table above the workbench, the cathode guide provided with the cathode ball head is driven. The rod performs electrolytic machining on the blank of the ball nut, which solves the problem of the rotation accuracy of the rotating shaft caused by placing the XY slide table or the rotating mechanism under the workbench and installing the workpiece on the rotating shaft drawn from the XY sliding table or rotating mechanism in the prior art. Technical problem with reduced sealing effect.

[0044] In order to make the purpose, features and advantages of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com