Insulation shielding sleeve material electrolytic machining cathode system and machining method

An insulating shielding and cathode technology, which is applied to machining electrodes, electric machining equipment, electrochemical machining equipment, etc., can solve the problems of secondary corrosion of the machined surface of the workpiece, and achieve the effect of improving surface quality and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

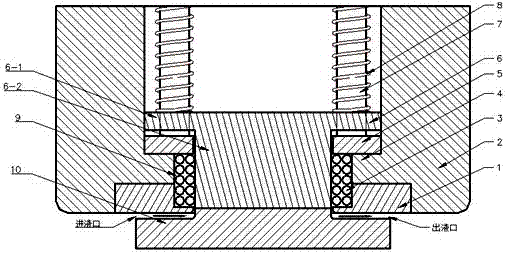

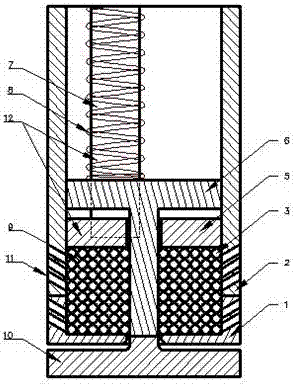

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Implementation of the present invention—"a cathode system and processing method for electrolytic processing of insulating and shielding casing", the device includes a casing cathode head, a casing cathode body, insulating particles, an insulating auxiliary block, an auxiliary positioning platform, a guide column, and a compression spring .

[0017] The casing cathode head and the casing cathode body are made of conductive metal materials; the insulating auxiliary block and the guide column are made of non-conductive materials; the shape of the cathode blade of the casing cathode head and the shape of the lower part of the insulating auxiliary block can be adjusted according to the processing The shape of the part is designed, and the size of the insulating auxiliary lower block is slightly smaller than the size of the spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com