Patents

Literature

98results about How to "Reduced fatigue life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium-magnesium alloy plate or extrusion

A high strength Al-Mg alloy in plate or extrusion form having significantly improved strength in both soft and work-hardened tempers as compared with AA5083 is provided. The materials have ductility, pitting, stress and exfoliation corrosion resistances equivalent to those of the AA5083. The materials have improved long term stress and exfoliation corrosion resistances at temperatures above 80° C. The composition is 5-6% Mg, >0.6-1.2% Mn, 0.4-1.5% Zn, 0.05-0.25% Zr, up to 0.3% Cr, up to 0.2% Ti, up to 0.5% each Fe and Si, up to 0.4% each Cu and Ag, remainder Al and inevitable impurities. Manufacture of plate of this alloy is by homogenizing an ingot, hot rolling the ingot into plate in the range 400-530° C., cold rolling the plate with or without inter-annealing, final and optionally inter-annealing of the cold rolled material at temperatures in the range 200-550° C.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

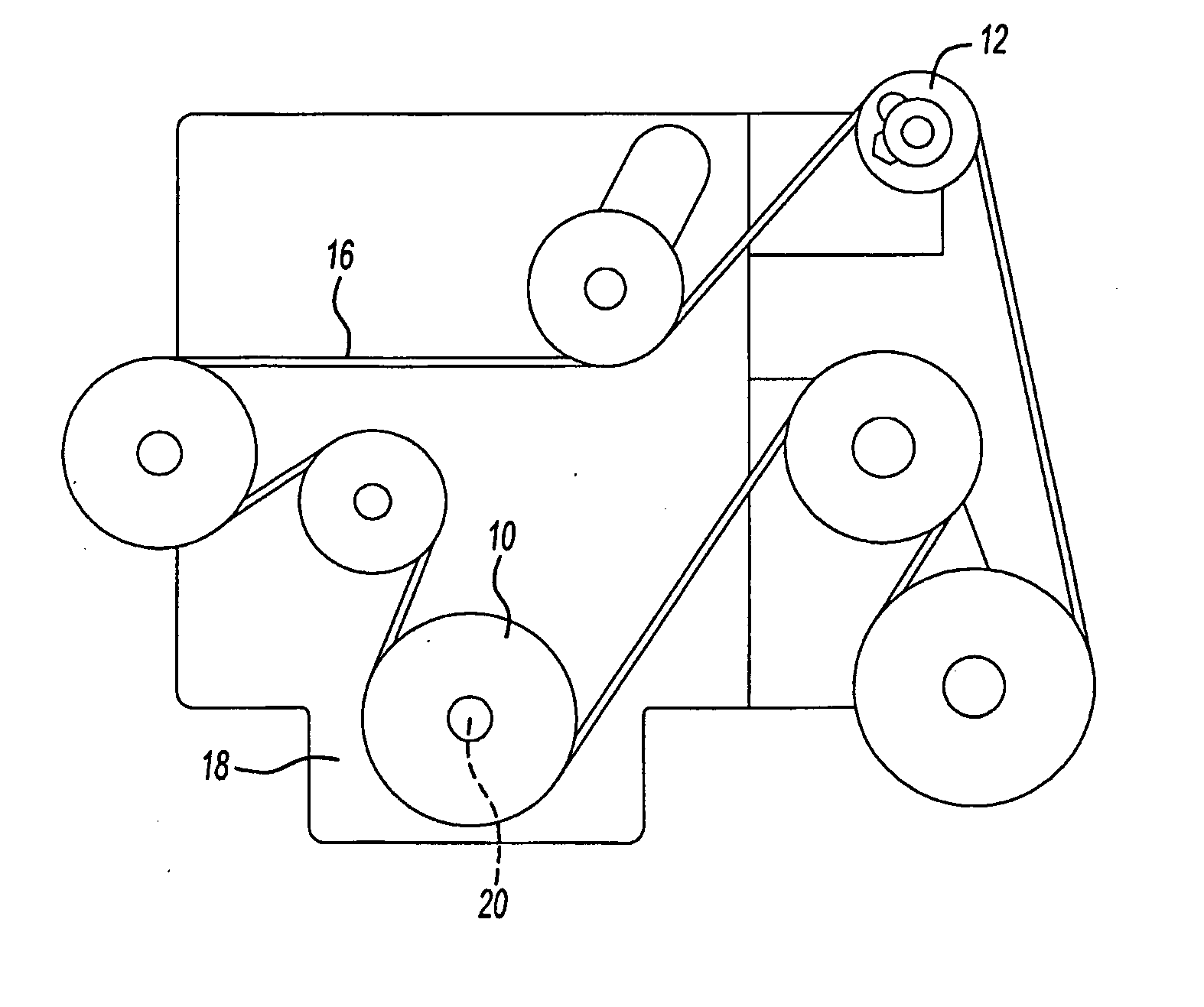

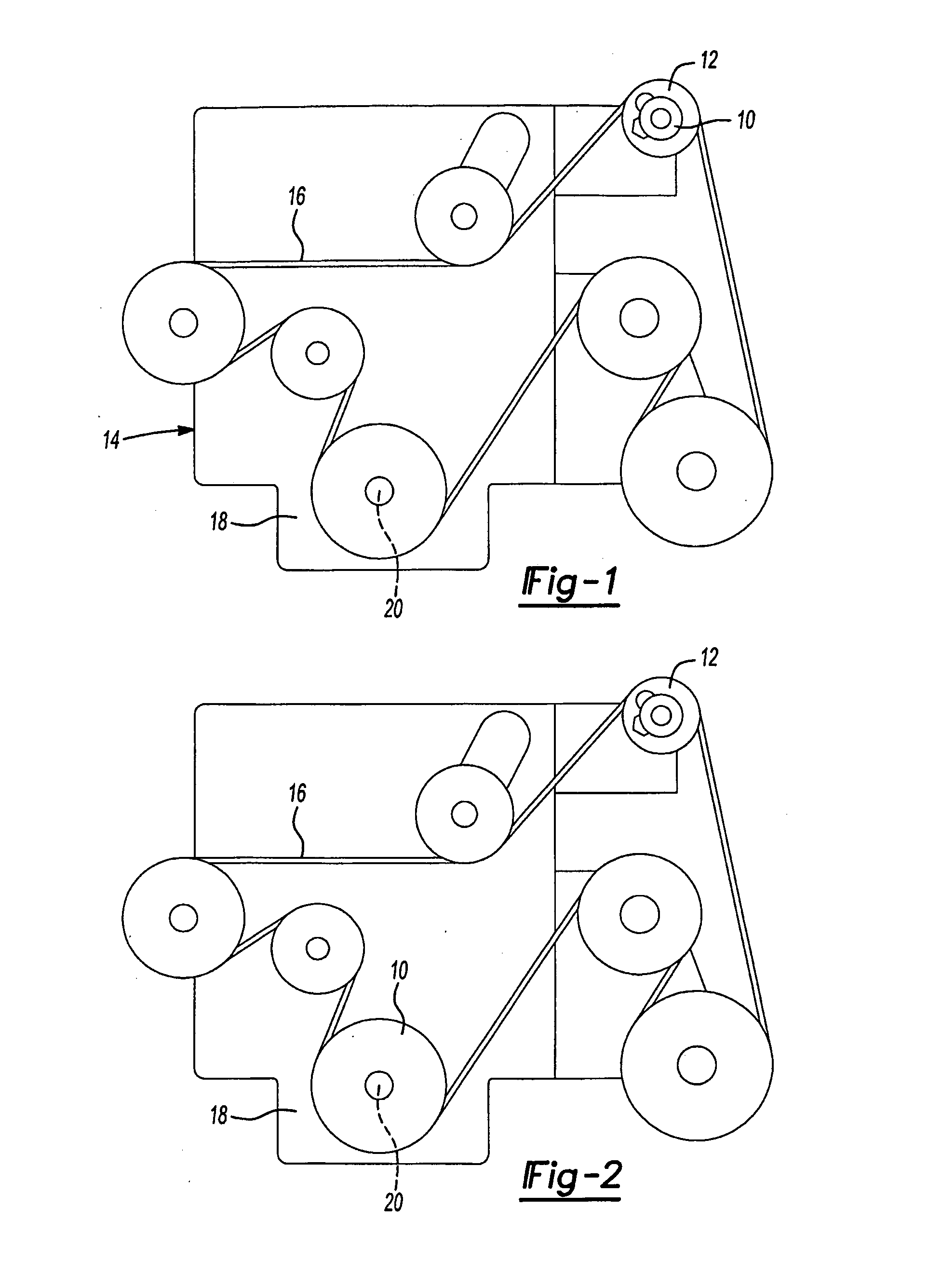

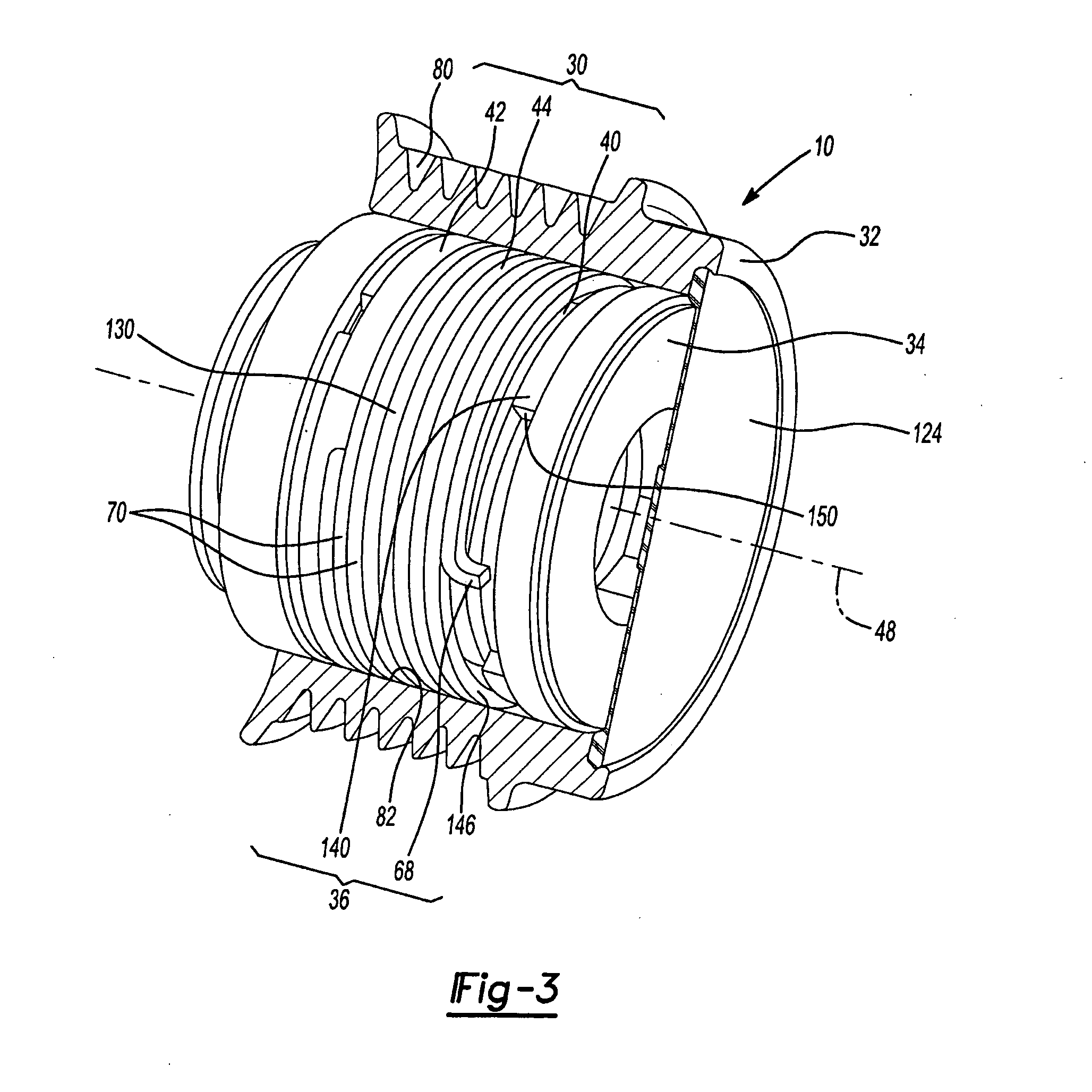

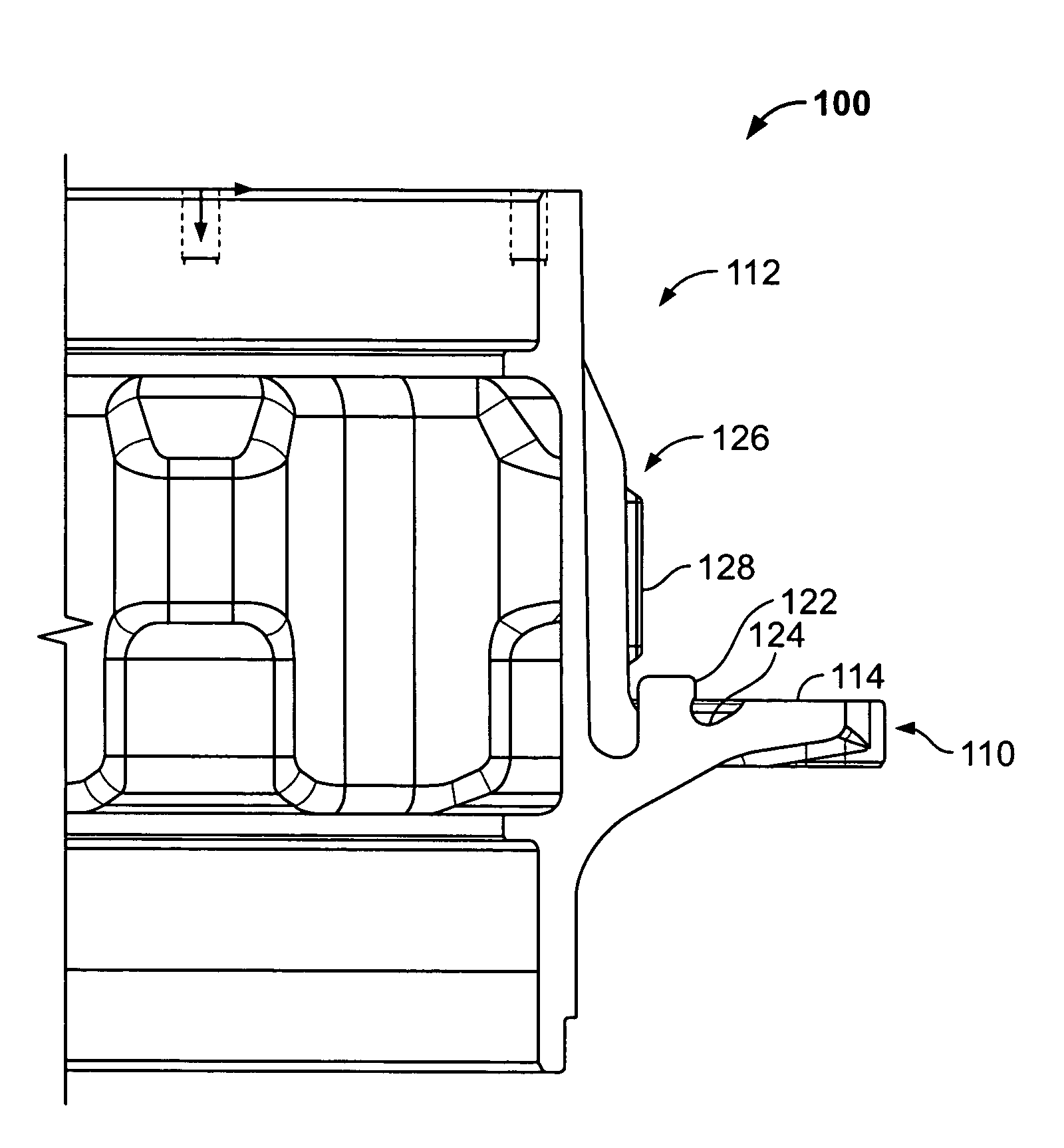

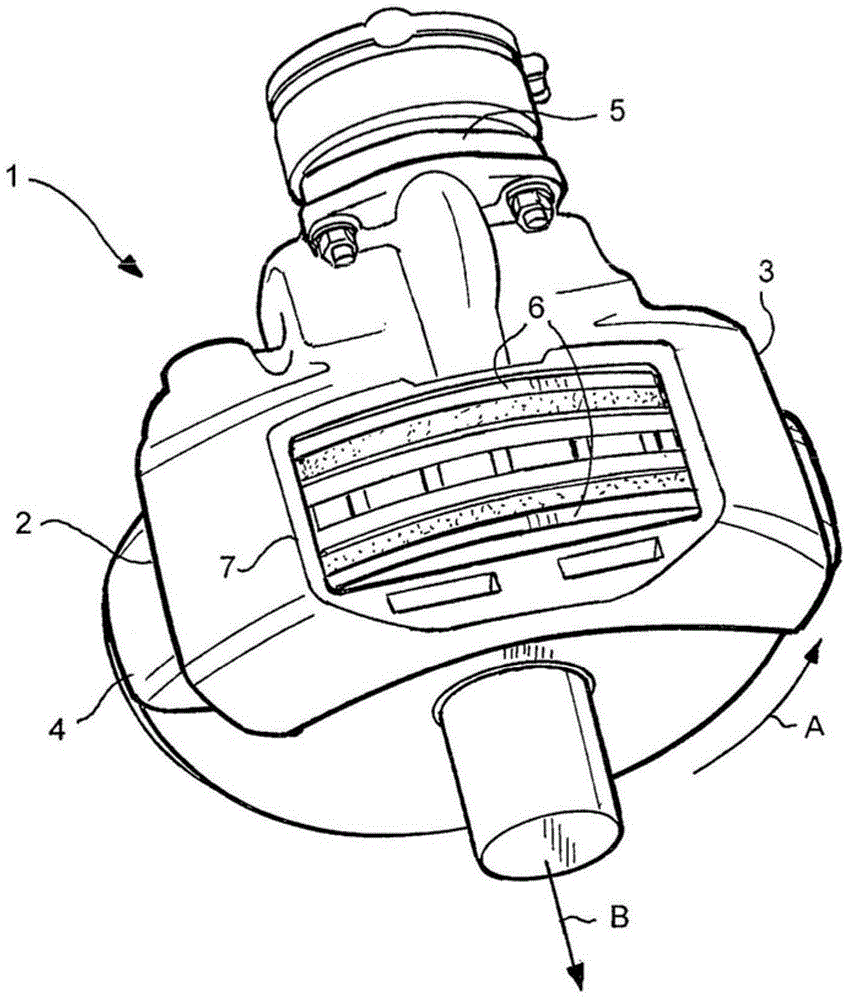

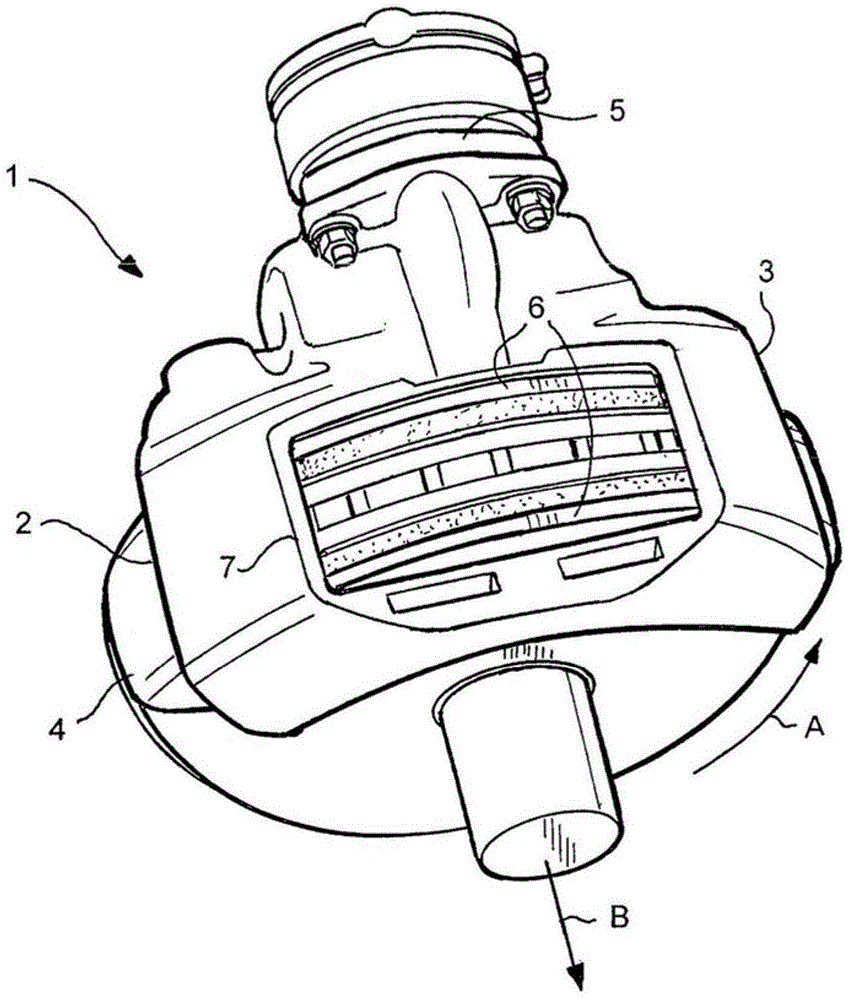

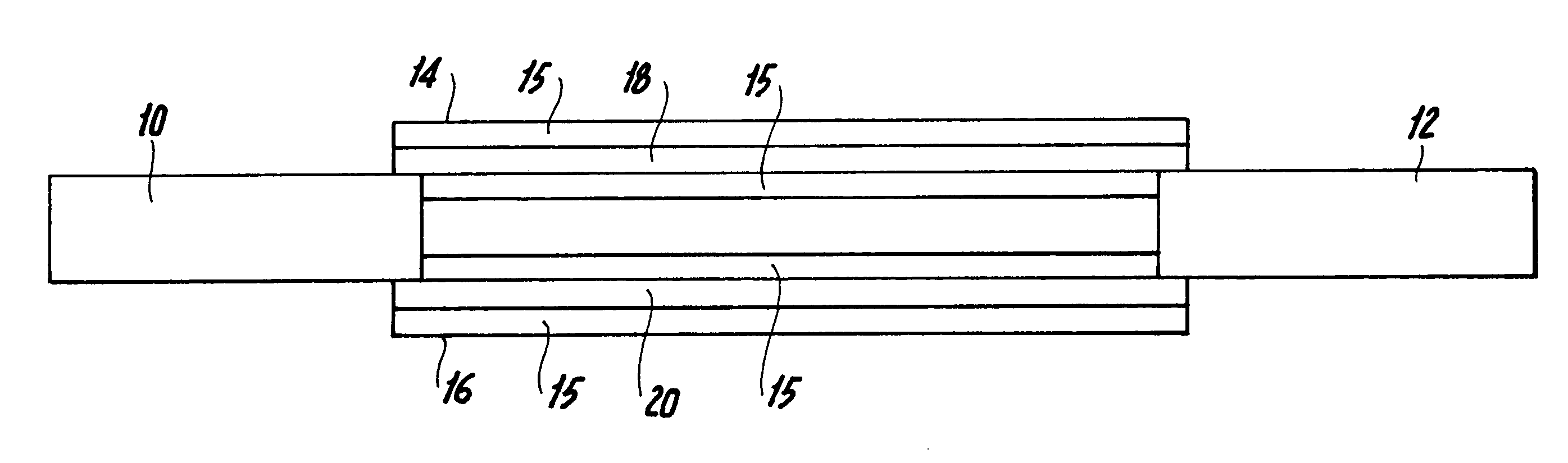

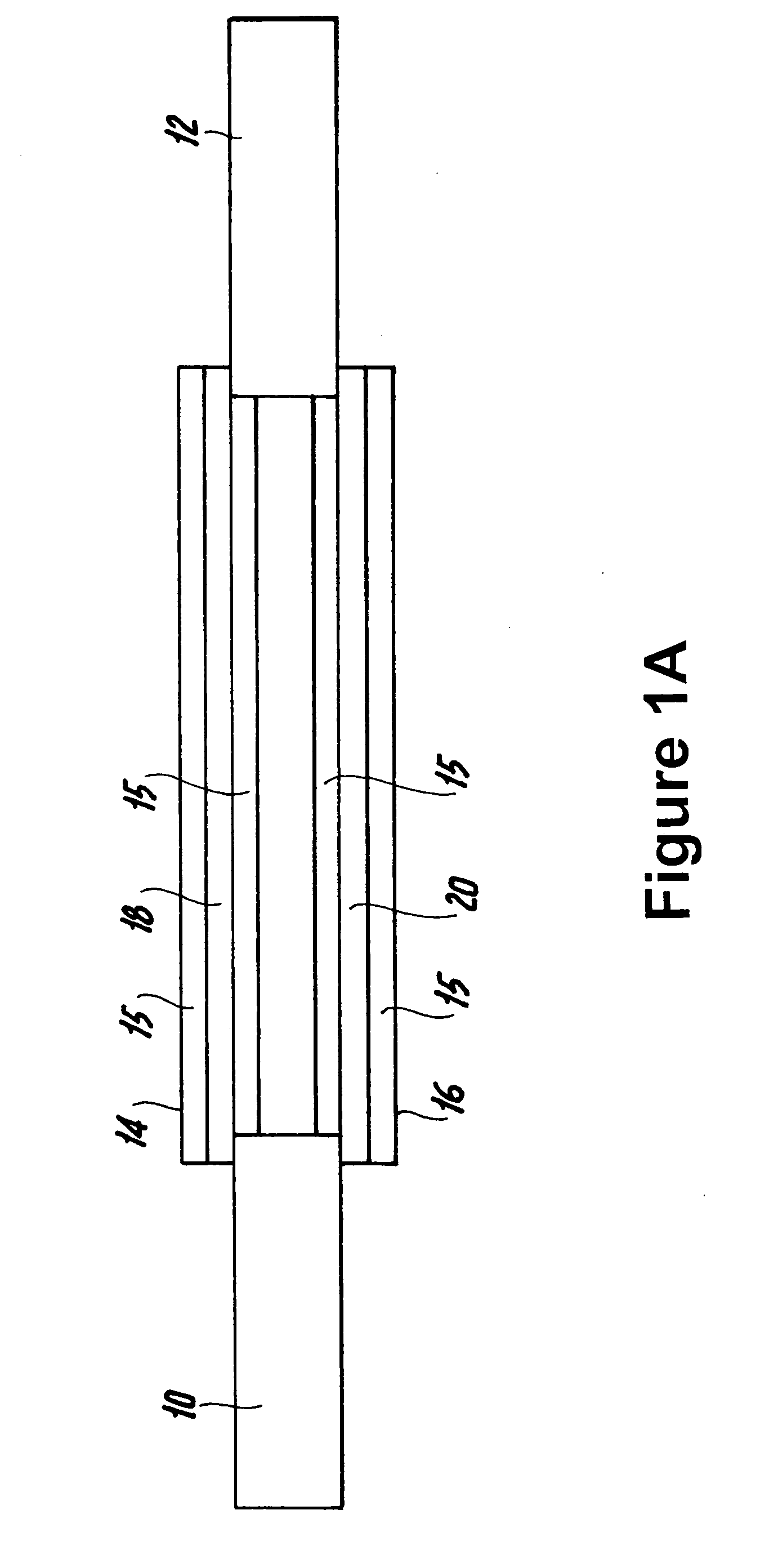

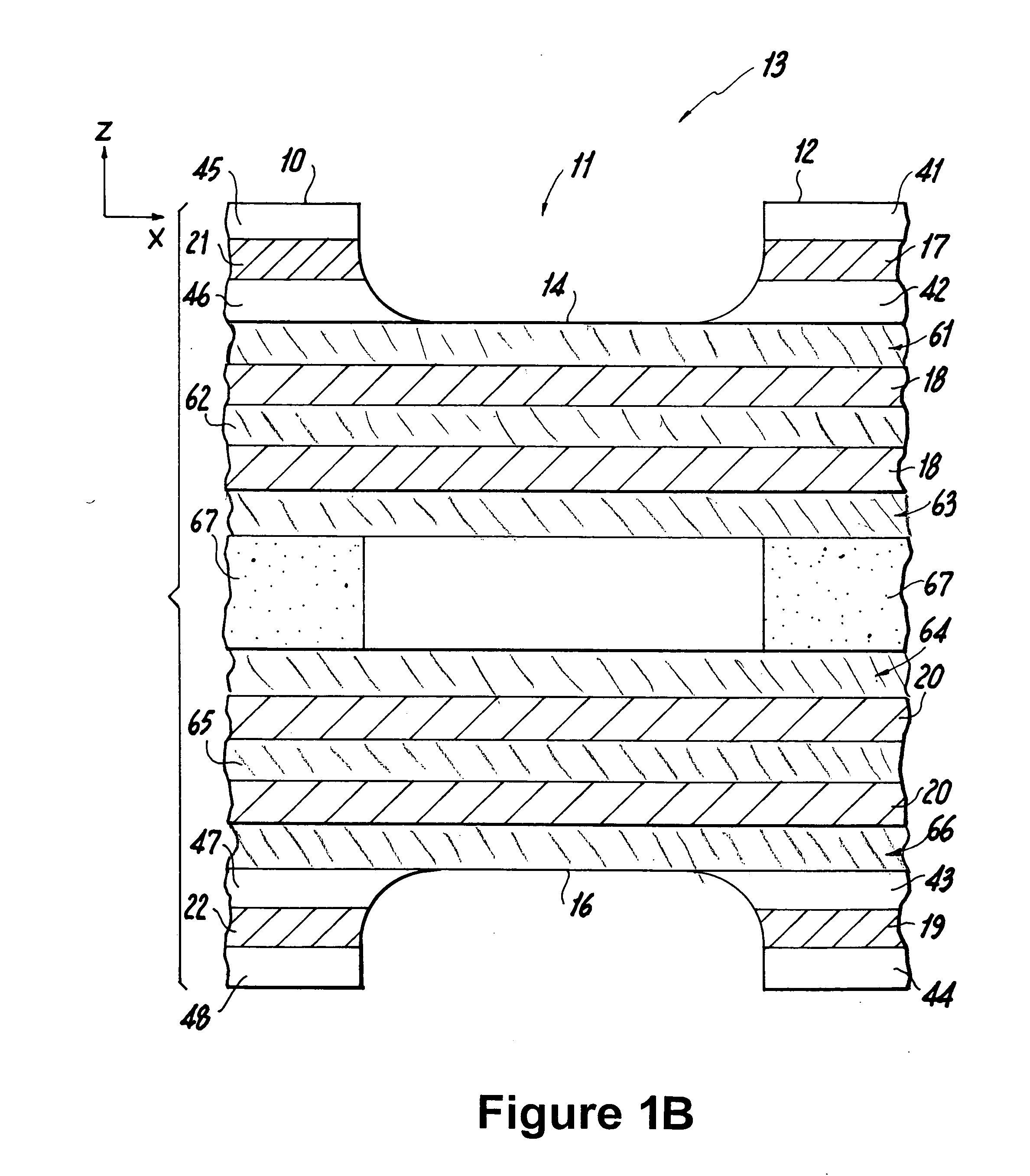

Over-Running Decoupler With Torque Limiter

ActiveUS20110224038A1Reduced fatigue lifeAvoid resonanceYielding couplingSlip couplingResonanceEngineering

A method for producing an over-running decoupler that is configured to transmit rotary power between a rotary member and a hub. The over-running decoupler includes a one-way clutch having a clutch spring, a carrier that is coupled to the clutch spring and at least one spring that resiliently couples the carrier to the hub. The method includes: establishing a desired fatigue life of the at least one spring; establishing a design deflection of the at least one spring during resonance, wherein deflection of the at least one spring at the design deflection during resonance does not reduce a fatigue life of the at least one spring below the desired fatigue life; and preventing resonance in the over-running decoupler by controlling a maximum deflection of the at least one spring such that the maximum deflection is less than or equal to the design deflection.

Owner:LITENS AUTOMOTIVE INC

Electronic module with integrated programmable thermoelectric cooling assembly and method of fabrication

InactiveUS6767766B2Reduce fatigue lifeLow junction temperatureThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsPower controlVoltage

An electronic module and method of fabrication are provided employing an integrated thermal dissipation assembly. The thermal dissipation assembly includes a thermoelectric assembly configured to couple to an electronic device within the module for removing heat generated thereby, and a programmable power control circuit integrated with the thermoelectric assembly. The programmable power control circuit allows cooling capacity of the thermoelectric assembly to be tailored to anticipated heat dissipation of the electronic device by adjusting, for a given power source, voltage level to the thermoelectric elements of the thermoelectric assembly. Power to the thermoelectric assembly can be provided through conductive power planes disposed within a supporting substrate. The power control circuit includes one or more voltage boost circuits connected in series between the given power source and the thermoelectric elements of the associated thermoelectric assembly.

Owner:IBM CORP

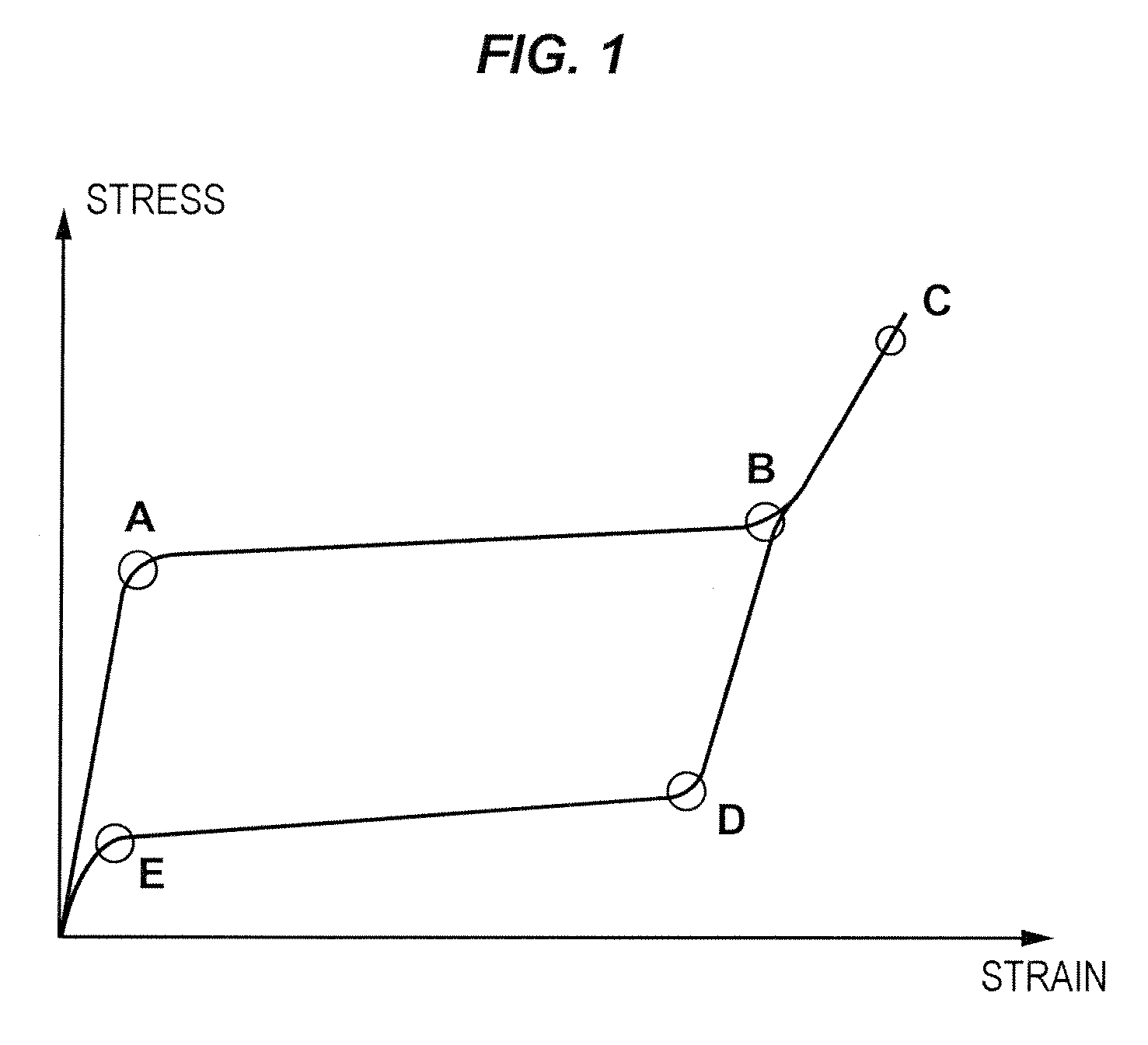

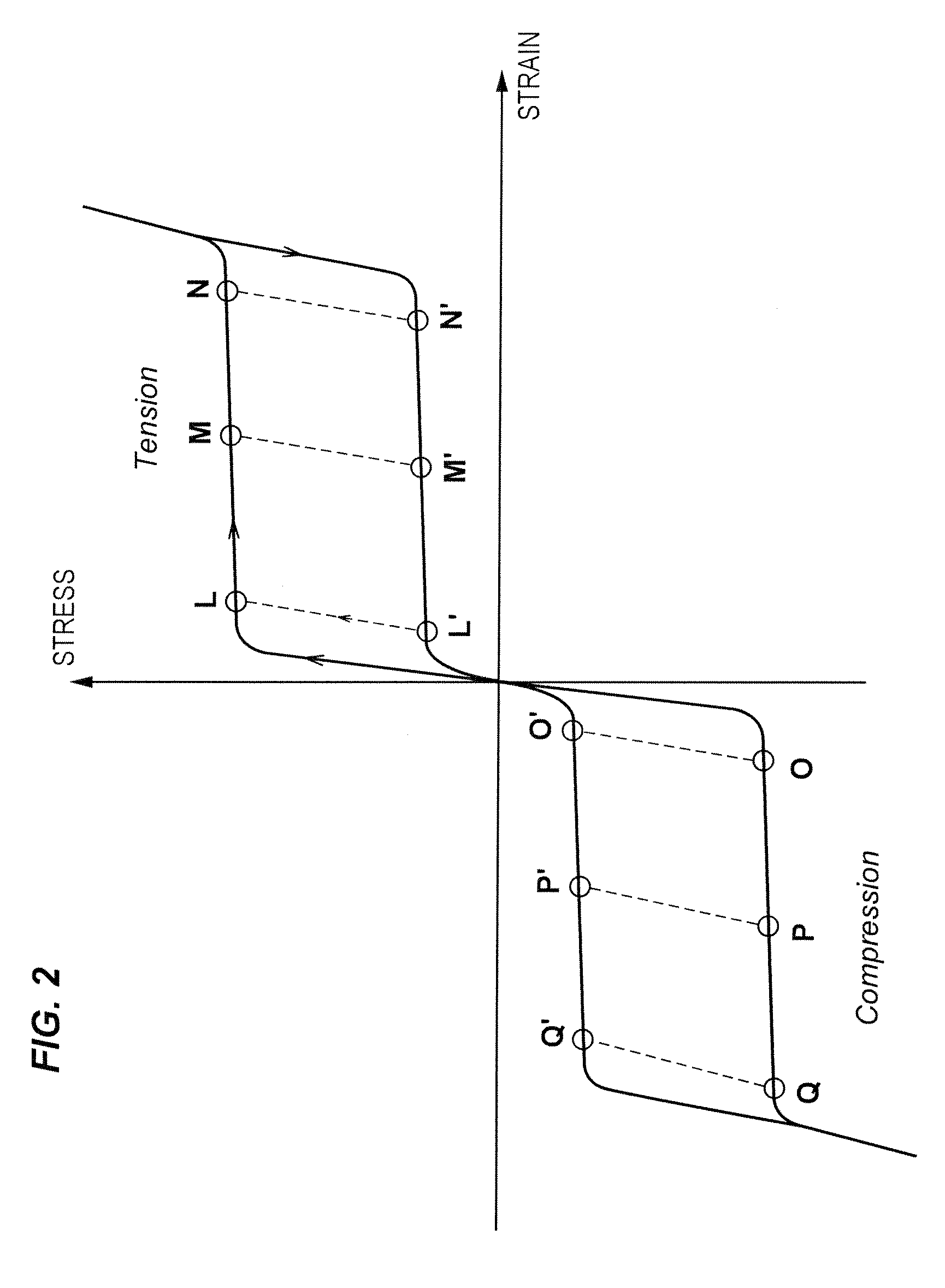

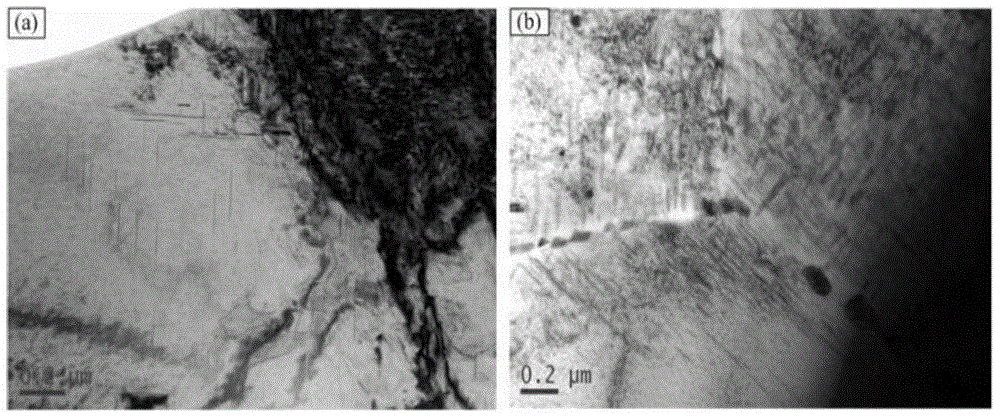

Damping apparatus, use of a shape memory alloy and method for changing damping characteristics

InactiveUS8328962B2Increase stiffnessImprove the immunityPortable framesInternal osteosythesisHysteresisChemical composition

Owner:ACANDIS

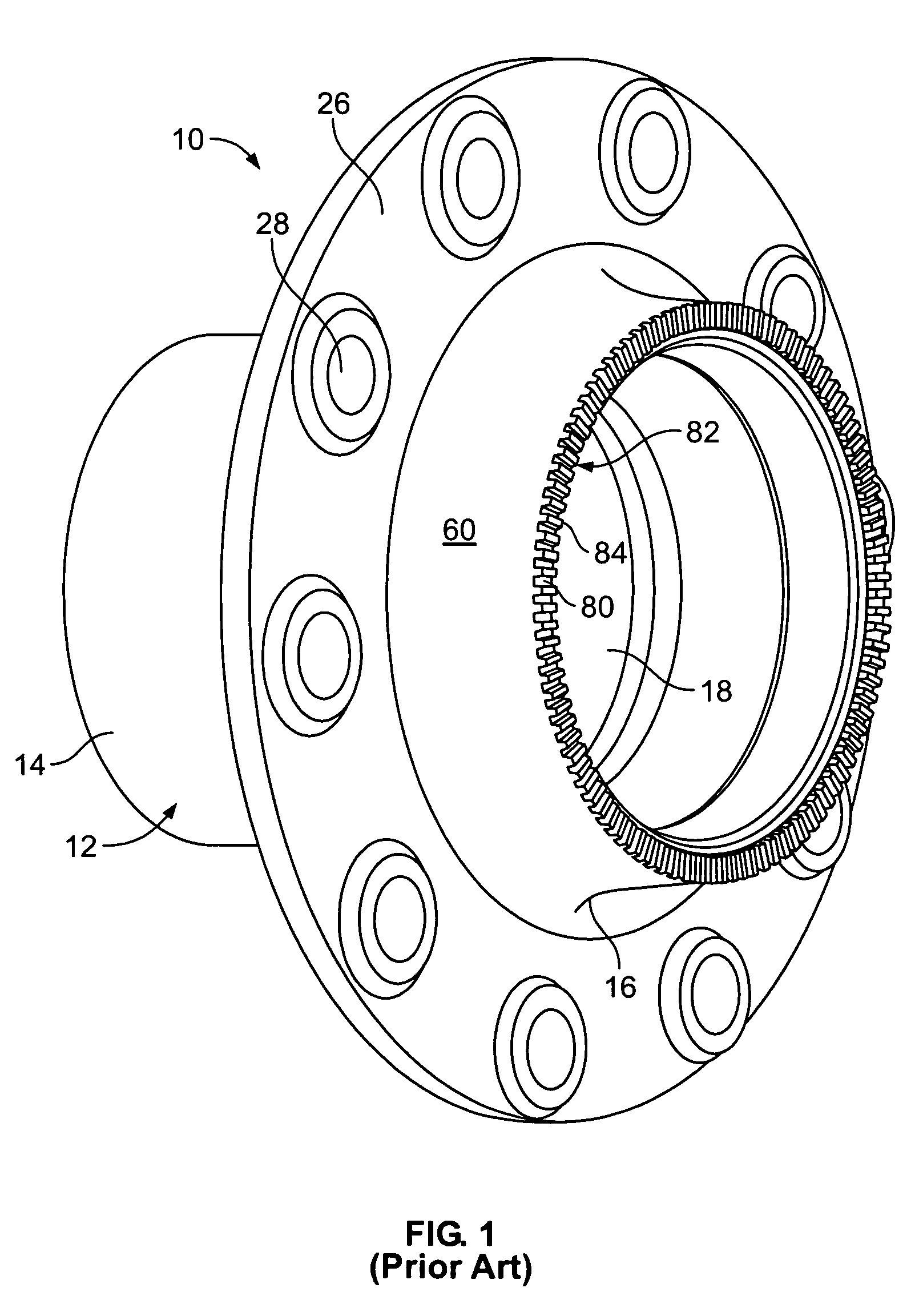

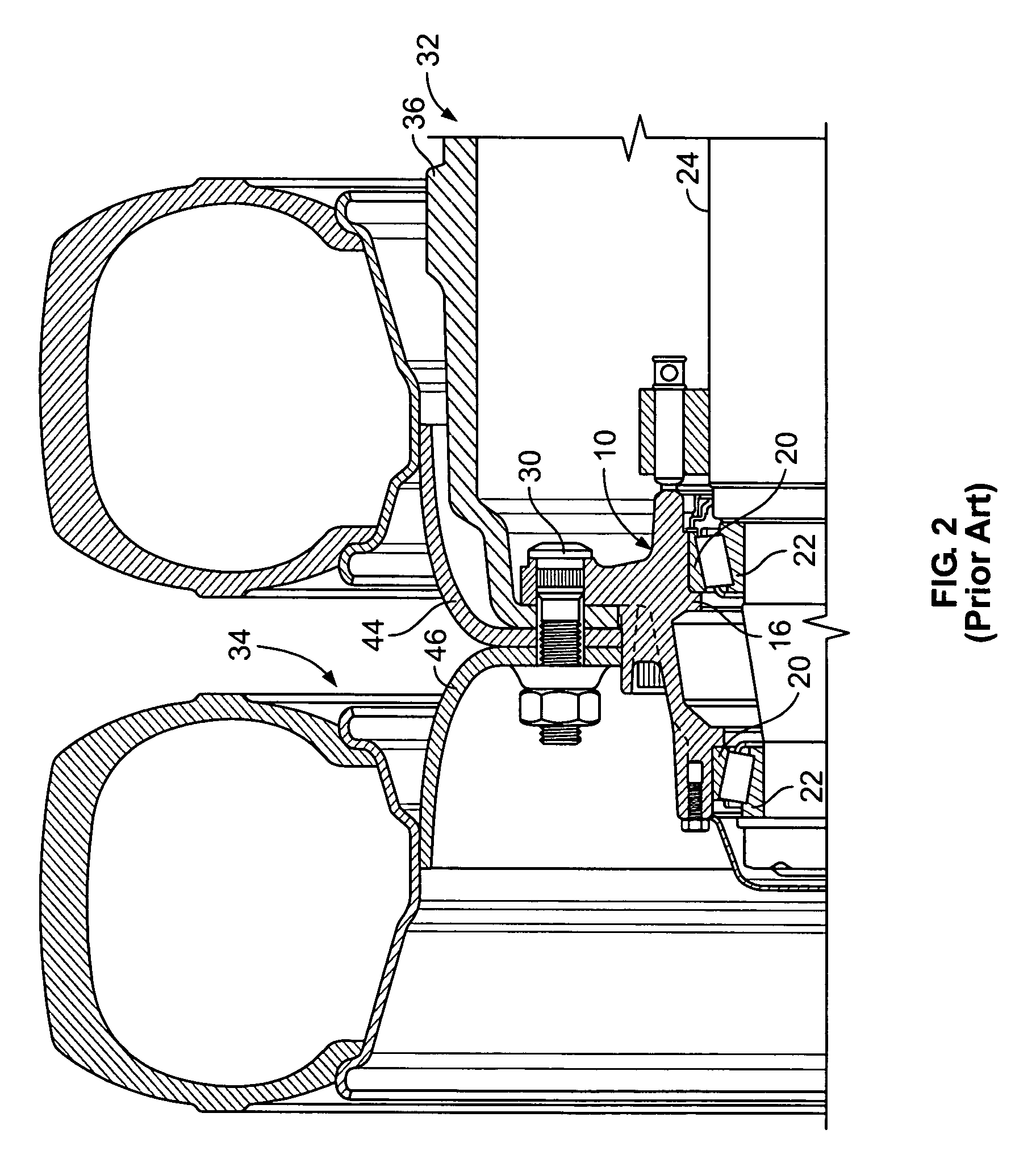

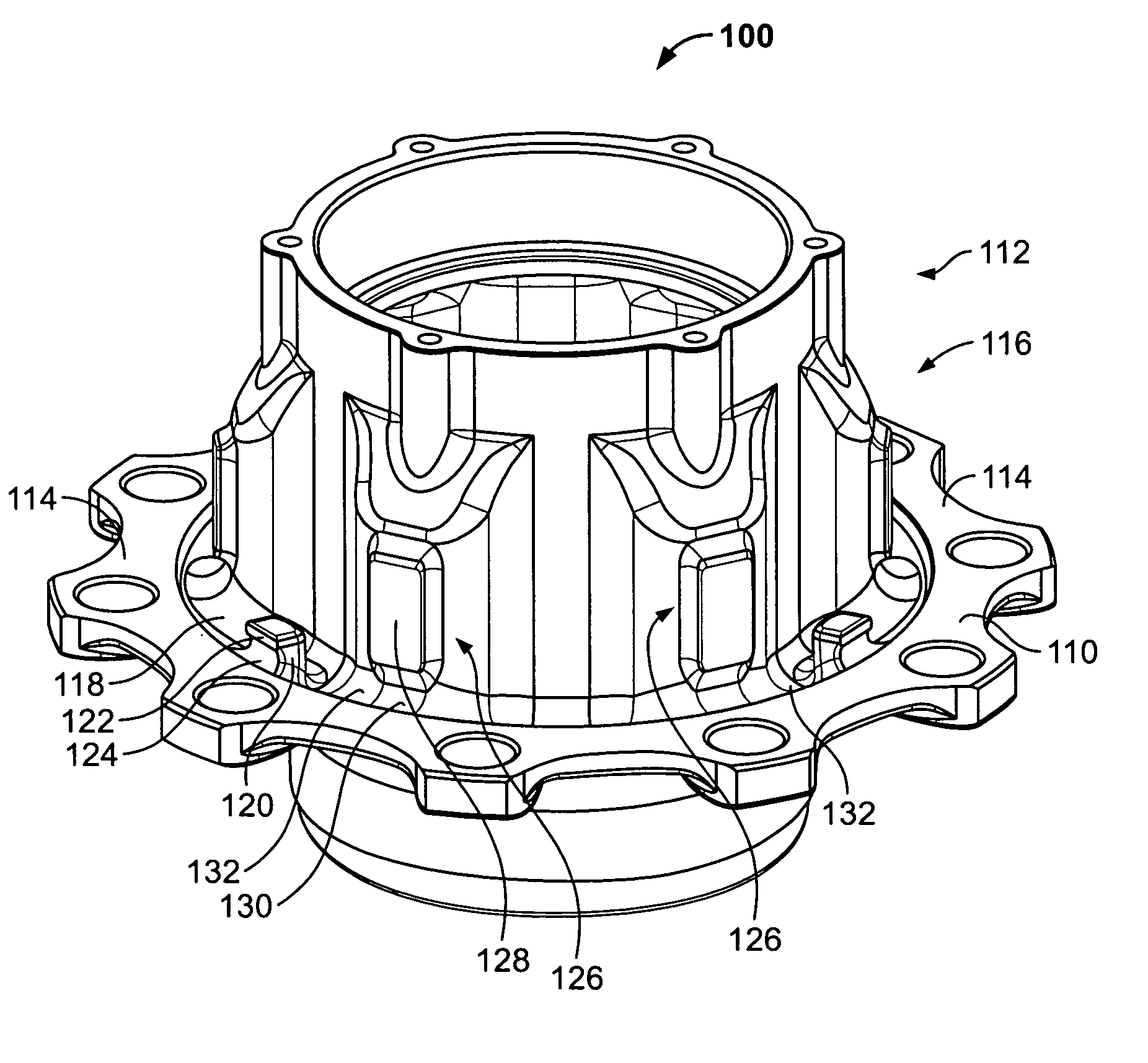

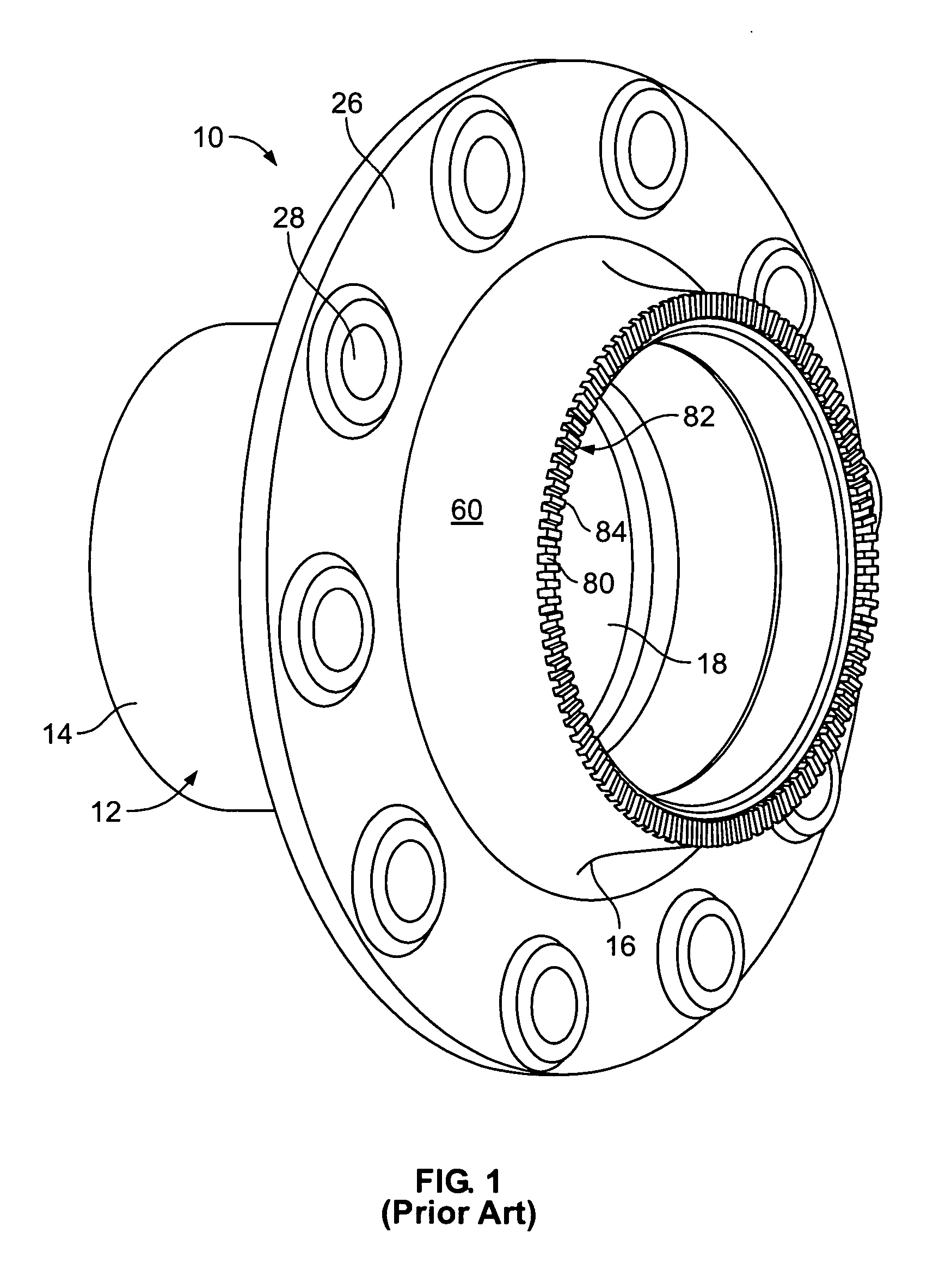

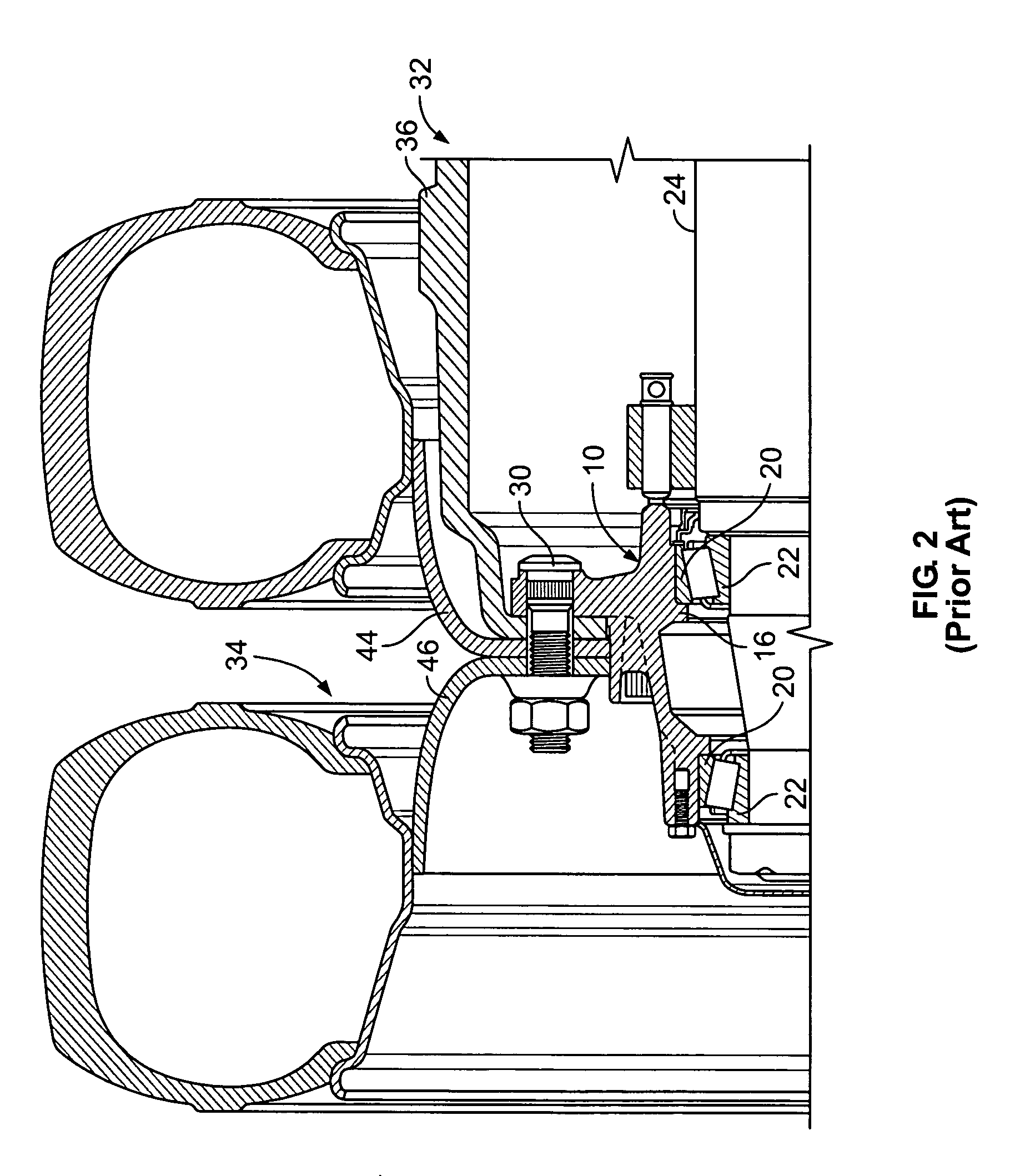

Wheel hub with improved pilot construction and a method for manufacturing

The present invention provides a drum or rotor wheel hub having a cast hub having a machined pilot in a flange portion and a machined pilot in a cylindrical portion, and a cast portion which separates the cylindrical pilot from the flange pilot, whereby a machined radii is not incorporated in the pilot construction.

Owner:WEBB WHEEL PROD INC

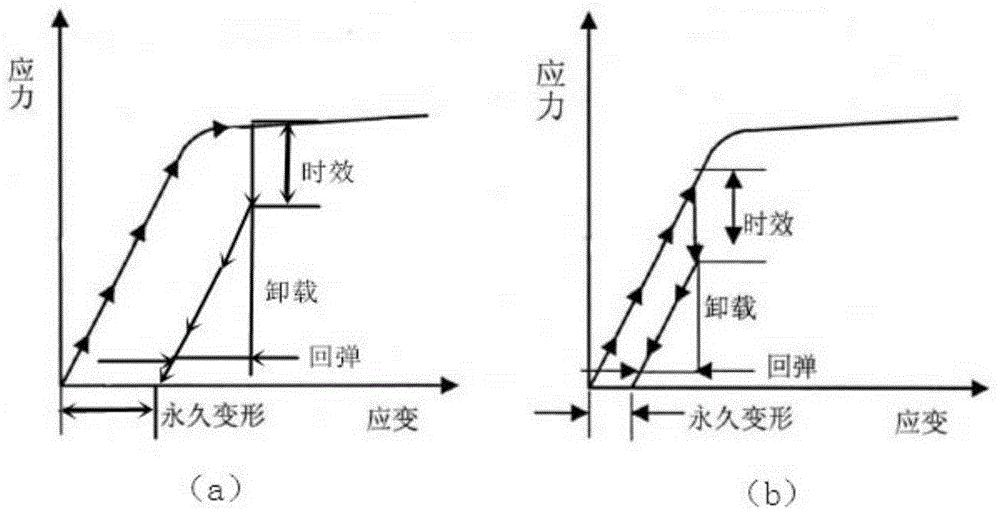

Method for manufacturing large-curvature aluminum alloy integral wall board component

The invention provides a method for manufacturing a large-curvature aluminum alloy integral wall board component. The method includes the steps that A, solution hardening is conducted on a wall board; B, the wall board obtained in the step A is arranged in a sealed environment formed by a thin film covering layer and a forming die jointly, the wall board is elastically deformed and plastically deformed in sequence under the vacuumized condition, and then the deformed wall board is obtained, wherein the temperature in the sealed environment where the wall board is located ranges from 15 DEG C to 35 DEG C, the vacuum degree ranges from -0.1 MPa to -0.05 MPa, and the treatment time ranges from 5 min to 60 min; C, in-situ creep stress relaxation aging is conducted on the deformed wall board obtained in the step B, wherein creep stress relaxation aging time is more than 2 h; D, unloading operation is conducted, and then the large-curvature aluminum alloy integral wall board component is obtained. When the method is used for manufacturing the large-curvature aluminum alloy integral wall board component, the residual stress of the product is greatly reduced, the strength of the product is improved, and the product with high forming accuracy and good performance is obtained.

Owner:CENT SOUTH UNIV

Thermally-formed steel plate with high fatigue strength for axle housing of heavy truck, and manufacturing method thereof

Owner:JIGANG GRP

Wheel hub with improved pilot construction and a method for manufacturing

The present invention provides a drum or rotor wheel hub having a cast hub having a machined pilot in a flange portion and a machined pilot in a cylindrical portion, and a cast portion which separates the cylindrical pilot from the flange pilot, whereby a machined radii is not incorporated in the pilot construction.

Owner:WEBB WHEEL PROD INC

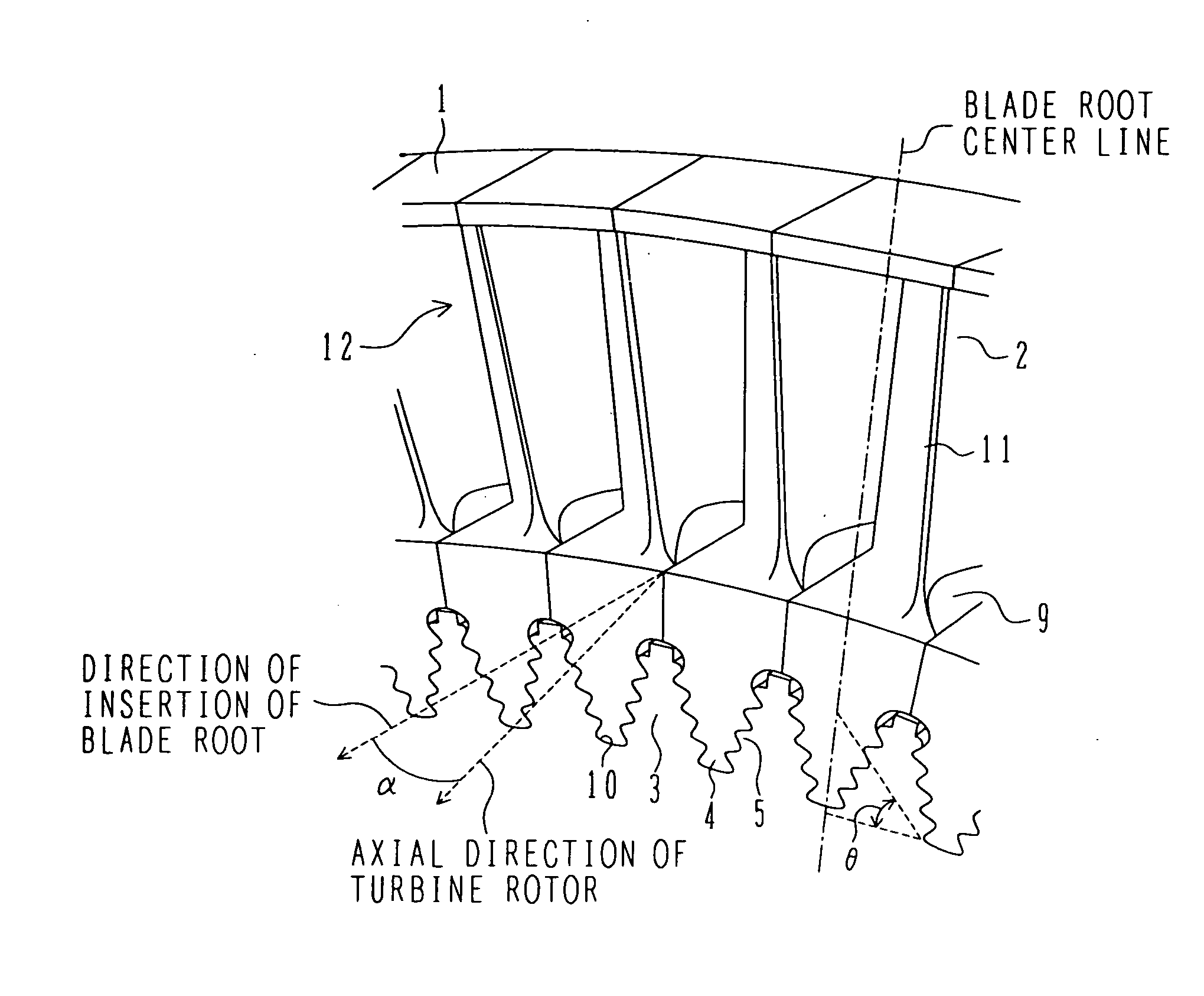

Steam turbine blade, steam turbine rotor, steam turbine with those blades and rotors, and power plant with the turbines

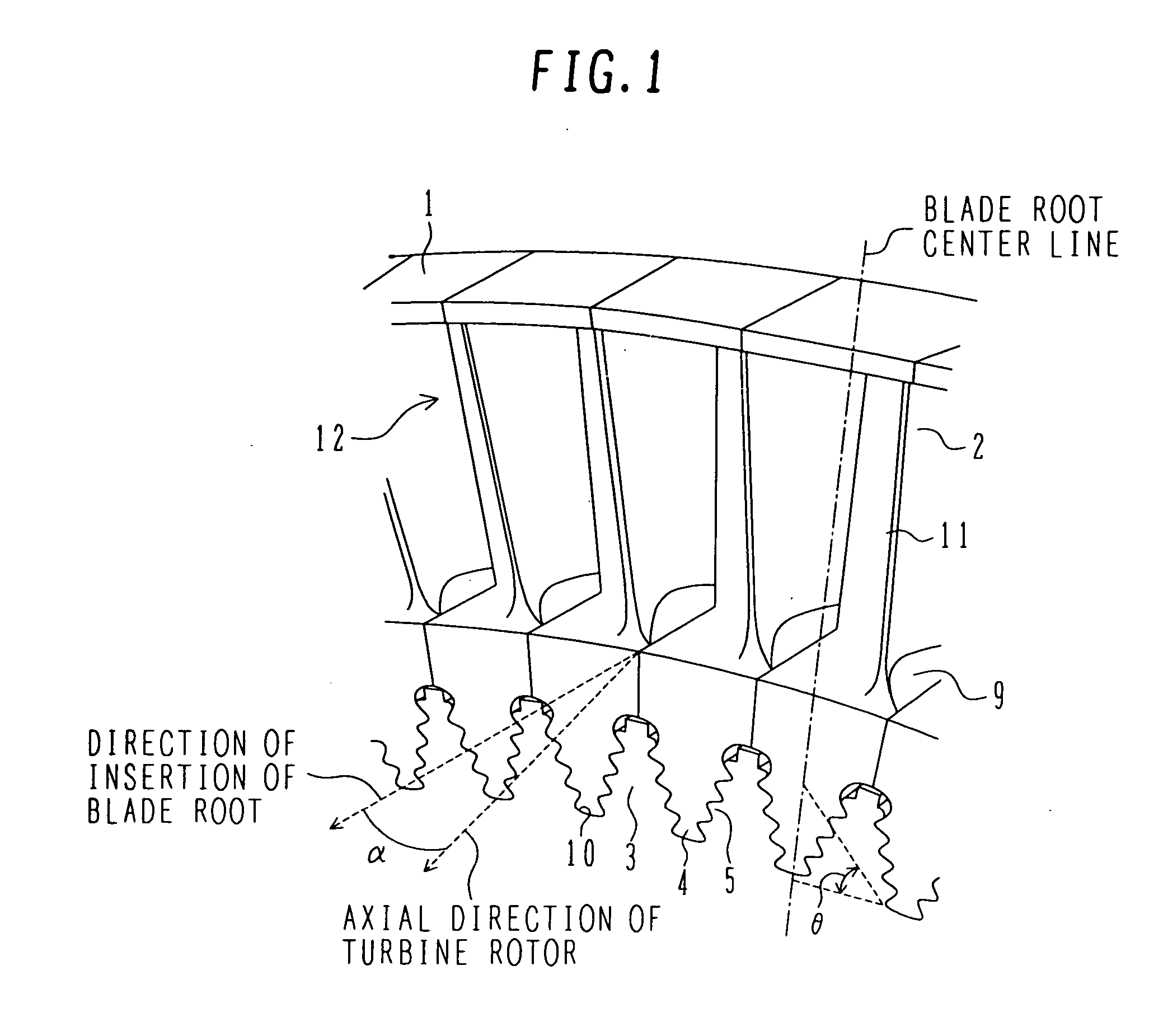

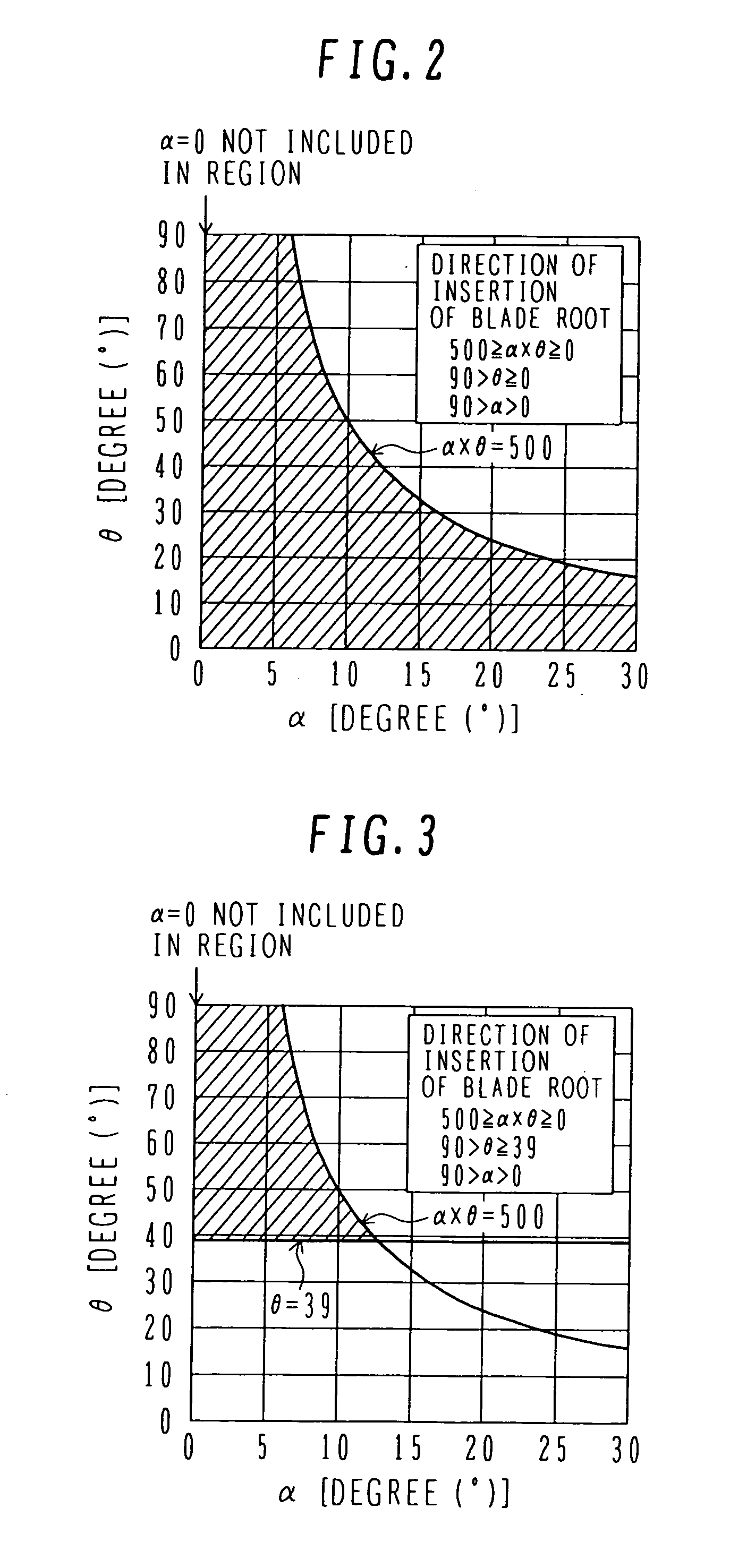

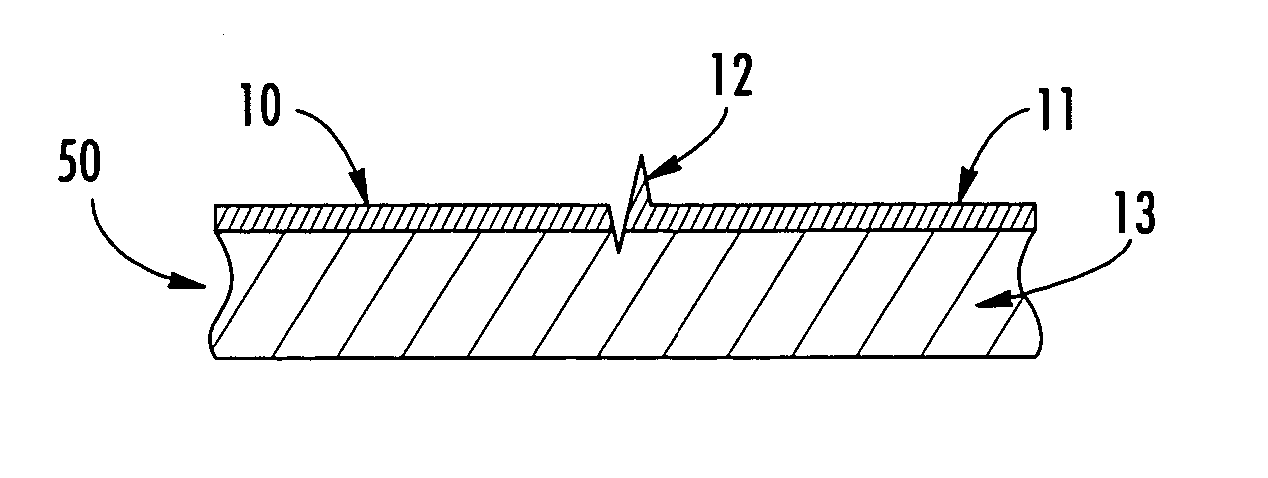

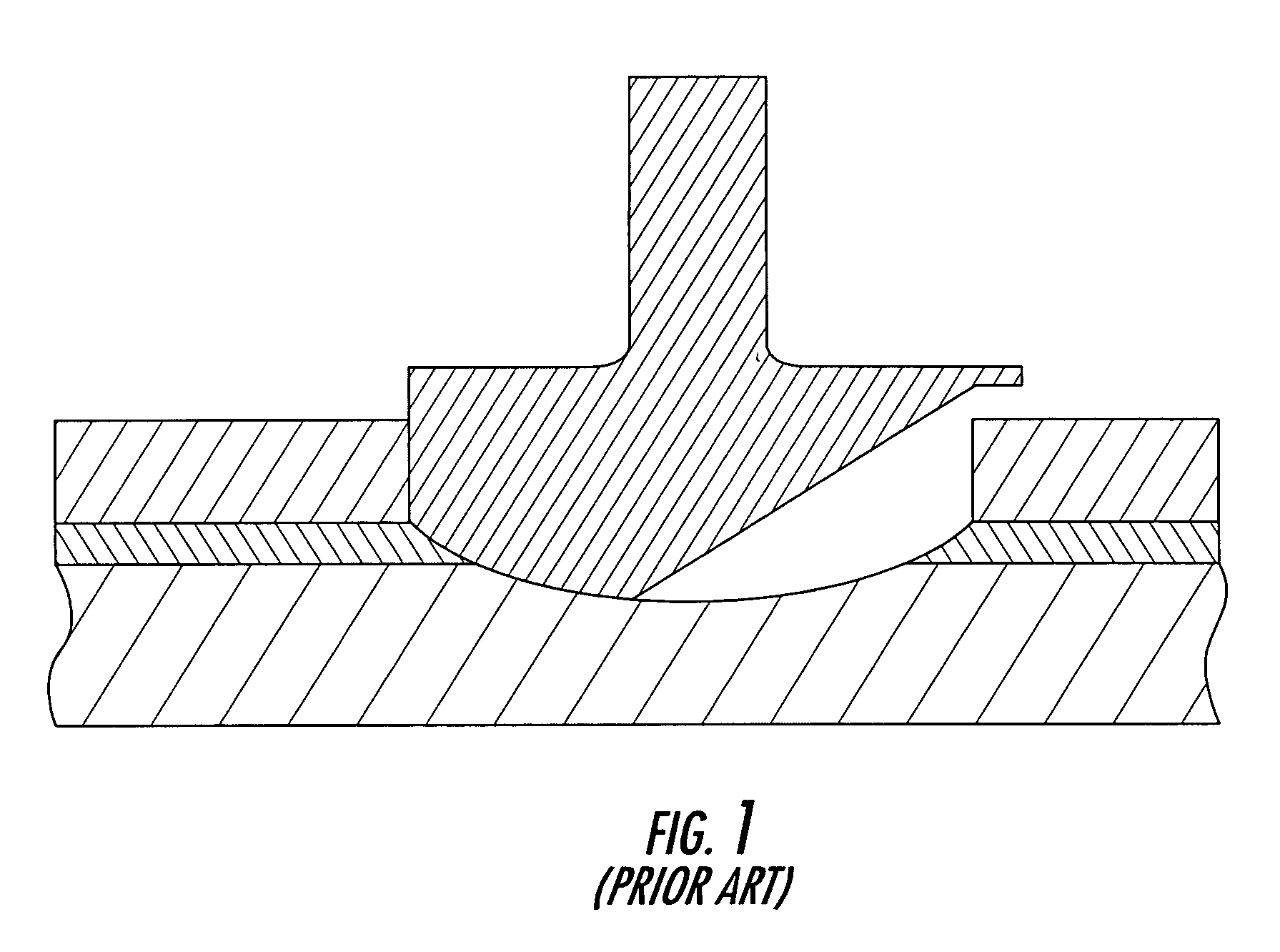

ActiveUS20060222501A1Suppress peak stressSuppress fatiguePropellersEngine manufactureSteam turbine bladeEngineering

A steam turbine blade in which the turbine blade has a blade root of the axially-inserted fir tree type and a larger number of turbine blades can be attached in a restricted outer peripheral region of a turbine rotor by arranging the blade root to be oriented in a direction forming a predetermined angle α larger than 0° relative to the axial direction of the turbine rotor. The steam turbing blade can suppress peak stresses generated at the bottoms of notches formed in the blade root and a blade groove and also suppress fretting fatigue from being induced by contact between peak stress generating areas and areas opposed to the peak stress generating areas at the notch bottoms. The steam turbine blade includes an airfoil, and a blade root attached to a turbine rotor and having plural stages of hooks in the radial direction of the turbine rotor.

Owner:MITSUBISHI POWER LTD

Method of repairing a workpiece

InactiveUS20050163921A1Reduce removalReduced fatigue lifeMolten spray coatingLayered productsEngineeringNew materials

A method for repairing minor defects in a workpiece using flame spraying is provided. The method includes first providing a workpiece having a defect and an area proximate to the defect. The method also includes routing a portion of the workpiece, including the defect, such that the routing removes at least a portion of the workpiece proximate to the defect. The depth to which the workpiece is routed may be controlled with a micro-stop countersink apparatus. A router bit is generally plunged into the workpiece in a direction orthogonal to the surface of the workpiece such that the routed portion of the workpiece defines a sidewall extending generally orthogonal to the workpiece and a conical bottom surface. The portion of the workpiece that has been removed by routing is then flame sprayed such that new material is added to fill the portion of the workpiece that has been routed.

Owner:THE BOEING CO

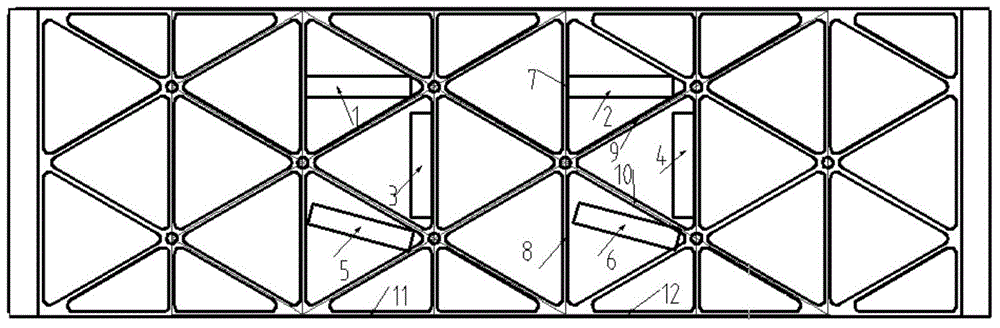

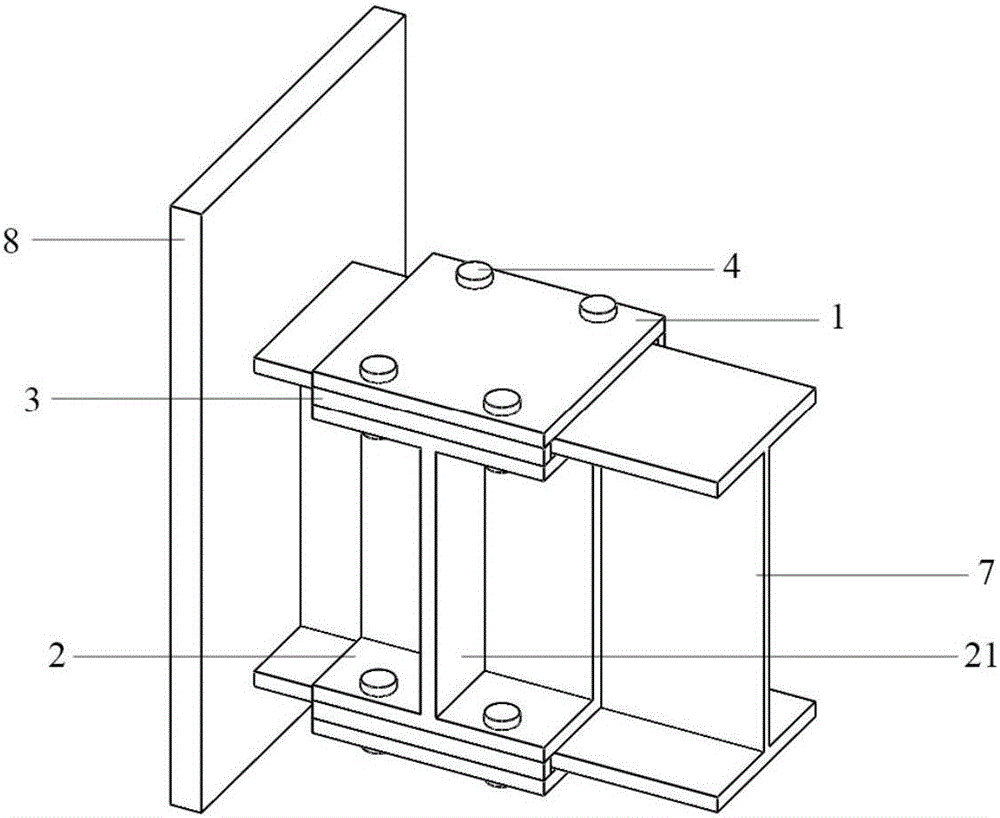

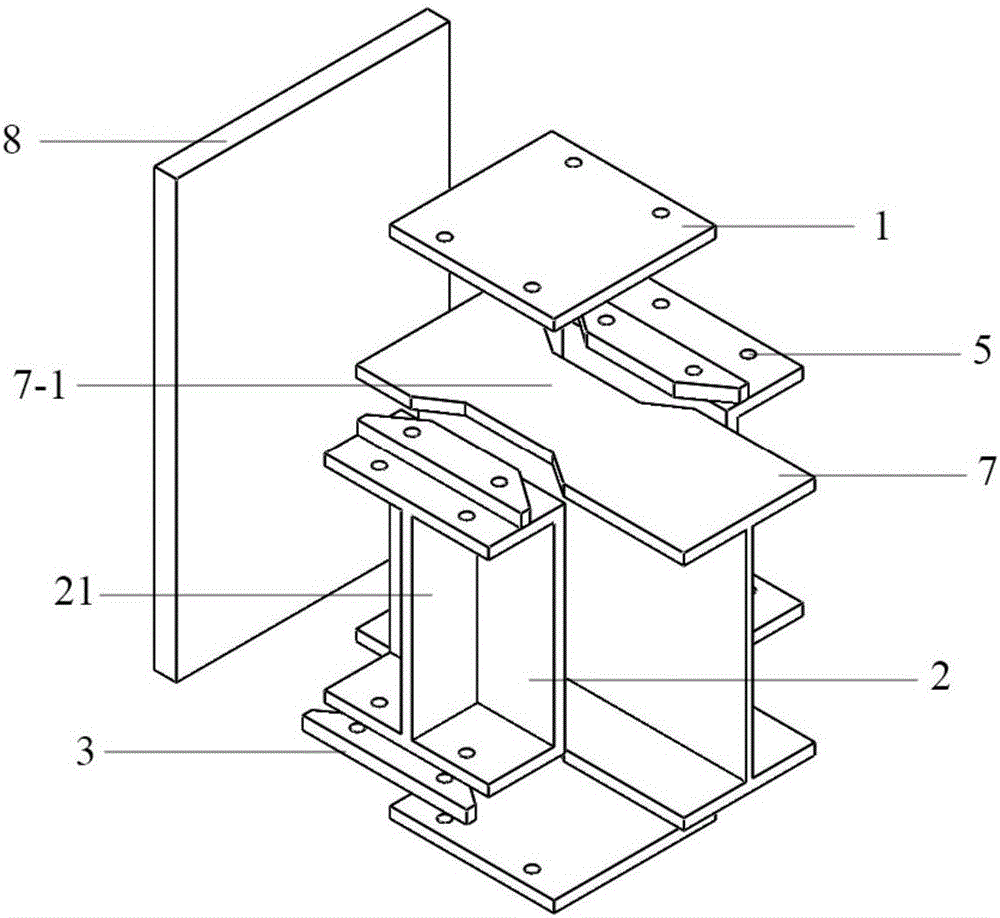

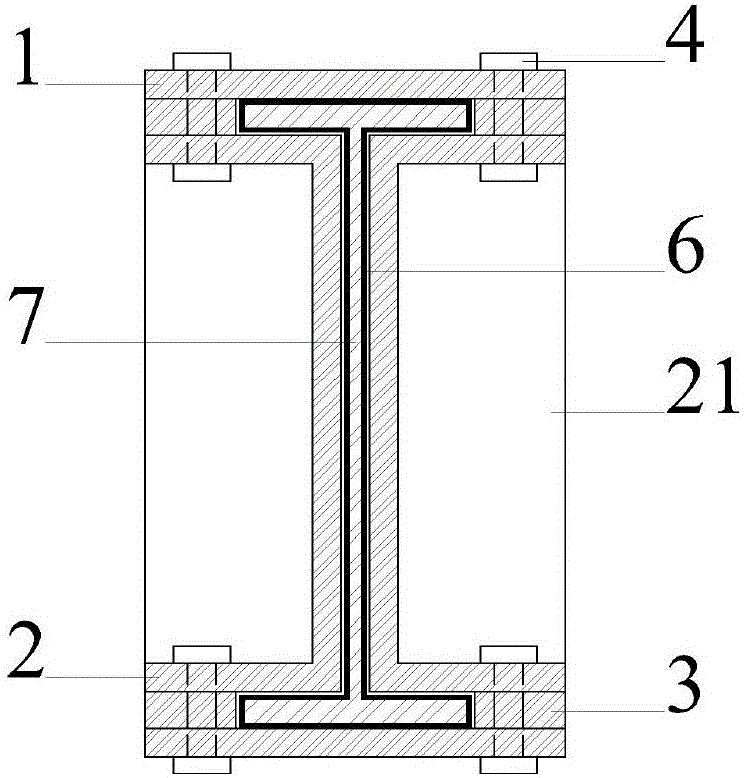

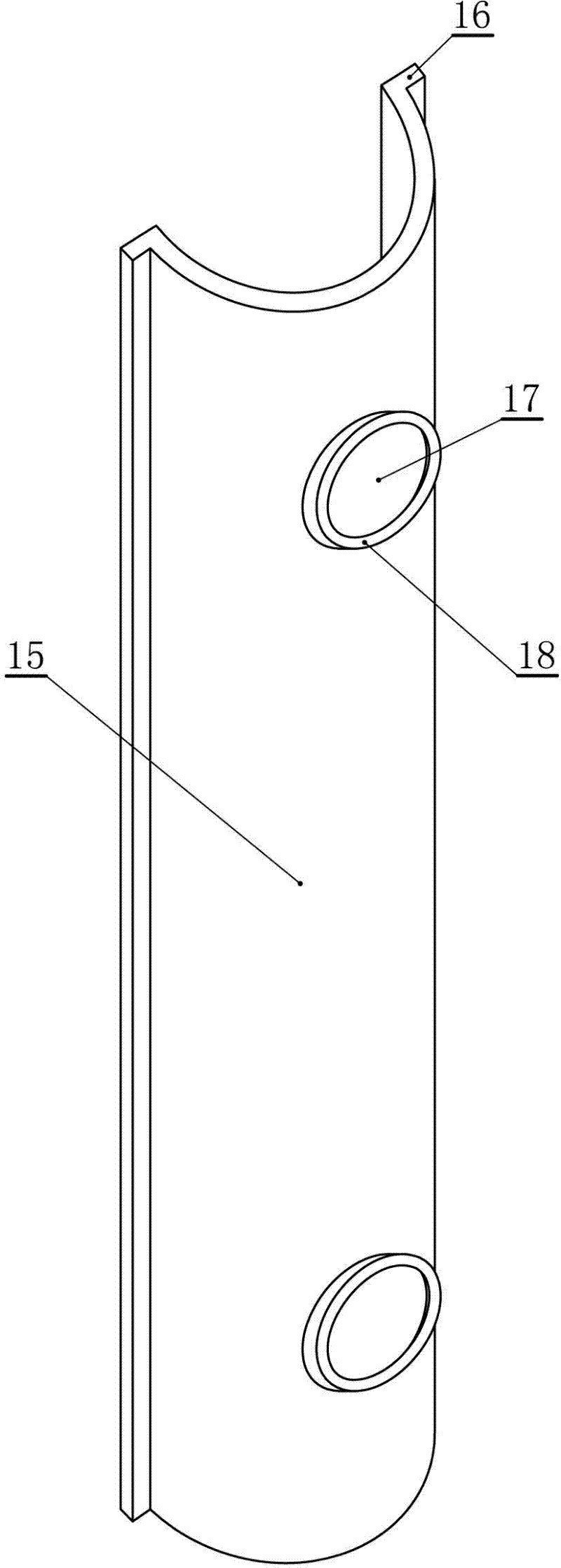

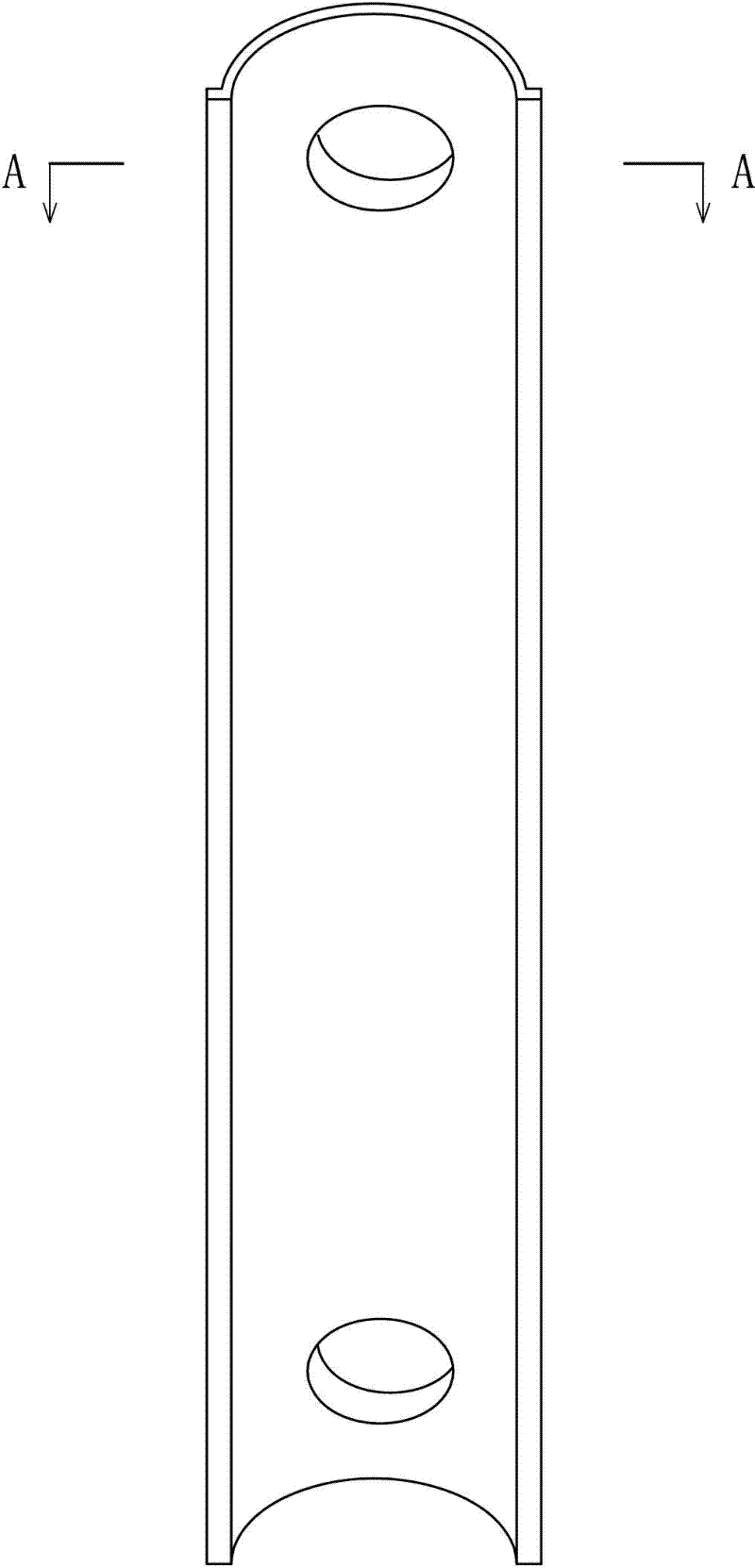

Dog-bone joint beam end buckling constraining device

ActiveCN106593059AGive full play to the excellent energy consumption performance of dog-bone nodesImprove energy consumptionProtective buildings/sheltersShock proofingBones jointsEngineering

The invention provides a dog-bone joint beam end buckling constraining device. The device comprises constraining cover plates (1), constraining U-steel (2), filling plates (3) arranged between the constraining cover plates and the constraining U-steel, and connecting bolts (4), wherein the constraining cover plates (1) are arranged on the outer sides of upper and lower flange weakening parts (7-1) at the ends of a steel beam (7) provided with a dog-bone joint; the constraining U-steel (2) is arranged on the portions, corresponding to the two sides of a web, of the flange weakening parts; and the connecting bolts (4) are used for connecting the constraining cover plates, the constraining U-steel and the filling plates to form the complete constraining device. When an earthquake occurs, the beam end flange weakening parts yield in advance of other parts and components, earthquake energy is dissipated through the hysteretic characteristic, and by adoption of the constraining device, press on the beam end flange weakening parts and large-amplitude buckling possibly occurring outside the plane of a steel plate when the corresponding web is pressed and sheared can be limited, shortening of the fatigue lives of the flange weakening parts and degradation of joint rigidity and strength are prevented, the steel beam (7) in a joint area is protected against complete buckling outside the plane, the fullness of a hysteretic curve is ensured, and the joint deformation capacity and ductility and the lateral stability of the beam are improved.

Owner:SOUTHEAST UNIV

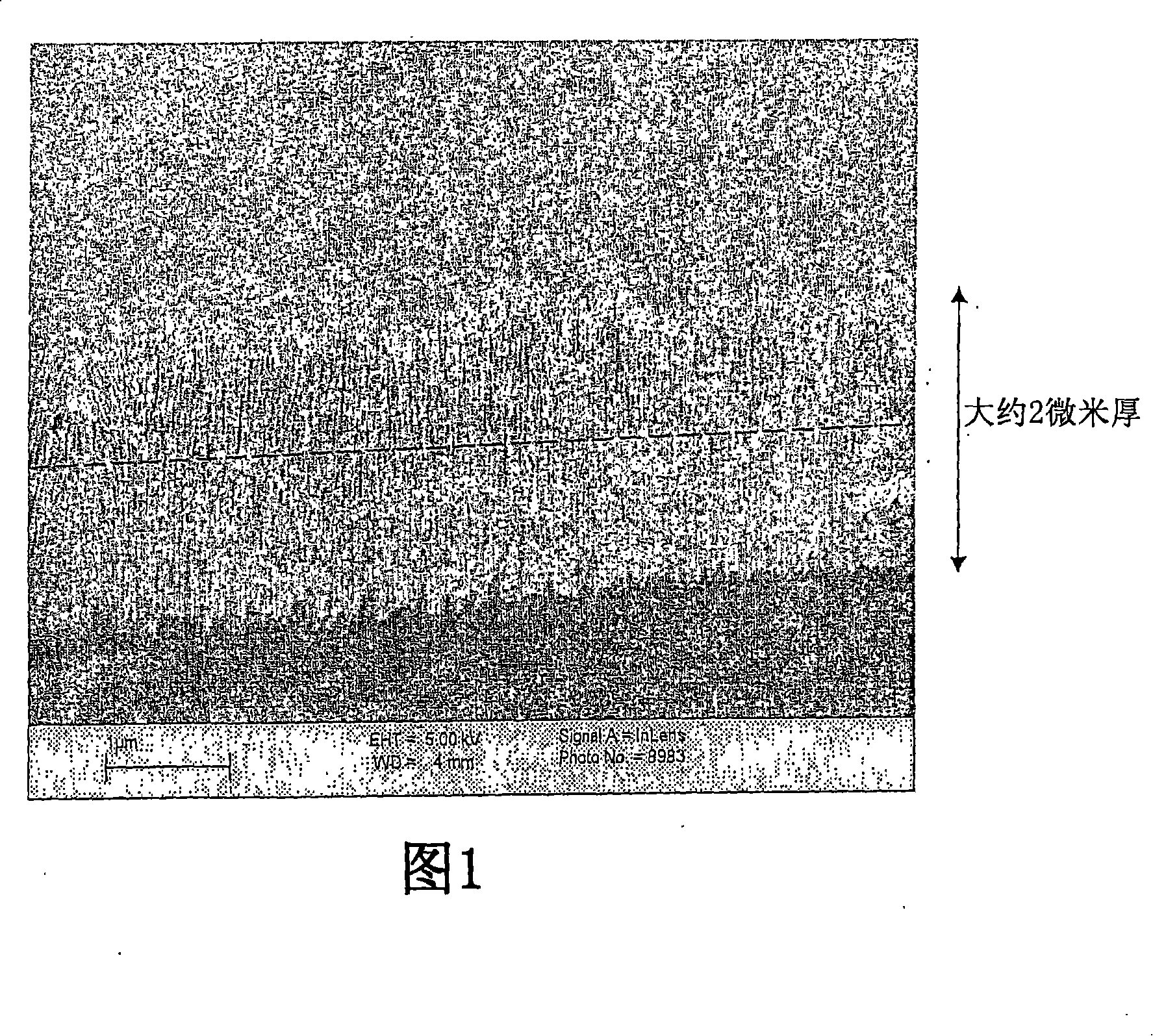

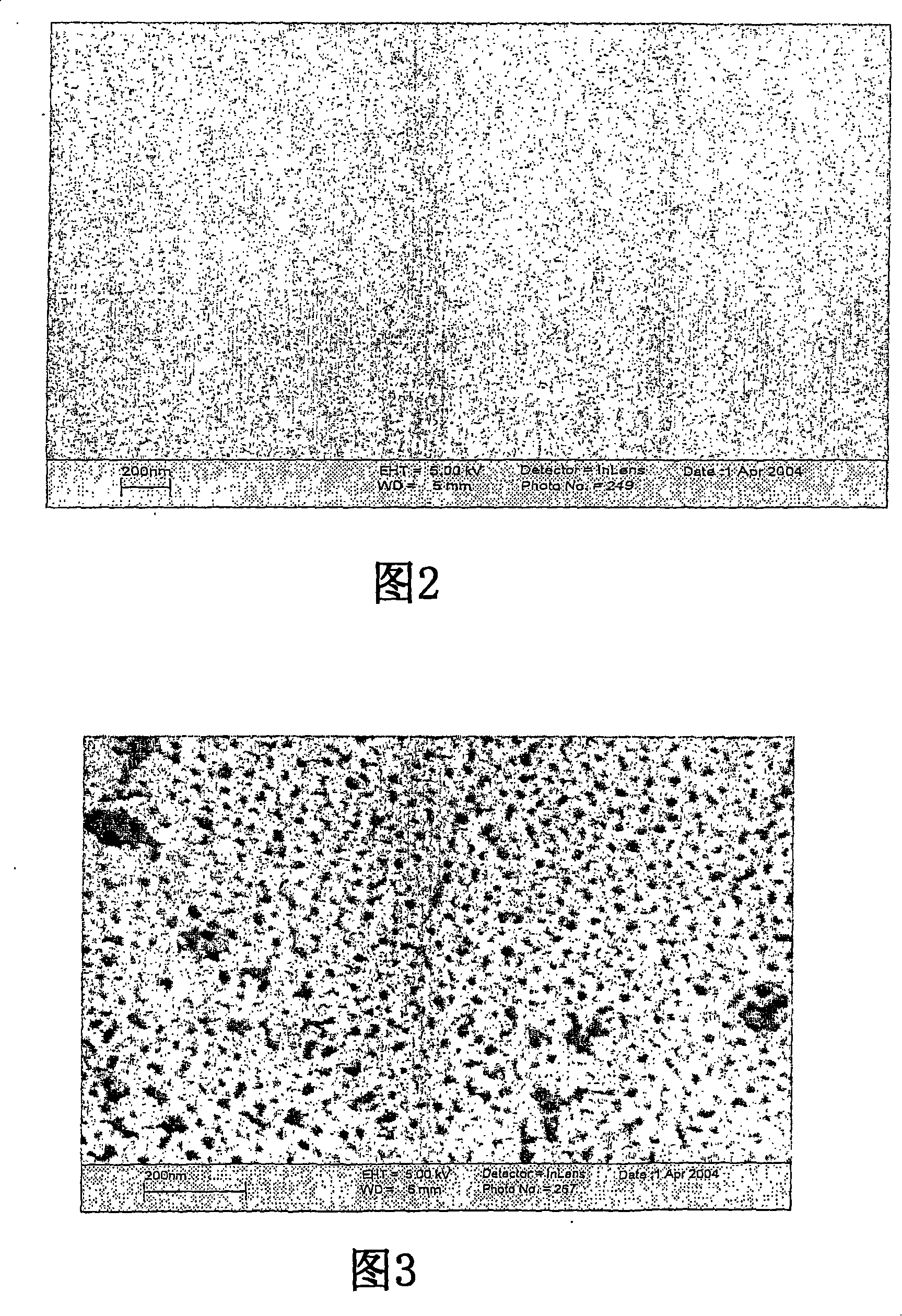

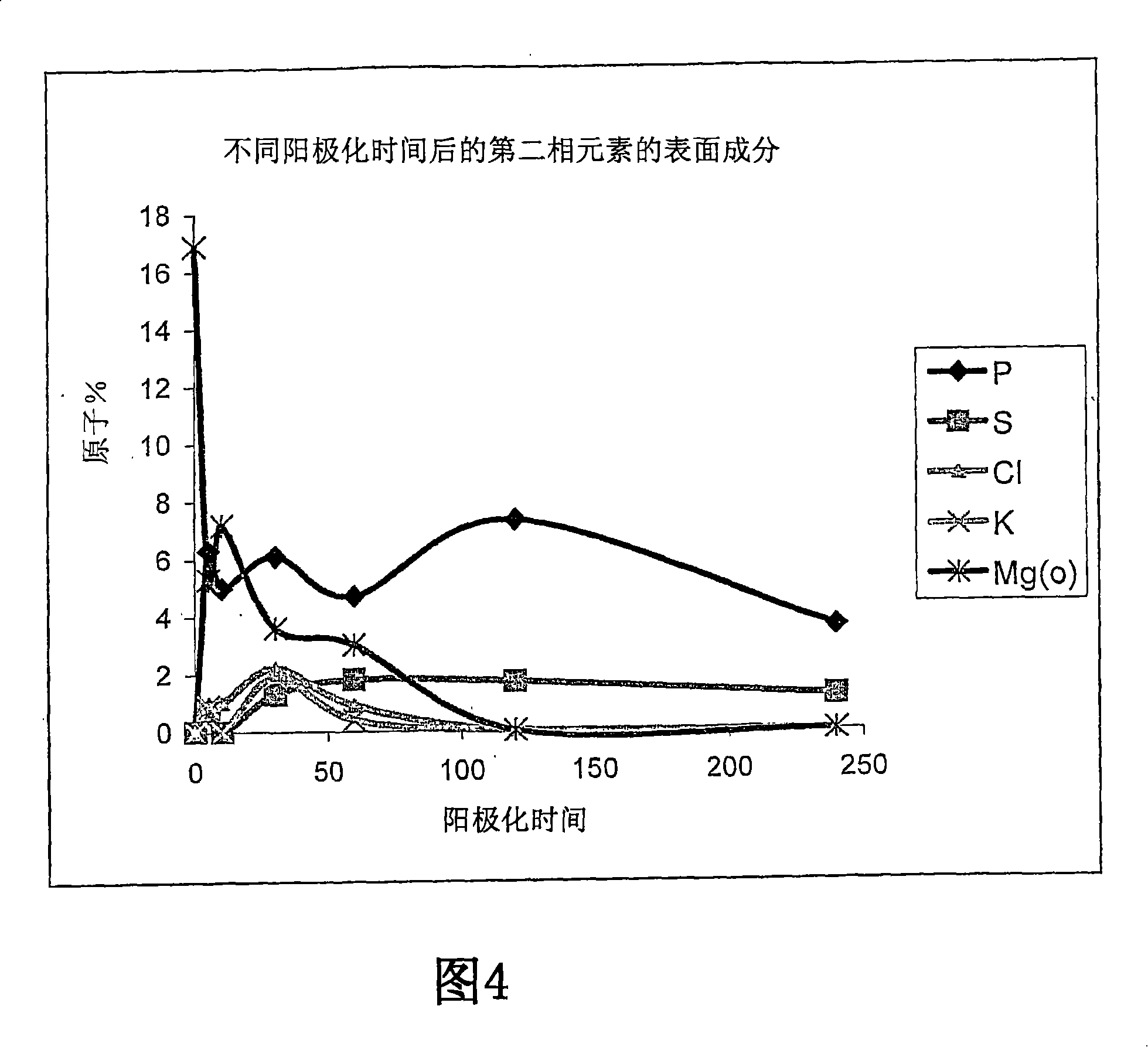

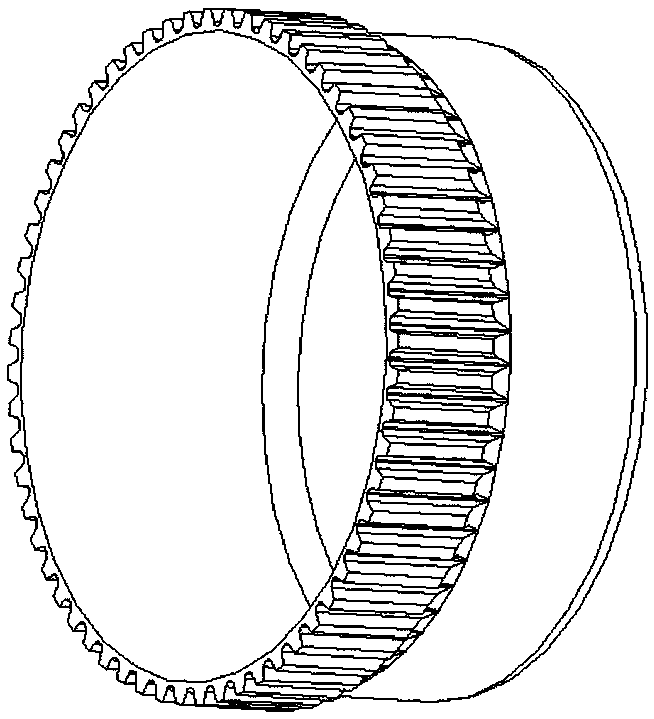

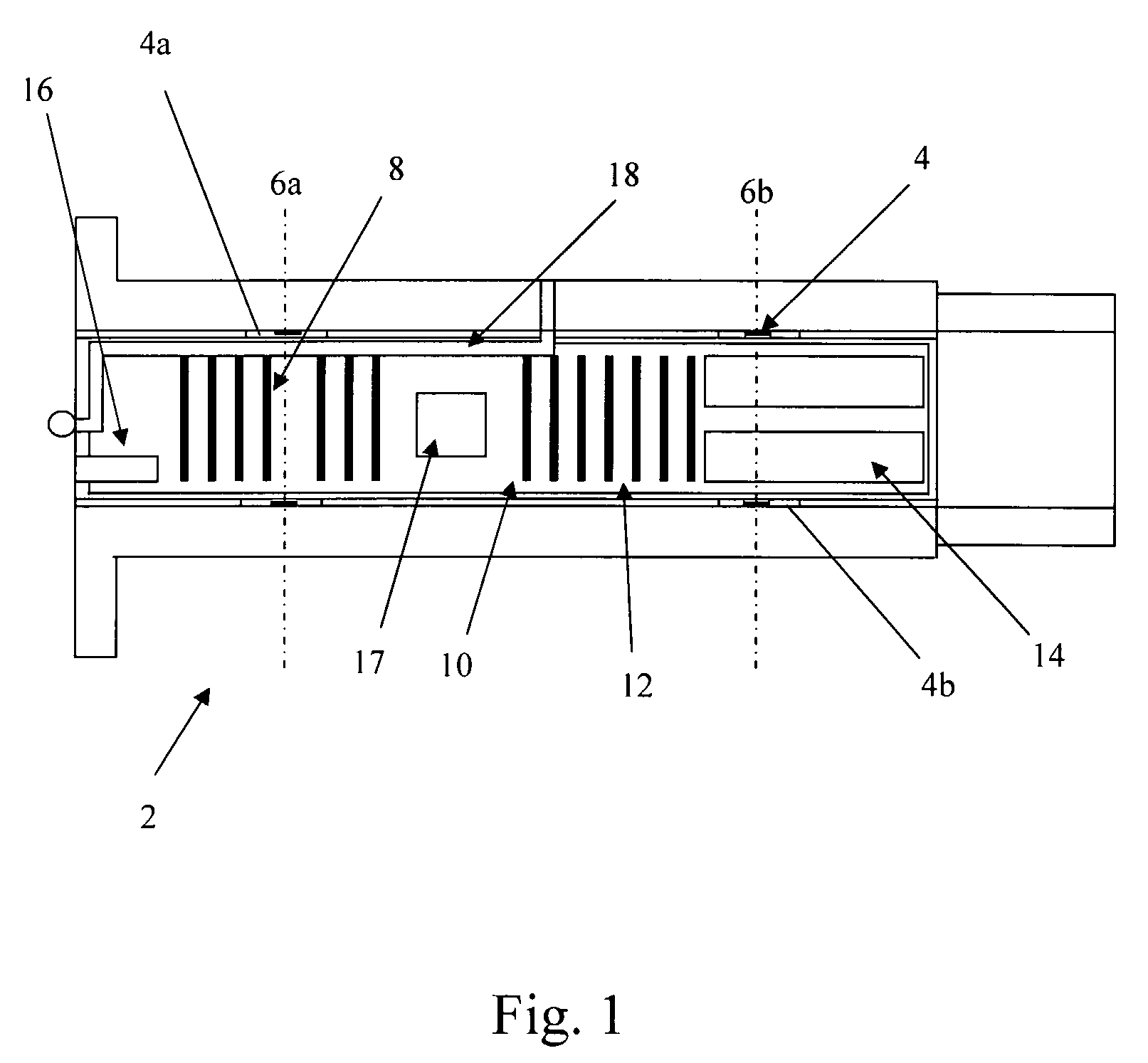

Anodising aluminium alloy

ActiveCN101128624AReduced fatigue lifeHigh peel strengthCellsAnodisationElectrolysis5052 aluminium alloy

An anodic oxide film is formed on an aluminium or aluminium alloy work piece by forming an anodic oxide film on the work piece by AC electrolysis followed by subjecting the work piece to DC electrolysis. The AC anodising step may be conducted at a voltage of 5 to 30V for 30 seconds to 10 minutes and the DC anodising step may be conducted at a voltage of 5 to 30V for a period of 1 to 20 minutes. The anodic oxide coating is suitable for adhesive bonding of aluminium alloy work pieces.

Owner:SHORT BROTHERS

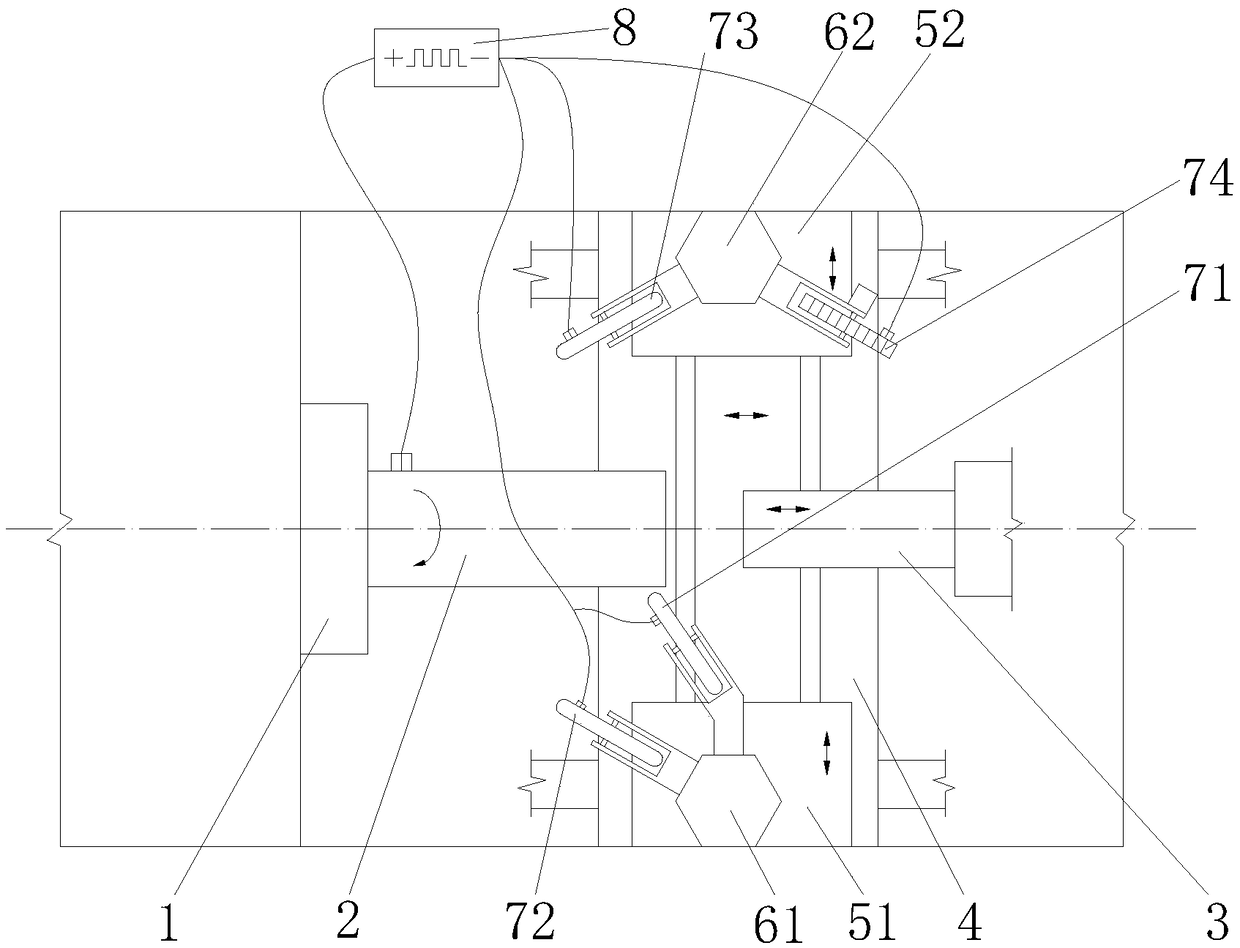

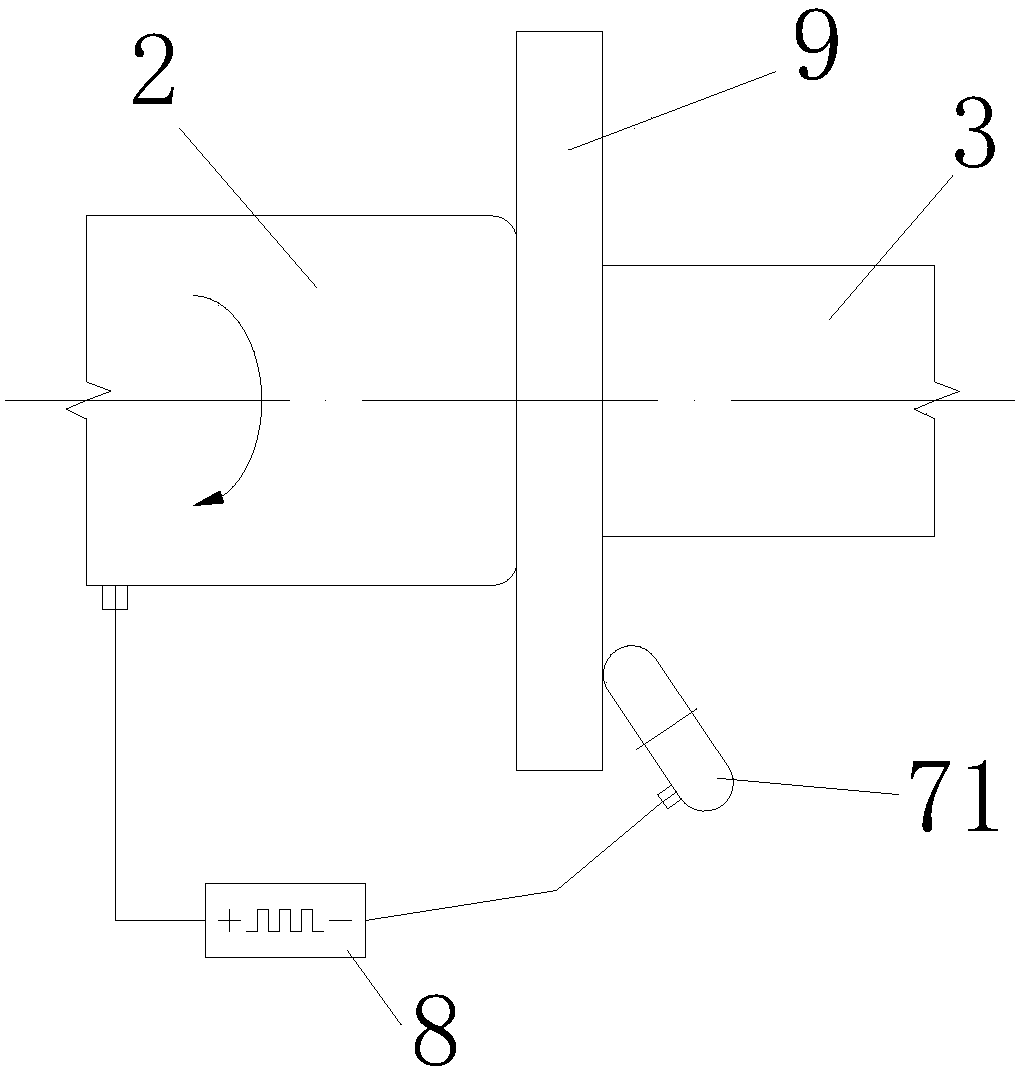

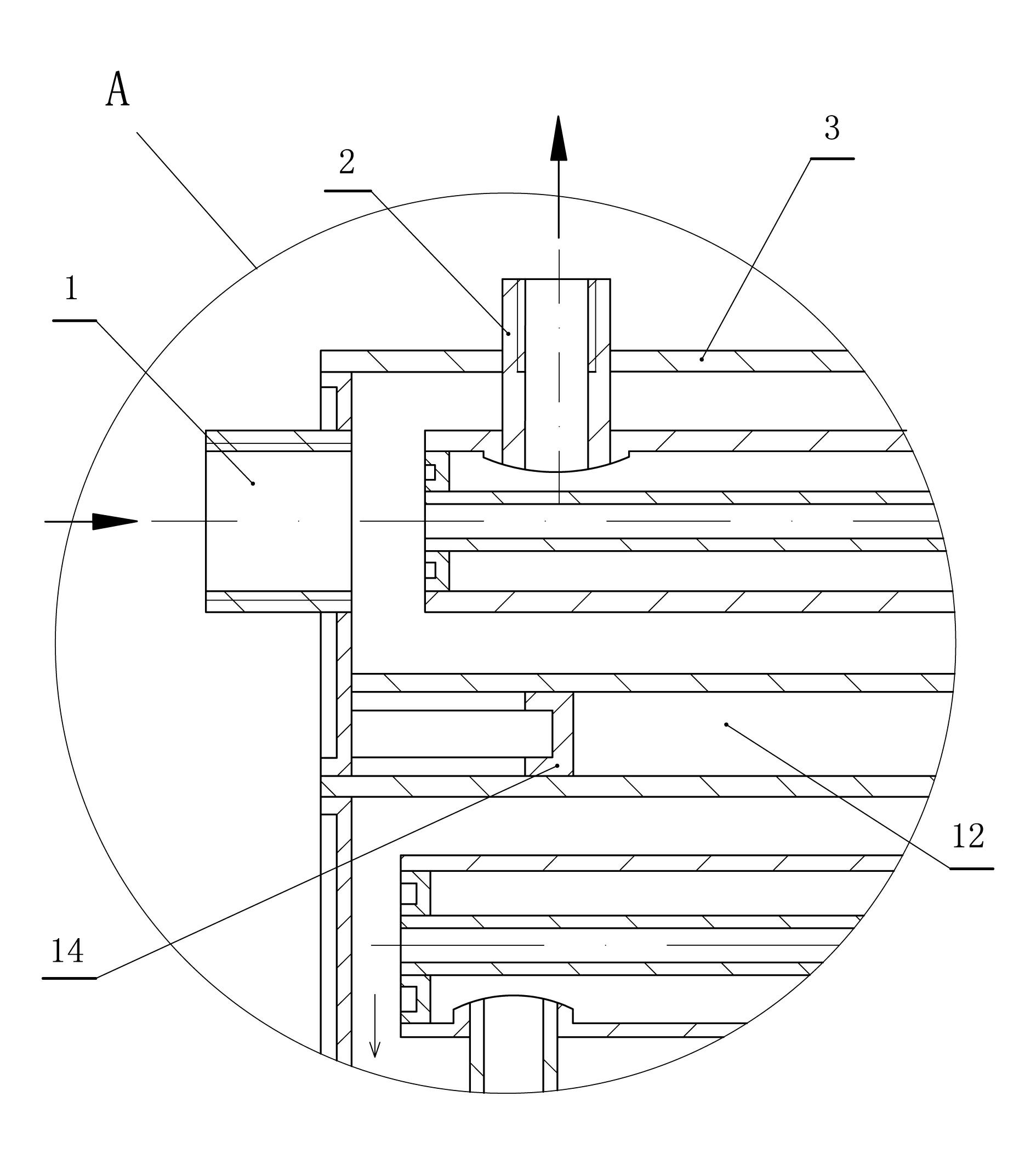

Preparation method of cup-shaped flexible wheel and device thereof

ActiveCN109351836AReduce intensityReduced fatigue lifeShaping toolsEngineeringMechanical engineering

The invention discloses a preparation method of a cup-shaped flexible wheel and a device thereof. A circular slab is tightened at the end of a core die by a tail top. A positive wire of a pulse powersupply is connected with the core die, and a negative wire is directly connected with each rotary wheel of a rotary wheel assembly. The circular slab is first spun and deformed into a cup-shaped workpiece with both inner and outer walls being straight walls by one rotary wheel. Then the cup-shaped workpiece is spun and deformed into two thickened cup-shaped workpieces with different straight wallthickness by another two rotary wheels, and a thicker smooth section is used as a tooth profile reserved section. Finally, the tooth profile reserved section is spun by one toothed rotary wheel to form a circle tooth profile around the outer circumference. At last, a small amount of cutting process is carried out to complete the processing process from the circular slab to the cup-shaped flexiblewheel workpiece. According to the cup - shaped flexible wheel manufacturing process based on plastic forming, streamline formed in the process of deformation can be completely retained, and the service life of parts is prolonged advantageously. The advantage of the method is more obvious for flexible wheels with an extremely small thickness.

Owner:SOUTH CHINA UNIV OF TECH

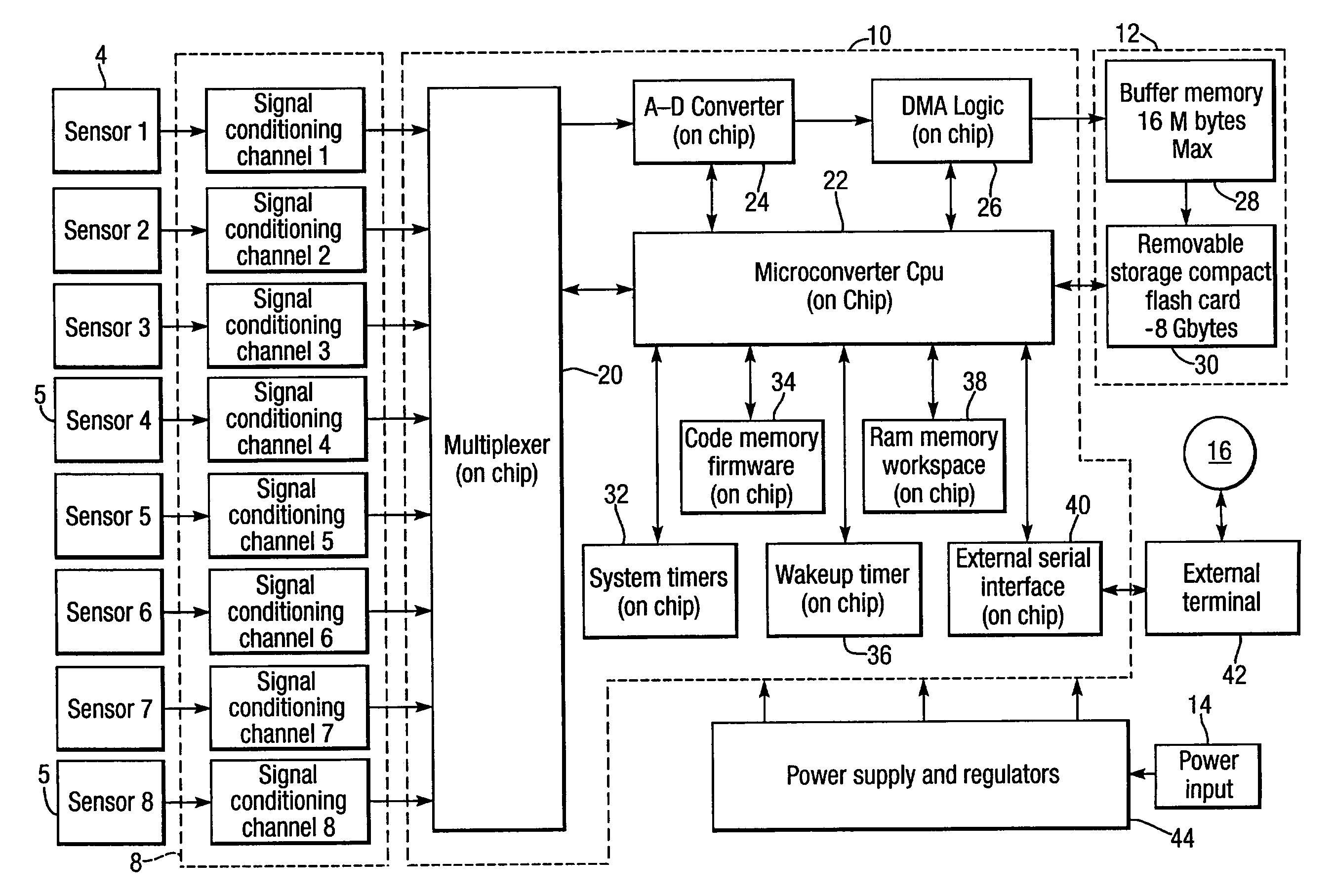

Apparatus and method for measuring loads sustained by a bearing pin

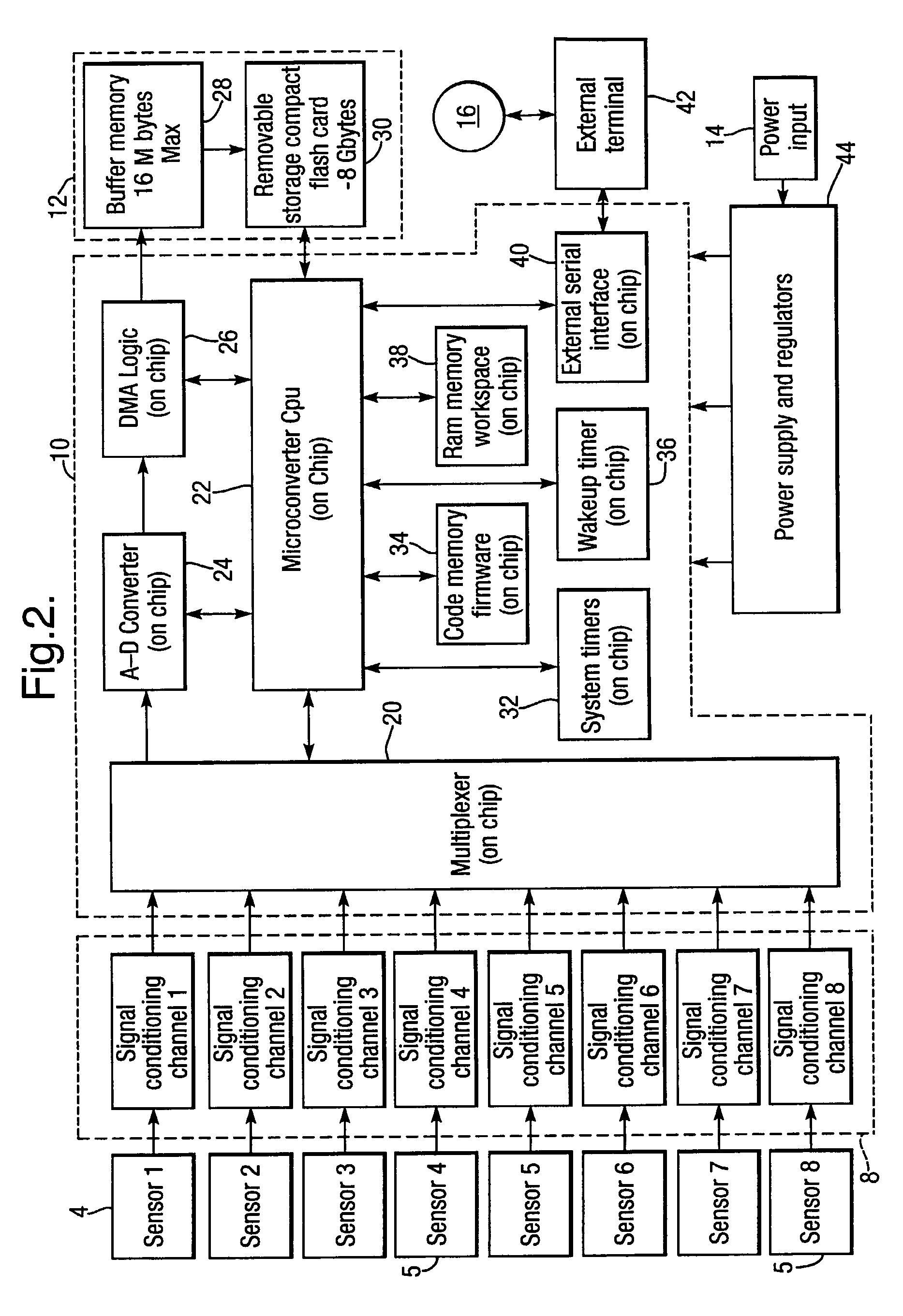

ActiveUS7747396B2Installed with relative easeSimple designPlug gaugesWave amplification devicesAccelerometerAircraft landing

A pin bearing arrangement for use on an aircraft landing gear includes a pin and a load sensor arrangement, which may include strain gauges for measuring shear loads and accelerometers for measuring loads sustained by the pin. The pin includes a self-contained data logging device for logging data concerning loads sustained by the pin. Thus, inside the pin, there may be provided a processing unit, a memory store, and a battery-based power source. During normal operation of the aircraft fatigue loads may be monitored, the processing unit receiving input signals from the means for measuring loads and storing load data in the memory. The stored load data may periodically be extracted from the memory during maintenance of the aircraft.

Owner:AIRBUS OPERATIONS LTD

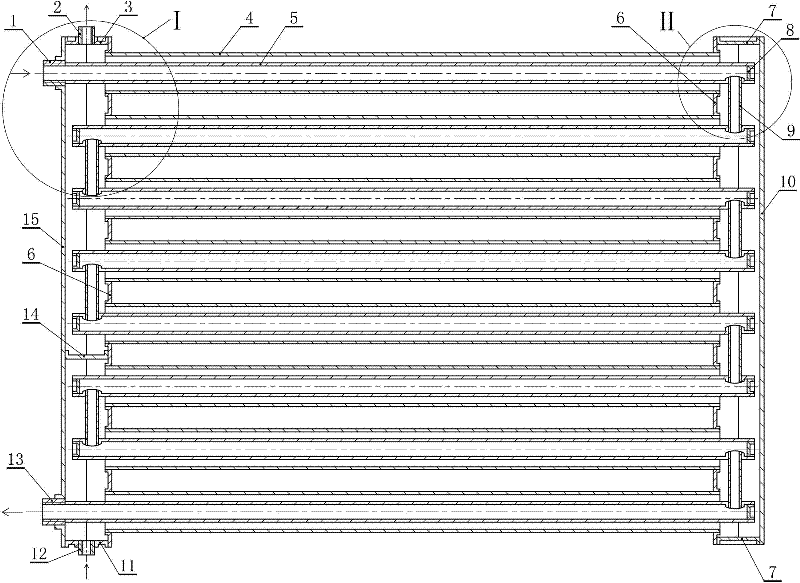

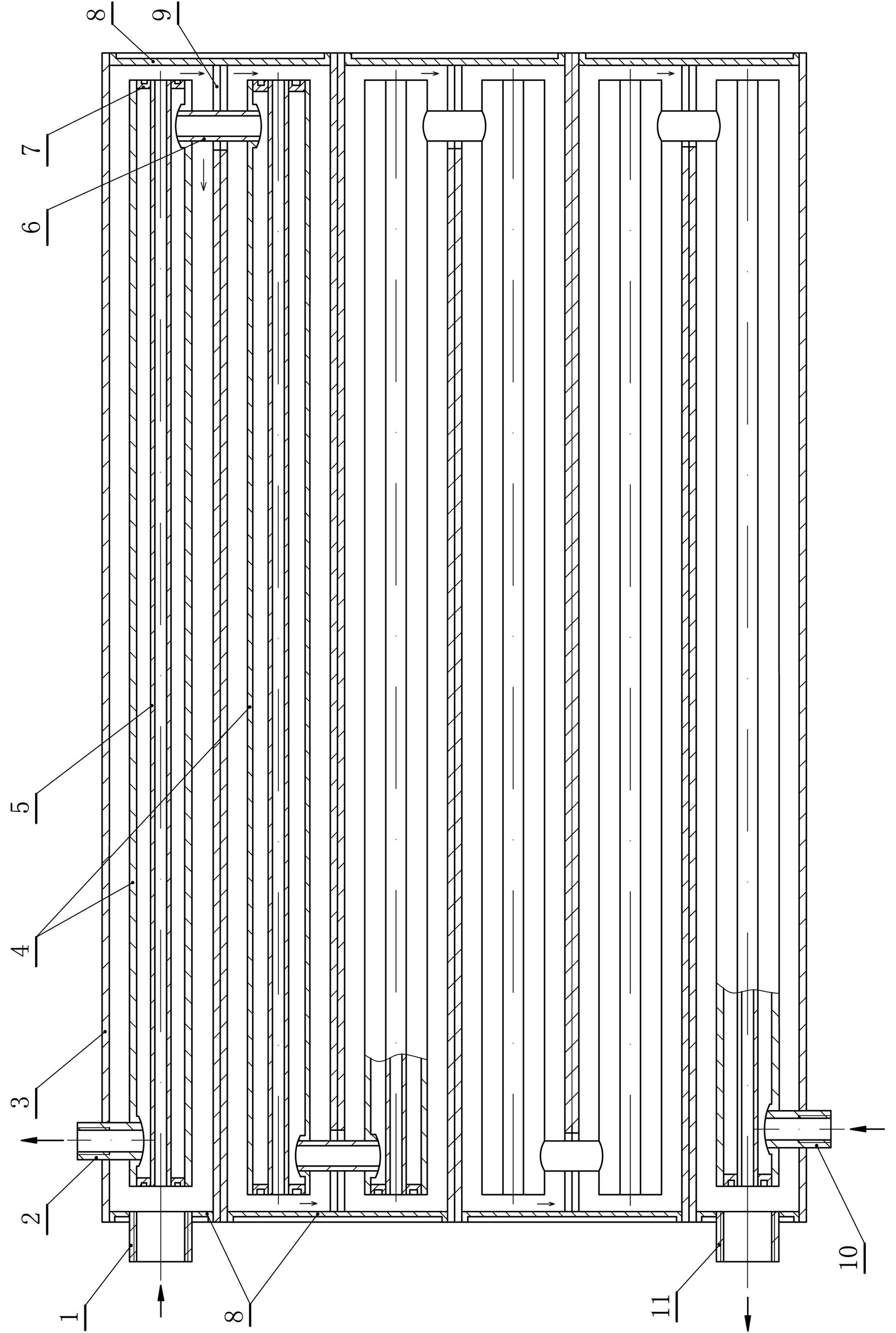

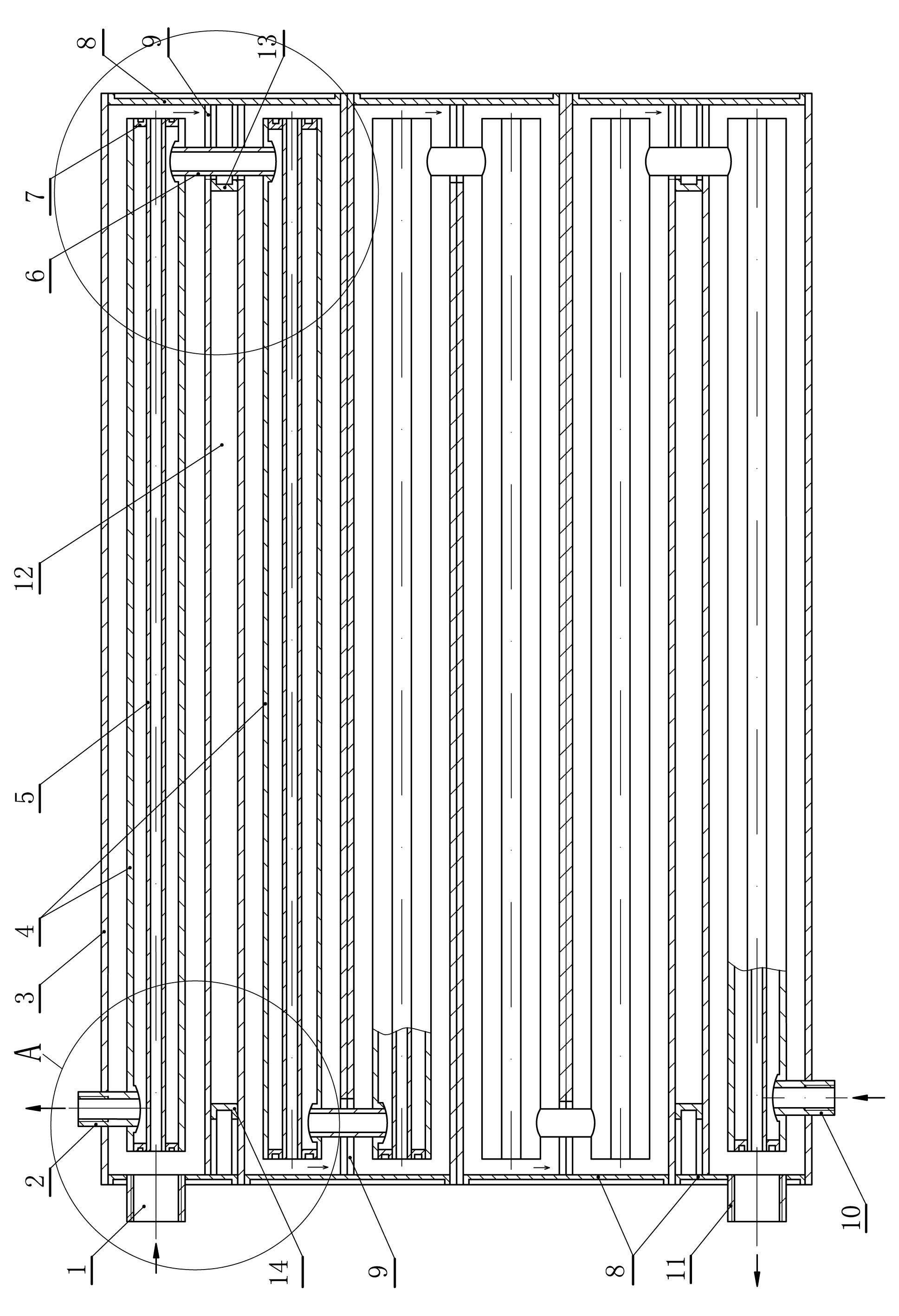

Circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and manufacturing process thereof

ActiveCN102418956ASolve the problem of water leakage under pressureReduce difficultySpace heating and ventilation detailsHeat exchanger casingsPlate heat exchangerWater leakage

The invention discloses a circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and a manufacturing process thereof. The heat exchanger comprises two headers, wherein a tap water communication pipe is fixedly connected between the two headers; a hot air heat supply pipe passes through the tap water communication pipe; each header is formed by welding two arc plates; the plate edges of the arc plates are flanged outwards; the plate edges of the two arc plates are aligned with each other and are subjected to edge-pinching and self-fluxing welding to form a circular tubular header cylinder body; head blocking plates of the headers are flanged outwards and are embedded at two ports of the circular tubular headers; and the two edges are aligned with a pipe wall surface, are spliced and are subjected to the edge-pinching and the self-fluxing welding to form the headers. An installation hole is punched on each arc plate; the installation hole is stretched inward an arc to form an edge; the aperture and the height of are stretched according to the arc plates; and the end surfaces of the two ends of the tap water communication pipe are subjected to R-angle cutting according to the stretching hole diameter and the stretching height of the arc plates, and then the tap water communication pipe is inserted into the installation holes stretched from the arc plates, are matched with each other, are spliced and are subjected to edge-pinching and self-fluxing welding connection. In the heat exchanger, welding seams are spliced, the edge-pinching welding is easy to realize, and water leakage is avoided; and the heat exchanger is good in pressure-bearing performance, and low in maintenance cost.

Owner:张伟

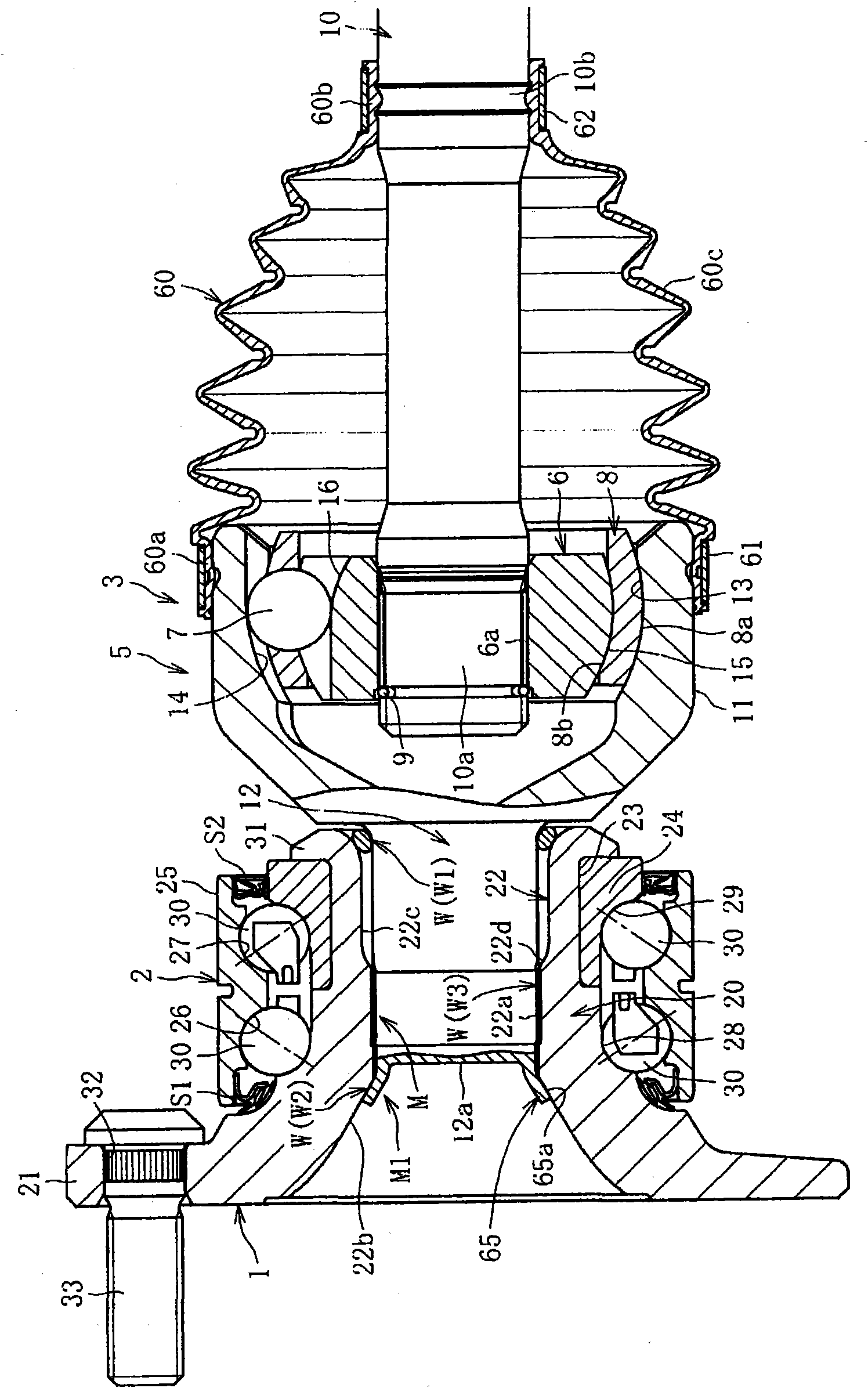

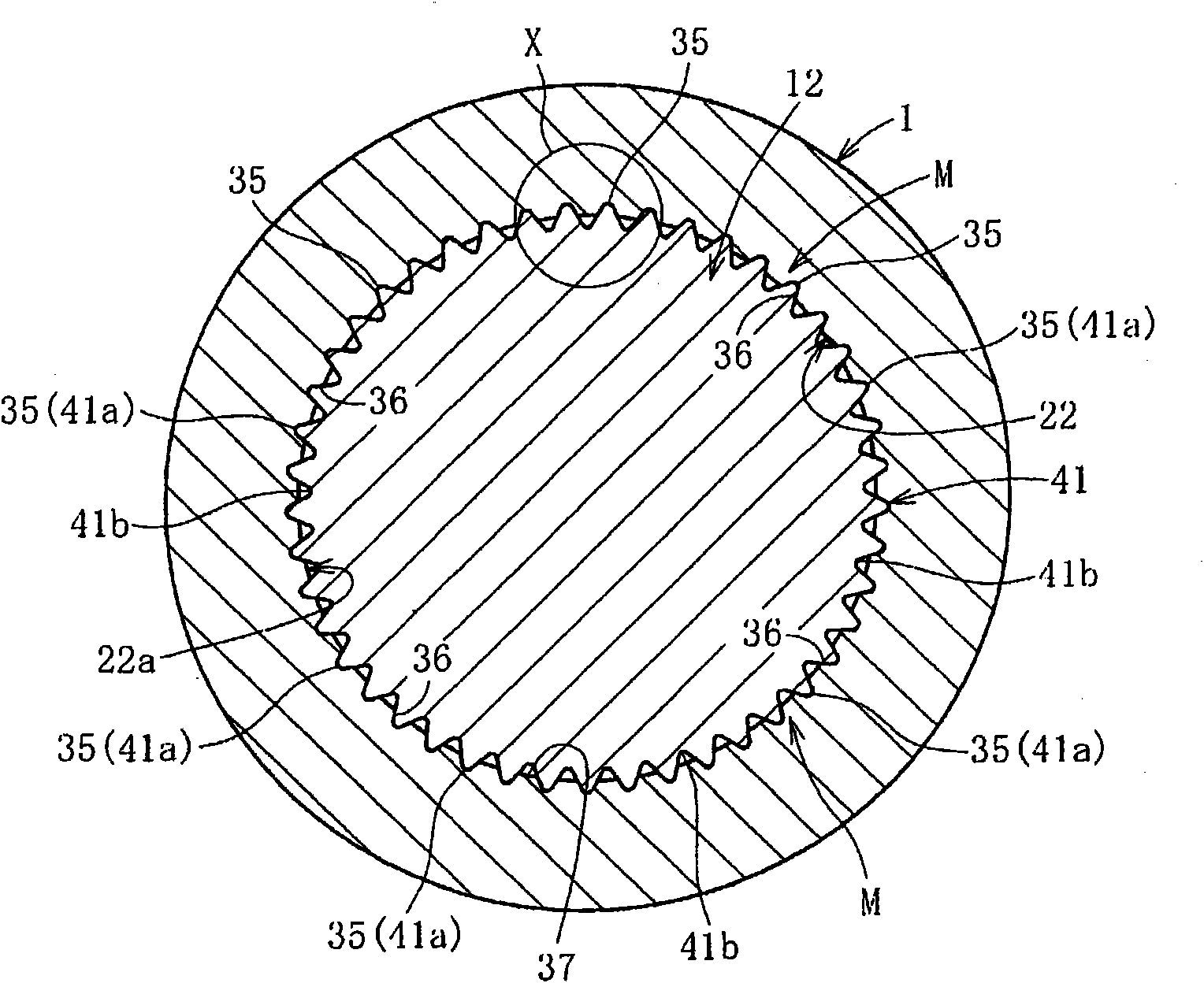

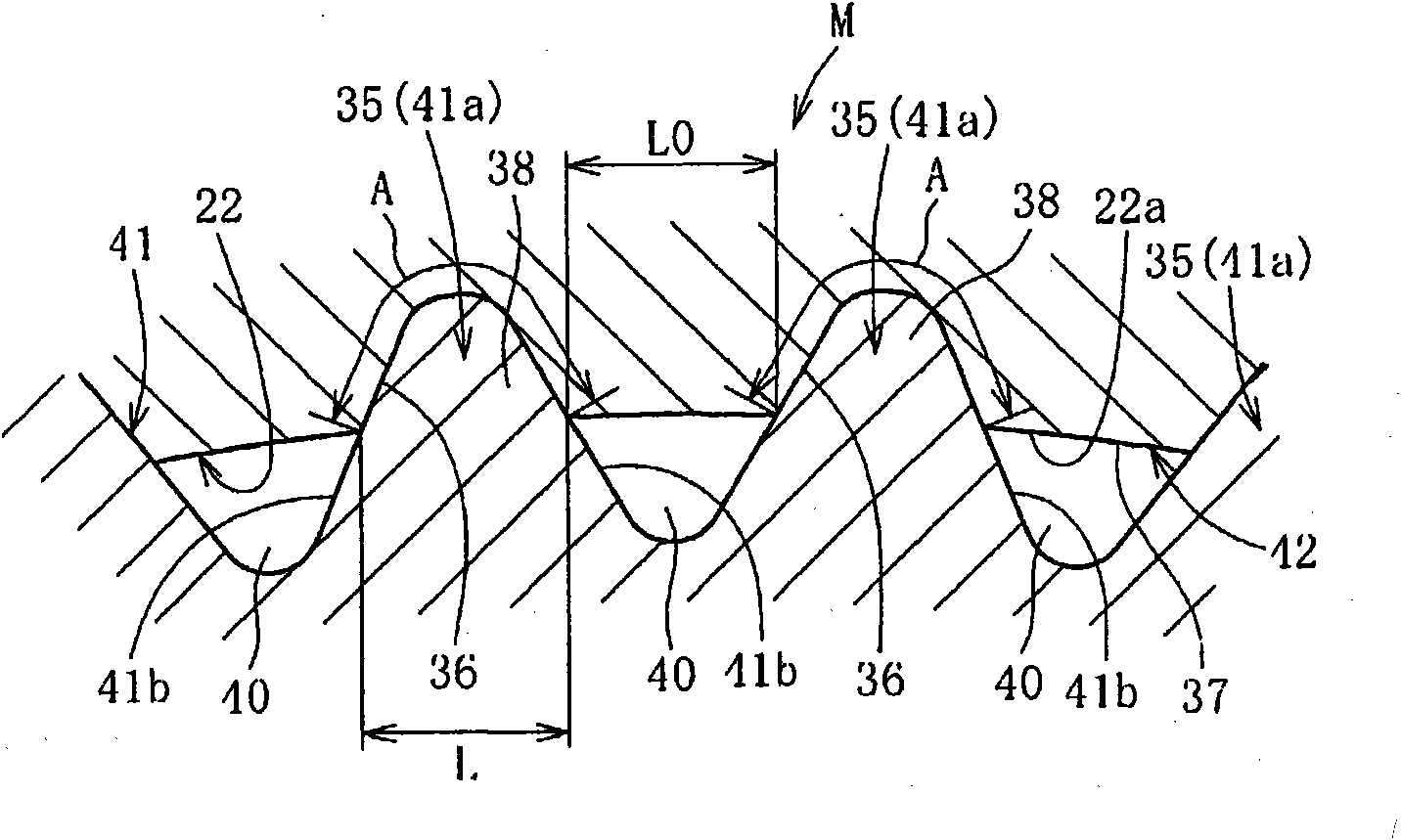

Bearing device for wheel, and axle module

Provided are a bearing device for a wheel, in which circumferential play is reduced, which provides excellent workability in connection between a hub ring and an outer joint member of a constant velocity universal joint, in which fitting between the hub ring and the outer joint member of the constant velocity universal joint is stable, and which has excellent strength, and an axle module using the bearing device. An axially extending projection is formed on either of the outer diameter surface of a shaft section of the outer joint member and the inner diameter surface of a hole of the hub ring. The projection is press-fitted to the other in the axial direction to form a recess in the other by the press-fitting. By this, a recess / projection fit structure is formed, in which the entire regions of those portions of the projection and the recess at which they are fitted to each other are in intimate contact with each other. The hardness of at least that portion of the projection at which the press-fit starts is higher than that of a portion where the recess is formed. The difference in hardness in HRC is 20 or more.

Owner:NTN CORP

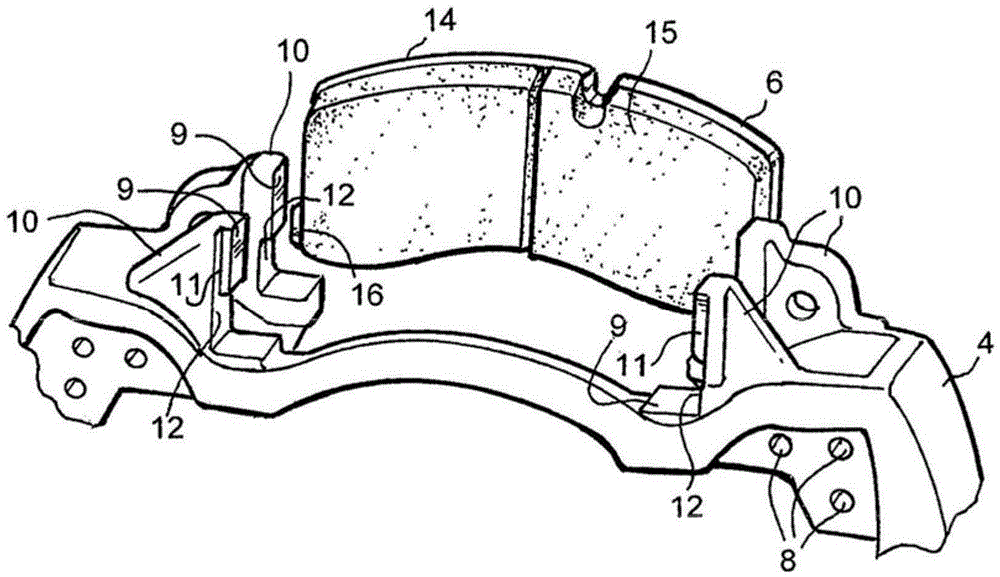

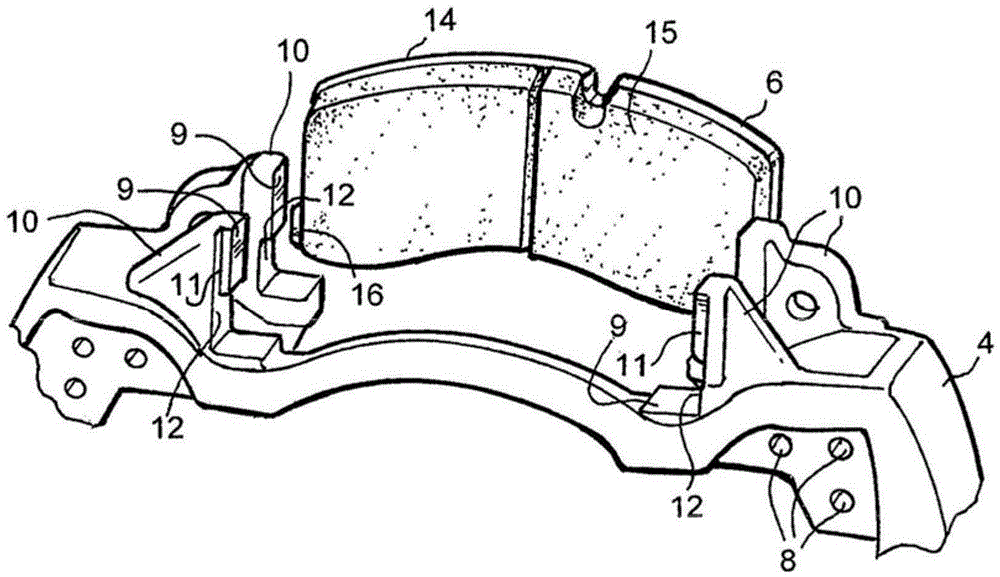

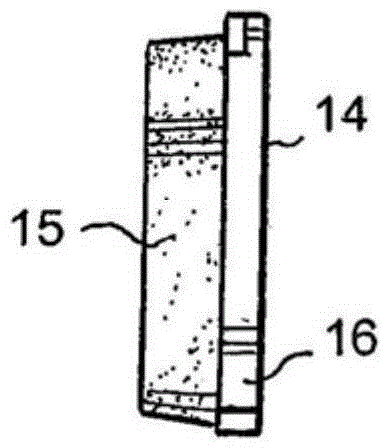

Disc brake pad mounting and retention system and method

ActiveCN104583634AEasy to change quicklyPrevent exitAxially engaging brakesBraking elementsAbutmentCalipers

A disk brake having a brake caliper mount (4) having brake pad abutment surfaces having radially-oriented (11) and lateral (12) grooves which permit a brake pad (6) with corresponding projections (16) on is lateral sides to be inserted through an opening of the brake caliper into the radially-oriented grooves (11) until the backing plate projections are aligned with the lateral groove (12), and advancing the brake actuator behind the brake pad (6) to place the brake pad (6) in an operating position in which the actuator prevents the brake pad (6) from realigning with the radially-oriented grooves (11) until the actuator is retracted to permit brake pad extraction.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

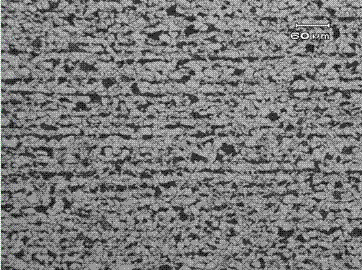

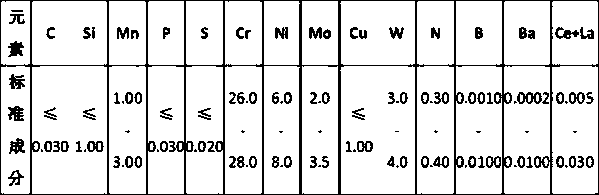

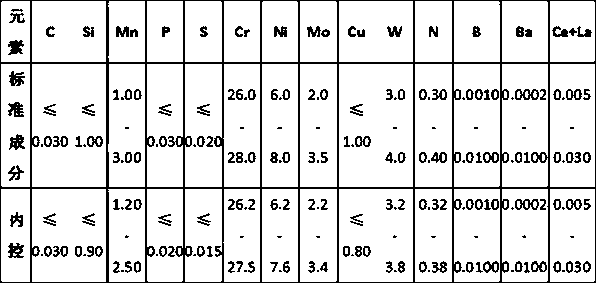

Super advanced double-phase stainless steel smelting process method of CD3MWN material

ActiveCN108823348AIncrease contentReduce precipitationProcess efficiency improvementHydrogenDouble phase

The invention relates to a super advanced double-phase stainless steel smelting process method of a CD3MWN material. According to the invention, internal control components during double-phase stainless steel smelting is designed, wherein C is less than or equal to 0.030 wt%, Si is less than or equal to 0.90 wt%, Mn is 1.20-2.50 wt%, P is less than or equal to 0.020 wt%, S is less than or equal to0.015 wt%, and Cr is 26.2-27.5 wt%, Ni is 6.2-7.6 wt%, Mo is 2.2-3.4 wt%, Cu is less than or equal to 0.80 wt%, W is less than or equal to 0.80 wt%, N is 0.32-0.38 wt%, B is 0.0010-0.0100 wt%, Ba is0.0002-0.0100 wt%, and Ce+La is 0.005- 0.030 wt%; and %Cr+3.3 (%Mo+0.5%W)+16%N is less than or equal to 45, the content of trace elements B, Ba, Ce, and La can be precisely controlled; the N content is increased to 0.30% or more, and at the same time, nitrogen holes in the casting can be avoided; and the content of harmful elements such as sulfur, oxygen, hydrogen and the like is minimized to improve the purity of the molten steel. The cast casting has high strength and excellent corrosion resistance. In the stainless steel, a ferrite phase and an austenite phase are close to 50%, the castinglife is prolonged. the production costs are greatly reduced, and purposes of energy saving and environmental protection can be realized.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Wheel rim fatigue analysis method

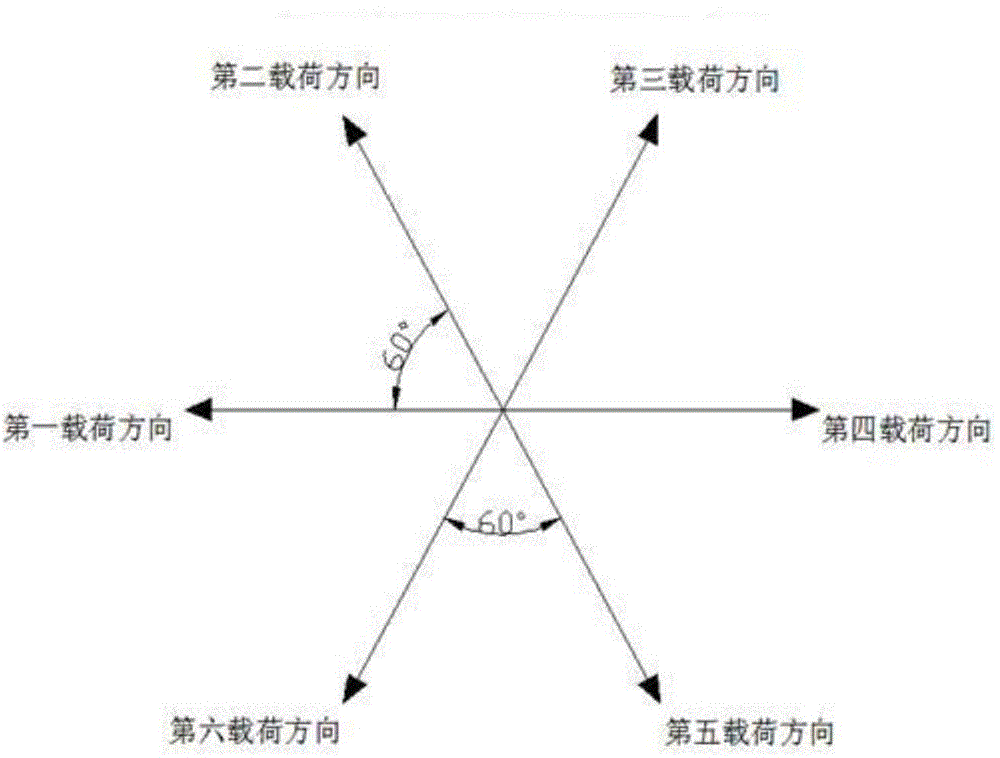

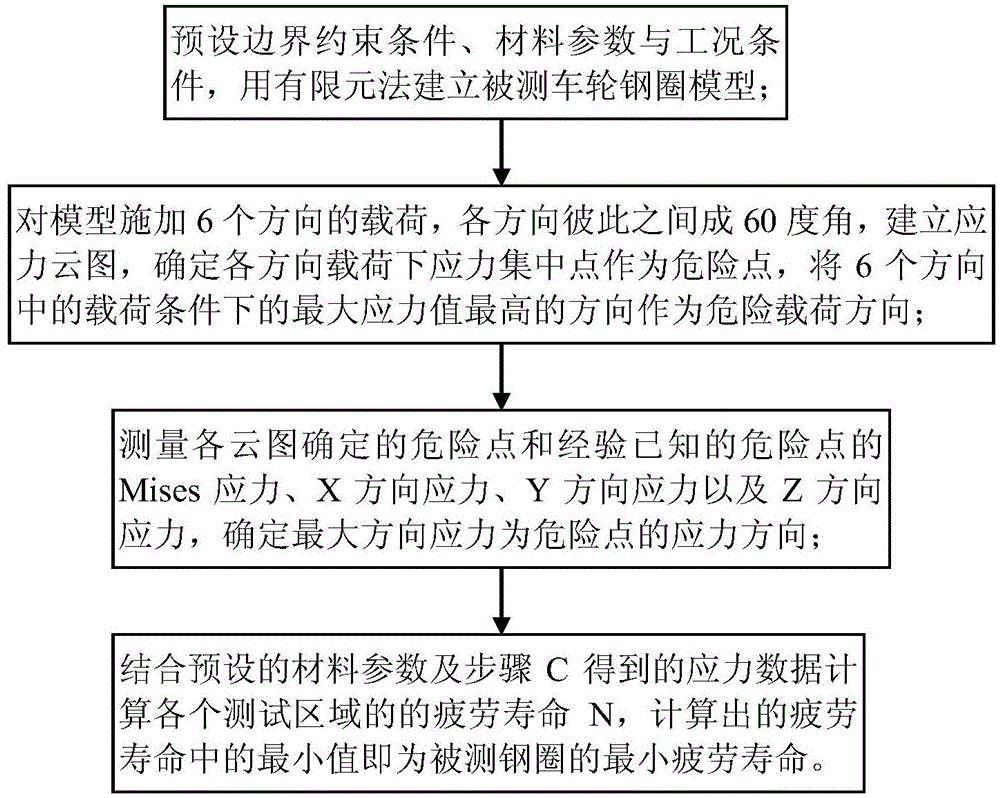

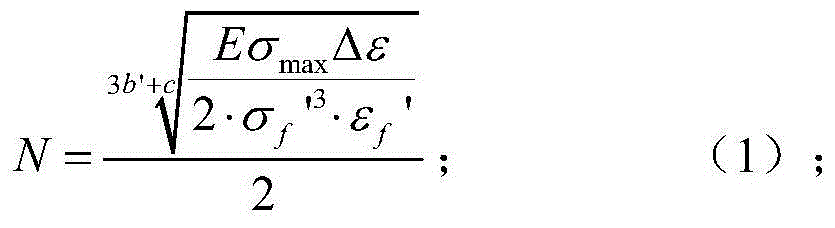

InactiveCN104537241AReduced fatigue lifeSimple calculationSpecial data processing applicationsStress concentrationFinite element method

The invention aims to provide a wheel rim fatigue analysis method which comprises the steps that A, boundary constraint conditions, material parameters and working conditions are preset, and a tested wheel rims model is established with a finite element method; B, loads in six directions are applied to the model, stress nephograms are established, stress concentration points under the loads in all directions are determined as dangerous points, and dangerous load directions are determined in the six directions; C, Mises stress ad stress in X, Y and Z directions of the dangerous points determined by all the nephograms and tested known dangerous points are measured, and the largest direction stress is determined as the stress direction of the dangerous point; D, fatigue lives N in all test areas are calculated by combining the preset material parameters and the strass data obtained in the step C, and the calculated minimum value in the fatigue lives is the minimum fatigue life of the tested wheel rim. The wheel rim fatigue analysis method overcomes the defects that the design and development cycle of a wheel rim is long and the cost is high in the prior art and has the advantages of accurate calculation and high calculation efficiency.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

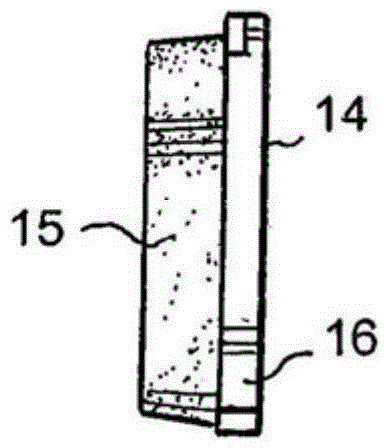

Disc brake pad mounting and retention system and method

ActiveCN104583633AEasy to change quicklyPrevent exitAxially engaging brakesBraking elementsControl theoryBrake pad

A brake pad for a disk brake comprising a brake pad backing plate(14), a brake pad lining material affixed to a brake diskside of the brake pad backing plate, wherein the brake pad backing plate includes a brake pad retaining feature (16, 16a) on at least two lateral sides configured to permit brake pad insertion through an installed brake caliper in a radially-inward direction and translation of the brake pad toward a brake disk of the disk brake while engaging at least one lateral brake pad receiving feature, and each brake pad retaining feature (16, 16a) on each of the at least two lateral sides is asymmetric to at least one other brake pad retaining feature on at least one of the at least two lateral sides.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

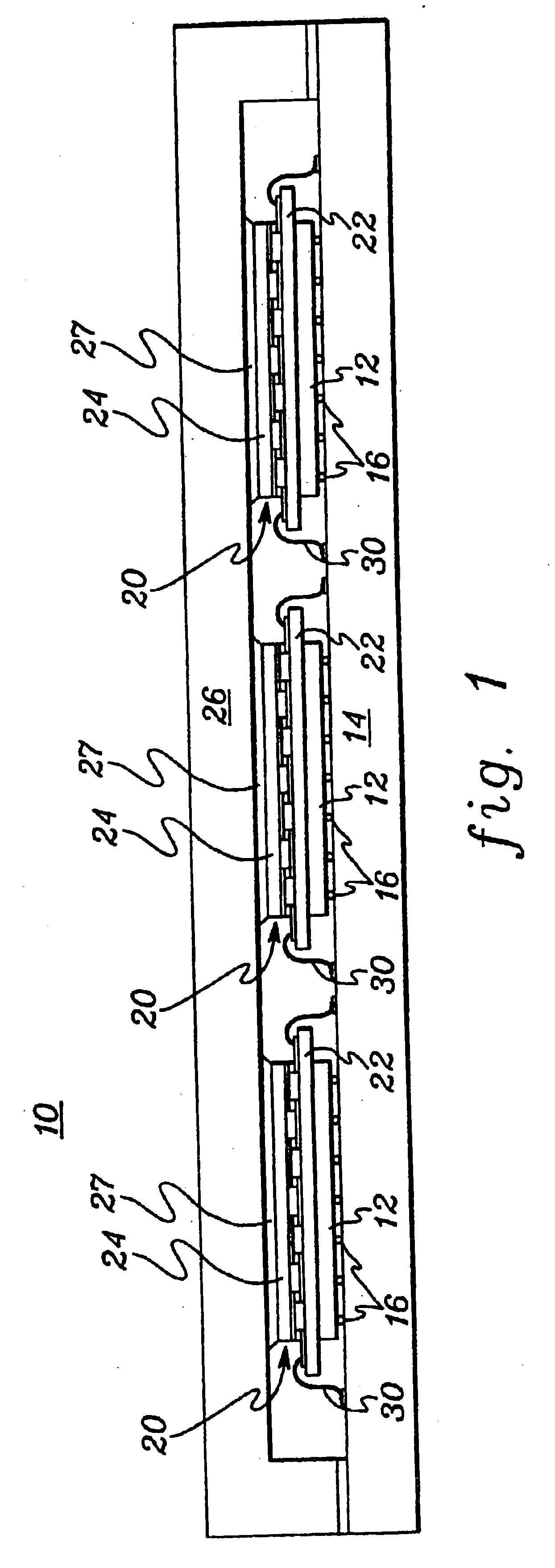

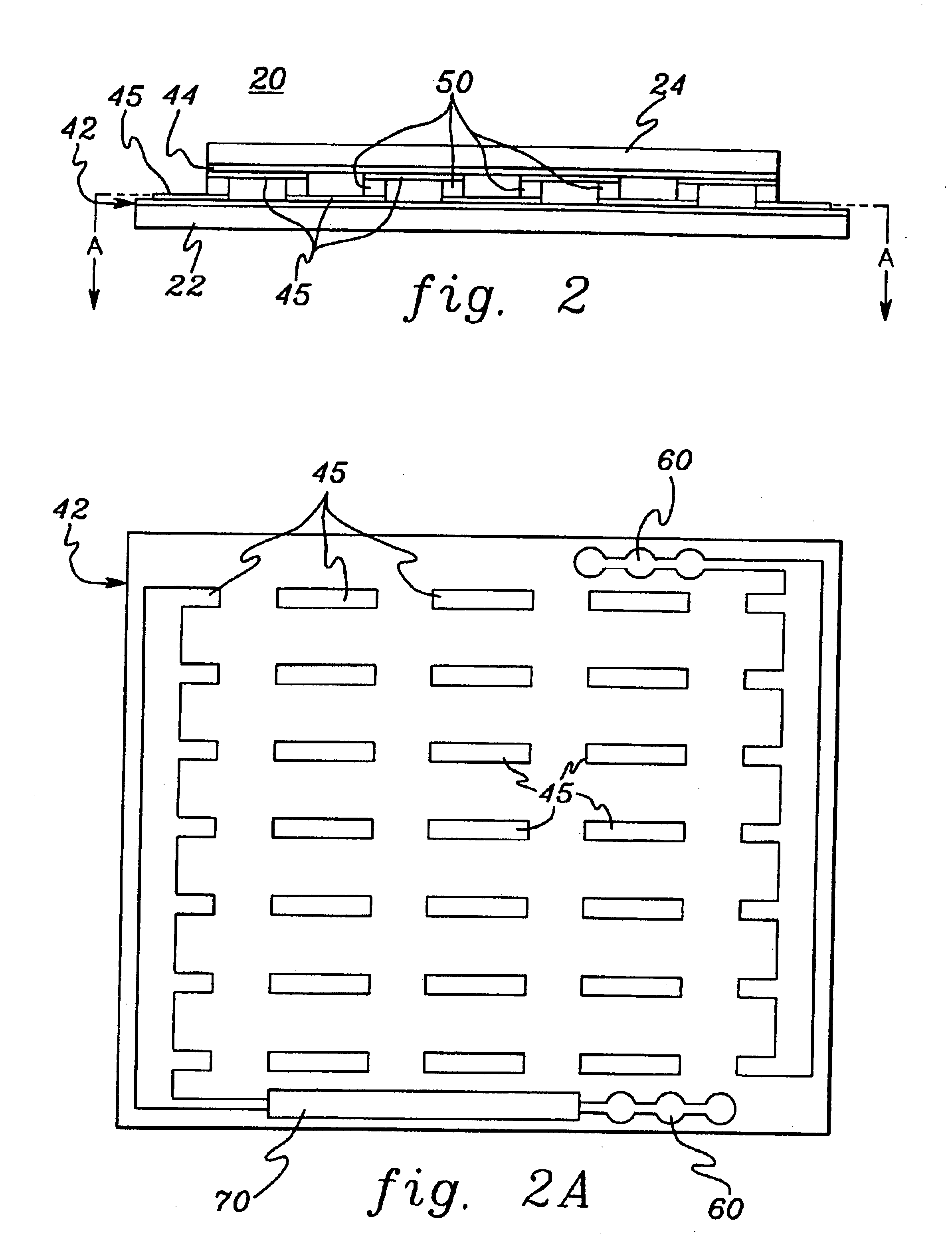

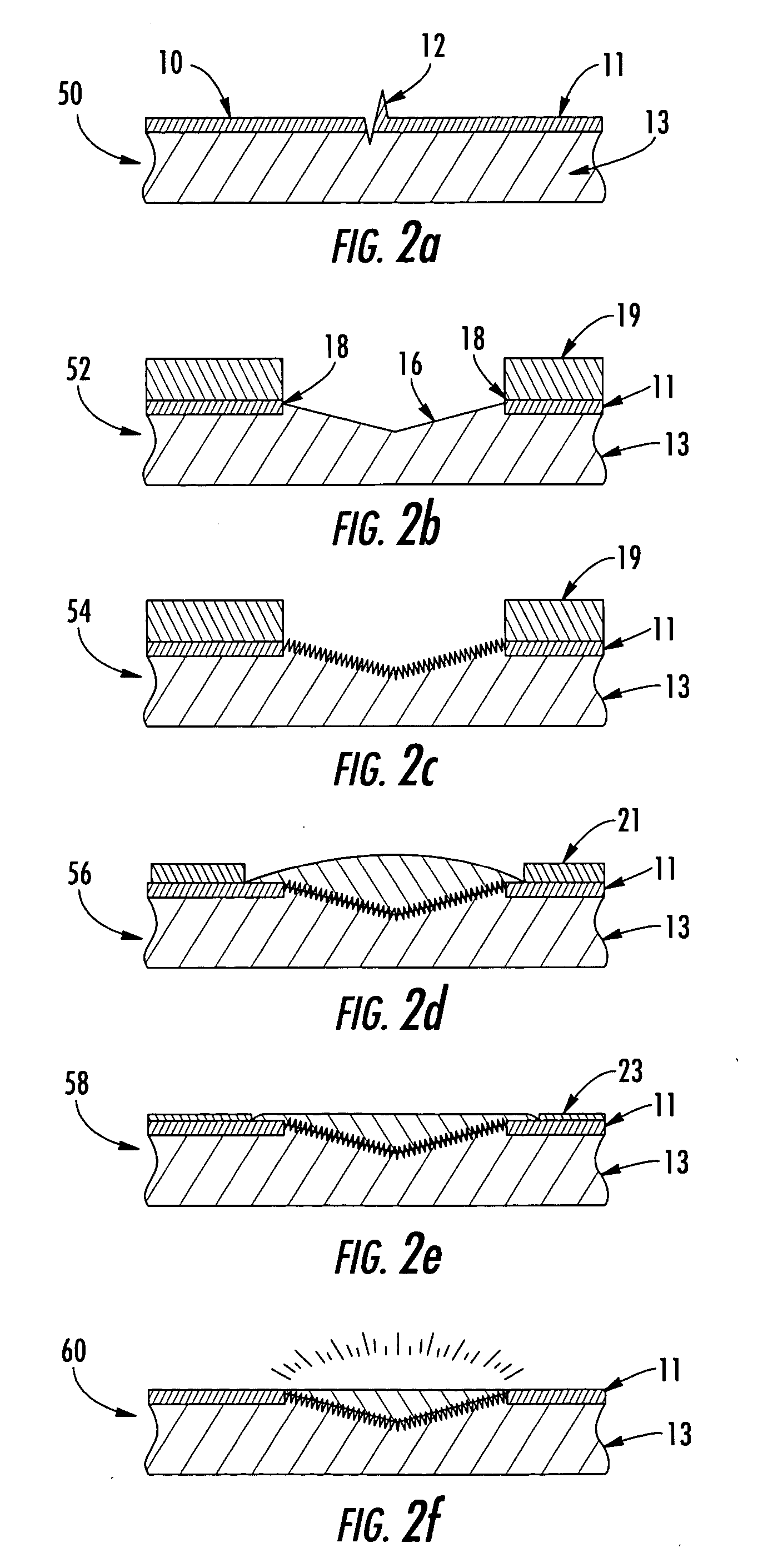

Method and apparatus to pre-form two or more integrated connectorless cables in the flexible sections of rigid-flex printed circuit boards

InactiveUS20050112910A1Reduce strainReduce stressLine/current collector detailsElectrically conductive connectionsElectrical conductorEngineering

A method for preforming of two or more flexible cables in an arrangement consisting of a combination of rigid printed circuit boards and flexible cable sections extending therebetween. Moreover, also provided is an apparatus for the preforming of two or more flexible cable sections of a combination of rigid printed circuit boards and therewith interposed flexible cable sections which are adapted to interconnect the rigid printed circuit boards. The apparatus consists of a tool constituted of an elongated cylindrical member having a tapered leading end which narrows into an ultra-thin flat end section of a blade-like configuration, and which is adapted to be pushed between the flexible cables and so as to preform the flexible cable sections and cause them to yield in a predetermined outwardly bowed permanently relationship between the rigid printed circuit boards at the opposite ends thereof to lengthen the fatigue life of the conductors in the flexible cable sections.

Owner:IBM CORP

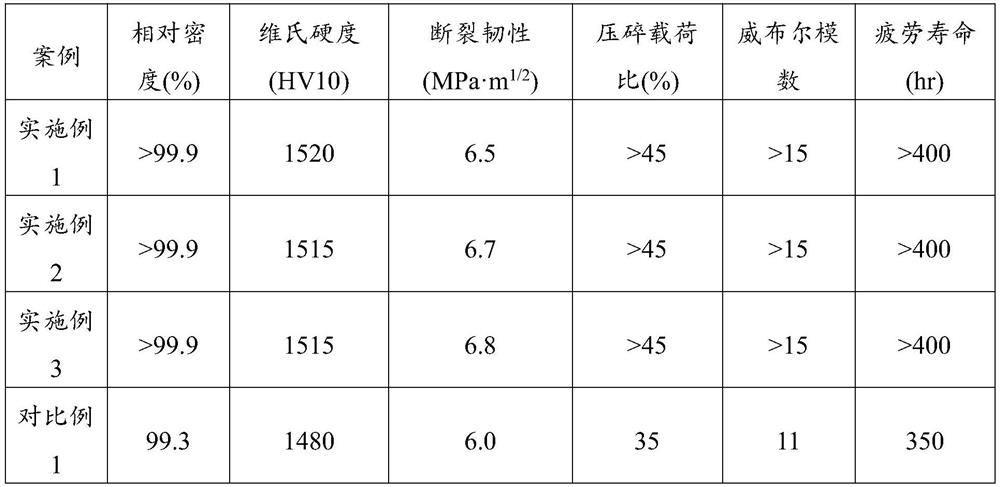

Preparation method of high-reliability long-life silicon nitride ceramic ball for aircraft bearing

The invention provides a preparation method of a high-reliability long-service-life silicon nitride ceramic ball for an aircraft bearing, and belongs to the technical field of silicon nitride ceramicball manufacturing. Metal organic salt (aluminum isopropoxide and metal acetate) is used as a precursor of a sintering aid, and the surface of silicon nitride can be coated with the sintering aid through hydrolysis, spray drying and calcination processes, so that uniform dispersion of the sintering aid in silicon nitride is realized; therefore, the reduction of reliability and fatigue life of theceramic ball caused by agglomeration and segregation of the sintering aid is avoided. The result of the embodiment shows that the density of the silicon nitride ceramic ball prepared by the method reaches 99.9% or above, the Vickers hardness (HV10) is larger than 1500, the crushing load ratio is larger than 45%, the Weibull modulus is larger than 15, the rolling contact fatigue life (RCF) is 400 hor above, and the silicon nitride ceramic ball is particularly suitable for manufacturing rolling elements for aviation bearings.

Owner:SINOMA ADVANCED NITRIDE CERAMICS CO LTD +2

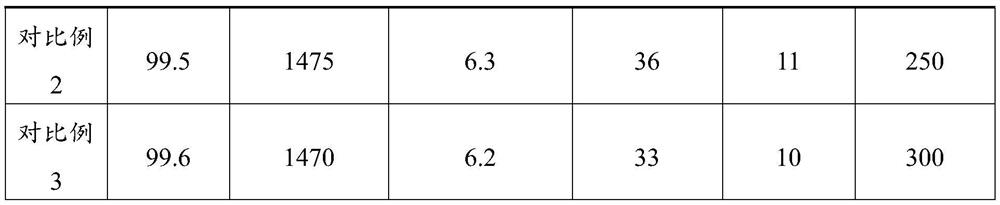

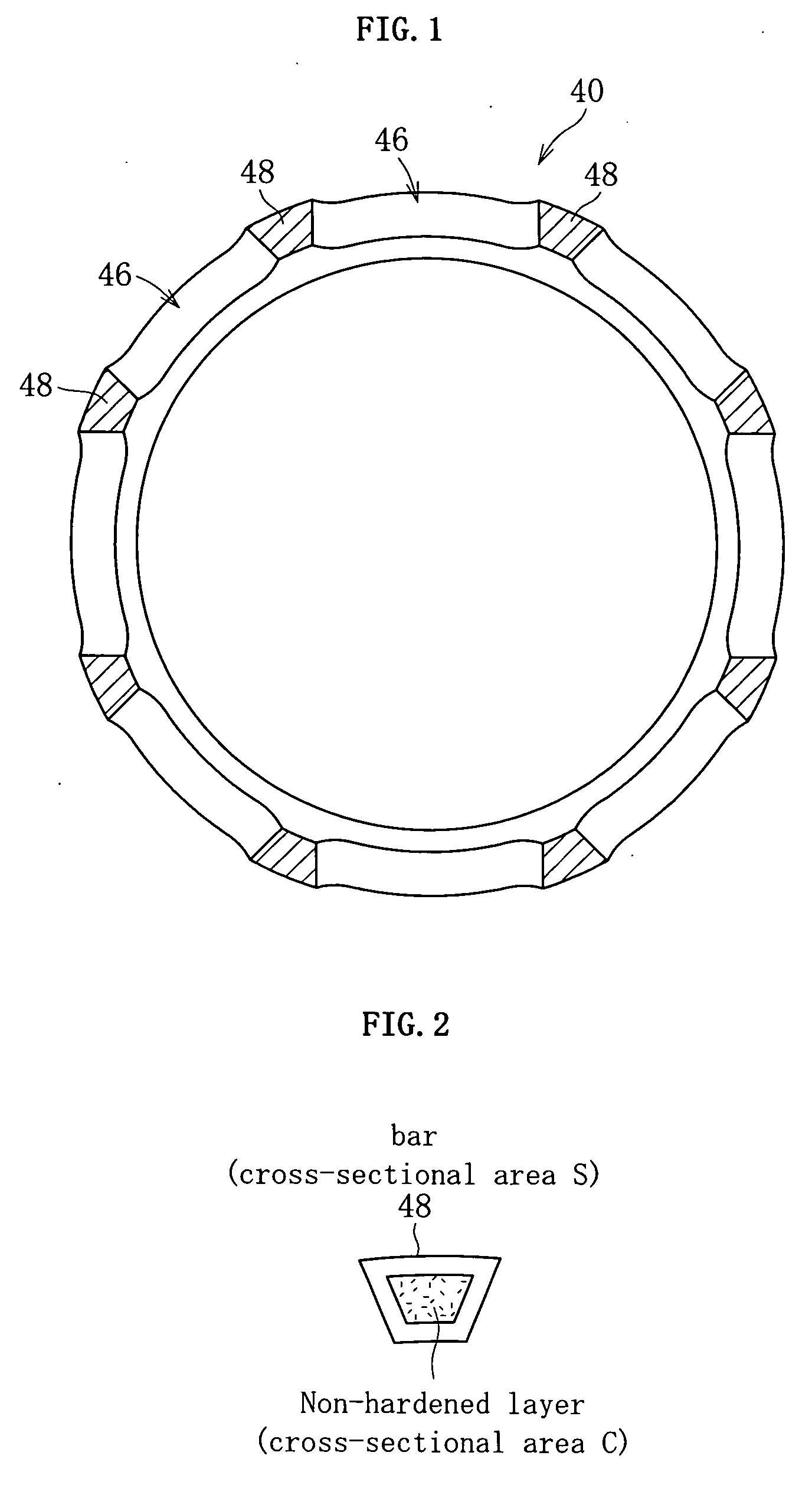

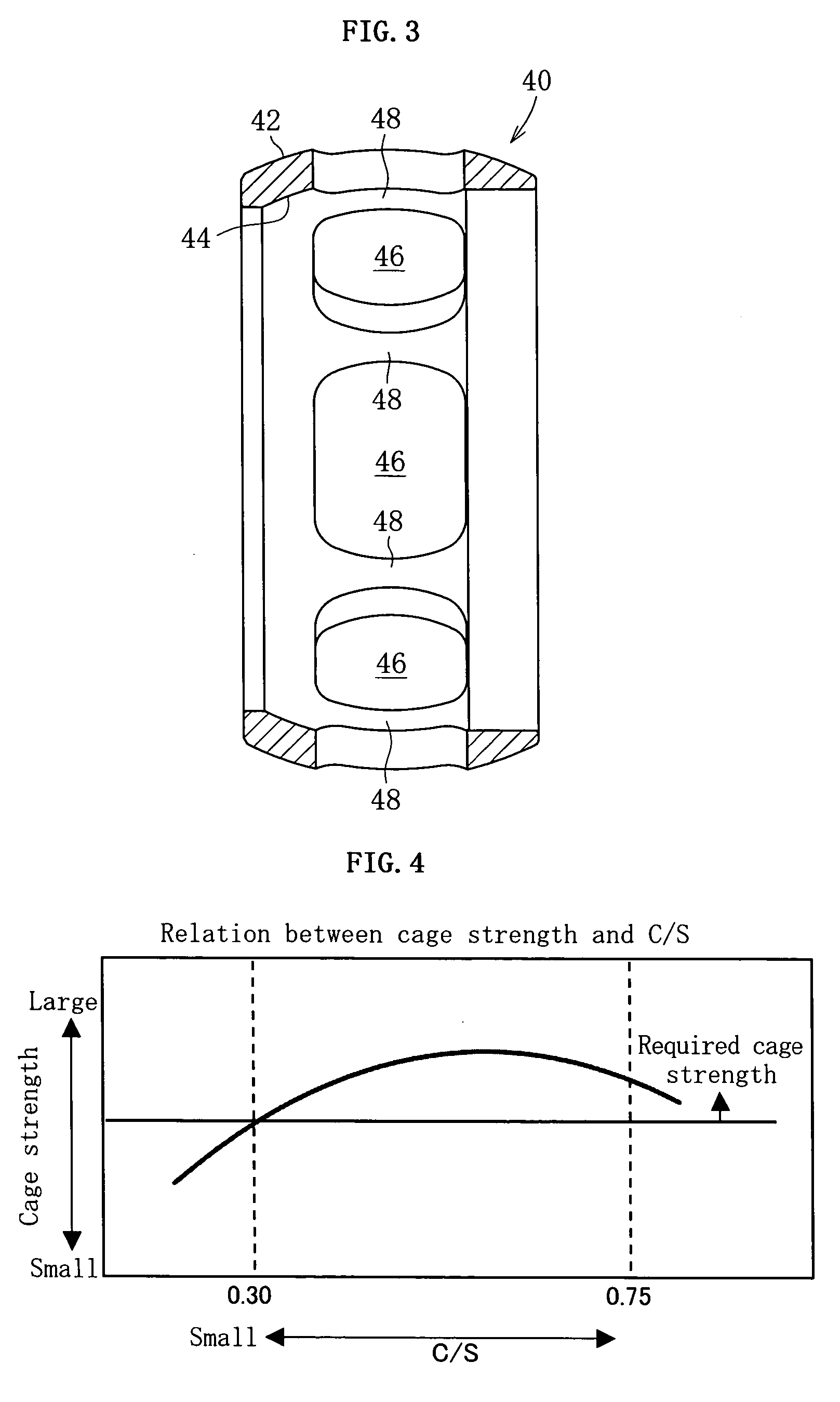

Fixed constant velocity universal joint

ActiveUS20060211503A1Decrease fatigue lifeImprove fatigue lifeClutchesYielding couplingConstant velocityControl theory

A fixed constant velocity universal joint using eight torque transmitting balls hasa ratio which a non-hardened layer assumes in a bar 48 of a cage 40 is set to be 0.30≦C / S≦0.75, where S represents a cross-sectional area of the bar 48 and C represents an area of the non-hardened layer.

Owner:NTN CORP

High strength casting aluminum alloy material

A high strength casting aluminum alloy material comprises (in weight %) Cu 2.0-6.0%, Mn 0.05-1.0%, Ti 0.01-0.5%, Cr 0.01-0.2%, Cd 0.01-0.4%, Zr 0.01-0.25%, B 0.005-0.04%, rare earth 0.05-0.3%, and balance aluminum and trace impurities. The alloy has reduced cost.

Owner:GUIZHOU ALUMINUMS FACTORY +2

Dual-channel heat transmission heat exchanger with rectangular heating pipe and manufacturing process thereof

InactiveCN102636053AIncrease costSmall thermal static pressureStationary tubular conduit assembliesThermal energyPunching

The invention relates to a dual-channel heat transmission heat exchanger with a rectangular heating pipe and a manufacturing process of the dual-channel heat transmission heat exchanger. The heat exchanger comprises outer heat supply pipes the longitudinal sections of which are rectangular, wherein the outer end of each outer heat supply pipe is plugged through an end socket closure plate; a notch is correspondingly arranged on the pipe walls of the same ends of the two adjacent heat supply outer pipes, another notch is arranged on the other same ends of the next adjacent outer heat supply pipes are correspondingly, and the outer heat supply pipes are communicated through the notches; the outer heat supply pipes are internally provided with tap water heat absorption pipes which are communicated through tap water communicating pipes, and the tap water communicating pipes pass through the notches; and inner heat supply pipes are arranged in the tap water heat absorption pipes, and the inner heat supply pipes are communicated with a cavity body of the outer heat supply pipes. According to the heat exchanger and the manufacturing process, the effective heat energy is utilized fully, a double-pipe cold fluid wall of at the center of a pipe cavity is heated, the heat-transfer area is increased, heat fluid and cold fluid are heated in a circulating manner by three channels, and the heat transfer efficiency is improved. A stainless steel thin wall pipe, a plate manufacture punching, stretching and flanging are adopted; the thin wall stainless steel welding difficulty is reduced due to the embedding type, the side pinched, so that the welding is easy, and acid is filled in an inner channel for cleaning scale generated in the inner channel.

Owner:张伟

Method for forging crossed die forgings

InactiveCN103878279ASmall mechanical propertiesReduced fatigue lifeForging/hammering/pressing machinesLower upperMaterials science

The invention relates to the technical field of forging of crossed die forgings, in particular to a method for forging the crossed die forgings. The method includes prefabricating an upper forming die and a lower forming die which are provided with deep grooves; heating a rod or a plate of a raw material, and forging the head portion or the upper portion and the tail portion and the lower portion to be the upper portion and the lower portion of a crossed forging to be forged respectively; heating a forged forging blank, placing the lower portion and the upper portion of the forging blank into the deep grooves of the upper forming die and the lower forming die after being preheated for forming die forging, taking the forging blank out of the forming dies after forging by a certain degree, rotating for 90 degrees by taking a transverse I-shaped line of the crossed forging blank as an axis for horizontal forging, forging a left rod portion and a right rod portion of the crossed forging blank respectively, and acquiring a needed crossed forging through shaping forging. By the method, lowering of mechanical performance and shortening of fatigue life of manufactured crossed forgings due to a discontinuous streamline in the forging process of the crossed forgings are avoided, and quality of the crossed forgings is improved.

Owner:SHAANXI HONGYUAN AVIATION FORGING

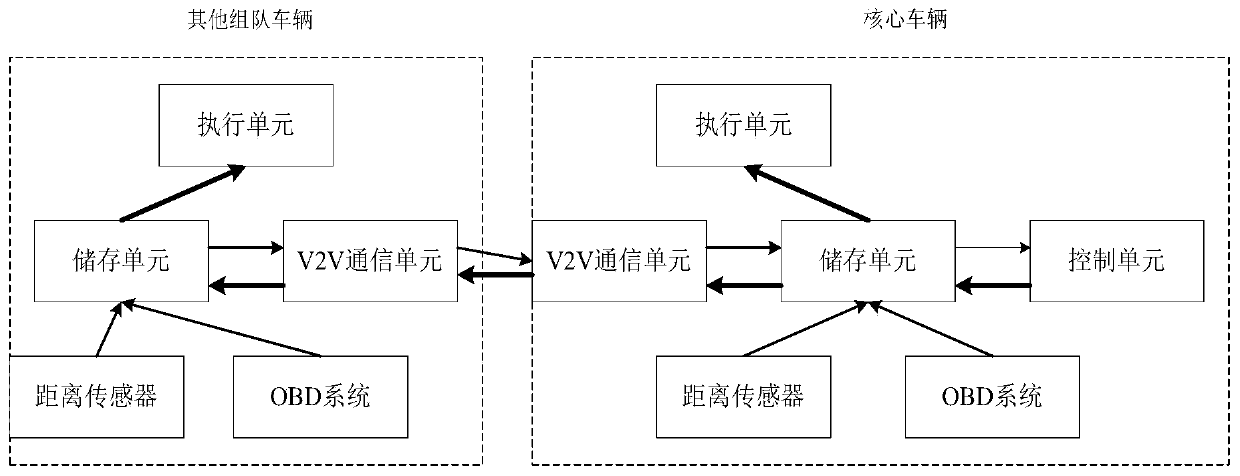

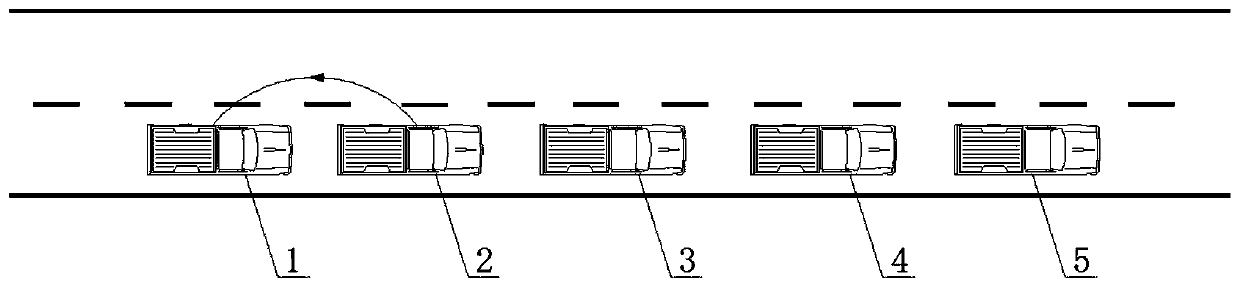

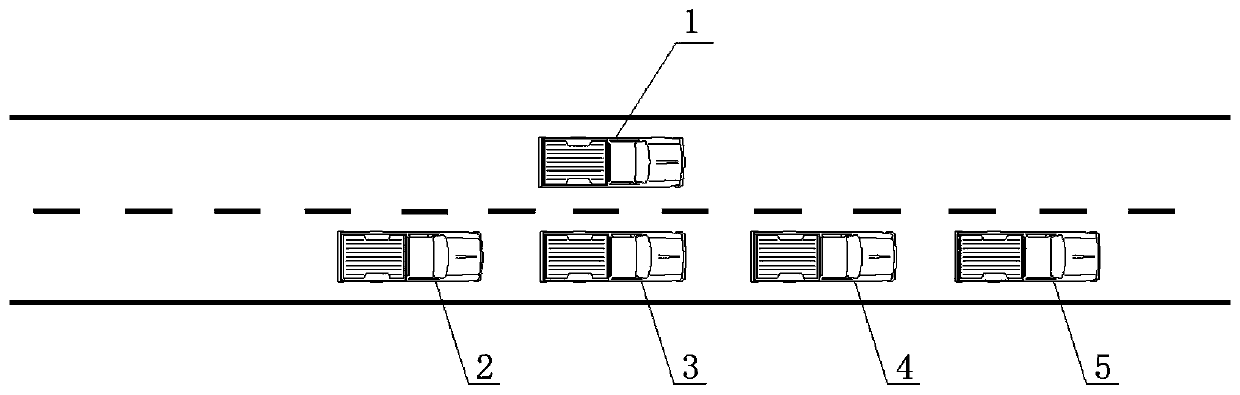

Fleet management system and fleet management method based on fleet management system

ActiveCN110047271AReduce dynamic pressureImprove fuel saving effectPlatooningFleet managementCommunication unit

The invention discloses a fleet management system. A fleet comprises one core vehicle and a plurality of team vehicles, wherein the core vehicle and the team vehicle are each provided with an OBD system, a V2V communication unit, a storage unit, a distance sensor and an execution unit, the core vehicle is further provided with a control unit, the V2V communication units communicate in a broadcasting manner among vehicles, on the one hand, the team vehicle receives a scheduling instruction form the core vehicle, on the other hand, the team vehicle transmits an equipment parameter and oil consumption condition to the core vehicle, the control unit of the core vehicle calculates an optimal distance between vehicles and load of the fleet, so that the fleet proceeds by a shortest vehicle distance, so as to reduce wind resistance loss and balance overall load of the fleet.

Owner:CHANGAN UNIV

Lubricant composition

ActiveUS7973001B2High indexPerformance deteriorationLiquid carbonaceous fuelsAdditivesChemical compositionViscosity index

A lubricating oil composition of the invention includes a lubricant base oil of which kinematic viscosity at 100 degrees C. is 1 to 5 mm2 / s; and at least one component selected from an olefin copolymer (OCP) and a poly-α-olefin (PAO) of which kinematic viscosity at 100° C. is 20 to 2000 mm2 / s, a kinematic viscosity of the lubricating oil composition at 100 degrees C. being 8 mm2 / s or less and viscosity index thereof being 155 or more.

Owner:IDEMITSU KOSAN CO LTD

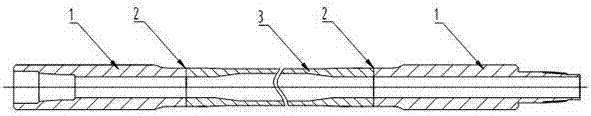

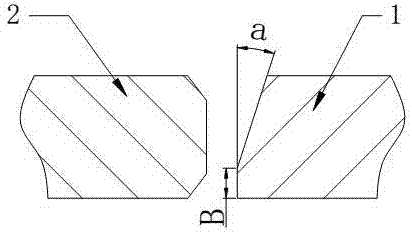

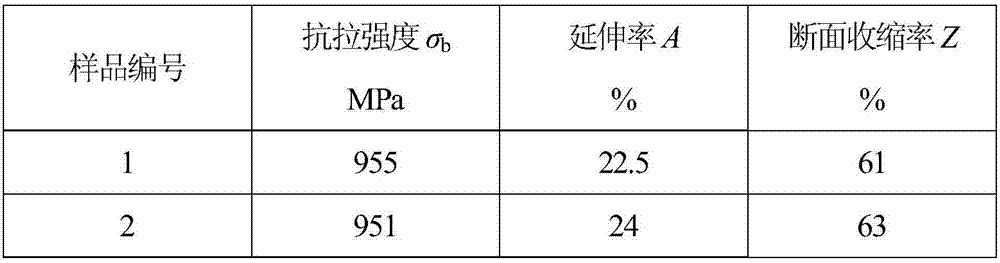

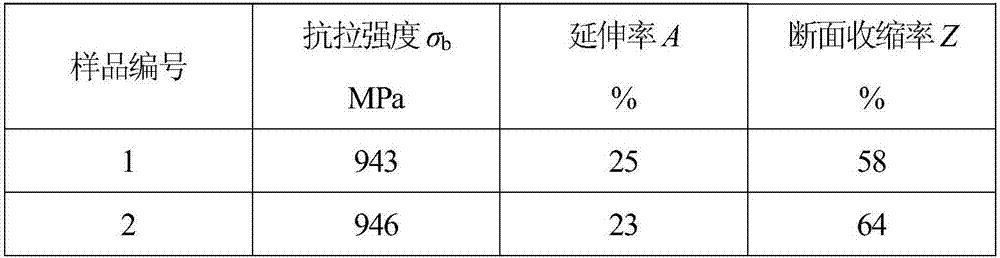

Friction welding type full titanium alloy drilling rod

InactiveCN107420049AStrong corrosion resistanceGood toughnessDrilling rodsDrilling casingsFriction weldingTitanium alloy

The invention discloses a friction welding type full titanium alloy drilling rod and belongs to the technical field of drilling rods. The drilling rod comprises a rod body made of titanium alloy and further comprises a joint made of titanium alloy, and the rod body is connected with the joint in a friction welding mode. The friction welding type full titanium alloy drilling rod aims at reducing the whole weight, preventing the connection segment between the drilling rod joint and the drilling rod body from generating displacement and bending stress, improving the connection stability, reducing the stress concentration and prolonging the fatigue life of the drilling rod.

Owner:CNPC BOHAI EQUIP MFG +1

Processing technology for spring made of titanium alloy wire with special-shaped section

ActiveCN107234192AExcellent corrosion resistanceExcellent fatigue resistanceIngotMaterials processing

The invention relates to a processing technology for a spring made of a titanium alloy wire with a special-shaped section and belongs to the field of metal material processing. Titanium alloy components include the following elements in percentage by mass: 2-4 of Al, 8-11 of V, 4-8 of Cr, 4-8 of Mo, 3.5-6 of Zr and the balance of Ti. The spring is wound by using the titanium alloy wire with the special-shaped section, the titanium alloy wire with the special-shaped section, which is used for winding the spring, is prepared by using processes of ingot forging and cogging, finish forging, hot drawing and cold rotary forging, and the section of the wire can be shaped like a square, a rectangle, a regular hexagon and a regular octagon. Compared with a steel spring, the titanium alloy spring has favorable corrosion resistance and fatigue resistance and is stable in performance and obviously prolonged in life when being used in environments such as sea and other corrosive environments. In addition, the titanium alloy is relatively low in density which accounts for about 60% of that of steel, and therefore, a weight reducing effect can also be achieved if the steel spring is replaced with the titanium alloy spring.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com