Dog-bone joint beam end buckling constraining device

A technology of buckling constraints and nodes, applied in the direction of protective buildings/shelters, building components, building types, etc., can solve the problems of steel beam out-of-plane stiffness reduction, affecting node energy dissipation capacity, node damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

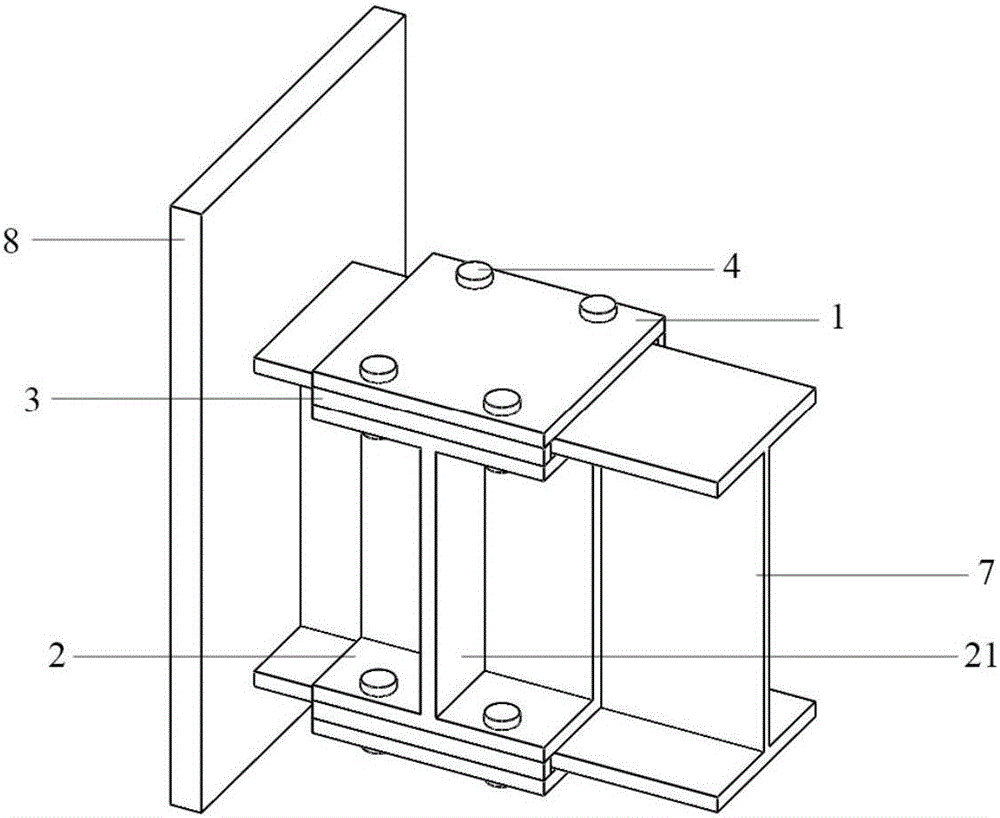

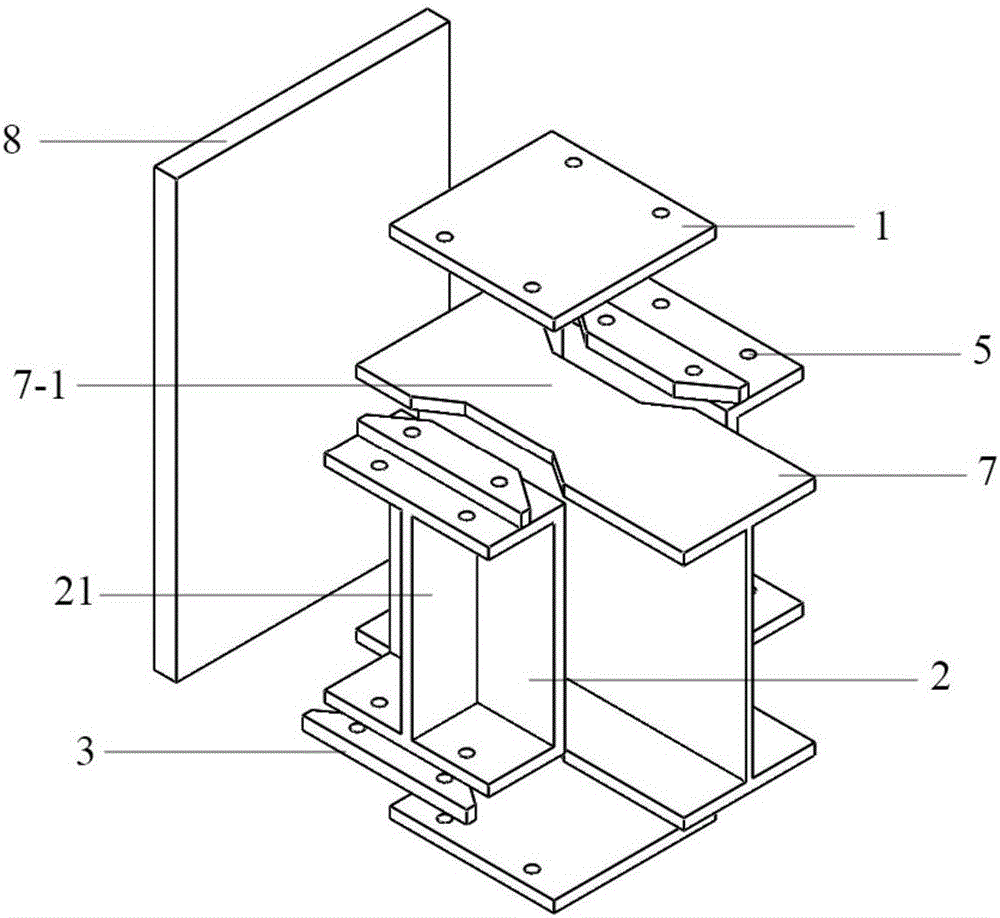

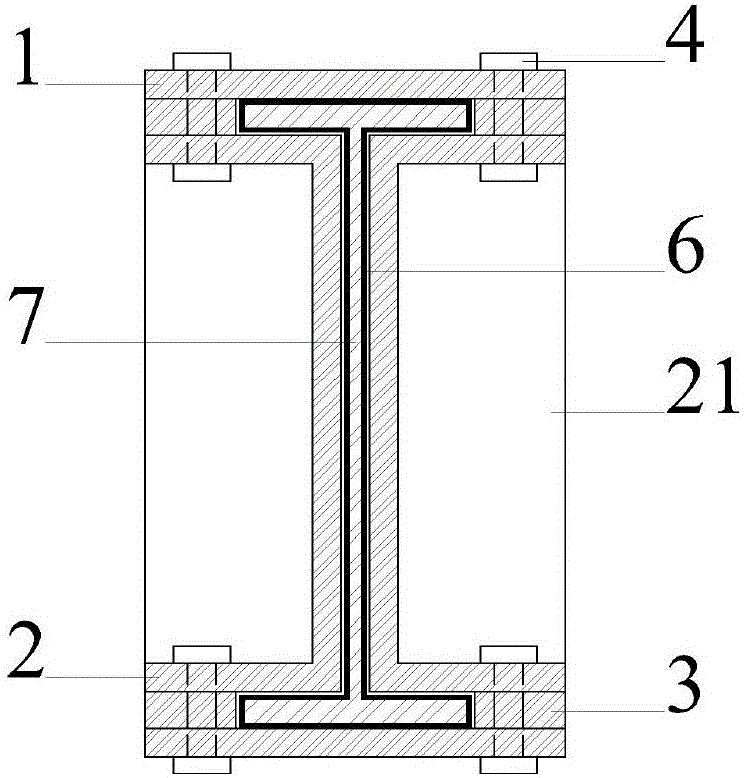

[0022] The dog-bone joint beam end buckling constraint device includes a restraint cover plate 1 arranged outside the weakened part 7-1 of the upper and lower flanges of the steel beam with a dog-bone joint 7, and a web plate corresponding to the weakened part 7-1 of the flange The restraint channel steel 2 on both sides, the filler plate 3 between the restraint cover plate 1 and the restraint channel steel 2, and the connecting bolt 4 connecting the restraint cover plate 1, the restraint channel steel 2 and the filler plate 3 to form a complete restraint device, Bolt holes 5 are opened on the constraint cover plate 1 , the constraint channel steel 2 and the filling plate 3 , so that the connecting bolts 4 can be aligned and passed through.

[0023] Stiffeners 21 that avoid the positions of the bolt holes 5 are welded inside the restraining channel steel 2 .

[0024] The lengths of the constrained cover plate 1 and the constrained channel steel 2 are slightly longer than the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com