Thermally-formed steel plate with high fatigue strength for axle housing of heavy truck, and manufacturing method thereof

A fatigue strength, heavy-duty truck technology, applied in the high-fatigue-strength thermoforming heavy-duty truck axle housing steel plate and its manufacturing field, achieves the effects of improving plasticity and toughness index, good welding performance, and improving fatigue strength limit performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The slab smelting composition is:

[0031] C: 0.18%, Si: 0.33%, Mn: 1.65%, P: 0.016%, S: 0.001%, Nb: 0.027%, V: 0.045%, Ti: 0.026%, Al: 0.021%, Cr: 0.32%; The rest is Fe and unavoidable impurities.

[0032] Slab soaking temperature (°C): 1150; soaking time (hours): 3.8; rough rolling temperature (°C): 1100; rough rolling single pass reduction rate (%): 22; finish rolling start temperature (°C ): 870; finish rolling finish rolling temperature finish rolling (℃): 820; single pass reduction rate (%): 18.

[0033] Steel plate mechanical properties:

[0034] Specifications: steel plate thickness 12mm; yield strength (MPa): 525; tensile strength (MPa): 690; elongation after fracture (%): 18; cold bending: qualified; V-shaped longitudinal impact energy (0°C): 119J, 123J, 126J, Pcm: 0.22; Ceq: 0.42.

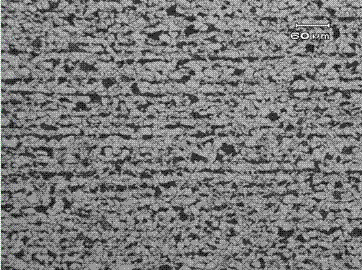

[0035] Metallographic structure: ferrite plus pearlite.

[0036] The finished axle housing was tested for fatigue test, the fatigue limit was 1.53 million times, and the fati...

Embodiment 2

[0038] With the above steel billets;

[0039] Slab soaking temperature (°C): 1120; soaking time (hours): 3.5; rough rolling temperature (°C): 1080; rough rolling single pass reduction rate (%): 21; finish rolling temperature (°C): 880; finish rolling finish rolling temperature finish rolling (°C): 820; single pass reduction rate (%): 18, Pcm: 0.23; Ceq: 0.41.

[0040] Steel plate mechanical properties:

[0041] Specifications: steel plate thickness 16mm; yield strength (MPa): 515; tensile strength (MPa): 675; elongation after fracture (%): 19; cold bending: qualified; V-shaped longitudinal impact energy (0°C): 132J, 136J, 129J;

[0042] Metallographic structure: ferrite plus pearlite;

[0043] The finished axle housing was tested for fatigue test, the fatigue limit was 1.52 million times, and the fatigue strength was 480MPa.

Embodiment 3

[0045] The slab smelting composition is:

[0046] C: 0.17%, Si: 0.27%, Mn: 1.55%, P: 0.013%, S: 0.001%, Nb: 0.027%, V: 0.045%, Ti: 0.017%, Al: 0.021%, Cr: 0.36%; The rest is Fe and unavoidable impurities.

[0047] Slab soaking temperature (°C): 1150; soaking time (hours): 3.2; rough rolling temperature (°C): 1120; rough rolling single pass reduction rate (%): 26; finish rolling start temperature (°C ): 860; finish rolling finish rolling temperature finish rolling (℃): 820; finish rolling single pass reduction rate (%): 17.

[0048] Steel plate mechanical properties:

[0049] Specifications: steel plate thickness 14mm; yield strength (MPa): 535; tensile strength (MPa): 685; elongation after fracture (%): 18; cold bending: qualified; V-shaped longitudinal impact energy (0°C): 140J, 142J, 140J; Pcm: 0.22, Ceq: 0.40.

[0050] Metallographic structure: ferrite plus pearlite.

[0051]The finished axle housing was tested for fatigue test, the fatigue limit was 2.11 million times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com