Disc brake pad mounting and retention system and method

A technology of disc brakes and brake pads, which is applied in the direction of brake types, brake components, axial brakes, etc., to achieve the effect of increasing strength and increasing the service life of calipers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

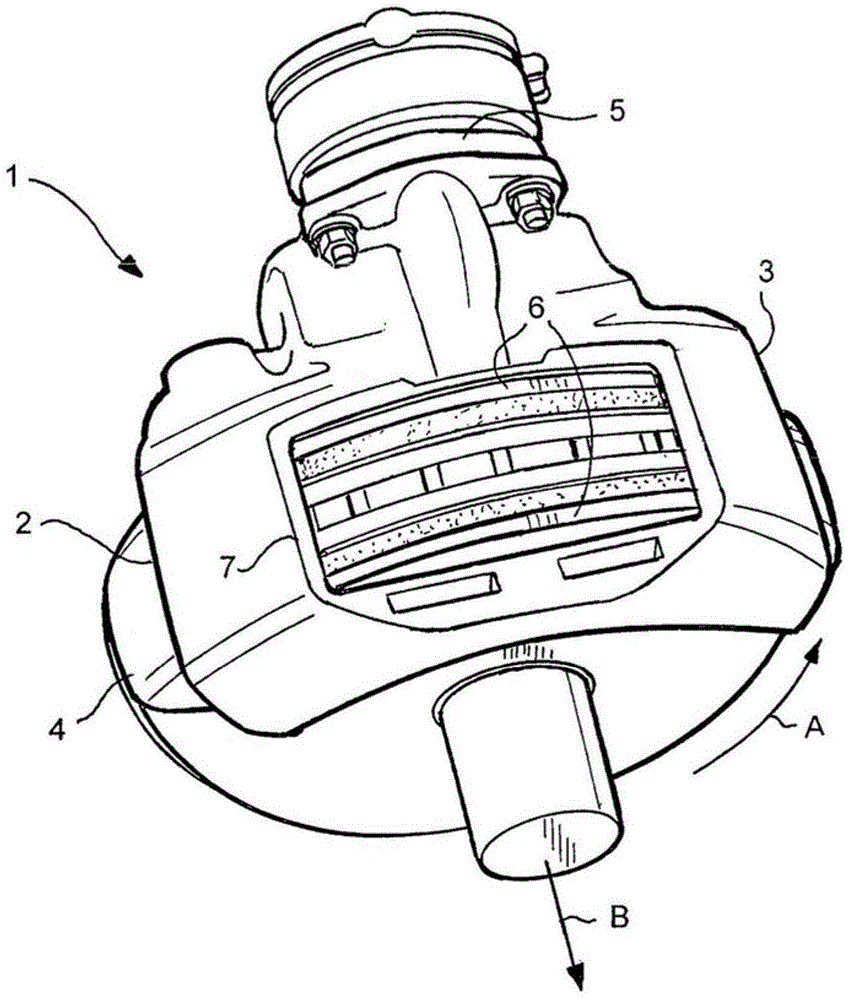

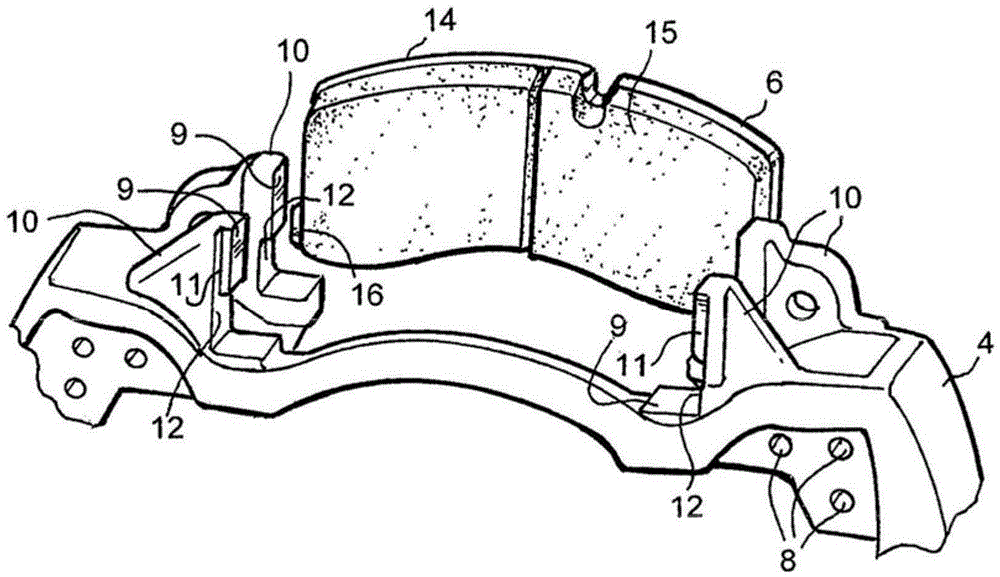

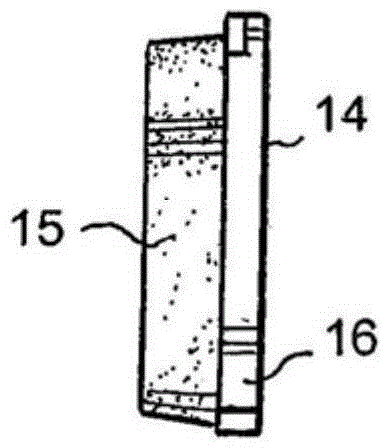

[0021] exist figure 1 In the illustrated embodiment, a disc brake 1 for a commercial vehicle comprises a brake disc 2 and a brake caliper 3 straddling the brake disc 2 . The caliper 3 is usually attached via a torque plate or brake mount (not shown) to a caliper base bracket 4 which in turn is secured to the vehicle wheel axle. The caliper 3 is actuated by an actuator 5, in this embodiment a spring brake actuator, controlled by the vehicle's pneumatic pressure. The actuator 5 acts on a brake pad application mechanism contained within the caliper 3 to press the brake pad 6 against the brake disc 2 to decelerate the vehicle. The invention is not limited to pneumatic actuators (e.g. electrically driven actuators could be used) or to particular types of brake caliper / mount arrangements (e.g. fixed bracket and sliding caliper with single sided brake pad application mechanism, or with fixing brackets and fixing calipers for the brake pad application mechanism on both sides). In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com