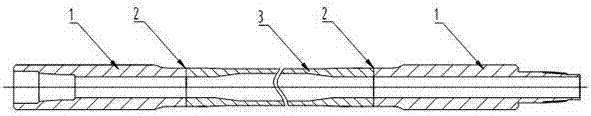

Friction welding type full titanium alloy drilling rod

A technology of friction welding and titanium alloy, which is applied in the direction of drill pipe, welding equipment, drill pipe, etc., can solve the problems of reduced fatigue life at the joint between the drill pipe joint and the drill pipe body, and achieve improved connection stability and strong corrosion resistance , The effect of long fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

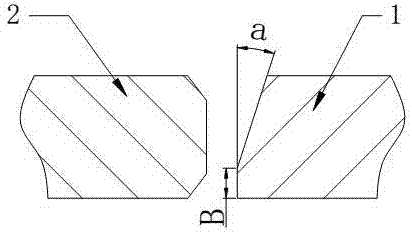

[0029] Specifically, as a specific implementation of a friction-welded all-titanium alloy drill pipe provided by the present invention, the secondary friction includes setting the secondary friction pressure to 100-110 kN, setting the secondary friction time It is 18-20 s, and the secondary friction speed is 530-560 rpm.

[0030] The secondary friction stage is the main stage of the friction heating process of titanium alloy. At this stage, the temperature of the friction surface is maintained at about 1200 °C, the bonding phenomenon of titanium alloy materials is reduced, the phenomenon of molecular interaction is enhanced, and the friction surface begins to deform. Under the action, the deformed titanium alloy layer is extruded from the friction surface to form a burr and grow continuously.

[0031] Specifically, as a specific implementation of a friction-welded all-titanium alloy drill pipe provided by the present invention, the top section treatment includes setting the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com