Dual-channel heat transmission heat exchanger with rectangular heating pipe and manufacturing process thereof

A heat-supply tube and dual-channel technology, which is applied in the field of stainless steel rectangular heat-supply tube dual-channel heat transfer edge heat exchangers, can solve the problems of small heat transfer area, low heat transfer efficiency, and poor effect, and achieve increased heat transfer. Thermal area, small flow resistance, and the effect of prolonging the adsorption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] In order to update the existing and patent knowledge technology structure, the present invention provides the following technical solutions:

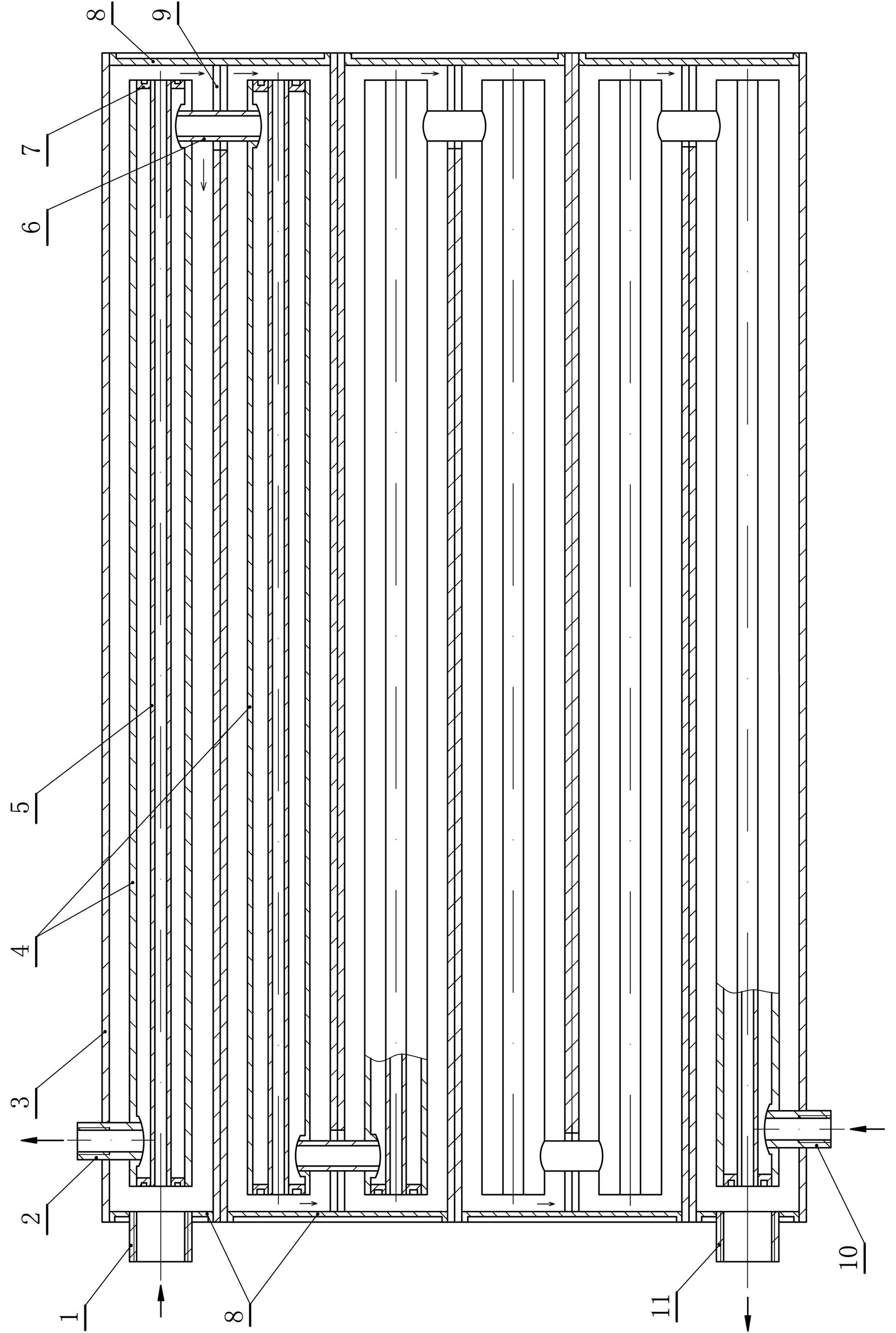

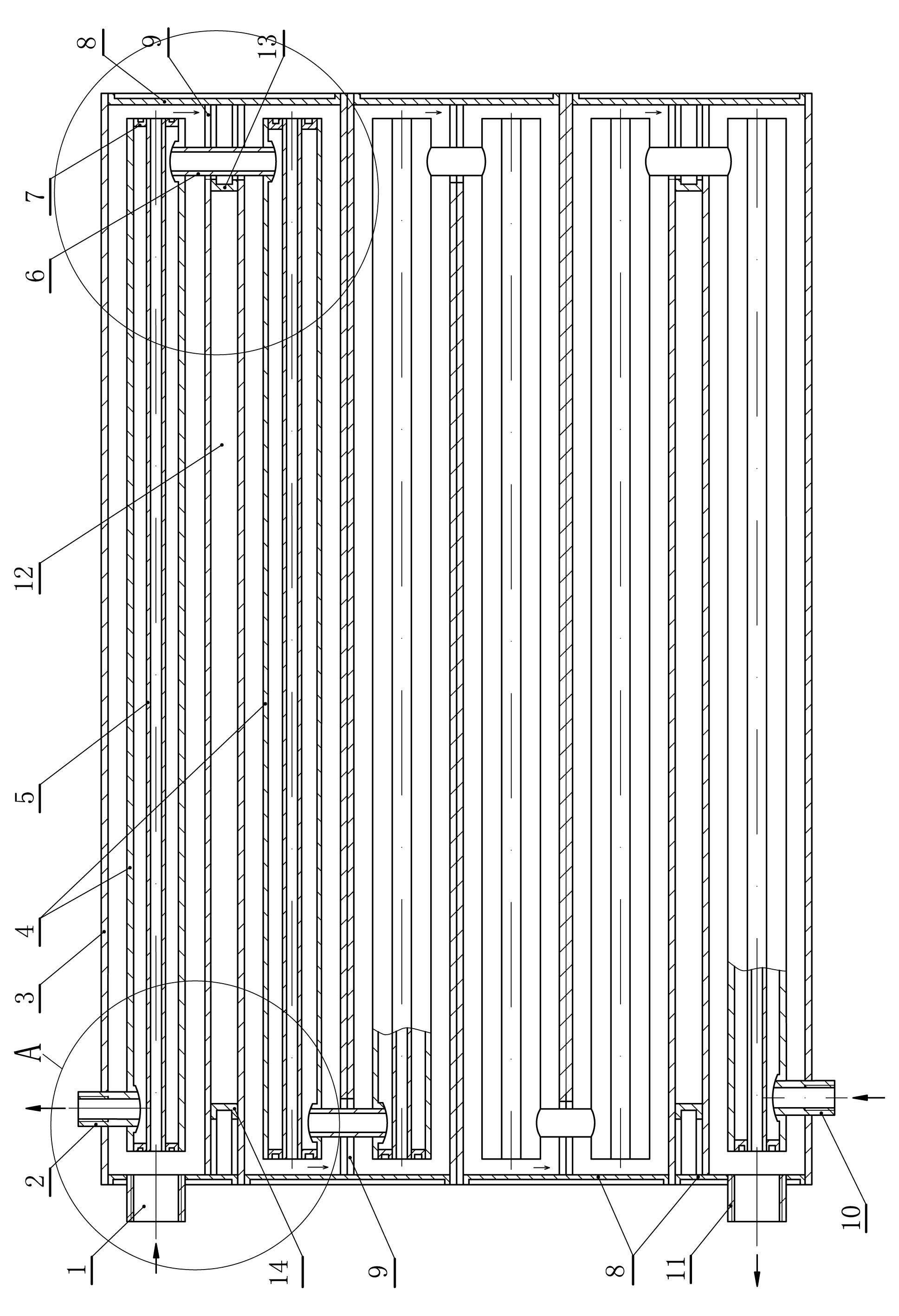

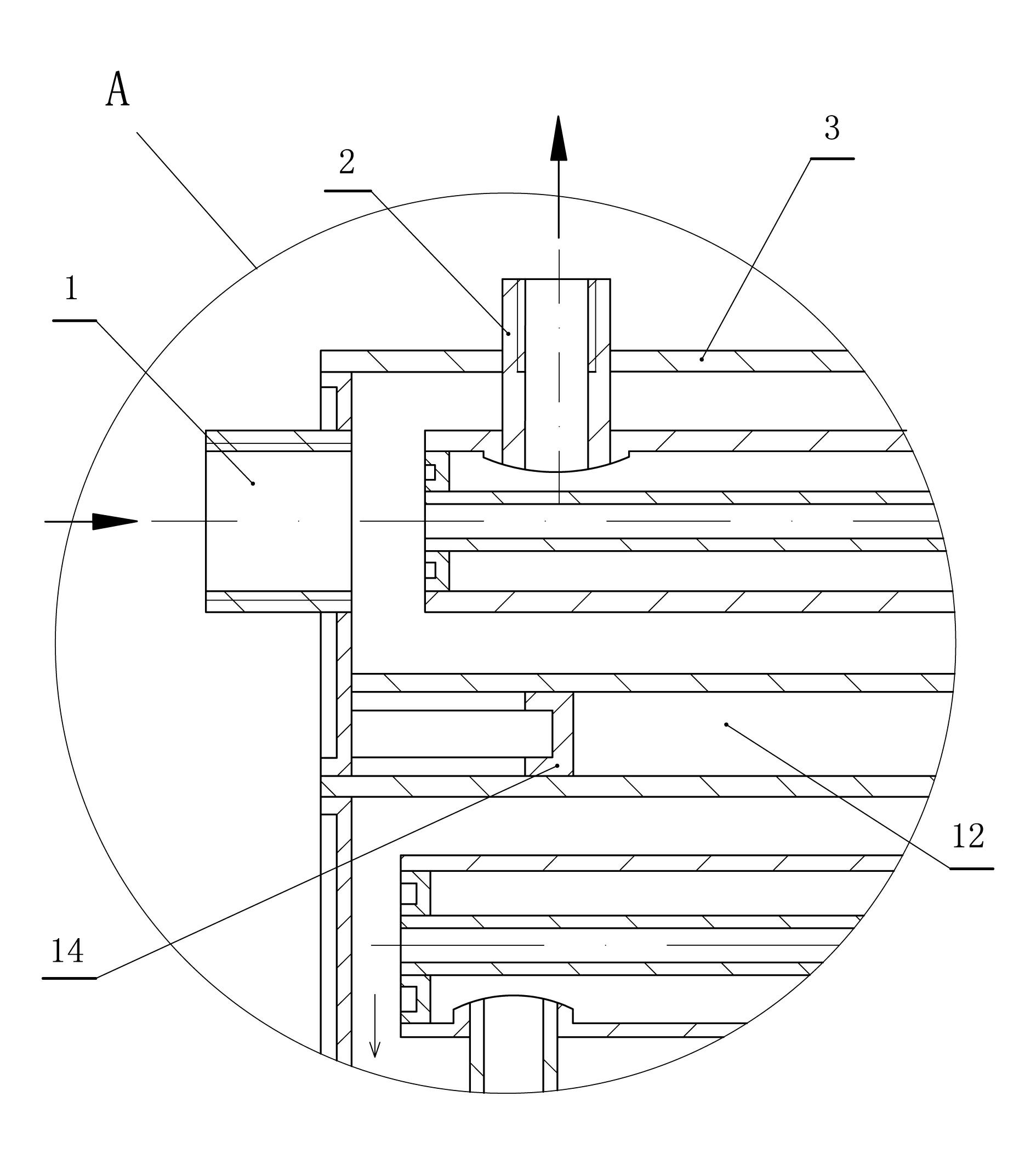

[0065] A rectangular heat supply tube double-channel heat transfer heat exchanger and its manufacturing process, including two or more heat supply outer tubes with a rectangular longitudinal section, and the outer heat supply tubes are arranged side by side with slots for supplying The heat outer pipe is connected by pinching and welding of the two pipes with slotted openings. The tap water heat absorption pipe is inserted into the heat supply outer pipe. The tap water heat absorption pipe is connected through the slot opening of the heat supply outer pipe. The tap water inlet, the other end of the tap water heat-absorbing pipe is connected to the tap water outlet, and the beginning and end of the heating outer pipe are connected to the heating inlet and heating outlet of the heating outer pipe, characterized in that: tap water ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com