Patents

Literature

88results about How to "Extend the adsorption time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

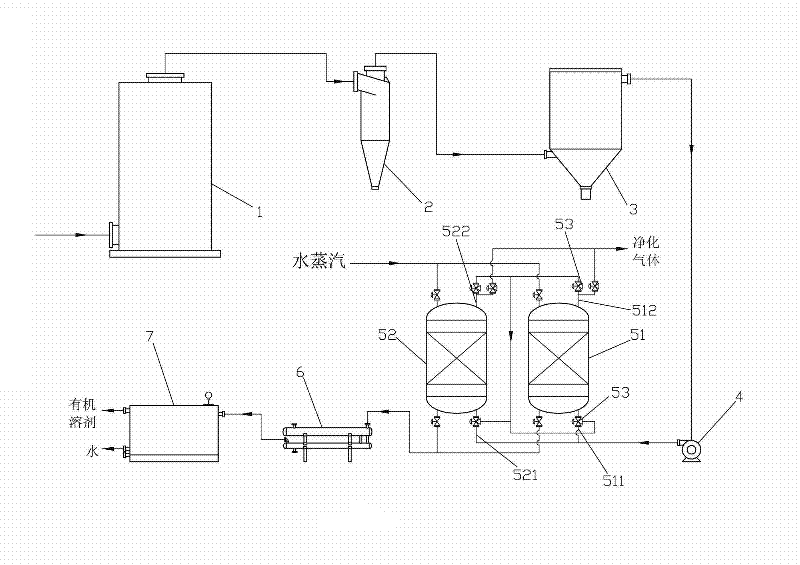

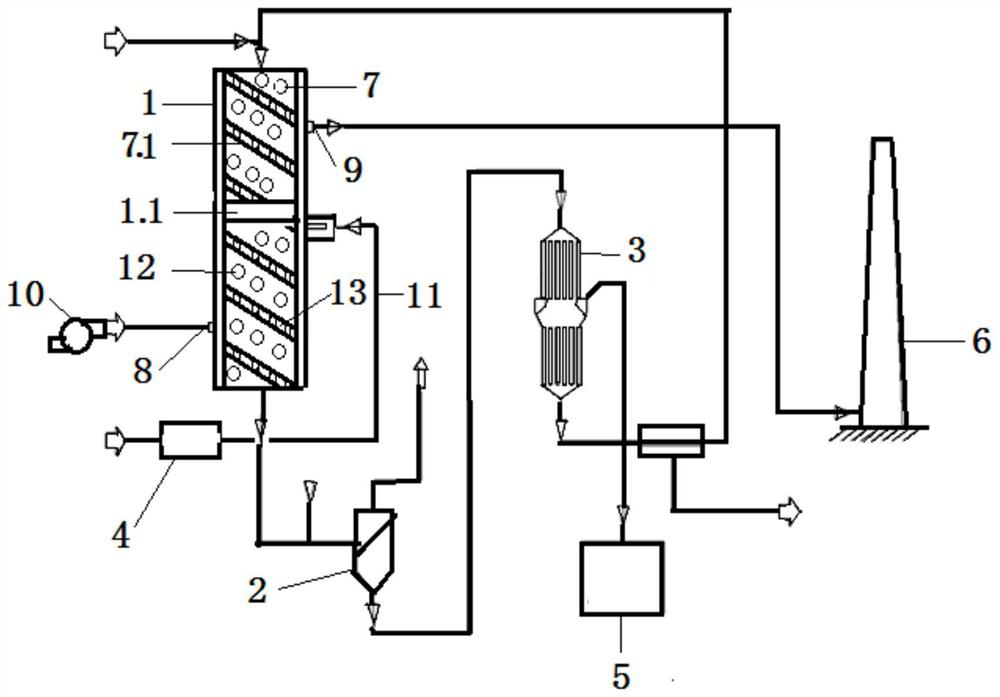

Recycling device for exhaust gas of painted organic solvent and method for recycling organic solvent

The invention discloses a recycling device for an exhaust gas of a painted organic solvent. The recycling device comprises a painting fog removing device, a fan, an absorbing jar, a condenser and an oil-water separator which are connected in turn, wherein the painting fog removing device comprises a gas collecting tank, a cyclone dust collector and a bag type dust collector; the gas collecting tank is used for temporarily storing the exhaust gas of the organic solvent; and the gas collecting tank, the cyclone dust collector and the bag type dust collector are connected in turn. All componentsof the recycling device are reasonably and compactly jointed; collection efficiency is high; and the painting fog is efficiently removed while a trouble in frequently exchanging filter cotton is avoided. The invention also discloses a method for utilizing the recycling device for the exhaust gas of the painted organic solvent to recycle the organic solvent. The method comprises the following steps: removing the painting fog; absorbing; desorbing steam; condensing; and separating oil from water, wherein the step of removing the painting fog is carried out by changing the painting fog into painting powder and then efficiently removing the painting fog. Compared with a traditional process, the method is more reasonable, compact and labor-saving.

Owner:中科天龙(厦门)环保股份有限公司

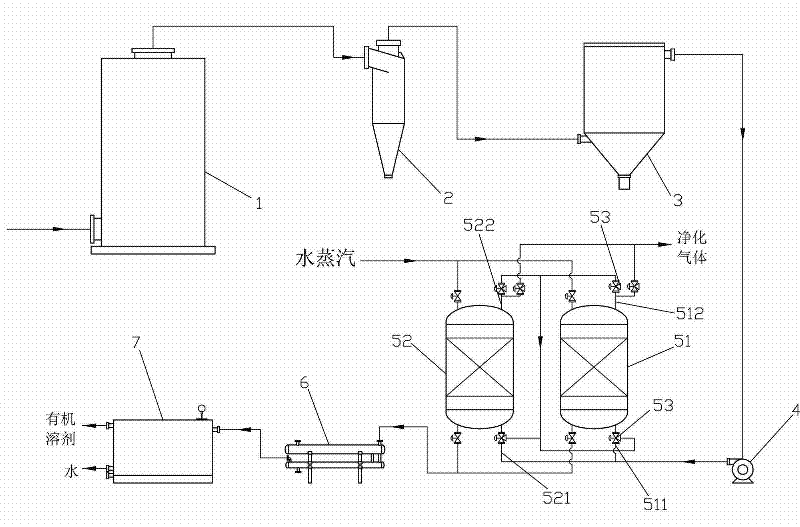

Waste heat regeneration absorption dryer

InactiveCN103272460ARealize external heat regenerationReduce power consumptionDispersed particle separationSorbentCooling effect

The invention belongs to the field of chemical equipment, and particularly relates to a waste heat regeneration absorption dryer. The waste heat regeneration absorption dryer comprises an air compressor, an absorption tower A, an absorption tower B, a first cooler, a second cooler, and a gas-water separator; valves of the absorption tower A and the absorption tower B are symmetrically arranged and use compressed air in the air compressor as a heat source during use, and the absorption tower A and the absorption tower B circularly work under programmed control. The waste heat regeneration absorption dryer fully utilizes waste heat of the compressor so that the power consumption of an electric heater, a fan and a steamer of traditional external heating or microheating drying is saved to achieve the external heating regeneration and maximally reduce the energy consumption; the two coolers are arranged so that the cooling effect is good; and the absorption towers have three-layer structures, and gas flow is distributed uniformly in a molecular sieve layer and an aluminum oxide layer under the action of a large water-absorption ball layer, so that the absorption time is prolonged, the absorption effect is enhanced, the gas flow is stable and uniform, the impact force on a sorbent is small, and the service life is prolonged.

Owner:山东道先为能源科技股份有限公司

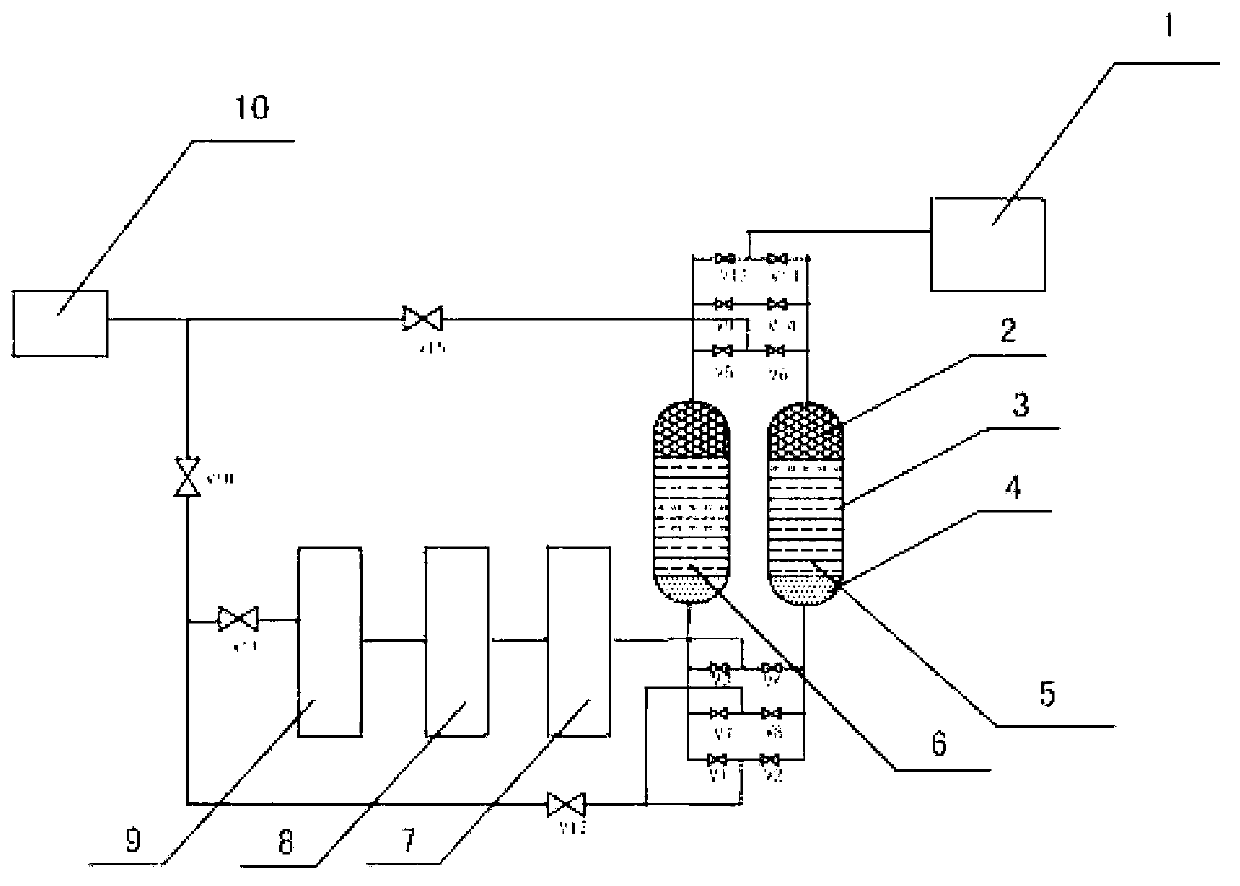

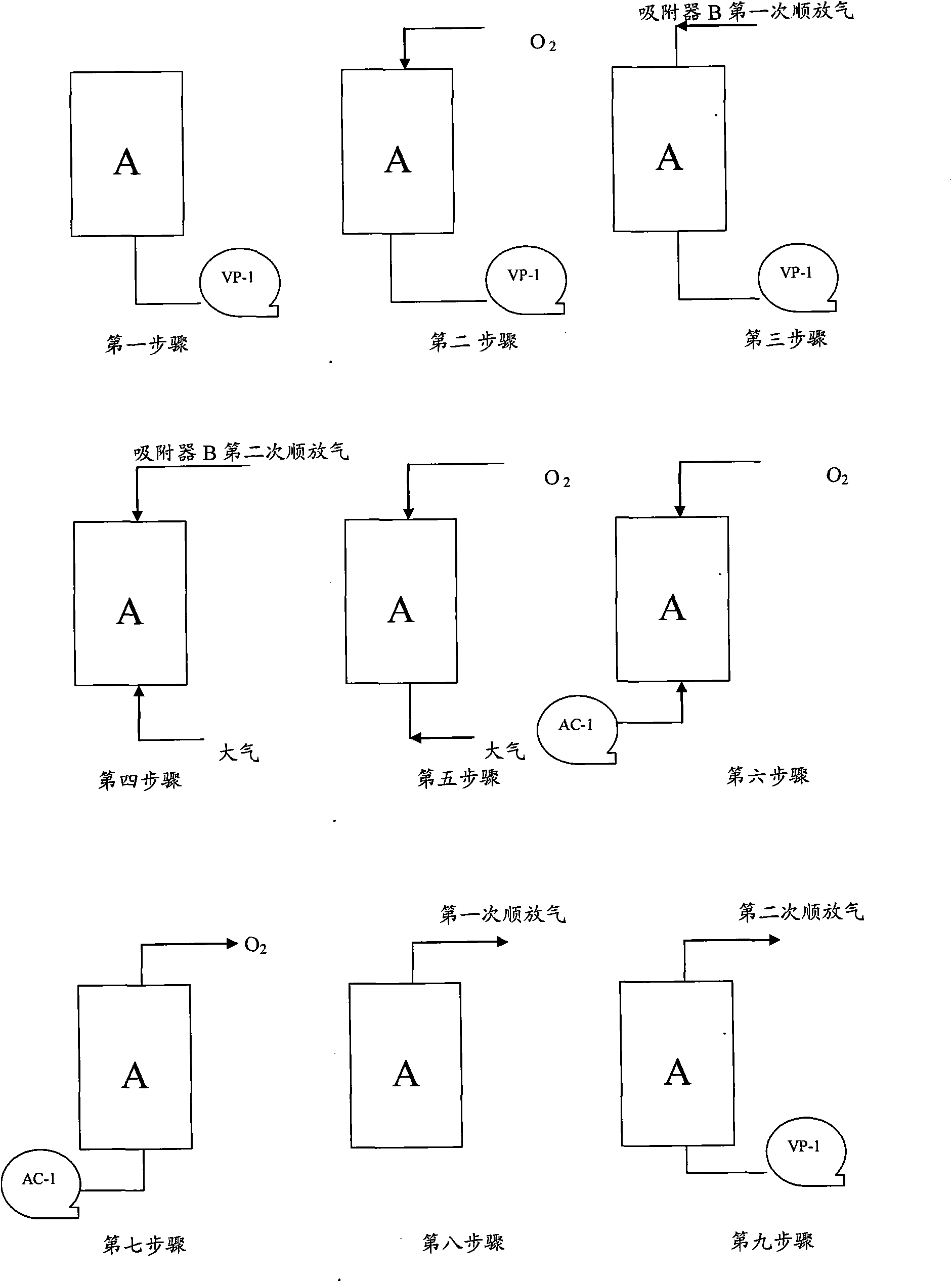

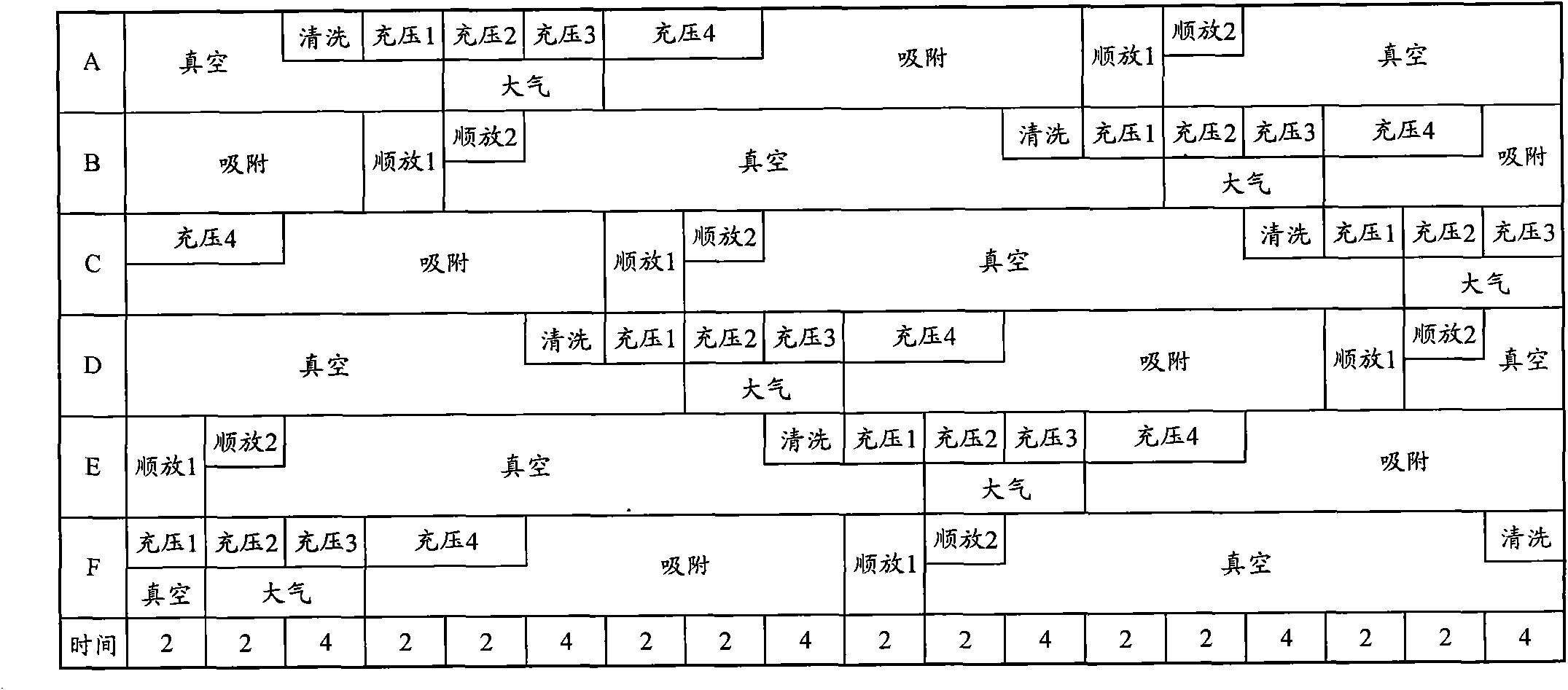

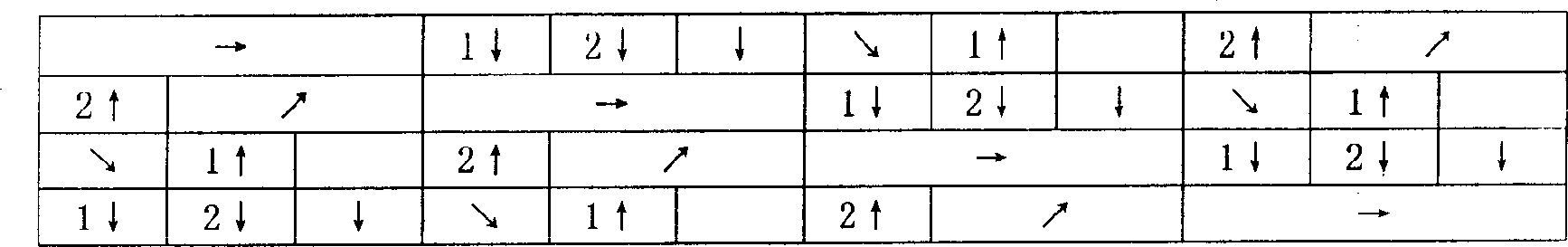

Vacuum pressure swing adsorption system

ActiveCN101862574AIncrease flow rateReduce exhaustDispersed particle separationAtmospheric airDesorption

The invention provides a vacuum pressure swing adsorption system, which comprises six adsorbers, two groups of independent blowers and three groups of independent vacuum pumps, wherein each group of blowers are connected with the inlet ends of four adsorbers respectively, each group of vacuum pumps are connected with the inlet ends of two adsorbers respectively, the inlet end of each adsorber is communicated with the atmosphere, the outlet ends of the two adsorbers connected with the each group of vacuum pumps are connected, and the outlet end of each adsorber is connected with a product gas tank. The vacuum pressure swing adsorption system cyclically executes the following steps of: adsorption, forward pressure release, vacuum desorption and pressure charge, wherein the ratio of the execution time of the adsorption step to the execution time of the vacuum desorption step is less than 1. The system can enlarge oxygen production scale, reduce the air quantity of the blowers, prolong the vacuum desorption time and reduce the pumping speed of the vacuum pumps so as to reduce energy consumption of the system and save the cost.

Owner:BEIJING PEKING UNIV PIONEER TECH

Demercuration catalyst taking metal organic framework as carrier and preparation method thereof

InactiveCN107812541ALarge specific surface areaImprove mercury removal efficiencyGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsMetal-organic frameworkNitrogen gas

The invention discloses a preparation method of a demercuration catalyst taking a metal organic framework as a carrier and belongs to the technical field of catalysts. According to the invention, trimesic acid is dissolved in an organic solvent to obtain a mixed solution A, transition metal salt is dissolved in deionized water to obtain a transition metal salt solution B, an active component and an assisting carrier salt are dissolved in the deionized water to obtain an active component aqueous solution C; adding the mixed solution A to the transition metal salt solution B for uniformly mixingwhile stirring at the temperature of 30-60 DEG C, introducing nitrogen, and then reacting for 1-3h under ultrasonic conditions; adding the active component aqueous solution C to the reaction solution, heating to 120-150 DEG C and performing thermostatic reaction for 12-36h, and cooling; and filtering, washing, drying, grinding, tabletting and sieving the reaction product to obtain the demercuration catalyst taking a metal organic framework as a carrier. The catalyst provided by the invention has relatively high adsorbing efficiency and adsorbing time.

Owner:KUNMING UNIV OF SCI & TECH

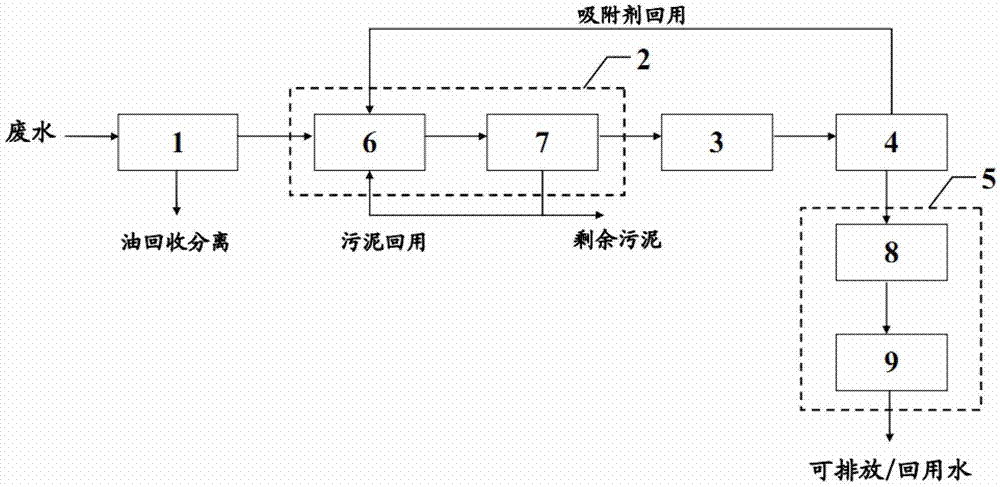

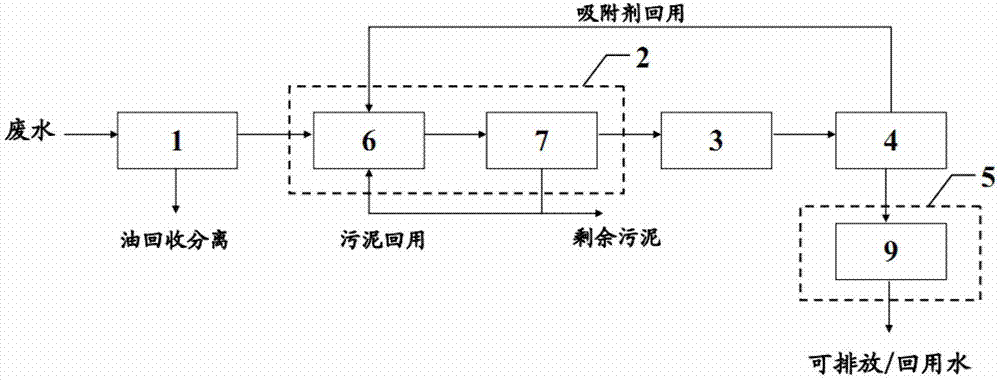

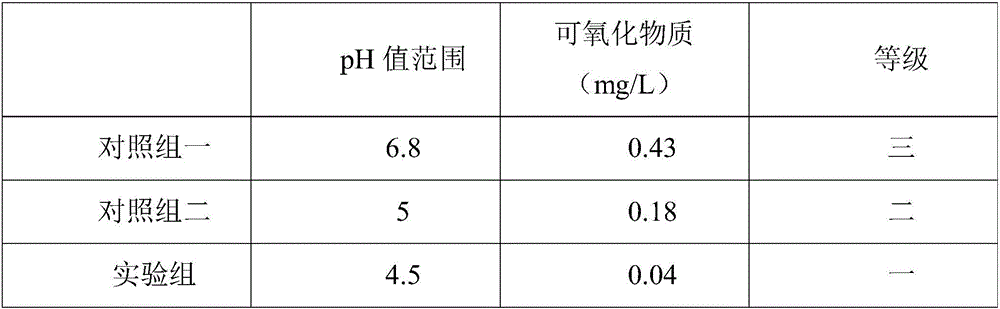

Slack coal pressure gasification wastewater resourceful treatment method and treatment system as well as application

InactiveCN103288311AAchieve reuseProportionally largeMultistage water/sewage treatmentFlocculationSludge

The invention provides a slack coal pressure gasification wastewater resourceful treatment method. The treatment method sequentially comprises the following steps of: (1) performing oil-water separation on the wastewater to obtain wastewater after the oil-water separation treatment; (2) treating the wastewater obtained by the step (1) by use of active sludge, and performing mud-water separation to obtain wastewater after the active sludge treatment; (3) adding an adsorbent into the wastewater obtained by the step (2), and performing solid-liquid separation to obtain wastewater after the adsorption separation treatment; (4) adding a flocculating agent and / or flocculation aid into the wastewater obtained by the step (3), and precipitating to obtain wastewater after the coagulation clarifying treatment; and (5) treating the wastewater obtained by the step (4) by use of a filter material loaded with microorganisms to obtain dischargeable / recyclable water. The invention also provides a system for the method to realize resourceful treatment on the wastewater, and application of the treatment method or treatment system in treating slack coal pressure gasification wastewater.

Owner:DATANG INT CHEM TECH RESINST

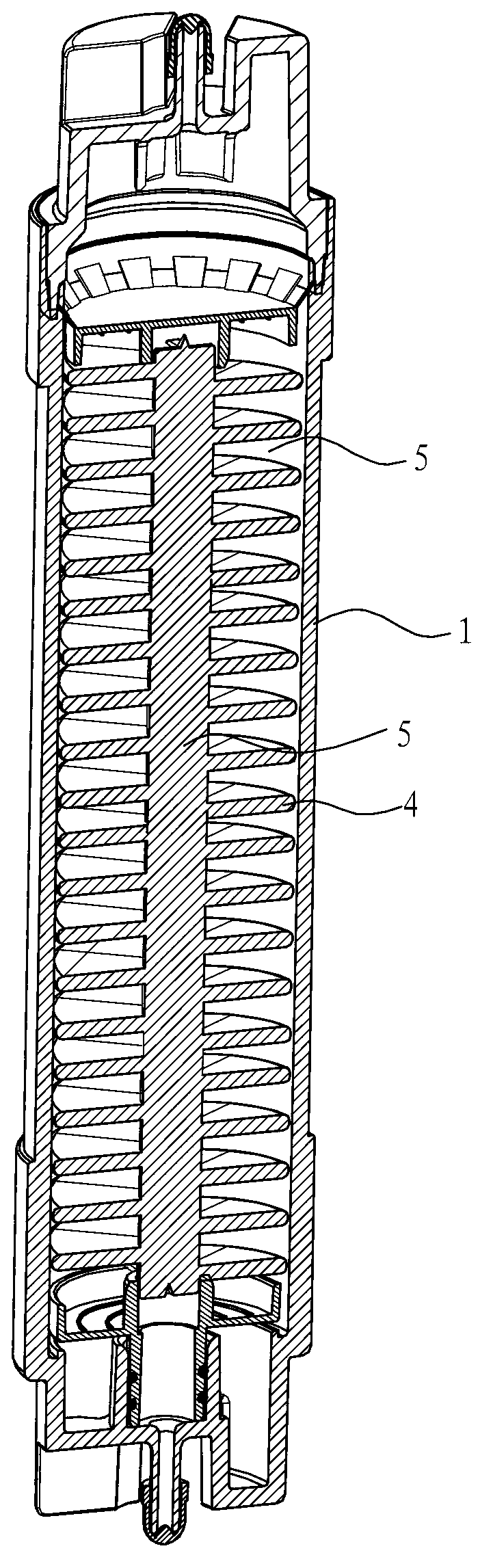

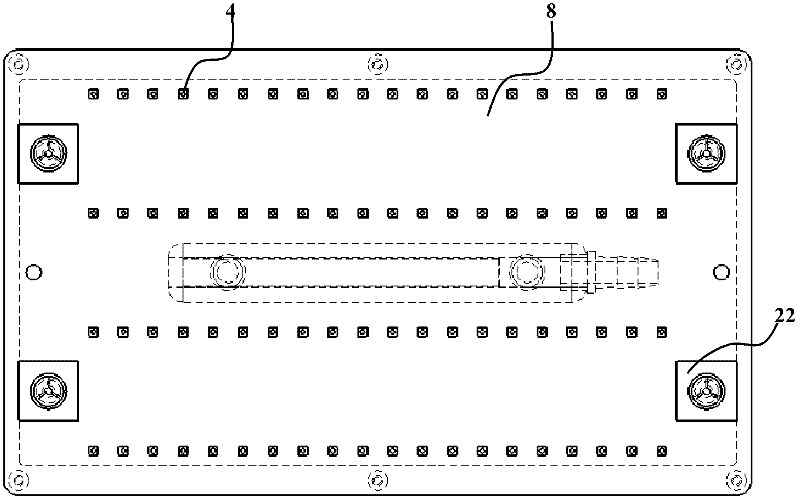

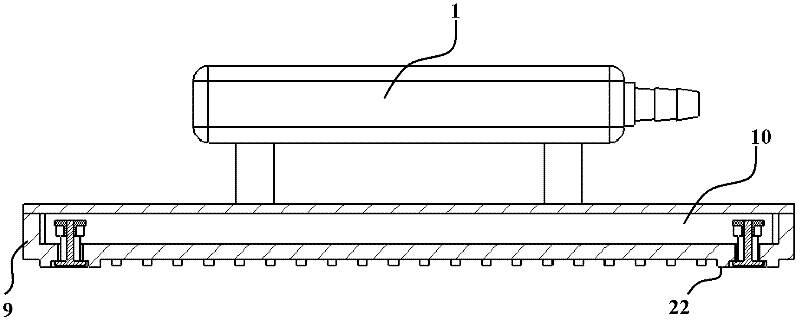

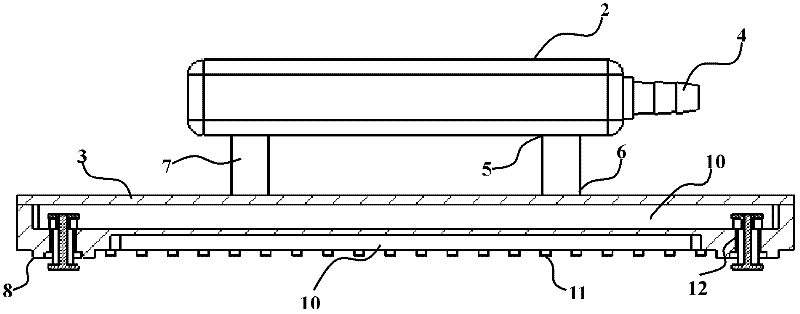

Water treatment filter element

InactiveCN102989212AReduce the degree of flow throughIncrease the lengthLoose filtering material filtersGravity filtersContact timeFilter media

The invention relates to a water treatment filter element which comprises a hollow tubular shell. The water treatment filter element is characterized in that the hollow tubular shell is internally provided with a separator axially arranged along the interior of the hollow tubular shell, and the separator is provided with shims which are helically distributed through winding the outer periphery of the separator; and a helical filtering channel is formed among the shims which are helically distributed, the separator and the inner wall of the hollow tubular shell, and the filtering channel is used for adding a filtering medium. Compared with the prior art, the water treatment filter element provided by the invention has the advantages that the interior of the hollow tubular shell is axially provided with the helical filtering channel, water can be subjected to flowage filtration through the helical filtering channel, and the contact time of the water and the filtering medium is increased; and the adsorptivity of the filtering medium is better displayed, harmful substances in water are more effectively filtered, and the filtering effect is better.

Owner:柯淇环境技术(宁波)有限公司

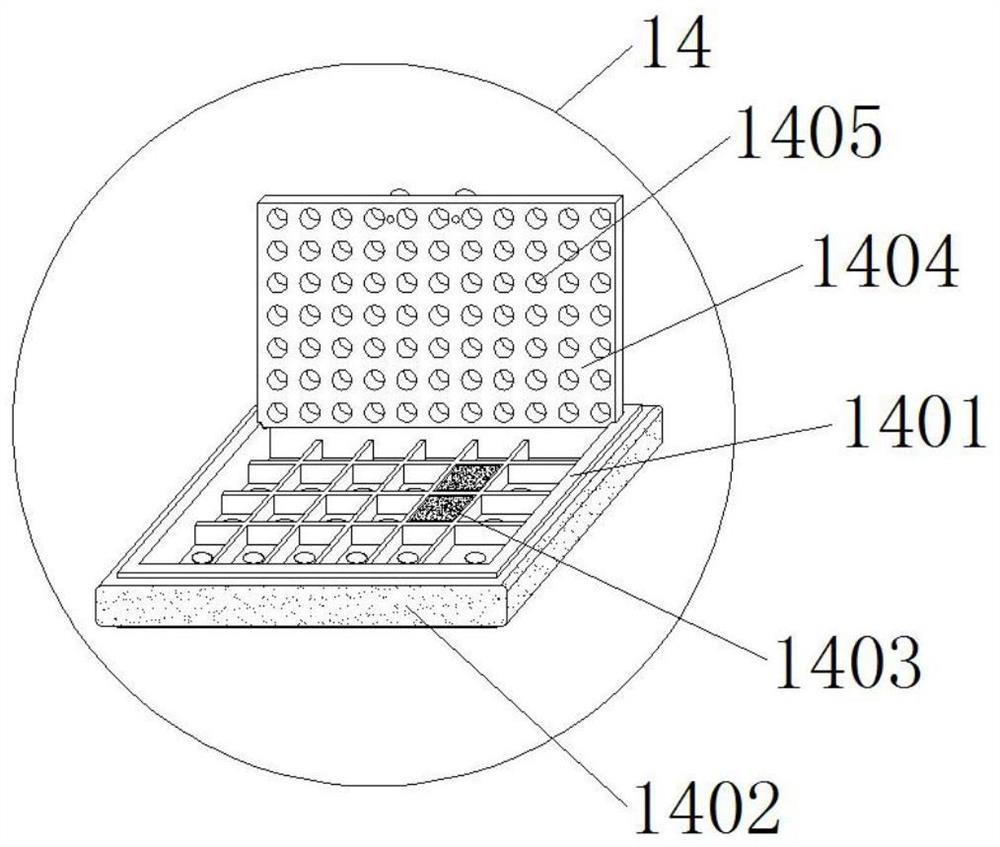

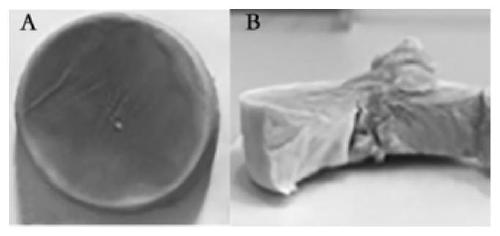

Sucking disc device used for transferring semi-conductor crystal grains on graphite boat

ActiveCN102543815AAvoid bumping intoRun into avoidSemiconductor/solid-state device manufacturingConveyor partsEngineeringGraphite

The invention discloses a sucking disc device used for transferring semi-conductor crystal grains on a graphite boat, which comprises a handle and a cover plate, wherein a baseplate is mounted on the lower surface of the cover plate; movable through hole plugs formed by upper plug bodies and lower plug bodies are in clearance fit with air leakage through holes; the width of an upper air guide rib is larger than that of a lower air guide rib; the diameter of the lower end surface part and the upper end surface part is larger than that of air leakage through holes; the distance between the upper end surface part and lower end surface part of each movable through hole plug is larger than the thickness of each air leakage through hole, so as to ensure that the movable through hole plugs can move up and down along the air leakage through holes; when the lower plug bodies of the movable through hole plugs seal the air leakage through holes, the airflow flows in from suction nozzles; and when the upper plug bodies of the through hole plugs seal the air leakage through holes, the airflow flows in from the air leakage through holes. The sucking disc device provided by the invention solves the technical problem that when absorbed, the semi-conductor crystal grains are easy to be damaged during the manufacturing process, greatly improves the adsorption rate and the product yield, and reduces the resource wastage.

Owner:SUZHOU GOODARK ELECTRONICS CO LTD

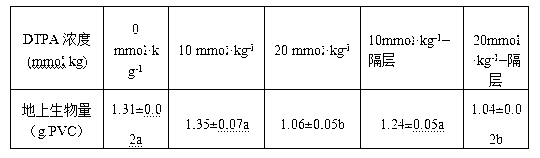

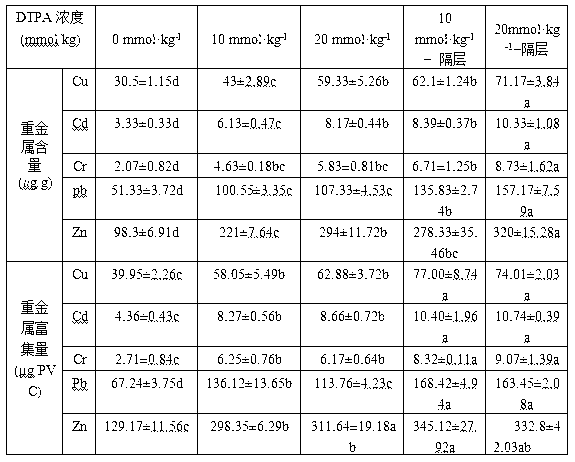

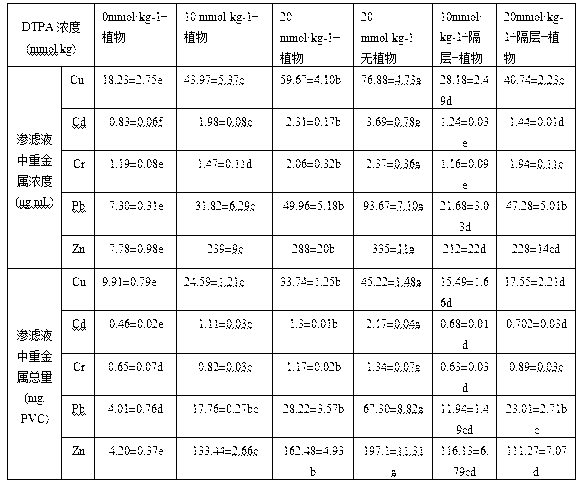

Method for repairing sludge heavy metal by combination of DTPA and ryegrass

InactiveCN103270869APromote enrichmentAbility to inhibit leaching migrationBiological sludge treatmentHorticultureSludgePollution

The invention discloses a method for repairing sludge heavy metal by combination of DTPA and ryegrass. According to the method, DTPA of different concentrations serving as chelating agents is combined with the ryegrass and a corn interlayer to improve enrichment of heavy metal on the upper portion of a ryegrass land and to restrain the ability of the sludge heavy metal to move to deep soil in a leaching mode. The corn interlayer comprises 40-60g of vermiculite, 40-80g of zeolite and 40-100g of corncobs. According to the method, sludge and soil mixed substrate serves as culture substrate of the ryegrass, when turfgrass grows to a certain stage, DTPA is used, rainfall and pH of TianJin are simulated for leaching, and the content of the heavy metal in the upper portion of the ryegrass land and in leaching solutions is tested. As is shown in an experiment result, a combination of 10mmol.kg-1 DTPA and the interlayer comprising the corncobs has the best repairing effect on the heavy metal in the sludge, repairing cost is low and pollution to underground water is least.

Owner:TIANJIN NORMAL UNIVERSITY

Sewage treatment agent and preparation method thereof

InactiveCN105948275AImprove adsorption capacityEfficient decompositionWater contaminantsWater/sewage treatment using germicide/oligodynamic-processParticulatesMicrobial agent

The invention provides a sewage treatment agent and a preparation method of the sewage treatment agent. The sewage treatment agent comprises the following components: 20 to 30 parts of modified diatomite, 20 to 40 parts of medical stone, 20 to 30 parts of slag, 20 to 30 parts of sodium lignosulfonate, 10 to 15 parts of chitosan, 10 to 20 parts of seabed mineral mud, 5 to 10 parts of polymeric silicate aluminum sulfate, 10 to 20 parts of polyferric chloride, 10 to 20 parts of phosphonate, 10 to 20 parts of ethylenediamine tetramethylene phosphonic acid, 10 to 20 parts of microbial agents and 100 to 160 parts of deionized water. The treatment agent disclosed by the invention can effectively adsorb particles in sewage, and further remove pathogenic bacteria and heavy metals in the sewage.

Owner:HEFEI TIANXIANG ENVIROMENT PROJECT

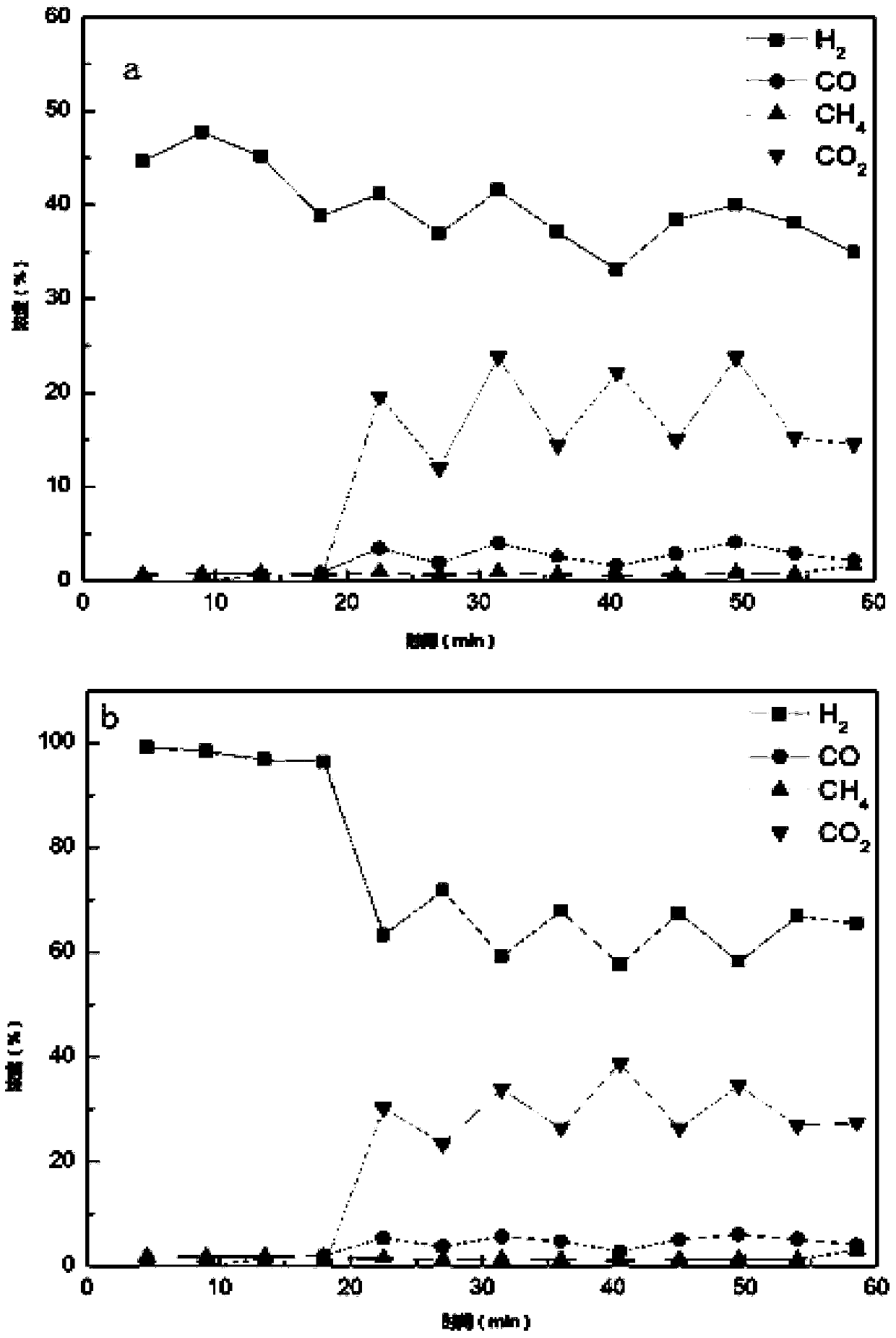

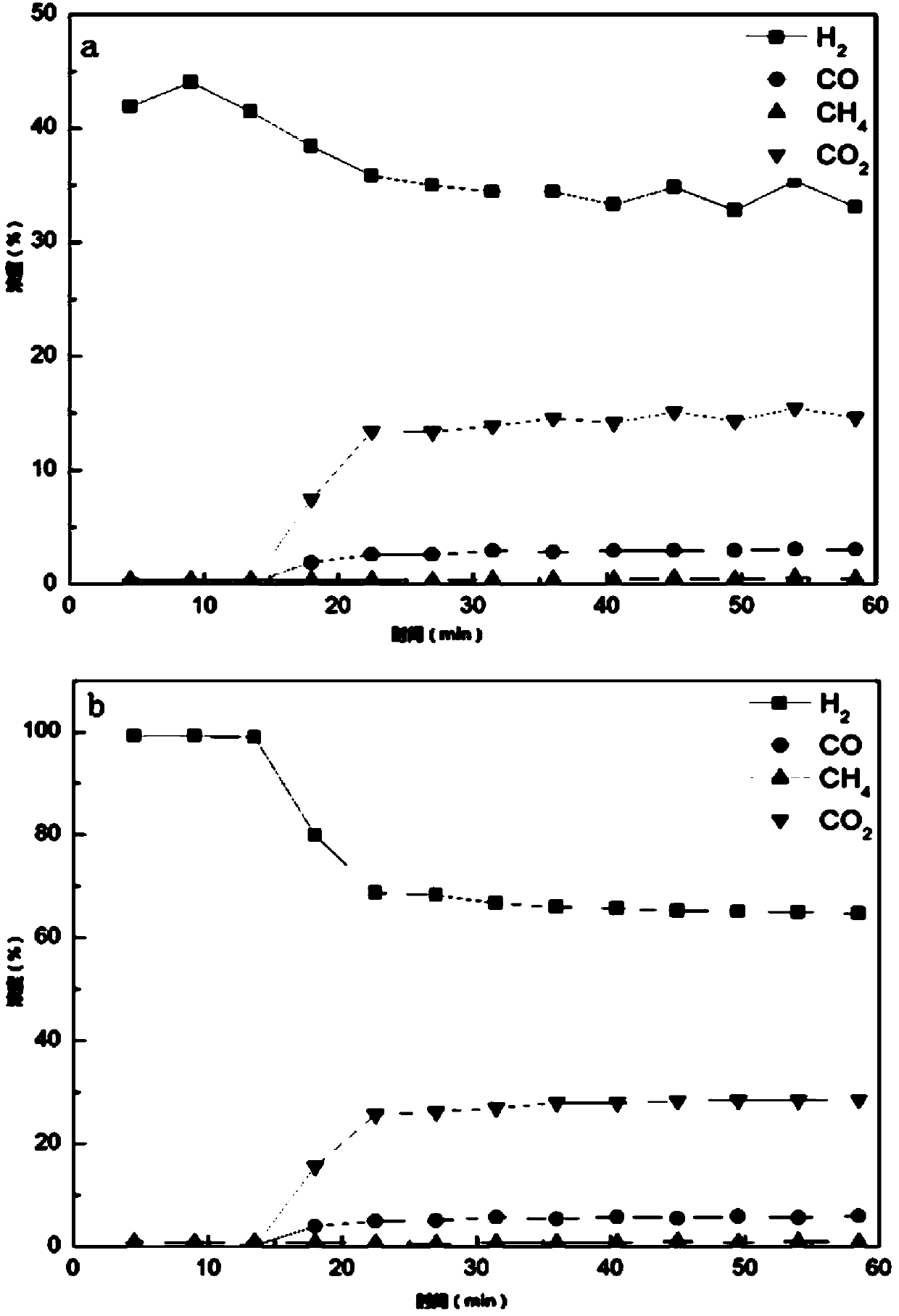

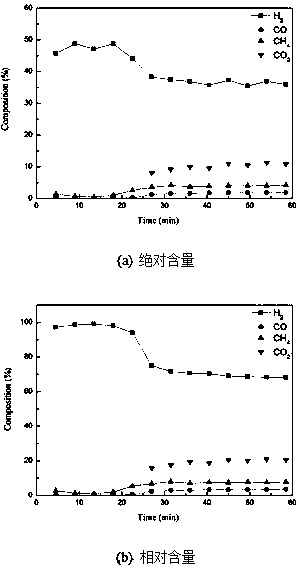

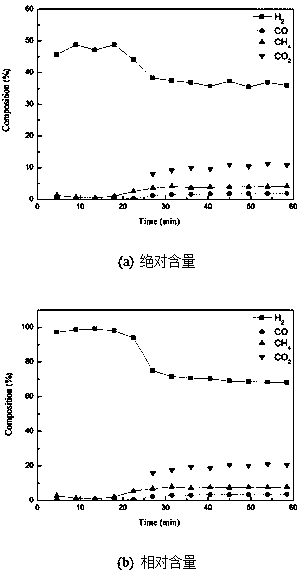

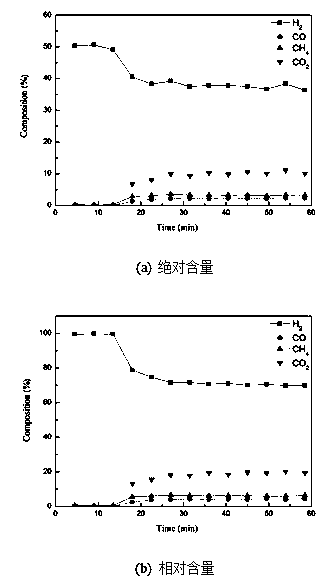

Biomass hydrogen production composite difunctional particle and preparation method and application thereof

InactiveCN103769107ALarge adsorption capacityIncrease contentHydrogenOther chemical processesAcetic acidWater vapor

The invention discloses a biomass hydrogen production composite difunctional particle and a preparation method and application thereof. The composite difunctional particle comprises CaO, FeO and NiO, wherein the mass of NiO accounts for 10-20 percent of mass of CaO, and the mass of FeO in accounts for 1-10 percent of the mass of CaO. The cyclic adsorption capacity of the biomass hydrogen production composite difunctional particle prepared by the preparation method disclosed by the invention is obviously higher than that of a non-modified calcium-based difunctonal particle and the prepared biomass hydrogen production composite difunctional particle has high adsorption capacity; hydrogen obtained by application of the biomass hydrogen production composite difunctional particle in reforming reaction between adsorption enhanced type glycerinum and acetic acid vapor is relatively high; compared with the conventional non-modified difunctional particle, the biomass hydrogen production composite difunctional particle disclosed by the invention has long adsorption time; the manufacturing time is simple; the requirement on equipment is low; the biomass hydrogen production composite difunctional particle can be applied to large-scale production.

Owner:NANJING UNIV OF SCI & TECH

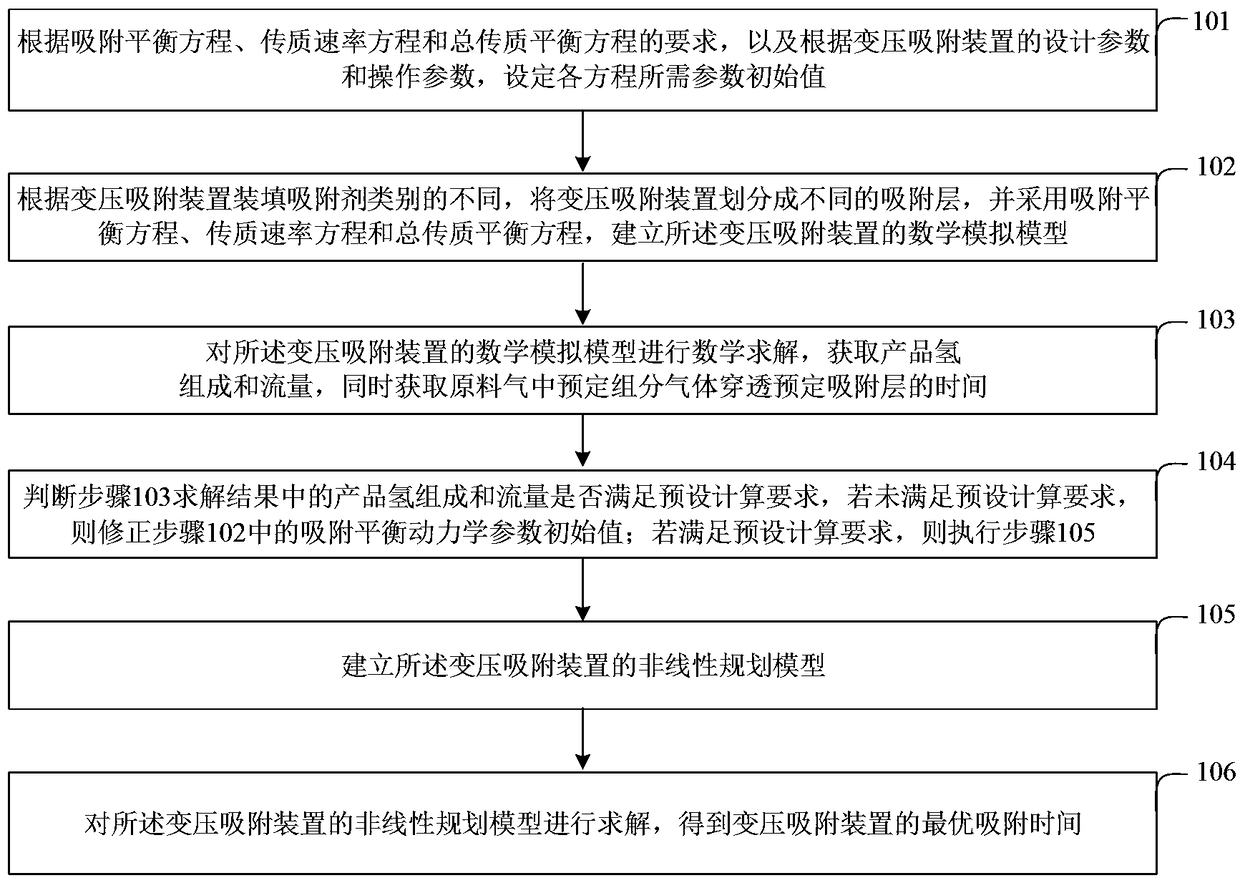

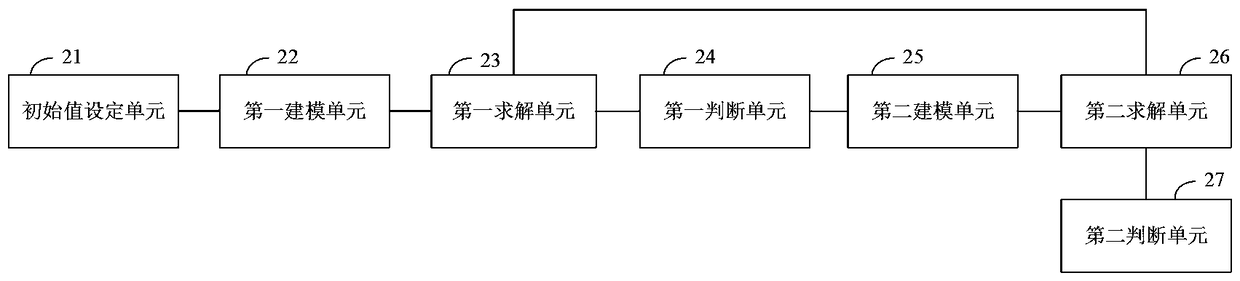

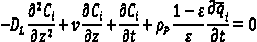

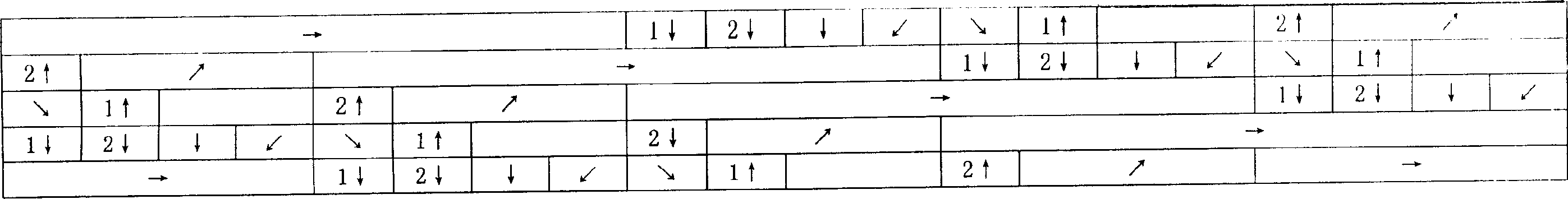

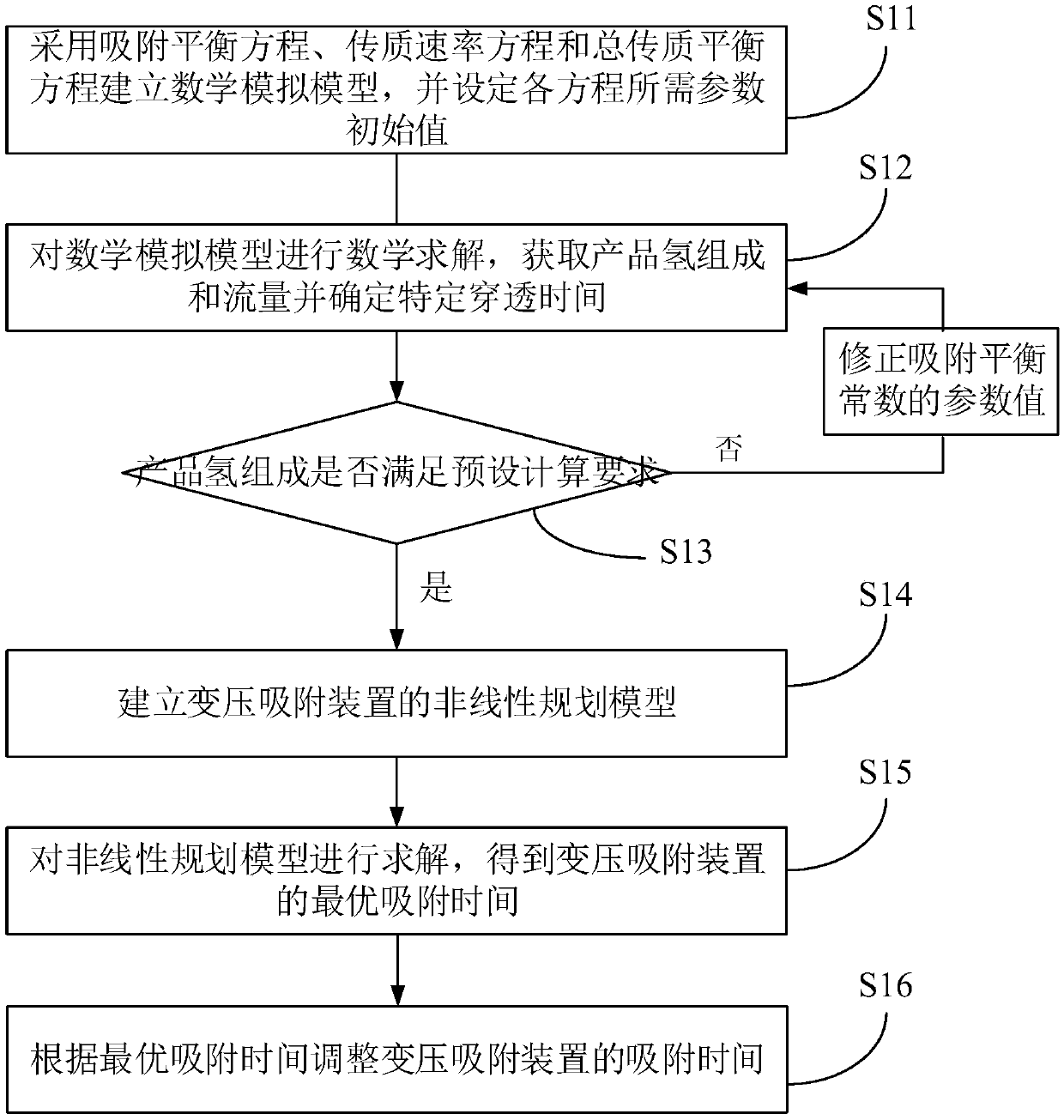

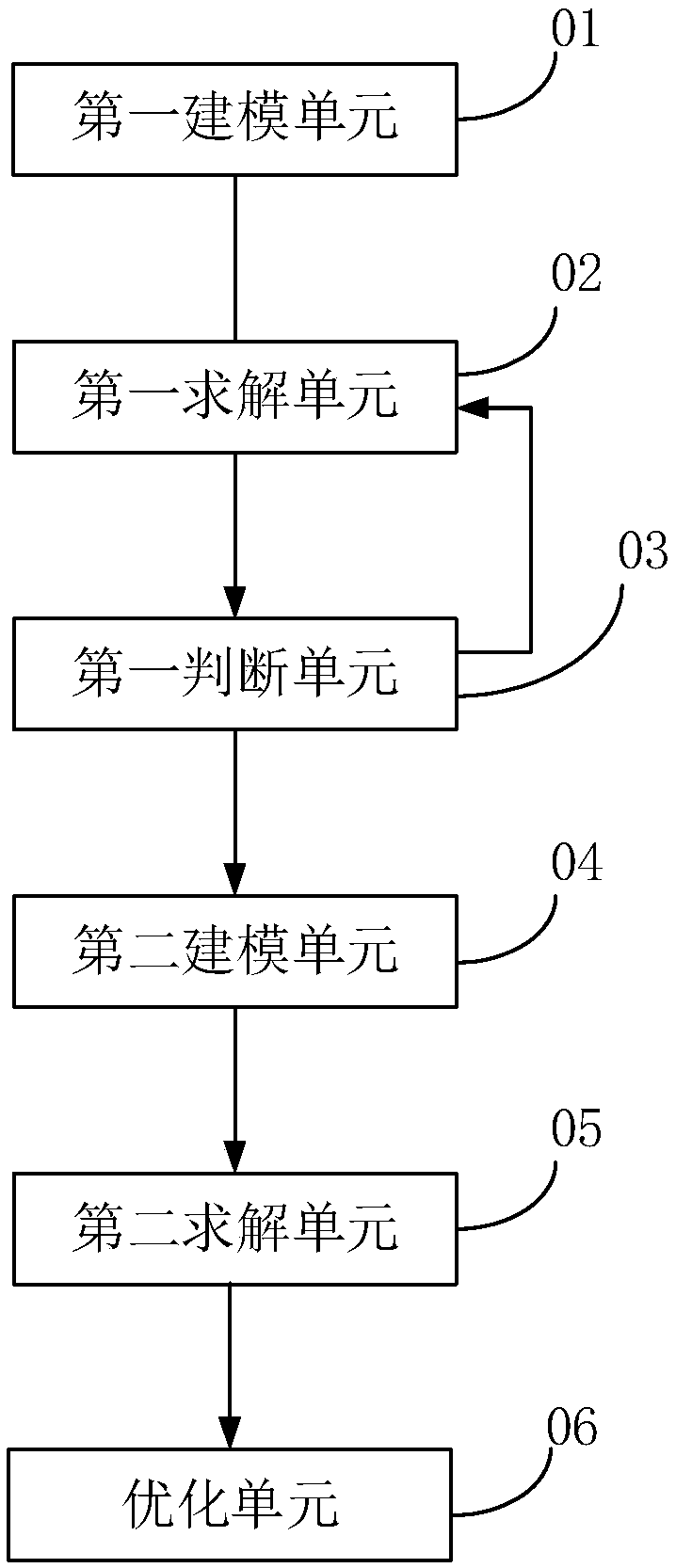

A method and system for determining optimal adsorption time of pressure swing adsorption

ActiveCN109255132AGood adsorption timeGuarantee stabilityDispersed particle separationForecastingAdsorption equilibriumSorbent

The invention discloses a method and a system for determining the optimal adsorption time of pressure swing adsorption. The method comprises the following steps of: according to the requirements of the adsorption equilibrium equation, the mass transfer rate equation and the total mass transfer equation, and according to the design parameters and the operation parameters of the pressure swing adsorption device, setting the initial values of the parameters required for each process; establishing Mathematical simulation model of pressure swing adsorption device; mathematically solving the mathematical simulation model; Judging whether the hydrogen composition and flow rate of the product in the solution result meet the preset calculation requirements, and if not, modifying the initial value of the adsorption equilibrium kinetic parameter; If the preset calculation requirement is satisfied, establishing a nonlinear programming model of the pressure swing adsorption device, and solving thenonlinear programming model to obtain the optimal adsorption time of the pressure swing adsorption device. The invention can determine the optimal adsorption time of the pressure swing adsorption device on the premise that the hydrogen recovery quality, efficiency and the adsorbent are not polluted.

Owner:CHINA PETROLEUM & CHEM CORP +1

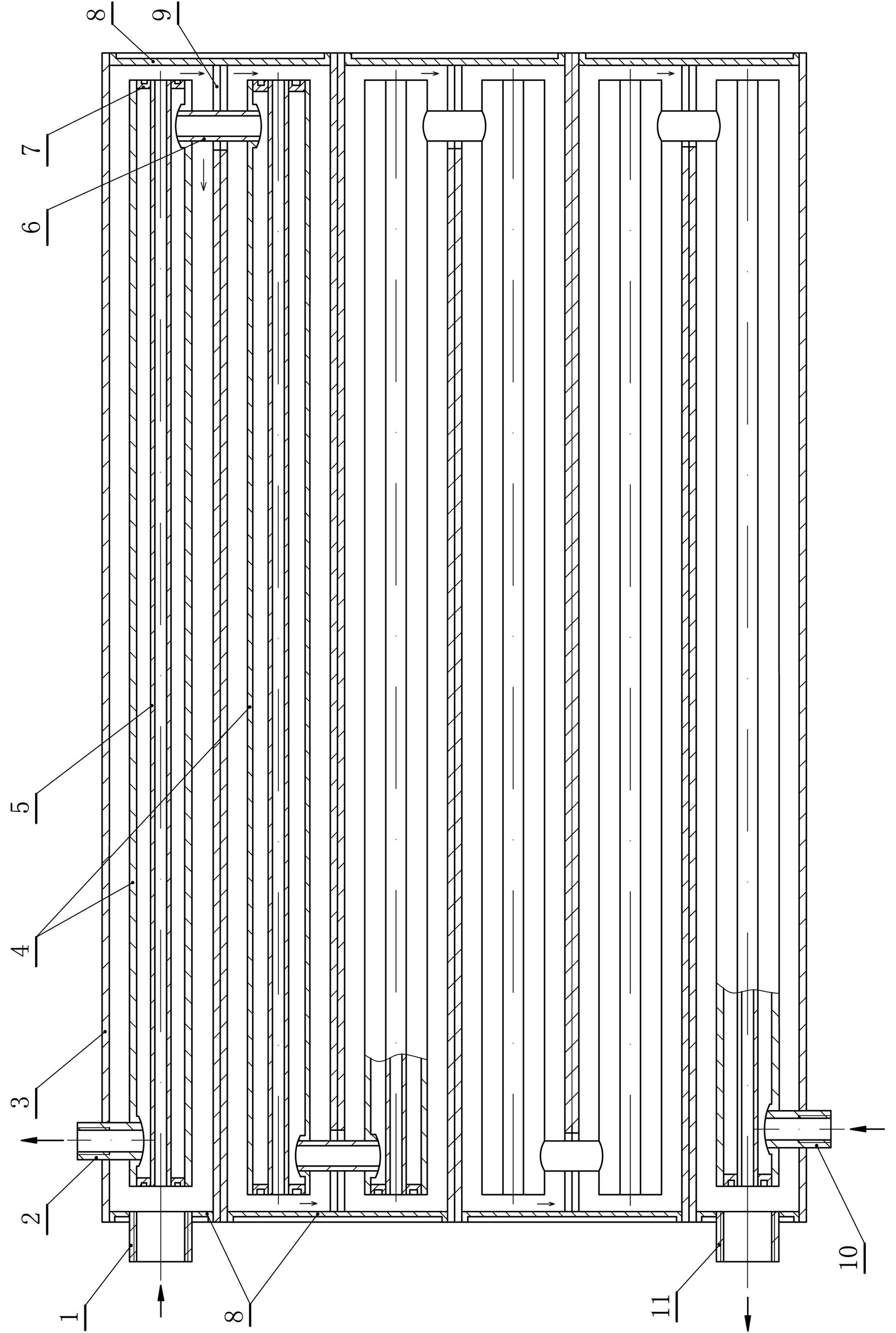

Dual-channel heat transmission heat exchanger with rectangular heating pipe and manufacturing process thereof

InactiveCN102636053AIncrease costSmall thermal static pressureStationary tubular conduit assembliesThermal energyPunching

The invention relates to a dual-channel heat transmission heat exchanger with a rectangular heating pipe and a manufacturing process of the dual-channel heat transmission heat exchanger. The heat exchanger comprises outer heat supply pipes the longitudinal sections of which are rectangular, wherein the outer end of each outer heat supply pipe is plugged through an end socket closure plate; a notch is correspondingly arranged on the pipe walls of the same ends of the two adjacent heat supply outer pipes, another notch is arranged on the other same ends of the next adjacent outer heat supply pipes are correspondingly, and the outer heat supply pipes are communicated through the notches; the outer heat supply pipes are internally provided with tap water heat absorption pipes which are communicated through tap water communicating pipes, and the tap water communicating pipes pass through the notches; and inner heat supply pipes are arranged in the tap water heat absorption pipes, and the inner heat supply pipes are communicated with a cavity body of the outer heat supply pipes. According to the heat exchanger and the manufacturing process, the effective heat energy is utilized fully, a double-pipe cold fluid wall of at the center of a pipe cavity is heated, the heat-transfer area is increased, heat fluid and cold fluid are heated in a circulating manner by three channels, and the heat transfer efficiency is improved. A stainless steel thin wall pipe, a plate manufacture punching, stretching and flanging are adopted; the thin wall stainless steel welding difficulty is reduced due to the embedding type, the side pinched, so that the welding is easy, and acid is filled in an inner channel for cleaning scale generated in the inner channel.

Owner:张伟

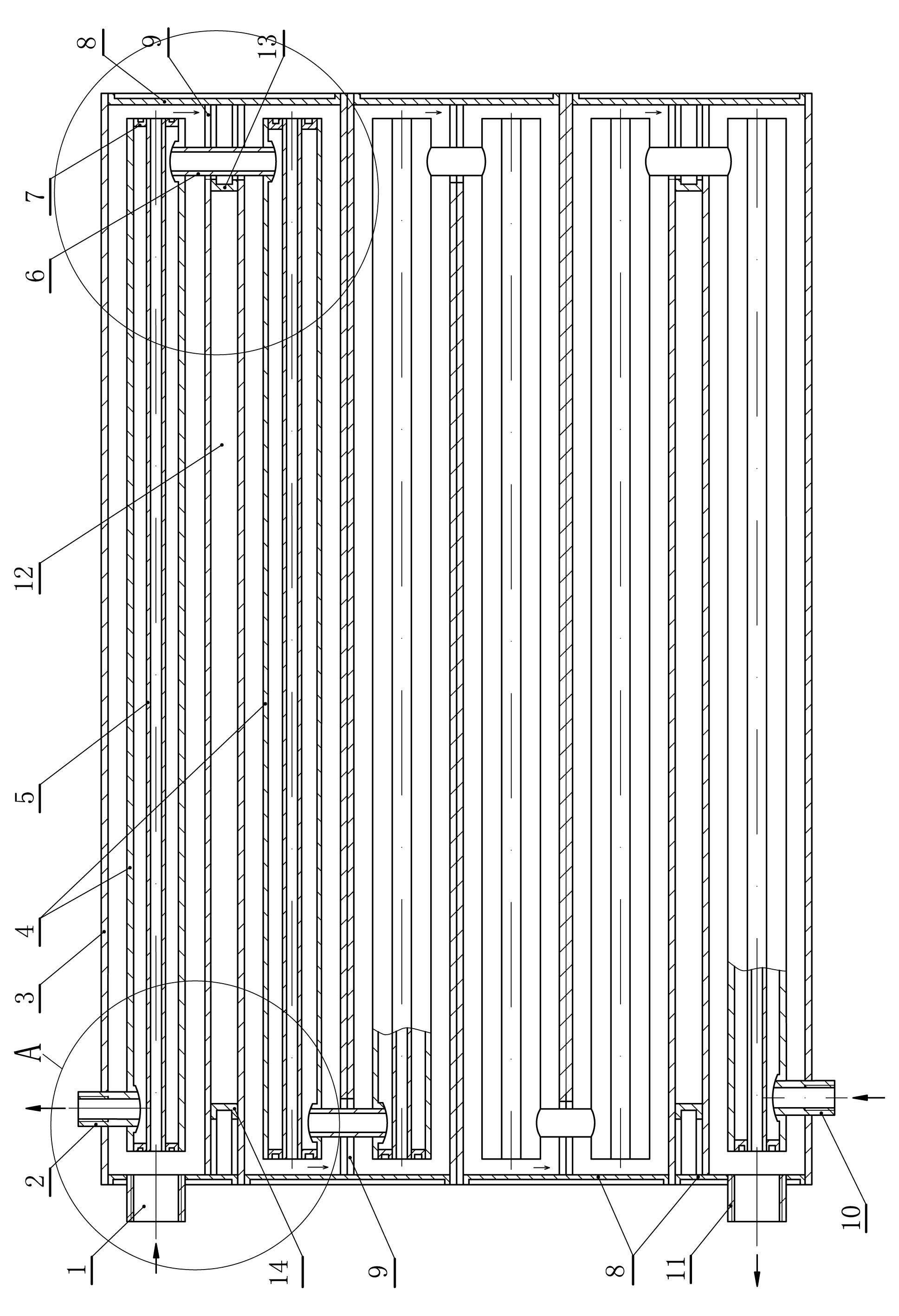

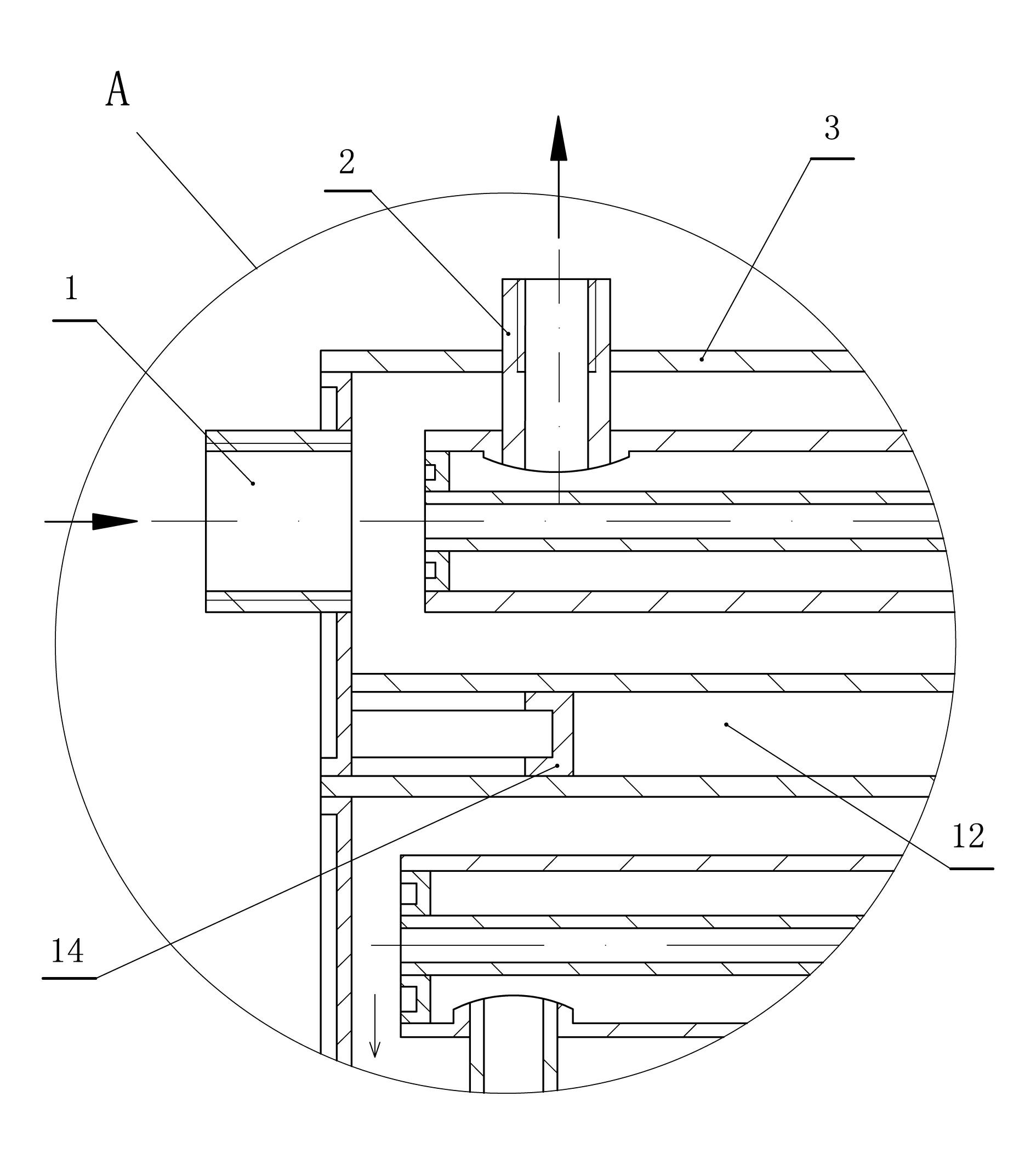

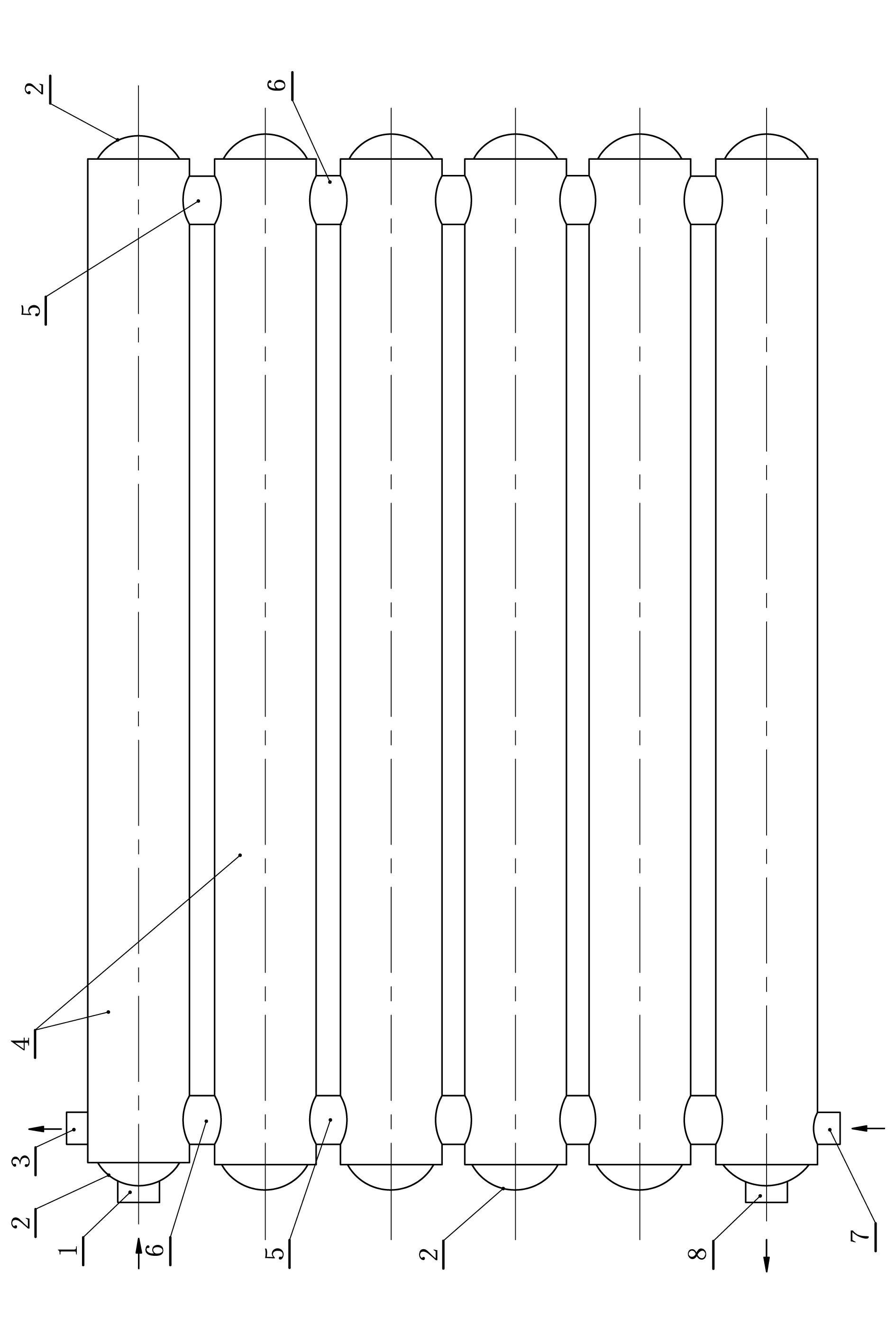

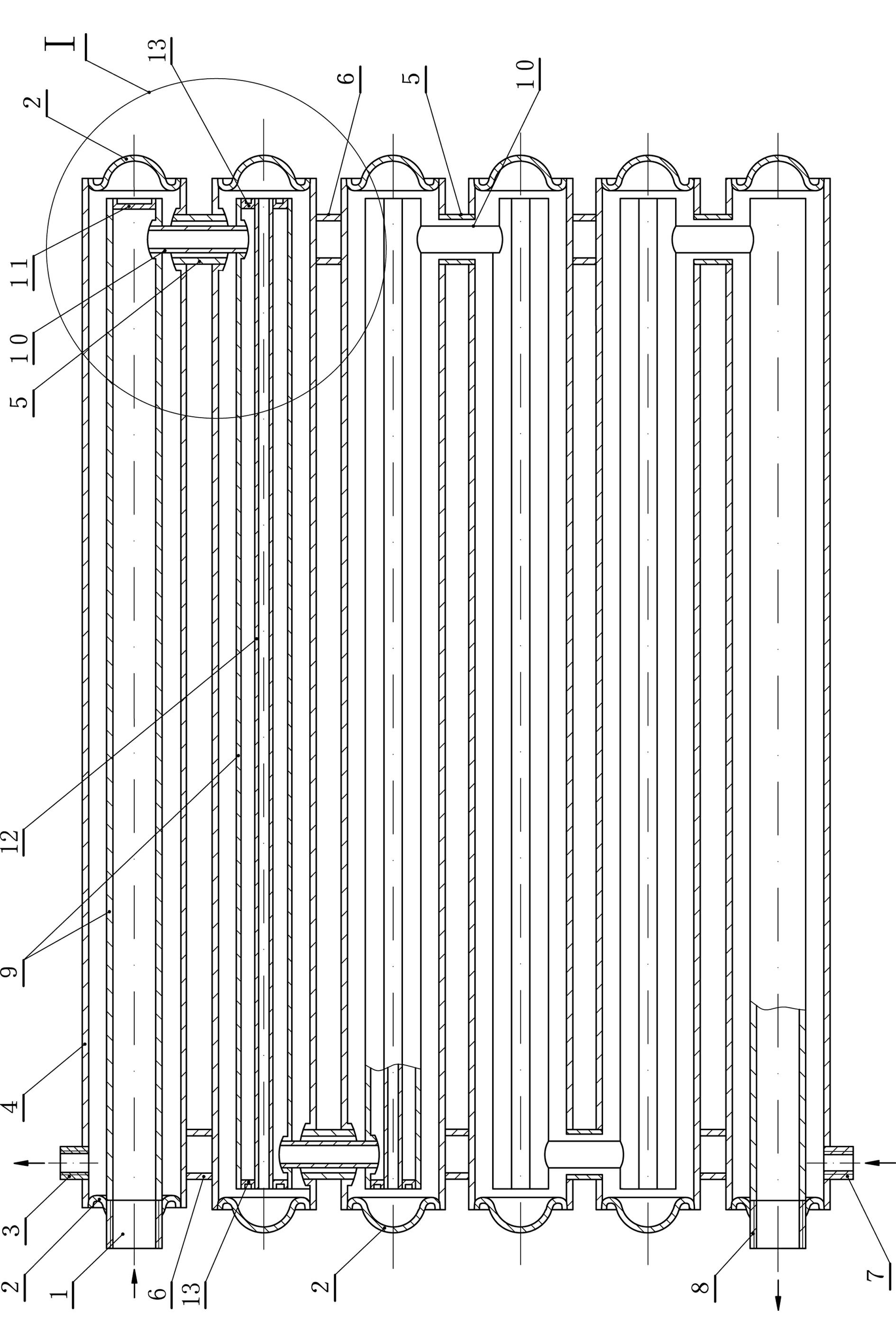

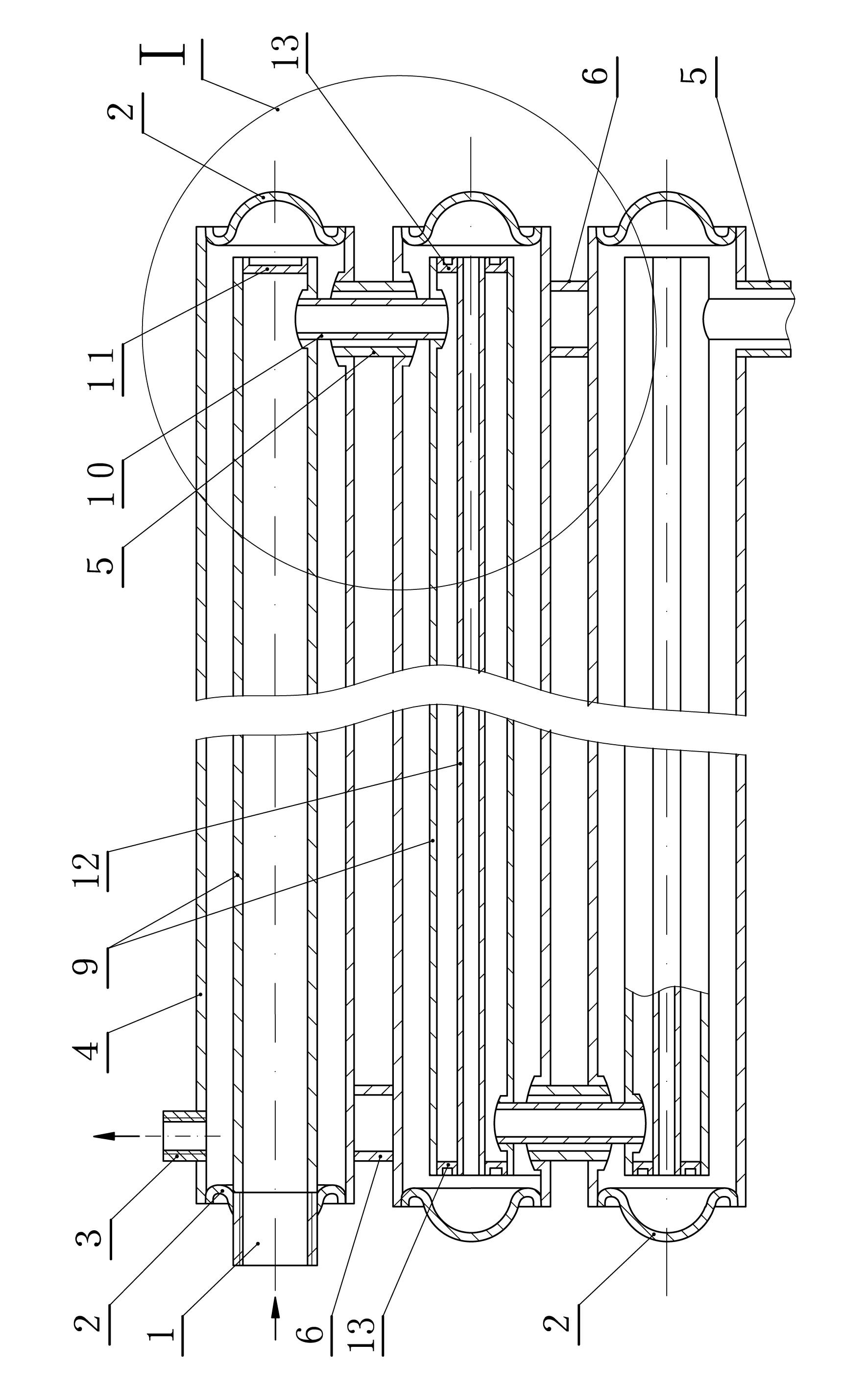

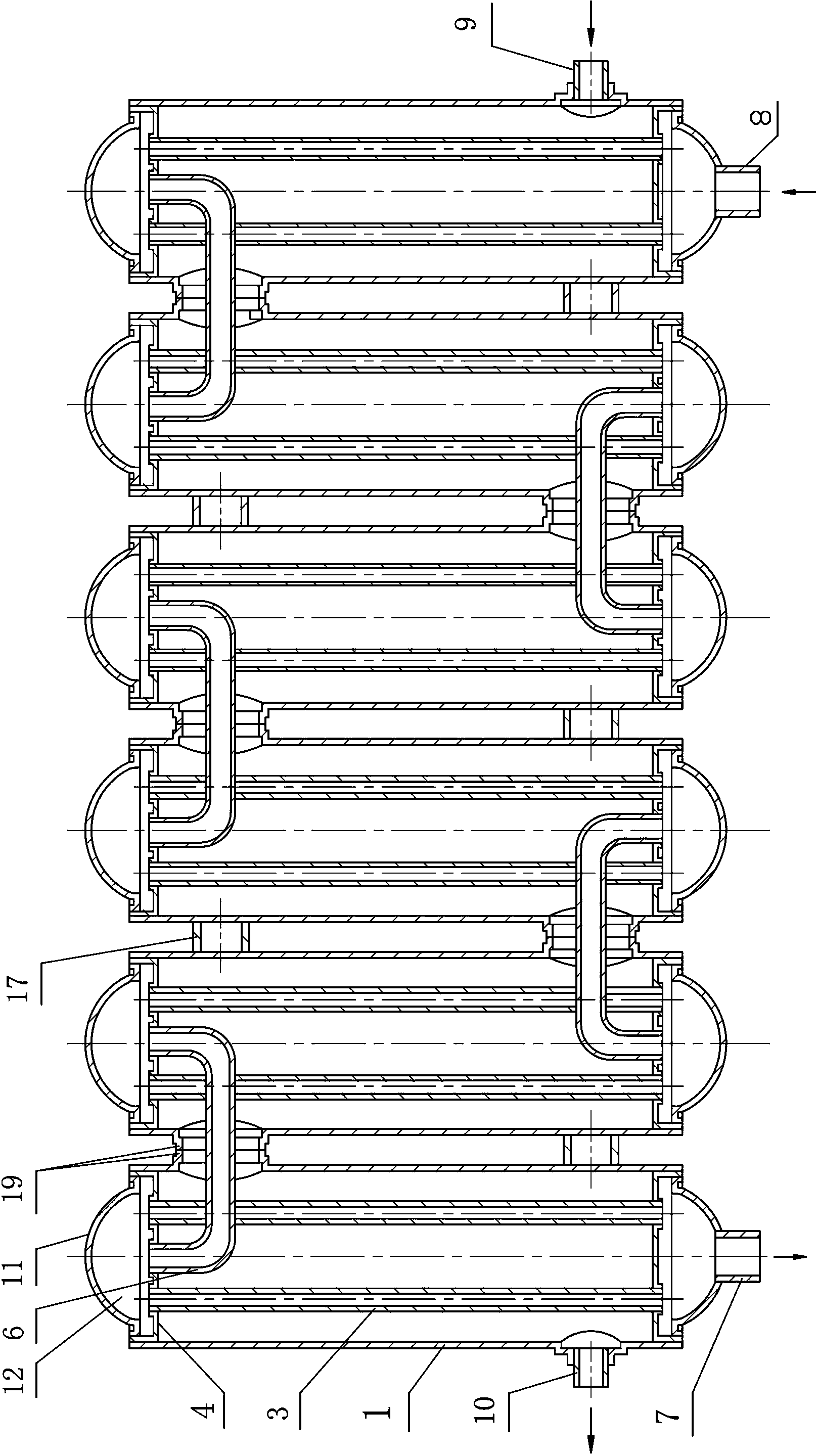

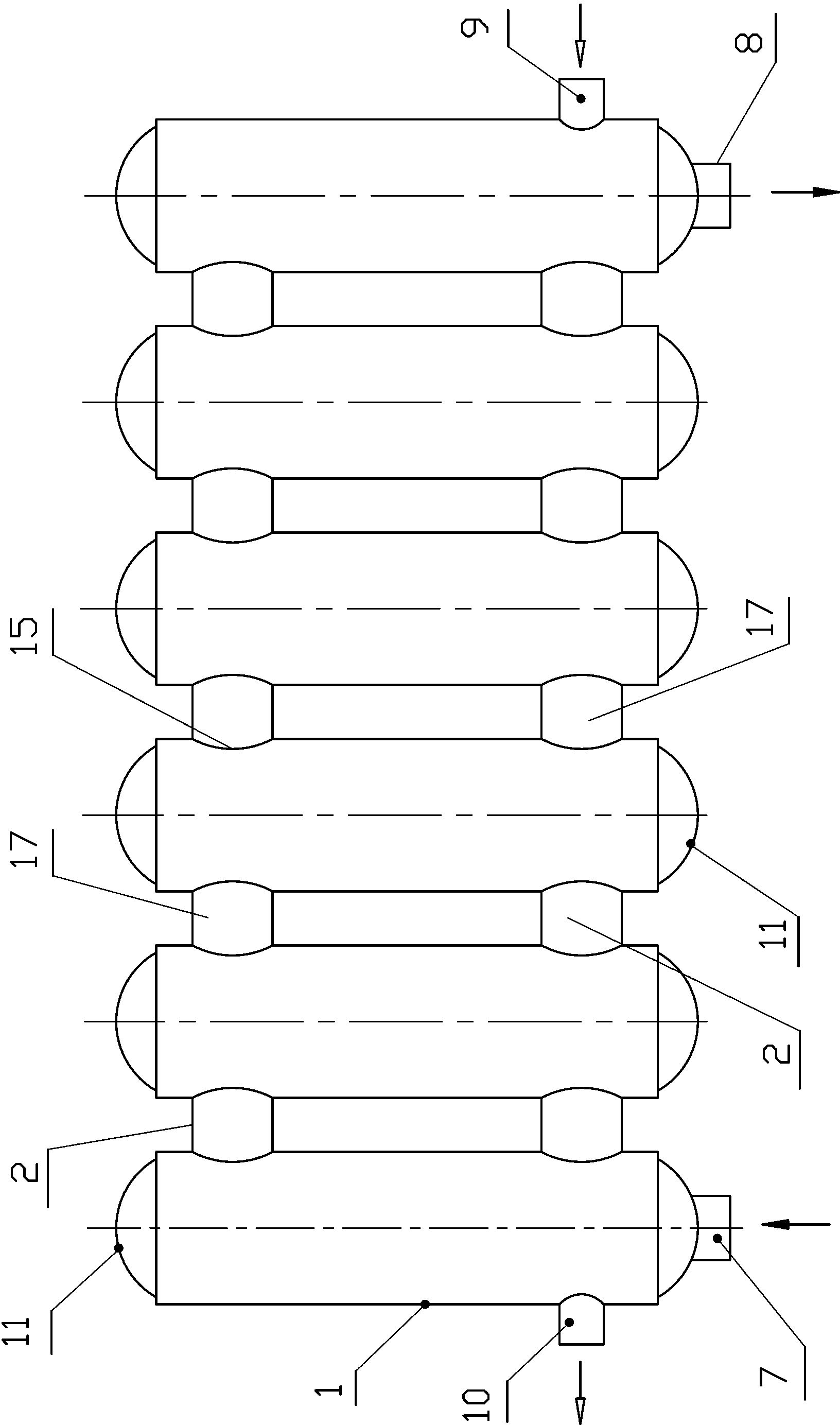

Pipe-communicated double-partition-wall heat transfer heat exchanger and manufacturing process thereof

ActiveCN102538513AImprove thermal efficiencyIncrease heat transfer areaStationary tubular conduit assembliesTap waterEngineering

The invention discloses a pipe-communicated double-partition-wall heat transfer heat exchanger and a manufacturing process thereof. The heat exchanger comprises two or more tap water heat absorbing outer pipes, wherein the tips of the tap water heat absorbing outer pipes are fixedly connected with tap water heat absorbing outer pipe sealing heads; heat supply pipes are arranged in the tap water heat absorbing outer pipes; the tap water heat absorbing outer pipes are communicated with each other through a tap water communicating pipe; the heat supply pipes are communicated with each other through a heat supply pipe communicating pipe; a hot air inlet and a hot air outlet are fixedly communicated with the inlet ends and the outer ends of the heat supply pipes respectively; and a tap water inlet and a tap water outlet are fixedly communicated with the inlet ends and the outlet ends of the tap water heat absorbing outer pipes respectively. The heat exchanger is characterized in that: tap water heat absorbing inner pipes are arranged in a part of or all of the heat supply pipes, and are communicated with the cavities of the tap water heat absorbing outer pipes. The heat exchanger has the advantages of simple structure, easiness for welding kneading edges, high pressure bearing, no water leakage and high heat exchange efficiency.

Owner:张伟

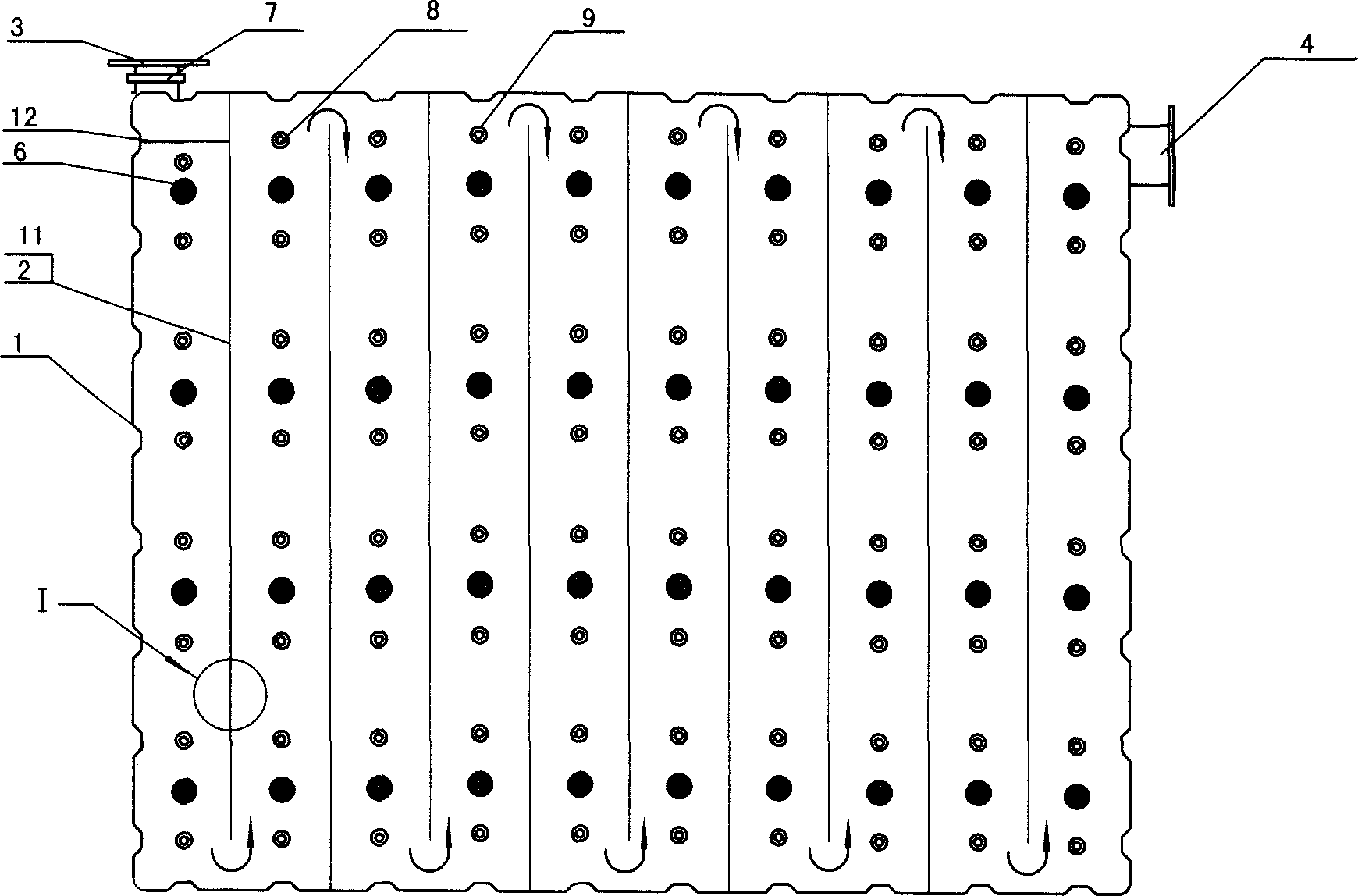

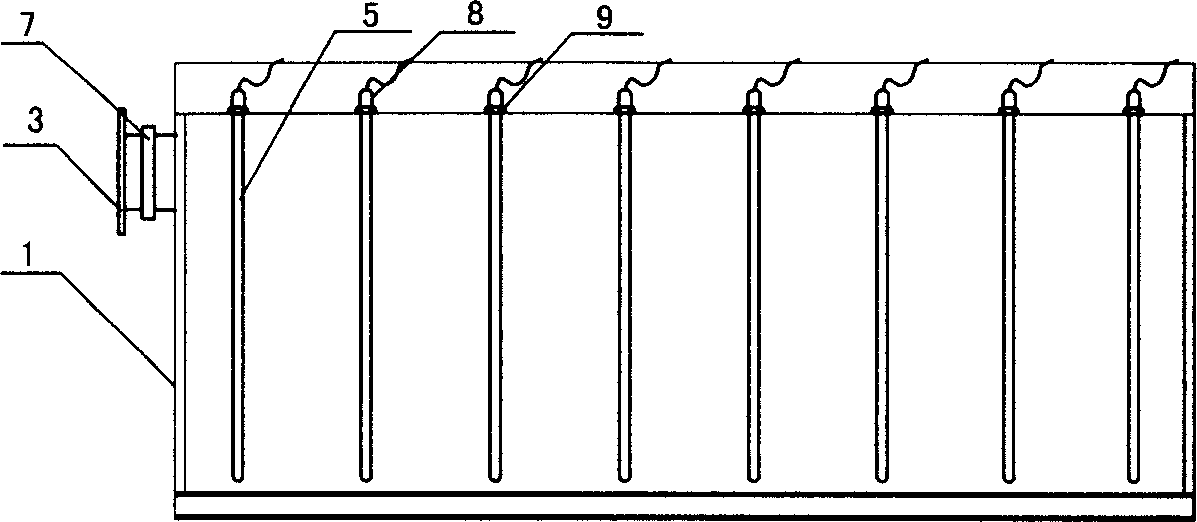

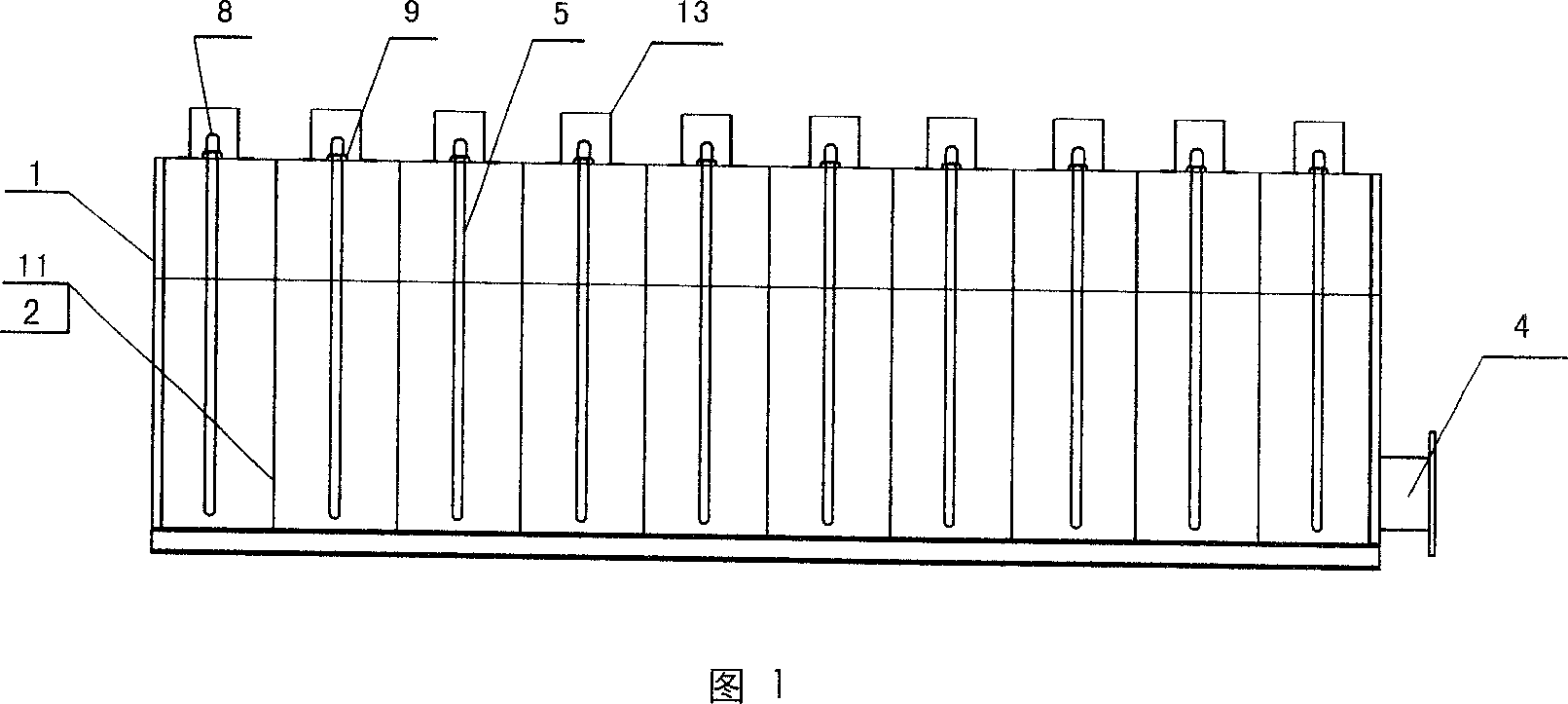

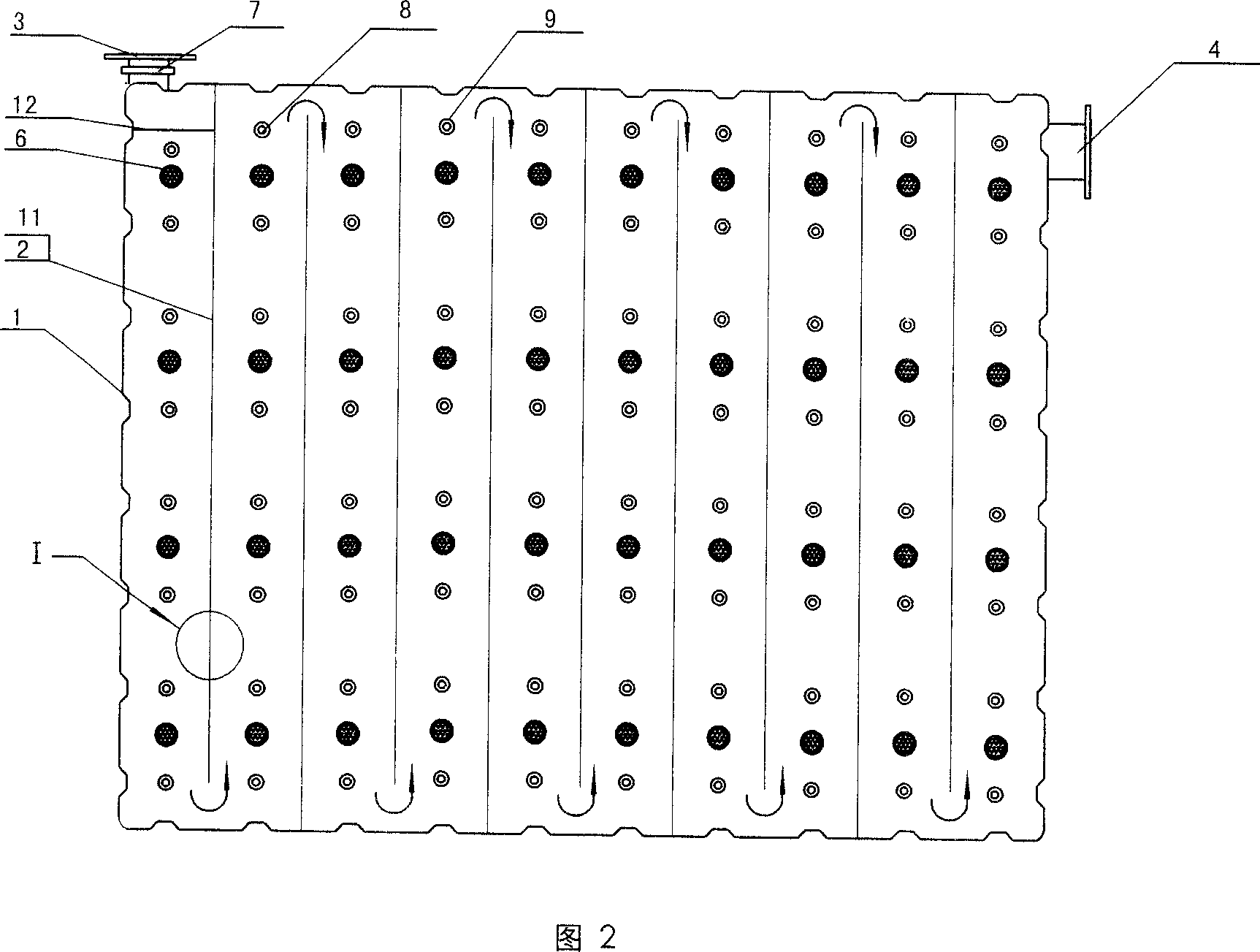

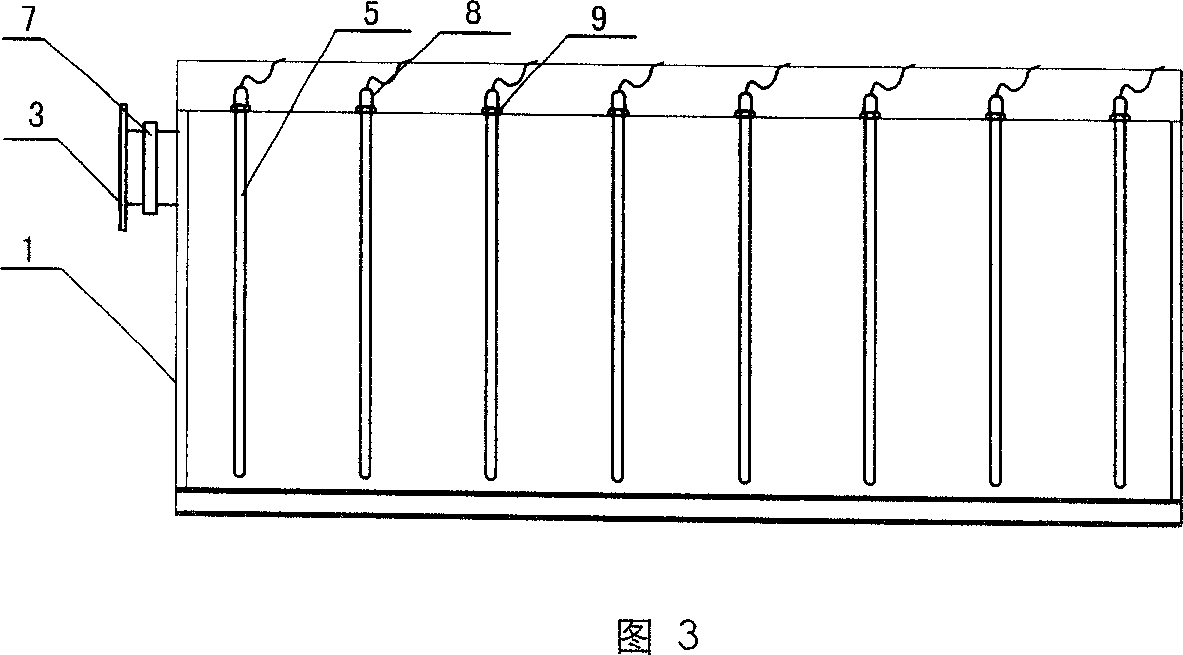

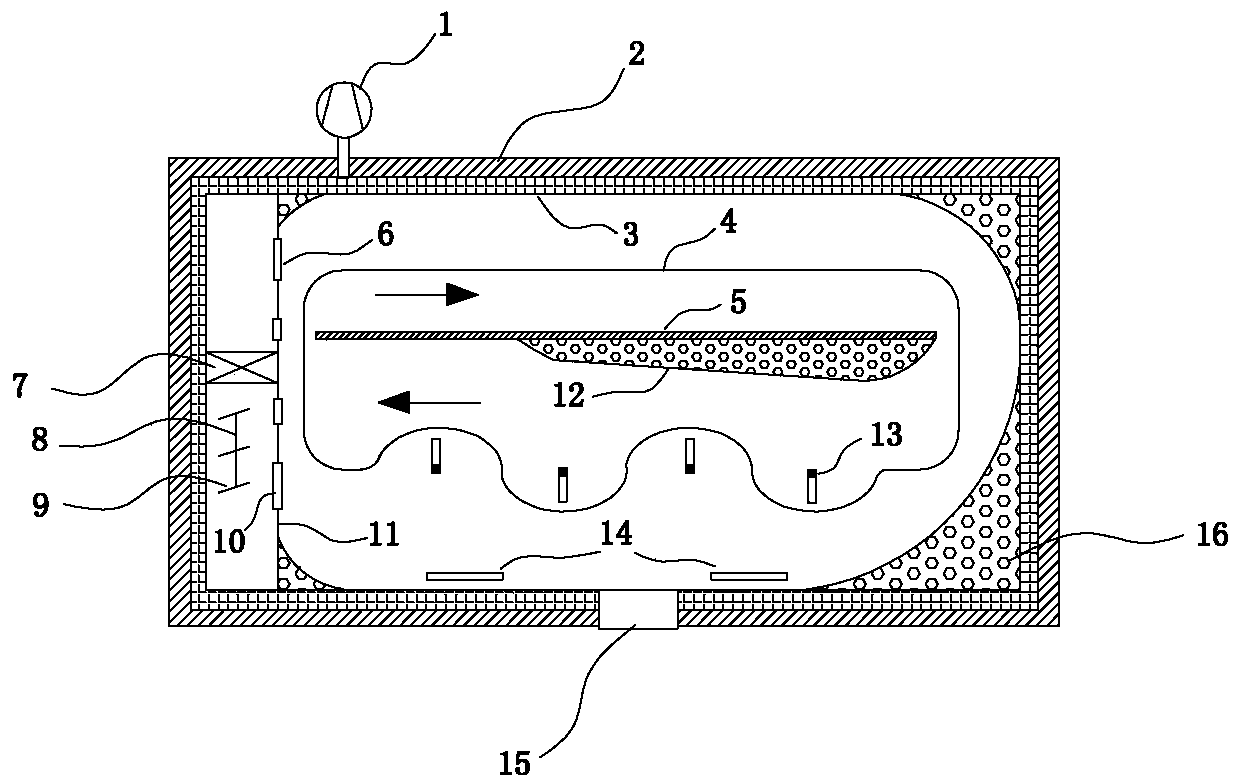

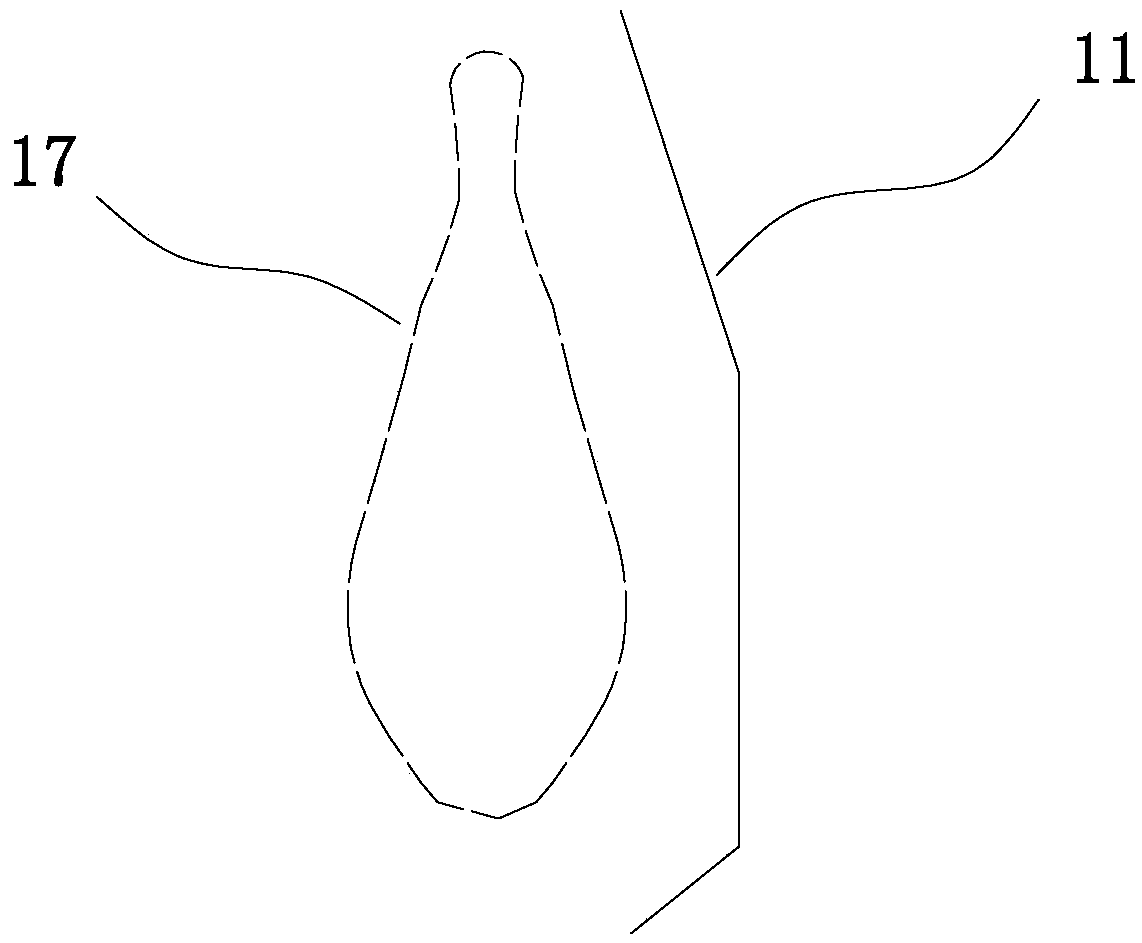

Running water and secondary water-supply deep-purifying method and apparatus

InactiveCN1709805AExtend the adsorption timeImprove the degree of purificationWater/sewage treatment by magnetic/electric fieldsTextile fiberPurification methods

The invention is the deeply purification method of one kind of running water and second supplying water, its step is: Carries on the magnetization to the running water softens, causes to treat the treated water supposes in its reactor box in vivo which includes the activated charcoal textile fiber and separates in the section which does back and forth flows when completes adsorption processing, finally through separates between the section alternate permutation ultraviolet lamp and pore aeration which causes the treated water back and forth in the mobile process and completes the adsorption archery target decomposes, finally completes a higher-level purification. This invention includes one kind of refining equipment, its characteristic is induction pipe and the wrap which set the magnetism link, the box body cavity establishes the stainless steel partition board and the thick hole stainless steel mesh which composes separate section, through the slot activity connection, the reactor box body sidewall as well as respectively separates between the section is loaded with the pore aeration head, between various pores aeration is loaded with ultraviolet lamp tube.

Owner:曹成

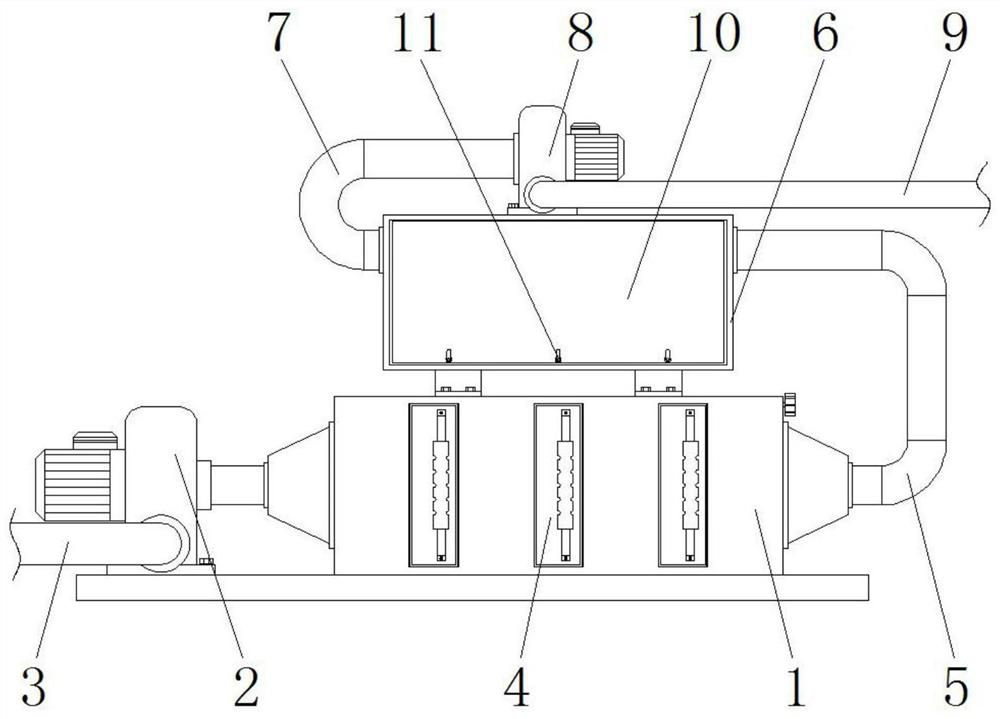

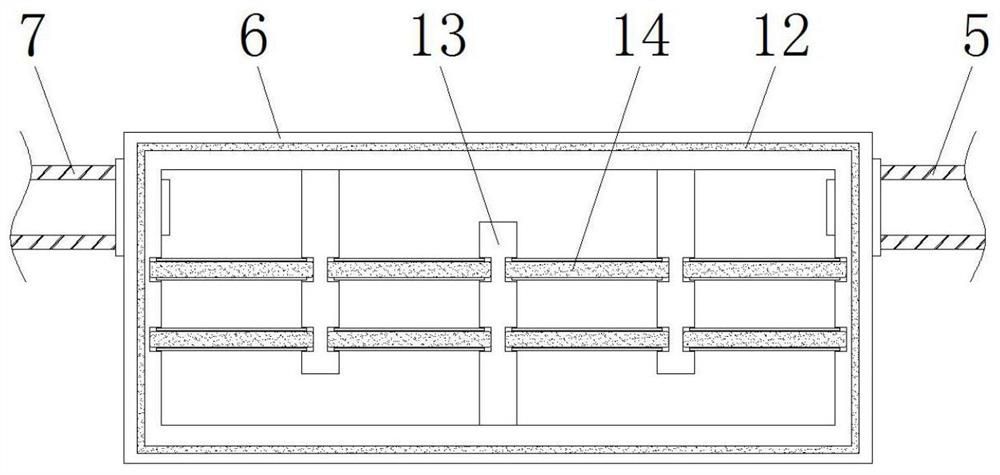

Detachable self-cleaning industrial waste gas purification device

InactiveCN112007433AExtend the adsorption timeImprove adsorption efficiencyDispersed particle filtrationTransportation and packagingEnvironmental engineeringMechanical engineering

The invention discloses a detachable self-cleaning industrial waste gas purification device. The device comprises a filter box, a first fan and a second fan, the first fan is mounted at an air inlet in the left side of the filter box, an air inlet pipe body is fixedly connected to an air inlet of the first fan, a mounting frame is connected to the inner side wall of the filter box in a clamping manner, and a first air conveying pipe is fixedly connected to an air outlet in the right side of the filtering box, the end, away from the filtering box, of the first air conveying pipe is fixedly connected with an opening in the right side wall of the adsorption box, a second air conveying pipe is fixedly connected to an opening in the left side wall of the adsorption box, and a second fan is installed at the end, away from the adsorption box, of the second air conveying pipe. According to the detachable self-cleaning industrial waste gas purification device, the filter screen is convenient toreplace and clean, disassembly is more convenient, impurities on the filter screen are convenient to automatically clean, the blockage phenomenon is avoided, in addition, the adsorption time of wastegas is prolonged, the adsorption efficiency of the waste gas is improved, and the practicability is improved.

Owner:惠永岗

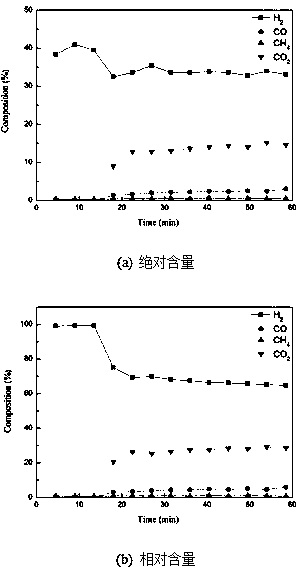

Preparation method and application of double-functional composite Co modified particle

InactiveCN103785344ALarge adsorption capacityExtend the adsorption timeHydrogenOther chemical processesIonChemistry

The invention discloses a preparation method and an application of a double-functional composite Co modified particle, belonging to the technical field of energy. A calcium-based carrier is added with two non-noble metals Co and Ni, and ions including Ca<2+> and the like are complexed by utilizing a sol-gel method, so that the adsorption efficiency and the catalytic efficiency are remarkably improved. The preparation method and the application disclosed by the invention can be applied to ethanol adsorption reinforced vapor reformation hydrogen production reaction or applied to glycerinum and acetic acid adsorption reinforced vapor reformation hydrogen production reaction and the like.

Owner:NANJING UNIV OF SCI & TECH

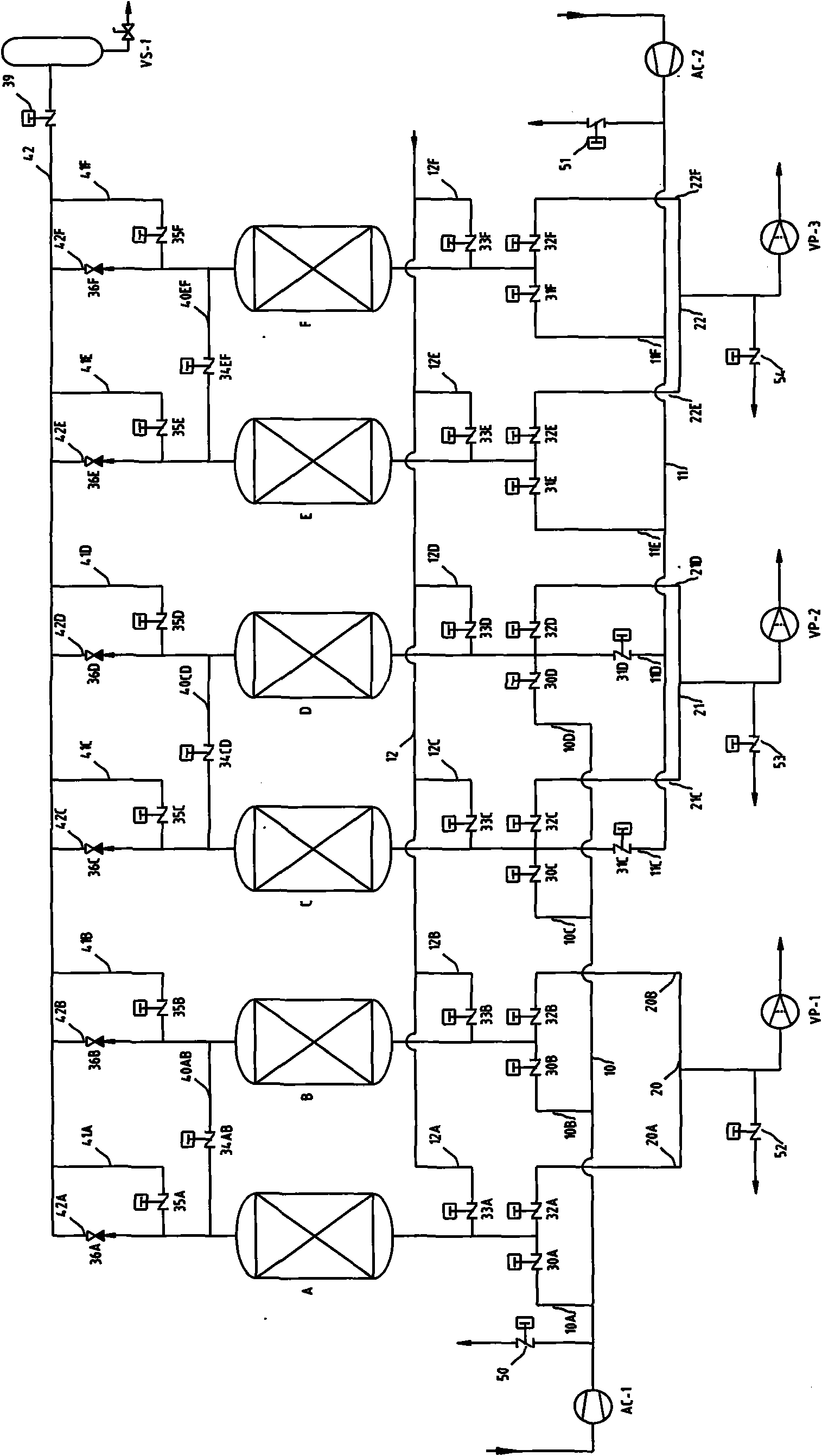

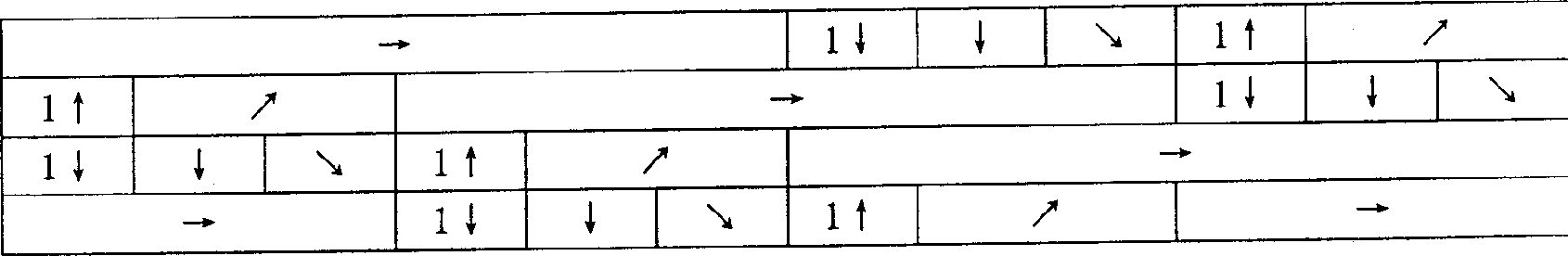

Practical pressure swing adsorption method

The practical pressure swing adsorption method for purifying gas or separating gas mixture is characterized by that in one circulating period every adsorption tower must be undergone the processes ofadsorption, decompession, rising pressure and stopping pressure, and also includes one of the following processes of flushing, vacuum-pumping and changing temp. Said invention utilizes the gas balancing treatment between the adsorption tower whose adsorption state is completed and the adsorption tower being in adsorption state and between the adsorption tower being in decompression state and the adsorption tower being in perssure-rising state to make utilization rate of adsorption tower be up to maximum.

Owner:中船(邯郸)派瑞氢能科技有限公司

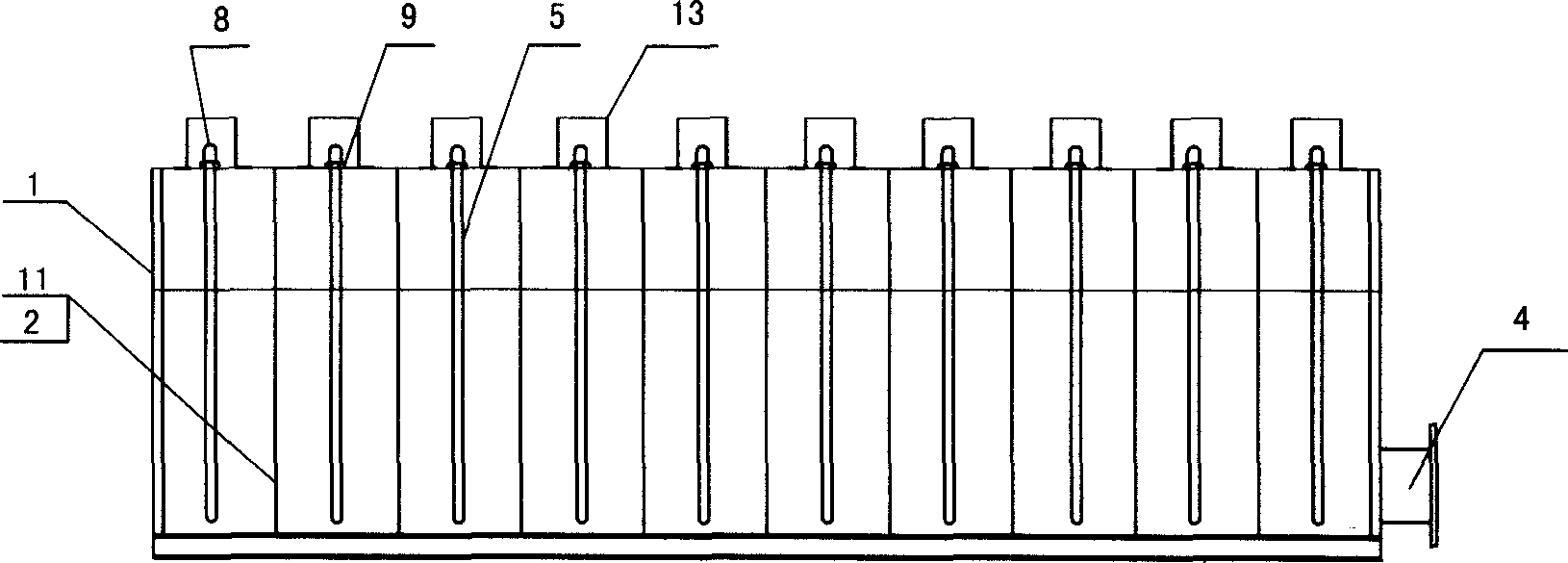

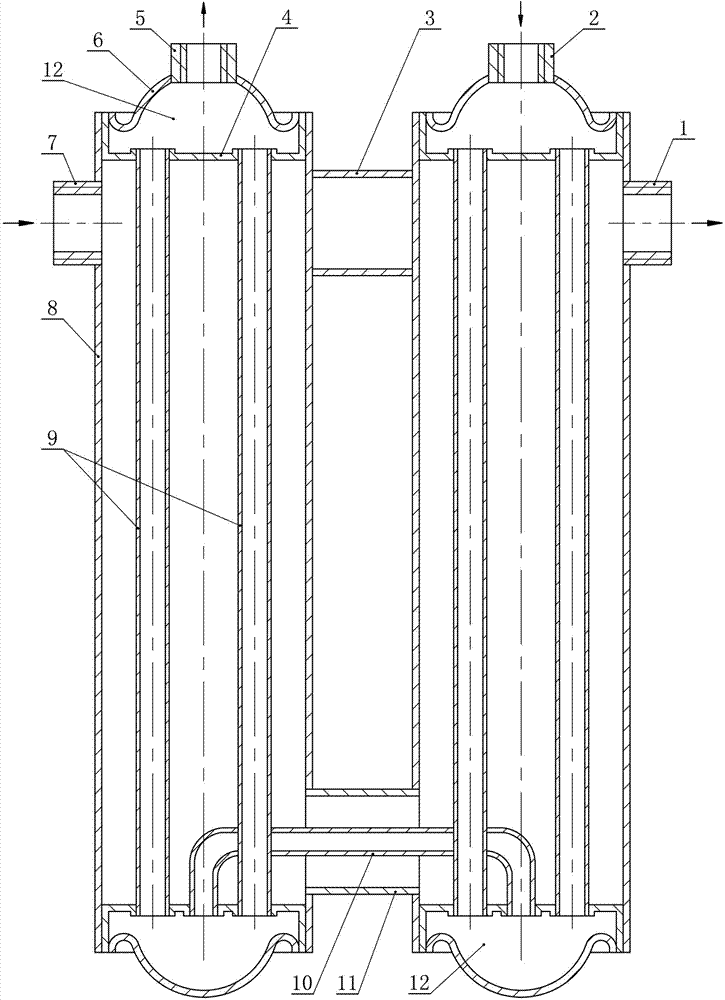

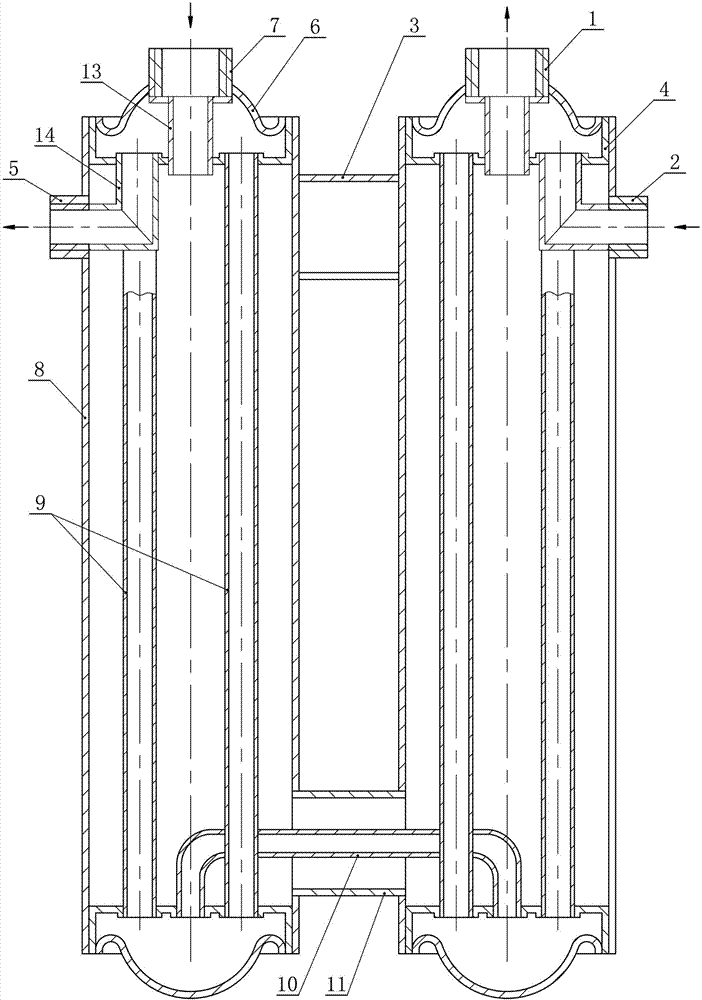

Heater multi-pipe heat conducting type shell-tube water storage bearing heat interchanger and manufacturing technology thereof

ActiveCN103851936ASave Unicom pipe materialsSave materialHeat exchanger casingsStationary tubular conduit assembliesWater storageManufacturing technology

The invention provides a heater multi-pipe heat conducting type shell-tube water storage bearing heat interchanger and a manufacturing technology thereof. The heat interchanger comprises multiple round cold water pipes; head external blocking plates are welded at two ends of the round cold water pipes; heater pipe connecting blocking plates are welded in pipe openings at two ends of the round cold water pipes; round heater pipe connecting openings are formed on the heating pipe connecting blocking plates; pipe cavities are directly welded and communicated by the adjacent round cold water pipes through straight round cold water communicating pipes or butt-welded wall pulling pipes; at least one round heater pipe is penetrated into the cavity of each round cold water pipe; pipe openings of two ends of each round heater pipe are in welded connection with connecting openings of the round heater pipe on the heater pipe connecting blocking plates; round heater communicating pipes are in welded communication with the heater pipe connecting blocking plates or the round heater communicating pipes are sequentially welded and communicated with the head external blocking plates and are communicated with a thermal fluid shunting cavity to form a thermal fluid circulated heat transmission passage. The heat interchanging structure is more scientific and reasonable; the heat transmission area is improved by 55%-100%; the heat conduction rate is accelerated; the heat exchanging effect is excellent. The welding joints of the communicating pipes among the cavities are difficultly subjected to water leakage.

Owner:山东利能换热器有限公司

Multi-cold water pipe and multichannel heat absorption open-type communicating heat exchanger and manufacturing process thereof

InactiveCN102788523AAchieve heat exchange effectSave materialArc welding apparatusStationary tubular conduit assembliesEngineeringThermal water

The invention discloses a multi-cold water pipe and multichannel heat absorption open-type communicating heat exchanger and a manufacturing process thereof and is used for changing cold water into hot water to take a bath in families. Porous inner plates are respectively and fixedly welded in both ends of more than two heat supply pipes; end sealing plates are fixedly welded outside both ends of each heat supply pipe; cold water heat collection distribution chambers are formed by the porous inner plates and the end sealing plates; each two heat supply pipes are welded to be communicated through a heat supply pipe communicating straight pipe; more than two cold water pipes are interpenetrated into each heat supply pipe; both ends of each cold water pipe and the porous inner plates are welded to be communicated in the manner of opening; a cold water communicating pipe penetrates through the heat supply pipe communicating straight pipe, and both ends of the cold water communicating pipe and the porous inner plates in the adjacent two heat supply pipes are welded to be communicated; a cold water inlet / outlet and the cold water heat collection distribution chambers of side pipes at both sides of the heat supply pipes are welded to be communicated; and a warm air inlet / outlet and the side pipes at both sides of the heat supply pipes are welded to be communicated. According to the multi-cold water pipe and multichannel heat absorption open-type communicating heat exchanger disclosed by the invention, the heat absorption area is increased by fully utilizing an effective heat source through multi-dividing wall heat absorption and stepped heat transfer, therefore, the heat absorption is rapid, and the heat exchange efficiency that the temperature is changed in the manner of gradient is high.

Owner:张伟

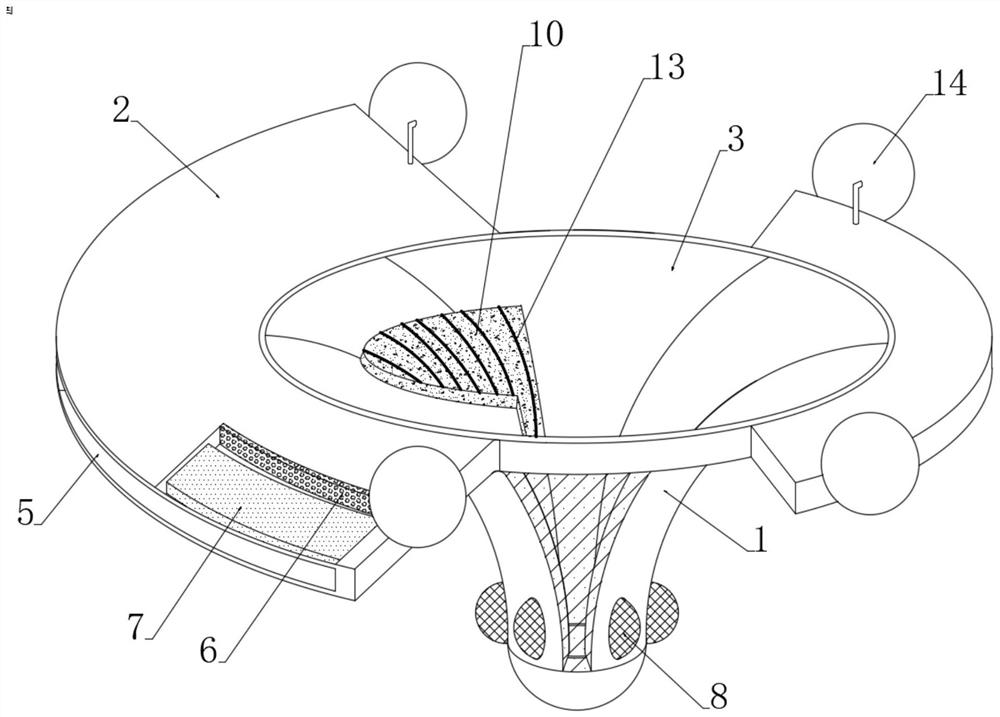

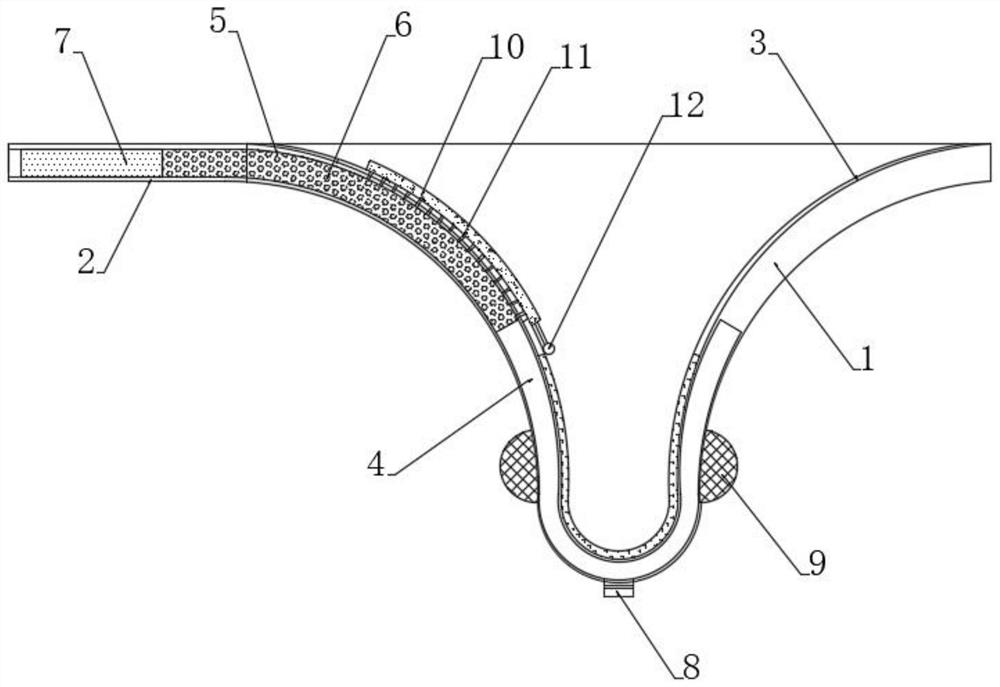

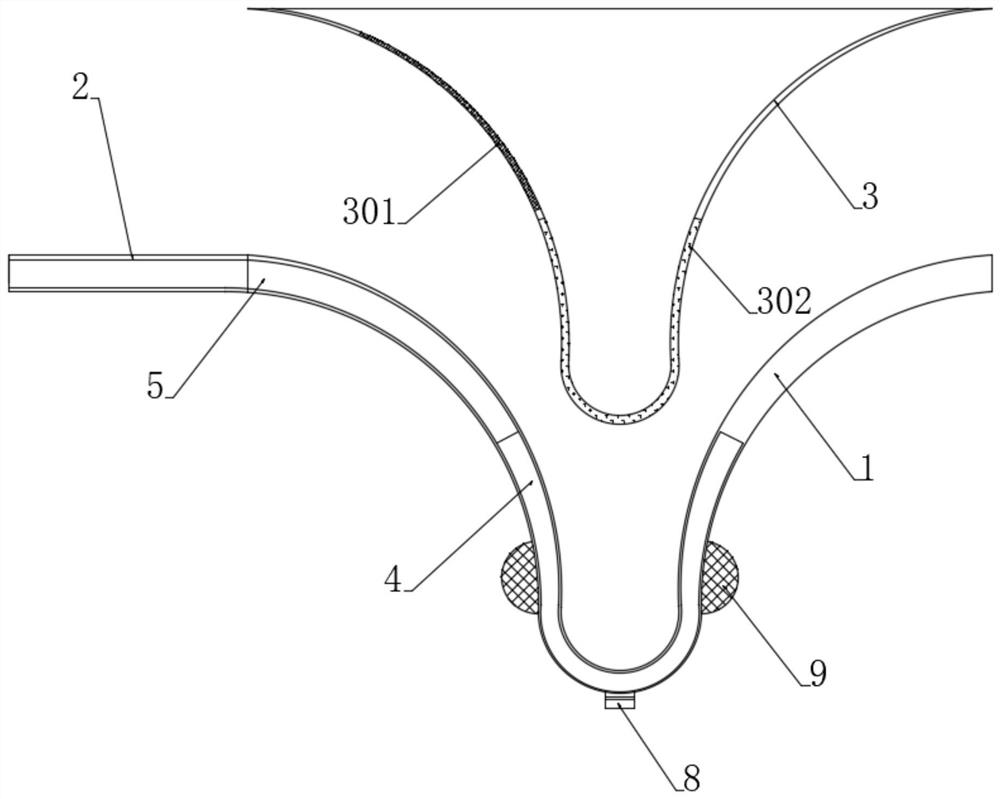

Floating trend type oil surface adsorption device

InactiveCN111874987AComprehensive adsorptionImprove adsorption service lifeFatty/oily/floating substances removal devicesWater/sewage treatment bu osmosis/dialysisSewageAdsorption separation

The invention discloses a floating trend type oil surface adsorption device, which belongs to the technical field of sewage oil-water adsorption separation, and is characterized in that a trumpet-shaped adsorption table is matched with an arc-shaped adsorption floating plate arranged on one side of the top end of the trumpet-shaped adsorption table, the arc-shaped adsorption plate is used for guiding and adsorbing water surface oil stains, the trumpet-shaped adsorption table and the arc-shaped adsorption floating plate are filled with a water-approaching oil absorption body, and multiple oil stain tendency bodies communicating with the outside are arranged at the top end of the water-approaching oil absorption body, so that the device tends to move towards the side where oil stains exist,and an oil layer can be effectively and comprehensively adsorbed by the water-approaching oil absorption body; in addition, the water-approaching oil absorption body has a water-repellent effect, somemoisture doped in the oil layer is guided out through cooperation of a drainage cavity and a one-way water outlet, by means of the cooperation of oil stain high-strength adsorption cotton and an oleophobic mechanism, oil stains adsorbed to the water-approaching oil absorption body are guided into the arc-shaped adsorption floating plate to be drained, guided and collected, and the adsorption service life of the device is prolonged to a certain extent.

Owner:何安静

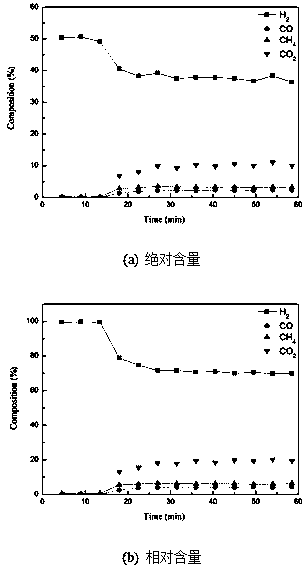

Preparation method of nickel-modified calcium-based dual-functional particles

InactiveCN103752256AHigh cycle adsorption capacityLarge cycle adsorption capacityHydrogenOther chemical processesSteam reformingWater vapor

The invention discloses a preparation method of nickel-modified calcium-based dual-functional particles, and belongs to the technical field of energy. The preparation method is characterized in that the sol-gel method is carried out, citric acid is added to enable ion complexing such as Ca<2+> as well as promote the formation of small holes in the particles during roasting, and thus the absorption efficiency and catalyzing effect are greatly improved. The preparation method is applied to absorption strengthened type steam reforming hydrogen production reaction of a biomass-derived compound, and also shows obvious effect on catalyzing ethanol.

Owner:NANJING UNIV OF SCI & TECH

Plant cellulose absorption sponge, and preparation method and application of plant cellulose absorption sponge

ActiveCN110354819AShape and size are easy to controlImprove mechanical propertiesOther chemical processesWater contaminantsCelluloseAbsorption capacity

The invention provides plant cellulose absorption sponge, and a preparation method and an application of the plant cellulose absorption sponge, and belongs to the field of absorption materials and water treatment. The preparation method of the plant cellulose absorption sponge comprises the steps of grinding or crushing a plant cellulose raw material, allowing the plant cellulose raw material to react with an alkali solution and carbon disulfide, collecting a solid product after reaction, washing to be neutral with deionized water, and performing refrigeration and freeze drying to form the plant cellulose absorption sponge. The plant cellulose absorption sponge prepared by the preparation method of the plant cellulose absorption sponge is controllable in shape and size, good in mechanicalproperty, unbreakable and strong in absorption capacity, has a rich communicated pore structure, and can be used for removing contaminants such as heavy metal ions from wastewater.

Owner:GUANGZHOU UNIVERSITY

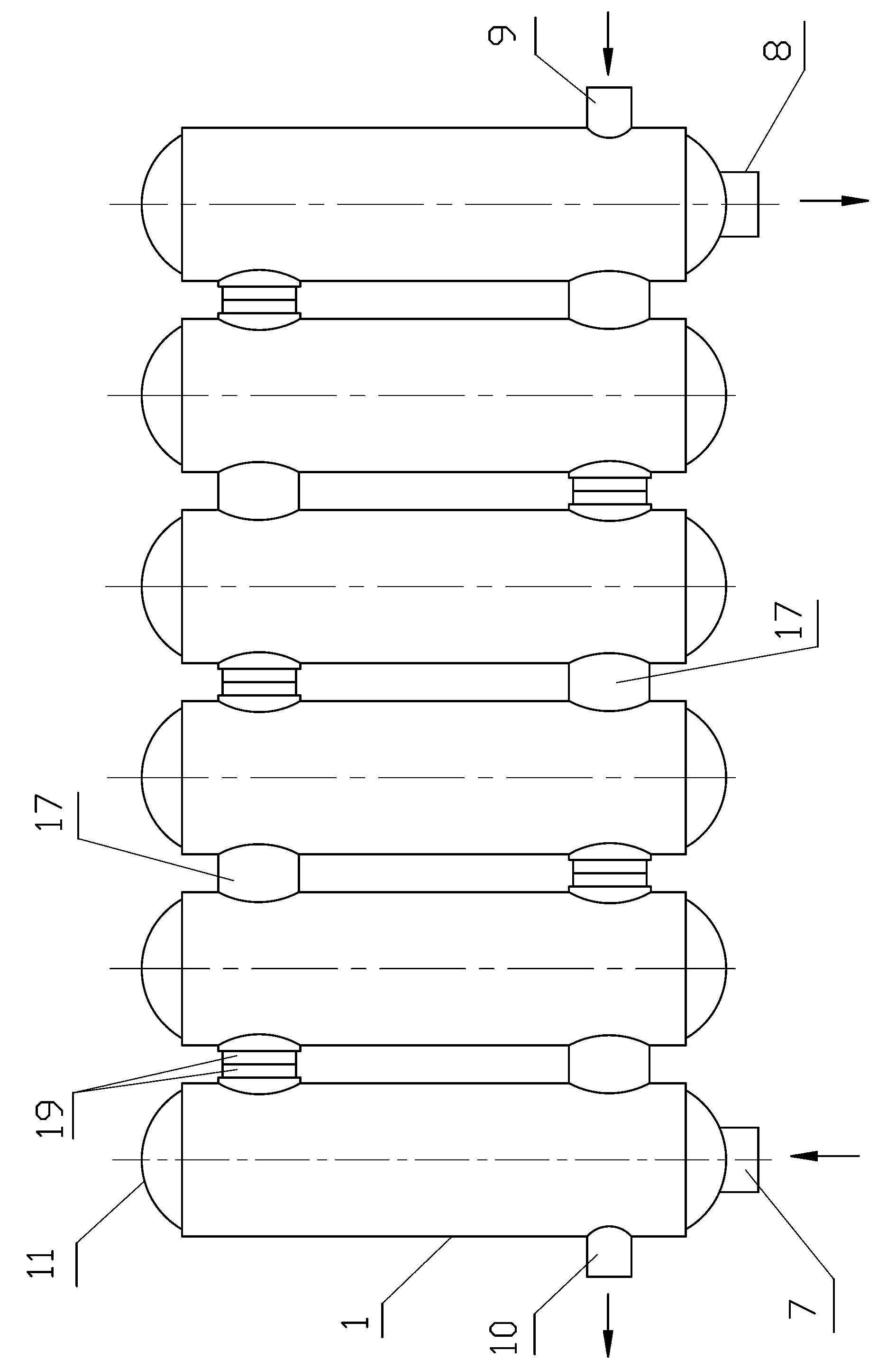

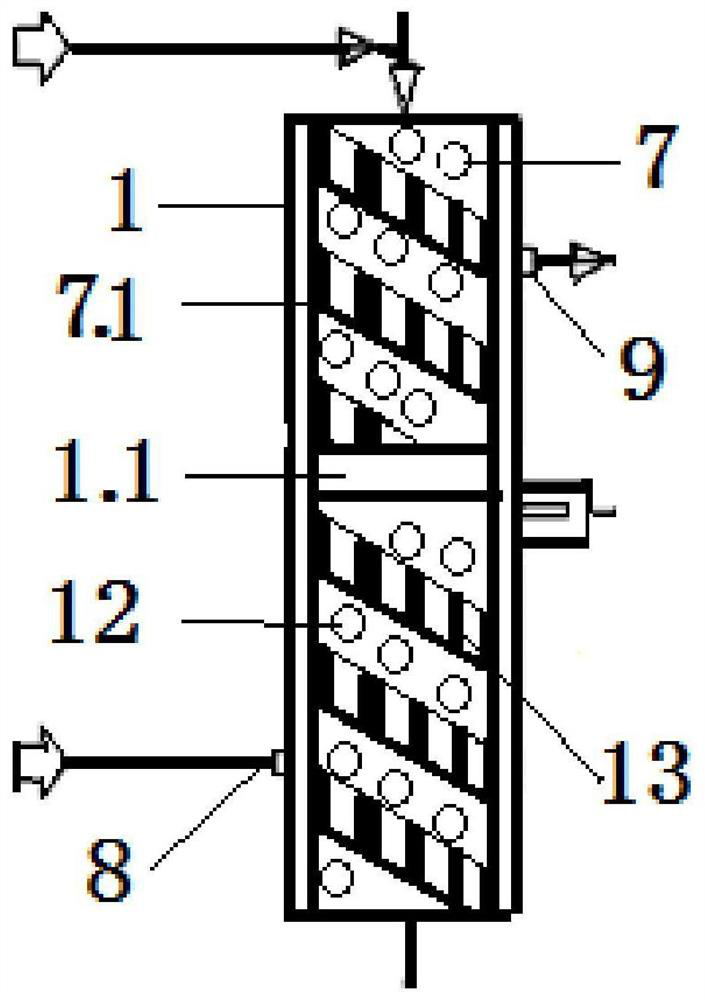

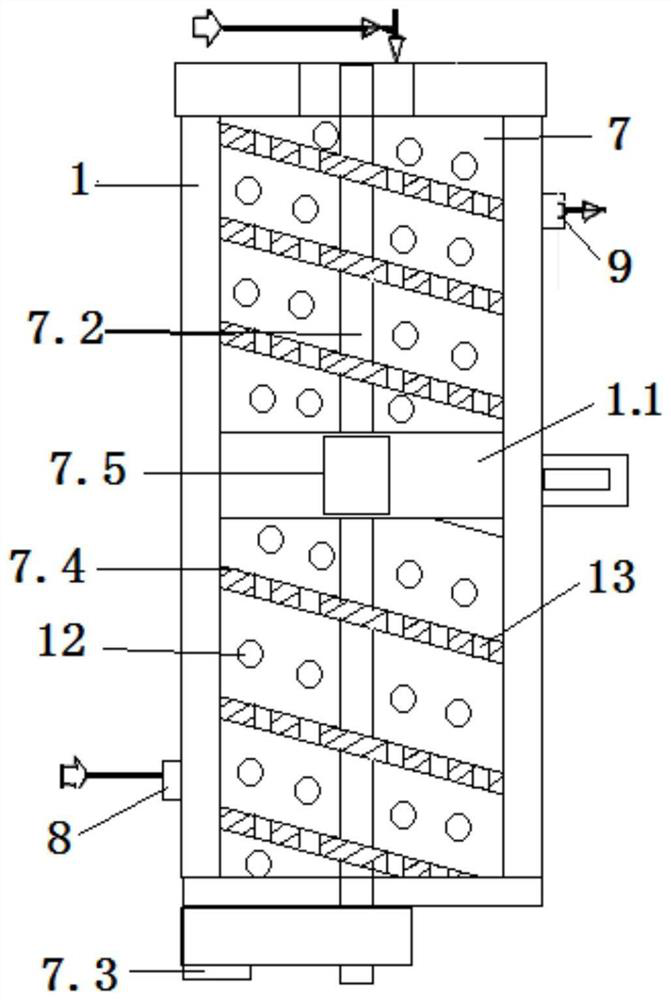

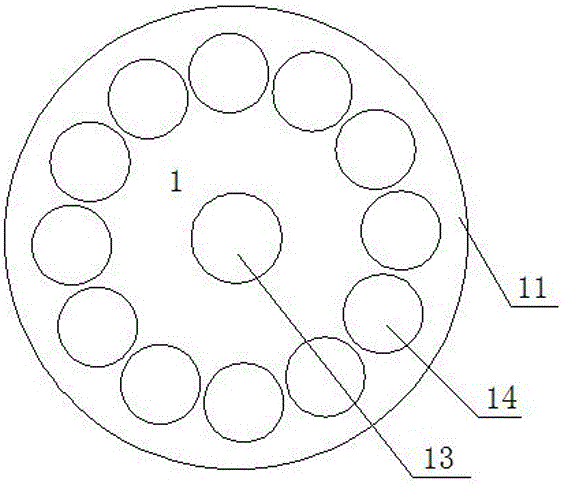

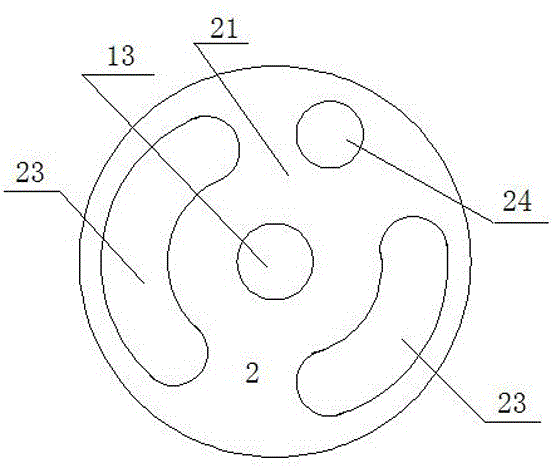

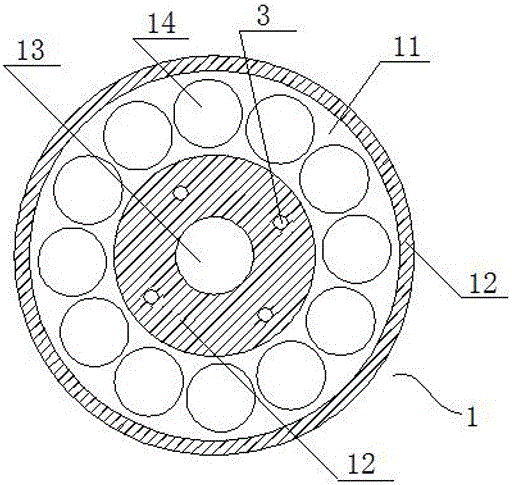

Integrated desulfurization and denitrification system for activated carbon

PendingCN113441007ALower the altitudeExtended absorption timeGas treatmentDispersed particle separationActivated carbonFlue gas

The invention discloses an integrated desulfurization and denitrification system for activated carbon. The integrated desulfurization and denitrification system comprises a booster fan, an adsorption tower, an activated carbon conveying device, an activated carbon desorption tower, an ammonia water supply device, an acid making device and a chimney which are connected in sequence, wherein a spiral conveying channel for activated carbon is arranged in the adsorption tower and is vertically arranged; a transverse smoke inlet channel communicating with the spiral conveying channel is arranged on one side of the adsorption tower; a transverse smoke exhaust channel communicating with the spiral conveying channel is arranged on the other side of the adsorption tower; the transverse smoke inlet channel is connected with the booster fan through a pipeline; the transverse smoke exhaust channel is connected with the chimney through a pipeline; and an ammonia gas conveying pipeline communicating with the spiral conveying channel is also arranged at the middle upper part of one side of the adsorption tower. According to the integrated desulfurization and denitrification system for activated carbon, activated carbon can fall at a constant speed in the absorption tower, time for absorption between the activated carbon and flue gas can be prolonged, a contact area between the activated carbon and flue gas is increased, and the overall height of the absorption tower can be reduced.

Owner:河北领阔环保科技有限公司

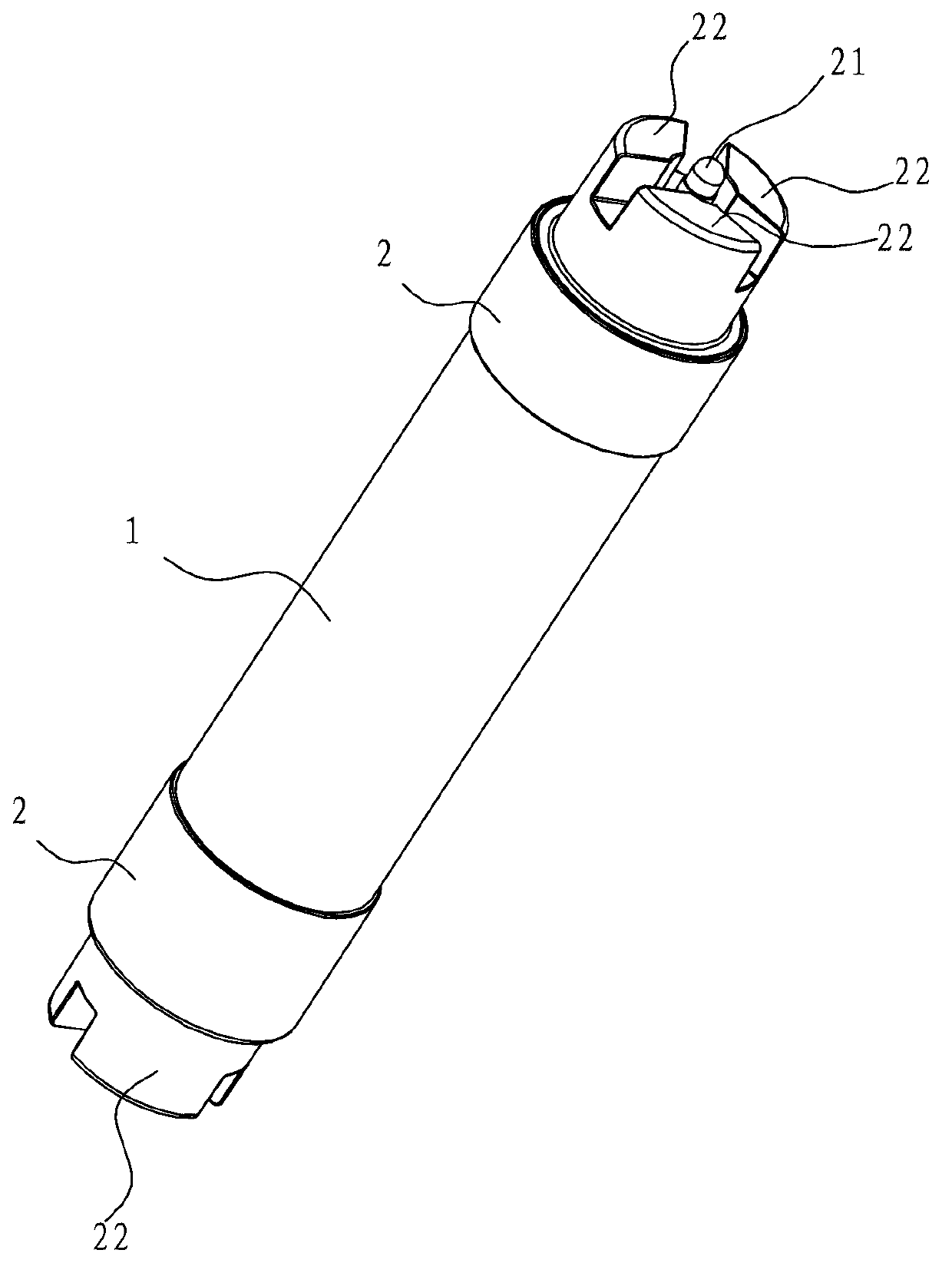

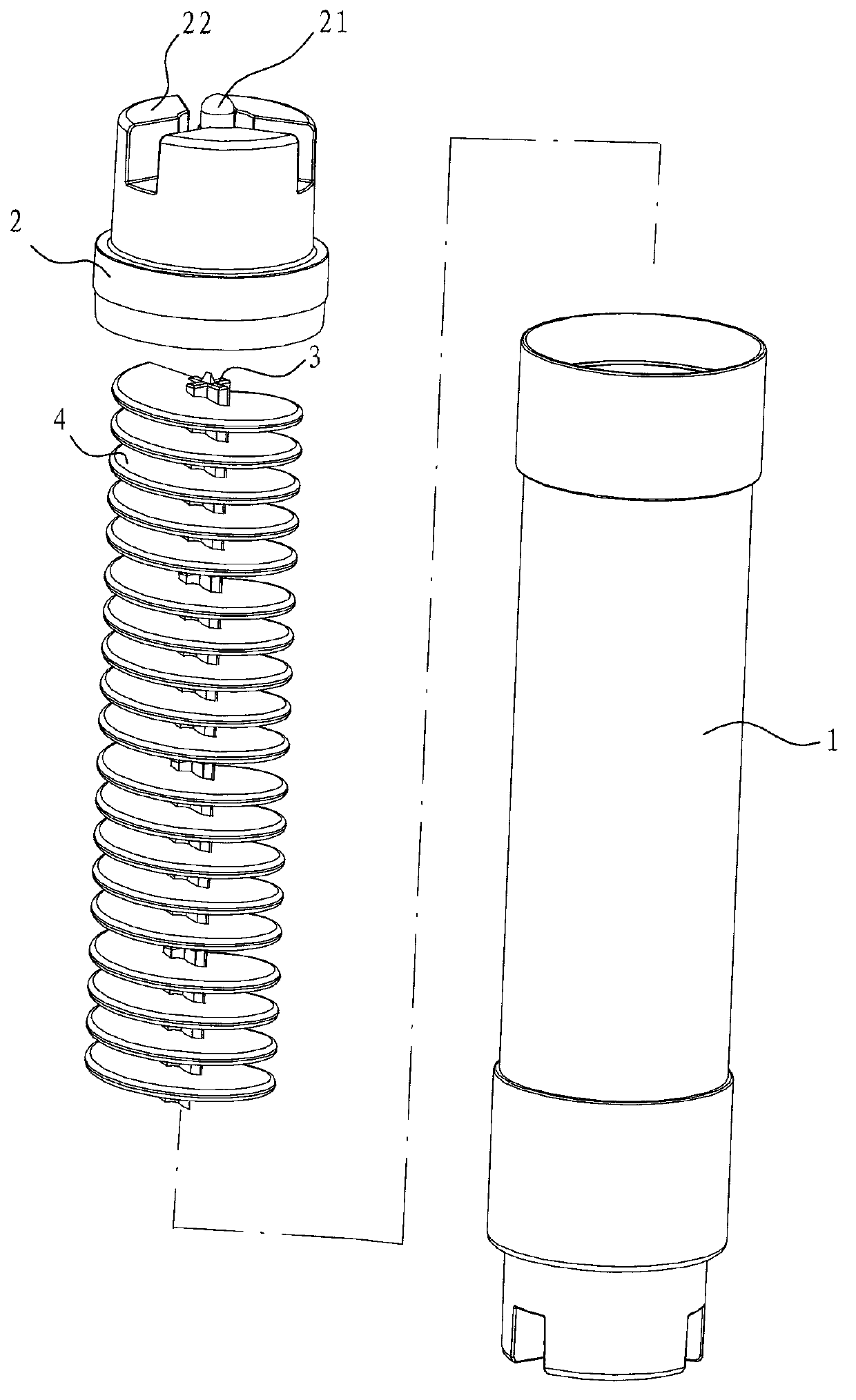

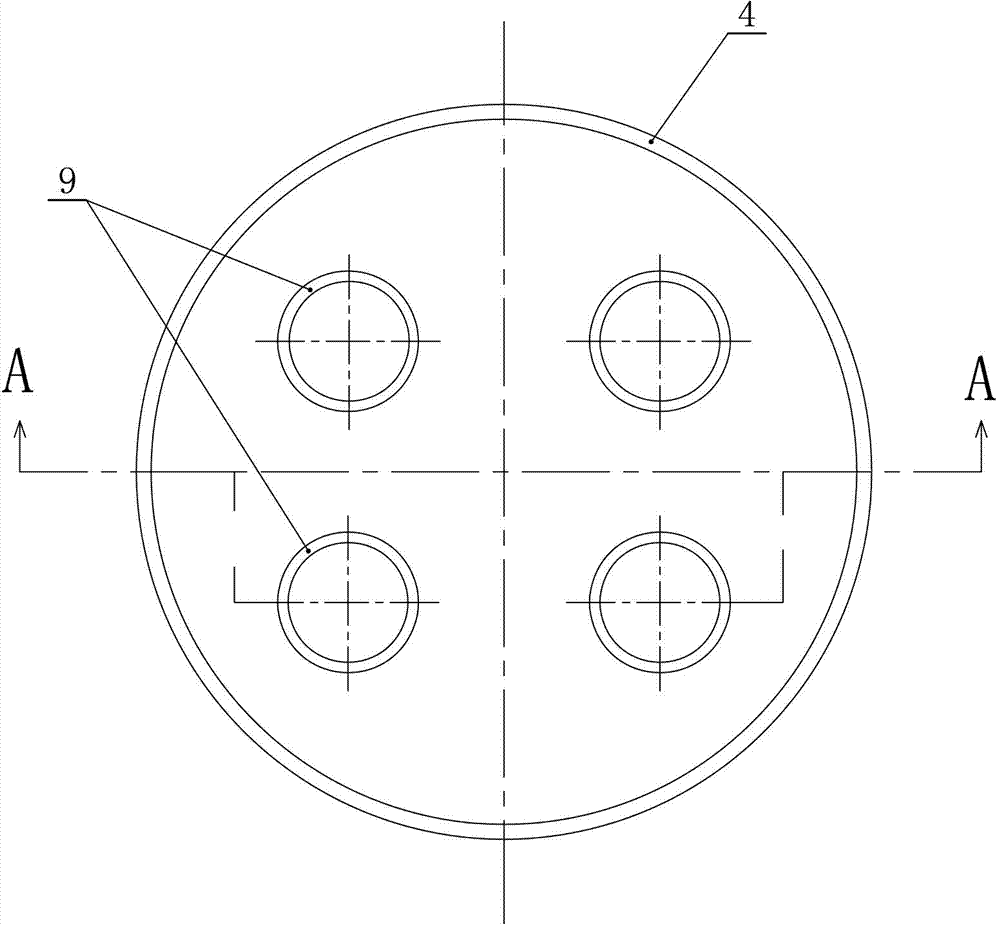

Distributing head of disk dewatering machine

PendingCN105833598AReduce contact areaImprove the finishMembrane filtersMoving filtering element filtersCircular discThermodynamics

The invention discloses a distributing head of a disk dewatering machine, wherein a rotating member is provided with a rotating part contact platform and rotating part sunk platforms; the rotating part contact platform is an annular platform which uses the center of the circle of a shaft of the dewatering machine as a center of a circle; the rotating part sunk platforms are arranged on the rotating member on the inner side and the outer side of the rotating part contact platform; a fixed member is provided with a fixed part contact platform and fixed part sunk platforms; the fixed part sunk platforms at least comprises areas, of which the widths are equal to the widths of slurry sucking grooves, between two slurry sucking grooves, and extend to positions which are 1 / 3 to 1 / 4 of the radius size of a flushing pipe away from the outer wall of the flushing pipe respectively along the size of the respective slurry sucking grooves and in a direction from the two slurry sucking grooves to the flushing pipe; the surfaces of the fixed part sunk platforms are sunk for 4mm to 6mm relative to the surfaces of the fixed part contact platforms. By using the distributing head of the disk dewatering machine, the adsorption efficiency is increased by 140 percent; the service life is greatly improved, thereby bringing the improvement of a dewatering effect and the prolonging of the service life of a disk piece and the service life of the whole machine; the economic benefit is extremely high; the distributing head of the disk dewatering machine has extremely wide application prospects in industrial and mining enterprises of a heat-engine plant, iron and steel, coal mining and the like, and is extremely high in popularization value.

Owner:ANHUI HUADIAN SUZHOU POWER GENERATION

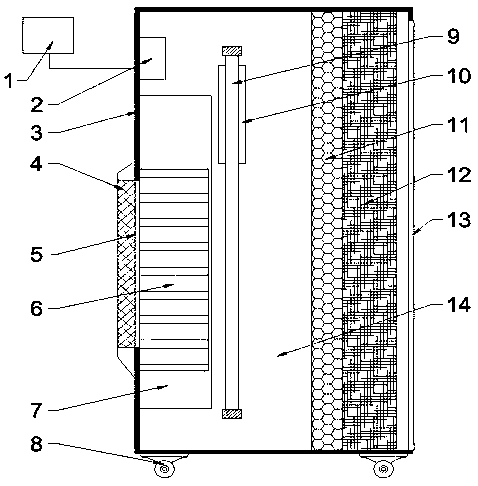

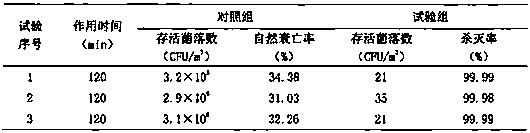

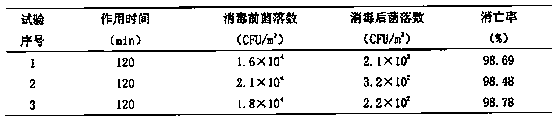

Air sterilizing-purifying method and device

PendingCN111306669AGuaranteed kill rateReduce generationMechanical apparatusLighting and heating apparatusLight irradiationUltraviolet lights

The invention discloses an air sterilizing-purifying method. The air sterilizing-purifying method is used for carrying out sterilizing and purifying operations on indoor air. According to the air sterilizing-purifying method, a one-way air duct equipped with a negative-pressure fan is utilized as an air treatment space; a cavity is arranged on the one-way air duct; on the air outlet side, an air pressure difference is formed between a filtering structure and the negative-pressure fan as well as utilized for sterilizing and purifying air through negative iron cloud which is formed by continuously-generated negative ions in the cavity; and during the sterilizing treatment process, bacteria and viruses are adsorbed and agglomerated, agglomerate aerogel is formed in the negative iron cloud, and then the filtering structure is utilized for adsorption. The invention further provides purifying equipment based on the above air sterilizing-purifying method. According to the purifying equipment,the negative ions are generated through the utilization of ultraviolet light irradiation and ionization, and favorable factors are provided for the sterilizing and purifying treatment of the negativeion cloud through structural optimization. The air sterilizing-purifying method has the beneficial effects that the sterilizing and purifying efficiency is high; the sterilizing cost is low; the effectiveness is rapid; and the man-machine symbiosis can be achieved in a closed indoor space.

Owner:上海紫骝医学科技有限公司

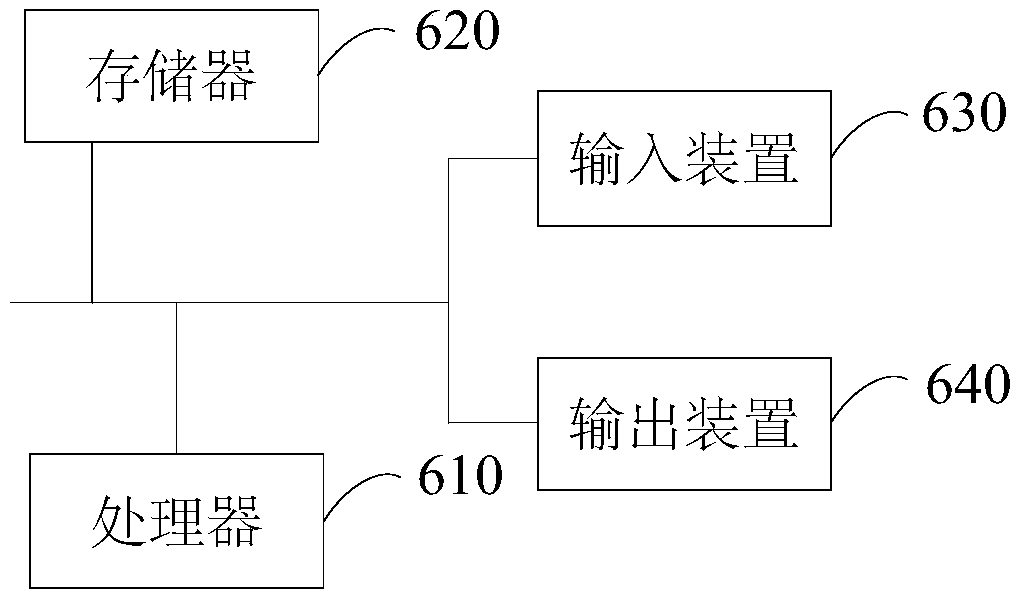

Storage device, pressure swing adsorption device optimization method, device and equipment

ActiveCN111375288AEasy to operateQuality improvementChemical property predictionGas treatmentMolecular sieveAdsorption equilibrium

The invention discloses a storage device, and pressure swing adsorption device optimization method, device and equipment. The method comprises the steps: establishing a mathematic simulation model ofa pressure swing adsorption device through employing an adsorption balance equation, a mass transfer rate equation and a total mass transfer balance equation, and setting parameter initial values needed by all directions; performing mathematical solution on the mathematical simulation model to obtain the hydrogen composition and flow of the product, and determining the specific penetration time according to the time required for the carbon monoxide and / or sulfide in the feed gas to penetrate through the special molecular sieve adsorption layer; determining whether the product hydrogen composition in the solving result meets a preset calculation requirement or not; and establishing a nonlinear programming model and solving the nonlinear programming model to obtain the optimal adsorption time of the pressure swing adsorption device. According to the method, the product hydrogen meeting the hydrogen demand of the special industry can be obtained on the premise of not increasing first-stage PSA or other hydrogen purification means, so that the economic benefits of enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Running water and secondary water-supply deep-purifying method and apparatus

InactiveCN1317201CExtend the adsorption timeImprove the degree of purificationWater/sewage treatment by irradiationWater/sewage treatment by magnetic/electric fieldsTextile fiberPurification methods

The invention is the deeply purification method of one kind of running water and second supplying water, its step is: Carries on the magnetization to the running water softens, causes to treat the treated water supposes in its reactor box in vivo which includes the activated charcoal textile fiber and separates in the section which does back and forth flows when completes adsorption processing, finally through separates between the section alternate permutation ultraviolet lamp and pore aeration which causes the treated water back and forth in the mobile process and completes the adsorption archery target decomposes, finally completes a higher-level purification. This invention includes one kind of refining equipment, its characteristic is induction pipe and the wrap which set the magnetism link, the box body cavity establishes the stainless steel partition board and the thick hole stainless steel mesh which composes separate section, through the slot activity connection, the reactor box body sidewall as well as respectively separates between the section is loaded with the pore aeration head, between various pores aeration is loaded with ultraviolet lamp tube.

Owner:曹成

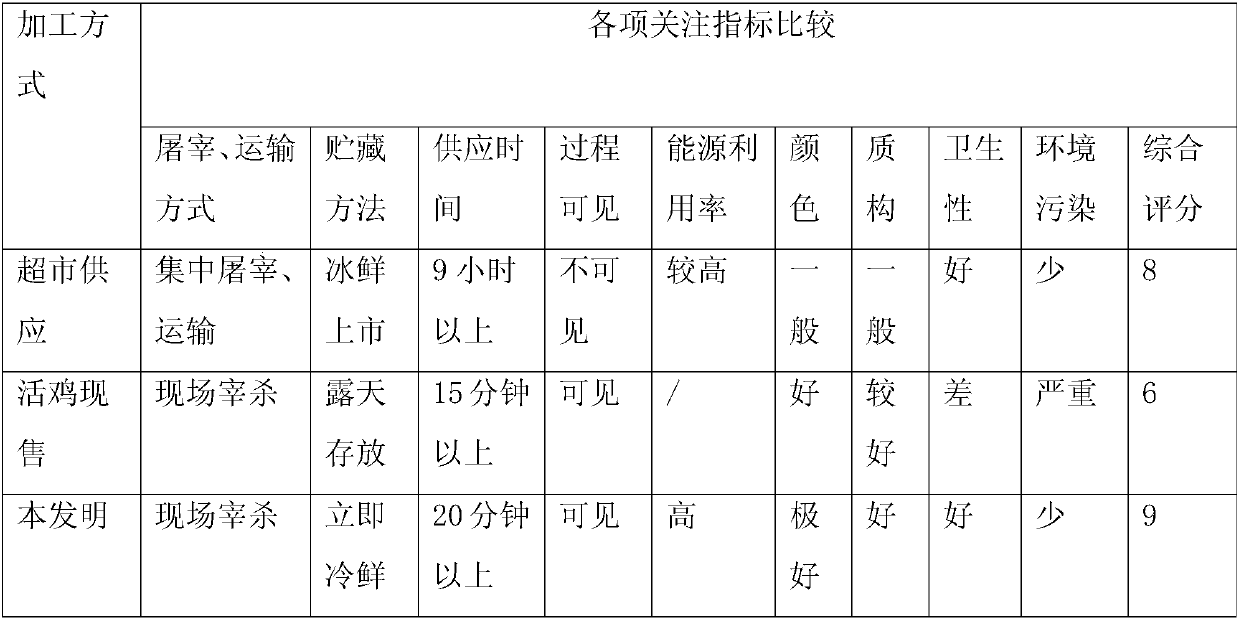

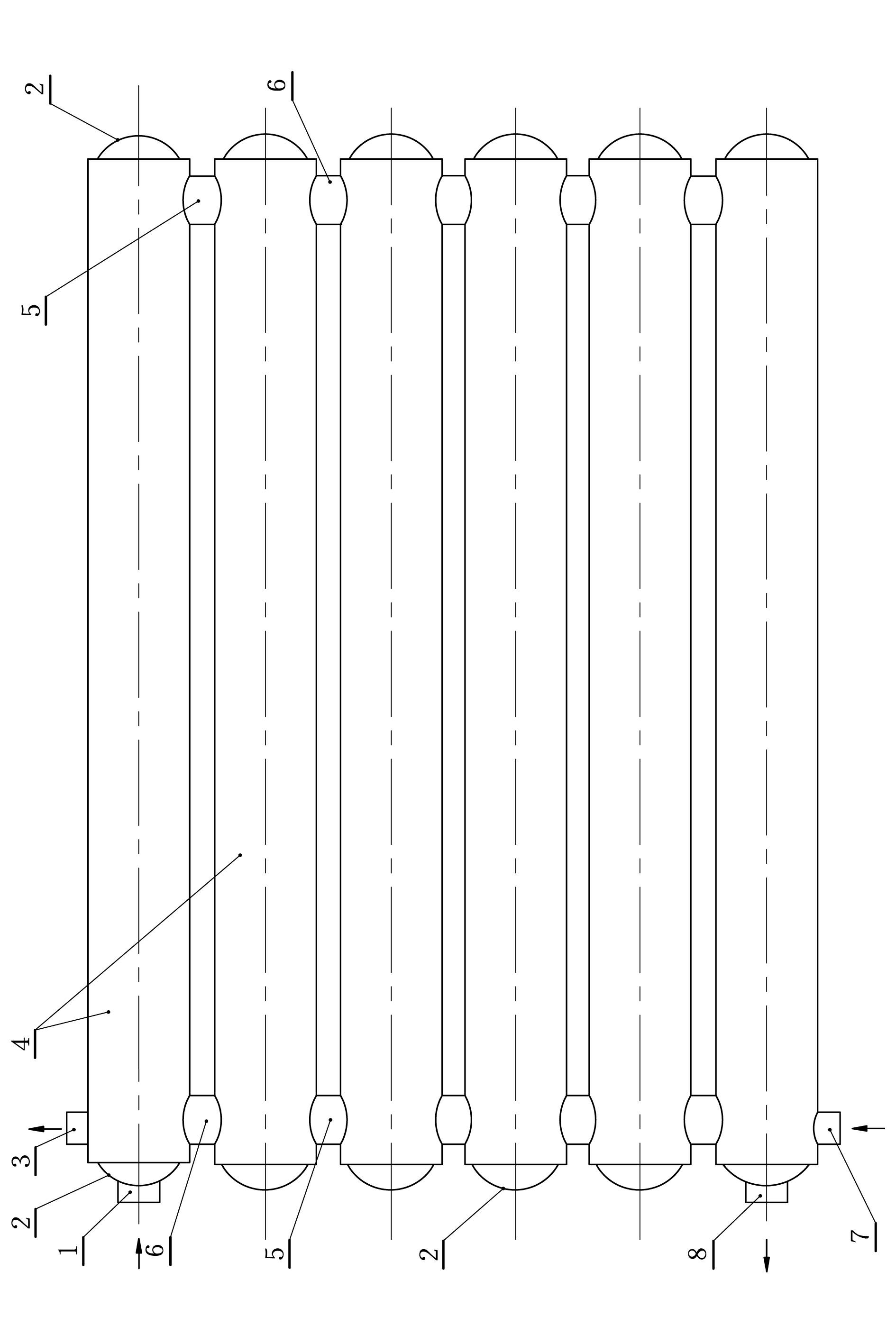

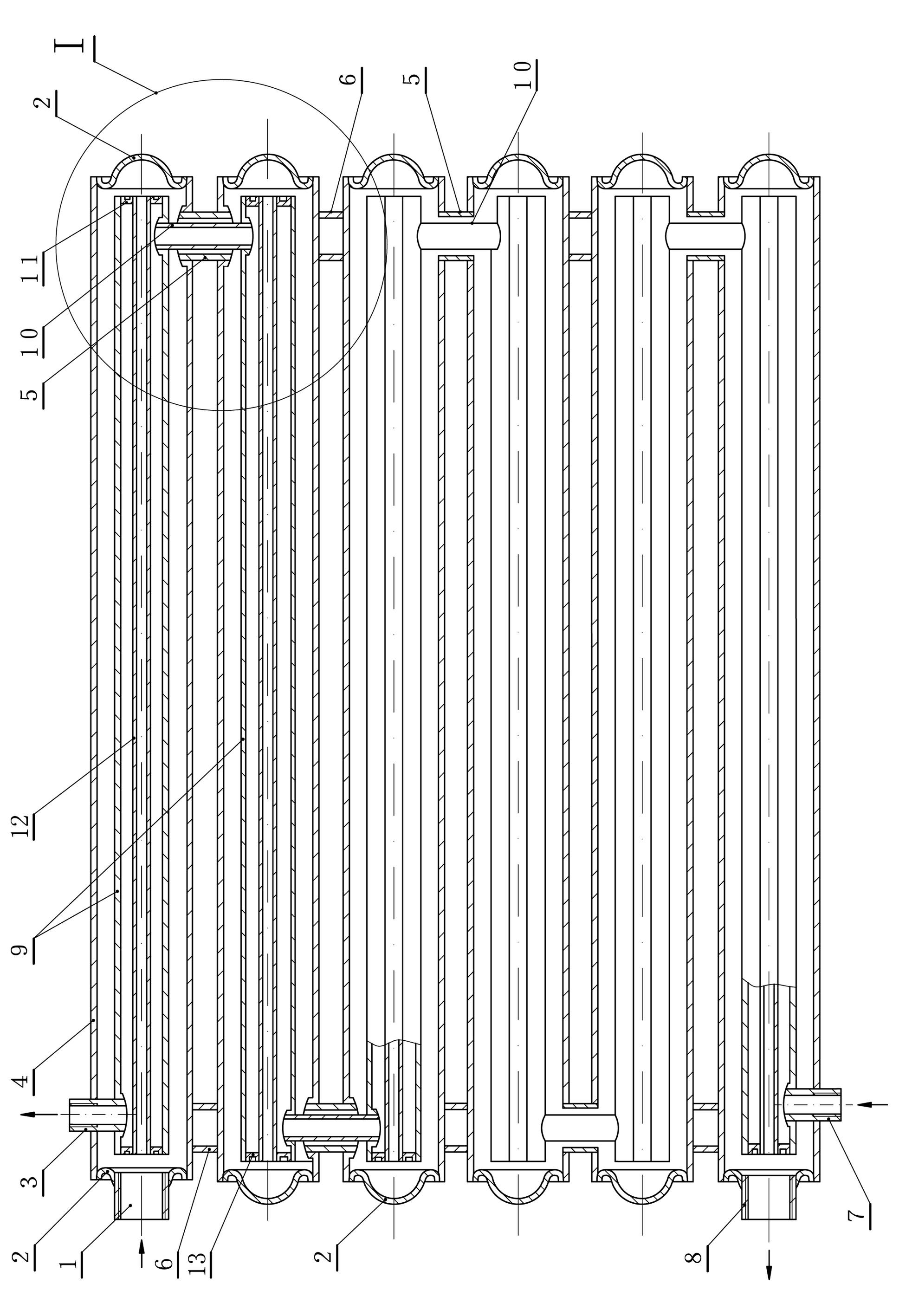

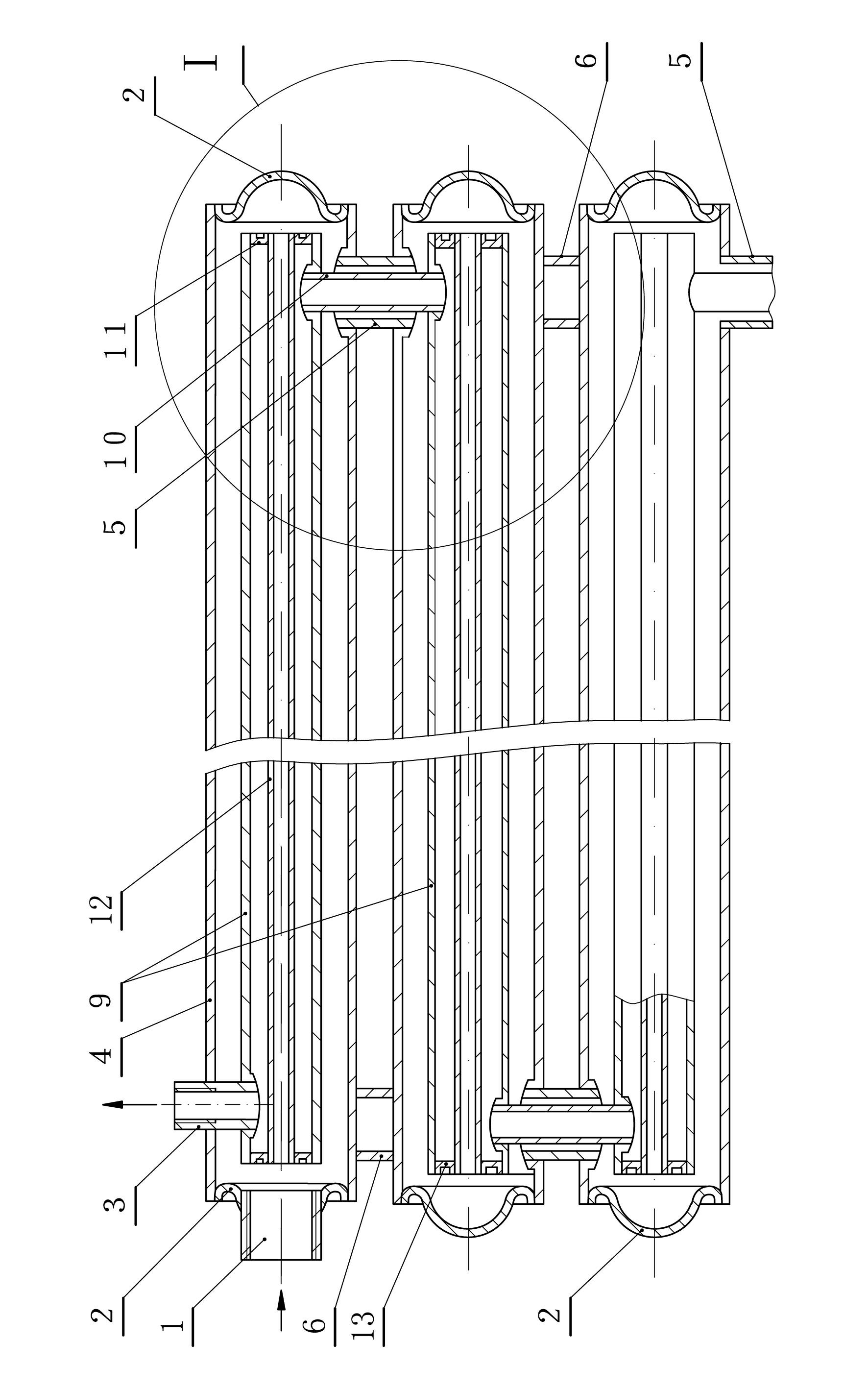

Self-selection type poultry product freshness retaining device and use method

ActiveCN107751342ACompact structureEasy to buyDispersed particle separationMeat/fish preservation by freezing/coolingPoultry productWastewater

The invention relates to a self-selection type poultry product freshness retaining device and a use method. The self-selection type poultry product freshness retaining device comprises a rectangular box body, wherein a condensing pipe connected with a compressor is arranged on the inner side of the side wall; a partition is arranged in the box body, and divides the interior of the box body into anair return region and a working region; an air supply opening and an air suction opening are formed in the partition; a fan located between the air supply opening and the air suction opening is arranged in the air return region; a curved rotary frame and a wind shield arranged in the longitudinal direction of the box body are arranged in the working region; a filter plate assembly capable of adsorbing flavor is arranged in the air return region; multiple adsorption bodies capable of adsorbing the flavor and sterilization lamp devices capable of killing poultry carcass bacteria are arranged inthe working region; a controller is arranged outside the box body; a wastewater discharging purifier is arranged at the inner bottom of the box body; moving pulleys are arranged at the bottom of thebox body. The self-selection type poultry product freshness retaining device can realize fast cooling of poultries killed at site, also kill pathogens carried by carcasses and eliminate fishy smell and peculiar smell.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Pure natural vegetable insecticide and preparation method thereof

InactiveCN106922760AImprove insecticidal effectReduce dosageBiocideAnimal repellantsAdditive ingredientPassion fruit

The invention provides a pure natural vegetable insecticide and a preparation method of the pure natural vegetable insecticide. The pure natural vegetable insecticide comprises the following ingredients by weight: 20-30 parts of black false hellebore, 8-13 parts of radix sophorae flavescentis, 12-15 parts of eucalyptus leaf, 2-5 parts of tobacco leaf, 1-3 parts of radix stemonae, 30-40 parts of rose willow floral leaf, 1-2 parts of surfactant, 0.4-0.8 part of sulfated castor oil, 0.00001-0.00002 part of microcrystalline cellulose, 0.2-0.4 part of passion fruit, and 10-15 parts of bitter gourd. The pure natural vegetable insecticide has the beneficial effects that: the pure natural vegetable insecticide has a good insecticidal effect, and gives out a smell hated by the insect to play a role in preventing; the pure natural vegetable insecticide acts for a long period of time, then the planting cost is reduced; the pure natural vegetable insecticide promotes the growth of plants, shortens the growing period of the plants, increases the volume of vegetables, the fruiting rate of a fruit tree and the yield; no pollution or residue is caused, no drug resistance is produced, and the use amount of the pure natural vegetable insecticide is not increased even for long term use.

Owner:嵊州市派特普科技开发有限公司

Heat-transfer heat exchanger with double-channel heat supply pipes and production process of heat-transfer heat exchanger with double-channel heat supply pipes

ActiveCN102564171AIncrease heat transfer areaIncreased turbulenceStationary tubular conduit assembliesProcess engineeringHeat transfer efficiency

The invention relates to a heat-transfer heat exchanger with double-channel heat supply pipes and a production process of the heat-transfer heat exchanger with the double-channel heat supply pipes. The heat-transfer heat exchanger comprises two or more outer heat supply pipes. An outer heat supply pipe seal is fixedly connected to the end of each outer heat supply pipe, a tap water heat absorption pipe is arranged in each outer heat supply pipe, the heat supply pipes are communicated with one another through heat supply pipe communication pipes, and the tap water heat absorption pipe are communicated with one another through water tap communication pipes. A hot air inlet and a hot air outlet are fixedly communicated with an inlet end and an outlet end of the outer heat supply pipes respectively, a tap water inlet and a tap water outlet are fixedly communicated with an inlet end and an outlet end of the tap water heat absorption pipes respectively, part or all of tap water heat absorption pipes are provided with inner heat supply pipes which are communicated with cavities of the outer heat supply pipes. By means of double-channel reverse-flow type convective heat transfer with the inner and outer heat supply pipes, heat transfer area is widened, heat transfer efficiency is improved, and hot water at a temperature higher than 38 DEG C can be outputted continuously for a long time without stopping. The heat-transfer heat exchanger with the double-channel heat supply pipes belongs to updated products.

Owner:张伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com