Sucking disc device used for transferring semi-conductor crystal grains on graphite boat

A semiconductor and graphite boat technology, applied in the field of diode production tools, can solve the problems of small semiconductor grain size, increased operating frequency, long grain adsorption time, etc., and achieves the reduction of operating requirements, avoiding offset, and saving time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

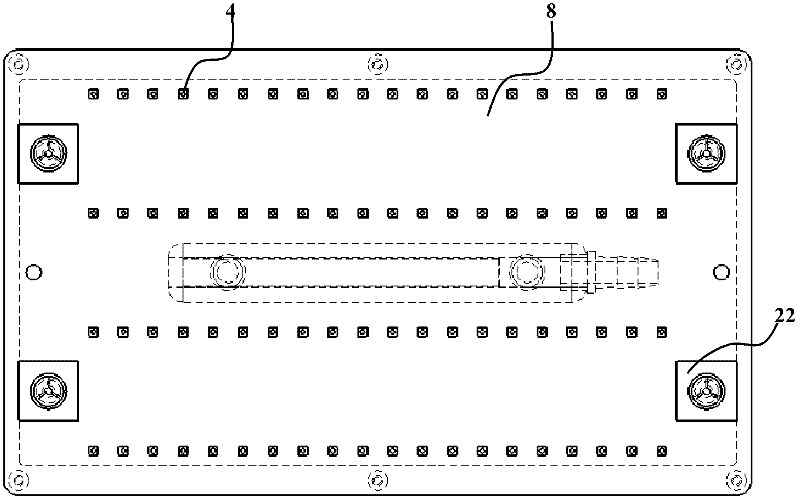

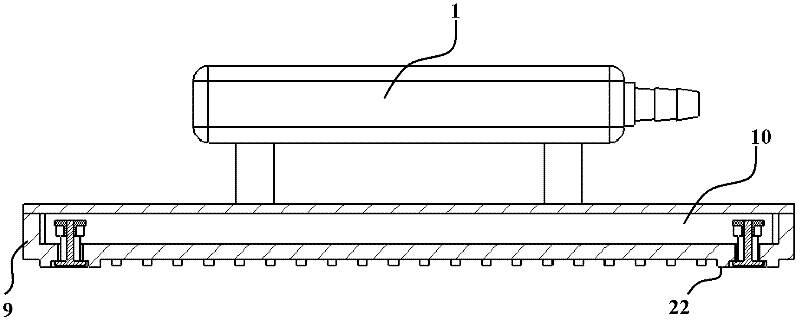

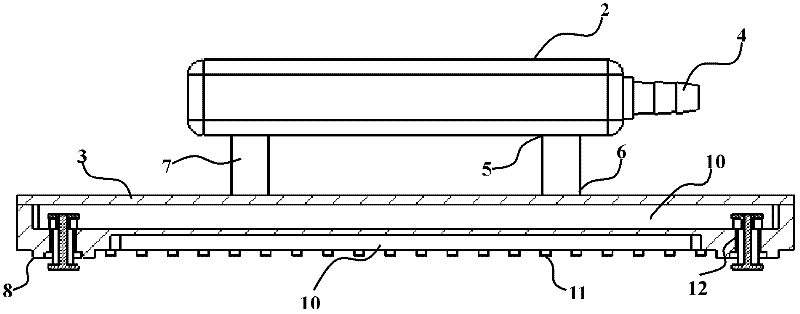

[0030] Embodiment: a kind of sucker device that is used to transfer semiconductor crystal grain on graphite boat, and described graphite boat has the grain groove that places semiconductor crystal grain, and described sucker device comprises: the handle 2 that is provided with first cavity 1 inside and a cover plate 3, one end of the handle 2 is provided with an air nozzle 4 communicating with the first cavity 1, and the lower surface of the handle 2 is provided with at least one first air hole 5 communicating with the first cavity 1, The cover plate 3 is provided with a second vent hole 6 corresponding to the first vent hole 5, and a gas connecting pipe 7 communicates with the first vent hole 5 and the second vent hole 6; a bottom plate 8 is installed on the The lower surface of the cover plate 3, the bottom plate 8 and the cover plate 3 form a second cavity 10 communicated with the first cavity 1 through the side plate 9, and the bottom plate 8 is provided with several holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com