Preparation method of nickel-modified calcium-based dual-functional particles

A dual-function, nickel-modified technology, applied in chemical instruments and methods, other chemical processes, physical/chemical process catalysts, etc., can solve the problems of low hydrogen yield and complex preparation process, and meet high equipment requirements and equipment requirements. No, the effect of large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

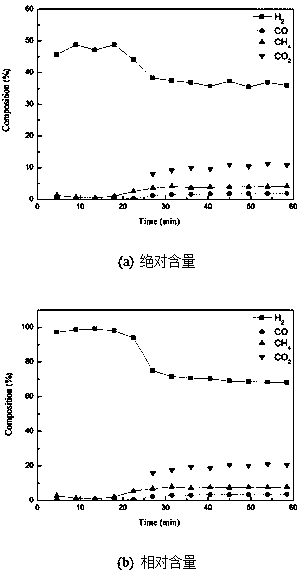

Embodiment 1

[0022] Weigh 9.42g of calcium acetate, 0.45g of nickel nitrate and 5.62g of citric acid, add distilled water and stir to dissolve them completely, keep stirring the solution at 100°C and dry it, then calcinate at 900°C for 3 hours and crush to obtain 24-50 mesh nickel Modified calcium-based bifunctional particles, wherein the mass of Ni in the nickel-modified calcium-based bifunctional particles accounts for 15% of the mass of CaO. In the adsorption-enhanced ethanol steam reforming hydrogen production reaction, 1.19 g of this bifunctional particle was used as a catalyst, and the space velocity of ethanol was 20 h -1 , the water-to-carbon ratio is 3:1, the reaction pressure is 0.1MPa, the pre-reduction temperature is 700°C, and the reaction temperature is 600°C.

Embodiment 2

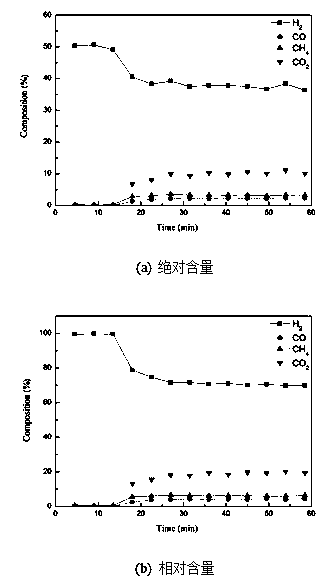

[0027] Weigh 9.42g of calcium acetate, 0.6g of nickel nitrate and 5.62g of citric acid, add distilled water and stir to dissolve them completely, keep stirring the solution at 120°C and dry it, then calcinate at 1100°C for 5 hours and crush to obtain 24~50 mesh nickel Modified calcium-based bifunctional particles, wherein the mass of Ni in the nickel-modified calcium-based bifunctional particles accounts for 10% of the mass of CaO. In the adsorption-enhanced ethanol steam reforming hydrogen production reaction, 1.19 g of this bifunctional particle was used as a catalyst, and the space velocity of ethanol was 55 h -1 , the water-to-carbon ratio is 5:1, the reaction pressure is 0.2MPa, the pre-reduction temperature is 700°C, and the reaction temperature is 500°C.

Embodiment 3

[0029] Weigh 9.42g of calcium acetate, 0.3g of nickel nitrate and 5.62g of citric acid, add distilled water and stir to dissolve them completely, keep stirring the solution at 80°C and dry it, and then calcined at 700°C for 2 hours and crush to obtain 24~50 mesh nickel Modified calcium-based bifunctional particles, wherein the mass of Ni in the nickel-modified calcium-based bifunctional particles accounts for 10% of the mass of CaO. In the adsorption-enhanced ethanol steam reforming hydrogen production reaction, 1.19 g of this bifunctional particle was used as a catalyst, and the space velocity of ethanol was 11 h -1 , the water-to-carbon ratio is 1.5:1, the reaction pressure is 0.3MPa, the pre-reduction temperature is 700°C, and the reaction temperature is 500°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com