Patents

Literature

57results about How to "Ease of large-scale industrial application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High silicon Y-type zeolite containing rare-earth and its preparing method

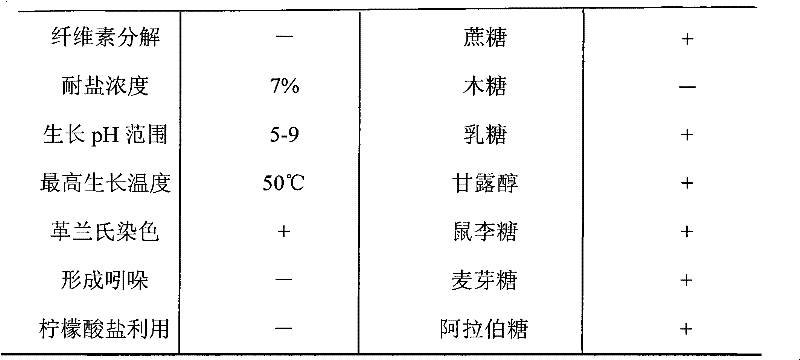

ActiveCN1281493CThe initial unit cell constant is smallThe equilibrium cell constant is largeFaujasite aluminosilicate zeoliteGasolineRare earth

A rare-earth-containing high-silicon Y-type zeolite, the zeolite contains rare earths, is characterized in that the silicon-aluminum ratio of the zeolite is 5-30, the initial unit cell constant is 2.430-2.465 nanometers, and the balance unit cell constant and the initial unit cell constant The ratio is at least 0.985. The zeolite has the characteristics of small initial unit cell constant and large equilibrium unit cell constant. It has high structural stability and hydrothermal stability. The cracking catalyst containing this zeolite is not easy to deactivate. The choice of gasoline, diesel oil, dry gas and coke Good sex.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for processing and separate-recycling printing and dyeing wastewater

InactiveCN101293726AEasy to handleQuick reuseTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentUltrafiltrationAnaerobic reactor

The invention discloses a method for processing and separate recycling of printing and dyeing wastewater, which comprises the following steps: after the printing and dyeing wastewater is firstly processed by an anaerobic reactor, a hypoxia reactor and an aerobic reactor, the separate recycling of part of the water is used for a desizing process of printing and dyeing technology; then, after the rest wastewater is processed by an aerator biofilter, the separate recycling of the part of the water is used for a boiling-off process of the printing and dyeing technology; then, after the rest wastewater is processed by an ultrafiltration reactor, the separate recycling of the part of the water is used for bleaching process and mercerization process of the printing and dyeing technology; finally, the rest water is processed by an anti-permeability reactor and the separate recycling of the part of the water is used for dyeing process, printing process and ordering process. After being processed by the invention, the printing and dyeing wastewater can be carried out the separate recycling quickly and high-efficiently and the recycling rate of the wastewater reaches more than 70 percent; meanwhile, the fee of processing and recycling the wastewater can be saved; the service life of advanced treatment equipment can be prolonged, which is easy for a large-scale industrialized application.

Owner:NANJING UNIV

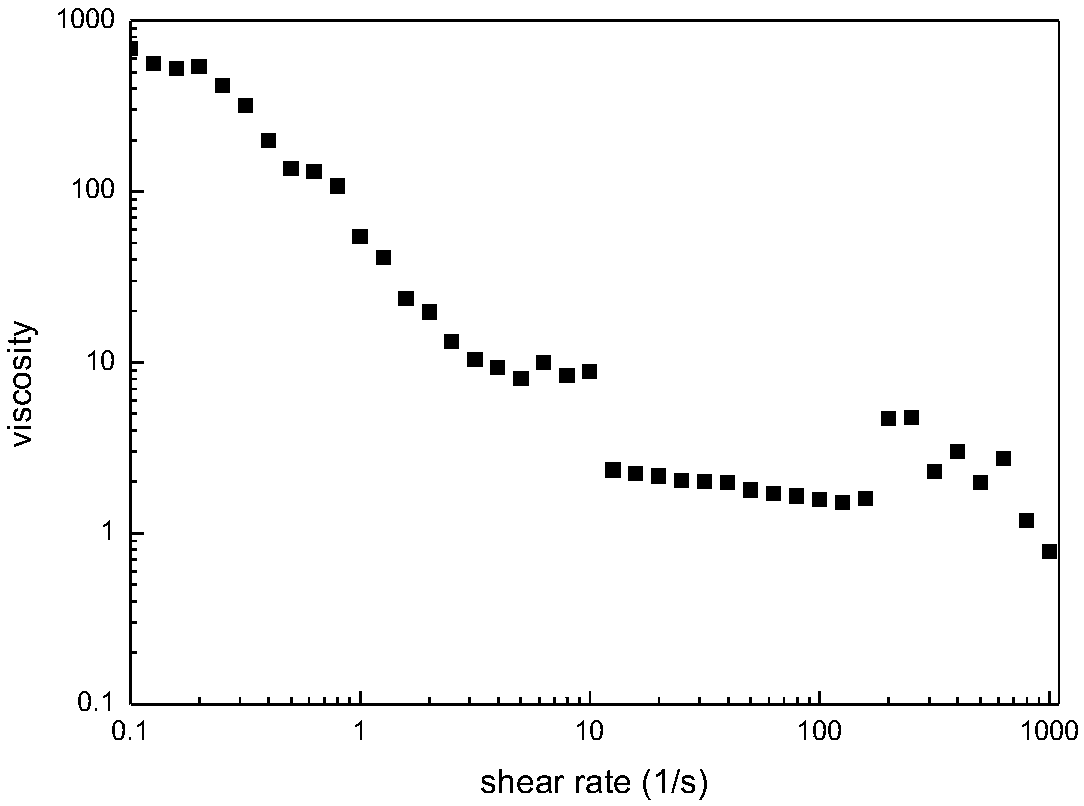

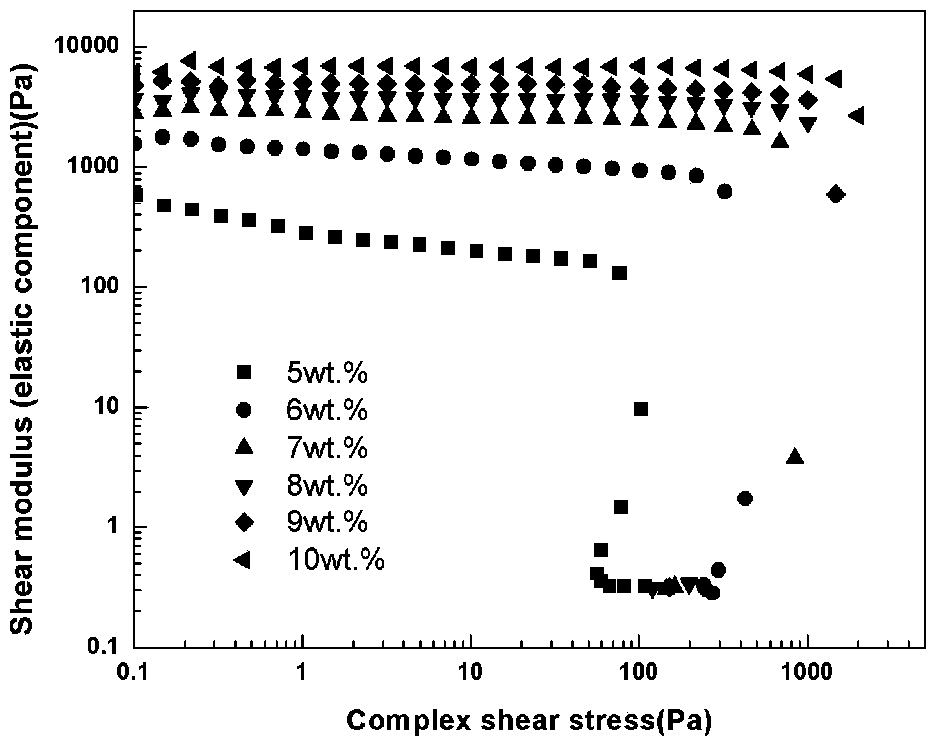

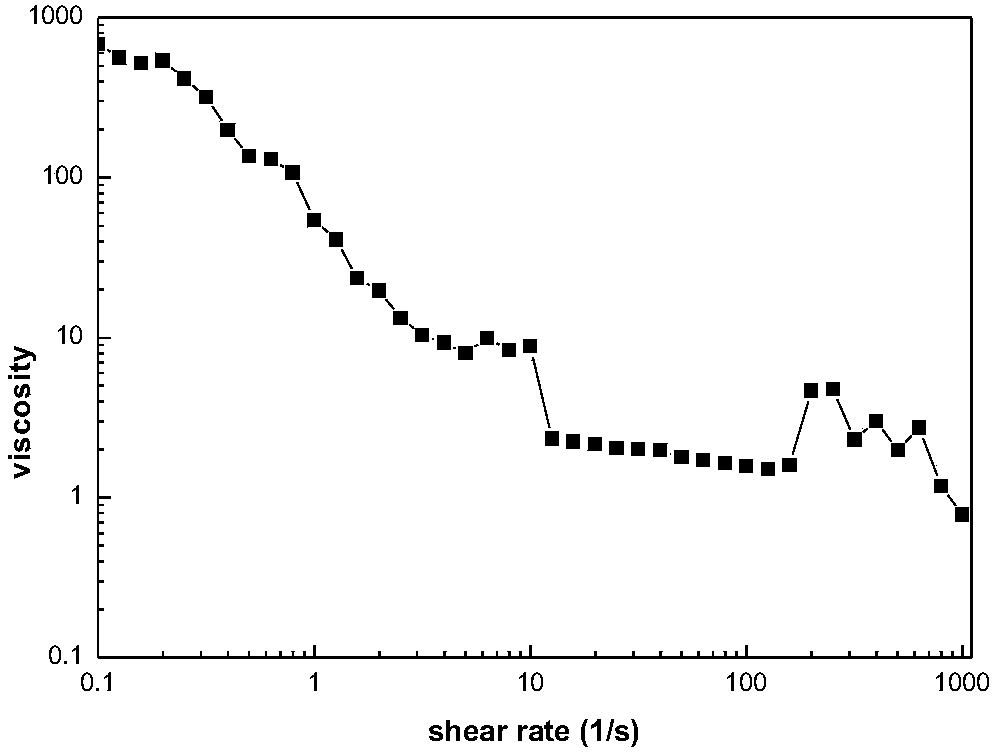

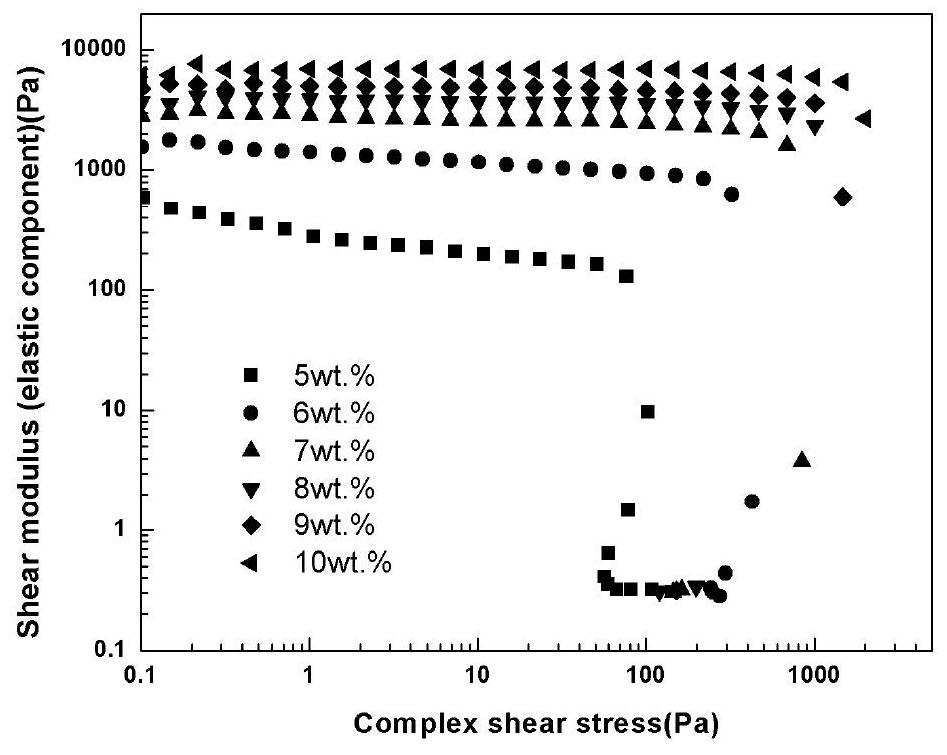

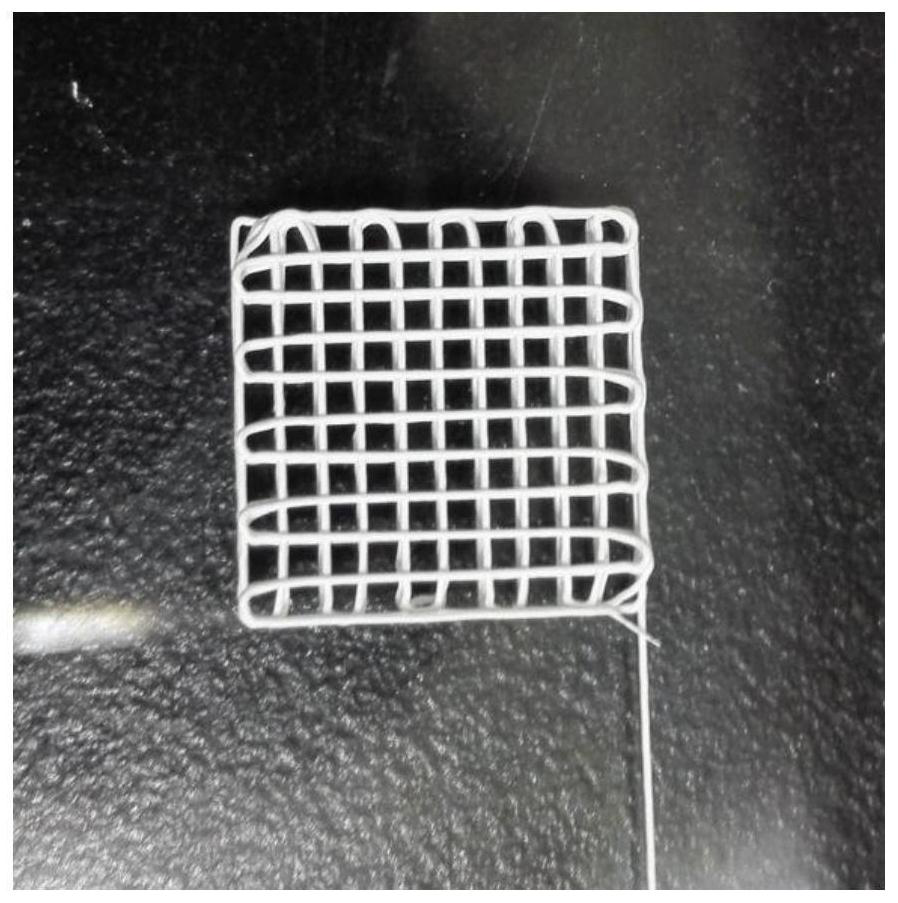

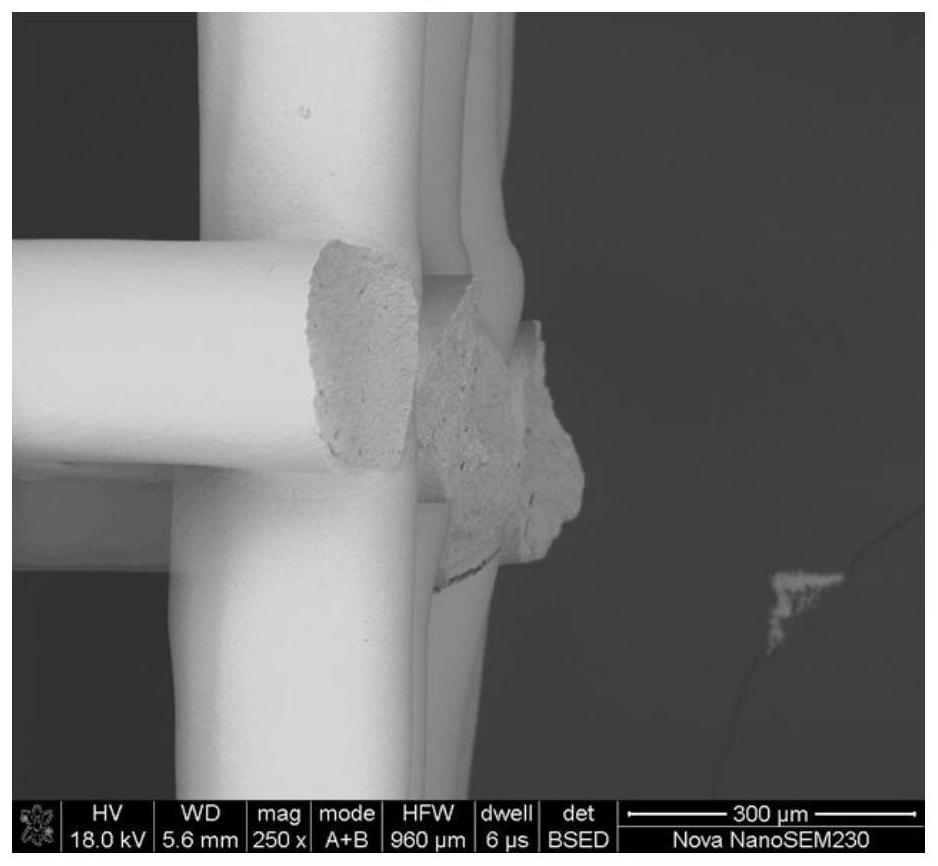

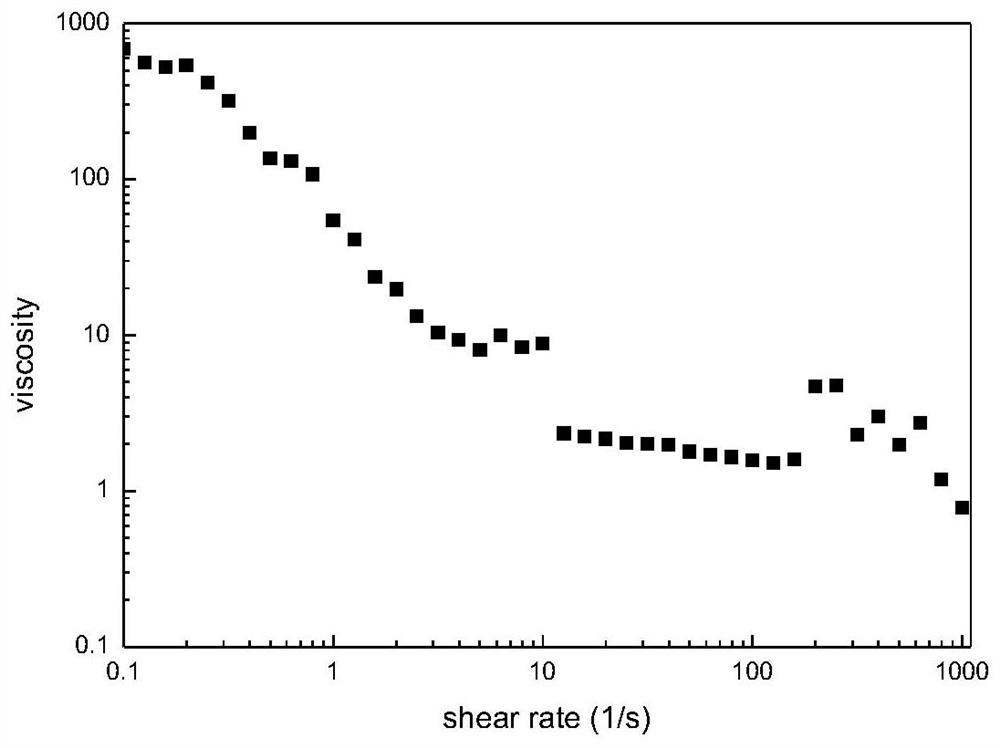

3D direct writing zirconium oxide ceramic ink

The invention relates to 3D direct writing zirconium oxide ceramic ink, which comprises zirconium oxide particles, a solvent, a binder, a dispersant and a salt, wherein the particle size of the zirconium oxide particles is 0.1-2 [mu]m, the solid content of the zirconium oxide particles in the ink is 40-58 vol%, the dispersant is one or a variety of materials selected from polyacrylic acid, polyvinyl acid, ammonium polyacrylate, polyvinyl acid salt, polyacrylate, polycarboxylate and polyacetyl imine, the dispersant accounts for 0.1-2% of the mass of the zirconium oxide particle dry powder, andthe salt is one or a variety of materials selected from ammonium chloride, zinc acetate, sodium chloride, magnesium chloride, potassium chloride, barium chloride, ammonium bicarbonate, anhydrous calcium chloride, potassium carbonate, sodium bicarbonate, sodium carbonate, anhydrous sodium carbonate, anhydrous sodium acetate, anhydrous calcium chloride, copper sulfate, basic copper carbonate, ammonium sulfate, ammonium bicarbonate, potassium aluminum sulfate and sodium citrate, and accounts for 0.001-0.1% of the mass of the ink. According to the present invention, the 3D direct writing zirconiumoxide ceramic ink can be printed at the room temperature, has high solid content while can flow out of the fine spraying nozzle and cannot cause the clogging, can be quickly cured into the fine wirewith a certain strength, and has good rheological property.

Owner:CENT SOUTH UNIV

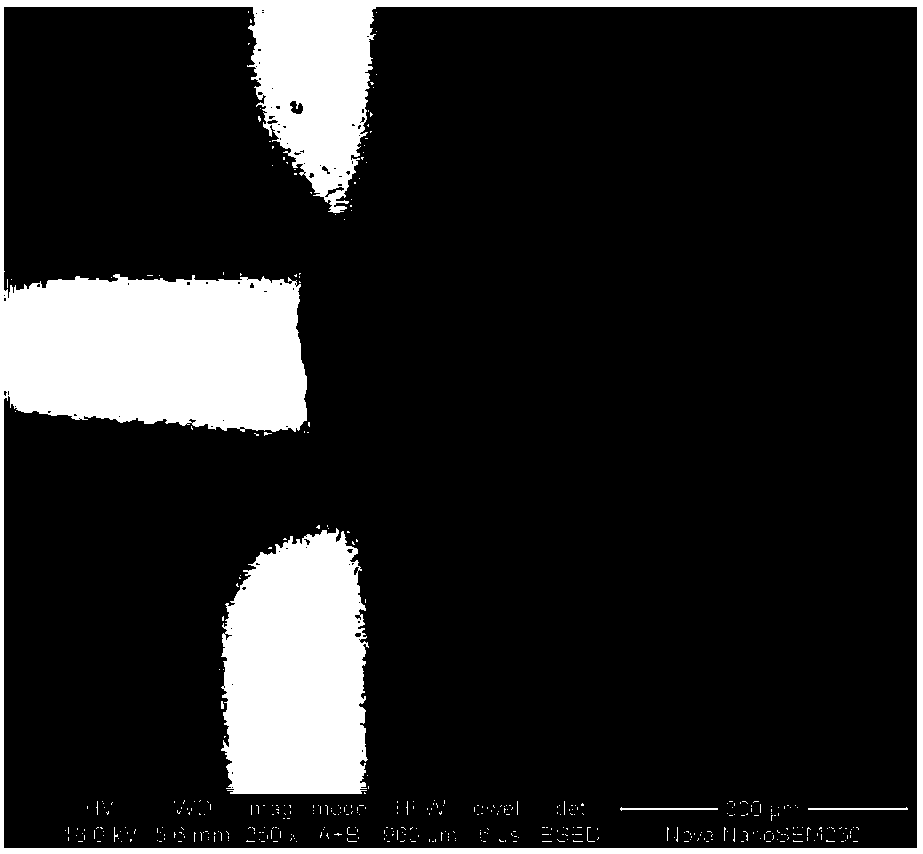

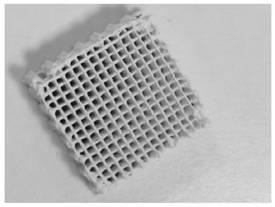

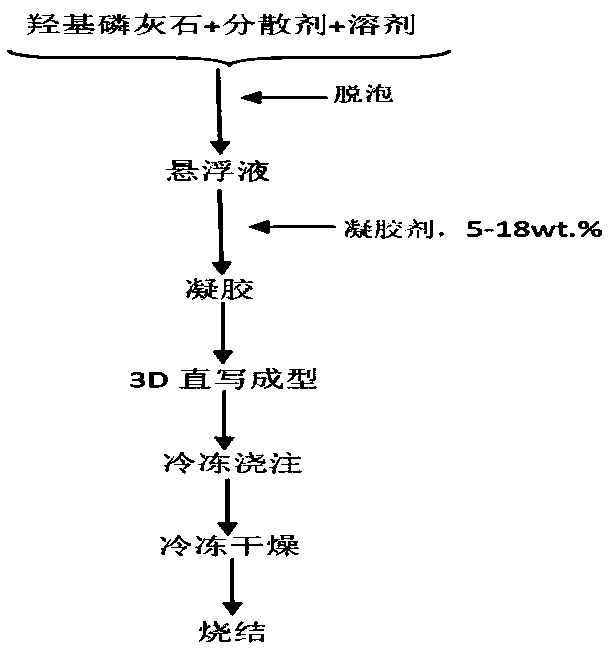

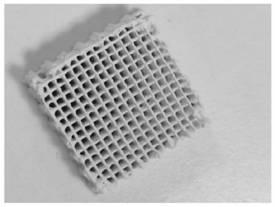

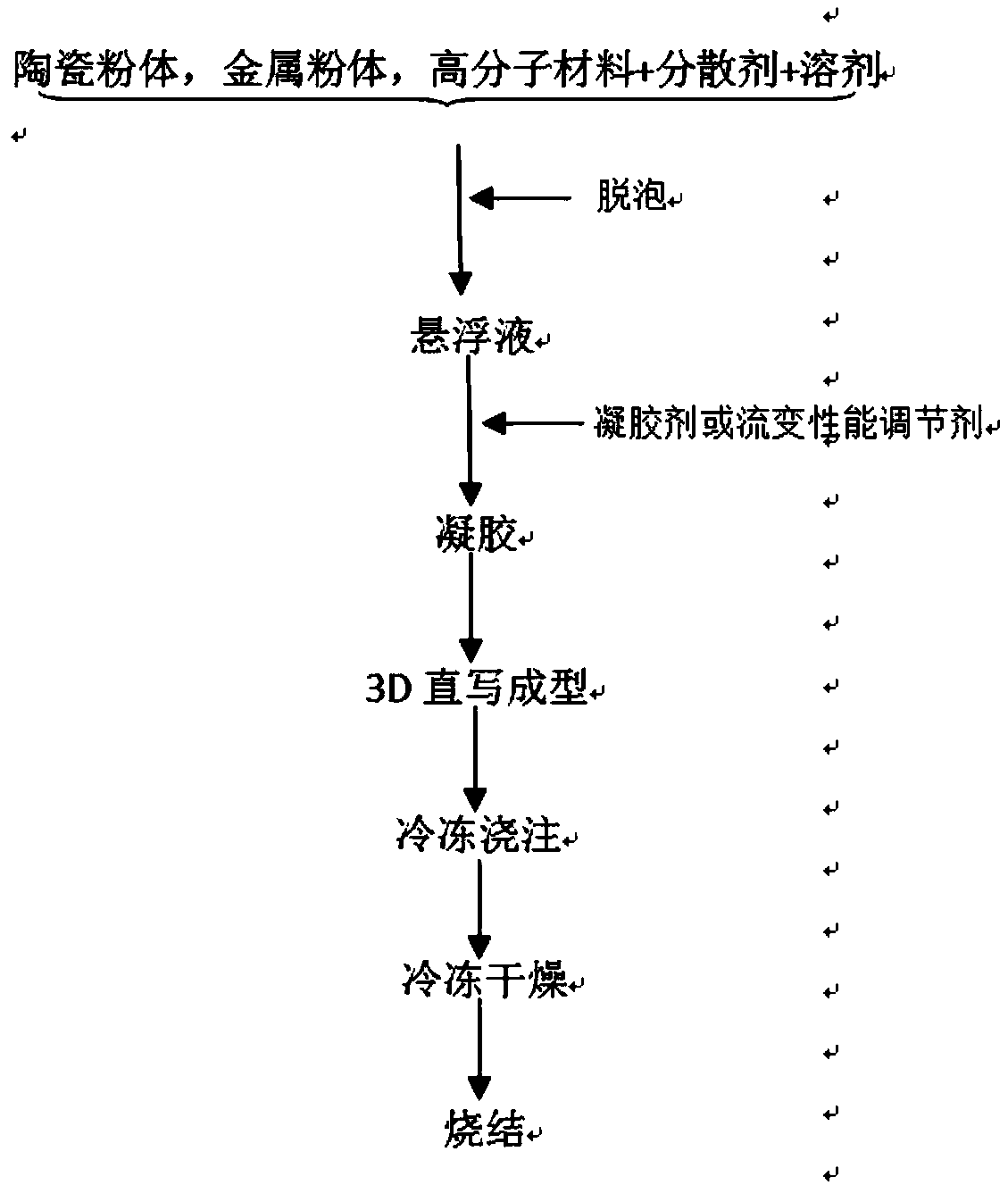

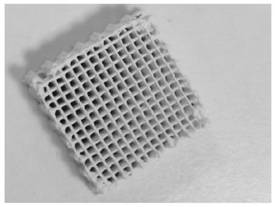

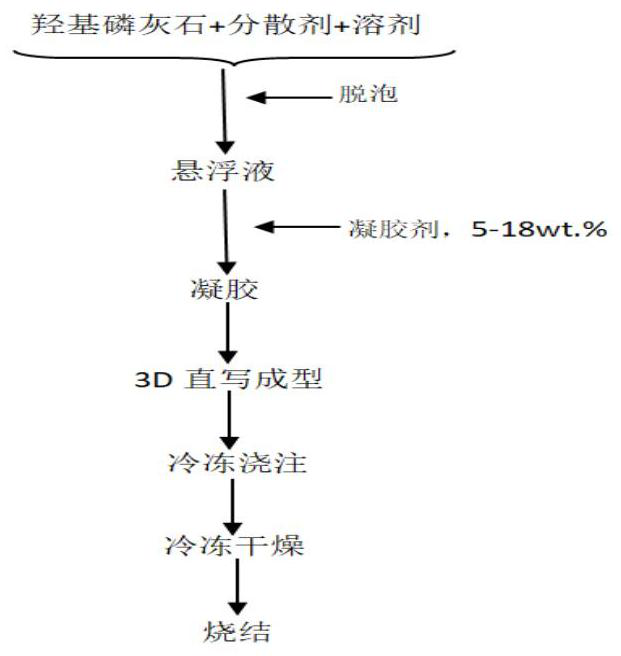

Macrostructure and microstructure controllable hydroxyapatite porous ceramic, preparation method thereof and application of ceramic

ActiveCN109400200ASimple processEasy to operateAdditive manufacturing apparatusTissue regenerationSolventMicrostructure

The invention discloses a macrostructure and microstructure controllable hydroxyapatite porous ceramic, a preparation method thereof and an application of the ceramic. The hydroxyapatite porous ceramic is subjected to 3D (three-dimensional) direct-writing to obtain a three-dimensional structure, and freeze pouring regulation is performed to obtain a microstructure porous structure. A raw materialA is added into a solvent containing dispersing agents and mixed with the solvent to obtain suspension liquid, and then gel is added into the suspension liquid and mixed with the suspension liquid toobtain slurry. The raw material A comprises hydroxyapatite powder, the slurry passes 3D direct-writing equipment and is controlled to be in a gel state when passing the direct-writing equipment, the slurry is printed and frozen to obtain a green body with a three-dimensional structure, and the green body is freeze-dried and sintered to obtain the macrostructure and microstructure controllable hydroxyapatite porous ceramic. Direct-writing and freeze pouring technologies are initiatively and efficiently combined, the obtained hydroxyapatite porous ceramic is used as a bone scaffold, and the customization requirements of different bone tissues can be met.

Owner:CENT SOUTH UNIV

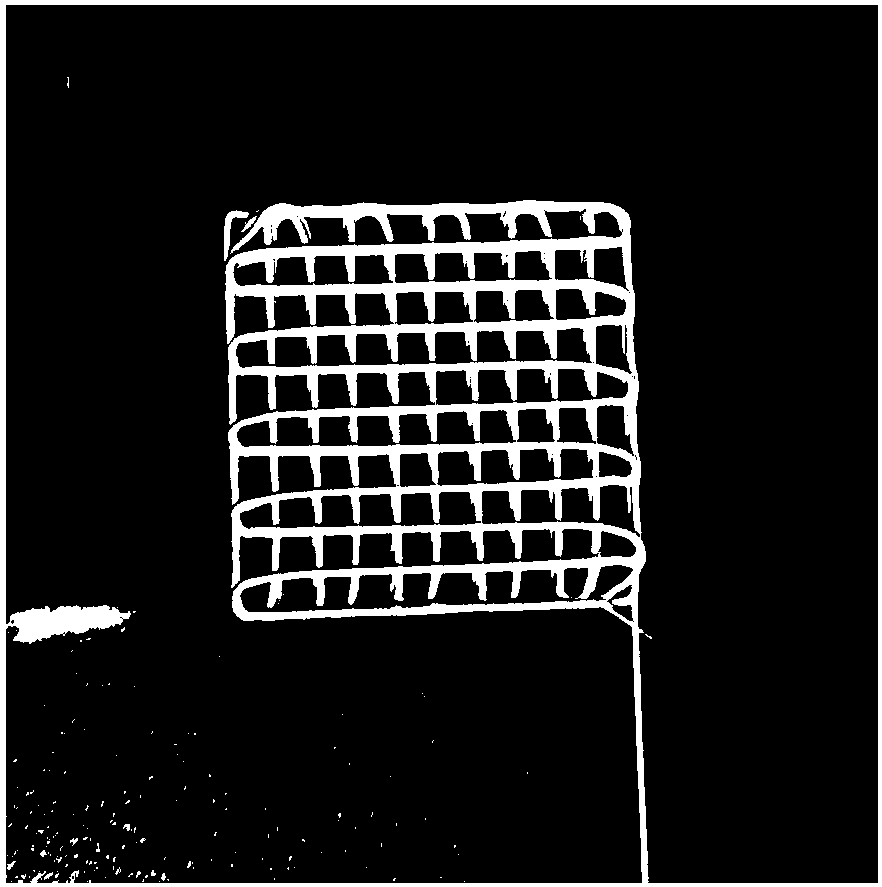

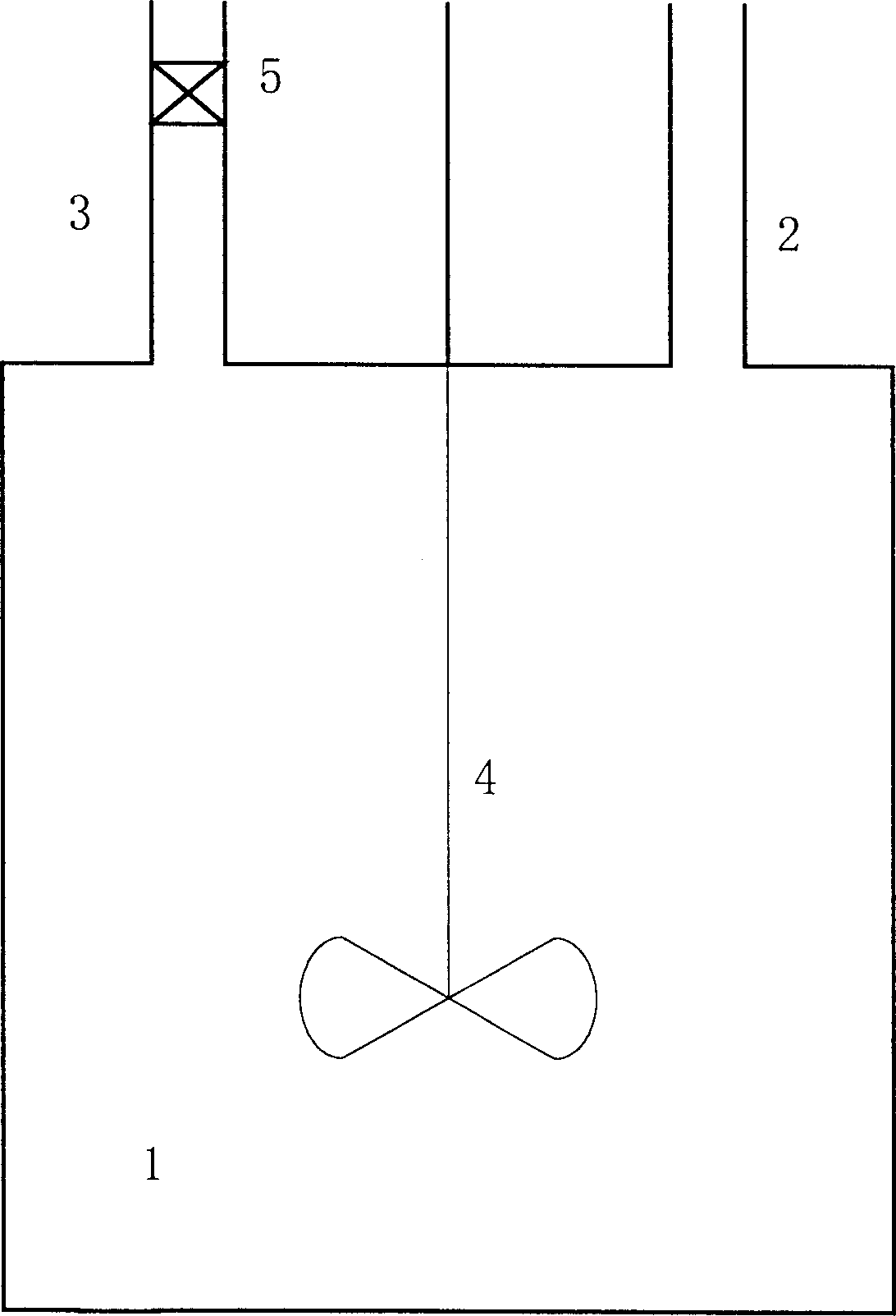

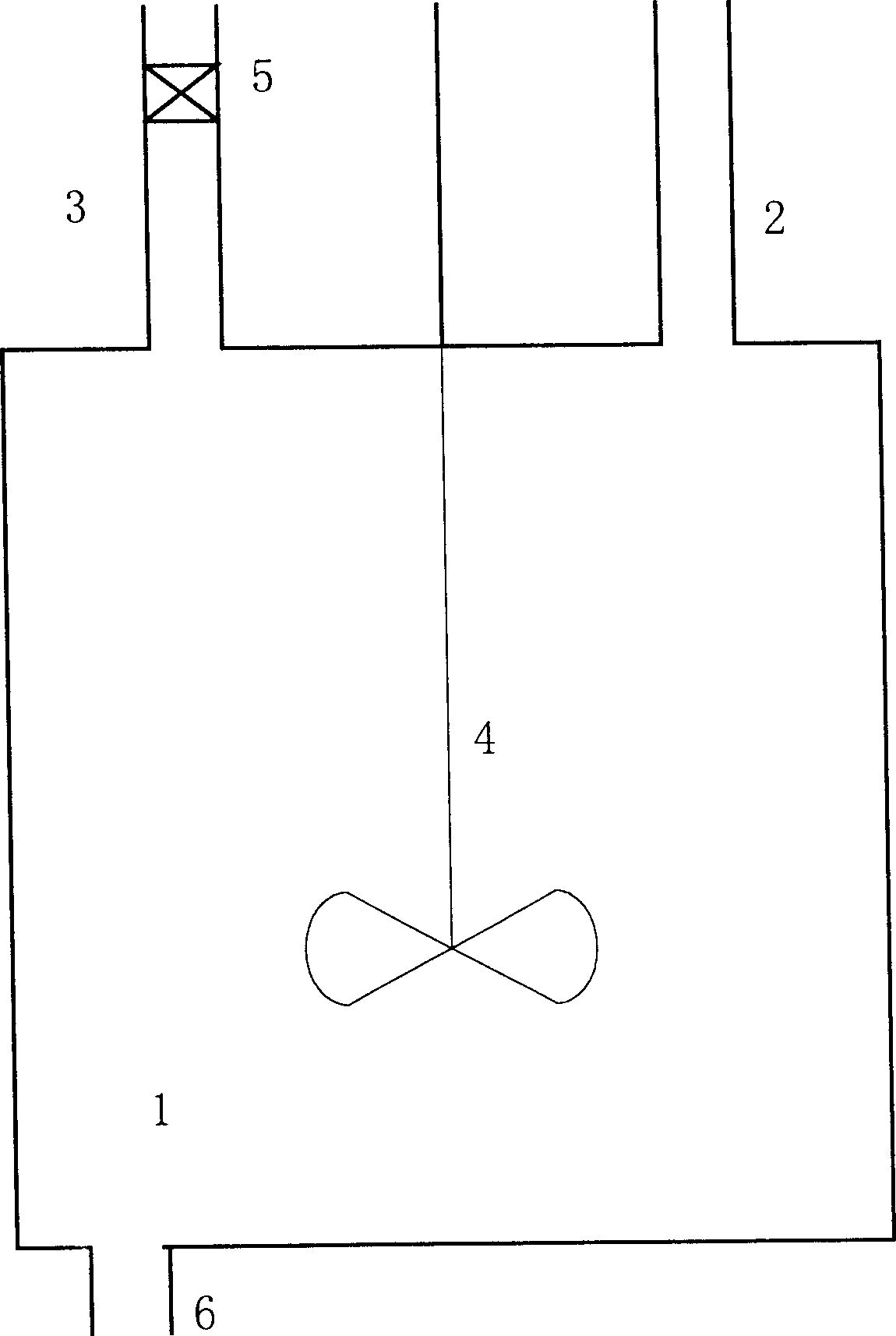

Gas phase aluminium extracting and silicon supplementing method of molecular sieve

ActiveCN1286721CEasy to unloadEasy to separateTobacco devicesCrystalline aluminosilicate zeolitesGas solidMolecular sieve

The gas phase method of extracting aluminum from and supplementing silicon to molecular sieve is to contact molecular sieve with silicon tetrachloride inside one reaction apparatus. The reaction apparatus includes one reactor with material inlet, gas outlet and stirrer, and one gas-solid separator in the gas outlet. The gas-solid separator has suck pore diameter and porosity that the gas can pass through and the solid particle can not. The stirrer has stirring rod extending beyond the reactor hermetically. The contact under stirring has contact temperature of 100-500 deg.c and time of 5-10 min, and the weight ratio between the molecular sieve and silicon tetrachloride is 1 to 0.05-0.5. The said method homogeneous contact reaction between gaseous silicon tetrachloride and solid molecular sieve, no coagulation of solid molecular sieve, less environmental pollution, lowered production cost and other advantages, and is suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mangneto modified ceramsite filler, preparation method thereof and application of modified filler in wastewater processing

InactiveCN102351306ALarge specific surface areaGood chemical stabilitySustainable biological treatmentBiological water/sewage treatmentRetention timeProcessing cost

The invention which discloses a mangneto modified ceramsite filler, a preparation method thereof and an application of the modified filler in wastewater processing belongs to the wastewater processing field. The modified filler is a magnetic filler which treats ceramsite as a base material and contains mixed magnetic powder, a biological affinity substance and a dispersant. The preparation methodof the modified filler comprises the following steps: 1, respectively immersing ceramsite in an acid liquor and an alkali liquor; 2, adding modification materials, and processing; and 3, mixing, and molding calcining. A method for improving the biological processing of the wastewater with the modified filler is characterized in that: the mangneto modified ceramsite filler is filled in an aerobic reactor according to a packing ratio of 35-50%, the wastewater is introduced, the retention time is 4-6, the volume loading is controlled at 0.5-2kgCOD / (m<3>.d), and the gas-water ratio in the aeration process is 5-15:1. Characteristics of the mangneto modified ceramsite filler are fully utilized in the invention to allow the wastewater processing efficiency to be improved, the wastewater processing cost to be saved, the service life of advanced processing equipment to be prolonged and large scale industrialization application to be easy.

Owner:NANJING UNIV

Method for preparing material with controllable macro and micro structures

ActiveCN109400179AImprove applicabilitySimple processAdditive manufacturing apparatusCeramicwareFreeze-dryingFreeze-casting

The invention discloses a method for preparing a material with controllable macro and micro structures. The method is realized by combining a 3D direct writing molding technology and a freezing casting method, and specifically includes adding a raw material A into a solvent containing a dispersant and mixing for the first time to obtain a suspension, and then adding a gel into the suspension and mixing for the second time to obtain a slurry material; and passing, by the slurry material, through 3D direct writing equipment, controlling the slurry material to be in a gel state when passing through the direct writing equipment, printing and freezing the material to obtain a blank body with a three-dimensional structure, freeze drying and sintering the blank body to obtain the material with controllable macro and micro structures. The method firstly realizes the high-efficiency combination of direct writing molding and the freezing casting technology, and overcomes the limitation of the traditional preparation technology in simultaneously realizing the microscopic pore structure and the complex three-dimensional structure.

Owner:CENT SOUTH UNIV

3D direct writing zirconium oxide colloid ink

The invention relates to 3D direct writing zirconium oxide colloid ink, which comprises the following raw materials: zirconium oxide particles, a solvent, a binder, an acid agent, an alkali agent anda dispersant, wherein the particle size of the zirconium oxide particles is 0.05-2 [mu]m, the solid content of the zirconium oxide particles in the ink is 40-56 vol%, the dispersant is one or a variety of materials selected from polyacrylic acid, polyvinyl acid, ammonium polyacrylate, polyethyleneimine, polyacrylate, polyvinyl acid salt and polycarboxylate, the dispersant accounts for 0.1-4 wt% ofthe mass of the zirconium oxide particle dry powder, the amount of the acid does not exceed 0.1% of the mass of the ink, the amount of the alkali does not exceed 0.1% of the mass of the ink, and a molar ratio of the hydrogen ion to the hydroxide ion in the acid agent and the alkali agent is (0.01-4):1. According to the present invention, with the application of the 3D direct writing zirconium oxide colloid ink to print at the room temperature, the high solid content can be provided while the 3D direct writing zirconium oxide colloid ink can be outflow from the fine spraying nozzle and the clogging cannot occur, the 3D direct writing zirconium oxide colloid ink can be rapidly cured into the fine wire with a certain strength so as to be used for various modeling, and the 3D direct writing zirconium oxide colloid ink has good rheological property.

Owner:CENT SOUTH UNIV

Preparation method of C/SiC composite material

The invention discloses a preparation method of a C / SiC composite material. The preparation method comprises the following steps: (1) depositing a pyrolytic carbon interface layer on the carbon fibersurface of a preform by adopting a chemical vapor deposition process, (2) depositing a SiC matrix by adopting a CVI process to form a C / SiC blank material, and (3) dipping the C / SiC blank material inthe SiC slurry, taking out the C / SiC blank material, and depositing a SiC matrix by adopting the CVI process to obtain the C / SiC composite material meeting the requirements. According to the method, aspecific carbon fiber raw material is selected, a process of combining a CVI deposition SiC matrix and a SiC slurry permeation process is adopted, and the prepared C / SiC composite material has excellent mechanical properties at normal temperature and high temperature of 1500 DEG C, and the preparation method is simple, efficient and easy for large-scale industrial application.

Owner:BEIJING INST OF ELECTRONICS SYST ENG

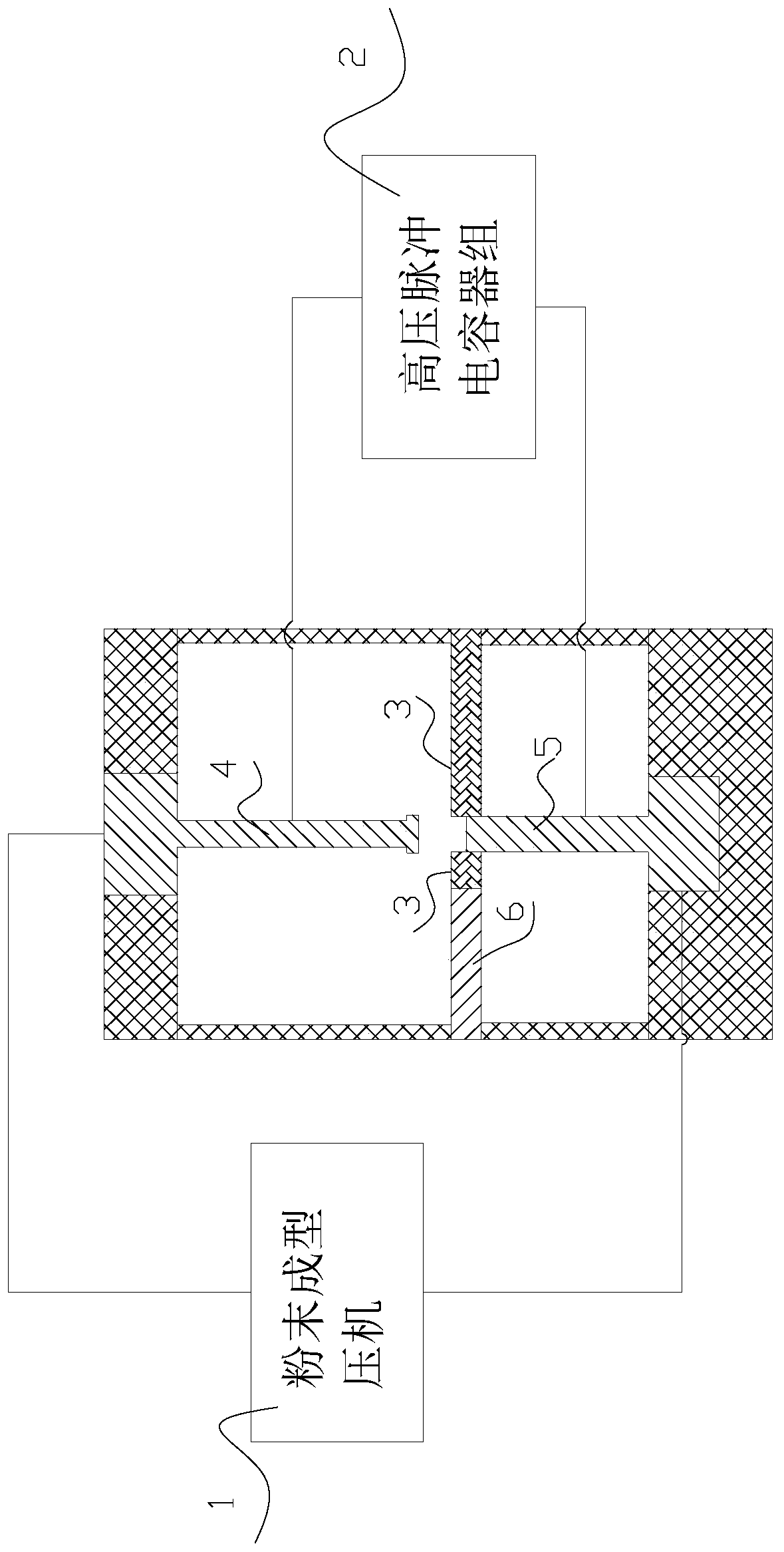

Pulse discharge flash sintering metal-based part near-net forming technology method

InactiveCN109894615ASimple processHigh energy consumptionAdditive manufacturing apparatusPorosityMetal powder

The invention discloses a pulse discharge flash sintering metal-based part near-net forming technology method, and belongs to the technical field of powder metallurgy. The problems that a traditionalpowder metallurgy part production process is high in power consumption, tedious and complex in process flow and low in production efficiency are solved. The method mainly comprises the steps of pushing metal powder into a mold, and forming the metal powder through stamping; enabling the inner wall, making contact with the metal powder, of the mold to have the insulation property; and enabling stamping to serve as an electrode of a pulse discharge body, and enabling stamping to synchronously carry out pulse discharge in the metal powder forming process. According to the method, the process flowis greatly simplified, large-scale industrialized application is easily achieved, the near-net forming advantage is achieved, the product quality is high, porosity adjusting control is convenient, practicality is high, and the method has the important significance in the powder metallurgy industry manufacturing field.

Owner:YANGZHOUSSHINE POWDER METALLURGY

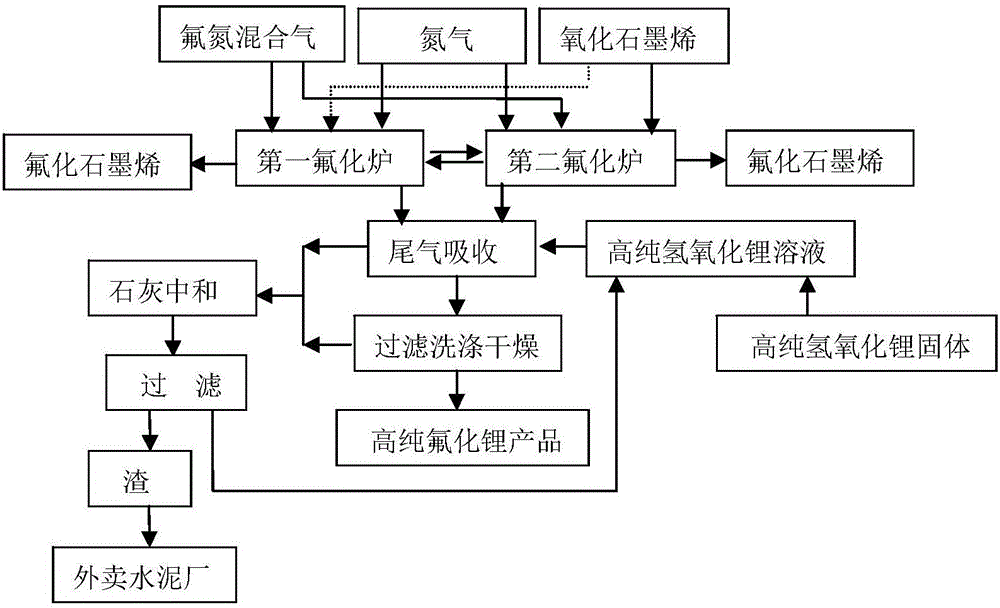

Method and device for preparing fluorinated graphene and high purity lithium fluoride as by-product

ActiveCN106379889ARealize continuous productionAchieving Alternate FluorinationGrapheneLithium halidesLithium hydroxideShielding gas

The invention relates to a method and device for preparing fluorinated graphene and high purity lithium fluoride as a by-product. The method comprises 1, putting graphene oxide in a fluorination furnace, carrying out vacuum-pumping on the fluorination furnace, feeding fluorine-containing gas into the fluorination furnace and carrying out a fluorination reaction process, and 2, feeding protection gas into the fluorination furnace to cool the materials and to replace the fluorine-containing gas, wherein the cooled materials in the furnace is fluorinated graphene, feeding the replaced fluorine-containing gas into a high purity lithium hydroxide solution for an absorption reaction and separating high purity lithium fluoride when the system pH is in a range of 2-3. The method and device can realize preparation of high-grade fluorinated graphene and preparation of high purity lithium fluoride from a fluorine resource, realize recovery and reuse of excess fluorine-containing gas in the high purity lithium hydroxide solution, greatly improve a fluorine raw material utilization rate, save a fluorine resource and solve the environmental bottleneck problems. The lithium fluoride as a by-product is used for preparation of a lithium ion battery key material lithium hexafluorophosphate, becomes a novel economic growth point and has good economic benefits and environmental benefits.

Owner:DO FLUORIDE CHEM CO LTD

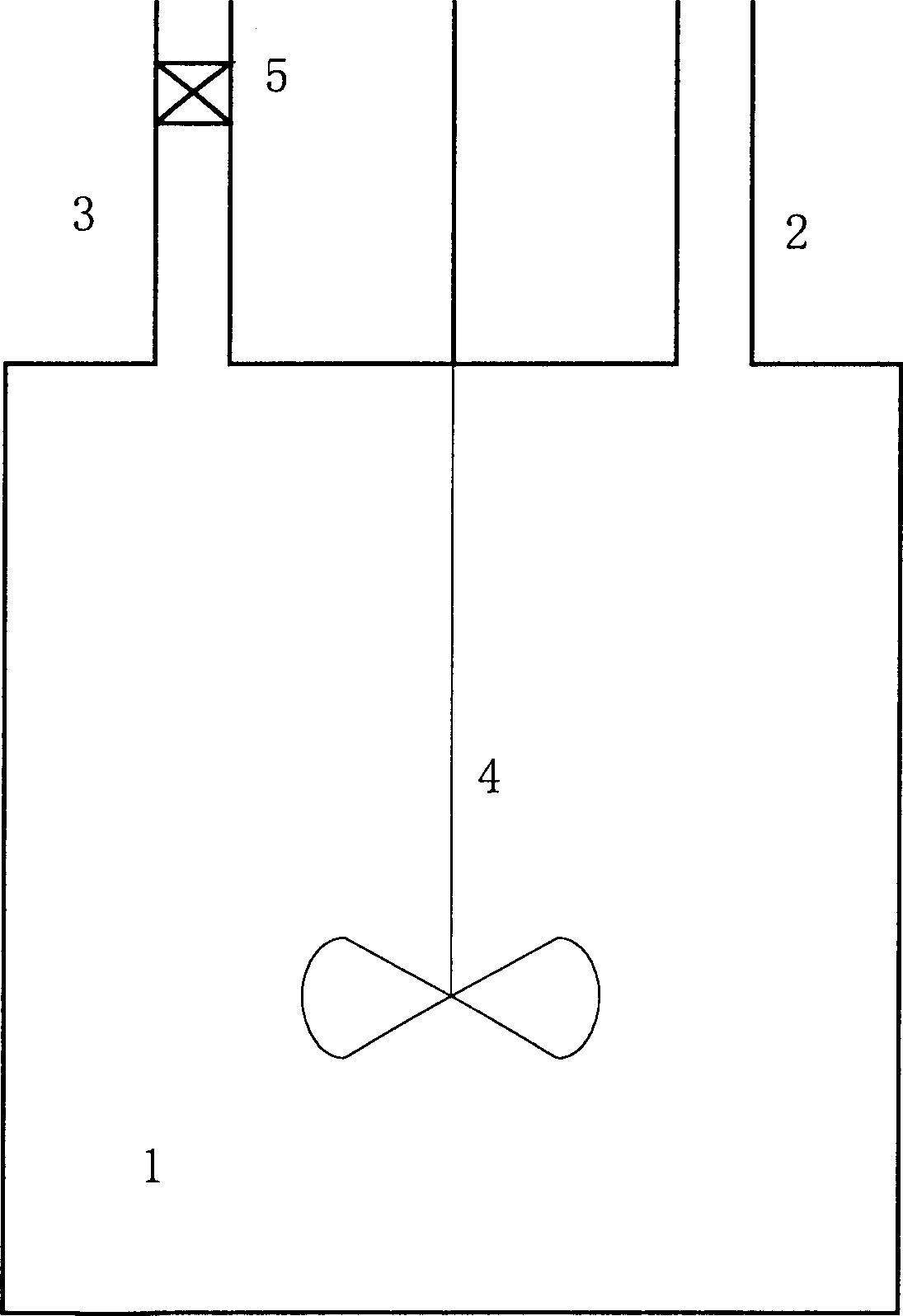

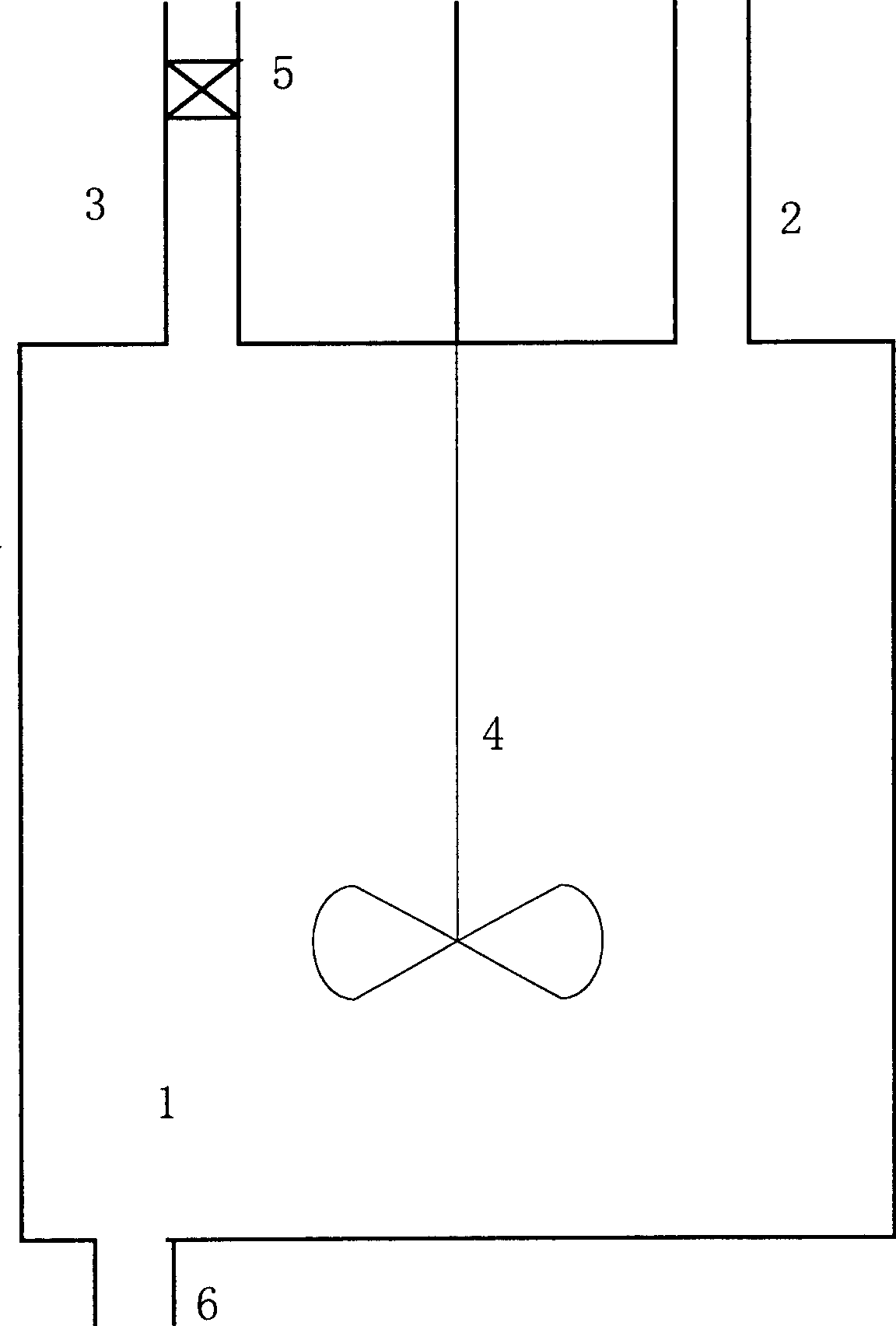

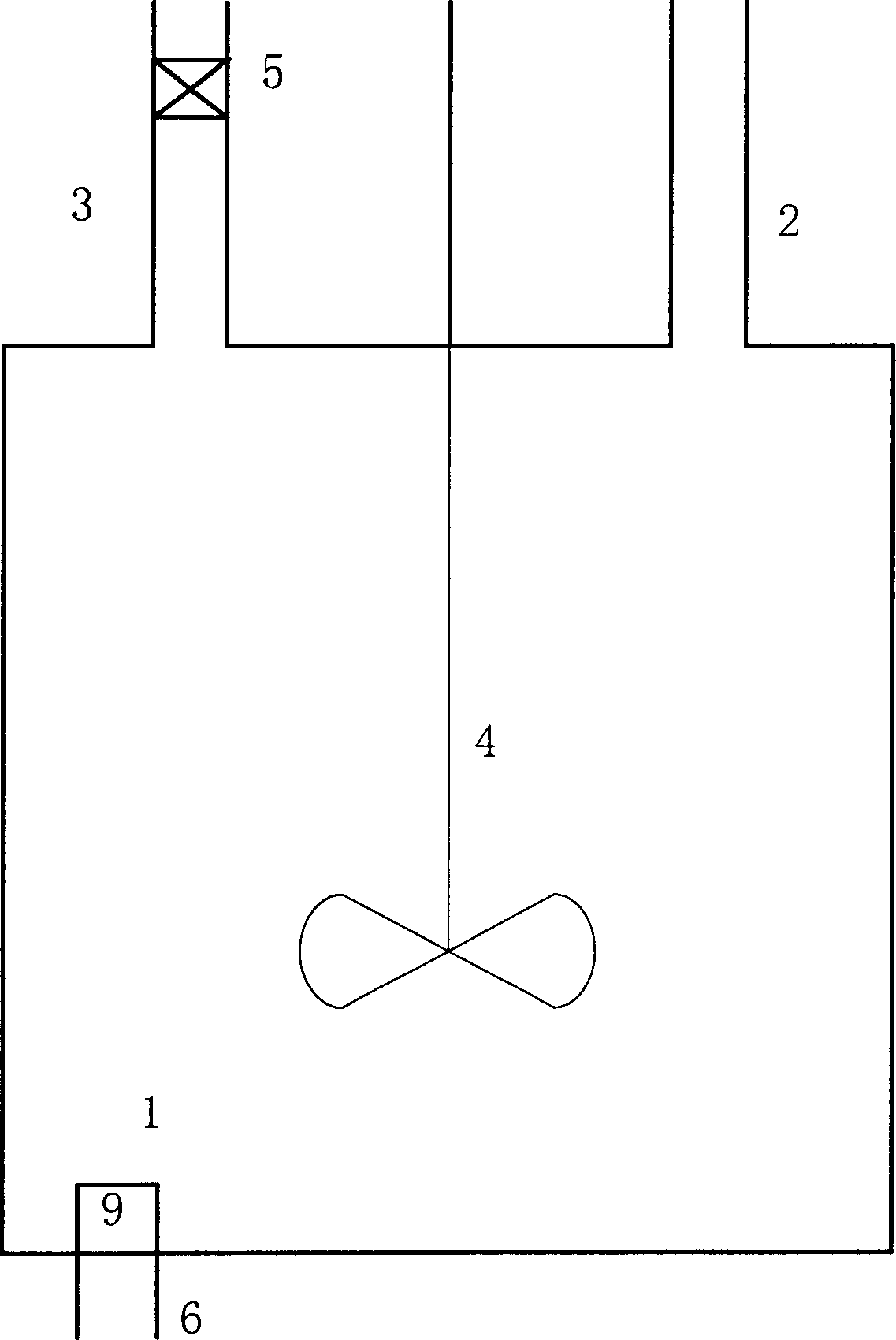

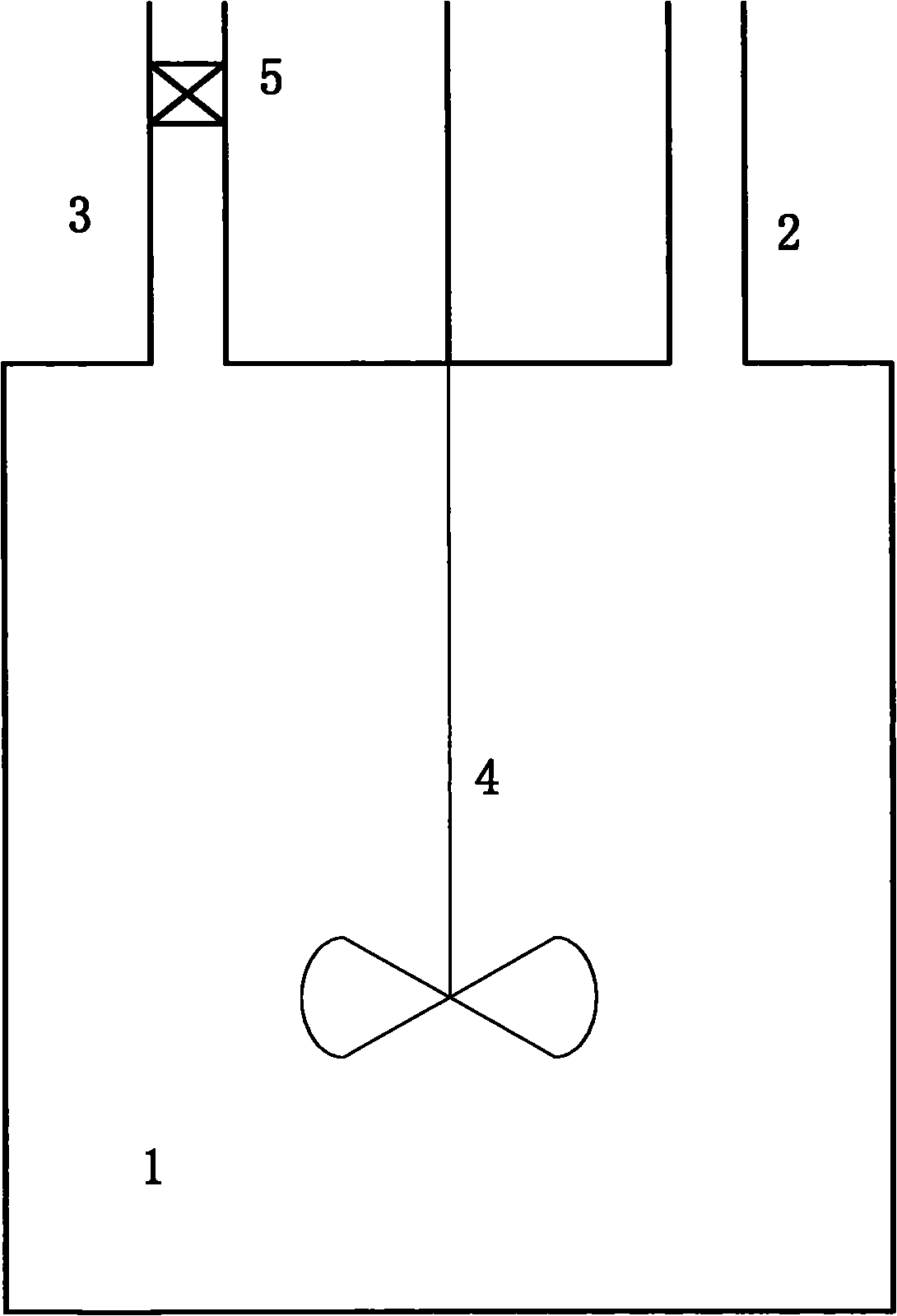

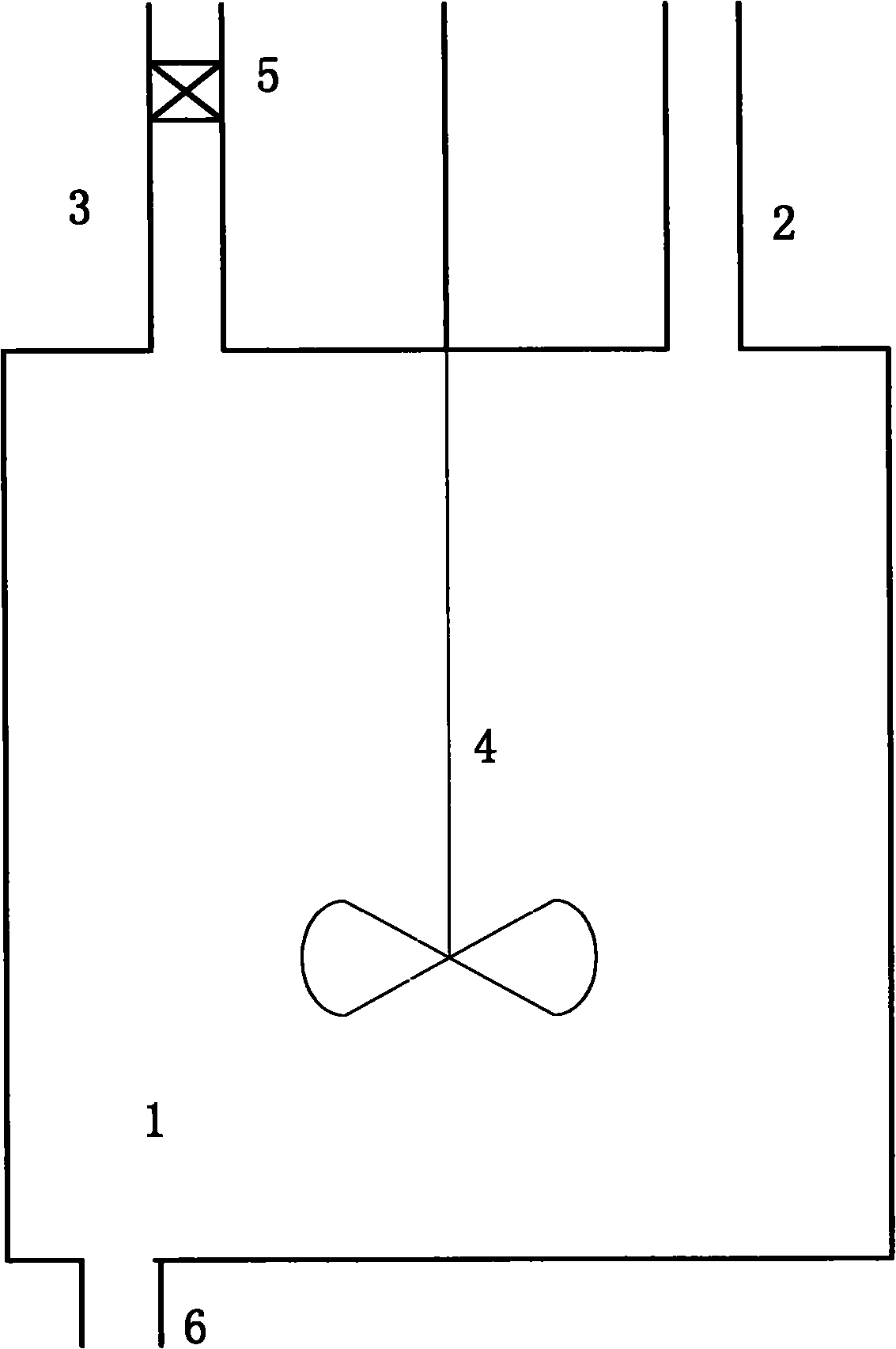

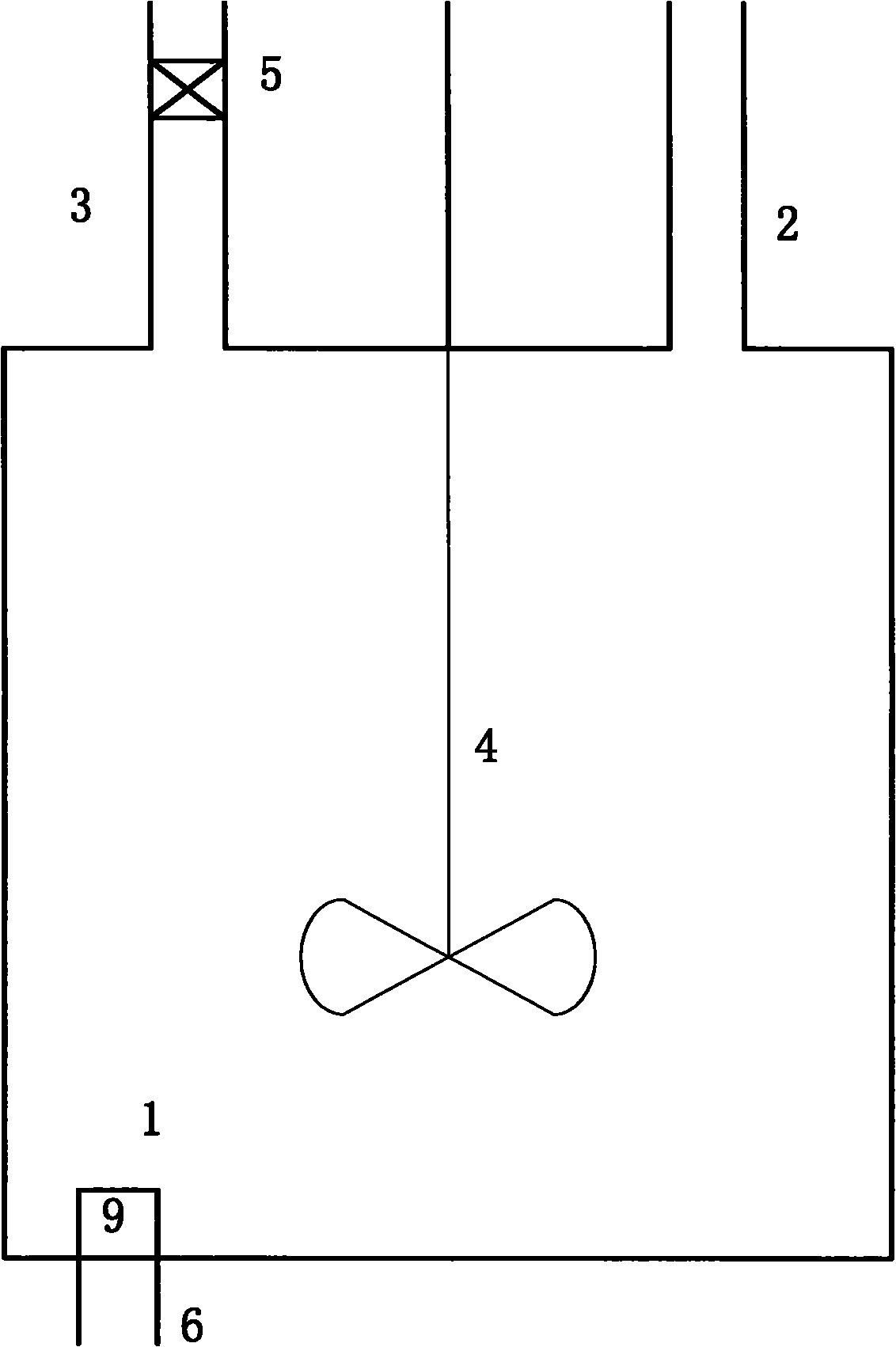

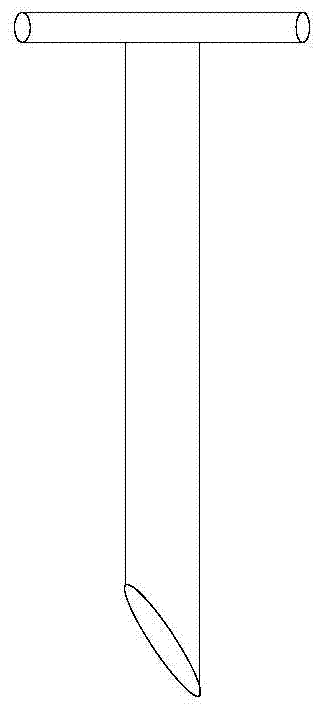

Method for reacting gas and solid particles

ActiveCN101884897AAvoid agglomeration into dense lumpsUniform contact reactionChemical/physical processesGas solidSolid particle

The invention discloses a method for reacting gas and solid particles, which comprises the step of contacting the gas with the solid particles. The contact is performed in reaction equipment, and the reaction equipment comprises a reaction kettle, a feed inlet and a gas outlet. The interior of the reaction kettle also comprises a stirrer; and a gas-solid separator is arranged on the gas outlet. The pore diameter and the porosity of the pores contained in the gas-solid separator guarantee that the gas can pass the pores and the solid particle cannot pass the pores. A stirring rod of the stirrer extends out of the reaction kettle, and the contacting position of the stirring rod and the reaction kettle is sealed, so that the reaction kettle does not communicate with the outside. The solid particles and the gas or substances capable of generating gas are added into the reaction kettle through the feed inlet, and the solid particles and the gas or the gas generated by the substances capable of generating gas contact to perform the reaction of the gas and the solid particles under the stirring of the stirrer. The contact reaction of the gas and the solid particles is more uniform and the phenomenon that the solid particles are coalesced into dense blocks is avoided. Therefore, the method for reacting the gas and the solid particles can lower the labor intensity and reduce the environmental pollution, obviously reduces the production cost, and is easy for large-scale industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

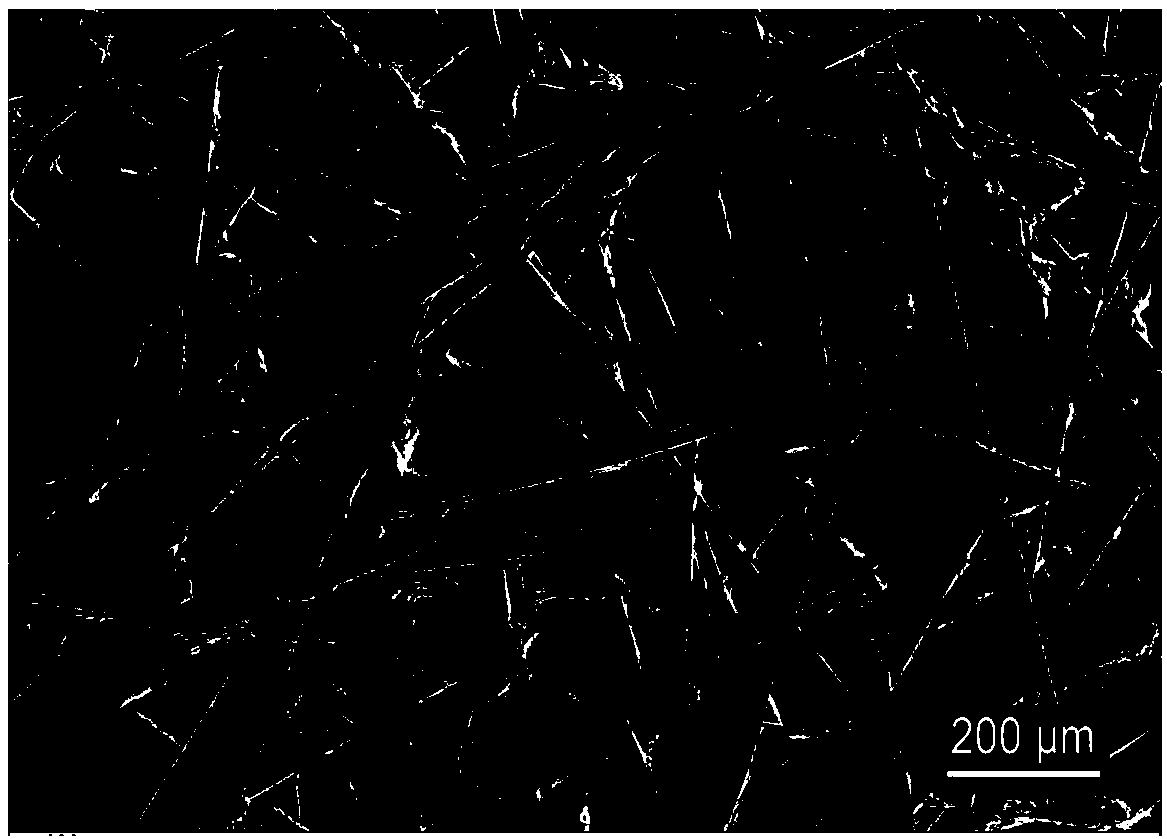

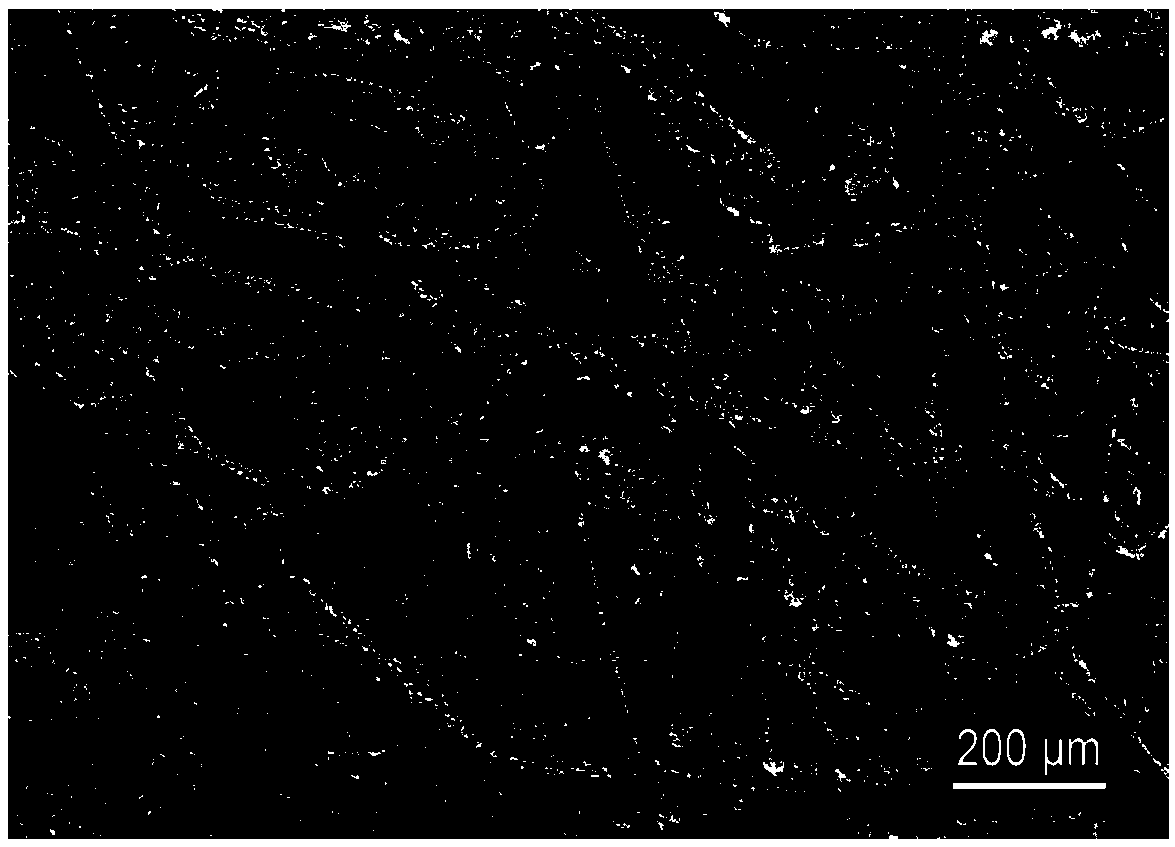

Self-cleaning type titanium dioxide nano-fiber membrane material as well as preparation method and application thereof

The invention relates to a preparation method and application of a self-cleaning type titanium dioxide nano-fiber membrane material. The method comprises the following steps: adding a titanium sourceinto a reaction container; while stirring, adding absolute ethyl alcohol; then adding glacial acetic acid and continuously stirring at room temperature until a reaction solution is milky white, so asto obtain titanium dioxide sol; immersing carbon paper into the titanium dioxide sol and adsorbing titanium dioxide nanoparticles on the surface of the carbon paper, so as to obtain carbon paper loaded with the titanium dioxide nanoparticles; putting the obtained carbon paper into a sodium hydroxide solution and carrying out hydrothermal reaction; forming titanium dioxide nano-fibers on the surface of the carbon paper and carrying out self-assembling to obtain the titanium dioxide nano-fiber membrane material. The self-cleaning type titanium dioxide nano-fiber membrane material prepared by thepreparation method has good filtering performance on organic molecules and nanoparticles with positive charges.

Owner:南京盈润门窗科技有限公司

Preparation of supported O3 catalyst and application thereof in COD removal of high-salt wastewater in coal chemical industry

ActiveCN109939695AUnique methodEasy to operateWater contaminantsCatalyst activation/preparationChemical industryCopper nitrate

The invention relates to a preparation method of a catalyst, in particular to a preparation method of a supported O3 catalyst. The preparation method of the catalyst adopts a hydrothermal method, andthe specific steps are as follows: firstly, a certain mass of gamma-Al2O3 is placed into a container, then potassium permanganate and copper nitrate trihydrate are added, 60-90L deionized water is added to dissolve fully, then the mixture is transferred to a reaction kettle for hydrothermal reaction, after the reaction, the mixture is washed by using deionized water until the water is colorless, the mixture is dried at 90-120 DEG C for 10-15h to obtain heterogeneous double metal oxide catalyst with gamma-Al2O3 supported with MnO2 and CuO, pseudo-boehmite and concentrated nitric acid are added,extruding is carried out, the mixture is dried at 90-120 DEG C for 10-15 h; the invention also provides the application of the catalyst in COD removal of high-salt wastewater in coal chemical industry: the method has the advantages of simple operation, low cost, reusable catalyst, good water treatment effect, large-scale application and no secondary pollution.

Owner:NINGXIA UNIVERSITY

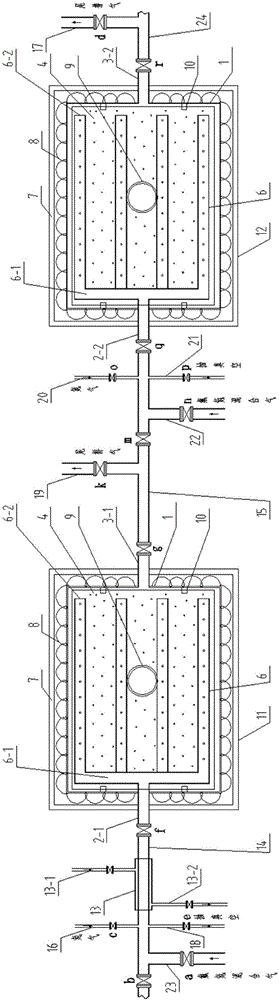

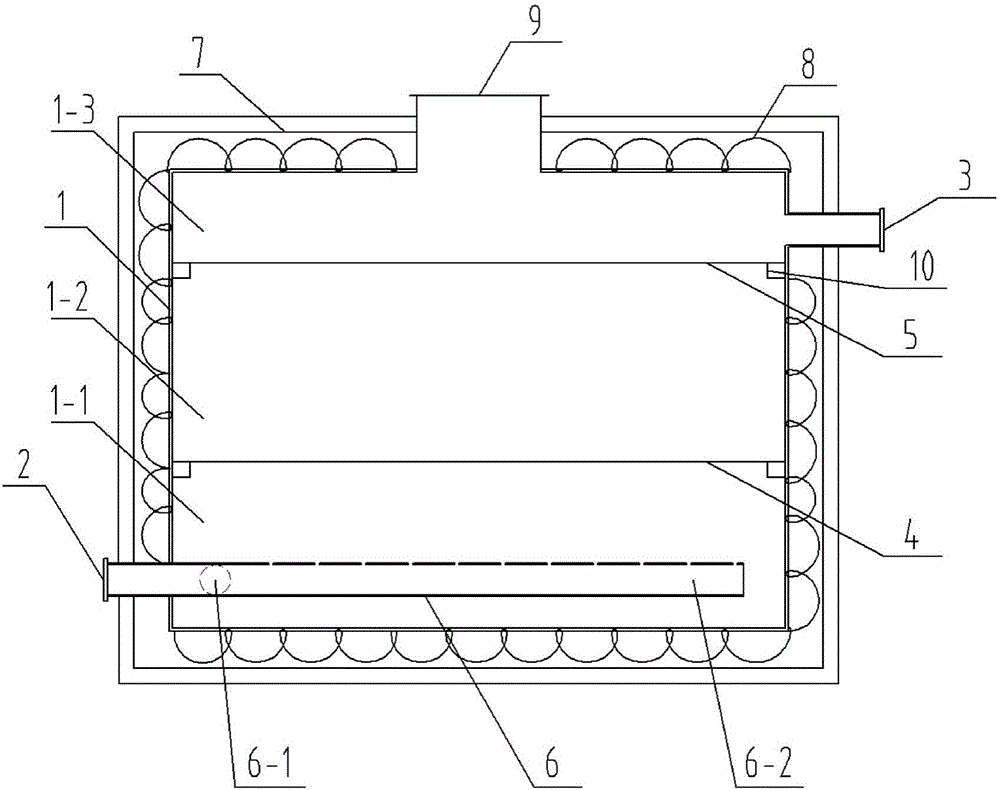

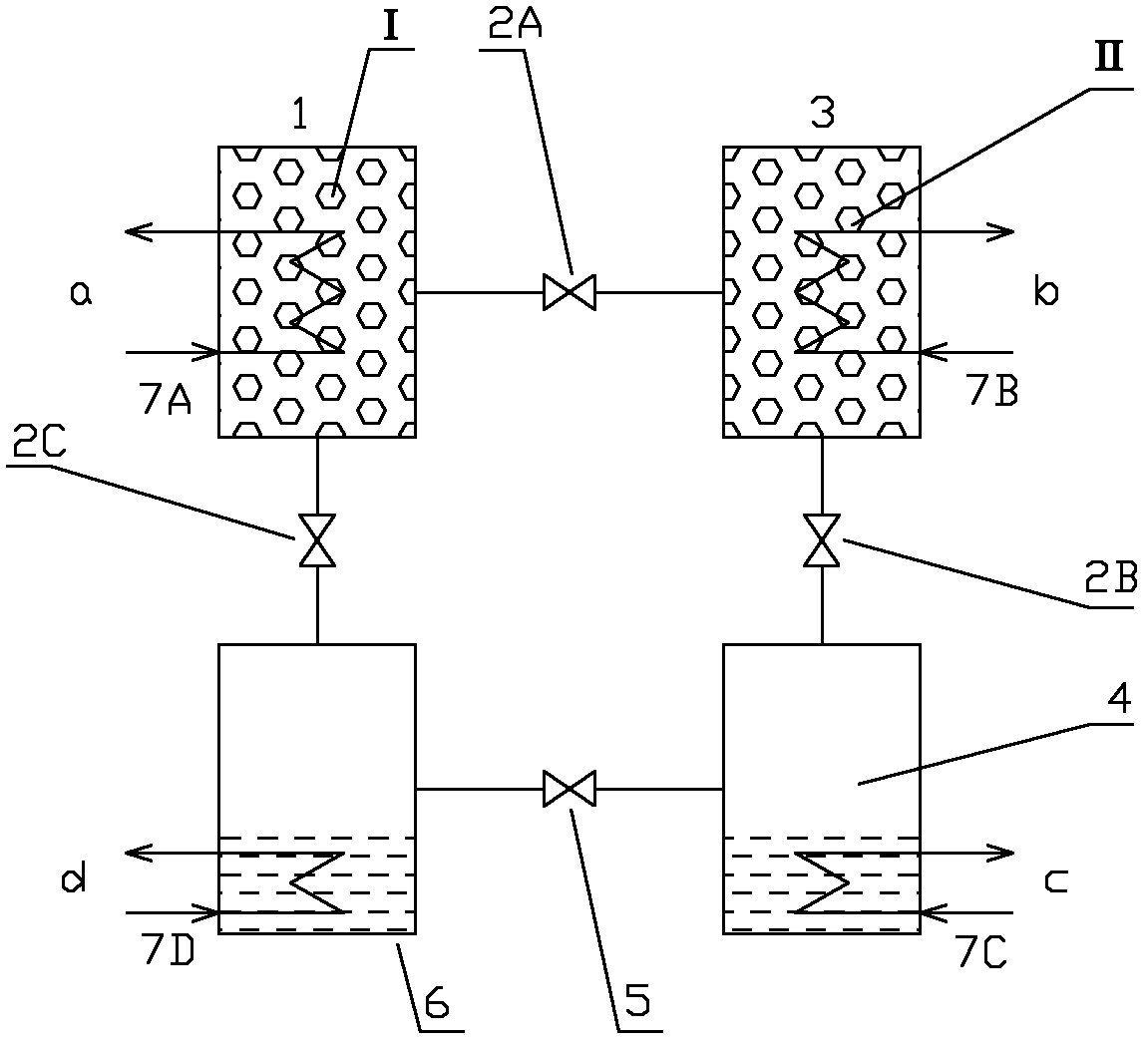

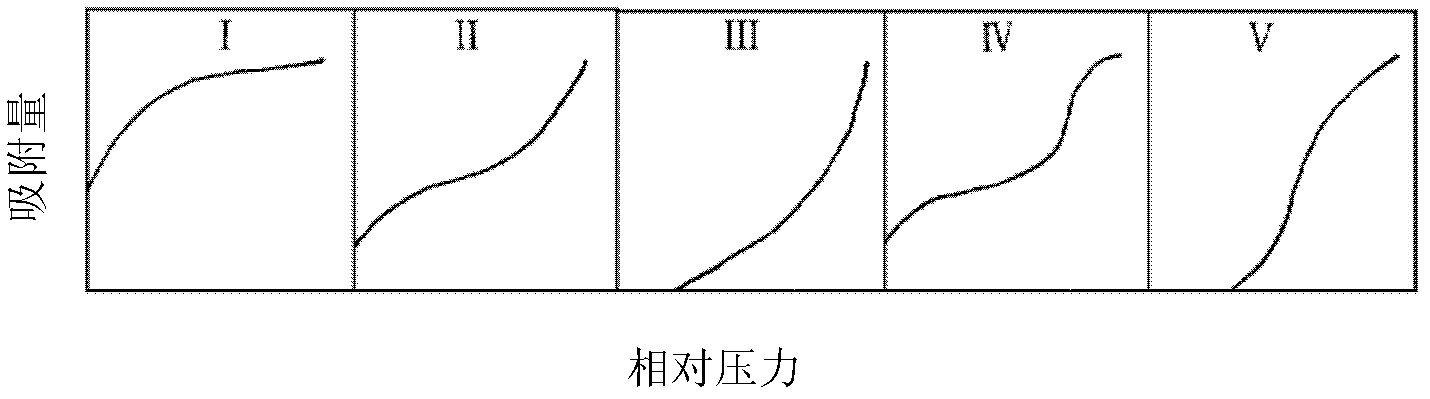

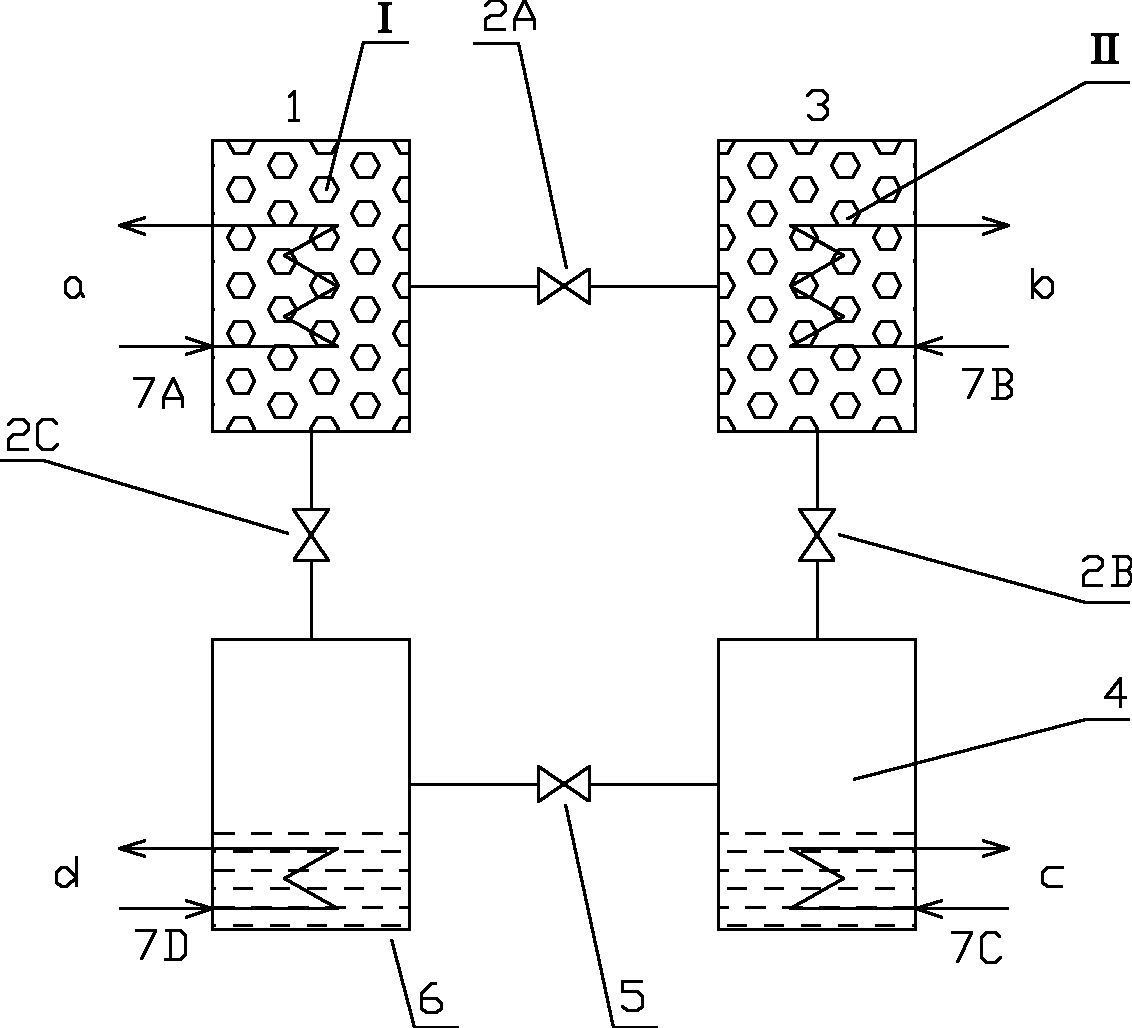

Double-stage adsorption refrigerating recycling system

InactiveCN102679616ALow desorption temperatureEase of large-scale industrial applicationEnergy efficient heating/coolingClimate change adaptationActivated carbonMolecular sieve

The invention relates to a double-stage adsorption refrigerating recycling system which is characterized by consisting of a primary adsorption bed, a secondary adsorption bed, a condenser, an evaporator, a heat exchange tube, a valve and an auxiliary pipeline. Heteroatom SAPO-34 molecular sieves are filled in the primary adsorption bed; and hydrophobic silica gel, activated carbon, pure silicon molecular sieves and at least one of MCM (mesoporous crystalline material) series mesoporous silica materials are filled in the secondary adsorption bed. A desorption process of the primary adsorption bed can be greatly improved by an adsorption effect of the secondary adsorption bed of the double-stage adsorption refrigerating recycling system, and the temperature of a driving heat source of the primary adsorption bed is reduced. The double-stage adsorption refrigerating recycling system has the advantages of low desorption temperature and high adsorbent recycling adsorption quantity, reduction of the size of the system is facilitated, and the efficiency of the adsorption refrigerating system is improved.

Owner:NANJING UNIV OF TECH

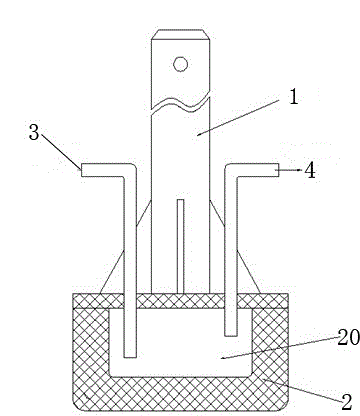

Inner-cooling inert anode for electrolytic aluminum

InactiveCN103820817AAffect production qualityAvoid defects such as high impact costCurrent distributionThermal stability

The invention relates to an inert anode for electrolytic aluminum, and belongs to the field of electrolytic aluminum equipment. The inner-cooling inert anode for the electrolytic aluminum comprises a conductive rod and a metal or metal matrix composite anode connected with the conductive rod, wherein an inner cavity of the metal or metal matrix composite anode adopts a hollow structure, and is communicated with an external circulatory cooling system and a heat exchanger via a cooling medium inlet and a cooling medium outlet which are formed in the metal or metal matrix composite anode. The inert anode has the following advantages that 1, the advantages of excellent conductivity, thermal conductivity, machining property, uniform anode current distribution and the like of a metal inert anode are inherited; the defects that the metal inert anode pollutes molten aluminum during electrolytic aluminum production and is high in cost are overcome; 2, the advantages of good thermal stability of metal oxide ceramic and metal ceramic anodes and easiness in large-scale industrial application are provided; the defects that a metal oxide ceramic inert anode is poor in conductivity and low in thermal vibration resistance, and connection between the metal oxide ceramic inert anode and a metal component of a power supply system is difficult are overcome; and 3, the novel inert anode can fully meet a technical requirement of the electrolytic aluminum production, and is very small in consumption.

Owner:饶云福 +5

Photoluminescent fiber and preparation method thereof

InactiveCN110670161AReduce reunionAvoid fluorescence quenchingArtificial thread manufacturing machinesWet spinning methodsFiberSpinning

The invention discloses a photoluminescent fiber and a preparation method thereof. Quantum dots are used as luminescent particles, high-molecular polymers are used as a spinning substrate, the quantumdots and the high-molecular polymers are blended to prepare a spinning solution, and then the photoluminescent fiber is prepared through a wet spinning process. The photoluminescent fiber prepared bythe method has excellent optical stability and mechanical properties, and has a good application prospect in the fields of clothing, pharmacy, environment, petrochemical industry, anti-counterfeitingindustry, gas sensors, human health monitors and the like. The preparation method provided by the invention is simple to perform, has a wide application range of spinning solutions, and is low in cost and easy to apply to large-scale industrial application.

Owner:WUHAN TEXTILE UNIV

Method for processing and separate-recycling printing and dyeing wastewater

InactiveCN101293726BLow costExtended service lifeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentUltrafiltrationAnaerobic reactor

The invention discloses a method for processing and separate recycling of printing and dyeing wastewater, which comprises the following steps: after the printing and dyeing wastewater is firstly processed by an anaerobic reactor, a hypoxia reactor and an aerobic reactor, the separate recycling of part of the water is used for a desizing process of printing and dyeing technology; then, after the rest wastewater is processed by an aerator biofilter, the separate recycling of the part of the water is used for a boiling-off process of the printing and dyeing technology; then, after the rest wastewater is processed by an ultrafiltration reactor, the separate recycling of the part of the water is used for bleaching process and mercerization process of the printing and dyeing technology; finally, the rest water is processed by an anti-permeability reactor and the separate recycling of the part of the water is used for dyeing process, printing process and ordering process. After being processed by the invention, the printing and dyeing wastewater can be carried out the separate recycling quickly and high-efficiently and the recycling rate of the wastewater reaches more than 70 percent; meanwhile, the fee of processing and recycling the wastewater can be saved; the service life of advanced treatment equipment can be prolonged, which is easy for a large-scale industrialized application.

Owner:NANJING UNIV

Mangneto modified ceramsite filler, preparation method thereof and application of modified filler in wastewater processing

InactiveCN102351306BLarge specific surface areaGood chemical stabilitySustainable biological treatmentBiological water/sewage treatmentRetention timeExpanded clay aggregate

Owner:NANJING UNIV

A kind of porous biological ceramsite prepared from waste incineration fly ash and biomass pyrolysis gasification residue and preparation method thereof

InactiveCN105712733BHarmlessRealize resource processingCeramicwareProcess engineeringEnvironmental engineering

The invention discloses a method used for producing porous biological ceramsite by taking waste incineration fly ash and biomass pyrolysis-gasification residue as raw materials. The method comprises following steps: household garbage incineration fly ash is subjected to high temperature treatment in the presence of a gasification agent so as to obtain residual ash; biomass is subjected to low temperature pyrolysis-high temperature steam gasification so as to obtain a pyrolytic residue; the residual ash, the pyrolytic residue, flyash, clay, and a pore-forming agent are subjected to mixing, pelleting, drying, and high temperature roasting so as to obtain the porous biological ceramsite product. Technology of the method is simple; operation is convenient; harmlessness treatment of fly ash and biomass pyrolysis gasification residue can be realized; the porous biological ceramsite product is prepared from waste incineration fly ash and biomass pyrolysis residue; quantity demand of ceramsite industrial on natural raw materials is reduced; and environment-protection value and economic value are both high.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Preparation and usage methods of high-temperature CO2 modified calcium-based adsorbent

InactiveCN107029660AImprove pore structureWell-developed pore structureGas treatmentOther chemical processesKaoliniteSorbent

The invention discloses preparation and usage methods of a high-temperature CO2 modified calcium-based adsorbent and a preparation method of a calcium-based CO2 adsorbent. Oil sand pyrolysis residues are selected as a main calcium source and is modified through the processes such as oil sand pyrolysis residue and kaolinite mixing and compounding, high-temperature calcination and ethanol solution hardening and tempering for forming to obtain a modified calcium-based CO2 adsorbent; the modified calcium-based CO2 adsorbent is large in adsorption capacity and has the good effect of removing CO2 in high-temperature flue gas of a thermal power plant and high cyclic adsorption stability, and the high-temperature CO2 adsorption removal rate after 25 times of cyclic regeneration is still kept to 65% or above. The preparation method has the advantages that the calcium source is the oil sand pyrolysis residues, and the preparation process is simple, quick and convenient to operate, low in cost and friendly to the environment and is used for adsorption and separation of high-temperature gas CO2; the CO2 in the flue gas can be directly adsorbed, and the advance influence of carbon emission on the environment and climate is reduced; the purpose of using waste to treat waste can be achieved, the methods conform to low-carbon green economy, and the effect is obviously improved compared with other calcium-based CO2 adsorbents.

Owner:CHINA UNIV OF MINING & TECH

A hydroxyapatite porous ceramic with controllable macroscopic and microscopic structures, its preparation method and application

ActiveCN109400200BSimple processEasy to operateAdditive manufacturing apparatusTissue regenerationMacroscopic scaleFreeze-drying

The invention discloses a hydroxyapatite porous ceramic with controllable macroscopic and microscopic structures and its preparation method and application. The hydroxyapatite porous ceramic first obtains a three-dimensional structure through 3D direct writing molding, and then freezes it by casting The microporous structure is regulated and controlled, and the preparation method is disclosed as adding raw material A to a solvent containing a dispersant and mixing to obtain a suspension, and then adding a gelling agent to the suspension and mixing to obtain a slurry; the raw material A contains hydroxyphosphorus Limestone powder, pass the slurry through the 3D direct writing equipment, and control the slurry to be in a gel state when passing through the direct writing equipment, print and freeze to obtain a green body with a three-dimensional structure, the green body is freeze-dried, and sintered to obtain a macroscopic The hydroxyapatite porous ceramics with controllable microstructure, the invention is the first to realize the efficient combination of direct writing molding and freeze casting technology; the obtained hydroxyapatite porous ceramics can be used as bone scaffolds, which can meet the customization of different bone tissues need.

Owner:CENT SOUTH UNIV

Method for simultaneously extracting limonin and crude fat from pomelo nucleus by using solvent acetone

ActiveCN108690117ASimple and fast operationFew stepsSteroidsFatty-oils/fats productionSolventFine chemical

The present invention relates to a method for simultaneously extracting limonin and crude fat from pomelo nucleus by using a solvent acetone. The method comprises: (1) pretreatment: peeling pomelo nucleus to obtain pomelo nucleus kernel, drying the pomelo nucleus kernel, and breaking; (2) extraction: adding an acetone solvent to the broken pomelo nucleus kernel, extracting 1-7 times, and recovering the solvent to obtain a mixture; and (3) separation: adding an ethanol aqueous solution with a volume fraction of 50-95% to the mixture, stirring, carrying out static layering or centrifugation to obtain crude fat and an ethanol solution containing limonin, and recovering the solvent in the solution to obtain limonin. According to the present invention, limonin and crude fat are simultaneously extracted from the pomelo nucleus by using the one solvent acetone, wherein the recovery rates of limonin and crude fat can respectively achieve more than 95% under the preferred conditions, the product is easy to separate, and acetone is the renewable solvent, has the low boiling point, and is easily recycled; the method is easy to enlarge, can be used for large-scale production, does not requirecomplicated equipment, and is easy to operate; and the prepared limonin can be used as the drug preparation raw material, and the crude fat can be used as food and feed after being refined, and can beused as the raw material for the preparation of fine chemicals, slow release fertilizers or controlled release fertilizers.

Owner:ZHONGKAI UNIV OF AGRI & ENG

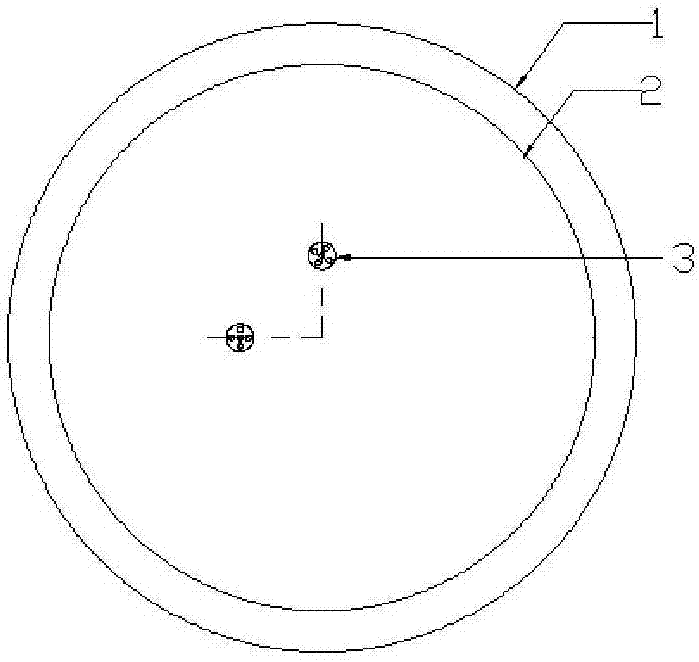

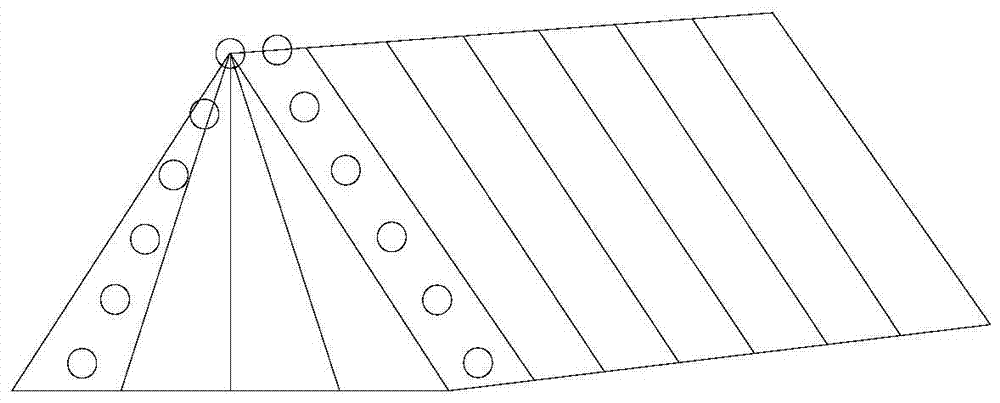

Silicon melt external refining device and method

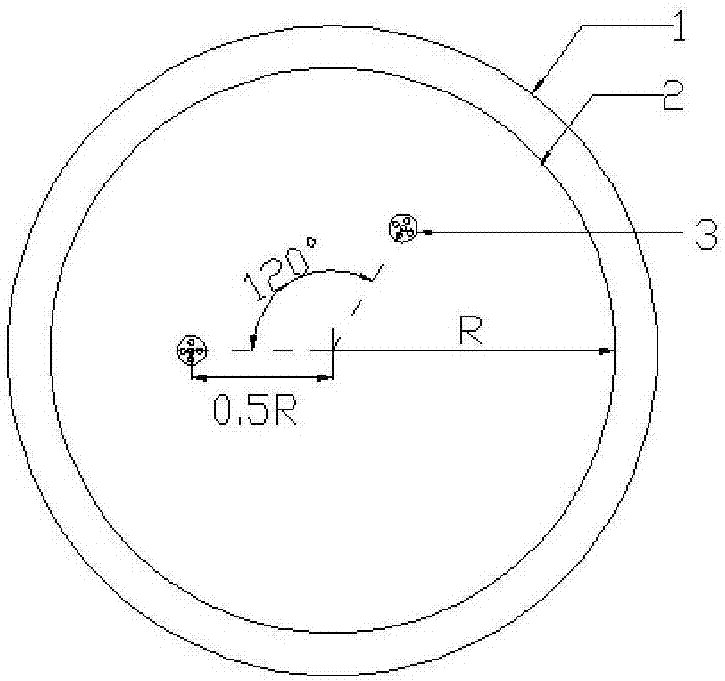

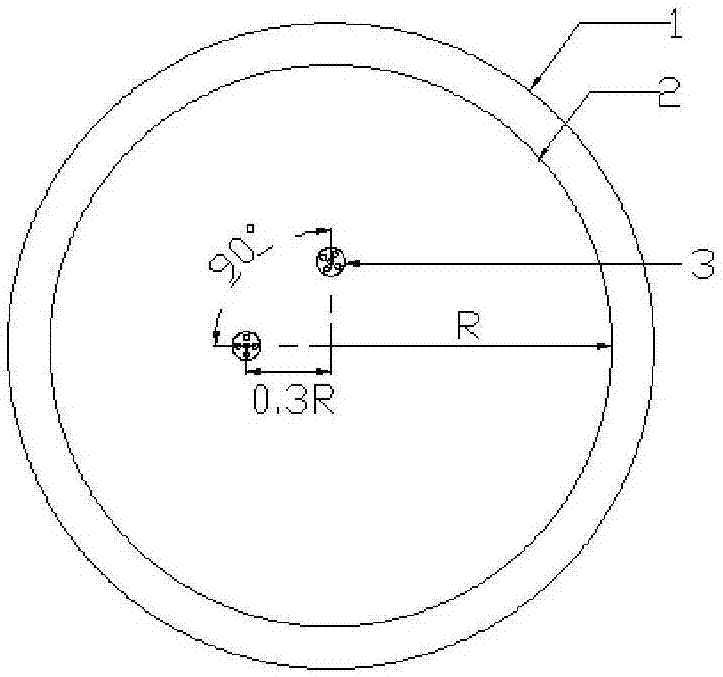

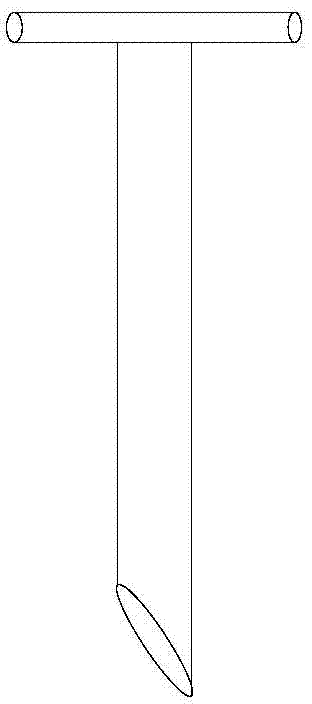

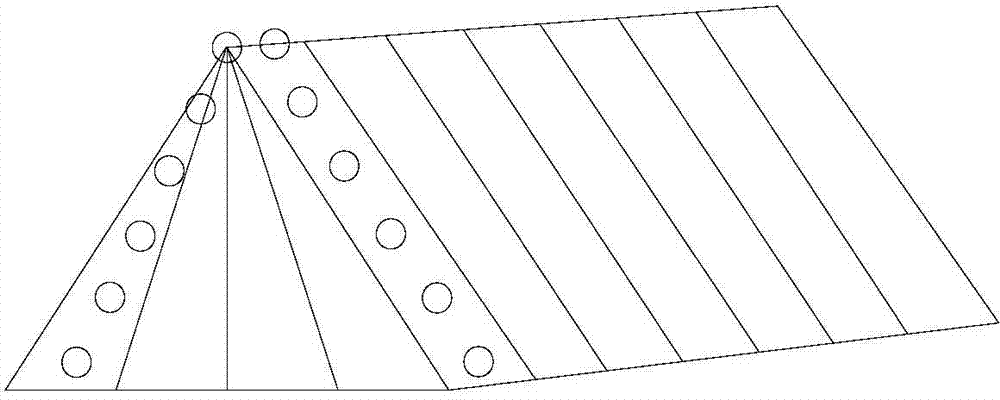

PendingCN107352546ANo pollution in the processLess investment in infrastructureSilicon compoundsSpray nozzleSilicon

The invention relates to a silicon melt external refining device and method and belongs to the technical field of industrial silicon purification. A ladle bottom of the device is equipped with two gas nozzles, and an included angle theta between each nozzle circle center and a ladle bottom circle center meets a relationship of 90 degrees<=theta<=180 degrees; and the distance between each nozzle circle center and the ladle bottom circle center, nozzle radius r and ladle bottom radius R meet a relationship shown in the description. Compressed air or refining gas is continuously introduced into the two gas nozzles arranged on the ladle bottom; silicon melt which is smelted from a submerged arc furnace is placed into a ladle; with the increase of silicon melt discharged from the ladle, refining agents are added and the refining gas component and flow are adjusted; external blowing and slagging refining are performed; dross on the surface of the silicon melt is skimmed; and pouring is performed on the silicon melt to obtain a high-purification industrial silicon product. The device and method provided by the invention ensure the dynamic conditions of the silicon melt in the specially-made ladle, eliminate stirring dead angles, and effectively increase qualities of the silicon product.

Owner:KUNMING UNIV OF SCI & TECH

Sample preparation method for mixed high-copper low-cobalt powdery alloys and high-cobalt low-copper granular alloys

ActiveCN104749008AImprove representationIncrease the pricing factorPreparing sample for investigationGranularityAlloy

The invention discloses a sampling and sample preparation method applied to mixed high-copper low-cobalt powdery alloys and high-cobalt low-copper granular alloys. The used device comprises a shovel, a carry-scraper, a drill bit, a double-roll crusher, a grinder, a 1 / 2 divider and a 1mm sieve. The method comprises the following steps: perform rapid mixing by matching the shovel and the carry-scraper, performing grid sampling by virtue of the drill bit with the special sampling function, screening alloy samples by virtue of the 1mm sieve, and allowing oversize products, namely large particle alloys, to pass through the double-roll crusher and the grinder, so that the alloy granularity is less than 1mm; and uniformly mixing the alloy samples, and rapidly separating the samples by virtue of the divider. According to the method disclosed by the invention, the alloys can be efficiently and rapidly mixed, sampled and prepared, and the prepared sample has the characteristics of high representativeness and high uniformity. Moreover, the operation is easy to operate, the occupied area is small, and the large-scale industrial application is easily realized.

Owner:北方矿业有限责任公司

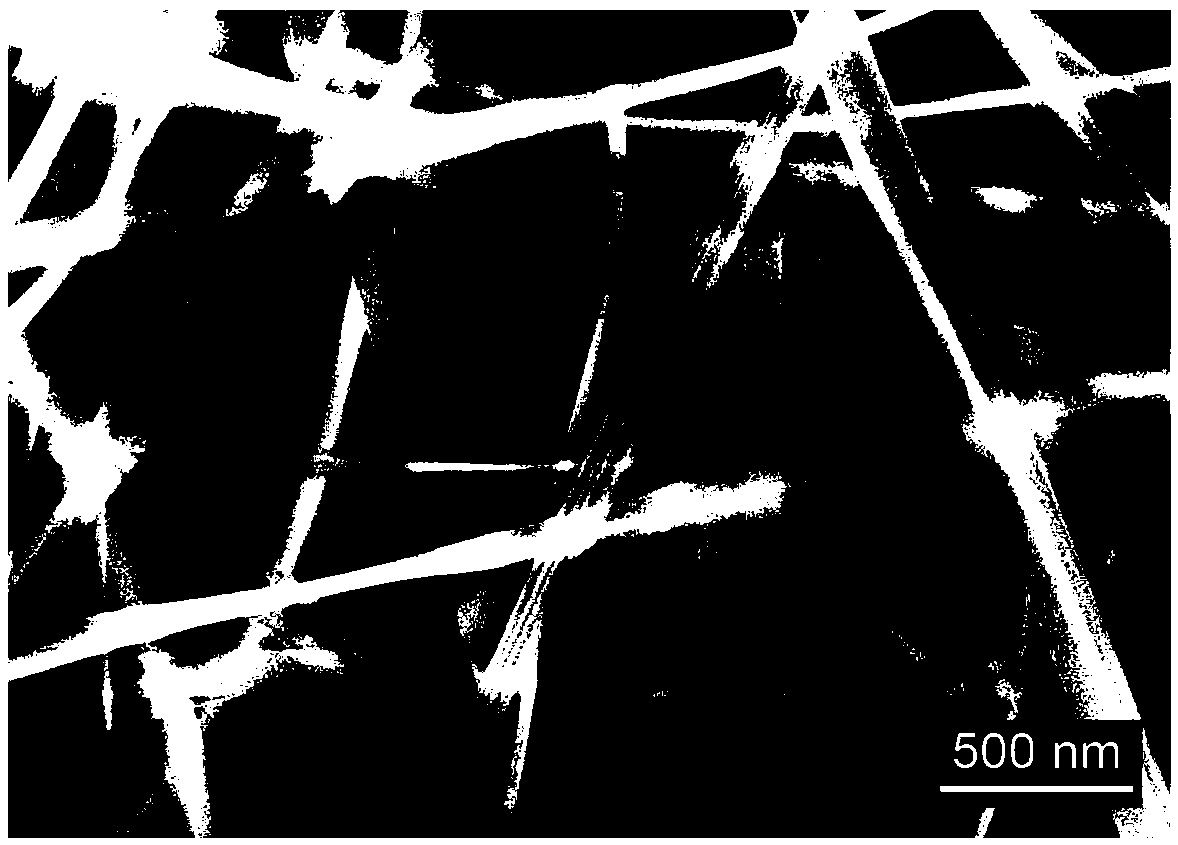

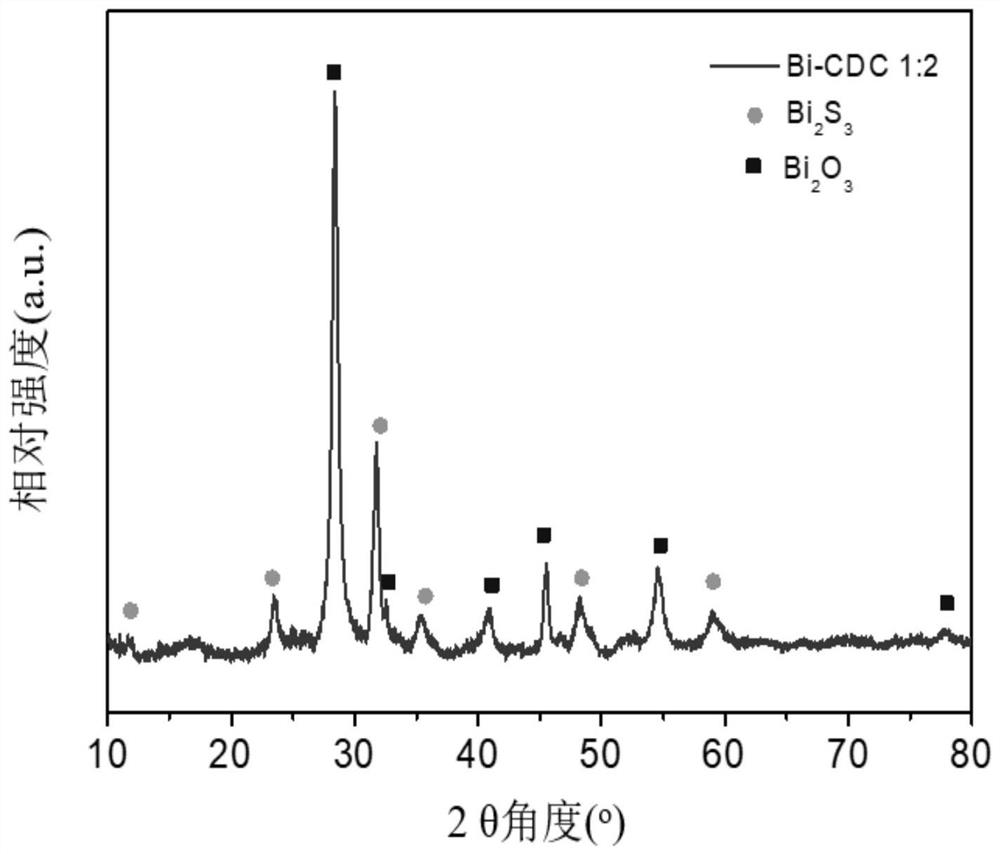

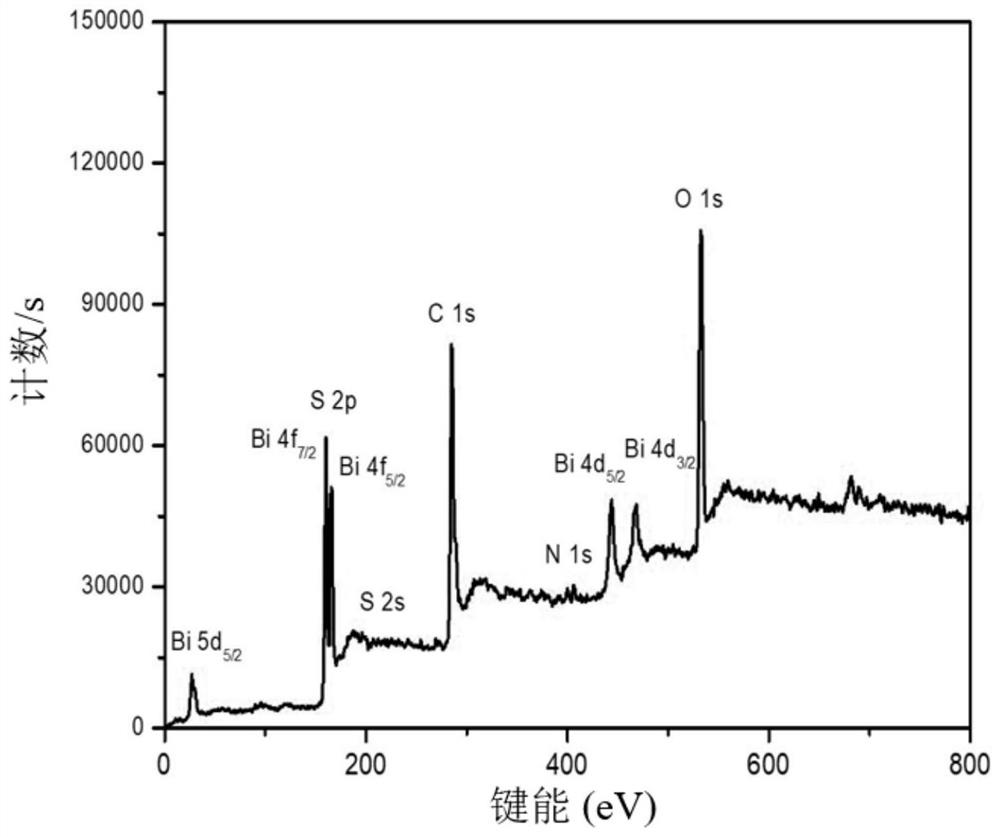

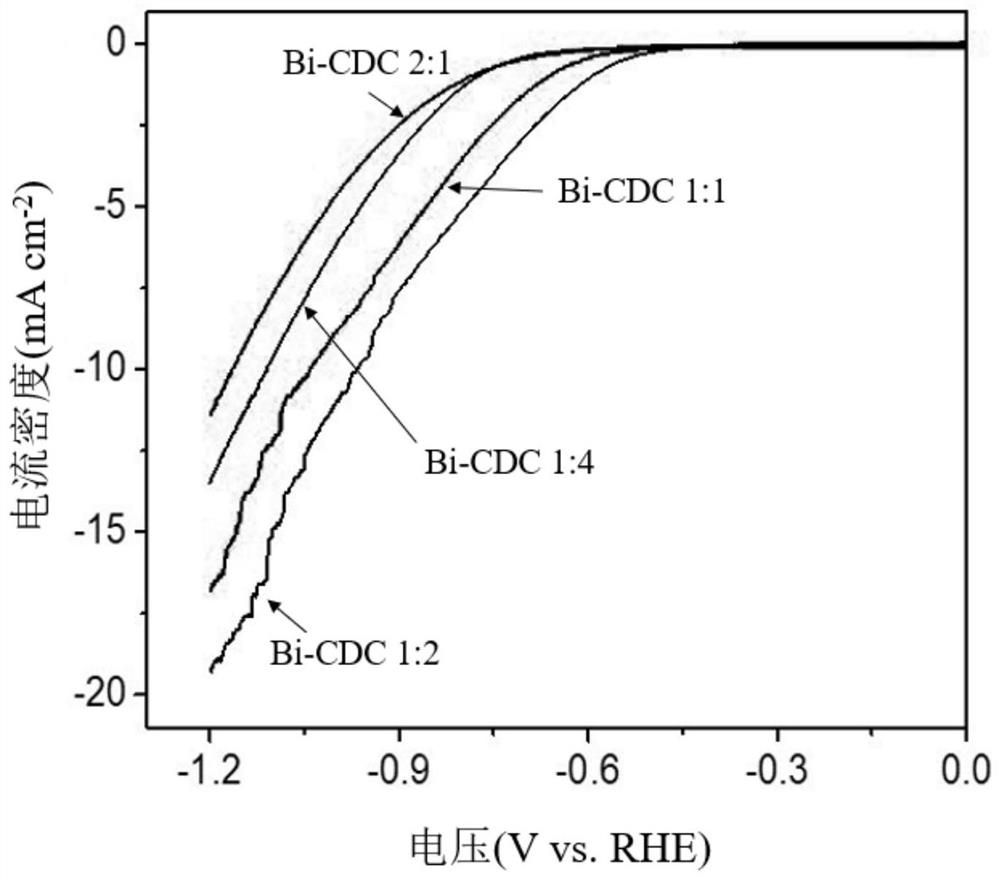

Three-dimensional porous carbon supported bismuth sulfide/bismuth oxide composite catalyst as well as preparation method and application thereof

ActiveCN113201759AImprove conductivityHigh catalytic activityElectrolytic organic productionElectrodesBismuth sulfideChemical industry

The invention relates to the technical field of energy chemical industry and nanometer materials, and discloses a three-dimensional porous carbon supported bismuth sulfide / bismuth oxide composite catalyst and a preparation method and application thereof. In the catalyst, bismuth sulfide and bismuth oxide are loaded on porous carbon nanosheets in the form of nanorods, and the bismuth sulfide nanorods and the bismuth oxide nanorods are staggered; and the surface of the porous nanosheet is of a porous structure, the pore diameter is 50-100 microns, the length of the bismuth sulfide or bismuth oxide nanorod is 3-10 microns, and the diameter is 80-120 nm. The preparation method comprises the following steps: roasting carrageenan to obtain porous carbon nanosheets, mixing the porous carbon nanosheets with a bismuth nitrate solution, carrying out a hydrothermal reaction, washing the precipitate with water, and conducting drying to obtain the composite catalyst. The catalyst is prepared by using biomass carrageenan as a raw material, and the catalyst is used as a cathode material for electrochemical CO2 reduction to prepare an HCOOH product. The catalyst has high selectivity and catalytic activity.

Owner:QUZHOU RES INST OF ZHEJIANG UNIV +1

3d direct writing zirconia ceramic ink

3D direct writing zirconia ceramic ink, including zirconia particles, solvents, binders, dispersants and salt substances; the particle size of zirconia particles is 0.1-2μm, and the solid phase content in the ink is 40-58vol%; dispersant It is one or more of polyacrylic acid, polyvinyl acid, ammonium polyacrylate, polyvinyl acid salt, polyacrylate, polycarboxylate, and polyacetimide, and the dispersant is 0.1-2% by mass of dry powder of zirconia particles; Salt substances are ammonium chloride, zinc acetate, sodium chloride, magnesium chloride, potassium chloride, barium chloride, ammonium bicarbonate, anhydrous calcium chloride, potassium carbonate, sodium bicarbonate, sodium carbonate, anhydrous sodium carbonate, anhydrous One or more of sodium acetate water, anhydrous calcium chloride, copper sulfate, basic copper carbonate, ammonium sulfate, ammonium bicarbonate, aluminum potassium sulfate, and sodium citrate, and the salt substance is 0.001-0.1% of the ink mass. The invention can be printed at room temperature, has relatively high solid content, can flow out from fine nozzles without clogging, can quickly solidify into filaments with certain strength, and has good rheological properties.

Owner:CENT SOUTH UNIV

Method for producing 3,6-dichloropyrimidine-2-carboxylic acid by biocatalysis

InactiveCN101906447BReduce poisonReduce inhibitionBacteriaMicroorganism based processesHigh concentrationOrganic solvent

The invention belongs to the field of biochemical engineering, and discloses a method for producing 3,6-dichloropyrimidine-2-carboxylic acid by biocatalysis. In the method, a nitrilase-producing active cell is taken as a biocatalyst, and a substrate 3,6-dichloro-2-cyanopyridine is hydrolyzed into the 3,6-dichloropyrimidine-2-carboxylic acid in a water-organic solvent biphasic system at the temperature of between 15 and 35 DEG C. In the method, biocatalytic reaction is coupled with product separation, so that the toxicity and inhibition effect of the high-concentration substrate and the product on the cell is effectively overcome, and the product is effectively separated; therefore, the method has the advantages of simple operation, mild reaction condition, and suitability for industrialized production.

Owner:NANJING HUAZHOU PHARMA

Waste water centralized processing method in chemical industrial park

InactiveCN101381187BLow costImplement safe handling technologyMultistage water/sewage treatmentWater/sewage treatment by sorptionActivated carbonElectrolysis

The invention discloses a centralized wastewater treatment method for chemical industrial parks, which belongs to the field of wastewater treatment. The method comprises the following steps: chemical wastewater is first pretreated through electrolysis; then the wastewater is subjected to biochemical treatment through an efficient biological flow bed reactor or an intermittent aeration biological granular bed reactor; and finally, the wastewater is subjected to advanced treatment through an ozone-activated carbon process. The method has the advantages that the method can adopt a pretreatment technique adapted to various water qualities of chemical wastewater to treat the chemical wastewater fast and efficiently according to the characteristic that the production wastewater of the chemical industrial parks is different in water quality and emission standard, develops a wastewater treatment integration technique for the chemical industrial parks, which combines point source pretreatment with centralized treatment and takes biological treatment as a core, realizes a safe treatment technique for tail water, has effluent indices meeting recycling standards, and is convenient for large-scale industrial application.

Owner:NANJING UNIV

Mixed sample preparation method for high-cobalt and low-cobalt powder alloy and high-cobalt and low-copper granular alloy

ActiveCN104749008BImprove representationIncrease the pricing factorPreparing sample for investigationParticulatesPrill

The invention discloses a sampling and sample preparation method suitable for mixing powdery red alloy with high copper and low cobalt and granular white alloy with high cobalt and low copper. Machine, 1 / 2 shrinking device, 1 mm sieve, use shovel and scraper to quickly mix samples, use cuttings with special sampling function to carry out grid sampling, alloy samples are sieved by 1 mm sieve, and the material on the sieve is large The granular alloy is passed through a double-roller crusher and a grinder to make the alloy particle size less than 1mm, and then the alloy sample is mixed and quickly separated by a shrinker. The invention can efficiently realize the rapid mixing, sampling and sample preparation of the alloy, and the sample has the characteristics of strong representativeness and good uniformity after the sample is made, and the method is simple to operate, occupies a small area, and is easy for large-scale industrial application.

Owner:北方矿业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com