Inner-cooling inert anode for electrolytic aluminum

An inert anode, electrolytic aluminum technology, applied in the field of electrolytic aluminum equipment, can solve the problems of inferior electrical conductivity as metal and metal matrix composite materials, increased physical pressure drop of anode components, and unsuitable for large-scale production, etc., to expand the selection range, The effect of meeting the technical requirements of aluminum electrolysis production and being easy for large-scale industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

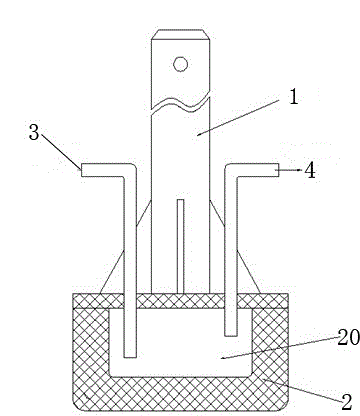

[0016] Attached below figure 1 The present invention is further described in detail: an internally cooled inert anode for electrolytic aluminum, including a conductive rod 1 and a metal or metal matrix composite material anode 2 connected thereto, and the inner cavity 20 of the metal or metal matrix composite material anode is hollow structure, the inner cavity 20 communicates with an external circulating cooling system (not shown in the figure) and a heat exchanger (not shown in the figure) through the cooling medium inlet 3 and outlet 4 provided on the metal or metal matrix composite anode.

[0017] The anode material of the metal or metal matrix composite material is aluminum, aluminum alloy material or aluminum matrix composite material; the cooling medium is water and its solution. In a high-temperature environment, water and its solution control the temperature of the anode within a certain range from the inside to the outside under the action of an external circulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com