Patents

Literature

90results about How to "Affect production quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

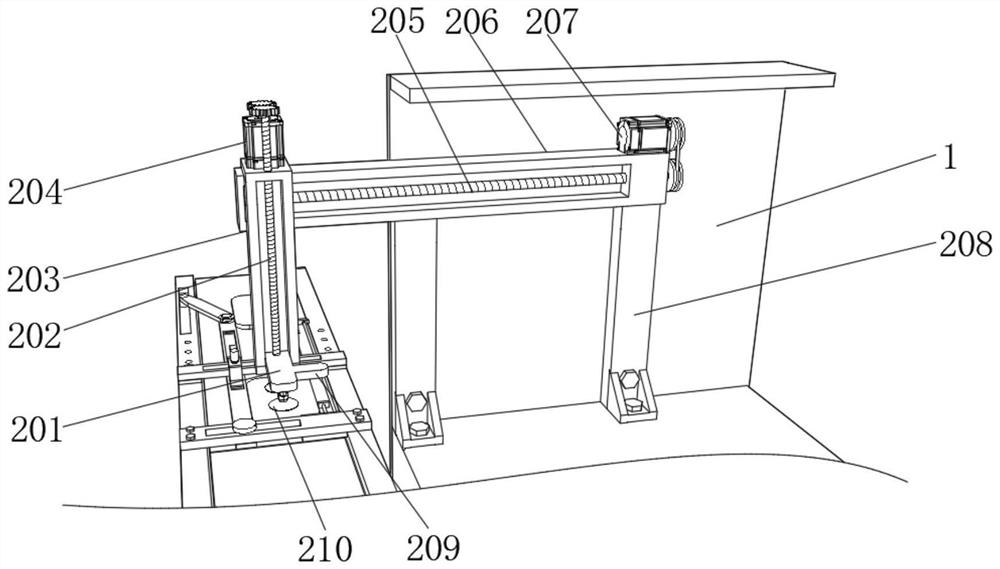

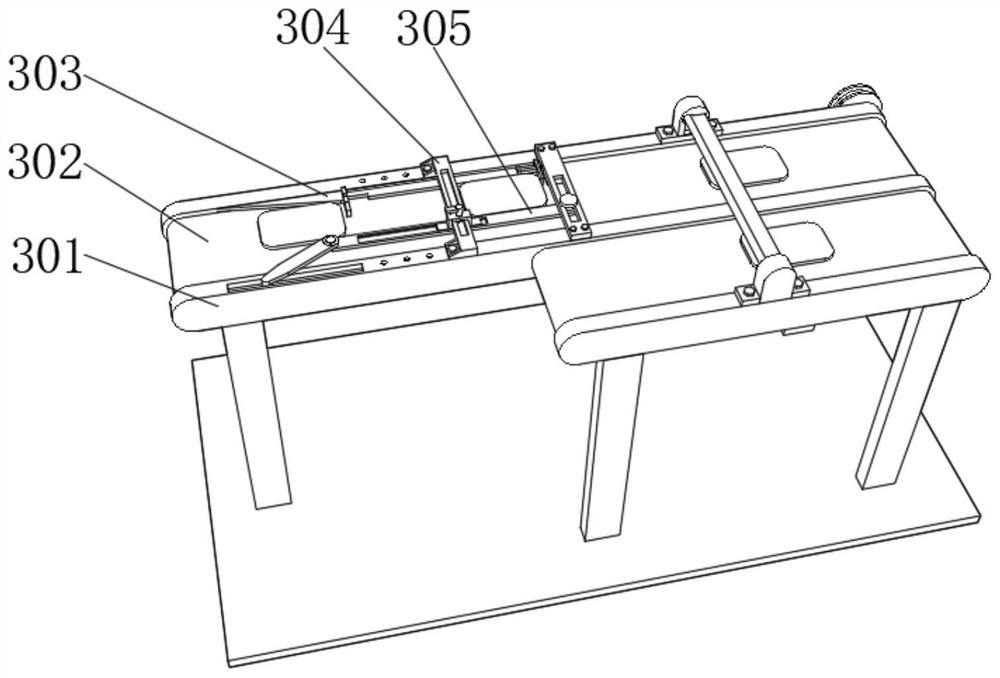

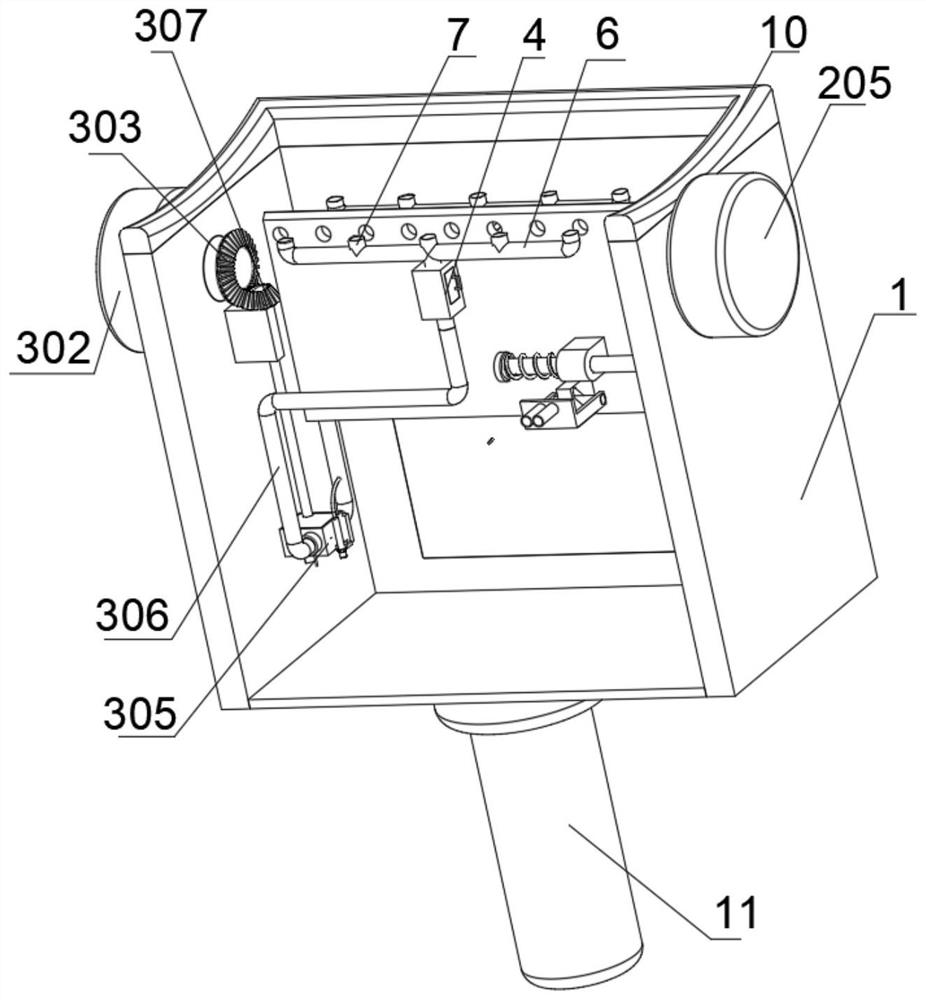

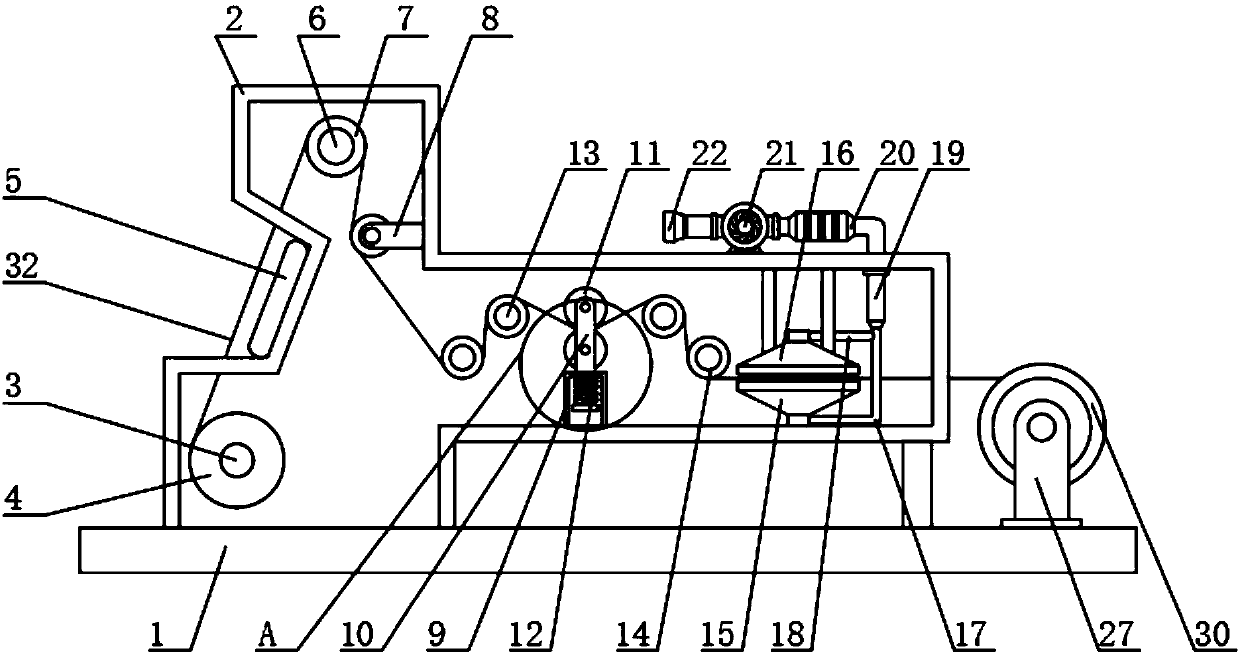

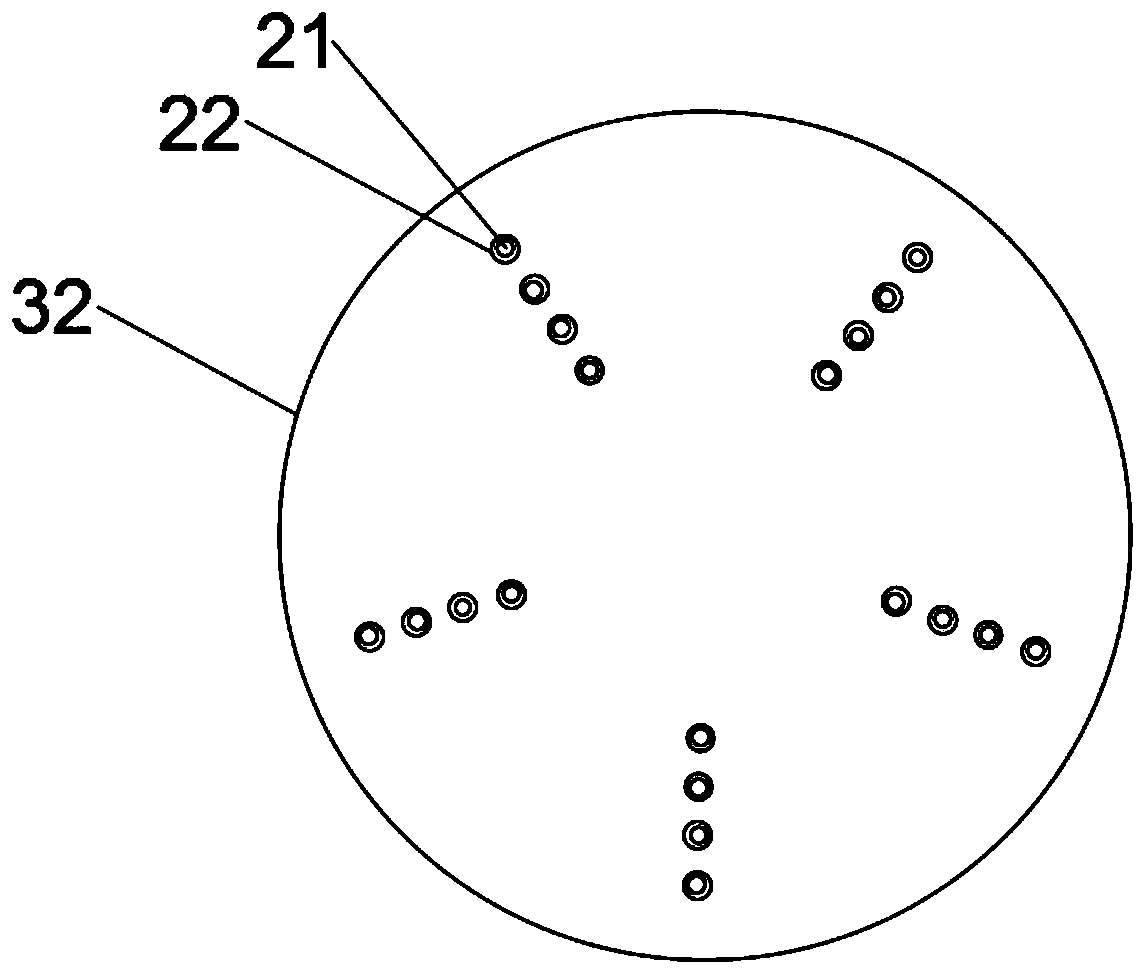

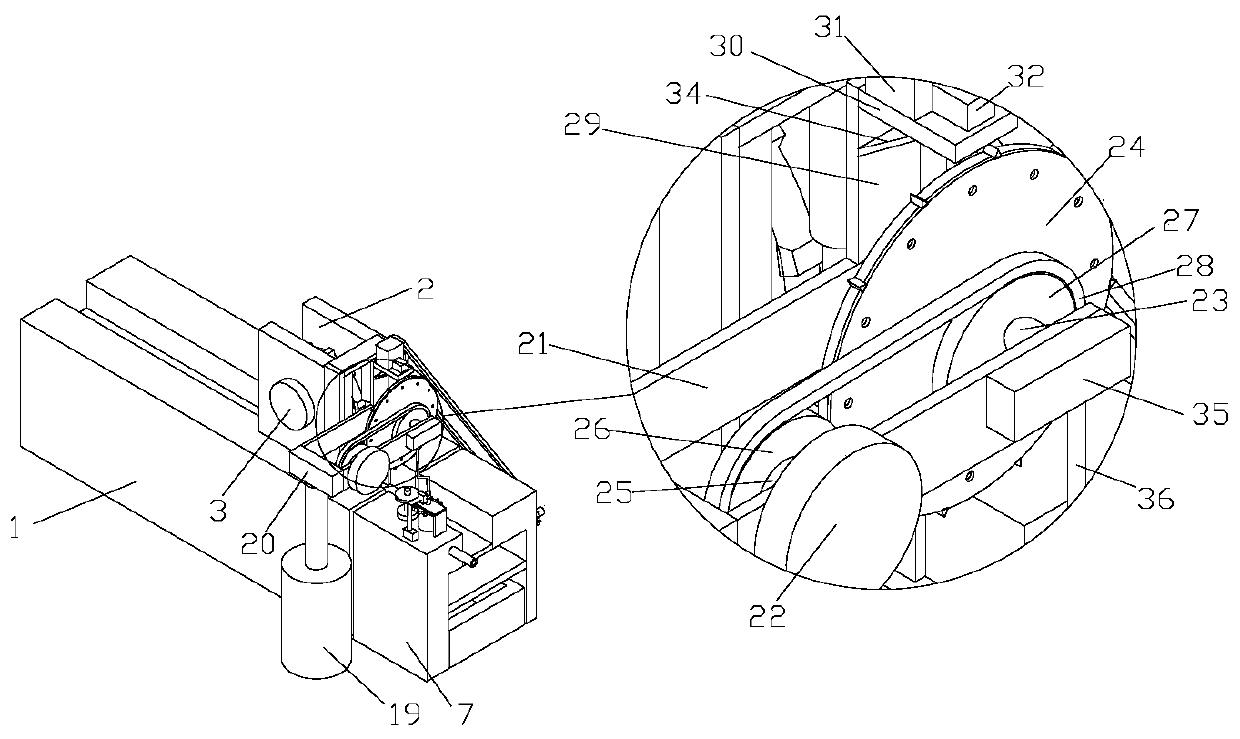

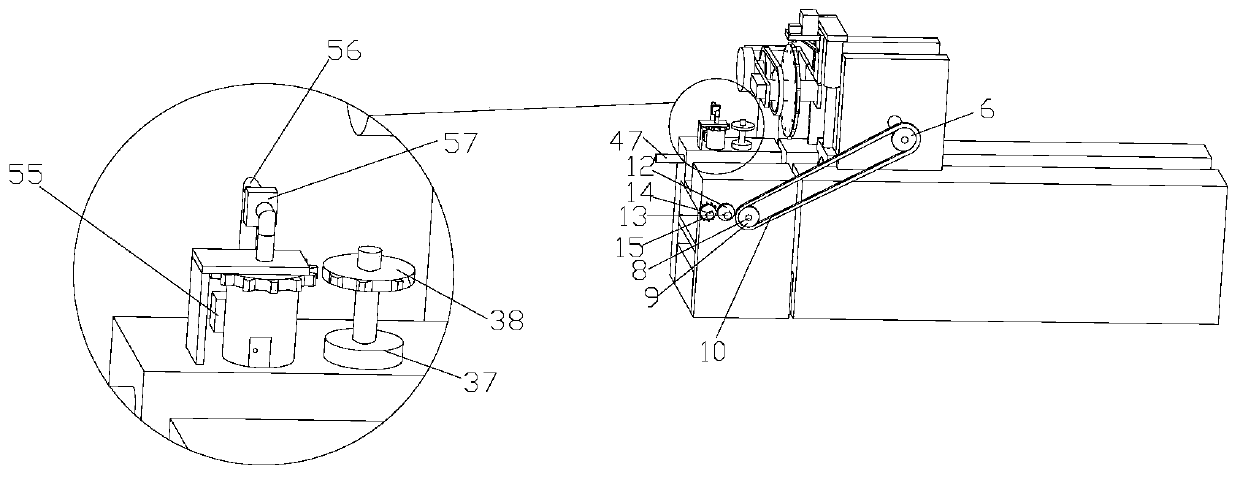

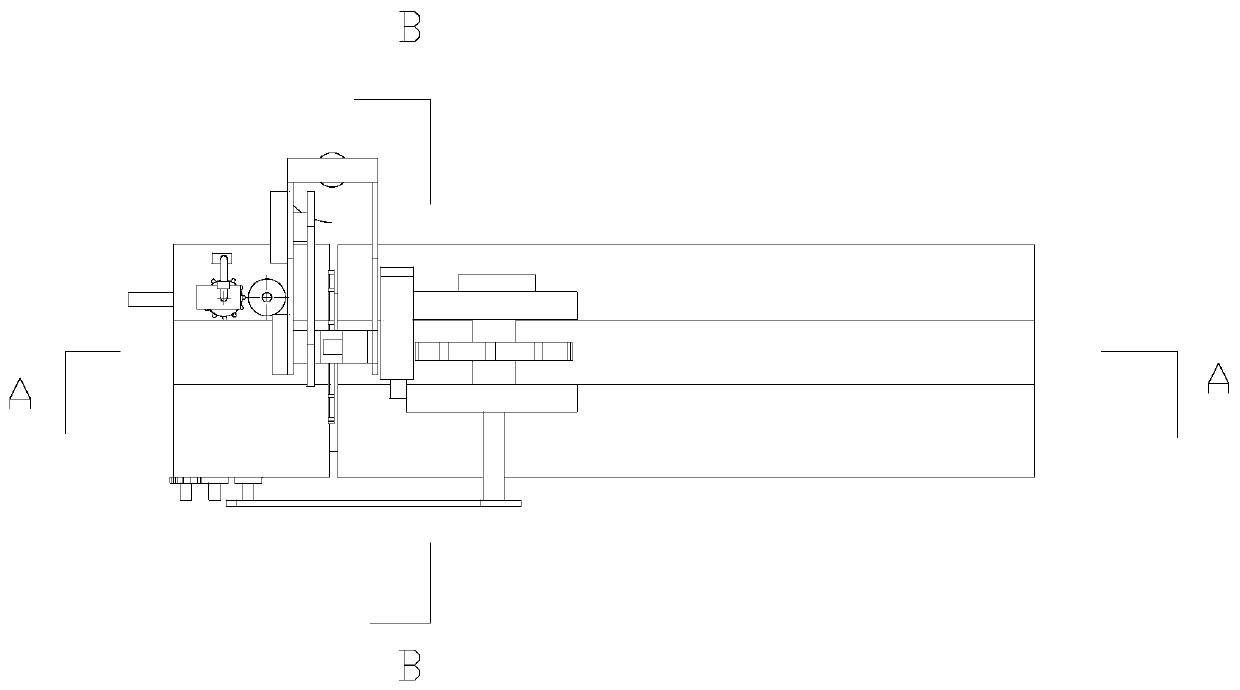

Connector device of cord fabric cutting machine and method thereof

ActiveCN101653992AReduce frictionSolve the problem of lack of motivationTyresElectric machineryEngineering

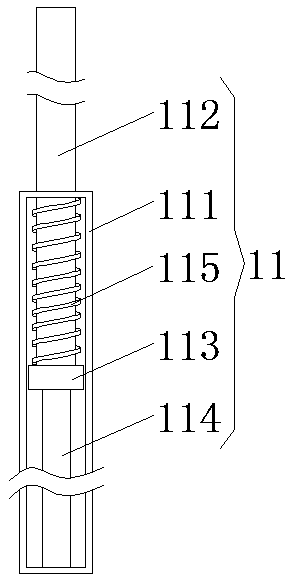

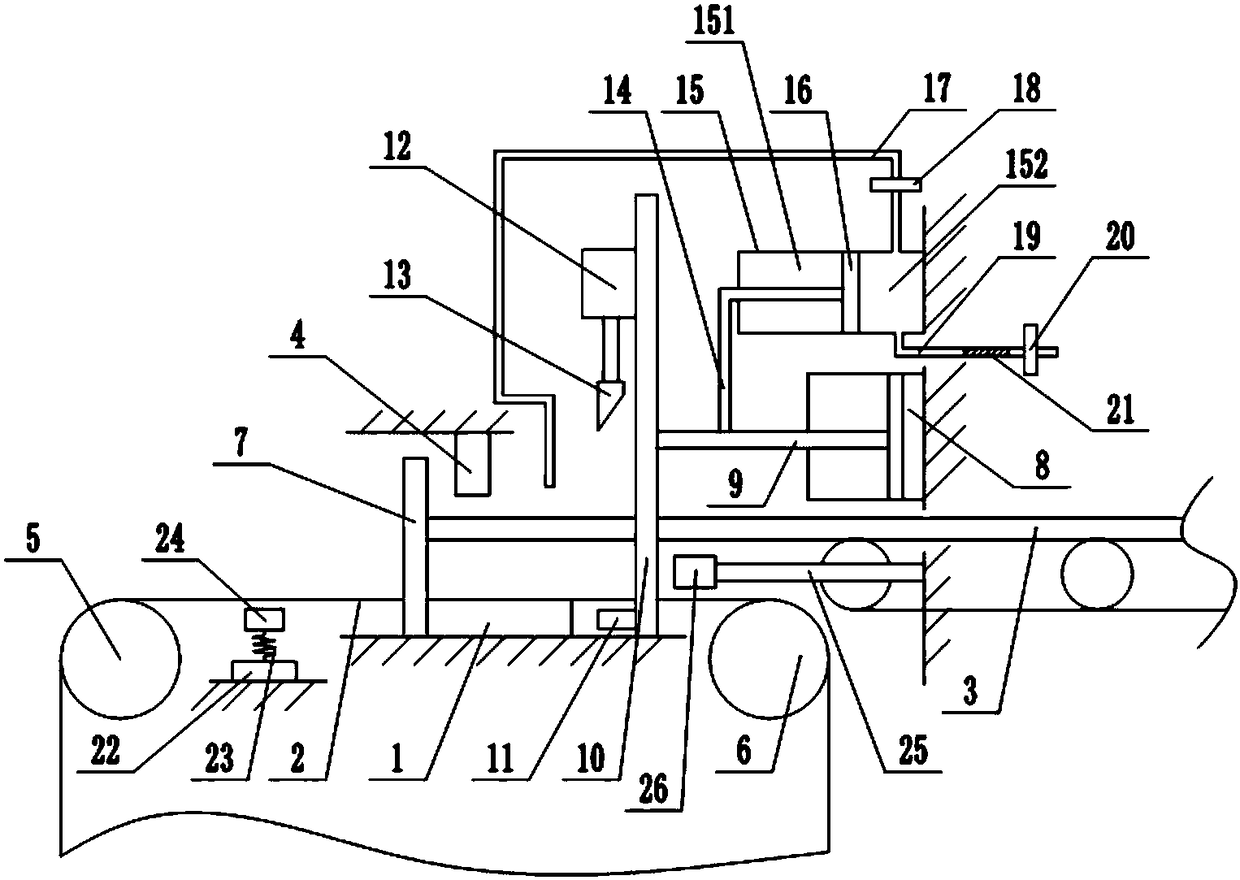

The invention provides a connector device of a cord fabric cutting machine and a method thereof, which feed the previous cord fabric and the next cord fabric in sequence forwards by adopting the same integrated connector conveying belt, and lift the tail part of the previous cord fabric from the conveying belt before the connector is stitched and position the cord fabric so as to completely solvethe problem of dynamic shortage of a strip of the cord fabric and realize a resistance-free conveying mode. The connector device of the cord fabric cutting machine is mainly provided with a frame carrying the connector conveying belt, wherein the connector conveying belt is driven by a servo motor and conveys the cord fabric along the vertical direction of the frame; the front end of the frame isprovided with a connector mechanism which is used for connecting the previous cord fabric and the next cord fabric together; the upper part of the frame is only provided with the integrated connectorconveying belt; the vertical length of the conveying belt is larger than the maximum length specification of the conveyed cord fabric; the front end of the connector conveying belt is provided with acord fabric lead device; and a cross beam of the connector mechanism is provided with an adsorption mechanism which is used for upwards lifting and positioning the end part of the cord fabric.

Owner:MESNAC

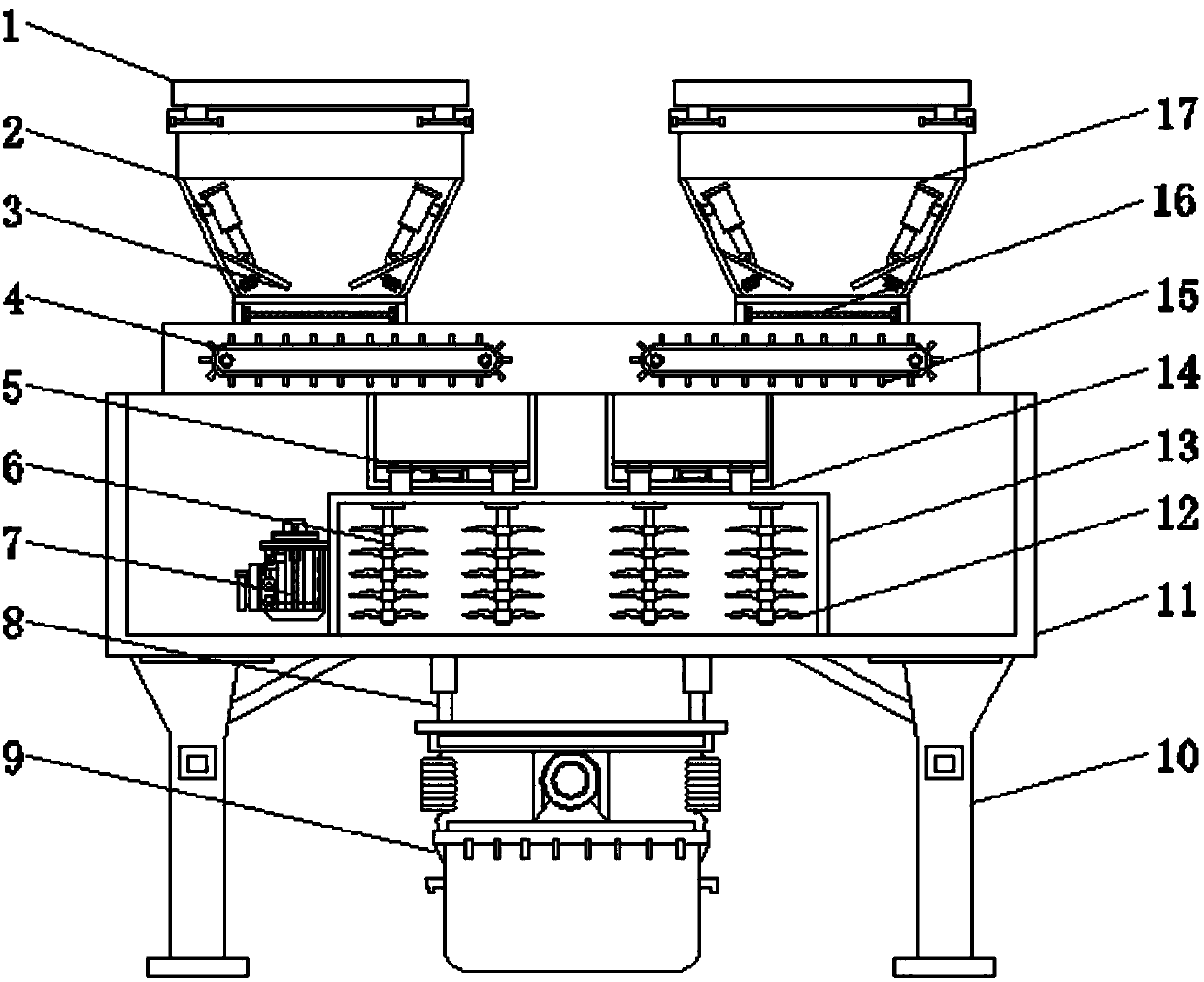

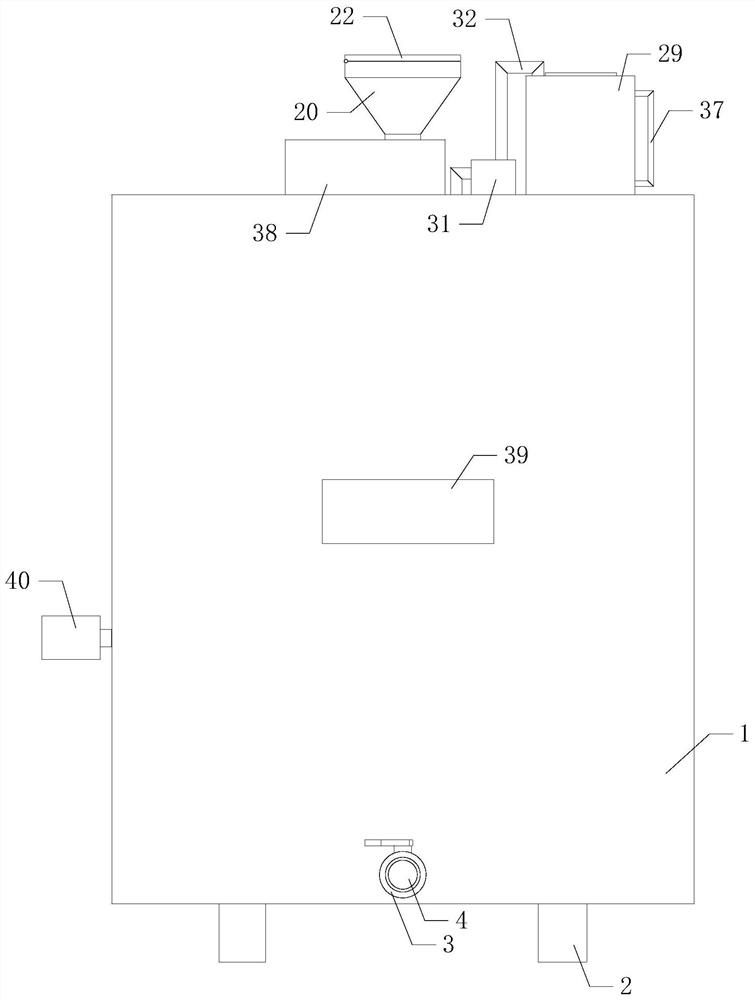

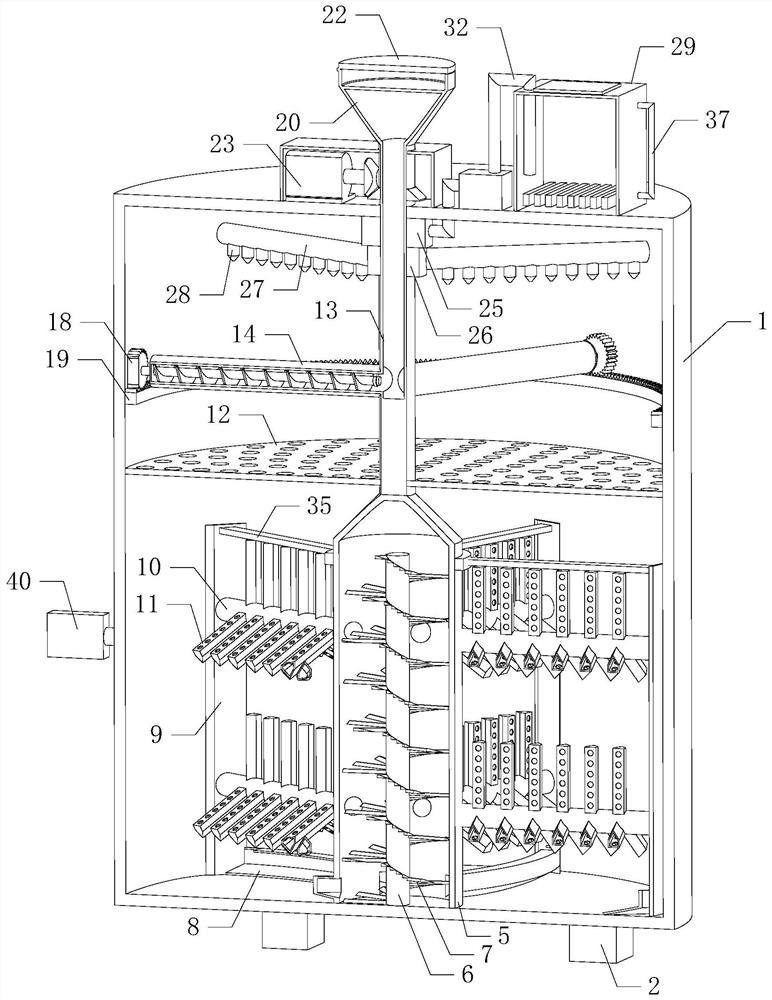

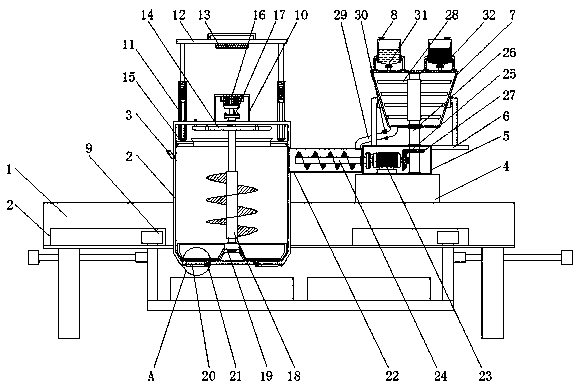

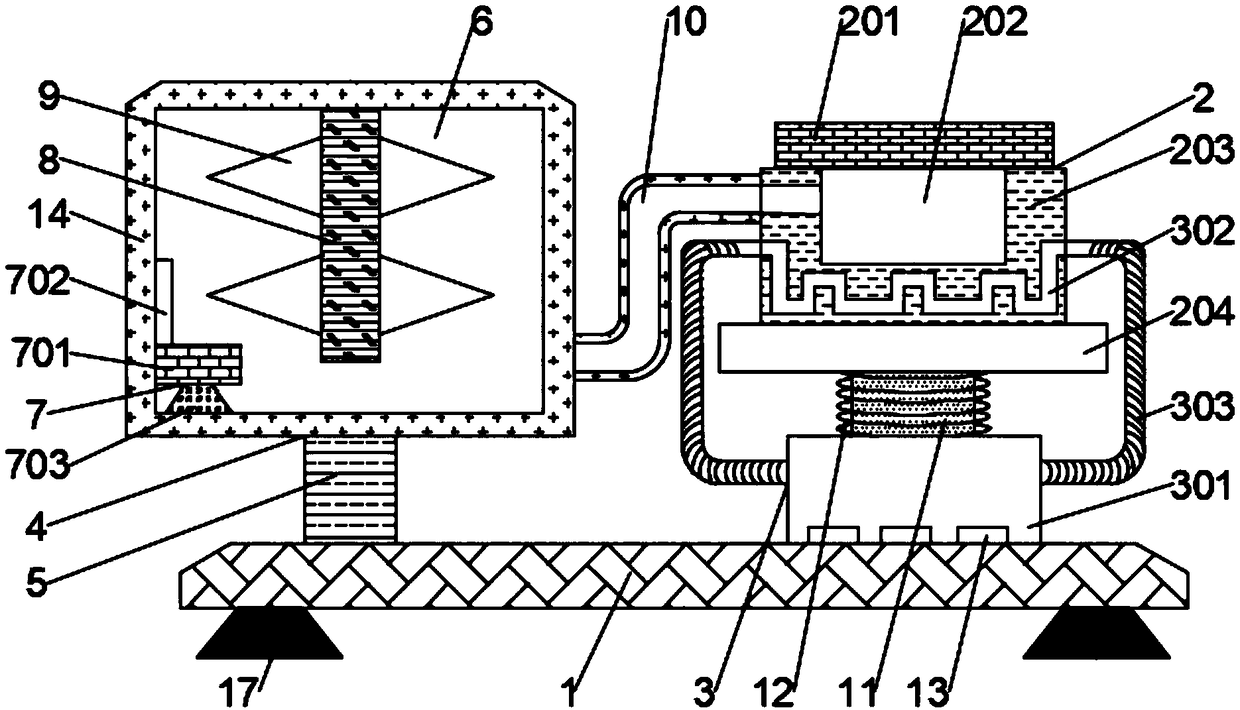

Concrete batching machine for construction

The invention discloses a concrete batching machine for construction. The machine comprises a storage bin, a support stand column, a batching machine body and a mixing bin; the batching machine body is mounted at the top end of the support stand column; four hydraulic extension rods are vertically mounted in the center position of the bottom end of the batching machine body; a mounting frame is mounted at the bottom ends of the hydraulic extension rods; a metal screen is horizontally mounted at the top end in the mounting frame; a collecting barrel is mounted at the bottom end of the mountingframe; the mixing bin is mounted at the lower end in the batching machine body; and weighing bins are mounted at the positions, located on two sides of the top end of the mixing bin, in the batching machine body. The machine is provided with pressure sensors, the weighing bins and bearing plates, when materials fall onto the bearing plates in the weighing bins, the pressure sensors timely detect the weight of the materials, and transfer signals to a control system, so that people can know the weight of the added materials at any time, and the accurate concrete batching is guaranteed.

Owner:临沂朕玮建材有限公司

Traditional Chinese medicine blender having impurity removing function

InactiveCN109092184AAffect production qualityStir wellTransportation and packagingRotary stirring mixersBiochemical engineeringImpurity

The invention discloses a traditional Chinese medicine blender having an impurity removing function. The traditional Chinese medicine blender comprises a supporting plate, wherein a stirring cylinderis arranged above the supporting plate, a supporting frame is welded at the connecting position of the supporting plate and the stirring cylinder, a second motor is arranged at the middle position ofthe lower surface of the stirring cylinder and is provided with a first transmission rod, two sides of the first transmission rod are provided with stirring rods, a filter screen is arranged above thefirst transmission rod, a smashing roller is arranged at the top end of the stirring cylinder, the bottom end of the stirring cylinder is provided with a discharging pipe, and a screening mechanism is arranged above the stirring cylinder. The screening mechanism is arranged on the traditional Chinese medicine blender, a user can screen impurities mixed in medicinal materials through the screeningmechanism and accordingly removes the impurities mixed in medicinal materials, and accordingly the left impurities are prevented from affecting the production quality of the traditional Chinese medicine blender.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

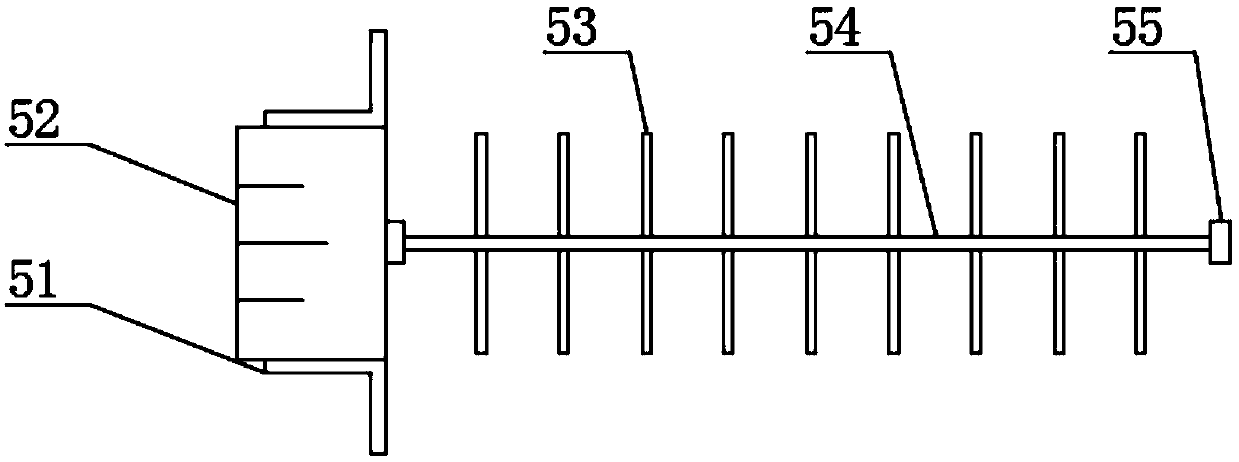

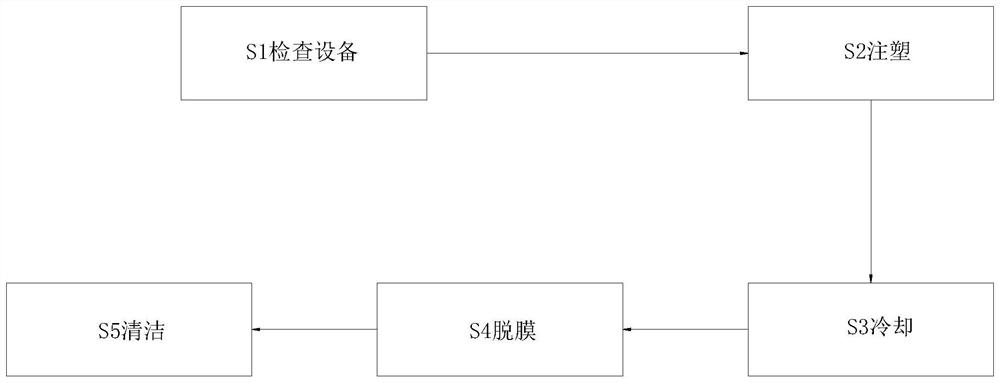

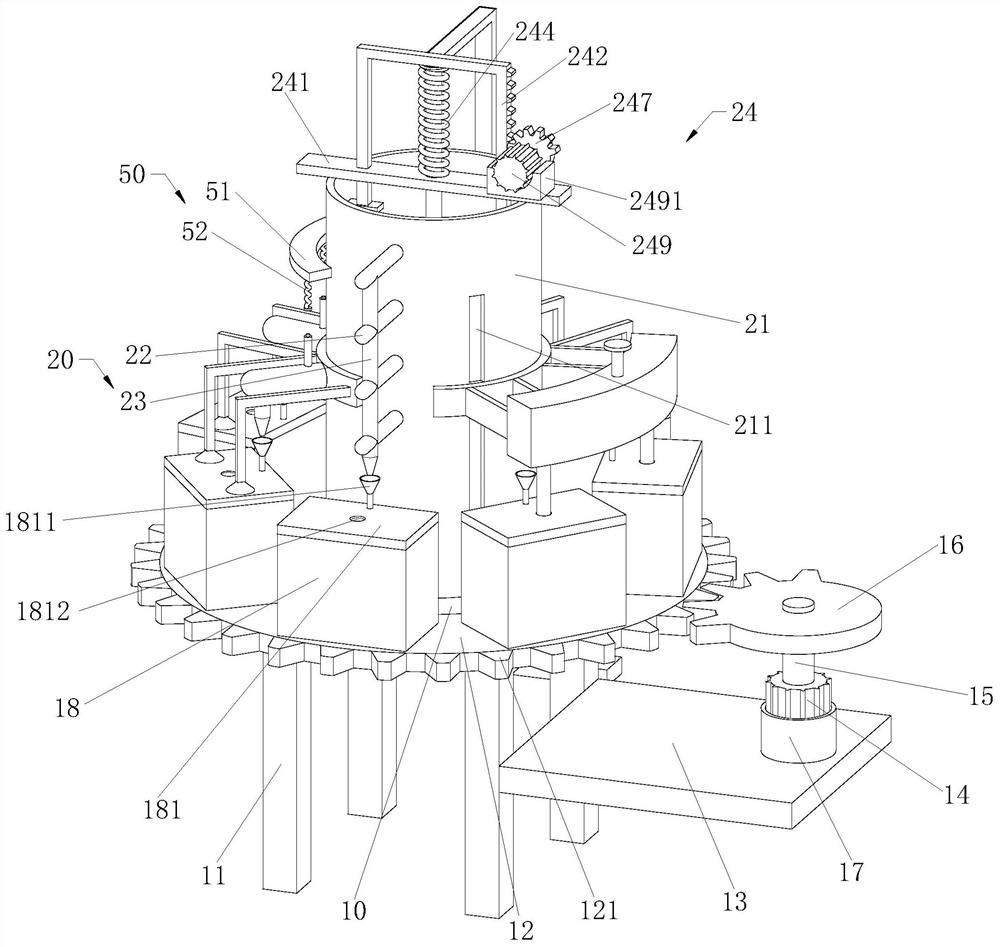

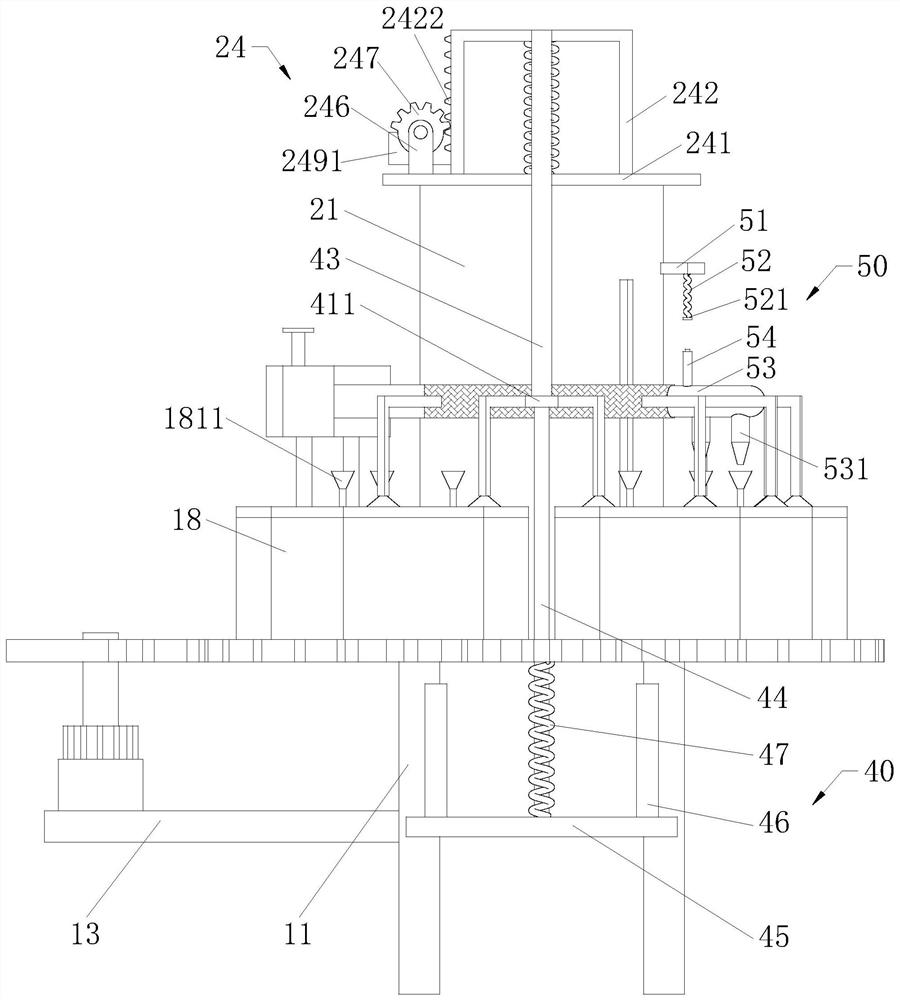

Injection molding method for environment-friendly plastic box

InactiveCN112829175APrevent overflowAffect production qualityDomestic articlesAir pumpProcess engineering

The invention relates to an injection molding method for an environment-friendly plastic box. Plastic box machining and manufacturing equipment is used and comprises a workbench and a placing table rotatably arranged on the outer wall of the workbench, a feeding device is arranged at the top of the workbench, a cooling device is arranged above the placing table, a dismounting device is arranged above the placing table, and a cleaning device is arranged above the placing table. According to the injection molding method for the environment-friendly plastic box provided by the invention, through cooperation of a current-conducting plate, an air pump and a battery, when the battery makes contact with the current-conducting plate, the air pump is powered on, airflow generated in the air pump is jetted to a feed hopper through an air blowing pipe, and therefore waste remaining on the inner wall of a mold box after demolding can be automatically cleaned, the waste in the mold box is prevented from being accumulated, the production quality of the plastic box is influenced, the cleaning time is saved, the working efficiency is improved, and the manpower is saved.

Owner:王晓春

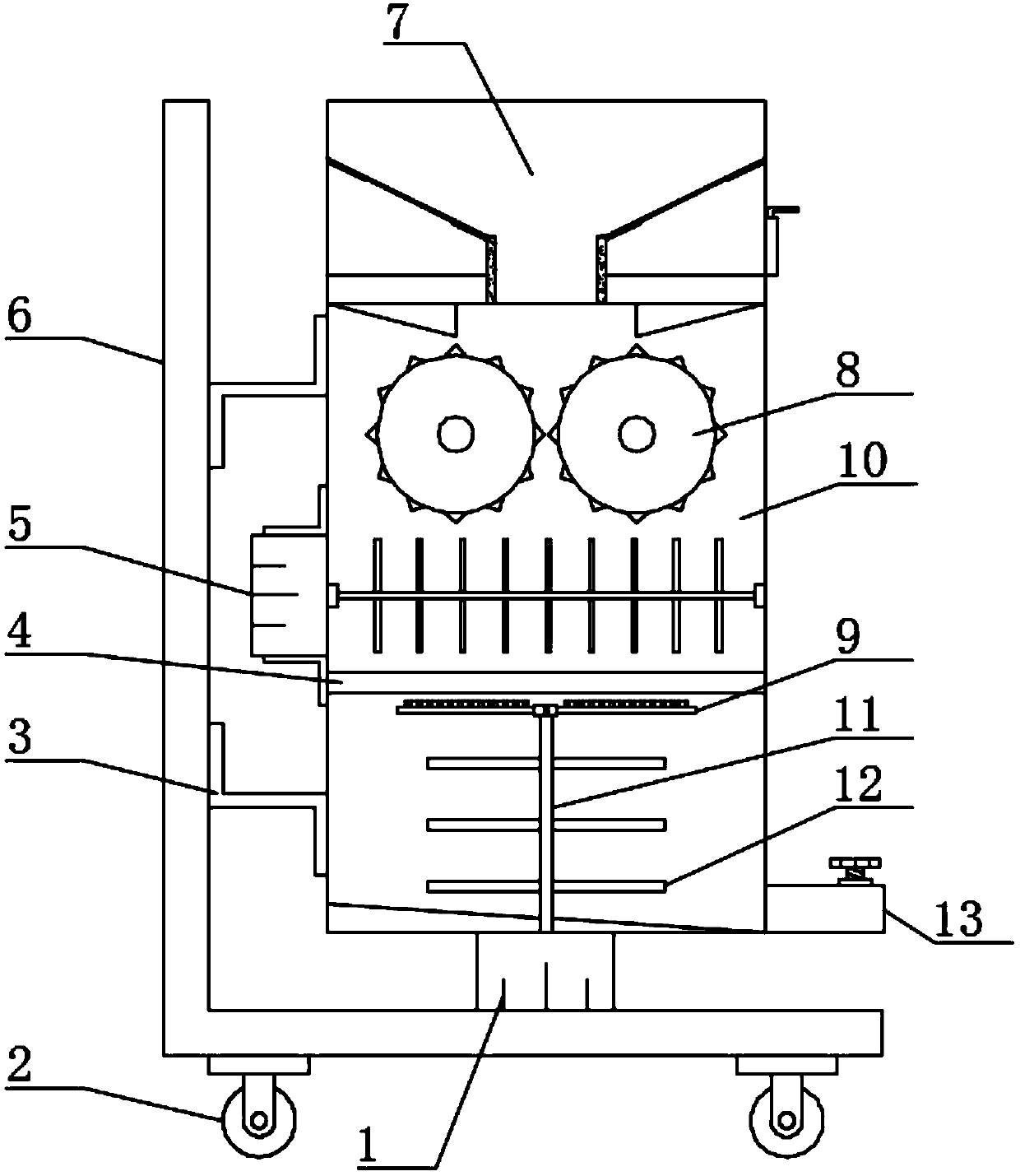

Deburring device for mold machining and using method

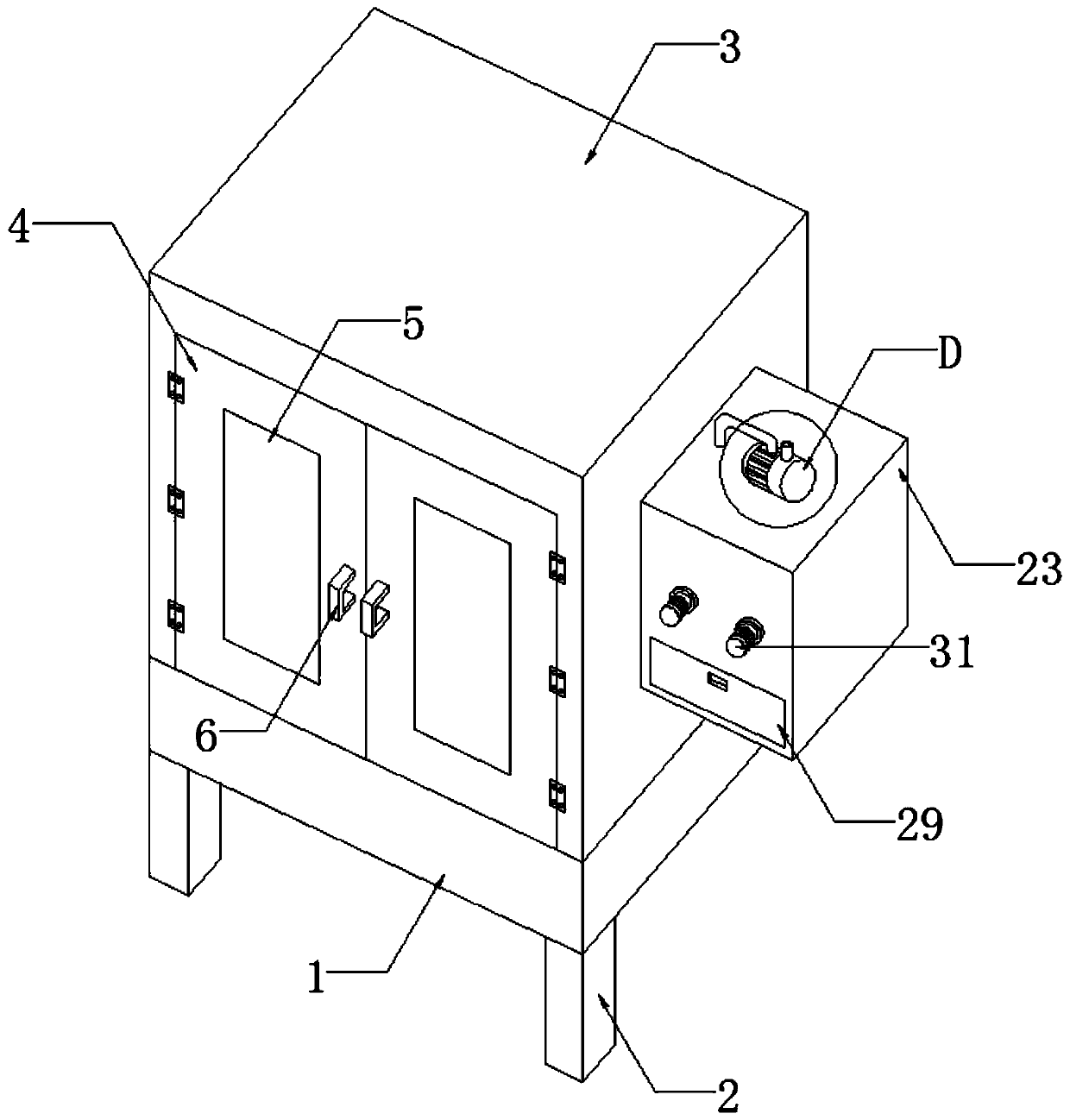

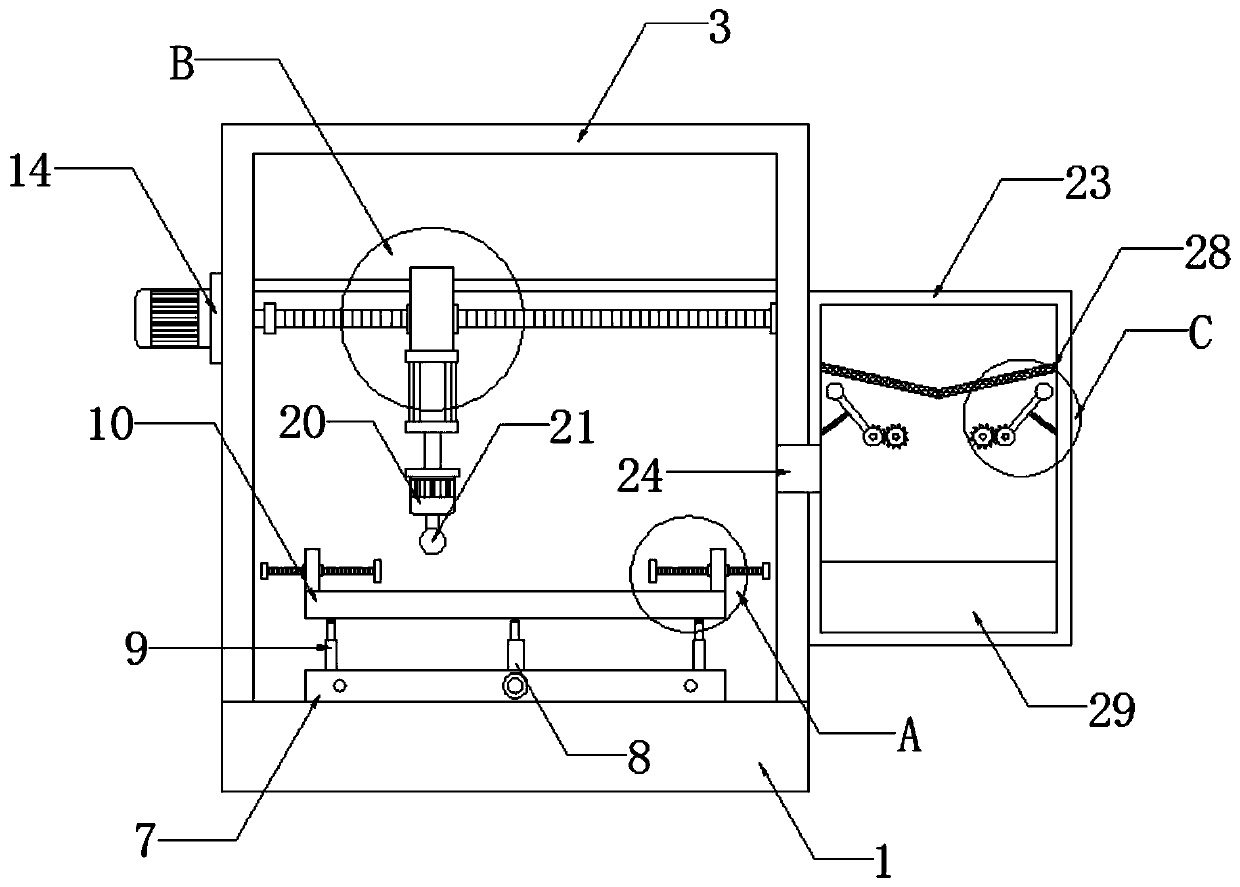

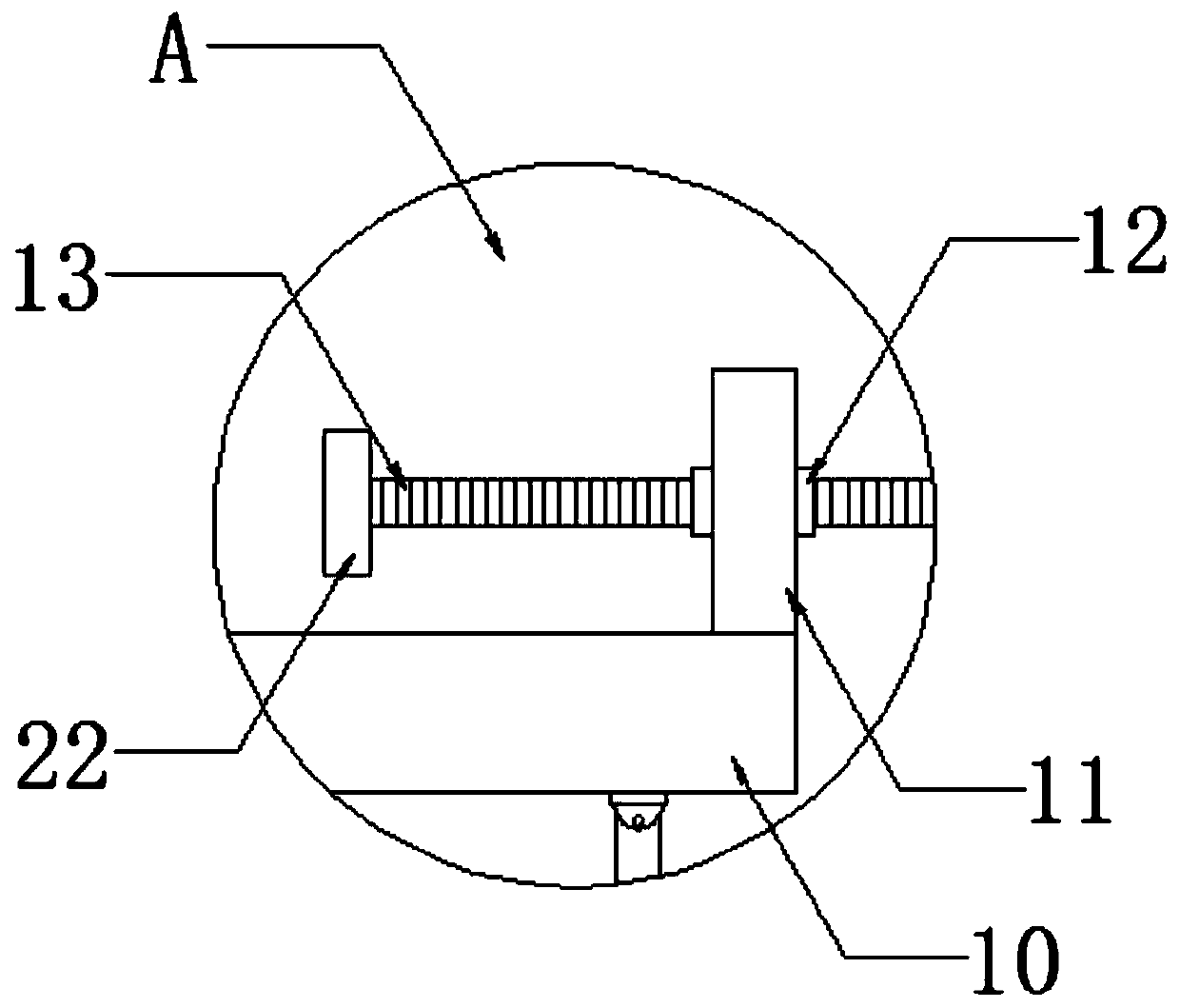

PendingCN111098196AAffect production qualityQuality improvementEdge grinding machinesDispersed particle filtrationHydraulic cylinderThreaded pipe

The invention discloses a deburring device for mold machining and a using method. The deburring device comprises a placement table and a dust removal box, supporting legs are fixedly arranged at the four corners of the bottom end of the placement table, a protective cover is fixedly arranged at the top end of the placement table, a supporting plate is arranged at the top of the placement table, afirst hydraulic cylinder is fixedly arranged at the axis of the top end of the supporting plate. The deburring device has the beneficial effects that through cooperation of an arranged screw rod and an threaded pipe, an round clamping plate is conveniently driven to clamp the mold, therefore the situation that the position of the mold is changed in the machining process, and the production qualityof the mold is influenced is avoided; the first screw rod can be conveniently driven to rotate through an arranged first forward and reverse rotation motor, a moving block can be driven to move in the X-axis direction under the action of a first limiting rod, accordingly, a grinding ball can be driven to move in the X-axis direction, a second screw rod can be conveniently driven to rotate throughan arranged second forward and reverse rotation motor; and under the action of the second limiting rod, the supporting plate can be driven to move in the Y-axis direction.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

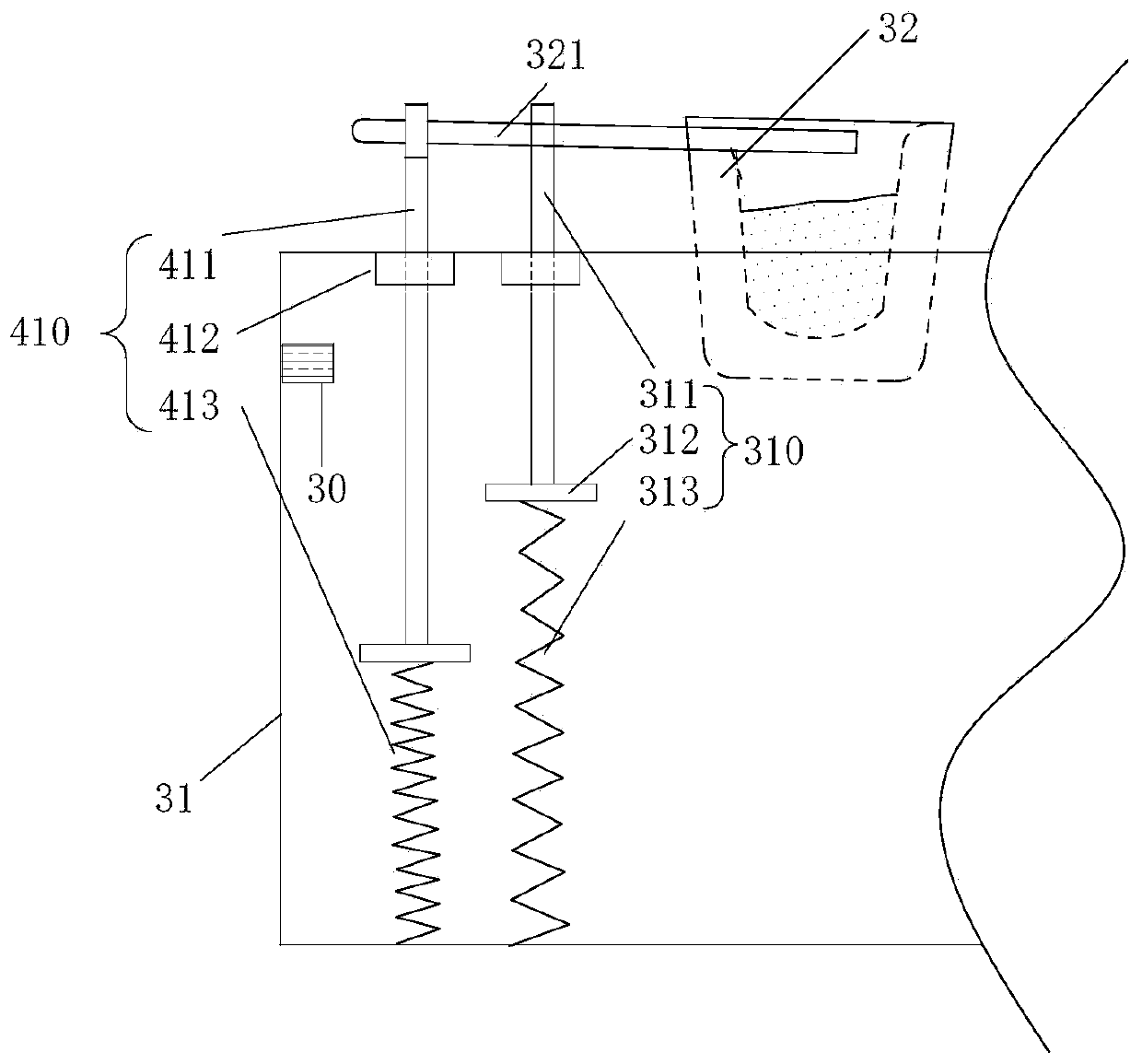

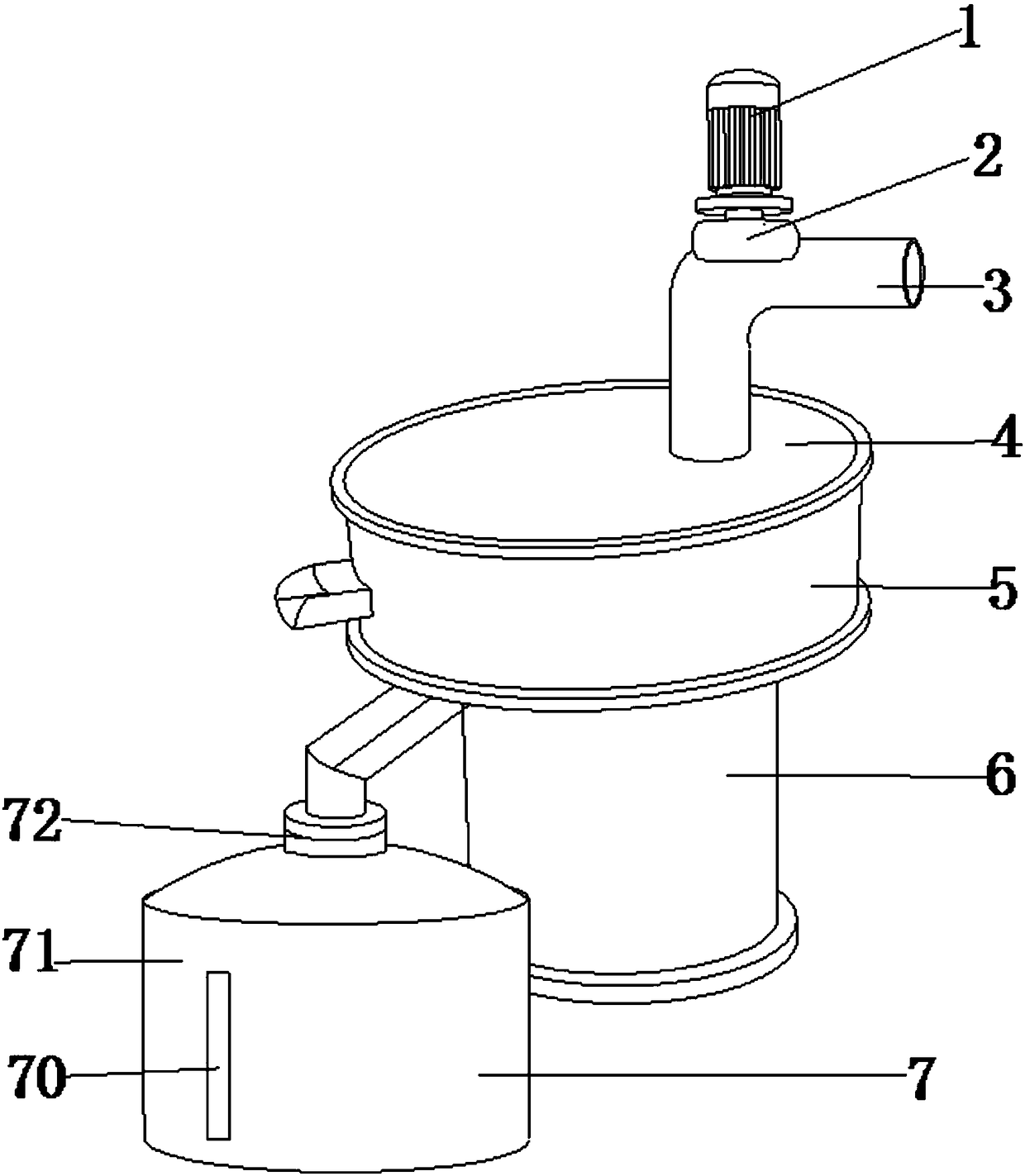

Multifunctional starch size mixing equipment

InactiveCN112569843AEasy to integrateIncrease generation speedTransportation and packagingMixer accessoriesFood processingFood products

The invention relates to the technical field of food processing equipment, in particular to multifunctional starch size mixing equipment, which can effectively improve the functional diversity of theequipment and the complexity degree of the structure by performing automatic size mixing treatment on starch size, is convenient for performing multi-form size mixing treatment on the starch size, effectively reduces particles and starch clusters in the starch size, improves the uniformity of starch slurry concentration, and avoids the phenomenon that the starch slurry concentration is reduced dueto the fact that starch is deposited on the inner wall of equipment, improves the starch slurry production quality, and improves the practicability and reliability; the equipment comprises a slurry mixing bin, four supporting legs, a discharging pipe, a discharging valve, a rotating barrel and a fixing shaft, the four supporting legs are evenly installed at the bottom of the slurry mixing bin, the discharging pipe is installed on the lower front side of the slurry mixing bin and communicated with the interior of the slurry mixing bin, the discharging valve is installed on the discharging pipe, and the rotating barrel is vertically installed at the bottom of the inner wall of the slurry mixing bin.

Owner:太仓联科工业设计有限公司

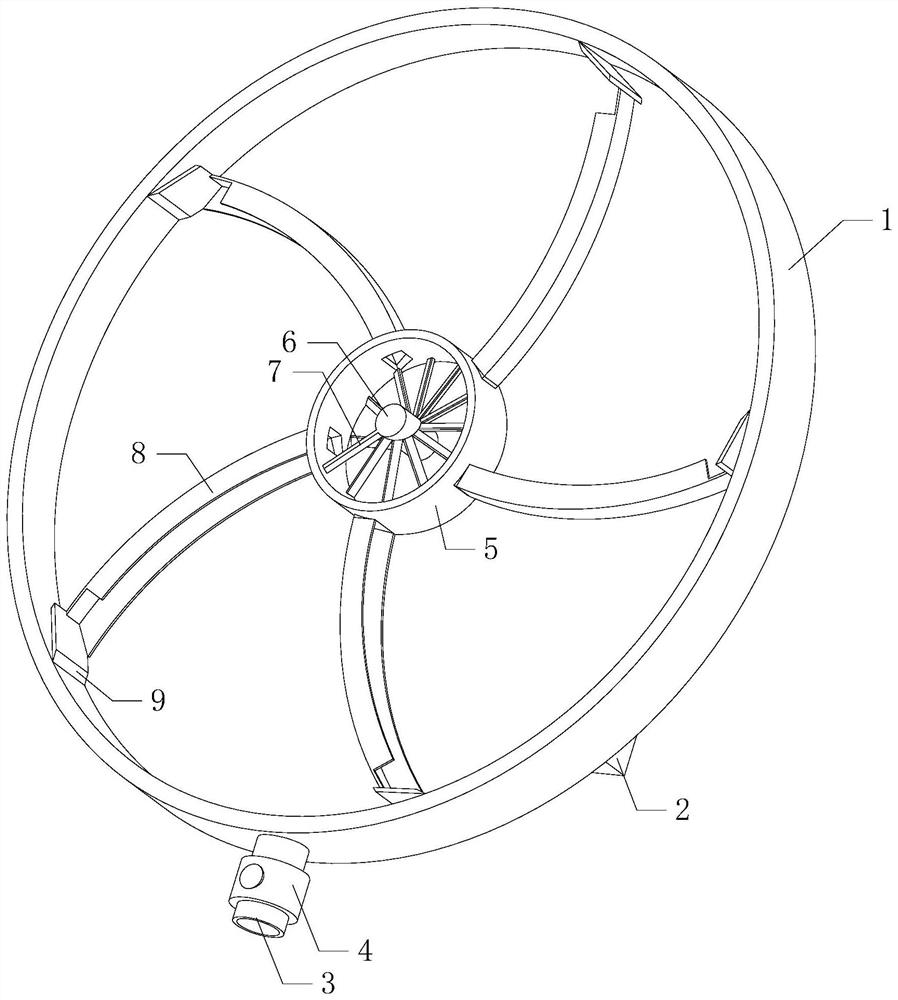

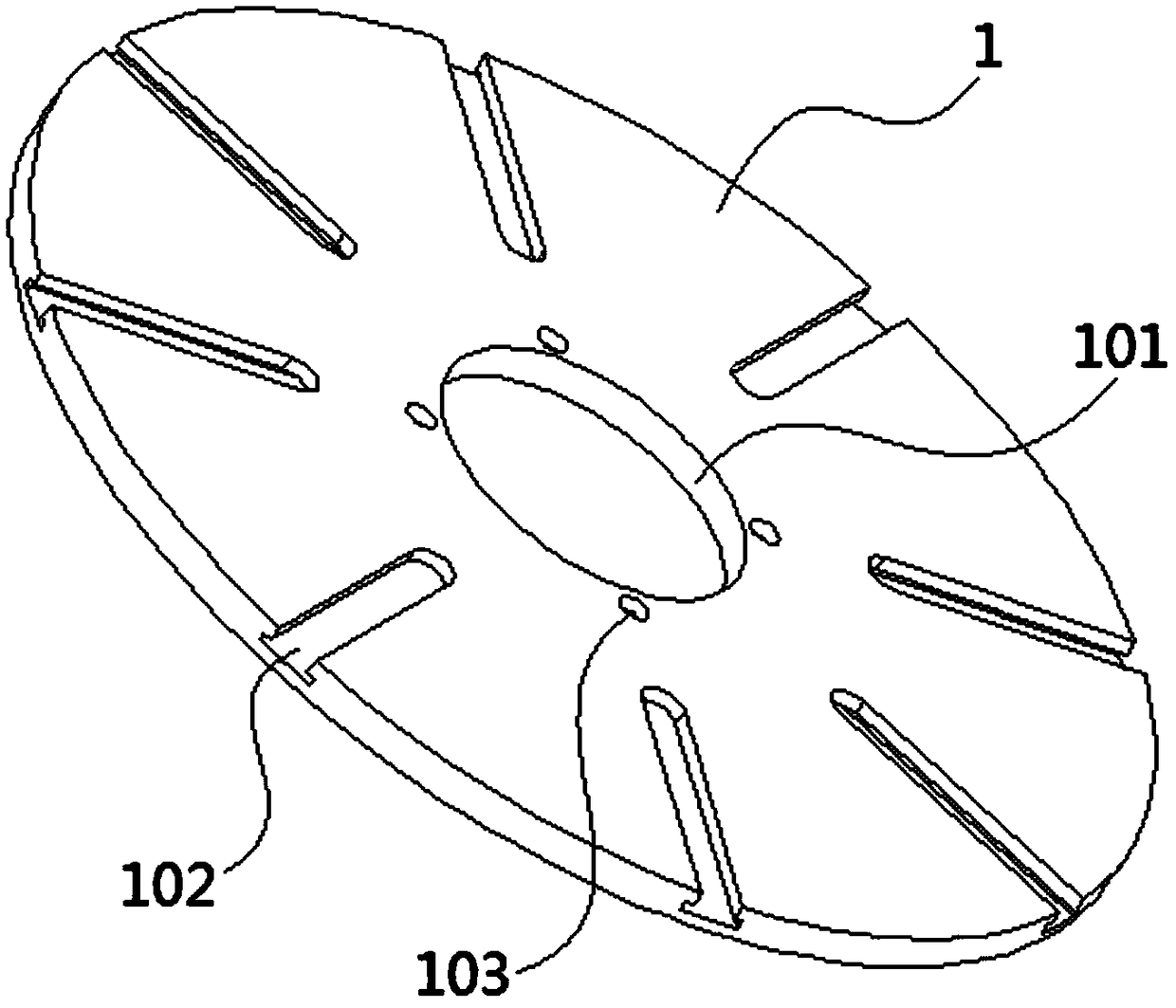

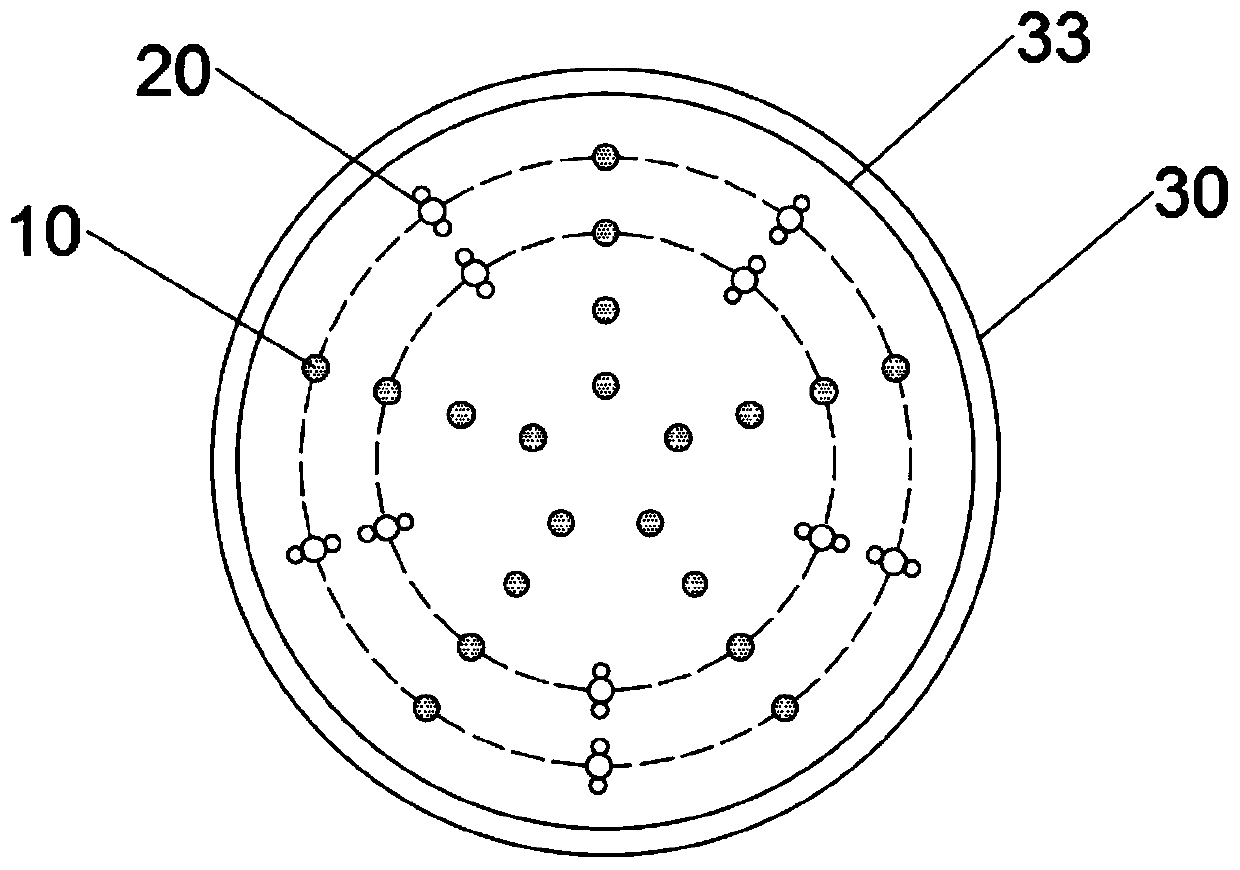

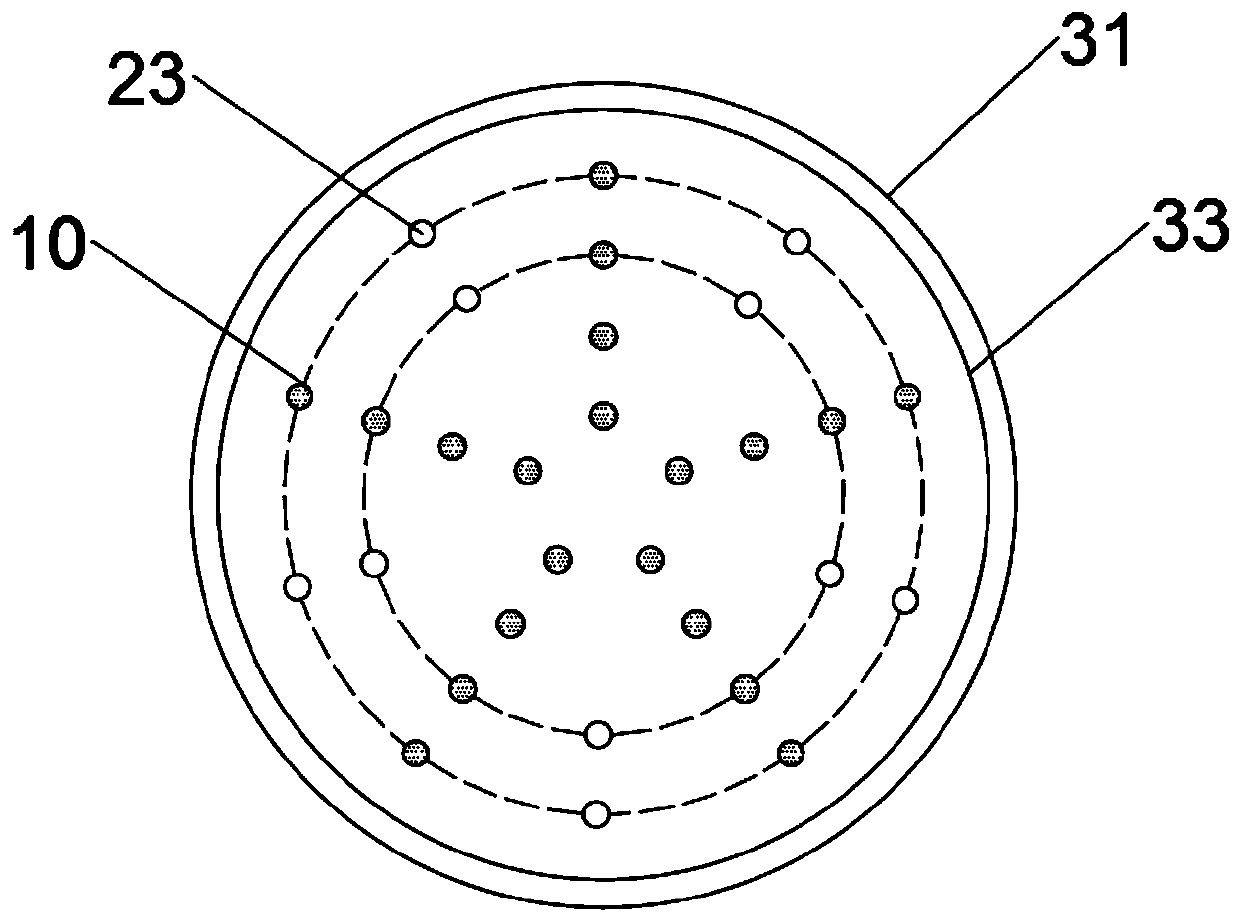

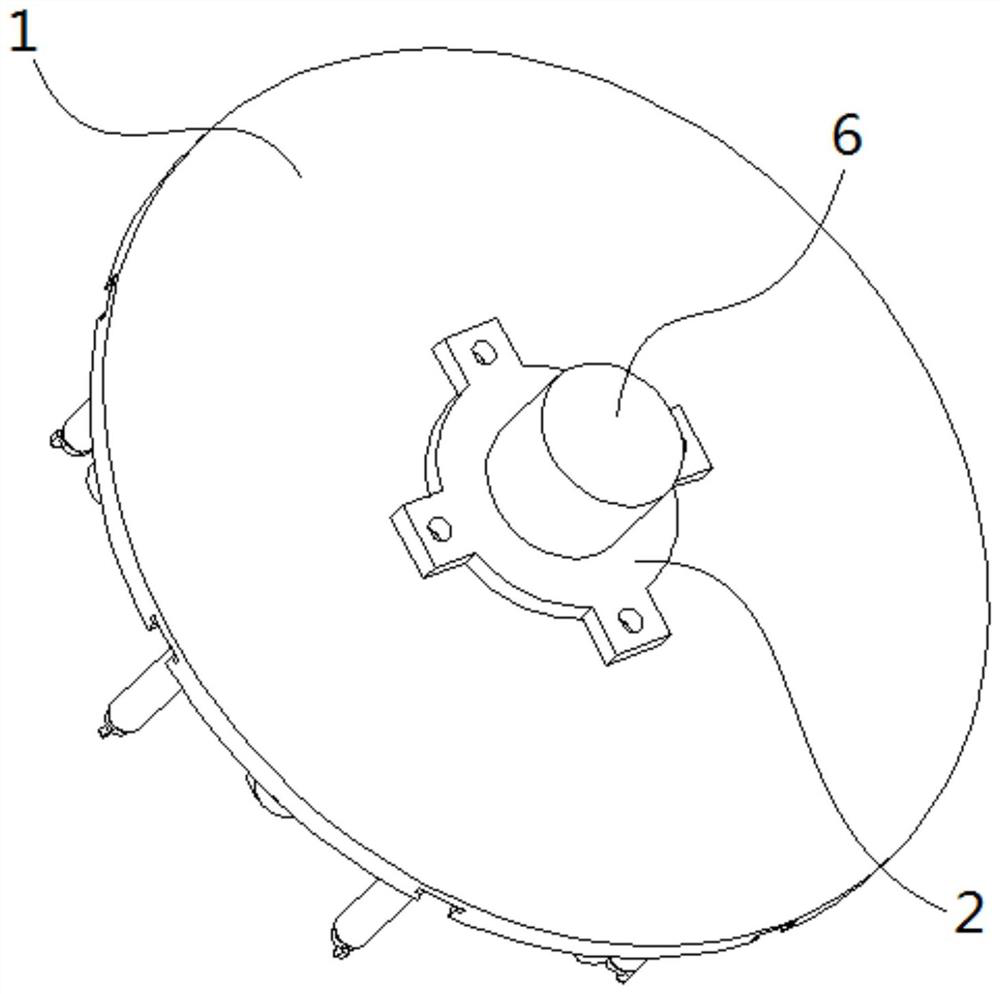

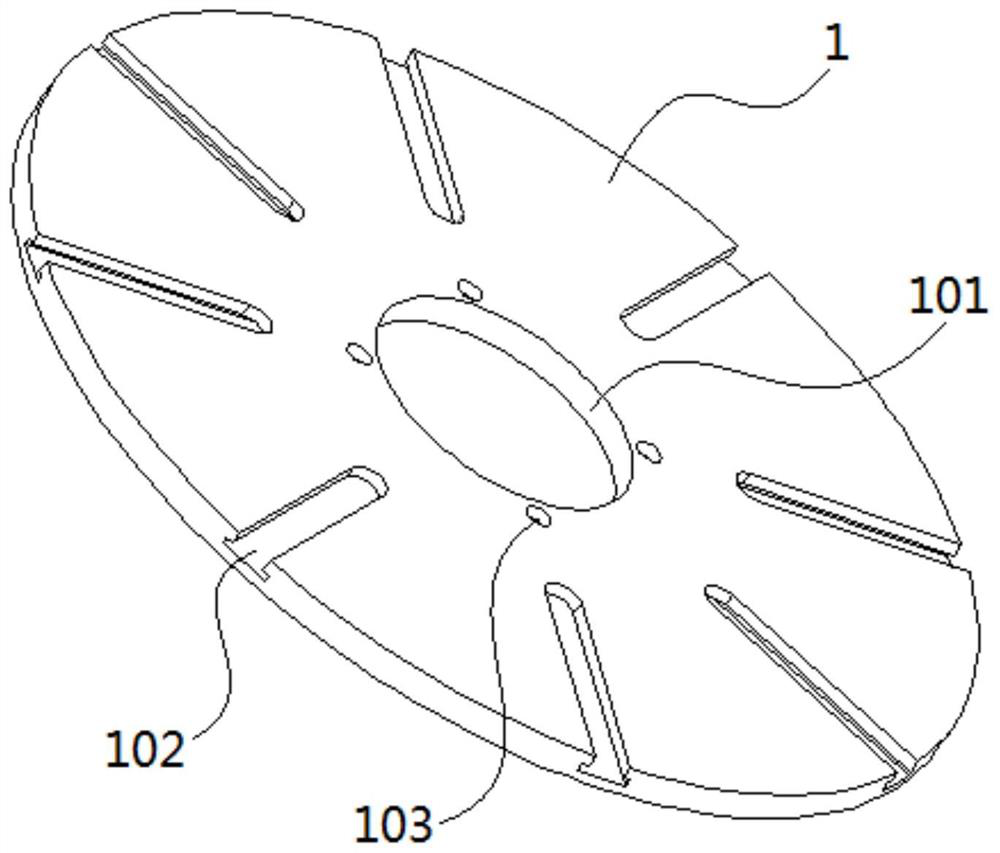

Cleaning device and cleaning method for mold

The invention discloses a cleaning device and a cleaning method for a mold, and relates to the technical field of mold cleaning. The cleaning device comprises a rotating disc, wherein a fixed supportis arranged at the axis position of the rotating disc in a penetrating manner, the axis position of the fixed support is fixedly connected with a cleaning agent bin, one surface of the fixed support is in sliding connection with a plurality of movable rods, and one surface of the rotating disc is in sliding connection with a plurality of fixed rods; one end face of each fixed rod is in threaded connection with a fixing device; the circumferential side faces of the multiple movable rods and the multiple fixed rods are sleeved with a cleaning belt; and the axis position of the fixed support is fixedly connected with a transmission shaft. The movable rods are mutually matched with the fixed rods, so that the cleaning belt can be independently adjusted according to the size of an inner cavityof the tire mold, the cleaning belt of the cleaning device is attached to the inner cavity for use, compared with an existing cleaning roller, the cleaning area of the cleaning belt is increased, internal grains and slots of the mold can be effectively cleaned, and the cleaning device has the beneficial effect of improving the cleaning efficiency.

Owner:ANHUI YULONG MOLD & CASTING

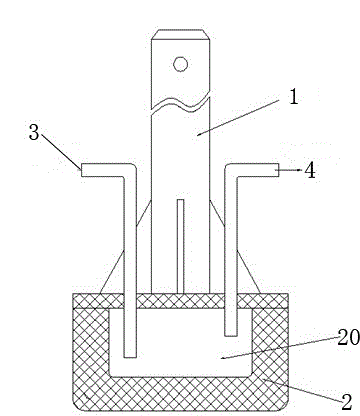

Inner-cooling inert anode for electrolytic aluminum

InactiveCN103820817AAffect production qualityAvoid defects such as high impact costCurrent distributionThermal stability

The invention relates to an inert anode for electrolytic aluminum, and belongs to the field of electrolytic aluminum equipment. The inner-cooling inert anode for the electrolytic aluminum comprises a conductive rod and a metal or metal matrix composite anode connected with the conductive rod, wherein an inner cavity of the metal or metal matrix composite anode adopts a hollow structure, and is communicated with an external circulatory cooling system and a heat exchanger via a cooling medium inlet and a cooling medium outlet which are formed in the metal or metal matrix composite anode. The inert anode has the following advantages that 1, the advantages of excellent conductivity, thermal conductivity, machining property, uniform anode current distribution and the like of a metal inert anode are inherited; the defects that the metal inert anode pollutes molten aluminum during electrolytic aluminum production and is high in cost are overcome; 2, the advantages of good thermal stability of metal oxide ceramic and metal ceramic anodes and easiness in large-scale industrial application are provided; the defects that a metal oxide ceramic inert anode is poor in conductivity and low in thermal vibration resistance, and connection between the metal oxide ceramic inert anode and a metal component of a power supply system is difficult are overcome; and 3, the novel inert anode can fully meet a technical requirement of the electrolytic aluminum production, and is very small in consumption.

Owner:饶云福 +5

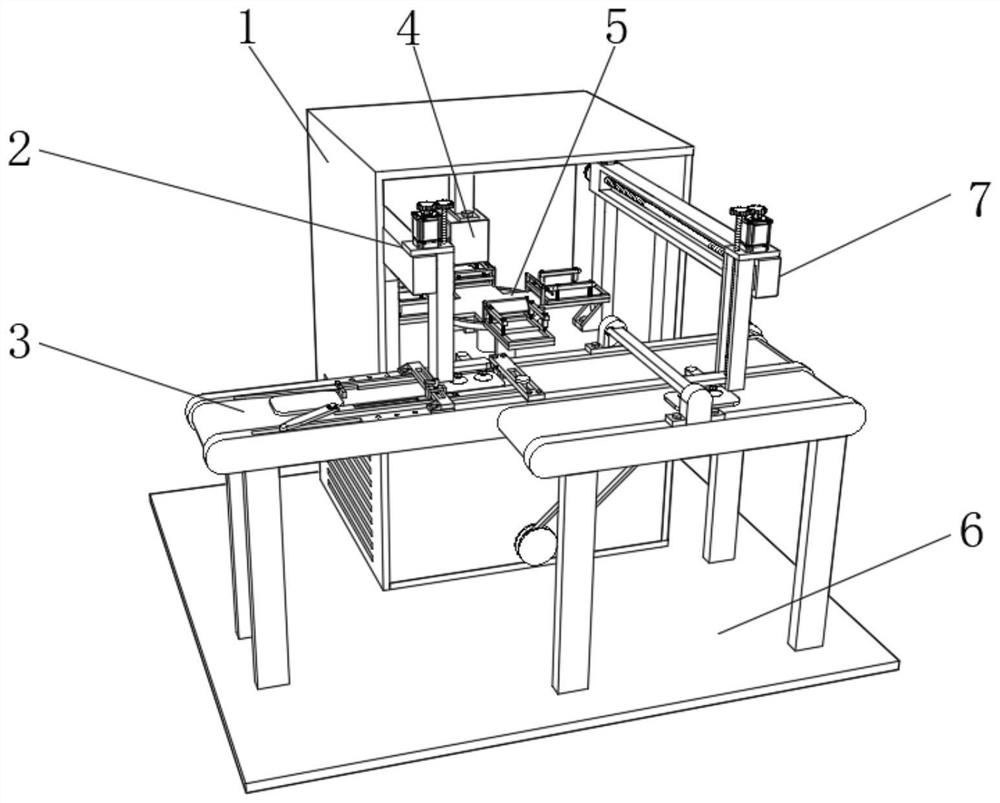

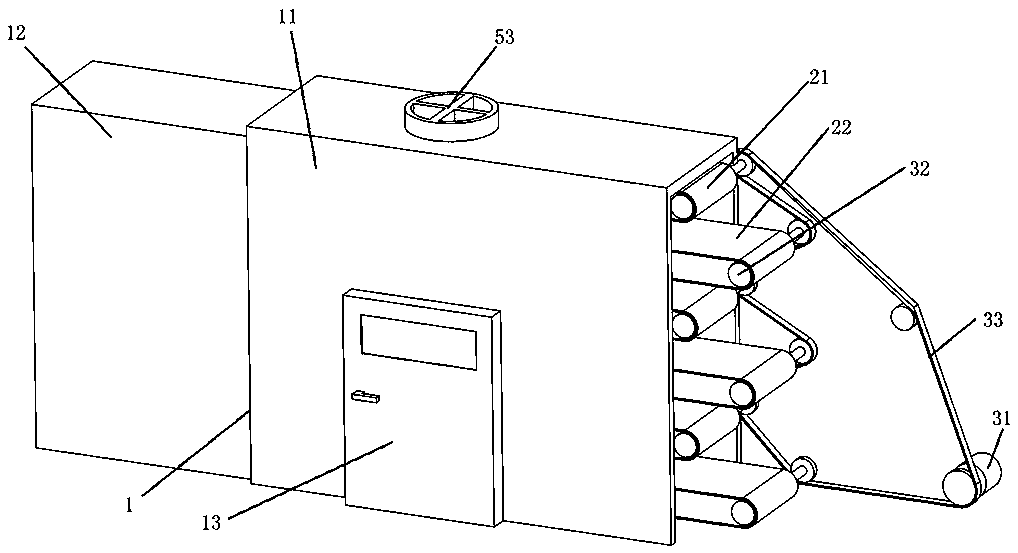

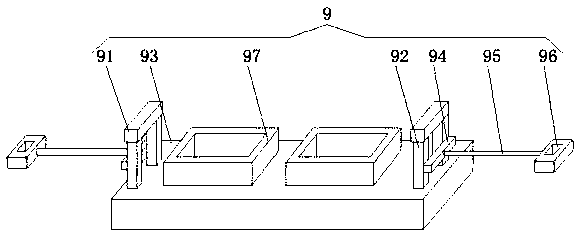

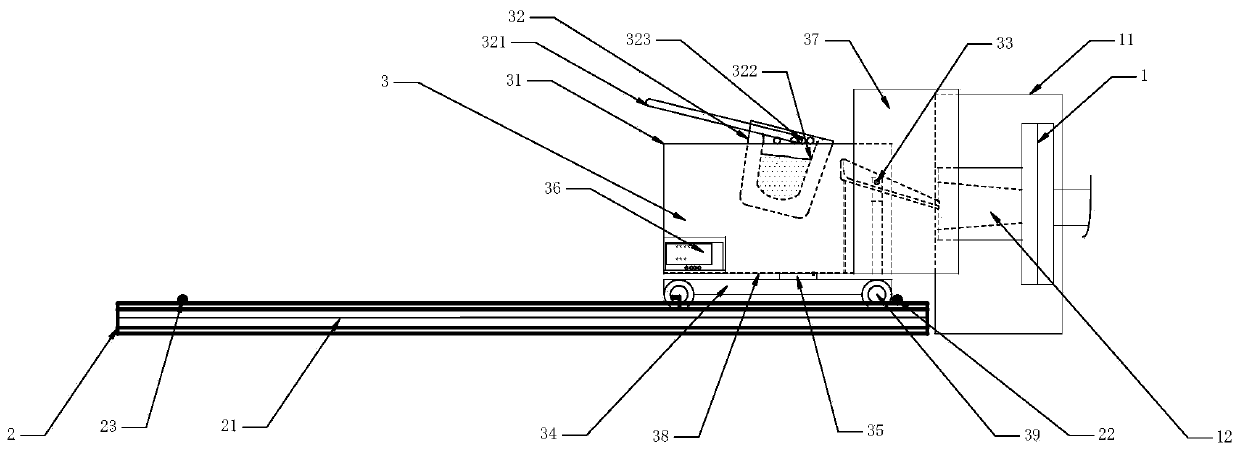

Rear cover double-side auxiliary material area array automatic detection machine

PendingCN111735820AAffect quality of lifeAffect production qualityMaterial analysis by optical meansUsing optical meansEngineeringMechanization

The invention relates to the technical field of automatic detection. The invention further discloses a rear cover double-side auxiliary material area array automatic detection machine. The detection machine comprises a shell, a base, a discharging mechanism, a conveying mechanism, a feeding mechanism and a detection mechanism. The detection mechanism comprises two detection heads, two first lensesand a plurality of second lenses. A supporting rod is welded to the inner wall of one side of the shell, a first detection box is fixed to one side of the supporting rod, one end of the supporting rod is fixedly connected with one detection head, the inner wall of one side of the first detection box is fixedly connected with one first lens, and a second detection box is fixed to the inner wall ofone side of the shell. According to the invention, the two sides of a detection piece can be positioned and detected, the detection precision is improved, a detection piece which does not accord withthe standard is prevented from flowing into the market to influence the life quality or production quality of people, the mechanization degree is higher, the labor productivity is greatly improved, and the reject ratio of the detection piece is greatly reduced.

Owner:南京鑫业诚机器人科技有限公司

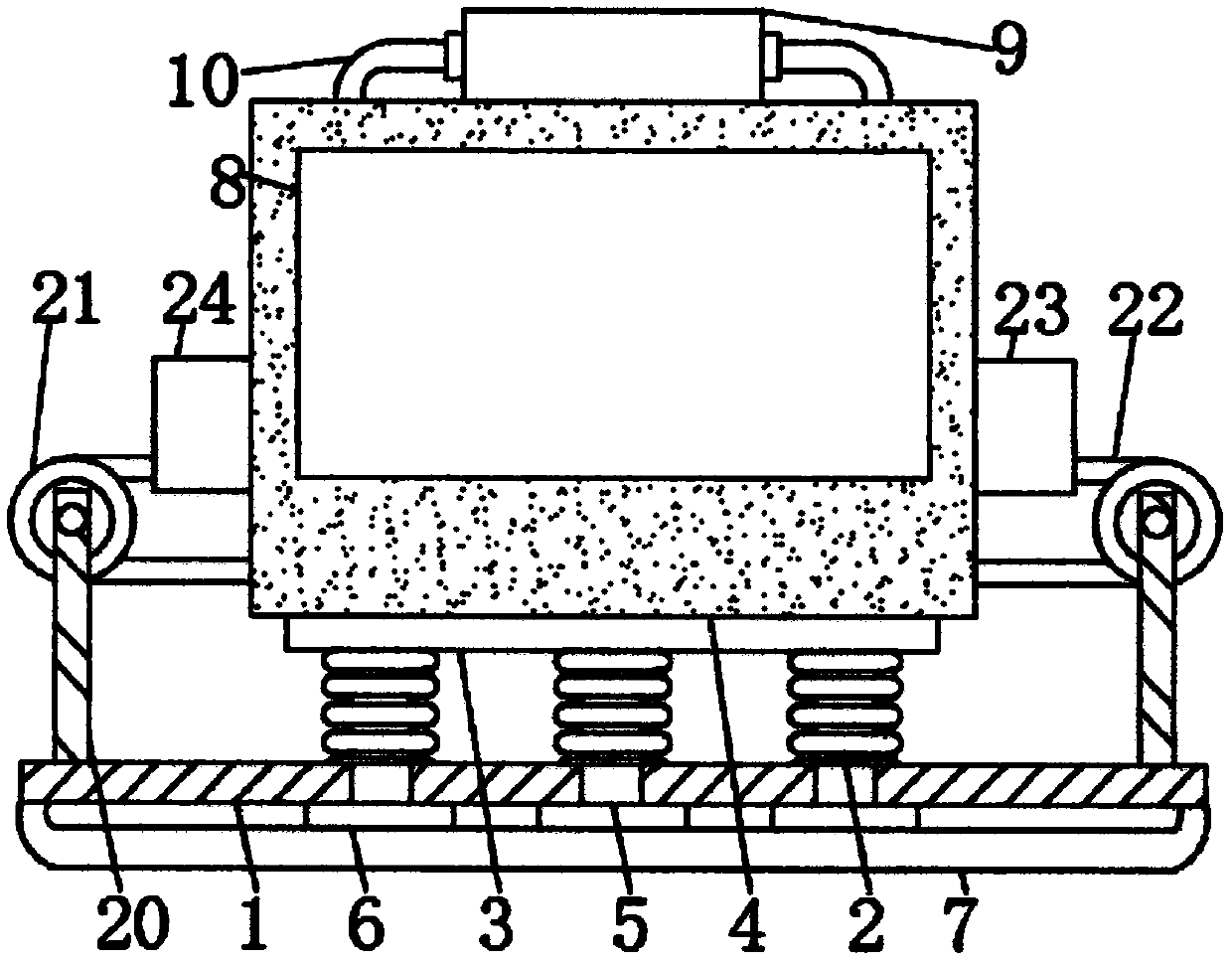

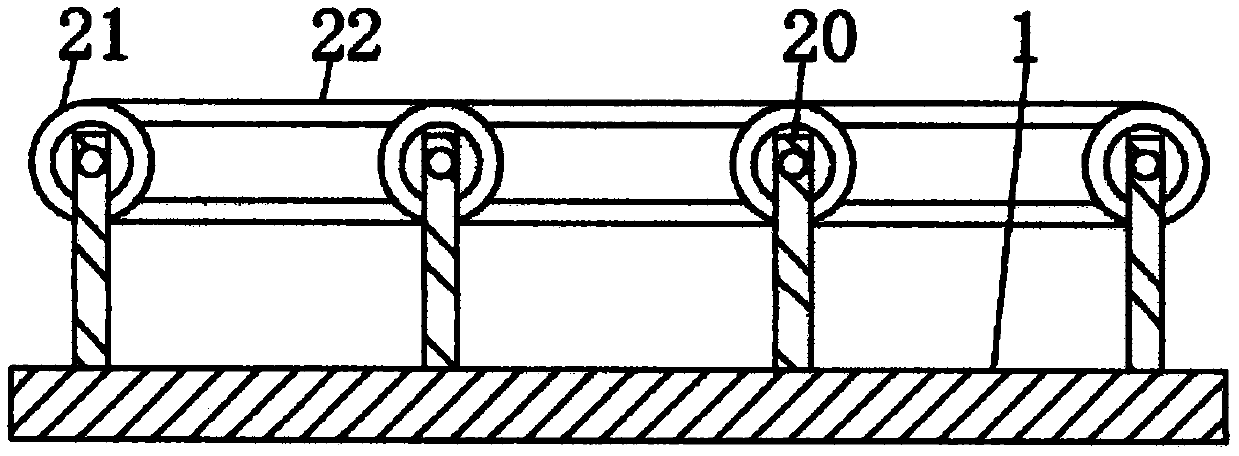

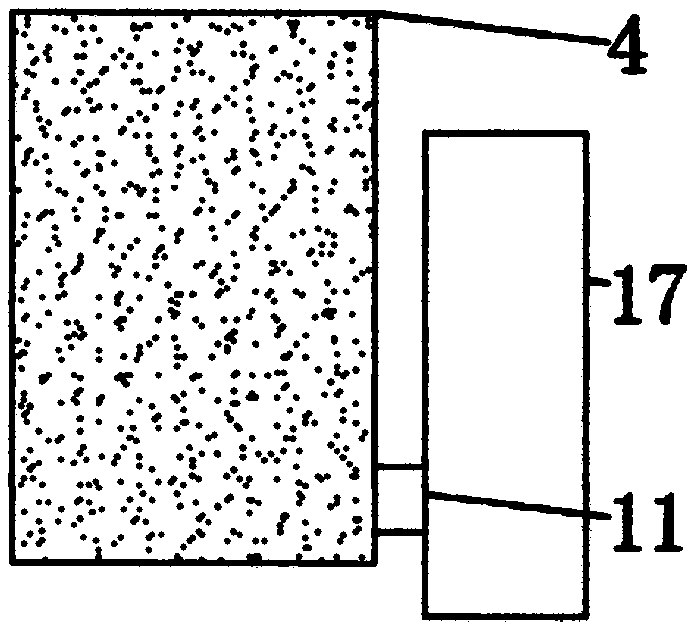

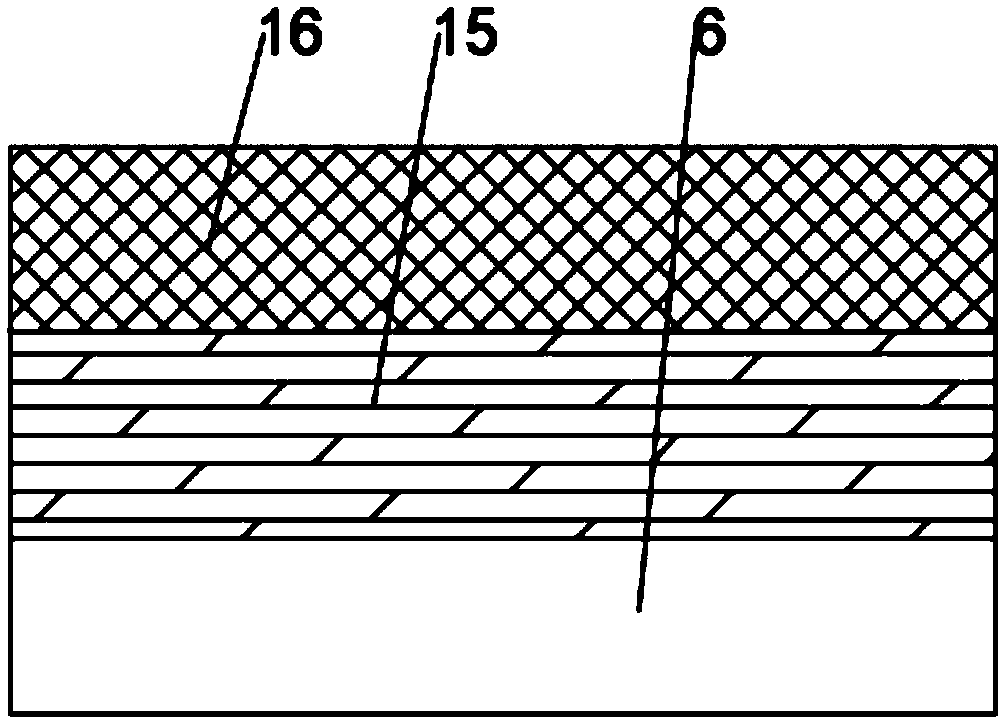

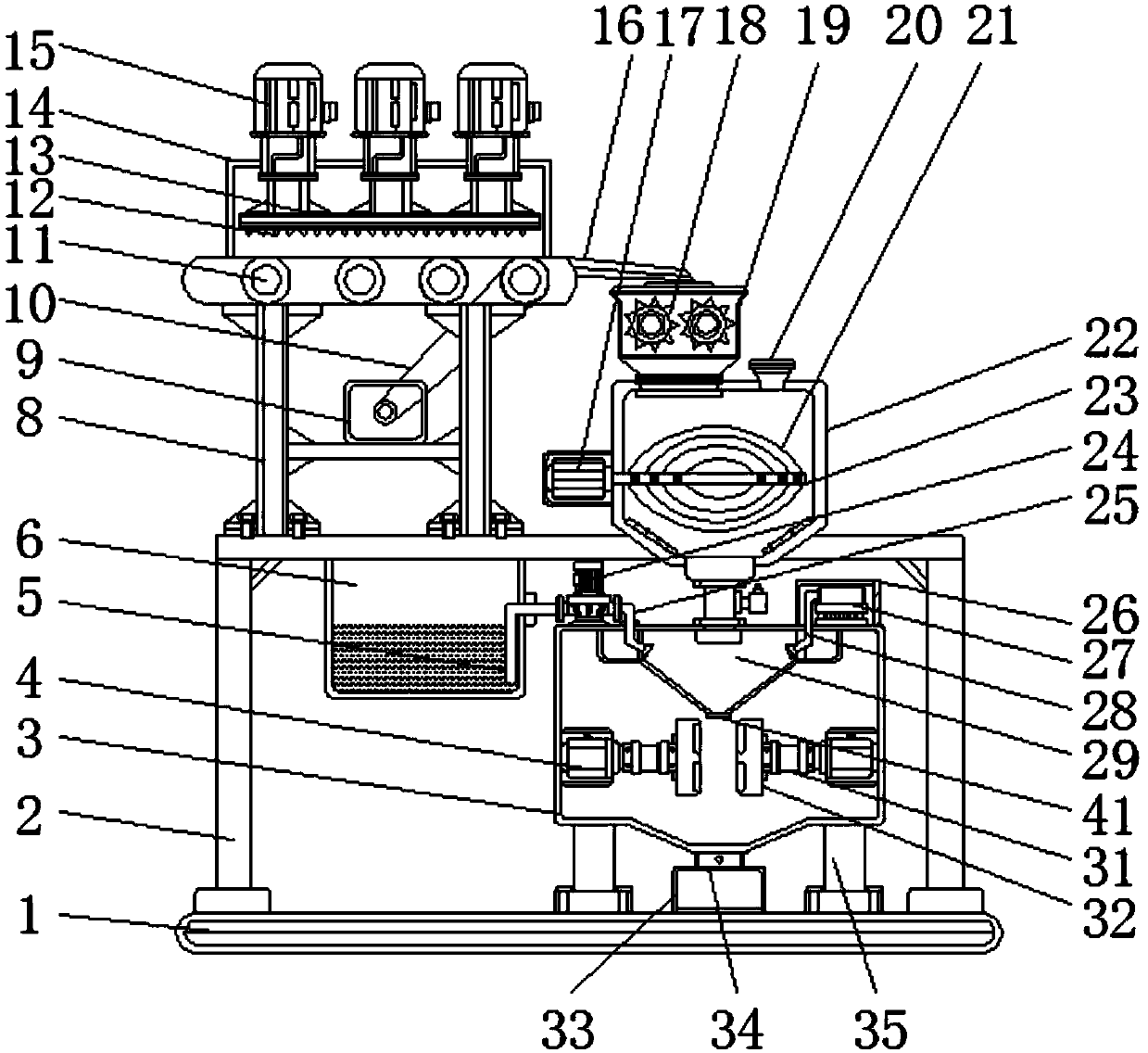

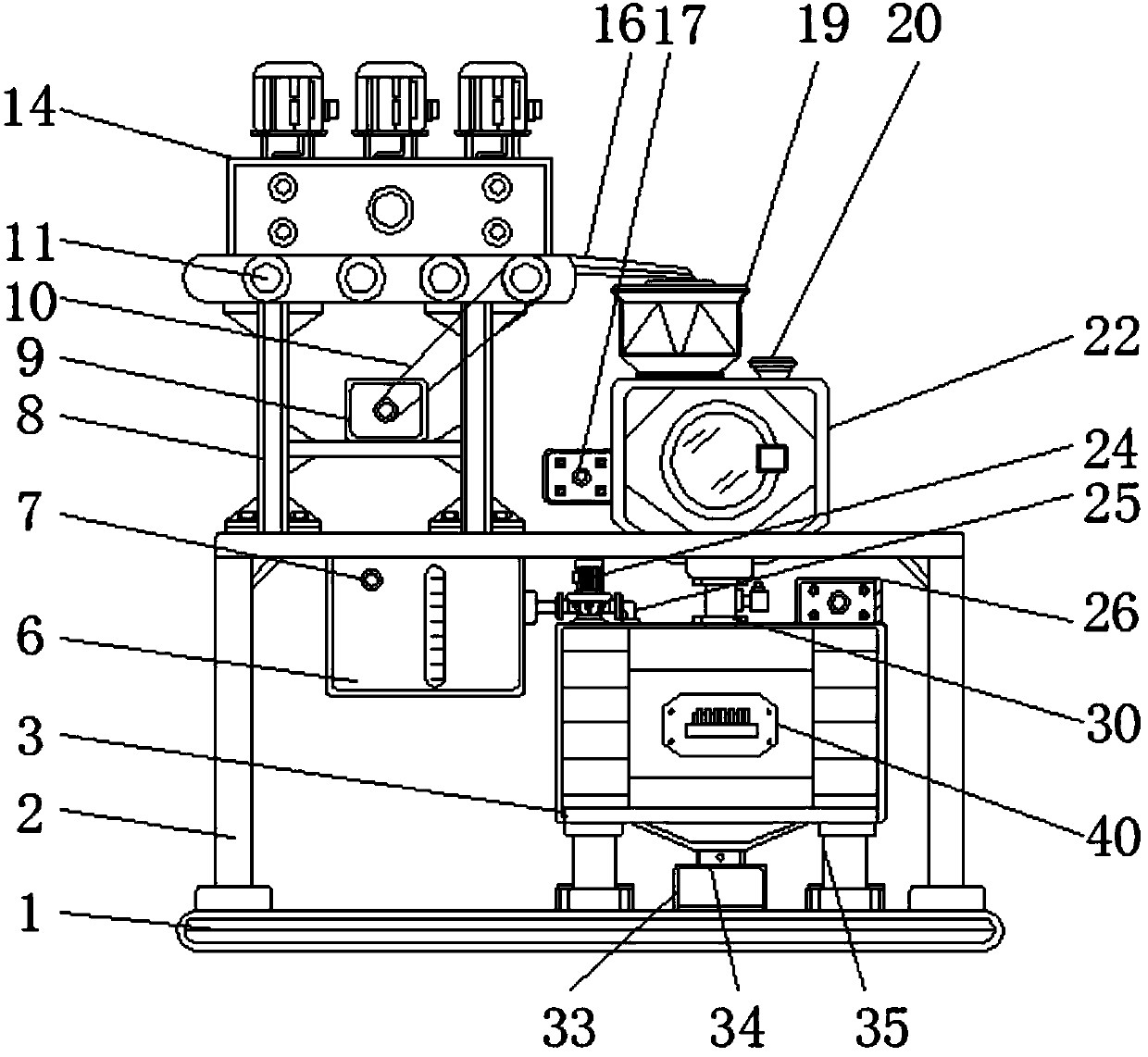

Full-automatic AG glass production and manufacturing equipment and technological process thereof

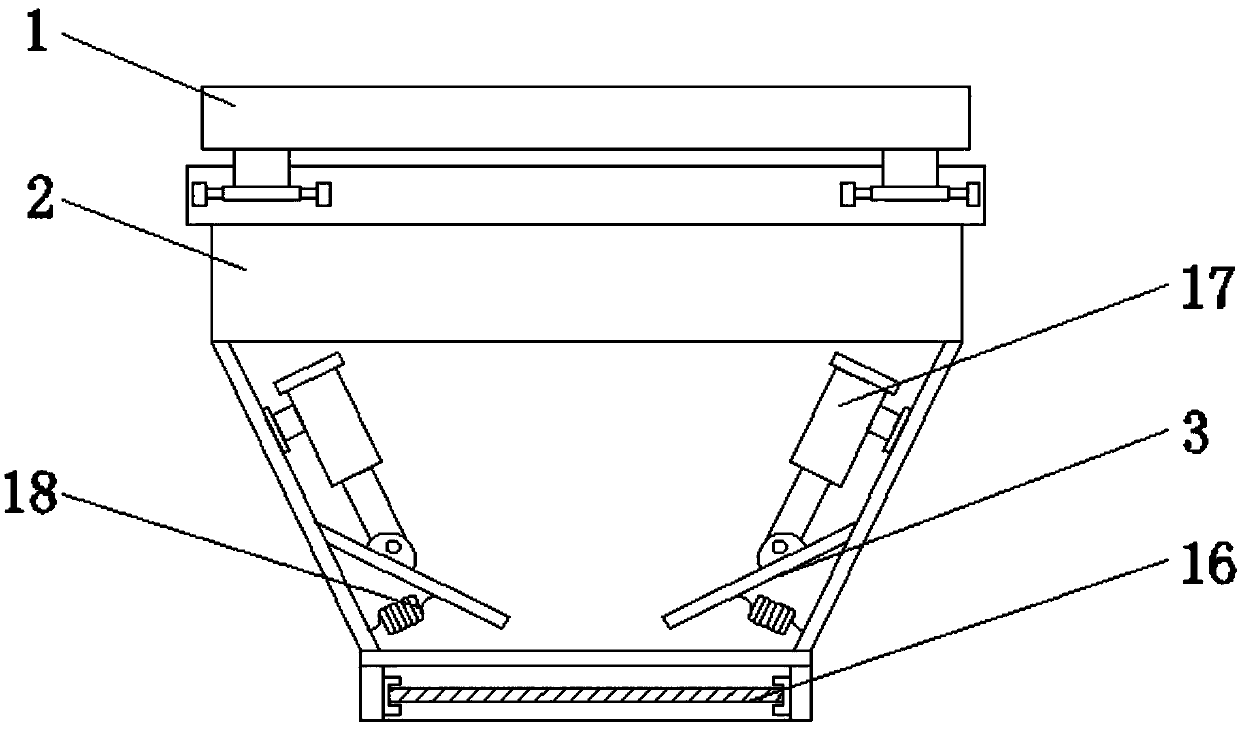

The invention discloses full-automatic AG glass production and manufacturing equipment, and relates to the related technical field of AG glass production. The full-automatic AG glass production and manufacturing equipment comprises a base, wherein the top of the base is fixedly connected to the bottoms of multiple springs, the tops of the springs are fixedly connected to the bottom of a pad plate,and the top of the pad plate is fixedly connected to the bottom of a processing device. The invention further discloses a technological process of the full-automatic AG glass production and manufacturing equipment, wherein the technological process comprises: A, work-piece glass cleaning section and blow-drying section; B, work-piece glass raw sheet inspection section; C, work-piece glass acid washing pretreatment section; D, work-piece glass EDI pure water spray washing section; E, work-piece glass frosting treatment section; F, work-piece glass rinsing, cleaning and blow-drying section after frosting; G, work-piece glass online inspection section after frosting; H, work-piece glass chemical polishing section; and I, work-piece glass cleaning and blow-drying section. According to the invention, the vibration generated by the processing device during use can be reduced through the springs, and the deviation of the processing device during use can be prevented through the guide rod.

Owner:云南宏华光电有限公司

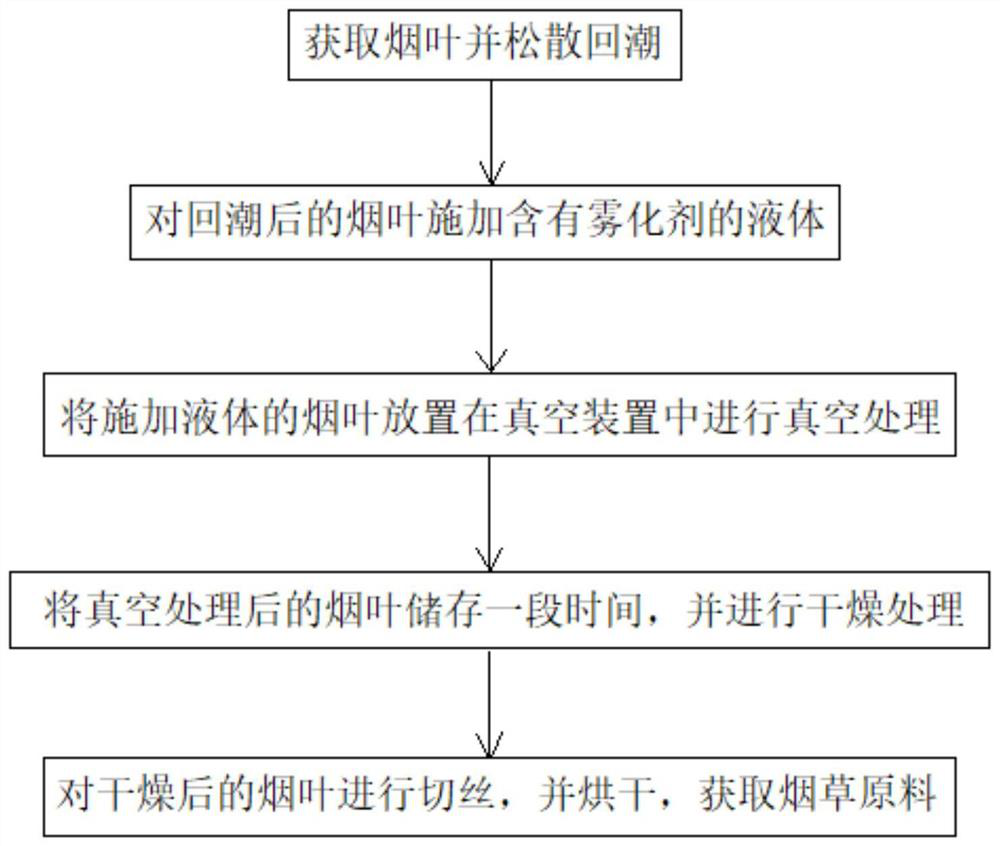

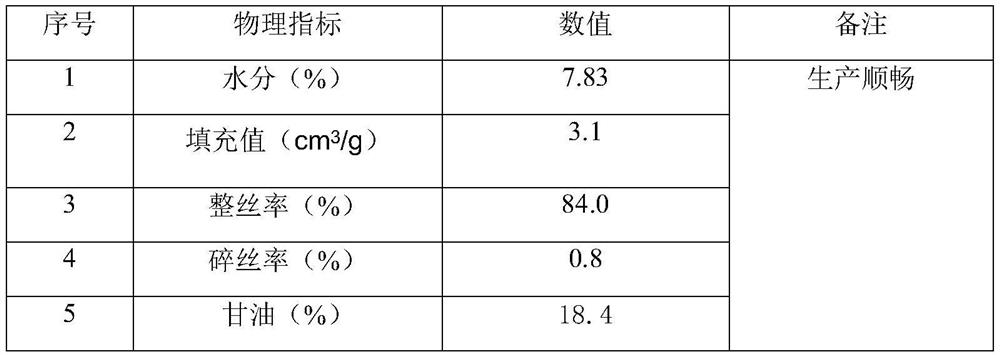

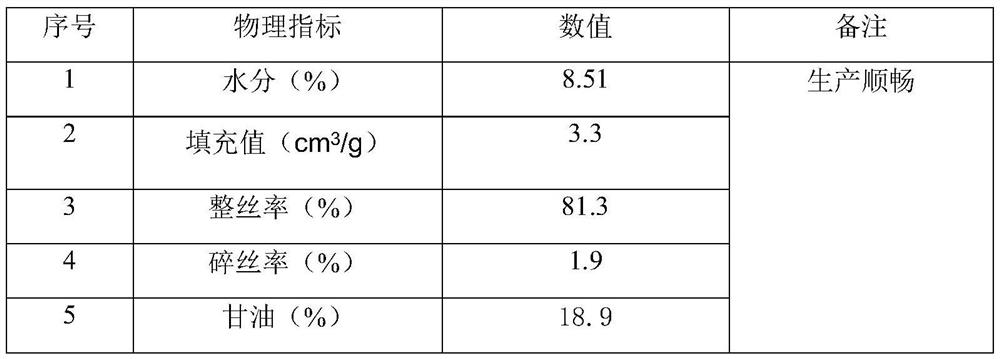

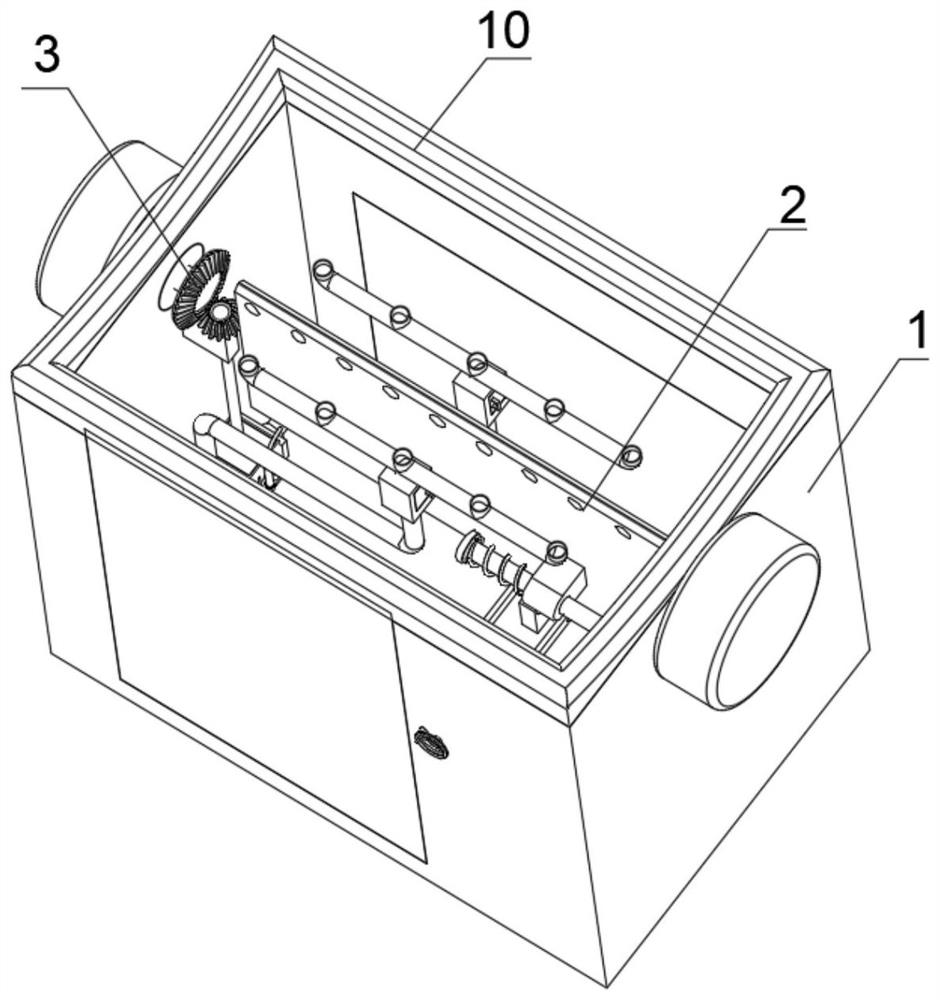

Preparation method of tobacco raw material and heat-not-burn cigarette with tobacco raw material

InactiveCN112369644AIncrease load capacityImprove adsorption capacityTobacco preparationTobacco treatmentBurn cigaretteProcess engineering

The invention discloses a preparation method of a tobacco raw material and a heat-not-burn cigarette with the tobacco raw material. The preparation method of the tobacco raw material comprises the steps of obtaining tobacco leaves and carrying out loosening and moisture regaining; applying liquid containing an atomizing agent to the tobacco leaves subjected to moisture regaining; putting the tobacco leaves to which the liquid is applied into a vacuum device for vacuum treatment; storing the tobacco leaves subjected to vacuum treatment for a period of time, and performing drying treatment; shredding and drying the dried tobacco leaves, and obtaining tobacco raw materials. The heat-not-burn cigarette comprises a filter tip and an atomized tobacco substrate section connected with the filter tip, and tobacco raw materials are arranged in the atomized tobacco substrate section. The loading capacity of the added atomizing agent can be improved, the adsorption effect of the atomizing agent isgood, meanwhile, the atomizing agent can be prevented from adhering to the surface of tobacco shreds to influence cigarette making and tipping production and process quality, and therefore the application range of tobacco raw materials can be widened, and the quality of the tobacco raw materials is improved.

Owner:HUBEI CHINA TOBACCO IND

High-temperature roller scraping tool

ActiveCN114104660AReduce the temperatureReduce lossCleaningCleaning using toolsDrive wheelEngineering

The tool comprises a shell, an opening is fixedly connected to the upper end of the shell, an arc-shaped groove is formed in the upper end of the shell, a scraping mechanism is arranged in the shell, and a cleaning assembly is arranged in the shell. The invention relates to the technical field of diaphragm production tools, the shell is arranged to be matched with the cleaning assembly, a scraping mechanism is utilized to clean the side wall of a conveying roller, meanwhile, a first driving wheel is utilized to be matched with an upper bevel gear and a lower bevel gear to drive fan blades to rotate, an air pipe close to sundries can adsorb the sundries, and then the cleaning effect is improved; and as the air can only circulate in the shell, heat loss is reduced, and the temperature of the cleaned area of the conveying belt is prevented from being reduced when the conveying rollers are cleaned, so that the production quality of a film is prevented from being influenced when the conveying rollers are cleaned.

Owner:HUIQIANG WUHAN NEW ENERGY MATERIAL TECH

Manufacturing method of ceramic tube

A manufacturing method of a ceramic tube comprises the following steps: a, an external mold and a wax-based internal mold are manufactured; b, the wax-based internal mold is positioned inside a holding cavity, and a gap between the wax-based internal mold and the holding cavity is left to form a cavity; c, a powder is poured into the cavity, and the powder is hardened to form a tube blank; d, the external mold is removed from the tube blank; e, the wax-based internal mold is removed from the inside of the tube blank; and f, the tube blank is sintered to form a ceramic tube. During the Step c, the powder is hardened by a static pressure method, and static pressure is set as 100kPa-200kPa / cm<2>. The Step e contains the following steps: e1, high temperature radiation is applied on the position where the wax-based internal mold and the tube blank are contacted by the use of external equipment, the temperature of the position where the wax-based internal mold and the tube blank are contacted is raised to more than 500 DEG C within 3-5 s, and the state lasts for 2-6 s; and e2, double heating is carried out on the wax-based internal mold so as to make the wax-based internal mold flow out. According to the manufacturing method, the internal mold and the powder have a single material component; no chemical reaction happens during the manufacturing process; and demoulding time is fast and the tube will not be cracked.

Owner:王伟军

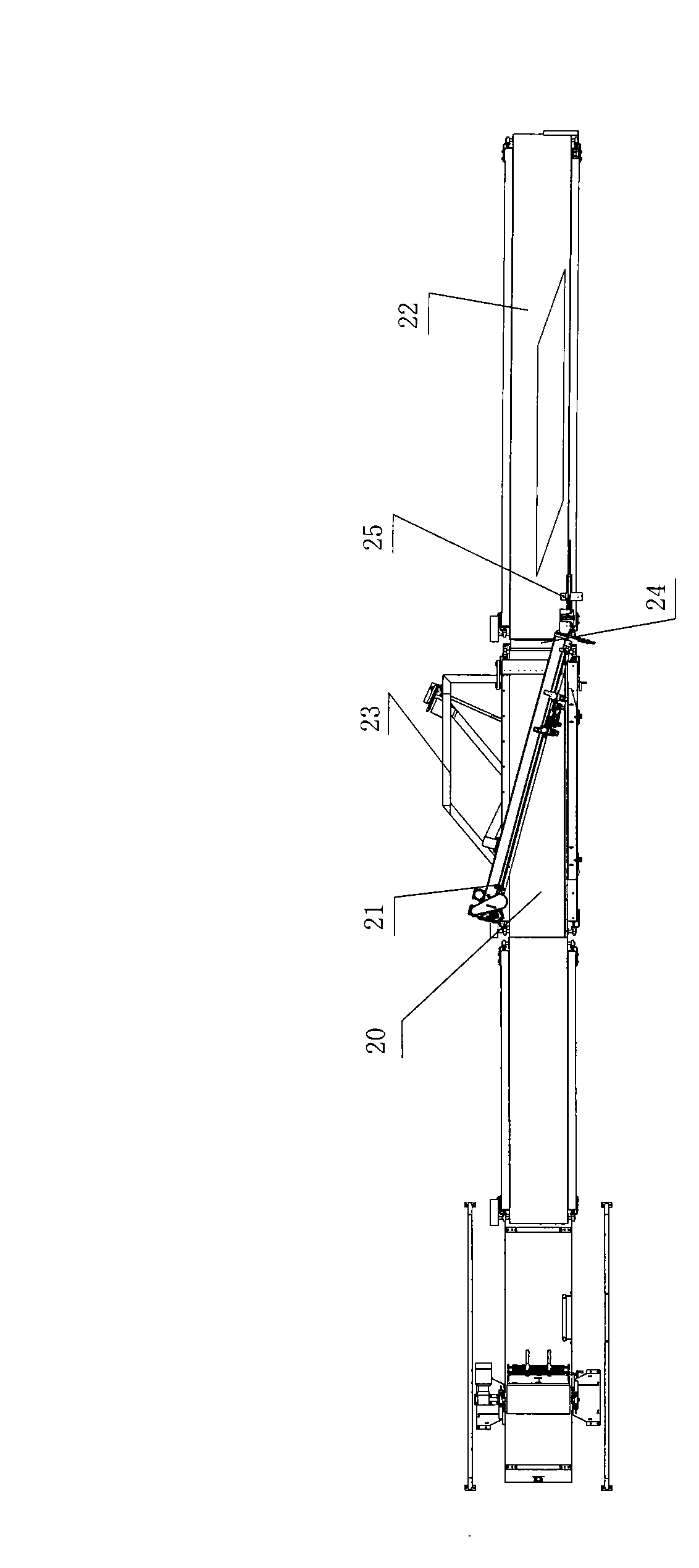

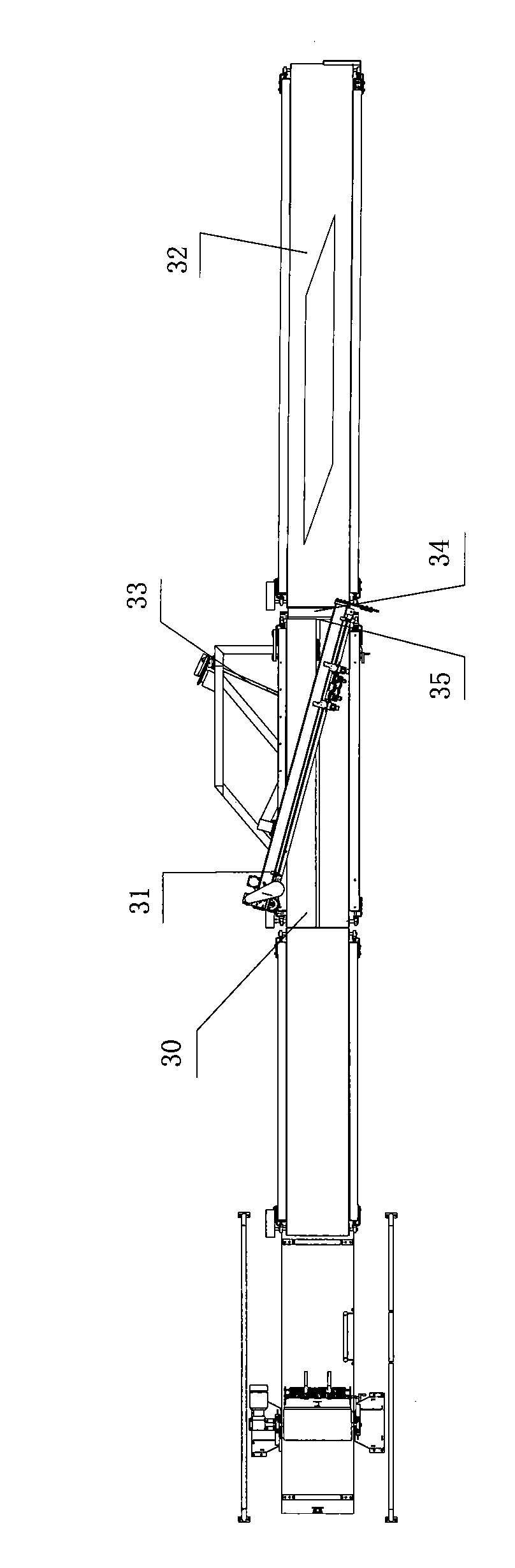

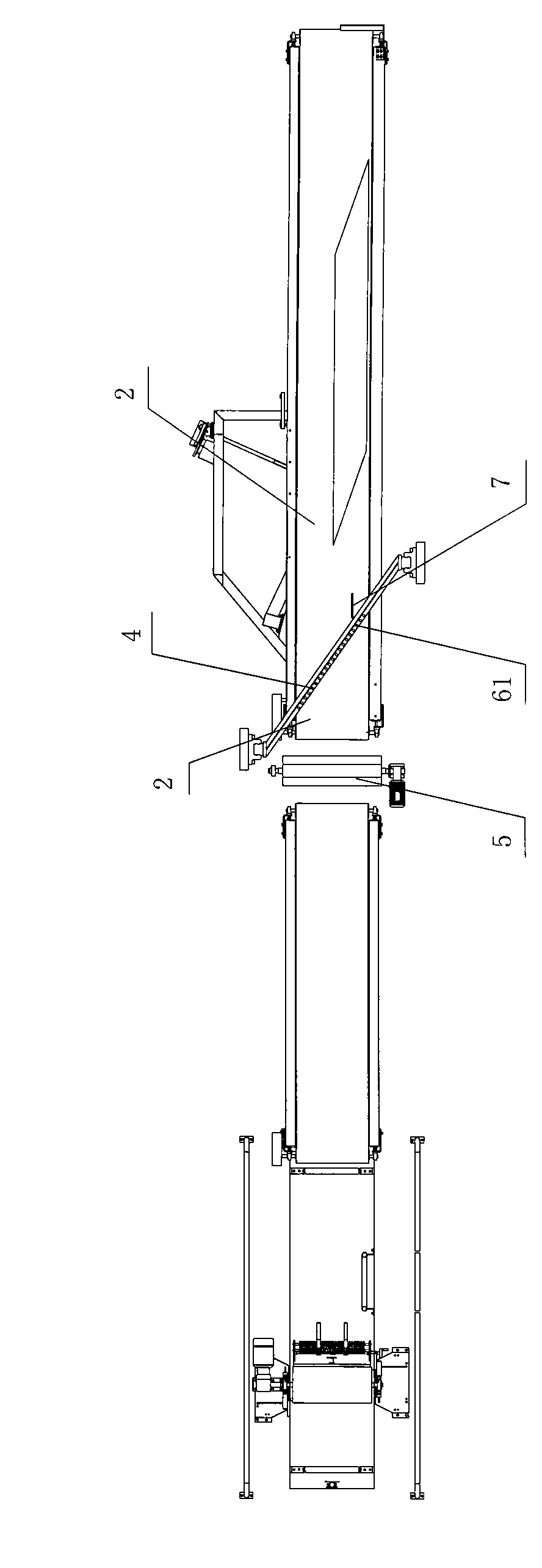

Stacking mechanism of cloth inspecting machine capable of cloth of inspecting school uniform rapidly

InactiveCN109534062AImprove practicalityReduce tensionCleaning using gasesArticle deliveryEngineeringMechanical engineering

The invention relates to the technical field of stacking mechanisms, and discloses a stacking mechanism of a cloth inspecting machine capable of inspecting the cloth of a school uniform rapidly. The stacking mechanism comprises a base, the top of the base is fixedly provided with a machine body, the back side of the machine body is fixedly provided with a first power motor, an output shaft of thefirst power motor is fixedly sleeved with a master gear, the right end of the master gear is connected with a sub-gear in a meshed mode, and a second rotating shaft is fixedly arranged in the middle of the sub-gear in a sleeved mode. According to the stacking mechanism of the cloth inspecting machine capable of inspecting the cloth of a school uniform rapidly, through an arranged adjusting spring,when the tension exerted on the cloth of the school uniform is too large, the cloth of the school uniform squeezes the base, in the meanwhile an adjusting rod descends, so that the tension exerted onthe cloth of the school uniform is reduced; and when the tension exerted on the cloth of the school uniform is too small, the adjusting spring pushes the adjusting rod to rise, so that the tension exerted on the cloth of the school uniform is increased, the quality of the cloth of the school uniform cannot be influenced due to the fact that the tension exerted on the cloth of the school uniform is too large or too small, and the practicability of the stacking mechanism is improved.

Owner:郭永祥

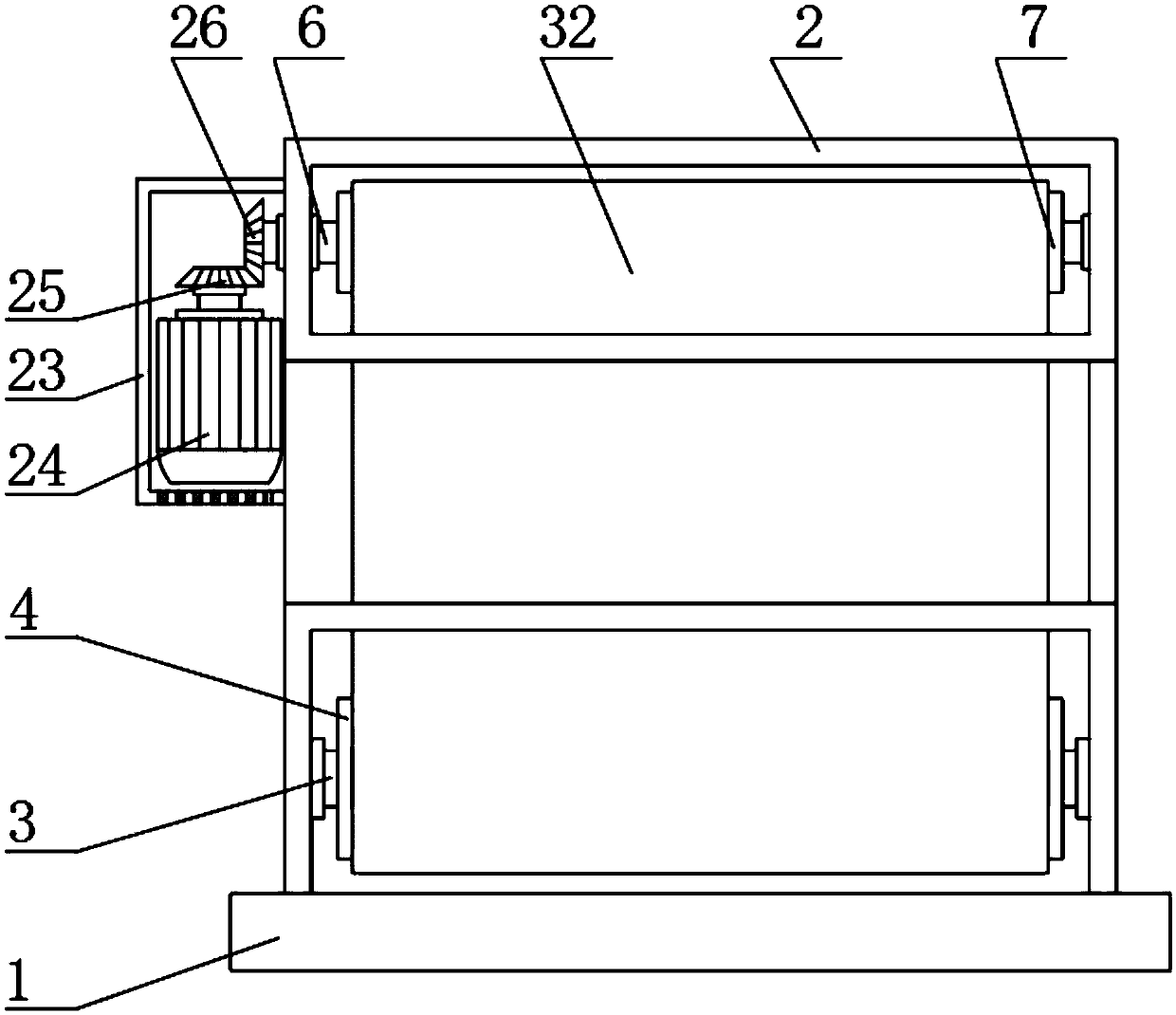

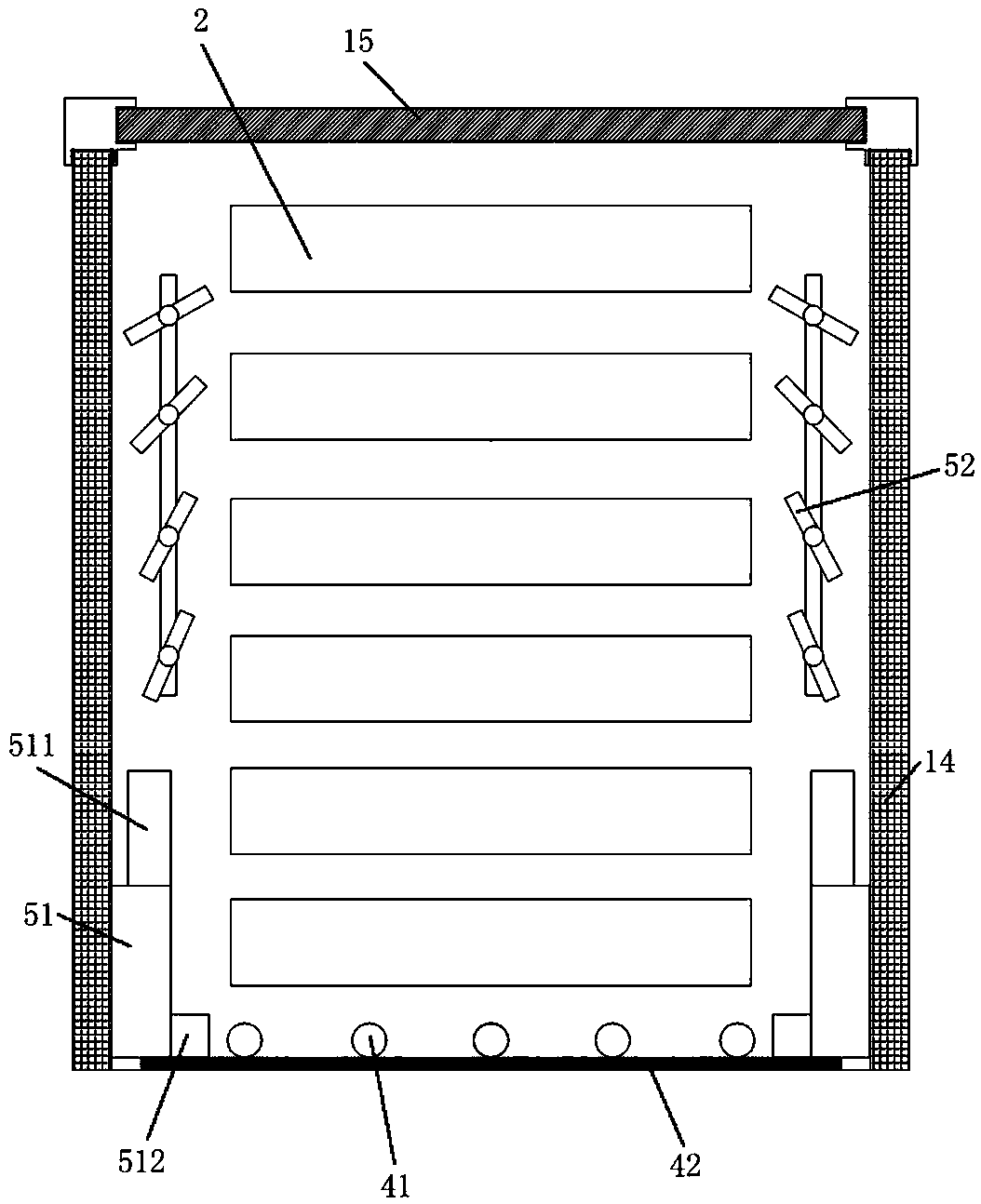

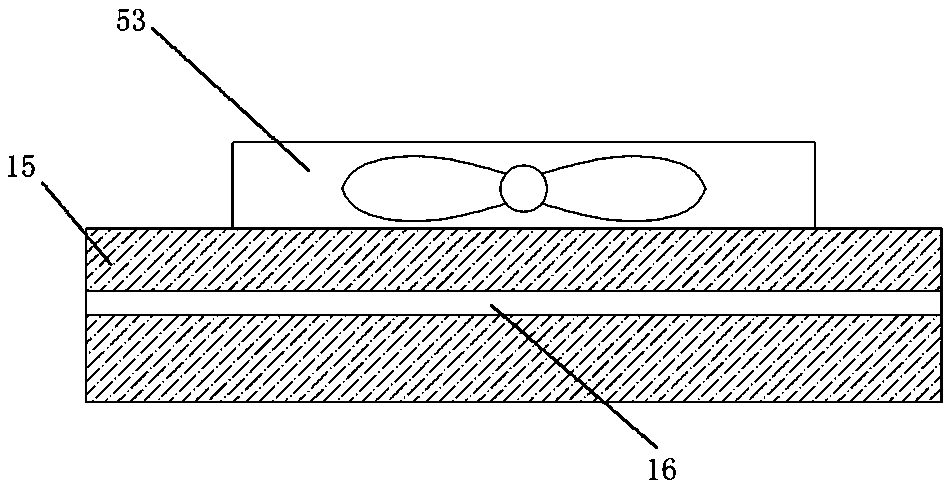

Sheet jelly drying device

InactiveCN108917363ASmall footprintSave production spaceFood preservationDrying gas arrangementsEngineeringDrive motor

The invention discloses a sheet jelly drying device and relates to the technical field of sheet jelly and bean vermicelli production equipment. The sheet jelly drying device comprises conveyor belts,a heat source device, a drying oven shell, a power device and an air supply device and is characterized in that the drying oven shell is a horizontal cuboid with openings in two ends; the conveyor belts are arranged in the drying oven shell and include a plurality of first conveyor belts and second conveyor belts which are horizontally arranged at intervals, and the conveying directions of the first conveyor belts and the second conveyor belts are opposite; the power device comprises a drive motor, transmission rollers arranged at the ends of the first conveyor belts and the second conveyor belts and a transmission chain connecting the drive motor and the transmission rollers; the heat source device is arranged inside the drying oven shell; the air supply device comprises first fans whichare symmetrically arranged on two sides of the conveyor belts. The sheet jelly drying device is small in floor space, capable of drying sheet jelly at temperature which cannot damage the sheet jelly,high in heat efficiency, good in drying effect and good in finished-product quality.

Owner:宣城市宣华食品有限公司

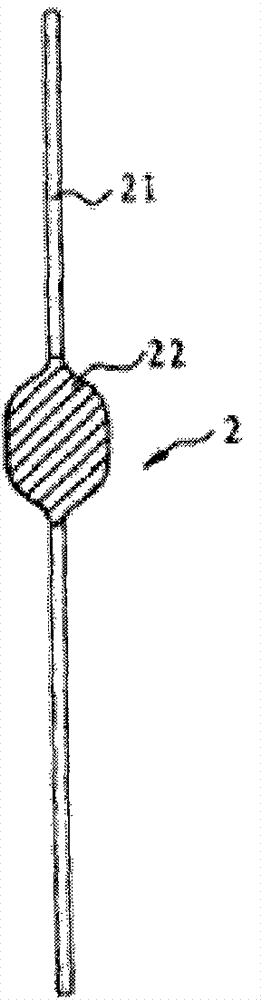

Composite interlaced yarn having variegated colour effect

The invention relates to a composite interlaced set yarn with dye effect, which is compositely made at a middle and low speed on a composite interlaced set yarn machine by adopting two or a plurality of sorts of yarn different in dry-hot shrinkage and yarn classes or color absorbing degrees. Due to the character differences in the nature of each component of the composite interlaced set yarn, the fabric surface of the products weaved by the invention can generate various mixed-color flash effects. If the invention is processed again by different dyeing processes, the invention can obtain dyeing effects of different characteristics, very natural star point-shaped, rain-shaped and strip-shaped dyeing effects. Simultaneously due to slight differences in nature among the components in selected materials, the physico-chemical properties of the product is uniform and the invention can not affect other characteristics except dyeing.

Owner:SHENGHONG GRP CO LTD

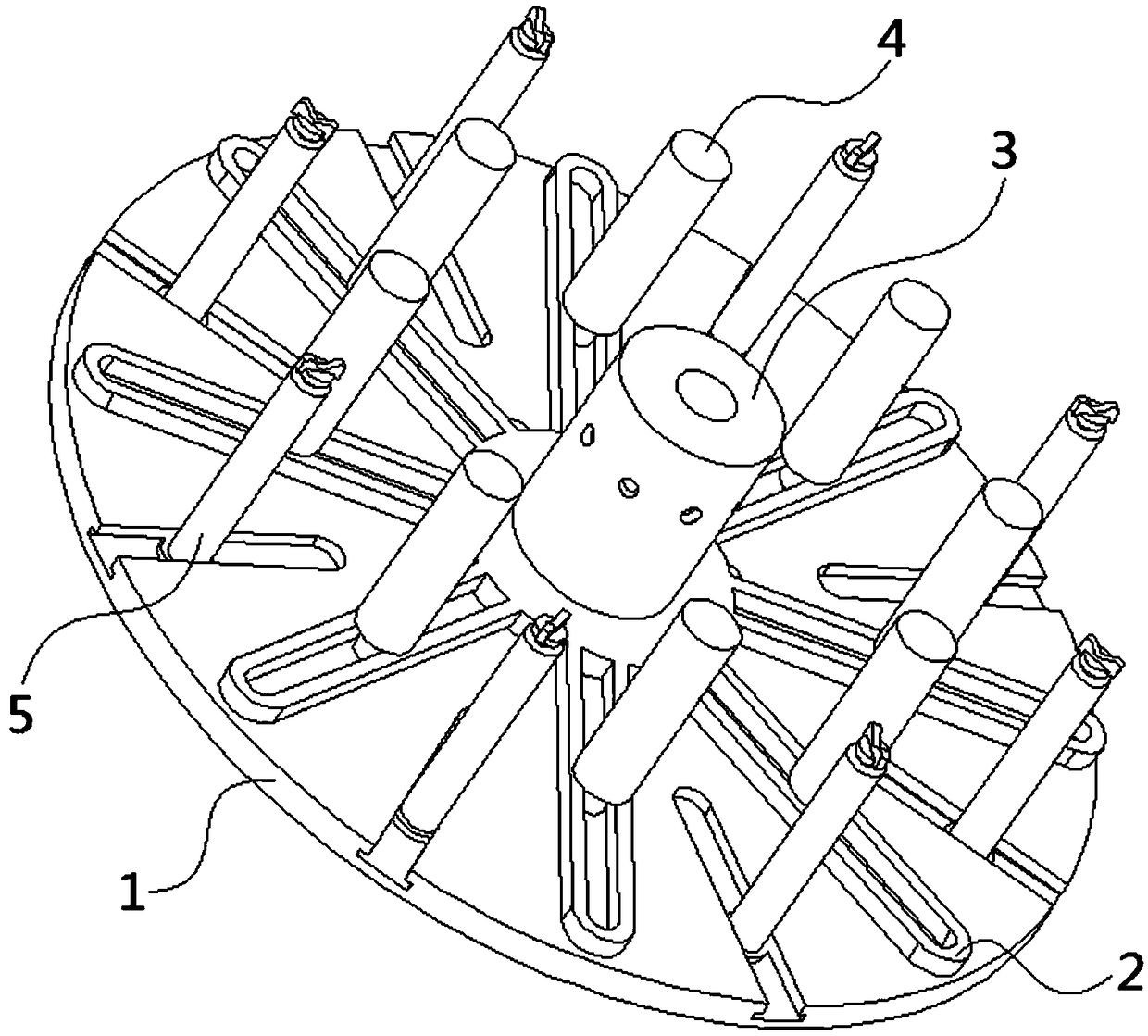

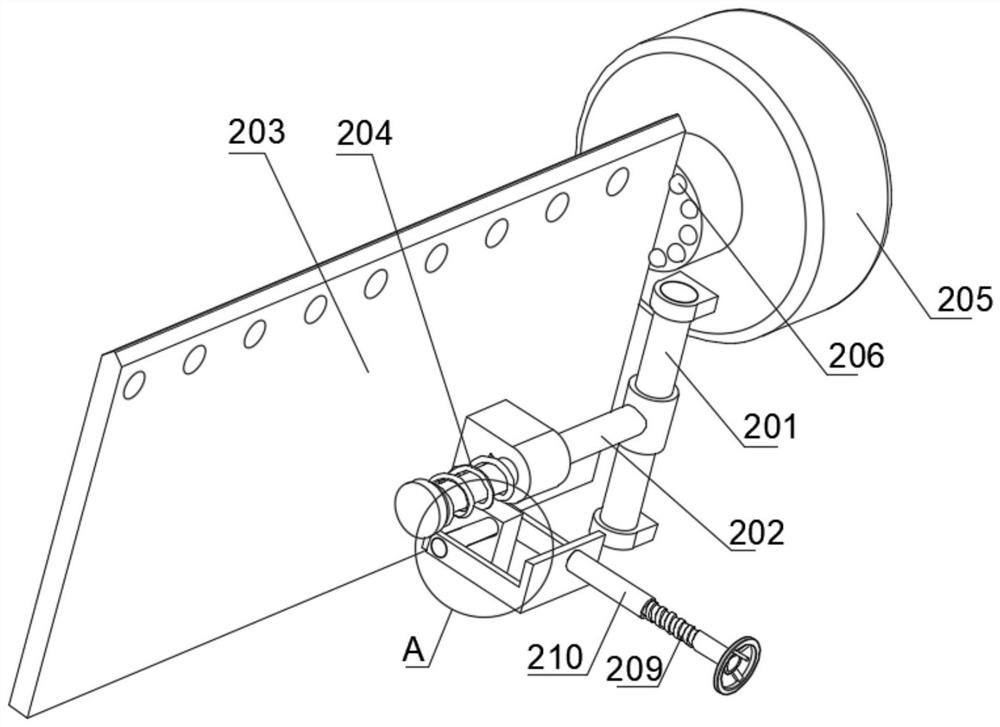

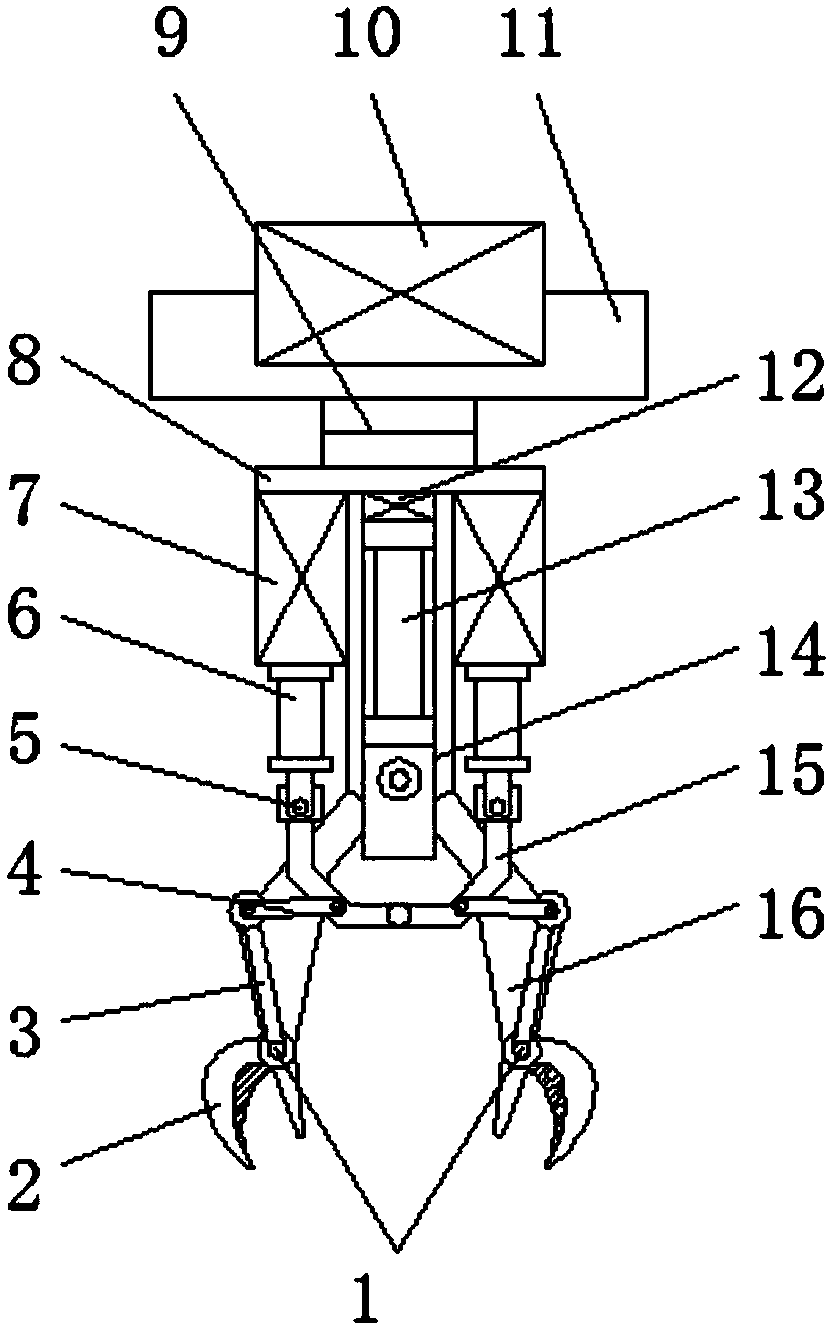

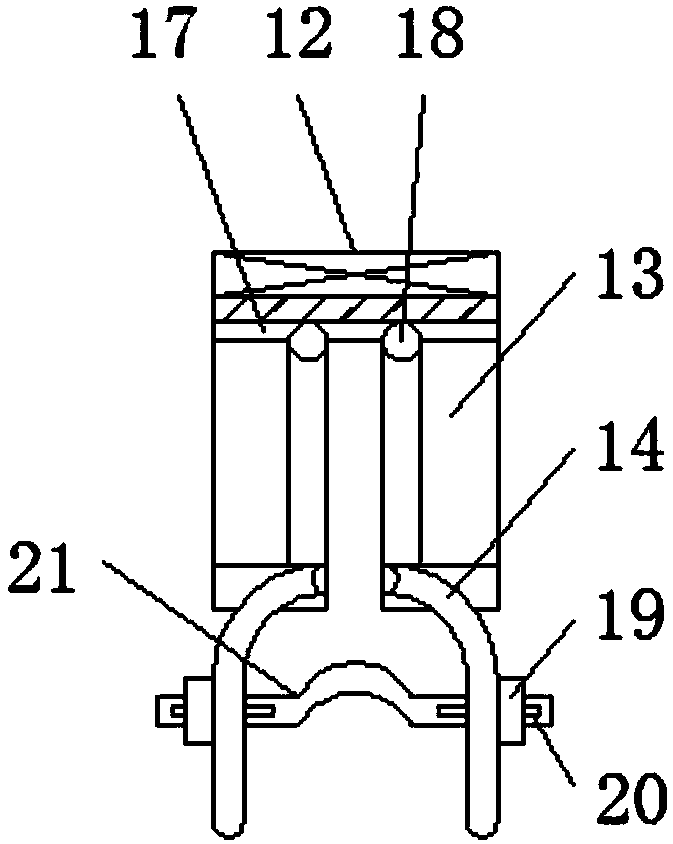

Textile bobbin clamping device with locking function

InactiveCN108545463AAchieve grippingRealize the locking functionConveyorsFilament handlingBobbinTextile

The invention discloses a textile bobbin clamping device with a locking function. The textile bobbin clamping device comprises telescopic connecting shafts, a balanced fixing plate, a machine frame body, a sliding connecting rod, movable clamping claws and a clamping frame limiting rod. The textile bobbin clamping device is characterized in that the balanced fixing plate is movably connected withthe bottom end of the machine frame body through a rotating connecting frame, and a driving device is mounted below the middle portion of the balanced fixing plate; an arc-shaped clamping frame is movably connected with the bottom end of the sliding connecting rod, and second sliding blocks are arranged on the outer side, near the arc-shaped clamping frame, of the clamping frame limiting rod; anda U-shaped frame is movably connected with the other ends of the telescopic connecting shafts through movable support lugs, and movable locking brackets are movably connected with the lower ends of the movable clamping claws through movable connecting shafts. The textile bobbin clamping device with the locking function realizes the functions of clamping and locking through the structures such as the movable locking brackets, the movable clamping claws and the arc-shaped clamping frame, the stability of textile bobbins is improved, and the clamping flexibility and the clamping efficiency are improved through matching of the structures such as the rotating connecting frame.

Owner:XIANGSHUI COUNTY XINHONG TEXTILE CO LTD

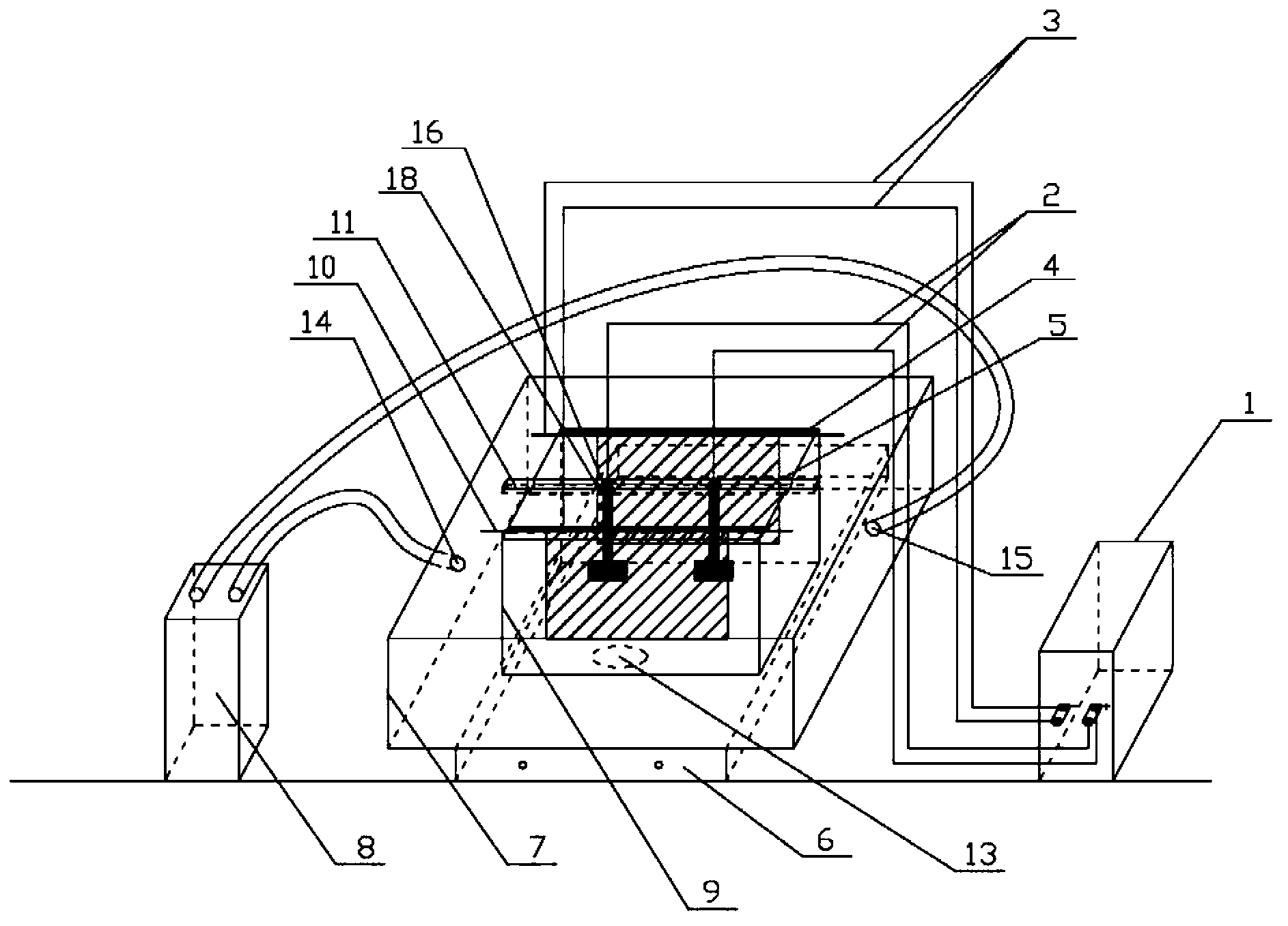

Aluminum anode oxidation dual-test-piece experiment device

InactiveCN103255460AAffect qualityAffect production qualityAnodisationElectrolysis componentsAluminum anodeLead electrode

The invention relates to an aluminum anode oxidation dual-test-piece experiment device which comprises a DC (direct-current) stabilized power supply and a glass container, wherein the glass container are symmetrically provided with two combined lead electrodes; the middle part of the glass container is provided with two anode oxidation test pieces; two negative electrode leads out of a DC stabilized power supply negative electrode terminal are respectively connected to the middle parts of the upper surfaces of the two combined lead electrodes; and two positive electrode leads out of a DC stabilized power supply positive electrode terminal are respectively connected with upper ends of the two anode oxidation test pieces. The experiment device has the most obvious characteristic that dual test pieces can be tested simultaneously, so that the speed and efficiency for preparing test pieces are greatly improved, the research process is accelerated greatly, and limited experiment resources can be saved.

Owner:ZHEJIANG COLLEGE OF CONSTR

Light stirring machine special for colored clay

InactiveCN108858745AControl the amount of dropEasy to control the amount of dropCement mixing apparatusPulp and paper industryMixed materials

The invention relates to the technical field of colored clay manufacturing equipment, and discloses a light stirring machine special for colored clay. The stirring machine comprises a supporting base,the four corners of the bottom of the supporting base are fixedly provided with supporting legs, a stirring tank is welded to the middle of the supporting base, the bottom of the stirring tank extends to the bottom of the supporting base, one side of the stirring tank is fixedly sleeved with a pigment adding pipe, the pigment adding pipe communicates with an inner cavity of the stirring tank, anda supporting block located on one side of the stirring tank is fixedly connected to the top of the supporting base. According to the light stirring machine special for colored clay, flour and pigmentare contained by two sets of same material storage buckets, the falling amount of the raw materials inside the material storage buckets is convenient to control through the adjusting effect of a falling control structure, the falling amount of raw materials is convenient to observe through annular scales on the material storage buckets, the falling amount of raw materials is precisely controlled,it is ensured that the raw materials in the two material storage buckets are precisely matched according to the matching ratio, and the mixing uniformity of mixed materials is improved.

Owner:鲁忠华

Plate packaging machine for installing polar plates

ActiveCN108336392AHigh degree of automationImprove work efficiencyElectrode manufacturing processesFinal product manufactureGlass fiberEngineering

The invention relates to the technical field of plate package for battery plates, and concretely discloses a plate packaging machine for installing polar plates. The machine comprises a frame, a conveying mechanism for conveying separator plates, as well as a driving wheel and a driven wheel for conveying glass fiber membranes; the frame is fixedly connected to a telescopic cylinder, a stamping mechanism, an automatic telescopic rod, and a baffle plate; the telescopic cylinder is fixedly connected to a slide plate, the slide plate is fixedly connected with a probe plate and an elevating cylinder, the elevating cylinder is fixedly connected to a cutter for cutting the separator plate, and the cutter and one end of the probe plate far from the telescopic cylinder are flat; an electromagnet is arranged between the driving wheel and the driven wheel, the electromagnet is fixedly connected to a spring, and the spring is fixedly connected to a magnet for tensioning a glass fiber membrane; the automatic telescopic rod is fixedly connected to a detecting mechanism for detecting flatness of the glass fibre membrane, and the detecting mechanism and the electromagnet are electrically connected. The invention aims at improving plate packaging efficiency and plate packaging quality of the battery polar plates, and prolonging usage life of the batteries.

Owner:GUANGZHOU ZHUOYUE POWER NEW ENERGY CO LTD

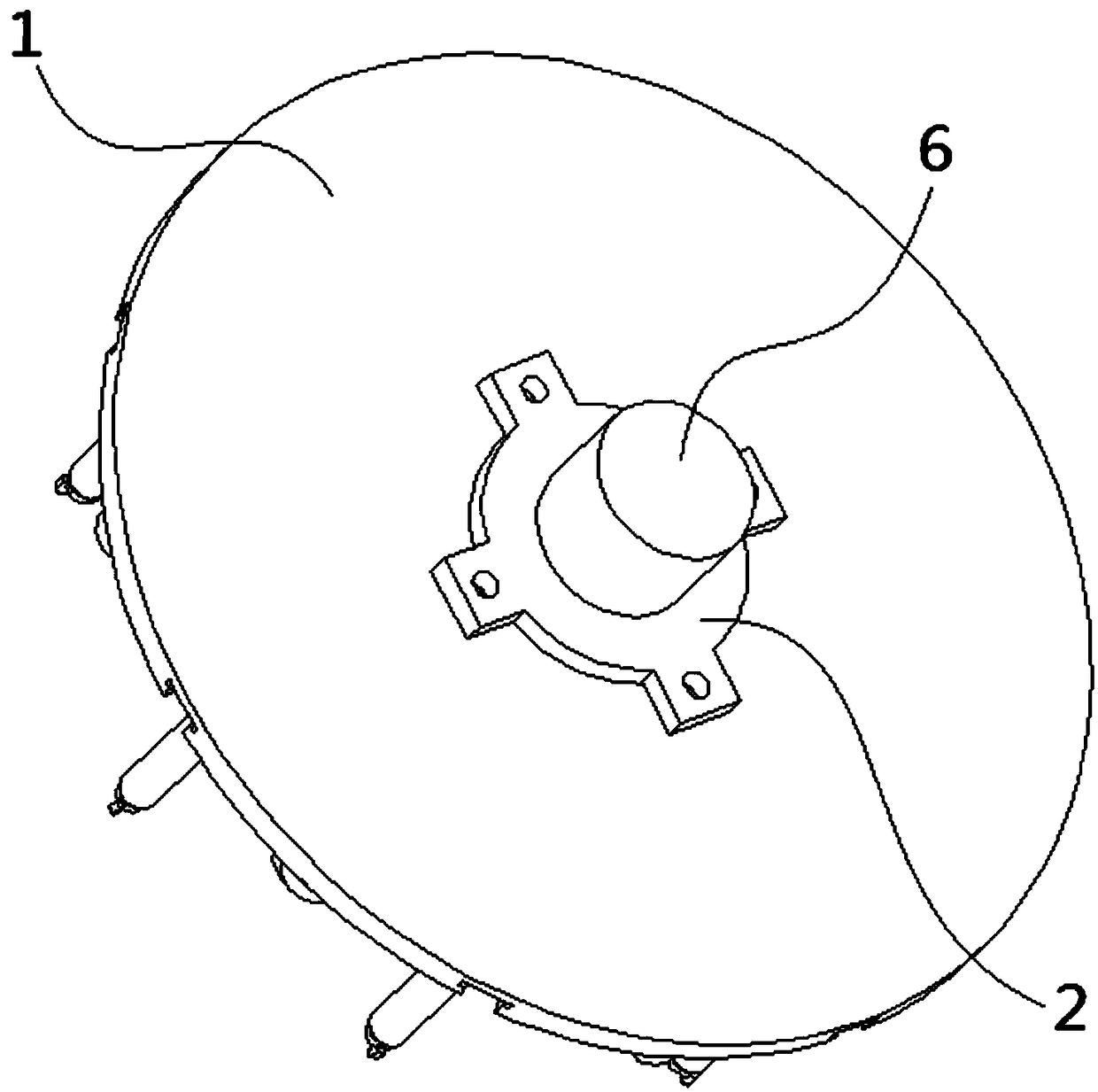

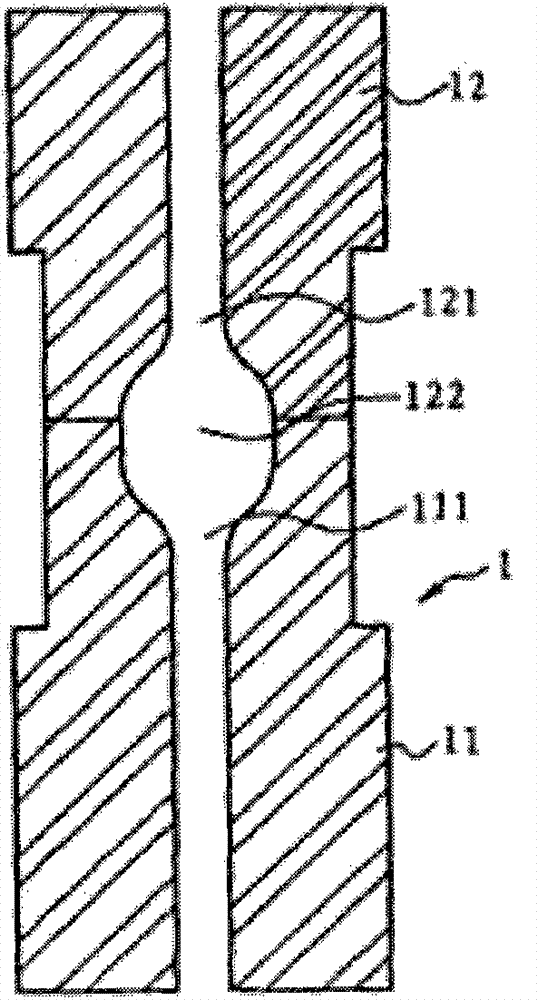

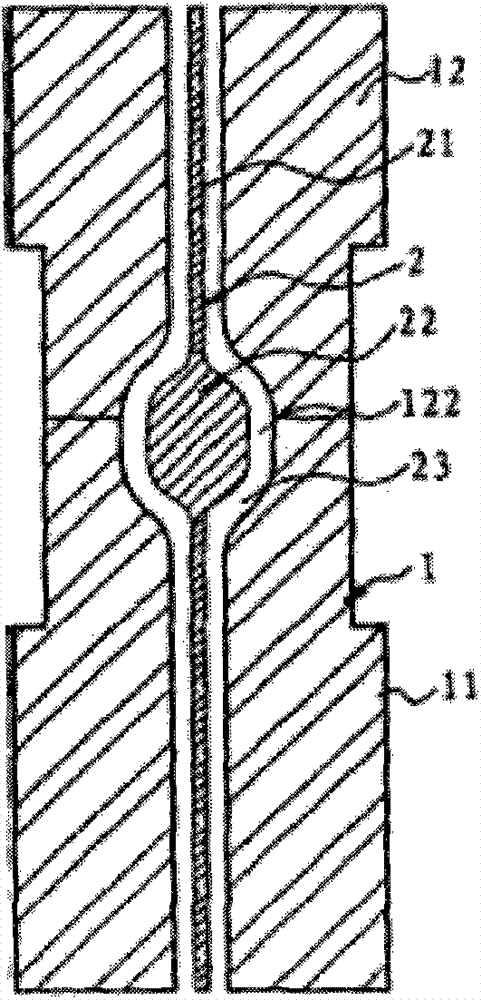

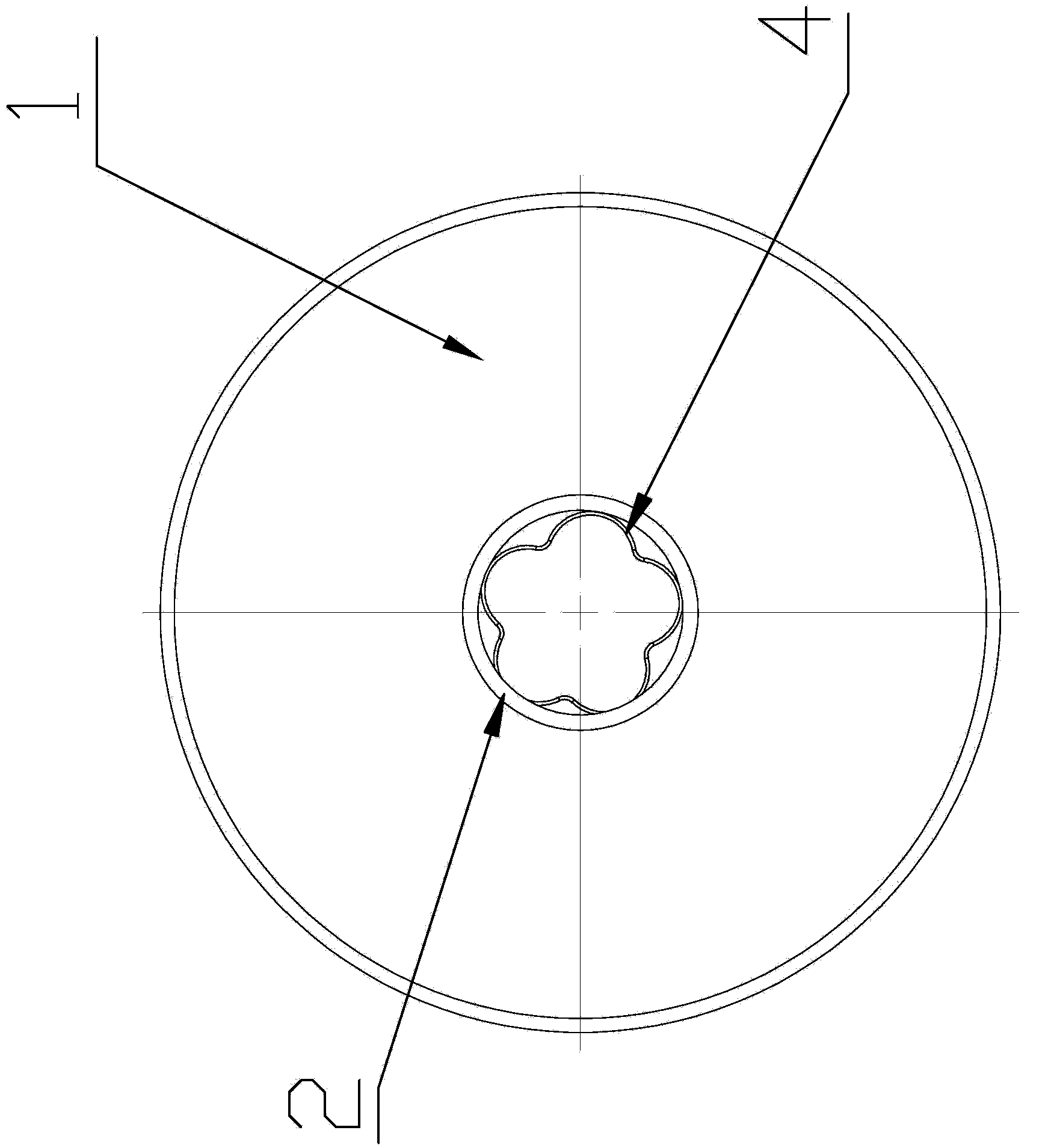

Die for manufacturing seamless five-petal plum-blossom-shaped steel pipe

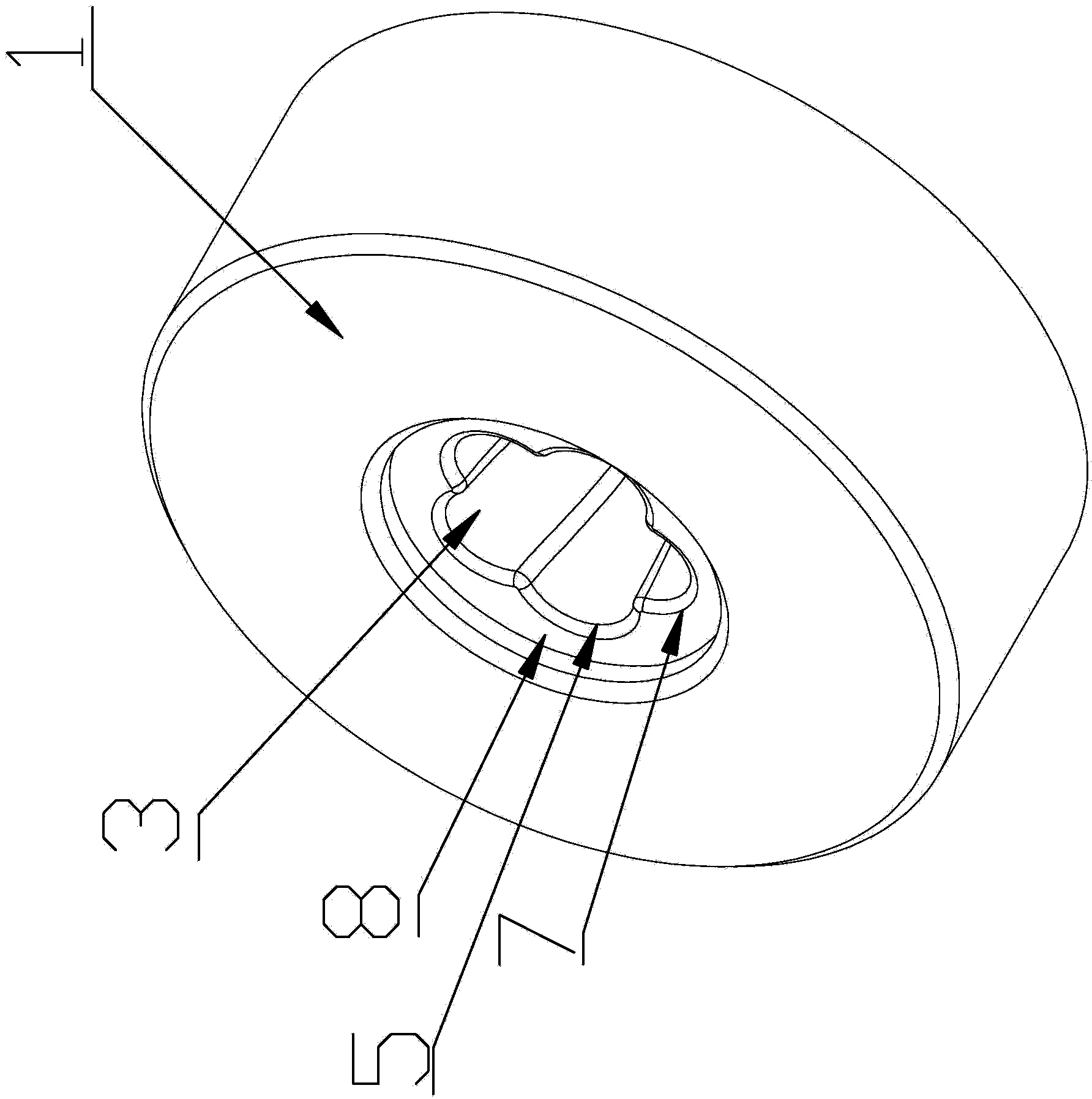

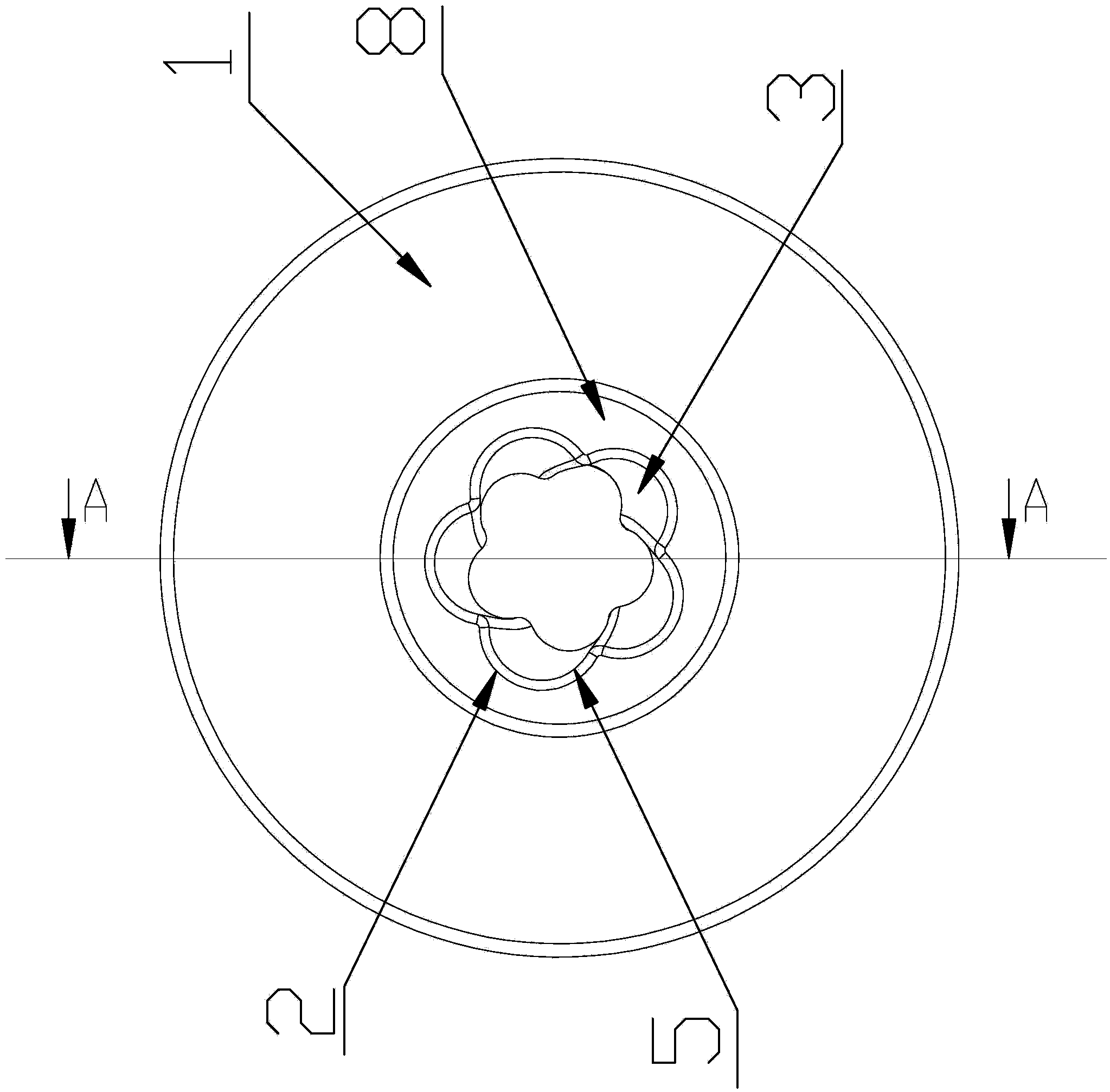

InactiveCN103894434AImprove performanceHigh tensile strengthDrawing diesEngineeringMechanical engineering

The invention discloses a die for manufacturing a seamless five-petal plum-blossom-shaped steel pipe. The die comprises a die body (1) arranged on cold-drawing equipment, wherein a forming channel (3) is formed in the die body (1), and is provided with an inlet (5) and an outlet (4); a feed opening (7) in which a round pipe can be inserted is formed in one end, close to the inlet (5), of the forming channel (3), and a discharge opening (3) is formed in one end, close to the outlet (4), of the forming channel (3); each of the inlet (5) and the outlet (4) of the forming channel (3) has a five-petal plum-blossom-shaped cross section; the forming channel (3) is a spiral channel. According to the die for manufacturing the seamless five-petal plum-blossom-shaped steel pipe, the performance of the produced seamless five-petal plum-blossom-shaped steel pipe is higher than that of a conventional cold-drawn seamless five-petal plum-blossom-shaped steel pipe, the filling of concrete is avoided, and the die is low in cost and convenient to use.

Owner:NINGBO DEYI STEEL PIPE MFG

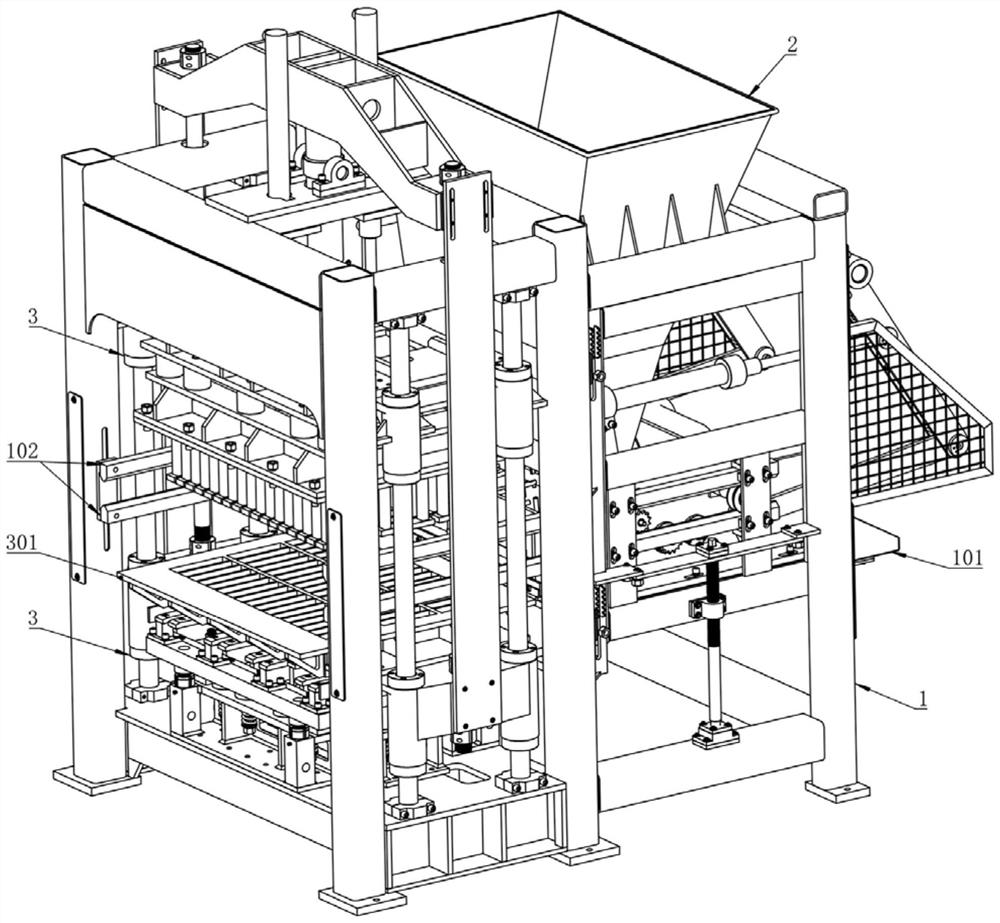

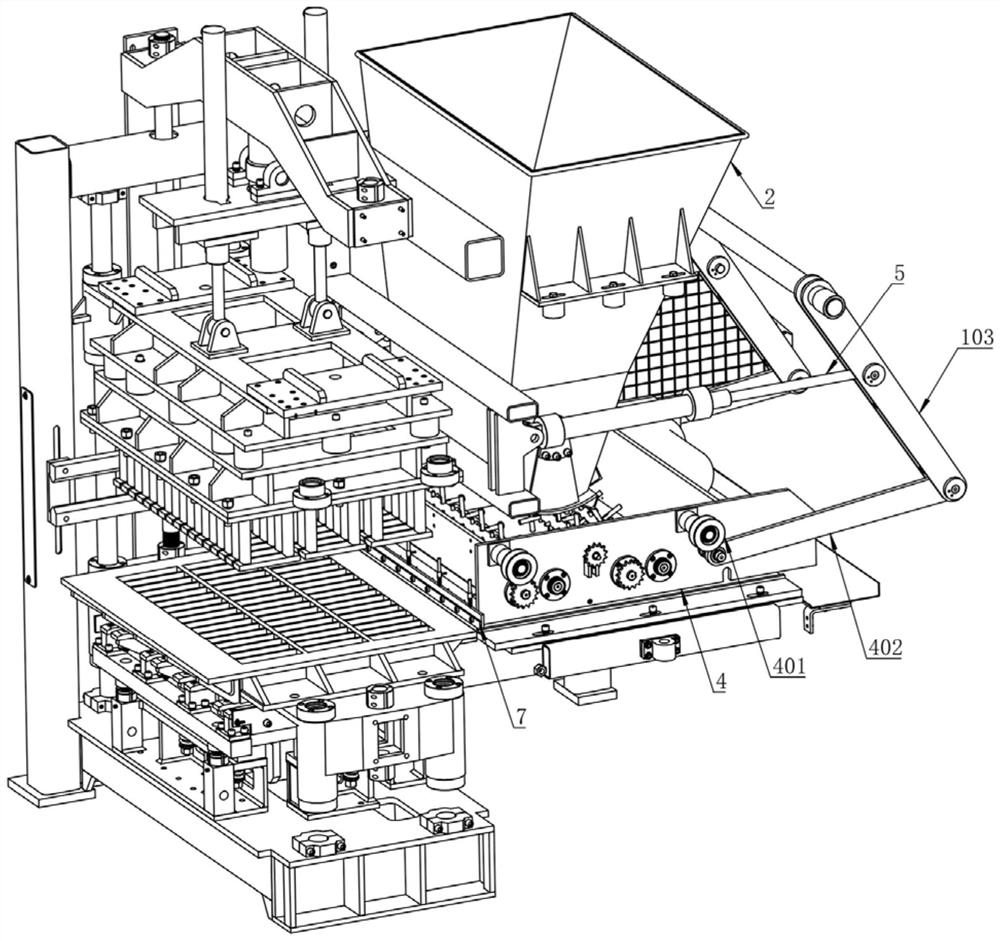

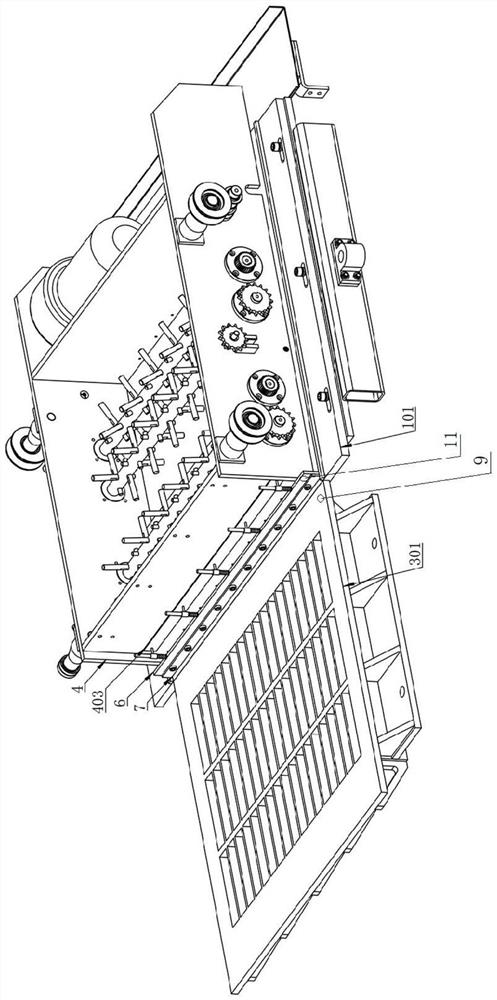

Novel brick making machine

PendingCN114516108AGuaranteed to stickQuality improvementSolid waste managementFeeding arrangmentsCoal wasteCoal

The invention relates to the technical field of brick making machines, in particular to a novel brick making machine which comprises a machine frame, a hopper, a compression molding brick making set, a stirring feeding drawer, an air cylinder, a base plate, a rubber scraper blade and the like. The rubber scraping plate can be tightly pressed on the feeding platform or the die pressing platform under the action of the spring, the rubber scraping plate can be driven to move together when the feeding drawer is retracted and reset after the feeding drawer is stirred for filling, impurities such as coal cinder on the feeding platform can be scraped clean when the rubber scraping plate is reset, and meanwhile the blowing device is arranged to be matched with the rubber scraping plate for use, so that the feeding drawer is convenient to use. And residues in the pressing die platform and the blank area are cleaned up. And a spray head is further arranged to wet a green brick area before the pile body is pressed, so that pressed green bricks are neat, the production quality of the brick bodies is high, and the problems that a small amount of ash and coal cinder are left on a die pressing platform and the coal cinder falls onto the green bricks to affect the production quality of the brick bodies in the left-right moving filling process of a stirring feeding drawer of a traditional brick making machine are solved.

Owner:胡佳彤

Automobile sealing strip injection molding and heat setting method and device thereof

ActiveCN108621362AGood physical and mechanical propertiesGood processing characteristicsDomestic articlesManipulatorInjection moulding

The invention discloses an automobile sealing strip injection molding and heat setting method and a device thereof. The method specifically comprises the following steps: S100, producing EPDM (Ethylene-Propylene-Diene Monomer) / PP-TPV injection molding raw materials by adopting a high-temperature resistant reactor; S200, adding the EPDM / PP-TPV injection molding raw materials produced in the S100 into an injection molding cavity, and realizing rapid injection molding of the product in the injection molding cavity under the effect of a cooling device; S300, taking out the product subjected to injection molding in the S200 from the injection molding cavity by a manipulator. The device comprises a mechanical worktable, wherein a supporting base is arranged below the mechanical worktable; a lifting injection molding device, a cooling device and a TPV vulcanization preparation device are arranged above the mechanical worktable; the TPV vulcanization preparation device is used for producing the injection molding raw materials; one end of the lifting injection molding device is connected with the TPV vulcanization preparation device, and the other end of the lifting injection molding deviceis connected with the cooling device; a rotary supporting column is arranged between the TPV vulcanization preparation device and the mechanical worktable. The device is simple in structure and easyand convenient to operate, automobile sealing strips with excellent properties can be produced, and the automobile sealing requirement is met.

Owner:HEBEI SHIDA SEALING PARTS

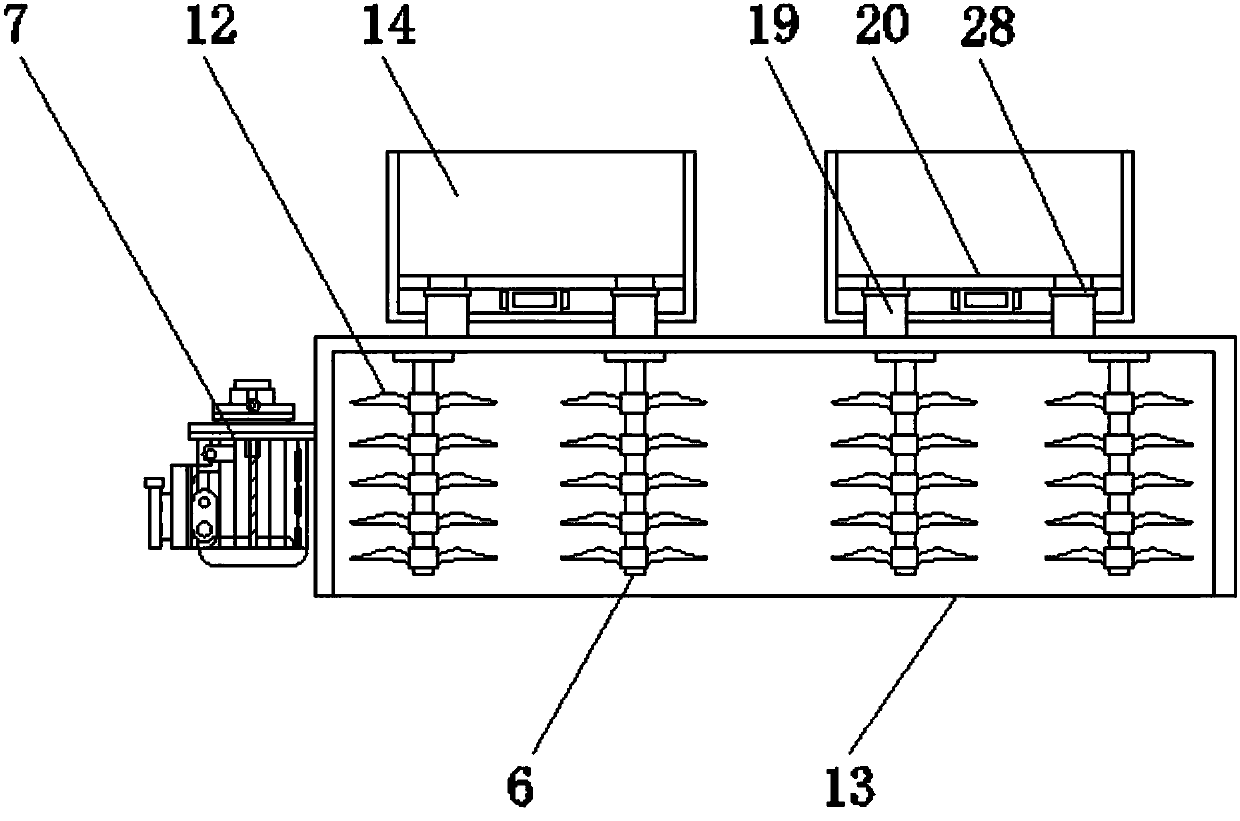

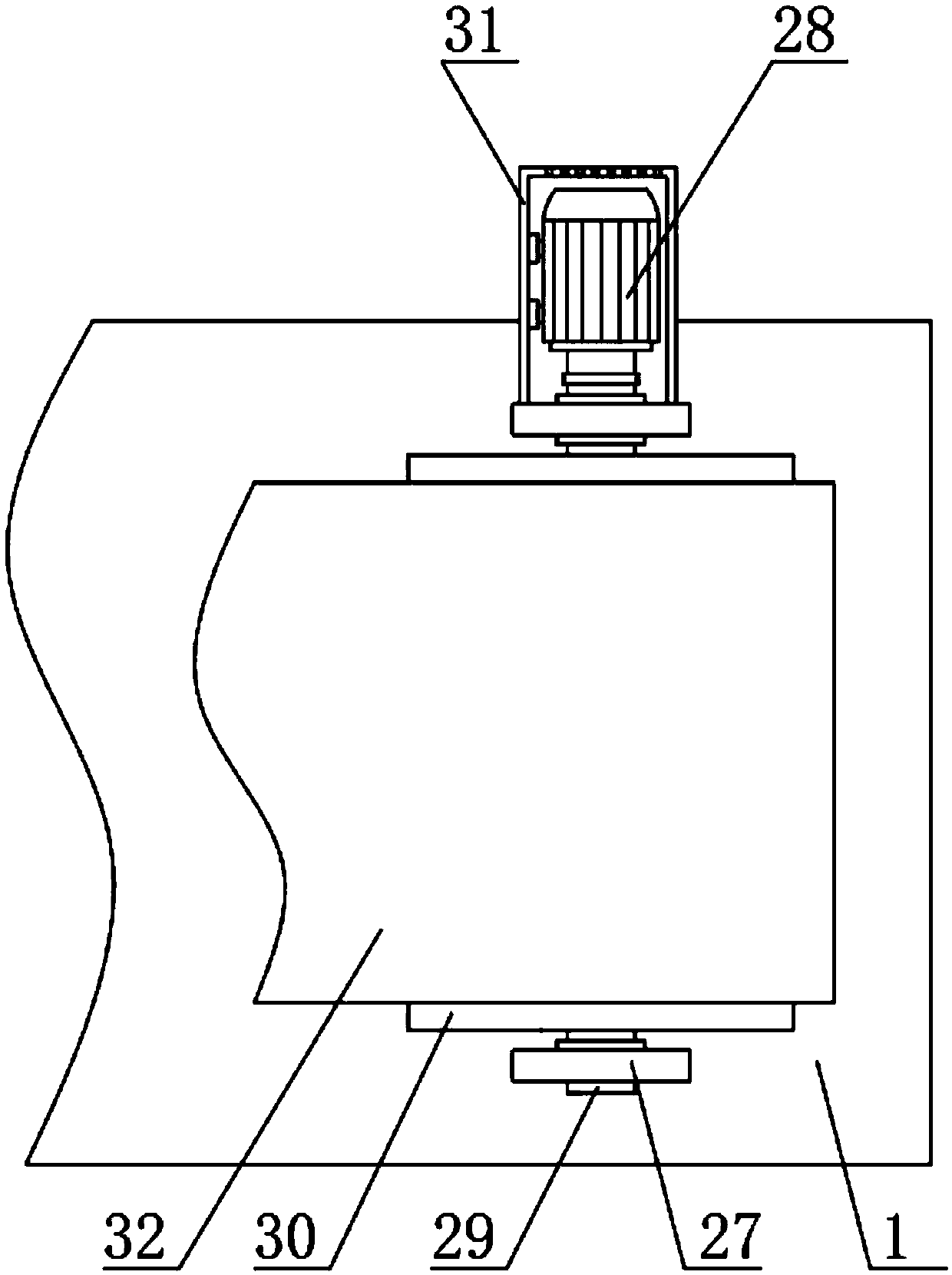

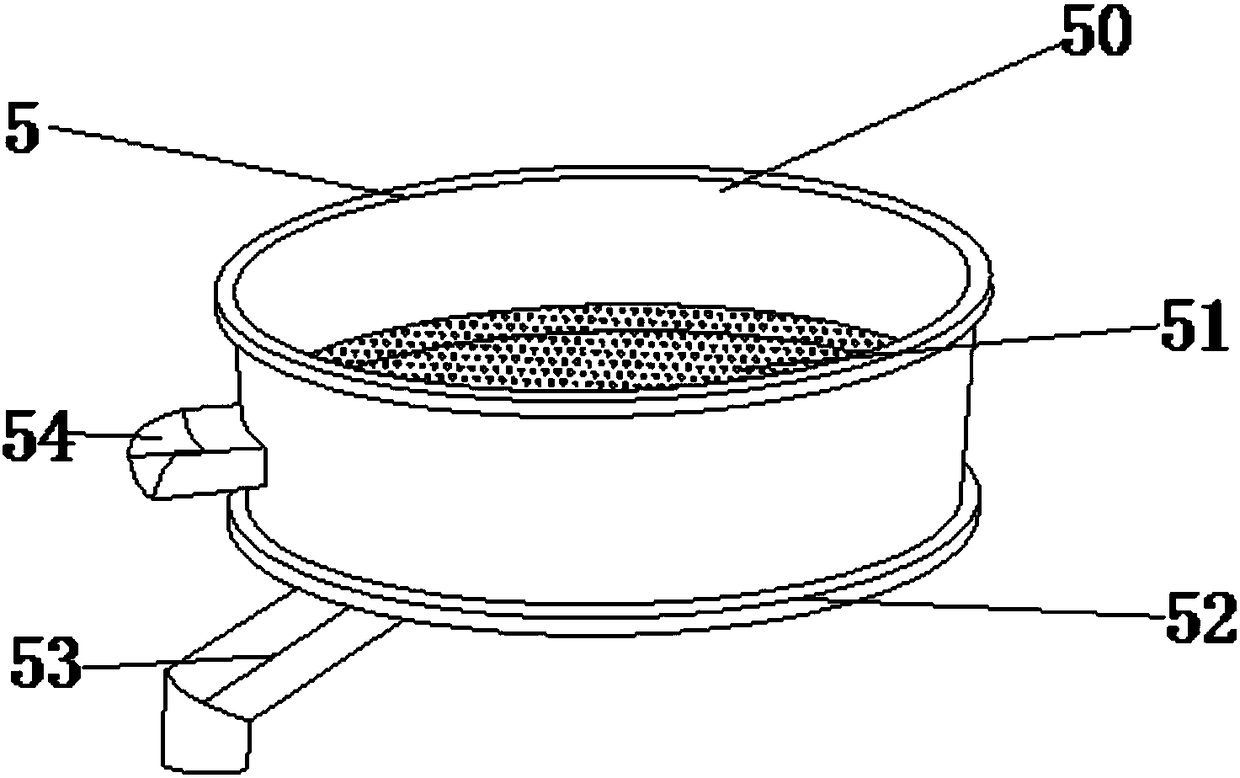

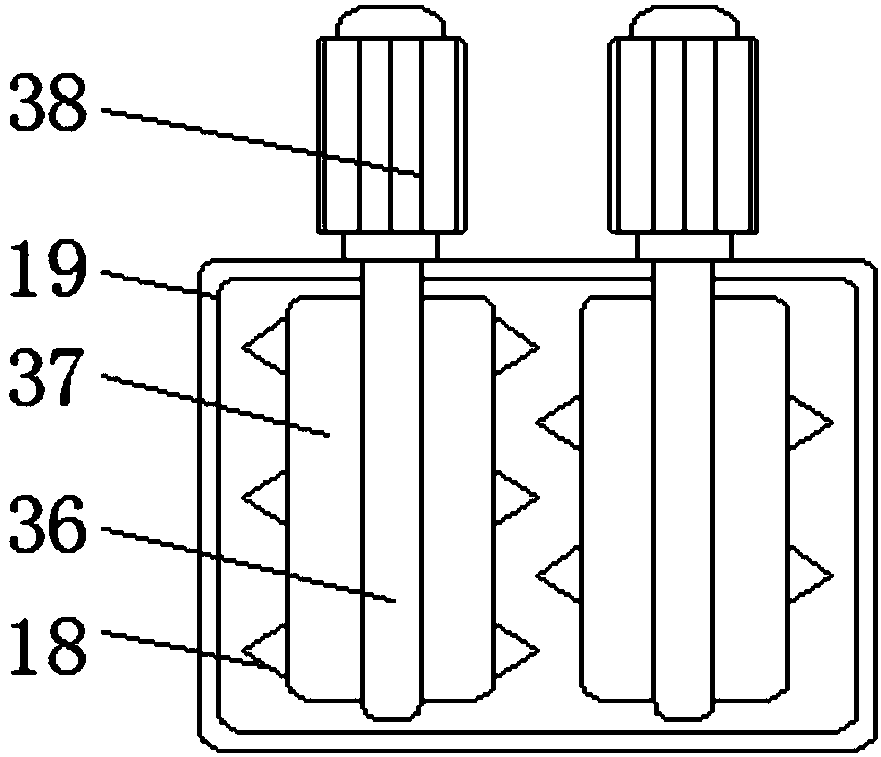

Mixing machine for gypsum boards

InactiveCN111111505AAffect production qualityIncrease stirringRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The embodiment of the invention discloses a mixing machine for gypsum boards. The mixing machine comprises a mixing cylinder and a plurality of rows of first stirring rollers rotationally mounted in the mixing cylinder, the plurality of rows of first stirring rollers are radially and uniformly distributed in the mixing cylinder by taking the circle center of the bottom surface of the mixing cylinder as a central point, a row of second stirring assemblies are arranged at one end, far away from the central axis of the mixing cylinder, of the bisector of the included angle between every two adjacent rows of the first stirring rollers, a plurality of second stirring assemblies are arranged in each column, and the vertical distance from at least one second stirring assembly to the central axisof the mixing cylinder is equal to the vertical distance from the adjacent first stirring rollers to the central axis of the mixing cylinder. According to the embodiment of the invention, the second stirring assembly is arranged at one end, far away from the central axis of the mixing cylinder, of the bisector of the included angle between every two adjacent columns of first stirring rollers, so that the stirring strength of outer ring layer raw materials is increased, and the problem that the gypsum board quality is influenced by uneven stirring is avoided.

Owner:北新建材(苏州)有限公司 +1

Corrugated pipe processing method

InactiveCN110181585AImprove cooling effectAffect production qualityMetal working apparatusTubular articlesFoaming agentEngineering

The invention discloses a corrugated pipe processing method. The corrugated pipe processing method comprises the steps that stirring and mixing are carried out, wherein polyethylene plastic and a foaming agent are added into a stirring drum for stirring and mixing; dissolving is carried out, wherein the stirred and mixed raw materials are put into an extruder to be dissolved; molding is carried out, wherein the dissolved raw materials are put into a mold for solidification molding; rinsing is carried out, wherein cold water is used for rinsing a molded corrugated pipe; and cutting is carried out, wherein a corrugated pipe cutting device is used for cutting the rinsed corrugated pipe. The method is simple to implement, the corrugated pipe can be sufficiently cooled during cutting, and the condition that the production quality of the corrugated pipe is influenced by corrugated pipe notch melting caused by too high temperature generated during cutting of the corrugated pipe is avoided.

Owner:广东捷凌电器股份有限公司

Cylinder sleeve casting device

PendingCN111360223AImprove casting efficiencyAffect production qualityMolten metal supplying equipmentsNozzleMaterials science

The invention provides a cylinder sleeve casting device which comprises a centrifugal casting machine, a supporting main body and a vehicle body. The vehicle body is slidably connected to the supporting main body; the vehicle body comprises a shell, a molten iron container is rotatably fixed to the shell, a casting nozzle is further fixed to the side wall of the molten iron container, and a weightsensor is further arranged on a base of the shell. A working process of the cylinder sleeve casting device is as follows: when it is needed to cast, the vehicle body slides to the lower side of the centrifugal casting machine through a slideway, the adding amount of molten iron in the molten iron container is controlled according to weight displayed by the weight sensor, and molten iron at a preset weight enters a casting die along the casting nozzle to be casted to obtain a cylinder sleeve blank. By arranging the weight sensor, the adding amount of the molten iron can be controlled precisely, and the weighing and pouring step are finished efficiently, so that the cylinder sleeve casting efficiency is improved and meanwhile, a condition that the production quality of the cylinder sleeve is affected as the molten iron is cooled too quickly is avoided.

Owner:湖南鑫源缸套有限责任公司

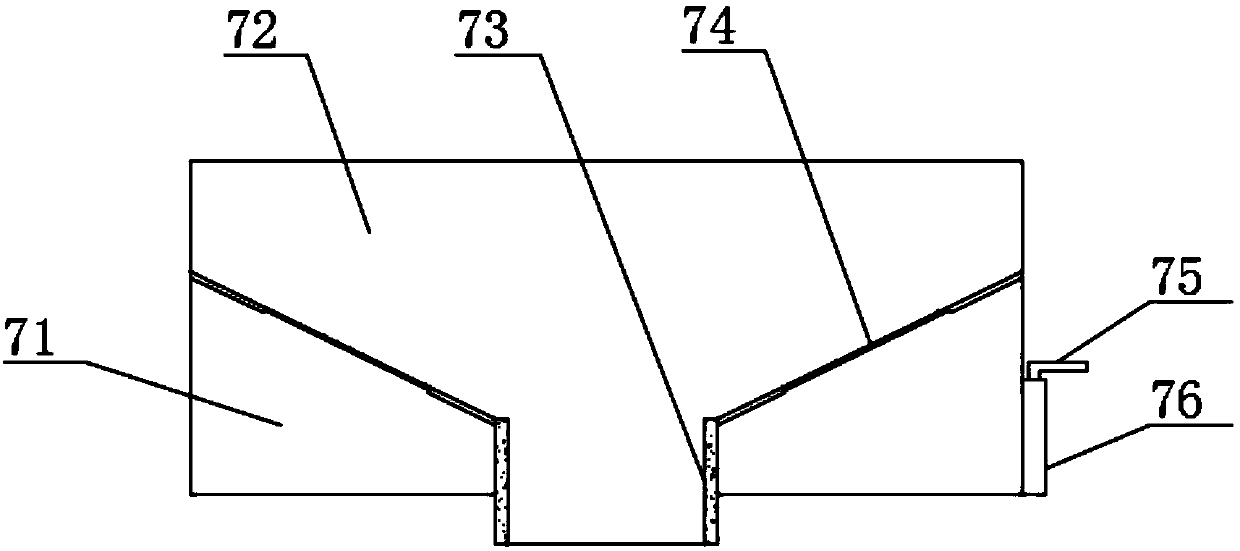

Flying slurry recycling device used for cardboard production lines

InactiveCN109276920AImprove recycling ratesAffect production qualityPaper material treatmentStationary filtering element filtersCardboardElectricity

The invention discloses a flying slurry recycling device used for cardboard production lines. The device includes a motor, a pump machine, a collecting pipe, a sealing cover, a filtering cylinder, a supporting stand and a recycling cylinder; the motor is arranged on the pump machine and connected to the pump machine through electric welding; the motor is connected to the pump machine through electric welding; the pump machine is connected to the collecting pipe through electric welding; one end of the collecting pipe is connected to cardboard production equipment, and the other end of the collecting pipe passes through the sealing cover and is connected to the filtering cylinder; and the sealing cover is arranged on the filtering cylinder and movably connected to the filtering cylinder. Through the arrangement of the filtering cylinder, recycled flying slurry can be filtered first and then loaded in the recycling cylinder to recycle, so that particulate matters can be prevented from mixing into the flying slurry to cause the flying slurry to be unable to reuse, or from entering the cardboard production equipment with the flying slurry to cause the damage of the equipment and influence the production quality of cardboards, and therefore, the recycling rate of the flying slurry and the production quality of the cardboards can be effectively enhanced, and production equipment canbe protected.

Owner:TIANJIN JIAHAO PAPER PROD CO LTD

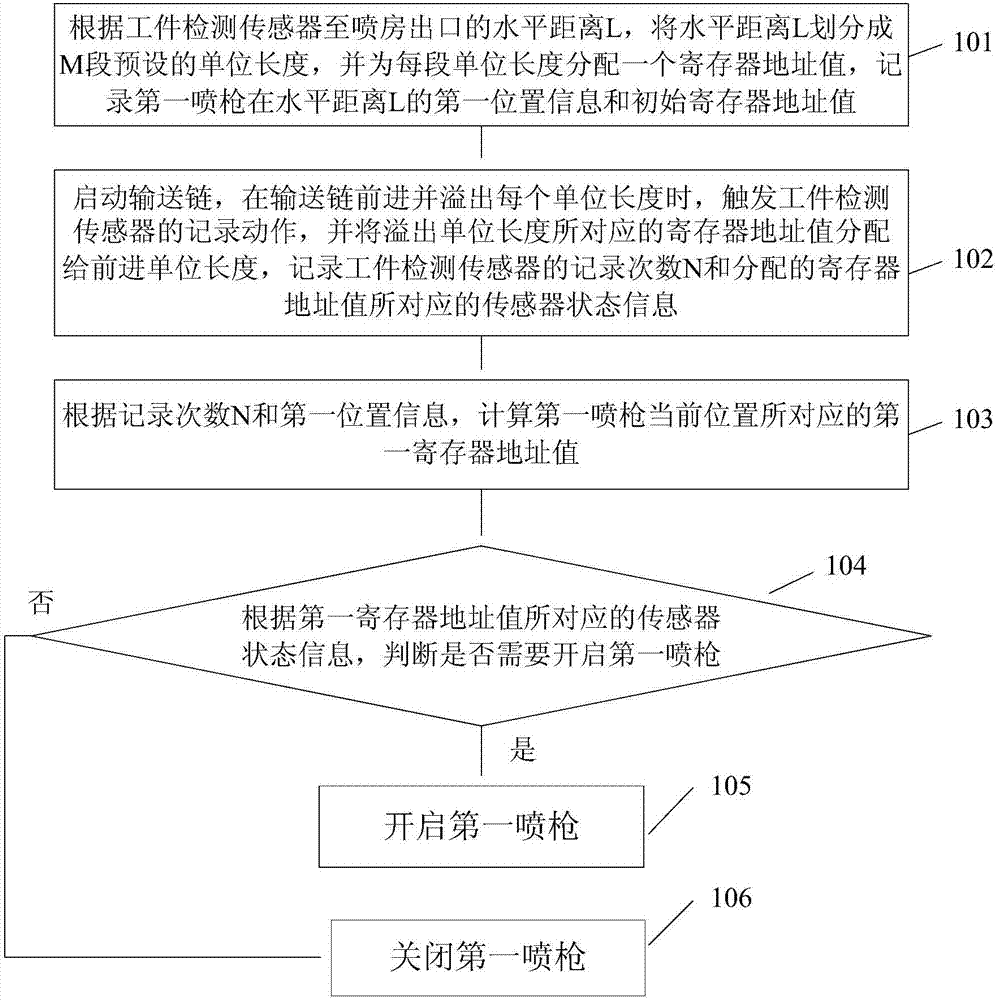

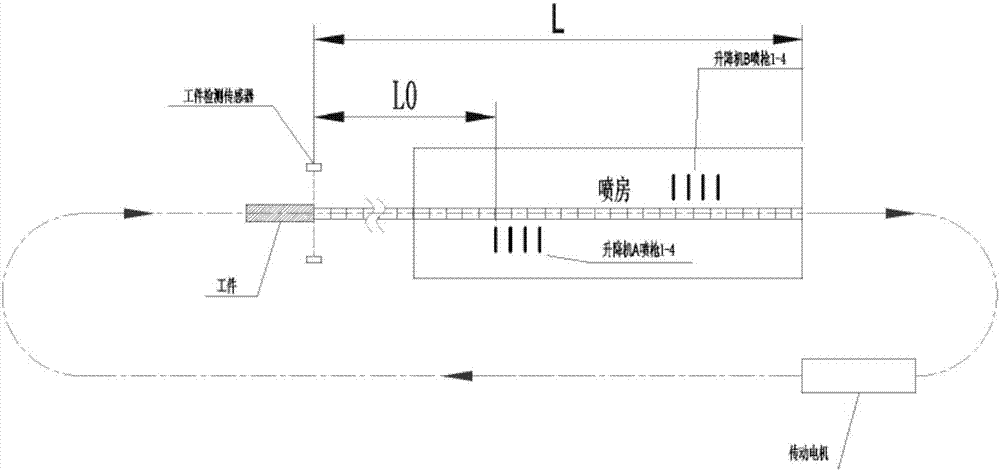

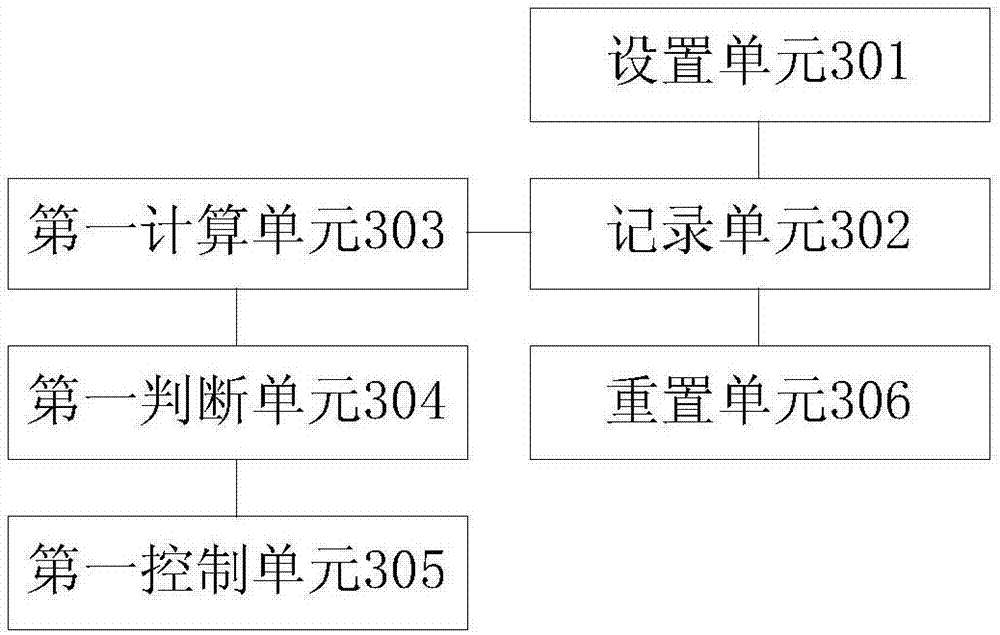

Spray control method and device

ActiveCN106861977AImprove spraying accuracyStability is not affectedSpraying apparatusProcessor registerComputer science

Owner:广州泽亨实业有限公司

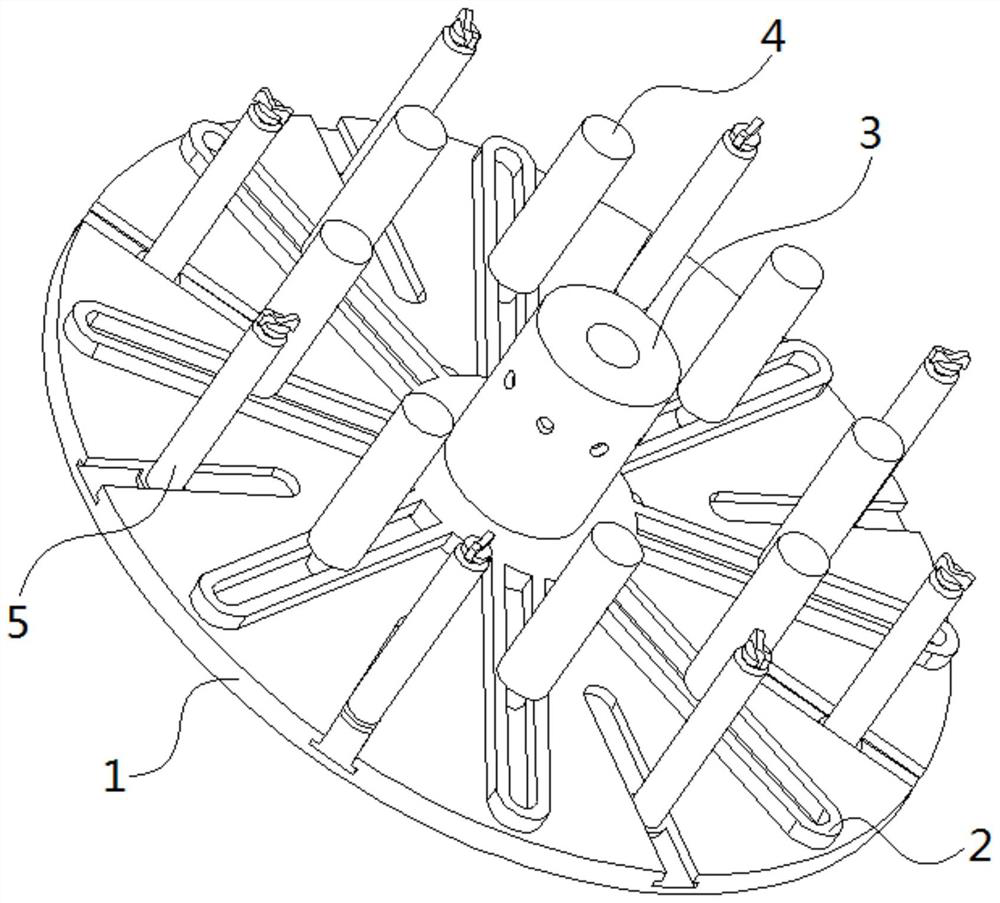

A kind of mold cleaning device and cleaning method

The invention discloses a cleaning device and a cleaning method for a mold, and relates to the technical field of mold cleaning. The cleaning device comprises a rotating disc, wherein a fixed supportis arranged at the axis position of the rotating disc in a penetrating manner, the axis position of the fixed support is fixedly connected with a cleaning agent bin, one surface of the fixed support is in sliding connection with a plurality of movable rods, and one surface of the rotating disc is in sliding connection with a plurality of fixed rods; one end face of each fixed rod is in threaded connection with a fixing device; the circumferential side faces of the multiple movable rods and the multiple fixed rods are sleeved with a cleaning belt; and the axis position of the fixed support is fixedly connected with a transmission shaft. The movable rods are mutually matched with the fixed rods, so that the cleaning belt can be independently adjusted according to the size of an inner cavityof the tire mold, the cleaning belt of the cleaning device is attached to the inner cavity for use, compared with an existing cleaning roller, the cleaning area of the cleaning belt is increased, internal grains and slots of the mold can be effectively cleaned, and the cleaning device has the beneficial effect of improving the cleaning efficiency.

Owner:ANHUI YULONG MOLD & CASTING

Food production equipment

InactiveCN107751325AAvoid uneven mixingImprove stabilityMeat mixing apparatusMeat processing devicesElectric machineryMotor drive

The invention discloses food production equipment, which comprises a pedestal, a first frame, a processing box, a second frame and a third frame. The third frame is mounted at one side above the pedestal, the processing box is mounted on the third frame, the first frame is mounted above the pedestal, the second frame is mounted above the first frame at one side far from the processing box, and a stirring box is mounted above the first frame at one side close to the processing box, a material storage box is mounted on the pedestal below the processing box, a material guide pipe is mounted underthe processing box, and the material guide pipe is communicated with the material storage box. The food production equipment provided by the invention is equipped with a second rotary motor, a firstrotating shaft and stirring blades, the second rotary motor drives the stirring blades to rotate through the first rotating shaft, so that raw materials and ingredients can be mixed evenly in the stirring box, thus avoiding low qualification rate of product caused by uneven mixing of the raw materials and ingredients, and effectively improving the equipment stability.

Owner:鄢碧珠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com